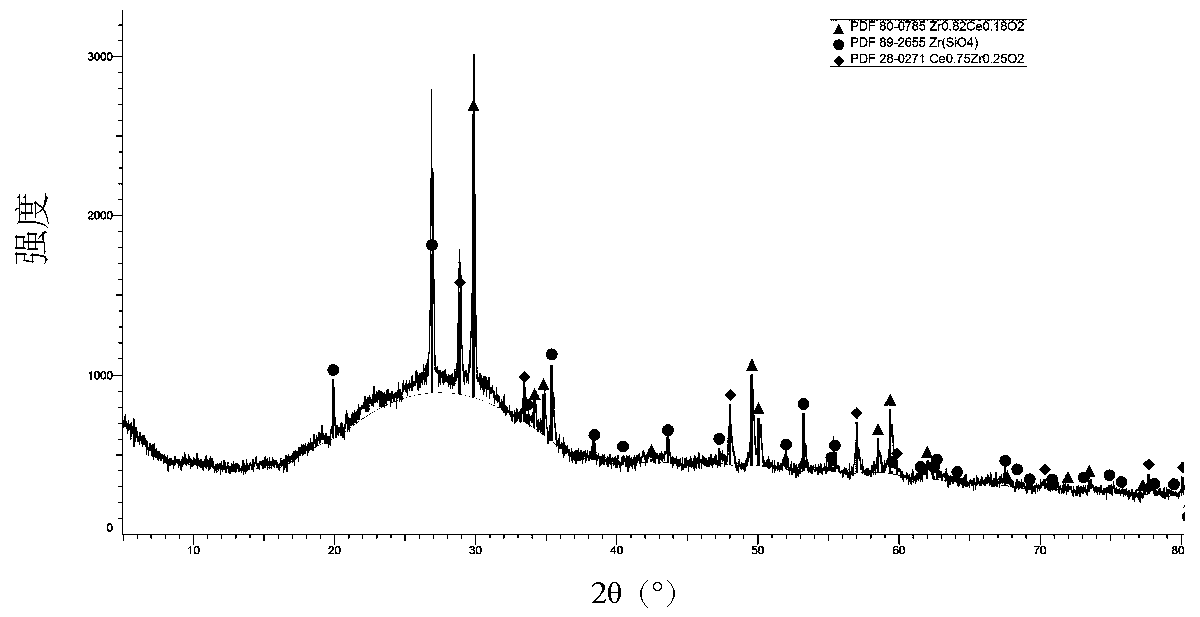

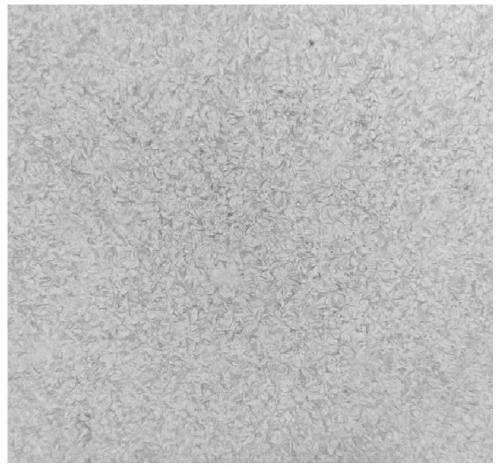

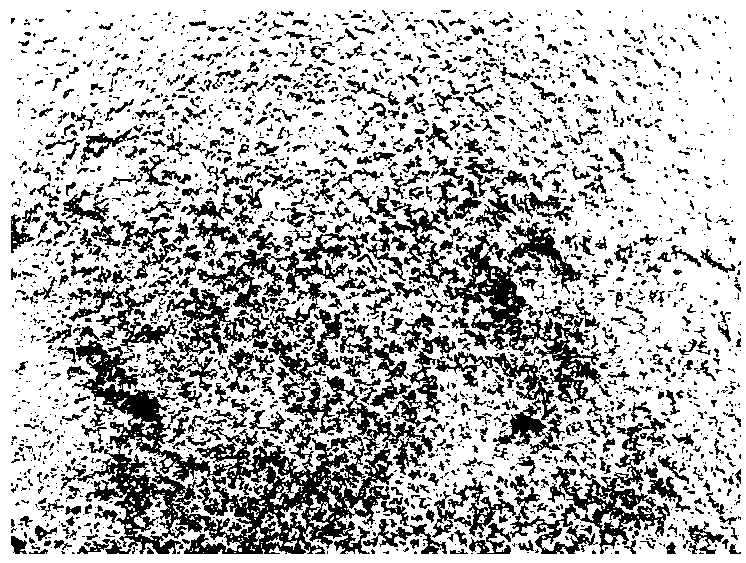

White crystal flower frit, white crystal flower decorative ceramic tile and preparation method thereof

A technology of ceramic tiles and crystal flowers, which is applied in the fields of white crystal flower decorative ceramic bricks and its preparation, crystal flower decorative ceramic tiles, and white crystal flower frits, to achieve natural crystal flowers, good crystallization effects, and improved grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Step 1: Press the adobe with ordinary ceramic base material.

[0061] Step 2: kiln drying, the drying time is 1 hour, and the moisture content of the dried billet is controlled within 0.5%.

[0062] Step 3: Spray the surface glaze, the chemical composition of the surface glaze is: IL (loss on ignition): 4.31%, SiO 2 : 50.42%, Al 2 o 3 : 29.41%, Fe 2 o 3 : 0.37%, TiO 2 : 0.07%, CaO: 0.71%, MgO: 0.20%, K 2 O: 5.62%, Na 2 O: 2.58%, P 2 o 5 : 0.26%, ZrO 2 : 6.05%, surface glaze specific gravity 1.44, glaze amount 500g / m 2 .

[0063] Step 4: Drying in a small electric kiln, the temperature of the drying kiln is controlled at 110°C, and the moisture after drying is controlled within 0.5%.

[0064] Step 5: Spray into protective glaze, specific gravity 1.21, glaze amount 280g / m 2 ; The chemical composition of the protective glaze is as follows by weight percentage: IL: 5.31%; SiO 2 : 56.19%; Al 2 o 3 : 17.50%; Fe 2 o 3 : 0.17%; BaO: 1.66%; CaO: 6.09%; MgO: 2.11%...

Embodiment 2

[0075] Basically the same as Example 1, the difference is:

[0076] Step 6: Sprinkle the white crystal flower frit, the spreading amount is 800g / m 2 . The chemical composition of the frit includes by mass percentage: IL: 0.44%; SiO 2 : 41.53%; Al 2 o 3 : 26.78%; Fe 2 o 3 : 0.16%; TiO 2 : 0.15%; CaO: 3.98%; MgO: 1.64%; K 2 O: 2.78%; Na 2 O: 1.73%; ZrO 2 : 3.98%; CeO 2 : 6.98%; ZnO: 5.98%; BaO: 2.45%; PbO: 0.97%; As 2 o 3 : 0.45%. The particle gradation of the frit is as follows: 40 mesh or less: 17%; 40 mesh to 60 mesh: 48%; 60 mesh to 80 mesh: 26%; 80 mesh to 100 mesh: 7%; 100 mesh or more: 2% . The thickness of the effective glaze layer finally obtained from the white crystal flower frit is 0.4mm.

[0077] Step 7: Spray glue fixative on the glaze cabinet. The glue fixative is obtained by mixing and diluting glue and water according to the mass ratio of 3:1, and the glue is purchased from Yidajia Company. The spraying amount of the glue fixing agent is 200g / m ...

Embodiment 3

[0080] Basically the same as Example 1, the difference is:

[0081] Step 6: Sprinkle white crystal flower frit, and its spreading amount is 1000g / m 2 . The chemical composition of the frit includes by mass percentage: IL: 0.52%; SiO 2 : 41.45%; Al 2 o 3 : 26.46%; Fe 2 o 3 : 0.09%; TiO 2 : 0.12%; CaO: 3.99%; MgO: 1.73%; K 2 O: 2.08%; Na 2 O: 2.15%; ZrO 2 : 4.45%; CeO 2 : 8.01%; ZnO: 6.02%; BaO: 2.01%; PbO: 0.83%; As 2 o 3 : 0.09%. The particle gradation of the frit is: 40 mesh or less: 17%; 40 mesh to 60 mesh: 45%; 60 mesh to 80 mesh: 28%; 80 mesh to 100 mesh: 8%; 100 mesh or more: 2% . Finally, the thickness of the effective glaze layer obtained from the white crystal flower frit is 0.5 mm.

[0082] Step 7: Spray glue fixative on the glaze cabinet. The glue fixative is obtained by mixing and diluting glue and water according to the mass ratio of 3:1, and the glue is purchased from Yidajia Company. The spraying amount of the glue fixing agent is 250g / m 2 . In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus of rupture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com