Mixed-acid acid washing liquid and acid washing method for 400-series stainless steel hot-rolled annealing wire

A technology of stainless steel and pickling solution, which is applied in the field of stainless steel surface treatment, and can solve problems such as difficult pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

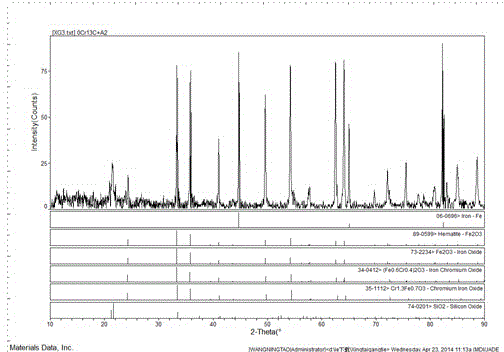

Image

Examples

Embodiment 1

[0021] Annealing and pickling process of 0Cr13

[0022] The main components of 0Cr13: C content <0.05%, Cr content 13%, Si content 0.5%. The specification of the wire is 5.5mm-42mm, and the annealing temperature is 700-800°C.

[0023] The pickling solution is composed of hydrochloric acid, hydrofluoric acid, corrosion inhibitor, acid mist inhibitor and water; the mass ratio of each substance is as follows: hydrochloric acid 22wt%, hydrofluoric acid 0.1wt%, corrosion inhibitor -1wt%, acid mist inhibitor The addition amount is 0.5wt%, and the balance is water; the corrosion inhibitor is an equal mass mixture of urotropine, quaternary ammonium salt, and sodium nitrite; the acid mist inhibitor is sodium dodecylsulfonate.

[0024] Pickling process: inject the pickling solution into the pickling tank, put the entire annealed hot-rolled wire rod directly into the pickling tank for pickling, the pickling temperature is 85°C, the pickling time is 30 minutes, rinse and wash after pickl...

Embodiment 2

[0027] Annealing and pickling process of 1Cr13

[0028] The main component of 1Cr13, C content <0.15%, Cr content 13%, Si content 0.5%. The specification of the wire is 5.5mm-42mm, and the high temperature annealing temperature is 860-920℃.

[0029] The pickling solution is composed of hydrochloric acid, hydrofluoric acid, corrosion inhibitor, acid mist inhibitor and water; The addition amount of the inhibitor is 0.1wt%, and the balance is water; the corrosion inhibitor is an equal mass mixture of urotropine, thiourea and sodium benzoate; the acid mist inhibitor is sodium dodecylsulfonate, benzenesulfonate , Equal mass mixture of fatty alcohol polyoxyethylene ether.

[0030] Pickling process: inject the pickling liquid into the pickling tank, put the whole annealed hot-rolled wire rod directly into the pickling tank for pickling, the pickling temperature is 70°C, the pickling time is 40min, rinse and wash after pickling Neutralize and store after drying.

[0031] The surfa...

Embodiment 3

[0033] Annealing and pickling process of 0Cr17

[0034] The main component of 0Cr17, C content <0.05%, Cr content 17%, Si content 0.5%. The specification of the wire is 5.5mm-42mm, and the annealing temperature is 780-820°C.

[0035] The pickling solution is composed of hydrochloric acid, hydrofluoric acid, corrosion inhibitor, acid mist inhibitor and water; the mass ratio of each substance is as follows: hydrochloric acid 17wt%, hydrofluoric acid 1.2wt%, corrosion inhibitor-0.05wt%, acid The amount of mist inhibitor added is 0.25wt%, and the balance is water; the corrosion inhibitor is an equal mass mixture of thiourea, sodium benzoate and citric acid; the acid mist inhibitor is sodium dodecylsulfonate, fatty alcohol polyoxyethylene Equal mass mixtures of ethers.

[0036] Pickling process: inject the pickling solution into the pickling tank, put the entire annealed hot-rolled wire rod directly into the pickling tank for pickling, the pickling temperature is 65°C, the pickli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com