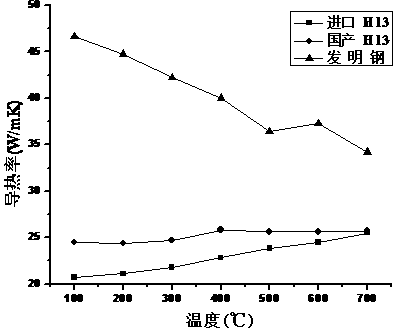

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

A hot stamping die, ultra-high heat technology, applied in the field of ultra-high thermal conductivity wear-resistant hot stamping die steel materials and its preparation, can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

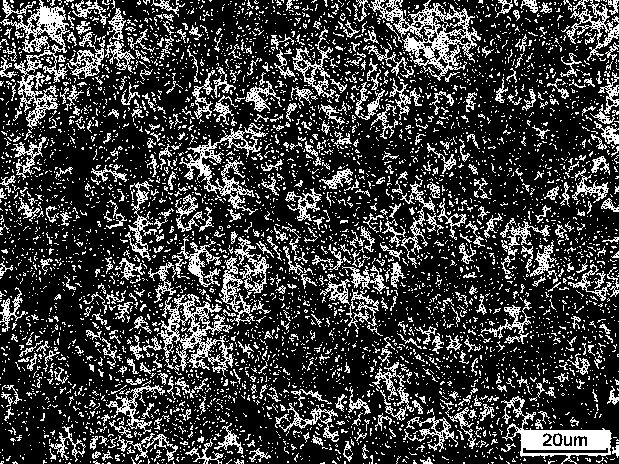

Examples

Embodiment 1

[0063] Present embodiment has produced a kind of steel, and its concrete composition is as follows:

[0064] C: 0.37%; Si: 0.06%; Mn: 0.12%; W: 1.65%; Mo: 4.43%; Cr: 0.12%; V: 0.12%;

[0065] The rest is Fe and unavoidable impurity elements, S: ≤0.01% in impurity elements; P: ≤0.02%; O: ≤30ppm

[0066] The preparation process and heat treatment process are as follows:

[0067] (a) Smelting: After the alloy is designed according to the above composition, it is smelted according to the traditional method, and the batch material in the above formula is placed in the electric furnace, and smelted at 1550°C; then the steel ingot is poured, and the next step is ready for use;

[0068] (b) Electroslag remelting: After electroslag remelting, the content of gas and inclusions can be reduced, and steel ingots with uniform composition, compact structure and high quality can be obtained;

[0069] (c) Annealing: heat at 750°C for 8 hours and then cool with the furnace;

[0070] (d) Homo...

Embodiment 2

[0076] Present embodiment has produced a kind of steel, and its concrete composition is as follows:

[0077] C: 0.36%; Si: 0.07%; Mn: 0.14%; W: 1.70%; Mo: 4.51%; Cr: 0.12%; V: 0.14%;

[0078] The rest is Fe and unavoidable impurity elements, S: ≤0.01% in impurity elements; P: ≤0.02%; O: ≤30ppm

[0079] The preparation process and heat treatment process are as follows:

[0080] (a) Smelting: After the alloy is designed according to the above composition, it is smelted according to the traditional method, and the batch material in the above formula is placed in an electric furnace, and smelted at 1500°C; then the steel ingot is poured, and the next step is ready for use;

[0081] (b) Electroslag remelting: After electroslag remelting, the content of gas and inclusions can be reduced, and steel ingots with uniform composition, compact structure and high quality can be obtained;

[0082](c) Annealing: heat at 800°C for 10 hours and then cool with the furnace;

[0083] (d) Homog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com