Coating of aluminum substrate for direct plate making of ink-jet printing, production method and use

An inkjet printing, aluminum plate-based technology, applied in the preparation, coating, printing and other directions of the printing surface, can solve the problems of easy environmental pollution and high plate cost, save the post-processing process, high specific surface area Can and avoid the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

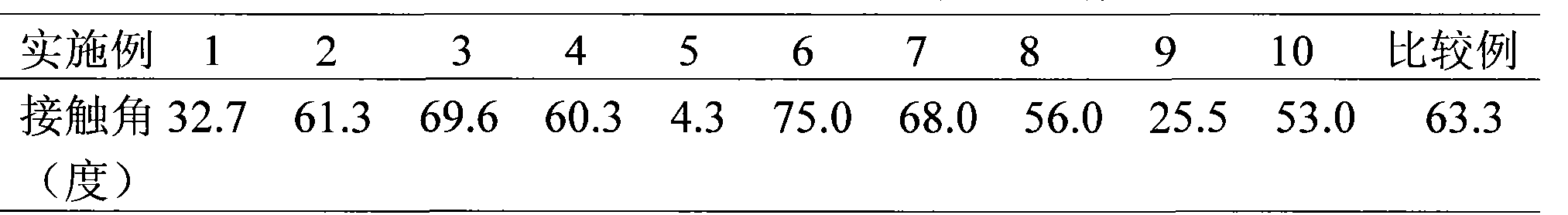

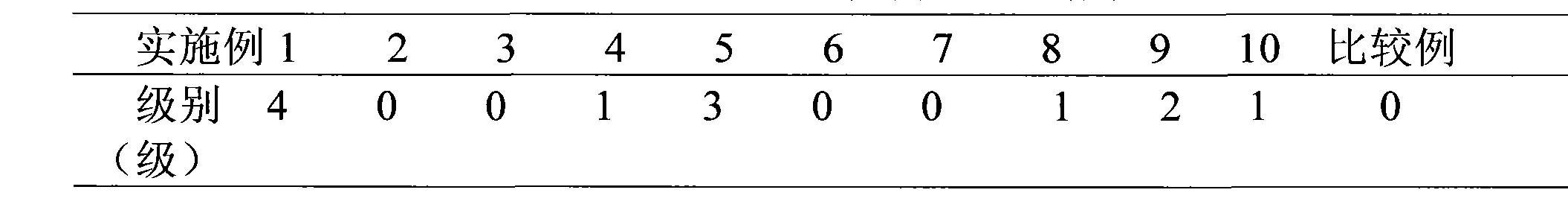

Embodiment 1

[0025] Weigh 1.25g polyvinyl alcohol (polymerization degree 1700, alcoholysis degree 99%), particle diameter is 2~3 μ m silicon dioxide 3.75g, put into 50ml Erlenmeyer flask, add 20g distilled water, stir 6~8 hours, make It dissolves well. Cut the aluminum plate into 10×10cm 2 , washed with acetone and distilled water successively, and dried. Spin the paint on the aluminum plate by spin coating on the glue leveler, bake it at 100°C for about 3 hours, and measure the contact angle and adhesion of the plate, see Table 1 and Table 2.

Embodiment 2

[0027] Weigh 1g of polyvinyl alcohol (polymerization degree 2500, degree of alcoholysis 88%), 0.5g of polyvinylpyrrolidone K-30, 0.25g of silicon dioxide with a particle size of 10-20nm, put them into a 50ml Erlenmeyer flask, add 23.75g Distilled water, 5ml of ethanol, stirred for 6-8 hours to fully dissolve. Cut the aluminum plate into 10×10cm 2 , washed with acetone and distilled water successively, and dried. The coating composition was coated on the aluminum plate by spin coating on a coater, and baked at 200° C. for 0.5 hour. The contact angle and adhesion of the plate were measured, as shown in Table 1 and Table 2.

Embodiment 3

[0029] Weigh 1g polyvinyl alcohol (polymerization degree 2500, alcoholysis degree 88%), particle diameter is 0.25g of silicon dioxide of 2~3μm, put into 50ml Erlenmeyer flask, add 23.75g distilled water, stir 6~10 hours, make It dissolves well. Cut the aluminum plate into 10×10cm 2 , washed with acetone and distilled water successively, and dried. The coating composition was coated on the aluminum plate by spin coating on a coater, and baked at 150° C. for about 1 hour. The contact angle and adhesion of the plate were measured, as shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com