Non-aqueous electrolytic solution and battery

A non-aqueous electrolyte, electrolyte technology, applied in the field of non-aqueous electrolyte, can solve the problem of unsatisfactory discharge characteristics, and achieve the effect of improving temperature characteristics and high output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]The positive and negative electrodes can be prepared by any desired method. Electrodes are generally prepared by adding active materials, binders, conductive agents, and the like to a solvent to form a slurry, applying the slurry to a current collector sheet, drying, and pressure bonding. The binder used herein is generally selected from polyvinylidene fluoride, polytetrafluoroethylene, styrene-butadiene rubber, isoprene rubber, and various polyimide resins. The conductive agent used herein is generally selected from carbonaceous materials such as graphite and carbon black; and metallic materials such as copper and nickel. As a current collector, aluminum and aluminum alloys are generally used for the positive electrode; and metals such as copper, stainless steel, nickel, and alloys thereof are used for the negative electrode.

[0039] The separator disposed between the positive electrode and the negative electrode is not particularly limited as long as it is stable wit...

Embodiment 1

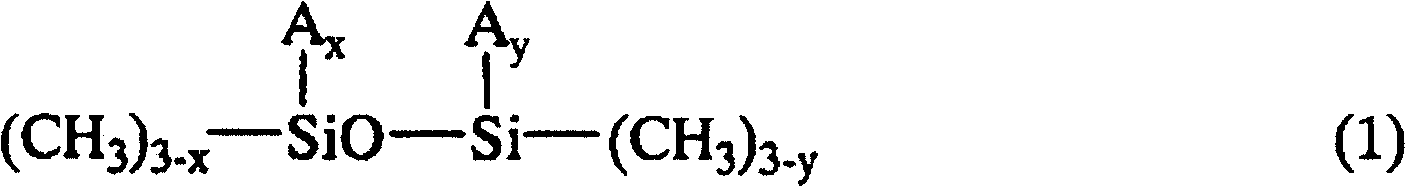

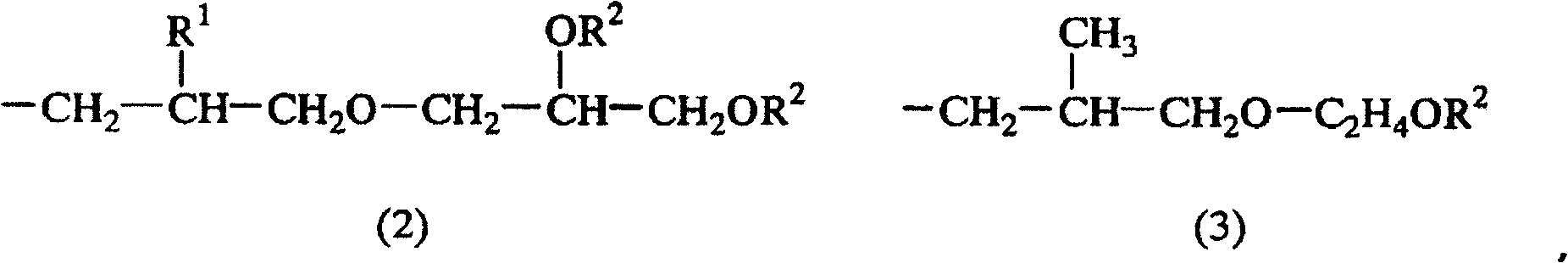

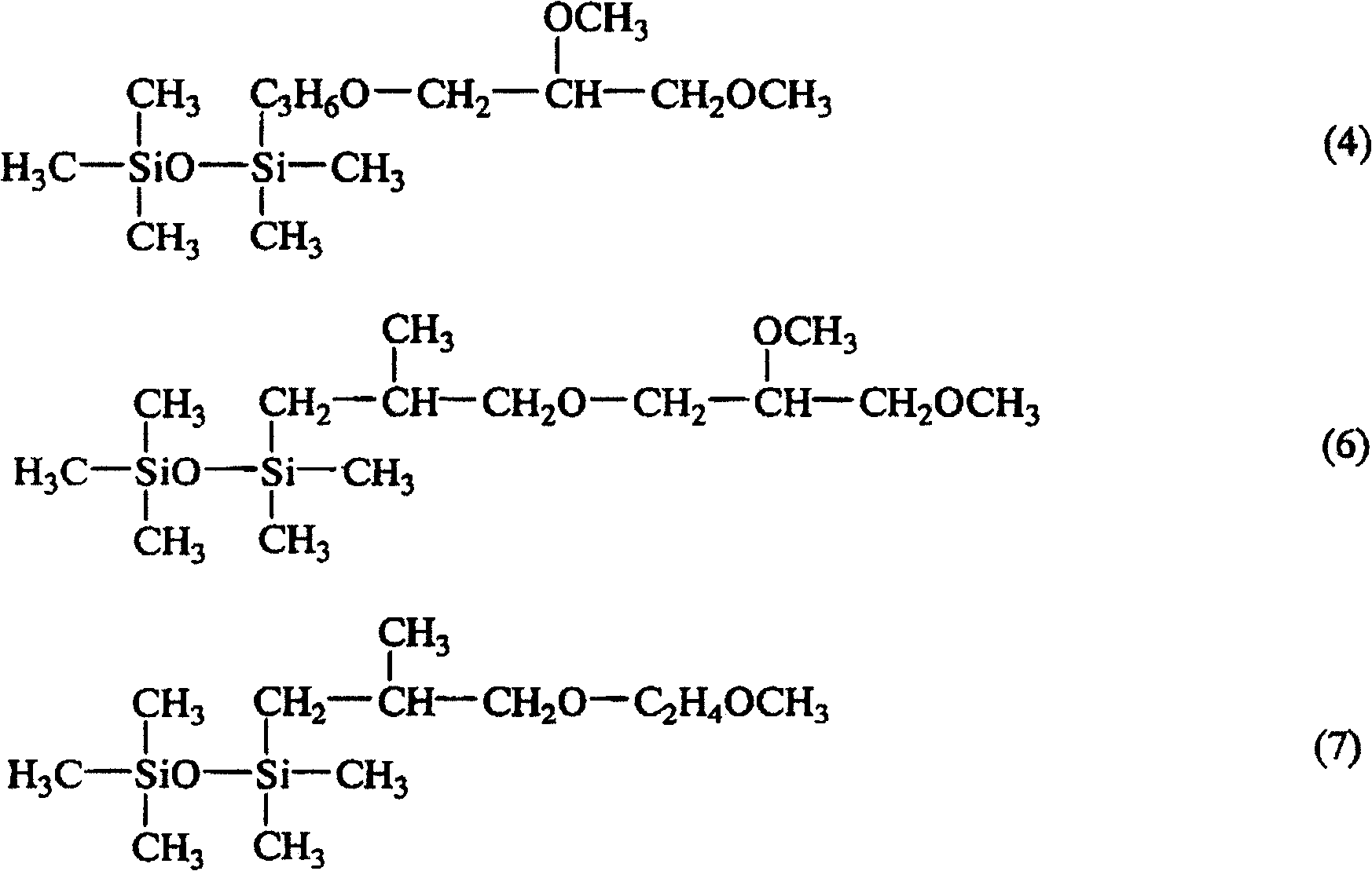

[0044] Synthesis of Siloxanes Modified with Organic Groups Bearing Ether Bonds

[0045] Siloxanes of formula (4) are synthesized as follows.

[0046] A reactor equipped with a stirrer, thermometer and reflux condenser was charged with 100 g of 1,2-dimethoxyglycerol monoallyl ether, 100 g of isopropanol (IPA) and 0.05 g of 0.5 wt% chlorine IPA solution of platinum acid. Stirring was performed at 60° C., and 107 g of pentamethyldisiloxane having the chemical formula (16) was added dropwise to the mixture. The reaction occurs when the molar ratio of terminal unsaturated groups to SiH groups is approximately 1.05. The reaction solution was finely distilled in a vacuum state to obtain the siloxane represented by the chemical formula (4) modified with an organic group having an ether bond. It has a 5.5mm 2 / s viscosity and 99.9% purity by gas chromatography analysis.

[0047] Preparation of non-aqueous electrolyte

[0048] The non-aqueous electrolytic solution is by dissol...

Embodiment 2-6

[0062] As listed in Table 1, other siloxanes modified with organic groups having ether linkages were tested according to Example 1 for their battery performance. The results are shown in Table 1 together with the results of Example 1 and Comparative Example.

[0063] Table 1

[0064]

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com