Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82 results about "Roller burnishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roller burnishing is a surface finishing technique where hardened rollers cold work surface imperfections to reduce surface roughness. Roller burnishing differs from abrasive surface finishing techniques in that material is displaced rather than removed. The tooling typically consists of a hardened sphere or cylindrical roller. The tooling is pressed into the surface of the part while it is rotated (in some applications, the tools are rotated instead of the part). The burnishing tool rolls against the surface of the part at a constant speed, producing a very consistent finish across the part. A surface finish of less than Ra 0.1 µm is achievable with roller burnishing. A side effect is that the outer surface of the part is work hardened.

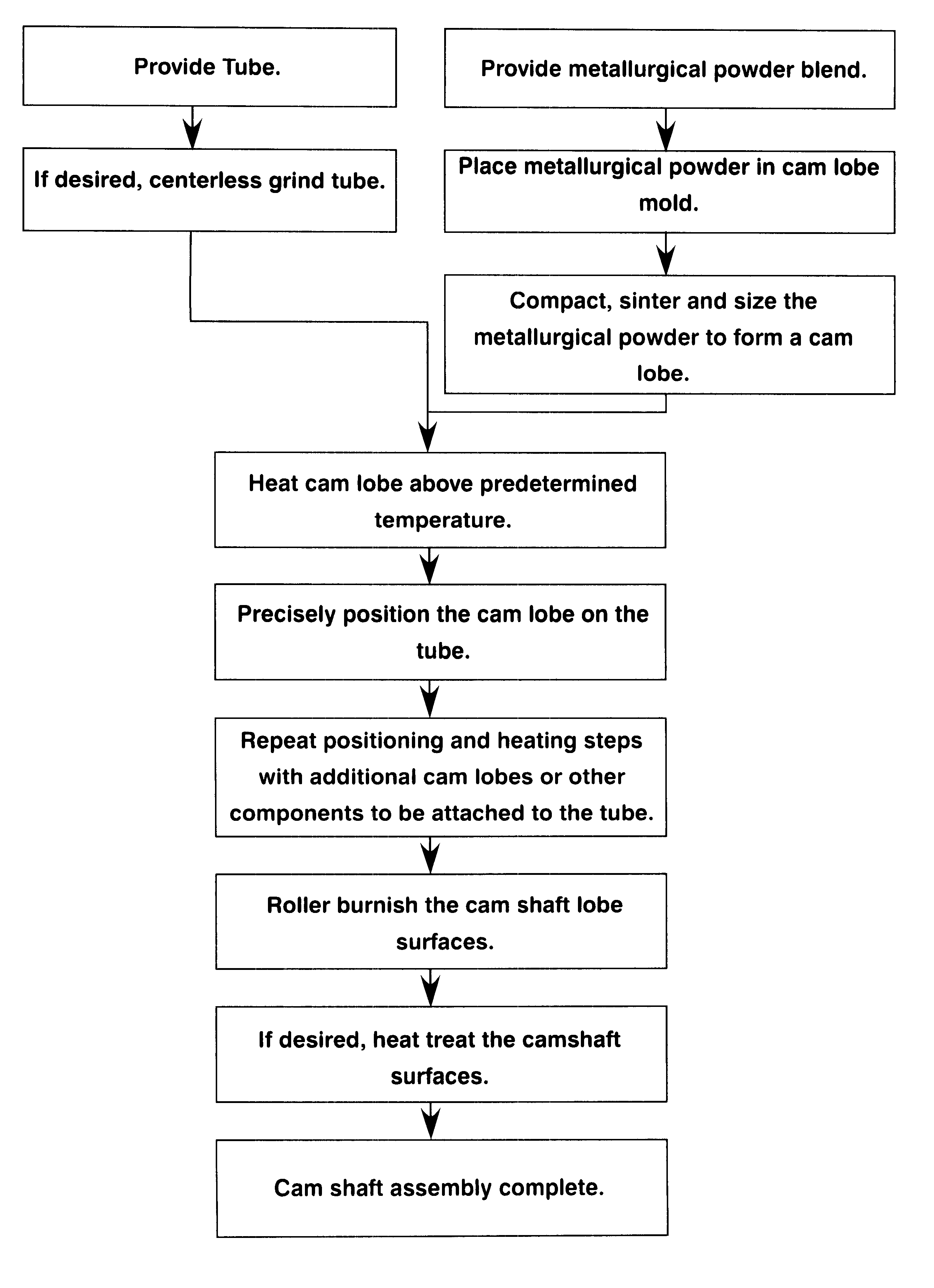

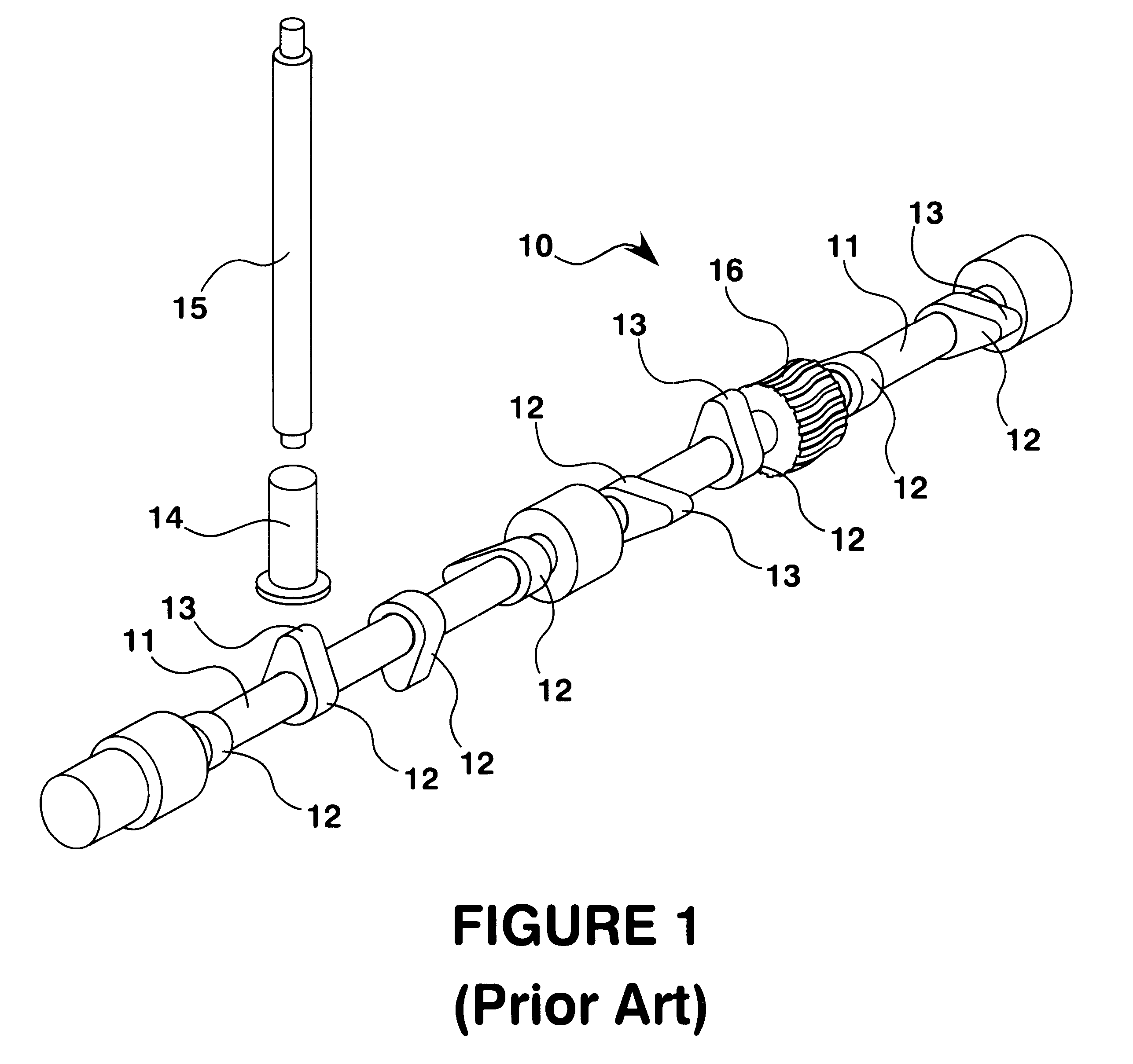

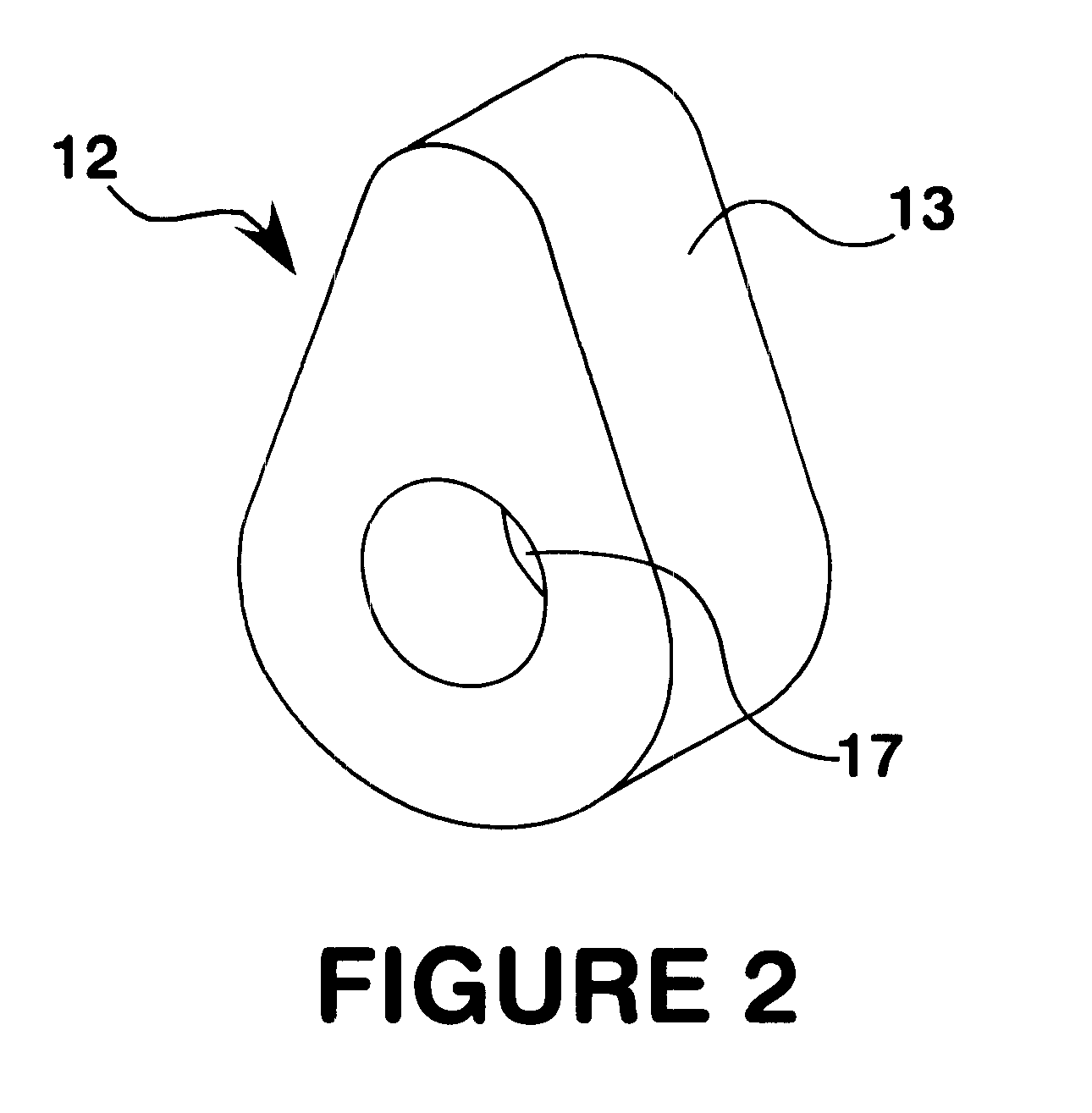

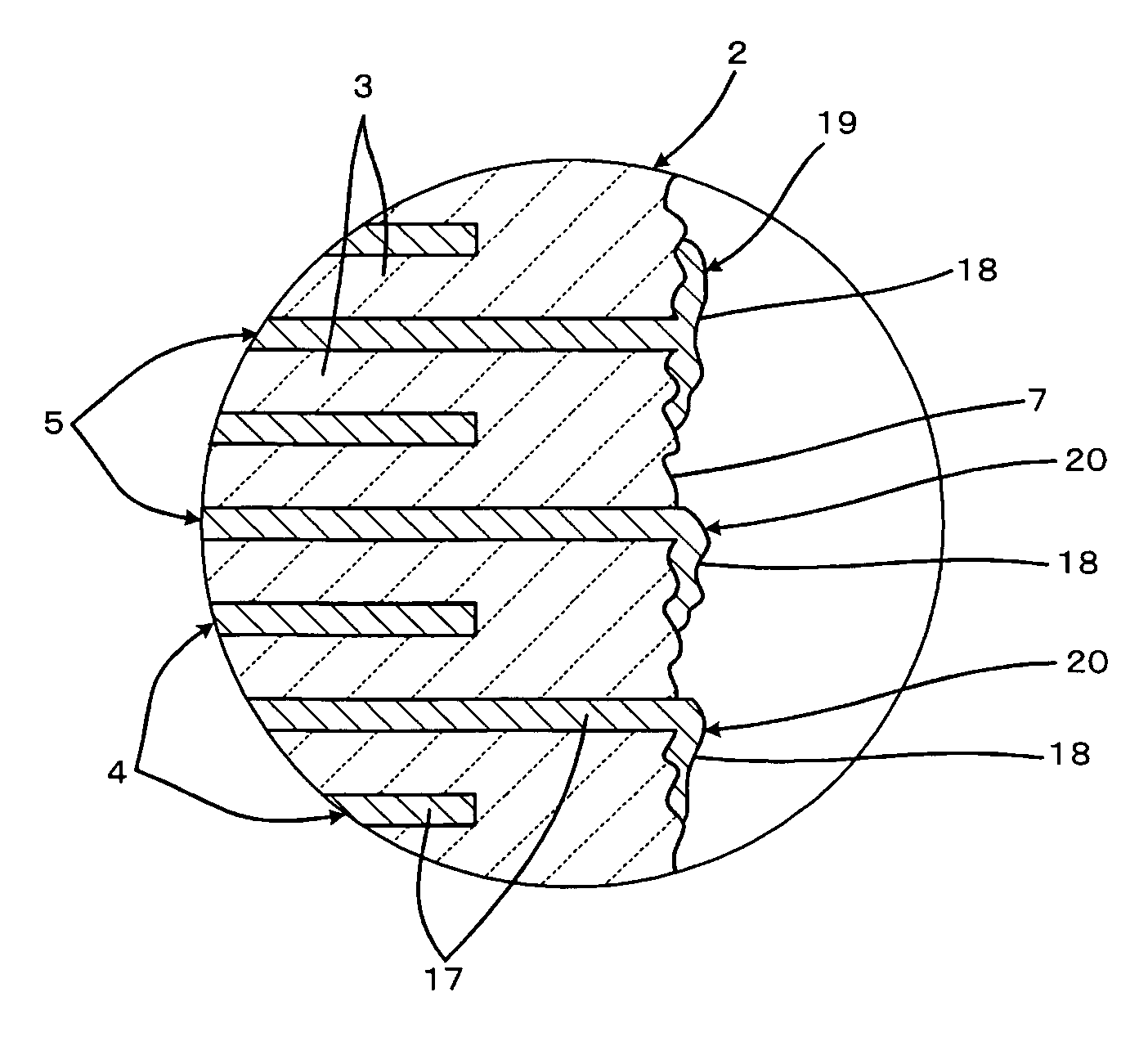

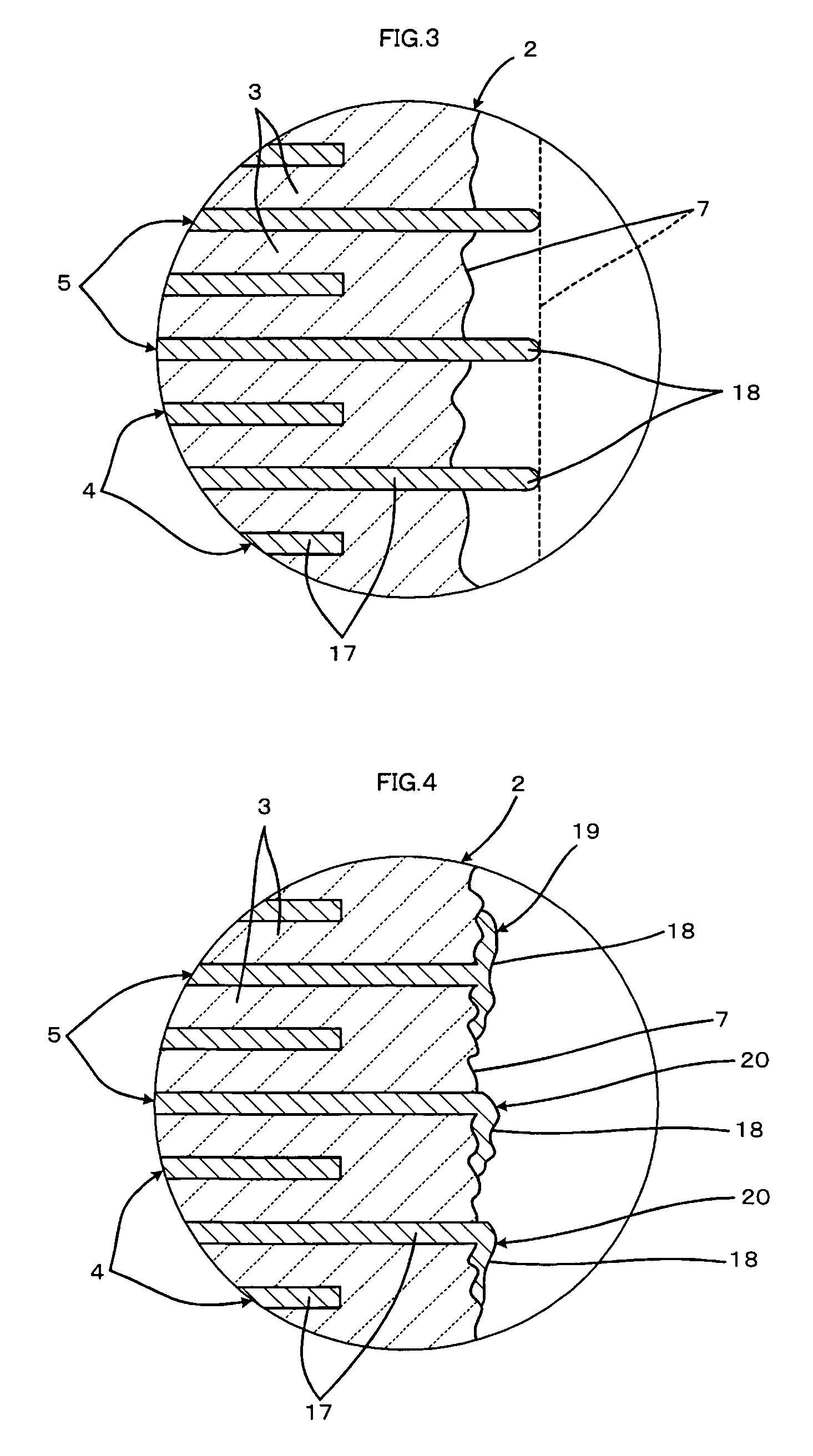

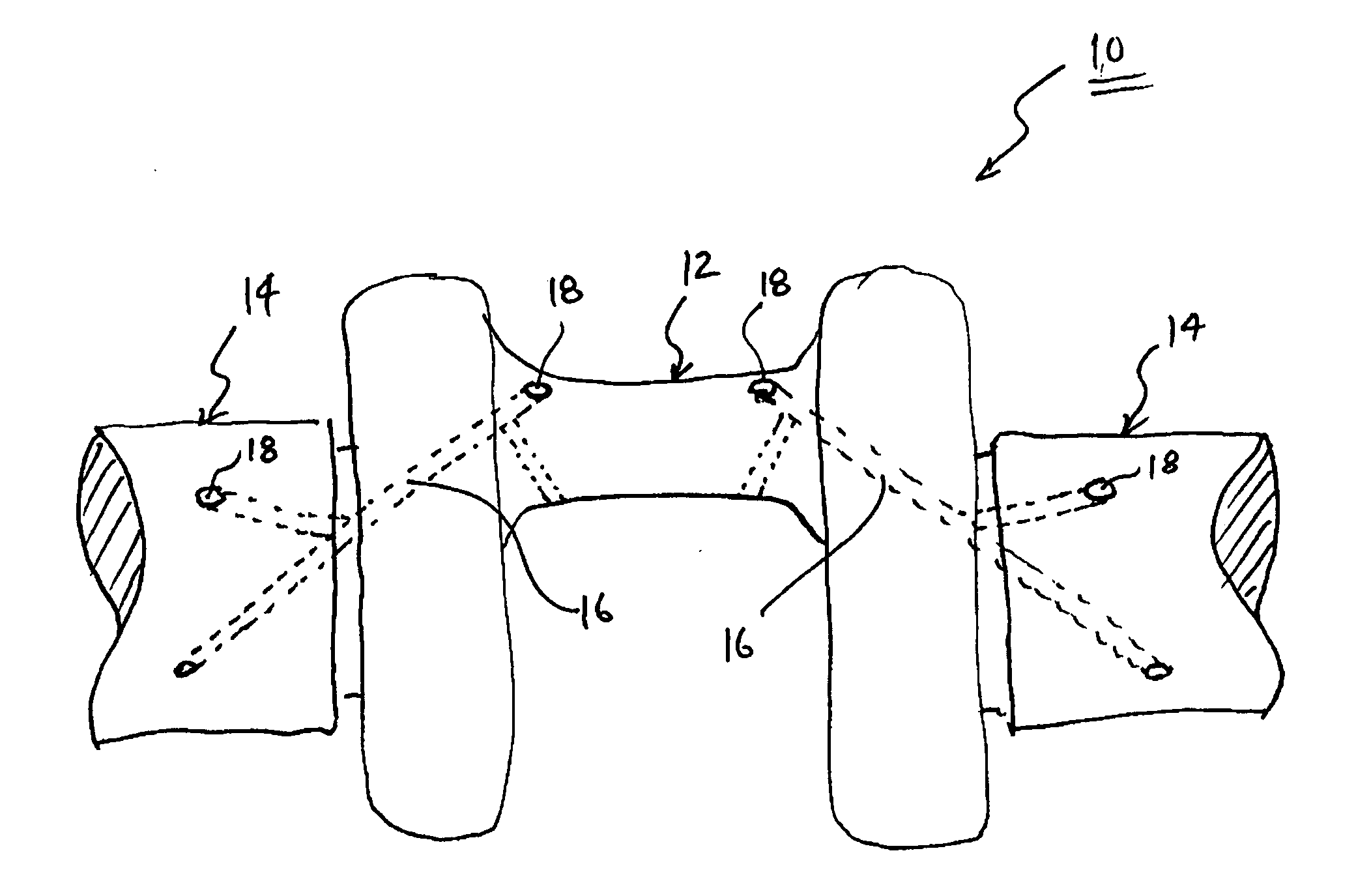

Method of fabricating camshafts

InactiveUS6473964B1Good flexibilitySmall sizeValve drivesMachines/enginesCombustionVolumetric Mass Density

A method of attaching and adjusting first and second members includes providing a first member having an outer surface and a second member. The second member is affixed to the outer surface of the first member at a desired axial position along the length of the first member and in a desired angular orientation. Subsequent to affixing the second member to the first member, the shape and / or dimensions of the second member is adjusted by increasing the density of at least a region of the second member. The densification may be accomplished by, for example, a mechanical working technique such roller burnishing, coining, sizing, shot peening, or laser impacting. In one embodiment of the invention, the method may is adapted to the production of combustion engine camshafts from separately provided camshaft tubes and cam lobes.

Owner:KEYSTONE INVESTMENT CORP

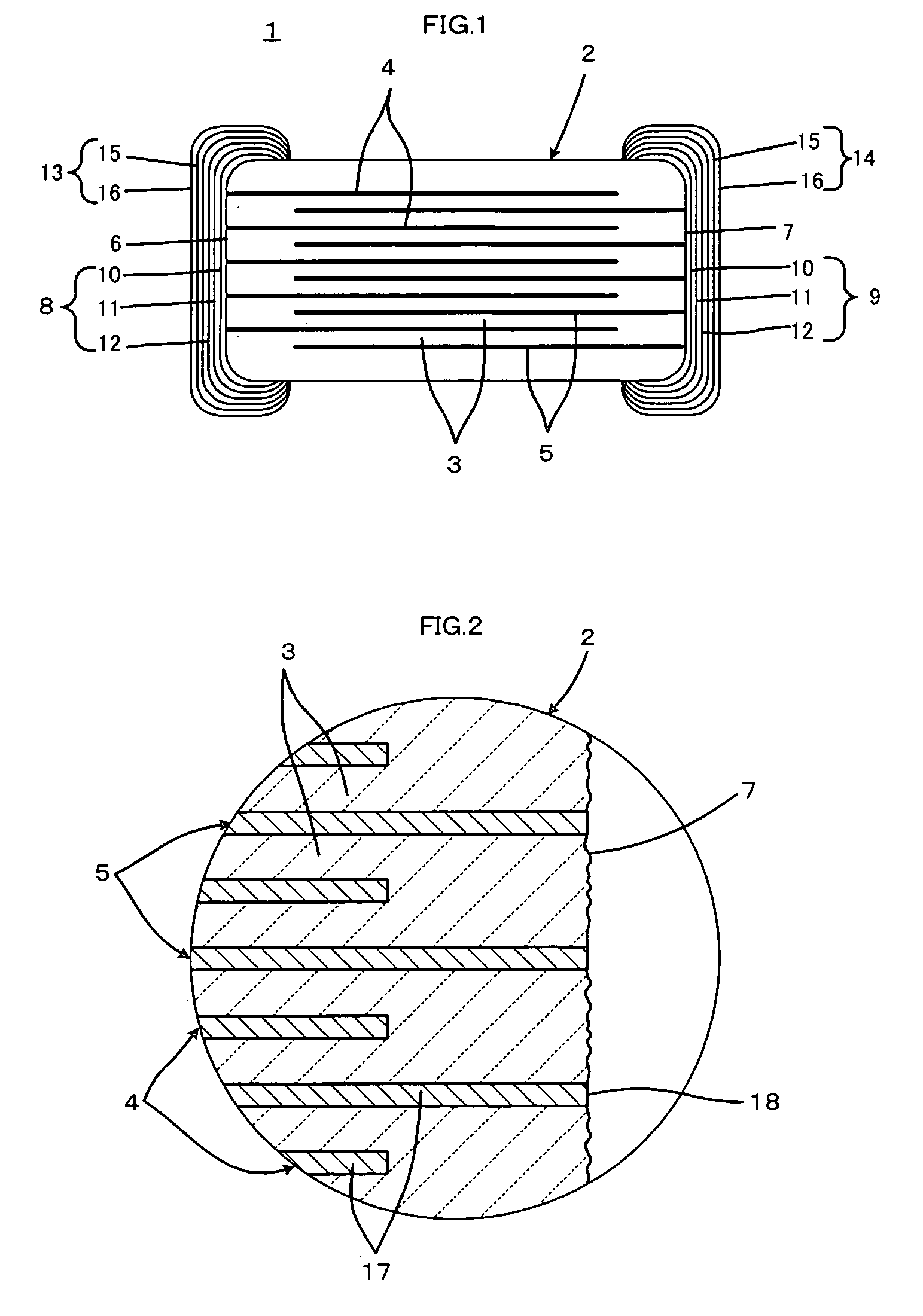

Multilayer ceramic electronic components and method for manufacturing the same

ActiveUS7295421B2Improve reliabilityFixed capacitor dielectricFixed capacitor terminalsElectrical connectionElectronic component

Owner:MURATA MFG CO LTD

Method for increasing torsional fatigue strength in crankshafts

InactiveUS20100107808A1Improve fatigue strengthImprove torsional fatigue strengthCrankshaftsEngine componentsTorsion fatigueUltimate tensile strength

A method for processing a cast iron crankshaft to improve the torsional fatigue strength of the crankshaft includes forming oil holes into a portion of the crankshaft, treating the portion of the crankshaft to harden an annular area of the portion, and roller burnishing a length of the interior of the oil holes to an increased diameter. The roller burnished length of the oil holes extending from a surface of the crankshaft to at least beyond the hardened annular area.

Owner:CUMMINS INTPROP INC

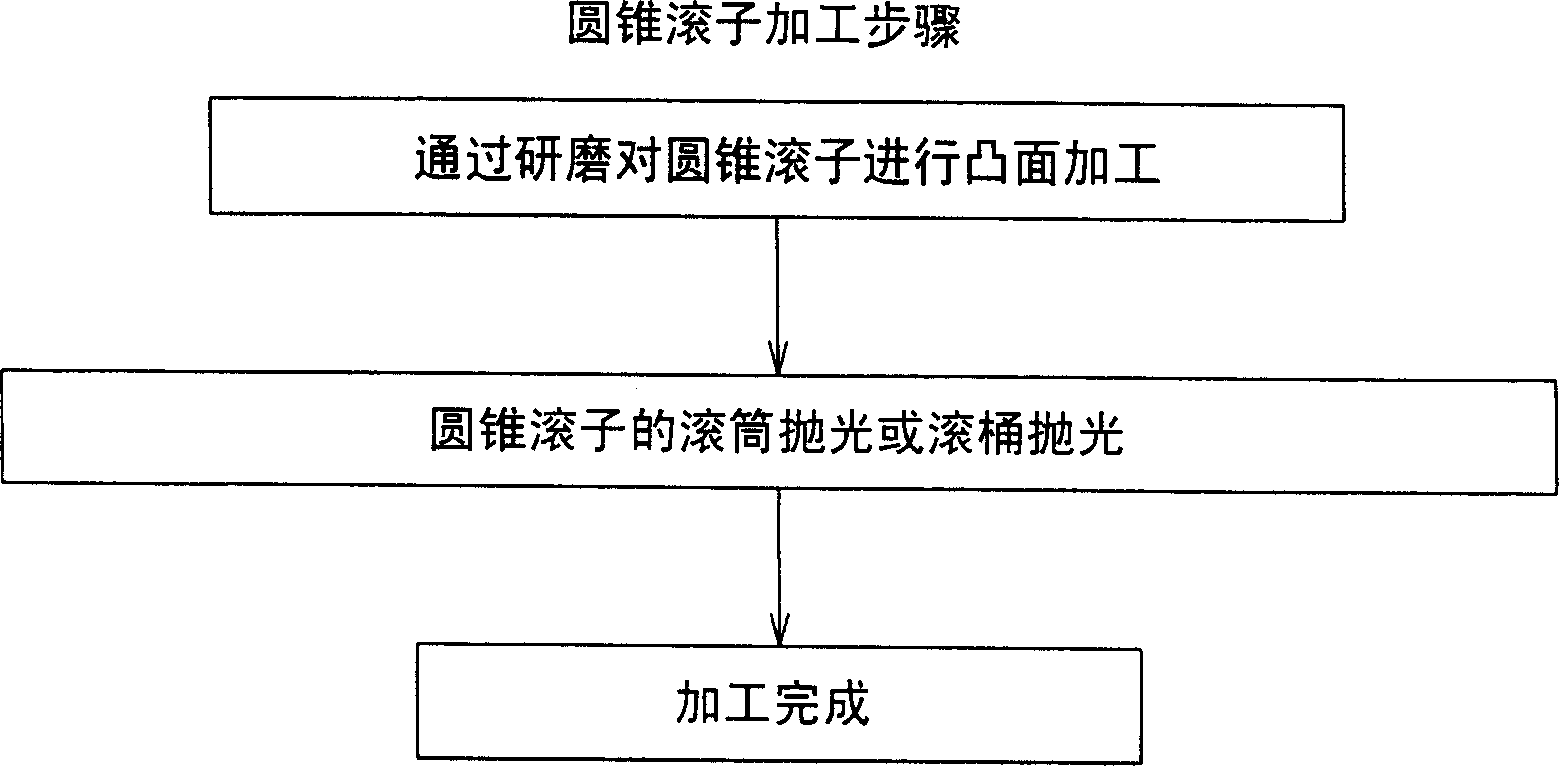

Tapered roller bearing and method of machining tapered roller

The invention discloses a method for machining the tapered roller of a tapered roller bearing, which is characterized in that a roller is subjected to crowning machining by grinding and then is subjected to fine machining by barrel polishing or tumbler polishing so as to remove grinding marks. Due to the adoption of the method, each tapered roller is crowning-processed by grinding and finished by barrel polishing or tumbler polishing so as to be provided with a large crowning, while the tapered roller is low in cost and deflection-resistant. Meanwhile, the super-processing operation, which causes peeling damage on the raceway surface and shortens the service life of the roller, is no longer adopted.

Owner:NTN CORP

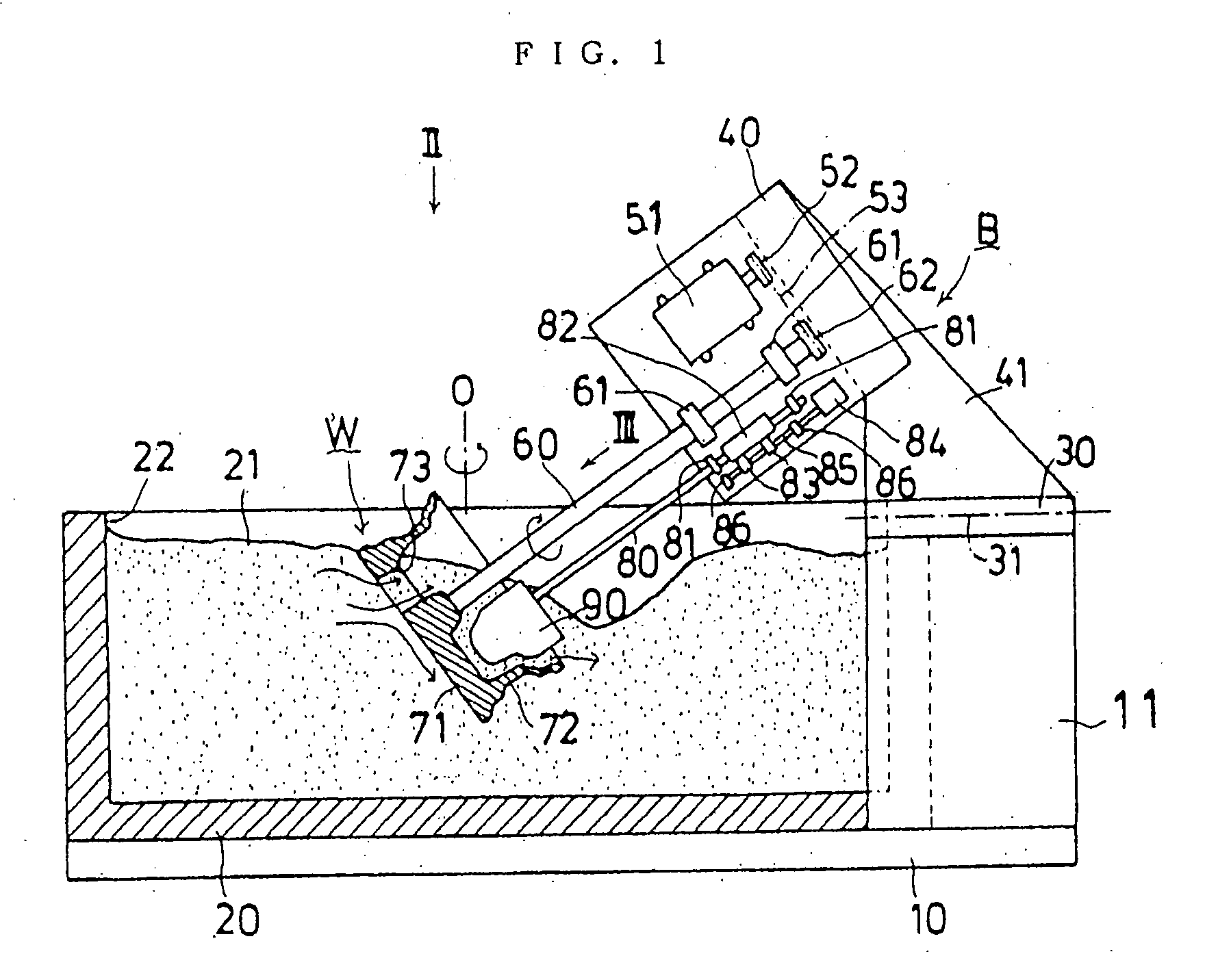

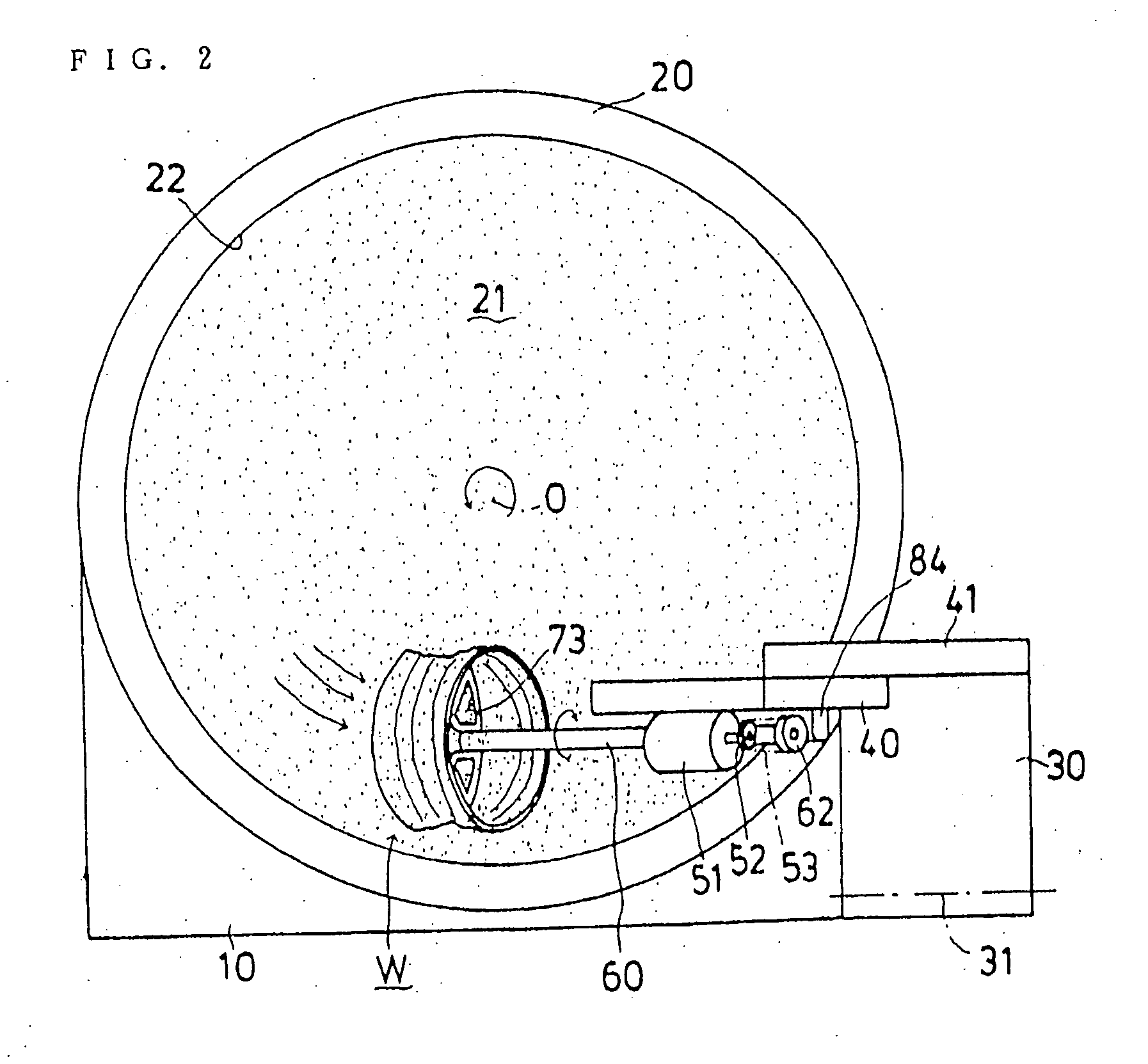

Barrel polishing device

InactiveUS6962522B1Reduce surface pressureIncrease surface pressureEdge grinding machinesPolishing machinesEngineeringMechanical engineering

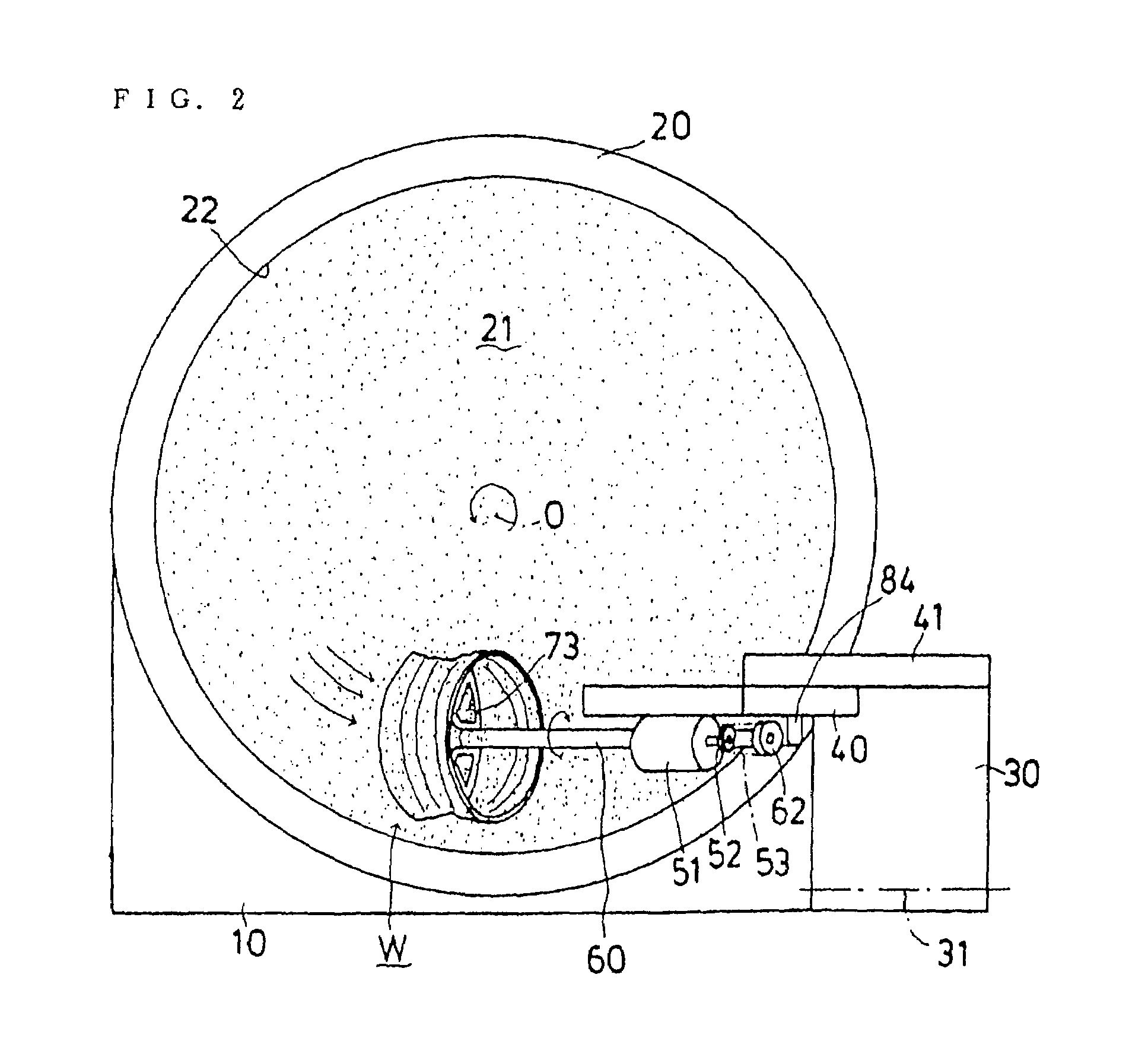

A barrel polishing device for polishing a workpiece having a relatively complicated shape such as a vehicle wheel. The barrel polishing device comprises a polishing medium storage tank for storing polishing media, a base, a workpiece supporting shaft mounted on the base, and a workpiece detachably mounted on a tip part of the workpiece supporting shaft, the polishing media stored in the polishing medium storage tank being flowed by an appropriate means, and the workpiece supporting shaft being disposed so that a front side of the workpiece opposes the flow of the polishing media, the workpiece supporting shaft being rotated about an axis thereof, and a baffle member being placed in the vicinity of a back side of the workpiece.

Owner:BBF YAMATE

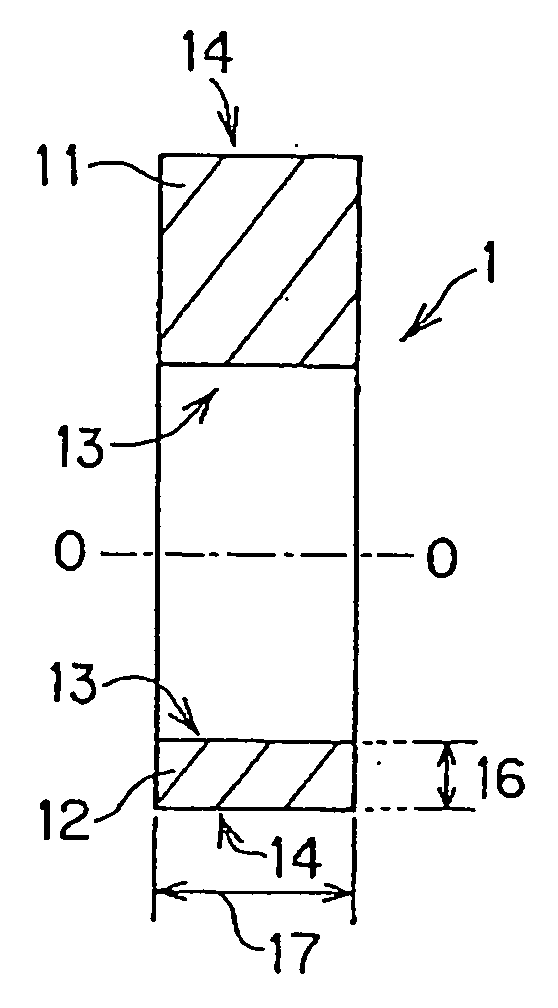

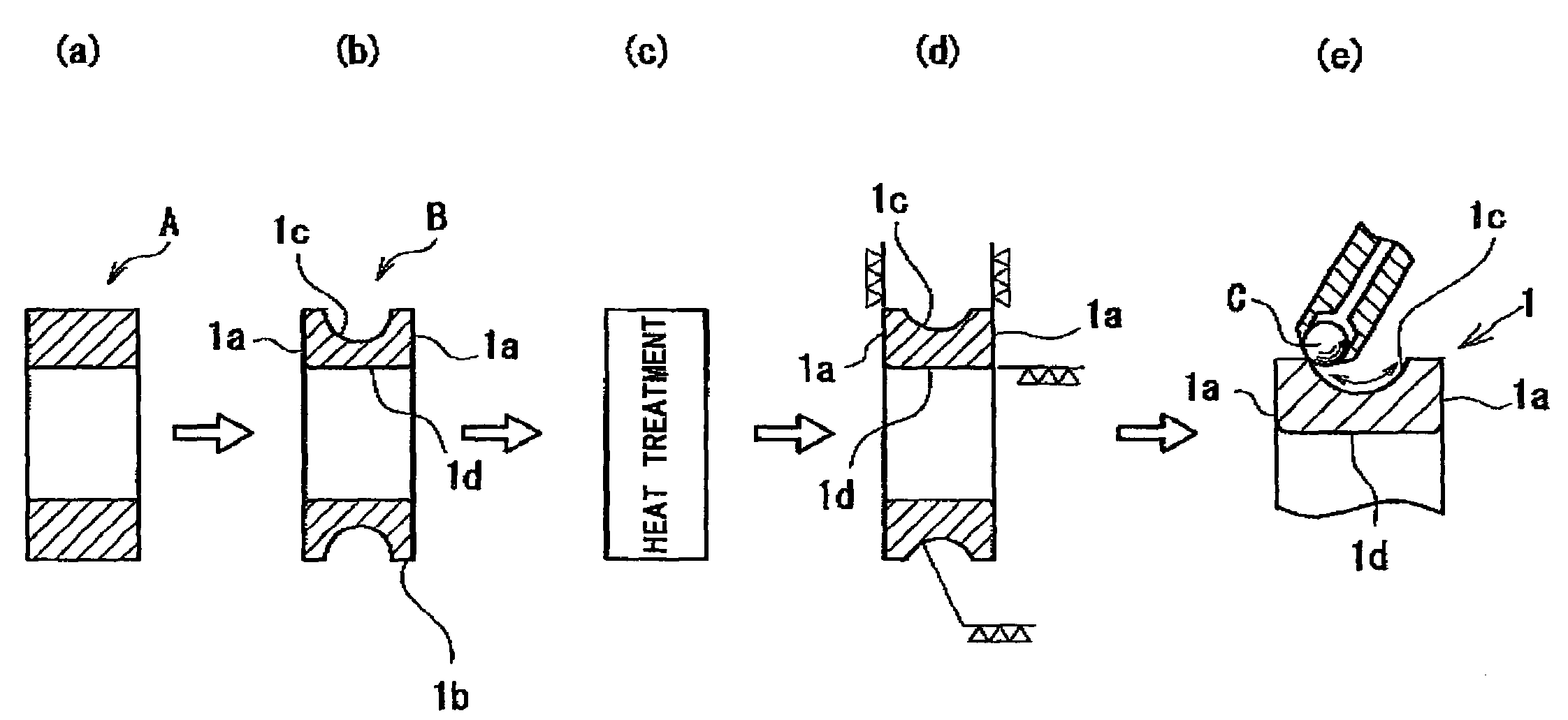

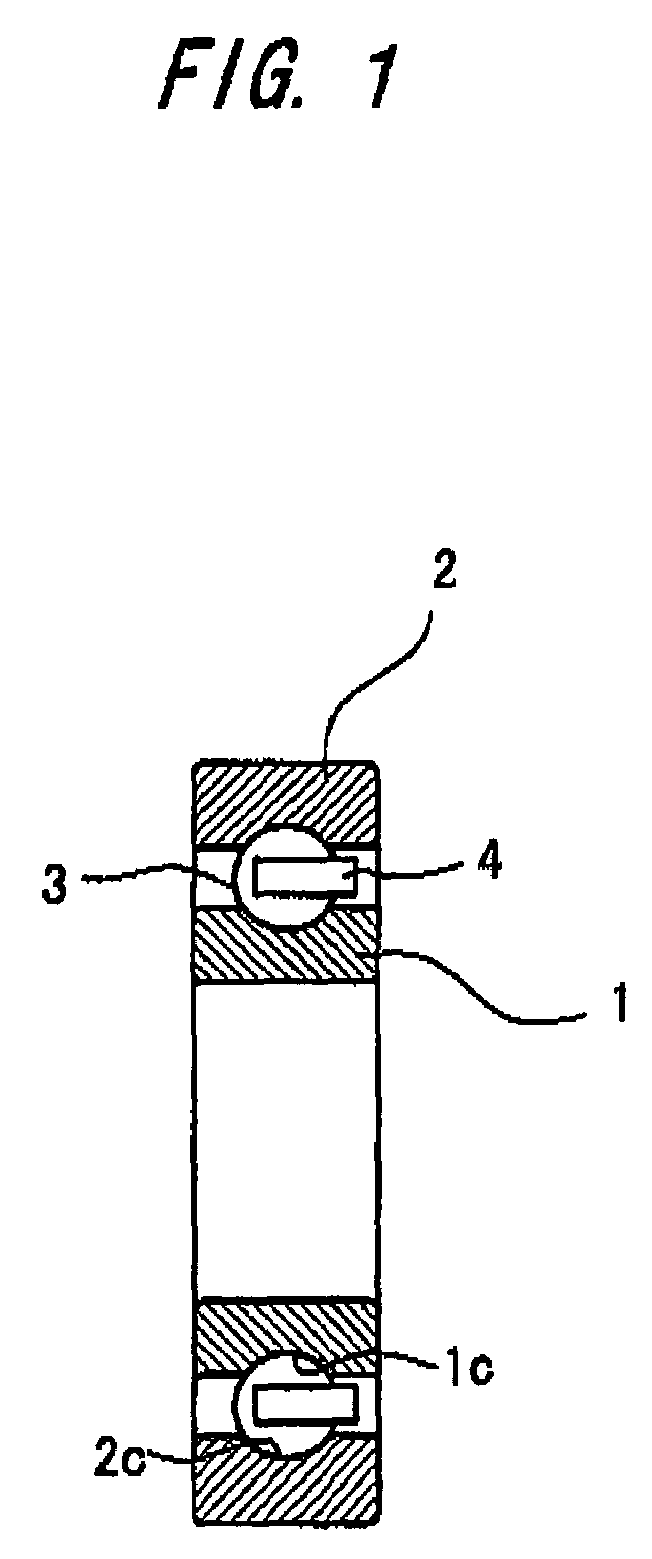

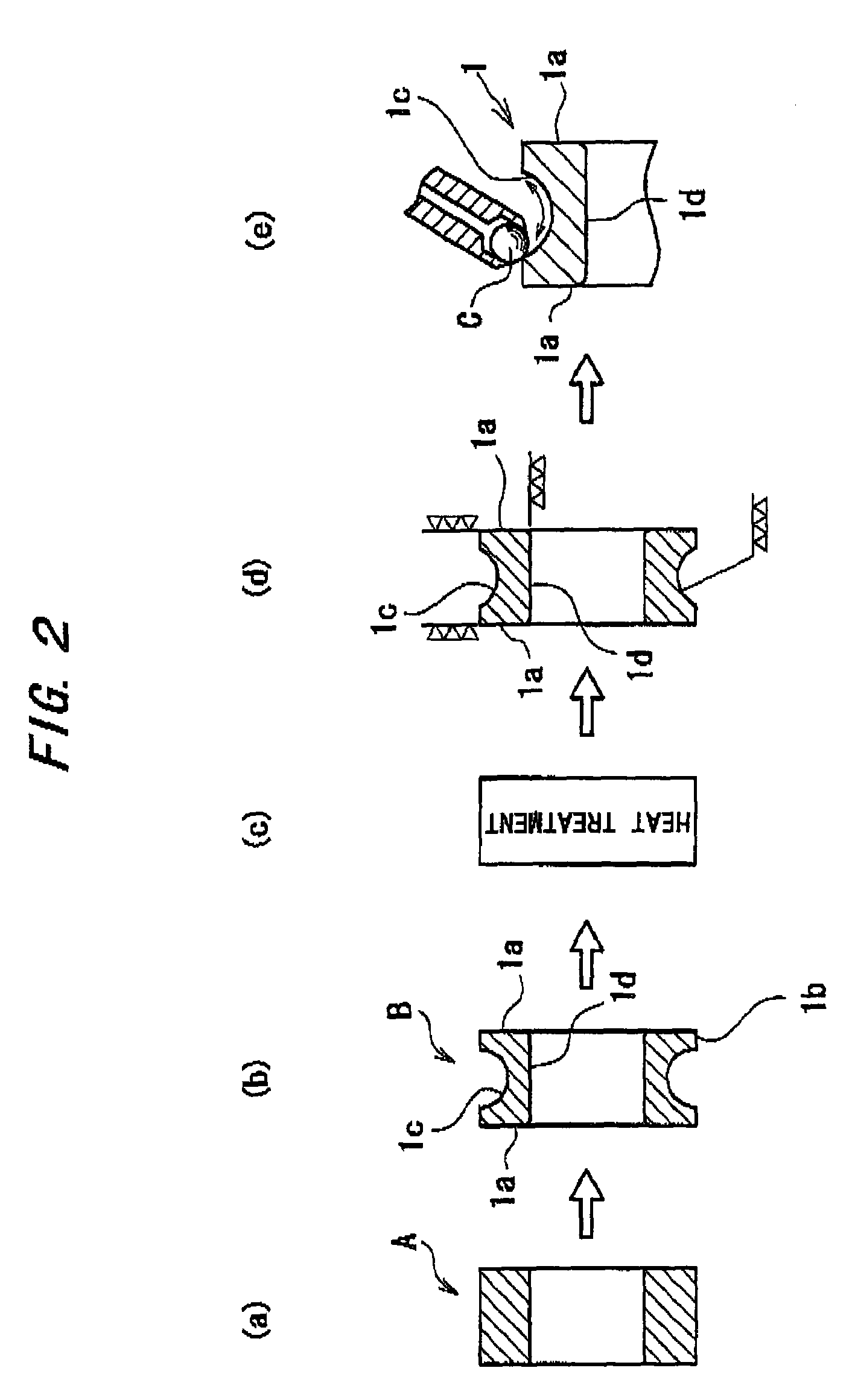

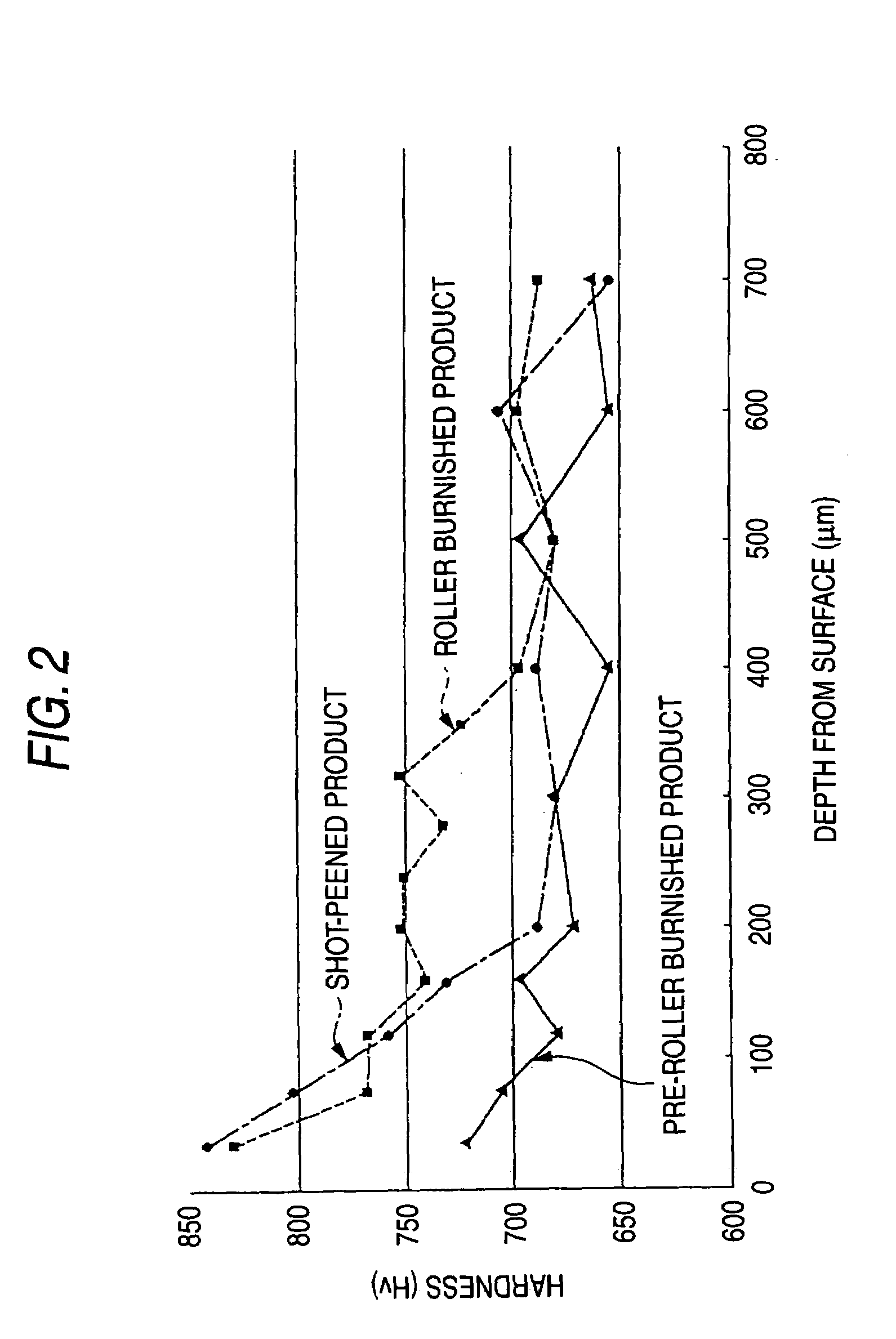

Method for manufacturing a bearing raceway member

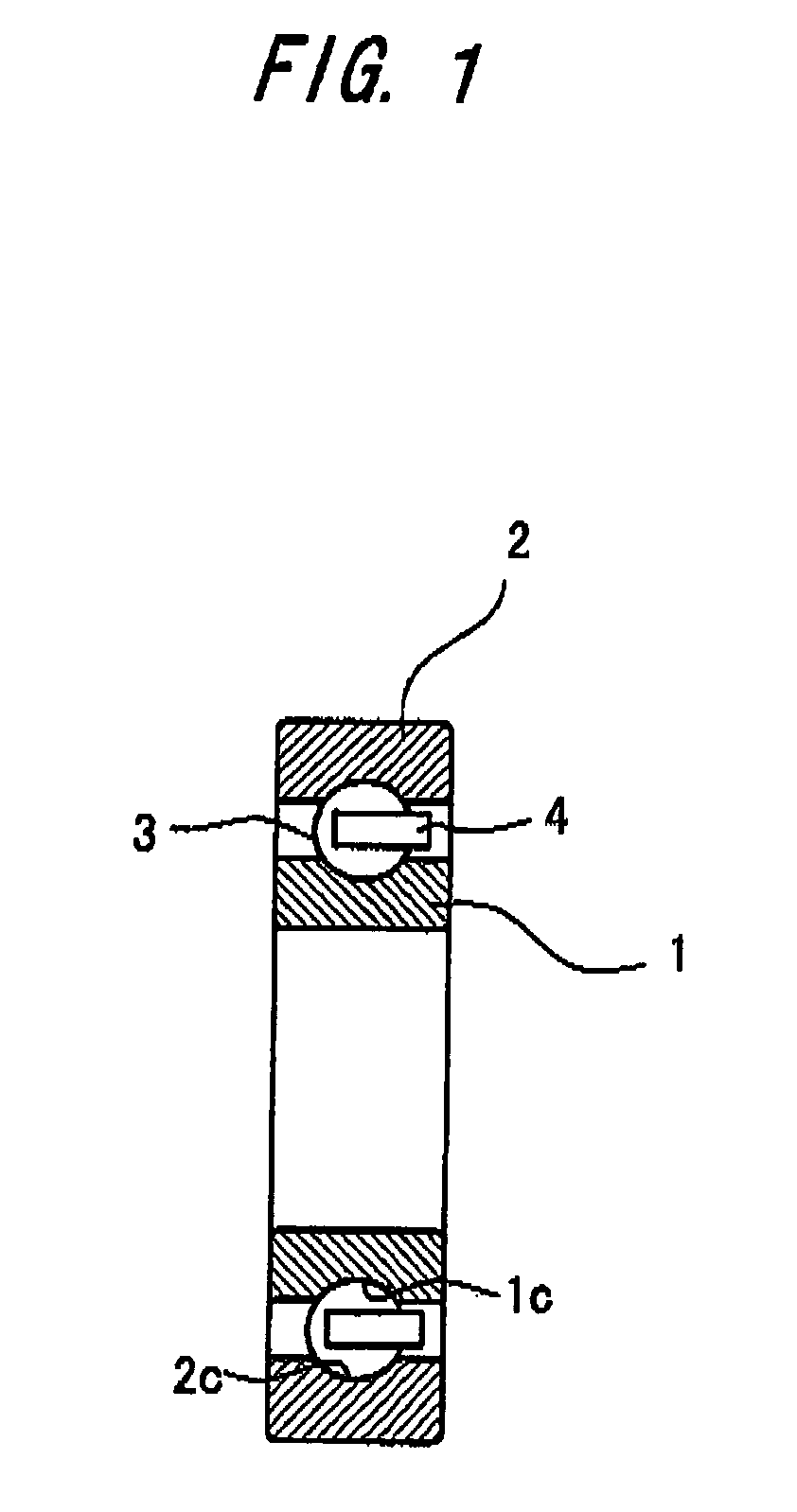

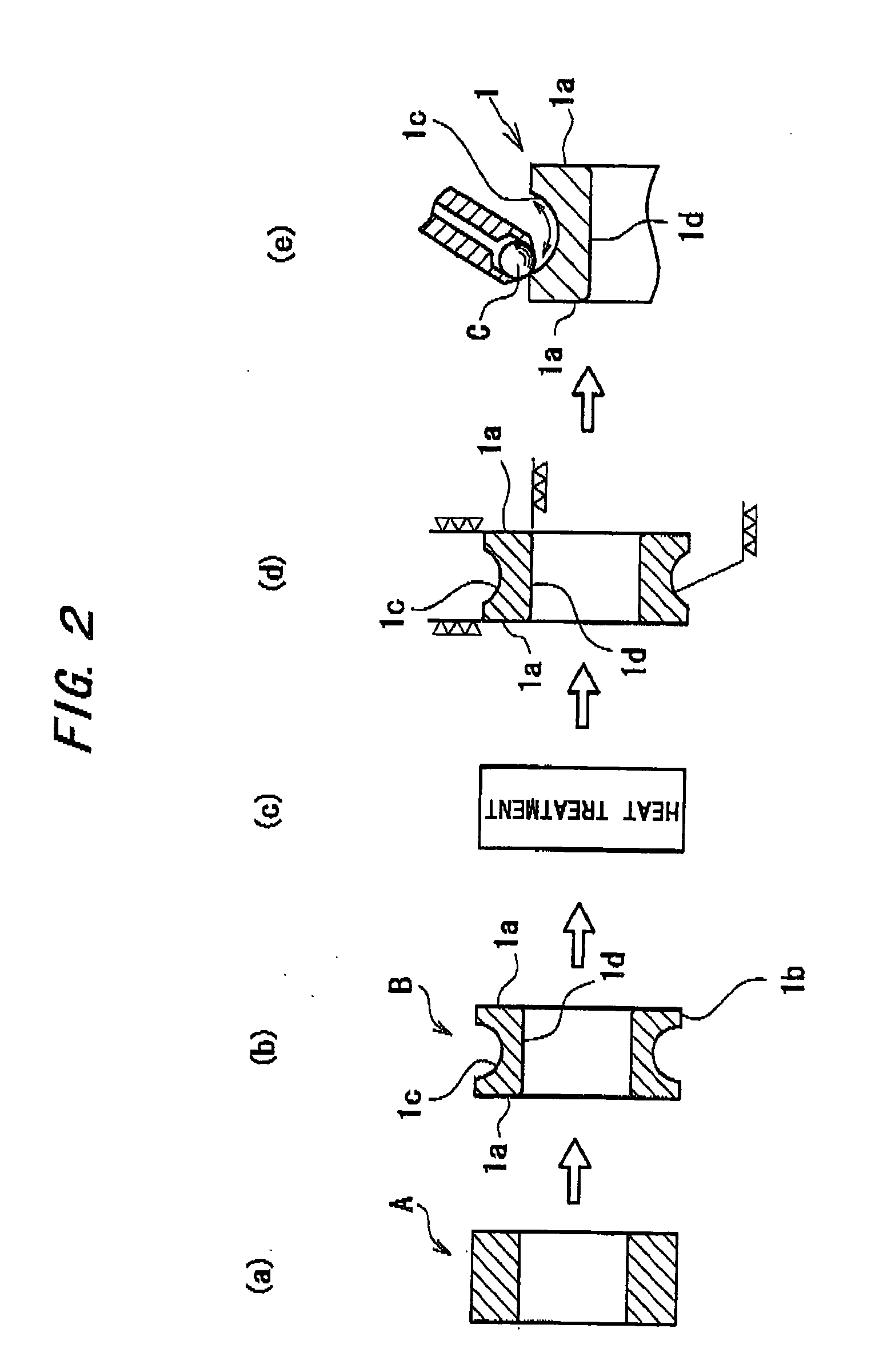

At least a race (1c) of a blank (B) for forming a bearing raceway member is hardened by heating. The race (1c) thus hardened by heating is finished to predetermined precisions. Subsequently, the race (1c) is roller burnished for hardening the race (1c). The blank (B) is formed from a steel for bearing manufacture or a carbon steel for machine structural use. The blank (B) formed from the steel for bearing manufacture is subjected to the roller burnishing, thereby achieving a hardness of HRC65 or more at a surface of the race (1c), and a center-line average roughness Ra of 0.1 μm or less at the surface of the race (1c). The blank (B) formed from the carbon steel for machine structural use is hardened by the roller burnishing, thereby achieving a hardness of Hv800 or more at depth of at least 0.2 mm from a surface of the race (1c). Where cutting by turning is adopted as the finishing process, the surface of the race (1c) is finished to a center-line average roughness Ra of 0.35 μm or more and then the race (1c) is subjected to the roller burnishing, thereby achieving a center-line average roughness Ra of 0.25 μm or less and a compressive residual stress of 1000 MPa or more at depth of at least 0.2 mm from the surface thereof. Where cutting by turning or grinding is adopted as the finishing process, the race (1c) is subjected to the roller burnishing, thereby achieving a center-line average roughness Ra of 0.15 μm or less at the surface thereof and a compressive residual stress of 1000 MPa or more at depth of at least 0.2 mm form the surface thereof.

Owner:JTEKT CORP

Method of Manufacturing Cam Shaft, Cam Shaft, and Cam Lobe Material Used in the Same

InactiveUS20080276753A1Expand allowanceReduce wall thicknessCamsValve drivesMetallurgyDegrees of freedom

A method of manufacturing a cam shaft that prevents cracks during the joining of a cam lobe to a shaft, and improves the degree of freedom of design of the cam lobe is provided.By a method of manufacturing a cam shaft that after an inner circumferential surface 13 of a cam lobe 1 is subjected to treatment for residual compressive stress addition treatment, the cam lob 1 is joined to a shaft, above problem is solved. It is preferred that the residual compressive stress on the inner circumferential surface 13 of the cam lobe 1 is not less than 100 MPa. In addition, an outer peripheral surface 14 of the cam lobe 1 can be also subjected to treatment for residual compressive stress addition treatment. As the treatment for residual compressive stress addition treatment, shot-peening treatment, induction hardening treatment, barrel polishing treatment, carburizing and quenching treatment or carbonitriding treatment is performed.

Owner:NIPPON PISTONRING CO LTD

Color ink-jet print paper and its producing method

InactiveCN1458337AImprove surface strengthPrint with rich and vivid colorsNon-fibrous pulp additionSulfatePulp and paper industry

The color ink-jetting print paper is produced with bleached sulfate needle leaved wood pulp, mechanical milled Italian poplar, bleached sulfate reel pulp or bleached broadleaf wood pulp and proper supplementary material and through making base paper, applying AKD glue, painting special paint, soft roller burnishing and finishing. The color ink-jetting print paper product has areal weight 70-100 g / sq m, black light density not lower than 1.2, drying time less than 20 s, color optical density not lower than 0.75, ink water dispersing time not less than 60 s, and whiteness higher than 88 %. Ithas high surface strength, and is level and smooth and results in images with bright color and clear netted points. It is suitable for color jetting printing.

Owner:YUEYANG FOREST & PAPER CO LTD

Method for manufacturing a bearing raceway member

At least a race (1c) of a blank (B) for forming a bearing raceway member is hardened by heating and is finished to predetermined precisions. Subsequently, the race (1c) is roller burnished for additional hardening. The blank (B) is formed from a steel for bearing manufacture and is subjected to the roller burnishing, thereby achieving a hardness of HRC65 or more at a surface of the race (1c), and a center-line average roughness Ra of 0.1 μm or less at the surface of the race (1c) and achieving a hardness of HRC60 or more at the depth of at least 0.2 mm from the surface of (1c).

Owner:JTEKT CORP

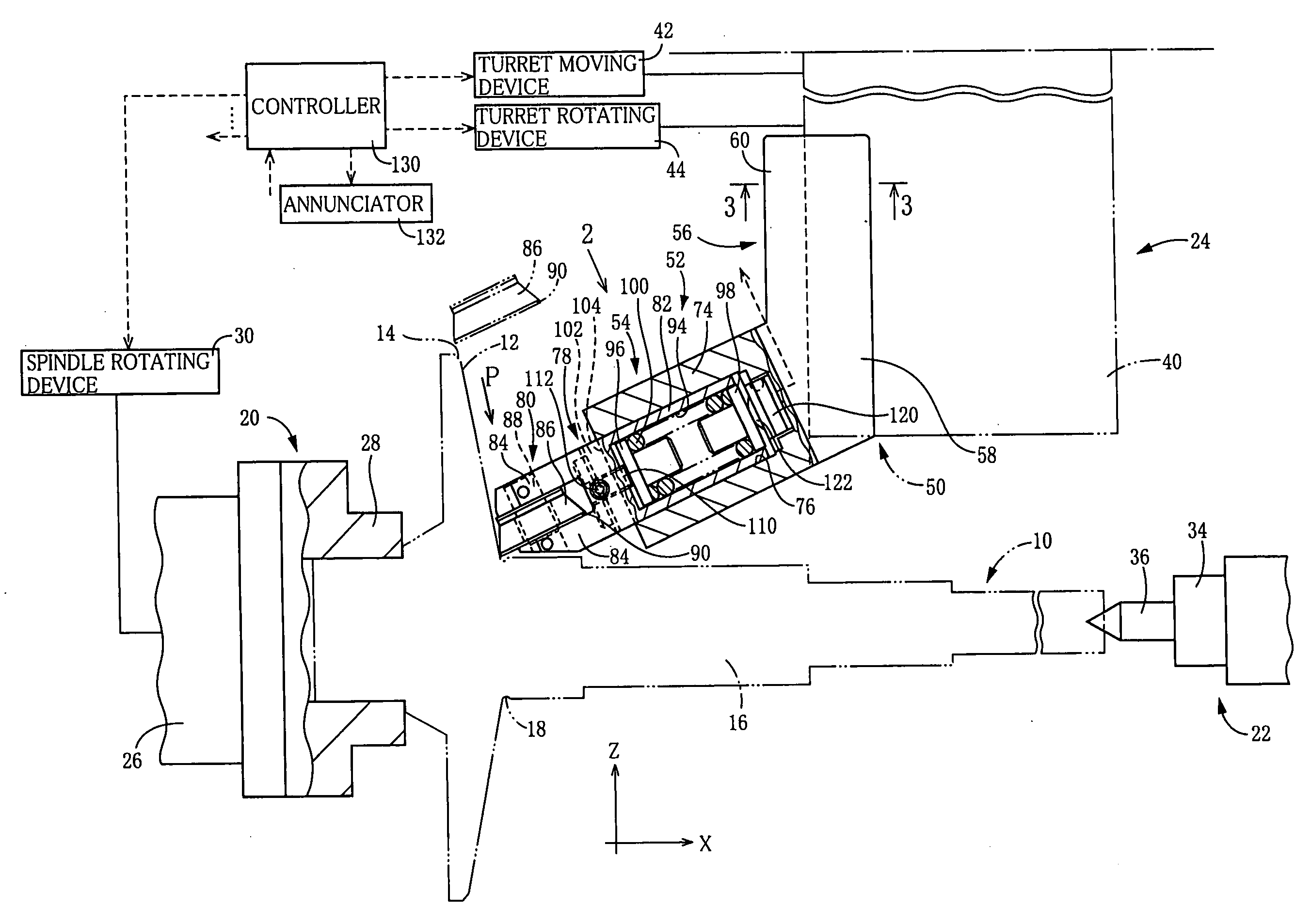

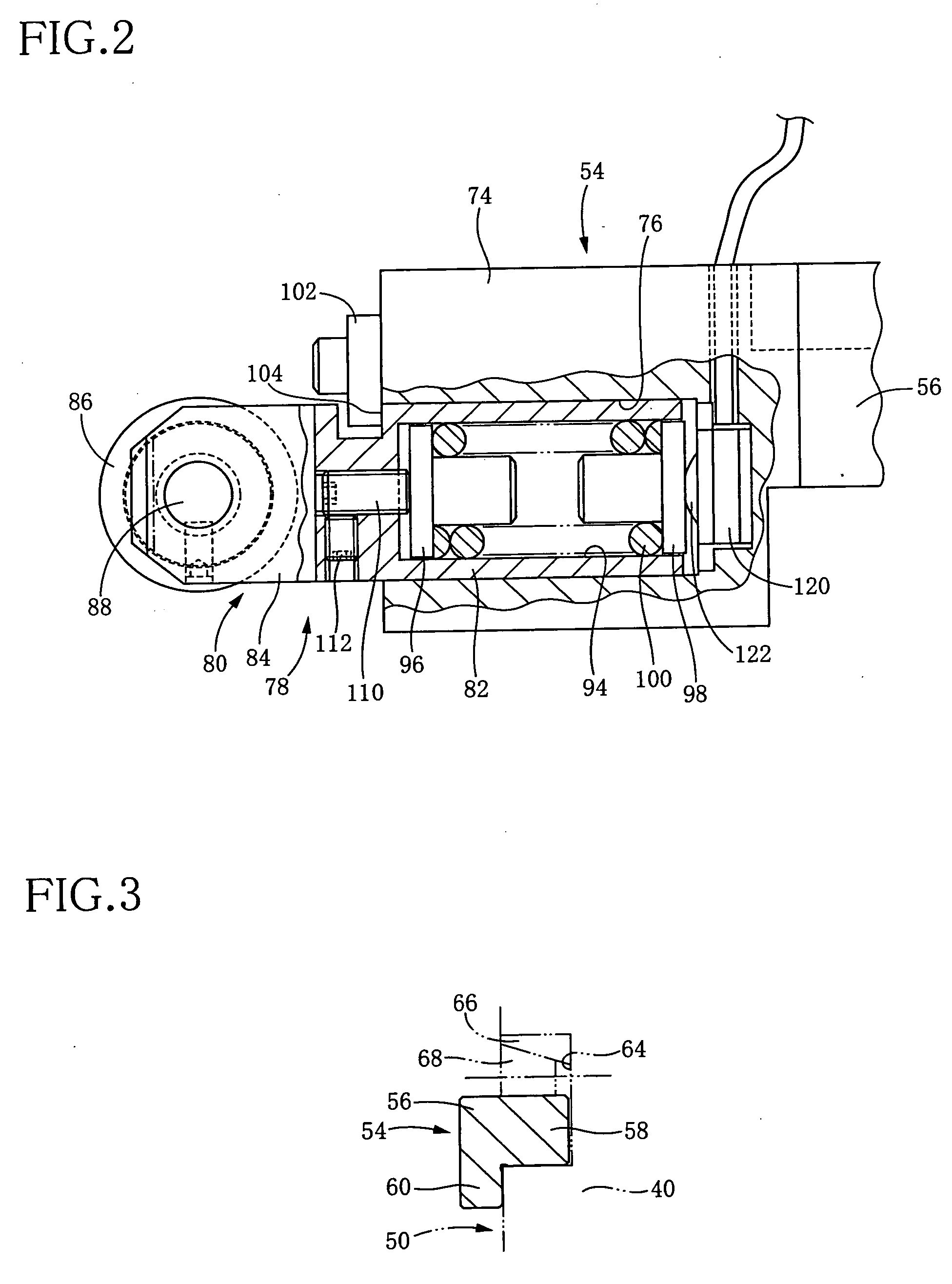

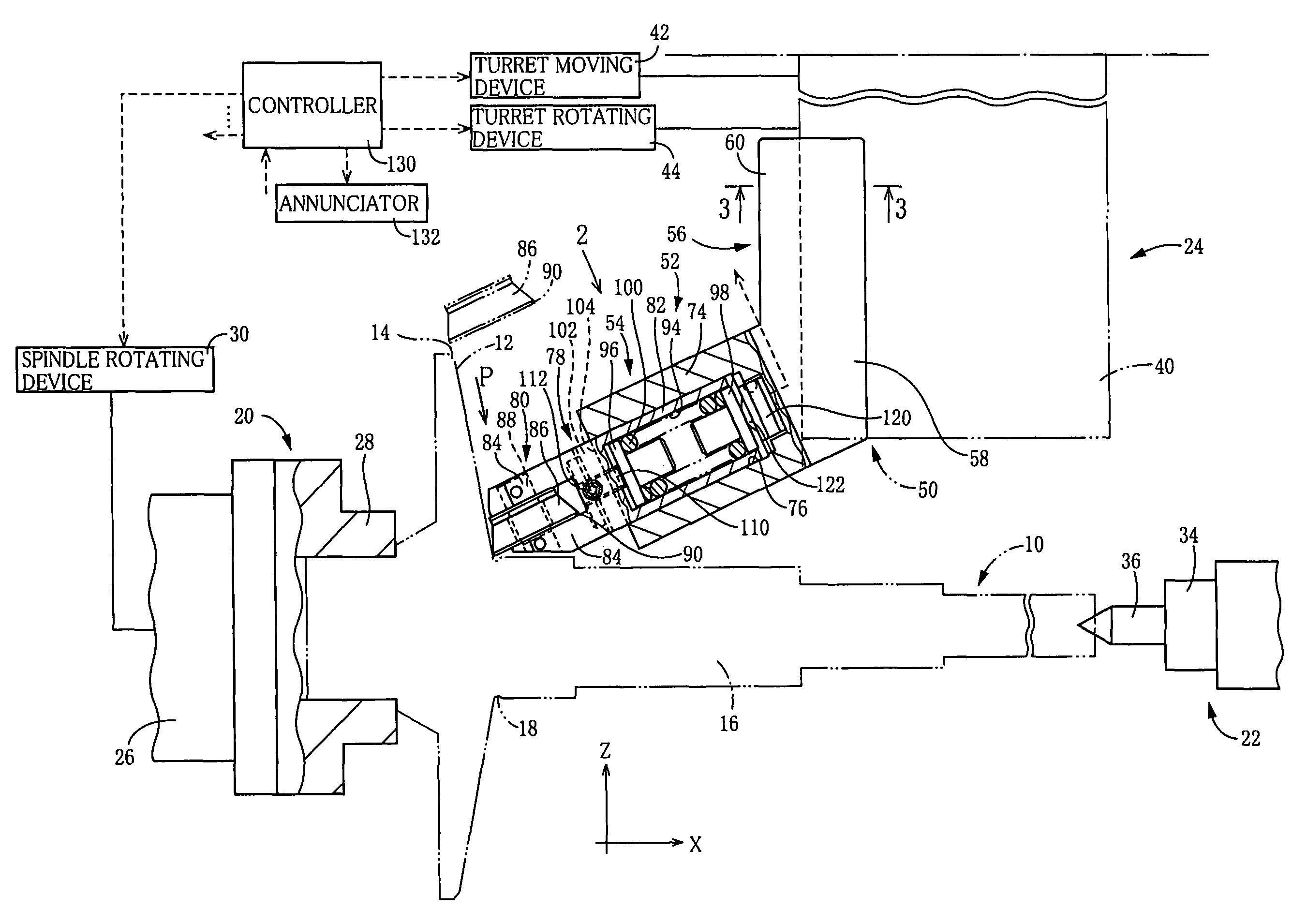

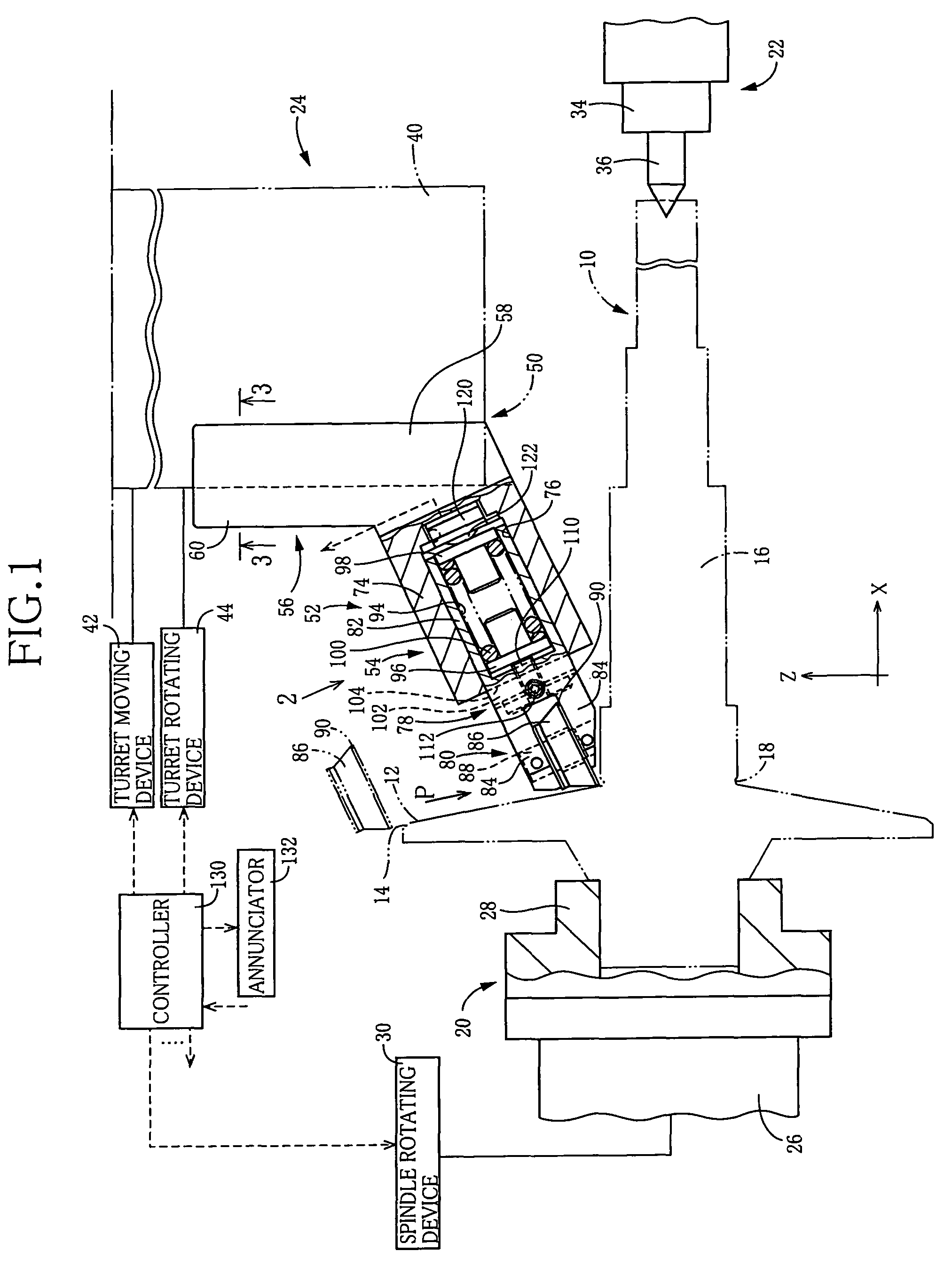

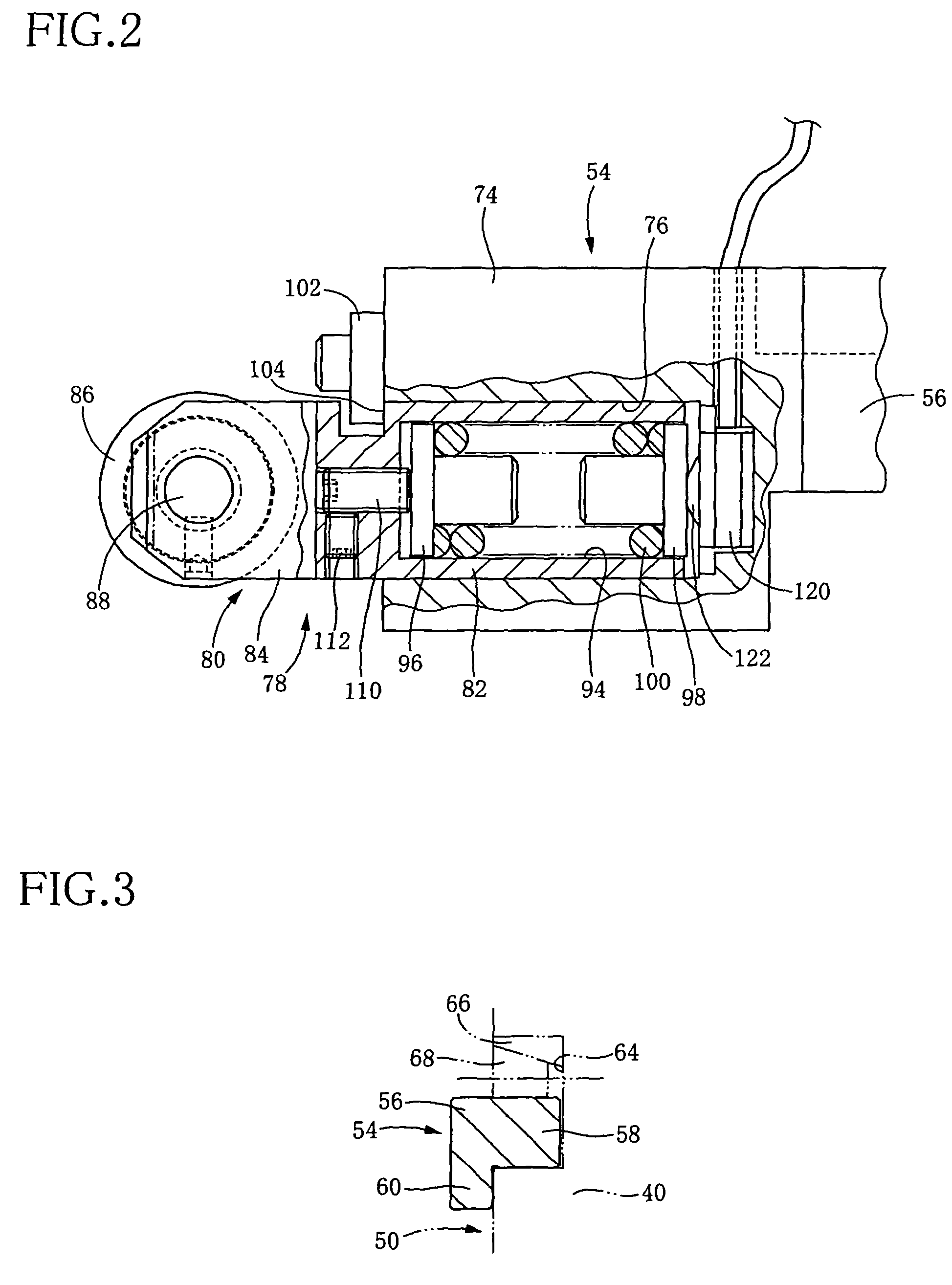

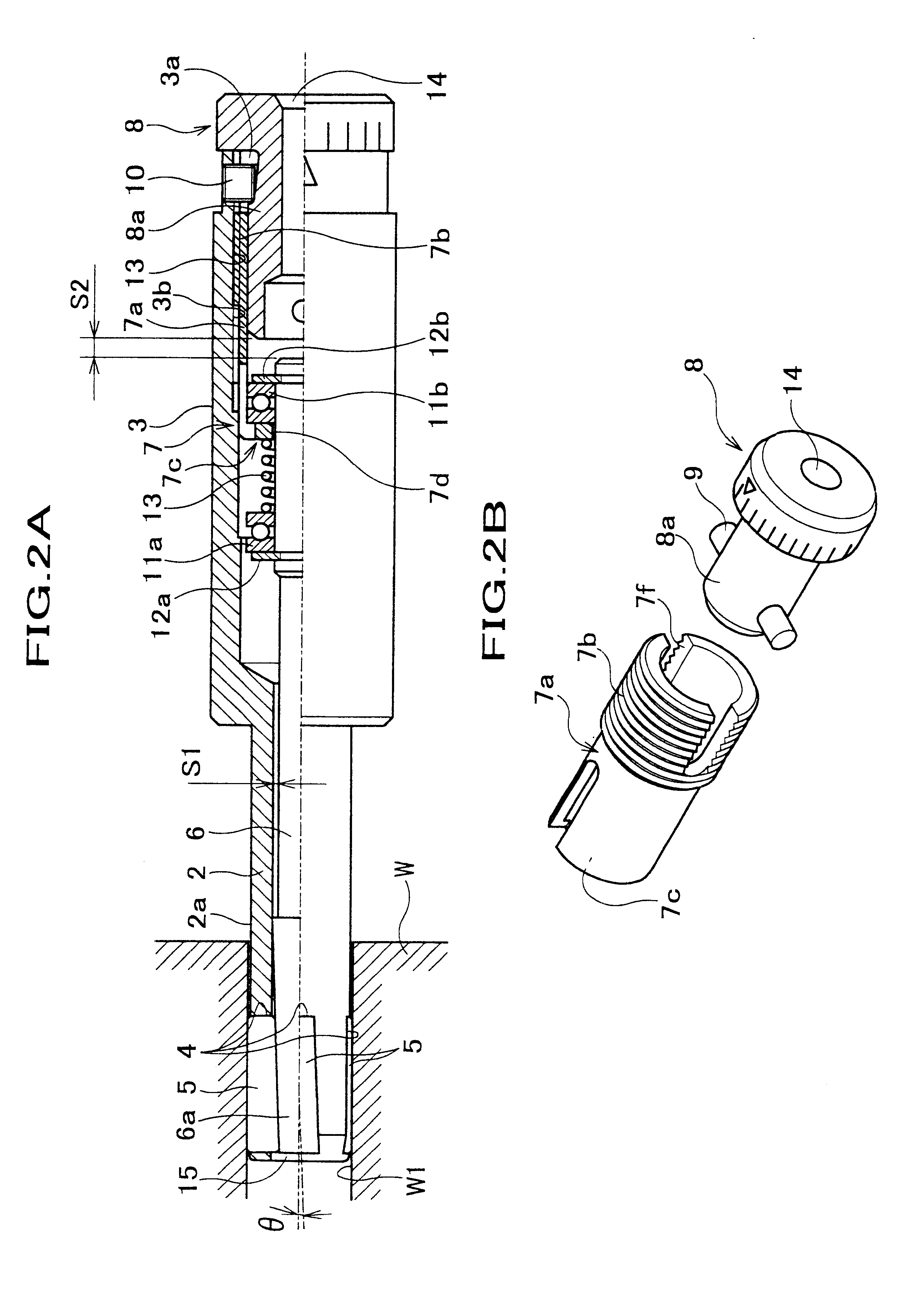

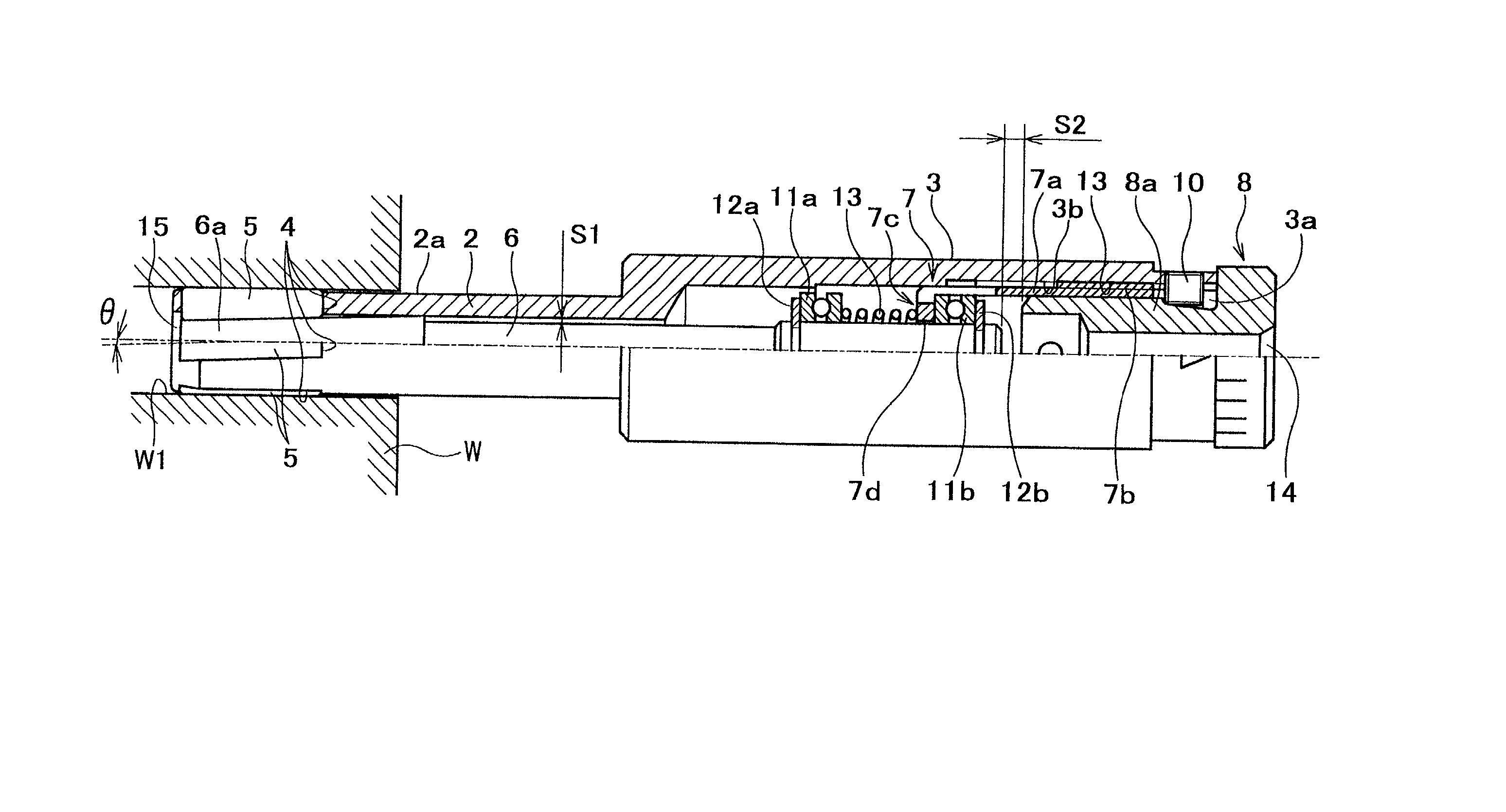

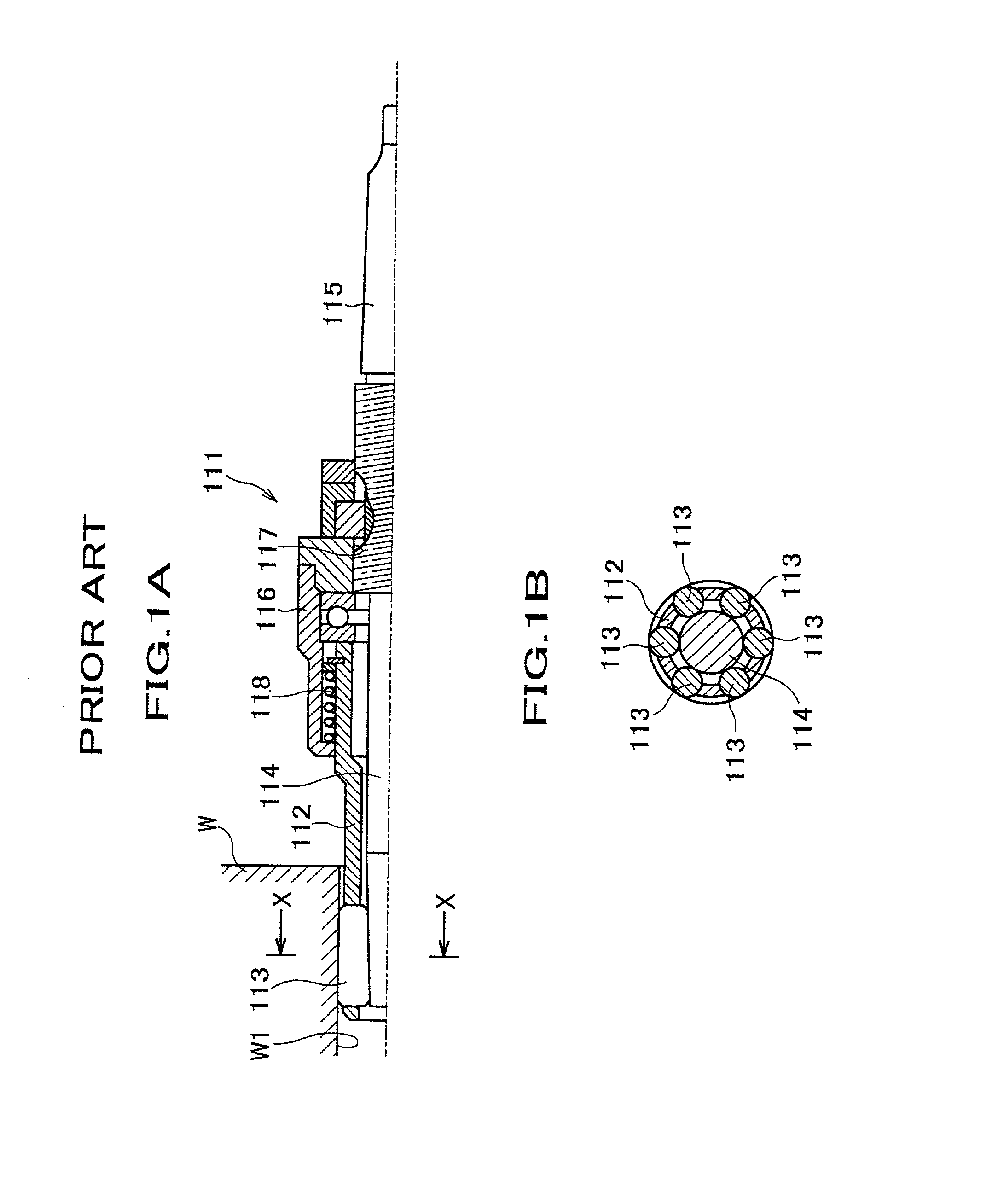

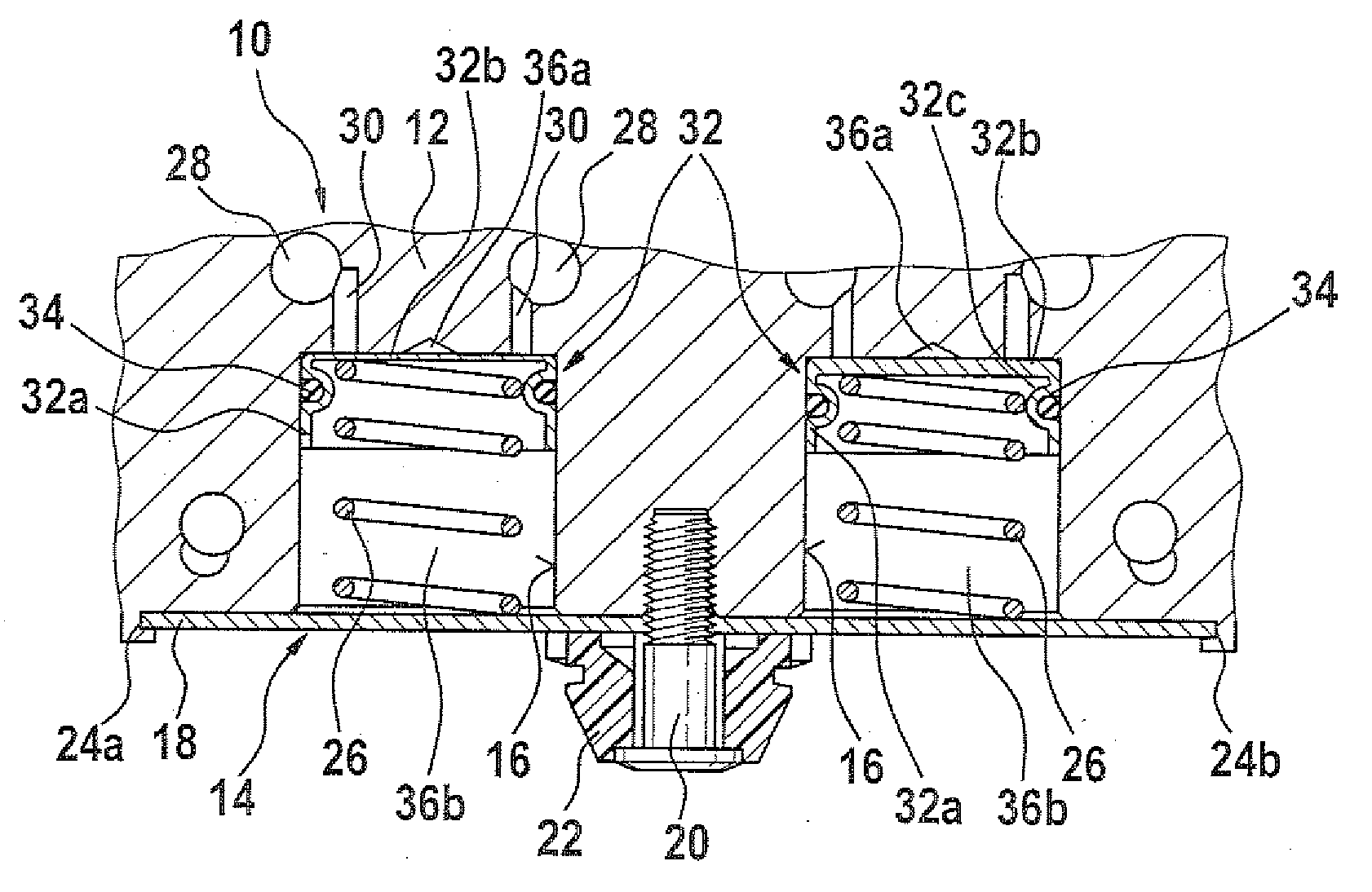

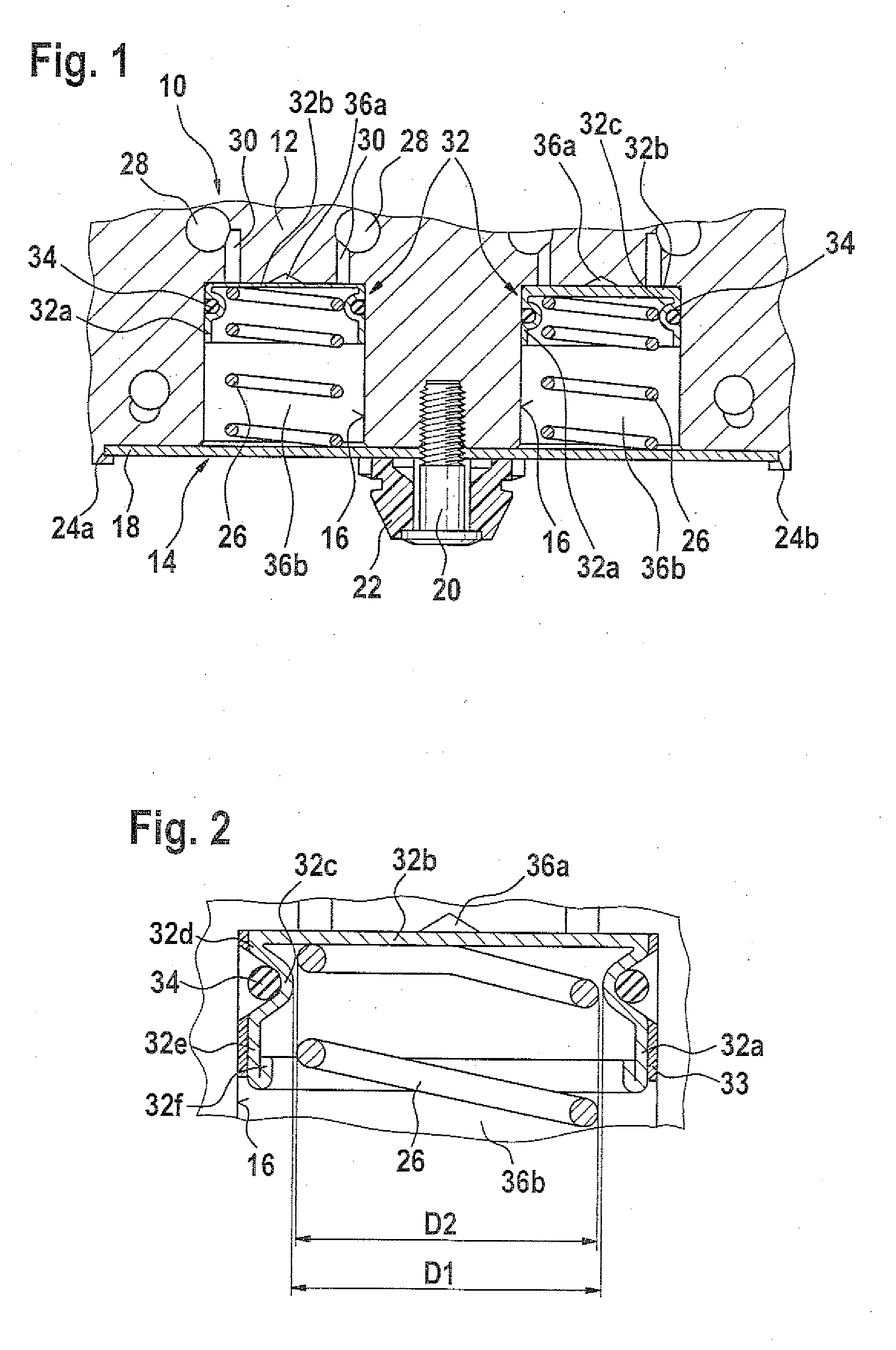

Roller burnishing apparatus with pressing-force detecting device

InactiveUS20090106961A1Improve fatigue strengthPressing forceGrinding feed controlBurnishing machinesEngineeringMechanical engineering

There is disclosed a roller burnishing apparatus including a first member moved relative to an object to be burnished, a second member movable relative to the first member in a relative movement direction, a burnishing roller held by the second member such that the burnishing roller is rotatable, a biasing device which biases with a biasing force the second member relative to the first member in one of two opposite directions along the relative movement direction, and a pressing-force detecting device that detects a pressing force with which the burnishing roller is pressed against the object and which is based on the biasing force of the biasing device.

Owner:NISSAN MOTOR CO LTD +1

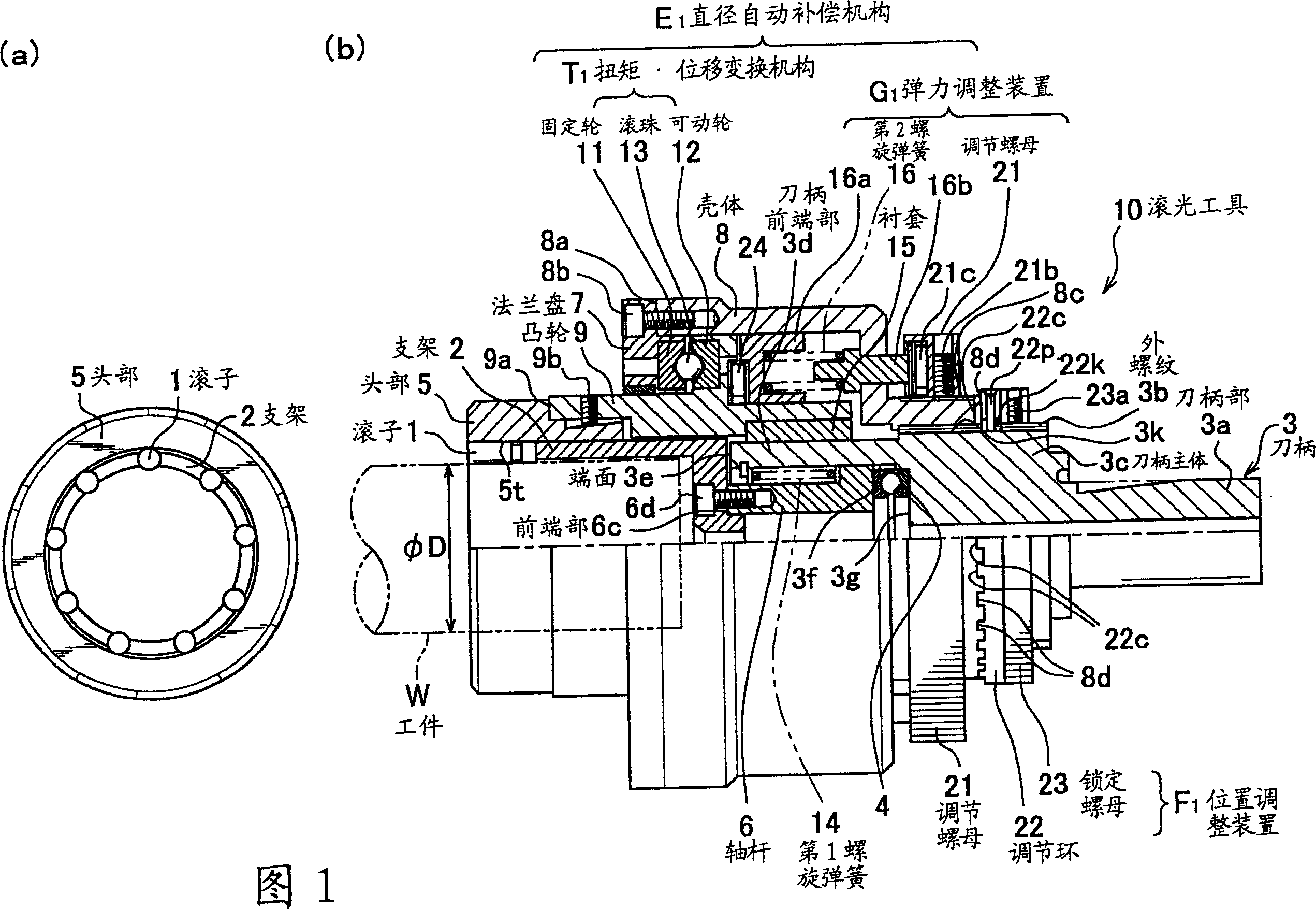

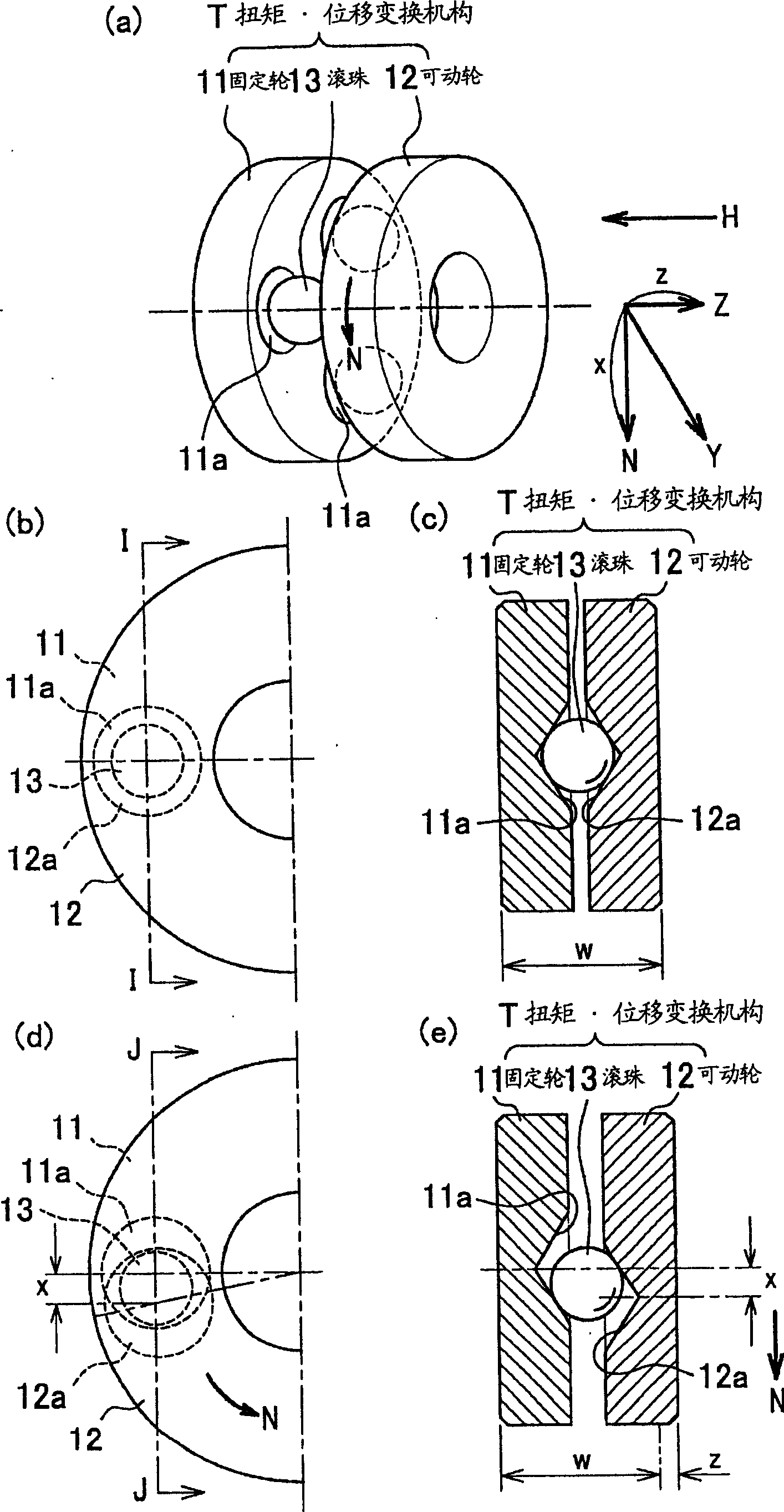

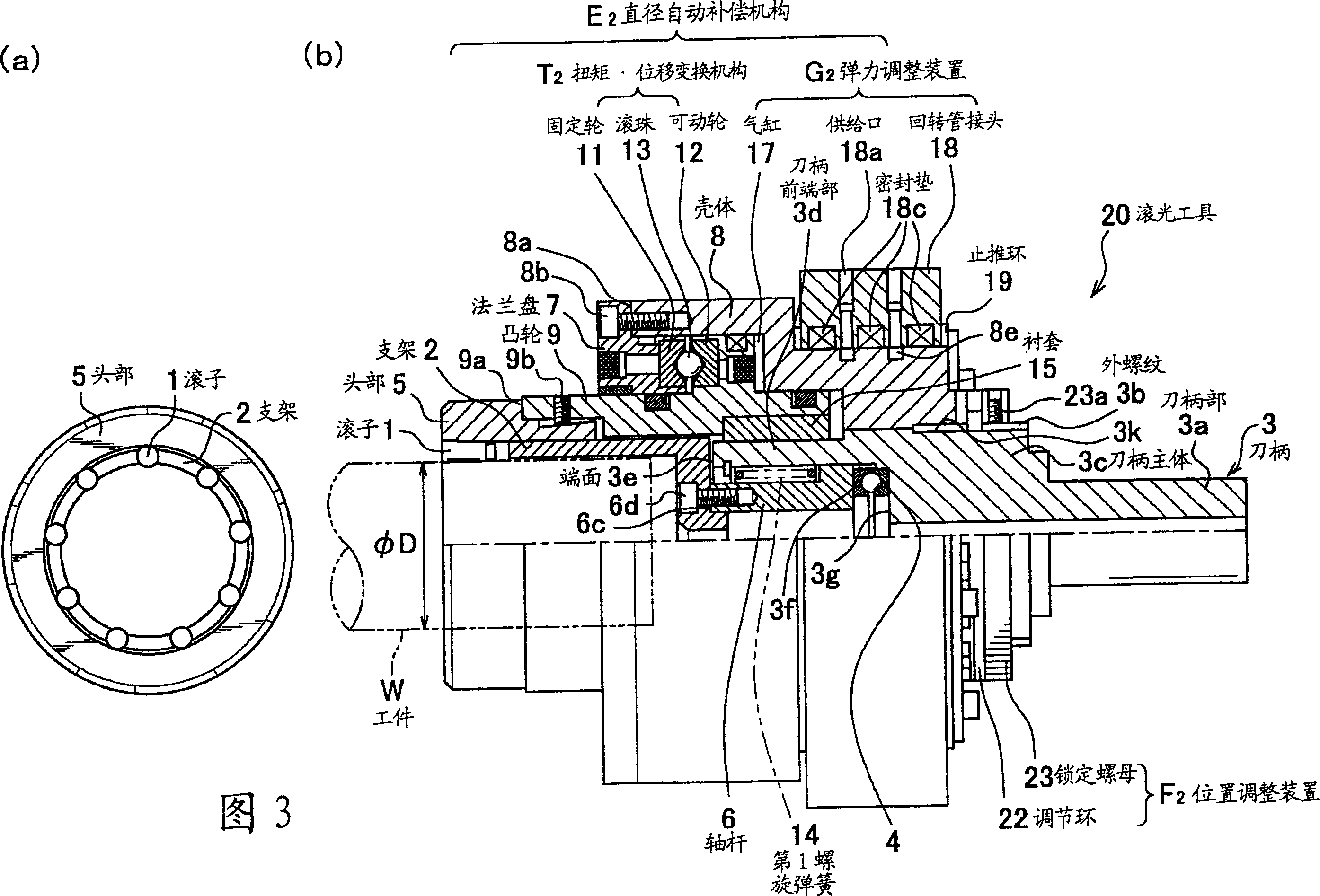

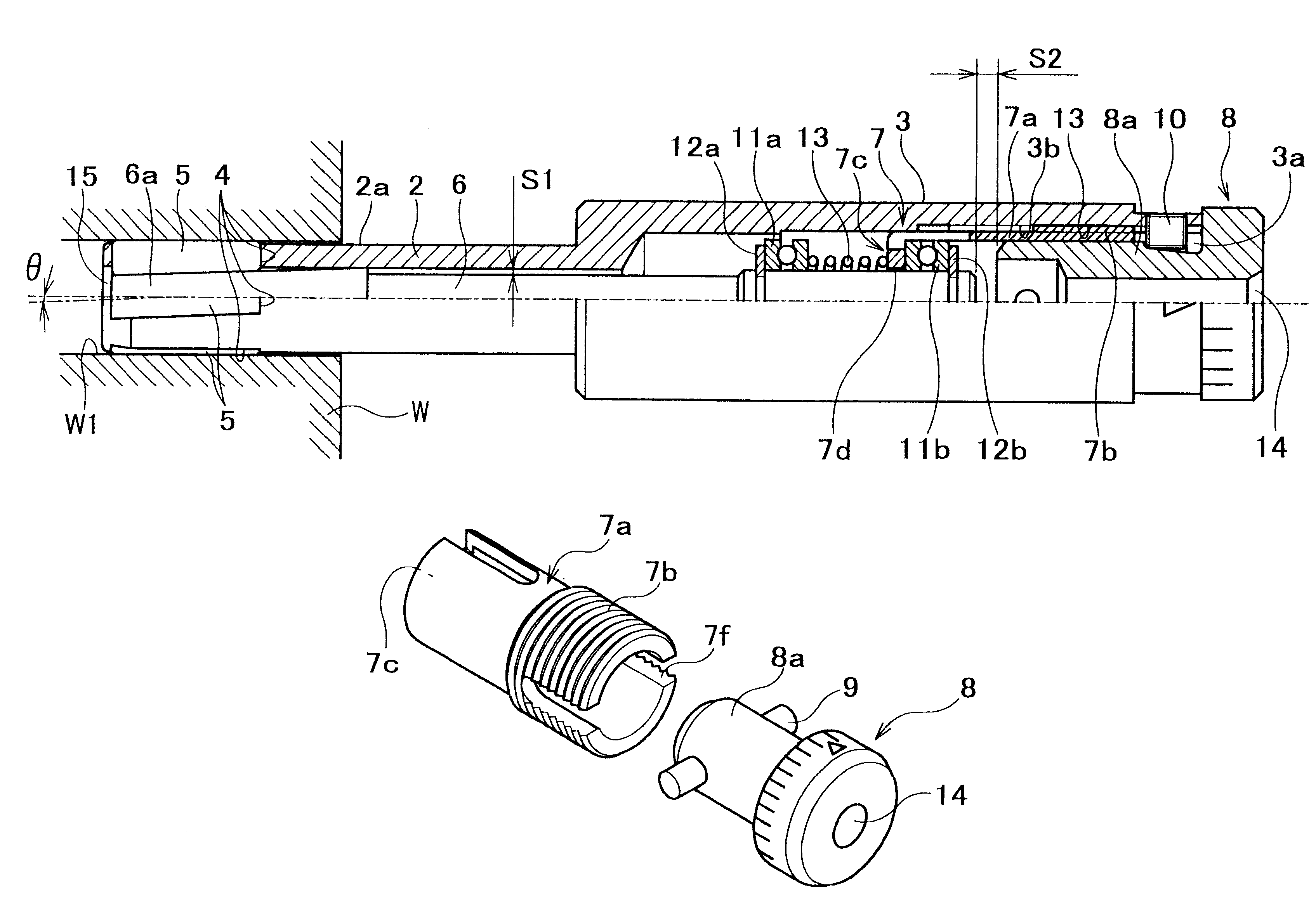

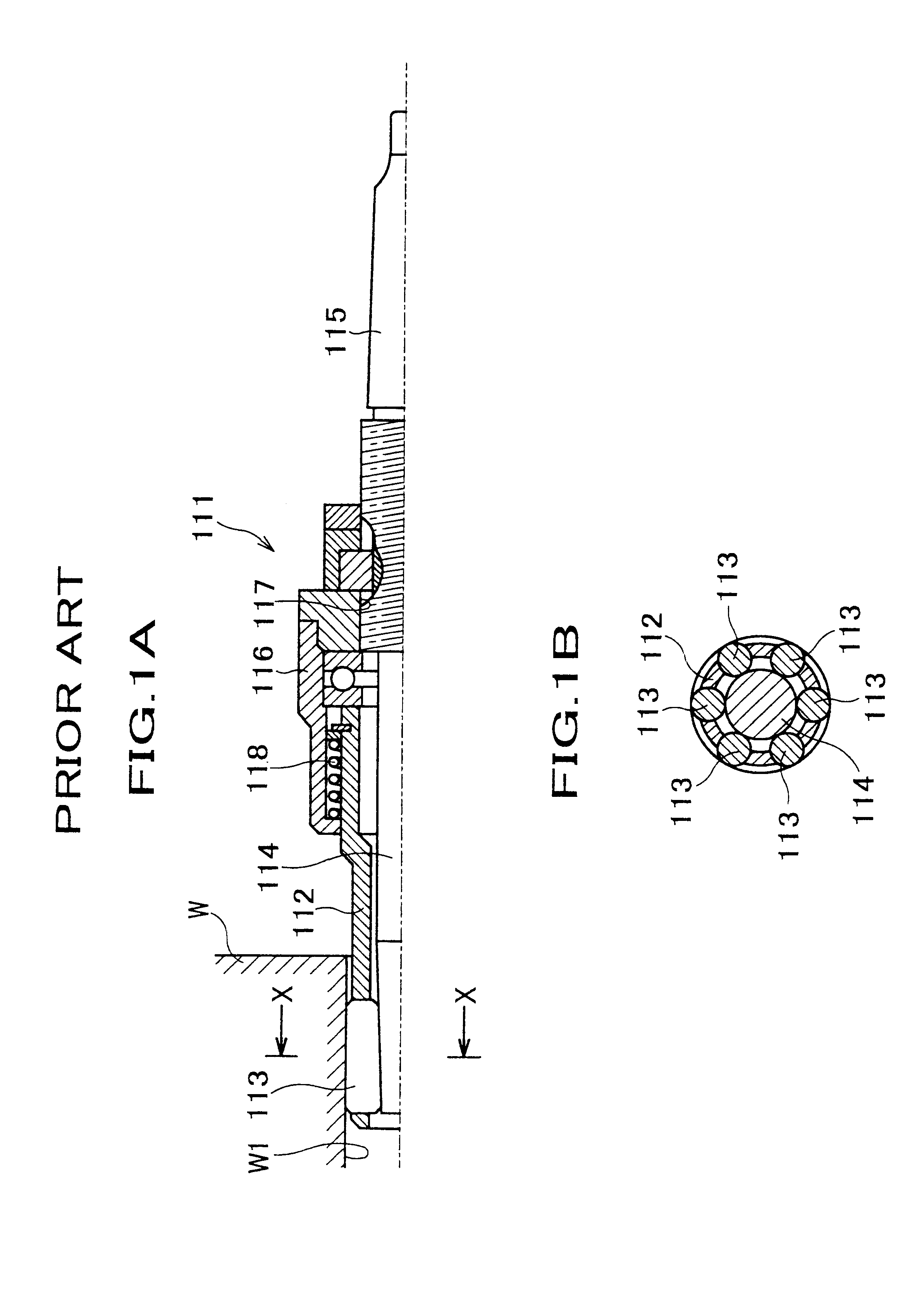

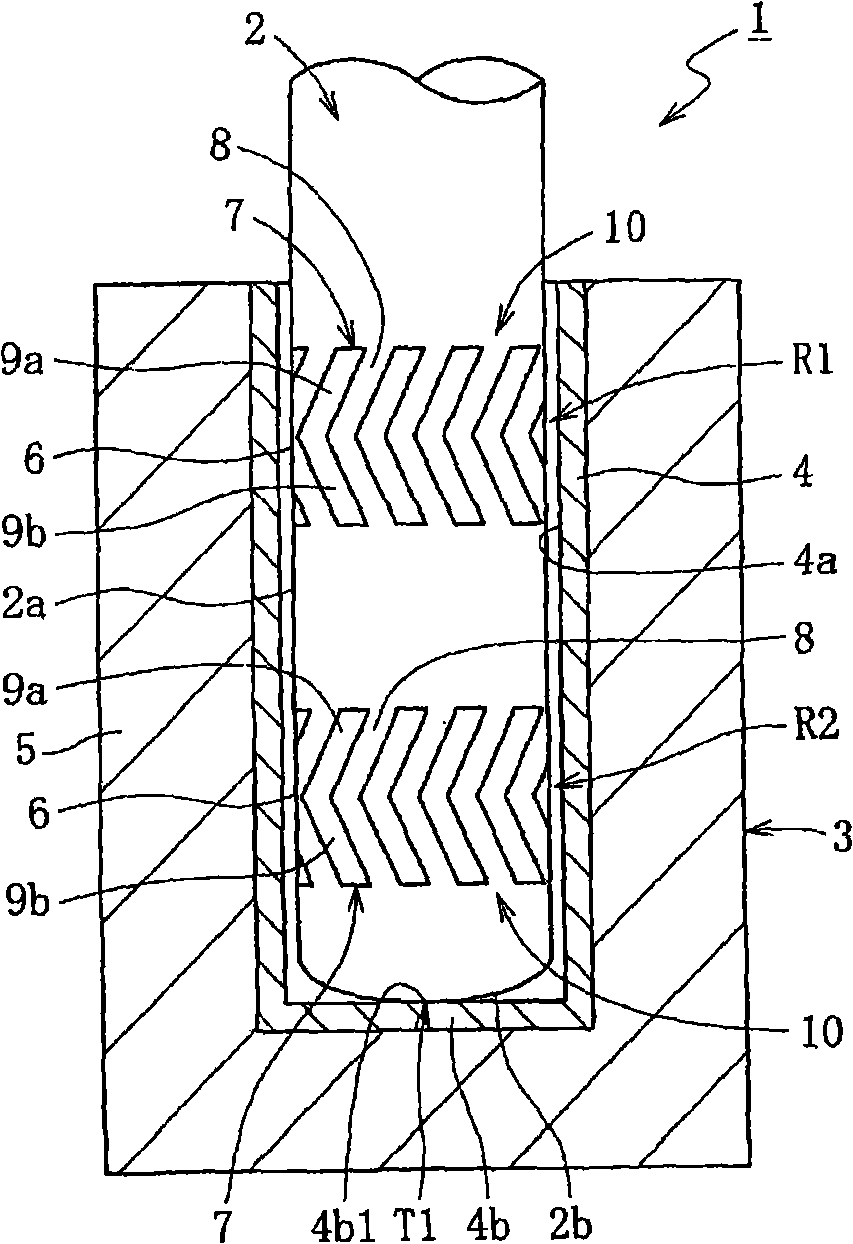

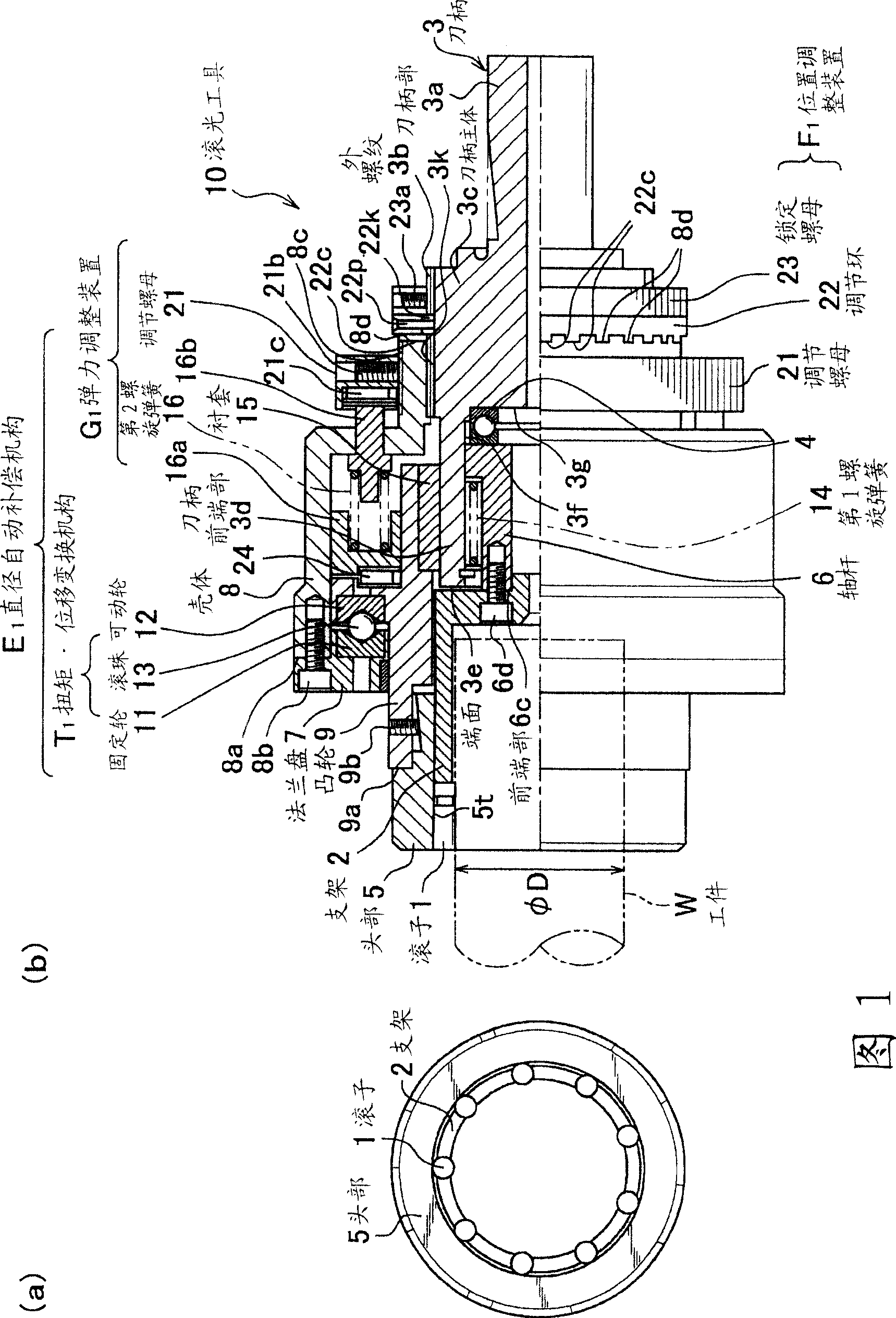

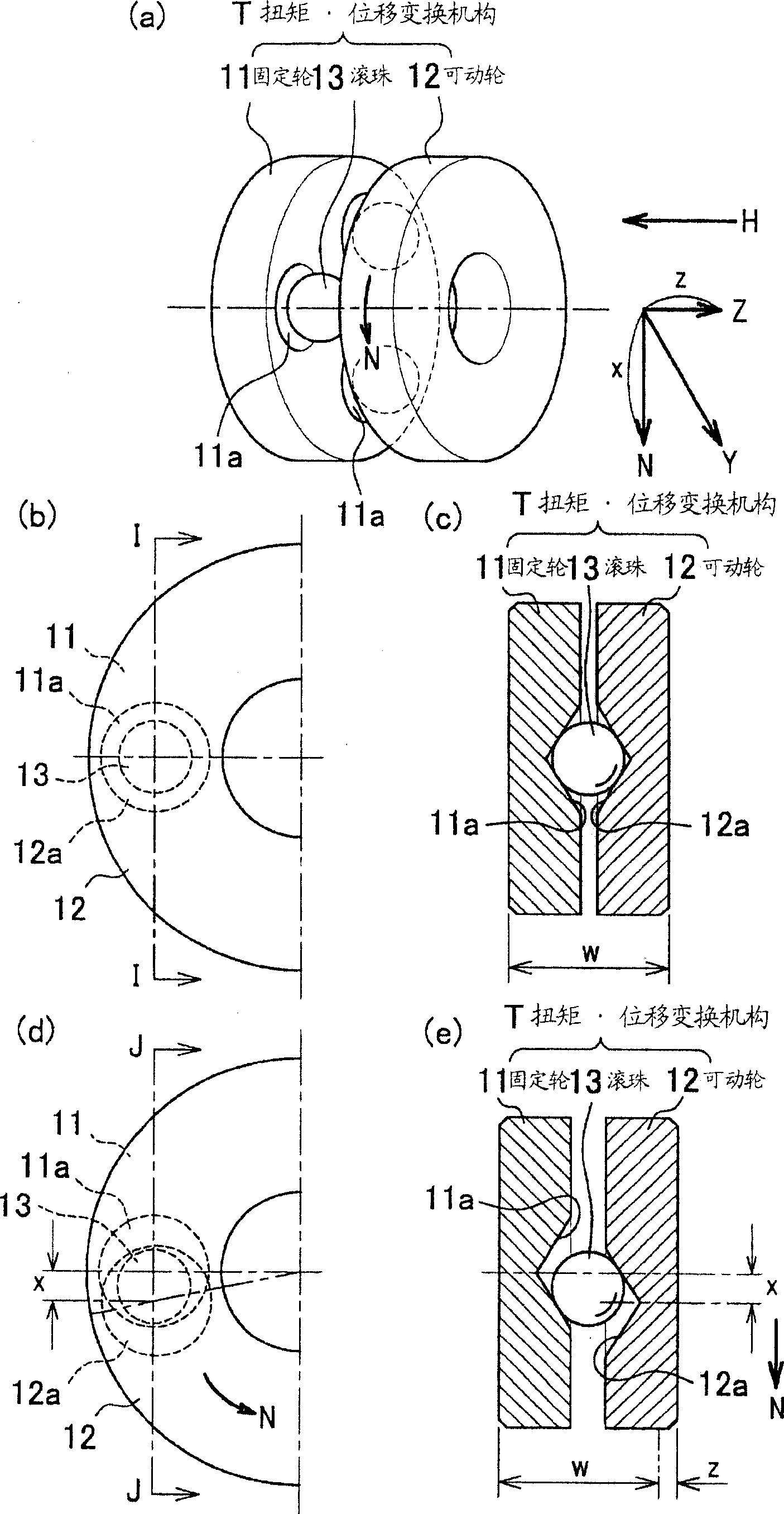

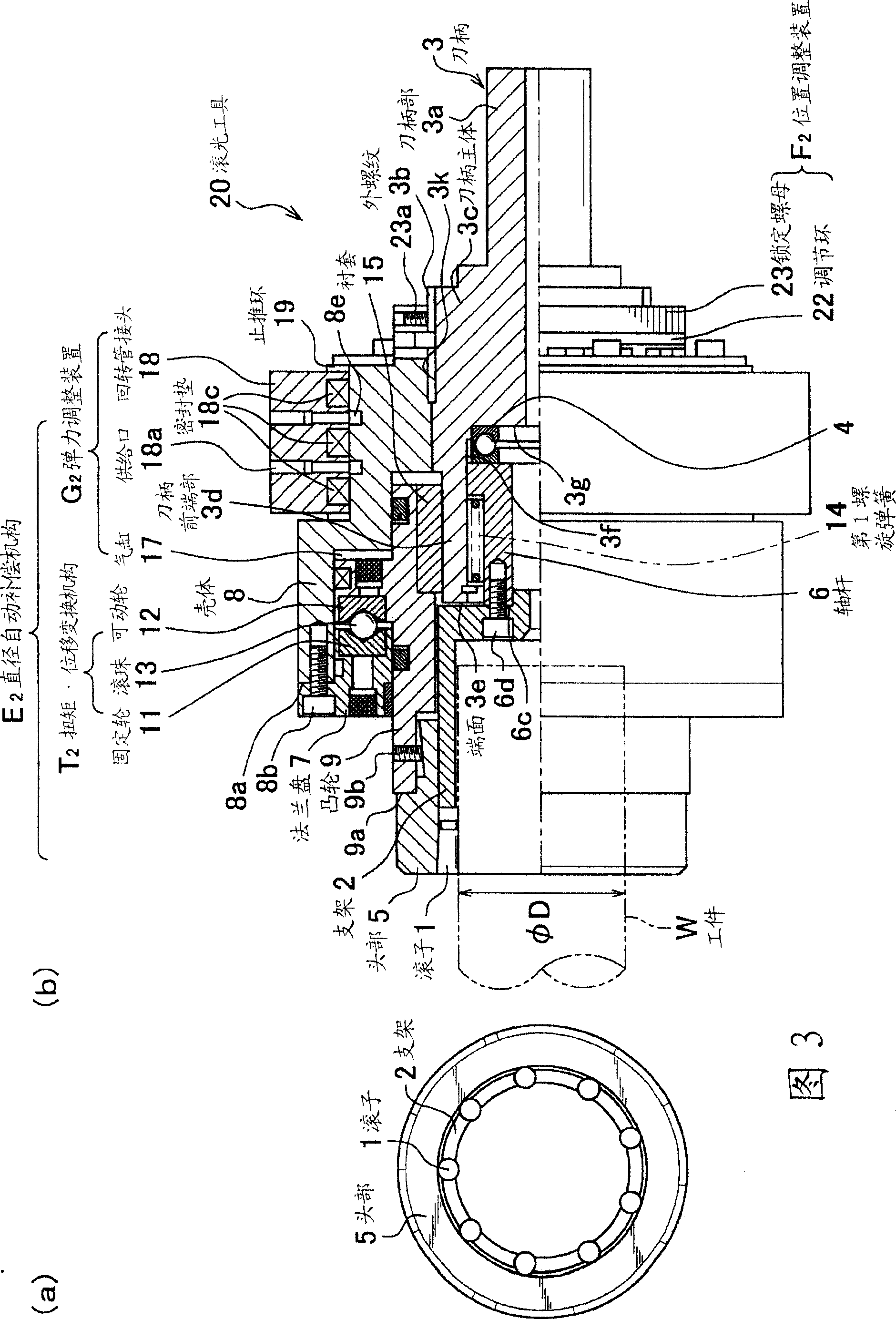

Barrel burnishing tool

ActiveCN1721136ALow costNo loss of elasticityPolishing machinesBurnishing machinesAxial displacementLoad torque

The invention provides a roller burnishing tool, accurately converting very small torque displacement to axial displacement, coping with a variation in pre-working diameter, causing no setting in spite of repeated use, and causing no change in a no-load position (original position). In this roller burnishing tool (10), a workpiece is inserted in a cylindrical frame (2) provided with a plurality of rollers (1) disposed for rolling compaction to perform rolling compaction working for the outer peripheral surface of the workpiece by the rollers. The roller burnishing tool (10)includes an automatic diameter correcting mechanism (E), in which the mechanism is provided with a torque converting mechanism (T) for converting the load torque received by the rollers to the axial displacement in pressing the outer peripheral surface of the workpiece by the rollers (1), thereby automatically correcting the diameter even if the pre-working dimension varies.

Owner:SUGINO MACHINE

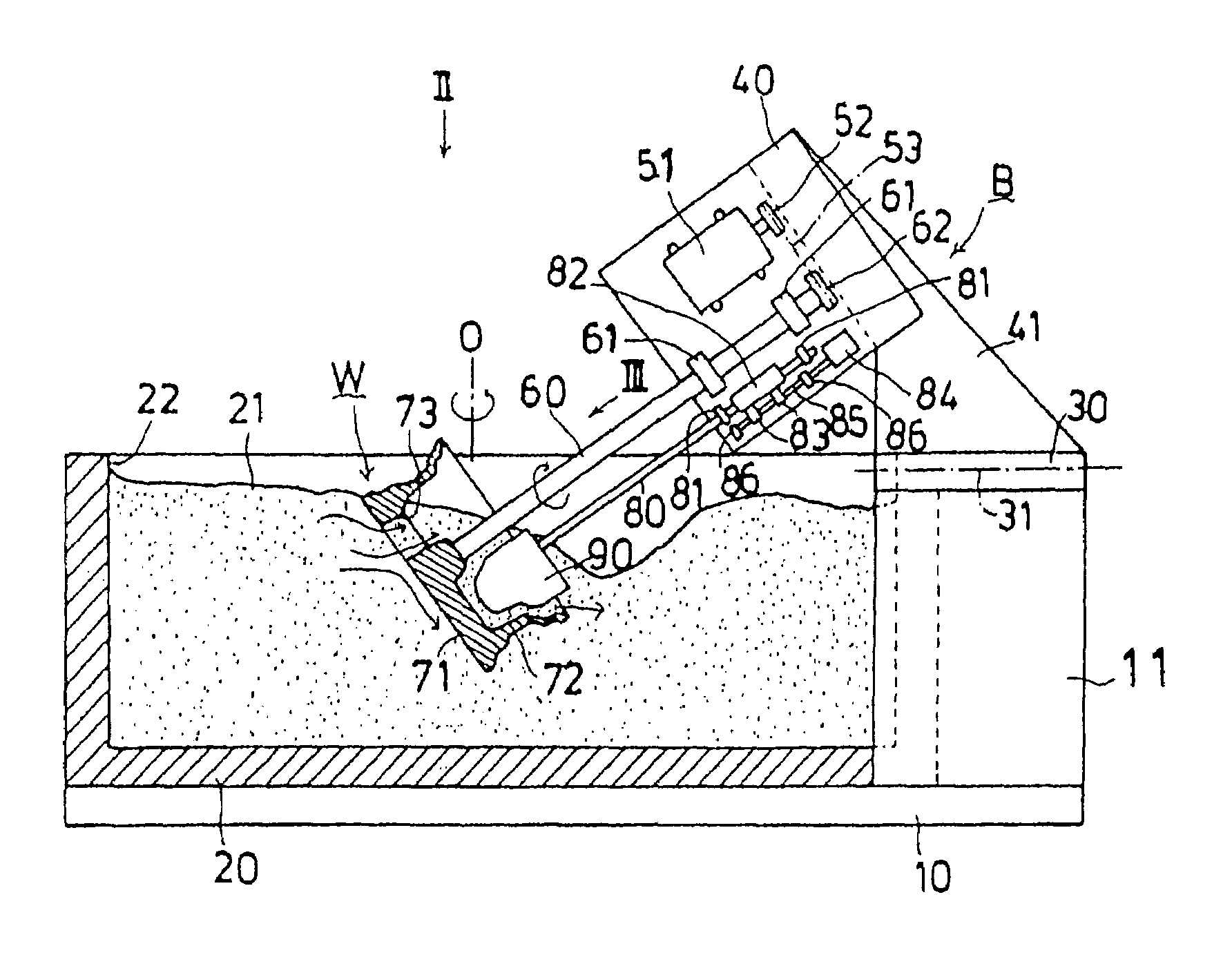

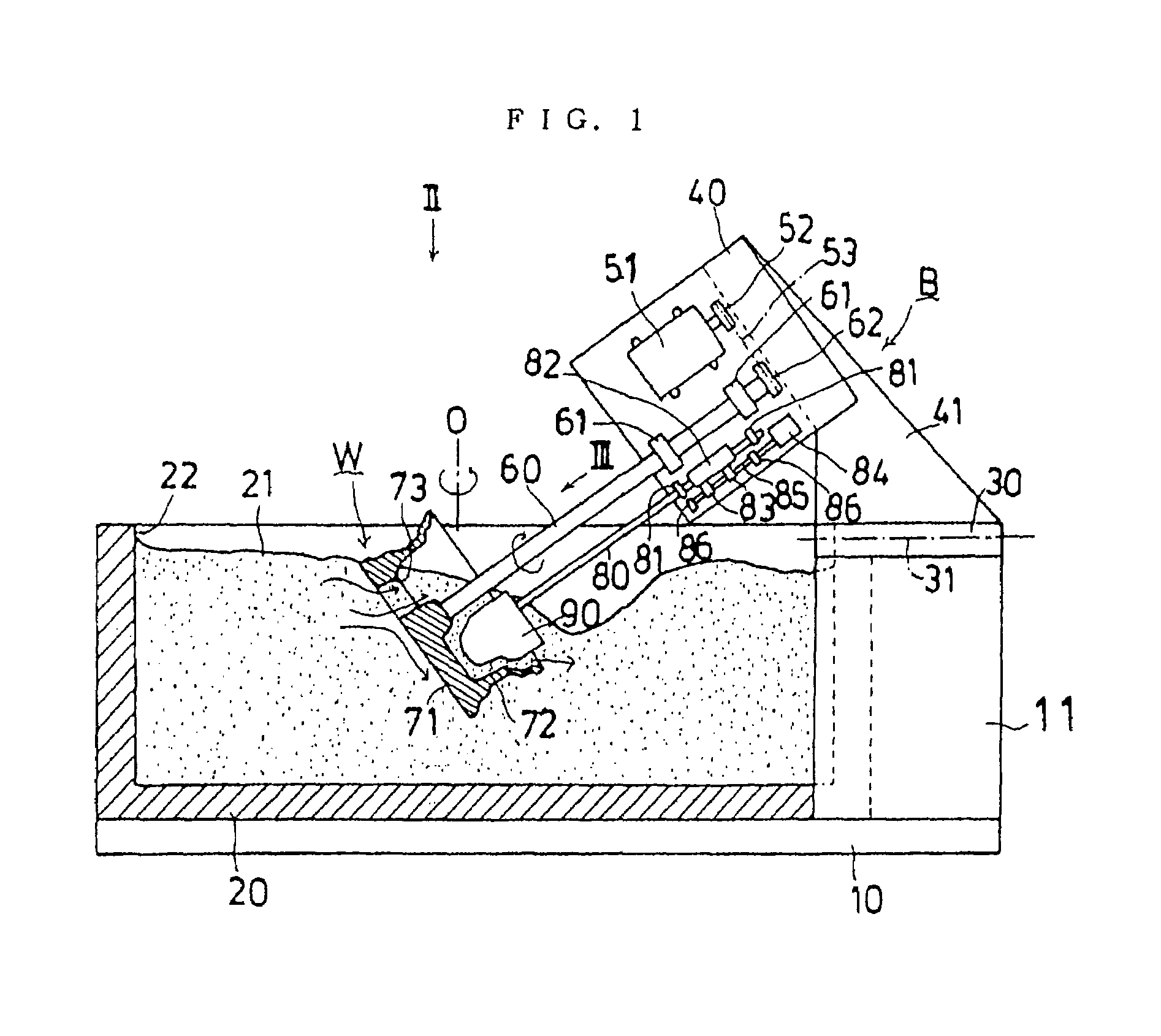

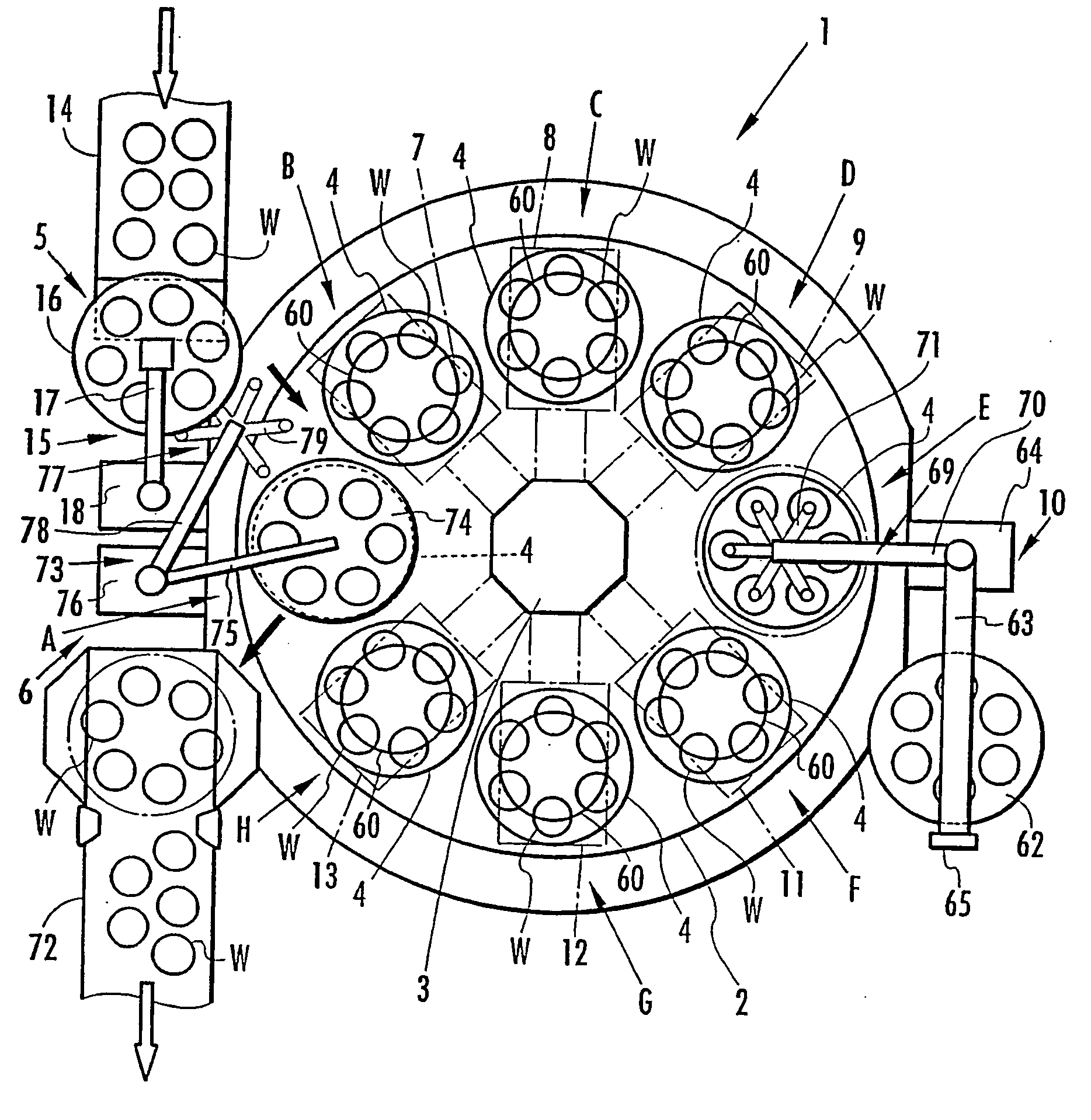

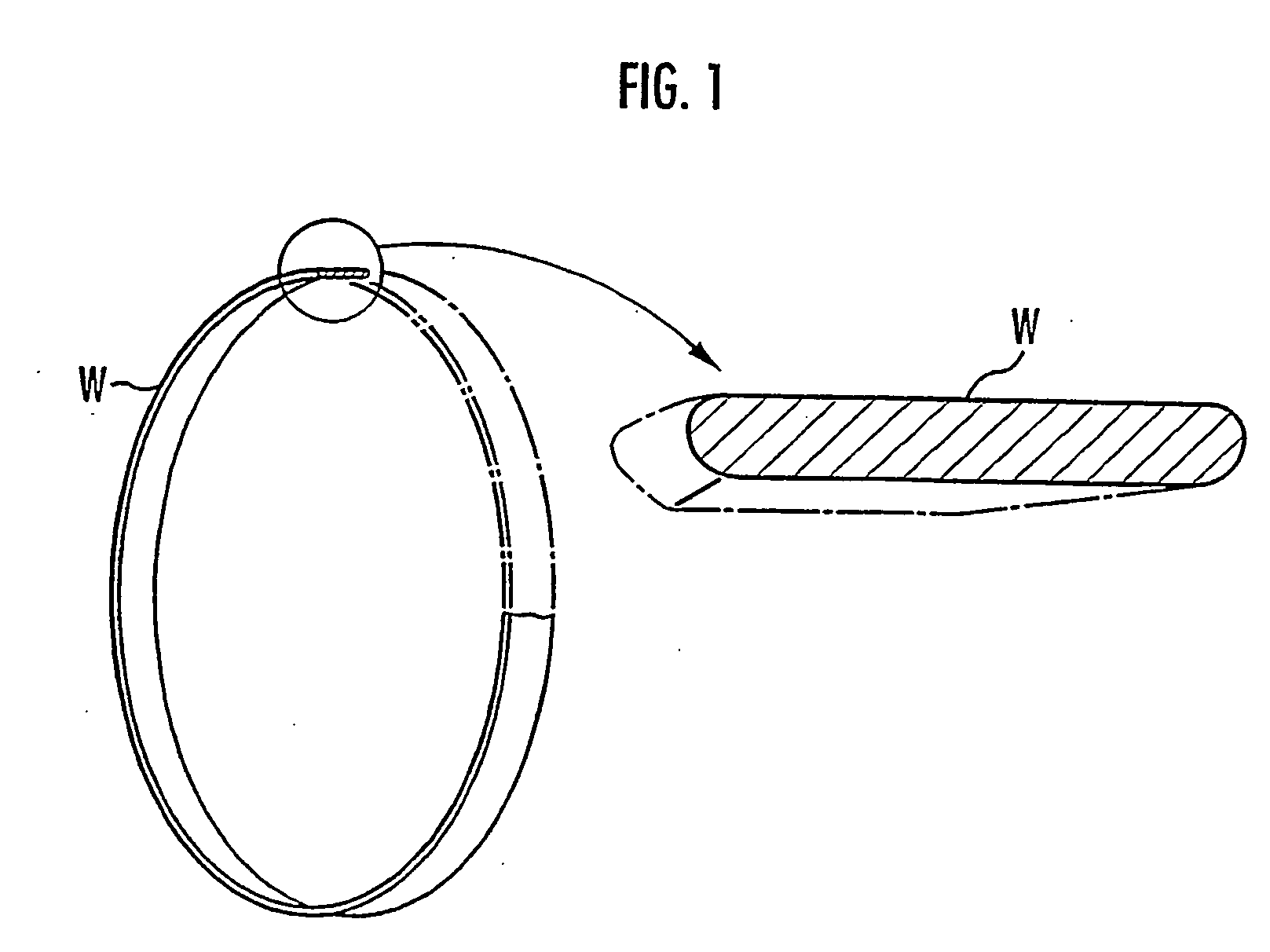

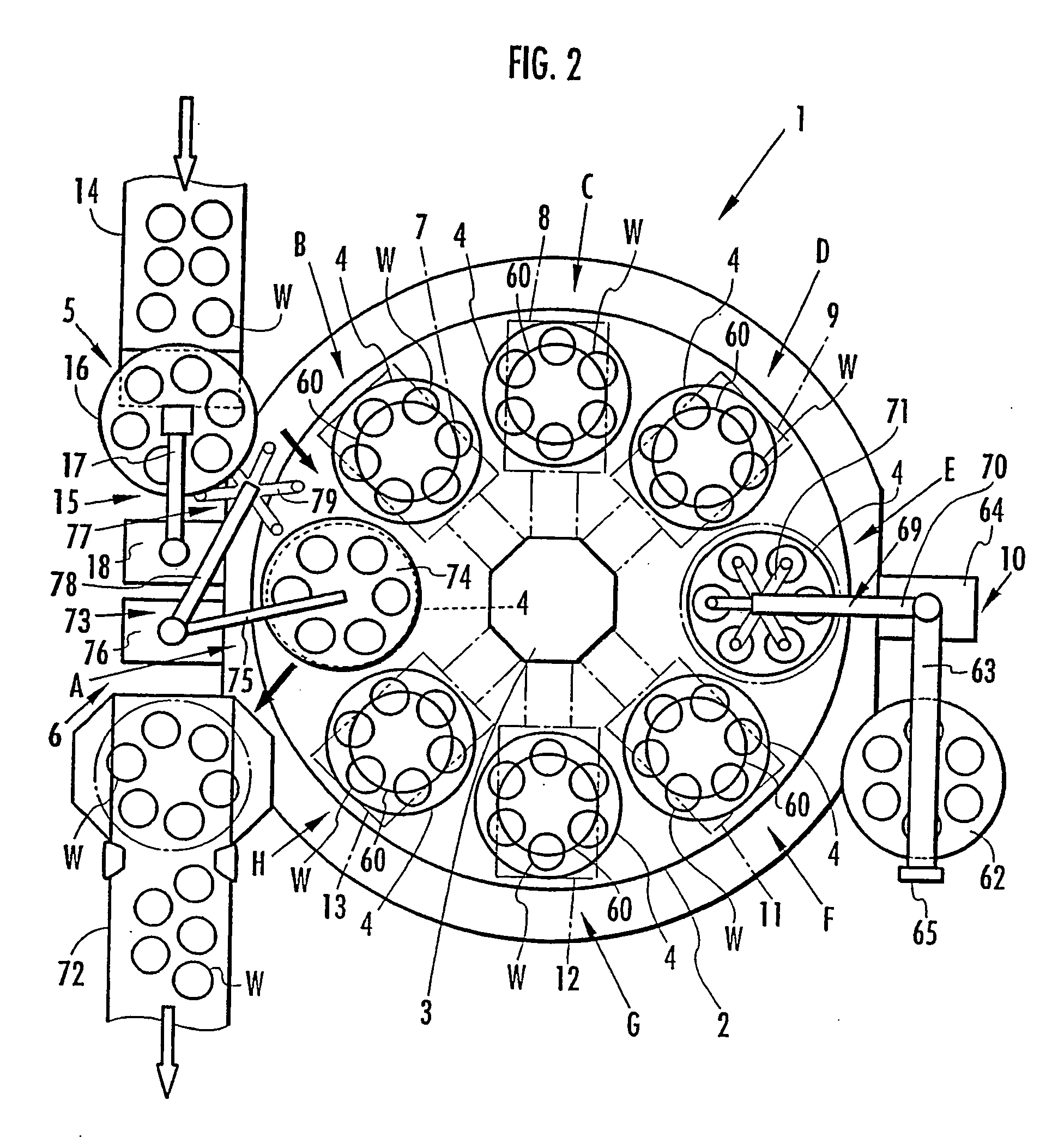

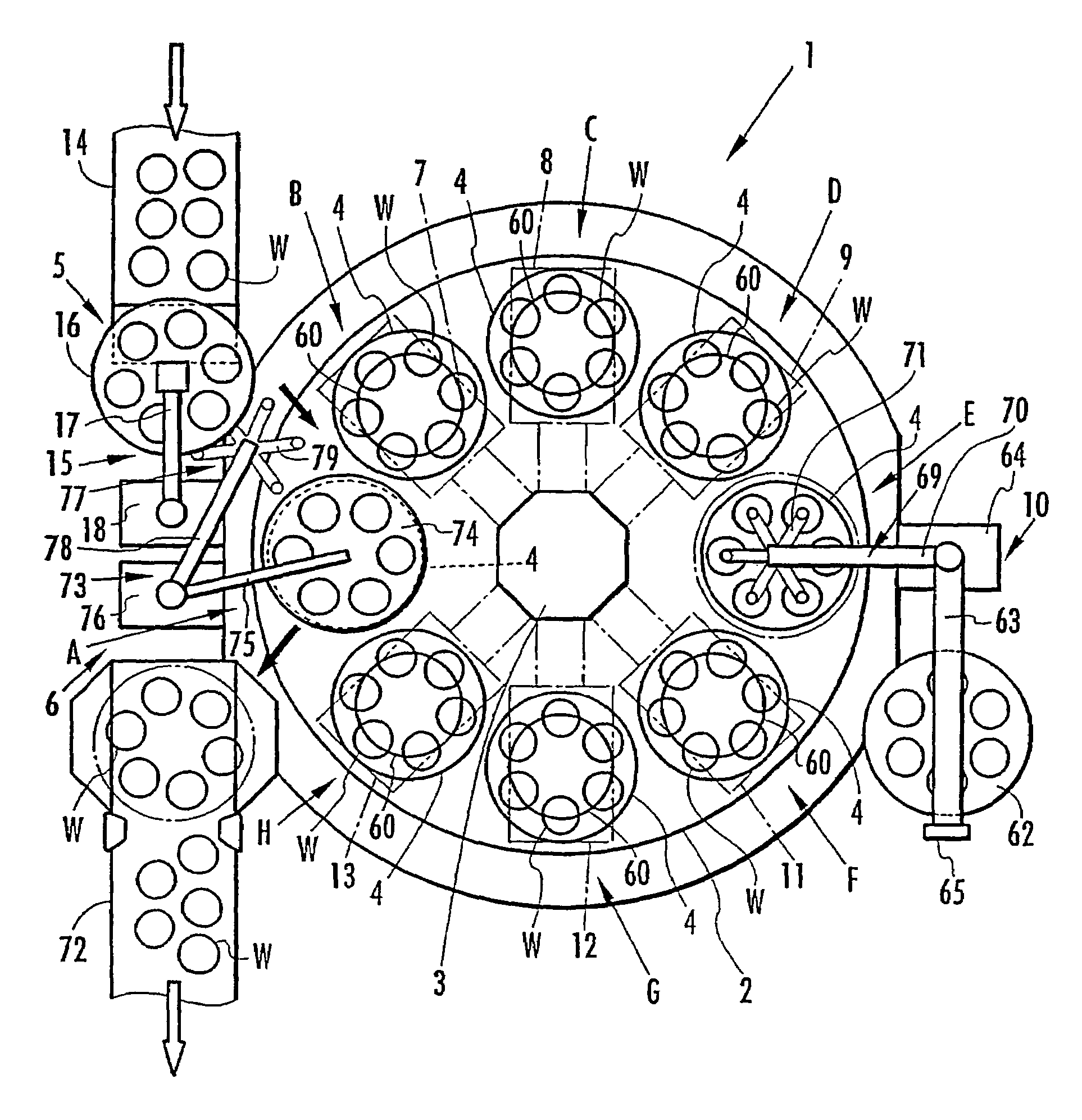

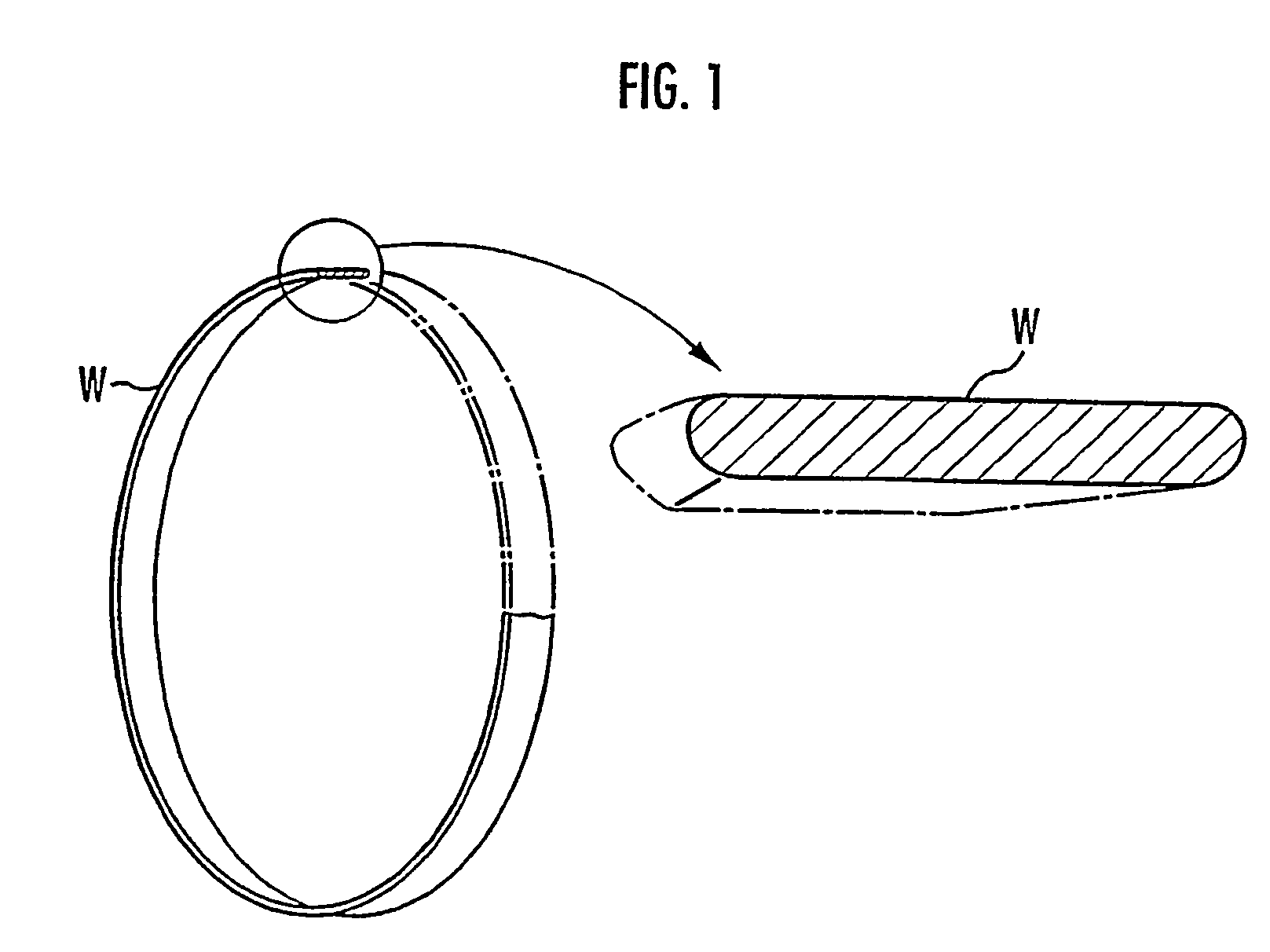

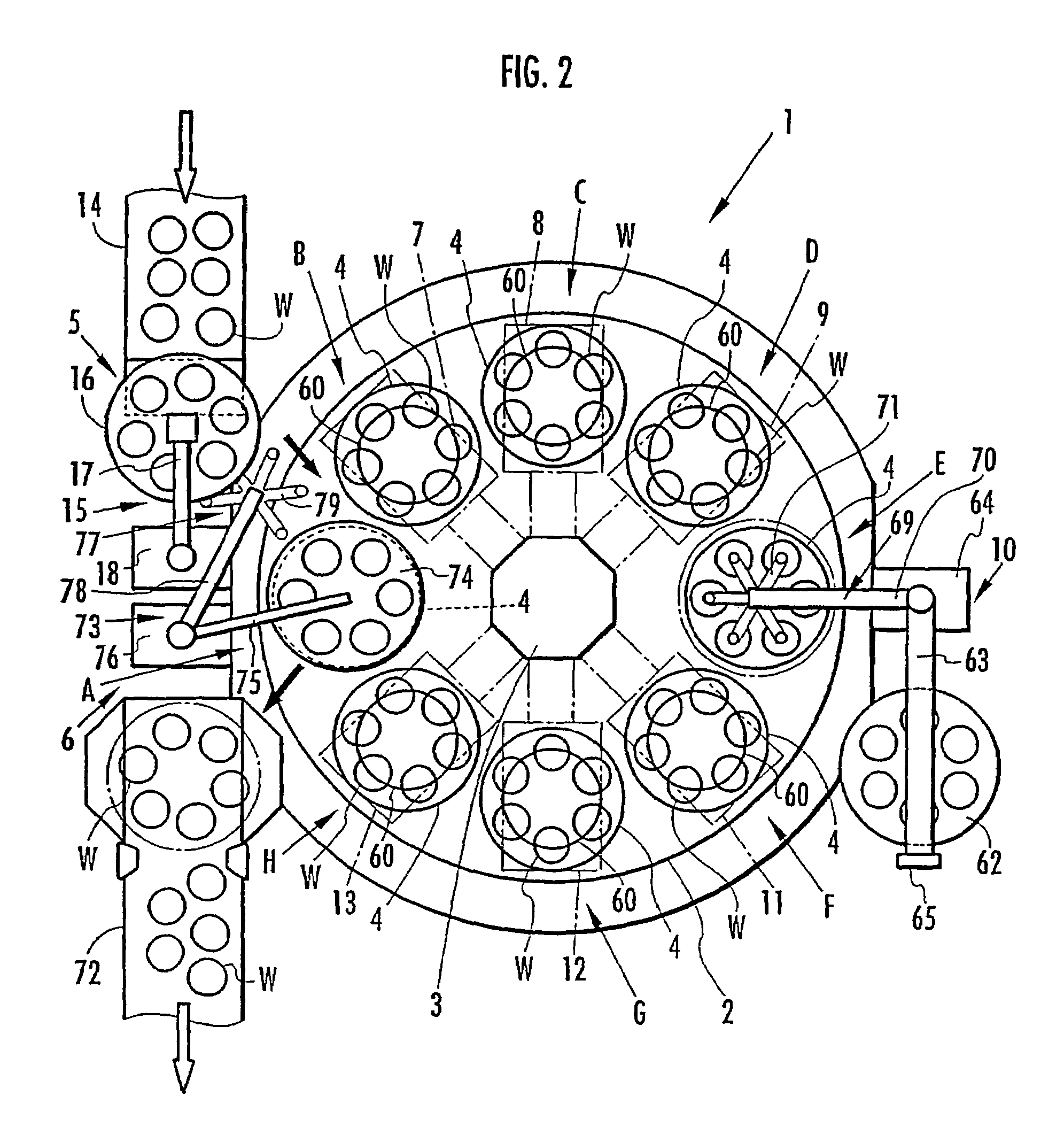

Method and device for polishing endless belt metal rings for continuously variable transmission

InactiveUS20060211343A1Improve efficiencyFrictionEdge grinding machinesPolishing machinesEngineeringMetal

There are disclosed a method and device for polishing a metal ring, which is capable of polishing a side edge of the metal ring without performing barrel polishing or polishing by grinding stones. Subsequently to a projecting step of projecting a metal ring W by clearing means 6, a first brush polishing step of polishing one edge of the metal ring W by a polishing brush 60 is performed. Subsequently, an inverting step of inverting the metal ring W whose one edge is polished by the first brush polishing step is inverted by the inverting means 10 is performed. Subsequently, a second brush polishing step of polishing the other edge of the metal ring W which is inverted by the inverting step by the polishing brush 60 is performed. Moreover, a clearing step of clearing the metal ring whose other edge is polished by the second brush polishing step by clearing means 7 is performed.

Owner:HONDA MOTOR CO LTD

Roller burnishing apparatus with pressing-force detecting device

InactiveUS8250720B2Improve fatigue strengthPressing forceGrinding feed controlBurnishing machinesEngineeringMechanical engineering

Owner:NISSAN MOTOR CO LTD +1

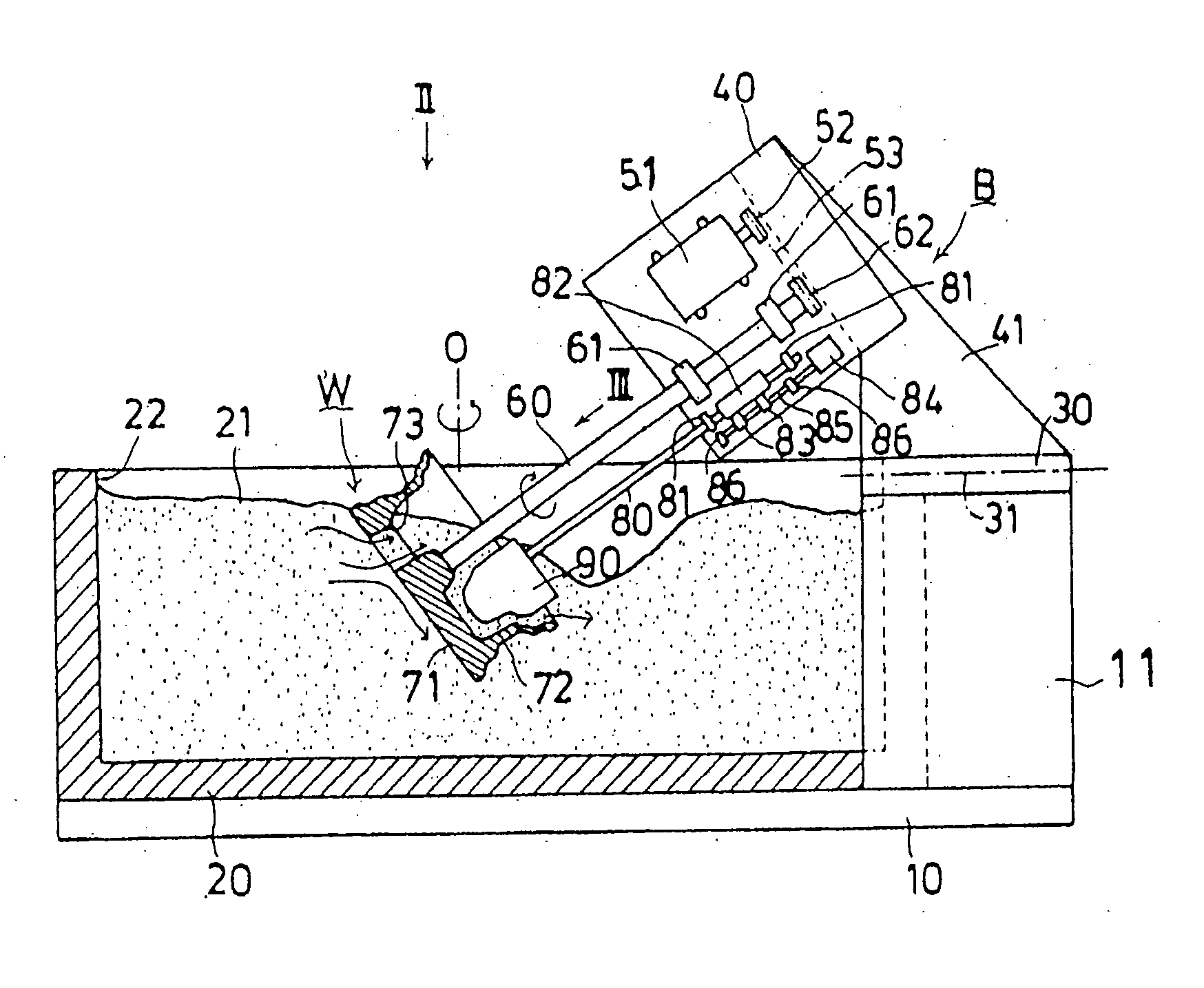

Barrel polishing device

InactiveUS20050255797A1Increase surface pressureReduce surface pressureEdge grinding machinesPolishing machinesEngineeringMechanical engineering

A barrel polishing device for polishing a workpiece having a relatively complicated shape such as a vehicle wheel. The barrel polishing device comprises a polishing medium storage tank for storing polishing media, a base, a workpiece supporting shaft mounted on the base, and a workpiece detachably mounted on a tip part of the workpiece supporting shaft, the polishing media stored in the polishing medium storage tank being flowed by an appropriate means, and the workpiece supporting shaft being disposed so that a front side of the workpiece opposes the flow of the polishing media, the workpiece supporting shaft being rotated about an axis thereof, and a baffle member being placed in the vicinity of a back side of the workpiece.

Owner:BBF YAMATE

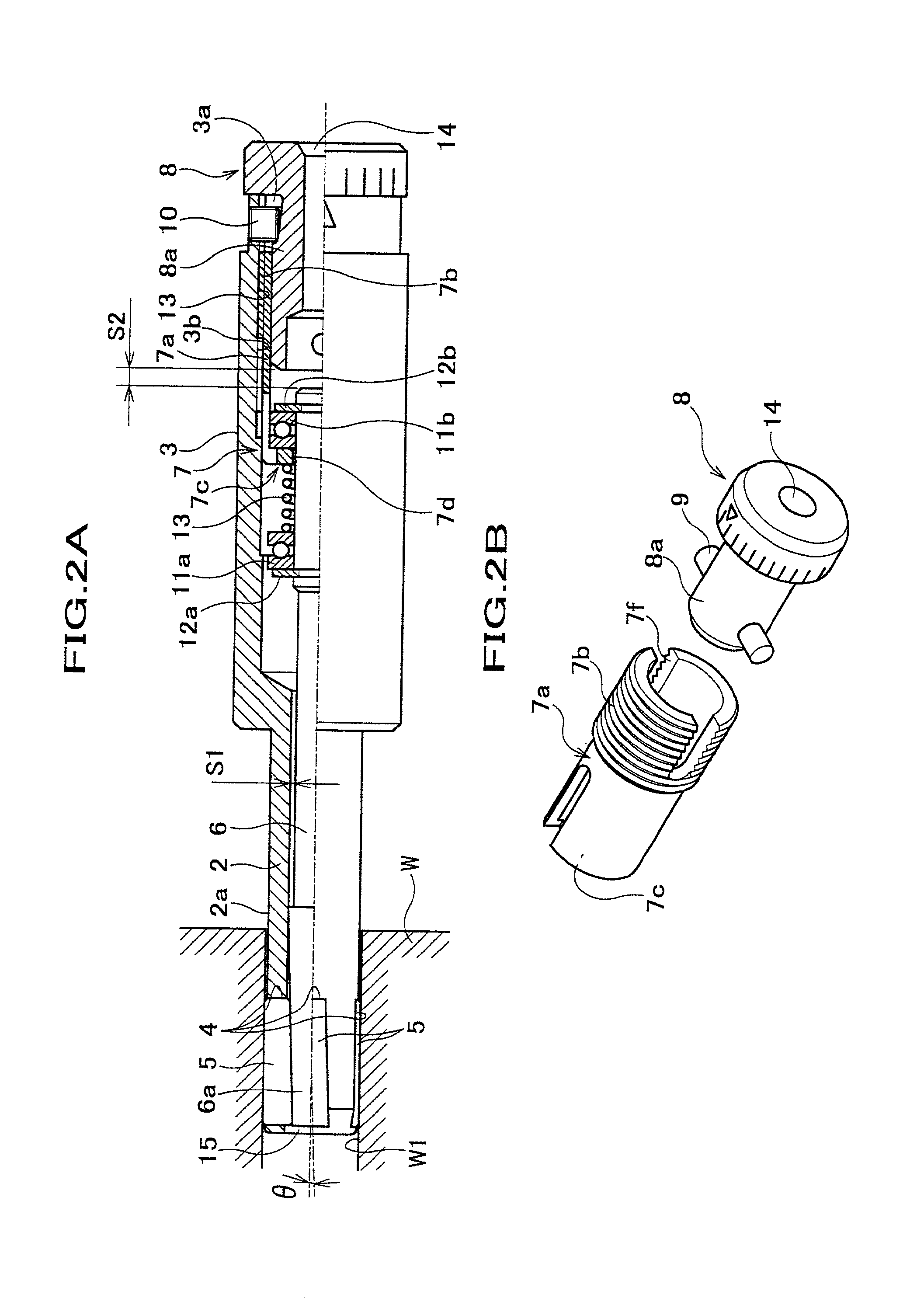

Roller burnishing tool

InactiveUS6568057B2Fast processingHigh rotation accuracyBurnishing machinesRotation functionCoil spring

To provide a roller-burnishing tool, for installing in a small machining center, small NC lathe and so forth. The frame for rolling compaction processing is coaxially connected with the shank portion which performs a rotary drive by mounting in a driving machine, and the mandrel is supported by this frame with a universal function for rotation. A tip end of the mandrel and the multiple rollers are formed into a taper shaped style for being supported for rotation from a radial direction. The mandrel and the compressing coil spring, which functions from the shank portion side to the frame side are provided in the shank portion as well as the adjustable ring, which allows adjustment of tool diameter by moving the position of the mandrel in an axial direction relative to the frame.

Owner:SUGINO MACHINE

Method and device for polishing endless belt metal rings for continuously variable transmission

InactiveUS7413496B2Good precisionEfficient polishingEdge grinding machinesPolishing machinesEngineeringMetal

There are disclosed a method and device for polishing a metal ring, which is capable of polishing a side edge of the metal ring without performing barrel polishing or polishing by grinding stones. Subsequently to a projecting step of projecting a metal ring W by clearing means 6, a first brush polishing step of polishing one edge of the metal ring W by a polishing brush 60 is performed. Subsequently, an inverting step of inverting the metal ring W whose one edge is polished by the first brush polishing step is inverted by the inverting means 10 is performed. Subsequently, a second brush polishing step of polishing the other edge of the metal ring W which is inverted by the inverting step by the polishing brush 60 is performed. Moreover, a clearing step of clearing the metal ring whose other edge is polished by the second brush polishing step by clearing means 7 is performed.

Owner:HONDA MOTOR CO LTD

Roller burnishing tool

InactiveUS20020046451A1Fast processingHigh rotation accuracyBurnishing machinesRotation functionCoil spring

To provide a roller-burnishing tool, the usage by installing in a small machining center, small NC lathe and so forth is offered. The frame 2 for rolling compaction processing is coaxially connecting with the shank portion 3 which is performing a rotary drive by mounting in a driving machine, and the mandrel 6 is supported by this frame 2 with universal function for rotation. A tip end 6a of the mandrel 6 and the multiple roller 5,5 are formed into a taper shaped style for being supported by a rotation from a radial direction. The mandrel 6 and the compressing coil spring 13, which is impetuous from the shank portion 3 side to the frame 2 side are provided in the shank portion 3 as well as the adjustable ring 8, which is to adjust a tool diameter by moving the position of an axial direction to the frame 2 of the mandrel 6.

Owner:SUGINO MACHINE

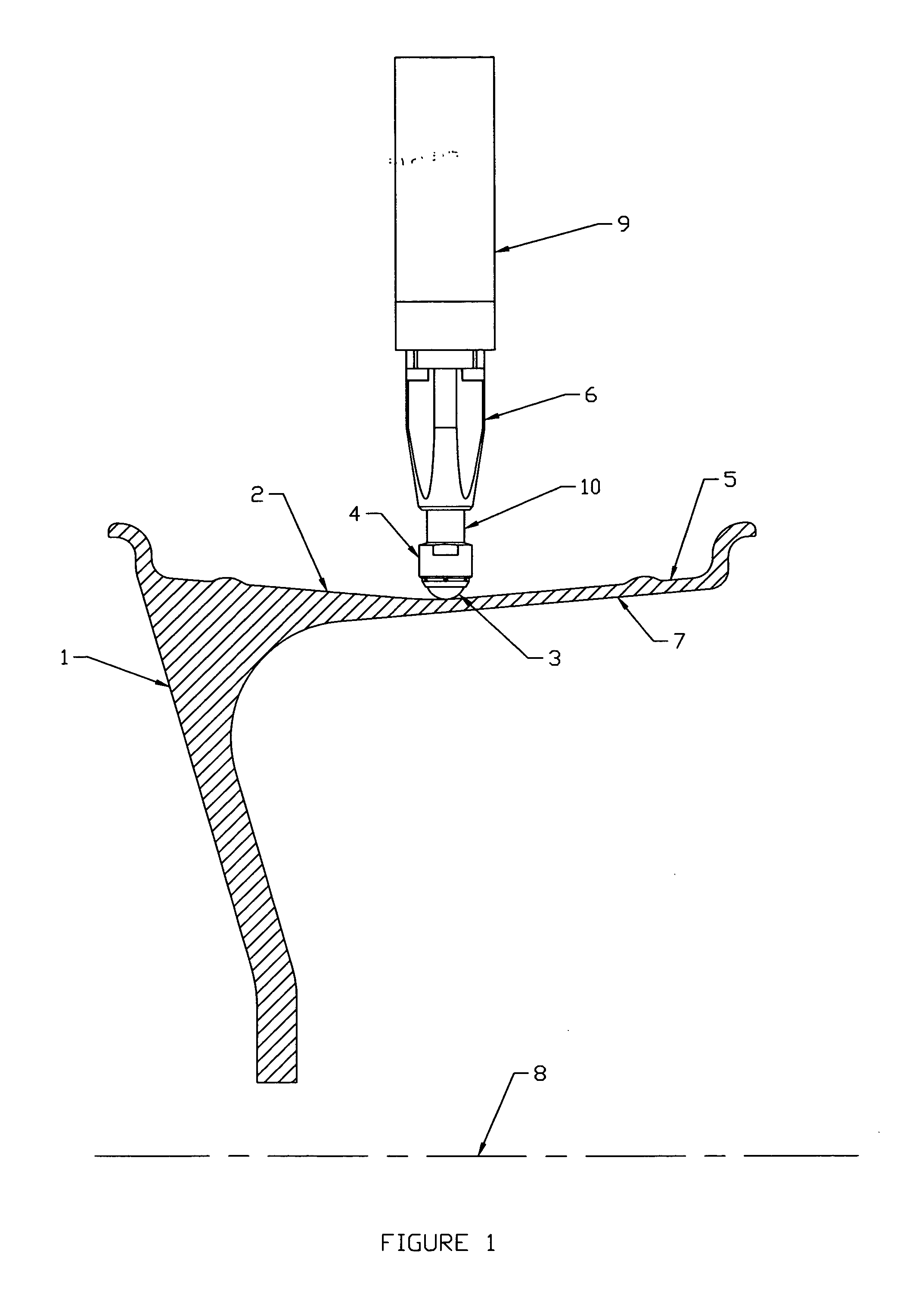

Leak repair method

The present invention is a novel method for the repair of cast aluminum wheels that leak air due to porosity caused during the casting process. It involves deep roller burnishing the surface of the wheel under controlled operating parameters to effectively seal the porosity so that the wheel no longer leaks air.

Owner:JACOBS TERRY LANE

Gold jewelry processing technology

The invention discloses a gold jewelry processing technology which includes following steps: 1) gold melting: burning gold in a high-temperature-resistant quartz crucible on acetylene fire to smelt the gold into a single material being suitable for processing jewelry; 2) mould pouring: melting the gold material with a high-frequency or medium-frequency centrifugal pouring machine and pouring the molten god material into a gypsum to form a casting; 3) polishing: polishing the surface of the casting with a magnetic polishing machine or a cylinder polishing machine; 4) mould finishing: welding, filing and hammering the casting with a swage iron to shaping the deformation and crude surface of the casting; 5) press-polish: contacting the gold surface and rubbing the workpiece with an agate pen to glossing the surface of the workpiece; 6) pattern lathing: sculpturing patterns on the surface of the product with a pattern lathe mounted with a diamond pattern lathing cutter; and 7) inspection and finished product storage in storerooms. The gold jewelry processing technology is simple to carry out. Gold jewelry produced through the technology is high in glossiness. The technology saves cost for manufacturers and can satisfy consumer demand.

Owner:卢家雄

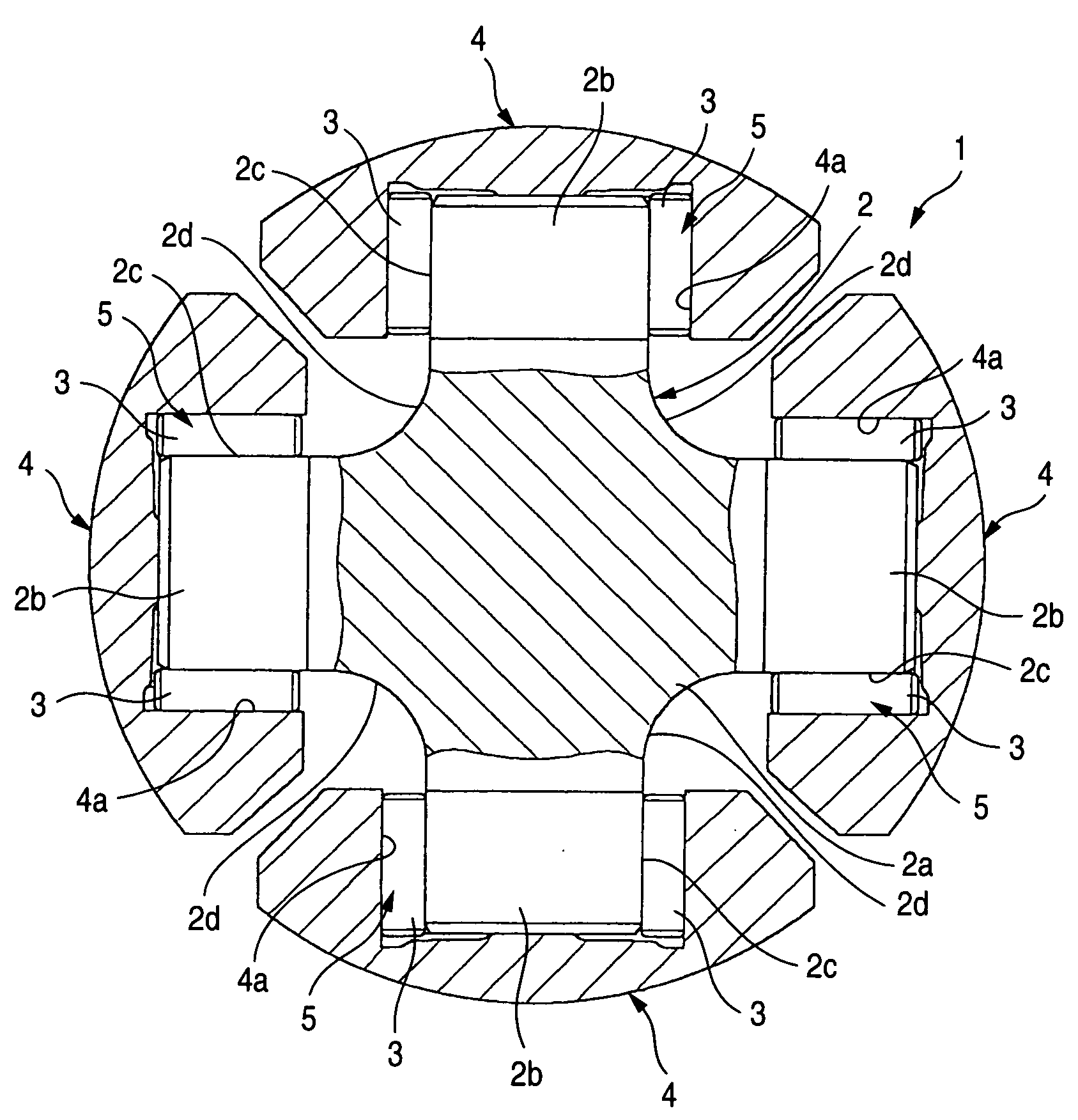

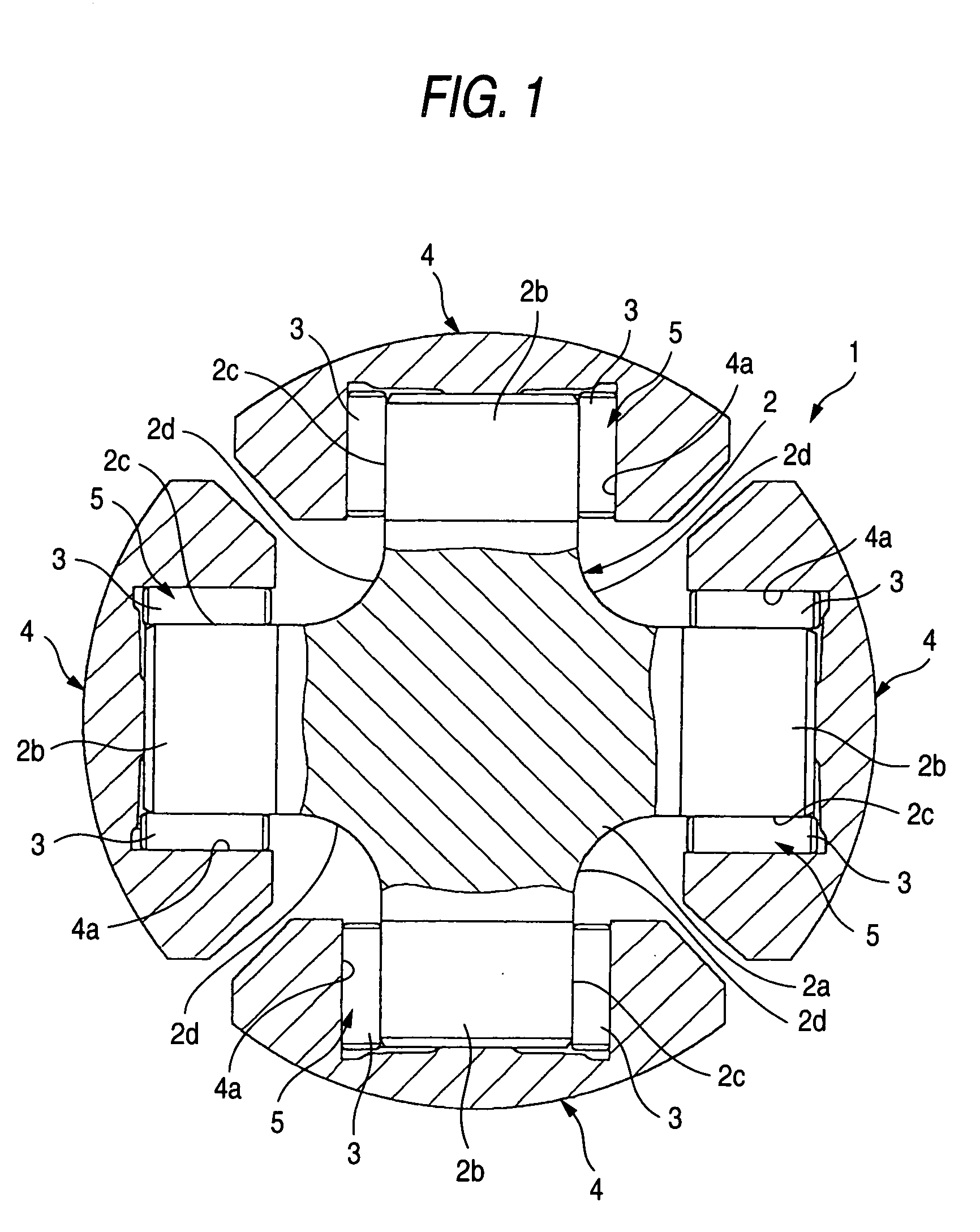

Cross joint

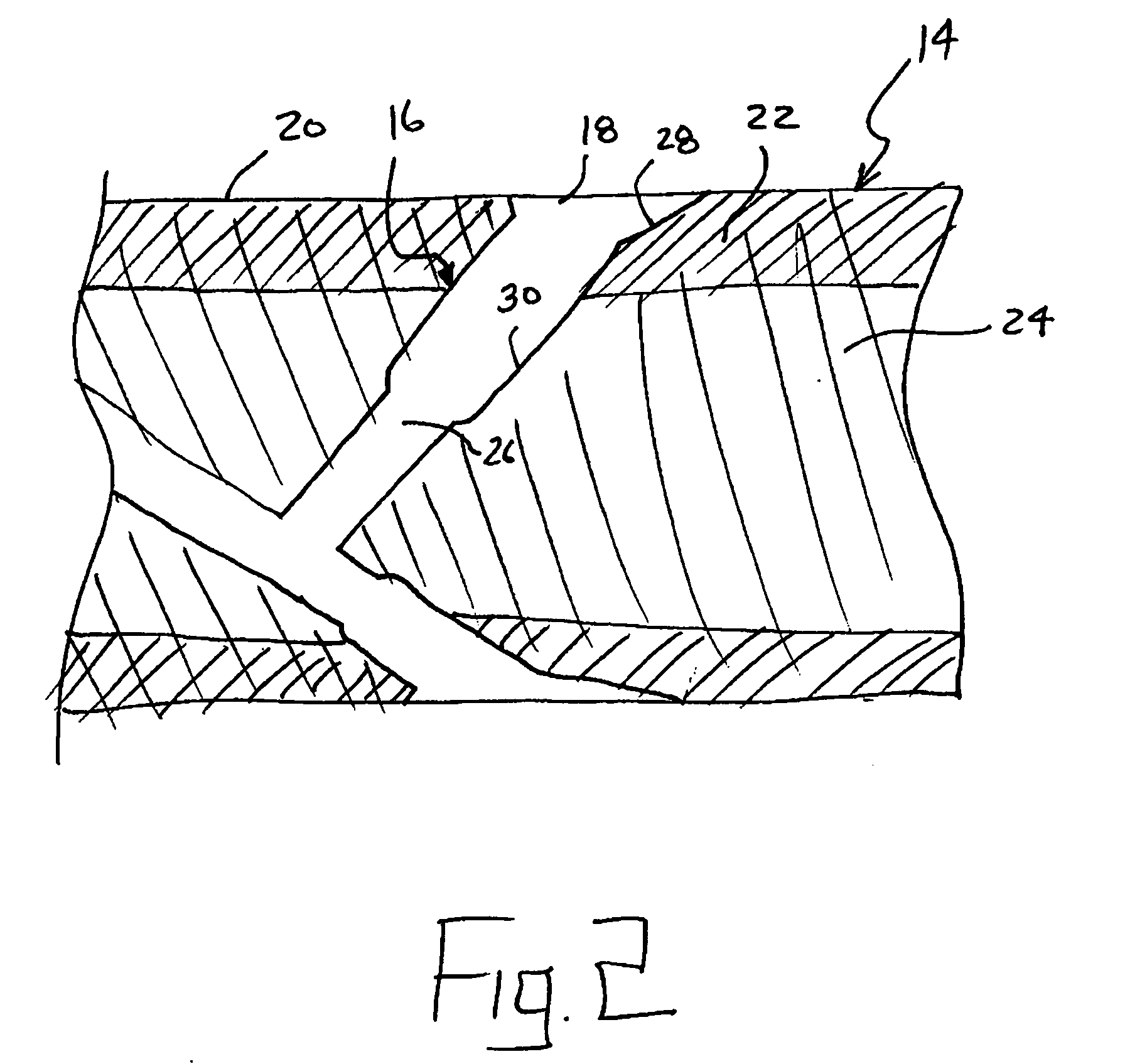

InactiveUS7163461B2Fine surfaceReduce roughnessYielding couplingBurnishing machinesEngineeringMechanical engineering

In a cross joint (1) outwardly fitting a bearing cup (outer ring member 4) to each of four pieces of shafts 2b of a cross shaft member (2) via a cylindrical member (rolling member 3), race portions (2c, 4a) formed on a side of the cross shaft member (2) and on a side of the bearing cup (4) and a shoulder portion (2d) provided between respectives of neck portions of two of the shafts (2b) of the cross shaft member (2) contiguous to each other are subjected to roller burnishing.

Owner:JTEKT CORP

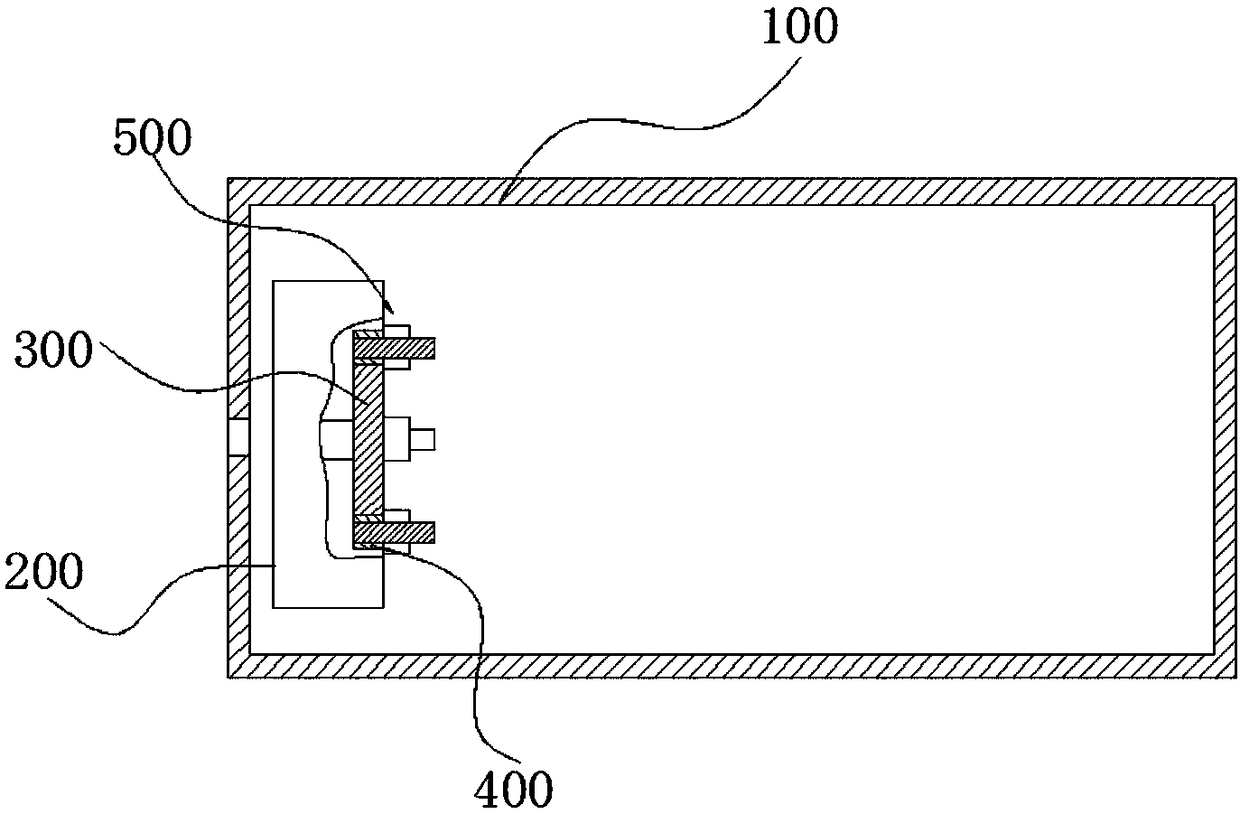

Cadmium plating method for metal product surface treatment

InactiveCN104264138AImproved corrosion resistance in salt spray testGuarantee product qualityLiquid/solution decomposition chemical coatingWater useCadmium Cation

A cadmium plating method for metal product surface treatment comprises steps of alkaline degreasing; first cleaning by hot water, and then cleaning by clear water with the temperature of 10 DEG C-30 DEG C; drying and baking in a drying oven at the temperature of 40 DEG C-80 DEG C; loosening and roller burnishing by a vibrating roller burnishing machine; second cleaning; first activating; third water washing; nickel preplating; fourth water washing; cadmium plating; fifth water washing; first bright dipping to remove surface oxide; sixth water washing; second cleaning by hot water; first spin-drying by a spin dryer for 5-10 minutes; hydrogen removal with the time of 6-8 hours; second activating; seventh water washing; second bright dipping; eighth water washing; passivating; ninth water washing, wherein water washing from the second time to the ninth time adopts clear water with the temperature of 10 DEG C-30 DEG C; third cleaning by hot water, wherein the temperature of hot water used by the first time, the second time and the third time is 50 DEG C-90 DEG C; second spin-drying for 5-10 minutes; ageing; inspecting; and packaging. The corrosion resistance test of a product is prolonged to be longer than 96 hours, and the quality is guaranteed.

Owner:GUIZHOU HANGRUI AVIATION PRECISION PARTS MFG

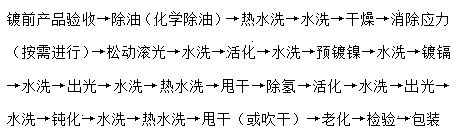

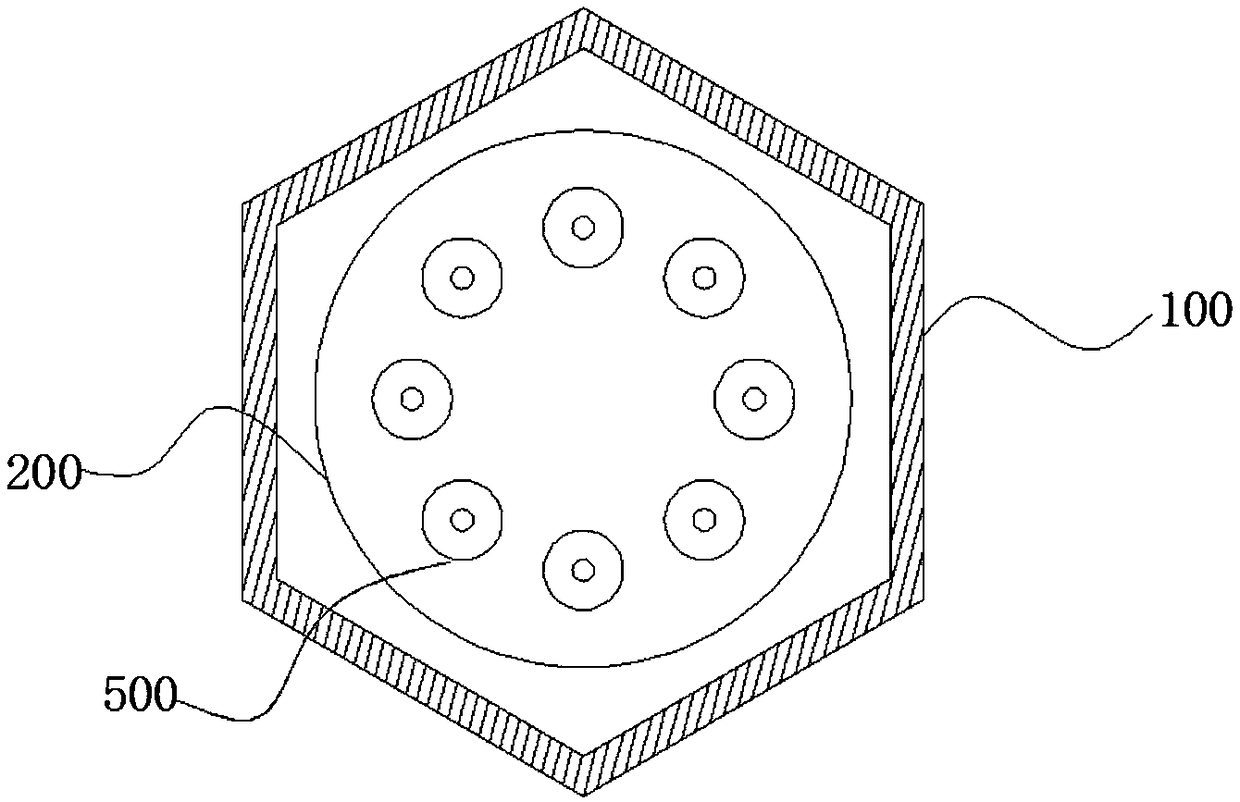

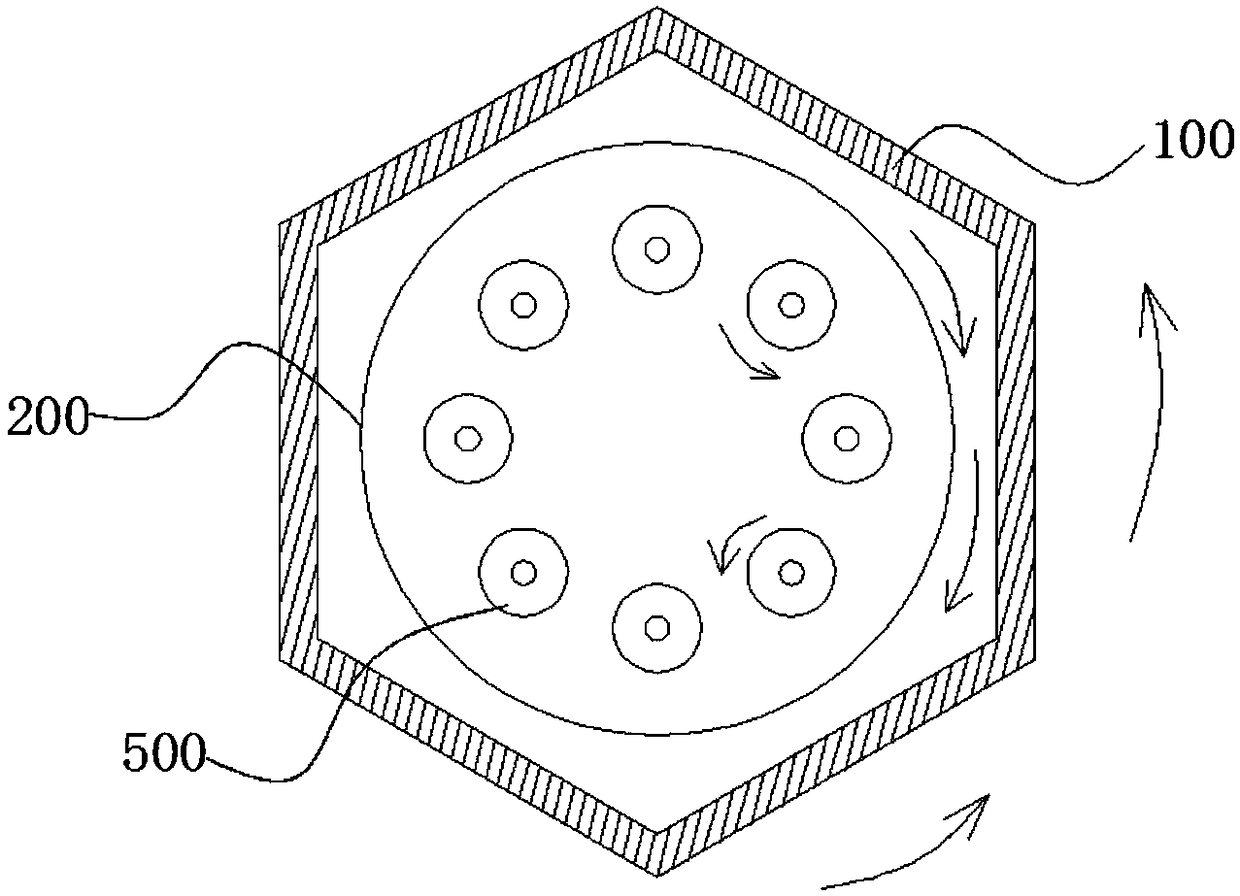

Polishing machine and polishing equipment

PendingCN108115540ASimple structureFirmly connectedEdge grinding machinesPolishing machinesEngineeringMachining time

The invention provides a polishing machine and polishing equipment, relates to the technical field of polishing equipment, and aims to the solve the technical problems that due to the fact that the rotation speed of the barrel of an existing barrel polishing machine is low, the polishing rate between an abrasive material in the barrel and a workpiece is low, and polishing is uneven. The polishingmachine comprises a barrel, an abrasive material and a support plate and is characterized in that the rotation direction of the barrel is opposite to the rotation direction of the support plate, and the rotation direction of a to-be-polished workpiece is identical with or opposite to the rotation direction of the support plate. The polishing equipment comprises a barrel, an abrasive material and two support plates and is characterized in that the two support plates are respectively arranged at the two opposite ends of the barrel; the rotation direction of the barrel is opposite to the rotationdirection of the support plates, and the rotation direction of a to-be-polished workpiece is identical with or opposite to the rotation direction of the support plates. The polishing machine and thepolishing equipment have the advantages that the workpiece can be polished by the polishing abrasive material in an omnibearing manner, the workpiece can be fast and evenly polished, machining time isreduced, and surface polishing degree is enhanced.

Owner:河北金音乐器集团有限公司

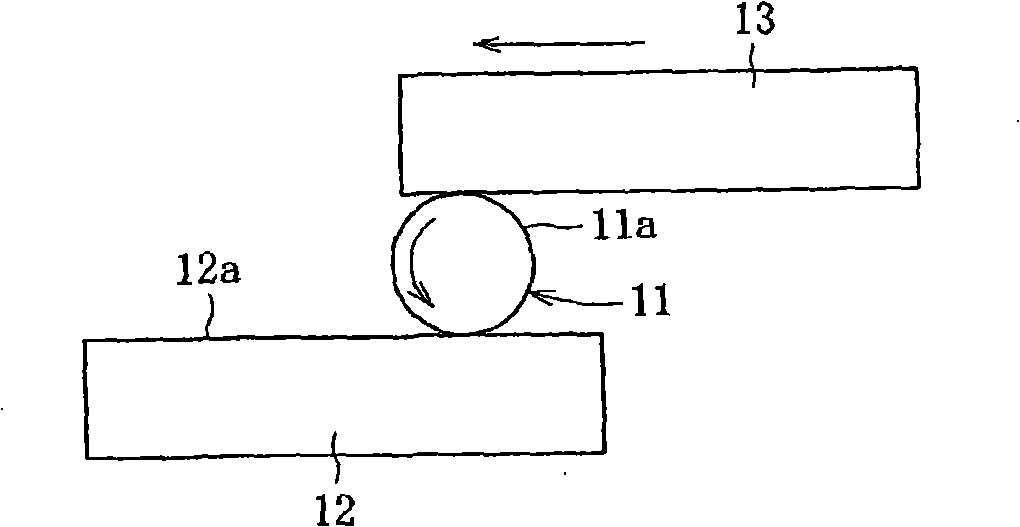

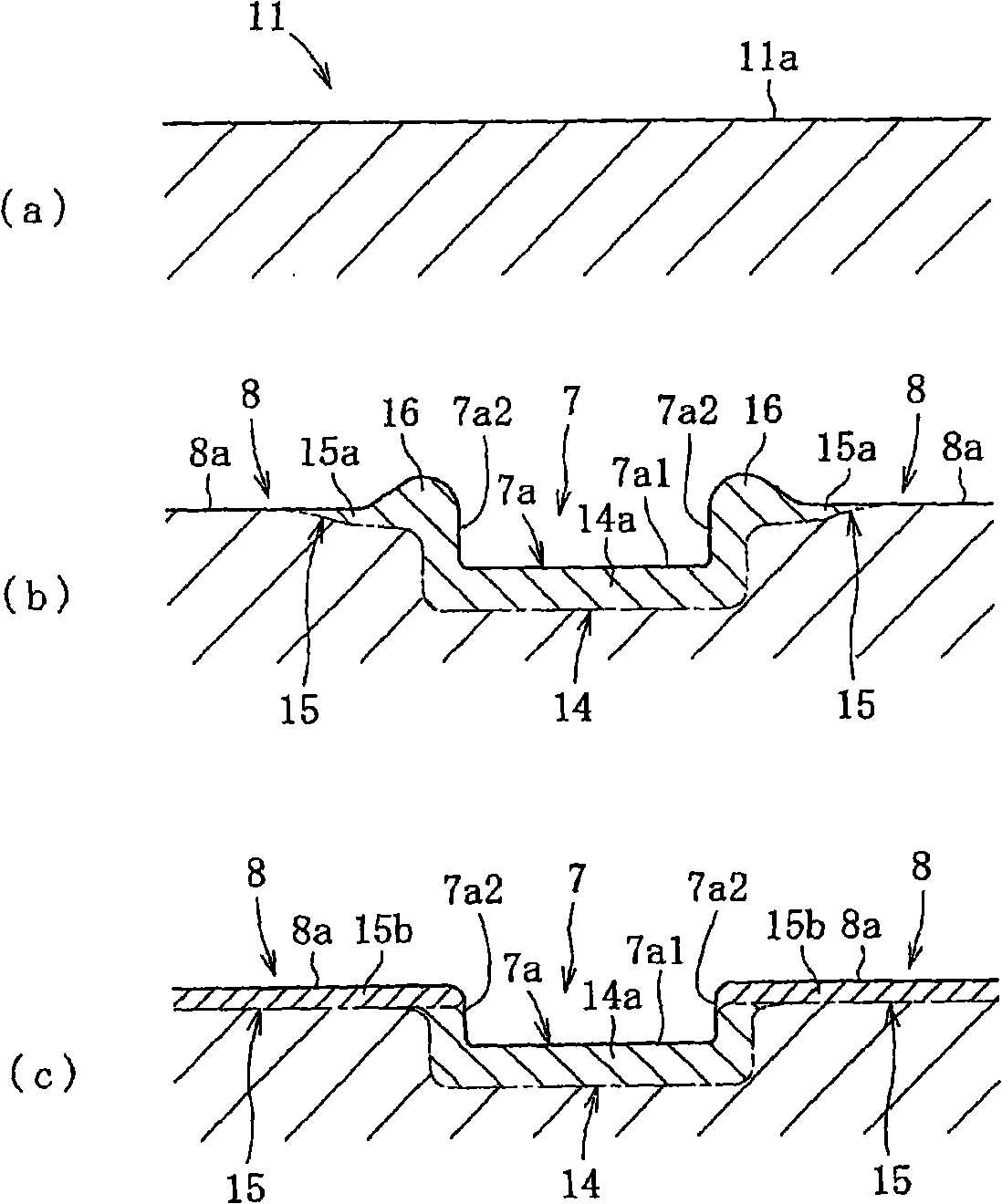

Shaft member for dynamic pressure bearing device

InactiveCN101356382AImprove wear resistanceEnhance the dynamic pressure effectBearing componentsSliding contact bearingsSurface layerHardness

Provided is a bearing member for a dynamic pressure bearing device, which is excellent in wear resistance and which can exhibit a high dynamic pressure action. A shaft material (11) is rolled to form a recess (7) for causing the dynamic action of a lubricant in a radial bearing clearance (6). Then, a surface layer portion (14) of the recess (7) to be formed on the outer circumference (11a) of the shaft material (11) is rolled to form a first hardened layer (14a). At the same time, a surface layer portion (15) of a surrounding area (8) of the recess (7) is also rolled to form a first hardened layer (15a) at its partial area. After the recess (7) was rolled, that shaft material (11) is barreled. As a result, the outermost surface layer of the surface layer portion (15) is barreled to form a second hardened layer (15b). The hardness of the second hardened layer (15b) formed in the surrounding area (8) is higher by 50 Hv to 200 Hv than that of the first hardened layer (14a) formed in the recess (7).

Owner:NTN CORP

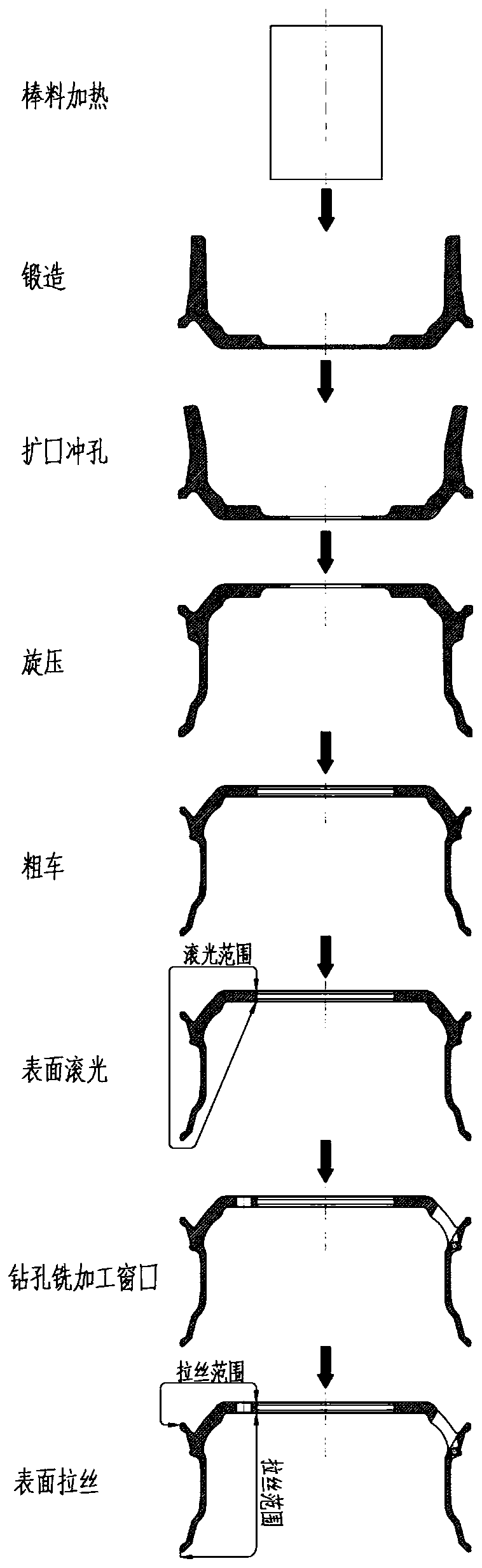

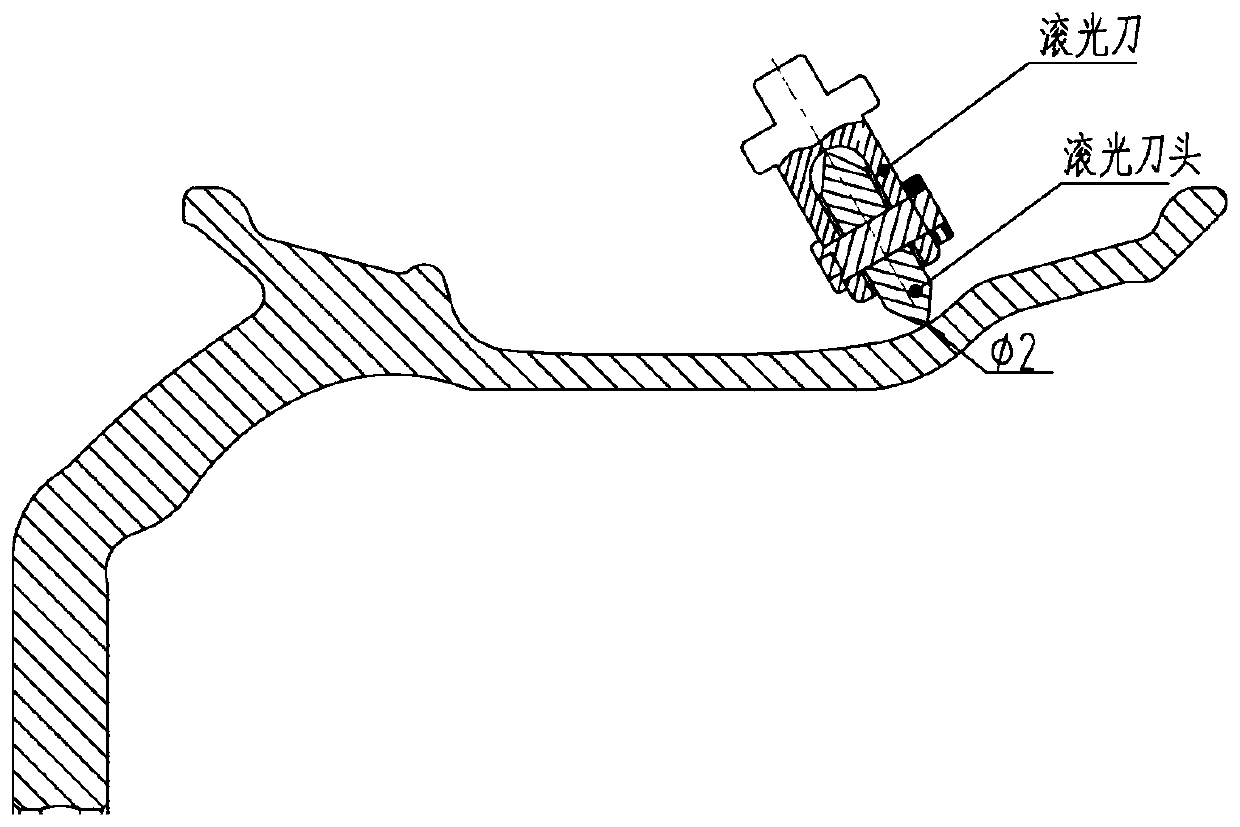

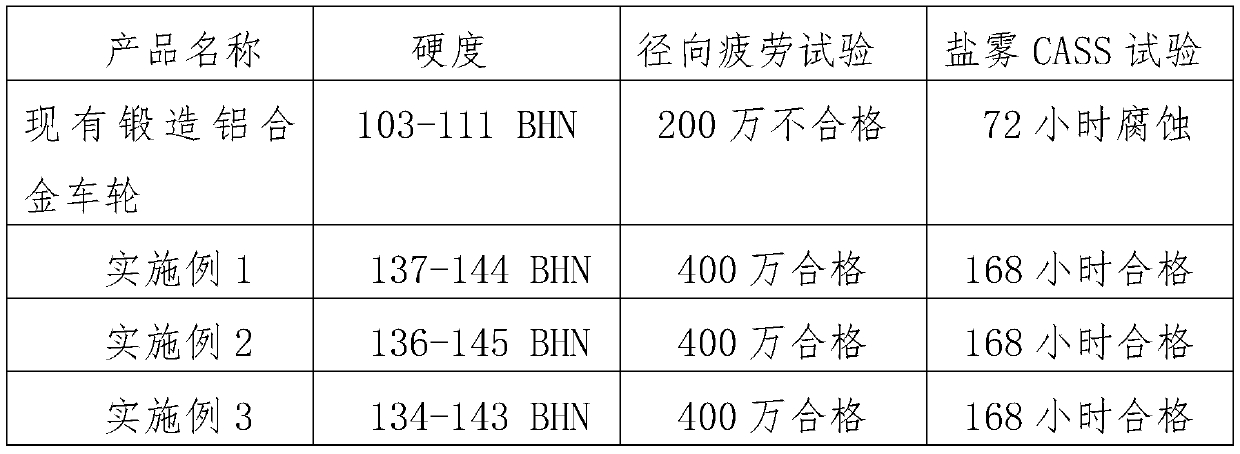

Manufacturing method of long-service-life forged aluminum alloy wheel

The invention relates to the technical field of aluminum alloy wheels, and particularly relates to a manufacturing method of a long-service-life forged aluminum alloy wheel. The manufacturing method is characterized in that the surface of the wheel is strengthened by adding a wheel surface treatment process so as to obtain a forged aluminum alloy wheel with long service life, wear resistance, corrosion resistance and oxidation resistance. The manufacturing method comprises the operation steps of S1, bar heating; S2, forging, specifically, conducting single-step forging on the heated bar; S3, punching and flaring, specifically, expanding rim legs by a certain angle, and punching the center of a forging stock at the same time; S4, cleaning and cooling, specifically, putting the forging stockinto a cleaning line for cleaning; S5, spinning, specifically, placing the forging stock on a spinning lower die for compaction; S6, heat treatment, specifically, conducting heat treatment by means of solid solution, quenching and artificial aging; S7, rough turning; S8, surface roller burnishing, specifically, conducting full roller burnishing on the front surface, a back cavity and an outer side rim of the wheel; S9, drilling and window milling; S10, surface wiredrawing, specifically, conducting wiredrawing treatment is conducted on the front surface and the back cavity of the wheel; and S11, surface passivation, specifically, putting the wheel into a passivation solution for soaking, washing with pure water after passivation and then drying.

Owner:QINHUANGDAO DICASTAL XIONGLONG WHEEL

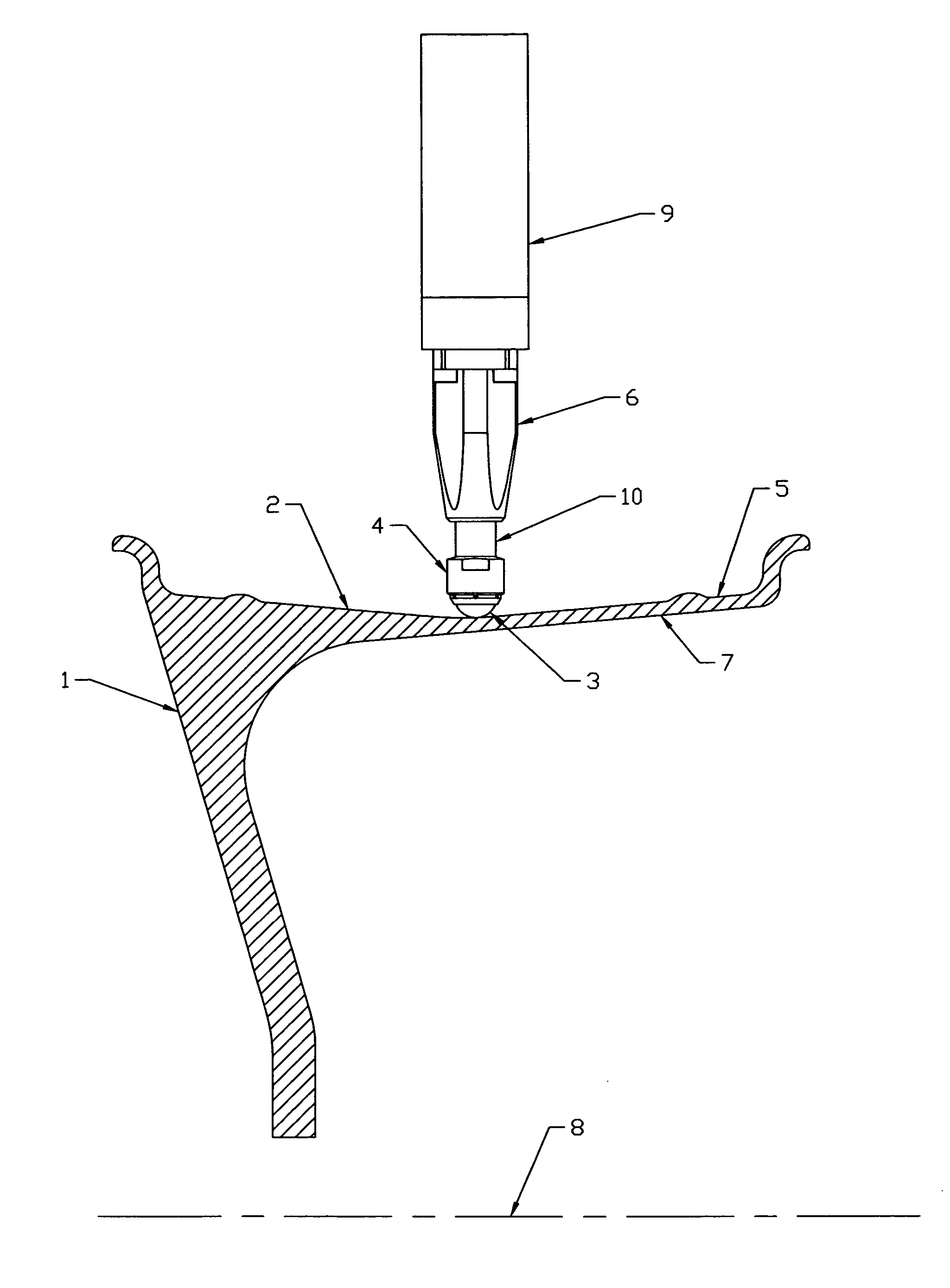

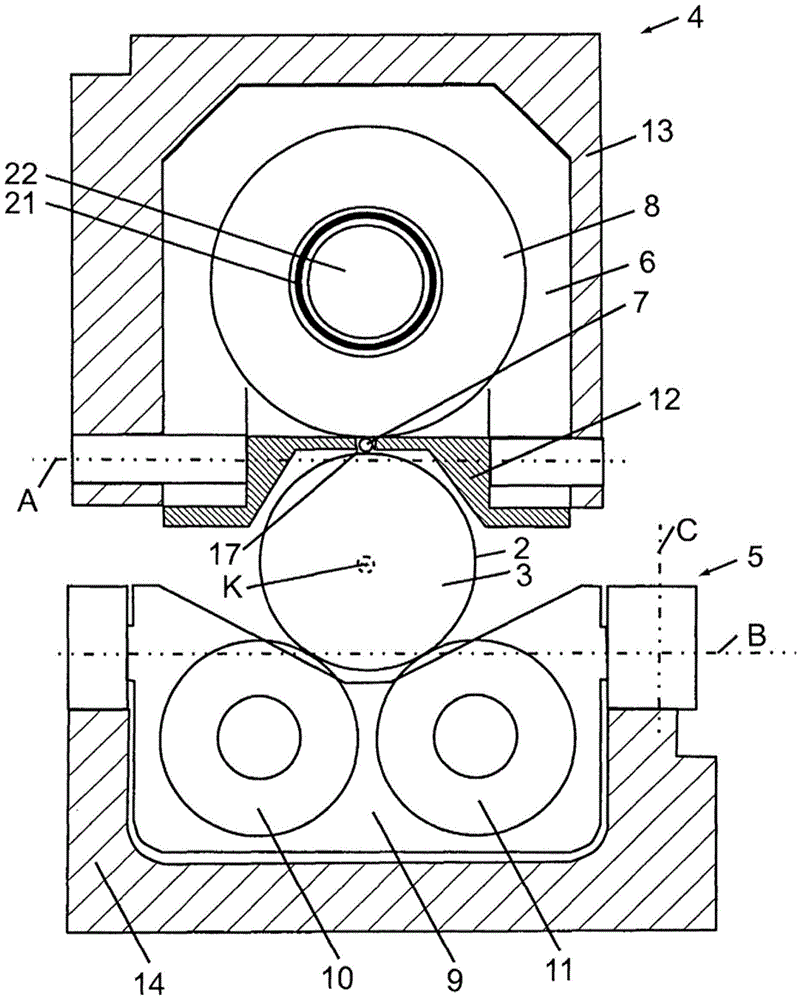

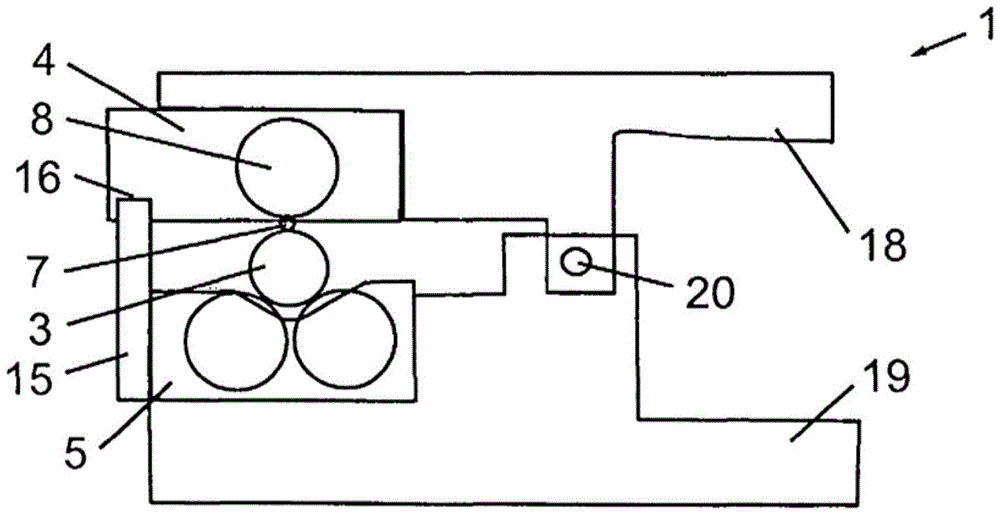

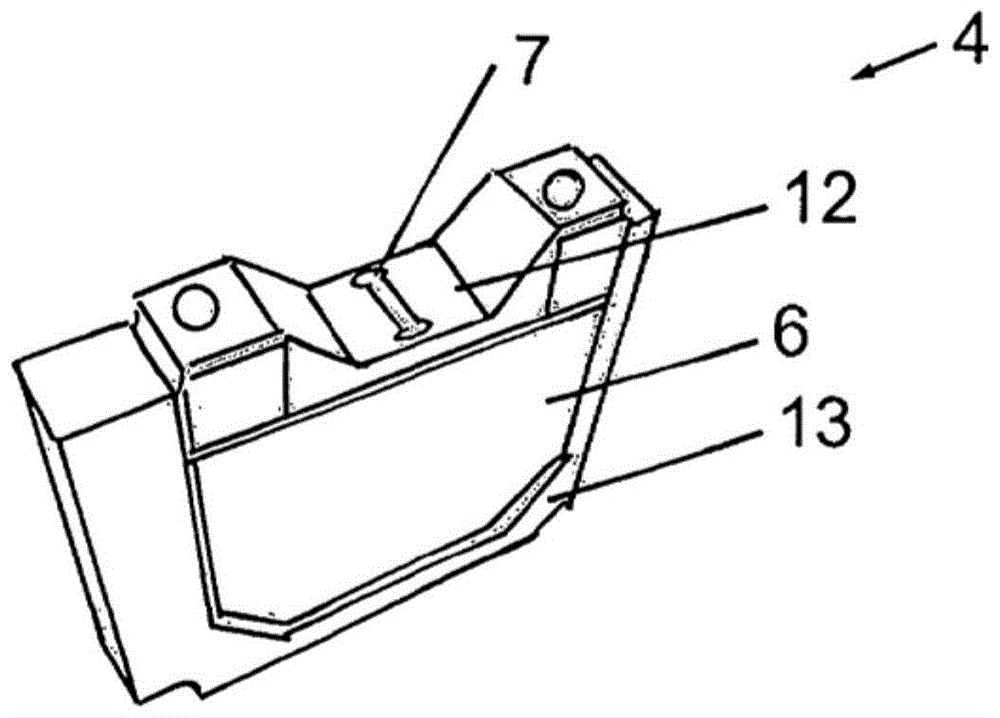

Rolling tool

ActiveCN105722642AAlignment helpsEasy to deviate fromCrankshaftsGrinding carriagesEngineeringBearing surface

The invention relates to a rolling tool (1) for the roller burnishing of bearing surfaces (2) of a crankshaft (3) that can be rotated about a crankshaft axis (K), comprising a roller burnishing head (4) and a supporting roller head (5). The problem addressed by the invention is that of designing such a rolling tool in such a way that damage to guides of the burnishing roller or of the crankshaft is largely impossible. This problem is solved in that the burnishing roller (7) is guided on all sides in a roller cage (12) and in that the roller burnishing head (4) has a roller burnishing head frame (13), in which the roller burnishing head housing (6) is supported pivotably about a first pivot axis, which is perpendicular to the crankshaft axis (K) and which extends parallel to a tangent to a working side of the burnishing roller (7). Additionally or alternatively thereto, the supporting roller head (5) comprises the supporting roller frame (14), in which the supporting roller housing (9) can be pivoted about a second pivot axis (B), which is perpendicular to the crankshaft axis (K) and parallel to the first pivot axis (A), and about a third pivot axis (C), which is perpendicular to the crankshaft axis (K) and perpendicular to the first pivot axis (A).

Owner:HEGENSCHEIDT MFD

Pressure Fluid Reservoir, Reservoir Unit, and Method For Producing a Pressure Fluid Reservoir

A pressure fluid reservoir for a traction-controlled vehicle brake system; a reservoir unit including a plurality of pressure fluid reservoirs; and a method for producing a pressure fluid reservoir are disclosed. The pressure fluid reservoir with its structural size unchanged, has a larger installation space for a restoring element cooperating with a reservoir piston and at the same time can be produced economically. To that end, as the reservoir piston, a component reshaped in non-metal-cutting fashion from a sheet-metal material is proposed, on whose circumference an encompassing receptacle for a piston seal is integrally formed, likewise in non-metal-cutting fashion. The reservoir piston can be produced by deep drawing; the receptacle for the piston seal can be produced by roller-burnishing. Both method steps can be performed economically in one combined operation.

Owner:ROBERT BOSCH GMBH

Method for processing gold jewelries

The invention discloses a method for processing gold jewelries. The method comprises the following steps: (1) melting gold, namely burning gold in a high-temperature quartz crucible by utilizing the flame of acetylene to melt the gold into a single auxiliary part suitable for processing a jewelry; (2) reversing a mold, namely melting the gold auxiliary by utilizing a high frequency or medium frequency centrifugal casting machine, and pouring the molten gold into a plaster mold to cast a casting; (3) polishing, namely polishing the casting surface by using a magnetic polishing machine or cylinder polishing machine to generate gloss; (4) benching, namely soldering, rasping and hammering the casting by utilizing swage and doming block to finish deformation and rough surface in the casting process; (5) performing press-polishing, namely contacting the gold surface with an agate pen, and rubbing the workpiece to enable the workpiece surface to generate gloss; and (6) embroidering; and (7) blasting fine quartz sands onto the exposed polished metal surface at high pressure to make a hazy and mild surface process. The method is simple in operation, the gold jewelries manufactured by the method has high gloss, cost is saved for manufacturers, and the requirement of consumers can be met.

Owner:HAIAN KEHAO TEXTILE CO LTD

Barrel burnishing tool

ActiveCN100467226CLow costNo loss of elasticityPolishing machinesBurnishing machinesAxial displacementLoad torque

The invention provides a roller burnishing tool, accurately converting very small torque displacement to axial displacement, coping with a variation in pre-working diameter, causing no setting in spite of repeated use, and causing no change in a no-load position (original position). In this roller burnishing tool (10), a workpiece is inserted in a cylindrical frame (2) provided with a plurality of rollers (1) disposed for rolling compaction to perform rolling compaction working for the outer peripheral surface of the workpiece by the rollers. The roller burnishing tool (10)includes an automatic diameter correcting mechanism (E), in which the mechanism is provided with a torque converting mechanism (T) for converting the load torque received by the rollers to the axial displacement in pressing the outer peripheral surface of the workpiece by the rollers (1), thereby automatically correcting the diameter even if the pre-working dimension varies.

Owner:SUGINO MACHINE

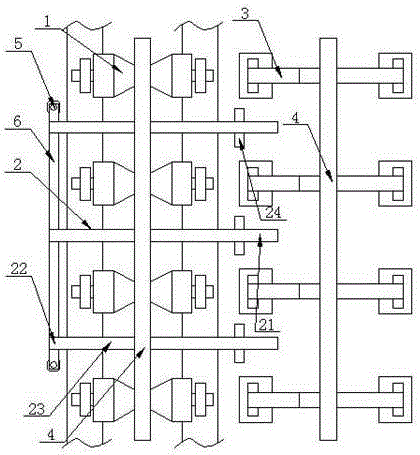

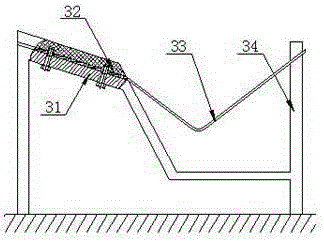

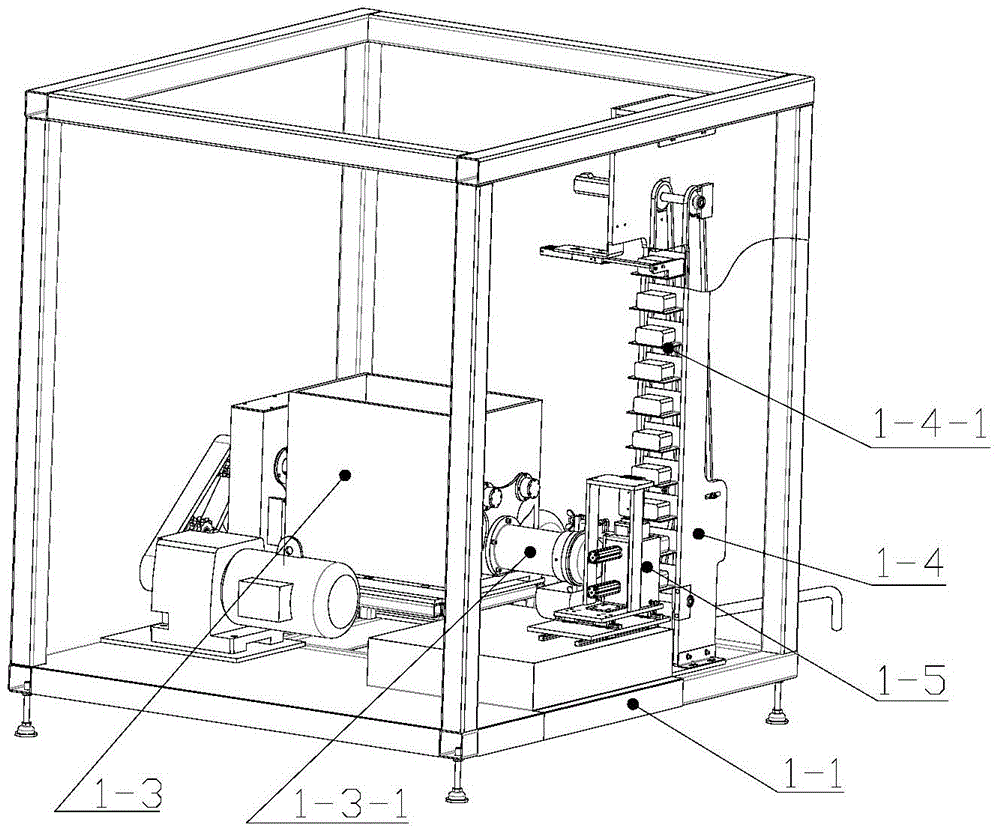

Automatic discharging mechanism for roller burnishing of universal joint transmission shaft levers

InactiveCN105314322AEasy to fixSo as not to damageConveyor partsRoller-waysUniversal jointEngineering

The invention discloses an automatic discharging mechanism for roller burnishing of universal joint transmission shaft levers. The automatic discharging mechanism comprises a plurality of axial feeding wheels, radial turnover blocking rods and a plurality of lateral containing supports. The axial feeding wheels are collinearly arranged in the conveying direction of the universal joint transmission shaft levers. The lateral containing supports are collinearly arranged in the conveying direction of the universal joint transmission shaft levers and disposed on one side of the axial feeding wheels. The two ends of each radial turnover blocking rod include a discharging end and a lifting end respectively, and each radial turnover blocking rod further comprises a lifting section and a turnover shaft. Each lifting section is arranged in a gap between the corresponding adjacent axial feeding wheels. Each discharging end is arranged in a gap between the corresponding adjacent lateral containing supports. Each turnover shaft is located between the corresponding lifting section and the corresponding discharging end and is parallel to the axial direction of the universal joint transmission shaft levers. Lifting air cylinders are arranged at the bottoms of the lifting ends.

Owner:WUHU TIANJIN MACHINERY

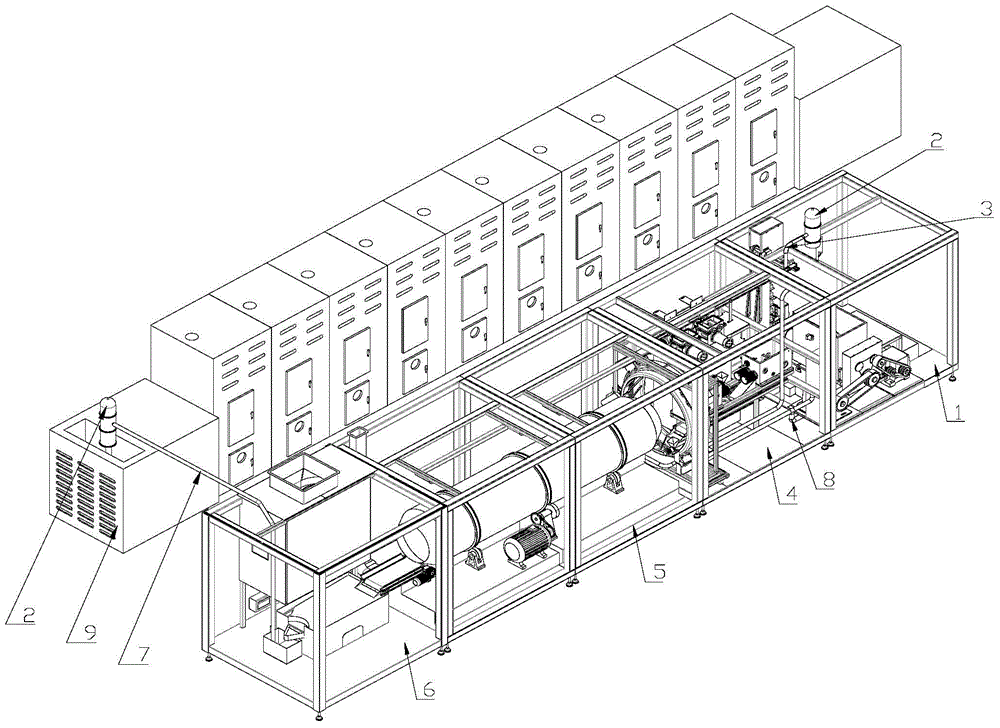

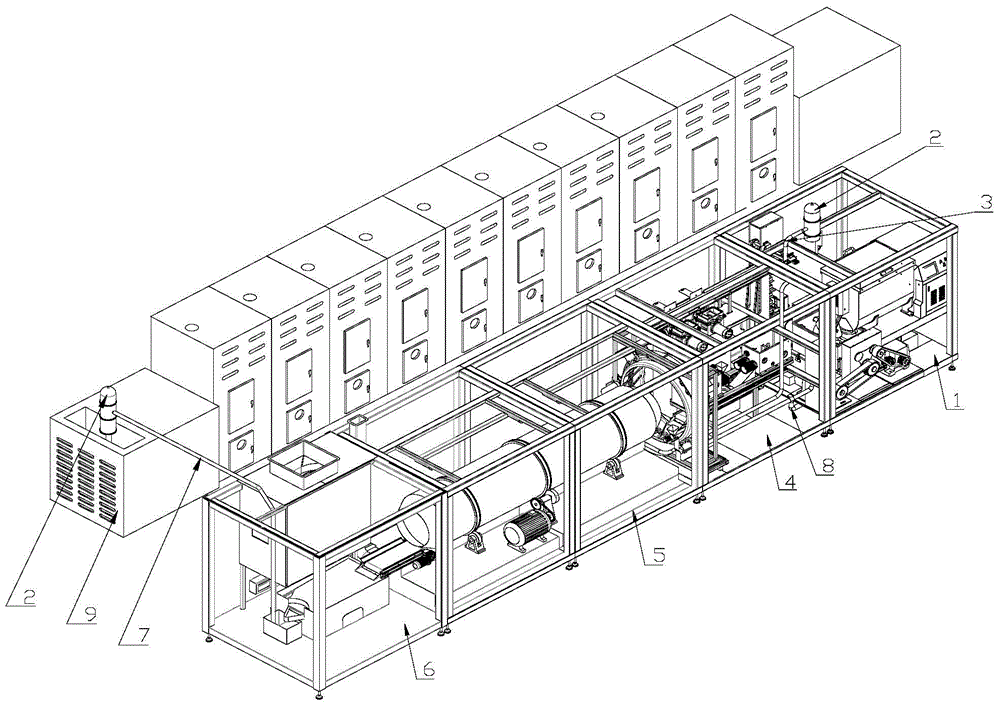

Mixed material pilling, barrel polishing and drying device

InactiveCN104546480AAchieve modularityFavorable connectionPharmaceutical product form changeProduction lineMicrowave

The invention mainly relates to a traditional Chinese medicine pill automatic production line in the field of pharmacy. A mixed material pilling, barrel polishing and drying device is mainly characterized by comprising a mixed medicine refining module, a pilling module, a polishing module, a pill selecting module and a microwave drying module, wherein the mixed medicine refining module, the pilling module, the polishing module, the pill selecting module and the microwave drying module are sequentially connected. According to the mixed material pilling, barrel polishing and drying device, the mixed medicine refining module comprises a double-paddle mixed medicine refining composite machine arranged on a module base; an outlet of the double-paddle mixed medicine refining composite machine is connected with a forming mold, and an elevator lifting device is arranged at the discharging end of the forming mold; a feeding chain plate is arranged on the elevator lifting device. The mixed material pilling, barrel polishing and drying device has the advantages that modularization of the traditional Chinese medicine pill automatic production line is achieved, and the problems that the field mounting and debugging time is long and special technicians are required for mounting and debugging are accordingly solved. Before each module leaves a factory, the modules are completely mounted and debugged, are conveyed to the field and are only required to be mounted in sequence, so that the time is greatly saved.

Owner:TIANSHUI HUAYUAN PHARMA EQUIP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com