CaO-MgO-Al2O3-SiO2 microcrystalline glass and preparation method thereof

A technology of glass-ceramics and glass pellets, which is applied in the field of CaO-MgO-Al2O3-SiO2 glass-ceramics materials, can solve problems such as crystallization difficulties of glass-ceramics, reduce crystallization activation energy, enhance crystallization ability, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Embodiment 1, a kind of CaO-MgO-Al containing mixed crystal nucleating agent 2 o 3 -SiO 2 Glass-ceramic:

[0029] First prepare glass pellets, the composition of which is: SiO 2 50%, MgO 6wt%, CaO 18wt%, Al 2 o 3 12wt%, Na 2 O 3wt%, K 2 O 2wt%, CaF 2 8%, Sb 2 o 3 1wt%. In addition, 3 wt% TiO2 was added. Each of the above-mentioned raw materials needs to pass through a 100-mesh sieve.

[0030] Then proceed to the following steps in sequence:

[0031] 1), according to the above ratio of glass pellets and TiO 2 Mix thoroughly and evenly, then place in a furnace and heat to 1450°C to melt and keep warm for 4 hours to obtain a clear and uniform molten glass.

[0032] 2) Pour the clear and uniform molten glass into the mold for molding, and anneal at 500°C for 0.5h to eliminate internal stress, and obtain a sheet-shaped mother glass with a thickness of 6mm.

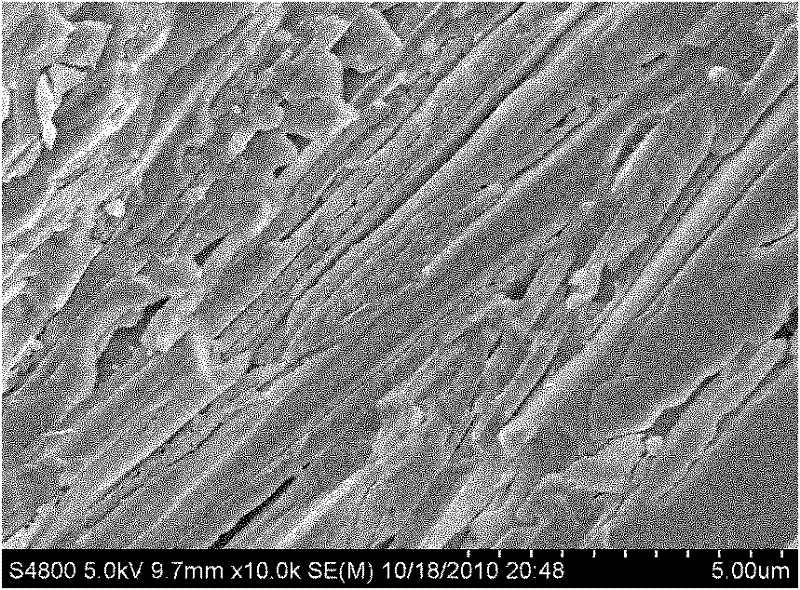

[0033] 3) Process the undecrystallized transparent glass sheet (namely the above-mentioned mother gla...

Embodiment 2

[0035] Embodiment 2, a kind of CaO-MgO-Al containing mixed crystal nucleating agent 2 o 3 -SiO 2 Glass-ceramic:

[0036] First prepare glass pellets, the composition of which is: SiO 2 50%, MgO 6wt%, CaO 18wt%, Al 2 o 3 12wt%, Na 2 O 3wt%, K 2 O 2wt%, CaF 2 8%, Sb 2 o 3 1wt%. In addition, add 3wt%P 2 o 5 . Each of the above-mentioned raw materials needs to pass through a 100-mesh sieve.

[0037] Then proceed to the following steps in sequence:

[0038] 1), according to the above ratio of glass pellets and P 2 o 5 Mix thoroughly and evenly, then place in a furnace and heat to 1450°C to melt and keep warm for 4 hours to obtain a clear and uniform molten glass.

[0039] 2) Pour the clarified and uniform molten glass into a mold for molding, and anneal at a temperature of 500°C for 0.5h to eliminate internal stress to obtain a sheet-shaped mother glass; the thickness of the mother glass is 6mm.

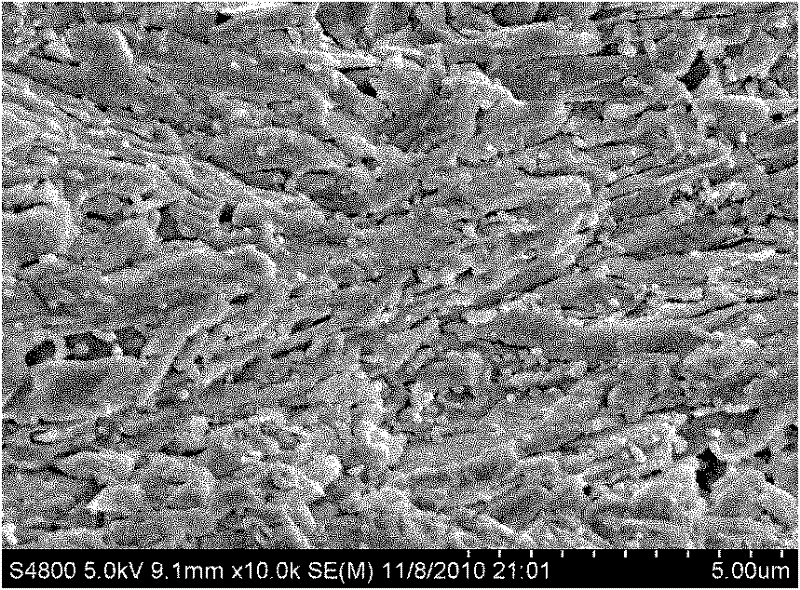

[0040] 3) Process the uncrystallized transparent glass sheet (na...

Embodiment 3

[0042] Embodiment 3, a kind of CaO-MgO-Al containing mixed crystal nucleating agent 2 o 3 -SiO 2 Glass-ceramic:

[0043] First prepare glass pellets, the composition of which is: SiO 2 50%, MgO 6wt%, CaO 18wt%, Al 2 o 3 12wt%, Na 2 O 3wt%, K 2 O 2wt%, CaF 2 8%, Sb 2 o 3 1wt%. In addition, add 1.5wt%P 2 o 5 +1.5wt%TiO 2 . Each of the above-mentioned raw materials needs to pass through a 100-mesh sieve.

[0044] Then proceed to the following steps in sequence:

[0045] 1), according to the above ratio of glass pellets and P 2 o 5 、TiO 2 Mix thoroughly and evenly, then place in a furnace and heat to 1450°C to melt and keep warm for 4 hours to obtain a clear and uniform molten glass.

[0046] 2) Pour the clarified and uniform molten glass into a mold for molding, and anneal at a temperature of 500°C for 0.5h to eliminate internal stress to obtain a sheet-shaped mother glass; the thickness of the mother glass is 6mm.

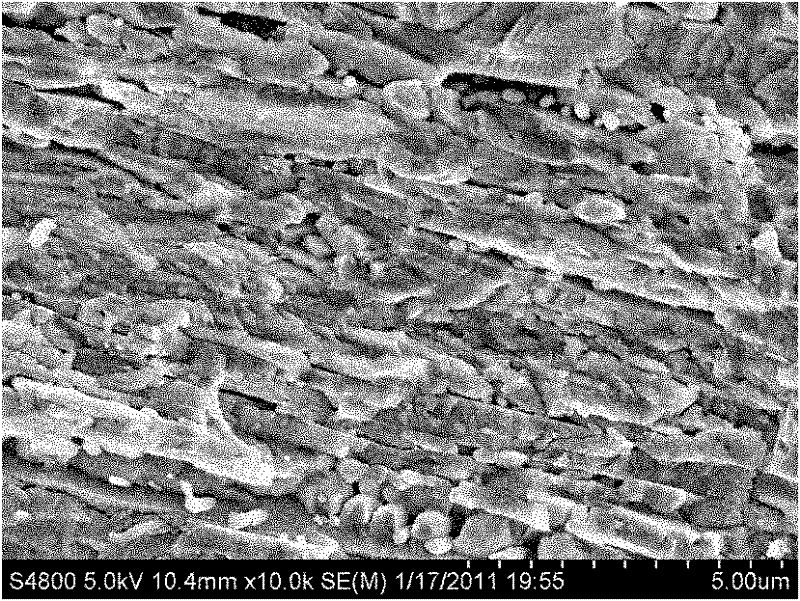

[0047] 3) Process the uncrystallized tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com