Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

352results about How to "Good ink absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

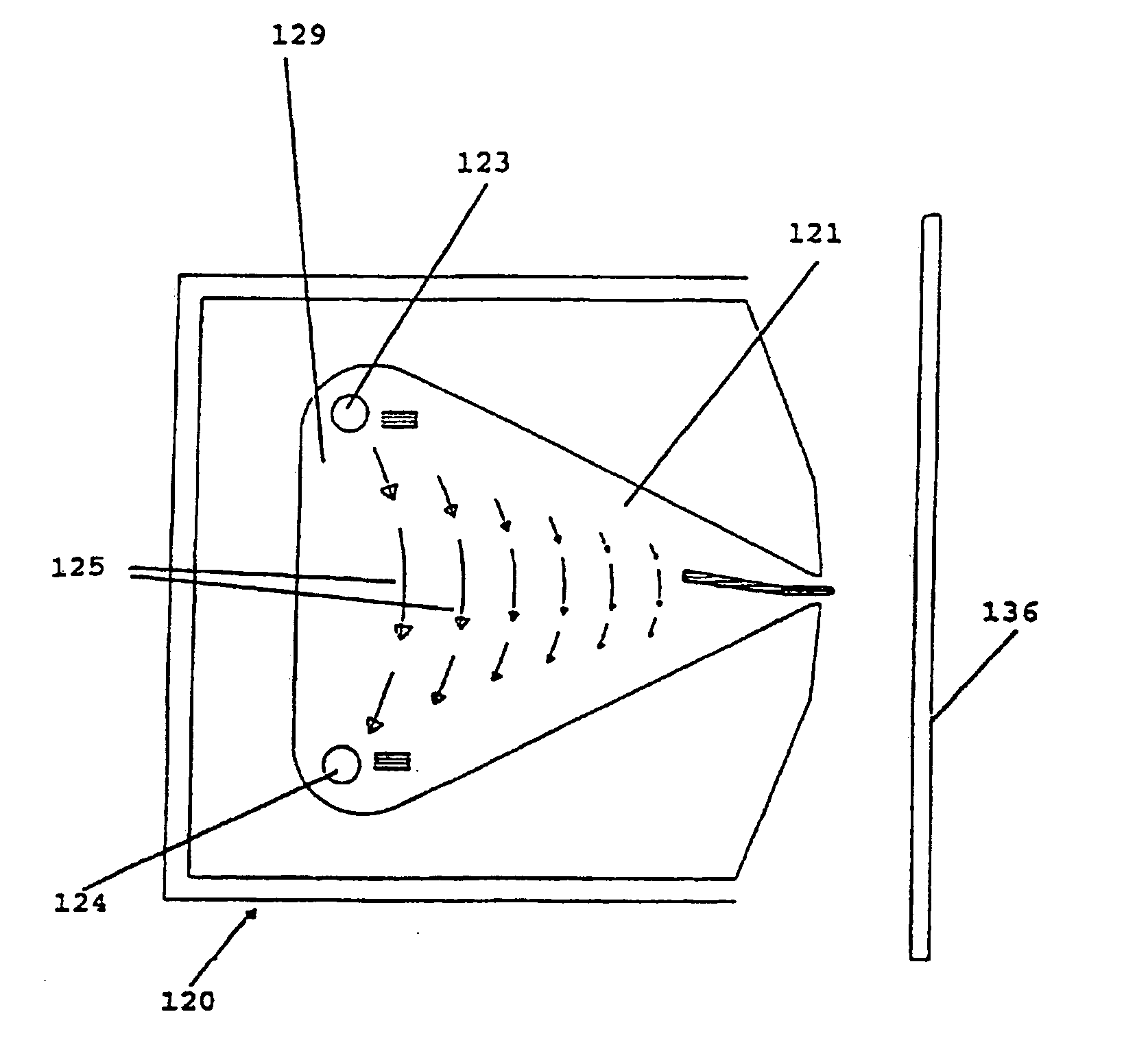

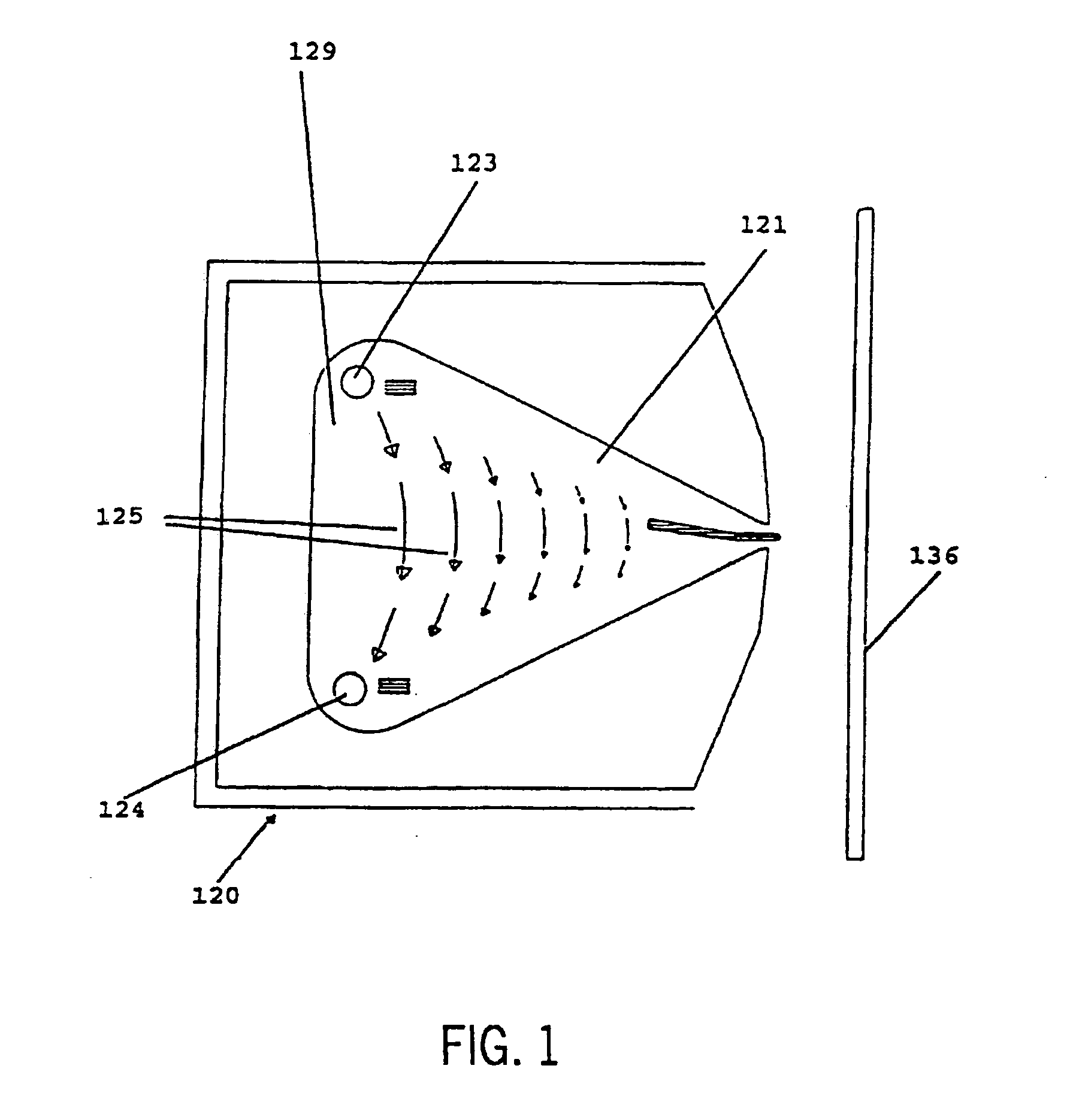

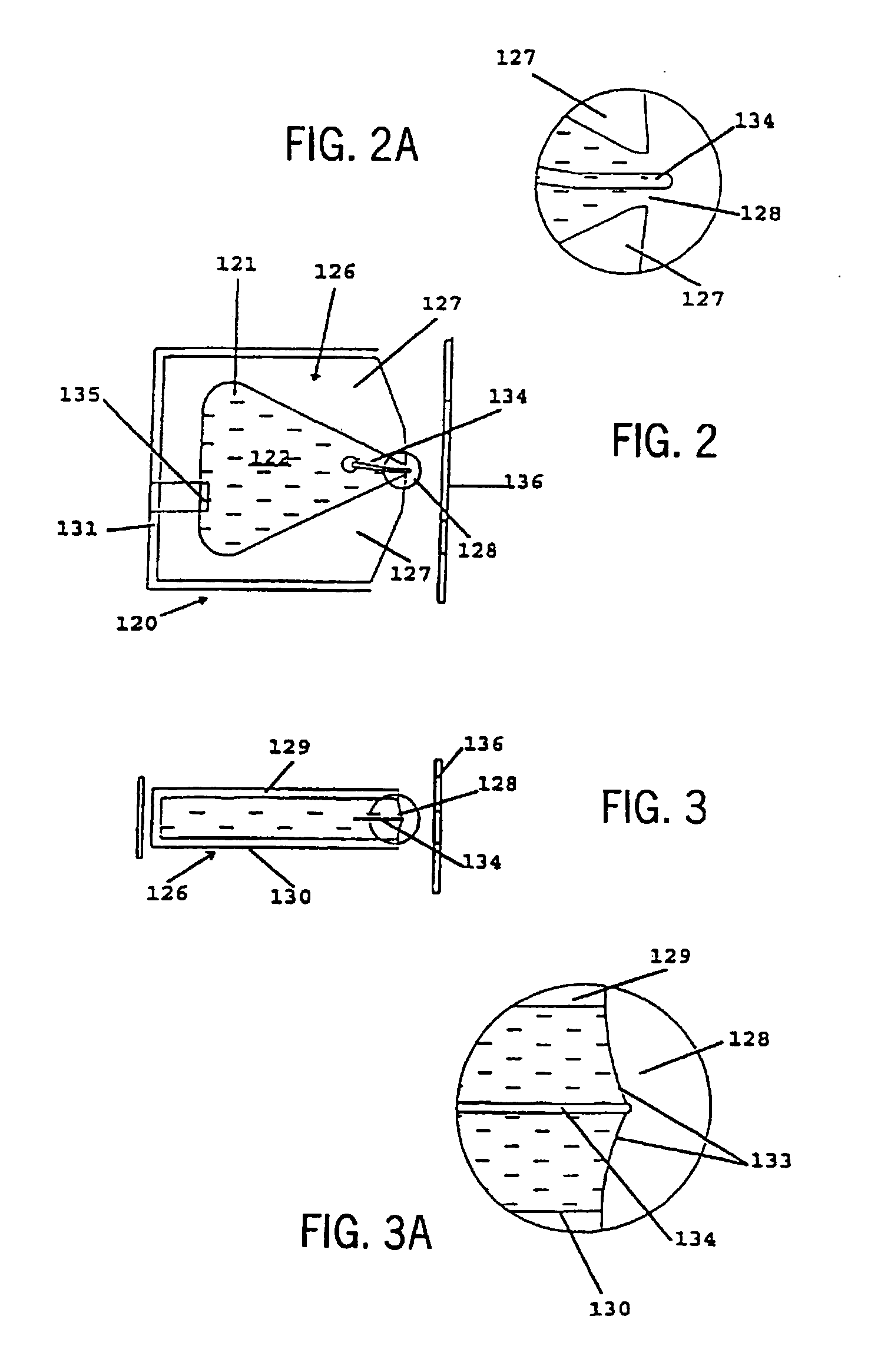

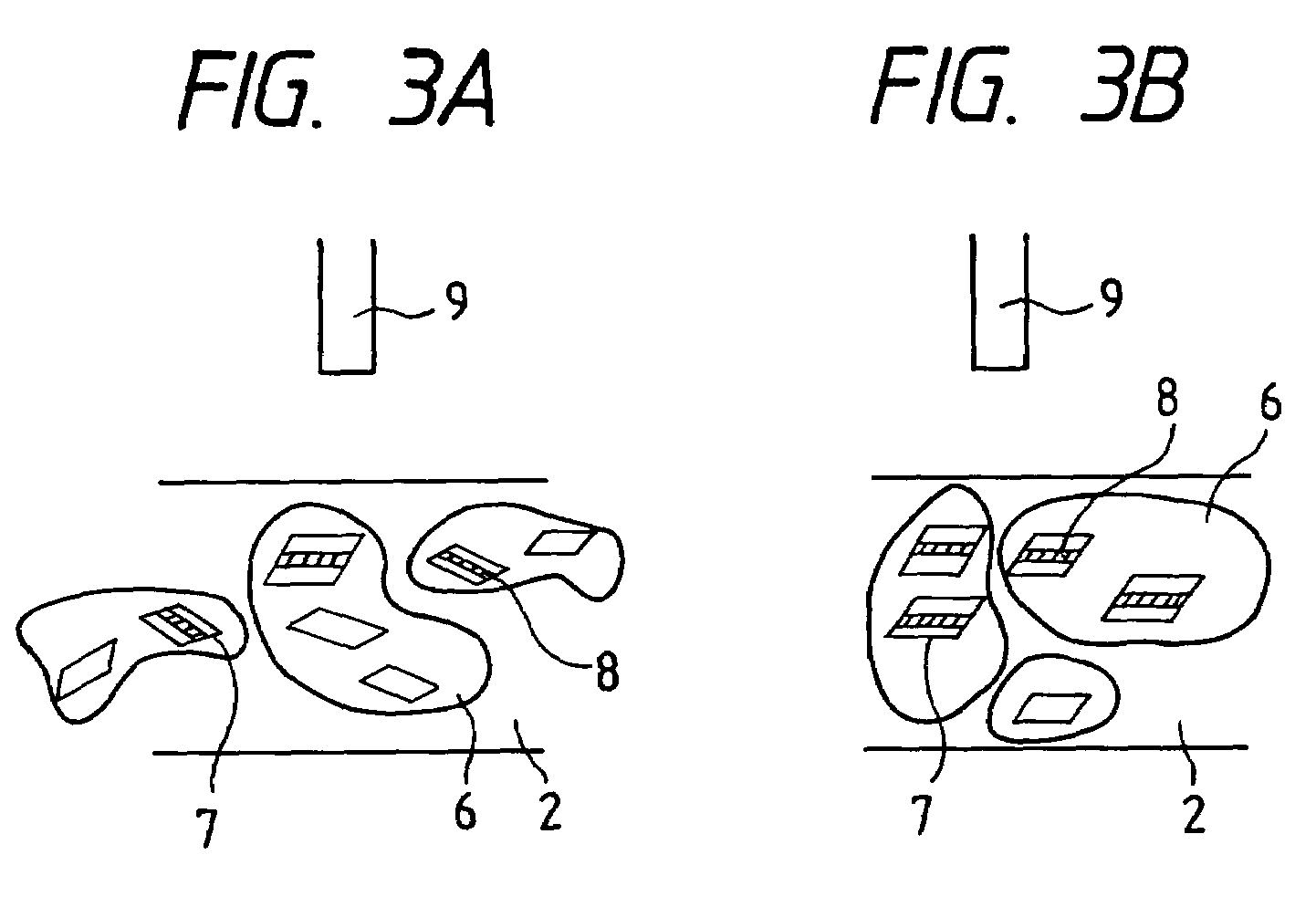

Ink-jet formation of flexographic printing plates

InactiveUS20050153243A1Well formedGood ink absorptionPhotosensitive materialsPhotomechanical apparatusInk printerEngineering

Owner:KODAK POLYCHROME GRAPHICS

Inkjet recording sheet

InactiveUS20020176970A1Improve abilitiesGood ink absorptionCoatingsThermographyPolyvinyl alcoholAcyl group

Disclosed is an inkjet recording sheet having a colorant-receiving layer on the surface of its support, in which the colorant-receiving layer contains at least one of compounds represented by the following general formula (1) and compounds represented by the following general formula (2), and contains a vapor-phase-process silica, a polyvinyl alcohol, a boron compound, and a mordant. In the formulae, R represents a saturated hydrocarbon group having from 1 to 12 carbon atoms, an unsaturated hydrocarbon group having from 1 to 12 carbon atoms, a phenyl group, or an acyl group, and n indicates an integer of 1 to 3. <paragraph lvl="0"><in-line-formula>RO(CH2CH2O)nH (1) < / in-line-formula><paragraph lvl="0"><in-line-formula>RO(CH2CH(CH3)O)nH (2) < / in-line-formula>

Owner:FUJIFILM HLDG CORP +1

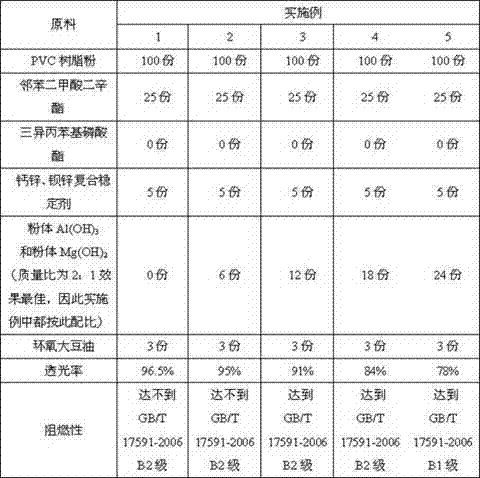

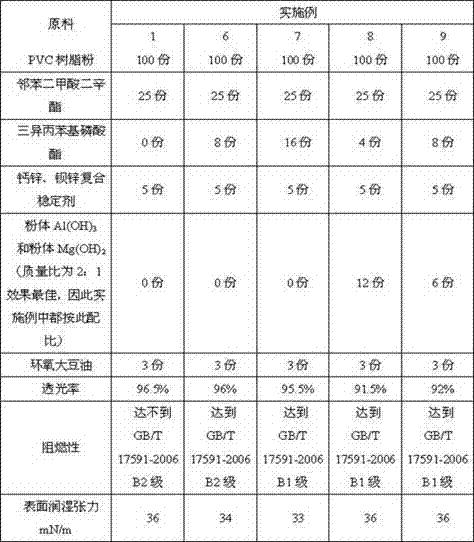

Flame-retardant transparent floor film and production technology thereof

The invention relates to a flame-retardant transparent floor film and a production technology thereof. The flame-retardant transparent floor film is prepared by treating the following main raw materials in parts by weight: 100 parts of PVC (Poly Vinyl Chloride) resin powder, 15 to 30 parts of a main plasticizer, 4 to 8 parts of a fire-retardant plasticizer, 4 to 6 parts of a stabilizer, 6 to 12 parts of an inorganic filler, and 2 to 4 parts of epoxidized soybean oil by a PVC die rolling technology. By adopting the flame-retardant transparent floor film and the production technology thereof, the conflict between the flame retardant performance, the transparence and the jet-printing performance is solved; the inorganic fillers are adopted, thus micromolecules separated by the liquid fire-retardant plasticizers are easily absorbed, and ideal transparence and the jet-printing performance can be provided for the product under efficient flame retardant performance; in addition, the generation of phenomena of wheel adhering, albinism and hard coiling can be effectively avoided by utilizing the flame-retardant transparent floor film; and simultaneously, the flame-retardant transparent floor film is excellent in wear resistance.

Owner:ZHEJIANG BOTAI PLASTIC

Method for preparing mineral-fiber-filled high-strength environment-friendly rich mineral paper

InactiveCN104119600AModerate roughnessHigh hardnessSynthetic resin layered productsFiberLinear low-density polyethylene

The invention relates to a mineral-fiber-filled high-strength environment-friendly rich mineral paper. The rich mineral paper is prepared by combining high-density polyethylene, linear low-density polyethylene resin, inorganic powder, non-metallic mineral fiber, a foaming agent, an antioxidant, a light stabilizer and additives as raw materials. The rich mineral paper comprises the following components in parts by weight: 10-15 parts of high-density polyethylene, 10-15 parts of linear low-density polyethylene resin, 65-75 parts of inorganic powder, 5 parts of non-metallic mineral fiber, 0.1-0.2 part of a foaming agent, 0.1-0.2 part of an antioxidant, 0.1-0.2 part of a light stabilizer and 0-2 parts of additives, wherein the total sum of the amount of the materials as the reference starting materials is 100 parts by weight. The preparation method comprises the steps of blending, mixing, granulating and molding. By virtue of the method disclosed by the invention, the dimensional stability, heat resistance, chemical resistance, flame resistance, electrical insulation and other properties of the rich mineral paper are improved. Due to the adoption of a three-layer co-extrusion process, the specific surface area is large, the specific weight is reduced, and the hardness, paper feeling, printing effect and ink absorption property are improved.

Owner:宋旭

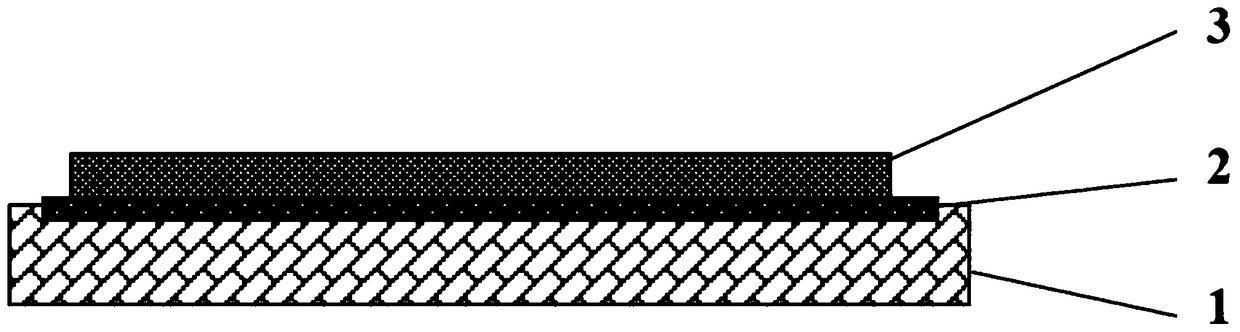

Thermal sublimation and transfer digital paper with high ink suction amount

ActiveCN103397576AIncrease ink absorptionQuick ink absorptionSurface covering paperCoatingsCalcium carbonatePolyacrylamide

The invention belongs to the field of transfer paper and particularly relates to a piece of thermal sublimation and transfer digital paper with high ink suction amount. The thermal sublimation and transfer digital paper comprises a piece of substrate paper, a hydrophobic layer coated on the surface of the substrate paper, an ink suction layer coated on the surface of the hydrophobic layer, and a surface layer on the upper surface of the ink suction layer. In terms of calculation by weight, the ink suction layer is a composite material of an inorganic material and cationic polyacrylamide cellulose interpenetrating network resin, wherein the inorganic material is one or a combination of two of porous silicon dioxide or porous calcium carbonate or porous alumina. The hydrophobic layer is organosilicone modified acrylic resin. According to the thermal sublimation and transfer digital paper, the composition material which is one or the combination of two of the porous silicon dioxide or the porous calcium carbonate or the porous alumina is added into the ink suction layer, the solid porous structure can rapidly and sufficiently absorb dye molecules, and the ink suction amount of the thermal sublimation and transfer digital paper is remarkably increased.

Owner:杭州华大海天科技股份有限公司

Raw paper for thermal transfer paper and preparation process thereof

ActiveCN104085214AImprove tightnessControl the concentration of plagiarism onlinePulp beating methodsDuplicating/marking methodsApparent densityGrammage

The invention provides raw paper for thermal transfer paper and a preparation process thereof. The raw paper for the thermal transfer paper has grammage of 70 to 95 g / m2, cross file grammage tolerance of no more than 5 g / m2, apparent density of 0.8 to 0.85 g / cm3, smoothness of 45 / 36S, transverse tearability of no less than 600 mN, vertical dry tensile strength of no less than 70 N / 15mm, vertical wet tensile strength of no less than 12 N / 15 mm, air permeability of no less than 60 S, a water absorption value of 30 to 50 g / m2, a deformation rate of no more than 1.5% and dust of no more than 10 / m2. The preparation process for the raw paper for the thermal transfer paper comprises the steps consisting of pulping, mixing, beating and rewinding so as to prepare the raw paper for the thermal transfer paper, and then packaging is carried out, wherein a surface sizing solution and a filling material are added during beating. The raw paper for the thermal transfer paper prepared in the invention has the advantages of low cost, good paper formation, great apparent density, small air permeability, high tensile strength, high heat resistance, etc.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

Picture-grade high-light water-proof colour ink-jet printing paper

InactiveCN1814913AHigh transparencyHigh whitenessSpecial visual effect coatingsMetal coatingsPulp and paper industrySilicon

Photo-stage high brightness water-proof color ink-jet printing paper includes a basic material and a coat coated on it characterizing that said coat contains nm modified Al2O modified by a strong anode ion dispersing agent and a bonder, since the coat contains modified Al2O with the diameter of 30-80nm and inorganic silicon sol with the diameter smaller than 20nm, the invented paper can either absorb water ink or make the ink not to disperse.

Owner:SHANTOU XINXIE SPECIAL PAPER TECH

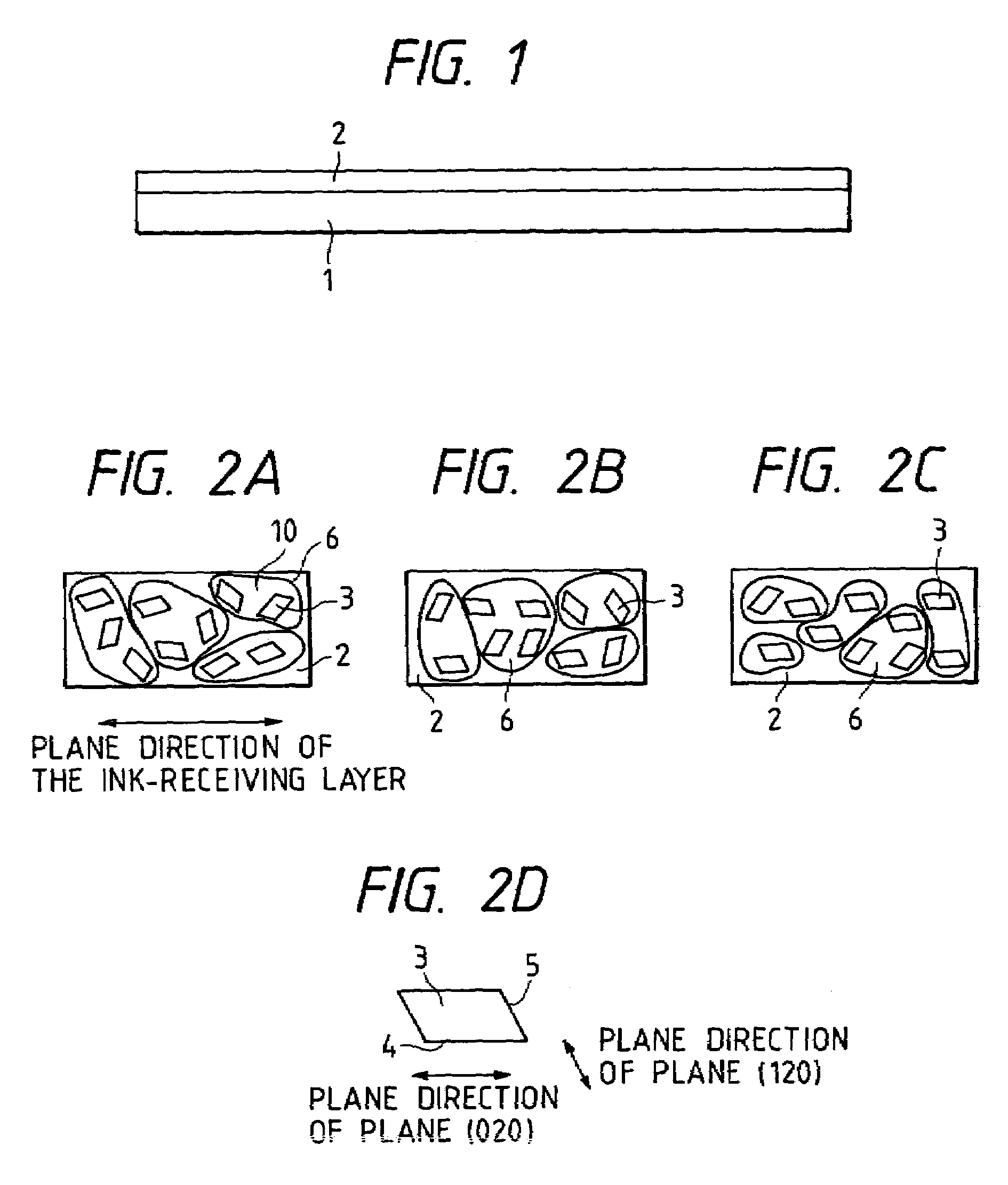

Recording medium, process for production thereof, and ink-jet recording method employing the medium

InactiveUS7144613B2High ink absorbencyHigh surface hardnessPretreated surfacesPattern printingBoehmiteChemistry

Owner:CANON KK

Color ink-jet print paper and its producing method

InactiveCN1458337AImprove surface strengthPrint with rich and vivid colorsNon-fibrous pulp additionSulfatePulp and paper industry

The color ink-jetting print paper is produced with bleached sulfate needle leaved wood pulp, mechanical milled Italian poplar, bleached sulfate reel pulp or bleached broadleaf wood pulp and proper supplementary material and through making base paper, applying AKD glue, painting special paint, soft roller burnishing and finishing. The color ink-jetting print paper product has areal weight 70-100 g / sq m, black light density not lower than 1.2, drying time less than 20 s, color optical density not lower than 0.75, ink water dispersing time not less than 60 s, and whiteness higher than 88 %. Ithas high surface strength, and is level and smooth and results in images with bright color and clear netted points. It is suitable for color jetting printing.

Owner:YUEYANG FOREST & PAPER CO LTD

Recording sheet for ink jet printing

InactiveUS20070196596A1Improve image qualityGood ink absorptionMaterial nanotechnologyThermographyNanoporous siliconEngineering

A recording sheet for ink jet printing is described, which consists of a support having coated onto said support at least two ink-receiving layers, wherein the ink-receiving layer situated next to the support contains nanoporous silicon dioxide with a positively charged surface and at least one binder and the ink-receiving layer situated further away from the support contains nanocrystalline, nanoporous aluminium oxide or aluminium oxide / hydroxide and at least one binder and, optionally, nanoporous silicon dioxide with a positively charged surface.

Owner:WIFAG POLYTPE HLDG AG

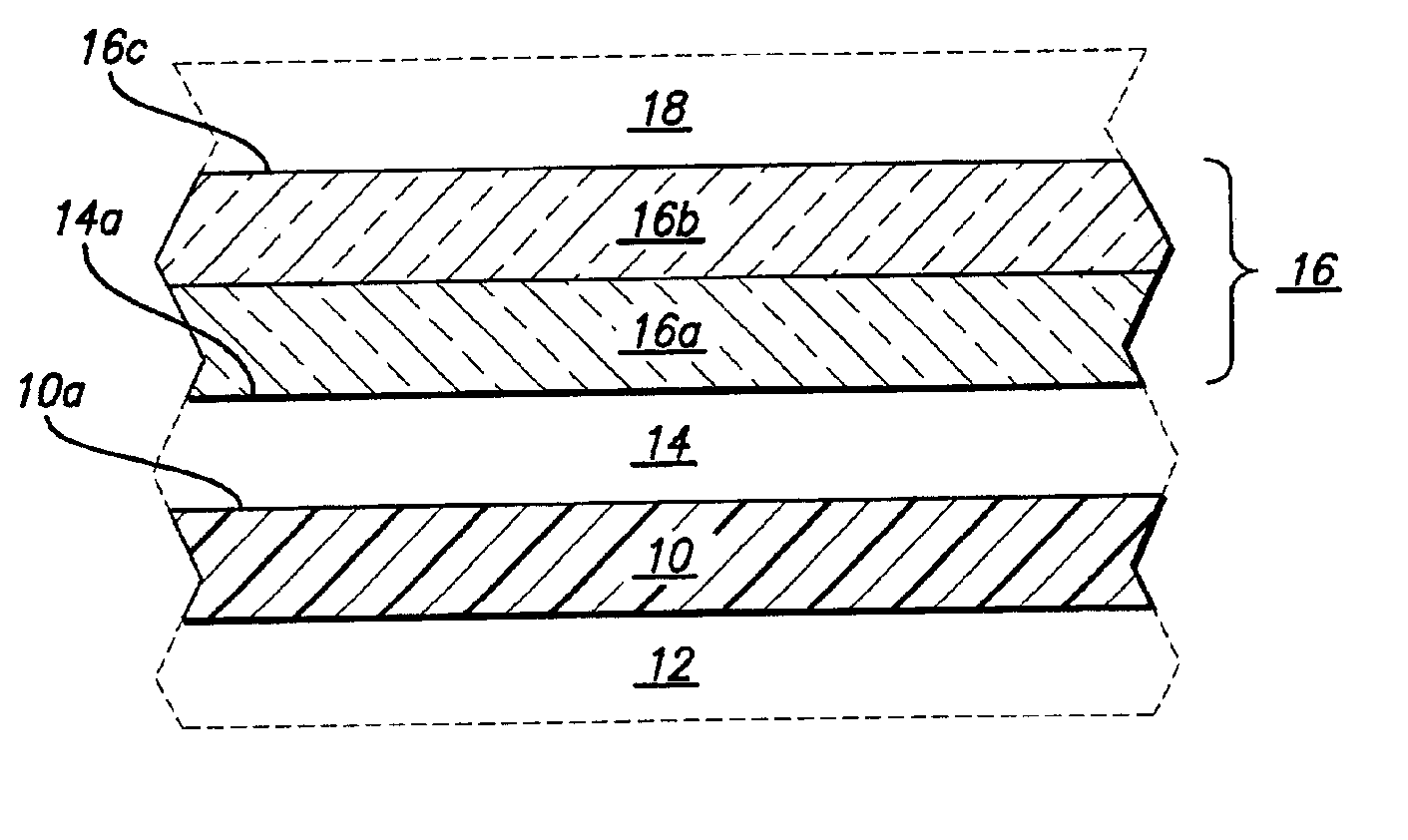

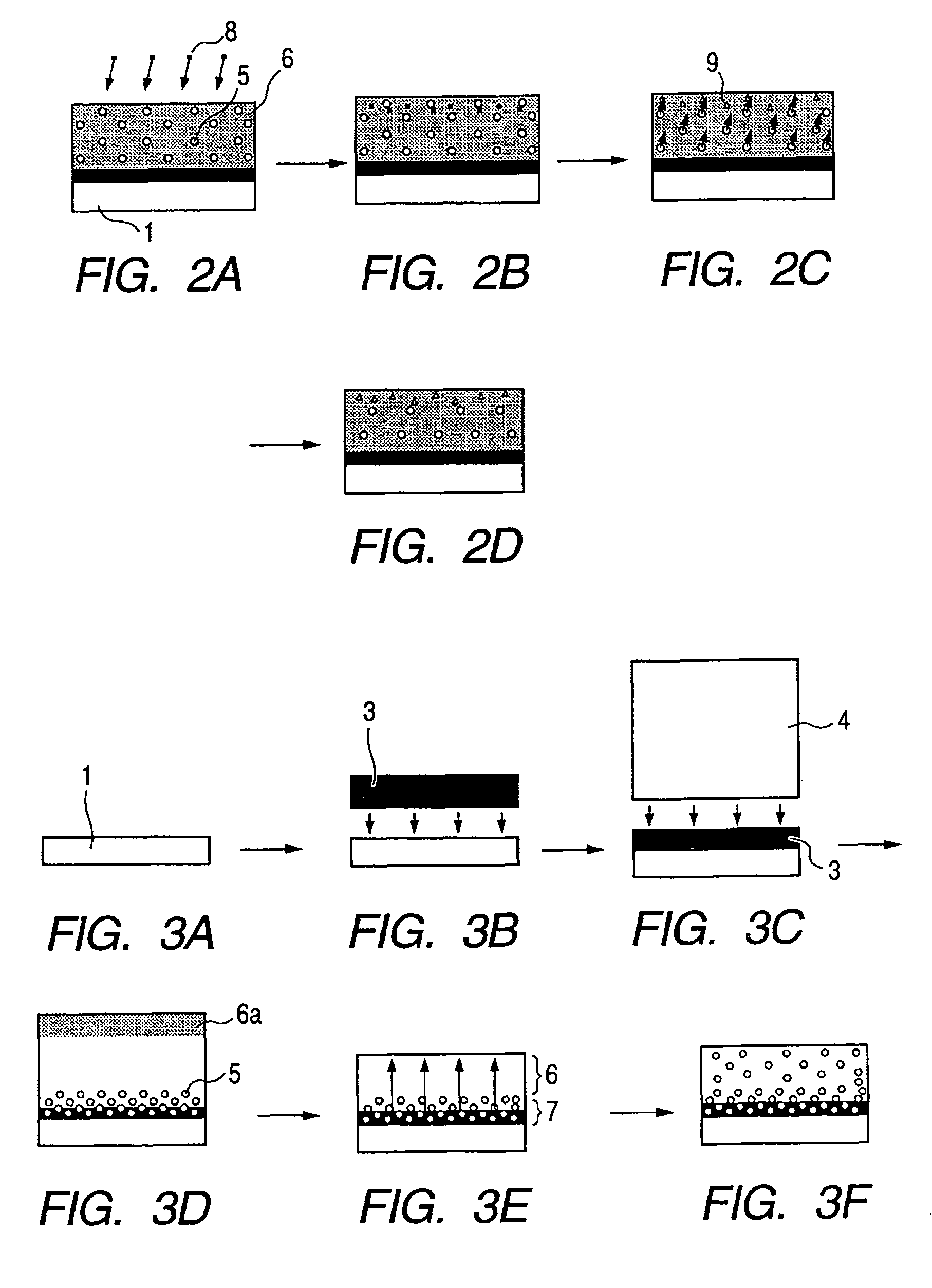

Heat-sensitive non-ablatable wasteless imaging element for providing a lithographic printing plate

InactiveUS6165679AGood ink absorptionImprove hydrophilic and hydrophobic propertiesPhotosensitive materialsSemiconductor/solid-state device manufacturingHeat sensitiveEngineering

Owner:AGFA NV

Method for preparing a lithographic printing plate by ablation of a heat sensitive ablatable imaging element

InactiveUS6455230B1Speed up the processIncreased durabilityX-ray/infra-red processesRadiation applicationsHeat sensitiveEngineering

According to the present invention there is provided a method for preparing a lithographic printing plate, the method including the steps of(1) providing an imaging element including on a lithographic hydrophilic support as contiguous top layer a heat-sensitive coating including a compound capable of converting light to heat and a compound, which becomes more hydrophilic under the action of heat;(2) imagewise exposing the imaging heat-sensitive composition with a high intensity laser emitting a laser beam with an intensity at the surface of the heat-sensitive composition of tat least 2 mW / mum2 thereby at least partially removing the heat-sensitive composition to expose at least partially the lithographic support.

Owner:AGFA NV

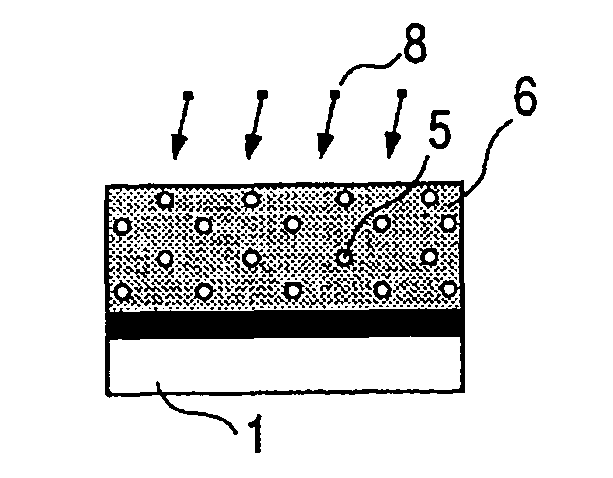

Porous inkjet receiver layer with a binder gradient

InactiveUS6872430B2Improve adhesionImprove featuresLayered productsDecorative surface effectsMaterials sciencePigment

Owner:HEWLETT PACKARD DEV CO LP

Article having microporous body part, production method of ink medium, diffusion method of sulfur-containing organic acid into microporous layer, production method of article having meicroporous body part, and inkjet recording medium produced therefrom

InactiveUS7867586B2Eliminate yellowingGood prevention effectCoatingsThermographyDiffusion methodsOrganic acid

Provided is an inkjet recording medium in which hydrated alumina and a sulfinic acid compound or thiosulfonic acid compound coexist in a pigment in an ink receiving layer, and which can prevent white-background yellowing during storage in a resin file holder or the like and ensure printing quality at the same time. The ink receiving layer of the inkjet recording medium contains the sulfinic acid compound or thiosulfonic acid compound, which functions to prevent yellowing, in a salt form or in a free form so as to be diffusible.

Owner:CANON KK

Coated copy paper and production method thereof

InactiveCN103556536AImprove surface smoothnessHigh opacityNon-fibrous pulp additionCoatings with pigmentsArray data structureAdhesive

The invention discloses coated copy paper, which comprises a base paper layer and a coating applying to the surface of the base paper layer. The coating is formed by applying a coating material; the coating material is prepared from the following components in parts by weight: adhesives: 1-30 parts of carboxylic butadiene-styrene latex, 1-30 parts of modified starch, 1-30 parts of CMC (Carboxy Methylated Cellulose) and 1-30 parts of PVA (Poly Vinyl Alcohol); a brightener: 0.1-5 parts of sodium hexasulfonate; ink absorbers: 2-25 parts of ultrafine silicon dioxide, 2-25 parts of hollow microspheres and 2-25 parts of titanium dioxide; fillers: 20-60 parts of CaCO3 and 20-60 parts of kaoline; and auxiliaries: 0.1-5 parts of a cationic color fixing agent and 0.1-5 parts of a nonionic color fixing agent. The coated copy paper has the beneficial effects that a production process is simple and the production cost can be reduced, and the key technology is that the ink absorbers are applied as the core of the coating of the coated copy paper and other auxiliaries (various color fixing agents) are the special feature of the coating, and the ink absorbers and the auxiliaries play a decisive and key role in the implementation effect of the coated copy paper.

Owner:曹志雄

Method for printing bar codes on iridescent paper

InactiveCN101973169AReduce sheddingReduce accumulationPhotomechanical apparatusOther printing apparatusInfrared lampBarcode

The invention discloses a method for printing bar codes on iridescent paper. The method comprises the following steps of: making films with the bar code pattern into a PS (Photoshop) printing plate; making a on-the-spot bar code pattern 1 to 2 mm longer than each side of the bar code pattern and making a photosensitive resin flexographic plate with the on-the-spot bar code pattern; printing a layer of UV (Ultra Voilet) base oil on the iridescent paper by utilizing an offset press and a polishing set and irradiating the printed UV base oil for drying through an infrared lamp; printing a layer of bar codes at the position the UV base oil printed on the surface of the iridescent paper by utilizing an offset press first set and irradiating for solidification and drying through an ultraviolet lamp; and printing a layer of UV gloss oil or UV matt oil on the solidified and dried surface of the bar codes, and solidifying and drying the printed UV gloss oil or the UV matt oil through the ultraviolet lamp to obtain the iridescent paper printed with the bar codes. The method has the characteristic of less printing process failure; and the bar codes printed on the iridescent paper according to the method has the characteristics of smooth ink layers, good hand touch and easy recognition.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing Nano calcium carbonate dedicated to printing ink

InactiveCN1916084AGood ink absorptionImprove drynessInorganic pigment treatmentInksCrystal morphologyNanometre

This invention discloses a method for preparing special nanoscale calcium carbonate for ink. The method comprises: calcining natural calcium carbonate, slaking, carbonzing, coating by a coating agent, vacuum-filtering and drying to obtain nanoscale calcium carbonate. The initial carbonization temperature is 15-40 deg.C, and crystal-morphology regulator and dispersant are added during carbonization. The coating agent is resinic acid and its derivatives. The obtained nanoscale calcium carbonate has such advantages as high dispersibility, good transparency, good luster, good ink absorbency and high dryness.

Owner:上海耀华纳米科技有限公司

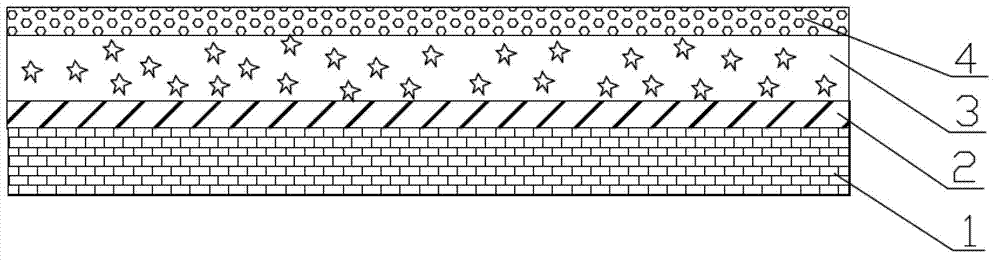

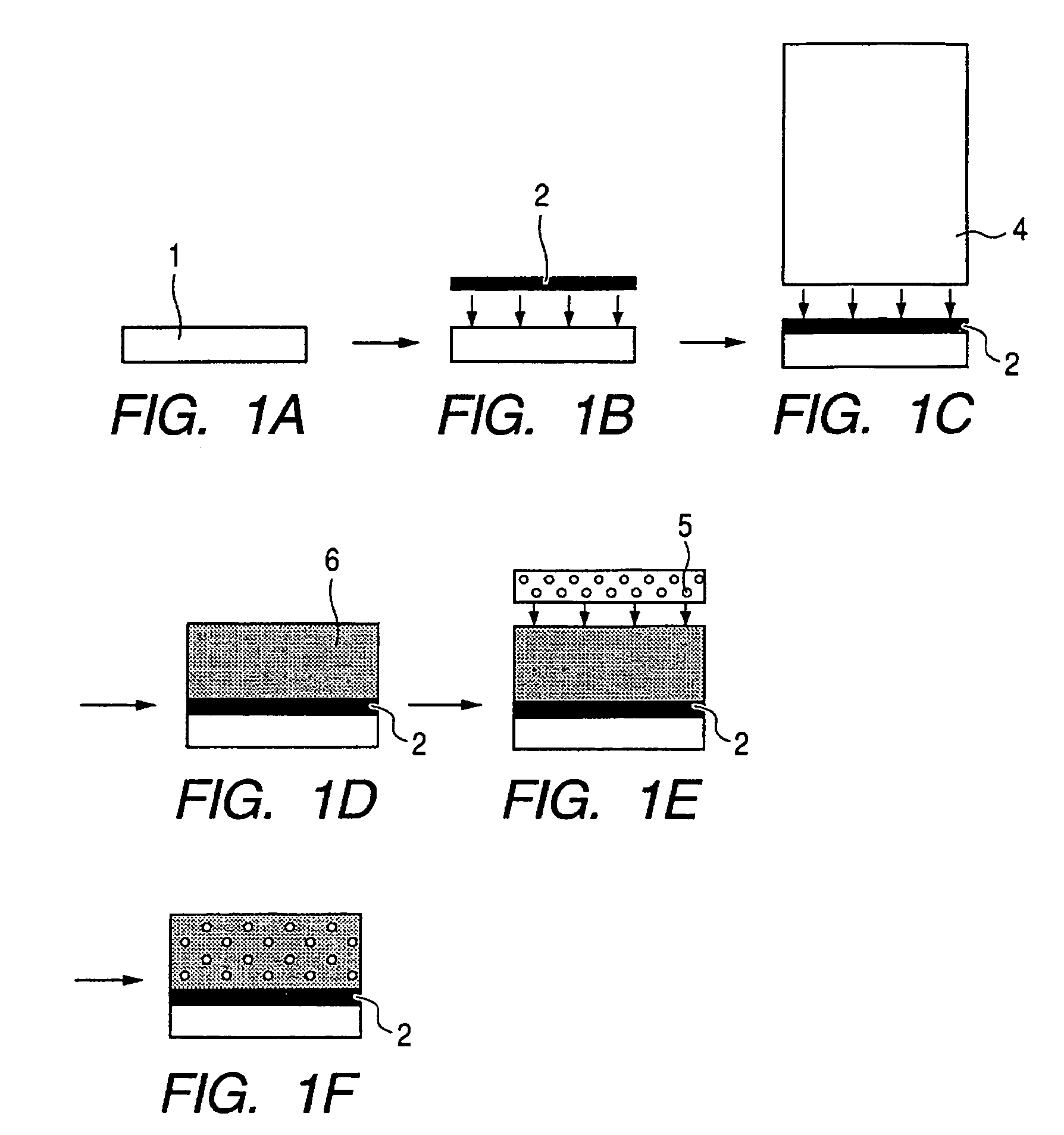

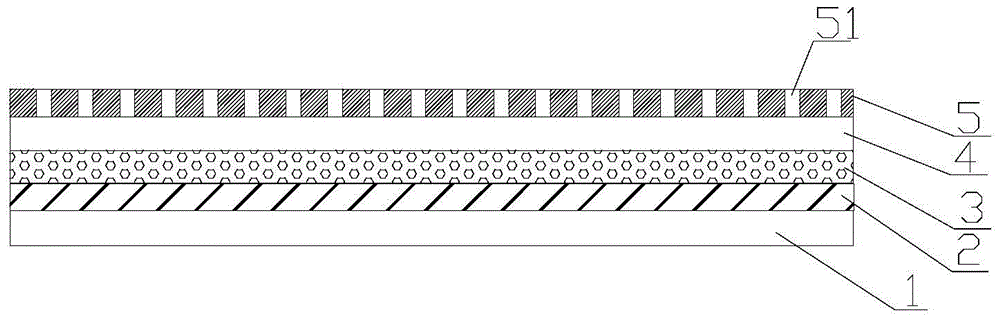

Self-adhesive quick-drying sublimation transfer printing digital paper

ActiveCN104553432AAvoid combiningGood sublimation effectDuplicating/marking methodsSynthetic resin layered productsPolyvinyl alcoholEngineering

The invention relates to the technical field of sublimation transfer printing, discloses self-adhesive quick-drying sublimation transfer printing digital paper. The paper includes, from the bottom to the top, a base material sheet (1), a hydrophobic layer (2), a water-absorbing layer (3), an ink-absorbing layer (4) and a net-shaped surface layer (5), wherein the water-absorbing layer (3) includes interspace holes and is made of acrylic acid-2-acrylamide-2-sodium methacrylate copolymer; the net-shaped surface layer (5) is prepared from, in parts by weight, 25-45% of polyvinyl alcohol-vinyl acetate copolymer and 55-75% of sodium carboxymethyl cellulose; holes are formed in the hydrophilic end of the water-absorbing layer, so that the water contained in the ink can be adsorbed into the holes, and the beneficial effect that the ink can dry quickly after being transferred to a medium material is achieved. According to the invention, the net-shaped surface layer (5) structure facilitates quick absorption of the ink during the printing process; during the transferring process, the net-shaped surface layer can realize maximized adhesion to the medium material; the technical problems that the pattern is blurred or overlapped with another because of easy displacement during the printing ink absorption and transferring processes are solved.

Owner:杭州华大海天科技股份有限公司

Writing paper and preparation method thereof

InactiveCN101787660AIncreased fiber lengthIncrease dosagePulp de-wateringReinforcing agents additionPollutant emissionsPulp and paper industry

The invention provides writing paper made of slurry comprising the following components by percentage: 20% to 100% of unbleached straw pulp and 0% to 80% of wood pulp. According to the ISO (International Standardization Organization), the whiteness of the writing paper is 35% to 75%; the opacity thereof is higher than or equal to 75%; and the basis weight thereof is 45.0g / m<2> to 80.0g / m<2>. The production process of the writing paper is energy-saving and cost-saving; and the pollutant emission can be greatly reduced.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Recording medium

ActiveUS8524336B2Good ink absorptionClear imagingLayered productsDuplicating/marking methodsAlumina hydrateRefractive index

The invention provides a recording medium having excellent ink absorbency and capable of forming a sharp image thereon. The recording medium has a substrate, and a first layer and an outermost layer provided on the substrate in this order, wherein the first layer contains at least one of alumina and alumina hydrate, the outermost layer contains a pigment and is lower in refractive index than the first layer, and the absolute dry coating amount of the outermost layer is 0.1 g / m2 or more and 0.5 g / m2 or less.

Owner:CANON KK

Formulation suitable for ink receptive coatings

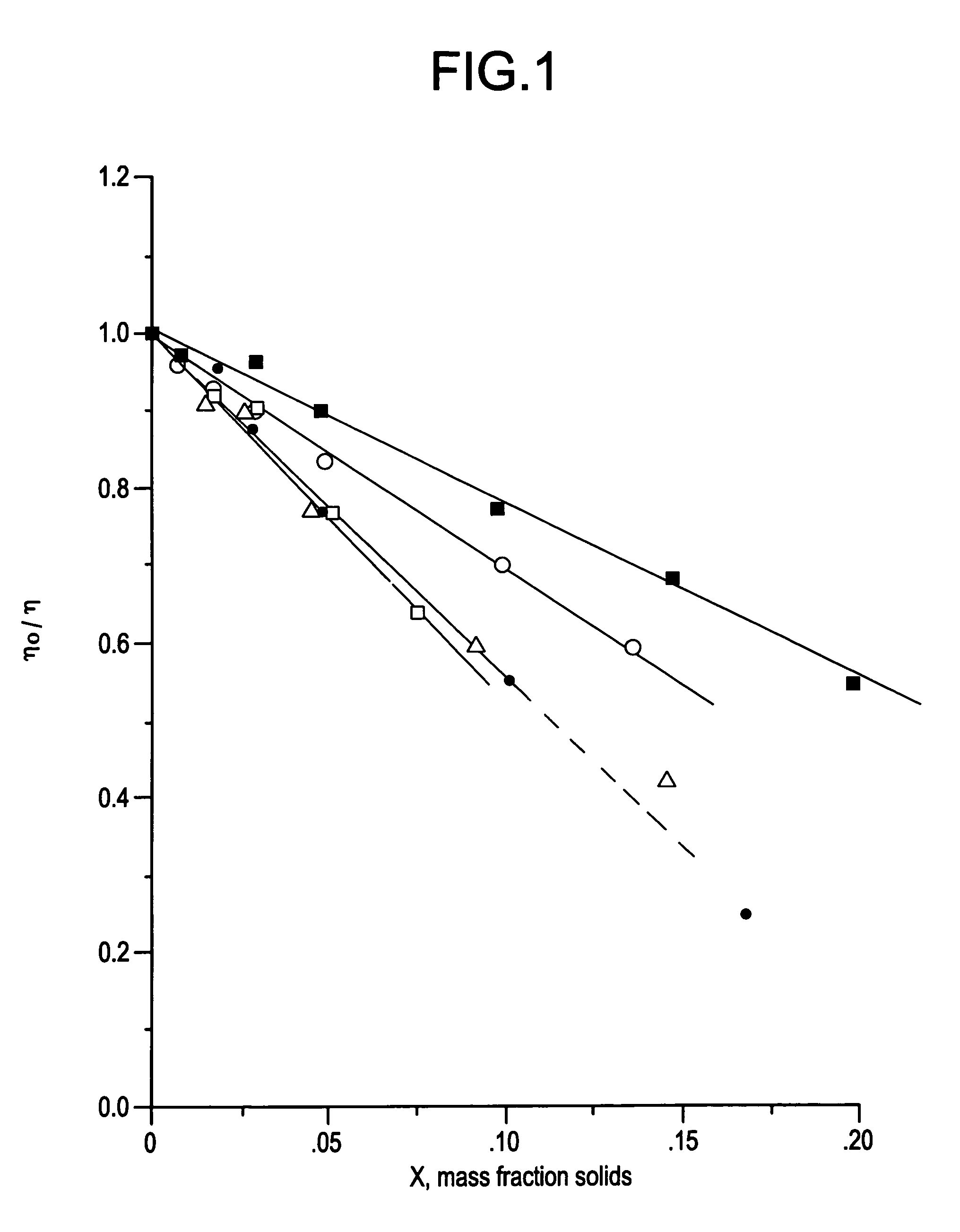

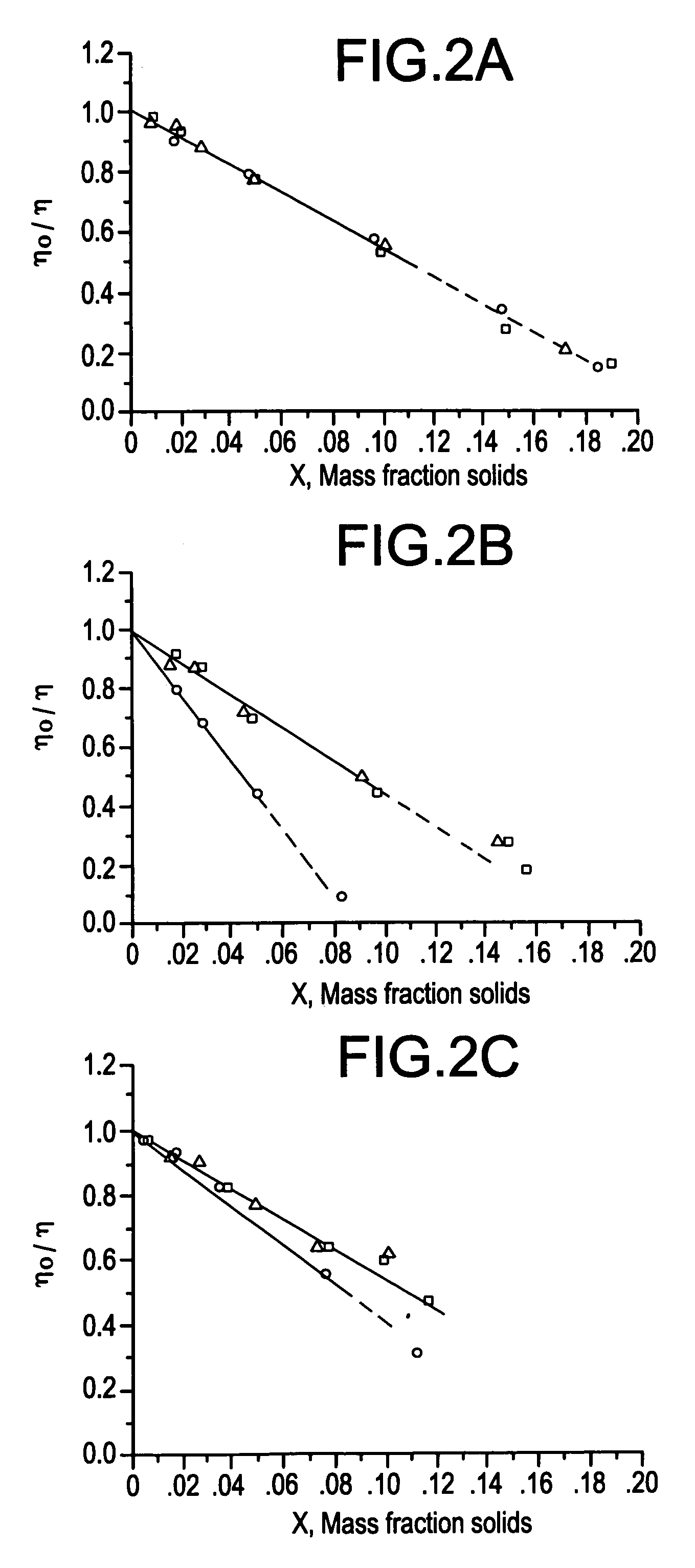

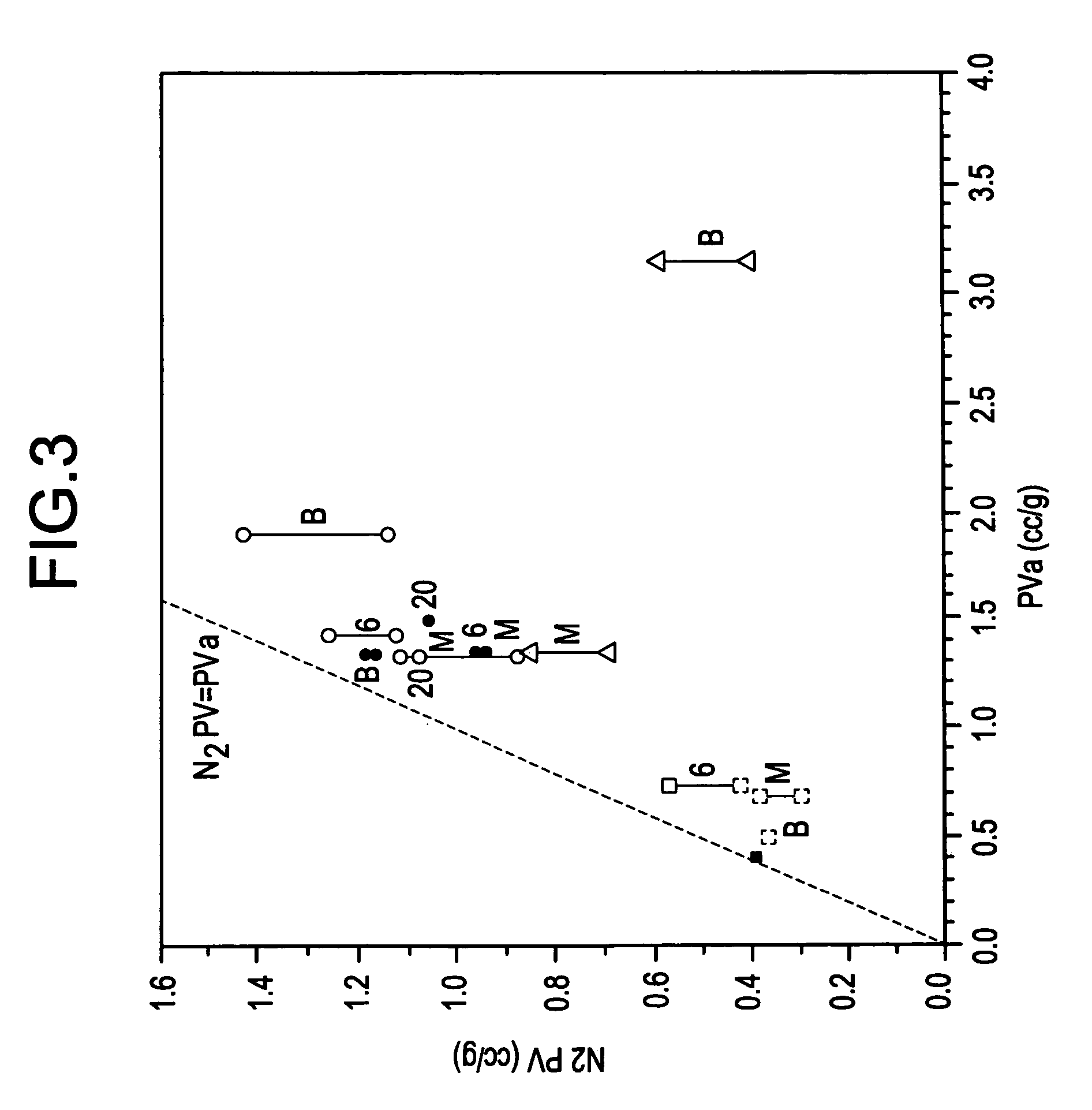

InactiveUS7393571B2Internal porosityGood ink absorptionSynthetic resin layered productsCellulosic plastic layered productsColloidPore diameter

Formulations comprising novel porous metal oxide particles and binder are particularly suitable for ink receptive coatings, e.g., for ink jet papers and films. The metal oxide particles used in this application have a porous structure that differs significantly from the nonporous silica colloids. The particles have a median particle size in the range of about 0.05 to about 3 microns and porosity such that when an aqueous dispersion of the particles is dried at least 0.5 cc / g of pore volume is from pores having a pore size of 600 Å or less. The particles also have a viscosity derived pore volume of at least 0.5 cc / g.

Owner:WR GRACE & CO CONN

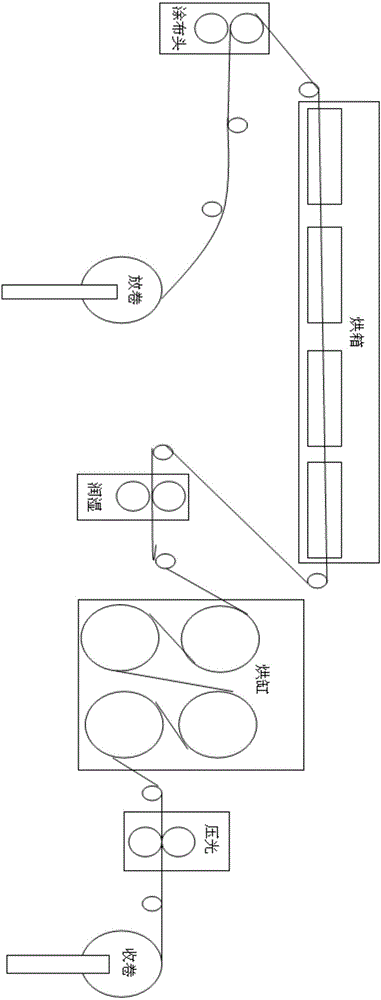

Production process of PVC (polyvinyl chloride) lamp-box fabric

ActiveCN103909711ASimple processReduce manufacturing costSynthetic resin layered productsChemistryCalcium carbonate

The invention relates to a production process of a PVC (polyvinyl chloride) lamp-box fabric. At present, a production process of a PVC lamp-box fabric which is uniform in plasticizing and remarkable in ink absorbing performance does not exist. The production process comprises the following steps: producing a PVC bottom membrane, producing a PVC surface membrane and jointing, wherein the PVC base membrane is prepared from 100 parts by weight of PVC resin, 18-23 parts by weight of calcium carbonate, 48-53 parts by weight of nano calcium, 28-55 parts by weight of phthalate, 3-5 parts by weight of epoxidized soybean oil, 4-6 parts by weight of a liquid stabilizing agent, and 5-15 parts by weight of condiments, and the step of producing the PVC base membrane comprises the procedures of firstly, preparing a main material, stirring the main material at a high speed for 30s, adding the condiments to obtain a material, cooling, mixing to obtain a ball, plasticizing and mixing, filtering for removing impurities, and calendaring to obtain the PVC base membrane; the step of producing the PVC surface membrane is similar to that of producing the PVC base membrane; the jointing step comprises the procedure of jointing the PVC base membrane and the PVC surface membrane on a fabric to obtain the PVC lamp-box fabric. The PVC lamp-box fabric is uniform in plasticizing and remarkable in ink absorbing performance.

Owner:浙江铭龙新材料科技有限公司

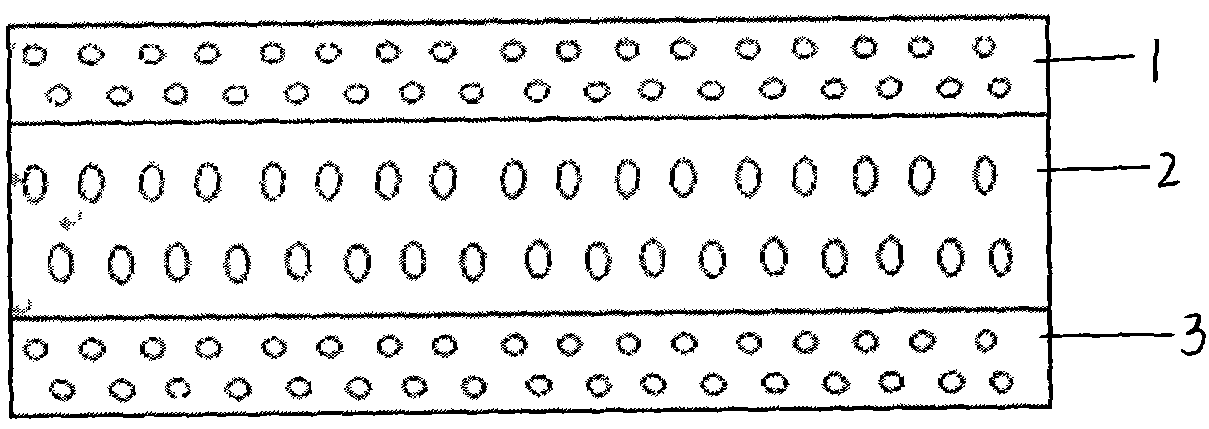

Calcium silicate high-filling polymer modified paper

InactiveCN102011347ALow lateral shrinkageWith whitenessSpecial paperPaper/cardboardLinear low-density polyethyleneCalcium silicate

The invention relates to calcium silicate high-filling polymer modified paper, which is compounded and formed by three layers of non-plant fiber calcium silicate substrates, wherein the first layer and the third layer are prepared from 2 to 6 percent of ethylene bis stearamide, 8 to 23 percent of high-density polyethylene, 3 to 9 percent of metallocene polyethylene, 0 to 1 percent of low-molecular polyethylene, 50 to 60 percent of activated calcium silicate, 10 to 25 percent of calcium silicate inorganic powder and 0 to 3 percent of addition agents, the first layer and the third layer accounts for 25 percent of the weight of the paper, the second layer is prepared from 50 to 60 percent of activated calcium silicate powder, 10 to 25 percent of calcium silicate, 2 to 9 percent of styrene-butadiene block copolymer, 7 to 21 percent of high-intensity polyethylene materials, 4 to 8 percent of linear low-intensity polyethylene and 0 to 3 percent of addition agents, and the second layer accounts for 50 percent of the weight of the paper. The modified paper has the same appearance, whiteness, sizing degree, opacity, strength, toughness and rigidity as plant fiber paper and has simple production processes, no bacteria and poison; and because the product is used for packing paper and can replace the traditional plastic packing paper, a great amount of petroleum can be saved.

Owner:宋旭

Article having microporous body part, production method of ink medium, diffusion method of sulfur-containing organic acid into microporous layer, production method of article having meicroporous body part, and inkjet recording medium produced therefrom

InactiveUS20060182906A1Eliminate riskEliminate effectiveCoatingsThermographyDiffusion methodsOrganic acid

Provided is an inkjet recording medium in which hydrated alumina and a sulfinic acid compound or thiosulfonic acid compound coexist in a pigment in an ink receiving layer, and which can prevent white-background yellowing during storage in a resin file holder or the like and ensure printing quality at the same time. The ink receiving layer of the inkjet recording medium contains the sulfinic acid compound or thiosulfonic acid compound, which functions to prevent yellowing, in a salt form or in a free form so as to be diffusible.

Owner:CANON KK

Ink Jet Recording Sheet

InactiveUS20080160232A1High white-paper glossEasy to operateCoatingsThermographyEngineeringSilicon dioxide

The present invention relates to an ink jet recording sheet comprising a sheet-like substrate, and an ink receiving layer formed on at least one surface of the sheet-like substrate, the ink receiving layer containing an amorphous silica having an average particle size 0.5 to 10 μm and a binder, the sheet-like substrate being subjected to a calendering treatment after forming the ink receiving layer thereon, thereby white-paper gloss of the recording sheet measured at 75° in accordance with JIS Z 8741 is from 30 to 90%.

Owner:OJI PAPER CO LTD

Ink-jet recording material for proof

InactiveUS6991330B2Less fadingGood ink absorptionDuplicating/marking methodsSynthetic resin layered productsWater resistantPolymer chemistry

Disclosed are an ink-jet recording material for proof including a water-resistant support and at least one ink-receptive layer containing inorganic fine particles and a hydrophilic binder provided on the support, wherein the water-resistant support has a center line average roughness Ra75 with a cut off value of 0.8 mm according to JIS-B0601 of 1.0 μm or less, and an uppermost ink-receptive layer farthest from the water-resistant support contains a colorless or white matting agent having an average particle size of 1 to 10 μm and a colored pigment having an average particle size of 1 μm or less, and use of the same for proof.

Owner:MITSUBISHI PAPER MILLS LTD

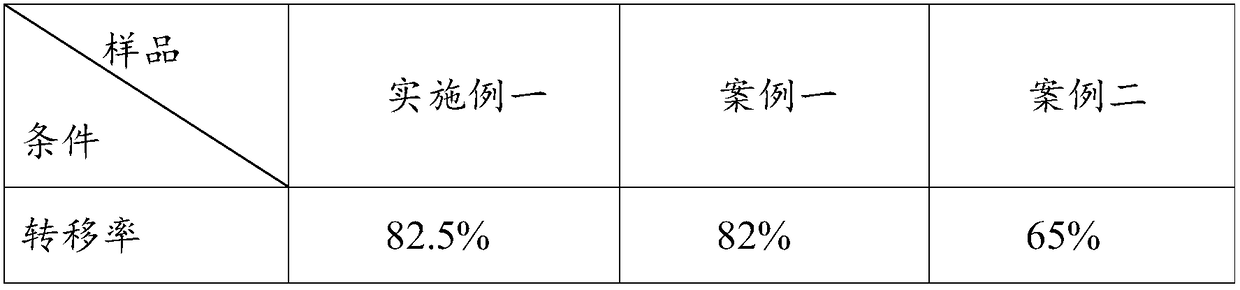

Thermal dye sublimation transfer paper suitable for on-line high-speed production

PendingCN108894053AFast dryingImprove transfer rateCoatings with pigmentsWater-repelling agents additionCarboxymethyl celluloseEngineering

The invention provides thermal dye sublimation transfer paper suitable for on-line high-speed production. The thermal dye sublimation transfer paper comprises body paper, a gluing layer and a coatinglayer, and the gluing layer and the coating layer coat the body paper in sequence according to an on-line processing technology; coating in the coating layer is at least prepared from a water absorbing material, an ink absorbing material and resin. The thermal dye sublimation transfer paper is characterized in that the water absorbing material is a composition containing one or more of sodium polyacrylate resin, aluminium silicate, calcined kaolin and silicon dioxide according to any proportion, and the ink absorbing material is a composition containing one or more of sodium carboxymethyl cellulose, polyacrylamide, sodium alginate, oxidized starch and natural polymer glue. The thermal dye sublimation transfer paper produced by means of the technology solves the problems in the prior art that thermal dye sublimation transfer paper prepared by means of an on-line coating method is low in ink absorbing amount, low in transfer rate, high in ink permeability and low in printing precision.

Owner:赵慧哲

Formula and preparation method for high gloss color ink-jet printing paper coating

InactiveCN104099807AHigh glossGood ink absorptionDefoamers additionCoatings with pigmentsEmulsionPolymer science

The invention relates to a formula and a preparation method for a high gloss color ink-jet printing paper coating. According to the method, 100 parts of pure water, 50-60 parts of nano-silica, 5-10 parts of a cationic color fixing agent, 3-6 parts of a 10% polyvinyl alcohol aqueous solution, 1-3 parts of an acrylic emulsion, and 0.5-1 part of a defoamer are subjected to preparation processing and coating. The color ink-jet printing paper prepared according to the formula and the preparation process provided by the invention not only has high gloss, high ink absorbency high color reducibility, high color density, high resolution, high pull-out capacity and other characteristics, but also has stable formula, the product qualification rate reaches over 95%, 24h uninterrupted coating production can be realized, and the production efficiency and product qualified rate are improved. Thus, the formula and the preparation method are suitable for wide popularization and use.

Owner:南京泛太克文化产业发展有限公司

Recording medium and method for producing recording medium

InactiveUS8795798B2Improve glossinessIncrease resistanceLiquid surface applicatorsCoatingsColloidal silicaAlumina hydrate

A method for producing a recording medium, including a step of coating one or more ink receiving layers provided on at least one surface of a substrate with an outermost layer coating liquid to form an outermost layer, where an ink receiving layer of the one or more ink receiving layers, which is nearest to the outermost layer contains alumina hydrate and a binder. The outermost layer coating liquid contains monodispersive and spherical cationic colloidal silica particles having an average particle size of 30 nm or more and 60 nm or less, polyvinyl alcohol having a saponification degree of 75% by mol or more and 85% by mol or less and a viscosity-average polymerization degree of 1,500 or more and 2,200 or less, and cationic polyurethane emulsion particles having an average particle size of 10 nm or more and 100 nm or less.

Owner:CANON KK

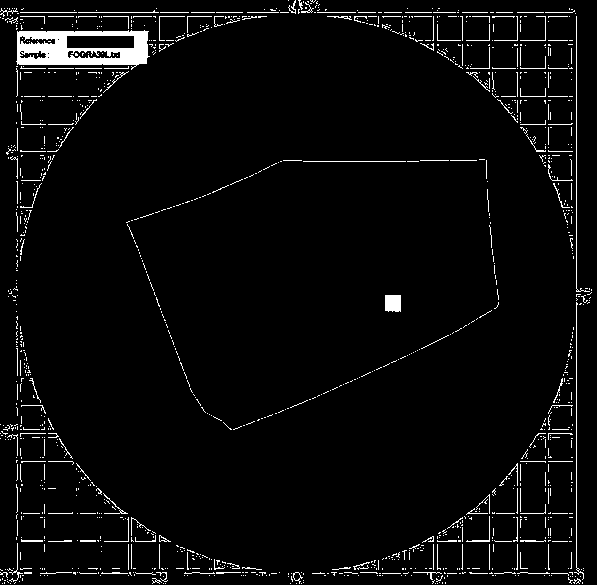

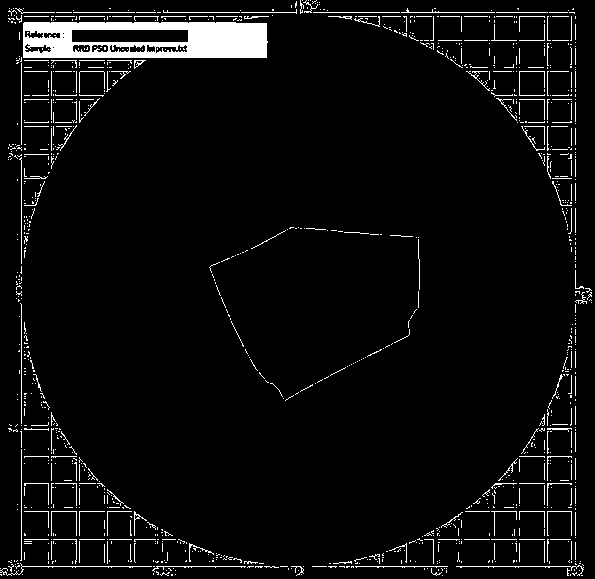

Color management method and device of maximized uncoated paper printing color gamut

ActiveCN107757166AGood ink absorptionIncrease the amount of inkMounting boardsOther printing apparatusContrast levelVolumetric Mass Density

The invention discloses a color management method and device of a maximized uncoated paper printing color gamut. The method comprises the following steps: (1) setting a dot shape to be compound screening through prepress setting; (2) increasing dots for reducing CMYK to 13%-16% through prepress compensating curve setting for increasing image contrast level; (3) increasing the density values of C,M, Y and K to 1.20-1.25, 1.20-1.25, 0.95 and 1.25-1.30 separately for increasing color saturation; (4) increasing a rubber blanket by adjusting the press setting for increasing the pressure between apress tape cylinder and an impression cylinder and improving the ink absorption performance of uncoated paper; and (5) adding 2%-4% of viscosity reducers in amount to original color ink by adjusting CMY ink viscosity. According to the color management method disclosed by the invention, the inking amount is increased by improving the paper ink absorbency, and the contrast level is increased by matching with the prepress treatment for increasing the color gamut. The printing color gamut is increased by 30% than the printing color gamut in ISO, so that the publication and production are convenient, and the uncoated paper production is easy apply; the manufacturing procedures of coated paper and the cost are reduced, and the method is friendly-environment.

Owner:DONGGUAN DANGNA PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com