Hydrochloric-acid acid washing liquid and acid washing method for 400-series stainless steel hot-rolled annealing wire

A technology of stainless steel and pickling solution, applied in the field of stainless steel surface treatment, can solve the problem of not easy pickling, and achieve the effect of stable pickling process and smooth and white surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

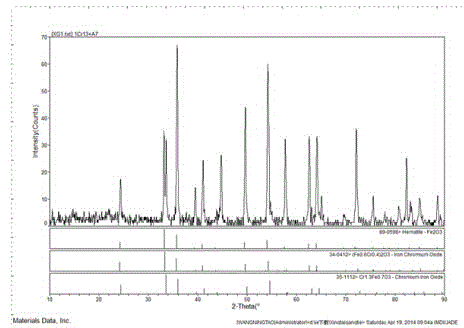

Image

Examples

Embodiment 1

[0024] Annealing and pickling process of 0Cr13

[0025] The main components of 0Cr13: C content <0.05%, Cr content 13%, Si content 0.5%. The specification of the wire is 5.5mm-42mm, and the annealing temperature is 700-800°C.

[0026] The pickling solution is composed of hydrochloric acid, nitric acid, corrosion inhibitor, surfactant, accelerator, solution stabilizer and water; the mass ratio of each substance is as follows: hydrochloric acid 22wt%, nitric acid 10wt%, corrosion inhibitor 1wt%, surface active 0.05wt% agent, 1wt% accelerator, 0.05wt% solution stabilizer, and the balance is water; the corrosion inhibitor is an equal mass mixture of urotropine and quaternary ammonium salt; the surfactant is sodium alkylbenzenesulfonate; The accelerator is hydrogen peroxide; the solution stabilizer is EDTA.

[0027] Pickling process: inject the pickling solution into the pickling tank, put the whole annealed hot-rolled wire rod directly into the pickling tank for pickling, the pi...

Embodiment 2

[0030] Annealing and pickling process of 1Cr13

[0031] The main component of 1Cr13, C content <0.15%, Cr content 13%, Si content 0.5%. The specification of the wire rod is 5.5mm-42mm, and the annealing temperature is 700-850°C.

[0032] The pickling solution is composed of hydrochloric acid, nitric acid, corrosion inhibitor, surfactant, accelerator, solution stabilizer and water; Active agent 1wt%, Accelerator 0.05wt%, Solution stabilizer 1wt%, The balance is water; Corrosion inhibitor is a mass mixture of urotropine, thiourea and citric acid; Surfactant is sodium alkylsulfonate; The accelerator is sodium fluoride; the solution stabilizer is disodium EDTA.

[0033] Pickling process: inject the pickling solution into the pickling tank, put the entire annealed hot-rolled wire rod directly into the pickling tank for pickling, the pickling temperature is 85°C, the pickling time is 0.5h, and rinse after pickling And neutralization, hot air can be stored after drying.

[0034] ...

Embodiment 3

[0036] Annealing and pickling process of 0Cr17

[0037] The main component of 0Cr17, C content <0.05%, Cr content 17%, Si content 0.5%. The specification of the wire is 5.5mm-42mm, and the annealing temperature is 700-820°C.

[0038]The pickling solution is composed of hydrochloric acid, nitric acid, corrosion inhibitor, surfactant, accelerator, solution stabilizer and water; the mass ratio of each substance is as follows: hydrochloric acid 16wt%, nitric acid 0.01wt‰, corrosion inhibitor 0.01wt%, Surfactant 0.6wt%, accelerator 0.7wt%, solution stabilizer 0.35wt%, the balance is water; corrosion inhibitor is equal mass mixture of thiourea, quaternary ammonium salt and citric acid; surfactant is OP-10 The accelerator is sodium fluoride; the solution stabilizer is disodium EDTA.

[0039] Pickling process: inject the pickling solution into the pickling tank, put the whole annealed hot-rolled wire rod directly into the pickling tank for pickling, the pickling temperature is 65°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com