Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

230results about How to "High heat intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

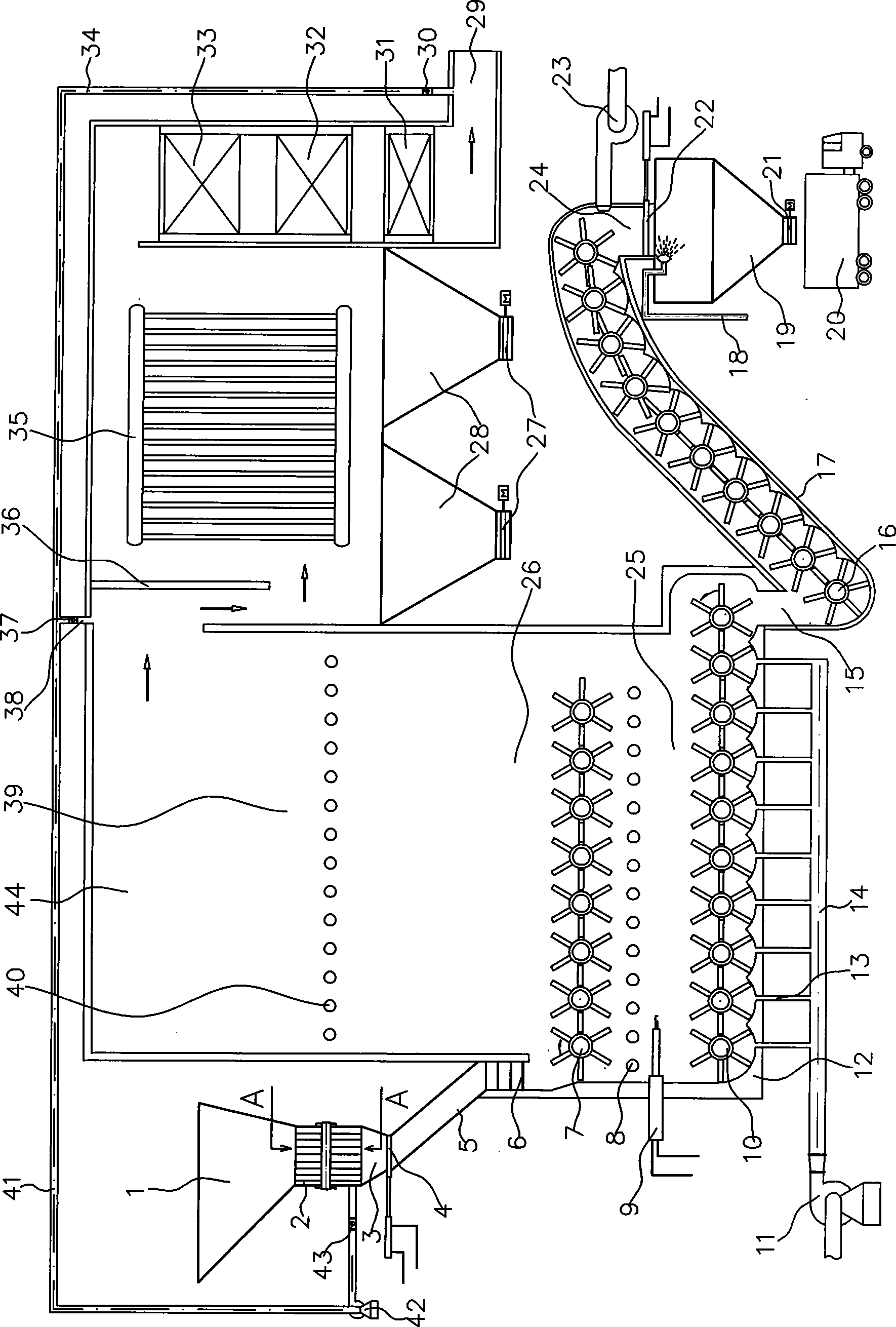

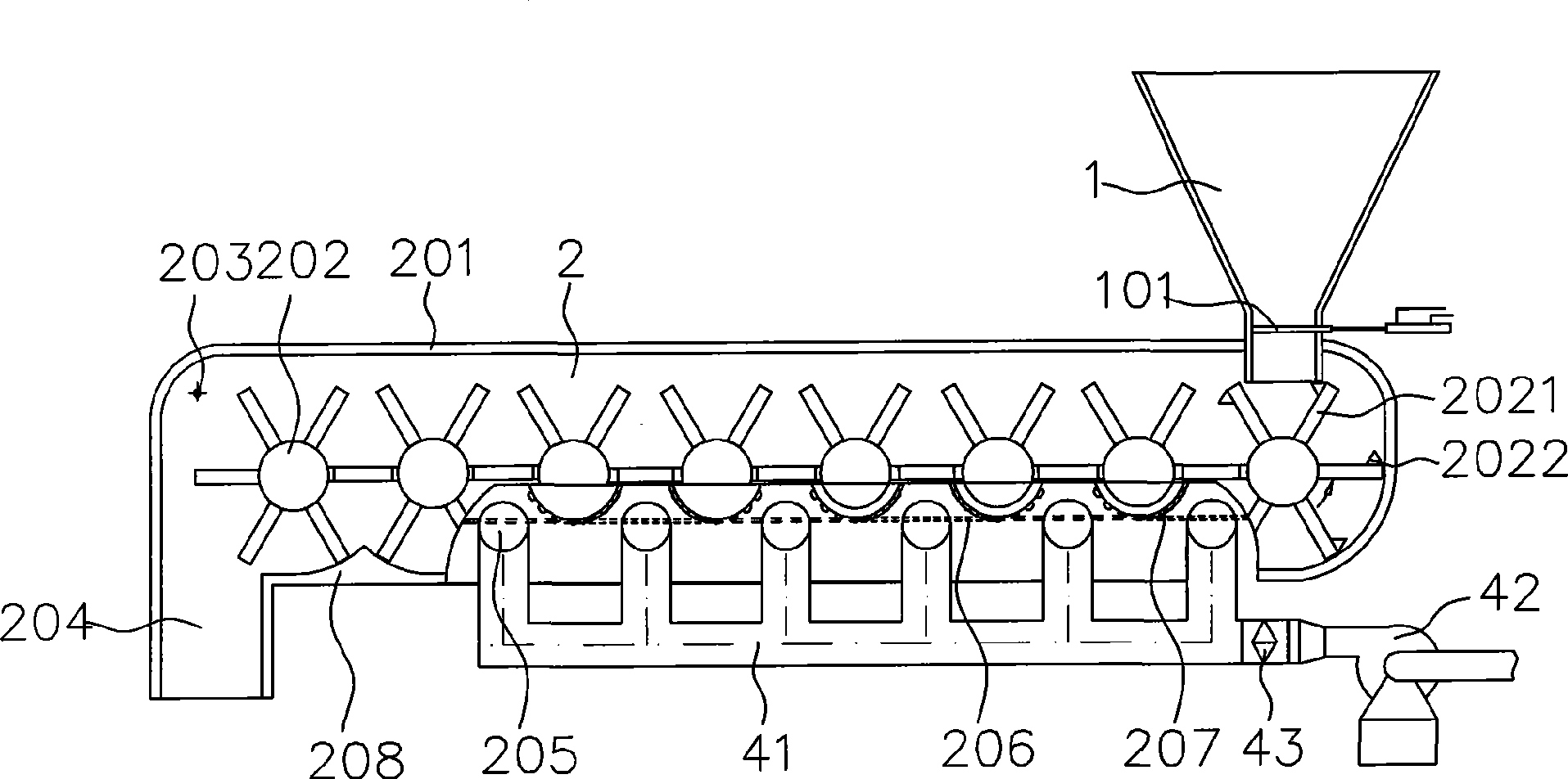

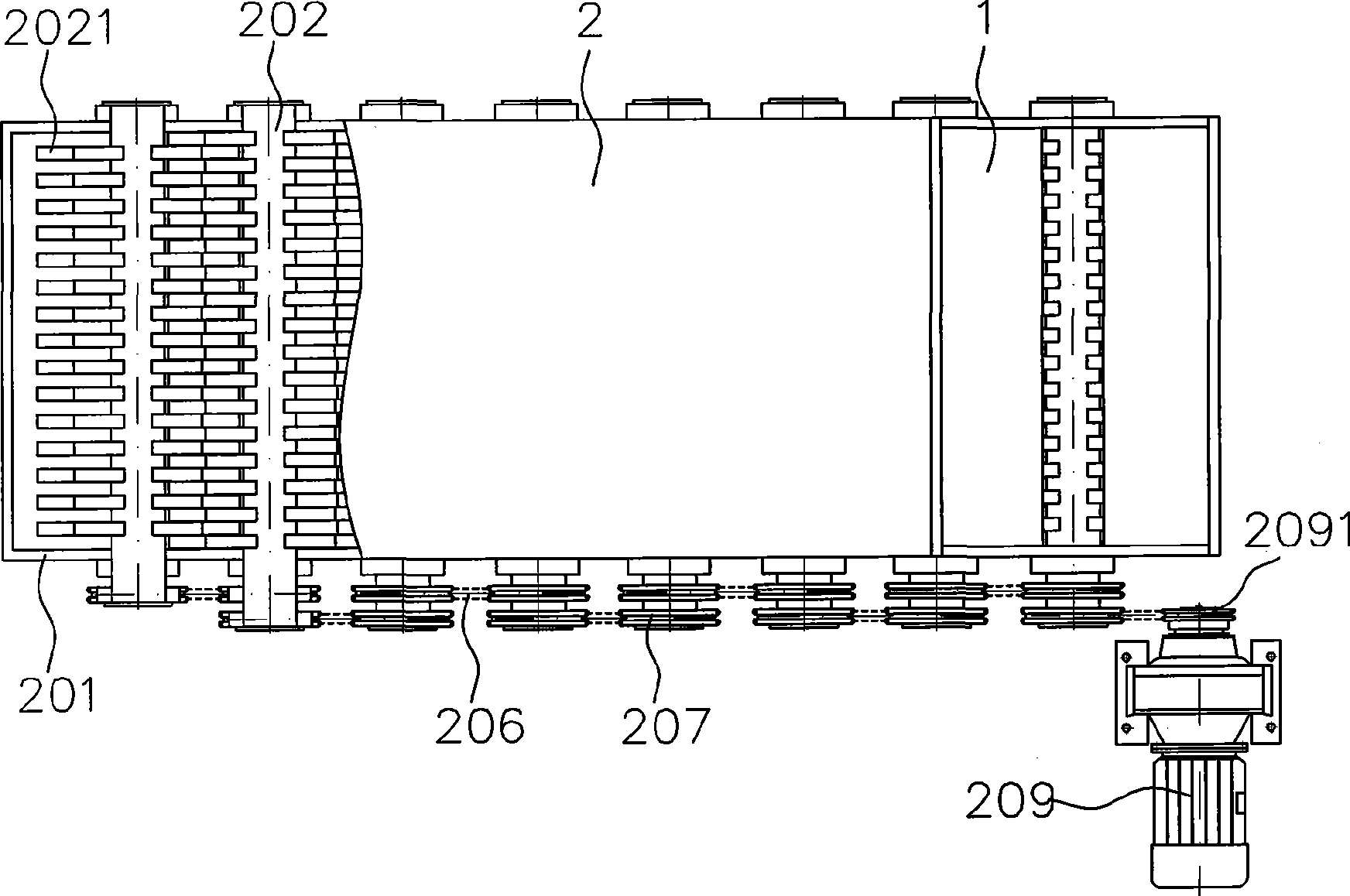

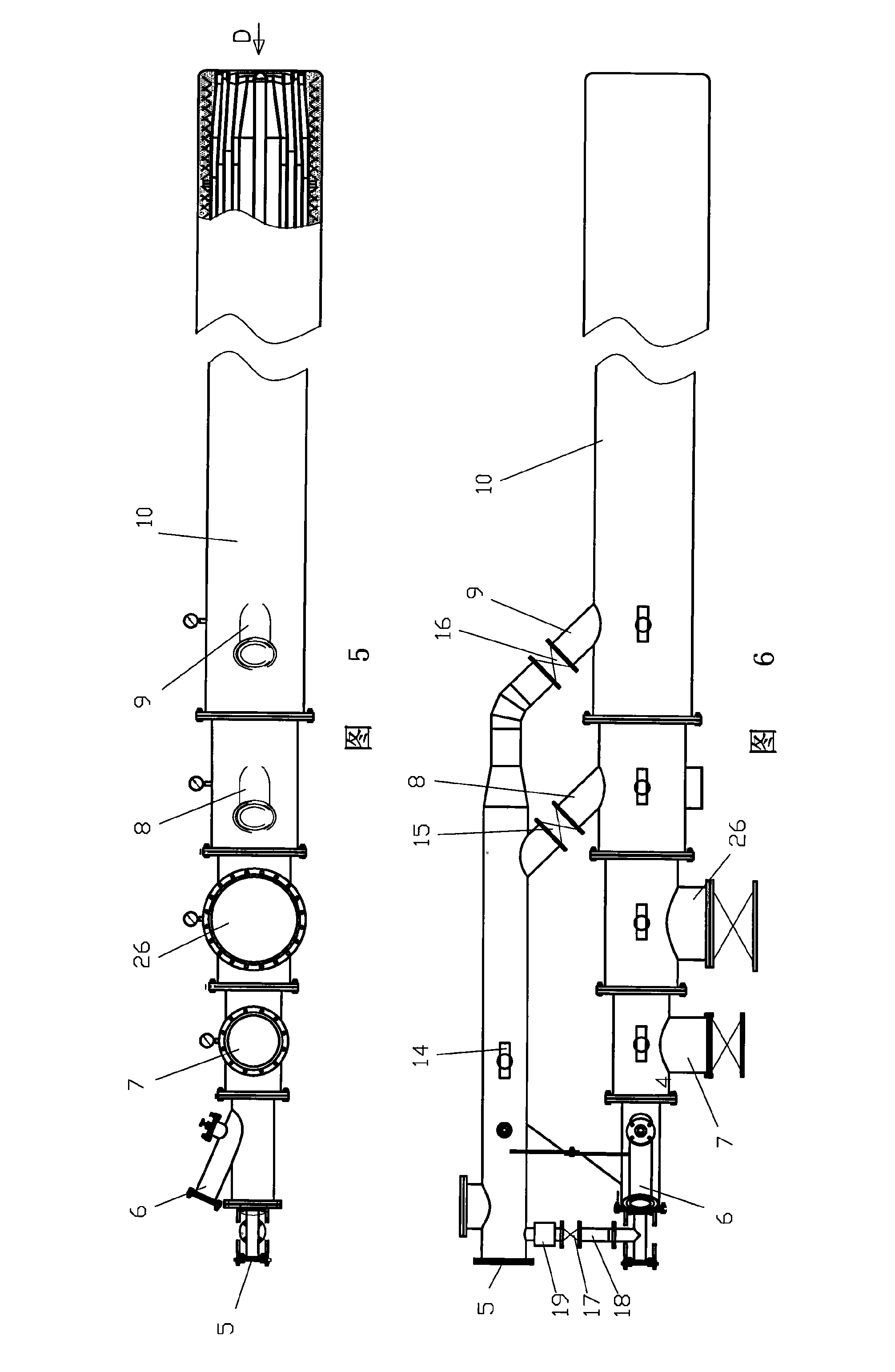

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

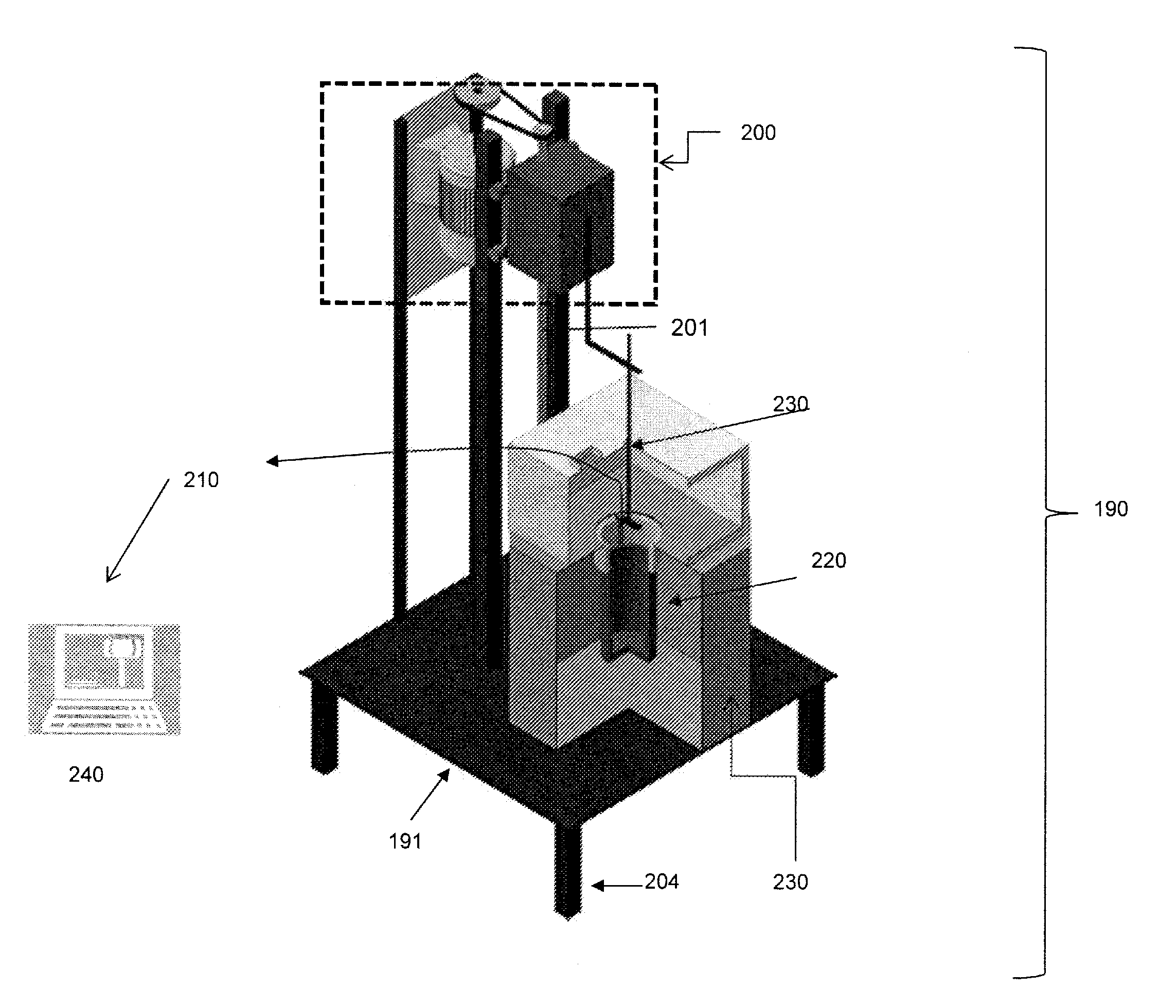

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

Coated low-nitrogen sand and its prepn

ActiveCN101088659AReduce usageReduce nitrogen contentFoundry mouldsFoundry coresLow nitrogenTetramine

The present invention discloses one kind of coated low-nitrogen sand and its preparation process. The coated low-nitrogen sand consists of phenolic resin 1.5-4.0 wt% of the material, hexamethylene tetramine in 0-6 wt% of the phenolic resin, lubricant in 3-7 wt% of the phenolic resin, and raw sand for the rest. It has greatly lowered hexamethylene tetramine consumption, low nitrogen content and capacity of ensuring the surface quality of the casting. During its heated formation, the thermosetting phenolic resin can speed the curing, raise the hardening rate and raising the hot strength of the sand mold.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

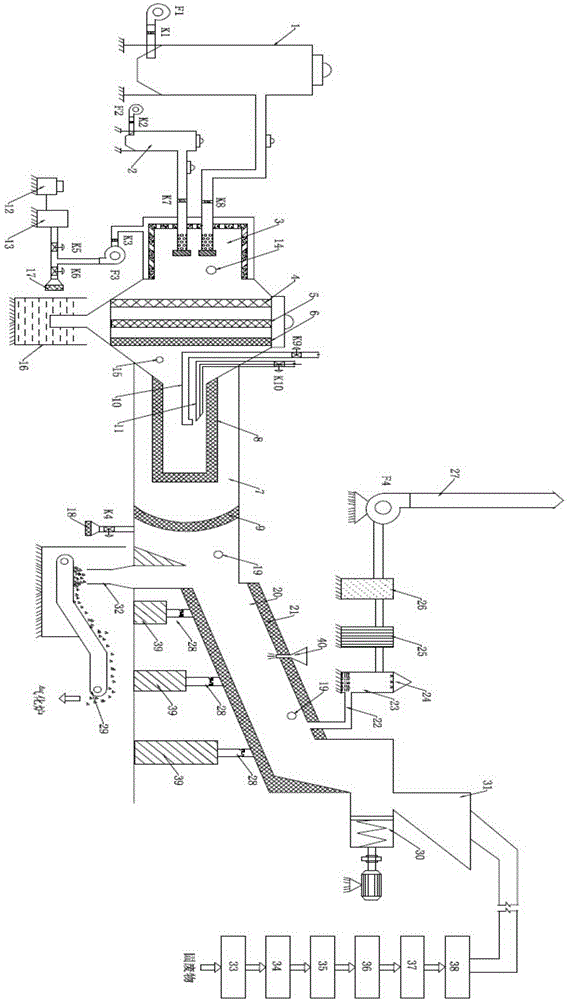

Solid waste innocent treatment device and method

ActiveCN104588402AExcellent emission indicatorsMeet environmental protection requirementsSolid waste disposalIncinerator apparatusCombustion chamberEmission standard

The invention discloses a solid waste innocent treatment device and a solid waste innocent treatment method. The solid waste innocent treatment device comprises a solid waste pyrolysis gasifier, a fuel gas oxygen replenishment premixing and filtering chamber, a fuel gas combustion chamber, a dechloridation and desulfurization drying device and a solid waste pretreatment device which are sequentially communicated; the solid waste innocent treatment device also comprises a biomass pyrolysis gasifier and a tail gas treatment device, wherein the biomass pyrolysis gasifier is communicated with the fuel gas oxygen replenishment premixing and filtering chamber; the tail gas treatment device is communicated with the top of the dechloridation and desulfurization drying device. When the method and the device are used for treating solid waste, the content of Dioxin in a detected emitted tail gas is lower than 0.023ng / m<3>, and the emission allowances of other gases, such as CO, SO2, HC1 and NOx, are also highly superior to the emission standard (GB18485-2014) issued by the nation in July 1st, 2014, and can completely meet the requirement of environment-friendliness.

Owner:深鹏环保工程有限公司

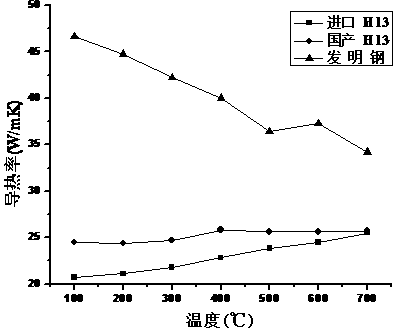

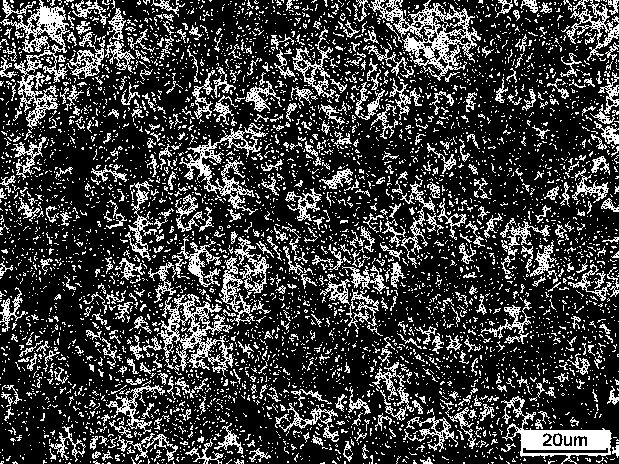

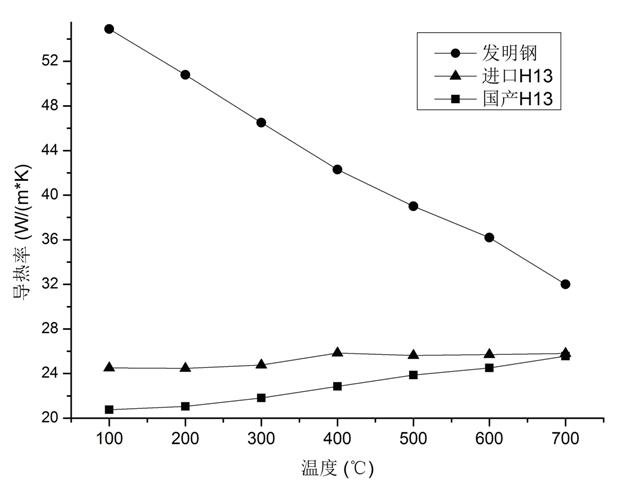

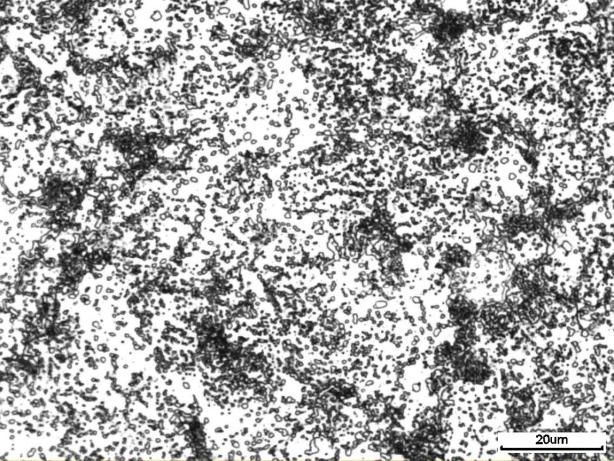

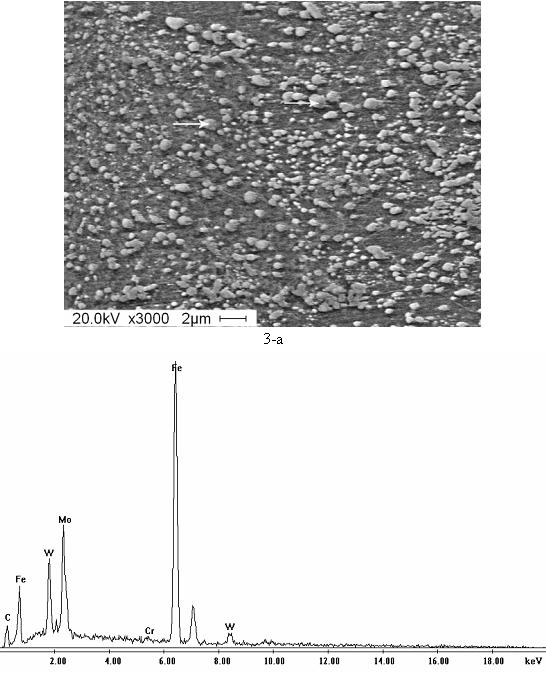

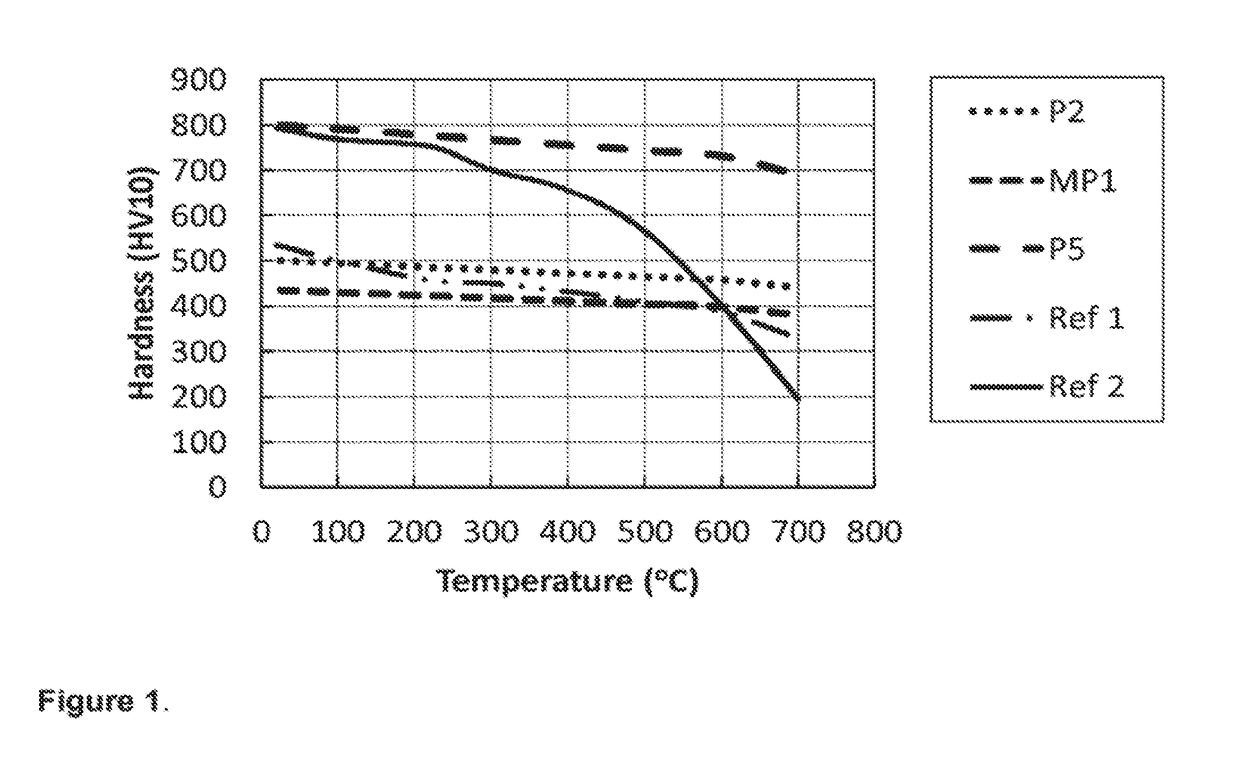

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

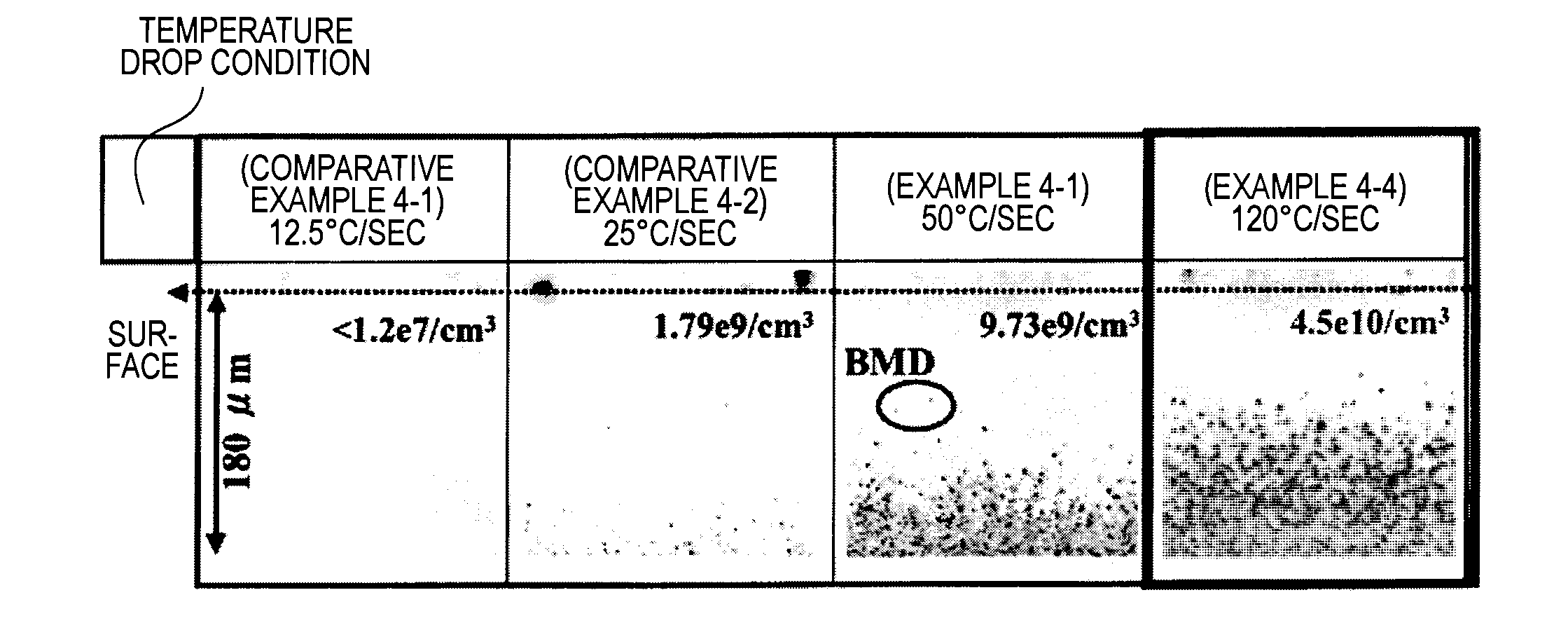

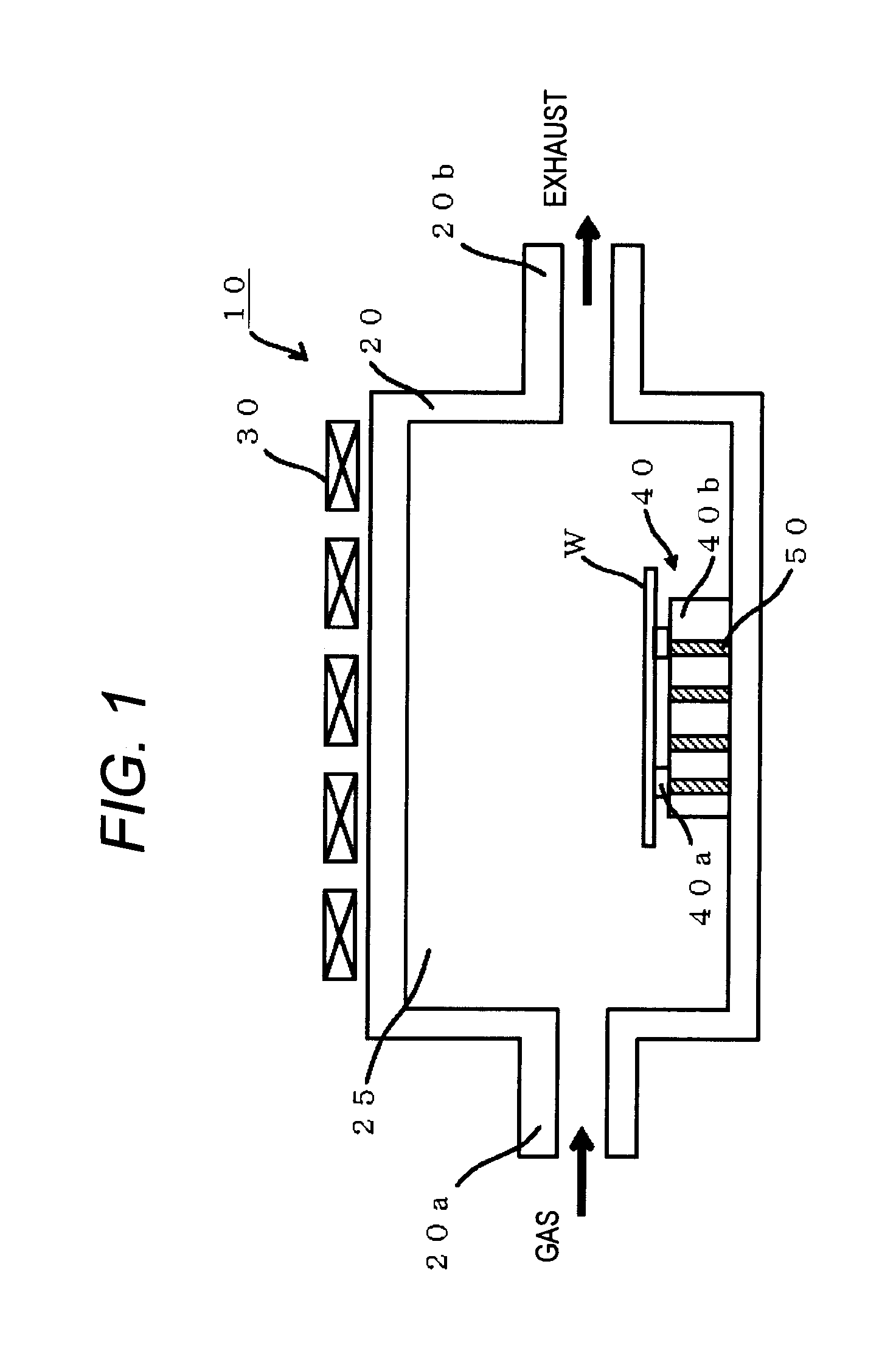

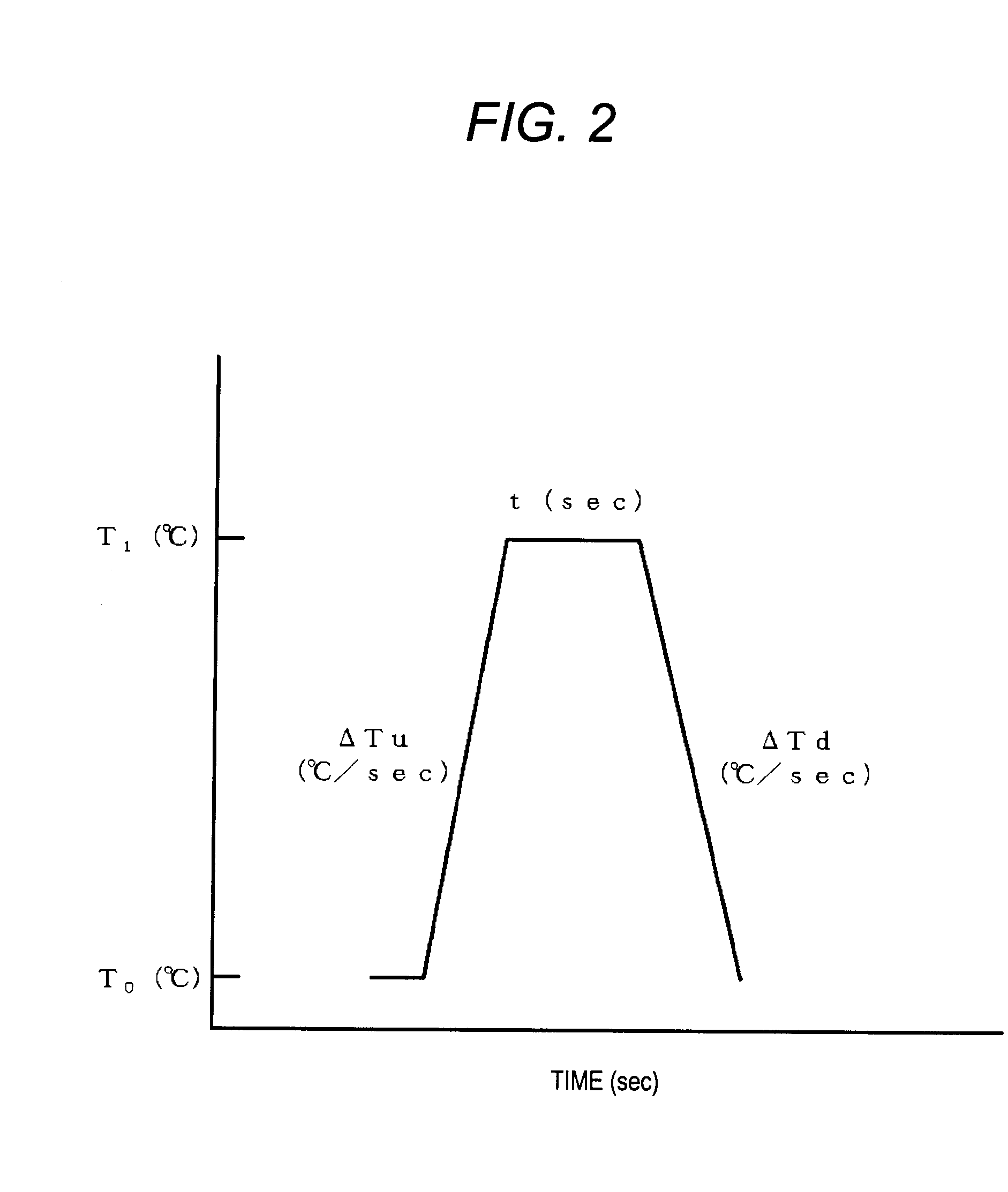

Silicon wafer, method for manufacturing the same and method for heat-treating the same

ActiveUS20100038757A1Reduce capacitySuppress generationPolycrystalline material growthAfter-treatment detailsSingle crystalIngot

A silicon wafer produced from a silicon single crystal ingot grown by Czochralski process is subjected to rapid heating / cooling thermal process at a maximum temperature (T1) of 1300° C. or more, but less than 1380° C. in an oxidizing gas atmosphere having an oxygen partial pressure of 20% or more, but less than 100%. The silicon wafer according to the invention has, in a defect-free region (DZ layer) including at least a device active region of the silicon wafer, a high oxygen concentration region having a concentration of oxygen solid solution of 0.7×1018 atoms / cm3 or more and at the same time, the defect-free region contains interstitial silicon in supersaturated state.

Owner:GLOBALWAFERS JAPAN

Plasma preparation method of spherical titanium powder for 3D printing

InactiveCN105562700AHigh sphericityUniform particle size distributionAdditive manufacturing apparatusTransportation and packagingPrillSpherical shaped

The invention discloses a plasma preparation method of spherical titanium powder for 3D printing. Titanium powder in an irregular shape is selected as the raw material; argon carries titanium powder particles to be sprayed into a plasma torch through a feeding gun; the titanium powder particles are rapidly heated and fused, and the fused particles form liquid drops with a high degree of sphericity under the action of surface tension; and crushing gas is introduced to crush the fused liquid drops again, the fused liquid drops are rapidly cooled and solidified to form spherical titanium powder particles under the two different progressively increasing temperature gradients, powder is separated from plasma gas due to the efficient filtering gas, and the spherical powder is collected through a powder collection device. The titanium powder prepared by the method is controllable in component, particle size and degree of sphericity; the prepared spherical titanium powder is high in degree of sphericity, good in mobility, uniform in size distribution, little in impurity, high in compactness, high in quality and used for 3D printing; the preparation process is rapid and easy, and one-time molding is achieved.

Owner:LONGYAN ZIJIN INNOVATION RES INST

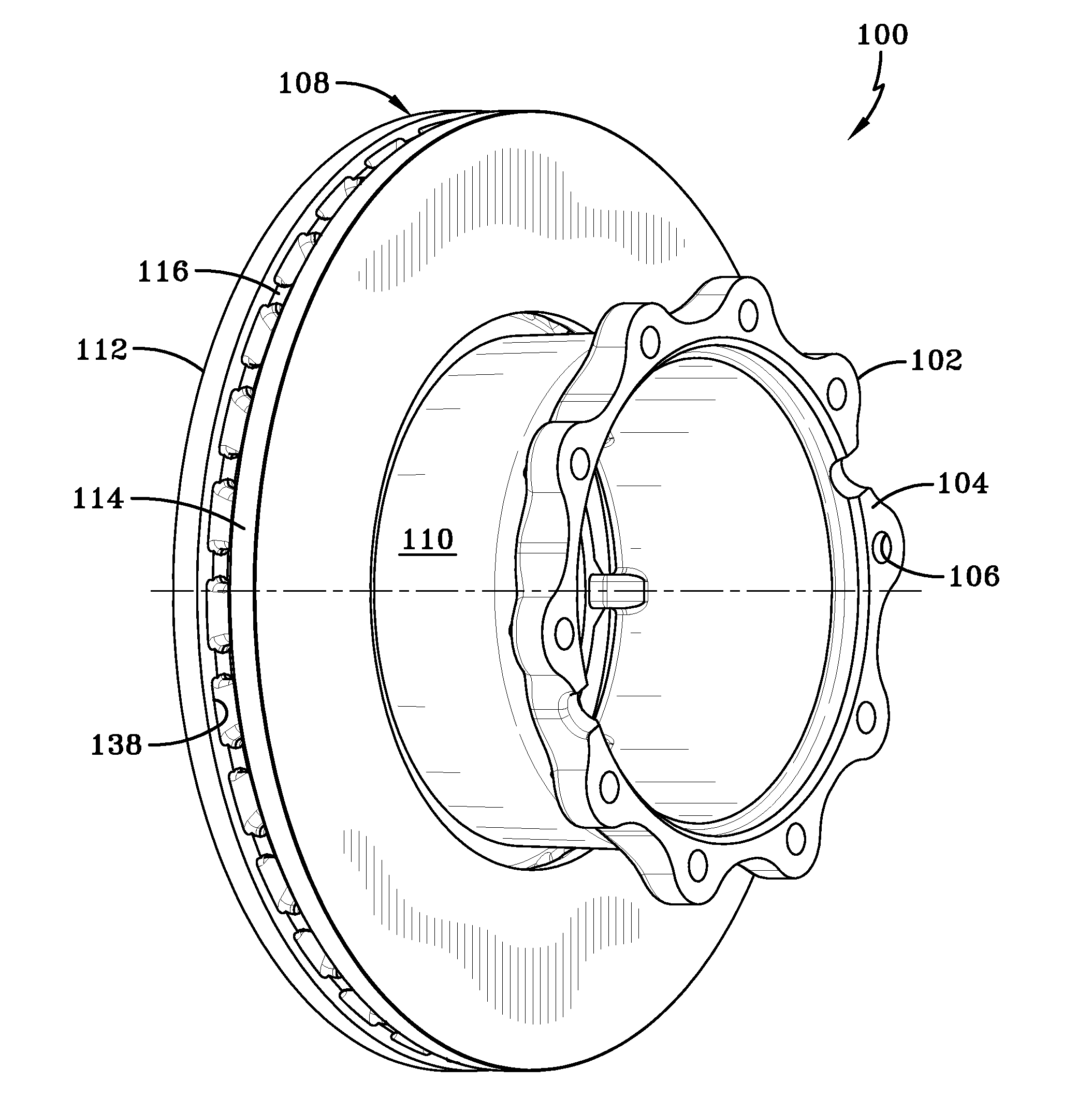

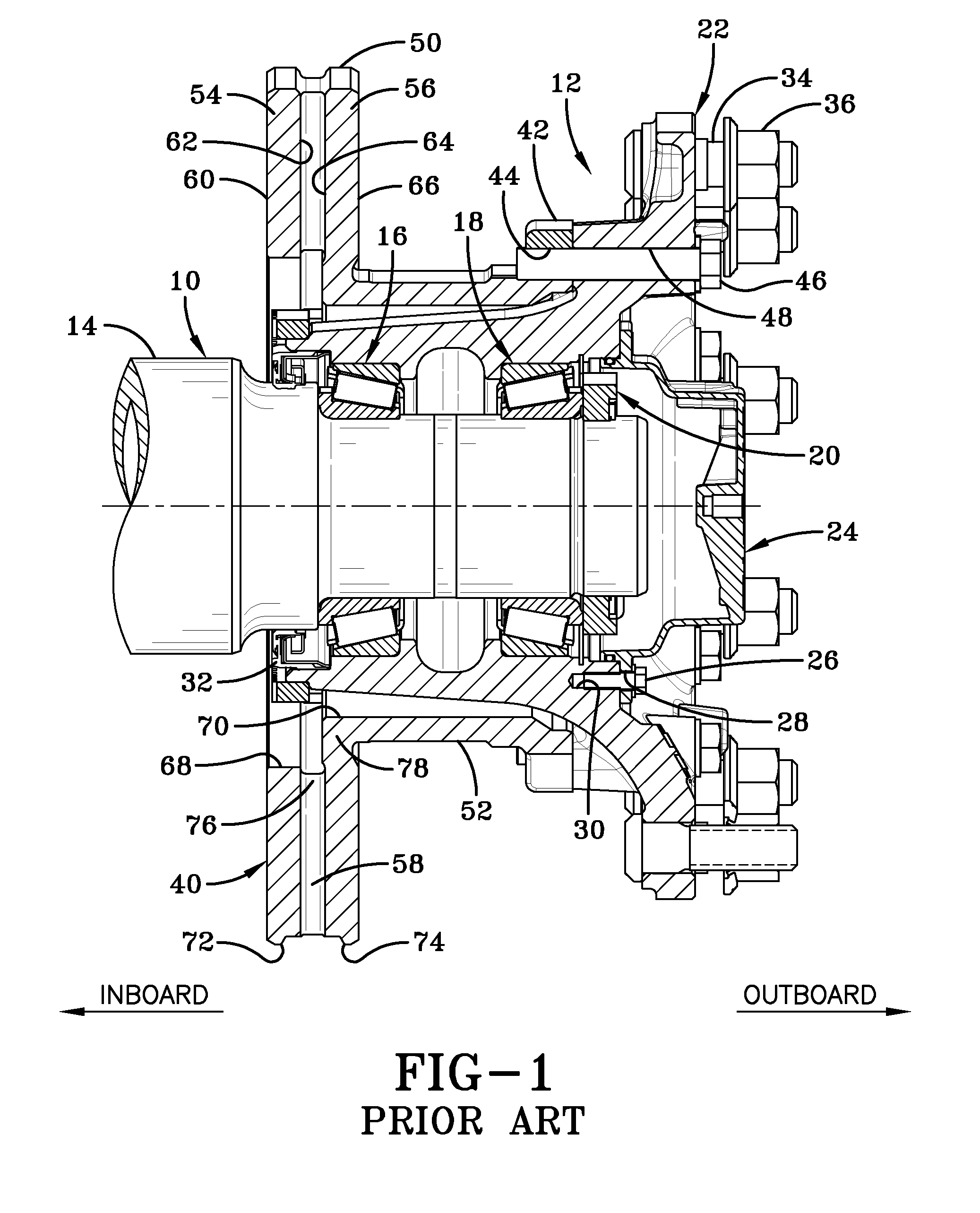

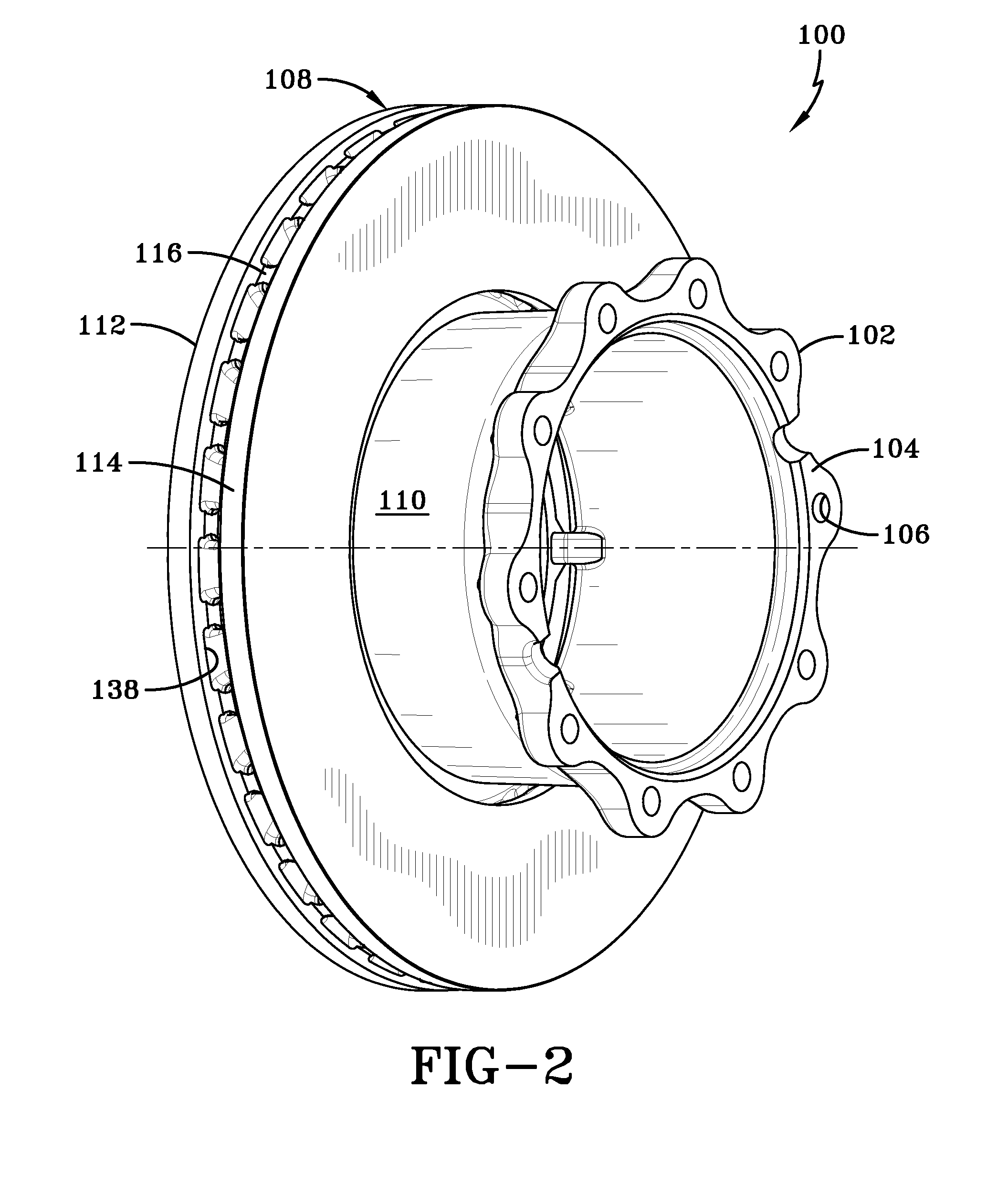

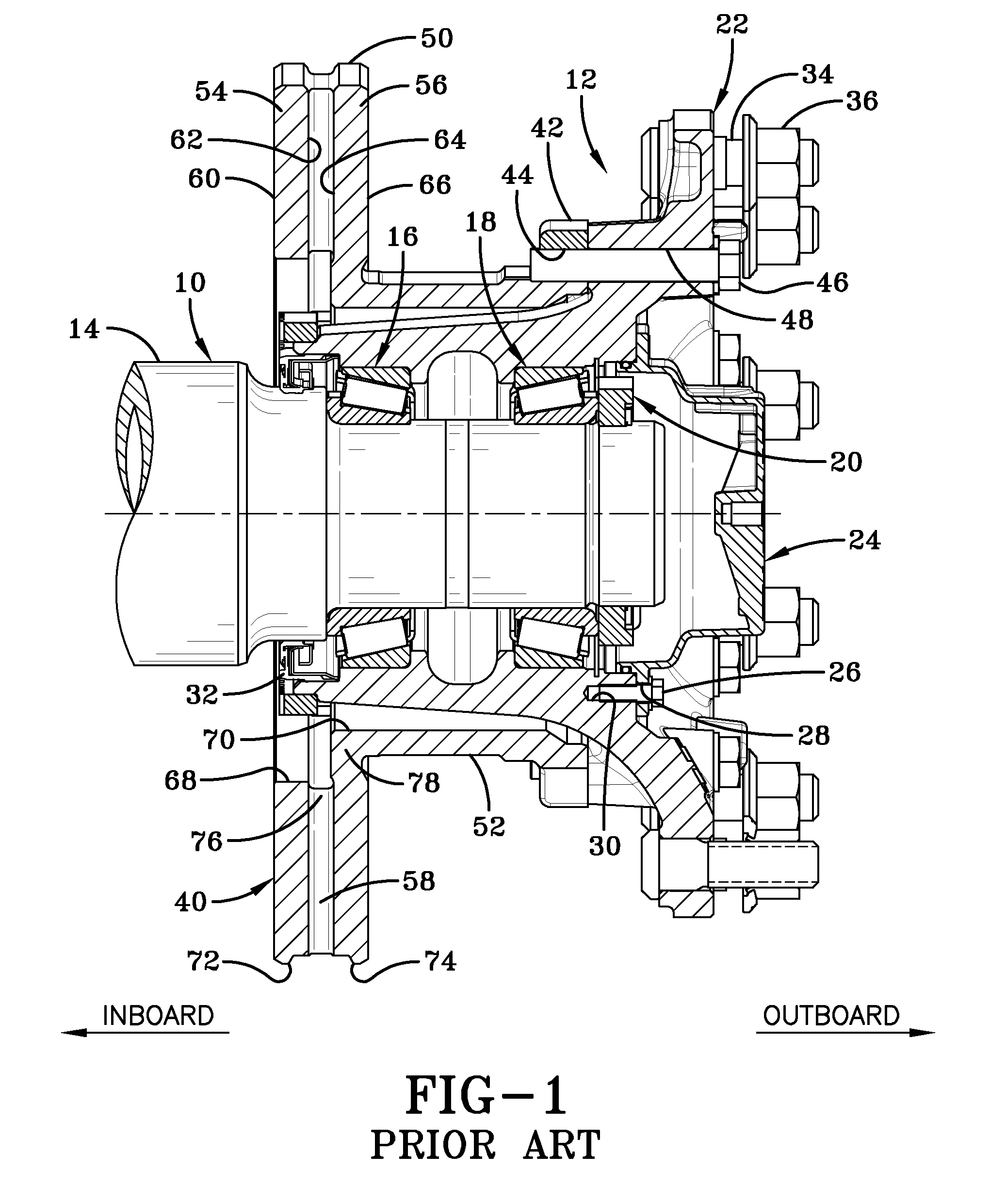

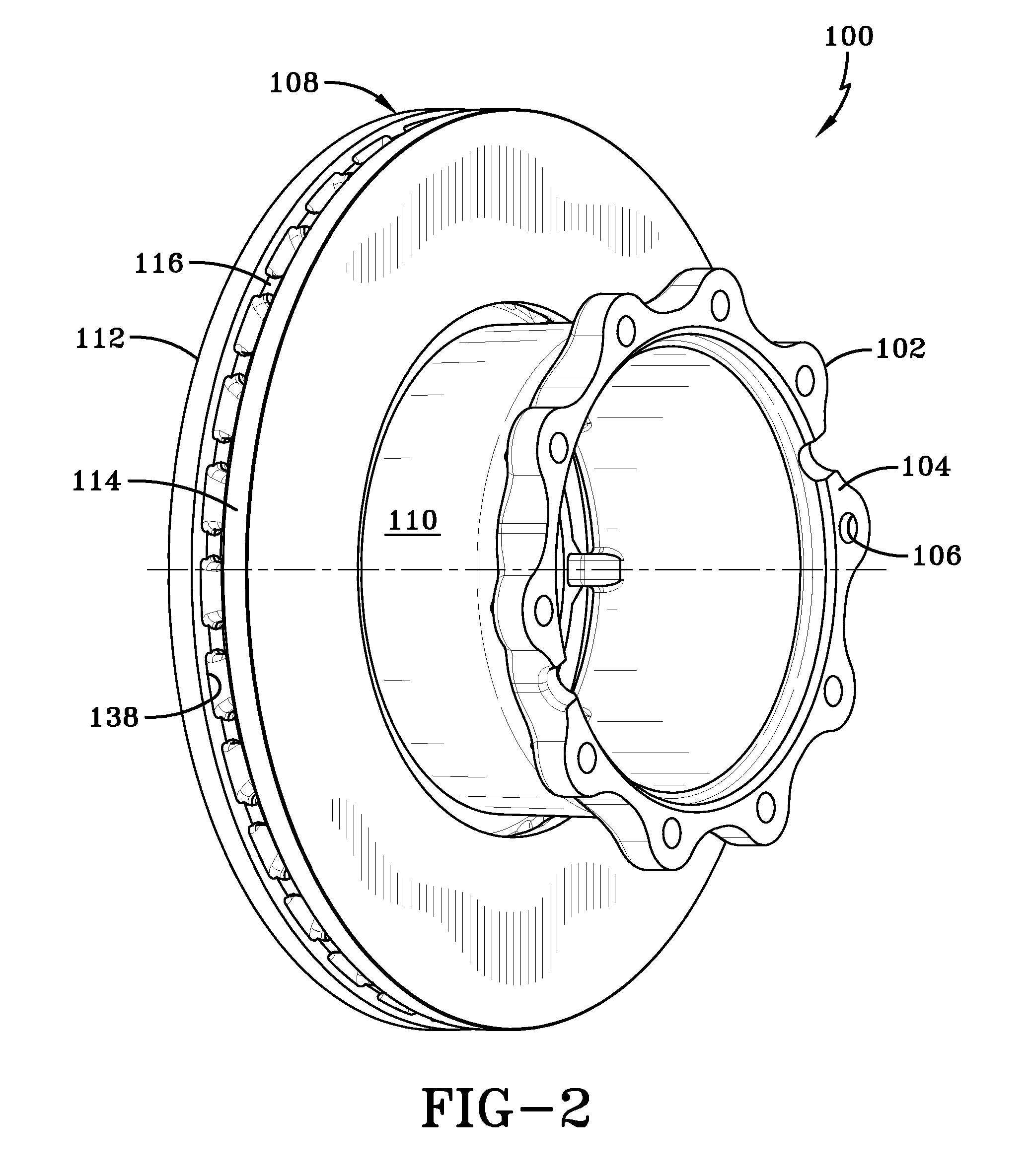

Disc brake rotor for heavy-duty vehicles

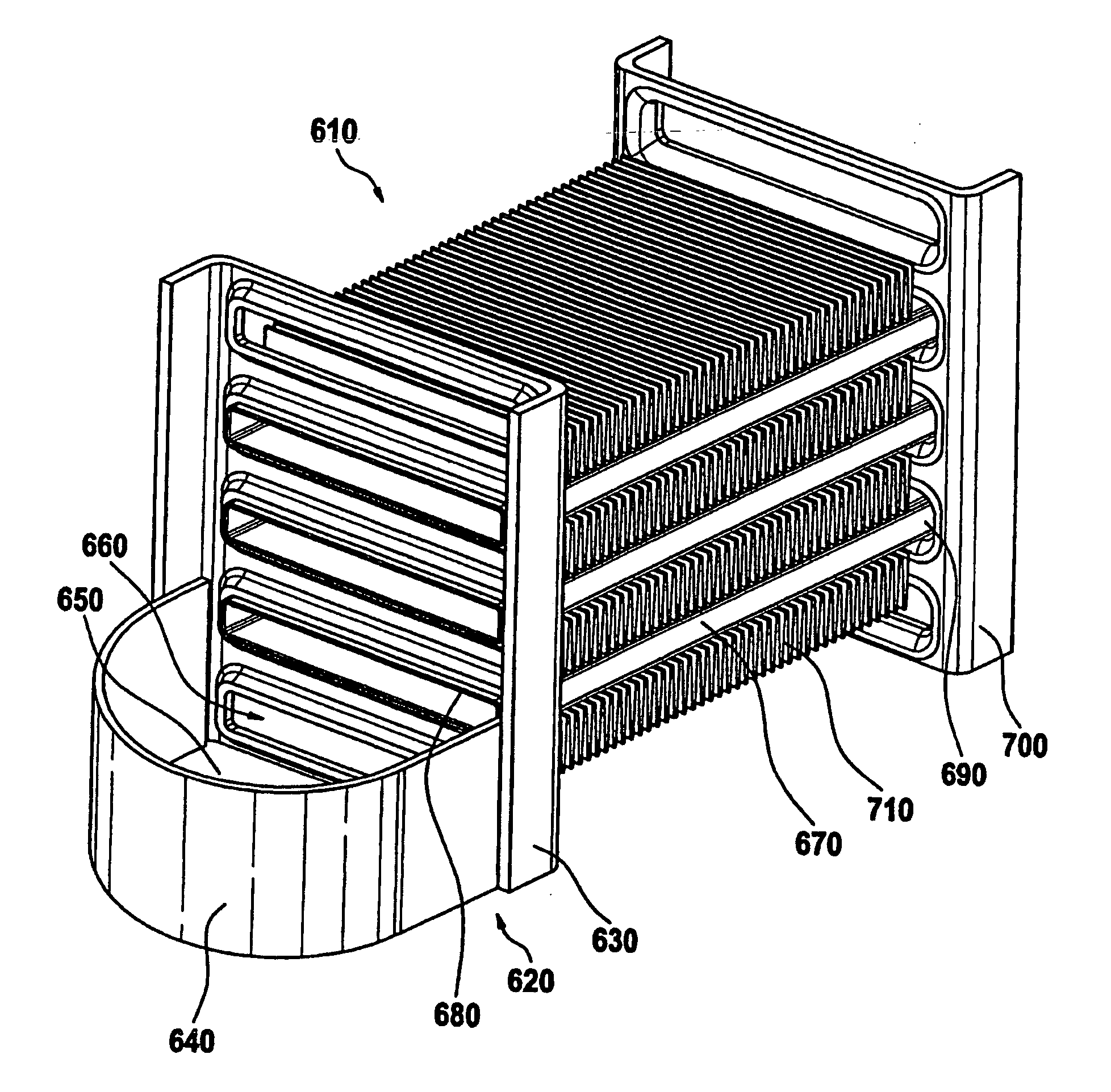

ActiveUS20150021128A1Increase airflowReduces coning of the rotor during brakingBraking discsEngineeringHeavy duty

The invention is directed to a rotor of a disc brake system for heavy-duty vehicles. The rotor includes an inboard disc and an outboard disc. The outboard disc is spaced apart from the inboard disc, and a plurality of pins extends between and rigidly connects the inboard disc and the outboard disc. A sleeve includes an inboard end and an outboard end, and is disposed inside an inner perimeter of the outboard disc. A connecting member extends between and rigidly connects an inner perimeter of the inboard disc to the inboard end of the sleeve. The inboard disc attachment to the sleeve and the interconnecting pins cooperate to improve the resistance of the rotor to thermal stress created during braking, thereby increasing the performance and the life of the rotor.

Owner:HENDRICKSON USA L L C

Ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method

InactiveCN104096958AReduce direct burning lossIncrease profitPlasma welding apparatusMelting tankChemical reaction

The invention provides a ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method, which comprises the following steps: 1) pretreatment before overlaying; 2) melting, injecting and feeding of powder outside a gun; 3) performing plasma overlaying to prepare a ceramic reinforced metal matrix composite welding layer. The ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method has the beneficial effects that the utilization ratio of reinforced ceramic in the overlaying process is increased, the chemical reaction rate of the reinforced ceramic and metal molten is lowered due to chemical coating, the trend that the defect is generated in the composite welding layer due to the sharp reaction between the reinforced ceramic and the metal interface is reduced, meanwhile, the composite welding layer prepared by the method has a lot of in situ generated large granular carbides, and thus the mechanical properties (such as strength, hardness and wear resistance) and thermal physical properties (such as thermal expansion coefficient, high temperature oxidation resistance and thermal intensity) of the composite welding layer are significantly improved.

Owner:WUHAN UNIV OF TECH

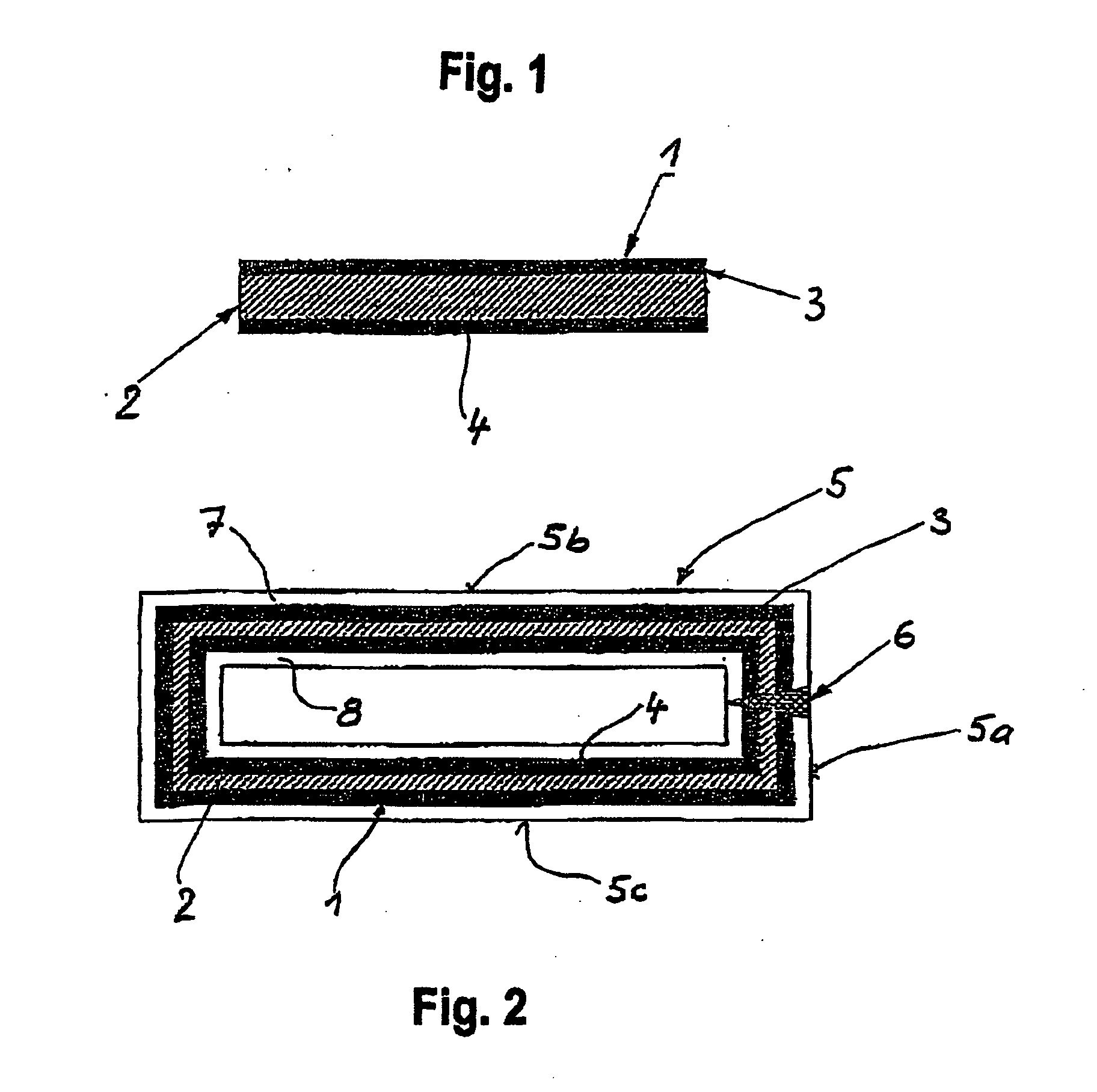

Silicon wafer, method for manufacturing the same and method for heat-treating the same

ActiveCN101638807AThe preparation method is simple and easyImprove productivityPolycrystalline material growthAfter-treatment detailsSingle crystalIngot

A silicon wafer produced from a silicon single crystal ingot grown by Czochralski process is subjected to rapid heating / cooling thermal process at a maximum temperature (T1) of 1300 DEG C or more, but less than 1380 DEG C in an oxidizing gas atmosphere having an oxygen partial pressure of 20% or more, but less than 100%. The silicon wafer (10) according to the invention has, in a defect-free region (DZ layer) (12) including at least a device active region of the silicon wafer, a high oxygen concentration region (12) having a concentration of oxygen solid solution of 0.71018 atoms / cm3 or more and at the same time, the defect-free region contains interstitial silicon (14) in supersaturated state.

Owner:GLOBALWAFERS JAPAN

Steel with ultra-high thermal conductivity for hot-stamping die and preparation method of steel

The invention relates to a novel material with ultra-high thermal conductivity for a hot-stamping die. The steels in the market for the hot-stamping die are mainly various types of improved H13 and H11 high-alloy hot work die steels. The steel in the invention comprises the following compositions in percentage by mass: 0.150-0.35% of C, less than or equal to 0.25% of Si, 0.08-0.20% of Mn,1.0-2.0% of W,2.0-4.5% of Mo, less than or equal to 0.30% of Cr,less than or equal to 0.02% of V and the balance of Fe and inevitable impurity elements, wherein S in the impurity elements is less than or equal to 0.005%, P in the impurity elements is less than or equal to 0.01 and O in the impurity elements is less than or equal to 30 ppm (parts per million). The invention is characterized in that simple elements i.e. C, Mo and W are used as the main elements, and proper proportion of carbide is adopted; the contents of Mn and Cr are maintained low, and the content of Si is maintained ultra-low; the steel has superior machining property after being subjected to electro-smelting, electro-slag remelting, annealing, high-temperature homogenization, forging and annealing; through thermal treatment (1060-1100 DEG C quenching and high-temperature annealing), the toughness of the steel can reach the toughness of common hot-stamping die steel such as H13, and the hardness, annealing stability and the fatigue property of the steel are more superior; particularly, the steel with lower coefficient of thermal expansion and ultra-high thermal conductivity is more suitable for hot stamping.

Owner:SHANGHAI UNIV

Phosphate binder for casting

InactiveCN101417315AHigh heat intensityLow collapsibilityFoundry mouldsFoundry coresPhosphatePhosphoric acid

The invention relates to a phosphate binder used for casting, which comprises the components by weight ratio: 45 to 55 percent of phosphoric acid, 33 to 45 percent of aluminium dihydrogen phosphate, 5 to 15 percent of boric acid and 6 to 12 percent of citric acid. The binder can also be mixedly matched with 0.5 to 2 percent of magnesium oxide curing agent by weight ratio. The binder adopts the phosphoric acid and the aluminium dihydrogen phosphate as a binder main body, and is added with the boric acid and citric acid for improving the bonding property, thus being one phosphate binder with good property used for casting. The binder has the advantages of low cost, little environmental pollution, high hot strength, good collapsibility and the like, can improve working environment to the utmost extent, and reduce production cost.

Owner:大连核心铸造技术工程研究所

Collagen or gelatin crumble composition and uses

InactiveUS6016862ALow structural integrityEasy to manufacturePeptide/protein ingredientsImmunoglobulinsParticulatesPreservative

An animal collagen or gelatin based crumble, and processes for the preparation of the particulate crumble, are useful in the preparation of collagen or gelatin based compositions. The crumble is prepared by extracting animal collagen from an animal tissue source and combining the collagen with sufficient water to form a composition comprising about 15-45 wt % animal collagen and about 0.01-5 wt % of a stabilizer or preservative. Such a combination of materials can be solidified and then processed into a large particulate format. The large particulate comprises a, regular or amorphous shaped, roughly crumbled or roughly divided, crumble product. The typical particle size of a majority of the crumble is about 0.2-5 cm. The crumble is easily manufactured, packaged, stored, handled and distributed. The crumble can be easily used as is. The material melts easily into a use locus. The crumble is also particularly adapted to a use in combination with an aqueous diluent to form an aqueous animal collagen or gelatin solution that have a variety of uses. The aqueous solution of the crumble can be made with minimal heating to dissolve the crumble in the aqueous liquid.

Owner:HORMEL FOODS

Molten metal casting die

InactiveUS20100243192A1Low costReduce stepsCasting safety devicesFoundry mouldsLiquid copperMaterials science

A molten metal casting die having a modified surface, a method for making such dies, and a method for making articles of manufacture from such dies is disclosed. The methods are designed to protect die steel surfaces from corrosion by molten metals substantially containing liquid copper.

Owner:NONFERROUS MATERIALS TECH DEV CENT

Method for extracting germanium from brown coal

The invention provides a process of germanium extraction from brown coal, which is germanium extraction by employing a cyclone furnace. The process includes that the brown coal is added in the cyclone furnace to mix with hot wind which is sent into the cyclone furnace, the brown coal is burned, the CO content inside the cyclone furnace is controlled within the range of 0.5-1%, germanium in the brown coal is reduced and volatilized into flue gas, and flue dust is collected as raw material of the germanium. The process can achieve the purposes that the flour shaped brown coal is fully used to enlarge the productivity of the germanium, the recovery ratio of the germanium is increased, and the excess energy is effectively recovered.

Owner:锡林郭勒通力锗业有限责任公司

Coking coal blending method for producing high-heat strength coke

The present invention relates to a method of coal blending for coking, in particular to a method of coal blending for coking, by which high-heat-intensity coke is produced. The present invention mainly resolves the technical problems of the prior coal blending method, such as inappropriate parameter selection and difficulty in promotion caused by the application of active components and inert components in ensuring the caking property of coal blending. The technical scheme of the method is as follows: the method of coal blending for coking, by which high-heat-intensity coke is produced, adopts rich coal, coking coal, gas coal and 1 / 3 coking coal, which are blended together; after blending, the microcosmic strong caking ratio is kept larger than 55 percent; the maximum thickness of the gelatinous layer is between 14mm and 18mm; and the caking index is between 80 and 85. The method is mainly used for the production of high-heat-intensity coke.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Collagen or gelatin crumble composition and uses

InactiveUS6090915AEasy to compressEasy to fallPeptide/protein ingredientsImmunoglobulinsParticulatesPreservative

An animal collagen or gelatin based crumble, and processes for the preparation of the particulate crumble, are useful in the preparation of collagen or gelatin based compositions. The crumble is prepared by extracting animal collagen from an animal tissue source and combining the collagen with sufficient water to form a composition comprising about 15-45 wt % animal collagen and about 0.01-5 wt % of a stabilizer or preservative. Such a combination of materials can be solidified and then processed into a large particulate format. The large particulate comprises a, regular or amorphous shaped, roughly crumbled or roughly divided, crumble product. The typical particle size of a majority of the crumble is about 0.2-5 cm. The crumble is easily manufactured, packaged, stored, handled and distributed. The crumble can be easily used as is. The material melts easily into a use locus. The crumble is also particularly adapted to a use in combination with an aqueous diluent to form an aqueous animal collagen or gelatin solution that have a variety of uses. The aqueous solution of the crumble can be made with minimal heating to dissolve the crumble in the aqueous liquid.

Owner:HORMEL FOODS

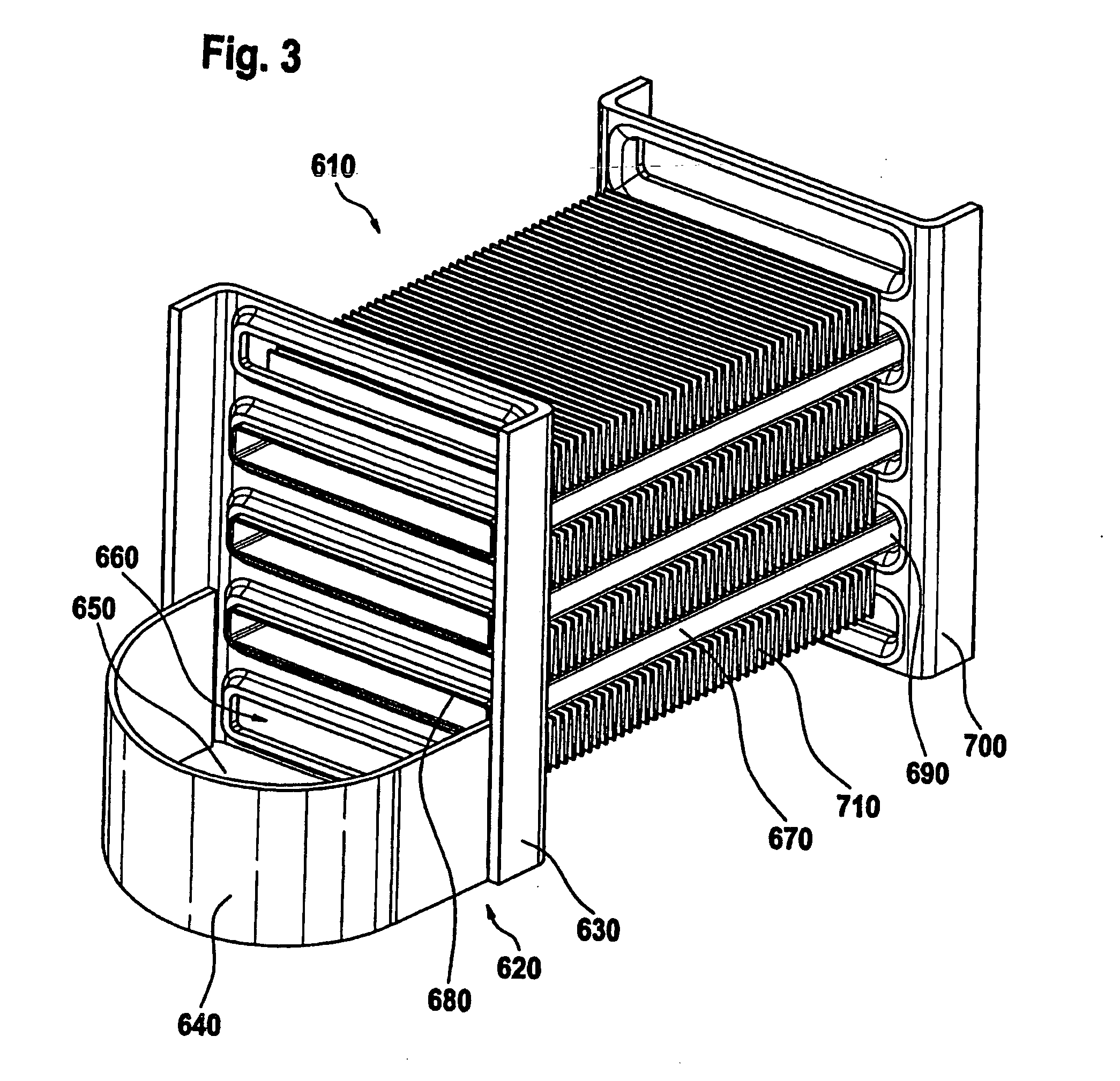

Heat exchanger useful as charge-air cooler for commercial vehicles

InactiveUS20050006066A1Improve hot strengthIncrease heat exchangeInternal combustion piston enginesCorrosion preventionChillerCommercial vehicle

The invention relates to a heat exchanger, preferably a charge-air cooler for motor vehicles, comprising: first members defining a plurality of passageways for guiding a first fluid in heat exchange relationship with a second fluid flowing over the outside of the members defining the passageways, and at least one second member forming a part of the heat exchanger structure in contact with either the first or second fluid, wherein at least one of the first members and the second member is comprised of a steel strip bearing at least one surface layer of aluminum and / or a brazing material.

Owner:BEHR GMBH & CO KG

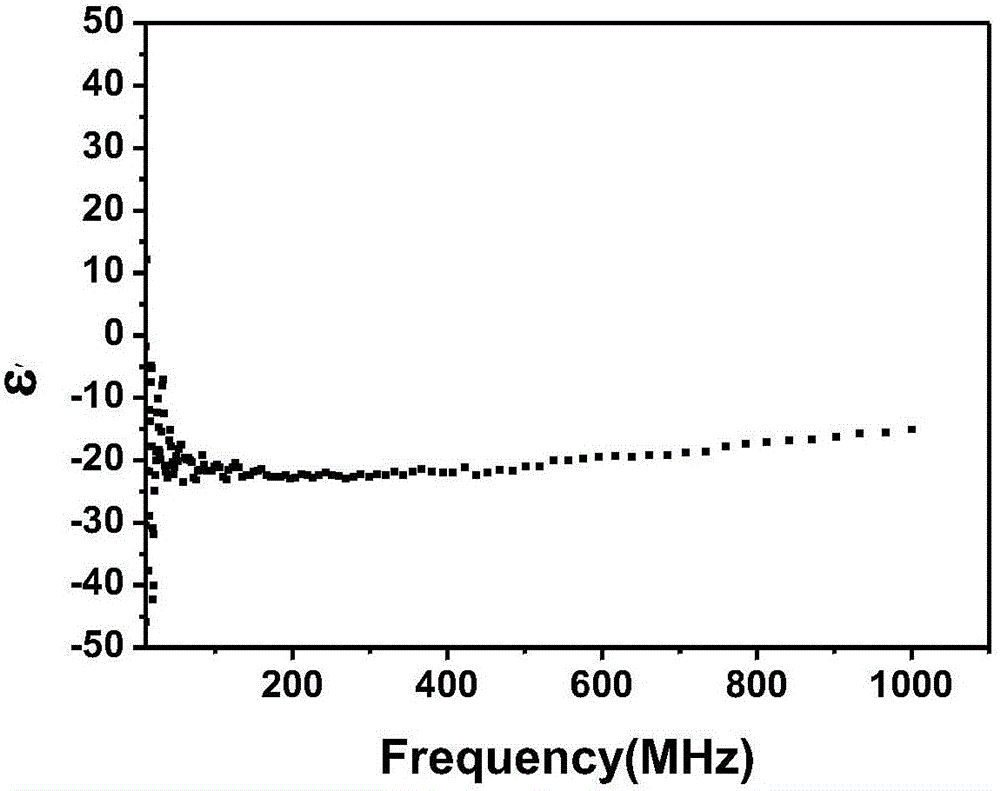

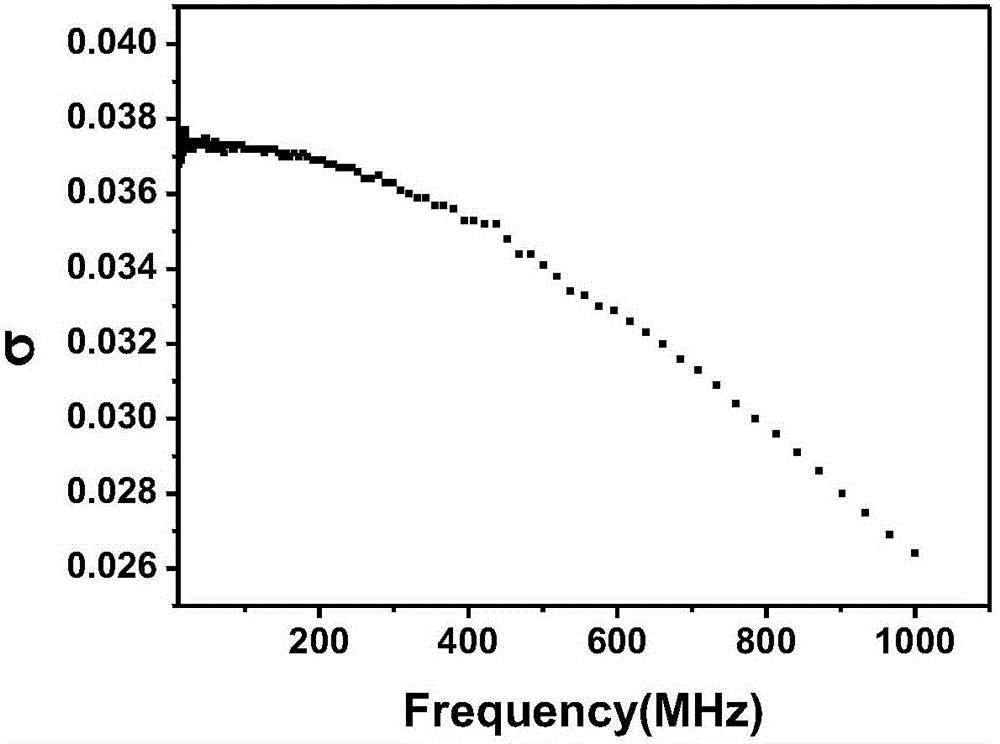

Method for preparing negative permittivity material from graphene, carbon nanometer tubes and phenolic resin

InactiveCN105802123APromotes conductive behaviorLimit leakage conduction currentDielectric lossCarbon nanotube

The invention discloses a method for preparing a negative permittivity material with graphene, carbon nanometer tubes and phenolic resin.The method includes the steps that graphene powder, carbon nanometer tube powder and phenolic resin powder are subjected to ball mill mixing, then a PVA solution is added, and the mixture is ground to be even; the powder is poured into a mold to be pressed into a sheet.A certain quantity of functional groups exist on the surface of the graphene in the composite material prepared with the method, and are not connected with each other and free of electric conduction, repulsive force exists between the functional groups, the functional groups are attached between sheet layers of the graphene and distributed on the surface of the graphene to form an interface layer used for limiting leakage conductive currents, and therefore dielectric losses are decreased.

Owner:SHANDONG UNIV

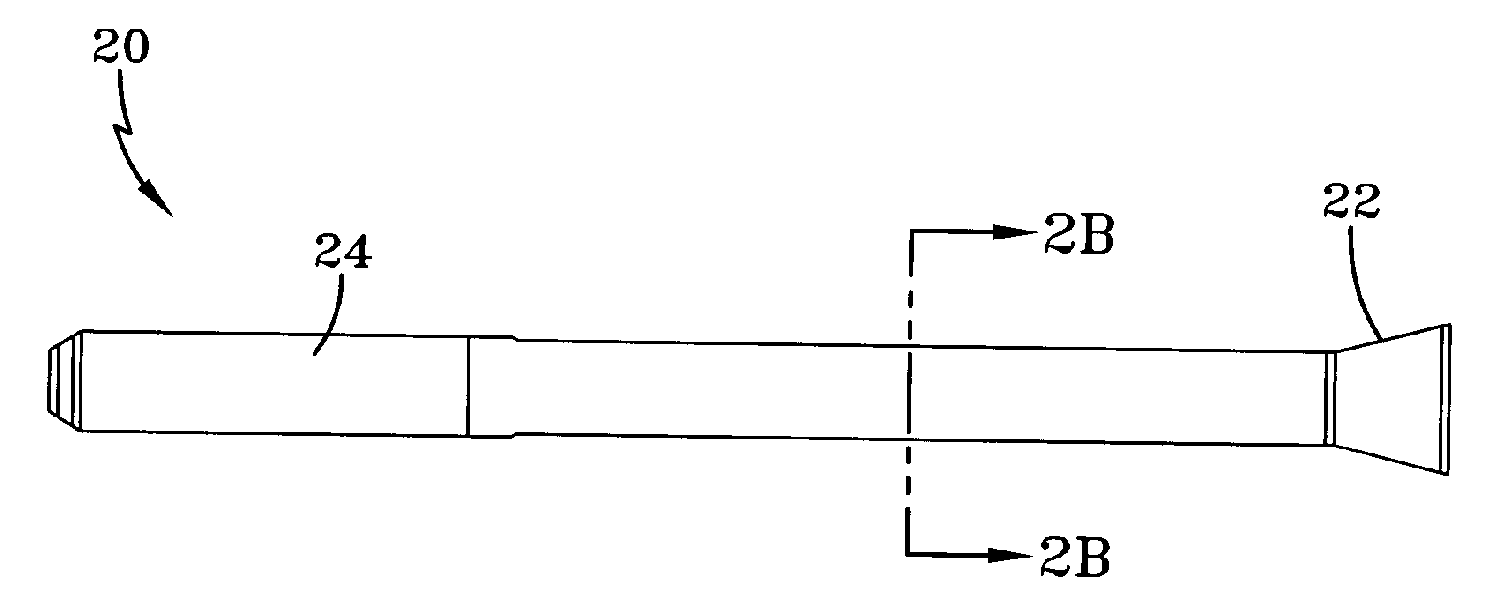

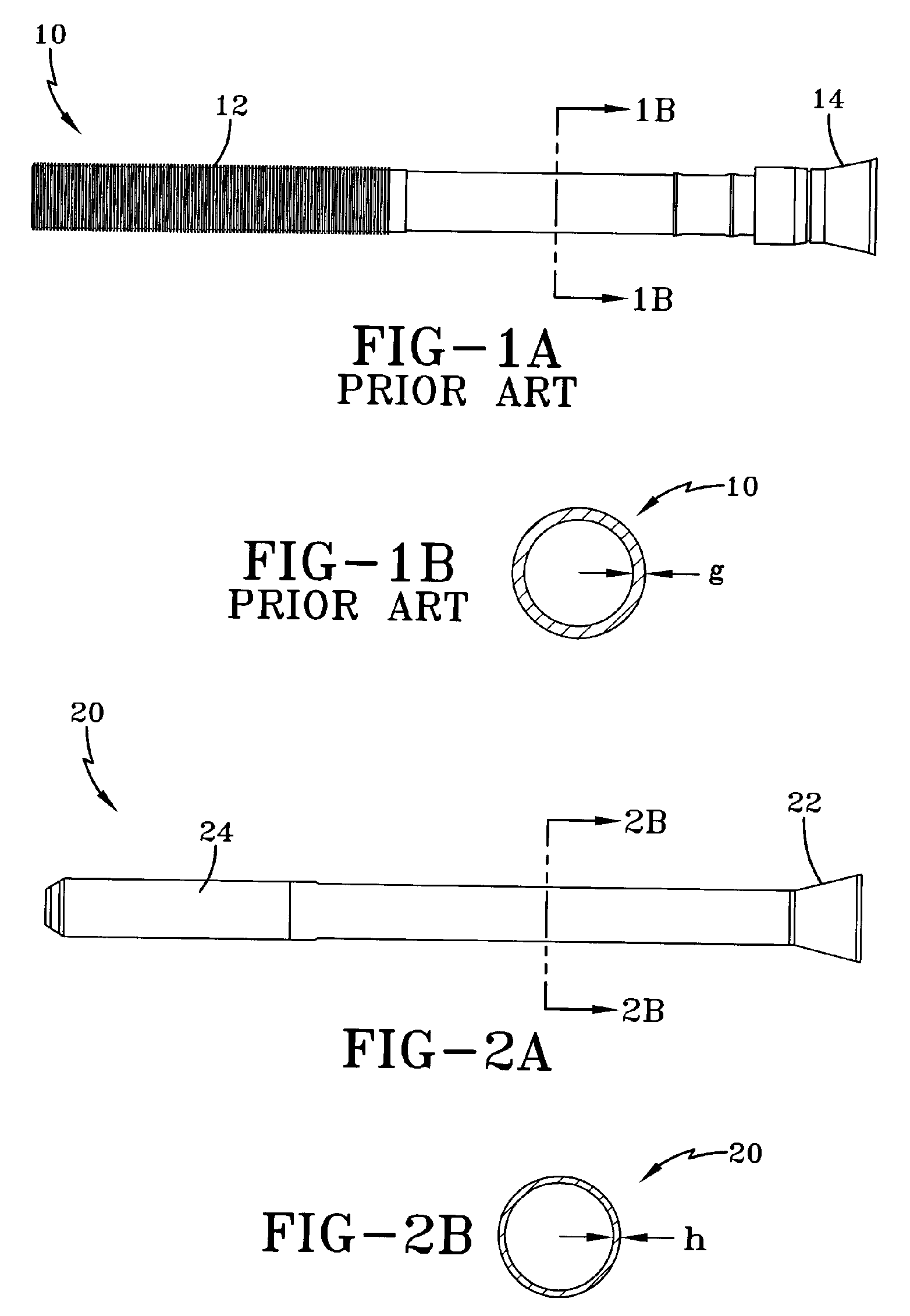

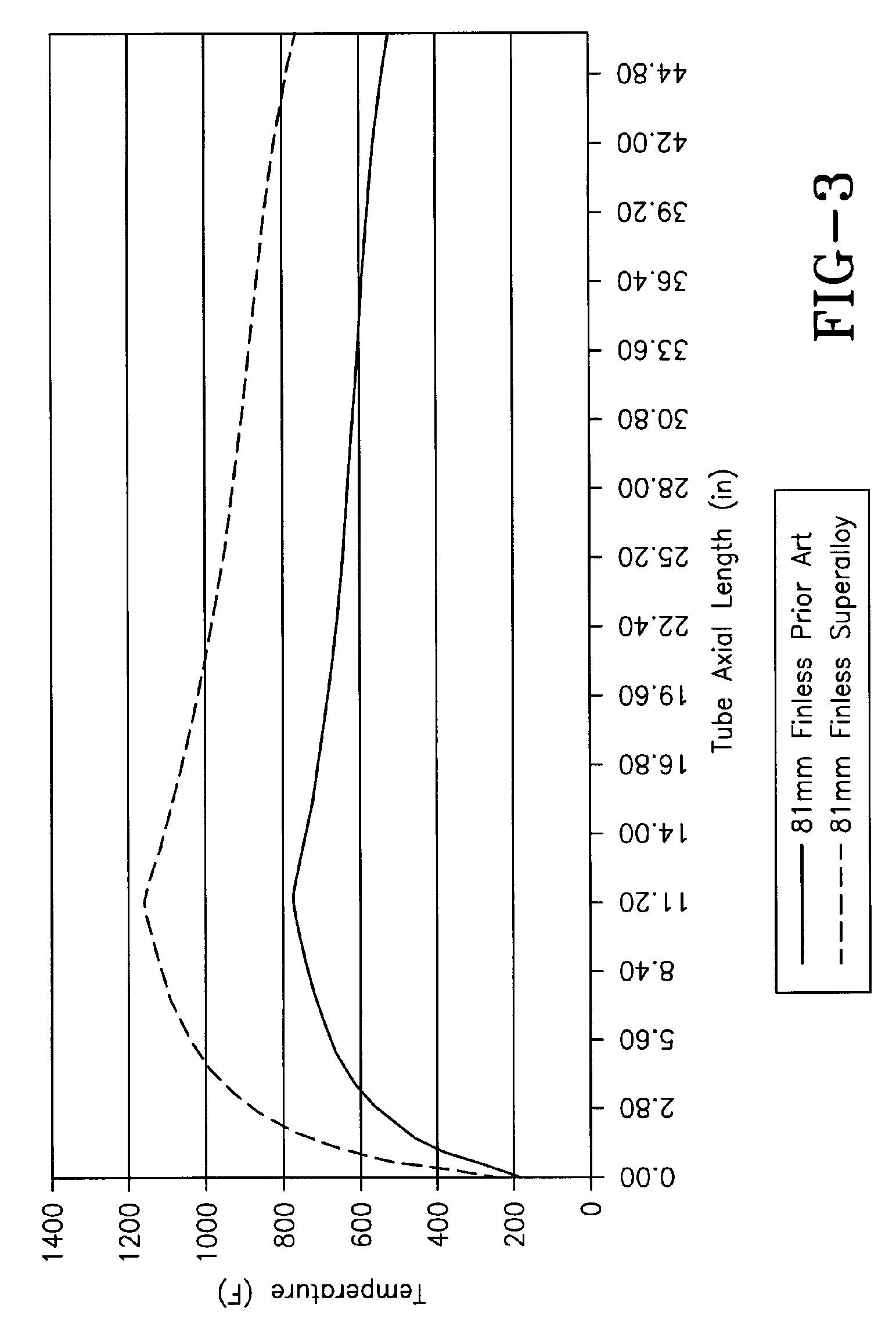

Superalloy mortar tube

A finless mortar tube is made of a superalloy. The superalloy is based on one of cobalt, iron and nickel. The finless mortar tube has an integrally formed blast attenuation device. The mortar tube may be 60, 81 or 120 mm. The mortar tube is capable of a substantial increase in the rate of fire compared to conventional mortar tubes.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

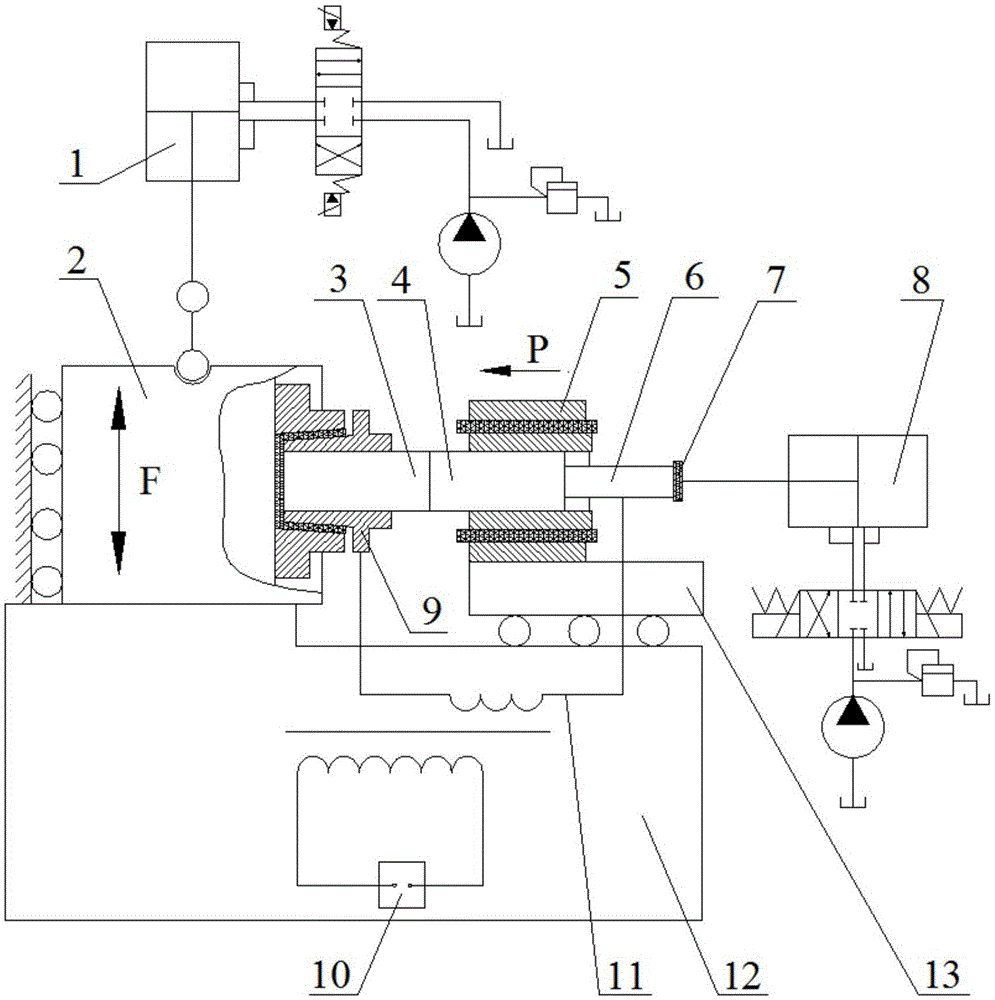

Linear friction-current compound heat source welding method

InactiveCN105562953AReduce loadSmooth vibration outputWelding apparatusFriction weldingElectrical resistance and conductance

The invention discloses a linear friction-current compound heat source welding method for solving the technical problem of weak joint quality in welding of a large-area workpiece by a traditional linear friction welding method. Current is introduced into a friction pair when performing linear friction welding; and a welding interface is heated by using resistance heat. When a welding interface material reaches a visco-plastic state and generates deformation, that is, when a stable friction phase is reached, the current is cut off by a power supply control device; quick workpiece alignment is controlled; and higher welding upset force is applied to the workpiece to finish the workpiece welding. A compound heat source heating mode can realize the welding of high-heat-strength and large-area workpiece, relieves the load of a machine tool, is stable in vibration output of the machine tool, is excellent in controllability, can form an excellent closed welding interface in the welding process, and improves the joint quality in linear friction welding of the large-area workpiece.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

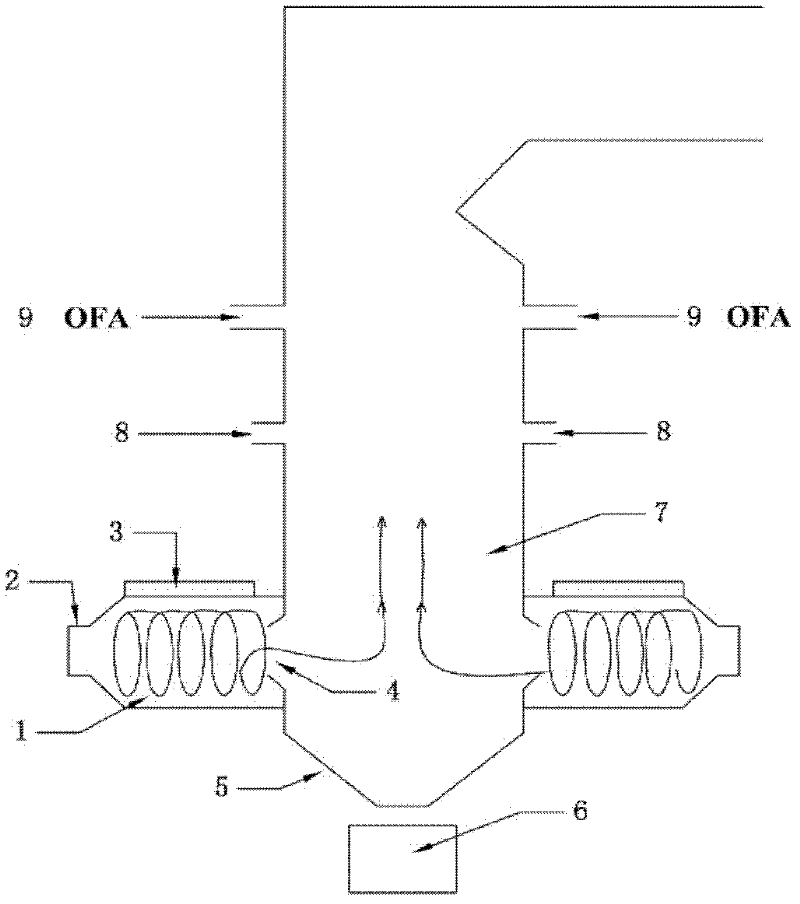

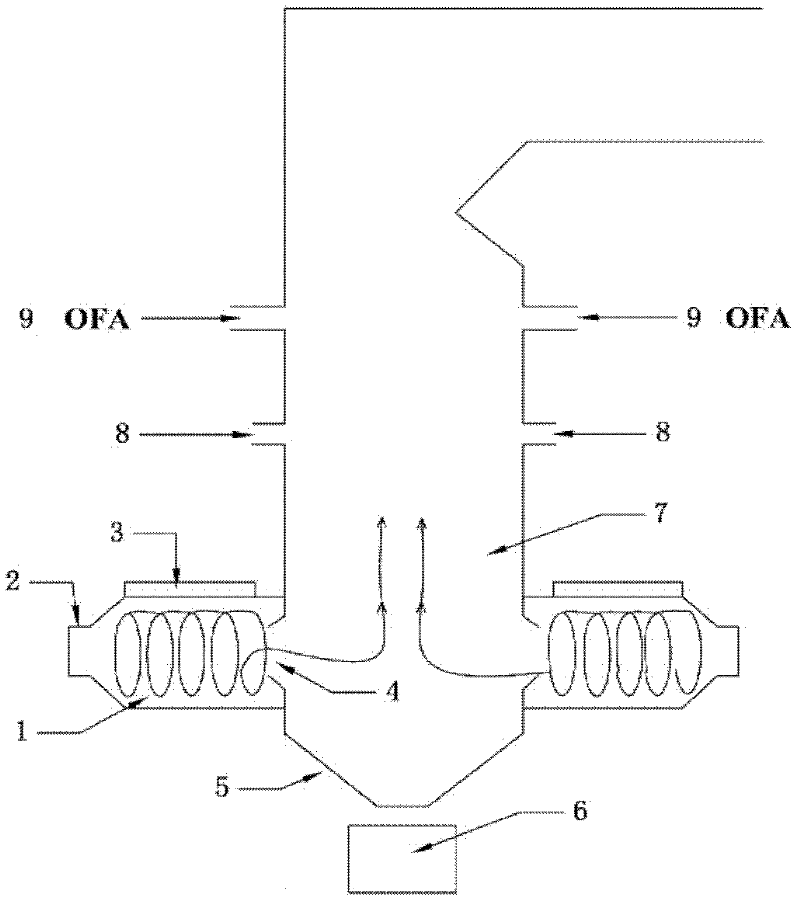

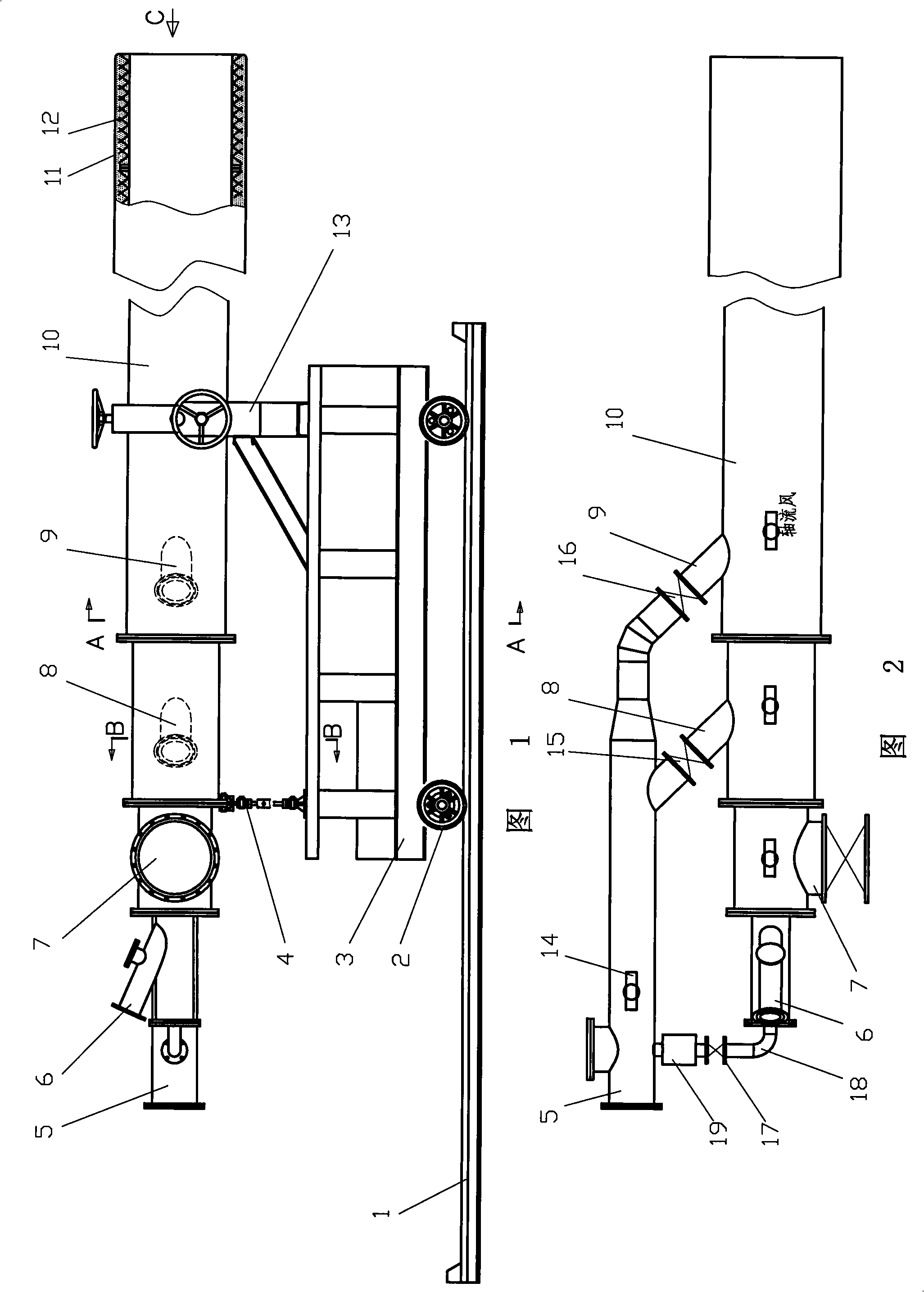

A boiler device using cyclone combustion method

InactiveCN102287813AReduce the power consumption of millingLow costFluidized bed combustionApparatus for fluidised bed combustionCycloneBoiler furnace

The invention discloses a boiler device adopting a cyclone combustion method, which comprises a cyclone tube, a boiler main furnace and a liquid slag granulation water tank. A primary air inlet is arranged at the front end of the cyclone tube, and a secondary air inlet is arranged in the middle of the cyclone tube. The tail of the cyclone is seamlessly connected with the main furnace of the boiler through a concave outlet; the lower tapered part of the main furnace of the boiler is a cold ash hopper, and the lower part of the cold ash hopper is arranged with a granulation water tank for granulating the boiler liquid slag discharge. The boiler device of the present invention has the following advantages: the fuel to be burned only needs to be simply crushed, which greatly saves the power consumption and cost of pulverizing; the combustion is stable; the heat intensity is high, and the boiler volume is small; the combustion efficiency is high and the economy is good; slag; ash and slag capture rate is high, fly ash content is greatly reduced; boiler size is compact; can burn a variety of fuels, fuel adaptability; boiler load adjustment capacity is large; ash slag is easy to comprehensive utilization; greatly reduce the occurrence of high temperature corrosion .

Owner:XI AN JIAOTONG UNIV

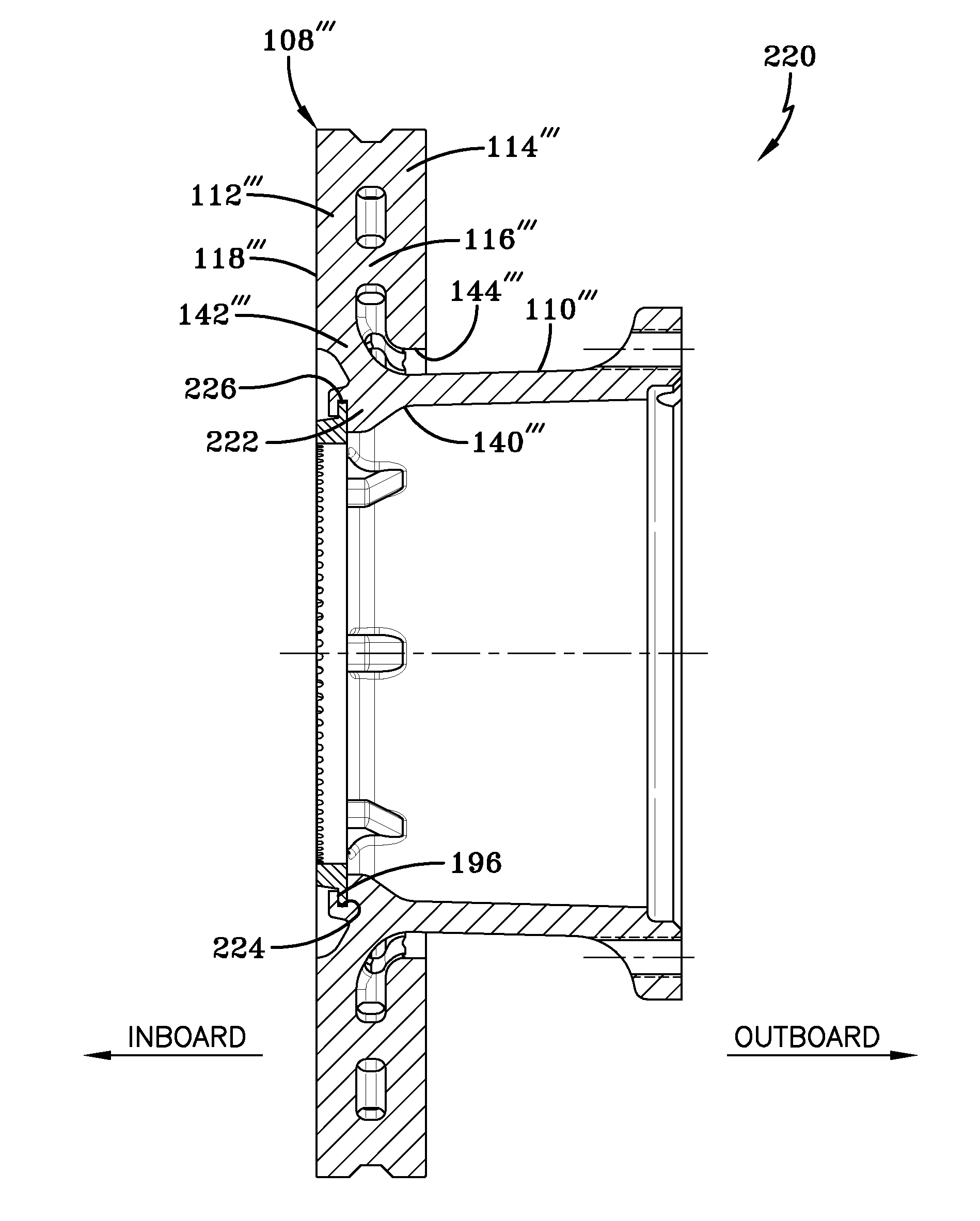

Disc brake rotor for heavy-duty vehicles

ActiveUS9506515B2Increase airflowReduces coning of the rotor during brakingBraking discsBraking membersEngineeringHeavy duty

The invention is directed to a rotor of a disc brake system for heavy-duty vehicles. The rotor includes an inboard disc and an outboard disc. The outboard disc is spaced apart from the inboard disc, and a plurality of pins extends between and rigidly connects the inboard disc and the outboard disc. A sleeve includes an inboard end and an outboard end, and is disposed inside an inner perimeter of the outboard disc. A connecting member extends between and rigidly connects an inner perimeter of the inboard disc to the inboard end of the sleeve. The inboard disc attachment to the sleeve and the interconnecting pins cooperate to improve the resistance of the rotor to thermal stress created during braking, thereby increasing the performance and the life of the rotor.

Owner:HENDRICKSON USA L L C

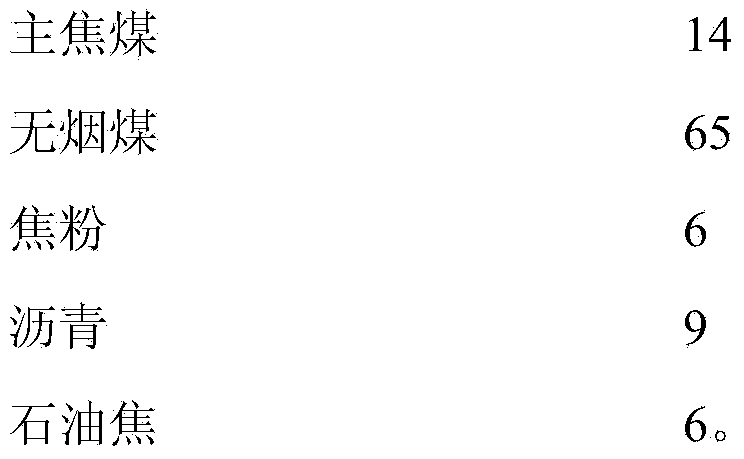

Method for preparing coke

ActiveCN104194813AQuality improvementHigh strengthSpecial form destructive distillationPorosityCoke oven

The invention provides a method for preparing coke. The invention provides a preparation method of formed coke in a vertical coke oven. The method comprises the step of carrying out dry distillation on the raw materials including coking coal, anthracite, coke powder, asphalt and petroleum coke. The formed coke is prepared by stirring blending coal at high temperature and high pressure according to a certain proportion and carrying out forming, charging and carbonizing processes. The method has the beneficial effects that a formula effectively solves the problem of impacts of plastic mass change under the conditions of high temperature and rapid heating; the coke quality reaches the A-level rate, which is above 95%, in the national standard; the coke has the characteristics of uniform product specification, high lumpiness, high strength, lower porosity and reactivity and low ash content and sulfur content.

Owner:SHANDONG JUMING ENERGY

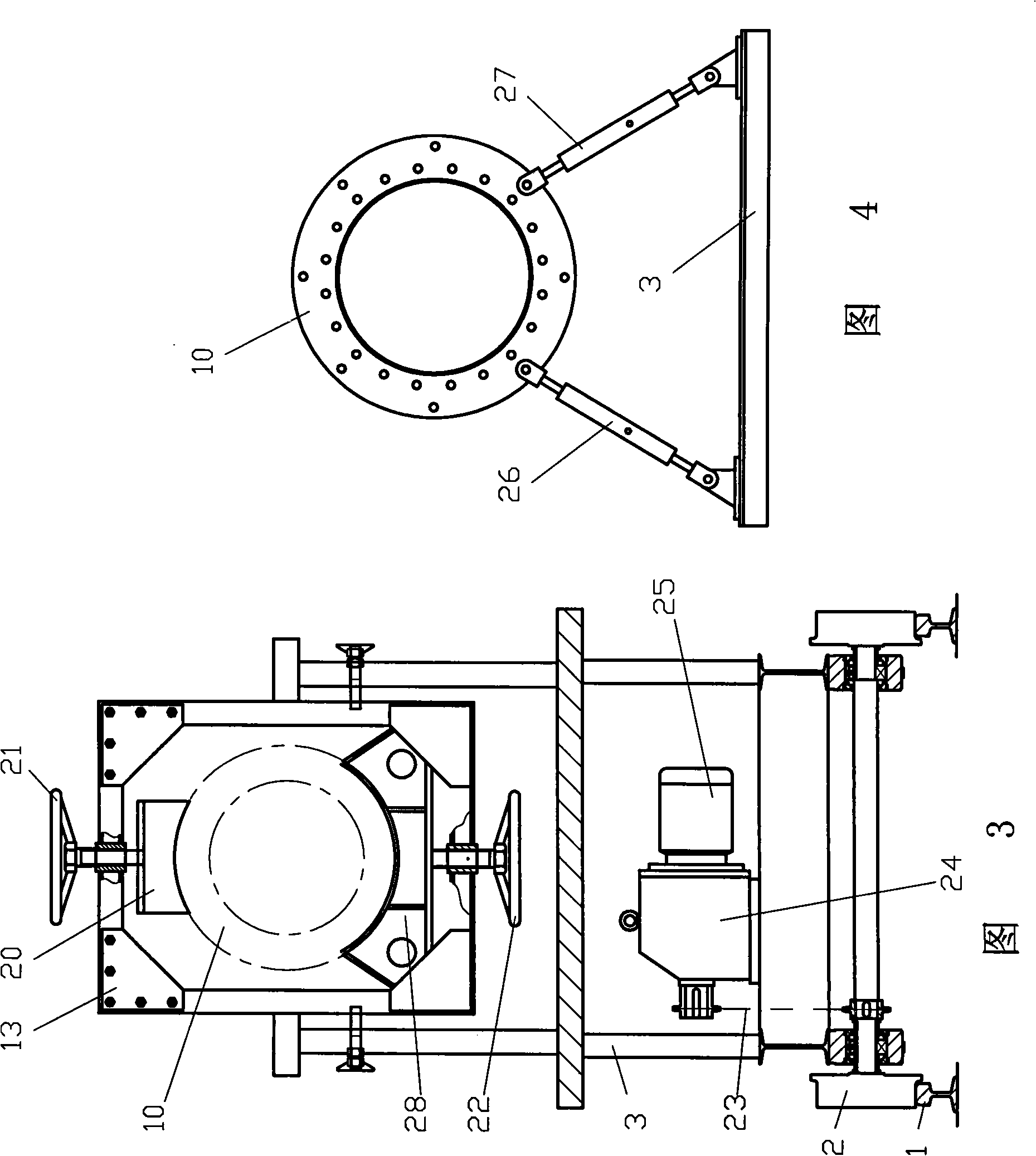

Multicenter combustor nozzle

ActiveCN101315185AExtended service lifeEfficient mixingPulverulent fuel combustion burnersCombustorDrive wheel

The invention relates to a multi-channel burner nozzle used for an active lime rotary kiln. A trolley is arranged on a guide rail via wheels. A front-end adjustment frame and a back-end adjustment frame are respectively fixed in front of and at the back of the upper end of the trolley. The front-end adjustment frame and the back-end adjustment frame support the main body of the burner nozzle. A motor is fixed on the trolley and drives wheels via a speed reducer, a chain wheel and a chain. The burner nozzle body comprises a plurality of tubes in coaxial sleeve arrangement. Except the thinnest central tube, the other tubes are ring-shaped. The tubes define a central duct, a coal duct, a blast furnace coal gas duct, a swirling flow duct and an axial flow duct, from the center to the edge. The central duct, the swirling flow duct and the axial flow duct communicate with a first-stage duct via butterfly valves. A refractory protective coating is formed at the front end of the main body of the burner nozzle and embedded inside with heat-insulating support nails. The multi-channel burner nozzle can prevent ring formation.

Owner:XINXING ENERGY EQUIP

Alloy material for crusher hammerhead and preparation method thereof

The invention relates to an alloy material for a crusher hammerhead, which contains the following chemical elements in percentage by mass: 0.2-0.4% of carbon, 0.7-0.9% of silicon, 3.2-3.5% of manganese, 3.6-3.8% of chromium, 1.7-1.9% of molybdenum, 0.2-0.5% of titanium, 0.02-0.04% of Sb, 0.01-0.02% of Lu, 0.02-0.03% of Ga, at most 0.05% of S, at most 0.05% of P and the balance of iron. By using the low-carbon steel as the main material, the material has favorable toughness; the material contains the Sb, Lu, Ga and many other alloy elements, so that the alloy has high hardness, high wear resistance and high hot strength; and the material is suitable for a medium-size crusher and used for crushing ores with moderate hardness, the service life can be prolonged by 1 time or so as compared with high-chromium cast iron, and the cost is lower. When the refining agent is used for casting production, no pores can be generated on the casting surface, and the included oxide content is obviously lowered.

Owner:MAANSHAN HENGYI MACHINERY MFG

A heat-resistant forged aluminum alloy

A heat-resistant wrought aluminum alloy is characterized by containing the following metal elements: silicon 0.05-0.10%, iron 0.8-1.5%, copper 1.5-3.0%, manganese 0.2-0.5%, magnesium 1-2%, nickel 1-2% %, zinc 0.1-0.5%, titanium 0.05-0.15%, molybdenum 0.01-1% and the balance aluminum. The alloy obtained by the invention is a heat-resistant wrought aluminum alloy with less silicon content and high thermal strength; after adding titanium element, the structure is fine; after adding silicon, molybdenum, nickel, copper, iron and other elements, it can form thermal stability with aluminum The better excess phases Al2CuMg, Al6Cu3Ni, Al2FeSi, Al3Ti, Al2Cu4Mg5Si4, etc., improve the thermal strength of the aluminum alloy, can be strengthened by heat treatment, and have high plasticity in the hot state; do not contain manganese, chromium, so there is no extrusion effect, resistance Good welding, spot welding and seam welding performance, good corrosion resistance and machinability. It can be used to manufacture pistons of internal combustion engines and complex forgings that work at high temperatures, such as compressor impellers, blower impellers, etc.

Owner:WUJIANG SHI FINE WORKMANSHIP & ALUMINUM WORD MANUFACTORY

New powder composition and use thereof

ActiveUS20180066343A1Improve thermohardnessHigh heat intensityArc welding apparatusMetallic material coating processesThermal sprayingAlloy

A laser cladding or plasma transferred arc overlay welding process may be used advantageously to apply and to control the material properties of a coating designed for protecting the substrate against wear, corrosion and oxidation at elevated temperature. Furthermore, a laser cladding or plasma transferred arc overlay welding process may be used to apply the coating alloy materials in applications where traditional thermal spray or weld-applied coatings are not practical. By using these welding methods very good bonding is achieved by fusion during welding. At the same time the properties of the clad layer is preserved by the limited dilution typical of these two welding methods compared traditional overlay welding, by e.g. Gas Tungsten Arc Welding and the like.

Owner:HOGANAS AB

Inferior coal catalysis sulphur-fixing agent used in cement industry and preparing and using methods thereof

InactiveCN105695035AHigh activityLower ignition temperaturePhysical/chemical process catalystsSolid fuelsChloride sodiumLanthanum oxide

The invention discloses an inferior coal catalysis sulphur-fixing agent used in the cement industry. Potassium perchlorate, sodium chloride and tween are used as oxygenate, a bulking agent and a dispersing agent respectively, and a catalyst is prepared from 10-18% of calcium carbonate, 6-17% of ferric oxide, 1-2% of boric oxide and 68-83% of rare earth tailings. The catalysis sulphur-fixing agent is prepared from, by mass, 30-36% of the oxygenate, 8-17% of the bulking agent, 2-5% of the dispersing agent and 48-55% of the catalyst, wherein the rare earth tailings are prepared from, by mass, 5-12% of ceric oxide, 10-22% of lanthanum oxide, 55-75% of neodymium oxide and 5-12% of cerous nitrate. The invention further discloses preparing and using methods of the catalysis sulphur-fixing agent. The catalysis sulphur-fixing agent can promote coal powder combustion and reduce emission of sulfide and has no negative effect on performance of cement clinker.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Ferrocoke production process adopting hot pressing

InactiveCN108085035ASelectiveHigh heat intensityBlast furnace detailsSpecial form destructive distillationCarbonizationShaft furnace

The invention relates to a ferrocoke production process adopting hot pressing. Ferrocoke produced with the production process can partially replace coke as a main raw material for a blast furnace. Theferrocoke production process comprises the following main steps: iron ore and non-coking coal are smashed, uniformly mixed, heated and hot pressed, a hot-press block is added to an external heating type carbonization chamber of a carbonization shaft furnace by a feed device, reduction of iron and carbonization of the non-coking coal are completed in the carbonization chamber, so that the ferrocoke is formed, and the ferrocoke is cooled, discharged out of the furnace and fed into a ferrocoke tank for the blast furnace. The process is advanced and reliable, large-scale production of the ferrocoke can be realized, the product quality is good, coke dose and production cost of blast furnace ironmaking are reduced, production efficiency of blast furnace ironmaking is increased, CO2 emission ofblast furnace ironmaking is reduced.

Owner:WUHAN COSRED SCI & TECH LTD

Binder additive and method for preparing calcium carbide by applying binder additive

InactiveCN106010355AWide variety of sourcesLow priceMacromolecular adhesive additivesAnthraceneNitrile rubber

The invention discloses a binder additive and a method for preparing calcium carbide by applying the binder additive. The binder additive is prepared from one of anthracene oil, waste nitrile rubber powder and regenerated phenolic resin particles. The binder additive is wide in raw material source, and therefore the price is low. The calcium carbide raw material prepared from the binder additive has the advantages that not only is the cold strength improved, but also the heat strength is improved to different extents, and the requirements of a novel heat accumulating type high temperature fuel gas melting calcium carbide production technology are met.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com