Super stain-resistant ceramic tile color-retaining glaze, stain-resistant ceramic tile and preparation process of stain-resistant ceramic tile

A preparation process, a technology of ceramic tiles, applied in the field of ceramic tiles, can solve the problems of graying and yellowing of ceramic tiles, and achieve the effects of good crystallization effect, smooth surface and reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

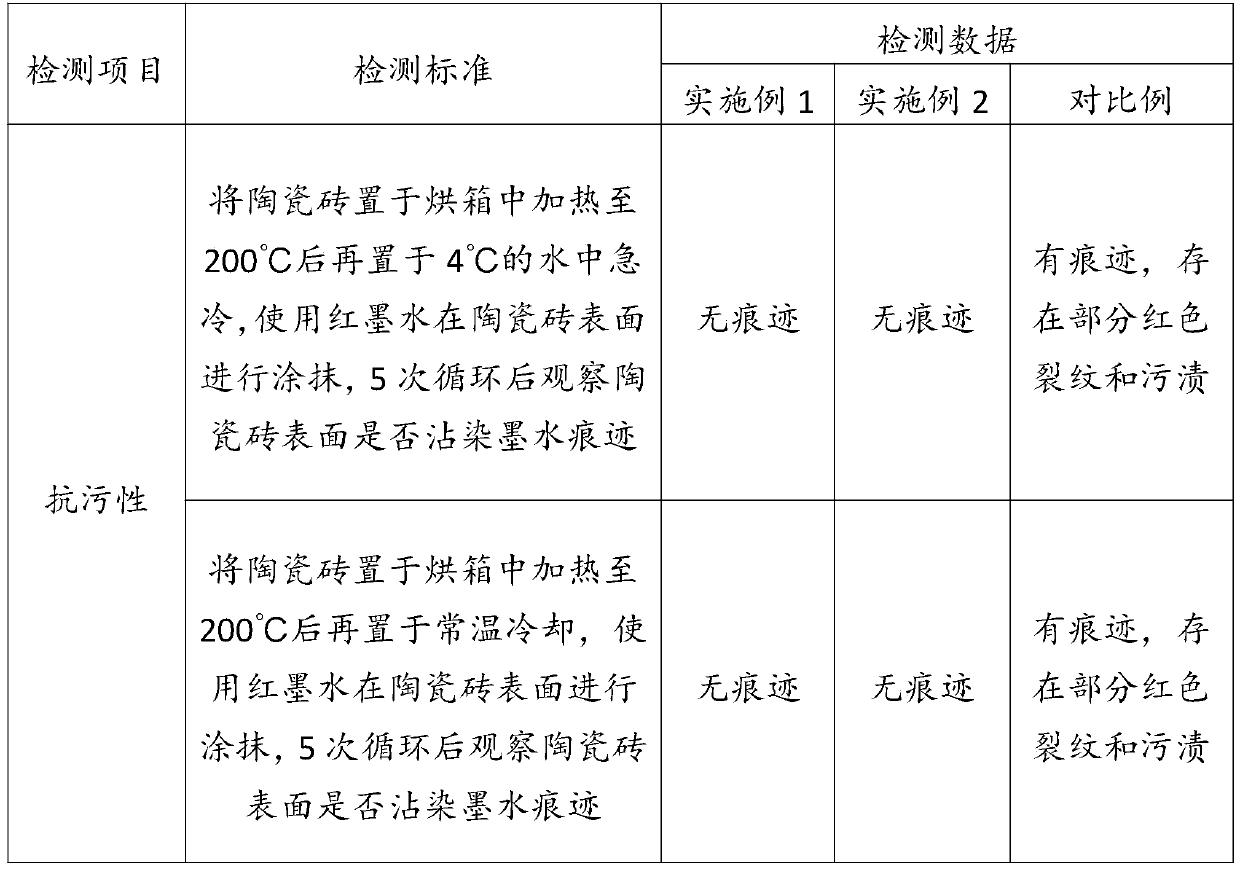

[0029] The present invention also proposes a preparation process for stain-resistant ceramic tiles, using the color-preserving glaze for super-pollution-resistant ceramic tiles described in any one of the above, including the following steps: weighing broken potassium feldspar, sodium Feldspar, kaolin, talc, quartz, zinc oxide, cerium oxide, boron-zirconium frit, attapulgite and calcium phosphate are mixed with water and then ball milled. The ball milling time is 6-7h, and the total mass of each component is equal to that of water. The mass ratio is 100: (40-50). After sieving, the color-preserving glaze of the super-pollution-resistant ceramic tile is obtained; after the body is dried, spray water on the surface of the body to moisten it, and then apply a primer on the surface of the body. On the surface of the bottom glaze, the color-preserving glaze of the super-pollution-resistant ceramic tile is applied, and it is fired in a kiln to obtain the anti-pollution ceramic tile. ...

Embodiment 1

[0041] Weigh broken potassium feldspar 24%, albite 18%, kaolin 16%, talc 2%, quartz 8%, zinc oxide 3%, cerium oxide 2%, boron-zirconium frit 3%, concave-convex 17% stick clay and 7% calcium phosphate, mixed with water and then ball milled, the ball milling time is 6h, wherein the mass ratio of the total mass of each component to water is 100:45, and the super stain-resistant ceramic tile is obtained after sieving Color-retaining glaze, the fineness of the color-retaining glaze for super-pollution-resistant ceramic tiles is 0.1% over a 325 mesh sieve, the proportion of the bottom glaze is 1.75g / ml, and the specific gravity of the color-retaining glaze for super-pollution-resistant ceramic tiles is 1.87g / ml;

[0042] After the green body is dried, spray water on the surface of the green body to wet it. The chemical composition of the green body is: 71.4% silicon oxide, 16% aluminum oxide, 3% calcium oxide, 1.5% magnesium oxide, 0.5% iron oxide, and 3% potassium oxide , 4% sodi...

Embodiment 2

[0044] Weigh broken potassium feldspar 20%, albite 20%, kaolin 10%, talc 3%, quartz 10%, zinc oxide 2%, cerium oxide 3%, boron zirconium frit 3%, concave-convex 20% clay and 9% calcium phosphate, mixed with water and then ball milled, the ball milling time is 7 hours, wherein the mass ratio of the total mass of each component to water is 100:50, and the super stain-resistant ceramic tile is obtained after sieving Color-retaining glaze, the fineness of the color-retaining glaze for super-pollution-resistant ceramic tiles is 0.2% over a 325 mesh sieve, the proportion of the bottom glaze is 1.84g / ml, and the specific gravity of the color-retaining glaze for super-pollution-resistant ceramic tiles is 1.9g / ml;

[0045] After the green body is dried, spray water on the surface of the green body to wet it. The chemical composition of the green body is: 69% silicon oxide, 18% aluminum oxide, 4% calcium oxide, 1% magnesium oxide, 0.6% iron oxide, and 4% potassium oxide , 3% sodium ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com