Flame-retardant transparent floor film and production technology thereof

A floor and transparent technology, applied in the field of decorative materials, can solve the problems of inkjet performance degradation, affecting apparent transparency, and difficulty in coiling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

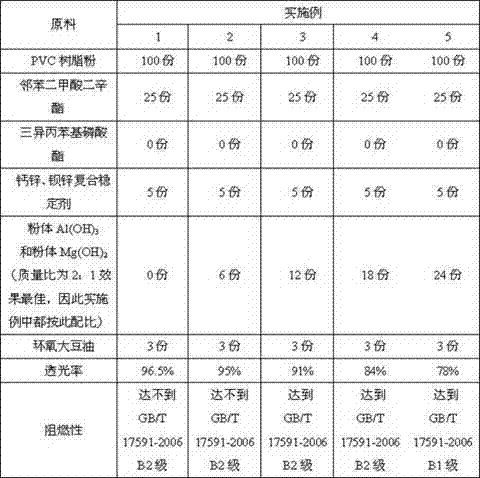

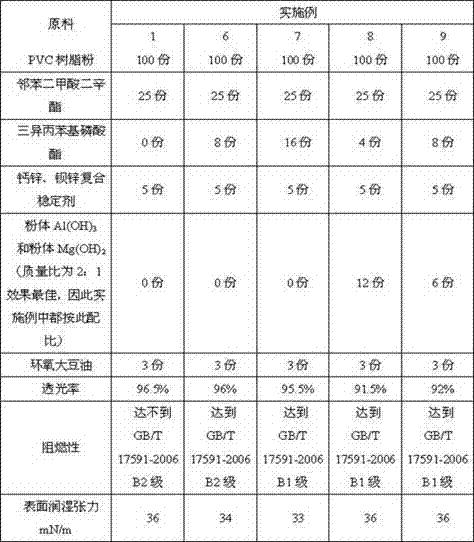

Embodiment 1

[0050] A flame-retardant transparent floor film and its production process, which is made of 100 parts by weight of PVC resin powder, 25 parts by weight of dioctyl phthalate, 5 parts by weight of calcium-zinc, barium-zinc composite stabilizer and 3 parts by weight of epoxy resin Soybean oil is the main raw material, and it is prepared through a PVC film calendering process; the specific process of the PVC film calendering process is as follows:

[0051] (1) Batching and stirring: weigh each raw material by weight and mix in order. First add liquid additives to the PVC resin powder and stir at 60°C. At this time, the stirring speed is 450r / min, and the stirring time is 6min. , after stirring, add powder additives at 95°C, at this time, the stirring speed is 650r / min, stir evenly and enter banburying;

[0052] (2) Internal mixing: Control the internal mixing temperature to 155°C, the pressure on the top bolt to 0.4Mpa, and the discharge time: 6 minutes;

[0053] (3) Two-wheel p...

Embodiment 2

[0061] A kind of flame-retardant transparent floor film and its production technology, it uses 100 weight parts PVC resin powder, 25 weight parts dioctyl phthalate, 5 weight parts calcium-zinc, barium-zinc composite stabilizer, 4 weight parts powder Al (OH) 3 , 2 parts by weight powder Mg(OH) 2 And 3 parts by weight of epoxy soybean oil is the main raw material, which is prepared through the PVC film calendering process; the specific process of the PVC film calendering process is as described in Example 1.

Embodiment 3

[0063] A kind of flame-retardant transparent floor film and its production technology, it uses 100 weight parts PVC resin powder, 25 weight parts dioctyl phthalate, 5 weight parts calcium-zinc, barium-zinc composite stabilizer, 8 weight parts powder Al (OH) 3 , 4 parts by weight powder Mg(OH) 2 And 3 parts by weight of epoxy soybean oil is the main raw material, which is prepared through the PVC film calendering process; the specific process of the PVC film calendering process is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com