Li series microwave dielectric ceramic material as well as preparation method and use thereof

A technology of microwave dielectric ceramics and powders, which is applied in the field of microwave dielectric ceramics, can solve the problems of high and low dielectric constant, and achieve the effects of high quality factor, low dielectric constant and loss reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The composition of the Li-based microwave dielectric ceramic material in this embodiment is shown in Table 1.

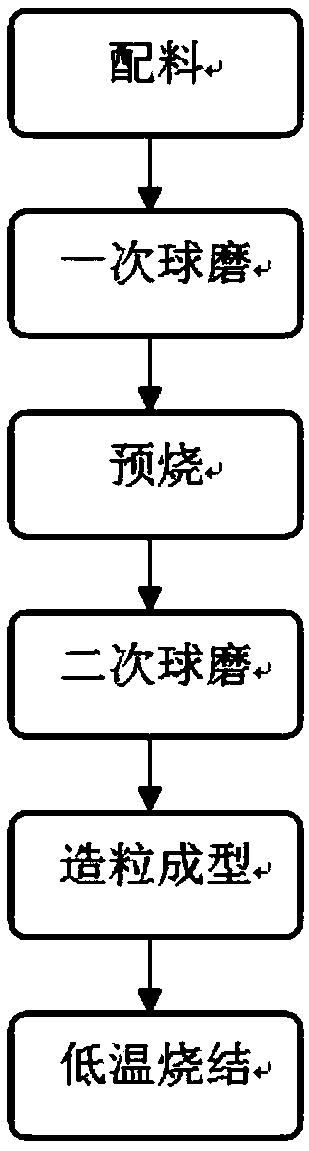

[0051] The preparation method of the Li-based microwave dielectric ceramic material of the present embodiment comprises the following steps:

[0052] 1) Carry out batching according to the material composition and proportioning of Table 1;

[0053] 2) After mixing the powder material weighed in step 1) with deionized water, perform a ball mill in a planetary ball mill, and the time of the first ball mill is 12 hours;

[0054] 3) The powder obtained in step 2) was dried and sieved, and then pre-fired at a temperature of 830° C., the heating rate was 5° C. / min, and the heat preservation was carried out for 3.5 hours;

[0055] 4) After mixing the powder obtained after pre-calcining in step 3) with deionized water, perform secondary ball milling in a planetary ball mill, and the time for the secondary ball milling is 12 hours;

[0056] 5) Add the powder obtained...

Embodiment 2

[0059] The composition of the Li-based microwave dielectric ceramic material in this embodiment is shown in Table 1.

[0060] The preparation method of the Li-based microwave dielectric ceramic material in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0062] The composition of the Li-based microwave dielectric ceramic material in this embodiment is shown in Table 1.

[0063] The preparation method of the Li-based microwave dielectric ceramic material in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com