Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

285results about How to "Efficient polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

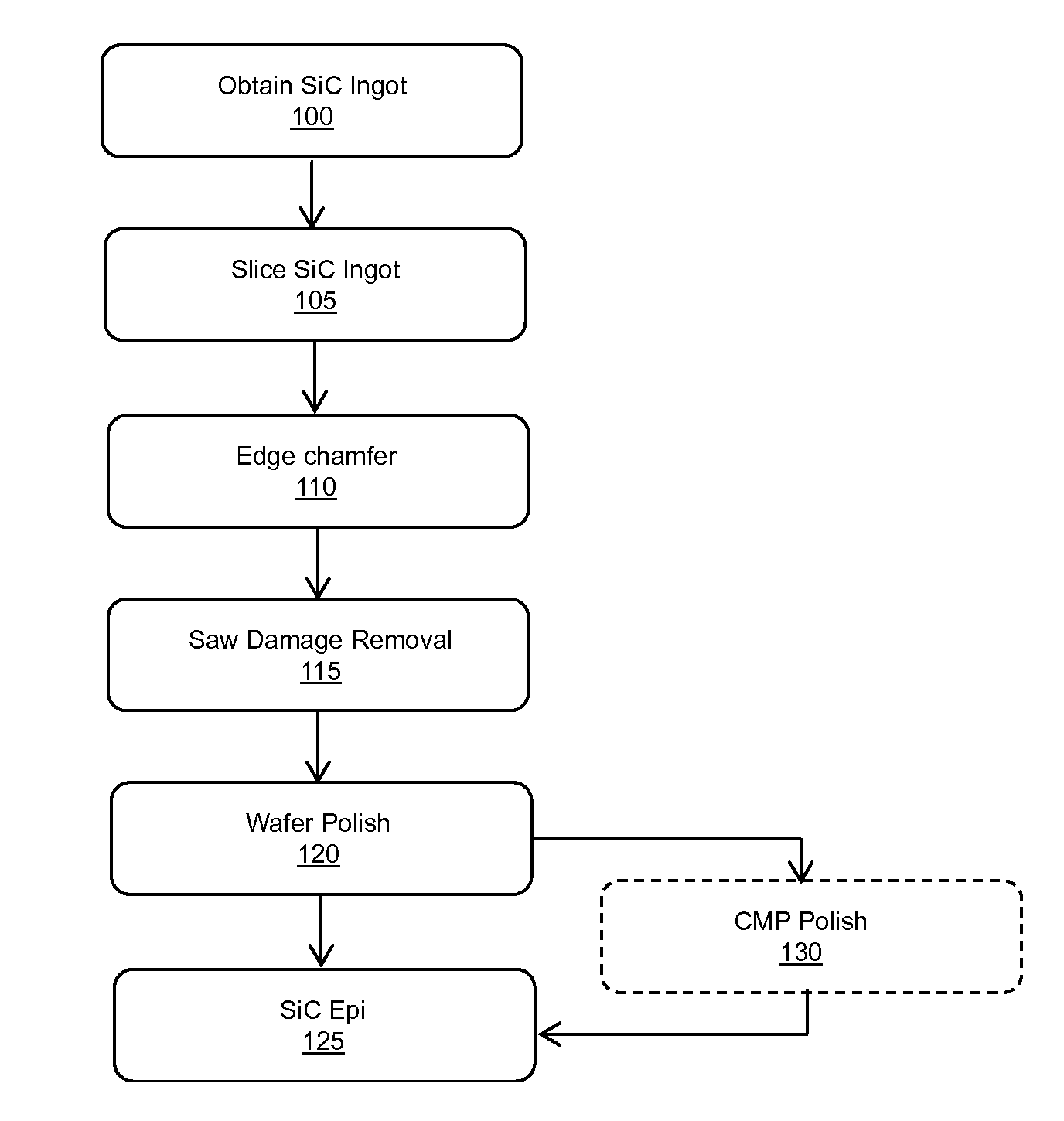

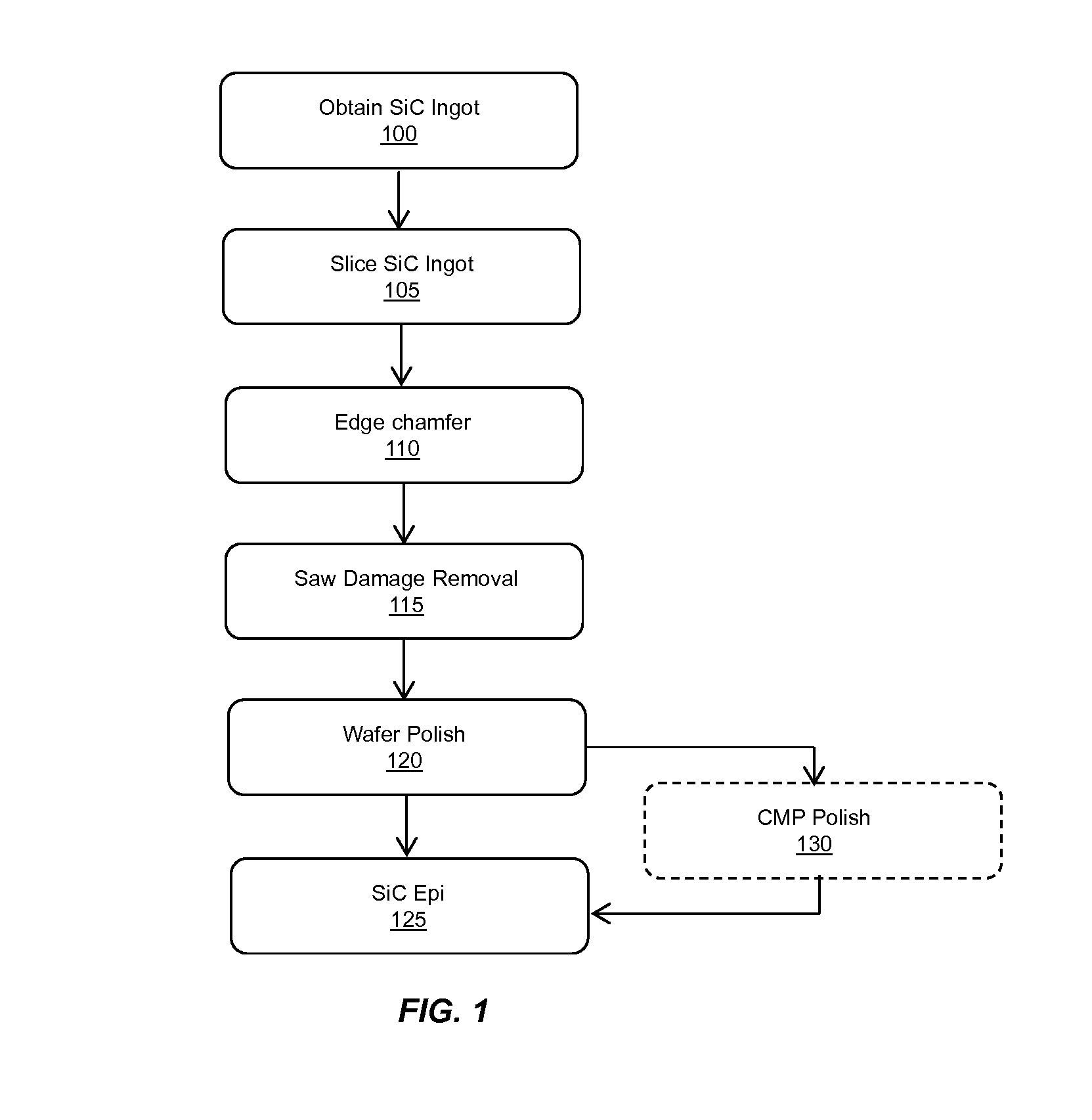

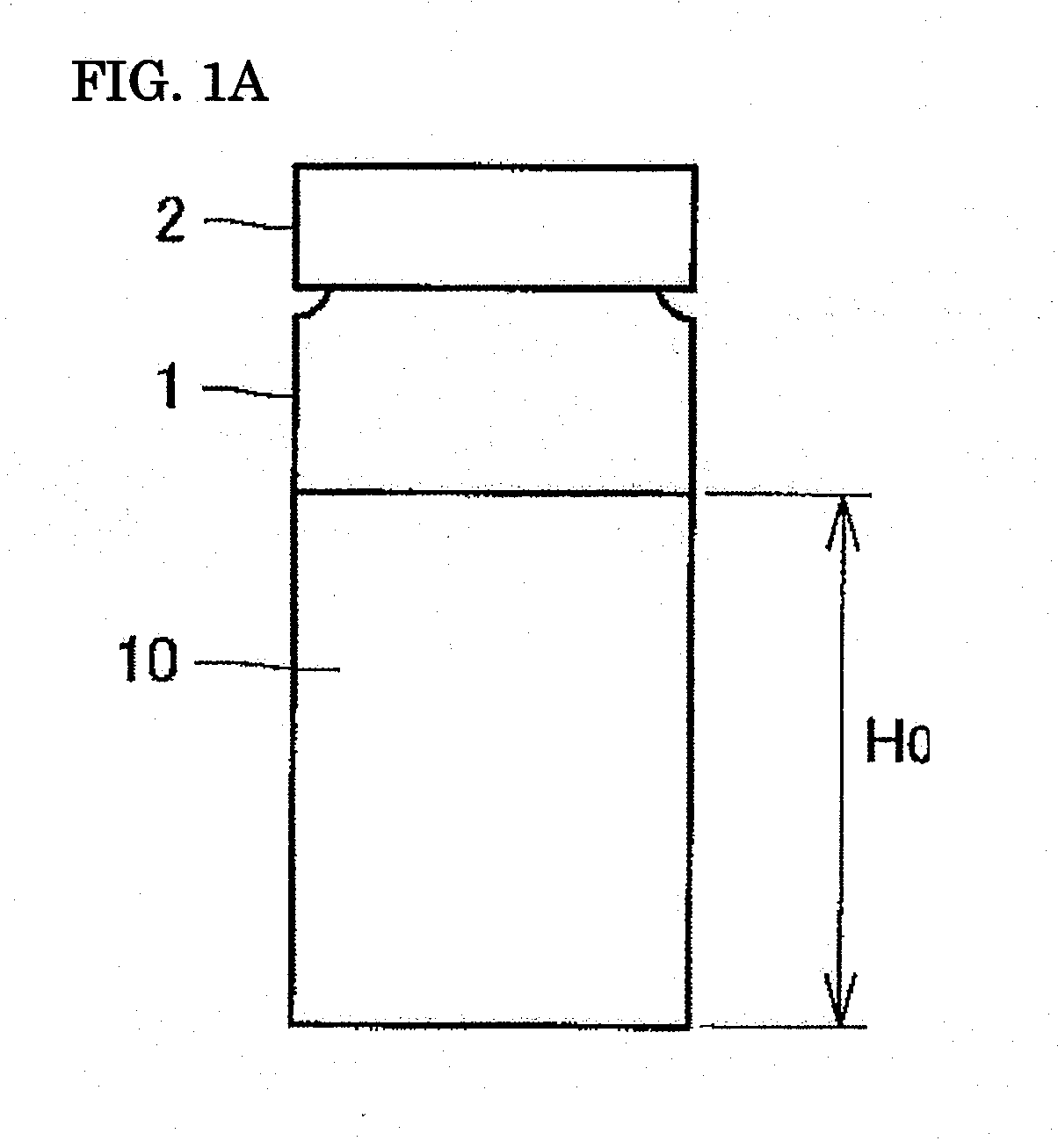

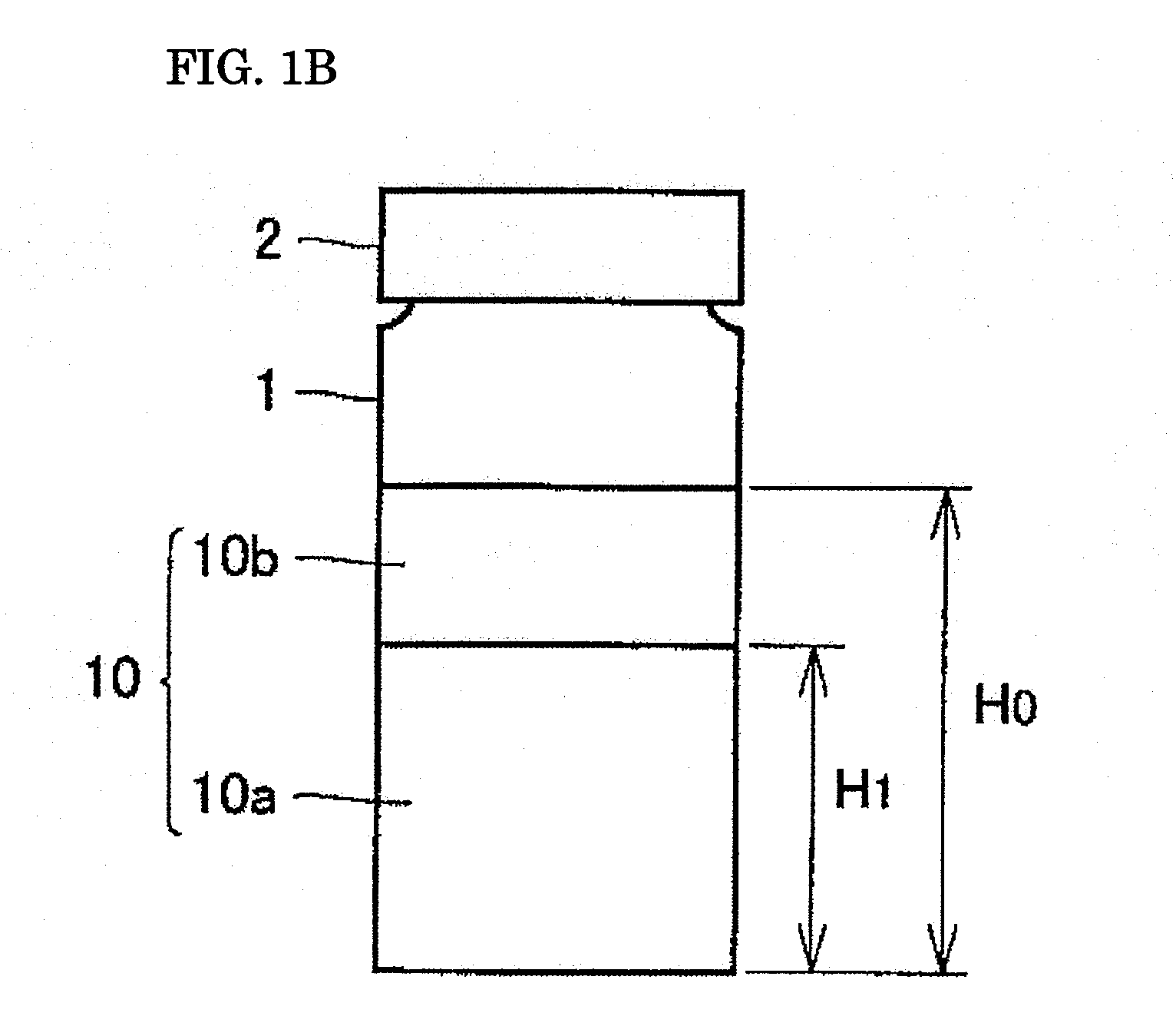

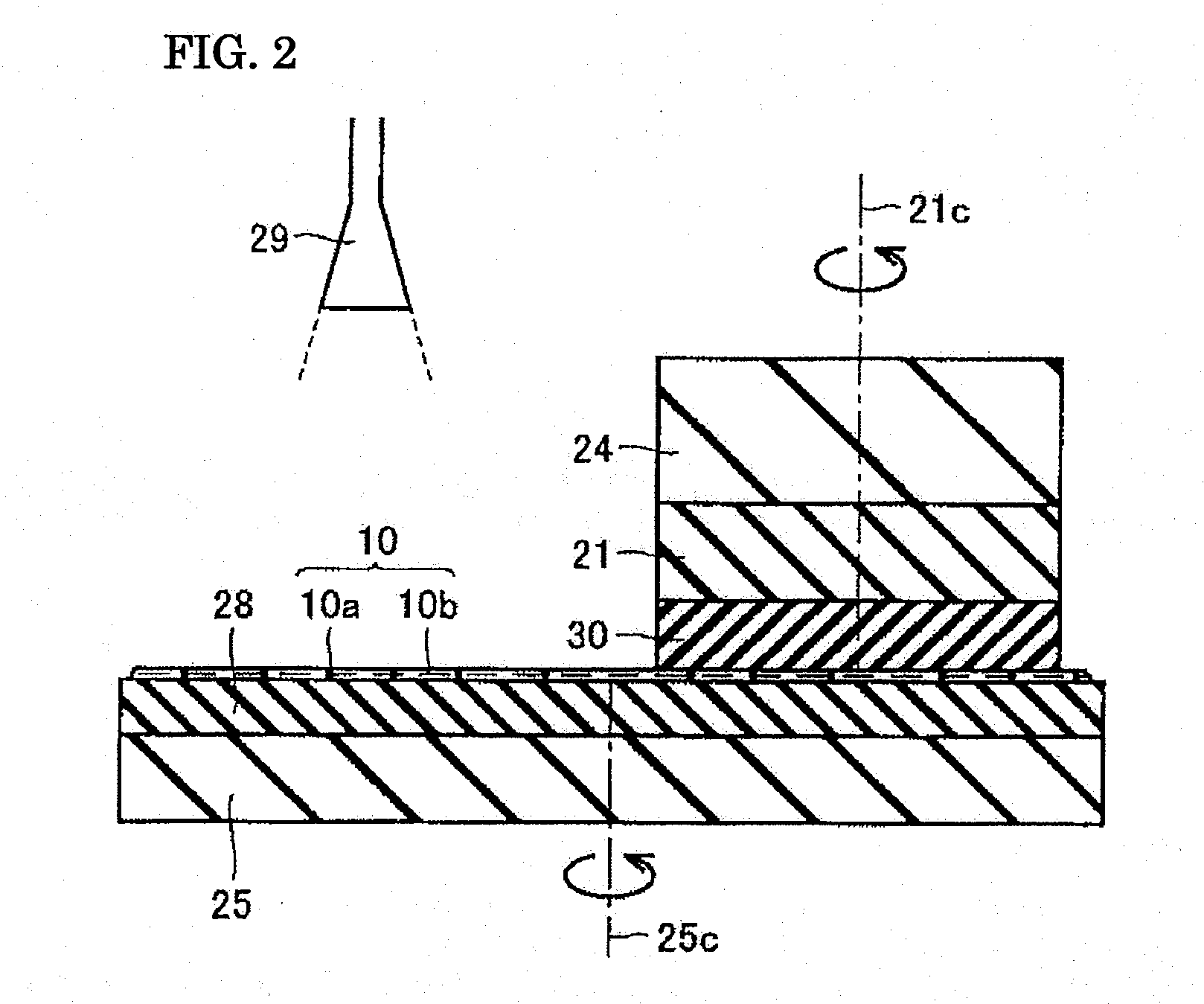

Flat sic semiconductor substrate

ActiveUS20140117380A1Efficient polishingImprove performanceEdge grinding machinesPolycrystalline material growthCrystallographyWafering

Methods for manufacturing silicon carbide wafers having superior specifications for bow, warp, total thickness variation (TTV), local thickness variation (LTV), and site front side least squares focal plane range (SFQR). The resulting SiC wafer has a mirror-like surface that is fit for epitaxial deposition of SiC. The specifications for bow, warp, total thickness variation (TTV), local thickness variation (LTV), and site front side least squares focal plane range (SFQR) of the wafer are preserved following the addition of the epitaxy layer.

Owner:SK SILTRON CSS LLC

Modified plating solution for plating and planarization and process utilizing same

InactiveUS6354916B1High dissolution rateHigh removal ratePigmenting treatmentOther chemical processesConductive materialsSolvent

A modified plating solution that can be used to electroplate a high quality conductive material that can be effectively polished and planarized includes (1) a solvent, (2) an ionic species of the conductive material to be deposited, (3) at least one additive to improve electrical and structural properties, and (4) a modifying agent.

Owner:NOVELLUS SYSTEMS

Polishing pad for semiconductor wafer and laminated body for polishing of semiconductor wafer equipped with the same as well as method for polishing of semiconductor wafer

InactiveUS6855034B2Lower performance requirementsEasy to detectPolishing machinesRevolution surface grinding machinesWater insolubleEngineering

An objective of the present invention is to provide a polishing pad for a semiconductor wafer and a laminated body for polishing of a semiconductor wafer equipped with the same which can perform optical endpoint detection without lowering the polishing performance as well as methods for polishing of a semiconductor wafer using them. The polishing pad of the invention comprises a water-insoluble matrix material such as crosslinked 1,2-polybutadiene, and a water-soluble particle such as β-cyclodextrin dispersed in this water-insoluble matrix material, and has a light transmitting properties so that a polishing endpoint can be detected with a light.

Owner:JSR CORPORATIOON

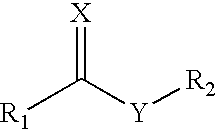

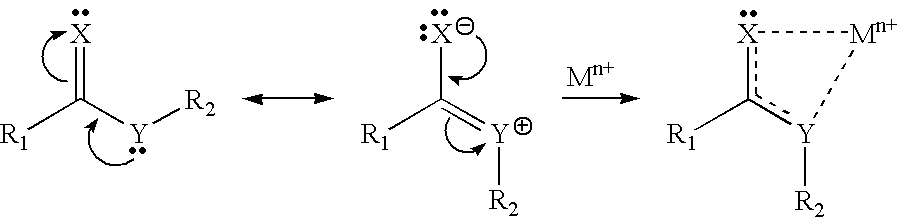

Chemical-mechanical abrasive composition and method

InactiveUS6436834B1Improve wearing rateHigh purityOther chemical processesDecorative surface effectsAtomic groupCompound (substance)

The invention provides a chemical-mechanical abrasive composition for use in semiconductor processing, which comprises an aqueous medium, an abrasive, and an abrasion accelerator. The abrasion accelerator mainly functions to enhance the removal rate of the substances to be removed, and selected from the compounds of the following formula, the acid-addition salts thereof, or mixtures of two or more of the foregoing compounds and salts:wherein X and Y are independently lone-pair electrons containing atoms or atomic groups; and R1 and R2 are independently H, alky, amino, aminoalkyl, or alkoxy. The chemical-mechanical abrasive composition of the invention may optionally comprise an acidic component and / or a salt thereof, so as to further enhance the abrasion rate. The invention further provides a method of using the above chemical-mechanical abrasive composition for polishing the surface of a semiconductor wafer.

Owner:EPOCH MATERIAL CO LTD

Method of polishing normal pressure plasma

The normal pressure plasma polishing method is provided. The normal pressure plasma polishing method includes providing plasma gas and reaction gas in the volume ratio of 4-1000; and starting RF power source and increasing power gradually while controlling the reflected power to zero, with the initial effective power being 180-240 W, normal power being 400-1200 W, and maximum power being 1500 W. The present invention realizes super smooth surface machining by means of plasma chemical reaction at normal pressure, and has no need of vacuum chamber, low cost, wide application range, high machining efficiency, no surface damage and contamination, and high surface smoothness up to 1nm Ra.

Owner:HARBIN INST OF TECH

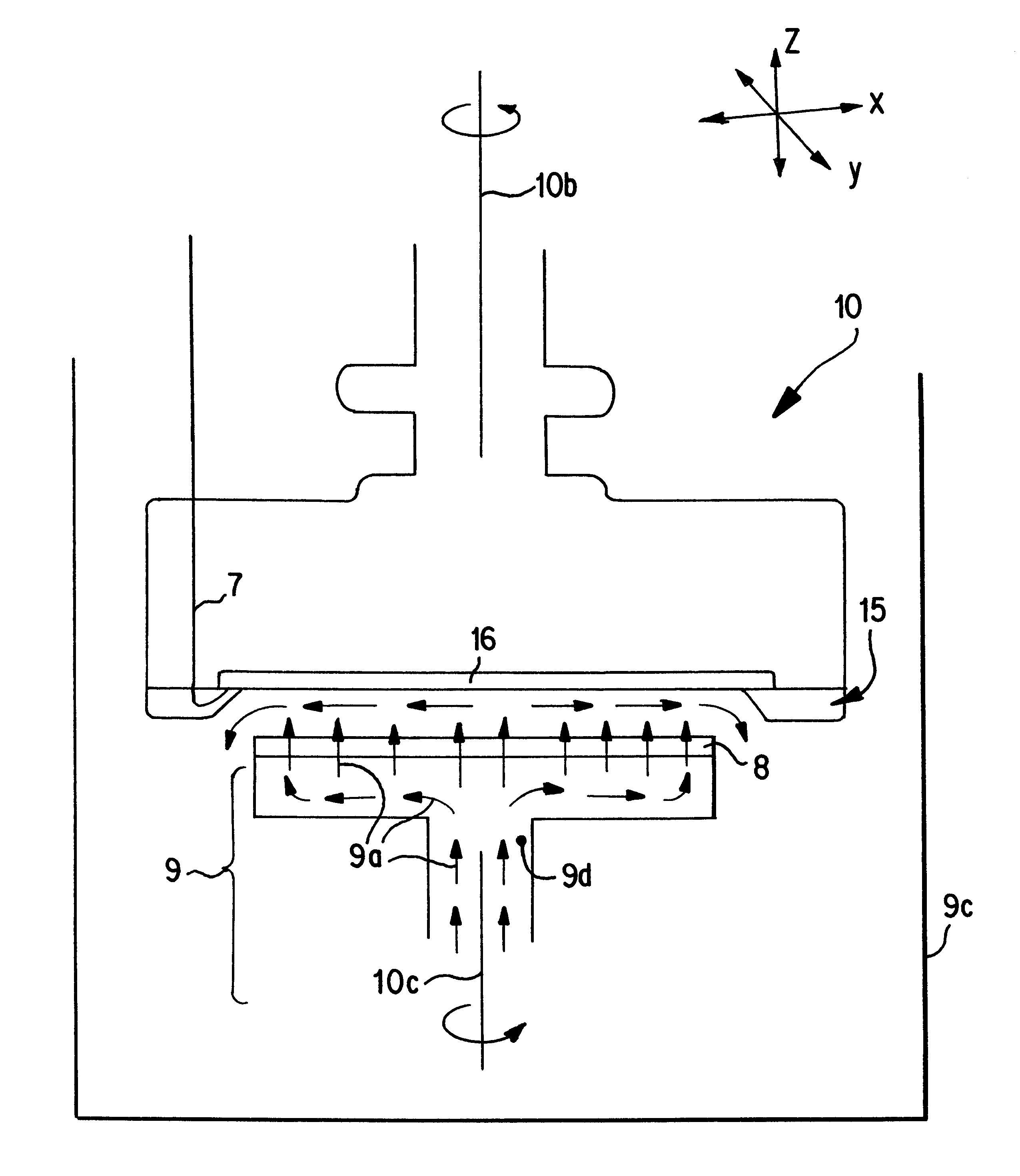

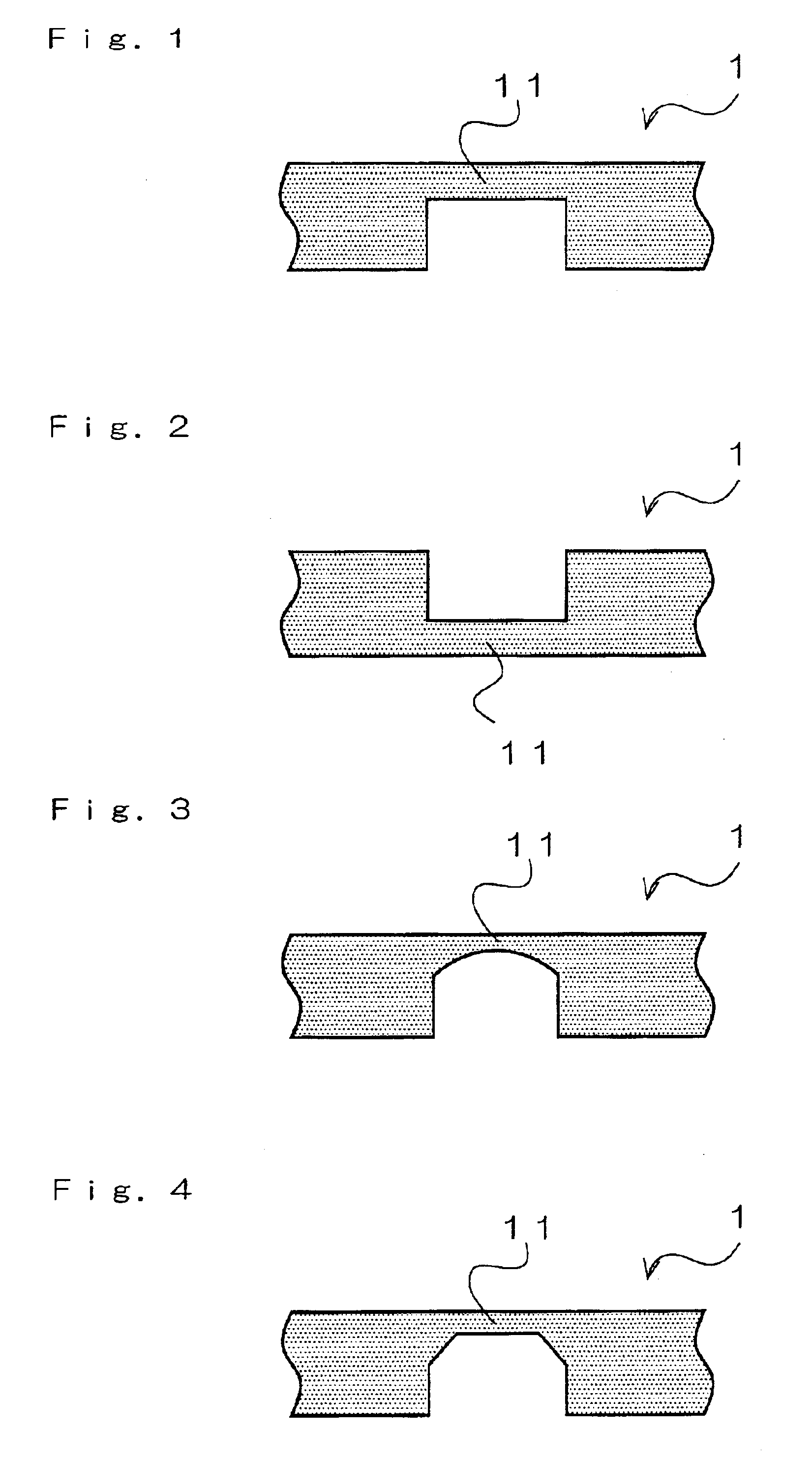

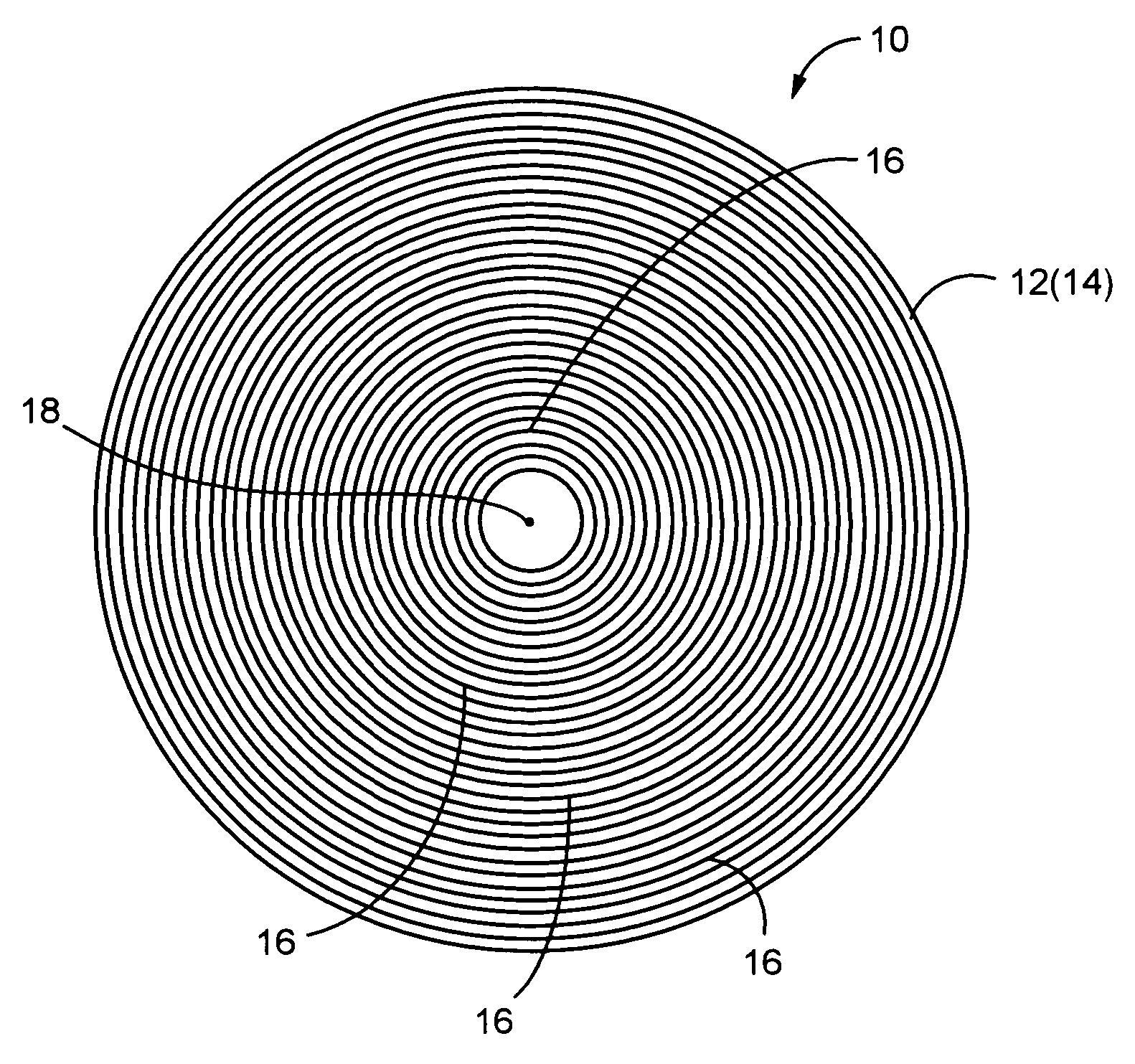

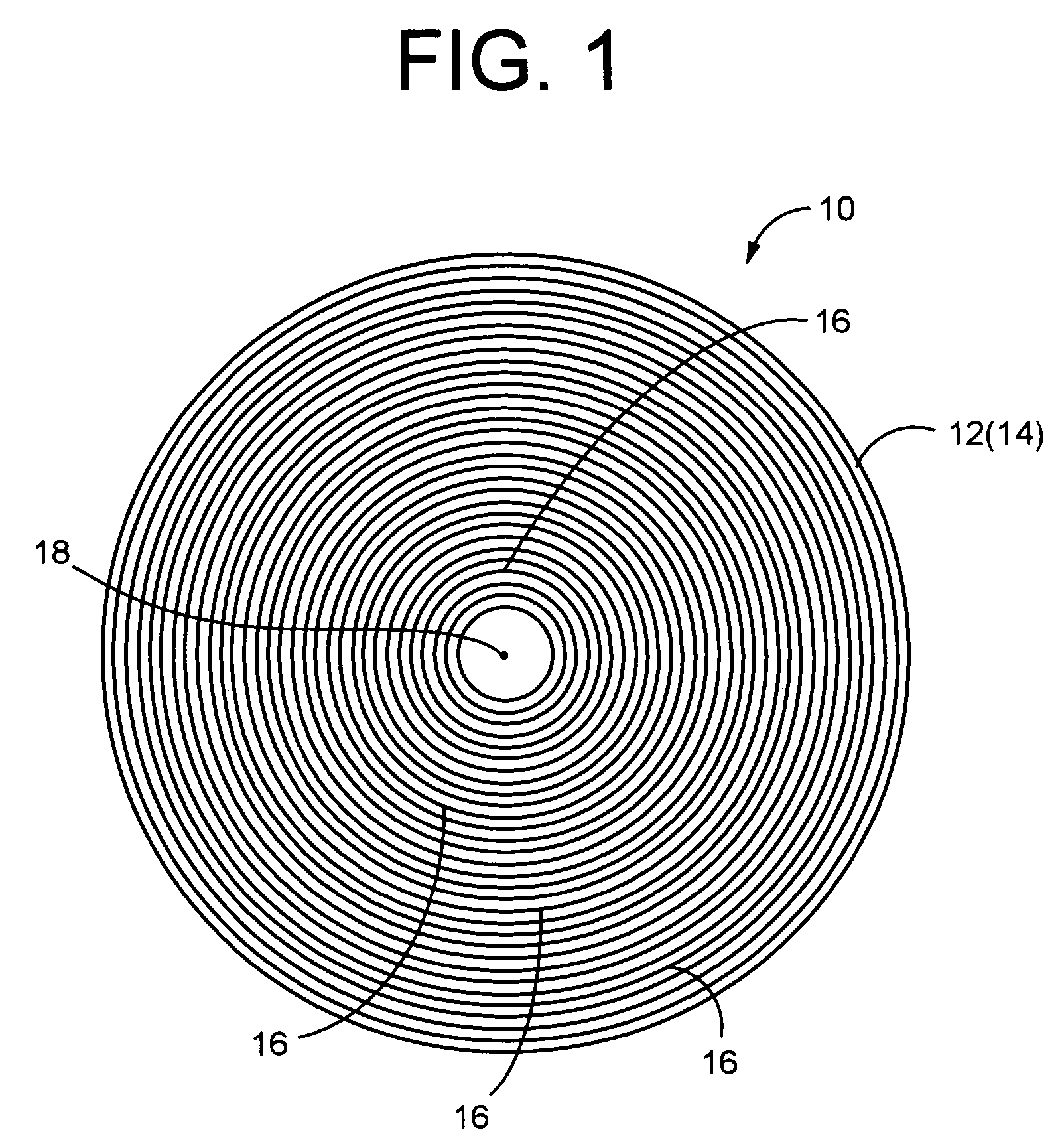

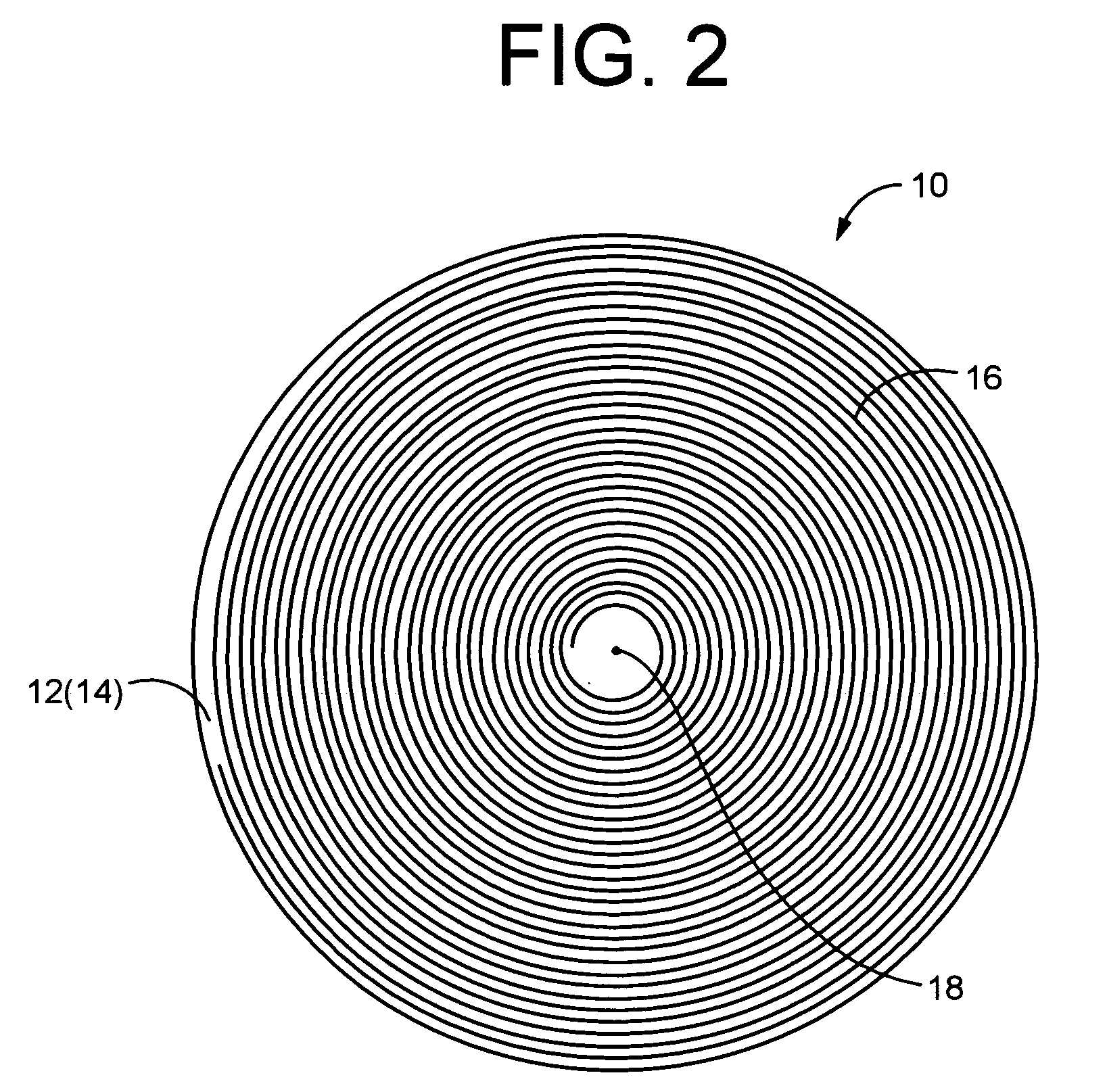

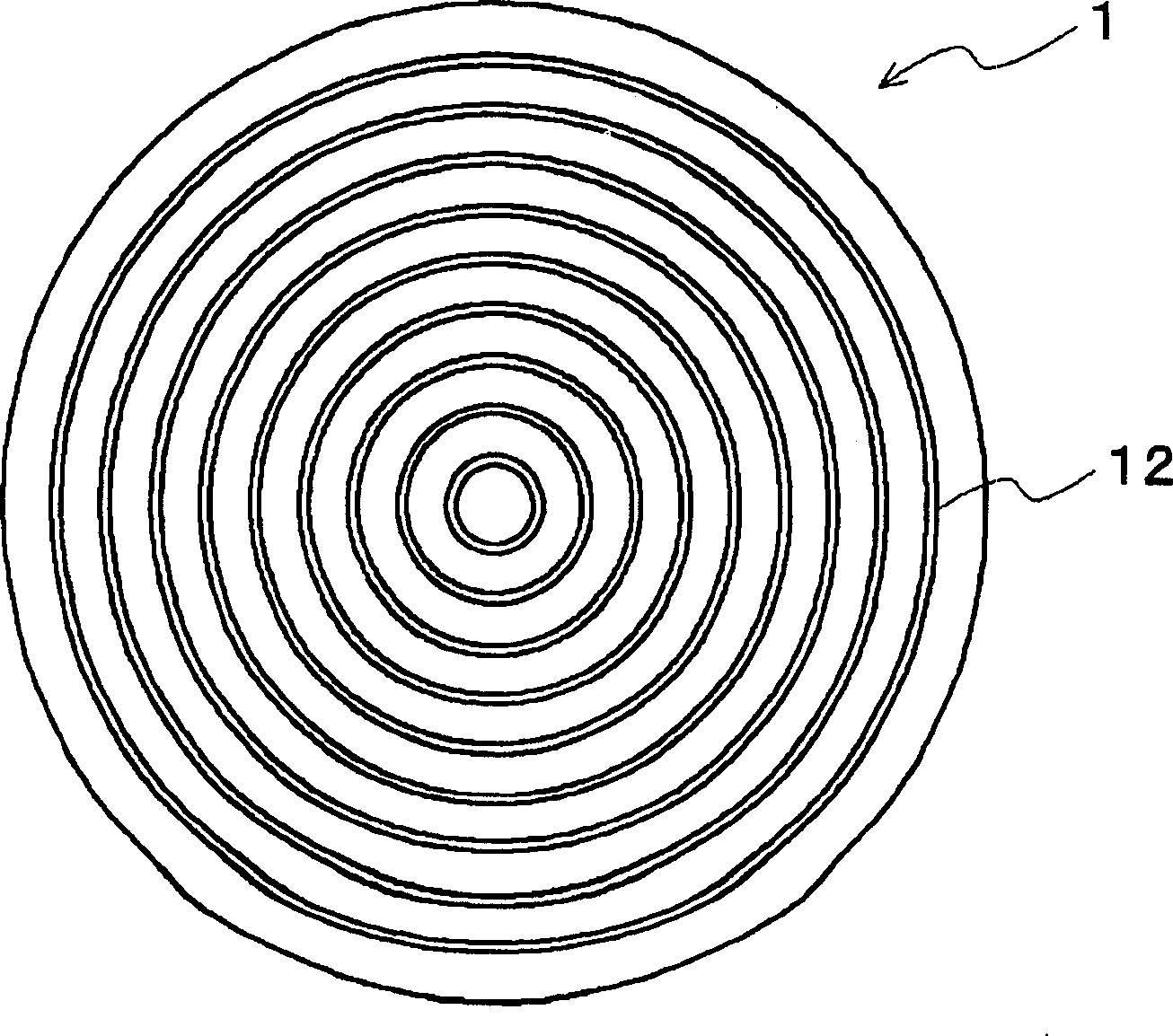

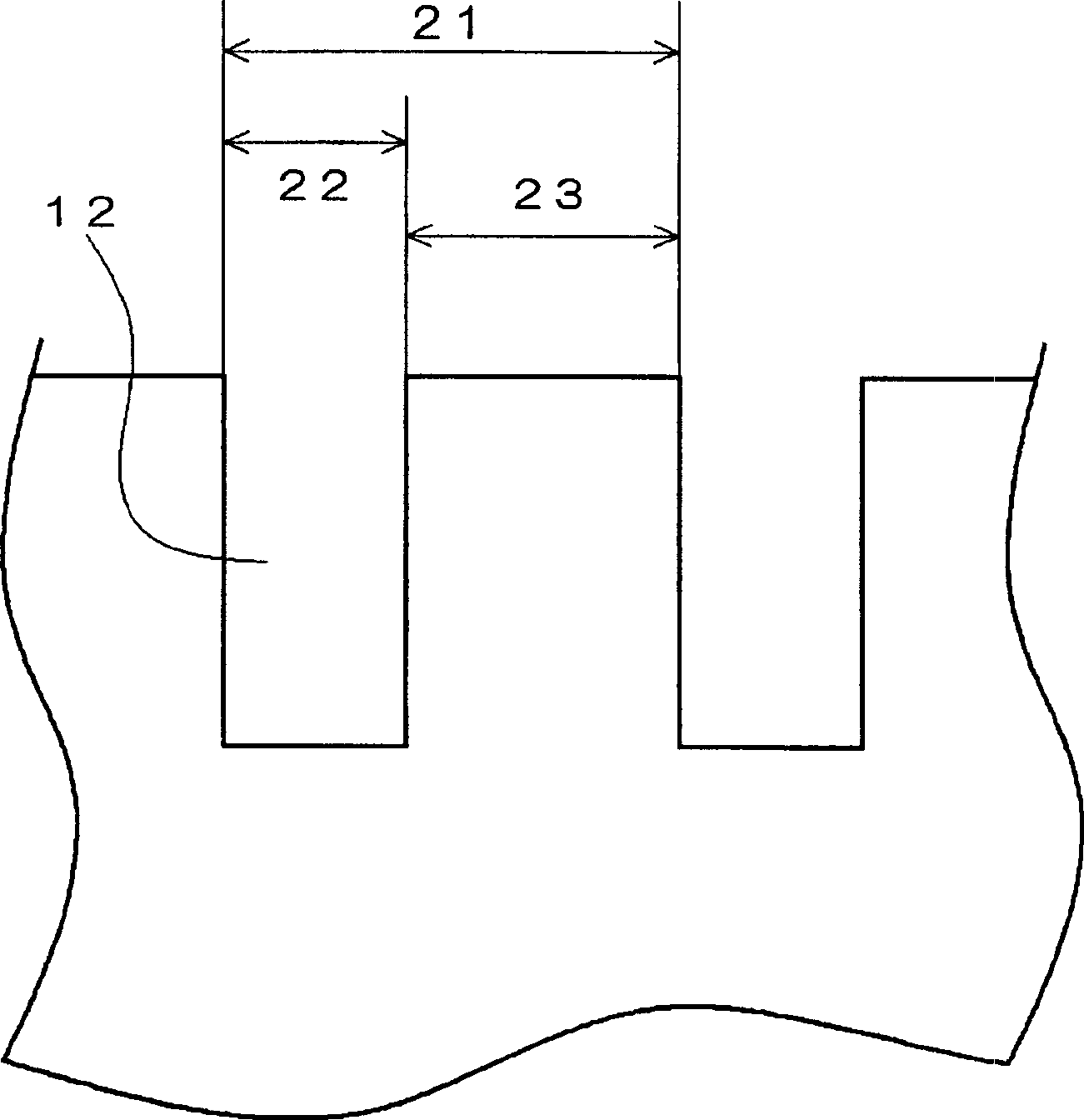

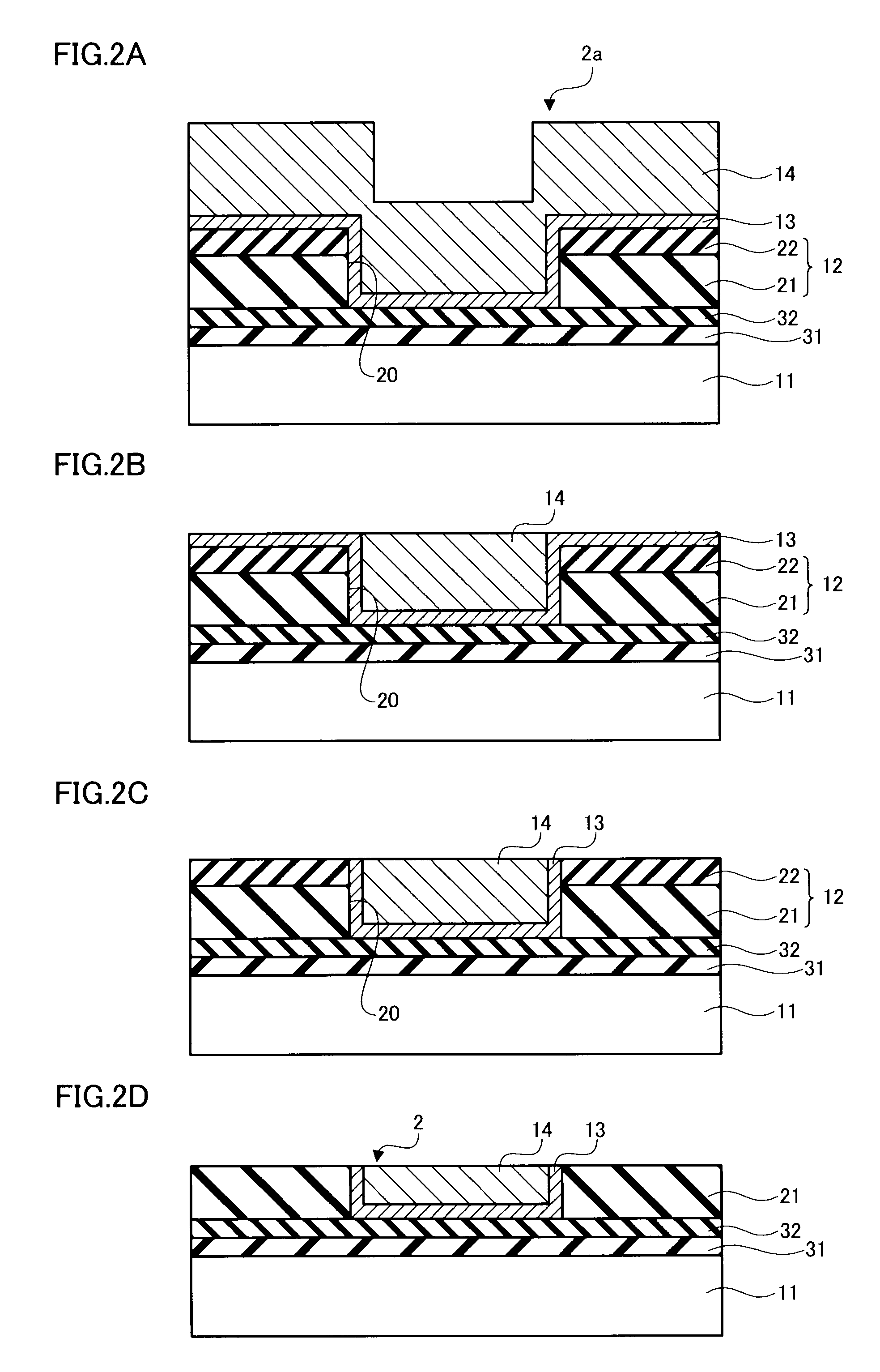

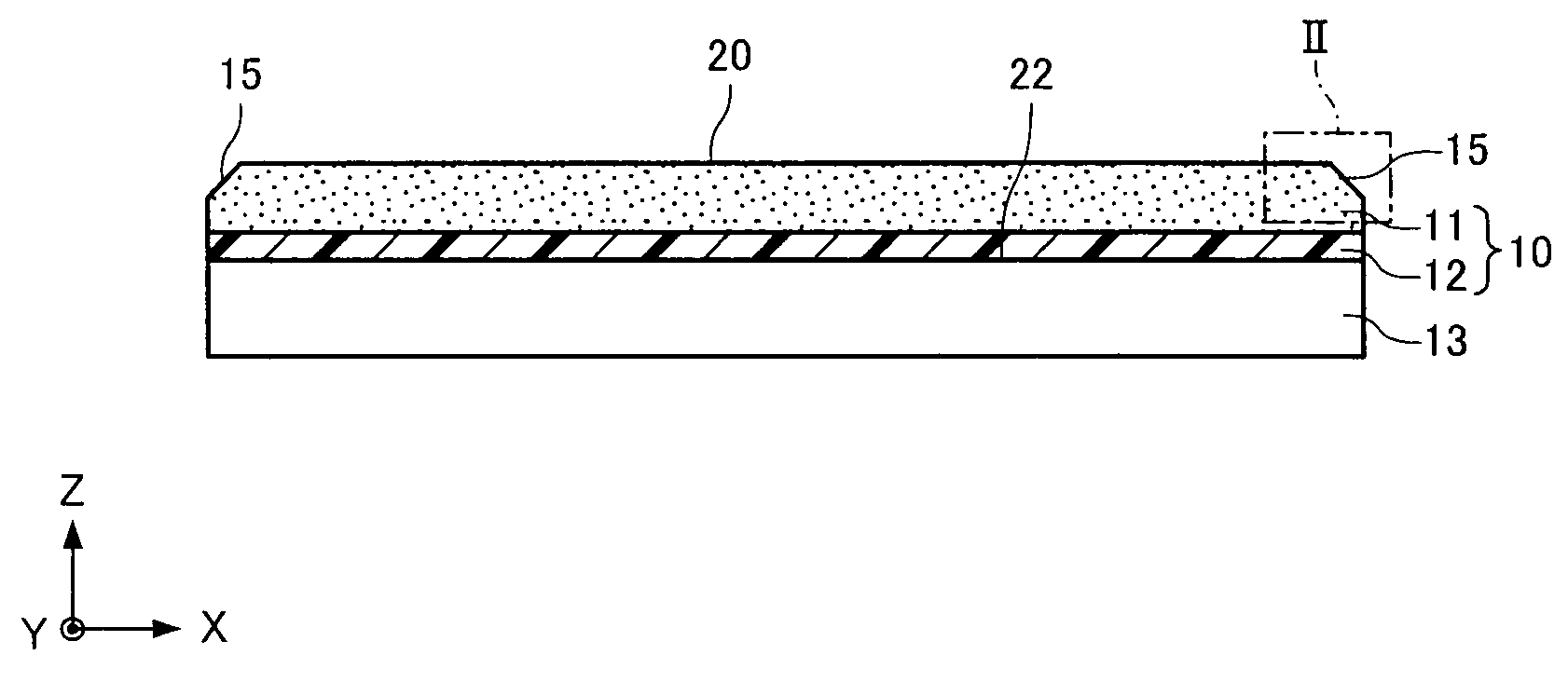

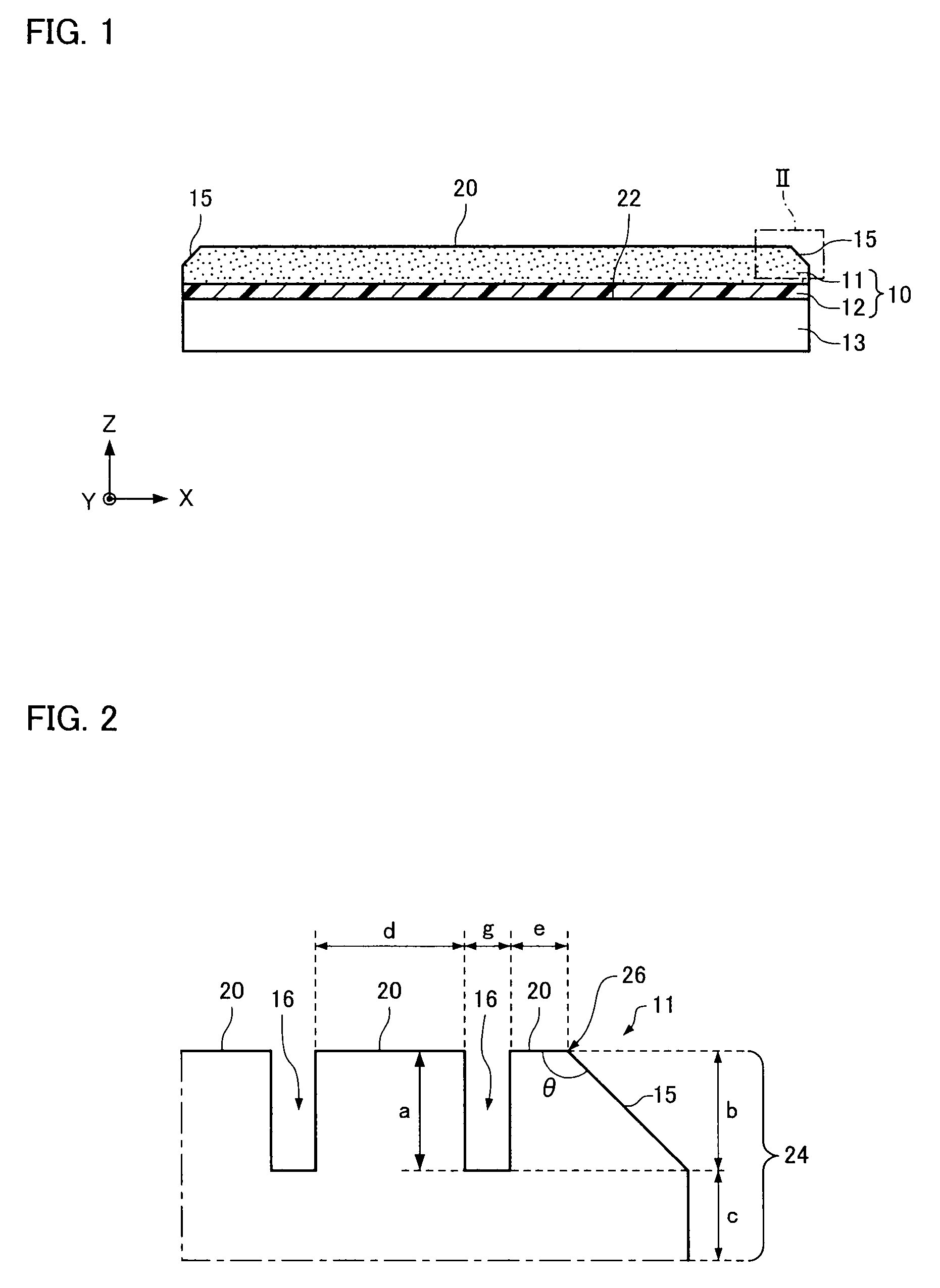

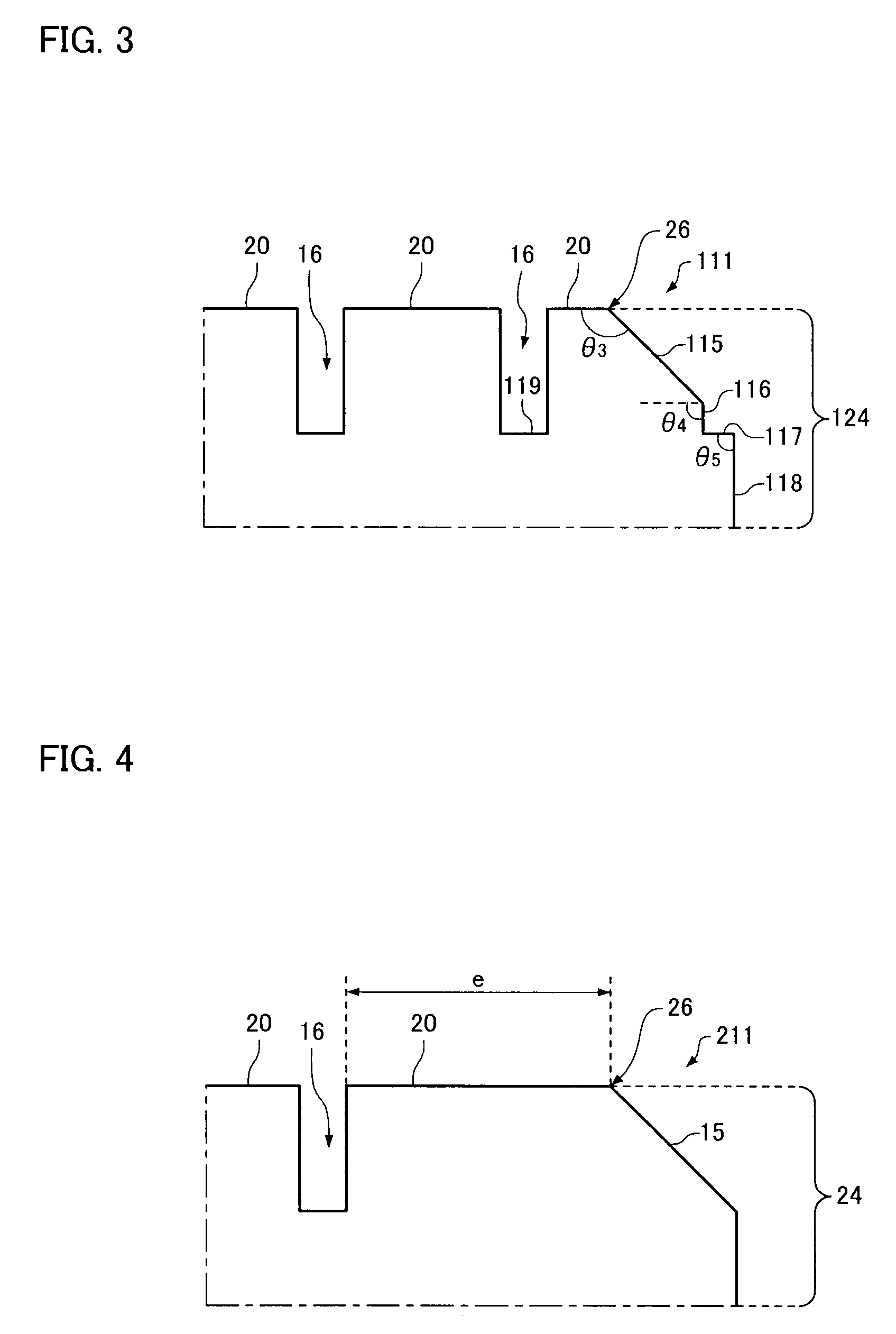

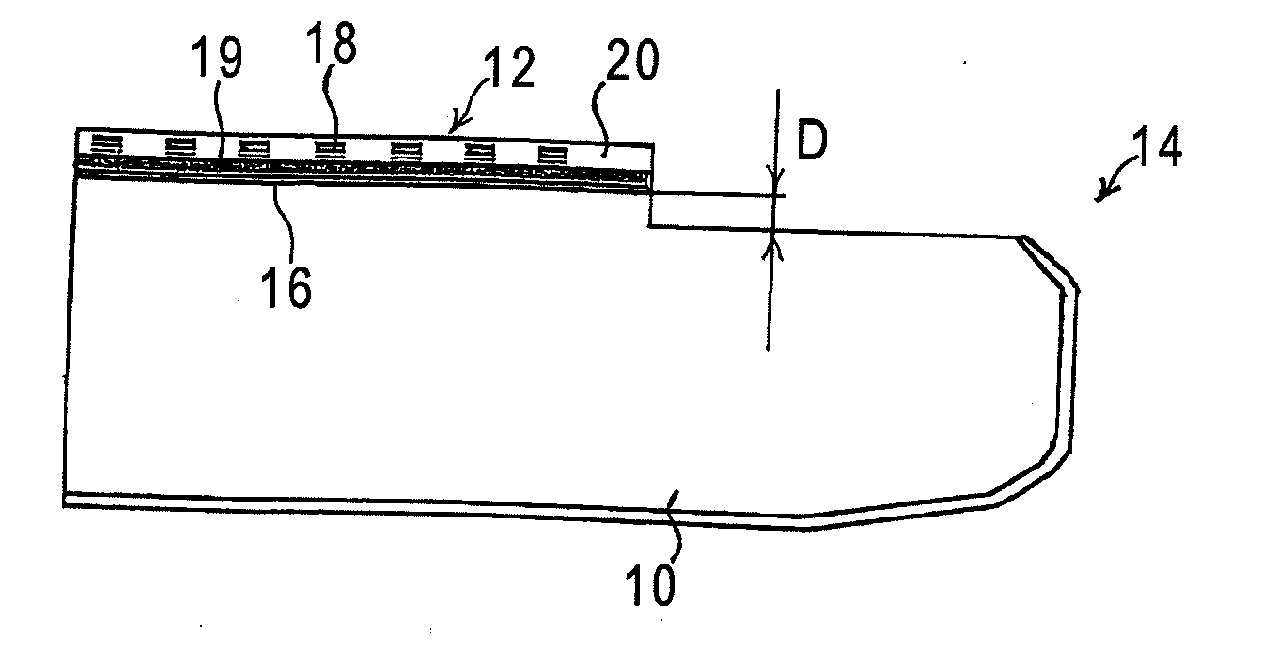

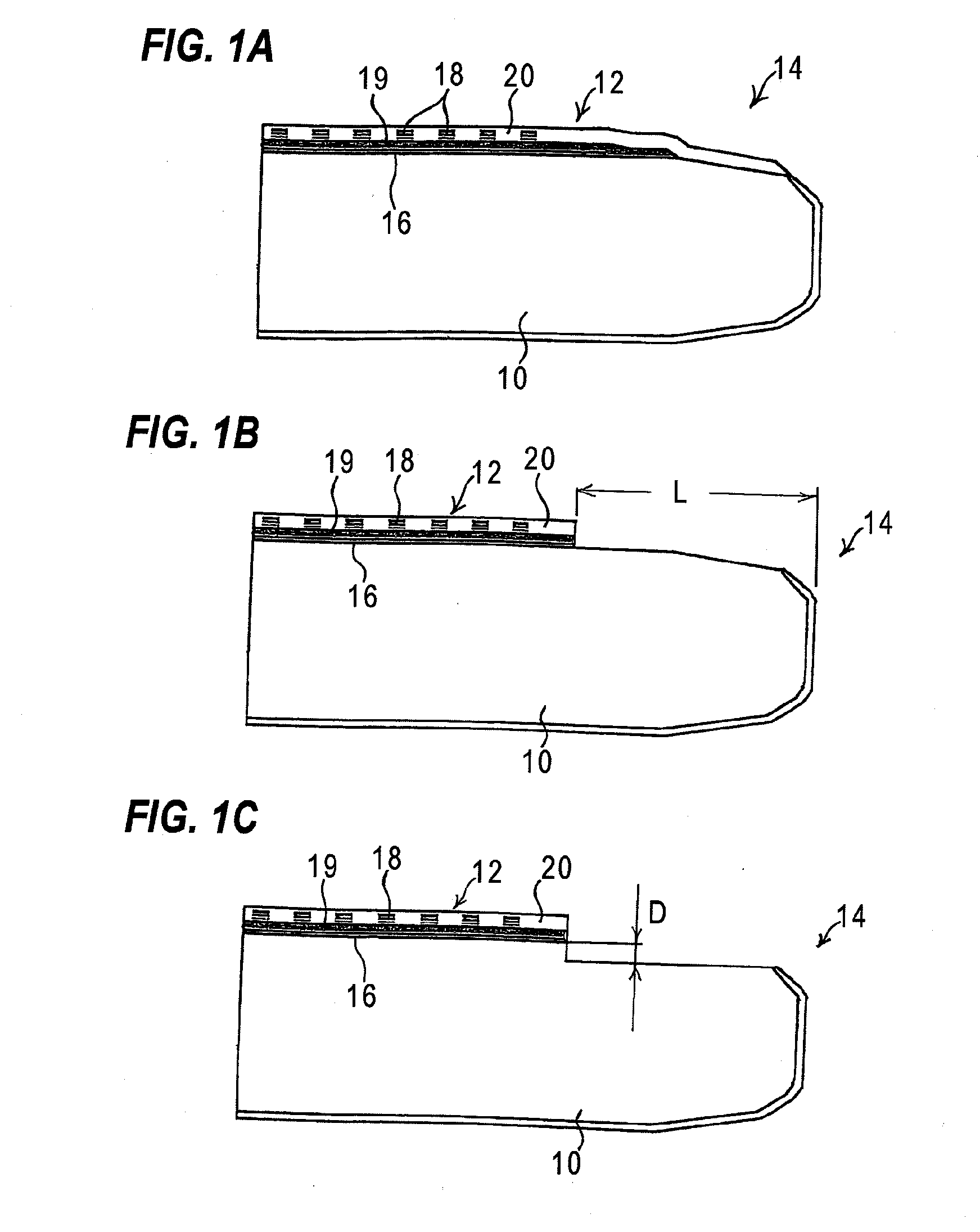

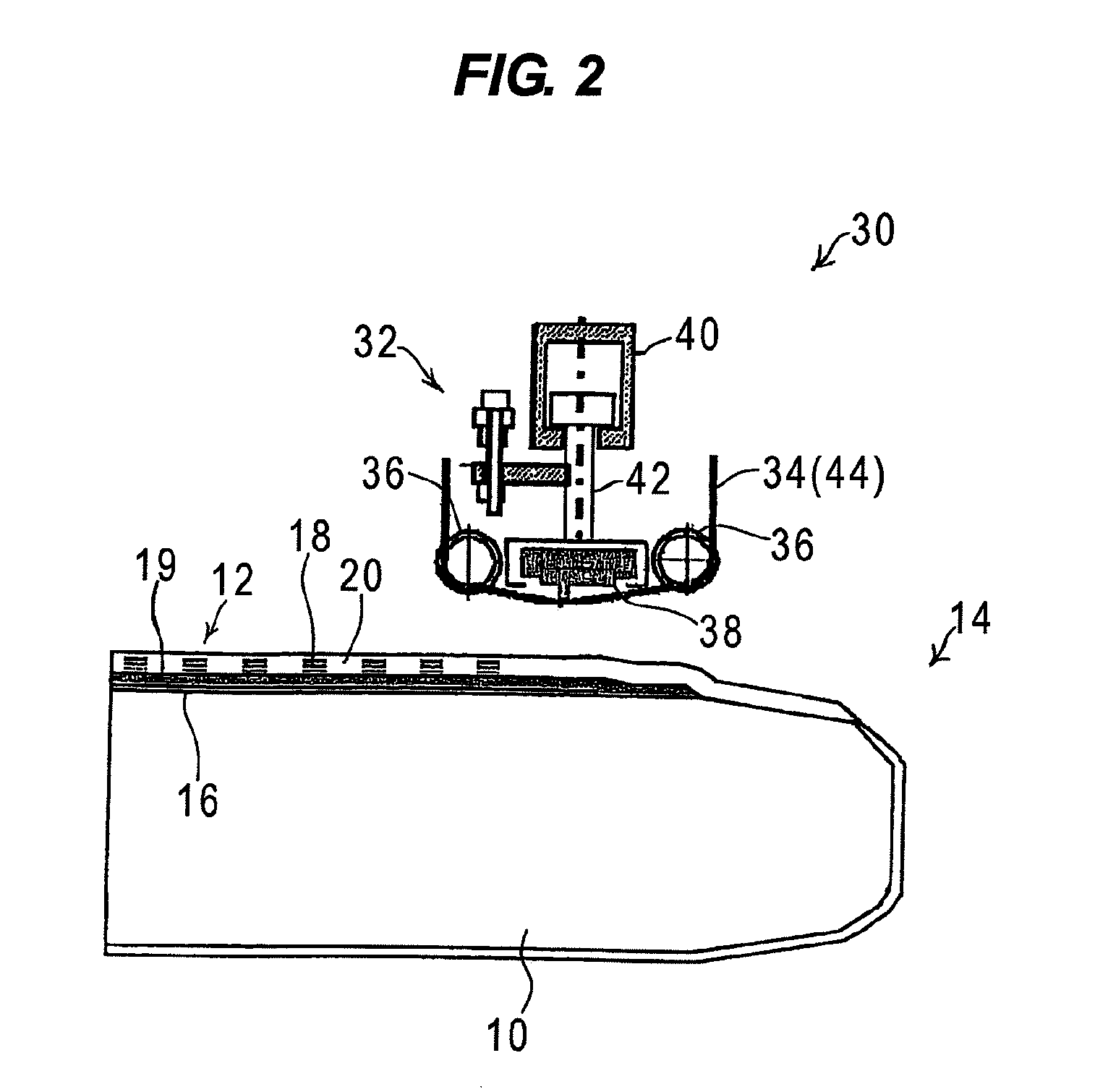

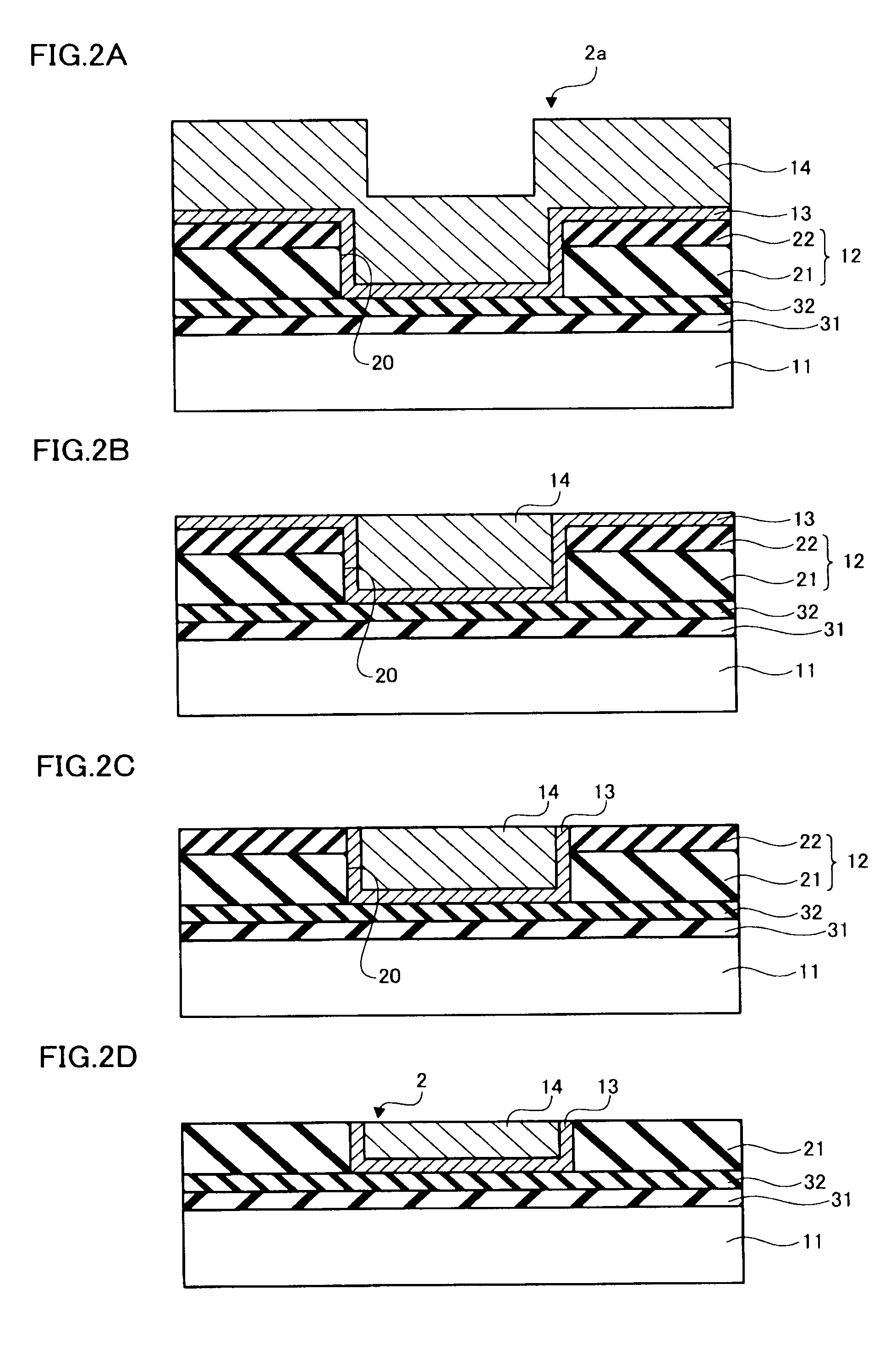

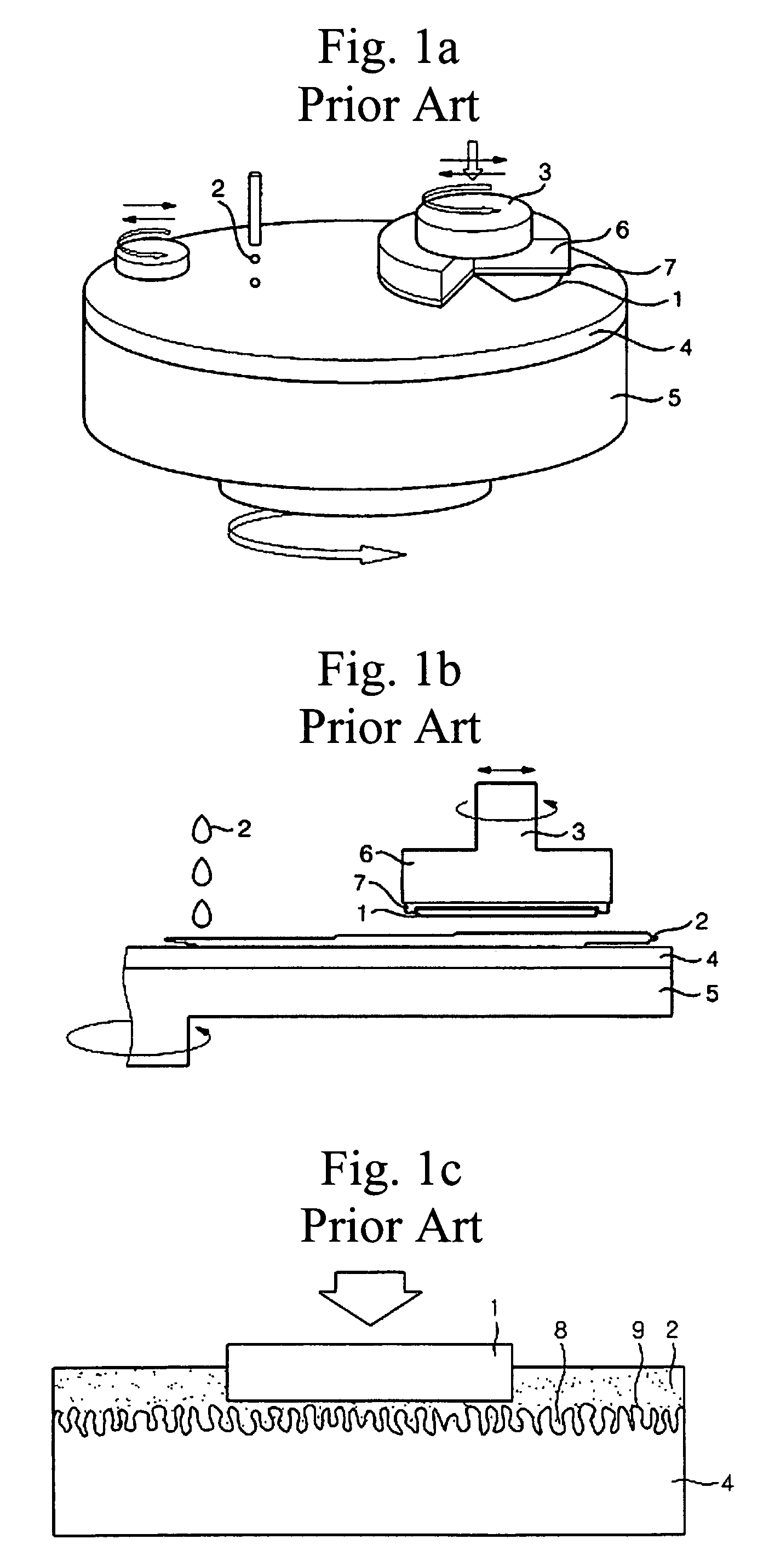

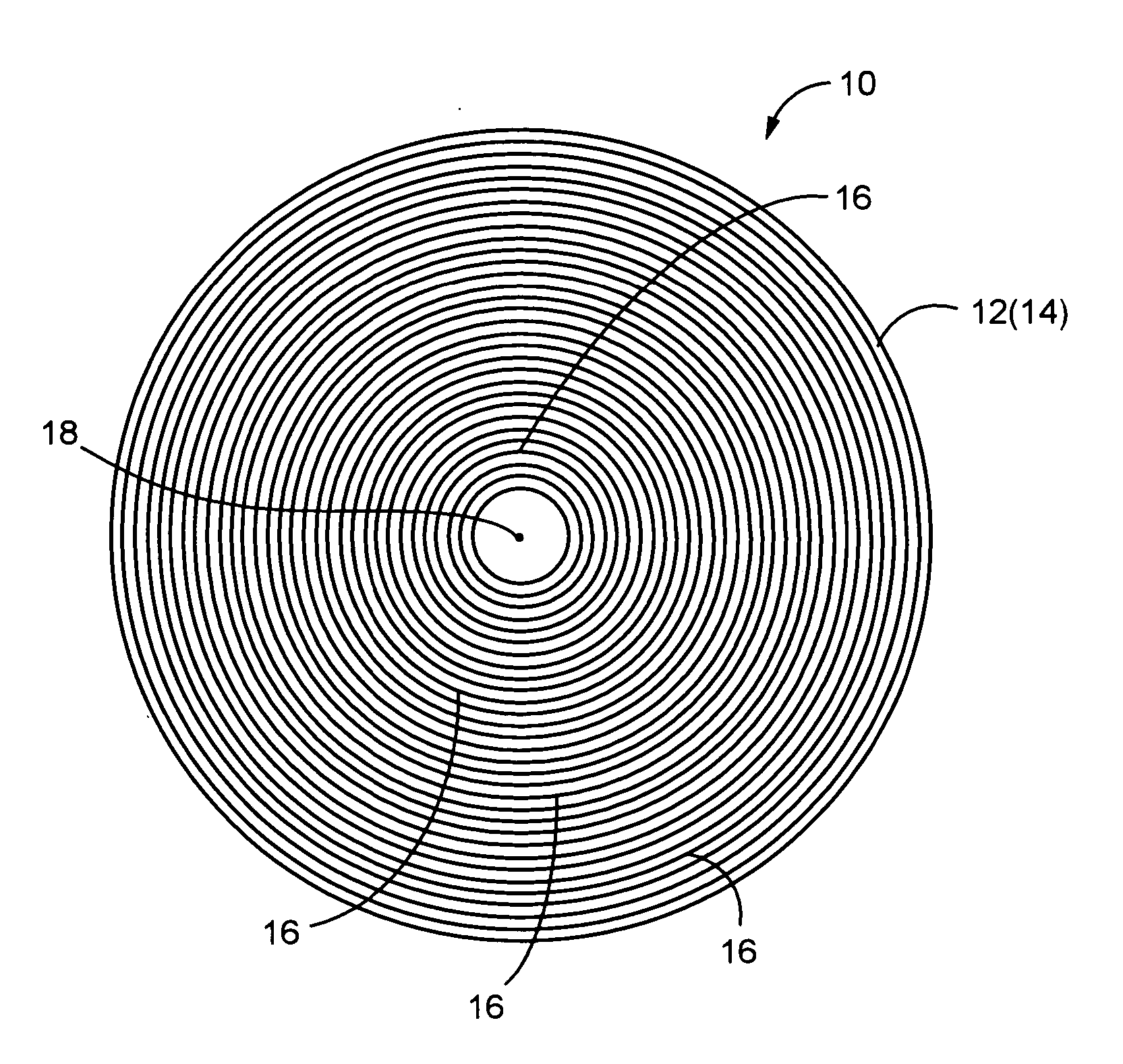

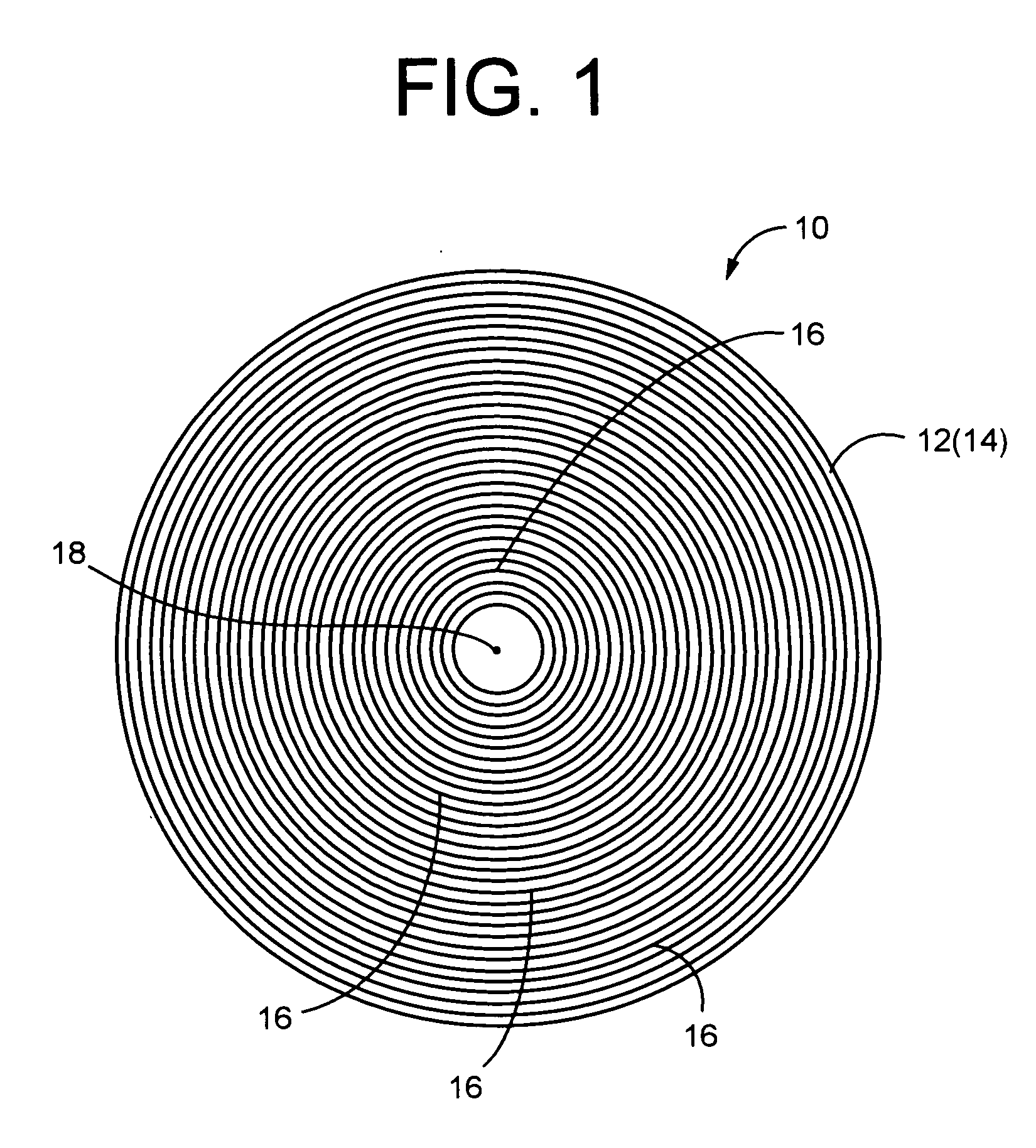

Polishing pad and method of fabricating semiconductor substrate using the pad

InactiveUS7121938B2Improve the level ofEfficient polishingPolishing machinesRevolution surface grinding machinesSynthetic resinBiomedical engineering

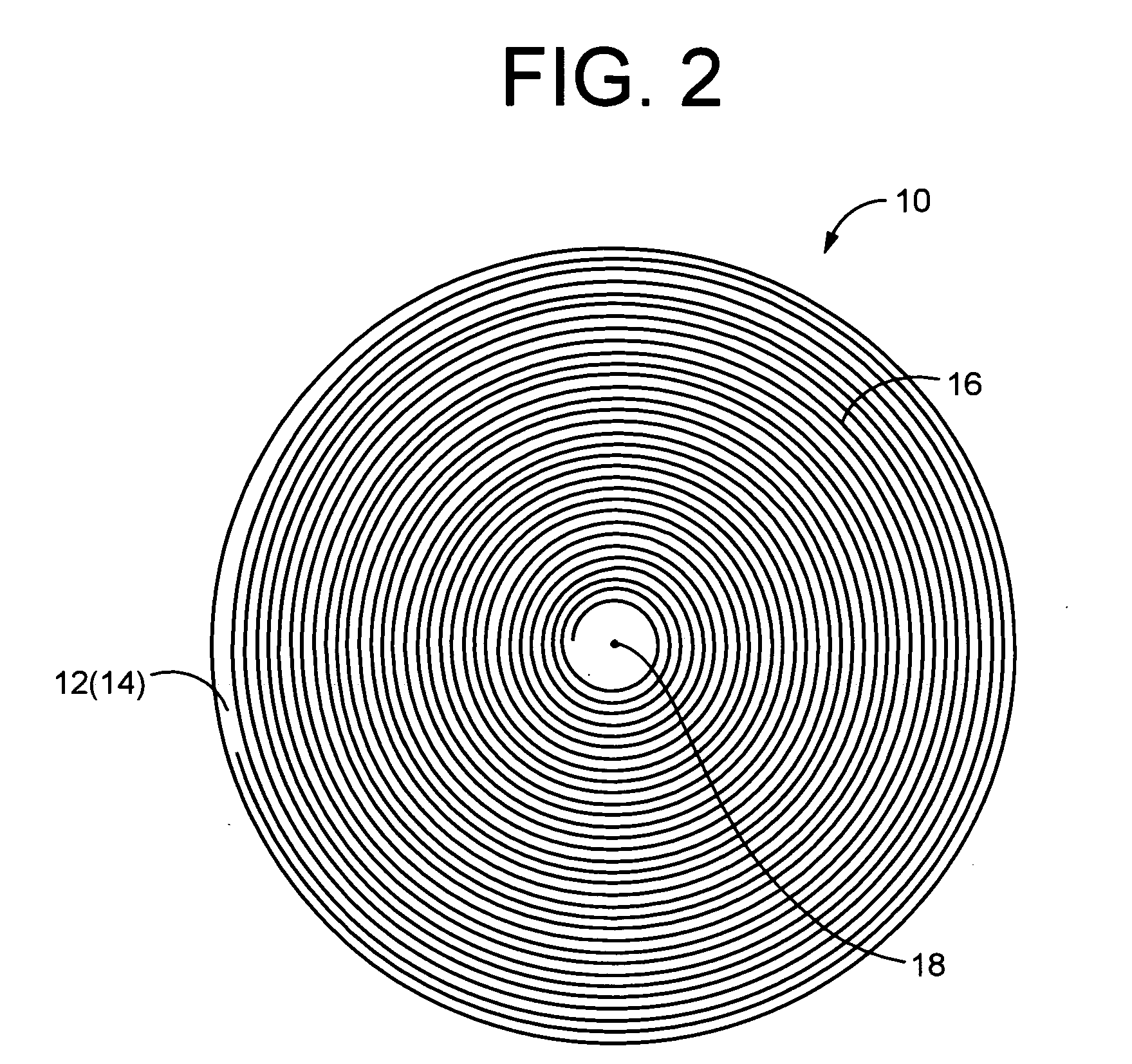

It is provided a polishing pad of novel construction capable of controlling actively and efficiently a slurry flow during polishing a surface of a semiconductor substrate, such as a wafer, thus making it possible to precisely and stably performing a desired polishing process. Onto a surface of a pad substrate 12 of synthetic resin material, formed is a groove 16 extending approximately circumferentially. An inner circumferential wall surface 20 and an outer circumferential wall surface 22 are made parallel to each other and slant with respect to a center axis 18 of the pad substrate 12.

Owner:TOHO ENG CO LTD

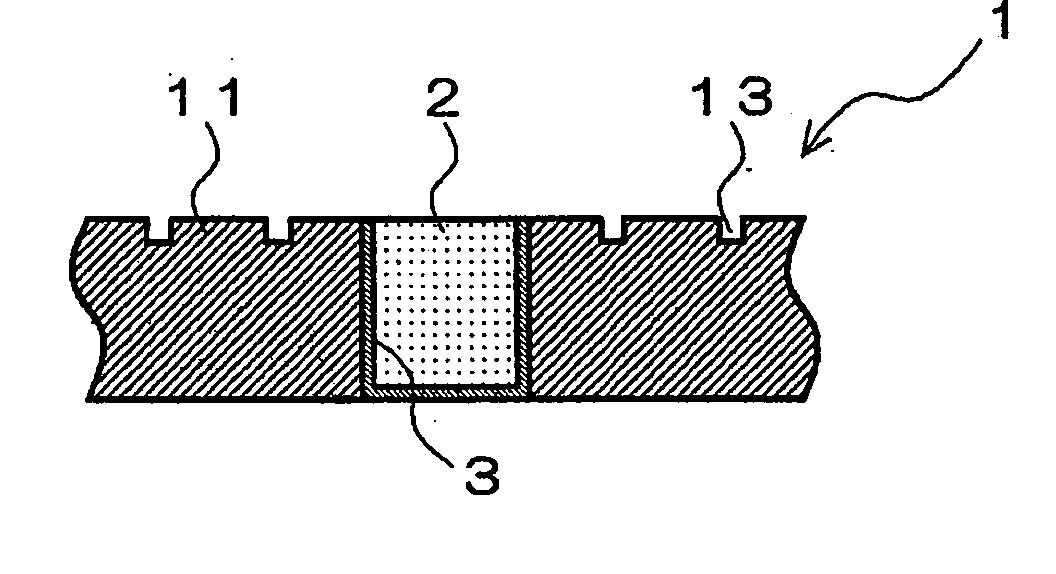

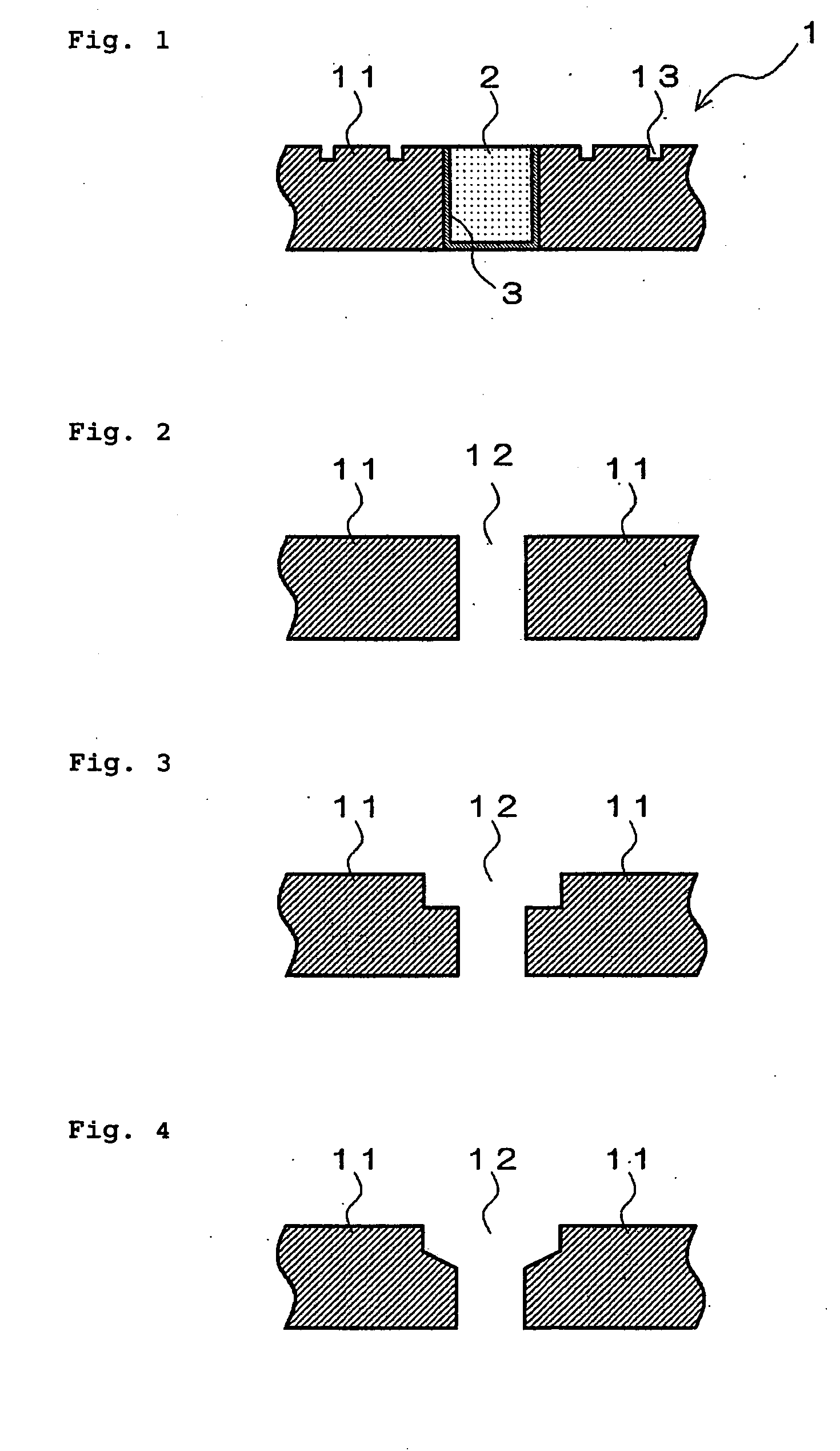

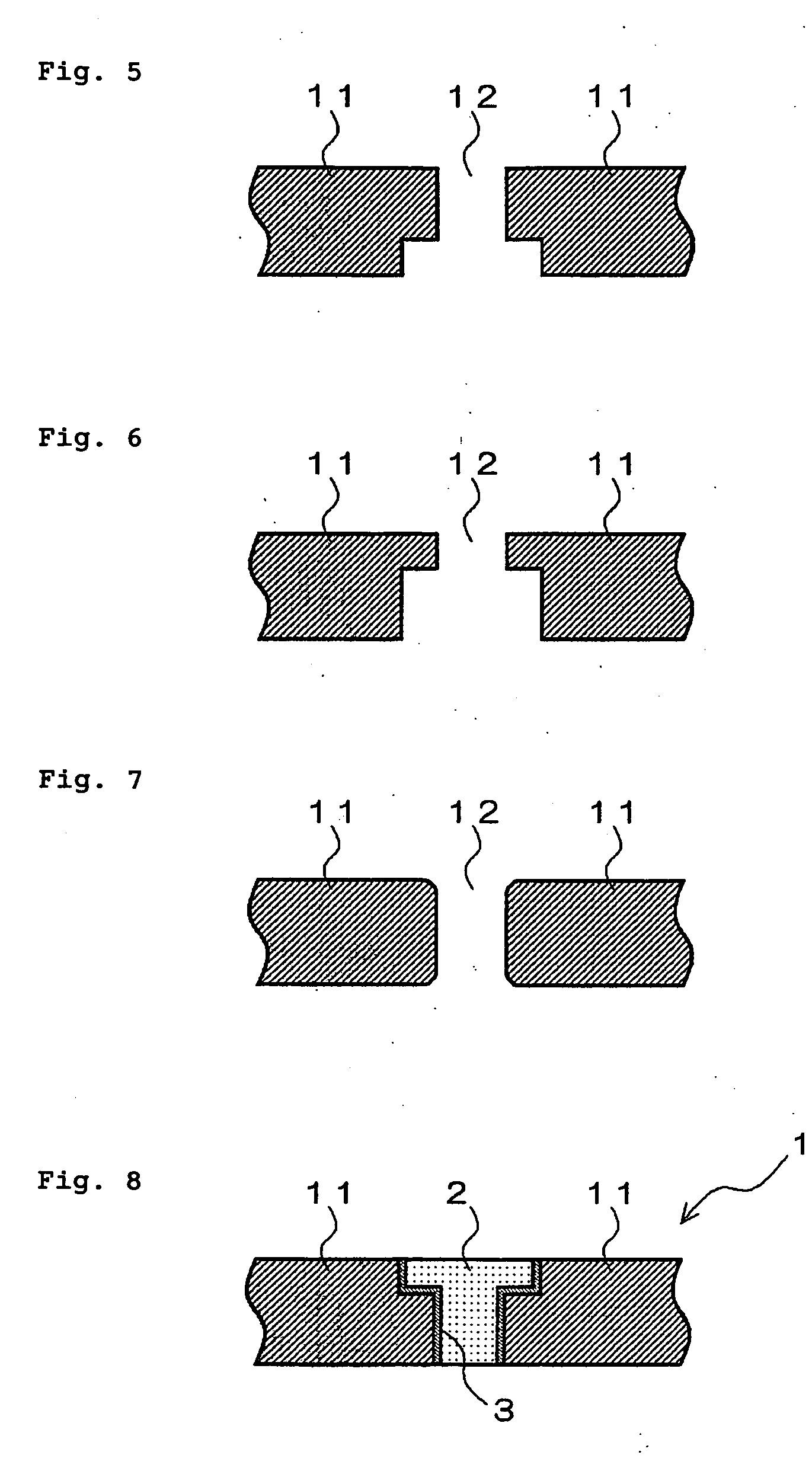

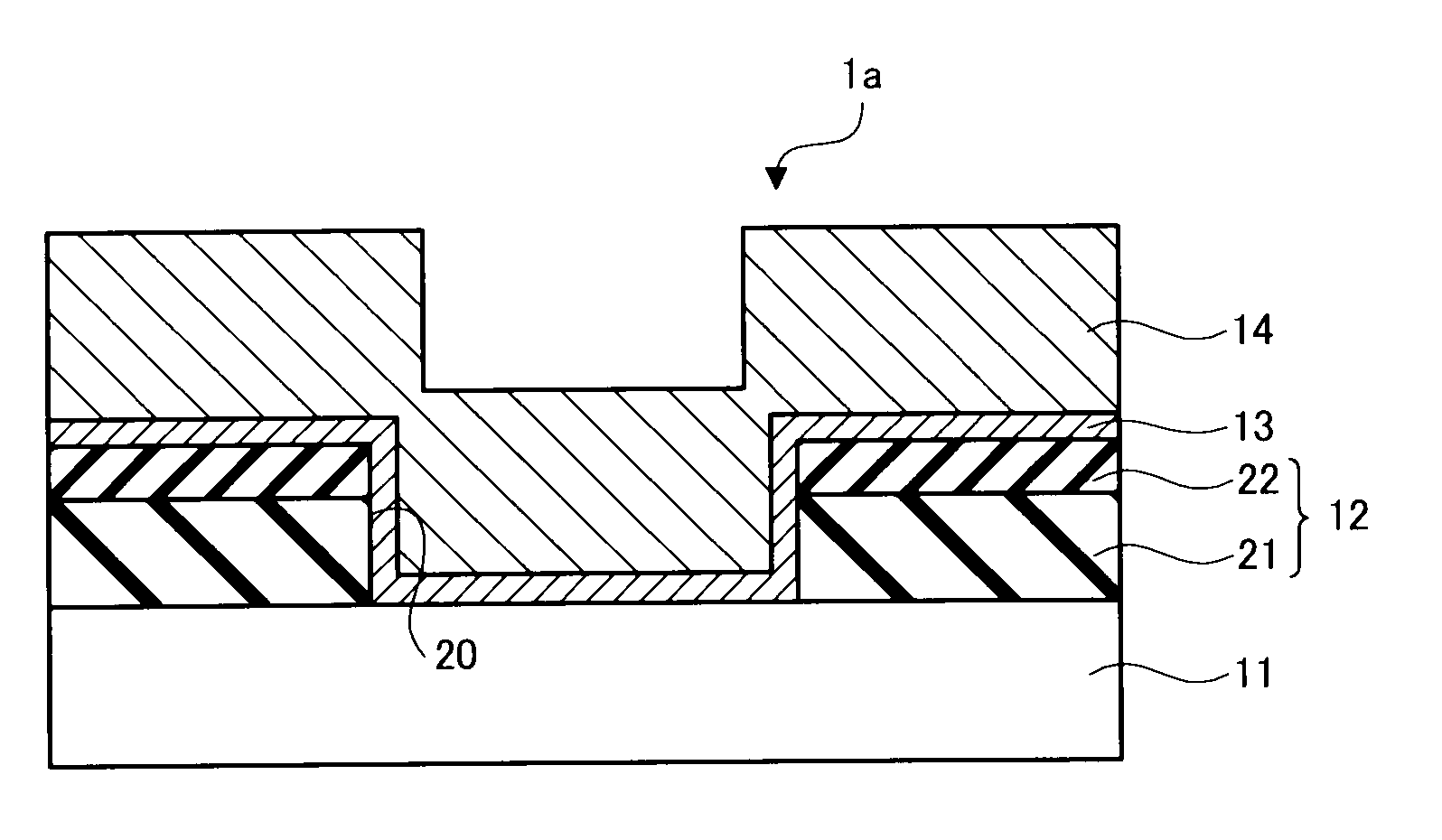

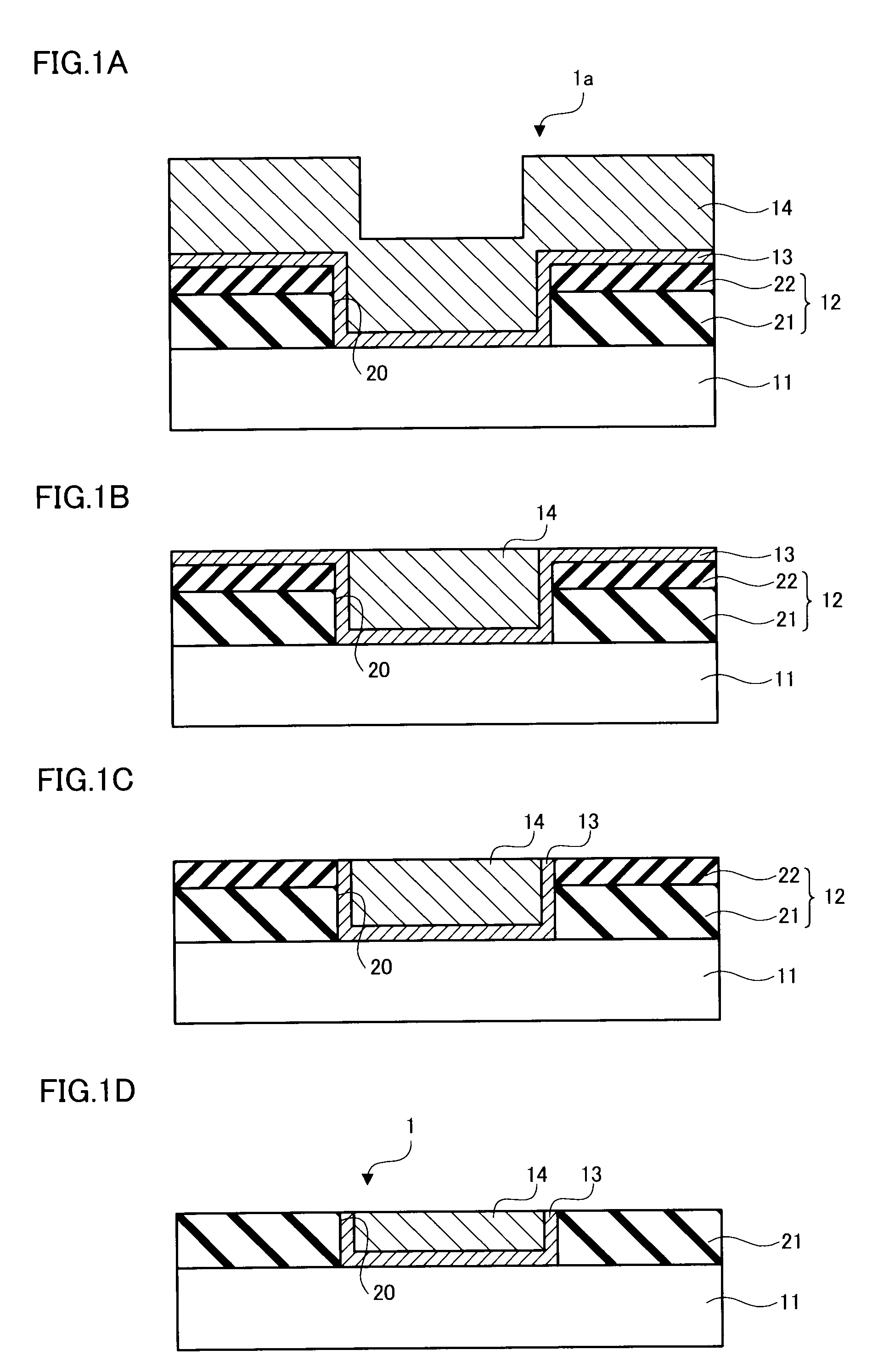

Polishing pad and method of polishing a semiconductor wafer

InactiveUS20040224611A1Efficient polishingSemiconductor/solid-state device manufacturingFlexible-parts wheelsAdhesiveEngineering

A polishing pad, a polishing laminated pad and a semiconductor wafer polishing method all of which prevent a leak of slurry from the gap between a polishing substrate and a reduction in polishing efficiency caused by a scratched and a window member and enable the optical detection of the polishing end point to be carried out efficiently. The polishing pad comprises a polishing substrate having a through hole extending from the front side to the rear side and a light transmitting member arranged in the through hole, and the outer wall of the above light transmitting member and the inner wall of the though hole opposite to the outer wall are bonded together with a photocurable adhesive such as a polyurethane(meth)acrylate to fix the above light transmitting member in the through hole.

Owner:JSR CORPORATIOON

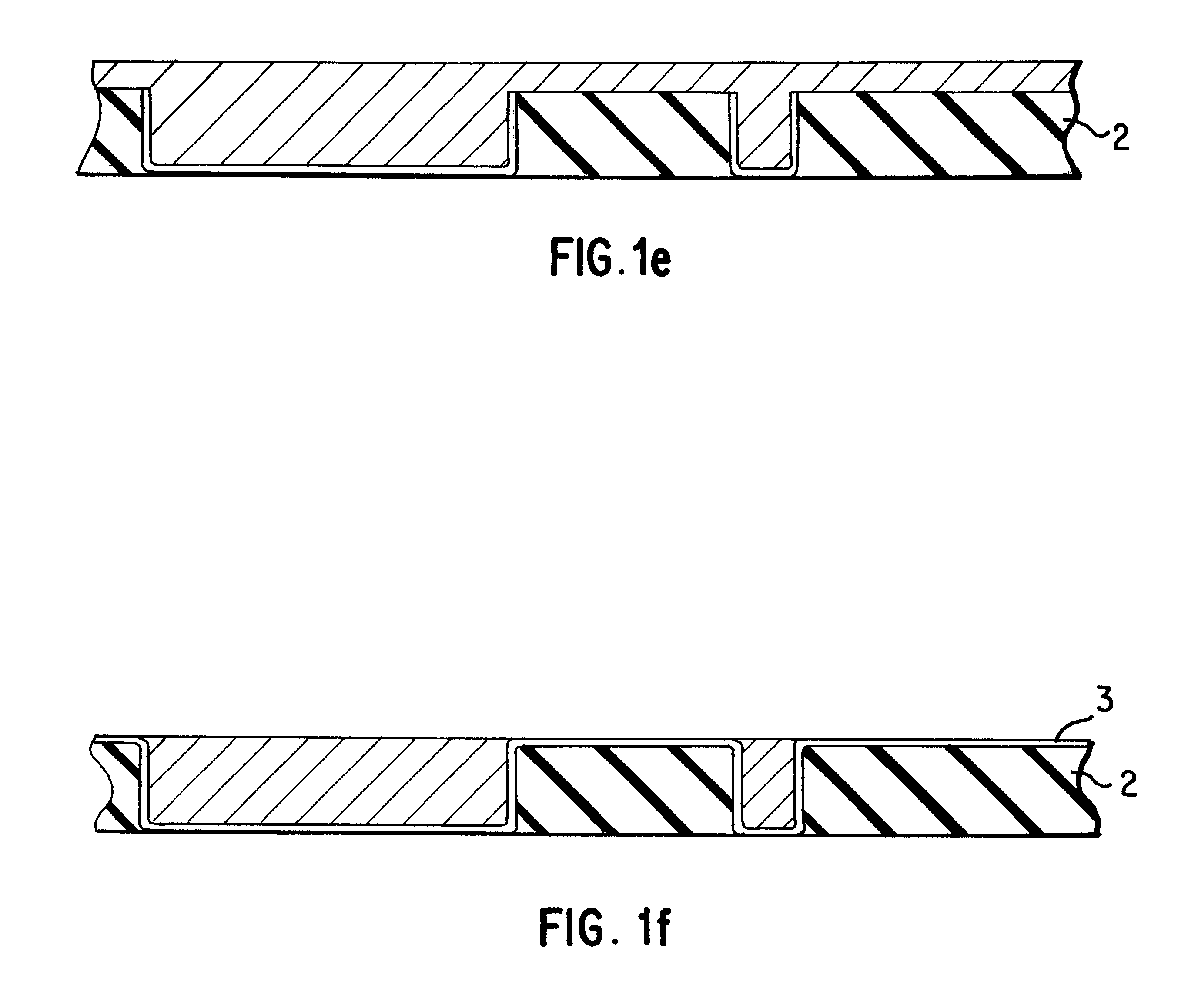

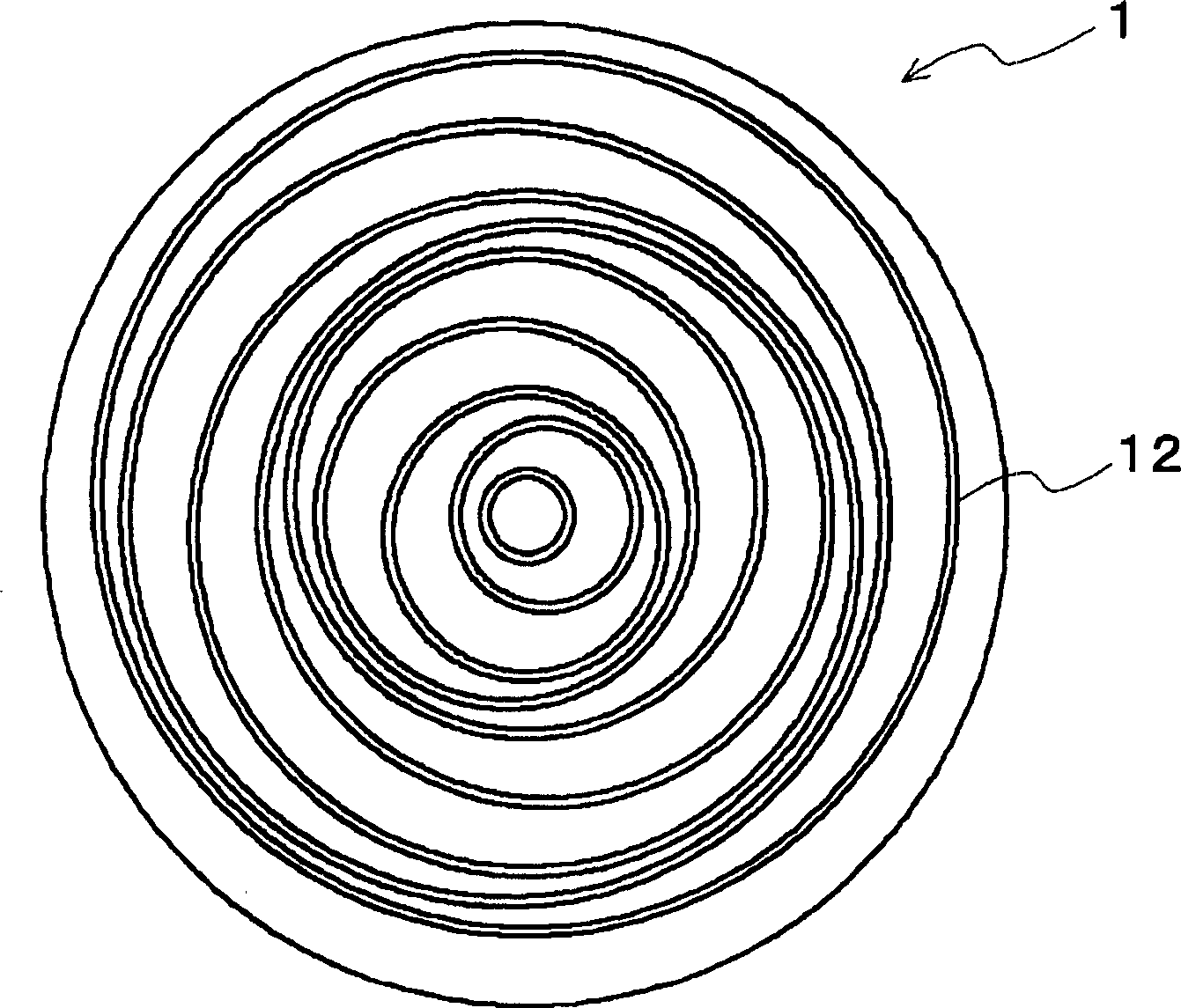

Polishing mattress and multilayer polishing mattress

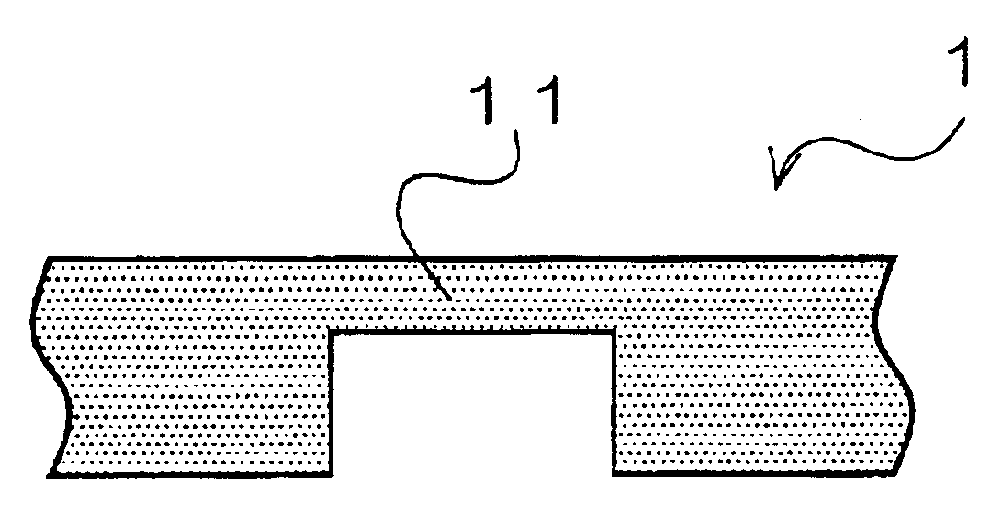

InactiveCN1494983AInhibit chafingImprove flatnessSemiconductor/solid-state device manufacturingFlexible-parts wheelsSurface roughnessBiomedical engineering

The present invention intends to provide a polishing pad and a multi-layer polishing pad (1) that can particularly effectively suppress scratch from occurring. The polishing pad (1) of the invention comprises at least one part selected from a groove (a) having at least one kind of shape selected from annular, lattice-like and spiral form on a polishing surface side, a concave portion (b) and a through hole (c). In the above, surface roughness of an inner surface of the part is 20 mu m or less and the polishing pad (1) is used for chemical mechanical polishing.

Owner:JSR CORPORATIOON

Aqueous dispersion for chemical mechanical polishing, chemical mechanical polishing method, kit for chemical mechanical polishing, and kit for preparing aqueous dispersion for chemical mechanical polishing

InactiveUS20090124172A1Efficient polishingSufficiently planarized and accurately finishedOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidMetallurgy

A chemical mechanical polishing aqueous dispersion comprises (A) abrasive grains, (B) at least one of quinolinecarboxylic acid and pyridinecarboxylic acid, (C) an organic acid other than quinolinecarboxylic acid and pyridinecarboxylic acid, (D) an oxidizing agent, and (E) a nonionic surfactant having a triple bond, the mass ratio (WB / WC) of the amount (WB) of the component (B) to the amount (WC) of the component (C) being 0.01 or more and less than 2, and the component (E) being shown by the following general formula (1),wherein m and n individually represent integers equal to or larger than one, provided that m+n≦50 is satisfied.

Owner:JSR CORPORATIOON +1

Chemical mechanical polishing pad

ActiveUS20090209185A1Reduce scratchExcellent durabilityAbrasion apparatusSemiconductor/solid-state device manufacturingChemical-mechanical planarizationEngineering

Owner:JSR CORPORATIOON

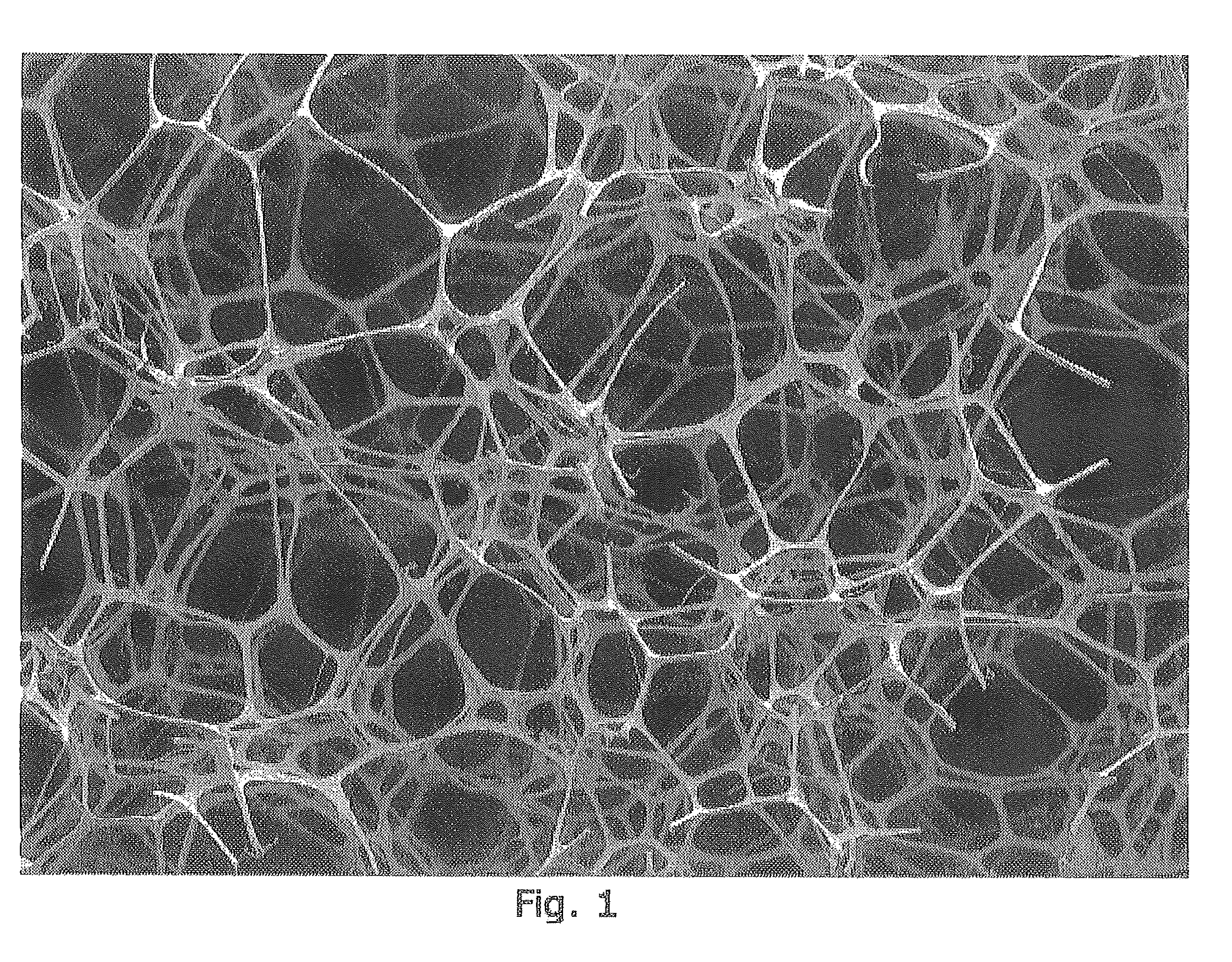

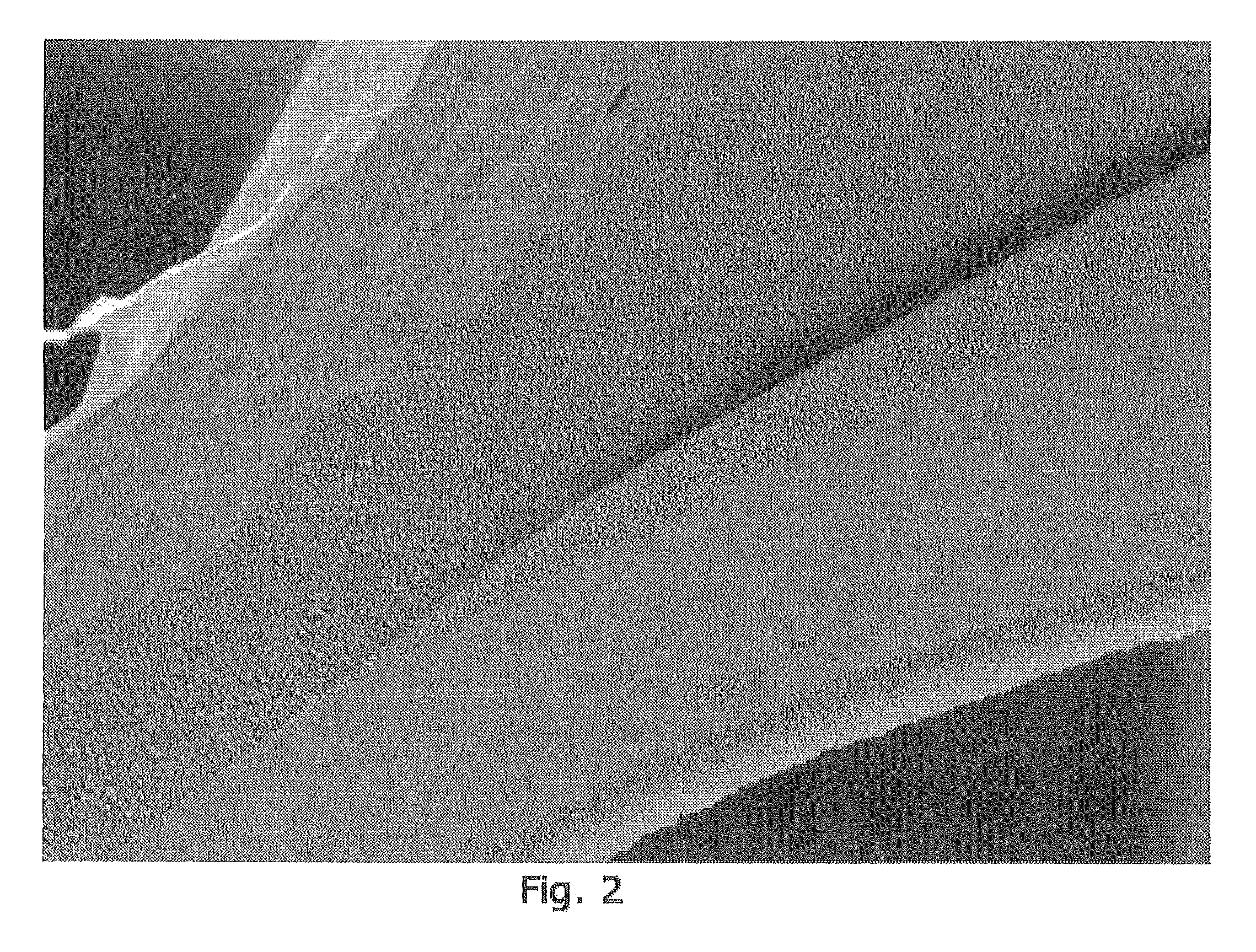

Method for the production of abrasive foams

InactiveUS8546457B2Increase elasticityMarkedly abrasive propertiesCarpet cleanersFloor cleanersMelamine formaldehydePolymer chemistry

A process for production of an abrasive foam based on a melamine-formaldehyde condensate comprising inorganic nanoparticles, comprising the steps of:(1) preparation of a solution or dispersion comprising a precondensate of the foam to be produced, and also comprising inorganic nanoparticles,(2) foaming of the precondensate via heating of the solution or dispersion from step (1), in order to obtain a foam which comprises inorganic nanoparticles, and also, if appropriate,(3) heat-conditioning of the foam obtained in step (2),leads to improved abrasion in the polishing of delicate surfaces.

Owner:BASF AG

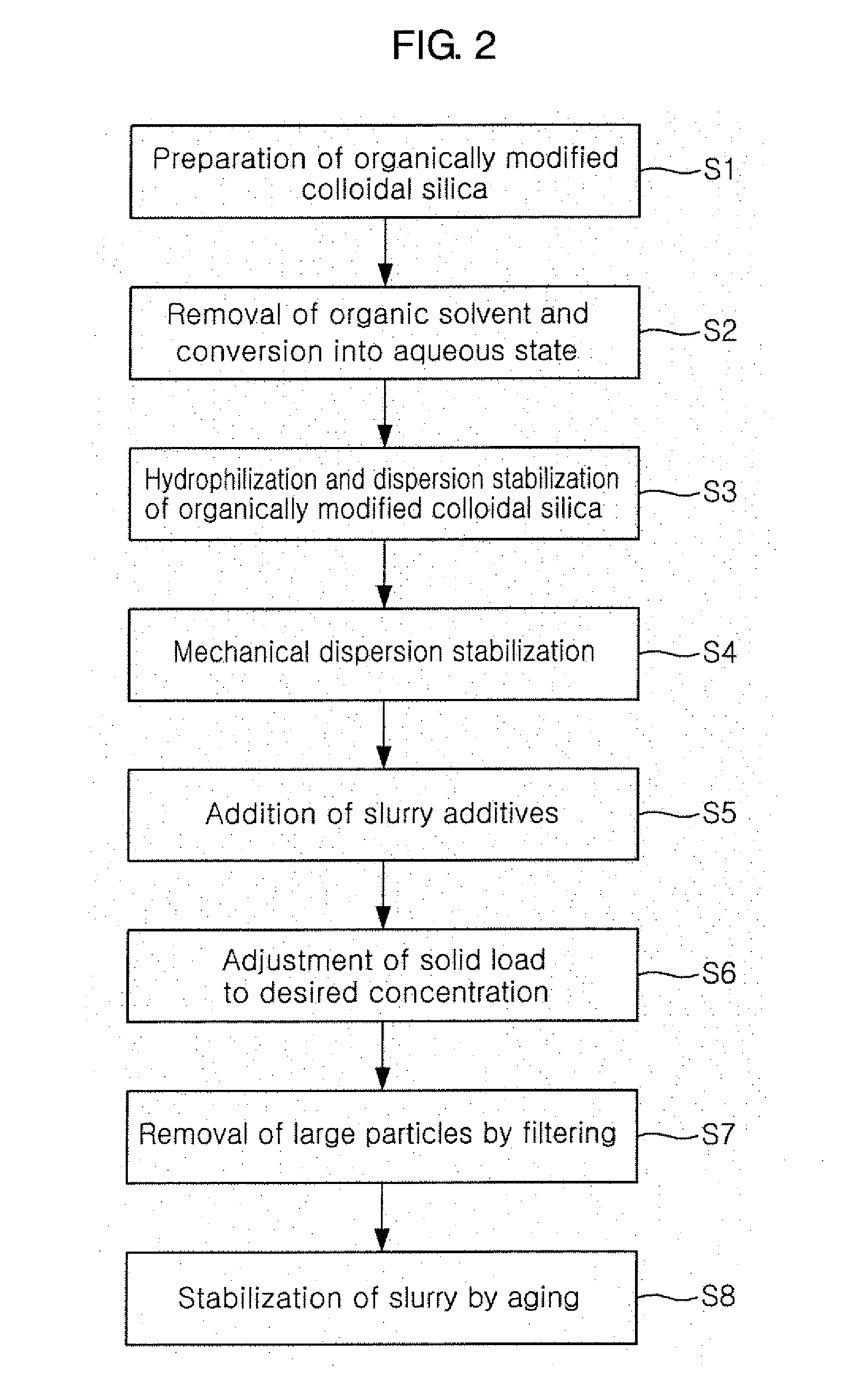

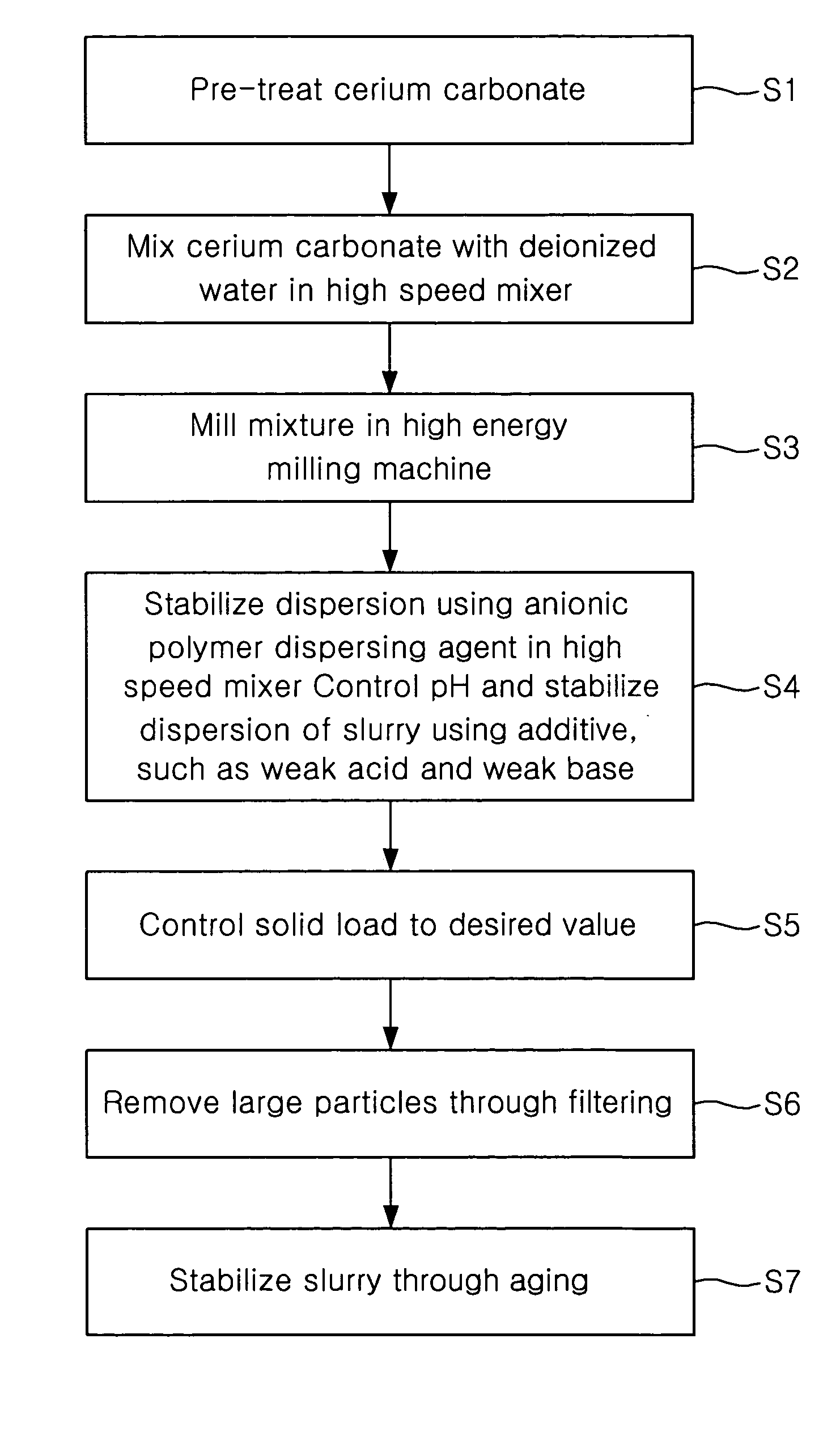

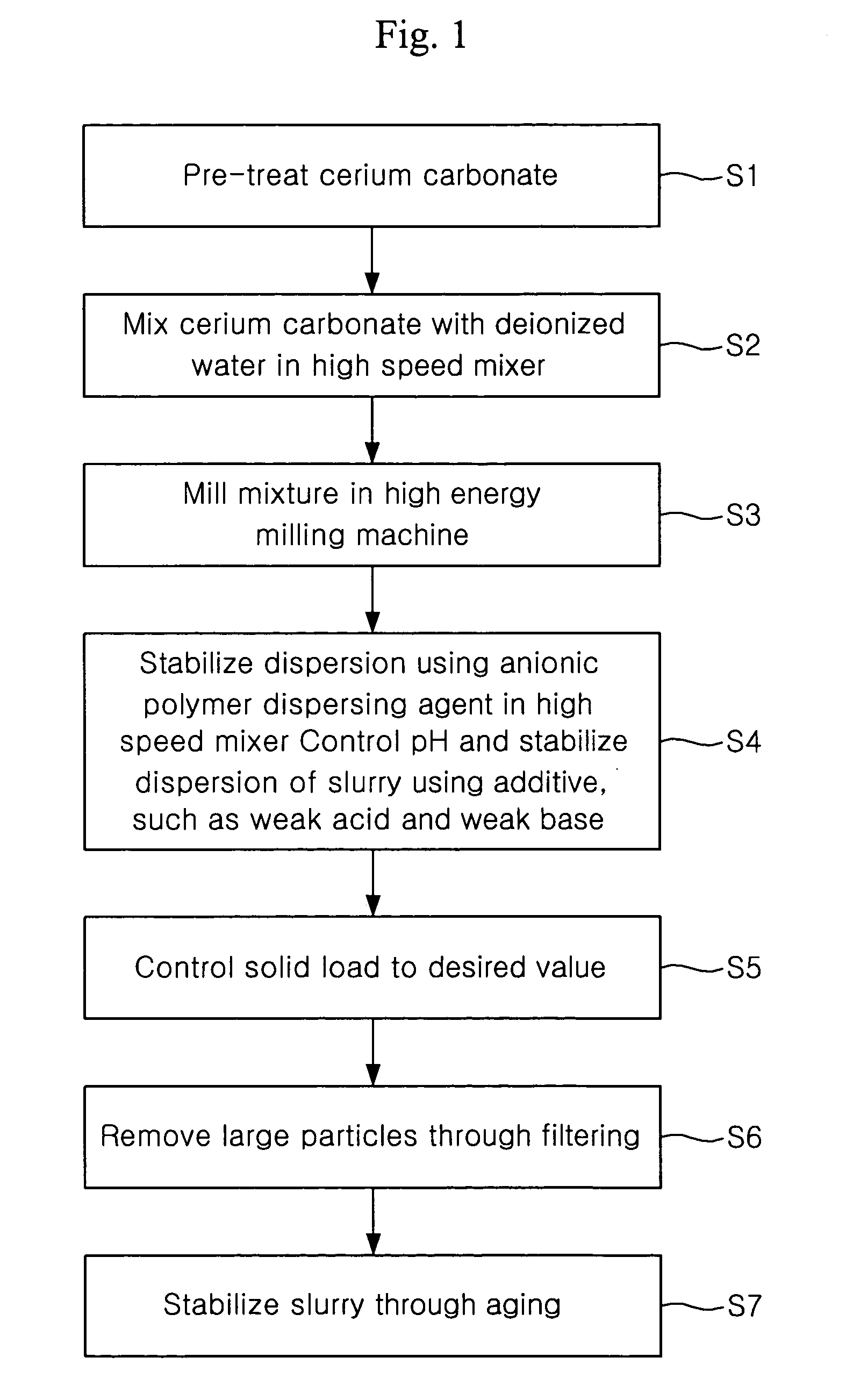

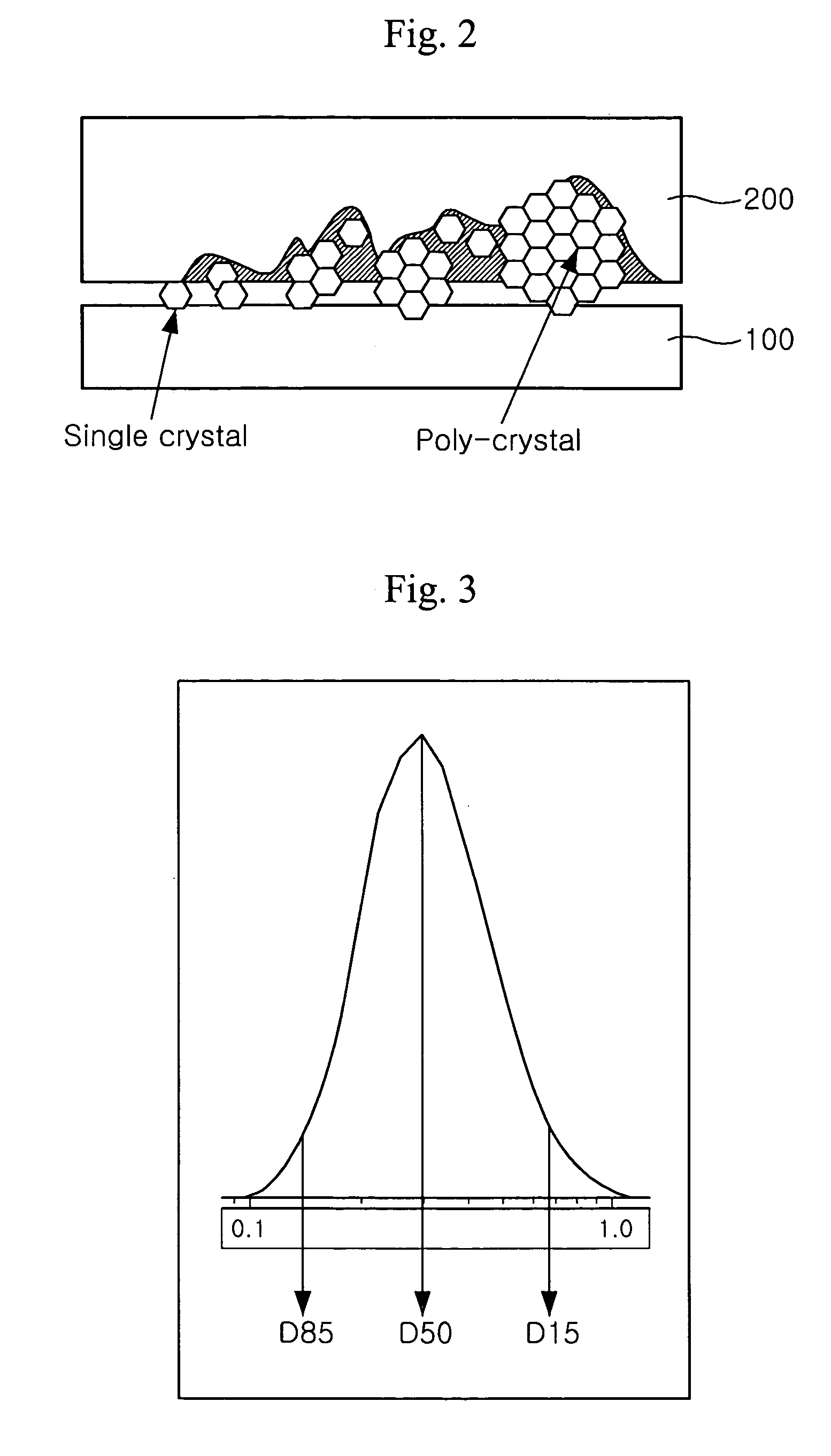

CMP Slurry, Preparation Method Thereof and Method of Polishing Substrate Using the Same

ActiveUS20070075291A1Optimal polishing particle propertyInhibitionOther chemical processesDecorative surface effectsColloidal silicaSlurry

A CMP slurry is provided comprising polishing particles, the polishing particle comprising organically modified colloidal silica. Also, a method of preparing a CMP slurry is provided, comprising the steps of: preparing polishing particles comprising organically modified silica; converting the polishing particles into an aqueous state; and adding pure water, a hydrophilic additive and a dispersing agent to the polishing particles. The polishing particles can be synthesized using a sol-gel process. According to the invention, a slurry having excellent polishing properties can be prepared, in which the surface properties of colloidal silica are changed to control the physical properties of the polishing particles and which can ensure a desired CMP removal rate while minimizing the occurrence of scratches.

Owner:K C TECH +1

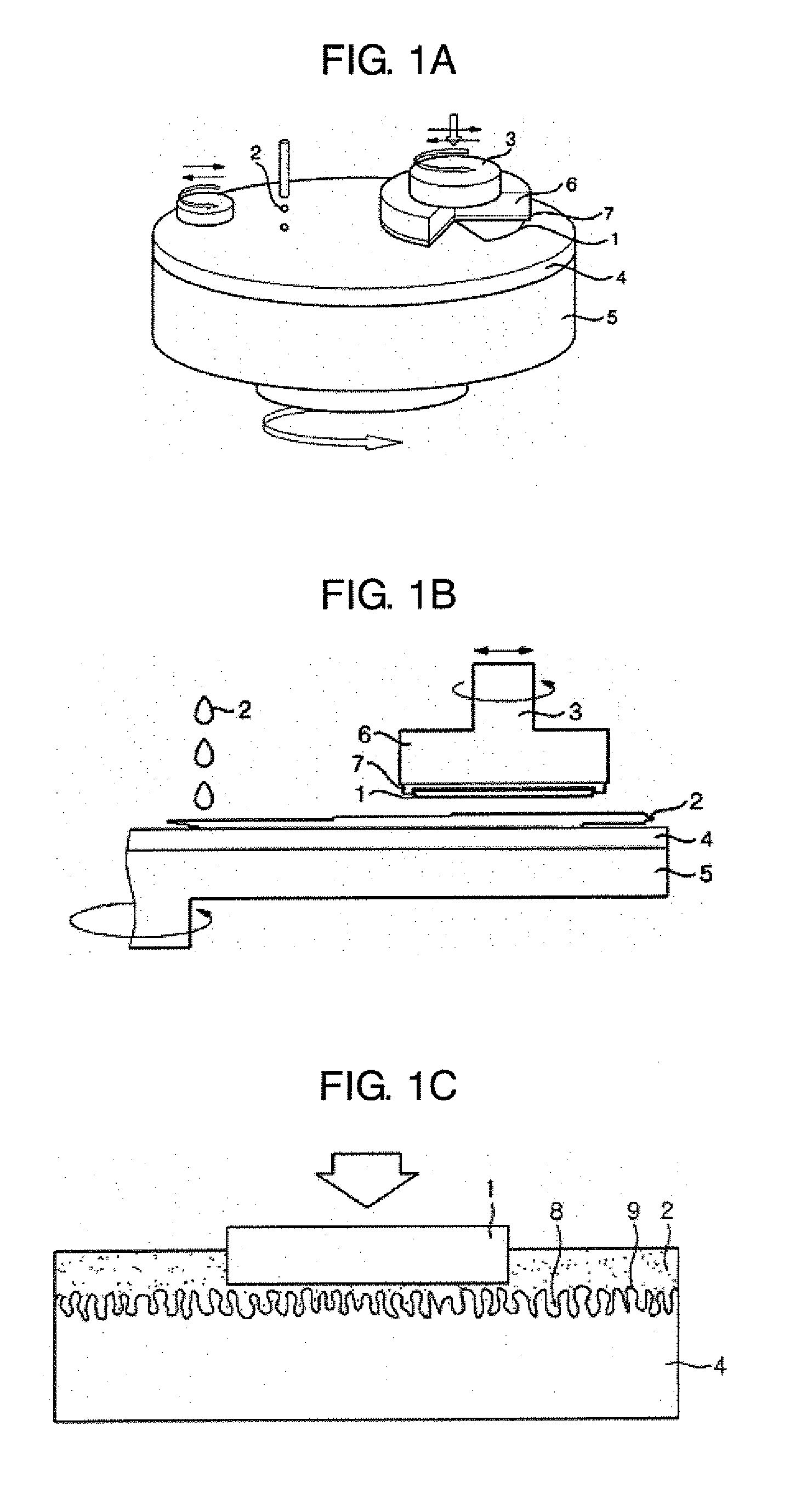

Method for manufacturing semiconductor device

ActiveUS20110207294A1Avoid crackingConstant polishing rateEdge grinding machinesBelt grinding machinesEngineeringSemiconductor

A method for manufacturing a semiconductor device makes it possible to efficiently polish with a polishing tape a peripheral portion of a silicon substrate under polishing conditions particularly suited for a deposited film and for silicon underlying the deposited film. The method includes: pressing a first polishing tape against a peripheral portion of a device substrate having a deposited film on a silicon surface while rotating the device substrate at a first rotational speed, thereby removing the deposited film lying in the peripheral portion of the device substrate and exposing the underlying silicon; and pressing a second polishing tape against the exposed silicon lying in the peripheral portion of the device substrate while rotating the device substrate at a second rotational speed, thereby polishing the silicon to a predetermined depth.

Owner:KIOXIA CORP +1

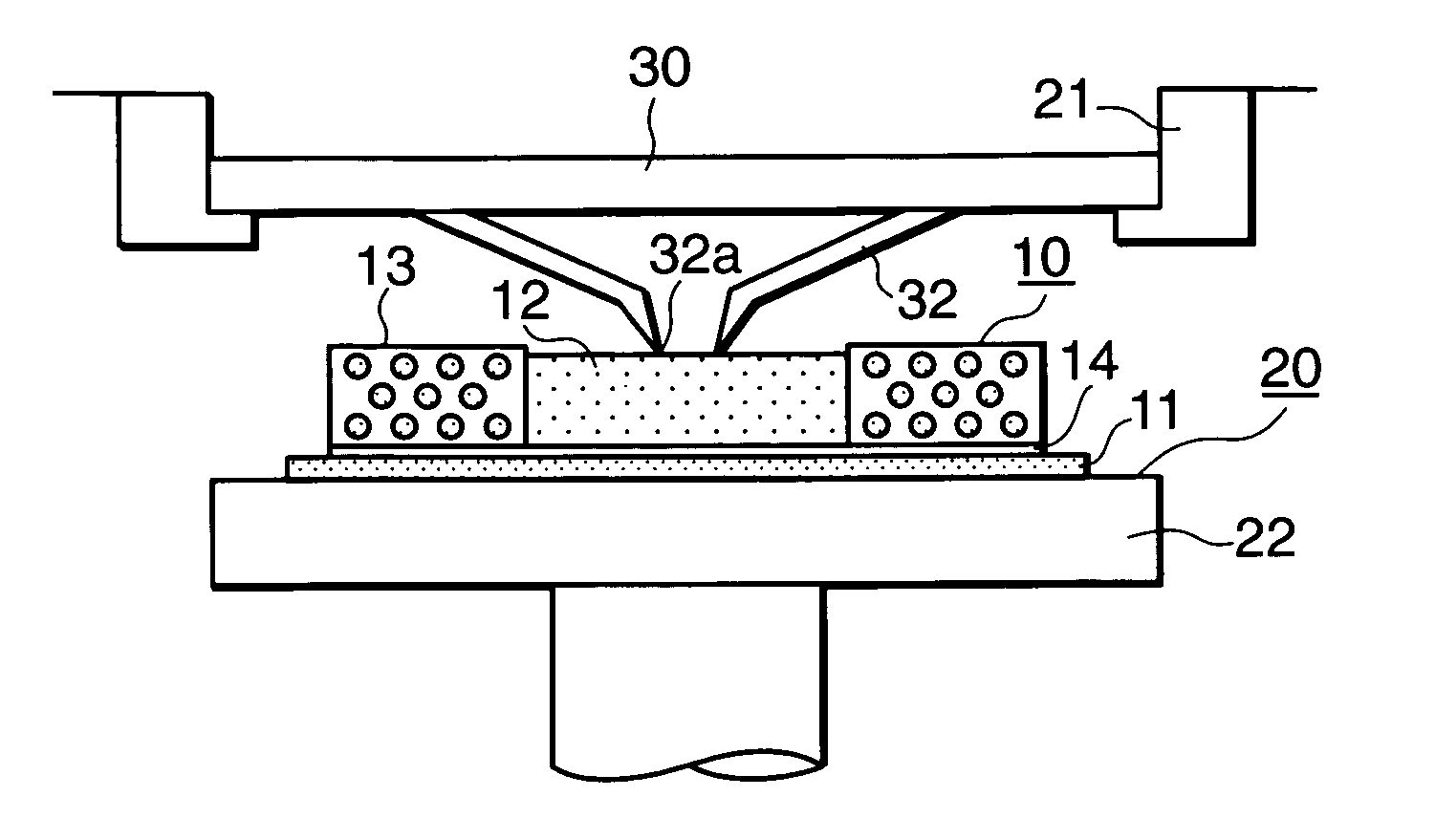

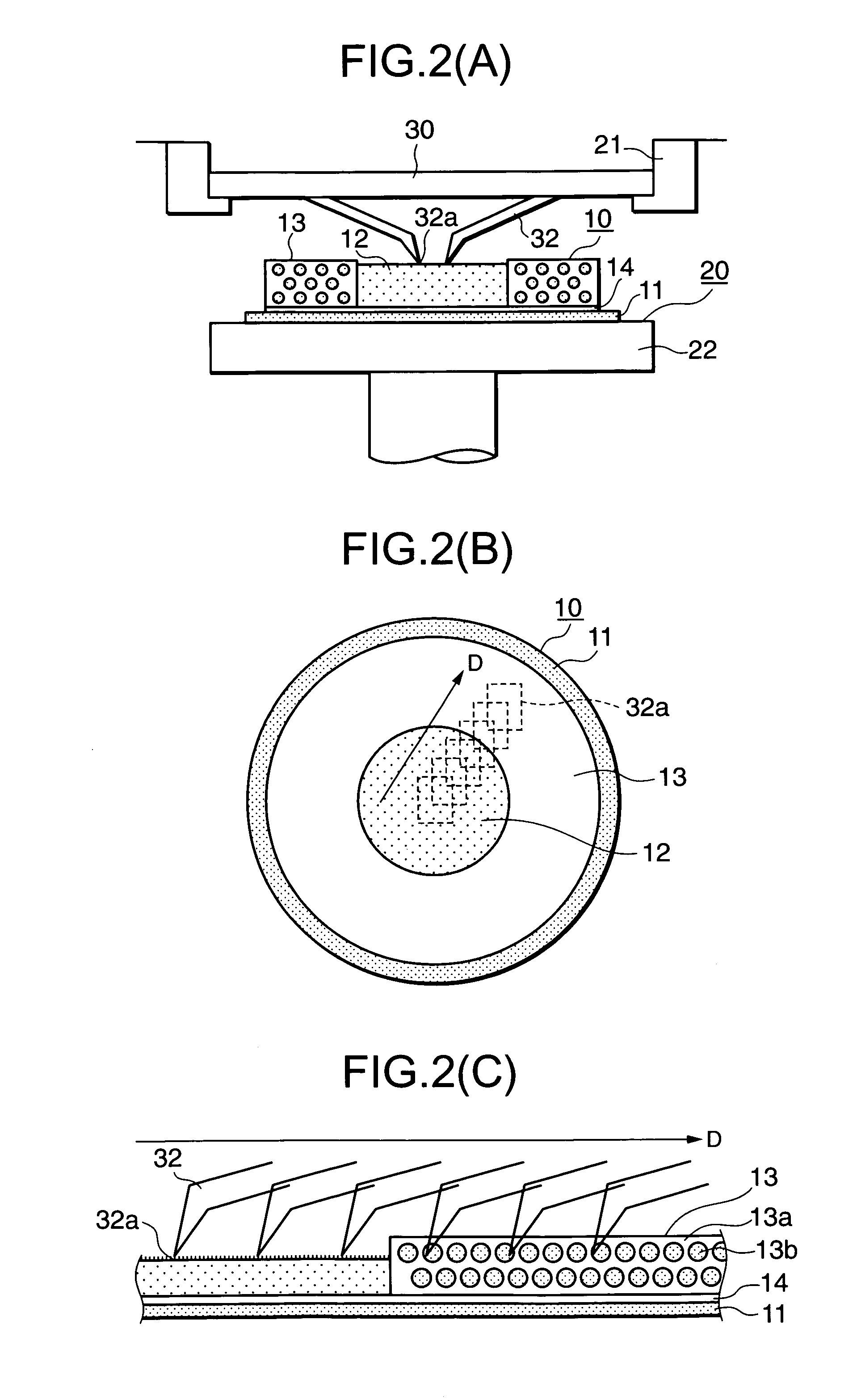

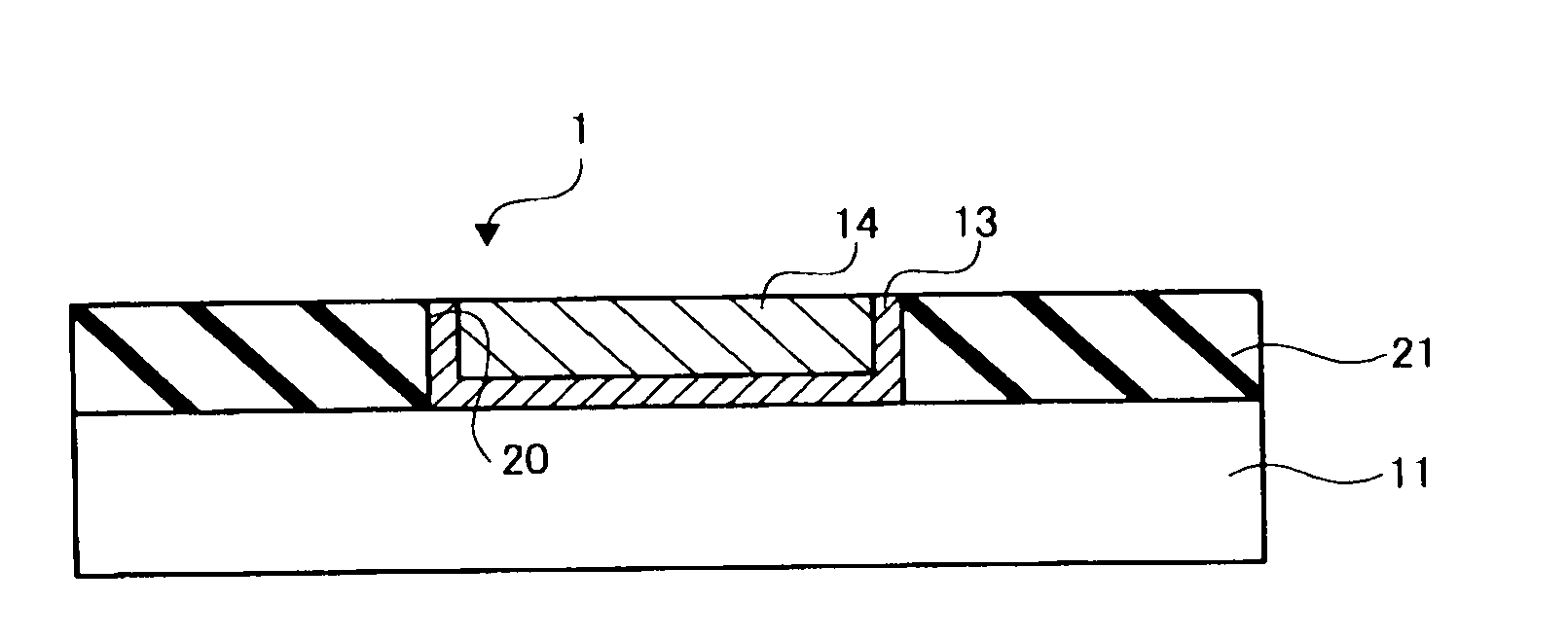

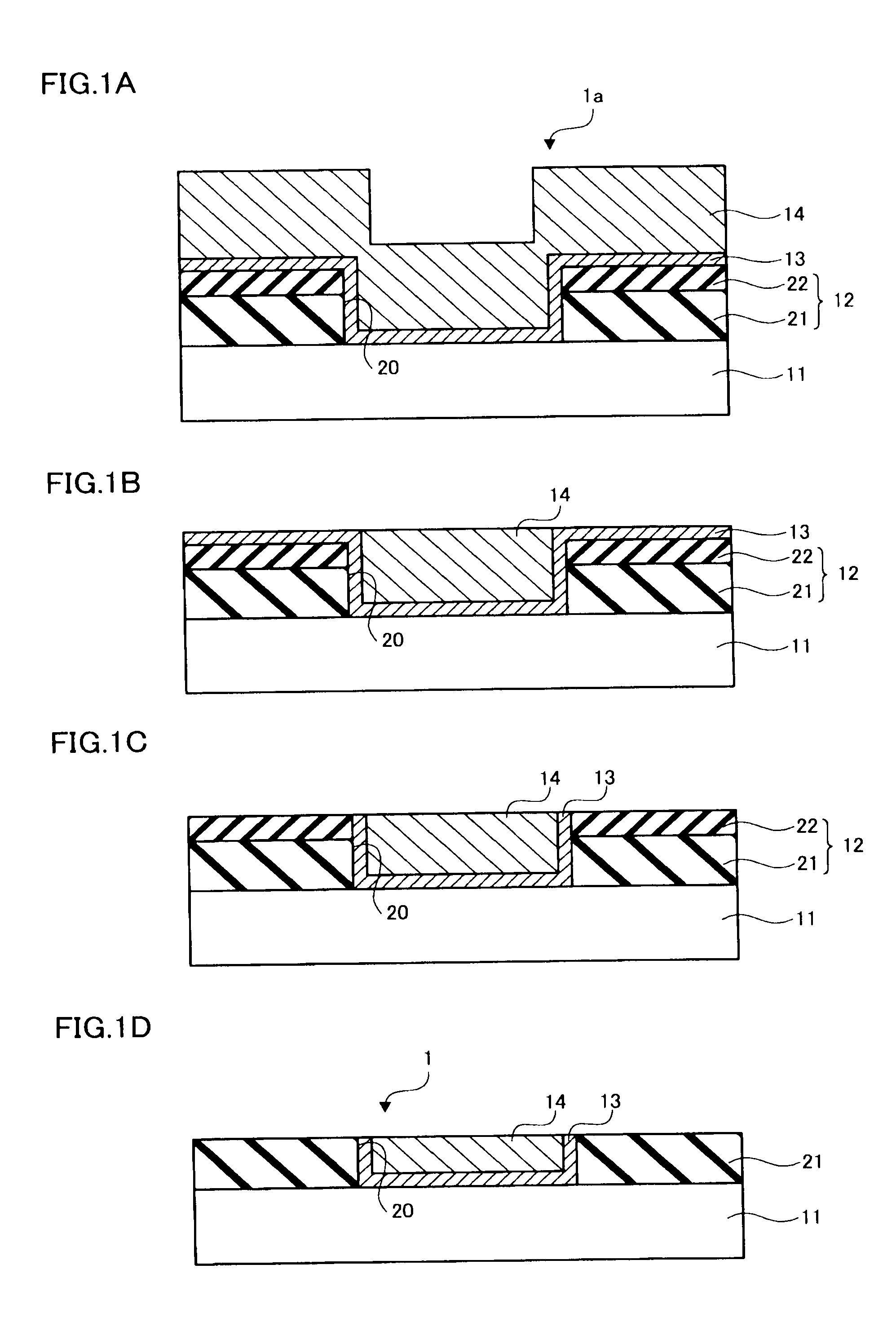

Cleaning sheet for probe needles

InactiveUS6960123B2Efficient polishingEfficient executionSemiconductor/solid-state device testing/measurementBathroom accessoriesElectrical conductionBiomedical engineering

A cleaning sheet has a disc-shaped substrate. First and second polishing layers are disposed over the substrate. The first polishing layer has a surface formed in a surface-roughened fashion to polish a tip section of each probe needle and has the function of removing adherents leading to inhibition of electrical conduction, which have been adhered to the tip of the needle in a coating or film form. The second polishing layer is a layer in which a large number of polishing grains are mixed into an elastic member and has the function of sticking the tip of the probe needle into the elastic member to remove foreign substances. The height of the surface of the second polishing layer is set so as to become identical to or slightly higher than that of the surface of the first polishing layer.

Owner:LAPIS SEMICON CO LTD

Aqueous dispersion for chemical mechanical polishing, chemical mechanical polishing method, kit for chemical mechanical polishing, and kit for preparing aqueous dispersion for chemical mechanical polishing

InactiveUS20110250756A1Efficient polishingSufficiently planarizedOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidMetallurgy

A chemical mechanical polishing aqueous dispersion comprises (A) abrasive grains, (B) at least one of quinolinecarboxylic acid and pyridinecarboxylic acid, (C) an organic acid other than quinolinecarboxylic acid and pyridinecarboxylic acid, (D) an oxidizing agent, and (E) a nonionic surfactant having a triple bond, the mass ratio (WB / WC) of the amount (WB) of the component (B) to the amount (WC) of the component (C) being 0.01 or more and less than 2, and the component (E) being shown by the following general formula (1),wherein m and n individually represent integers equal to or larger than one, provided that m+n≦50 is satisfied.

Owner:KK TOSHIBA

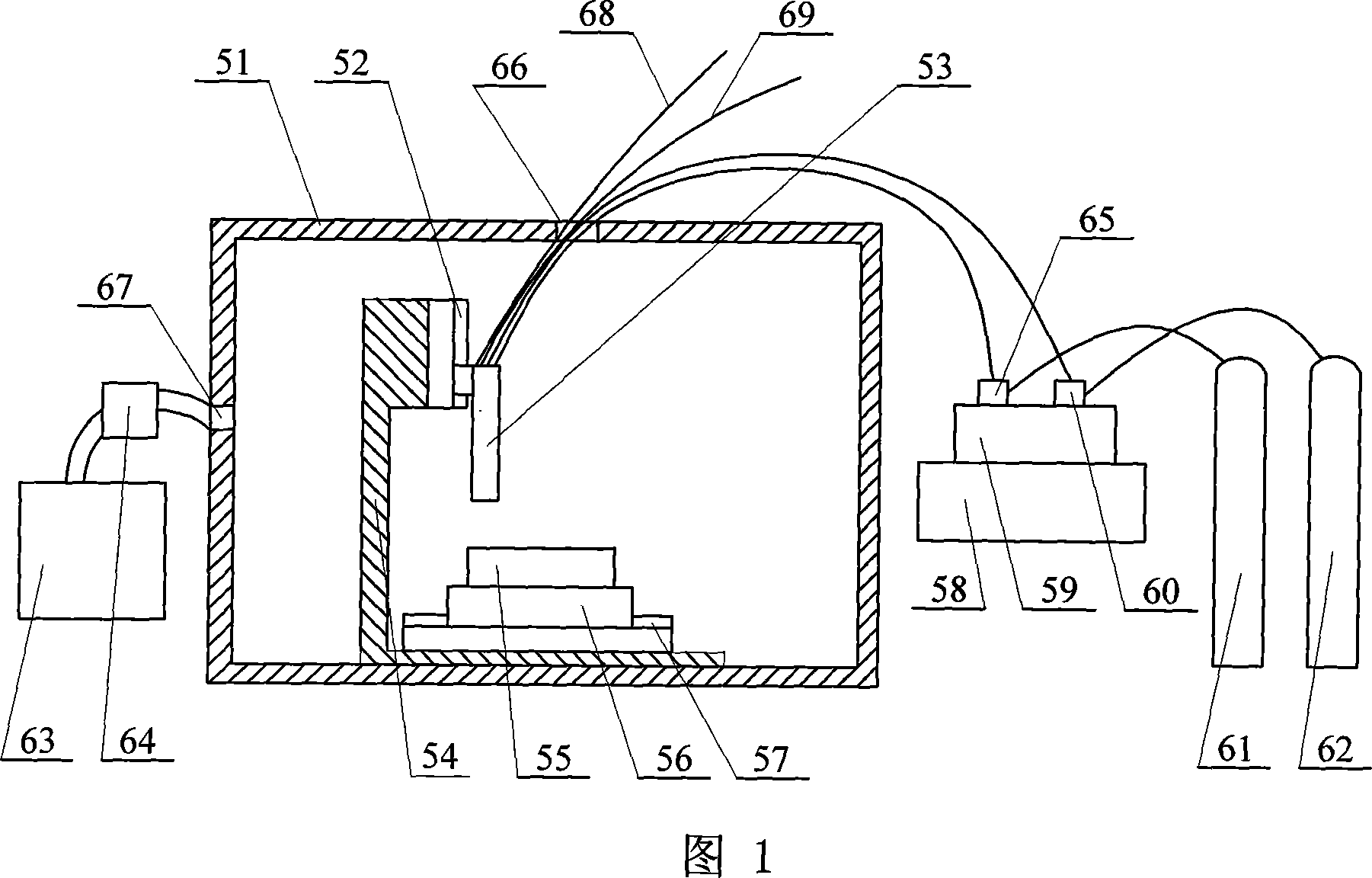

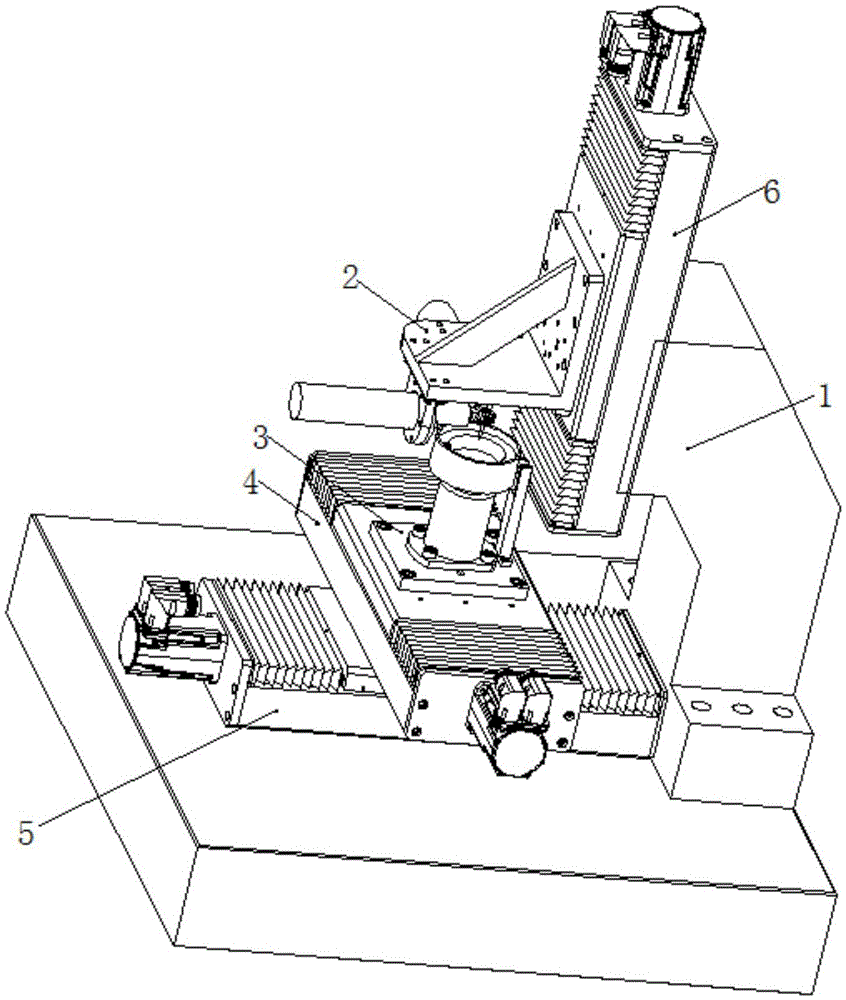

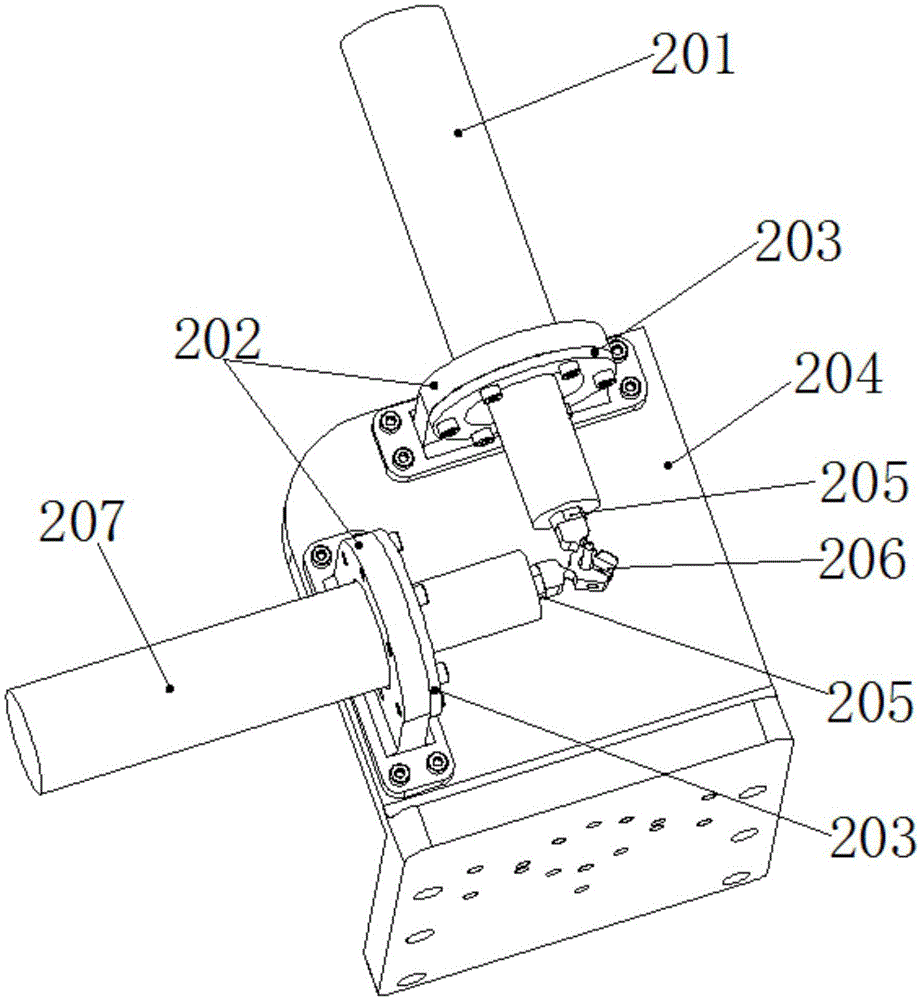

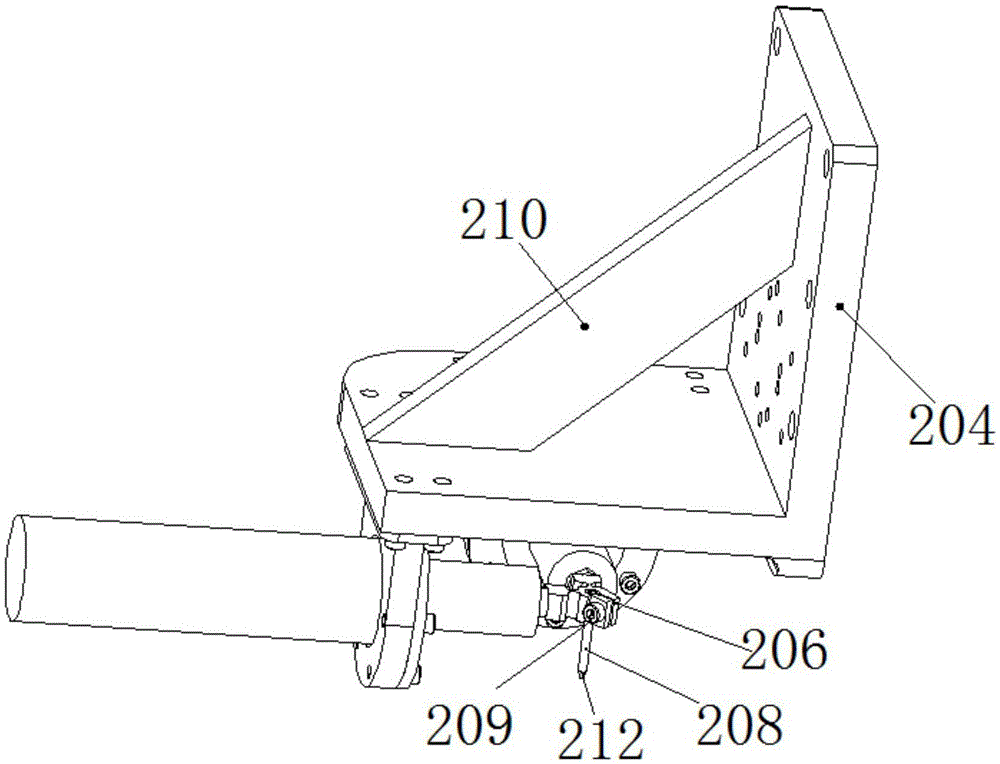

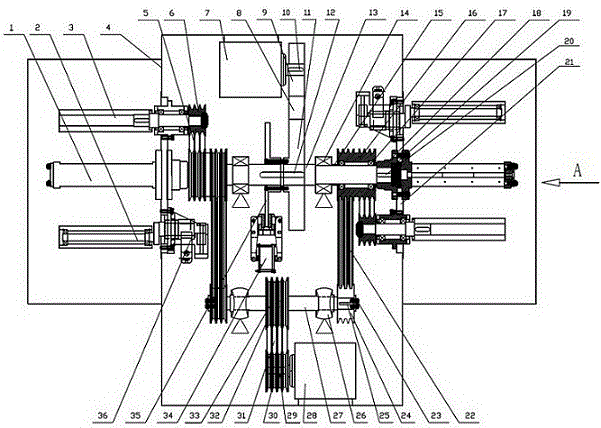

Two-dimensional ultrasonic vibration polishing device and method

InactiveCN105619187AIdeal Instantaneous Random Motion TrajectoryStrong profiling abilityVibratory signalEngineering

The invention relates to a two-dimensional ultrasonic vibration polishing device and a two-dimensional ultrasonic vibration polishing method, and belongs to the technical field of machine manufacturing. A two-dimensional ultrasonic vibration polishing tool is fastened to the z-axis of a machine tool by screws; a workpiece fixture is fastened to the x-axis of the machine tool by the screws; and the x-axis, the y-axis and the z-axis of the machine tool are fixedly connected with a machine tool main body after debugging. The two-dimensional ultrasonic vibration polishing device provides elliptical vibration in a polishing tangent plane, vibration signals of an x-direction ultrasonic vibrator and a y-direction ultrasonic vibrator are coupled to form two-dimensional vibration at a pivoting joint, and are output to a polishing head, the polishing head acquires a perfect instantaneous random motion track in a processing area, and motion composited by the vibration is polishing primary motion, so that a polishing force can be controlled to be stable on the premise that no polishing head rotates; the polishing head has high profile modeling capability, so that various complicated curved surfaces can be processed; deterministic polishing is realized; stable and uniform removal of a polishing material is realized; and high-efficiency and high-quality polishing can be realized simply by controlling the polishing force.

Owner:JILIN UNIV

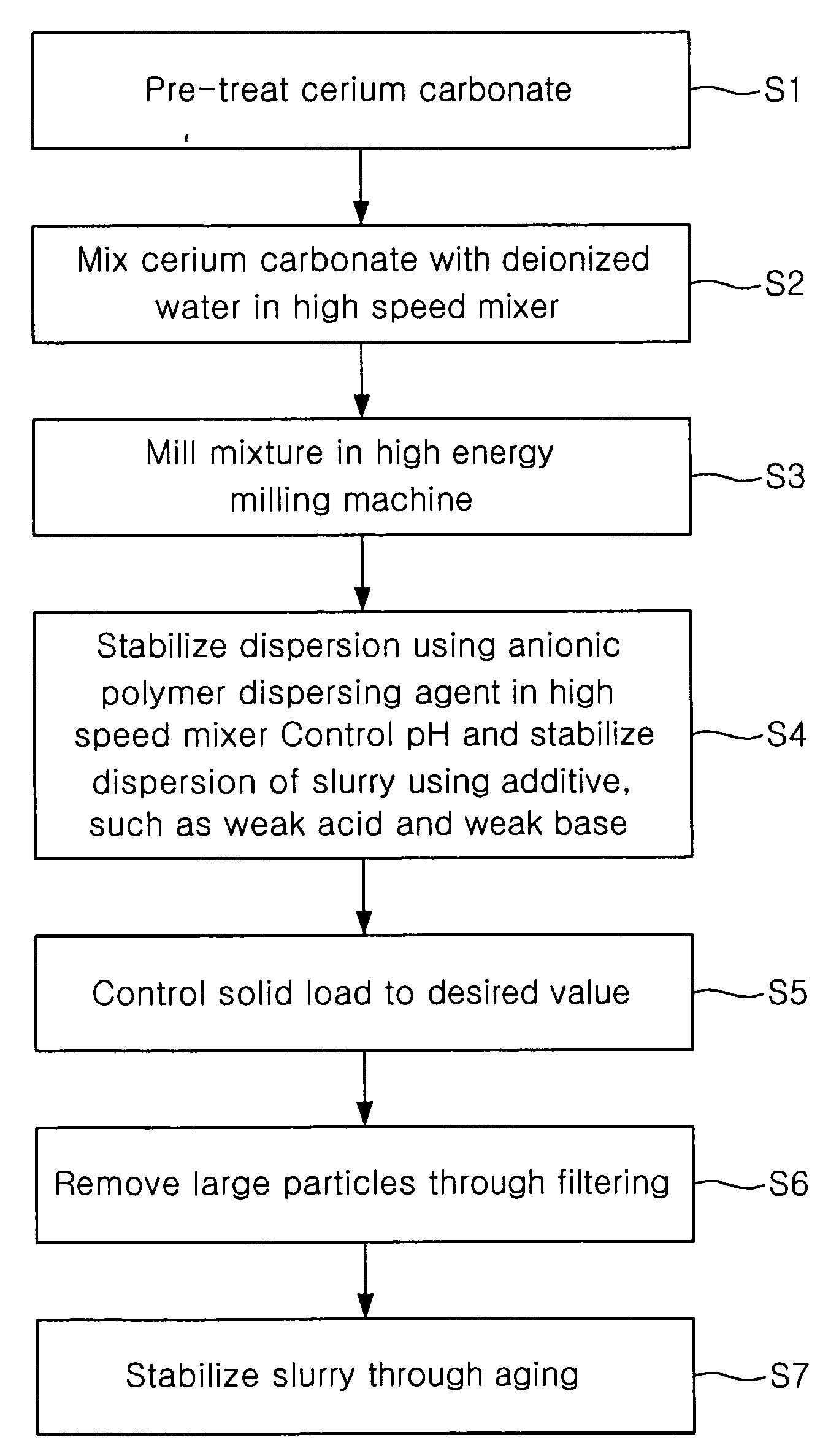

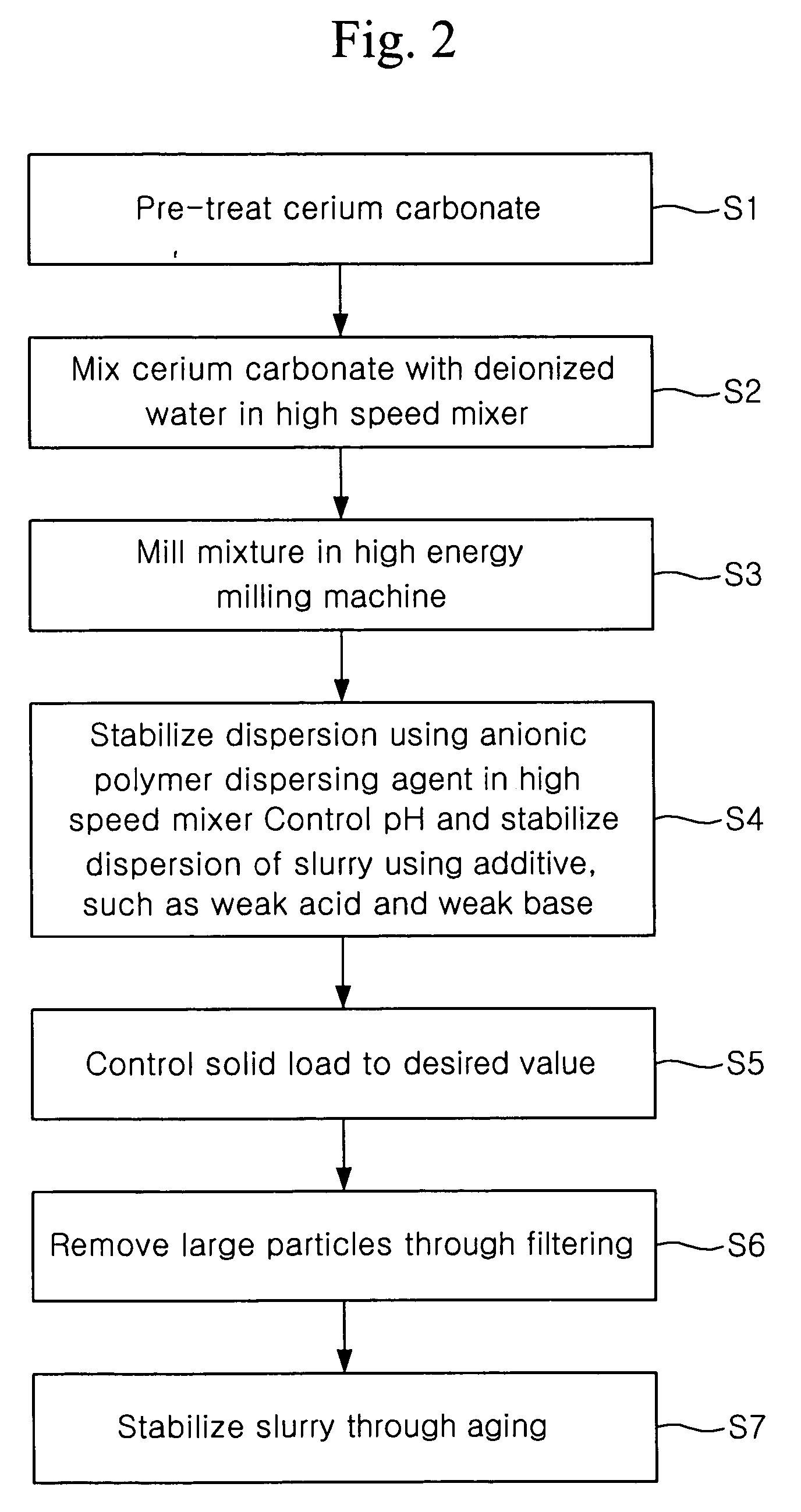

Polishing slurry, method of producing same, and method of polishing substrate

ActiveUS20050198912A1Good dispersionWeight controlPigmenting treatmentOther chemical processesCompound (substance)Slurry

Disclosed herein is a polishing slurry for chemical mechanical polishing. The polishing slurry comprises polishing particles, which have a particle size distribution including separated fine and large polishing particle peaks. The polishing slurry also comprises polishing particles, which have a median size of 50-150 nm. The present invention provides the slurry having an optimum polishing particle size, in which the polishing particle size is controlled and which is useful to produce semiconductors having fine design rules by changing the production conditions of the slurry. The present invention also provides the polishing slurry and a method of producing the same, in which a desirable CMP removal rate is assured and scratches are suppressed by controlling a polishing particle size distribution, and a method of polishing a substrate.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV) +1

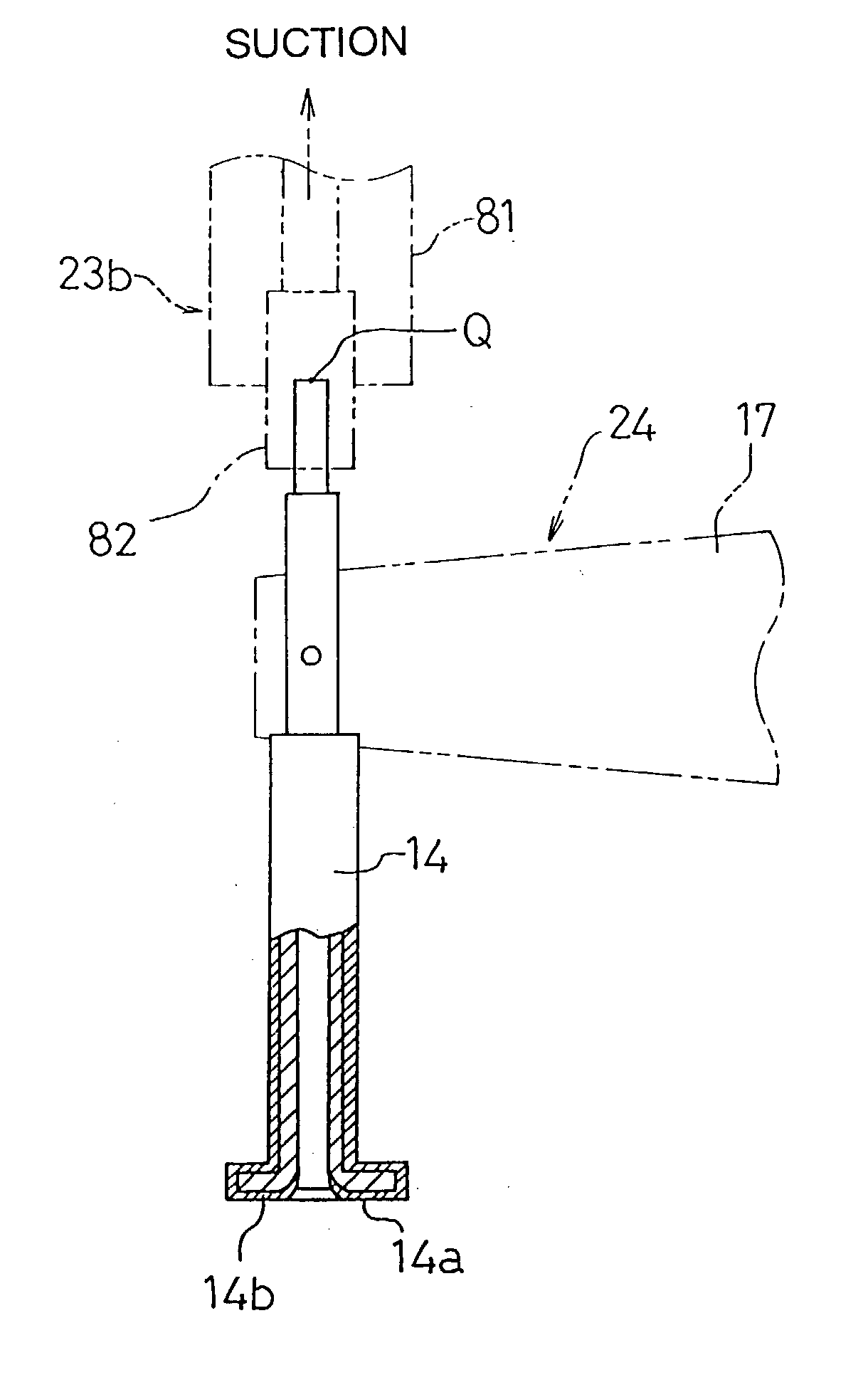

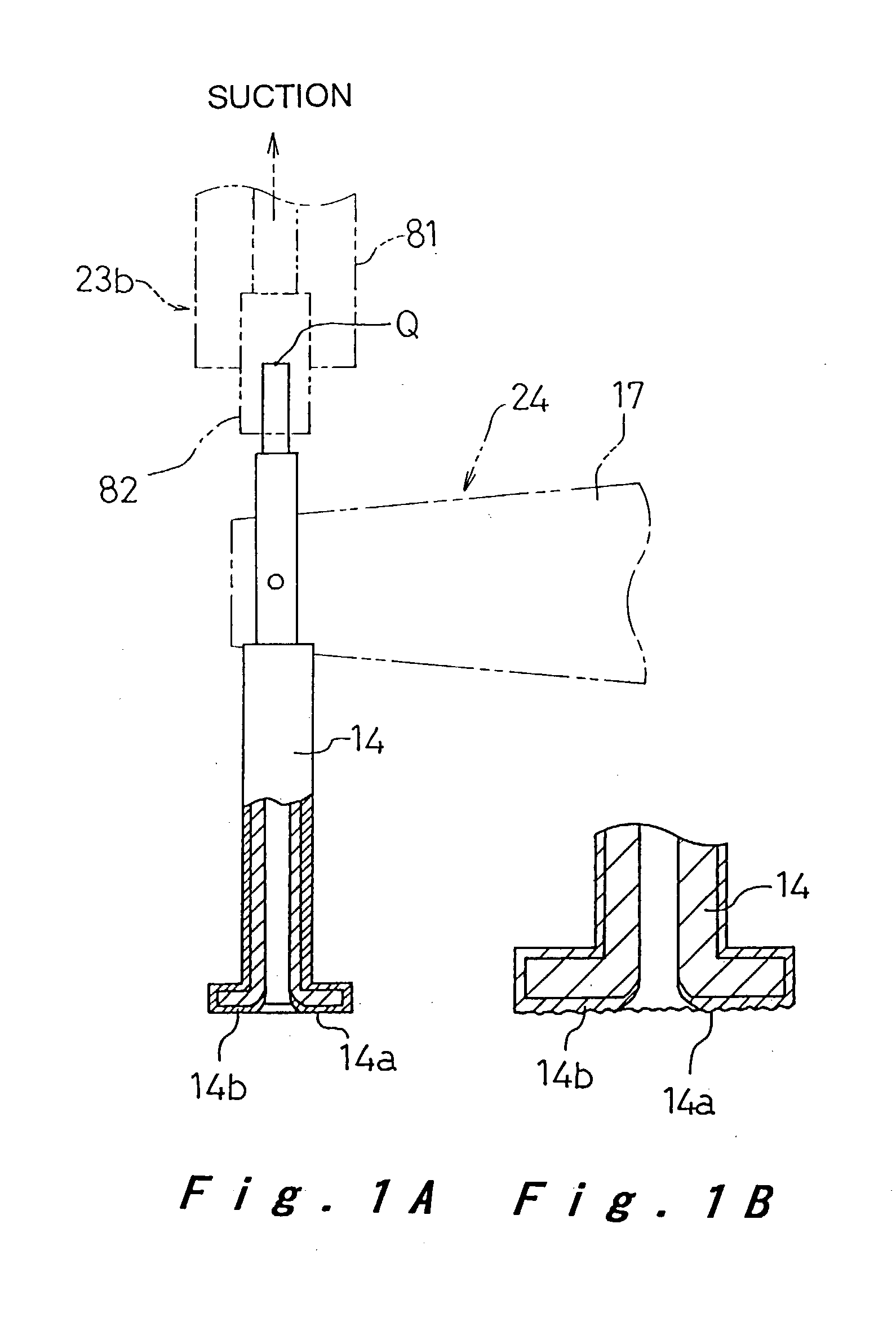

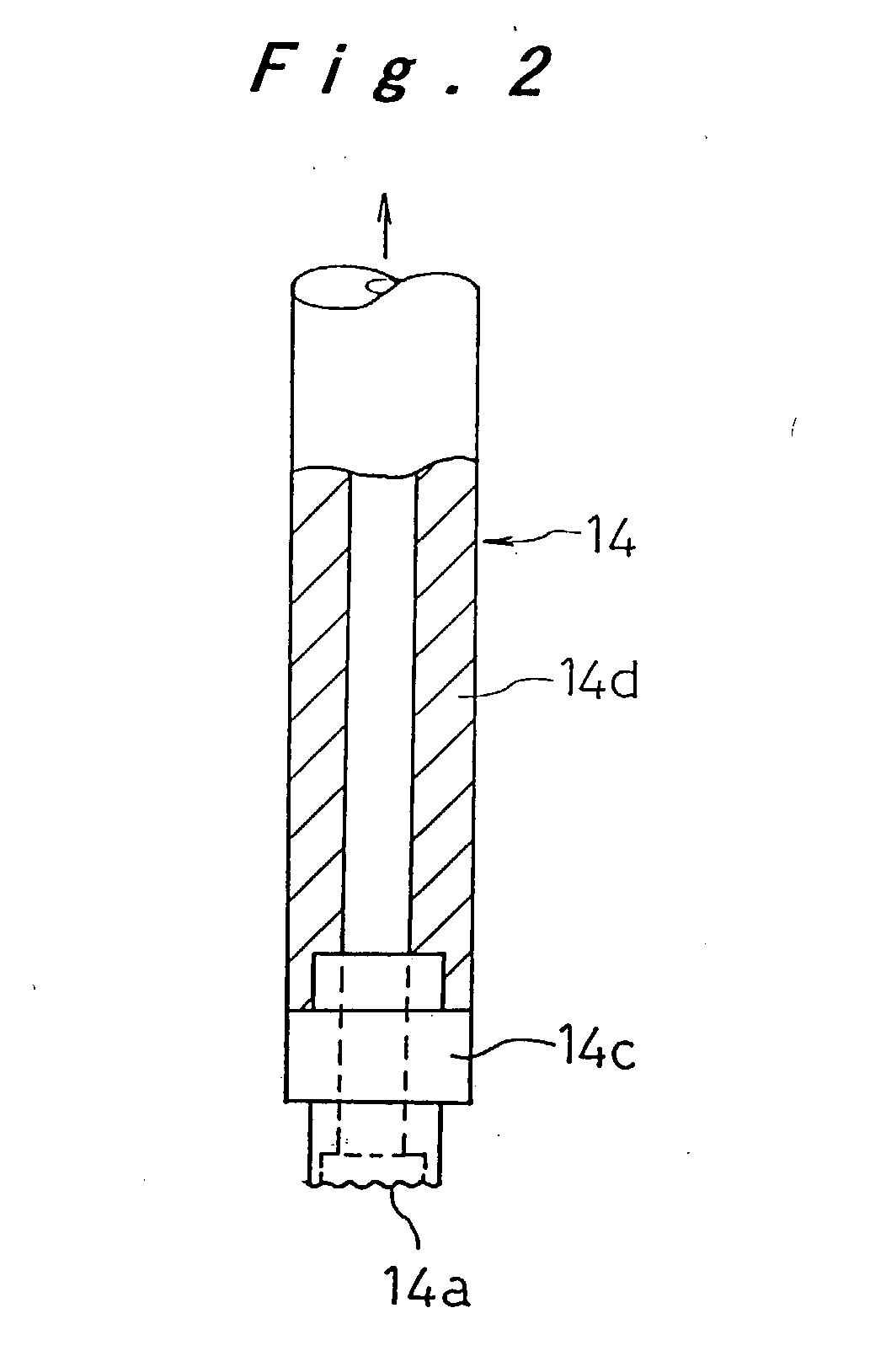

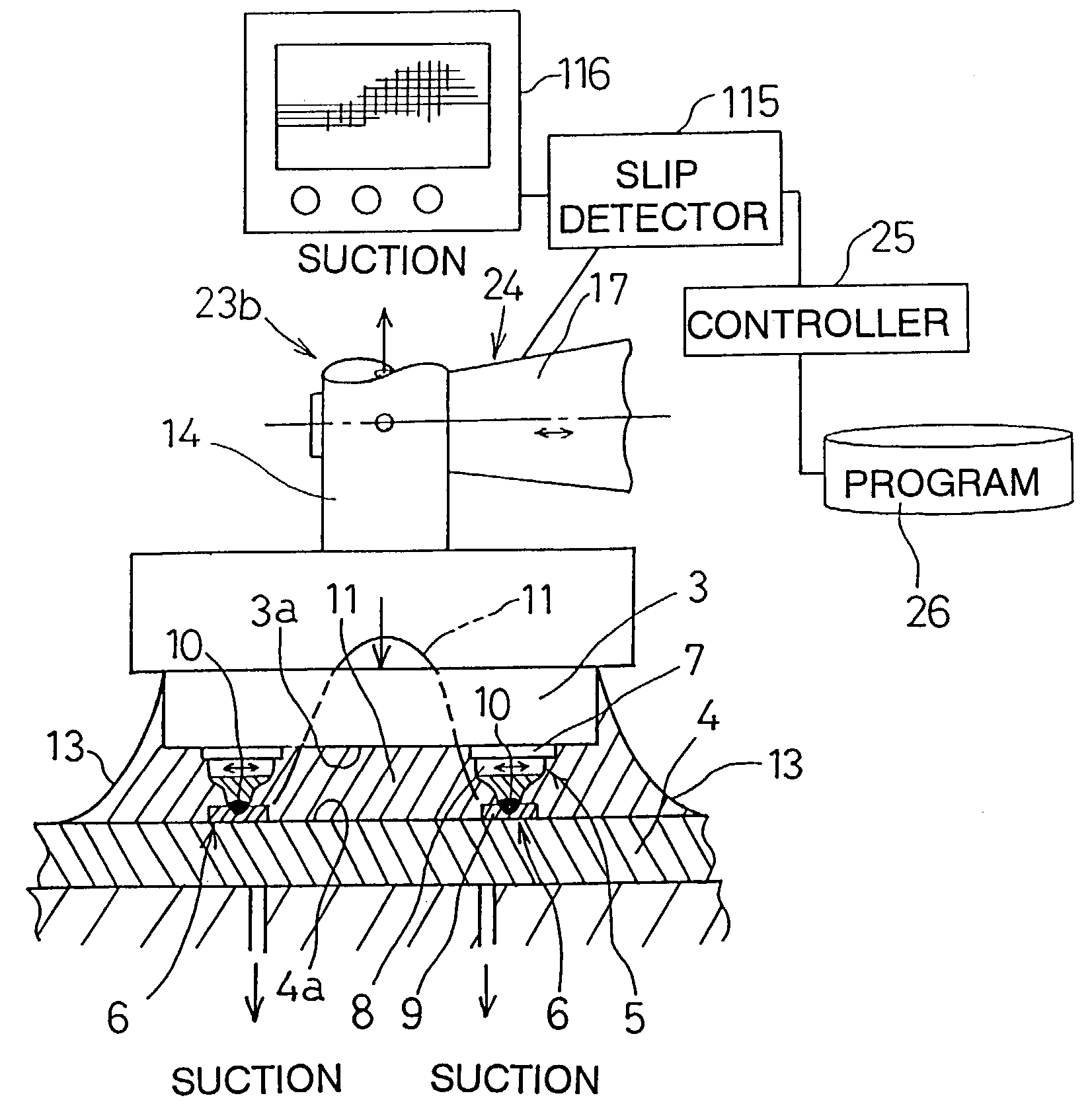

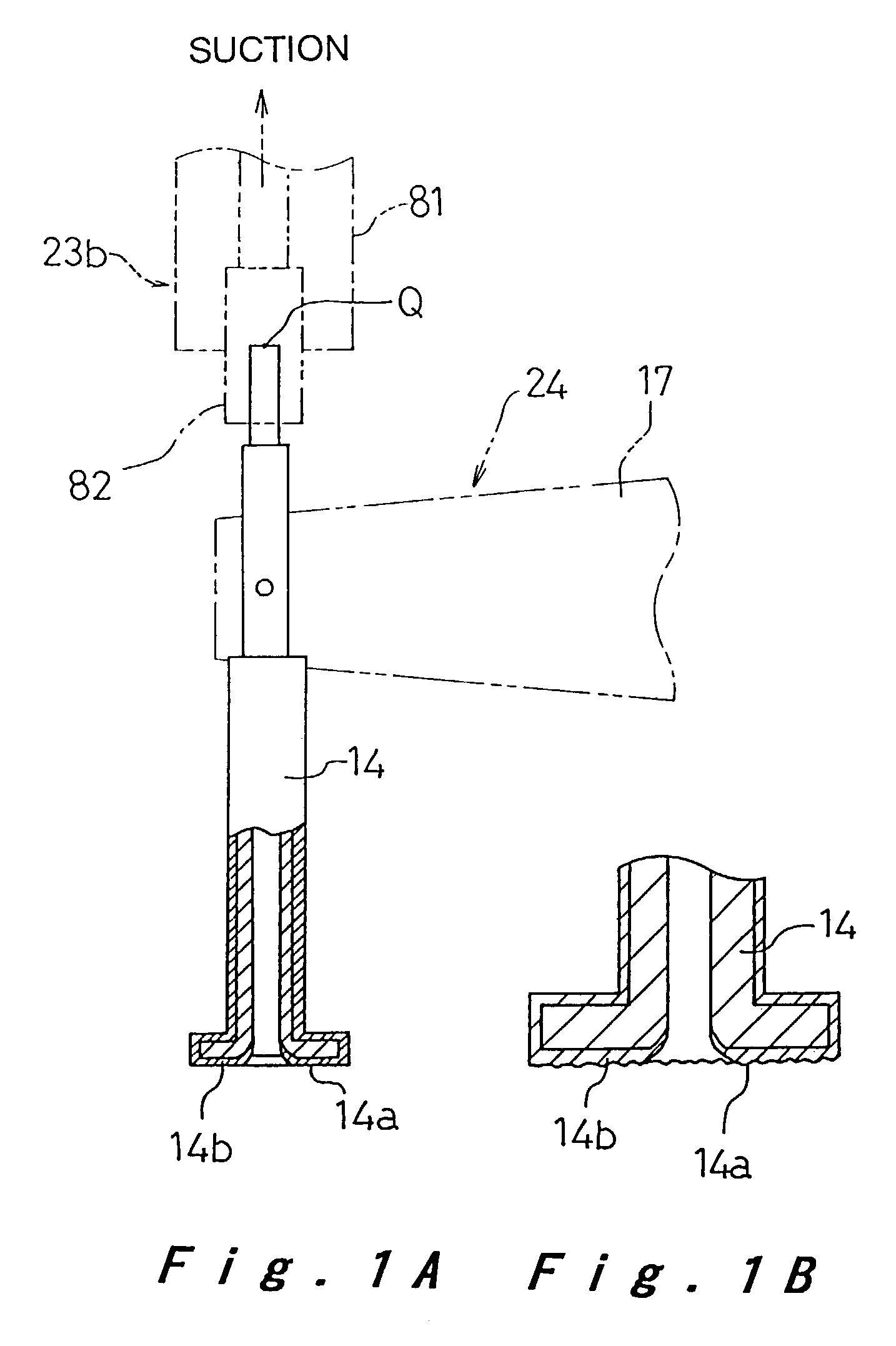

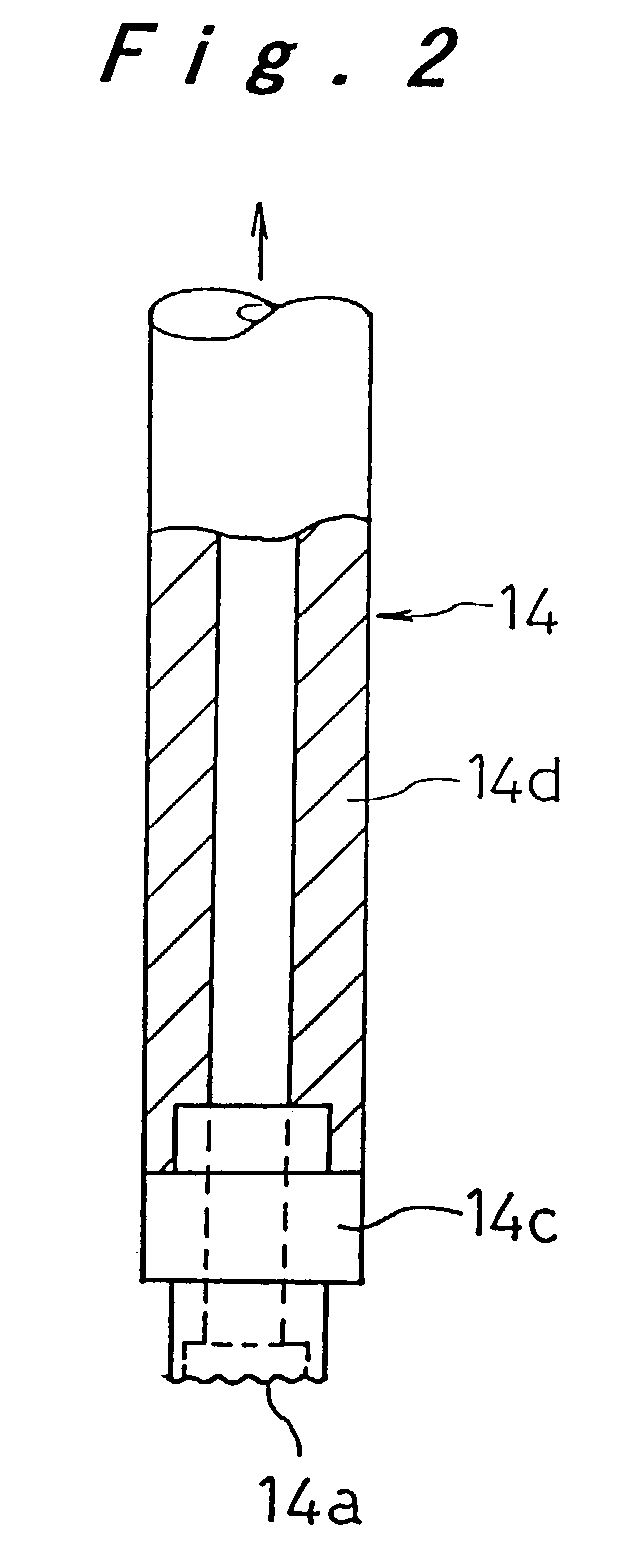

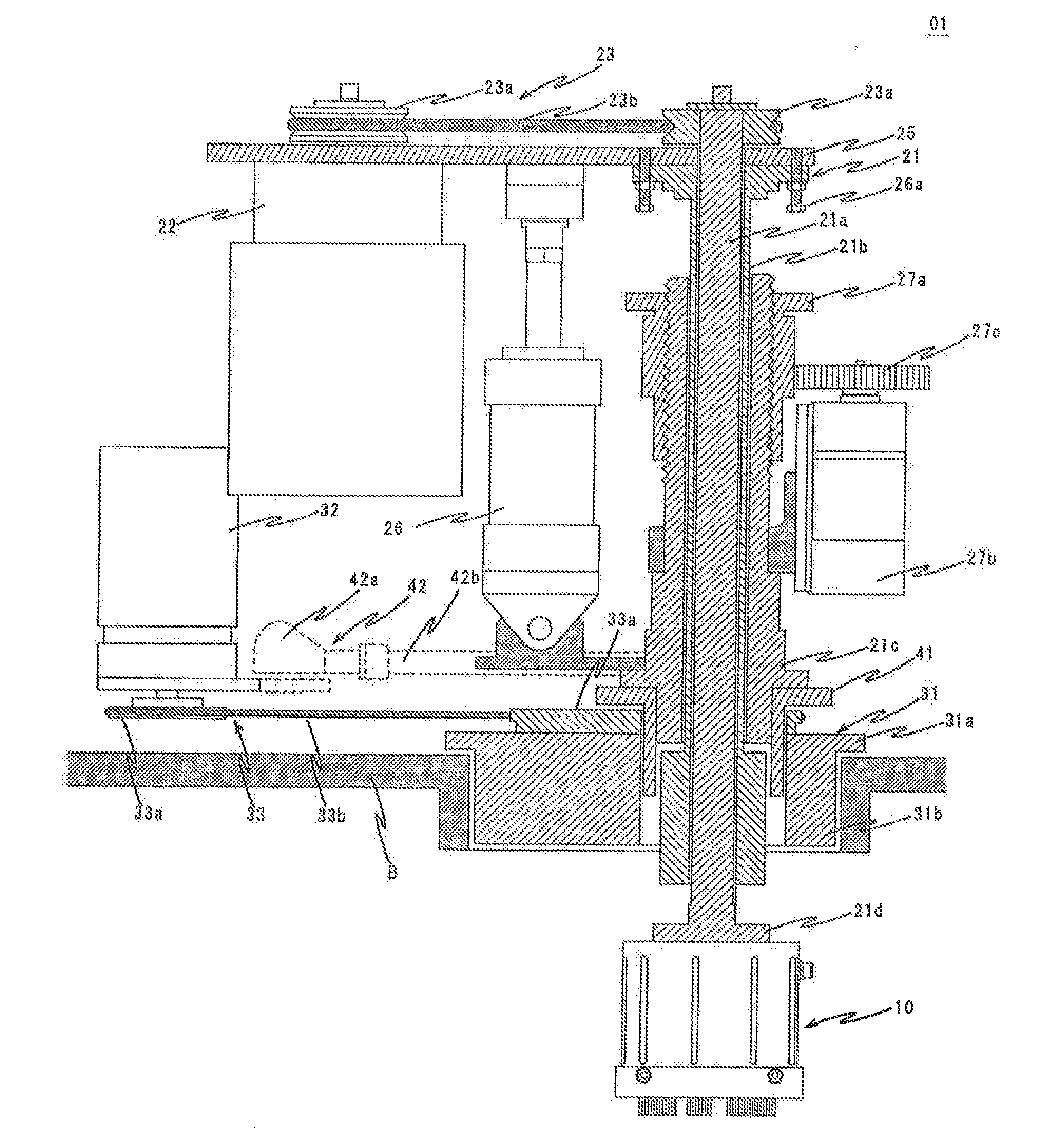

Component mounting tool, and method and apparatus for mounting component using this tool

InactiveUS20030150108A1Deterioration of surface regularity and flatnessExcellent Adhesive PropertiesWelding/cutting auxillary devicesSolid-state devicesMetal interconnectUltrasonic vibration

Component 3 is pressed onto a circuit board 4 so that their respective metal interconnects 5, 6 are in close contact with each other, and ultrasonic vibration is applied to the suction nozzle 14 holding the component 3. Friction is thereby generated between metal interconnects 5, 6 whereby the component 3 is bonded on circuit substrate. Suction nozzle 14 for handling components is made of stainless steel and has a working face 14a provided with a hardened layer 14b, or alternatively, suction nozzle 14 may have a suction head 14c having a working face 14a made of cemented carbide. Working face 14a of suction nozzle 14 is refined by polishing as required during the mounting operation.

Owner:PANASONIC CORP

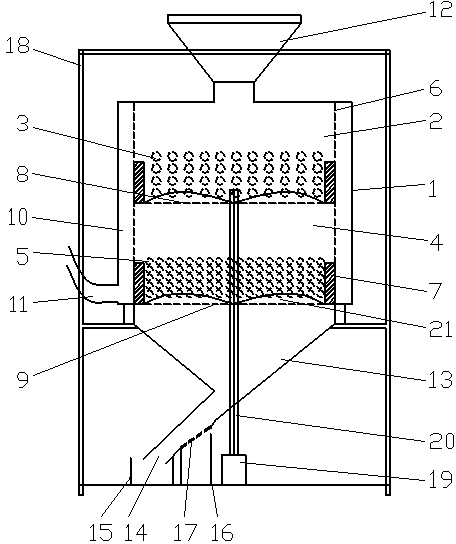

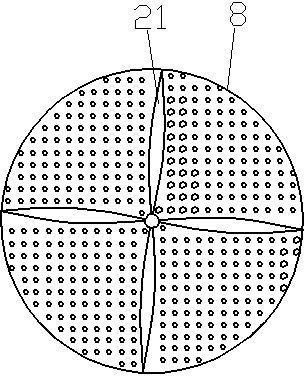

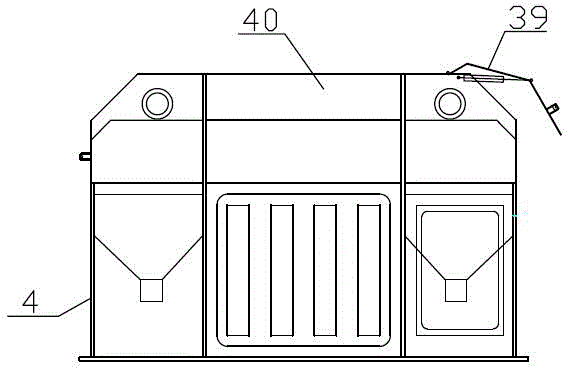

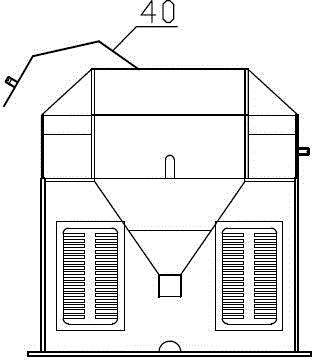

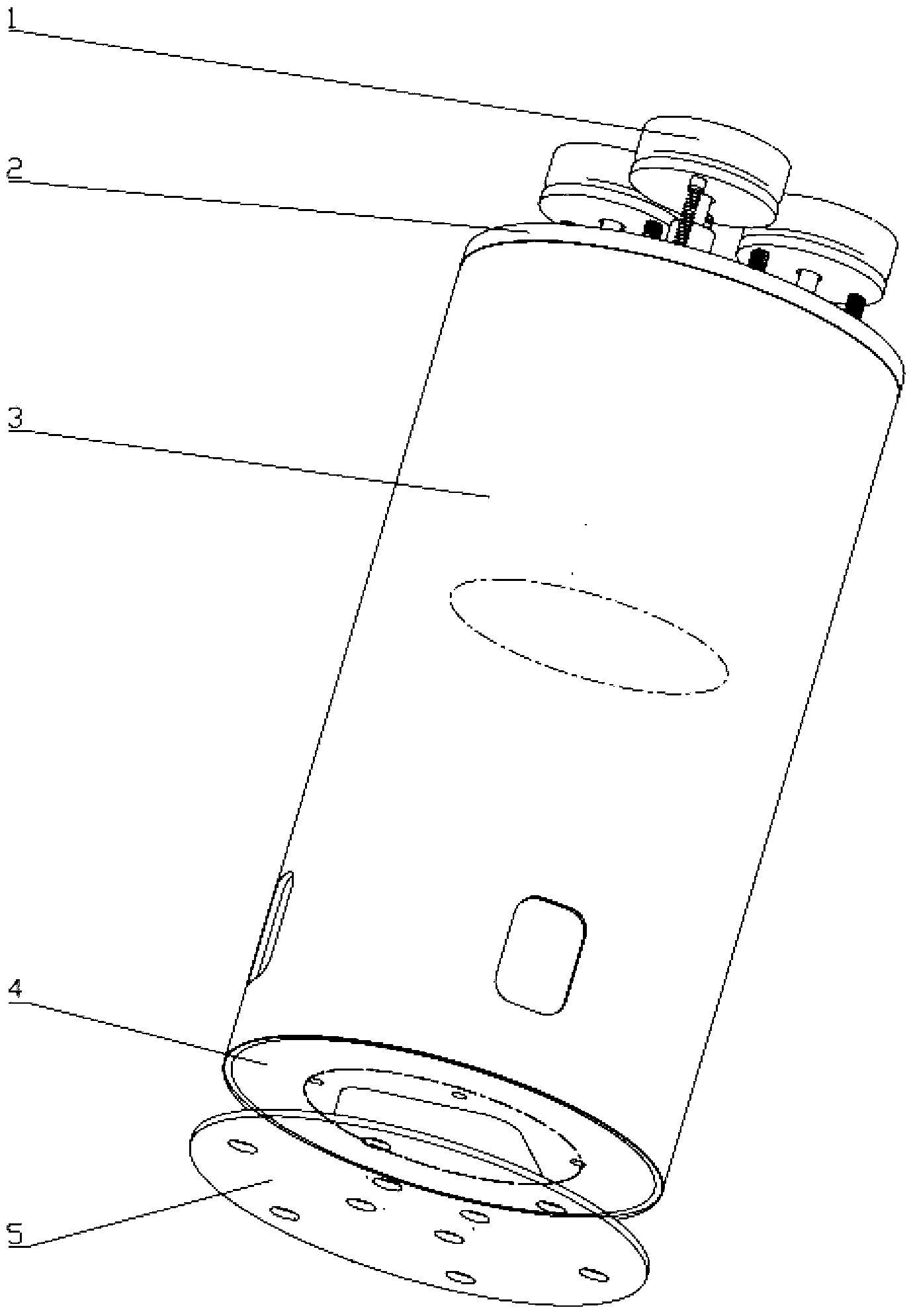

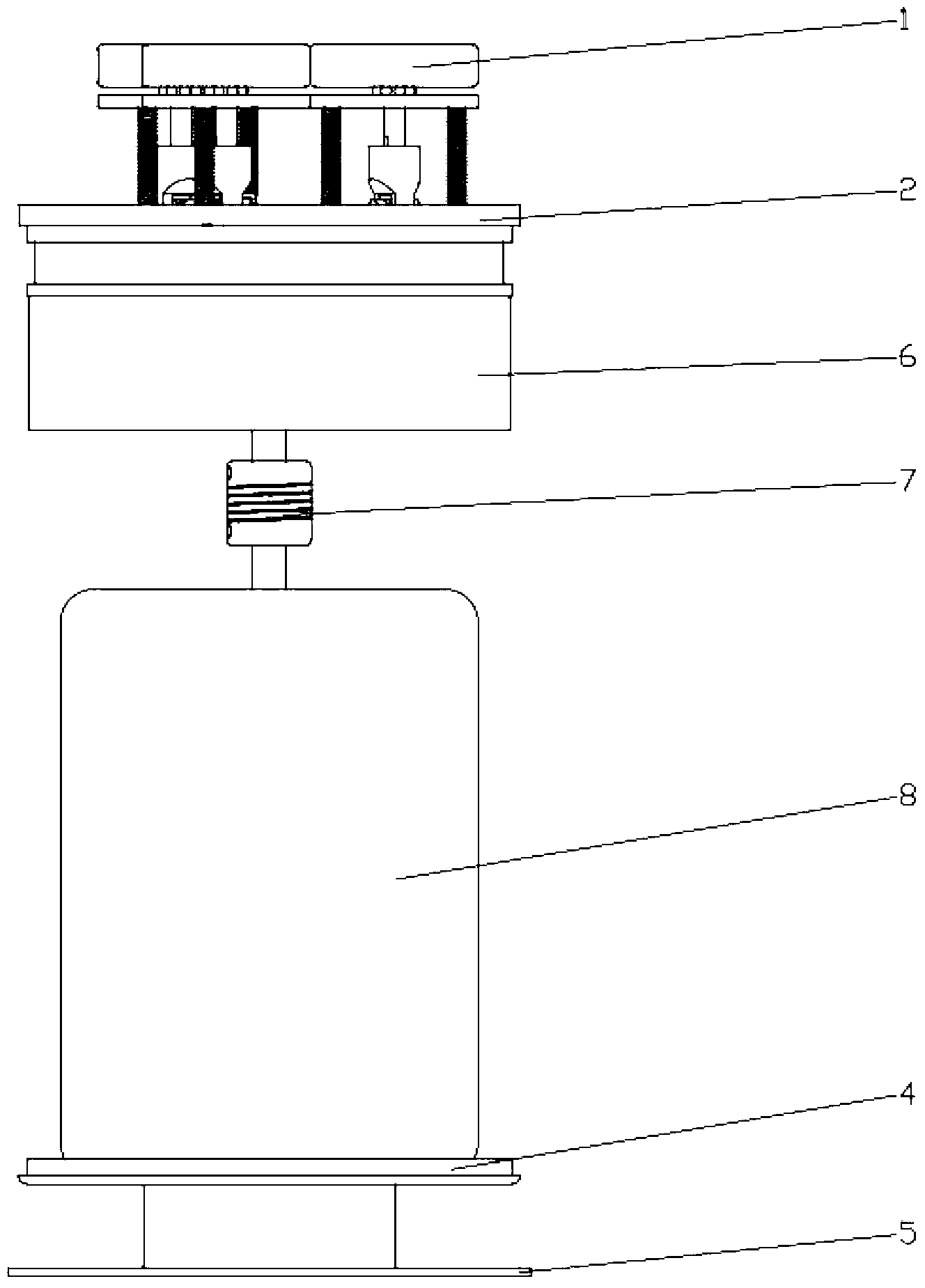

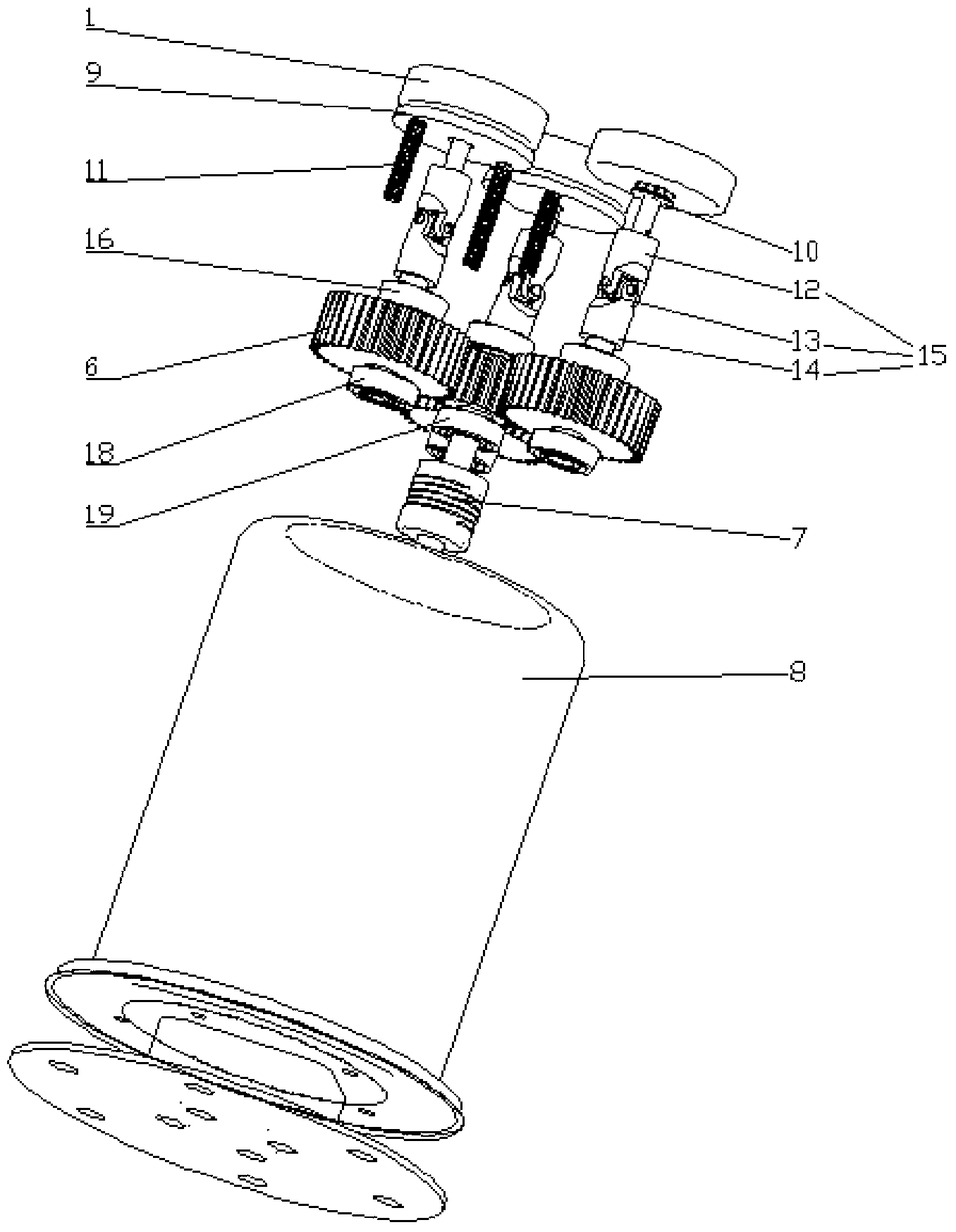

Polishing grain type rice polishing machine

ActiveCN104258920APolished evenlyEfficient polishingGrain huskingGrain polishingBroken riceEngineering

The invention relates to the field of rice machining, in particular to a polishing grain type rice polishing machine. The polishing grain type rice polishing machine comprises a polishing barrel, a to-be-polished rice inlet, a polishing barrel hopper chamber and a polishing rice outlet, wherein the to-be-polished rice inlet is arranged above the polishing barrel, the polishing barrel hopper chamber is arranged below the polishing barrel, and the polishing rice outlet is arranged below the polishing barrel hopper chamber. The polishing chamber comprises an upper polishing chamber, coarse-grain polishing grains, a lower polishing chamber and fine-grain polishing grains, the upper polishing chamber and the lower polishing chamber are arranged on the upper portion and the lower portion of the polishing barrel respectively, and the coarse-grain polishing grains and the fine-grain polishing grains are filled in the upper polishing chamber and the lower polishing chamber respectively. The polishing grain type rice polishing machine can well polish rice uniformly, and broken rice rate is decreased.

Owner:南雄市香溢工贸有限公司

Polishing slurry, method for manufacturing the polishing slurry, nitride crystalline material and method for plishing surface of the nitride crystalline material

InactiveUS20090317638A1Efficiently polishing surfaceEfficient polishingNitrogen compoundsOther chemical processesCrystalline materialsSlurry

The invention offers a slurry for polishing the surface of a nitride crystal. The polishing slurry contains oxide abrasive grains, at least one dispersant selected from the group consisting of an anionic organic dispersant and an inorganic dispersant, and an oxidizing reagent. The polishing slurry has a pH of less than 7. The slurry efficiently polishes the surface of the nitride crystal.

Owner:SUMITOMO ELECTRIC IND LTD

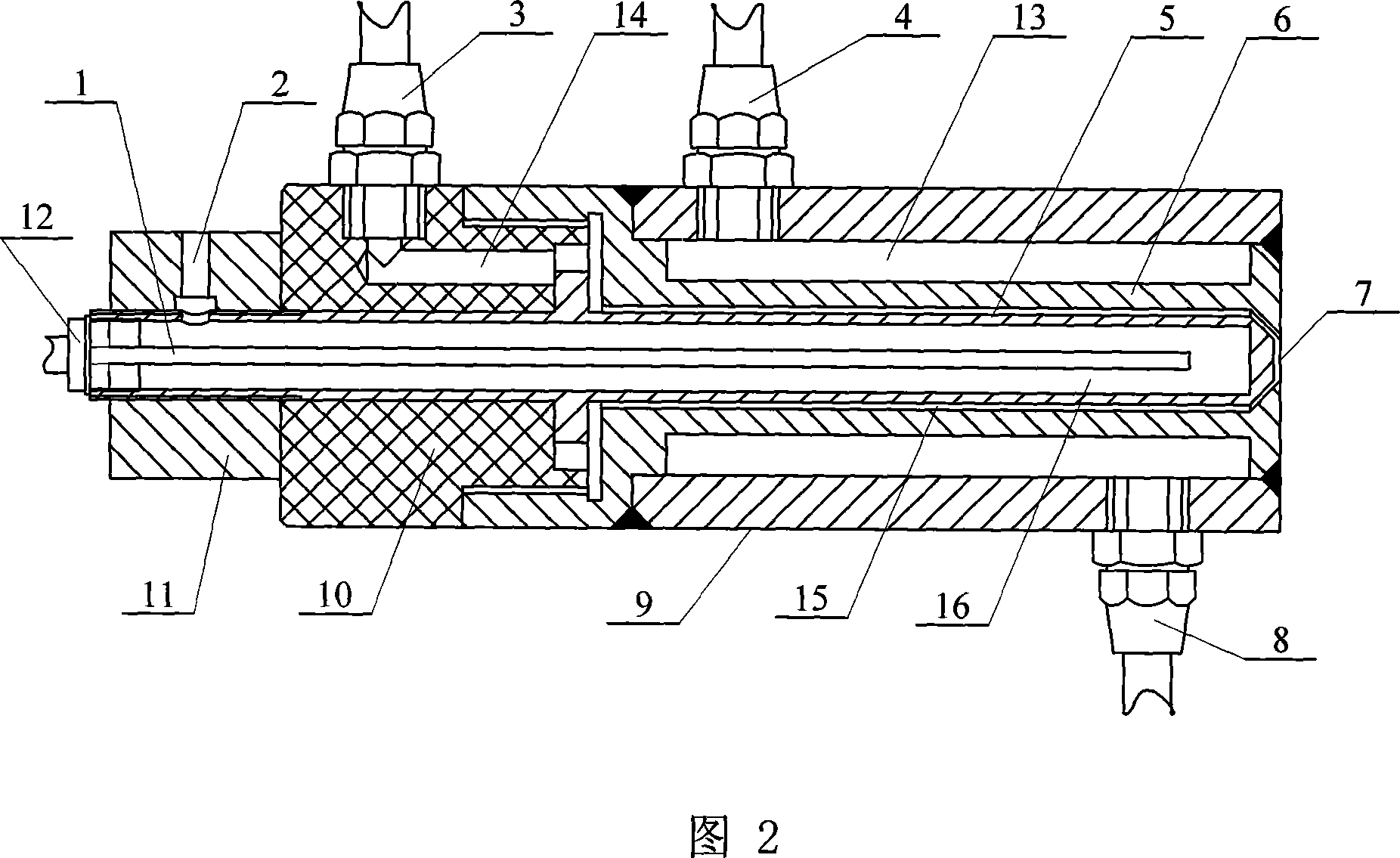

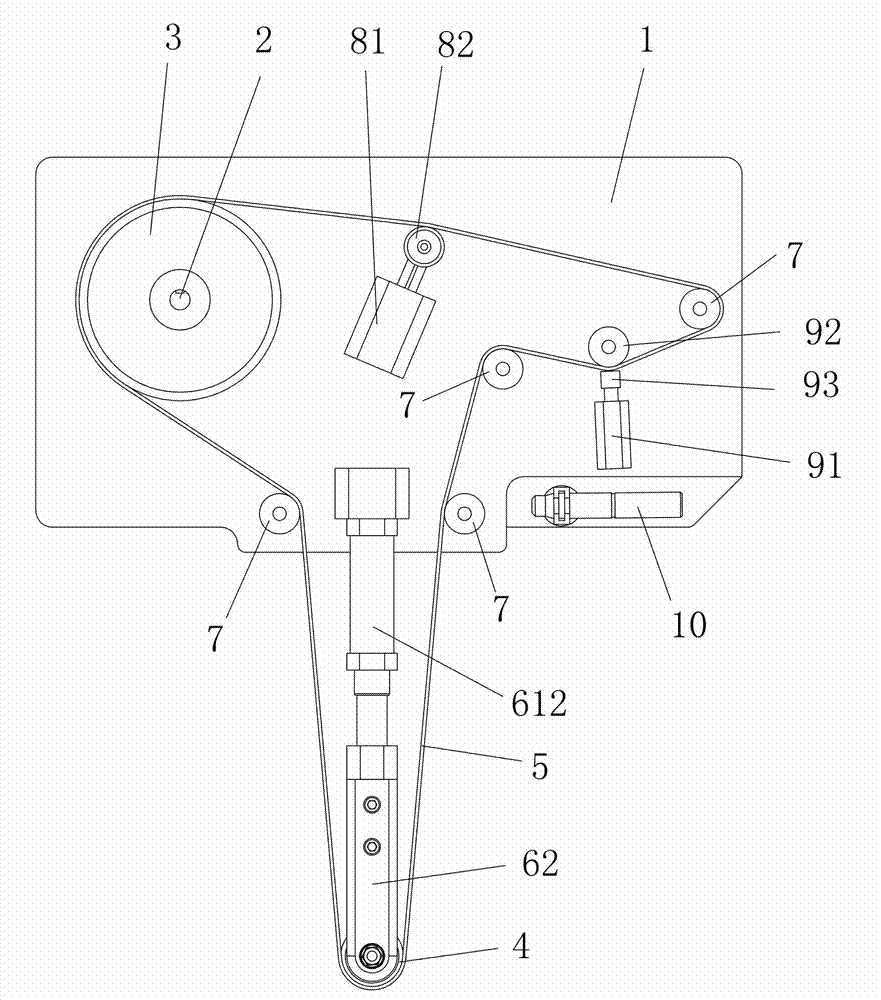

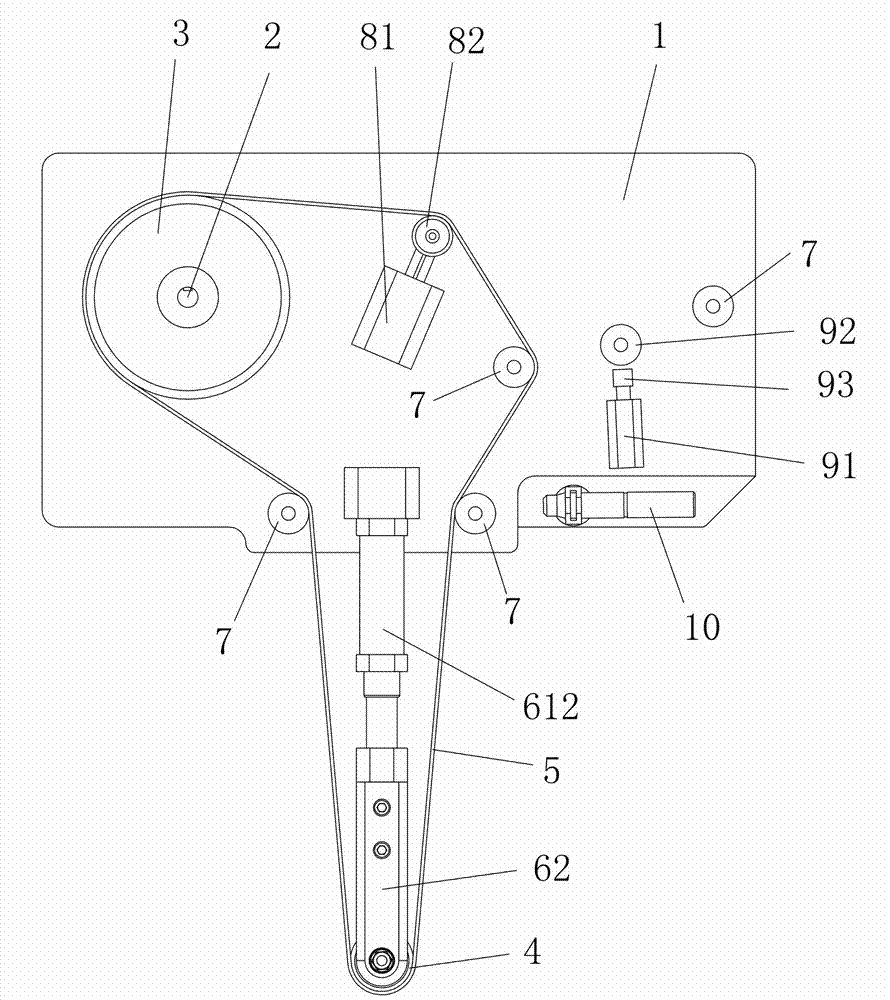

Wheel and belt polishing device and machine tool for inner and outer surfaces and free-form surfaces of high-steepness parts

InactiveCN102814715AEfficient polishingImprove polishing efficiencyGrinding carriagesBelt grinding machinesDrive wheelFree form

A wheel and belt polishing device for inner and outer surfaces and free-form surfaces of high-steepness parts comprises a mounting bedplate, a driving mechanism, a driving wheel, a contact wheel, a polishing belt and a long supporting arm. The driving mechanism is mounted on the mounting bedplate, the driving wheel is connected with an output end of the driving mechanism, the polishing belt is wound on the driving wheel and the contact wheel, one end of the supporting arm is fixed onto the mounting bedplate, the other end of the supporting arm extends out of the mounting bedplate and can extend into an inner cavity of a workpiece, and the contact wheel is mounted at the end of the supporting arm extending out of the mounting bedplate. The invention further discloses a machine tool which comprises a tool body. The wheel and belt polishing device for inner and outer surfaces and free-form surfaces of high-steepness parts is arranged on the tool body. By the wheel and belt polishing device and the machine tool, the inner cavity of the part can be polished conveniently, and polishing efficiency is high.

Owner:NAT UNIV OF DEFENSE TECH

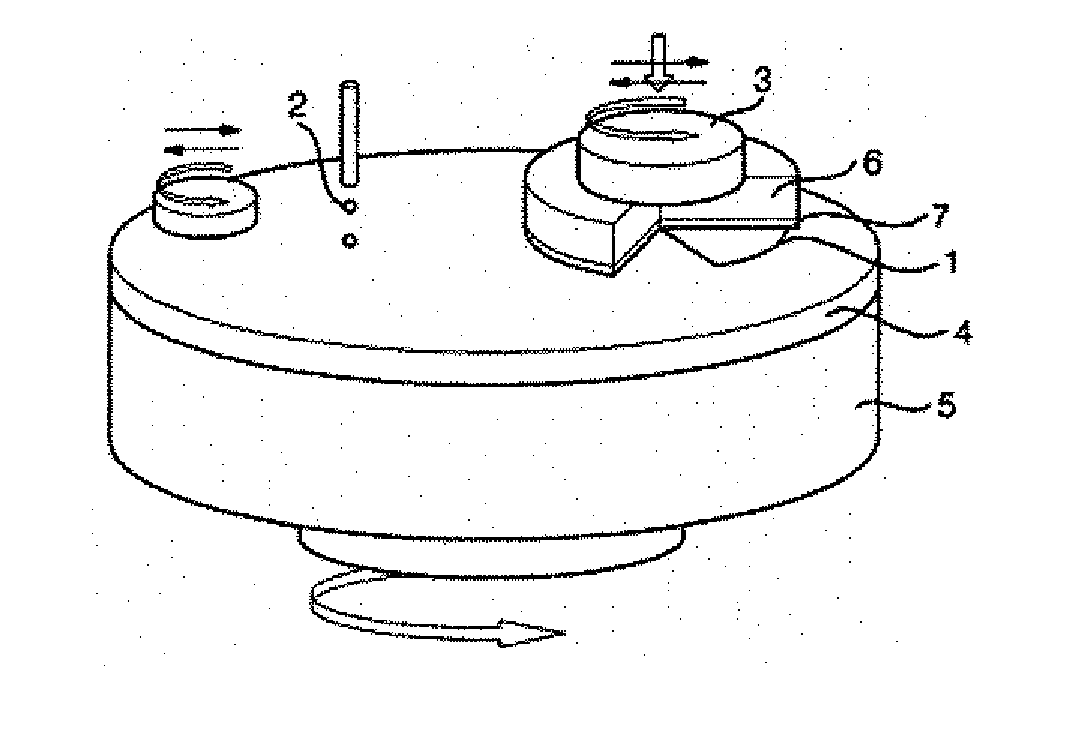

Polishing pad and semiconductor substrate manufacturing method using the polishing pad

InactiveUS20040198056A1Improve the level ofEfficient polishingPolishing machinesRevolution surface grinding machinesSynthetic resinSemiconductor

It is provided a polishing pad of novel construction capable of controlling actively and efficiently a slurry flow during polishing a surface of a semiconductor substrate, such as a wafer, thus making it possible to precisely and stably performing a desired polishing process. Onto a surface of a pad substrate 12 of synthetic resin material, formed is a groove 16 extending approximately circumferentially. An inner circumferential wall surface 20 and an outer circumferential wall surface 22 are made parallel to each other and slant with respect to a center axis 18 of the pad substrate 12.

Owner:TOHO ENG CO LTD

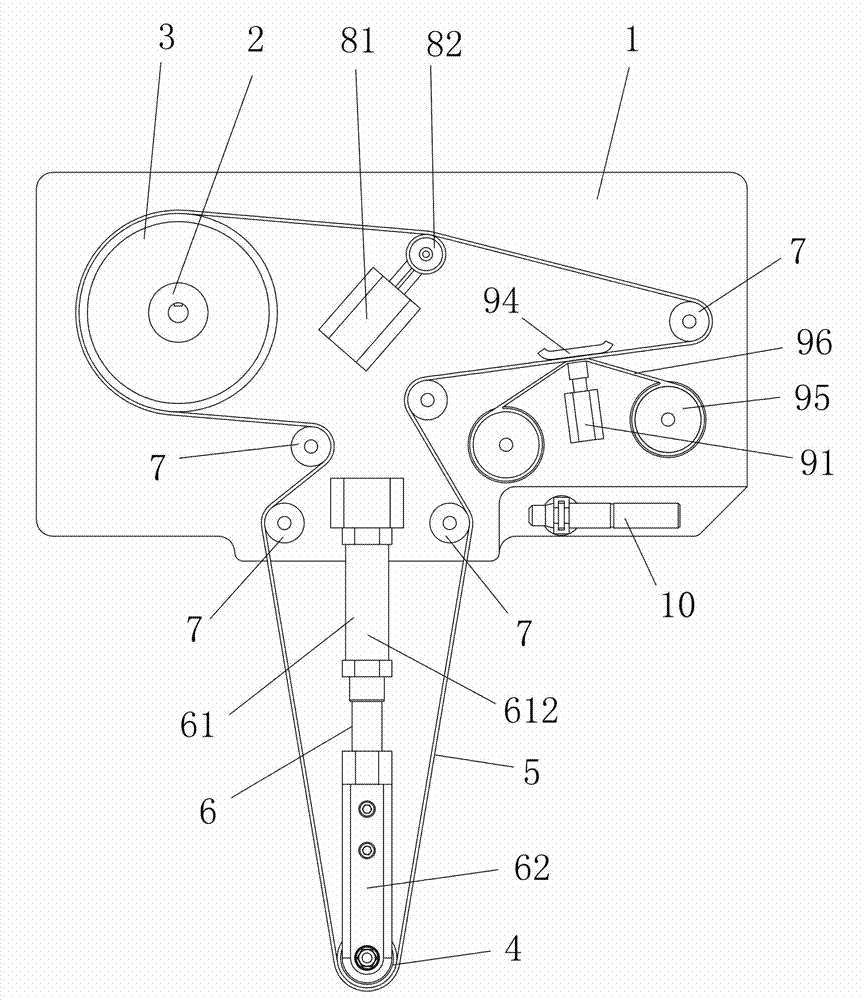

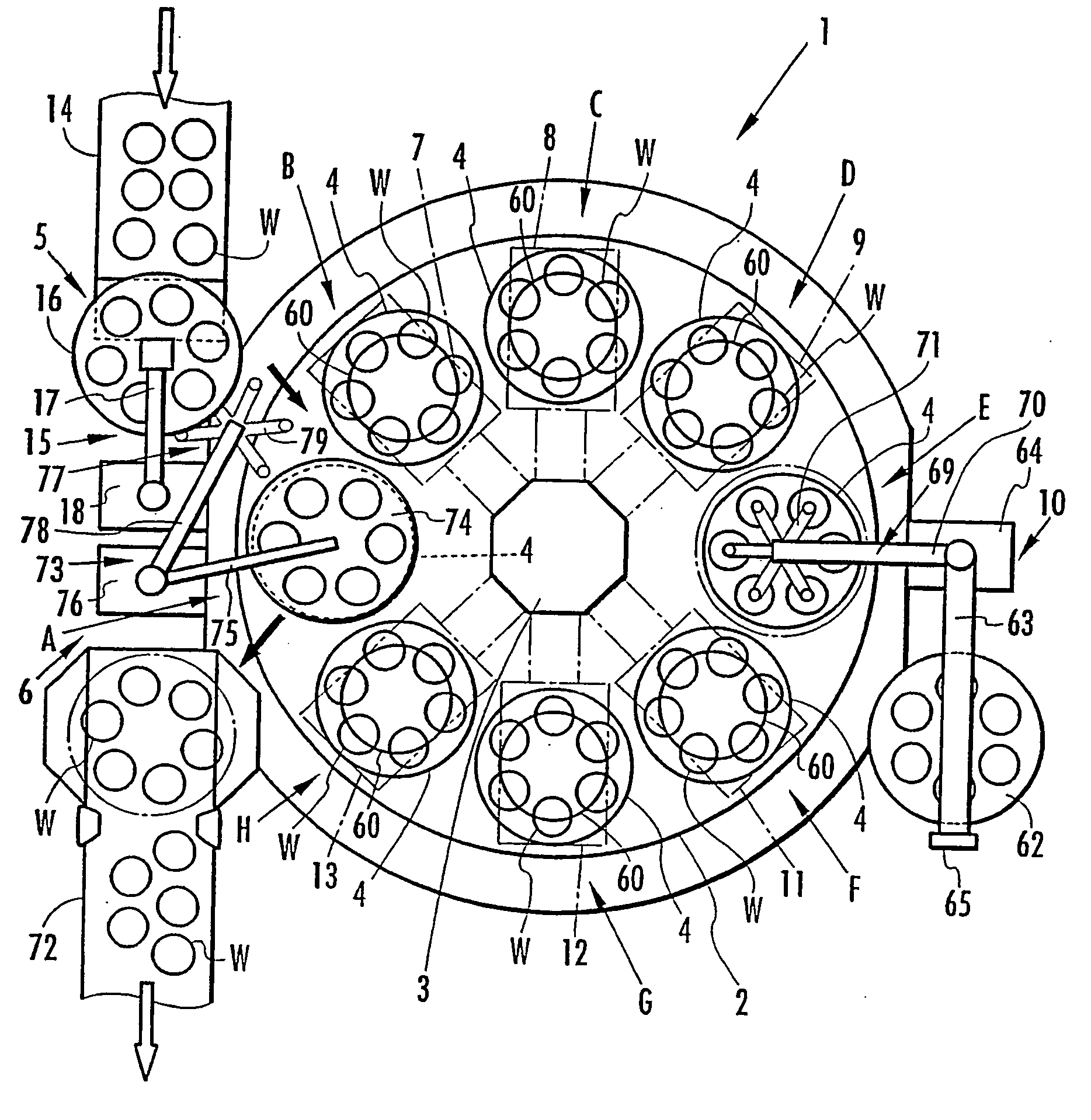

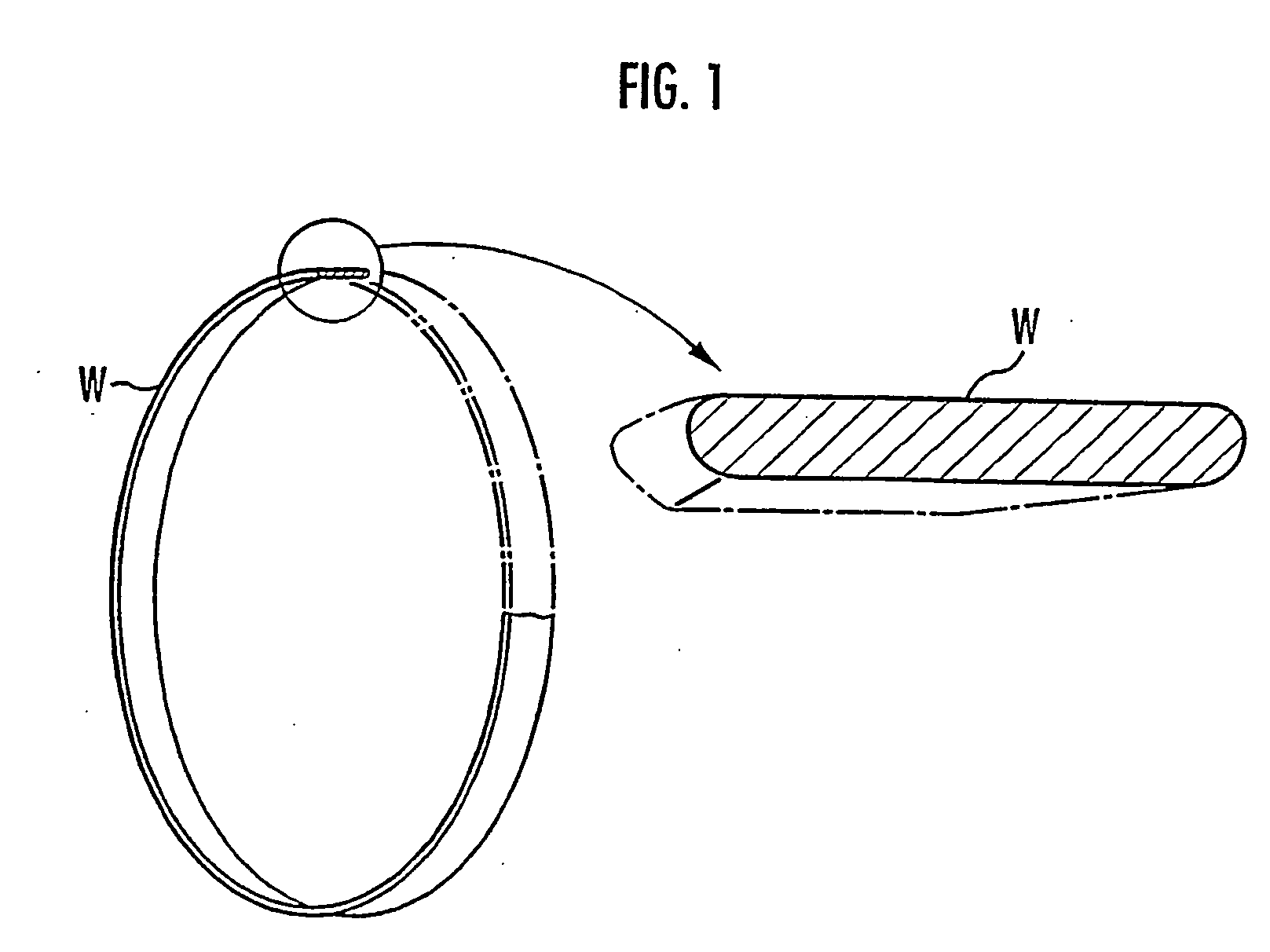

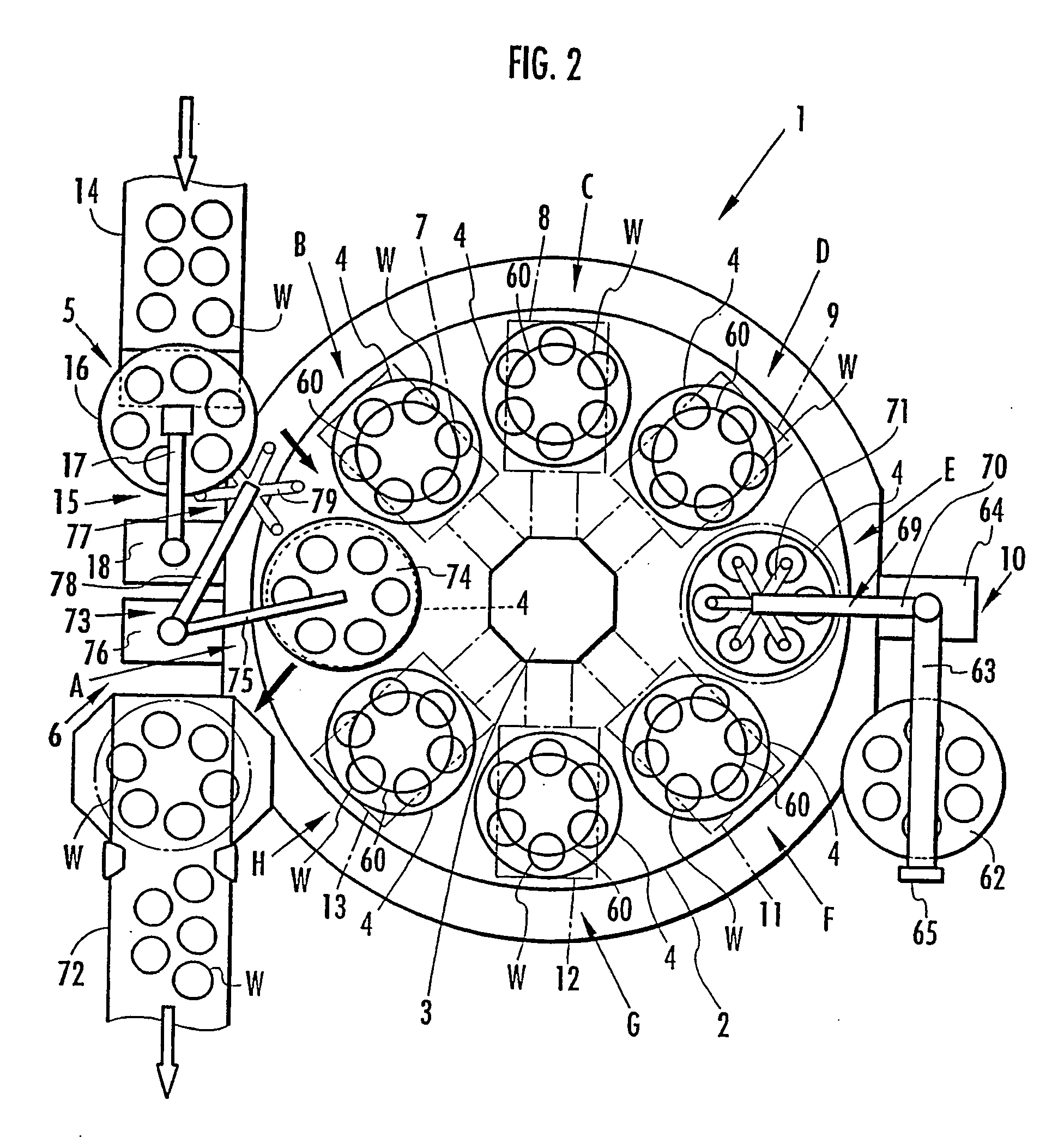

Method and device for polishing endless belt metal rings for continuously variable transmission

InactiveUS20060211343A1Improve efficiencyFrictionEdge grinding machinesPolishing machinesEngineeringMetal

There are disclosed a method and device for polishing a metal ring, which is capable of polishing a side edge of the metal ring without performing barrel polishing or polishing by grinding stones. Subsequently to a projecting step of projecting a metal ring W by clearing means 6, a first brush polishing step of polishing one edge of the metal ring W by a polishing brush 60 is performed. Subsequently, an inverting step of inverting the metal ring W whose one edge is polished by the first brush polishing step is inverted by the inverting means 10 is performed. Subsequently, a second brush polishing step of polishing the other edge of the metal ring W which is inverted by the inverting step by the polishing brush 60 is performed. Moreover, a clearing step of clearing the metal ring whose other edge is polished by the second brush polishing step by clearing means 7 is performed.

Owner:HONDA MOTOR CO LTD

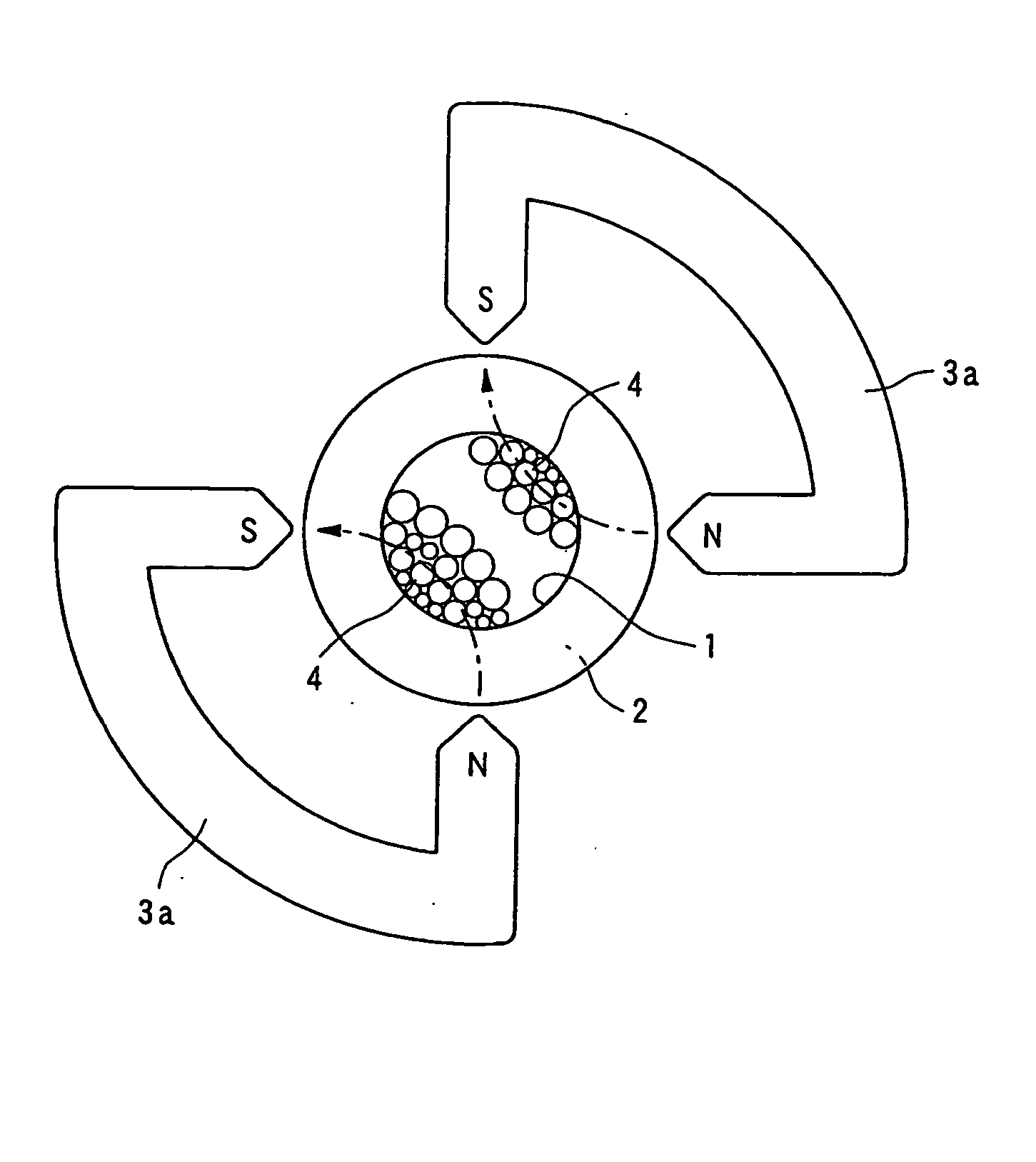

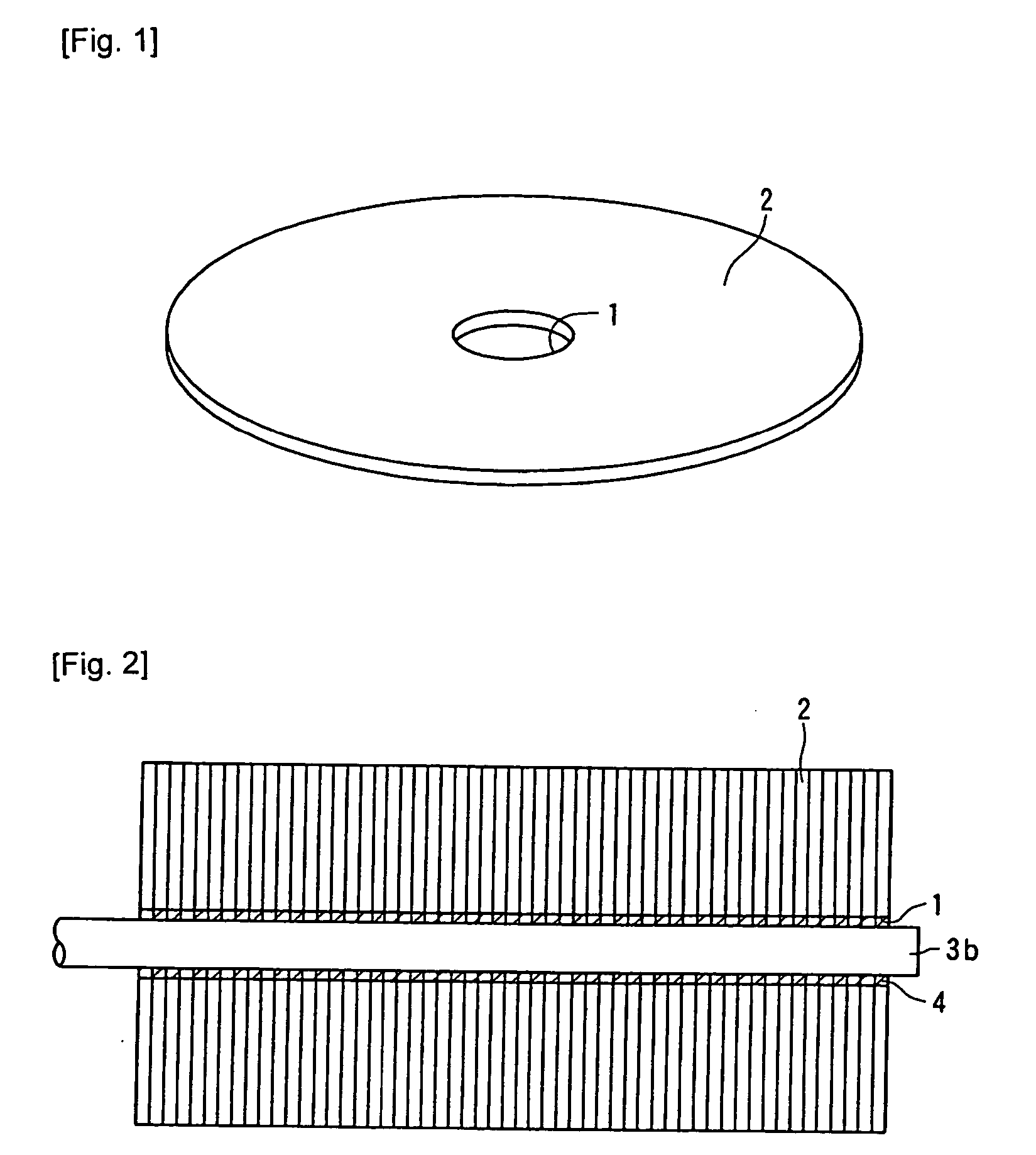

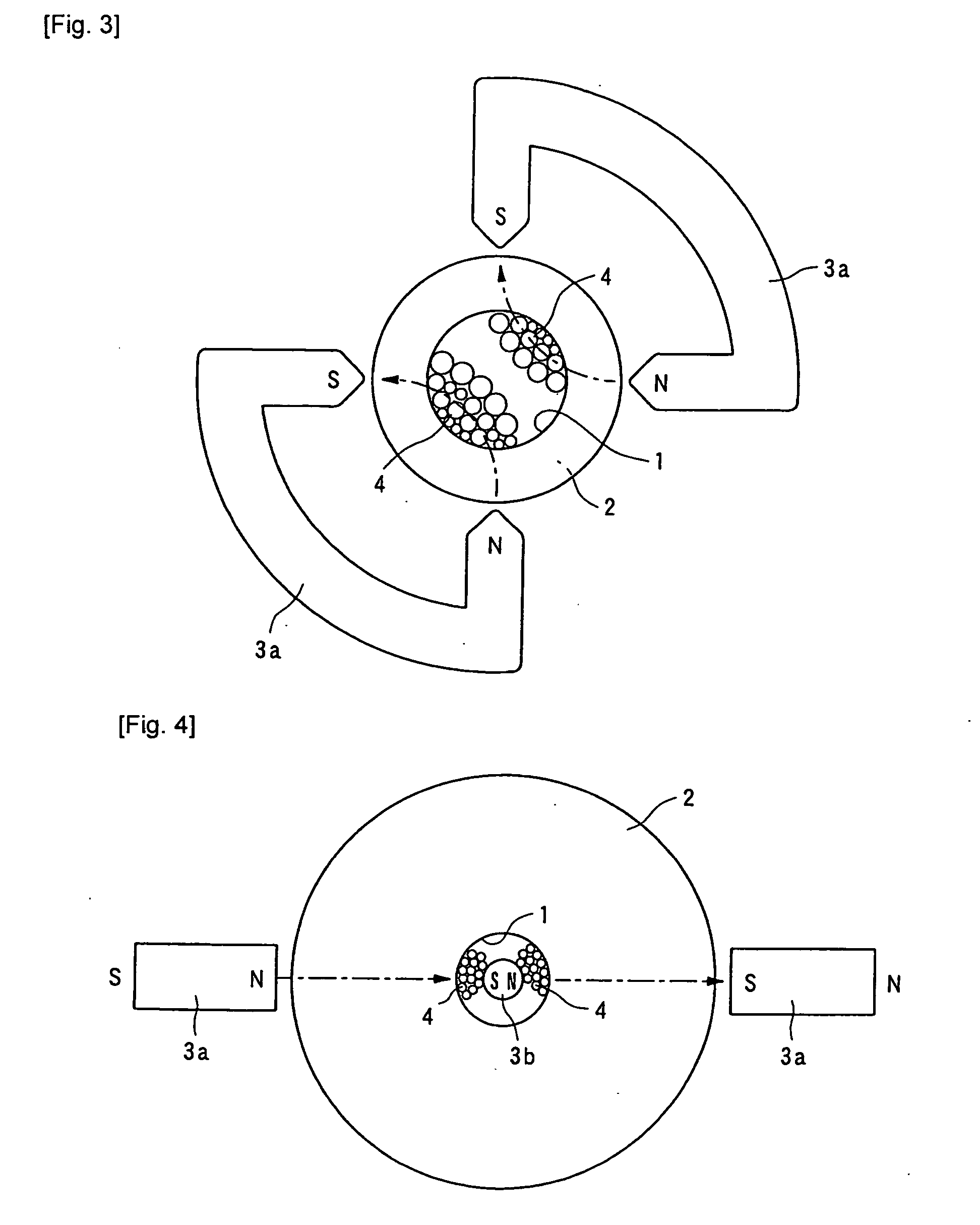

Method and device for manufacturing substrate for magnetic disk, and method of manufacturing magnetic disk

InactiveUS20060148386A1Easily and satisfactorily polishedEfficient polishingPolishing machinesRevolution surface grinding machinesEngineeringVolumetric Mass Density

A magnetic polishing method capable of easily and satisfactorily polishing the inner peripheral end face of a circular hole (1) at the center part of a disk substrate (2) even if the diameter of the circular hole is reduced. By this method, a large quantity of disk substrates with stable quality can be supplied, thermal asperity trouble and head crush can be prevented from occurring on a magnetic disk, and the density of the information recording surface of the magnetic disk can be increased. In the method for polishing the inner peripheral end face of the circular hole (1) at the center part of the disk substrate (2), a magnetic field is formed on the inner peripheral side of the circular hole (1), abrasive materials (4) including magnetic particles and abrasive grains are held by the magnetic field in the circular hole, and the magnetic field is moved to the inner peripheral end face of the circular hole (1) to move the abrasive materials (4) to the inner peripheral end face of the circular hole (1) for polishing the inner peripheral end face of the circular hole (1).

Owner:HOYA CORP

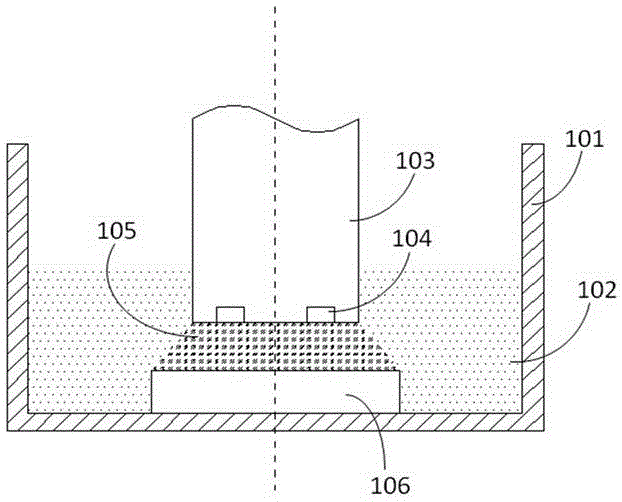

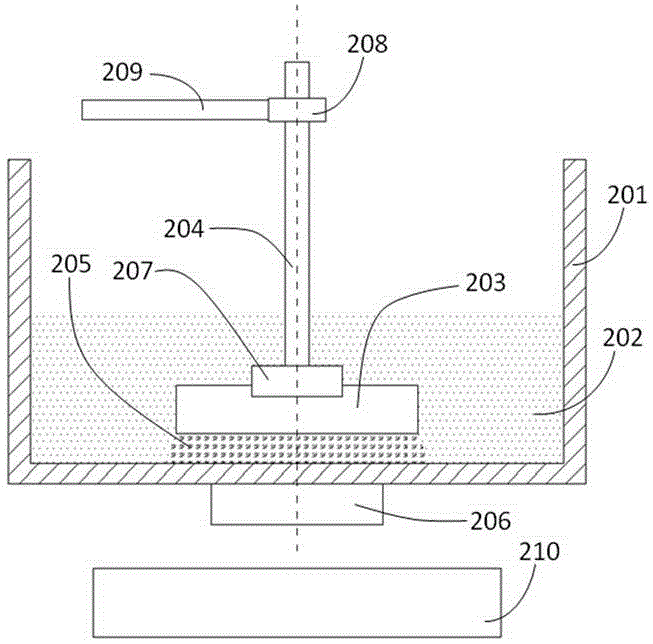

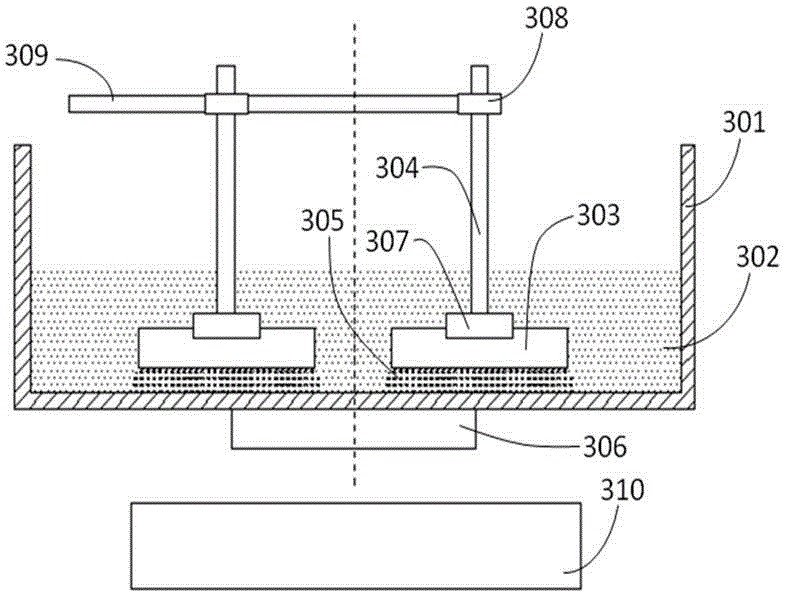

Magneto-rheological amorphous alloy polishing device, polishing agent and polishing method

InactiveCN105904332AEfficient polishingHigh gloss mirror effectEdge grinding machinesPolishing machinesReciprocating motionAlloy

The invention discloses a magneto-rheological amorphous alloy polishing device which comprises a polishing groove, a fixed clamping device, a motor and a magnetic field generation device, wherein a magneto-rheological polishing agent is stored in the polishing groove; a to-be-polished work piece is fixed in the polishing agent by the fixed clamping device, so that a gap is formed between a polishing face of the work piece and the bottom of the polishing groove; the magnetic field generation device is disposed outside the polishing groove, and an external magnetic field generated by the device makes magnetic particles in the magneto-rheological polishing agent generate rheological effects, so that a magneto-rheological aggregate is formed between the work piece polishing face and the bottom of the polishing groove; and the motor is connected to the polishing groove and can drive the polishing groove to rotate or move back and forth. The polishing device disclosed by the invention has the advantages that a magneto-rheological polishing technology is applied in amorphous alloy polishing; the polishing device applicable to use is provided; an amorphous alloy product can be polished effectively, so that a surface with specular gloss can be obtained; the polishing technology is simple and can be implemented easily; and the polishing device is applicable to large-scale production.

Owner:宋佳

Component mounting apparatus including a polishing device

InactiveUS7219419B2Improved vibration characteristicsImprove wear resistanceSolid-state devicesWelding/cutting auxillary devicesMetal interconnectEngineering

Component (3) is pressed onto a circuit board (4) so that their respective metal interconnects (5), (6) are in close contact with each other, and ultrasonic vibration is applied to the suction nozzle (14) holding the component (3). Friction is thereby generated between metal interconnects (5), (6) whereby the component (3) is bonded on circuit substrate. Suction nozzle (14) for handling components is made of stainless steel and has a working face (14a) provided with a hardened layer (14b), or alternatively, suction nozzle (14) may have a suction head (14c) having a working face (14a) made of cemented carbide. Working face (14a) of suction nozzle (14) is refined by polishing as required during the mounting operation.

Owner:PANASONIC CORP

Wire surface rust removal polisher

ActiveCN104907907AAvoid dust pollutionReduce manufacturing costGrinding drivesBelt grinding machinesBelt grindingEngineering

The invention relates to a wire surface rust removal polisher. Rust removal polishing is performed on the surface of a wire in the mode that an abrasive belt moves to grind the wire and rotates around the circumference of the wire, the abrasive belt conducts helical motion on the surface of the wire due to linear movement of the wire, and therefore grinding dust removal can be performed on the whole surface of the wire. In addition, removed iron rust can be recycled, and therefore the production cost is lowered; a physical abrasive belt grinding method replaces a traditional chemical electrolysis pickling method, and therefore air pollution is reduced.

Owner:HANGZHOU XINGGUAN MACHINERY

Metal curved surface flexible polishing tool

ActiveCN103317423AHarm disappearsIncrease productivityPolishing machinesGrinding machine componentsIsoetes triquetraUniversal joint

The invention relates to a polishing tool, in particular to a metal curved surface flexible polishing tool. The metal curved surface flexible polishing tool comprises a polishing head, an outer shell, a front end cover, a rear end cover, a gasket, a thrust bearing, a universal joint, a gear transmission mechanism, a coupler, a motor and a flange, wherein the polishing head is provided with three round polishing heads which are evenly distributed on a circumference, the center connecting lines of the three round polishing heads form an equilateral triangle, the gasket is located at the bottom of the polishing head, the thrust bearing is located between the polishing head and the gasket, the thrust bearing and the gasket are fixed together, a spring is located at the bottom of the gasket, the two ends of the spring are fixed on the gasket and the front end cover, a shaft of the polishing head is connected with a gear shaft of the gear transmission mechanism through the universal joint, and a driving gear shaft of the gear transmission mechanism is connected with a power output shaft of the motor through the coupler. The gear transmission mechanism, the coupler and the motor are packaged inside a shell body formed by the outer shell, the front end cover and the rear end cover, heat radiation holes are formed in the outer shell, and the flange is externally connected with an industrial robot.

Owner:XIAMEN UNIV

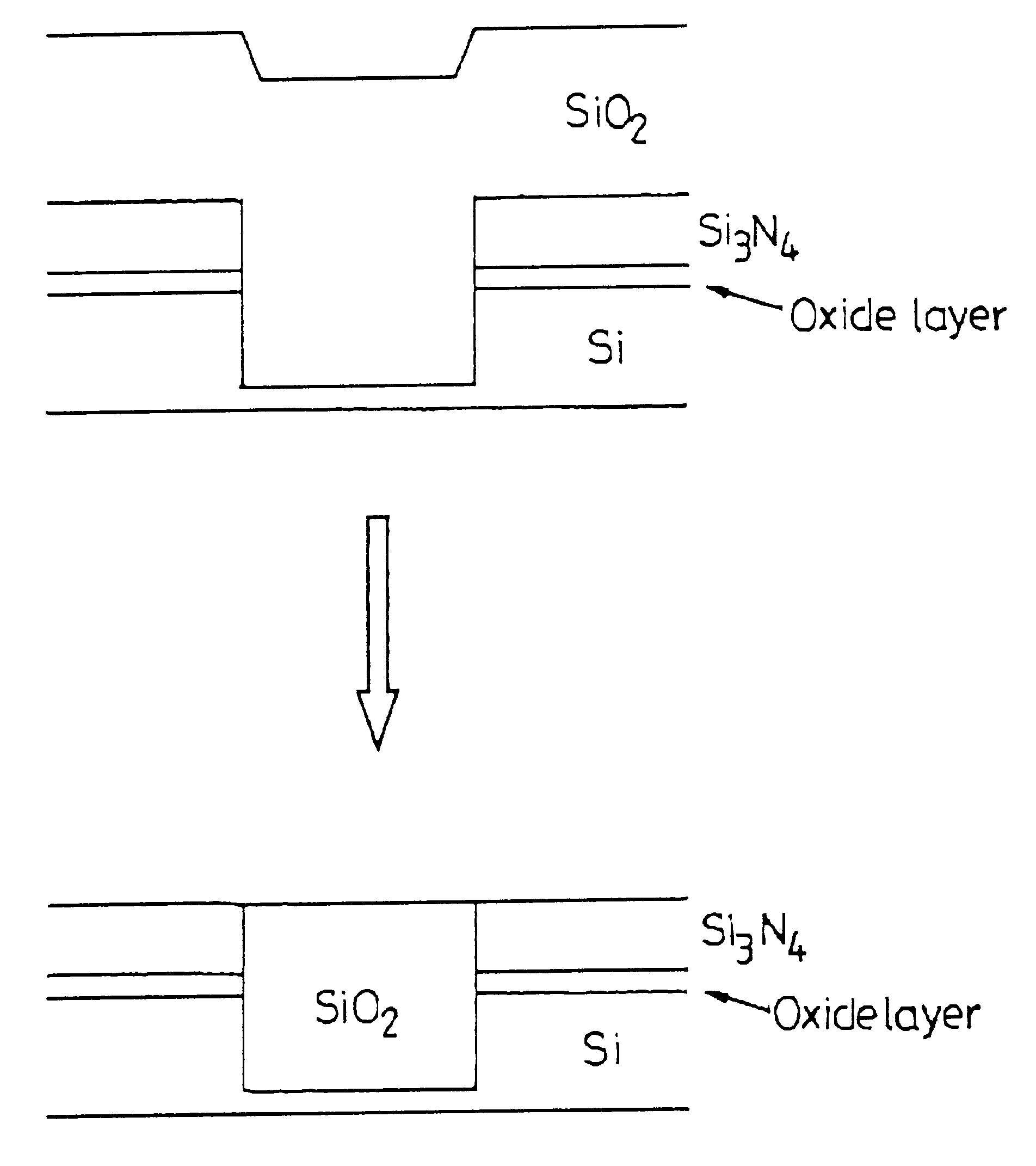

Polishing slurry, method of producing same, and method of polishing substrate

InactiveUS20060032149A1Minimizing micro-scratchesSuitable removal ratePigmenting treatmentMaterial nanotechnologySlurryNitride

Disclosed is a polishing slurry, particularly, a slurry for chemical mechanical polishing, which is used in a chemical mechanical polishing process for flattening a semiconductor laminate. More particularly, the present invention provides a method of producing a slurry which has high removal selectivity to a nitride layer used as a barrier film in a shallow trench isolation CMP process needed to fabricate ultra highly integrated semiconductors of 256 mega D-RAM or more (Design rule of 0.13 μm or less) and which decreases the occurrence of scratches on a flattened surface, and a method of polishing a substrate using the same.

Owner:K C TECH +1

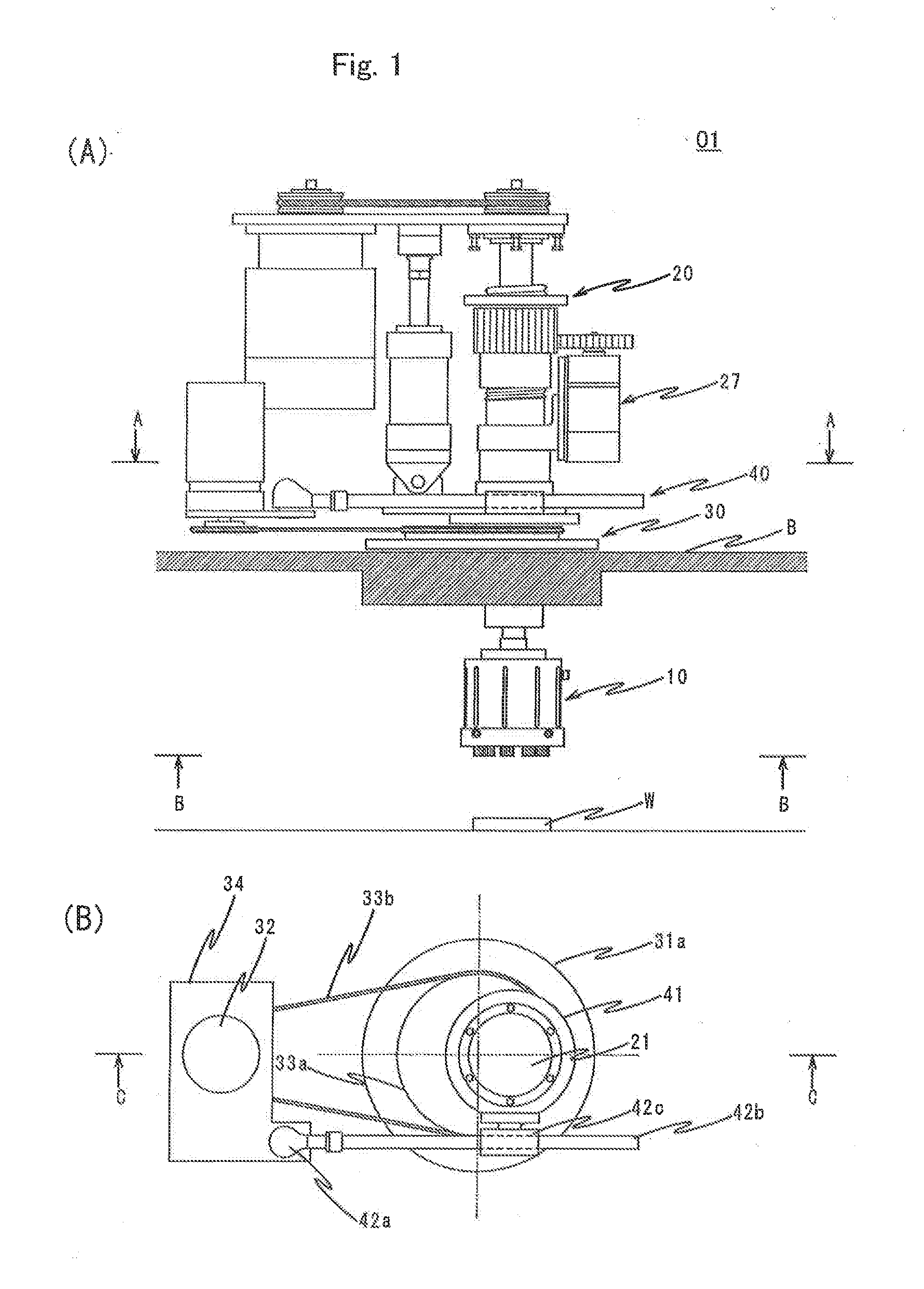

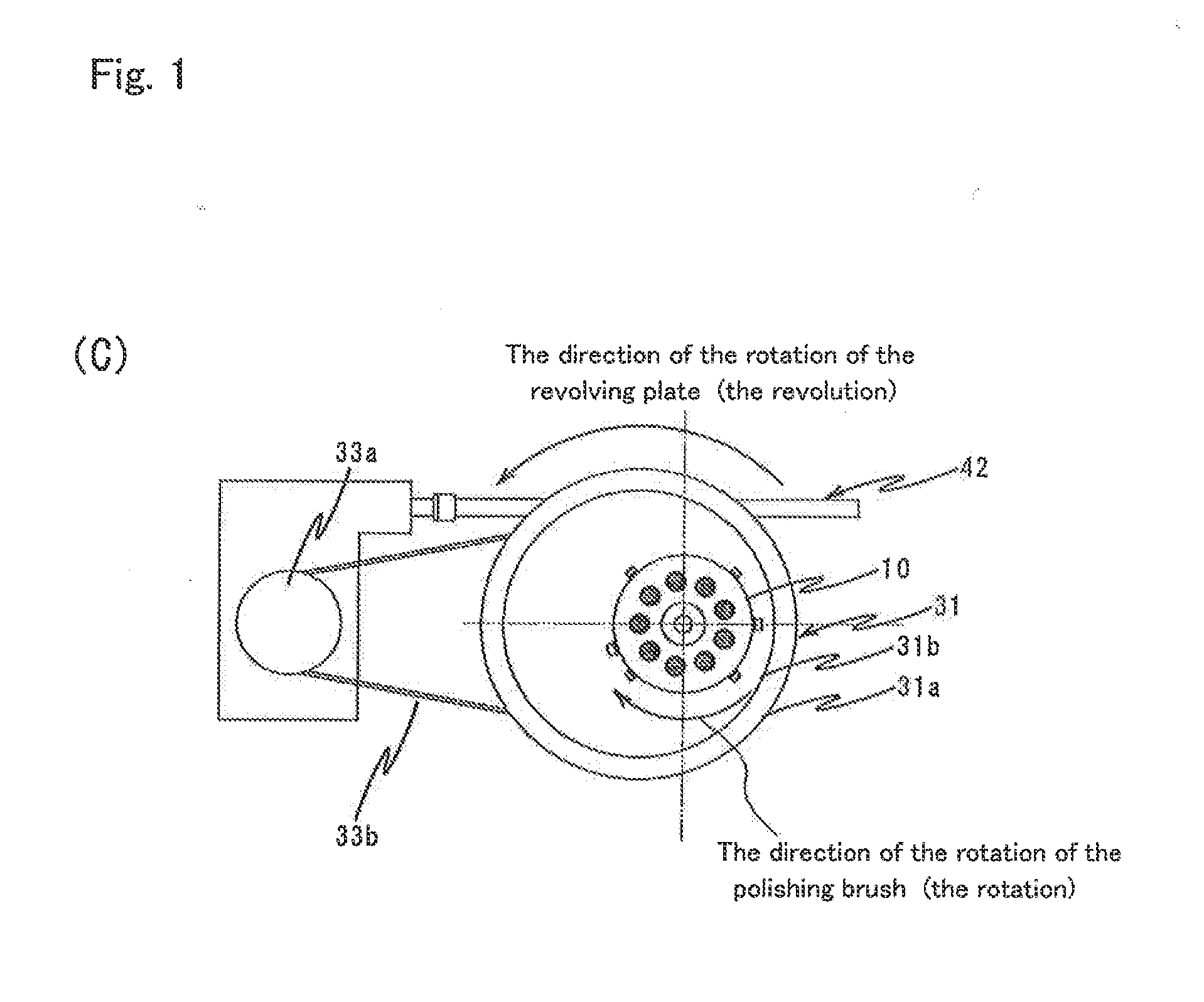

A brush unit, a device for brush-polishing that uses the brush unit, a system for brush-polishing, and a method for brush-polishing

ActiveUS20150367477A1Small loadReduce troubleEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The purpose of the present invention is to provide a device for brush-polishing by means of a polishing brush that rotates and revolves as in a planetary motion, wherein the conditions to polish can be easily set in accordance with the properties of the workpiece and the purposes to polish. A brush unit has a polishing brush that rotates and revolves. The brush unit includes a mechanism for driving the rotation that rotates the polishing brush and the mechanism for driving the revolution that revolves it. By adjusting the speed of the rotation by the mechanism for driving the rotation the capabilities to polish the workpiece are enhanced. By adjusting the speed of the revolution by the mechanism for driving the revolution the entire workpiece is uniformly polished.

Owner:SINTOKOGIO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com