Colour printing PU foaming product

A printing layer, transfer printing film technology, applied in the direction of layered products, synthetic resin layered products, decorative arts, etc., can solve the problems of heavy pollution, inconsistent physical properties, and failure to protect the environment, so as to reduce production costs and save production processes , Improve product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 High-elastic PU foam color printing ball

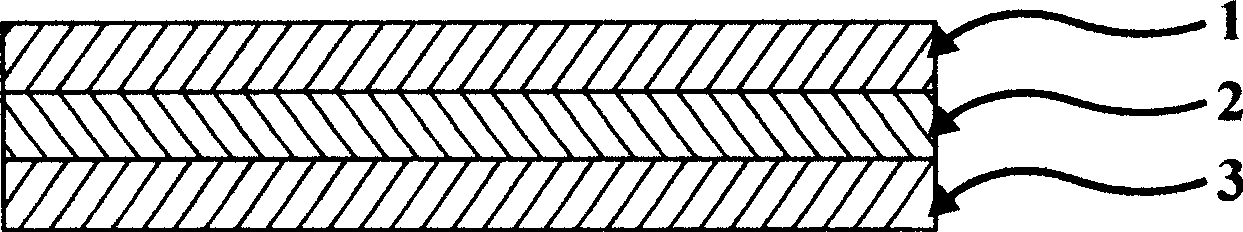

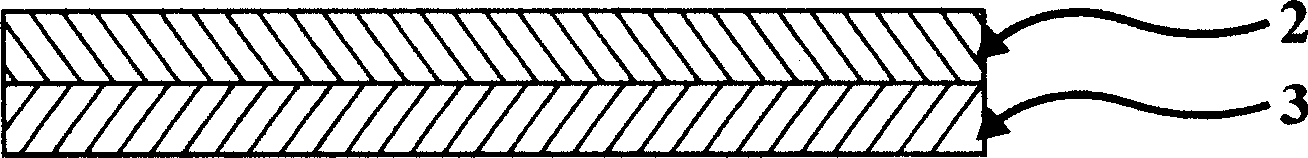

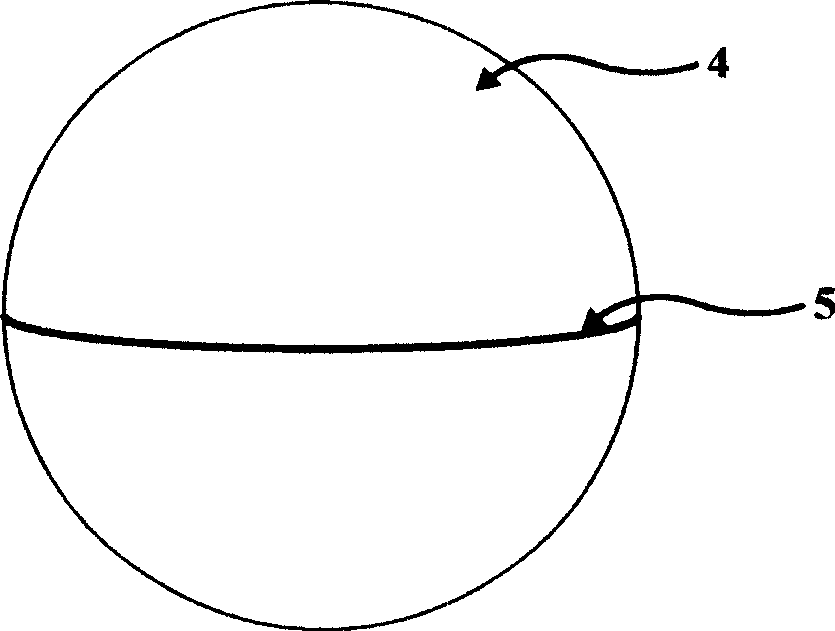

[0035] figure 1 The PS plastic base material 1 is selected, the non-polar PP material 2 is selected as the peeling layer, and the printing layer 3 is surface lithographically printed by offset printing to obtain fine printed graphics. choose image 3 The shown ball 4 is the target product, the middle circumference line of the ball is used as the parting line 5, and the printing transfer mold composed of 1, 2, and 3 is passed through Figure 5 The plastic deformation mold 7 in carries out plastic deformation, obtains Figure 6 As shown in the pre-deformed post-transfer printing film 9, as Figure 10 As shown, 9 is placed in the PU foaming mold 10, and the printing layer is placed inward, as Figure 9 As shown, the mixed material 13 of A and B mixed with high resilience PU foam is injected into the foaming mold 10 through the mixing injection port 12, as Figure 10 As shown, A and B materials are mixed and placed i...

Embodiment 2

[0036] Example 2 PU foam color printing ball on leather surface

[0037] figure 1 The PVC plastic base material 1 is selected, the non-polar wax 2 is selected as the peeling layer, and the surface printing layer 3 is lithographically printed by gravure printing to obtain fine printed graphics. choose image 3 The shown ball 4 is the target product, the middle circumference line of the ball is used as the parting line 5, and the printing transfer mold composed of 1, 2, and 3 is passed through Figure 5 The plastic deformation mold 7 in carries out plastic deformation, obtains Figure 6 As shown in the pre-deformed post-transfer printing film 9, as Figure 10 As shown, 9 is placed in the PU foaming mold 10, and the printing layer is placed inward, as Figure 9 As shown, the mixed material 13 of A and B foamed from the crust PU is injected into the foaming mold 10 through the mixing injection port 12, as Figure 10 As shown, A and B materials are mixed and placed in 10. Afte...

Embodiment 3

[0038] Embodiment 3 Color-printed PU foam product with concave-convex surface

[0039] figure 1 The PS plastic base material 1 is selected, the non-polar PE material 2 is selected as the peeling layer, and the surface printing layer 3 is lithographically printed by gravure printing to obtain fine printed graphics. choose Figure 12 The illustrated 15 is the target product, and the parting line 5 is used to pass the printing transfer mold composed of 1, 2, and 3 Figure 13 The plastic deformation mold in the process is subjected to plastic deformation, and the transfer printing film is obtained after pre-deformation, such as Figure 14 As shown, the uneven ones are placed in the foaming mold corresponding to each other, and the other operations are the same as the examples, and a color-printed PU foamed product with a concave-convex surface can be obtained.

[0040]Concrete embodiment can also enumerate a lot, for the sake of brevity, no longer go into details, only emphasiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com