Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Improve crystallization ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

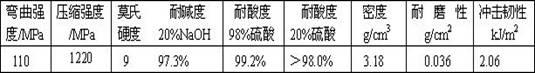

Slag glass ceramic pipe and preparation method thereof

The invention relates to a glass ceramic pipe and a preparation method thereof. The glass ceramic pipe is prepared from the following raw materials in percentage by weight: 20 to 40 percent of coal ash, 20 to 50 percent of slag obtained by separating Baiyunebo tailings again, 0 to 40 percent of blast furnace slag or steel slag, 15 to 30 percent of quartz sand, 2 to 5 percent of sodium carbonate, 2 to 7 percent of borax, 0 to 5 percent of dolomite or lime stone, and 0 to 6 percent of albite or potash feldspar; and the preparation method comprises the following steps of: measuring the raw materials according to the ratio and then adding into a ball-milling mixing machine and mixing uniformly and melting the mixture at the temperature of between 1,350 and 1,450 DEG C; and performing centrifugal casting and molding; annealing, coring and crystallizing the molded pipe, and reducing the temperature at a speed of 1 to 5 DEG / min to the temperature of less than 100 DEG C and then discharging. The product has good performance, the abrasive resistance of the product is three times higher than that of a glass-ceramic tube, the weight of the product is only one third that of a glass-ceramic composite tube, the service life of the product is 3 to 5 times that of the glass-ceramic composite tube, and the cost performance of the product is high. The utilization rate of industrial waste residue in the raw materials is more than and equal to 70 percent, and the pipe is energy-saving and environment-friendly, has low production cost, is suitable for large-scale industrial production and has a wide application range.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Preparation method of polyester chip for solar battery back film

InactiveCN105542138AImprove crystallization abilityReduce contentPhotovoltaic energy generationSemiconductor devicesSolid phasesChemistry

The present invention discloses a preparation method of a polyester chip for a solar battery back film. A polyester chip semi-finished product with intrinsic viscosity of 0.60-0.64 dl / g and terminal carboxyl group content of 12-18 mol / t is subjected to solid phase polycondensation to obtain the polyester chip for solar battery back film with intrinsic viscosity of 0.75-0.80 dl / g and terminal carboxyl group content of 5-10 mol / t. The preparation method has simple reaction conditions and low production costs; the obtained polyester chip can be separately produced into polyester film suitable for solar battery back without the addition of an anti-hydrolysis agent or an ultraviolet absorber, wherein the polyester film has good water vapor barrier property, resistance to wet heat aging and resistance to light aging. The method is not only friendly to the environment and human, but also avoids the problems of uneven dispersion and inconsistency of product performance of blend film production.

Owner:HEFEI LUCKY SCI & TECH IND

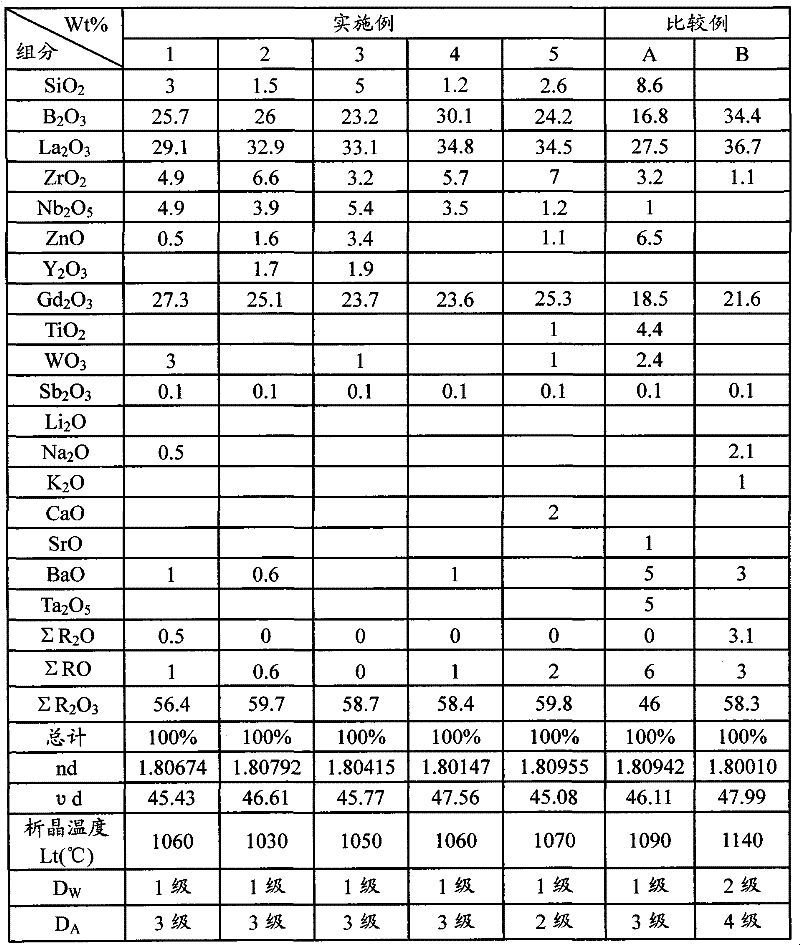

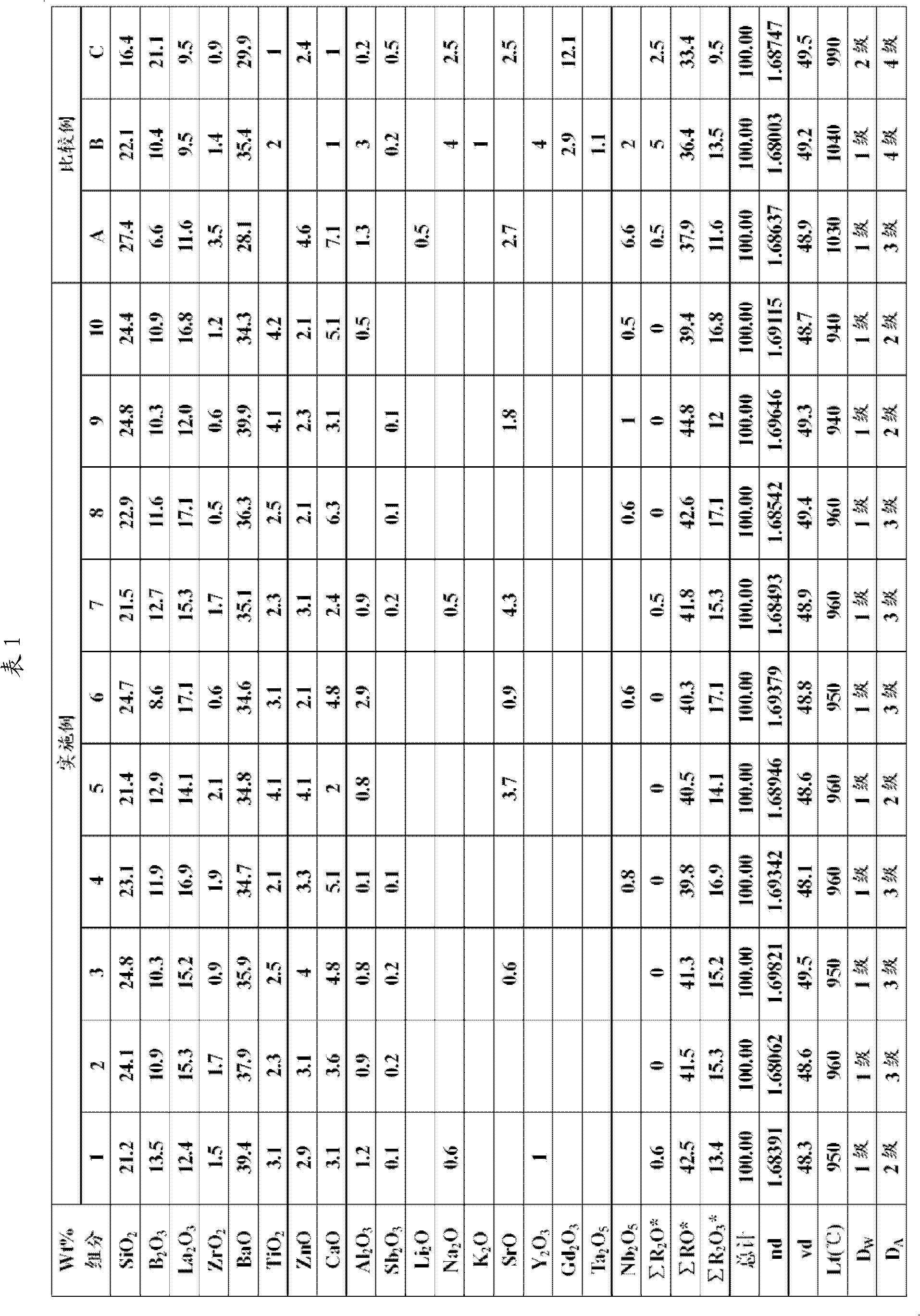

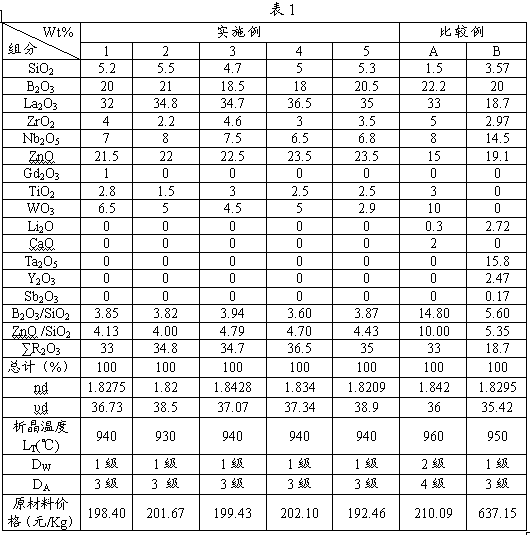

Optical glass

The invention provides optical glass with B2O3, La2O3 and Gd2O3 as the main components, and the optical glass contains no thorium, cadmium and arsenic, and preferably contains no lead and fluorine. The refractive index (nd) of the optical glass is in a range of 1.80 to 1.81, and the Abbe number (vd) of the optical glass is in a range of 45 to 48. According to tests by the method of GB / T17129, water resistance (DW) of the optical glass is of grade 1, and acid resistance (DA) is of grade 3 or of a higher grade. On a mass percentage basis, the optical glass comprises 0 to 5% of SiO2, 23 to 32% of B2O3, 28 to 36% of La2O3, 3 to 7% of ZrO2, 0 to 6% of Nb2O5, 0 to 5% of ZnO, less than 2% of Y2O3, 20 to 28% of Gd2O3, 0 to 4% of WO3, 0 to 3% of TiO2, 0 to 2% of Sb2O3 and 0 to 5% of sigma(R2O + RO). The optical glass has good crystallization performance and is suitable for production.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Low-melting point optical glass

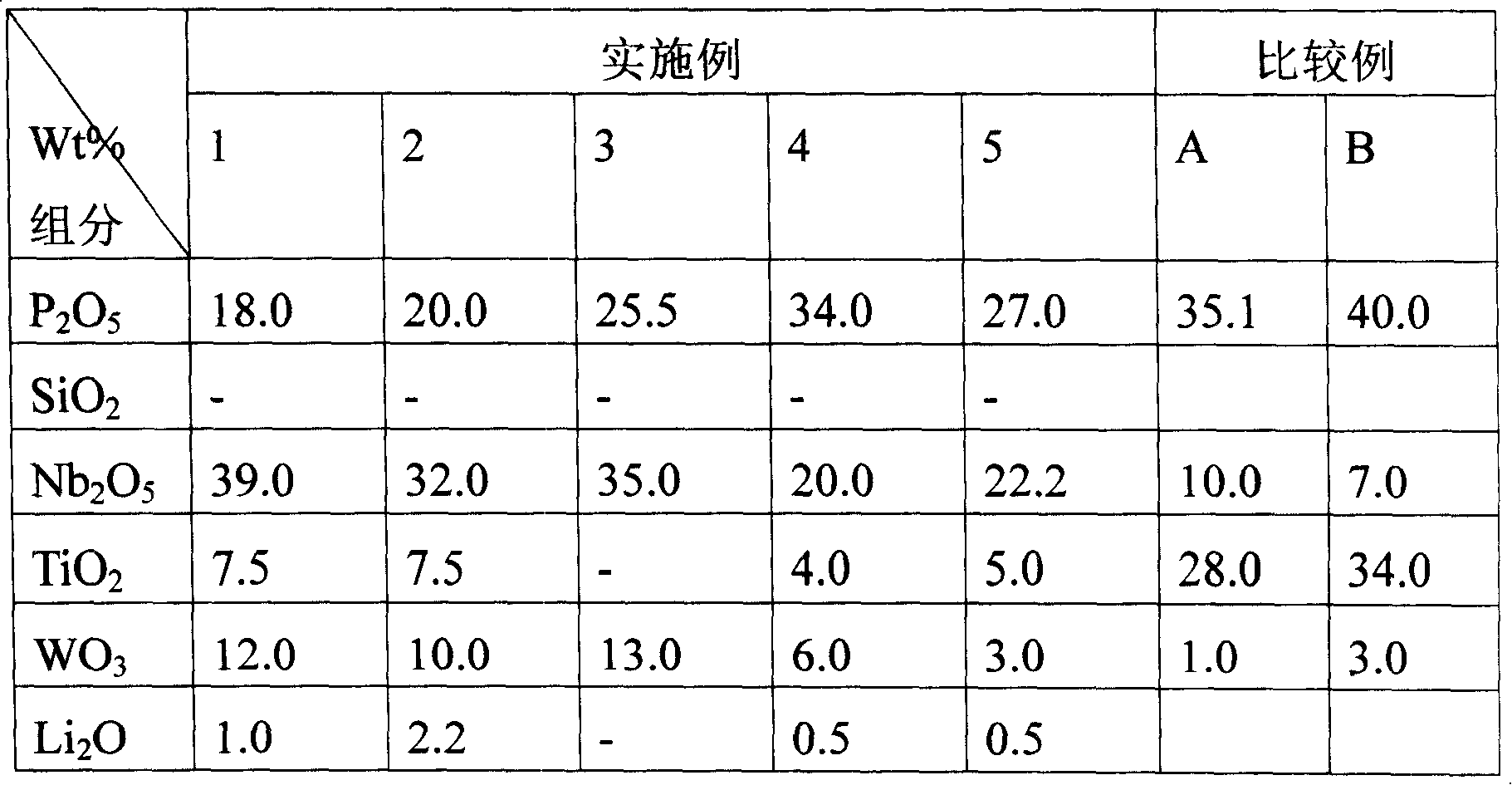

InactiveCN101215086ALower transition temperatureImprove crystallization abilityRefractive indexOptical glass

The invention relates to low melting point optical glass, belonging to the low melting point optical glass without lead, arsenic, bismuth and fluorine, which resolves the problem that the existing optical glass has high transformation temperature, insufficient chemical stability, big glass specific weight and the like. the technical scheme of the invention is that the content of percentage by weight comprises: P2O5 holding 18-40%, Nb2O5 holding 20-40%, TiO2 holding 0-10%, WO3 holding 0-15%, B2O3 holding0-15%, R2O holding 10-45%, RO holding 0-20%, Sb2O3 holding 0-1% and total content holding 100%. The glass of the invention does not contain lead, arsenic, bismuth and fluorine, the transformation temperature of which is low (Tg < 500DEG C), the glass is adaptable to precise compression, the refractive index is 1.65-1.85, Abbe number is 20-35, chemical stability is good, bending and separation property is good, and the glass is easy in melting and processing, low in density and comparatively light in color.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Microcrystalline glass solder and method for soldering porous Si3N4 (silicon nitride) and dense Si3N4 by using microcrystalline glass solder

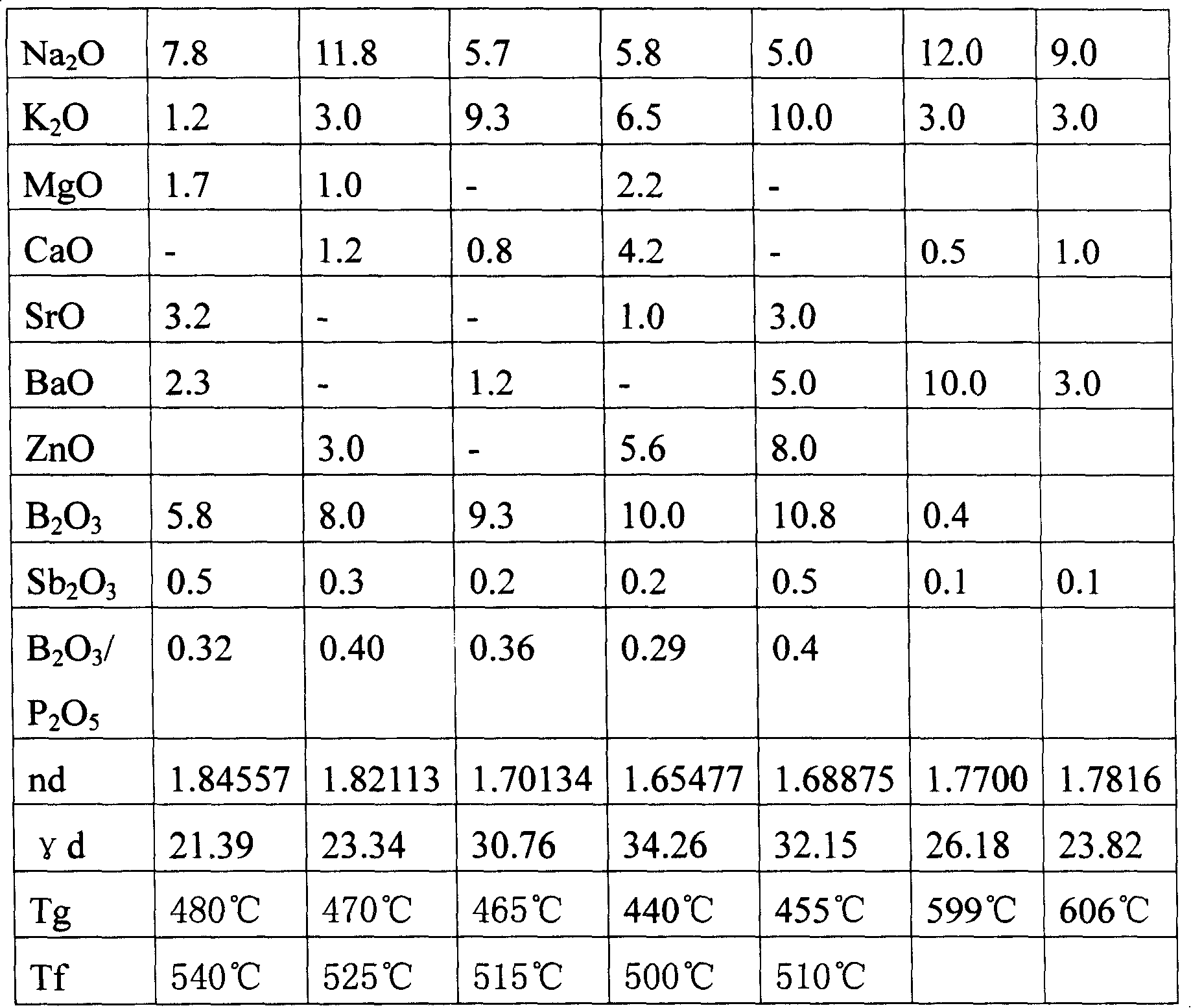

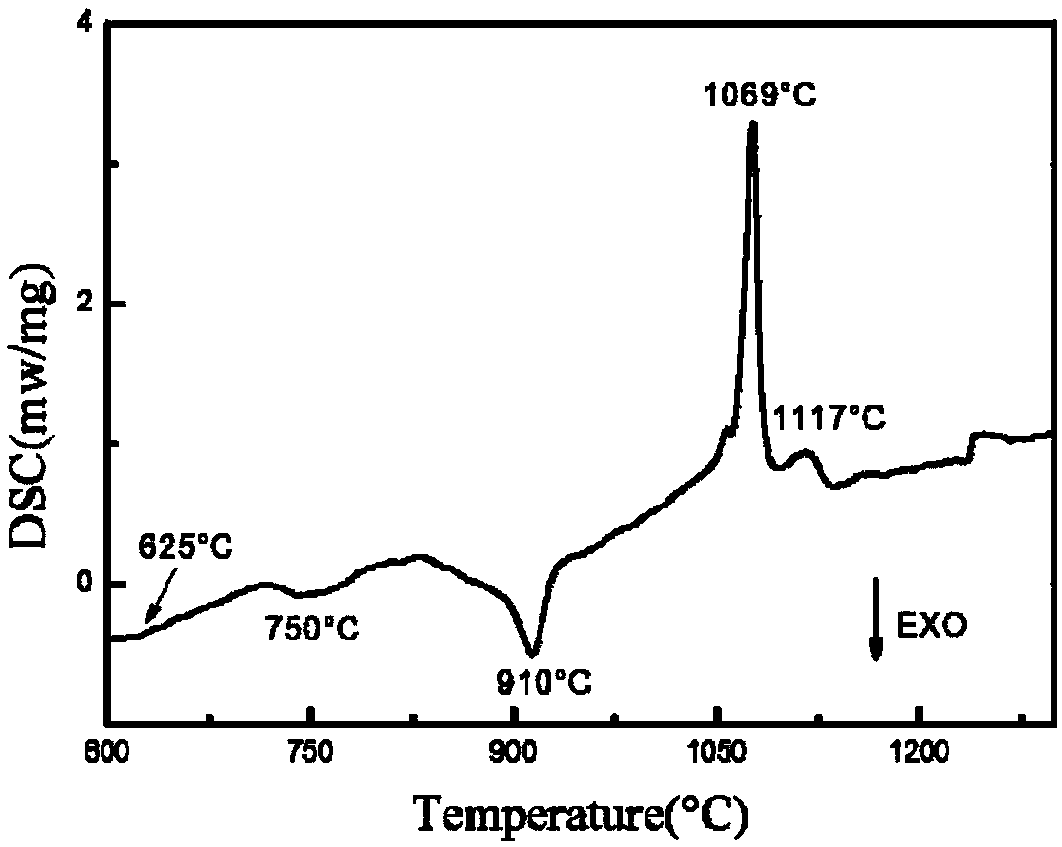

ActiveCN108640522ALower melting temperatureSmall coefficient of thermal expansionLithium oxideThermal expansion

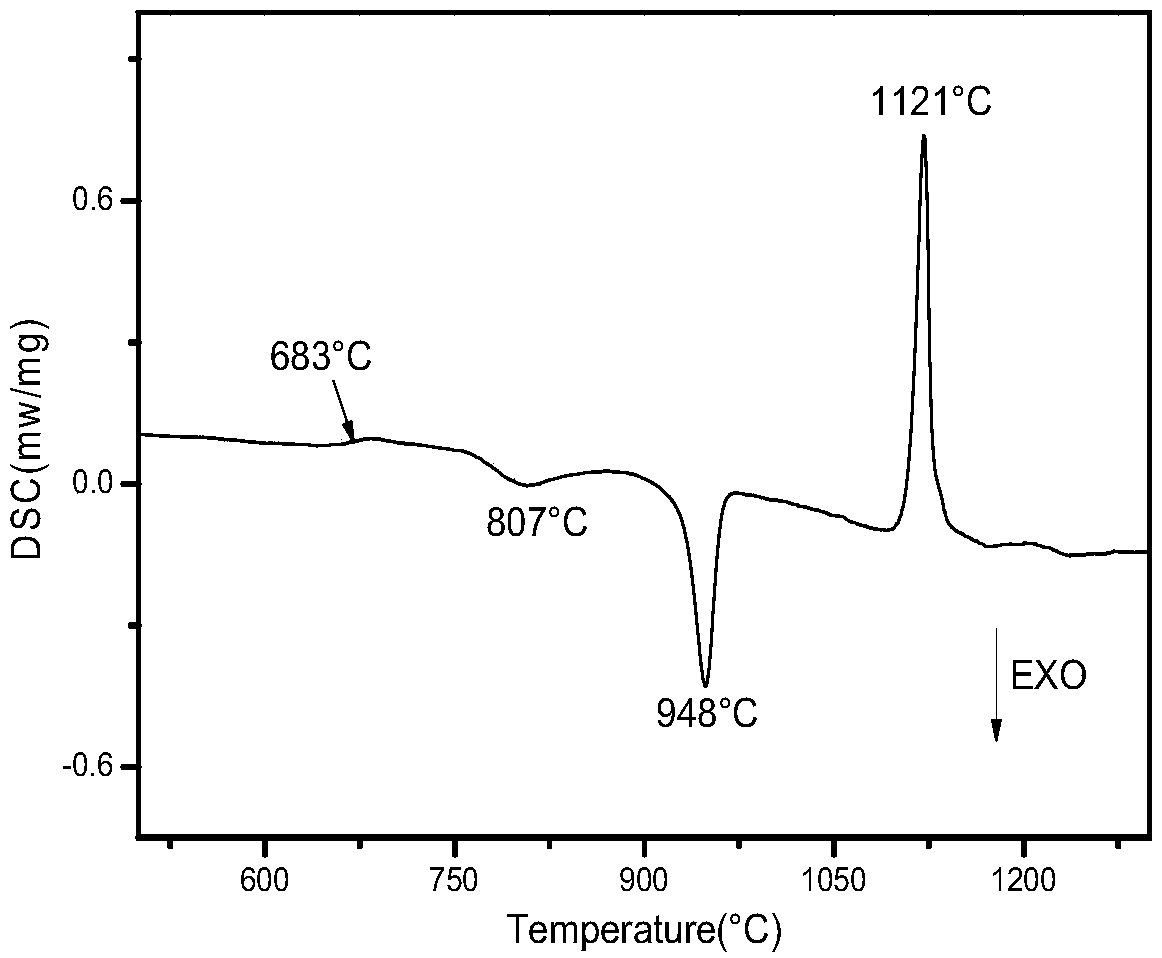

The invention relates to a microcrystalline glass solder and a method for soldering porous Si3N4 (silicon nitride) and dense Si3N4 by using the microcrystalline glass solder, in particular to a methodfor soldering dense Si3N4 and porous Si3N4 by the microcrystalline glass solder, which aims at solving the problem of mismatching between the existing common microcrystalline glass solder and the thermal expansion coefficients of porous Si3N4 ceramic and dense Si3N4 ceramic. The microcrystalline glass solder is prepared from the following components of CaO (calcium oxide), Al2O3 (aluminum oxide),SiO2 (silicon dioxide) and Li2O (lithium oxide). The method comprises the following steps of 1, preparing the microcrystalline glass solder; 2, soldering the dense Si3N4 ceramic and the porous Si3N4ceramic. The method is characterized in that the Li2O is added into a CaO-Al2O3-SiO2 system using separated anorthite as a main crystal phase, so as to reduce the melting temperature; spodumene with low thermal expansion coefficient is separated out, so as to reduce the thermal expansion coefficient, thereby matching with the thermal expansion coefficient of base metal. The microcrystalline glasssolder is applied to connect the dense Si3N4 ceramic and the porous Si3N4 ceramic.

Owner:HARBIN INST OF TECH

Optical glass

ActiveCN102674686AGood crystallization performanceGood chemical stabilityRefractive indexAcid resistance

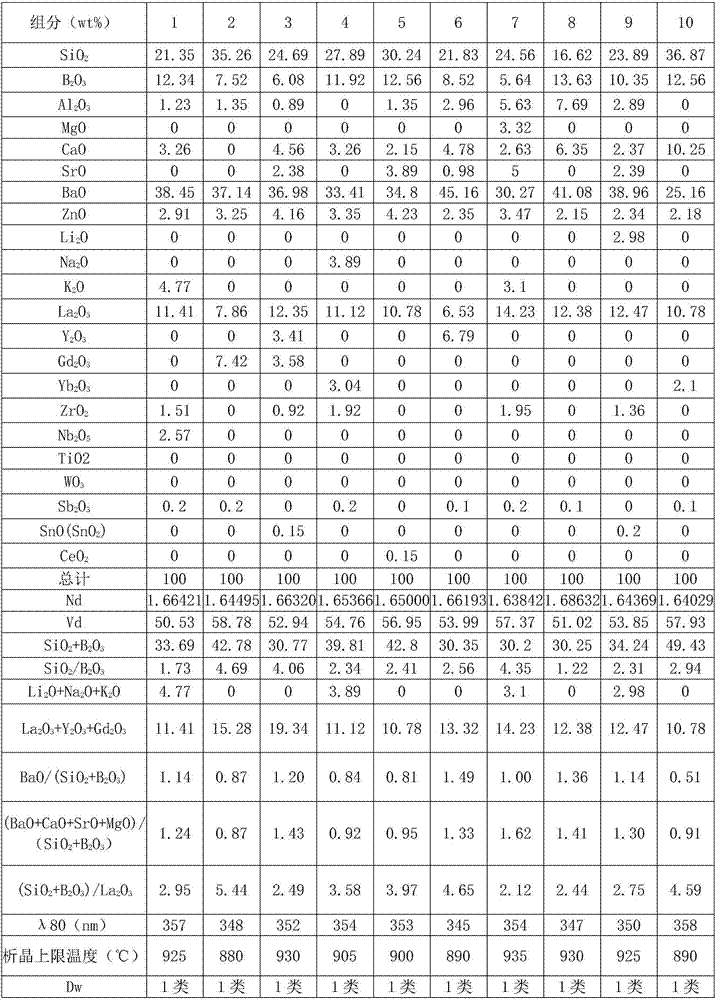

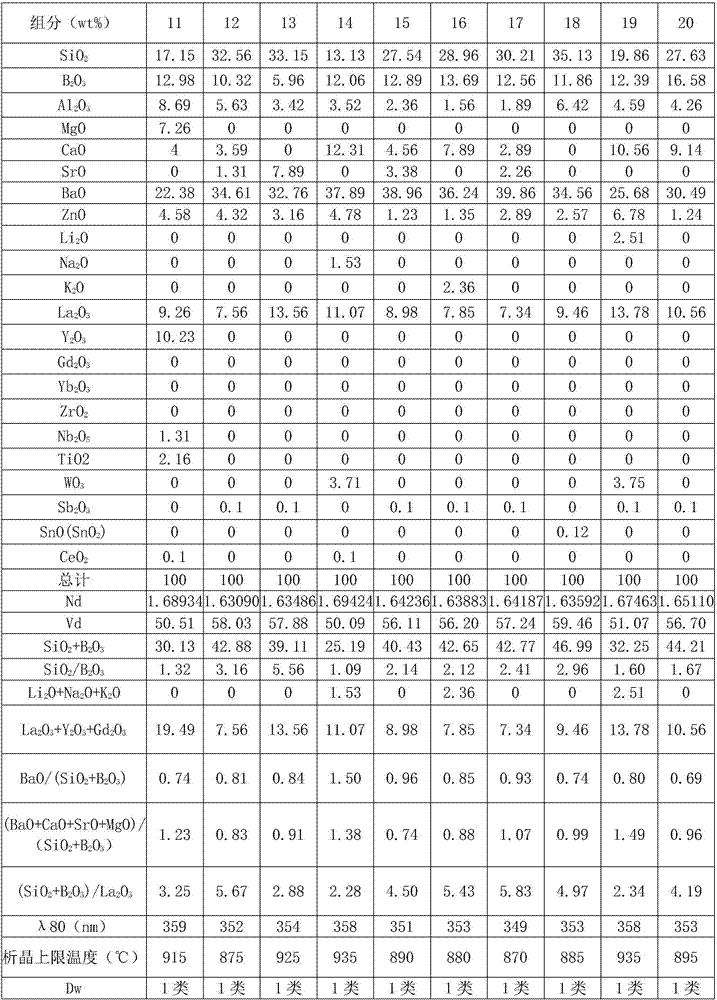

The invention provides optical glass which takes SiO2, B2O3, BaO and La2O3 as main components and contains no lead, thorium, cadmium, arsenic and fluorine. The refractive index (nd) of the optical glass is between 1.68-1.70, and the abbe number (vd) of the optical glass is 48-50. The optical glass has the characteristic of good crystallization property and is suitable for production. Through test according to a GB / T 17129 method, the water resistance (DW) of the optical glass is grade 1, and the acid resistance of the optical glass (DA) is grade 3 or above. The optical glass comprises the following components in percentage by weight: 21-25 percent of SiO2, 8-14 percent of B2O3, 12-18 percent of La2O3, 0.5-3 percent of ZrO2, 34-40 percent of BaO, 2-5 percent of TiO2, 2-5 percent of ZnO, 2-7 percent of CaO, 0-3 percent of Al2O3 and 0-1 percent of Sb2O3, and the total content of the components is above 95 percent, and the total content of glass components is 100 percent.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

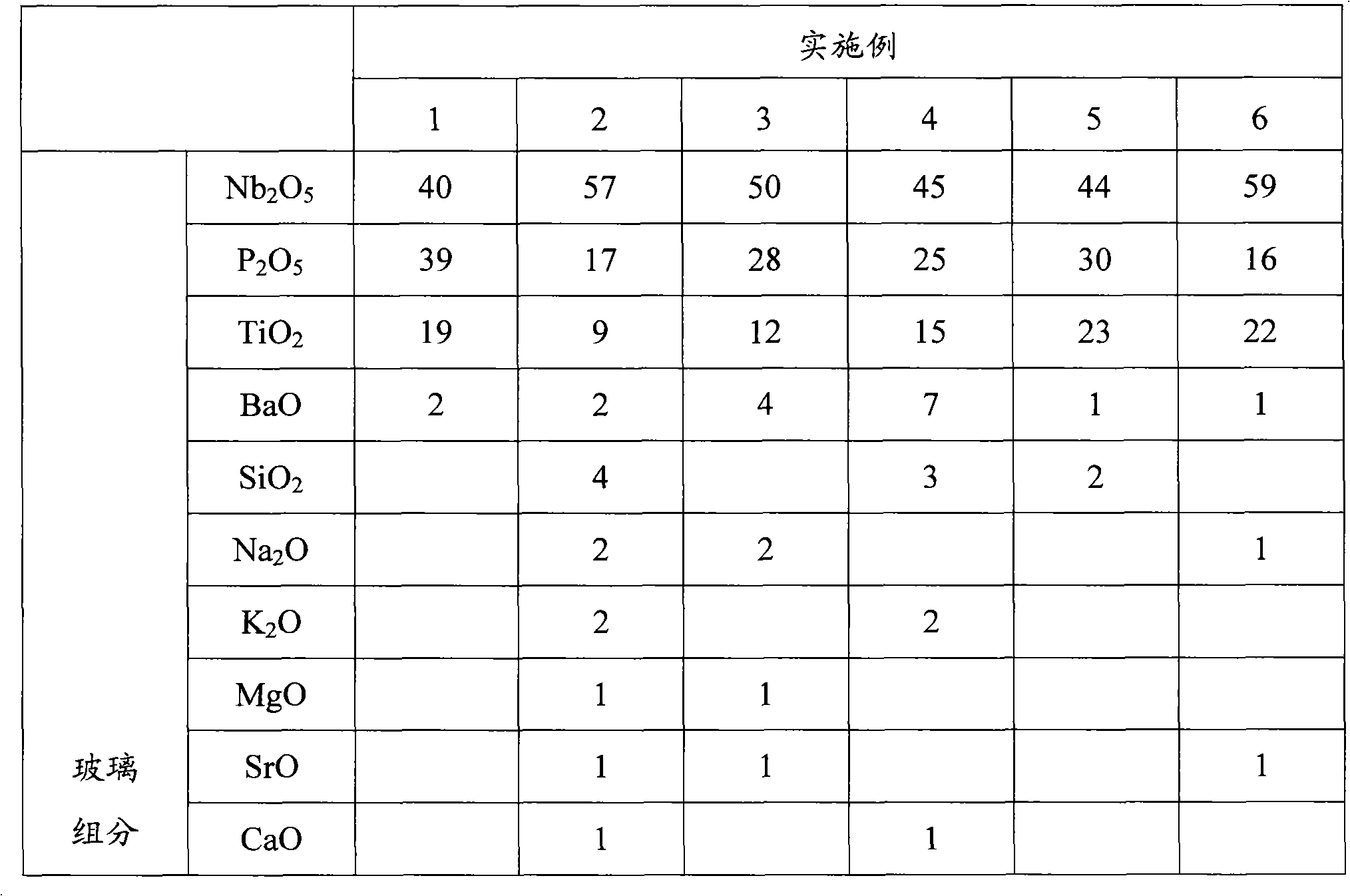

Optical glass and optical element

ActiveCN101941797AHigh refractive indexImprove mechanical propertiesOptical elementsRefractive indexTransmittance

The invention discloses optical glass and an optical element, wherein the optical glass comprises the following components: 40-60wt% of Nb2O5, 16-40wt% of P2O5, 8-25wt% of TiO2 and 0.5-10wt% of BaO; and the optical glass does not contain a clarifier. Experimental results indicate that the optical glass provided by the invention does not need to be added with the clarifier or a non-environment-friendly substance Sb2O3, and when the refractive index of the optical glass is 1.91-1.98, the Abbe number is 14-20, and the transmittance is 70 percent, the corresponding wavelength is smaller than 470nm, and the requirement on modern imaging equipment is satisfied.

Owner:CDGM OPTICAL GLASS

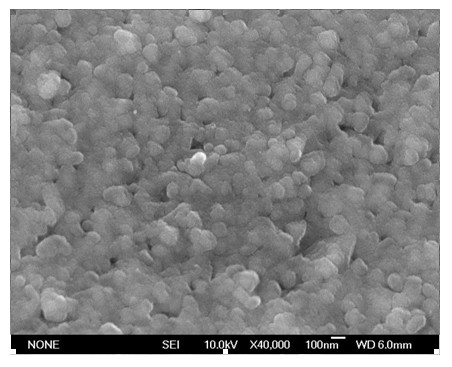

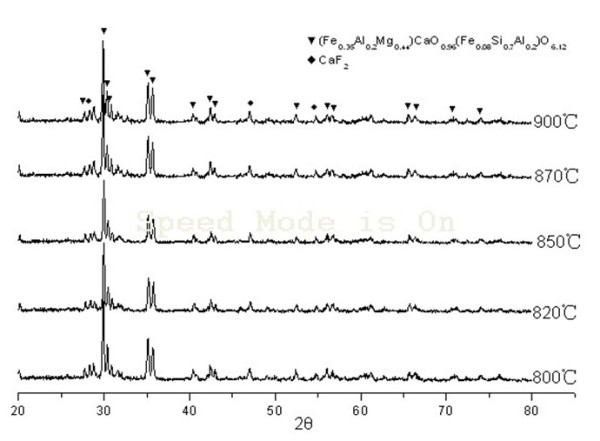

CaO-MgO-Al2O3-SiO2 microcrystalline glass and preparation method thereof

InactiveCN102173592ALower crystallization activation energyImprove growth indexDevitrificationActivation energy

The invention discloses a CaO-MgO-Al2O3-SiO2 microcrystalline glass which is composed of glass aggregate and oxide nucleating agent accounting for 3wt% of glass aggregate, wherein the glass aggregate is composed of the following components in percentage by weight: 50-55wt% of SiO2, 6-10wt% of MgO, 15-18wt% of CaO, 10-12wt% of Al2O3, 3-6wt% of Na2O and / or K2O, 8wt% of CaF2 and 1wt% of Sb2O3. The invention simultaneously provides a preparation method of the CaO-MgO-Al2O3-SiO2 microcrystalline glass. In the CaO-MgO-Al2O3-SiO2 microcrystalline glass, nucleating agent of oxide and fluoride is adopted, so that the devitrification activation energy of a system is lowered, a crystal growth index is improved, and the devitrification capability of the microcrystalline glass is greatly enhanced, thereby bringing convenience for preparing the microcrystalline glass with a whole method.

Owner:ZHEJIANG UNIV

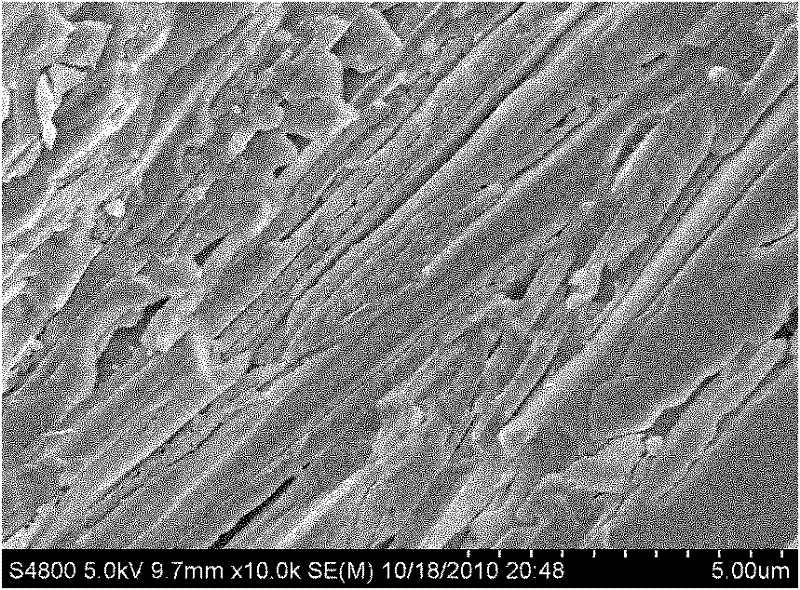

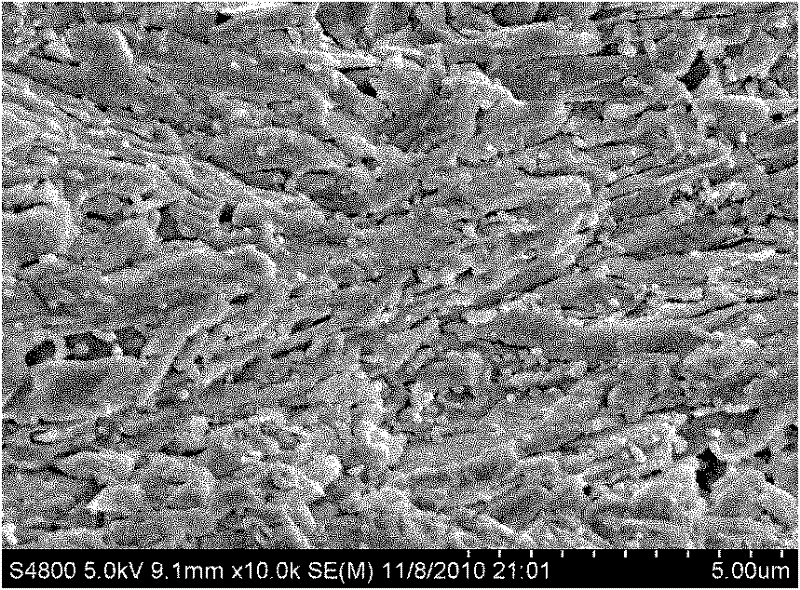

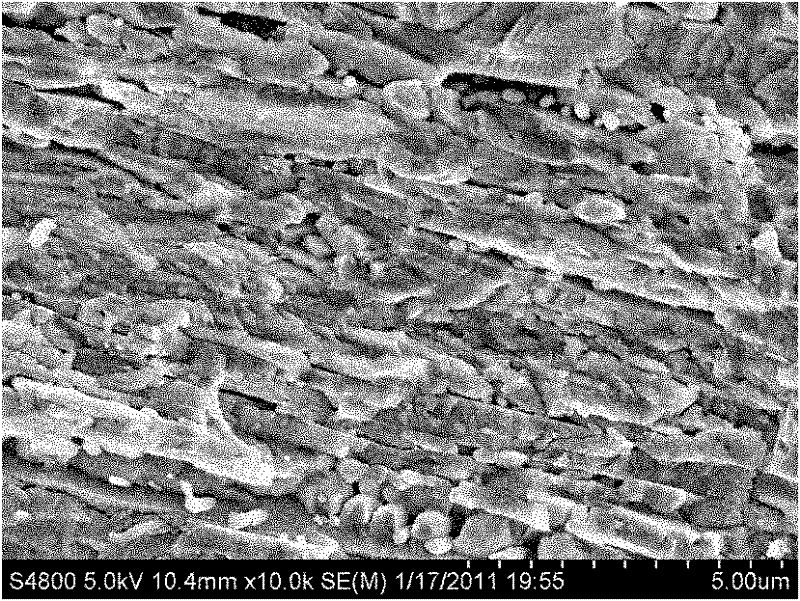

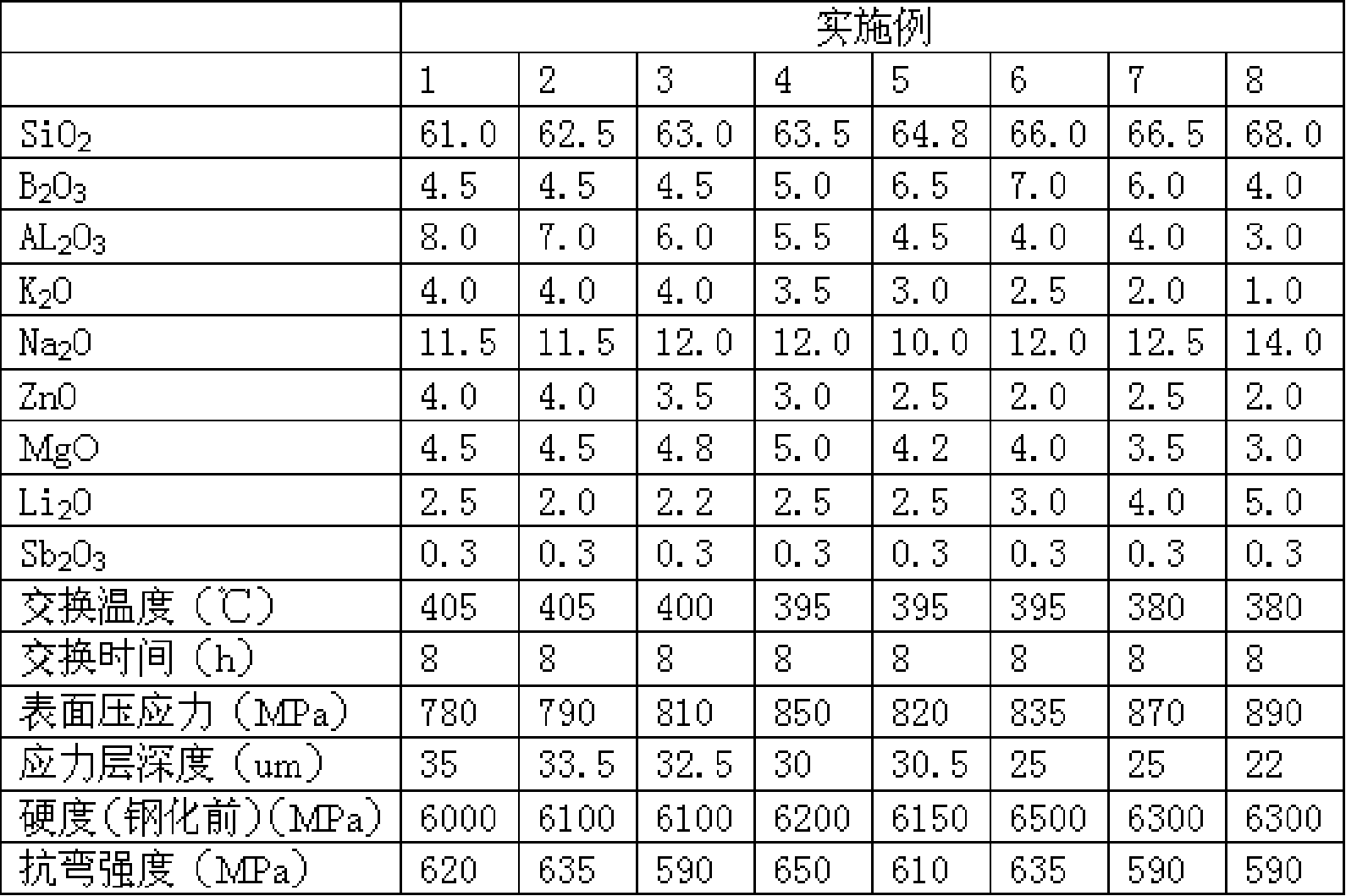

Glass for chemical tempering

ActiveCN101172771AImprove crystallization abilityEasy to produce by down-draw methodDevitrificationHardness

The invention relates to glass used for chemical strengthening, the weight percentage component of the glass comprises 60 to 70 percent of SiO2, 3 to 8 percent of Al2O3, 4 to 8 percent of B2O3, 10 to 15 percent of Na2O, 3 to 8 percent of MgO, 1 to 5 percent of ZnO, 1 to 5 percent of Li2O, 1 to 5 percent of K2O. The melting temperature of the invention is lower than 1450 DEG C, the surface compressive stress is higher than 750 MPa, and the liquidus temperature is lower than 900 DEG C. The invention has good devitrification performance and is easy to be produced through down-draw process. The transformation temperature of the invention is lower than 500 DEG C, thereby being applicable for the low-temperature ion transformation. The invention has good ion transformation performance, the ion transformation layer of the chemical strengthened glass obtained by transformation in short time is 20 to 35 microns, the buckling strength is 550 to 650 MPa, and the hardness is 6000 to 7000 MPa, so the invention can be widely used in windows such as a watchcase and a cell phone faceplate.

Owner:CDGM OPTICAL GLASS

Optical glass

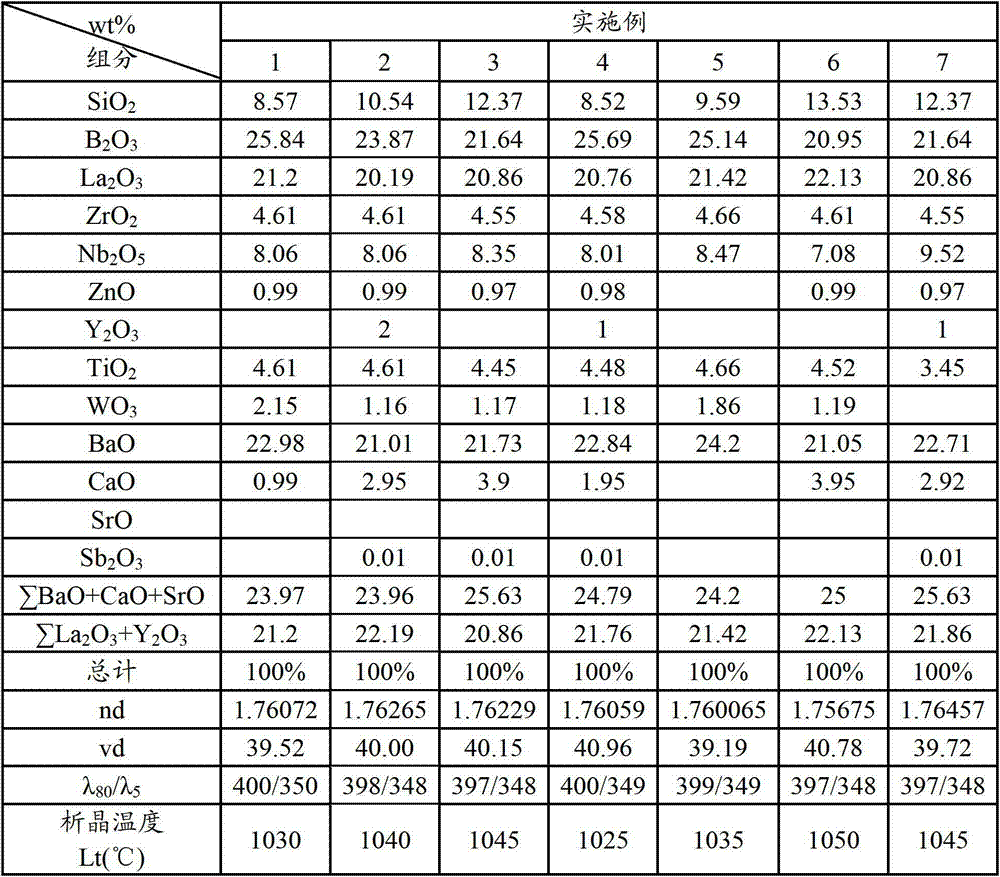

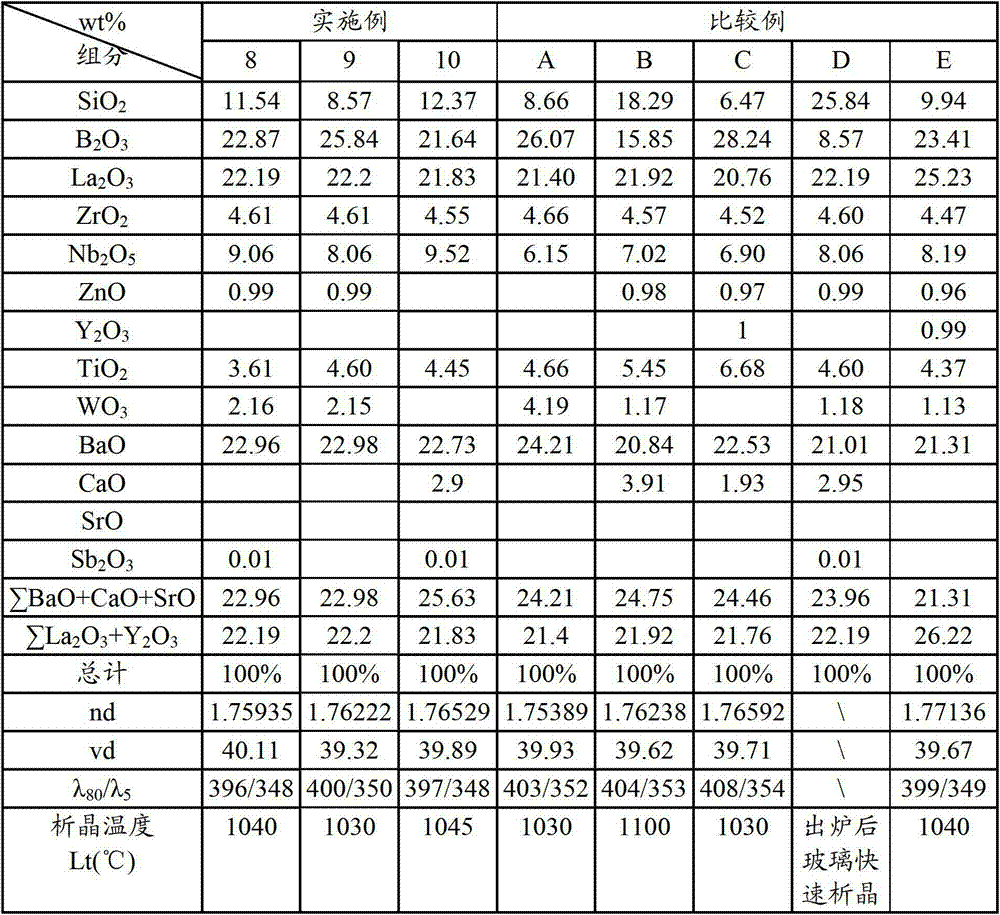

The invention provides lanthanum borosilicate optical glass taking SiO2, B2O3, La2O3, Nb2O5, ZrO2 and TiO2 as primary ingredients, wherein the optical glass does not contain substances harmful to the environment, for example, lead, thorium, cadmium, arsenic, fluorine and the like, and does not contain valuable materials such as Ta2O5, Gd2O3 and the like; the refractive index (nd) of the optical glass is 1.75-1.77; the abbe number (vd) is 39-41; and the optical glass has the characteristics of being good in crystallization properties, good in pigmentation degree, and suitable for production. Based on the weight percent of the compound, the optical glass contains 8-14% of SiO2, 19-26% of B2O3, 18-23% of La2O3, 0-5% of Y2O3, 2-5% of ZrO2, 5-10% of Nb2O5, 20-25% of BaO, 0-4% of SrO, 0-5% of CaO, 0-2% of ZnO, 0-3% of WO3, 1-5% of TiO2, and 0-1% of Sb2O3, wherein the sum of the contents of La2O3 and Y2O3 is 19-25%; and the sum of the contents of BaO and CaO and SrO is 22-27%.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Optical glass

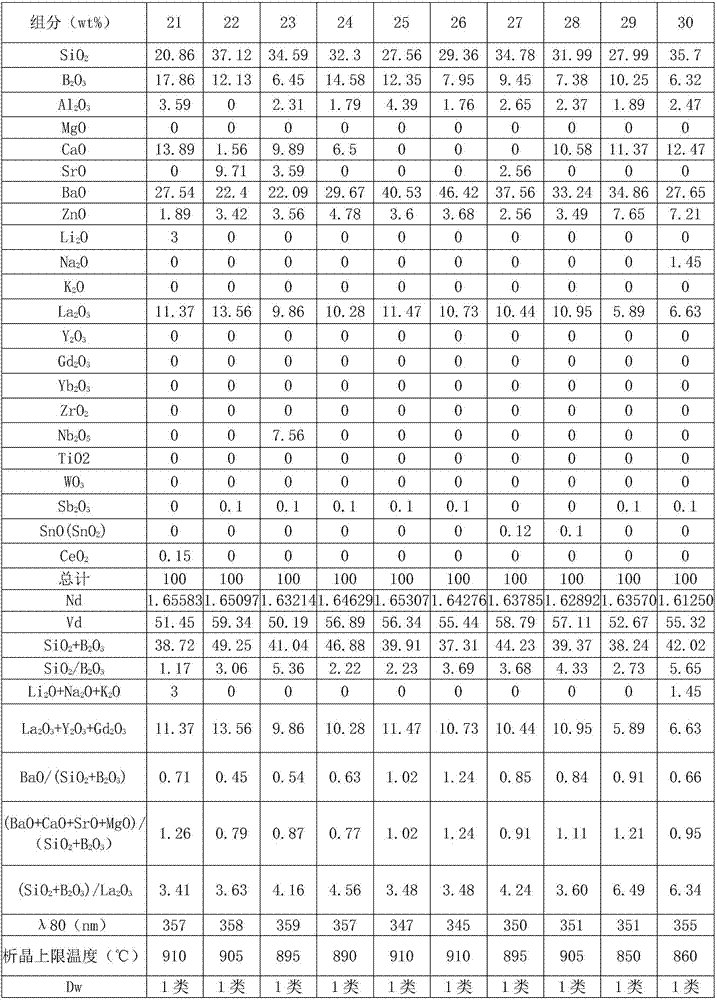

InactiveCN107399906AGood chemical stabilityImprove crystallization abilityOptical elementsTransmittanceRefractive index

The invention provides optical glass without containing fluorine, phosphorus or tantalum. The optical glass is high in chemical stability, excellent in crystallization property and high in transmittance. The optical glass comprises the following components in percentage by weight: 10-40% of SiO2, 5-20% of B2O3 (not including 20%), La2O3 more than 5% but less than or equal to 15%, and 20-50% of BaO. According to the reasonable formula design, the optical glass lambda 80 is less than or equal to 360nm when the optical glass has the refractive index of 1.62-1.70 and the abbe number of 50-60, the upper limit of a devitrification temperature of the glass is below 940 DEG C, and the water resistance stability DW of the glass is over class 1. Moreover, the optical glass does not contain fluorine, phosphorus or tantalum, and has excellent chemical stability, crystallization property and transmittance.

Owner:CDGM OPTICAL GLASS

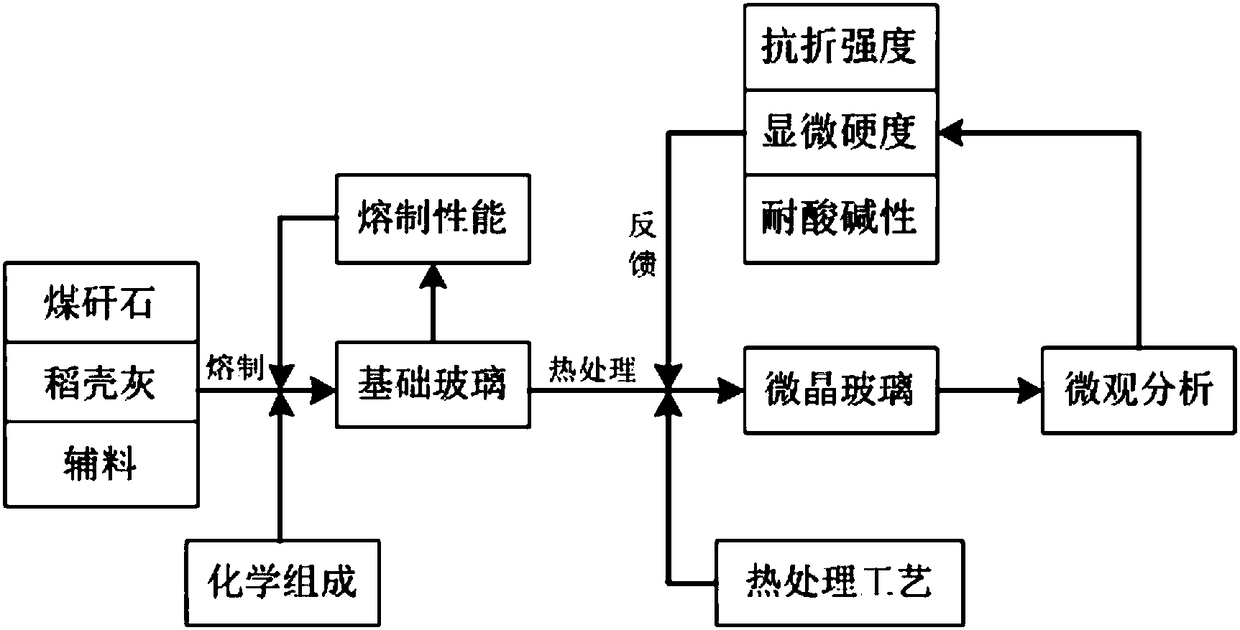

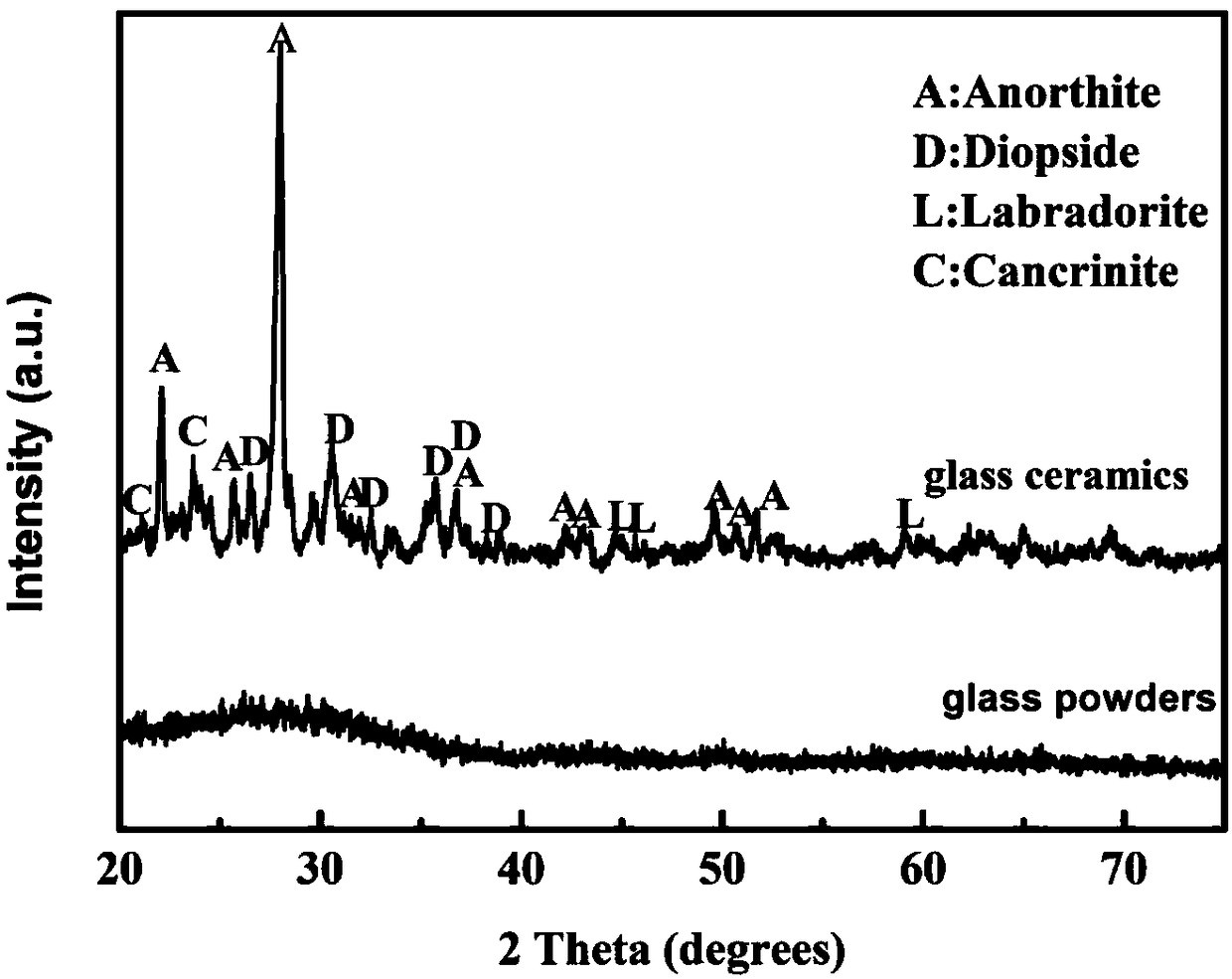

Glass ceramic mainly prepared from coal gangue and rice husk ash and preparation method thereof

ActiveCN108503224ALow costPromote healthy ecological developmentGlass shaping apparatusQuenchingMaterials science

The invention discloses a method for preparing glass ceramic by sintering bulk of solid waste coal gangue and rice husk ash serving as main raw materials. The glass ceramic provided by the invention is prepared from the following raw materials in parts by weight: 28.1 to 32.5 parts of coal gangue, 4.0 to 6.5 parts of rice husk ash, 3.5 to 5.0 parts of sodium carbonate, 7.0 to 8.5 parts of calciumcarbonate, 2 to 3 parts of magnesium oxide and 2 to 3 parts of titanium dioxide. The method comprises the following steps: mixing the ingredients evenly, and heating to a melting temperature of 1,400to 1,450 DEG C; performing quenching, ball milling and tableting on the obtained glass melt, preserving heat at 740 to 790 DEG C and 820 to 870 DEG C for 1 to 1.5 hours, and performing heat treatmentto obtain glass ceramic which takes calciclase as a principal crystalline phase and takes diopside as a secondary crystalline phase. A large amount of SiO2 in the rice husk ash serving as a raw material reduces the high aluminum characteristic of the coal gangue, adjusts the ratio of Si to Al in the formula, and improves the utilization ratio of the solid waste coal gangue and rice husk; moreover,the method has the advantages of simple formula composition, low melting temperature and relatively low heat treatment temperature; the prepared glass ceramic has high compactness, corrosion resistance and wear resistance, and the added value of two solid wastes of coal gangue and rice husk is greatly increased.

Owner:ANHUI UNIV OF SCI & TECH

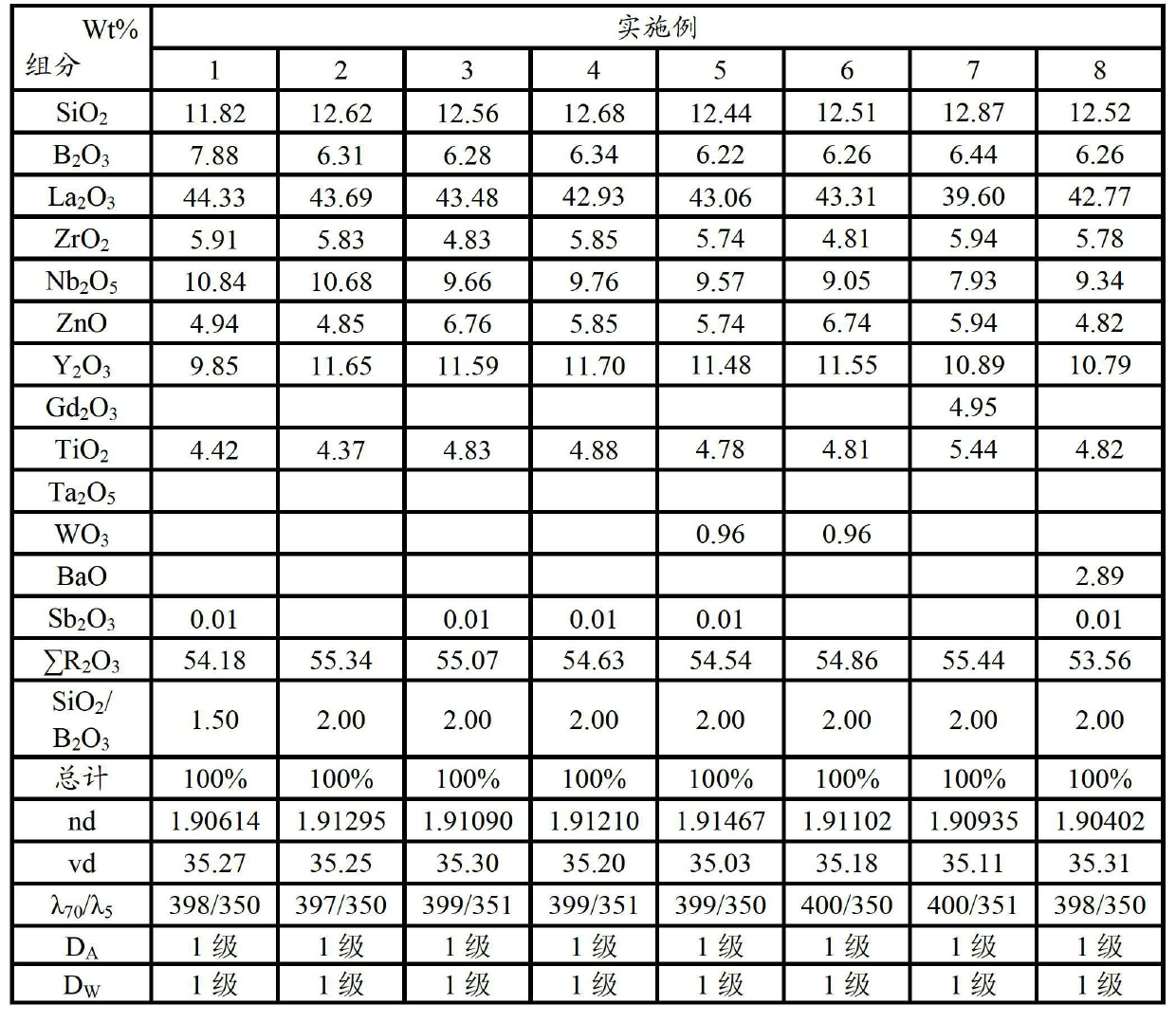

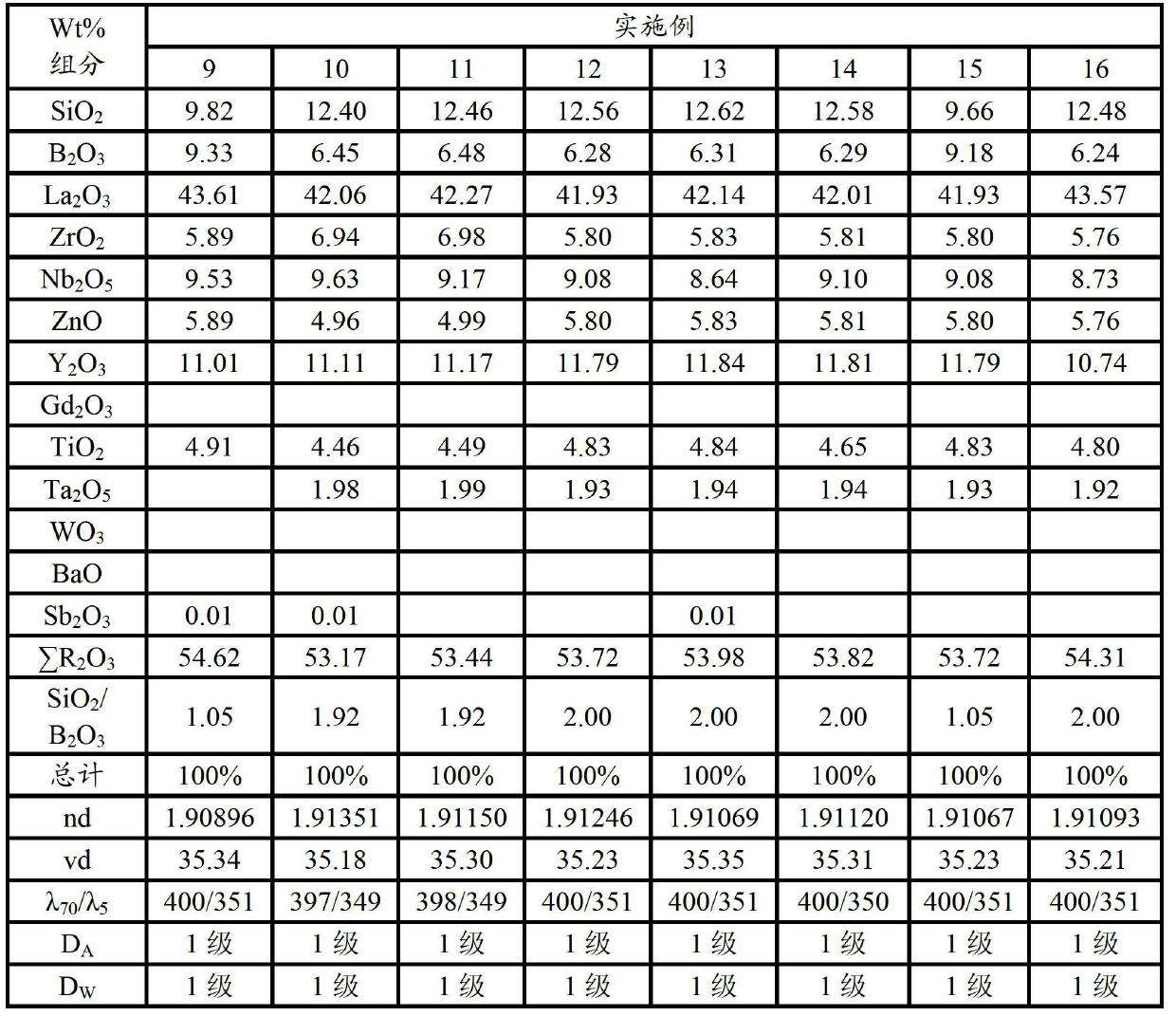

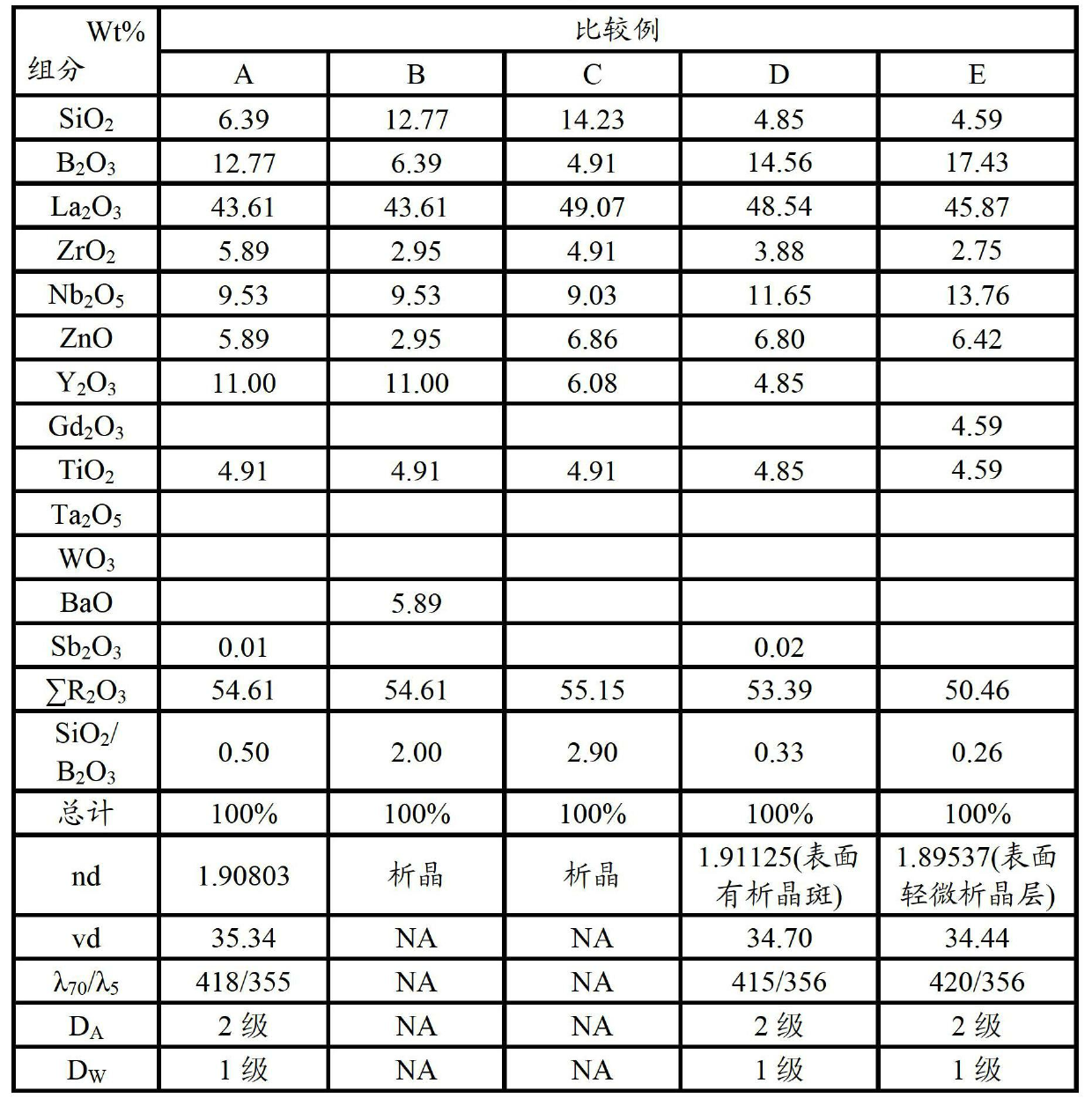

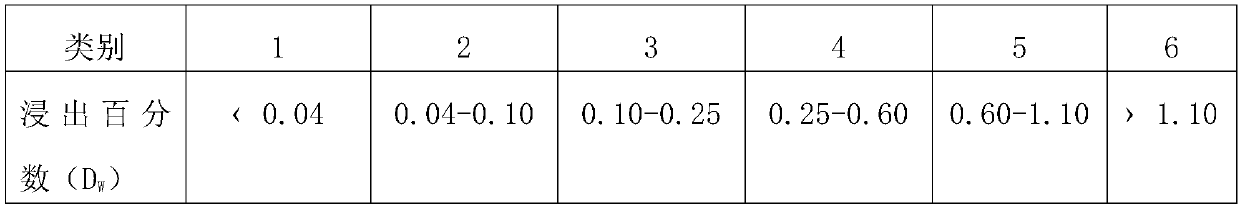

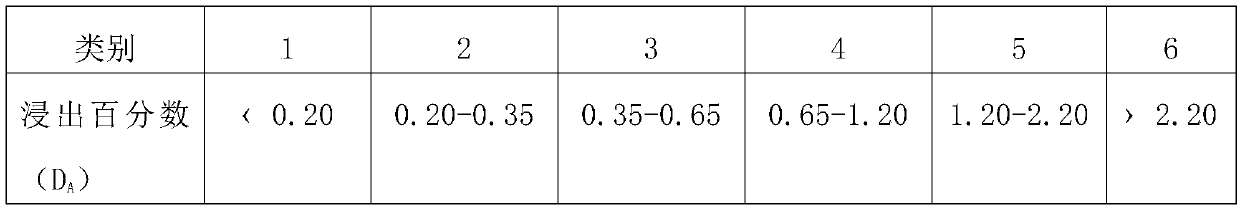

Optical glass

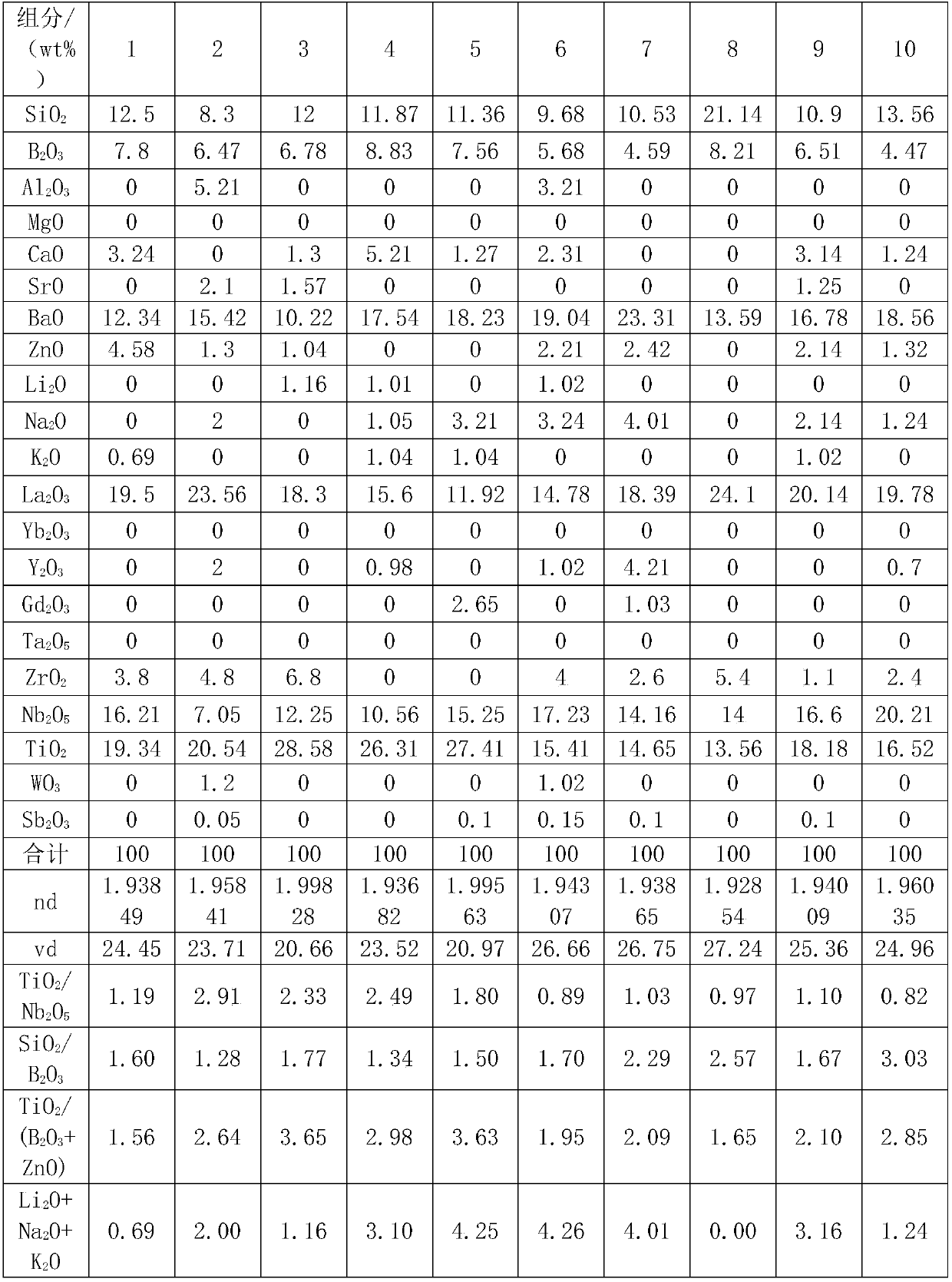

The invention provides high refractive index and low dispersion lanthanide-series optical glass which is suitable for production and secondary compression. The high refractive index and low dispersion lanthanide-series optical glass comprises SiO2, B2O3, La2O3, ZrO2, Nb2O5, ZnO, Y2O3 and TiO2 which are taken as necessary components, and 0-1wt% of Sb2O3 taken as optional component; the optical glass does not contain Th, Cd or As; the content of SiO2 is more than that of B2O3; the refractive index (nd) is between 1.90 and 1.92; and the Abbe number (vd) is between 33 and 36.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Optical glass

ActiveCN109650717AGood chemical stabilityImprove crystallization abilityOptical elementsDigital videoRefractive index

The invention provides optical glass. The optical glass is prepared from, by weight, 5-25% of SiO2, 0-15% of B2O3, 10-30% of La2O3, 13-35% of TiO2, 2-25% of Nb2O5 and 5-25% of BaO. According to the optical glass, through the reasonable formula design, the refractive index of the optical glass is 1.92-2.0, the Abbe number is 20-28, and the optical glass has excellent chemical stability and good crystallization resistance and transmittance and can be widely applied to equipment such as surveillance cameras, digital cameras, digital video cameras and camera mobile phones.

Owner:CDGM OPTICAL GLASS

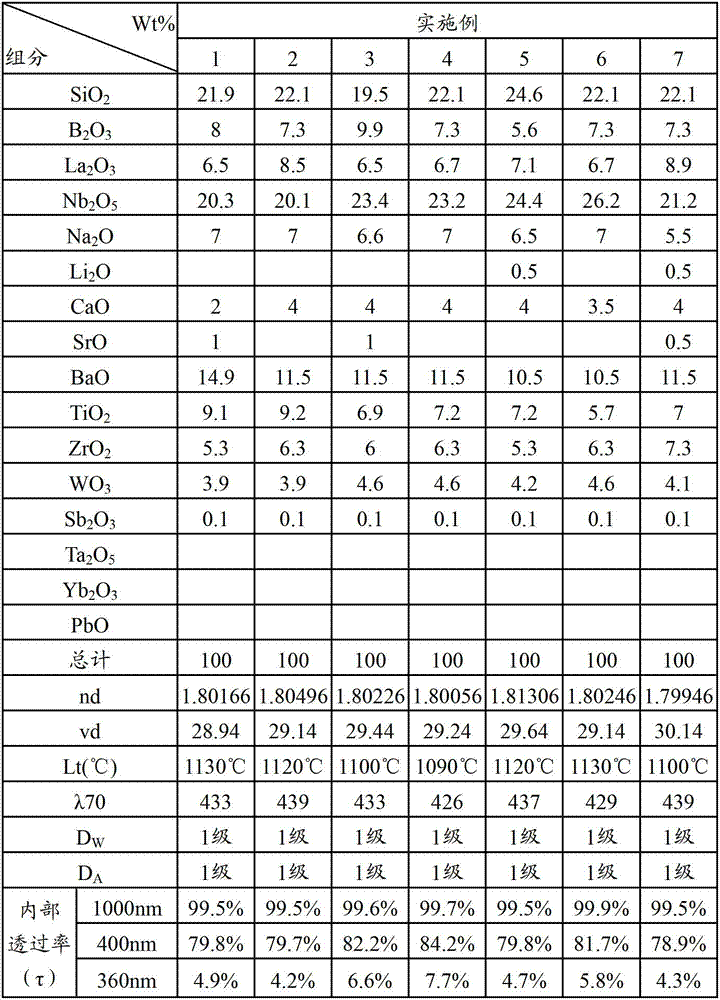

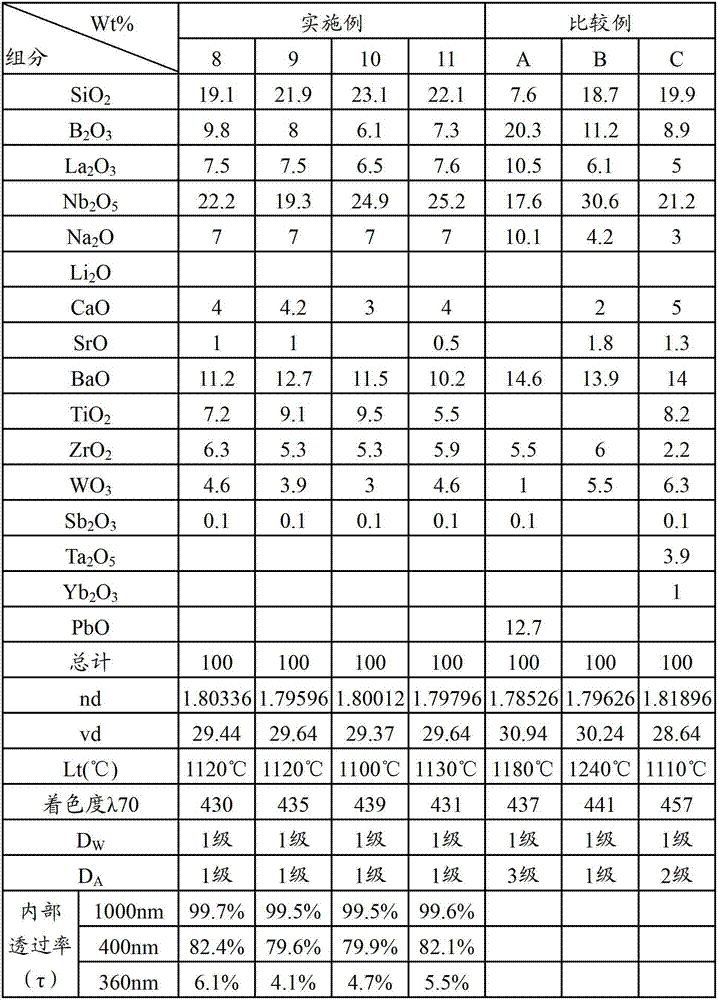

Optical glass

The invention provides optical glass taking SiO2, Nb2O5, BaO and La2O3 as main components of the optical glass without lead, thorium, cadmium, arsenic and fluorine. The refractive index (nd) of the optical glass is between 1.78 and 1.82, and the abbe number (vd) is between 27 and 32. The optical glass has the characteristics of being good in pigmentation degree and crystal separation performance and suitable for production. The optical glass comprises the following compounds by weight percentage: 19% to 25% of SiO2, 5% to 10% of B2O3, 4% to 9% of La2O3, 19% to 27% of Nb2O5, 4% to 10% of Na2O, 0% to 3% of Li2O, 2% to 6% of CaO, 10% to 15% of BaO, 0% to 4% of SrO, 5% to 10% of TiO2, 4% to 8% of ZrO2, 3% to 8% of WO3 and 0% to 1% of Sb2O3, wherein the total content of the oxides accounts for more than 99%.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

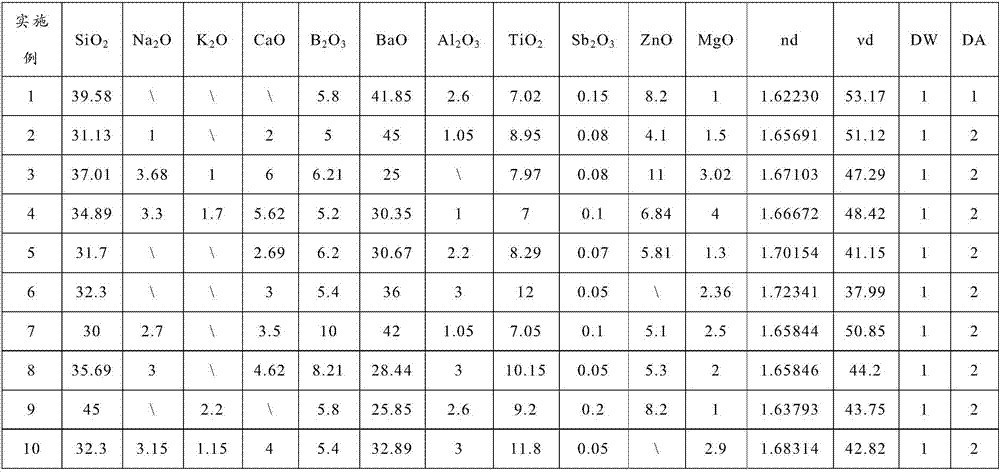

H-ZBaF type optical glass and preparation method thereof

The invention discloses H-ZBaF type optical glass and a preparation method thereof. The H-ZBaF type optical glass is prepared from the following chemical components in parts by weight: 30 to 45 parts of SiO2, 0 to 6 parts of CaO, 5 to 10 parts of B2O3, 25 to 45 parts of BaO, 0 to 3 parts of Al2O3, 7 to 12 parts of TiO2, 0 to 0.2 part of Sb2O3, 0 to 11 parts of ZnO, 1 to 4 parts of MgO and 0 to 5 parts of R2O, wherein R2O is selected from one or two of K2O and Na2O. The H-ZBaF type optical glass disclosed by the invention does not contain components including PbO, As2O3, CdO and the like which have great environmental hazards; a product has the refractive index (nd) of 1.62 to 1.72, the Abbe number (vd) of 38 to 53 and good smelting performance, and is easy to mold; the product does not contain expensive components including Nb2O5, Ta2O5, Bi2O3, GeO2 and the like, so that the product has a cheap price and can meet market requirements on the optical glass relatively well.

Owner:湖北戈碧迦光电科技股份有限公司

Method for preparing calcium-aluminum-silicon (CAS) glass ceramics by quickly sintering waste lamp tube glass

The invention discloses a method for preparing calcium-aluminum-silicon (CAS) glass ceramics by quickly sintering waste lamp tube glass, belonging to the building decorative material field. The method comprises the following steps of: (1), melting, water-quenching, grinding and screening the waste lamp tube glass to obtain glass powder; (2), adding proper quick lime to satisfy CAS glass ceramics component requirement; and (3), pressing and molding the uniformly-mixed powder material and sintering the powder material in a quick warming furnace to obtain the CAS glass ceramics. By taking the waste lamp tube glass powder as a main material and using the quick sintering process to process the CAS glass ceramics, the method has the characteristics of low material cost, low sintering temperature, short sintering time and high bending strength of the bending strength, and the like, achieves environment protection, energy saving, high added value and large-scale recycling of the waste lamp tube glass, and has notable economic and social benefits.

Owner:NANCHANG HANGKONG UNIVERSITY

Environmental-friendly microsphere glass with high refractive index and preparation method thereof

InactiveCN101948249ALow costGood crystallization performance and high temperature viscosity performanceGlass shaping apparatusSpray methodRefractive index

Owner:CHENGDU XIWU KERUI PHOTOELECTRIC MATERIAL

Lanthanides optical glass TZLaF5 with high refraction index, low dispersion and environmental protection

The invention discloses a formula of lanthanides optical glass TZLaF5 with high refraction index, low dispersion and environmental protection, and a production technology thereof. The lanthanides optical glass comprises the following components in percentage by weight: 5 to 10% of SiO2, 15 to 20% of B2O3, 25 to 36% of La2O3, 28 to 40% of Gd2O3, 4 to 10% of ZrO2, 5 to 10% of Ta2O5, 1 to 5% of ZnO, 1 to 5% of BaF2, and 1 to 5% of Al2O3. The lanthanides optical glass is produced by the steps of mixing the components, founding at the temperature of 1430 to 1480 DEG C, molding at 1200 DEG C, and performing fine annealing on the molded mixture for about 7 days at the temperature of 650 to 700 DEG C. The TZLaF5 is the lanthanides optical glass with high refraction index and low dispersion for producing digital camera, digital video, high-grade mobile phone and the like.

Owner:NANTONG JINGXIN OPTICAL GLASS

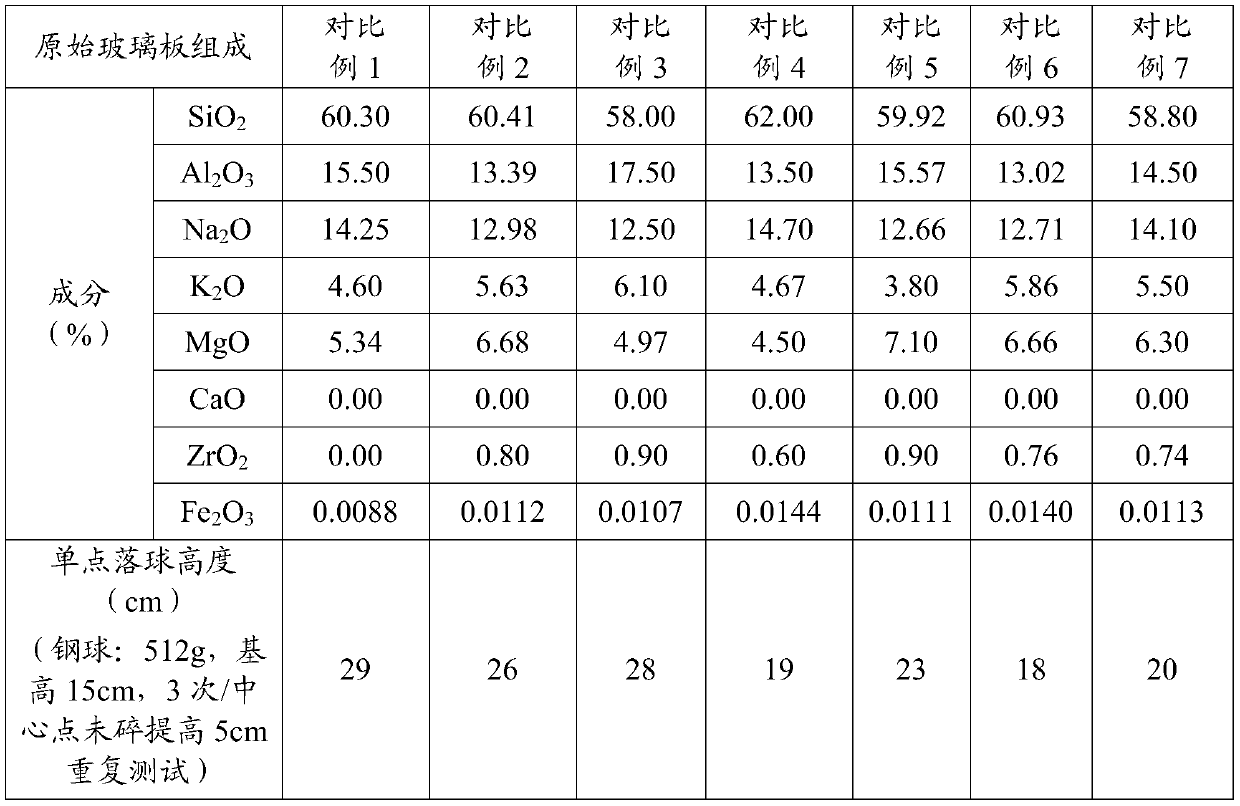

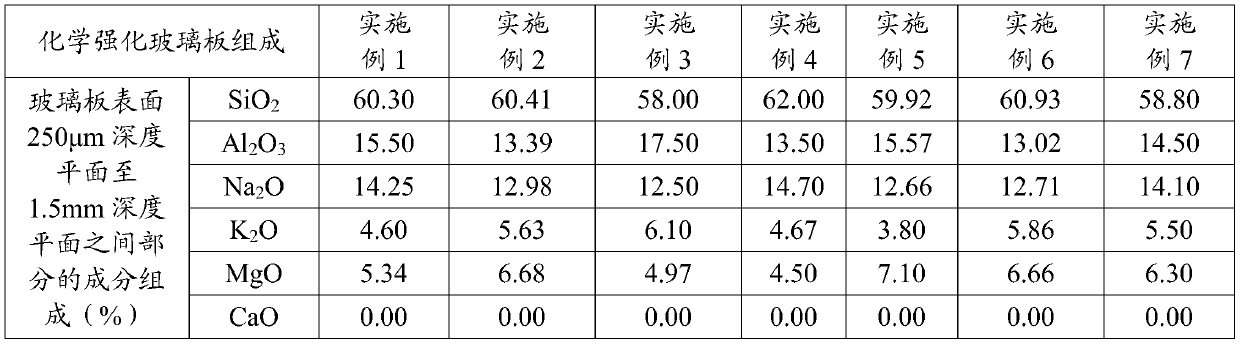

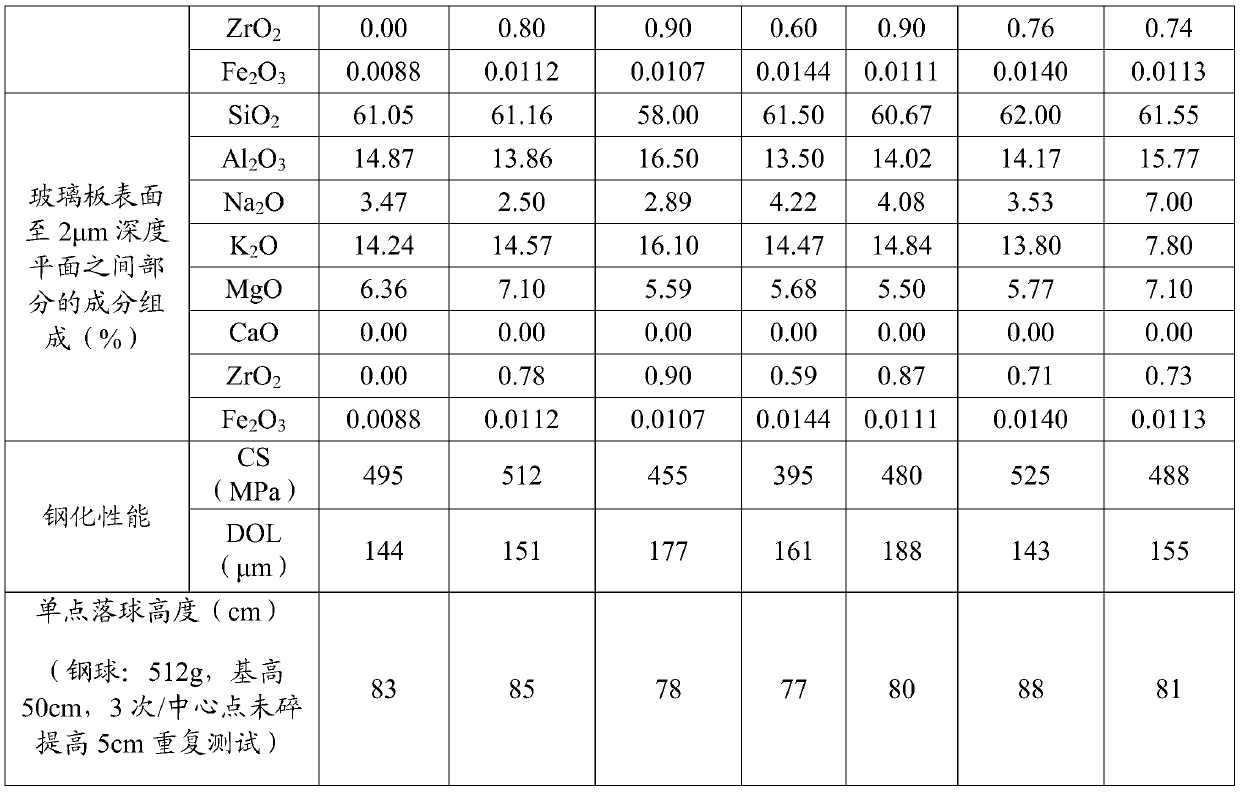

Chemically strengthened glass plate and preparation method thereof

InactiveCN109694186AImprove crystallization abilityFast hardeningGlass severing apparatusGlass sheetChemically strengthened glass

The invention discloses a chemically strengthened glass plate comprising a surface compressive stress layer and a base layer; the compressive stress layer consists of an outer layer and an inner layer, the inner layer is located between the outer layer and the base layer; the outer layer satisfies the requirements: the outer layer comprises, by the weight percentage based on oxides in the outer-layer, 58-62% of SiO2, 13-16.5% of Al2O3, 2.5-7% of Na2O, 7.8-16.1% of K2O, 5.5-7.1% of MgO, 0-0.9% of ZrO2, 0.005-0.015% of Fe2O3, and 0% of CaO. The inner layer satisfies the requirements: the inner layer comprises, by the weight percentage based on oxides in the inner layer, 58-62% of SiO2, 13-17.5% of Al2O3, 2.5-14.7% of Na2O, 3.8-16.1% of K2O, 4.5-7.1% of MgO, 0-0.9% of ZrO2, 0.005-0.015% of Fe2O3, and 0% of CaO. The base layer satisfies the requirements: the base layer comprises, by the weight percentage based on oxides in the base layer, 58-62% of SiO2, 13-17.5% of Al2O3, 12.5-14.7% of Na2O, 3.8-6.1% of K2O, 4.5-7.1% of MgO, 0-0.9% of ZrO2, 0.005-0.015% of Fe2O3, and 0% of CaO.

Owner:四川虹科创新科技有限公司

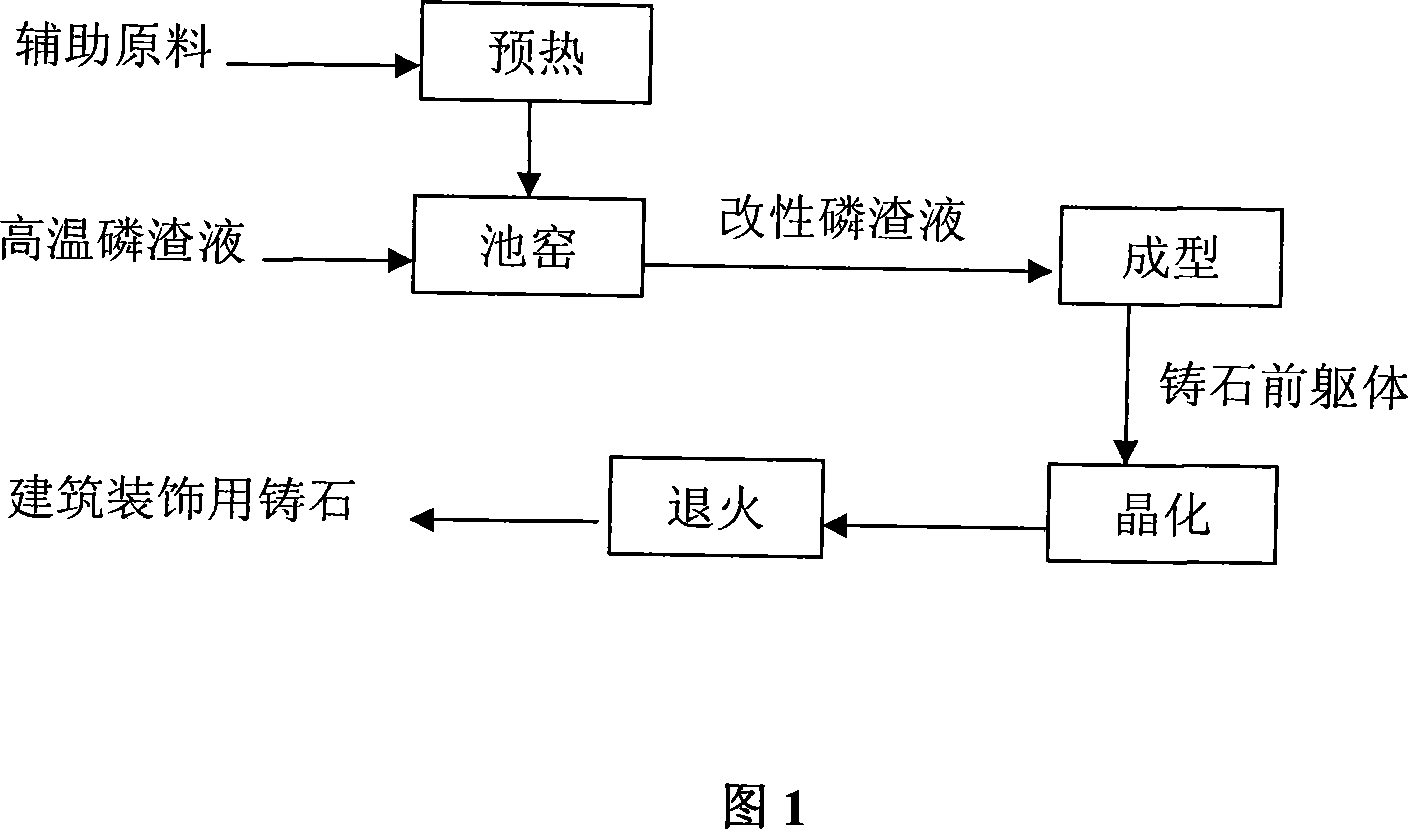

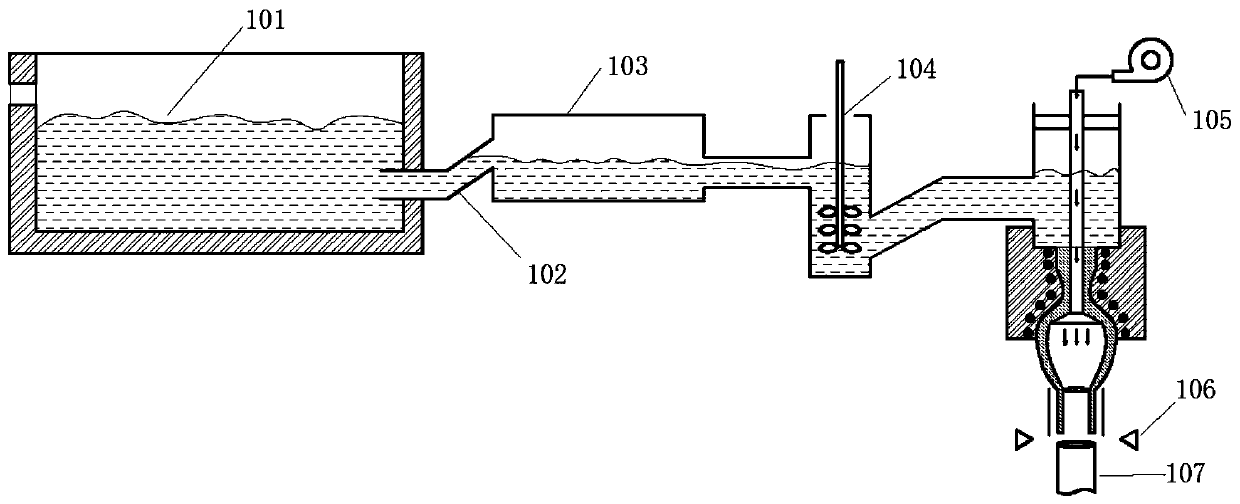

Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

The invention relates to a technique for the preparation of phosphorus dregs cast stone used for construction decoration and using high temperature phosphorus dregs fluid. The invention is characterized in that: firstly, the configuration and the preheating of auxiliary raw material: quartz sand and kaoline are taken as auxiliary raw materials and heated to 1,300-1,450 DEG C; secondly, hot ingredient: the high-temperature phosphorous dregs fluid, which is discharged from a phosphorus electric stove, passes a fluid groove and flows into a pond kiln, and the auxiliary raw material is put into a pond kiln simultaneously, wherein, the quality ratio of the phosphorus dregs to the auxiliary raw material is 65-75:25-35; thirdly, melting: the melting mix of the phosphorous dregs and the auxiliary raw material reaches 1,450-1,580 DEG C; fourthly, shaping; last, crystallization and annealing: the crystallization is processed under 1,000-1,150 DEG C for 60-120 minutes, and then is annealed to room temperature, thus a product is made. The invention can effectively use the thermal energy of the high-temperature phosphorous dregs fluid to realize the conversion of the phosphorous dregs fluid into the resources and reduce the energy consumption and the cost of cast stone production, thereby causing the phosphorous dregs cast stone adaptive to the purpose of large-scale construction decoration.

Owner:浙江中地大科技有限公司

Borate lanthanide optical glass

ActiveCN102849941AReduce manufacturing costGood chemical stabilityNear infrared absorptionLanthanide

The invention relates to a borate lanthanide optical glass, belongs to the technical field of borate lanthanide optical glass, and provides a borate lanthanide optical glass which adopts B2O3, La2O3, Nb2O5 and ZnO as main components, does not contain harmful substances comprising Pb, Th, Cd, Hg, As, Cr or F, and does not contain a near-infrared absorption component Yb2O3 or an expensive raw material Ta2O5. The refractive index (nd) and the Abbe number (nud) of the optical glass are 1.82-18.4 and 35-39 respectively. Results of tests carried out according to a GB / T17129 method show that the grade of water durability (DW) of the optical glass is 1, and the grade of the acid durability (DA) of the optical glass is 3 or more. The optical glass comprises 3-6wt% of SiO2, 15-25wt% of B2O3, 20-40wt% of La2O3, 2-5wt% of ZrO2, 5-10wt% of Nb2O5, 20-30wt% of ZnO, 3-8wt% of WO3, 1-4wt% of TiO2, 0-5wt% of Gd2O3 and 0-1wt% of Sb2O3. The optical glass provided in the invention has the advantages of low costs of the above raw materials, good chemical stability, and low crystallization tendency, so batch production of the optical glass can be easily realized.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

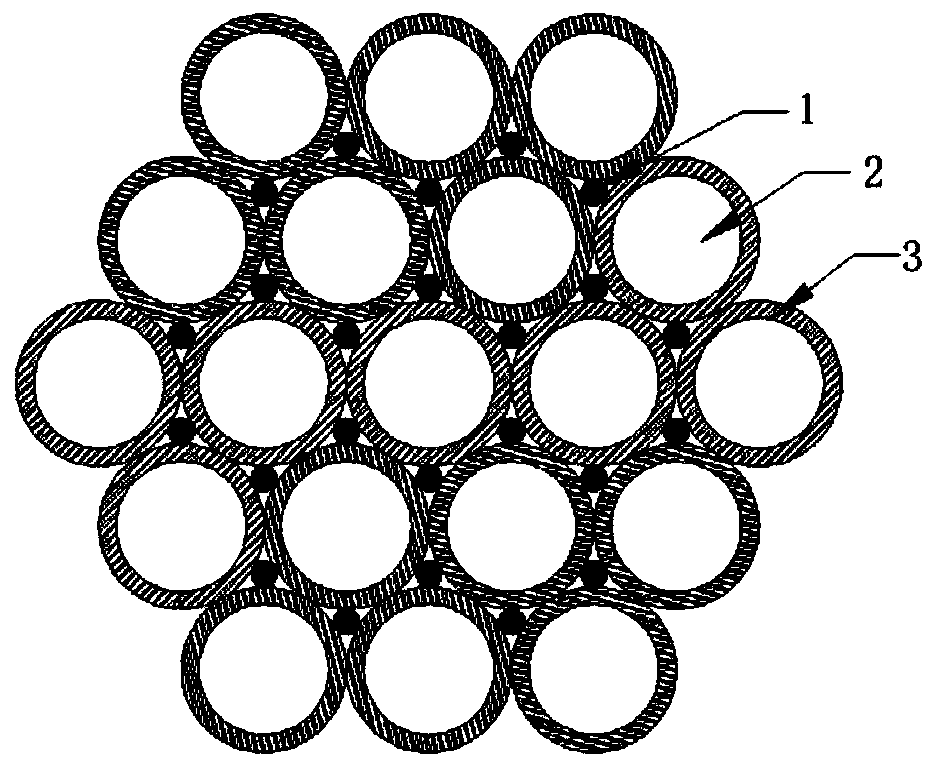

Optical fiber skin layer glass for optical fiber image transmission element and mechanical pipe-drawing forming method of optical fiber skin layer glass

ActiveCN110183108AGood anti-devitrification performanceImprove featuresCladded optical fibreGlass forming apparatusRefractive indexEngineering

The invention discloses an optical fiber skin layer glass for an optical fiber image transmission element and a mechanical pipe-drawing forming method of the optical fiber skin layer glass. The optical fiber skin layer glass composition for the optical fiber image transmission element comprises the following components in percentage by mole: 72.0-80.0% of SiO2, 5.5-7.0% of Al2O3, 2.0-8.0% of B2O3,3.0-8.0% of Na2O, 2.0-7.0% of K2O, 1.0-3.0% of CaO, 0.1-2.0% of SrO, 0.1-2.0% of ZnO, 0.1-0.9% of ZrO2, 0.1-0.9% of TiO2 and 0.1-0.2% of Sb2O3. The preparation method by the mechanical pipe-drawing forming comprises the following steps: melting glass; carrying out clarifying and homogenizing; carrying out pipe-drawing forming; and carrying out cutting and annealing. The disclosed skin material for the optical fiber image transmission element is excellent in chemical property, stable in glass composition, low in refractive index and excellent in anti-crystallization property.

Owner:CHINA BUILDING MATERIALS ACAD

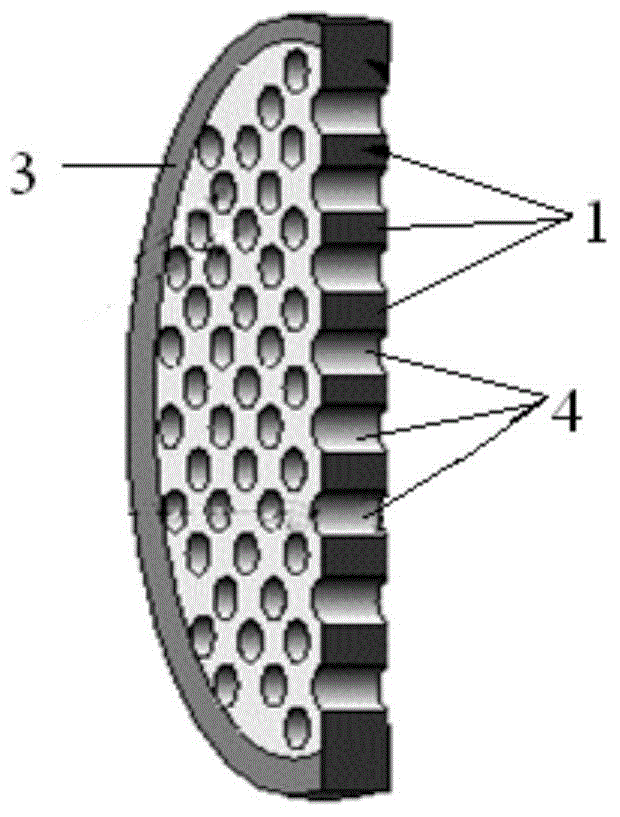

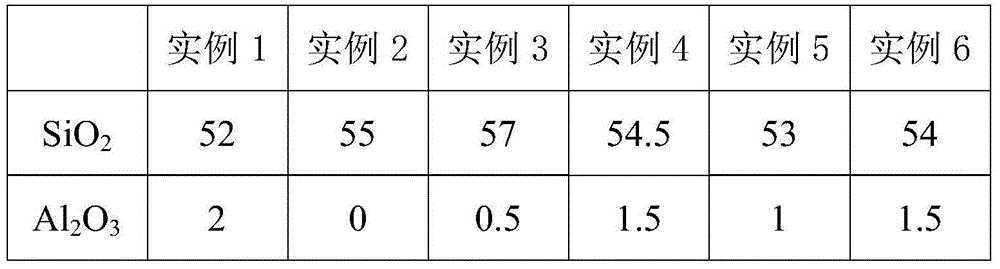

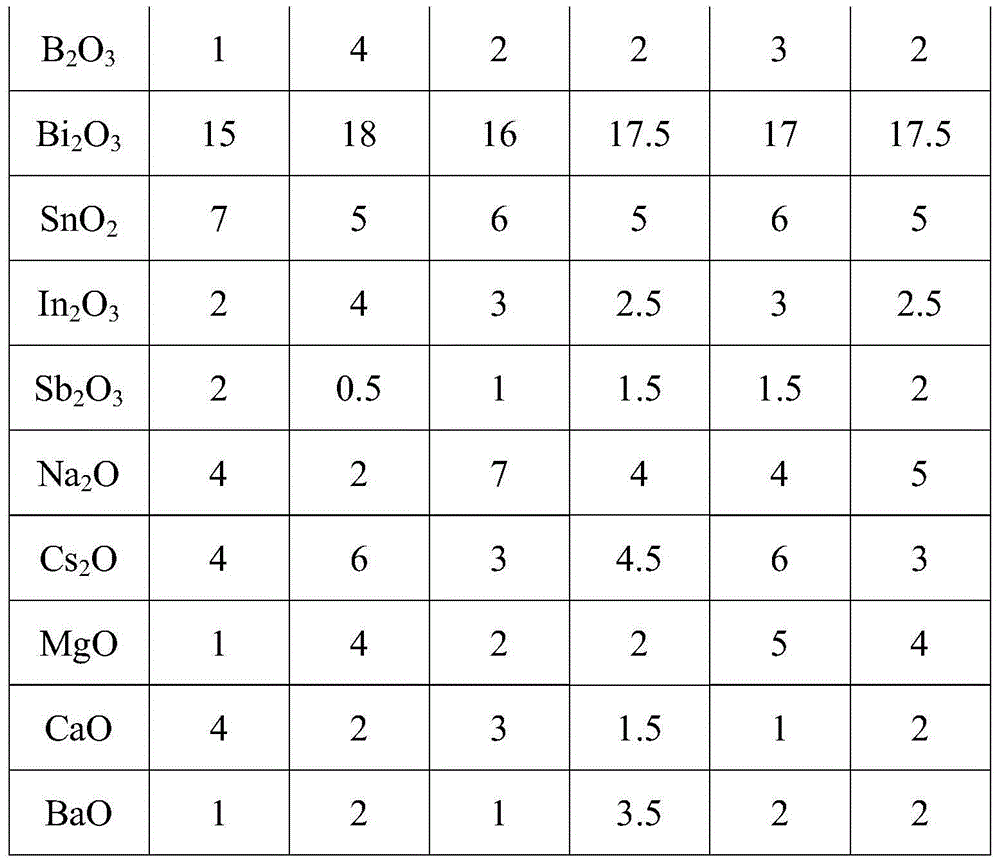

Micro-channel plate cladding glass and preparation method thereof

The invention relates to a micro-channel plate cladding glass, a micro-channel plate, and a preparation method thereof. The micro-channel plate cladding glass comprises the following components in parts by weight: 52 to 57 parts of SiO2, 0 to 2 parts of Al2O3, 1 to 4 parts of B2O3, 15 to 18 parts of Bi2O3, 5 to 7 parts of SnO2, 2 to 4 parts of In2O3, 0.5 to 2 parts of Sb2O3, 8 to 10 parts of Na2O and Cs2O, and 6 to 8 parts of MgO, CaO, and BaO. The micro-channel plate cladding glass and micro-channel plate prepared therefrom have the characteristics of non-toxicity, innocuousness, and environment-friendliness.

Owner:CHINA BUILDING MATERIALS ACAD

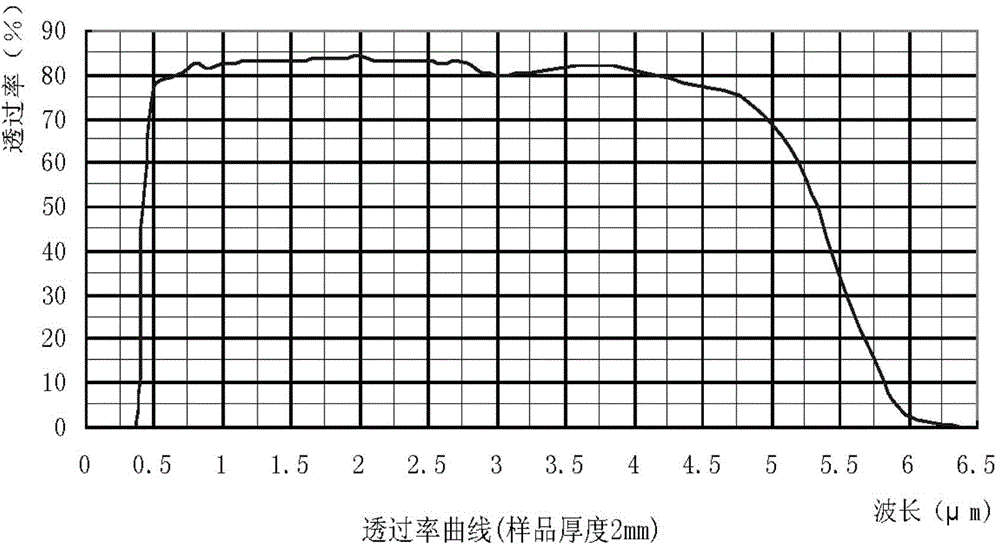

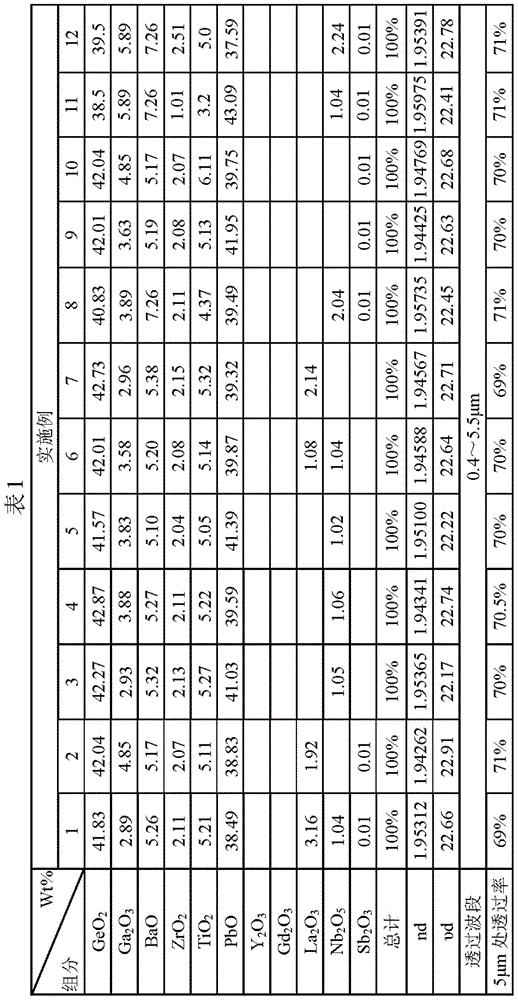

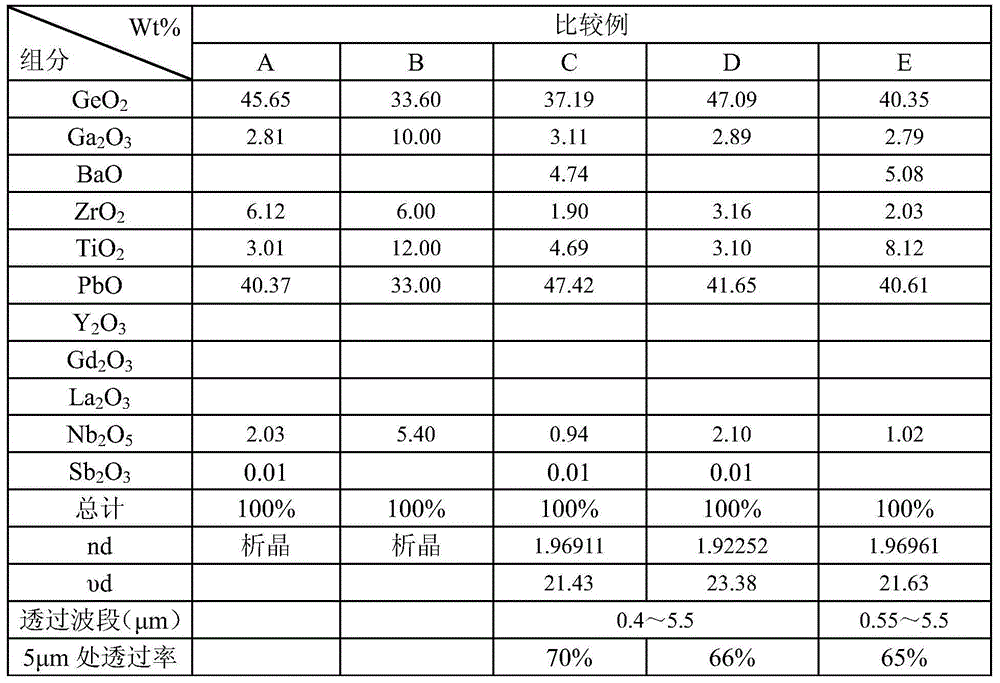

Optical glass

The invention relates to optical glass, and provides infrared-transmitted germanium-gallate optical glass which is suitable for volume production and secondary profiling, and is high in refraction and high in dispersion. The glass contains GeO2, Ga2O3, BaO, ZrO2, TiO2 and PbO as necessary components, and does not contain thorium, cadmium or arsenic; the refractive index (nd) is 1.94-1.96; and the abbe number (upsilon d) is 21-23. The optical glass disclosed by the invention has good physical and chemical properties and infrared spectrum transmitting performance, and is mainly applied to infrared-transmitted windows and optical path lenses; the infrared cutoff wavelength is greater than 5.5 microns; and the ultraviolet cutoff wavelength is smaller than 400nm.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

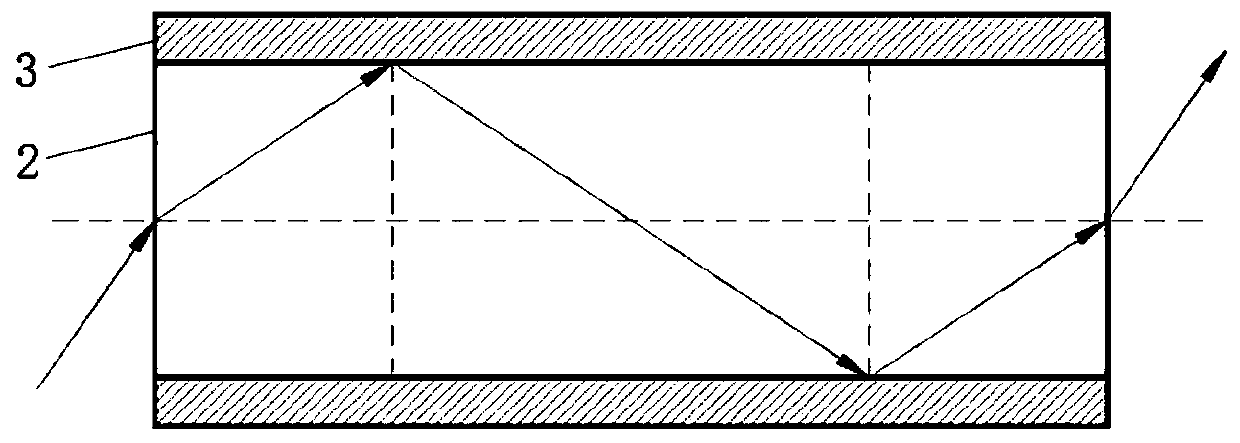

Optical fiber faceplate core glass with refractive index of 1.5-1.6 and method for preparing optical fiber faceplate core glass

InactiveCN109485256AGood anti-devitrification performanceRaise the lower limit of crystallization temperatureGlass shaping apparatusRefractive indexChemical stability

The invention discloses optical fiber faceplate core glass with the refractive index of 1.5-1.6 and a method for preparing the optical fiber faceplate core glass. The optical fiber faceplate core glass with the refractive index of 1.5-1.6 comprises boric acid, quartz sand, aluminum hydroxide, calcium carbonate, zinc oxide, potassium carbonate, sodium carbonate, barium carbonate, lanthanum oxide and diarsenic trioxide. The optical fiber faceplate core glass with the refractive index of 1.5-1.6 and the method for preparing the optical fiber faceplate core glass have the advantages that glass formulas and the method can be used for core glass for optical fiber faceplates, the refractive index of the optical fiber faceplate core glass is within the range of 1.50-1.60, the expansion coefficientof the optical fiber faceplate core glass is (87+ / -5)*10<-7> / DEG C, and the optical fiber faceplate core glass is high in transmittance; the softening temperature of the optical fiber faceplate coreglass is 630-720 DEG C under the control, the lower limit of the crystallization temperature of the optical fiber faceplate core glass is higher than or equal to 850 DEG C, crystallization can be prevented under the condition of heat preservation at the temperature of 850 DEG C for 2 hours, and accordingly the optical fiber faceplate core glass is good in crystallization-resistant performance andchemical stability.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

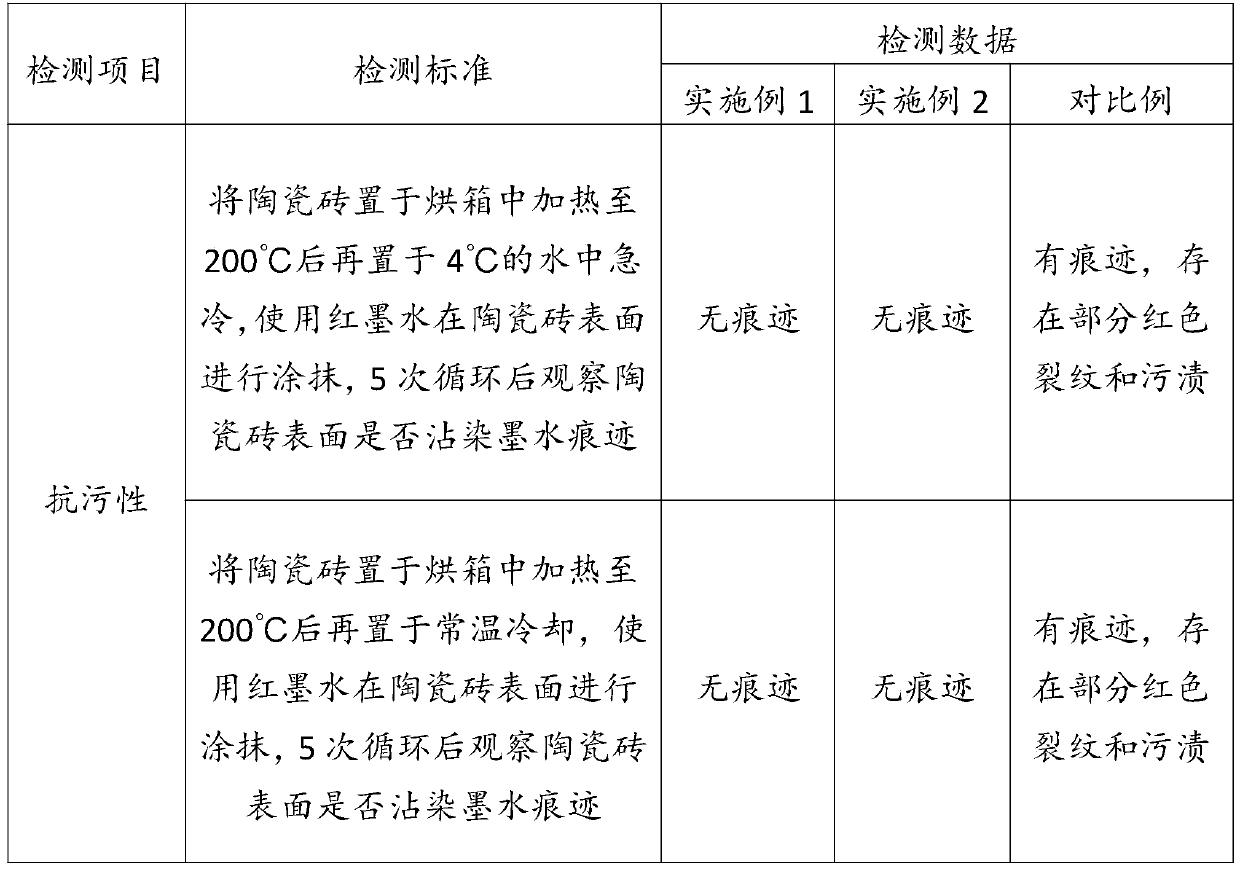

Super stain-resistant ceramic tile color-retaining glaze, stain-resistant ceramic tile and preparation process of stain-resistant ceramic tile

ActiveCN111170638ADense tissueExpand the melting rangeCeramic materials productionCalcium biphosphateGlaze

The invention discloses a super-stain-resistant ceramic tile color-retaining glaze, a stain-resistant ceramic tile and a preparation process of the stain-resistant ceramic tile. The super-stain-resistant ceramic tile color-retaining glaze is prepared from the following components in percentage by weight: 20 to 25 percent of potassium feldspar, 15 to 20 percent of albite, 6 to 15 percent of kaolin,0.5 to 3 percent of talc, 6 to 10 percent of quartz, 2 to 3 percent of zinc oxide, 2.5 to 3 percent of boron-zirconium frit, 10.5 to 20 percent of attapulgite and 5 to 9 percent of calcium phosphate;wherein the mass ratio of the boron-zirconium frit to the attapulgite to the calcium phosphate is 1: (3-6): (2-3). According to the invention, attapulgite with a layered structure is added; both theglaze and agreen body contain a large amount of bound water; during firing, the glaze discharges water; more air holes are generated in the drainage process; formed capillary channels are used for allowing gas generated in the sintering process of carbonate raw materials in the subsequent glaze to escape; the glaze continues to be heated, the components are further molten to fill and level up thecapillary channels, pores in the surface of the ceramic tile are reduced, gas generated during firing is discharged along the capillary channels, the pores of the ceramic tile are obviously reduced, the surface is smooth, and the stain-resistant effect of the super-stain-resistant ceramic tile color-retenting glaze is enhanced.

Owner:广东和陶立方陶瓷有限公司

Method for preparing high-tenacity high-hardness anti-dazzle glass

The invention provides a method for preparing high-tenacity high-hardness anti-dazzle glass. The method comprises the steps that firstly, raw materials needed for manufacturing the glass are prepared, then the raw materials are evenly mixed and ground to obtain a mixture, the mixture is placed in a smelting furnace, and then composite clarifying agents are added for clarifying; the mixture is cooled to room temperature, a material a is obtained, the material a is formed, then annealing treatment is carried out, and a material b is obtained; after coring treatment and crystallization treatment are carried out on the material b, a material c is obtained; the material c is preheated, preheating temperature ranges from 720 DEG C to 820 DEG C, and heat preservation is carried out for 1-2 h; then the material c is placed in frosting liquid to be soaked for 60-80 s, a polishing solution is sprayed to the material c for 3-10 min, then the material is taken out to be washed, dried and air-cooled to room temperature, and the high-tenacity high-hardness anti-dazzle glass is obtained.

Owner:徐州高运新型材料有限公司

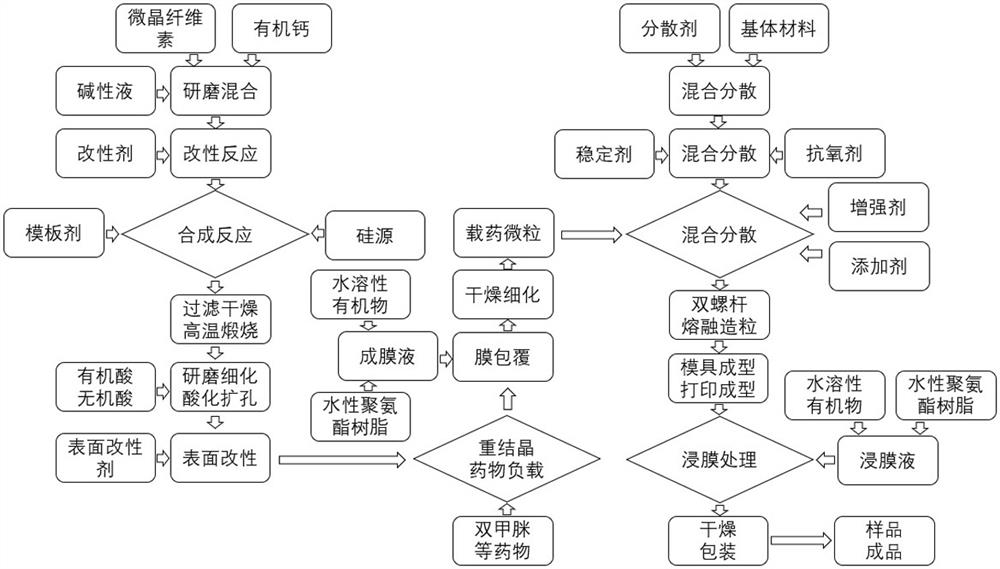

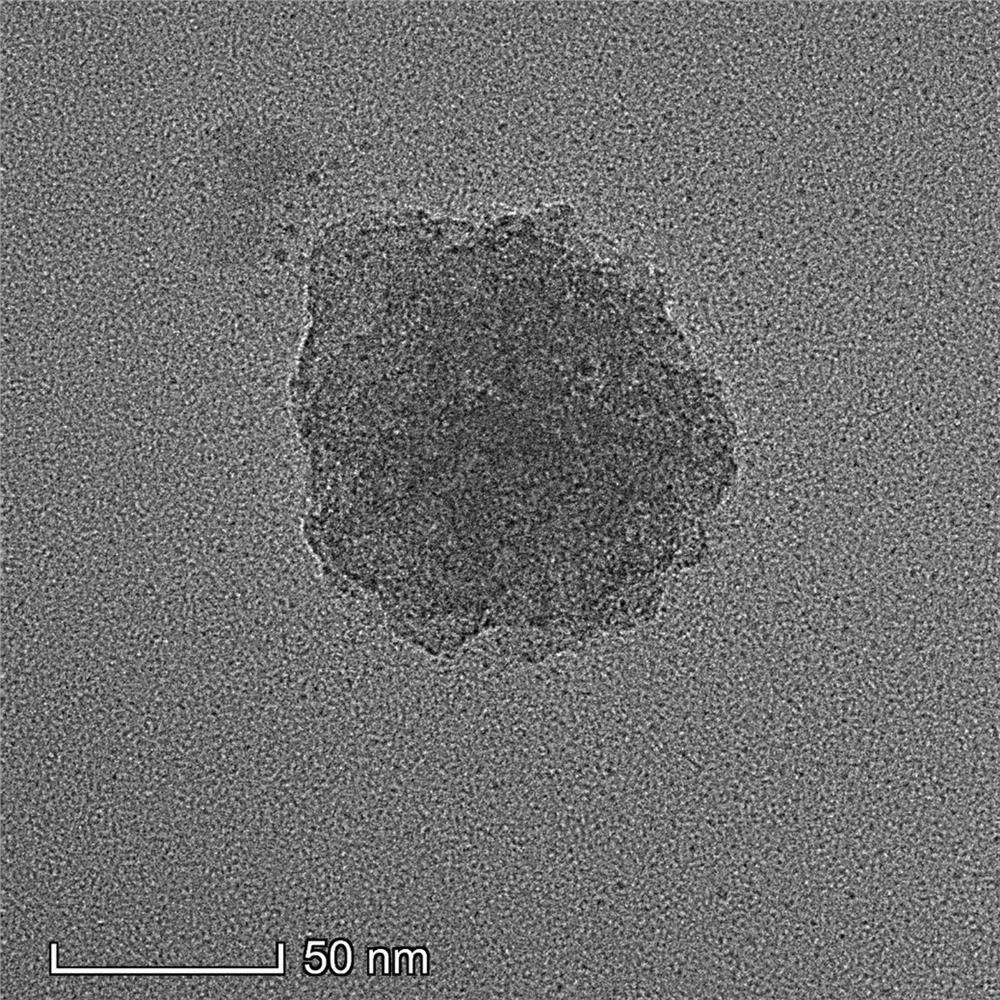

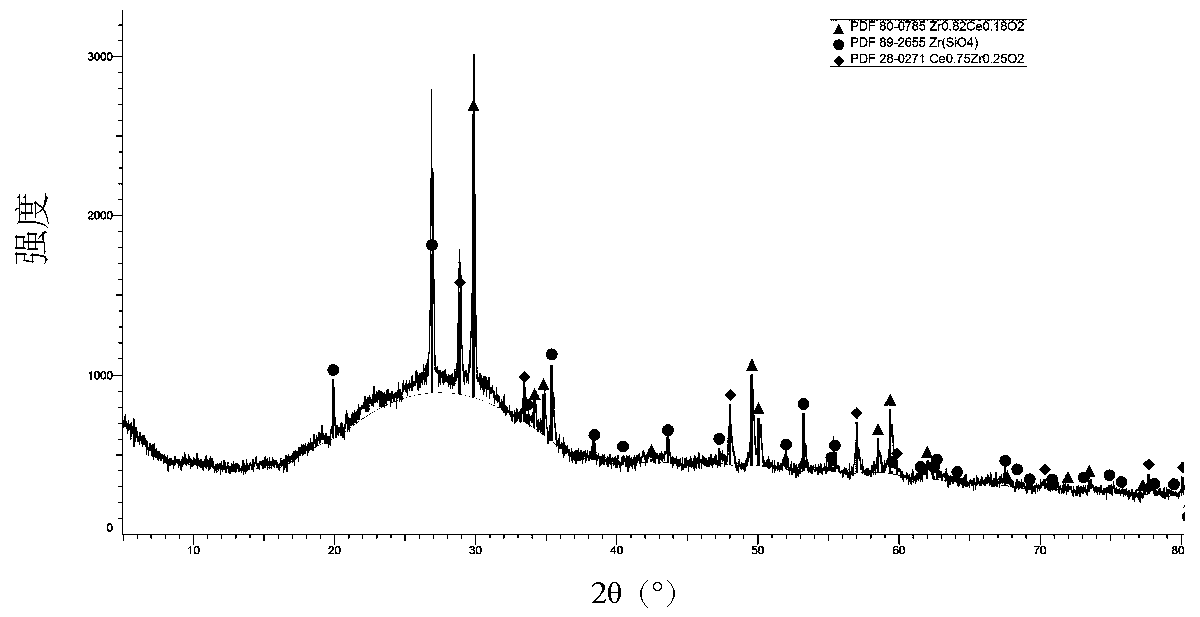

Membrane-coated drug-loaded microspheres, drug-sustained-release parasite-expelling pet collar and preparation method thereof

ActiveCN113575575AFacilitate cross-linkingEasy to useBiocideAdditive manufacturing apparatusMicrosphereEthyl group

The invention discloses membrane-coated drug-loaded microspheres. Microcrystalline cellulose, organic calcium and bis (2-ethylhexyl) sodium sulfosuccinate are adopted as pore-forming agents of macroporous porous silicon, mesoporous or hollow or three-dimensional penetrating porous silicon dioxide is obtained after calcination, then acidizing treatment is conducted through hydrochloric acid, calcium in a silicon-calcium skeleton is dissolved and removed, and macroporous and three-dimensionally penetrated porous silica is obtained, the porous silicon framework and the surface of the porous silicon are very rough, pits and grooves are very rich, and loading and adhesion of drugs are facilitated. Besides, a drug-sustained-release parasite-expelling pet collar is prepared by using the membrane-coated drug-loaded microspheres so that the obtained pet collar has a good parasite-expelling effect, a long-acting sustained-release effect and a good quality guarantee effect. The product technology is mature, the production operation is simple and easy to understand, and the production cost is relatively reasonable.

Owner:SOUTH CHINA AGRI UNIV

White crystal flower frit, white crystal flower decorative ceramic tile and preparation method thereof

The invention discloses a white crystal flower frit, a white crystal flower decorative ceramic tile and a preparation method thereof. The white crystal flower frit comprises the following chemical components in percentage by mass: 0.34%-0.52% of ignition loss, 40.89%-42.10% of SiO2, 26.46%-28.31% of Al2O3, 0.09%-0.25% of Fe2O3, 0.12%-0.16% of TiO2, 3.98%-4.62% of CaO, 1.64%-2.28% of MgO, 2.08%-3.95% of K2O, 1.73%-2.15% of Na2O, 3.78%-4.45% of ZrO2, 6.98%-8.01% of CeO2, 5.98%-7.78% of ZnO, 2.01%-2.78% of BaO, 0.83%-1.07% of PbO, and 0.09%-1.12% of As2O3.

Owner:MONALISA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com