Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

399 results about "Vibratory signal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

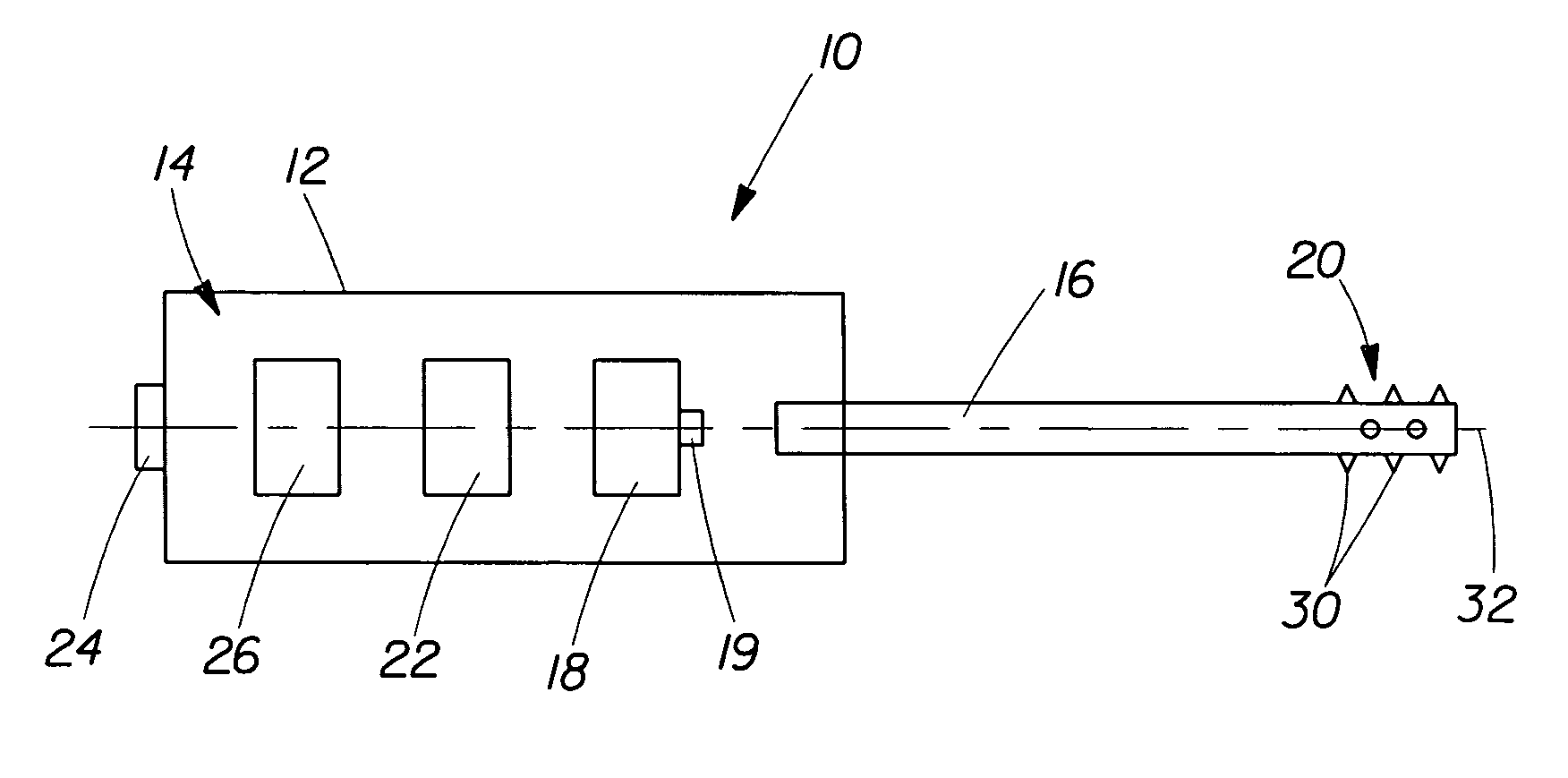

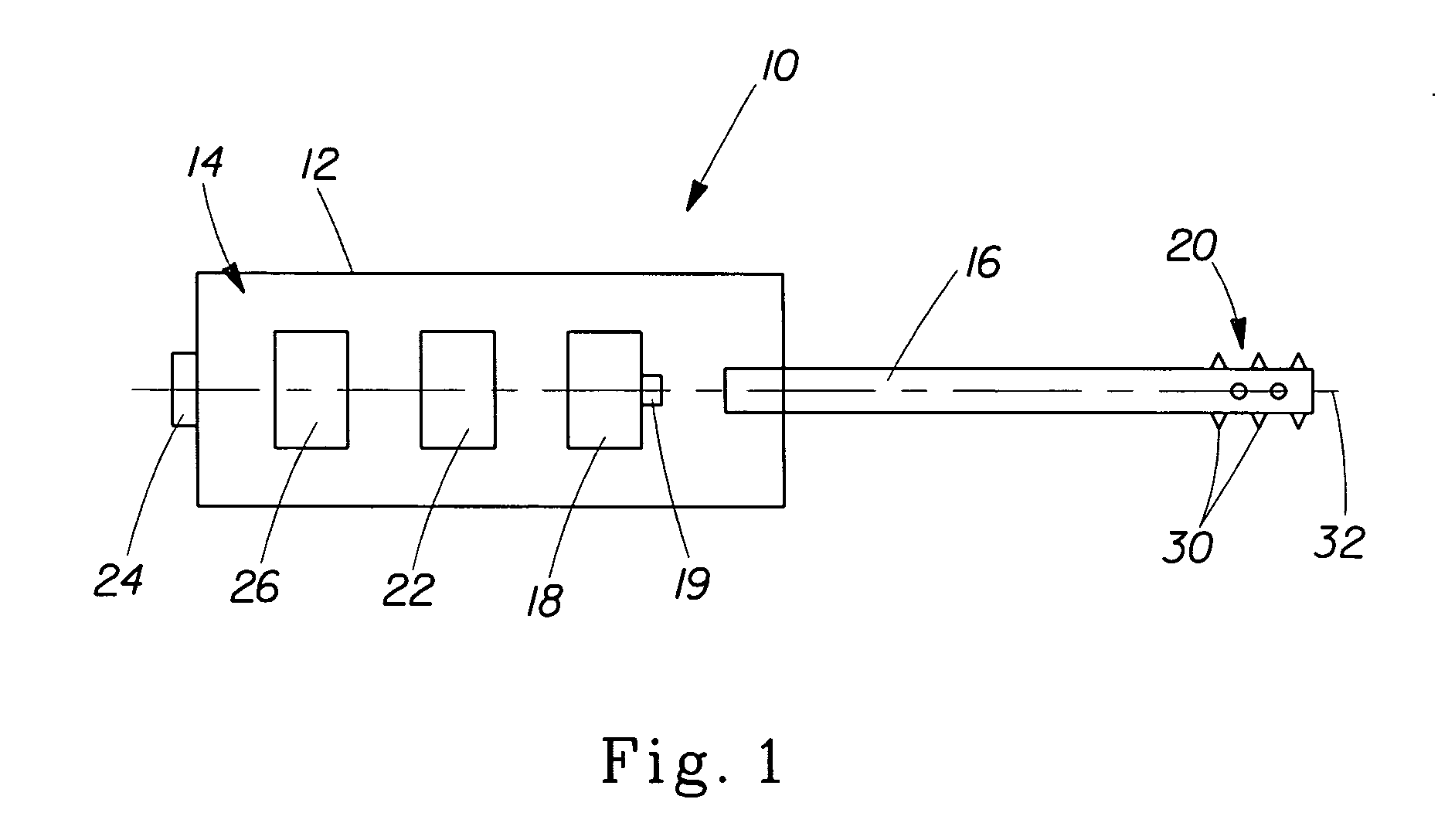

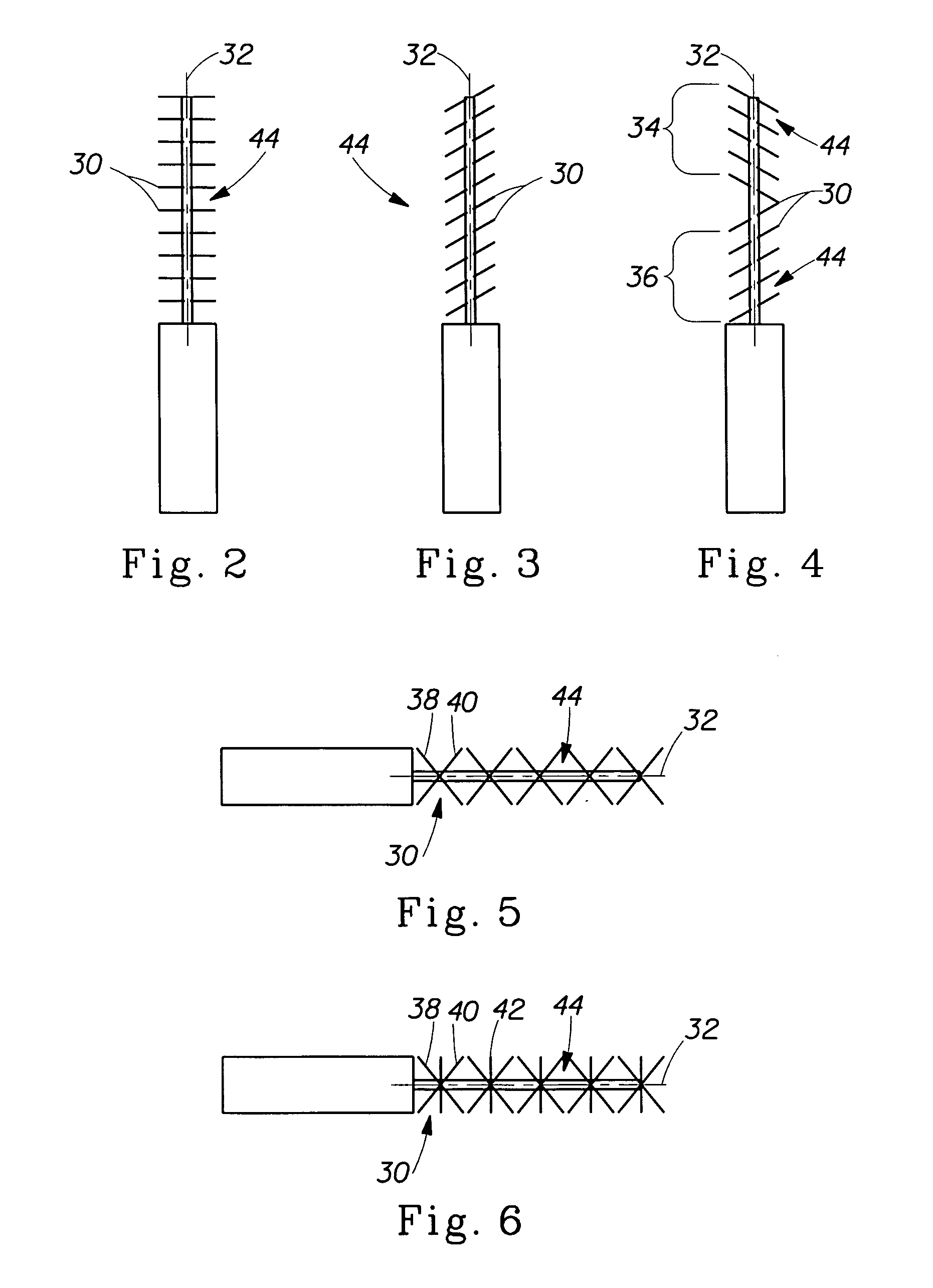

Cosmetic applicator

An apparatus for applying a cosmetic, such as mascara to eyelashes, includes a handle, a stem, and an applicator head coupled to the stem and supported for rotation relative to the handle. An actuator moves the applicator head in a vibrational motion. Additionally or alternatively, the applicator head may include a first set of protrusions having a first stiffness and a second set of protrusions having a second stiffness, wherein the first stiffness is greater than the second stiffness. The actuator may further be coupled to the handle to provide a tactile vibratory signal to the user.

Owner:THE PROCTER & GAMBLE COMPANY

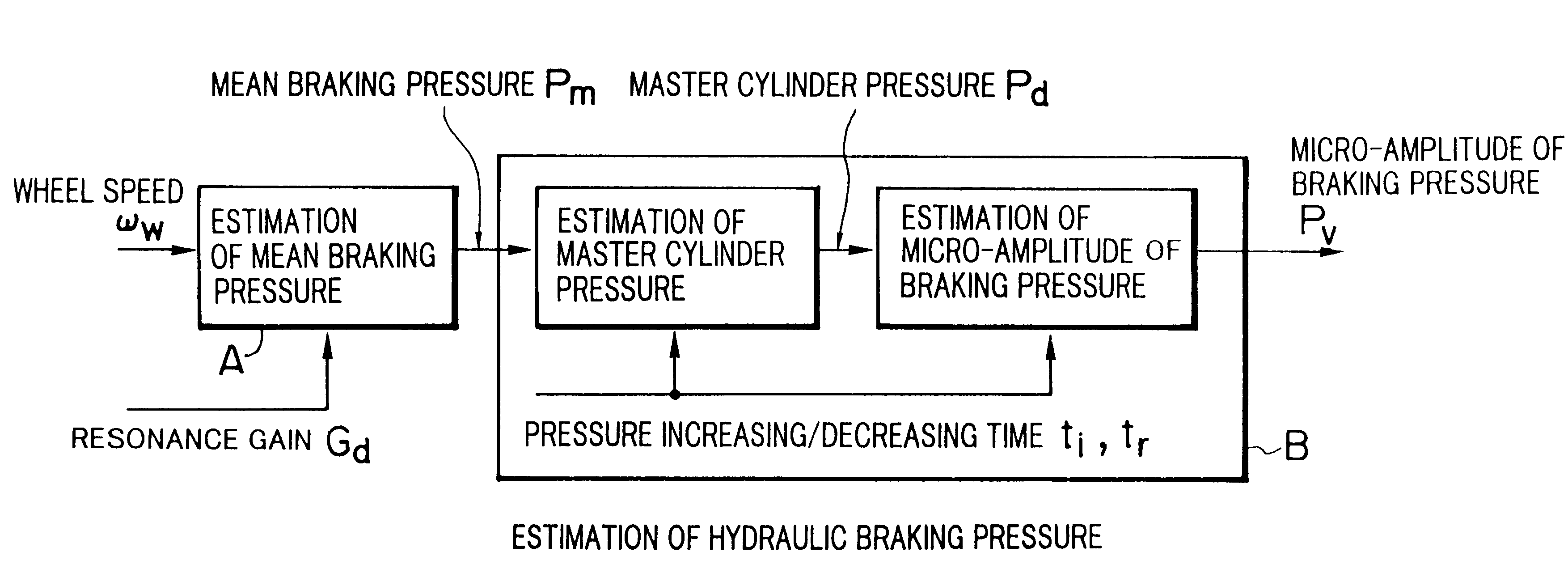

Braking estimation device, anti-lock brake controller, and braking pressure controller

InactiveUS6182001B1Inflated body pressure measurementDigital data processing detailsVibratory signalAtmospheric pressure

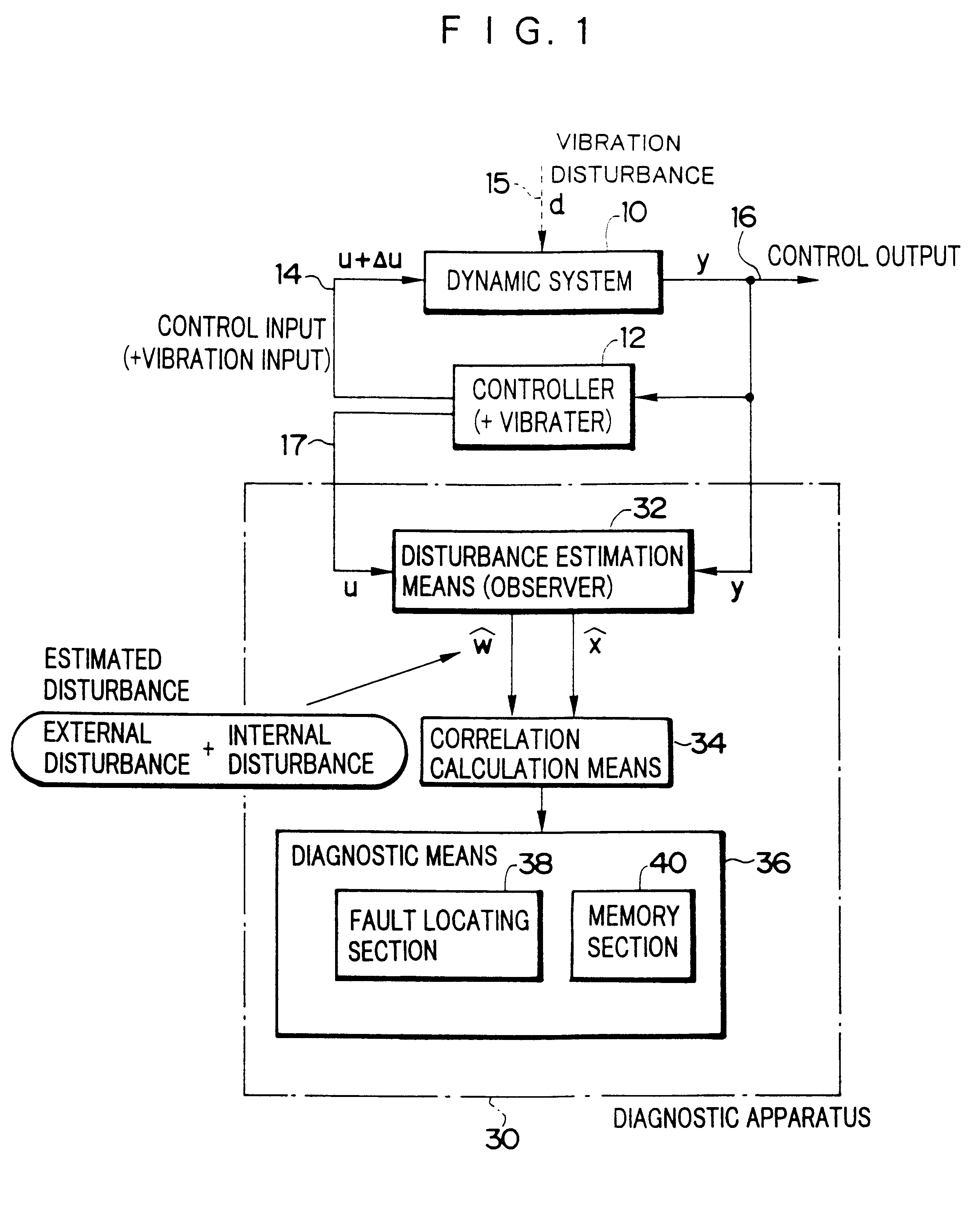

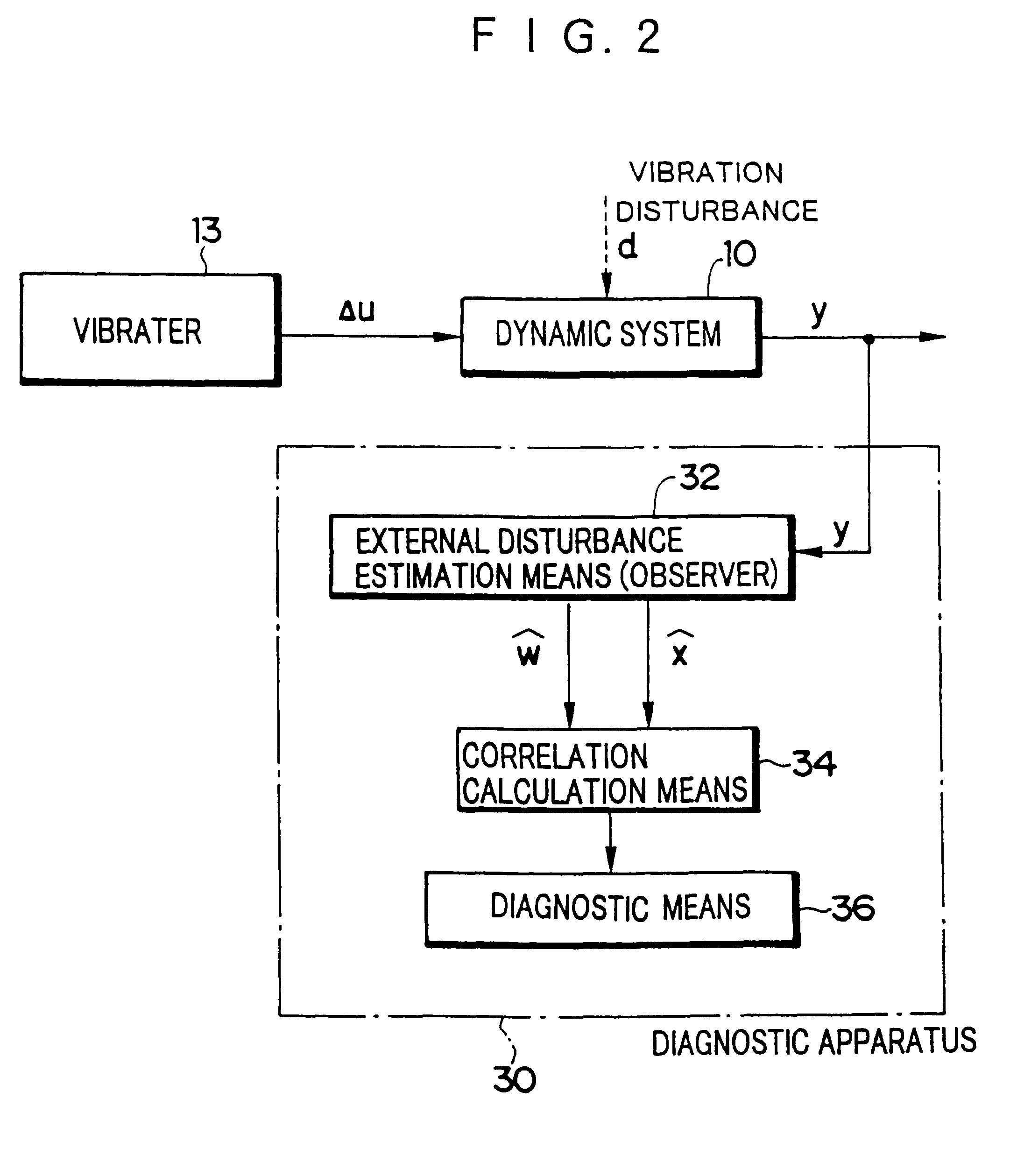

An apparatus for diagnosing a fault in a dynamic system includes a controller which controls the dynamic system through use of a control input signal and vibrates the dynamic system through use of an vibration signal irrelevant to the internal state quantity of the dynamic system; an observer for estimating, on the basis of a response output from the vibration dynamic system, total disturbance which is a sum of an internal disturbance vector stemming from a fault in the dynamic system and a vibration disturbance vector occurring in the dynamic system through vibration; a correlation calculation unit which calculates cross-correlation between the thus-estimated total disturbance and the internal state quantity of the dynamic system and separates a component related to the internal disturbance from the total disturbance; and a diagnostic unit for diagnosing a fault in the dynamic system on the basis of the thus-separated component related to the internal disturbance. Since the dynamic system is vibrated, the response output can be increased even when there exists small external disturbance. As a result, a fault or a variation in air pressure in a tire can be highly accurately diagnosed.

Owner:TOYOTA CENT RES & DEV LAB INC

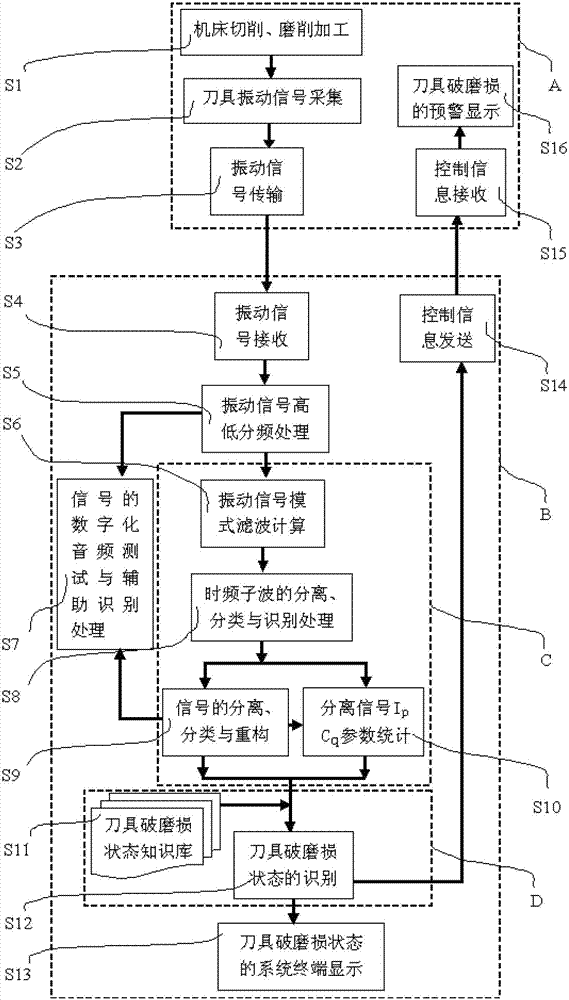

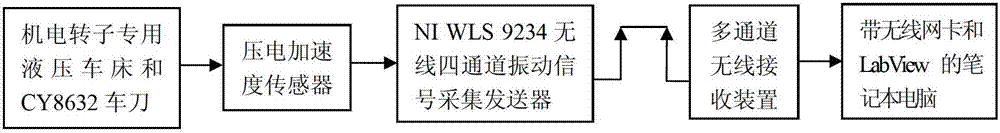

Cutter damage and abrasion state detecting method and cutter damage and abrasion state detecting system

ActiveCN102765010ARealize online dynamic monitoringHigh precisionMeasurement/indication equipmentsProduction rateFeature extraction

The invention relates to a cutter damage and abrasion state detecting method, which comprises the following steps that 1, vibration signals in the cutter cutting and grinding processes are measured; 2, the vibration signals are subjected to mode filtering calculation; 3, time-frequency wavelets of the vibration signals are subjected to classification sorting and feature extractions; and 4, the time-frequency wavelets are subjected to classification, collection and signal separation processing, various kinds of time-frequency wavelets are subjected to signal reconstruction, the kurtosis index (Cq) and the peak index (Ip) of various kinds of signals are then counted, the cutter damage and abrasion state and the machine tool operation state are detected under the dynamic distribution condition of a Cq-Iq plane according to various kinds of separation signal index parameters, and the identification detection and the quantitative early warning and forecast of the cutter damage and abrasion state are realized. Through single monitoring equipment, the detection of the cutter damage and abrasion state is realized, the signal identification stability is good, the mechanical processing production safety is ensured, the precision of processing parts is improved, and the production rate and the utilization rate of a machine tool are improved.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

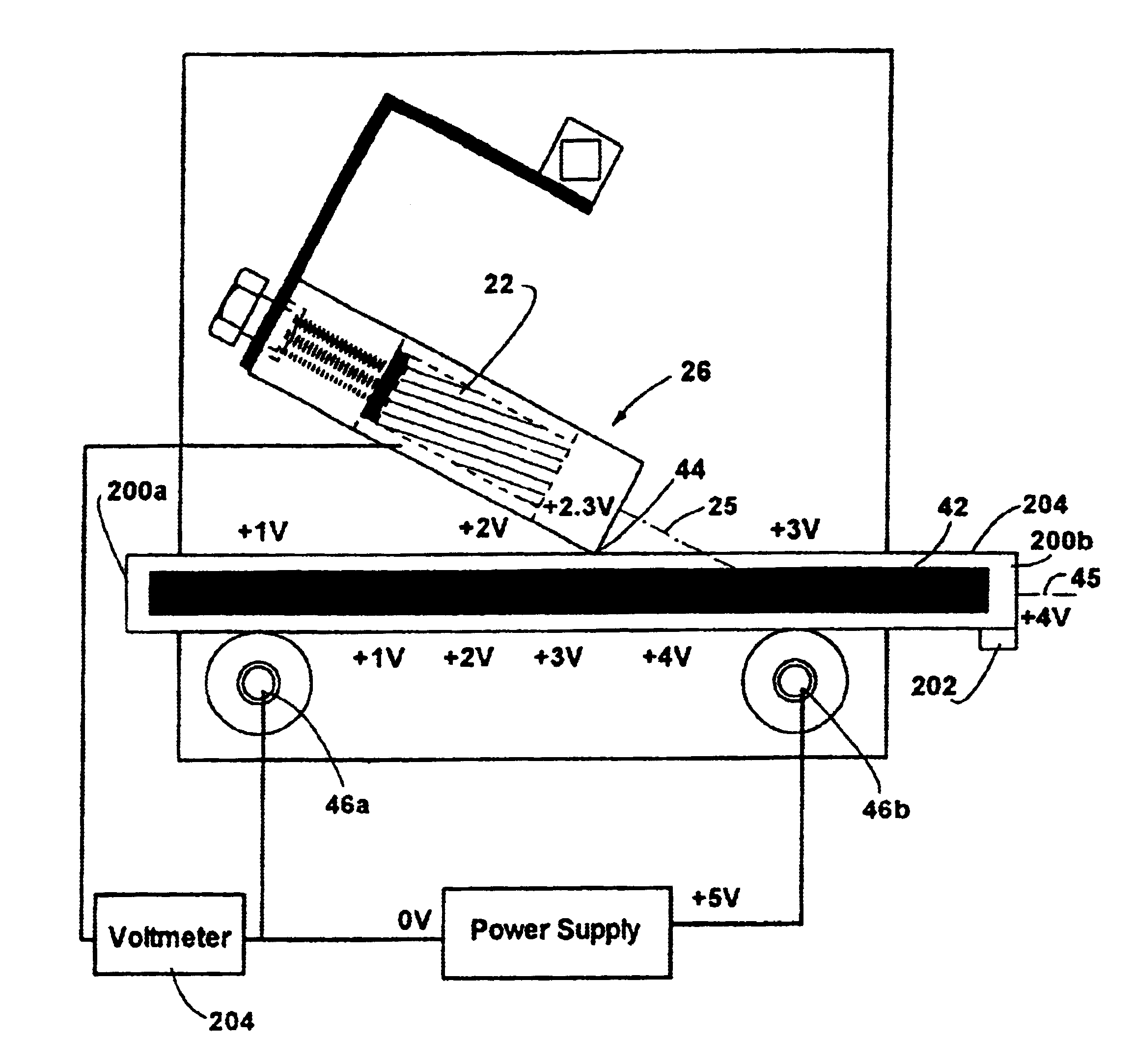

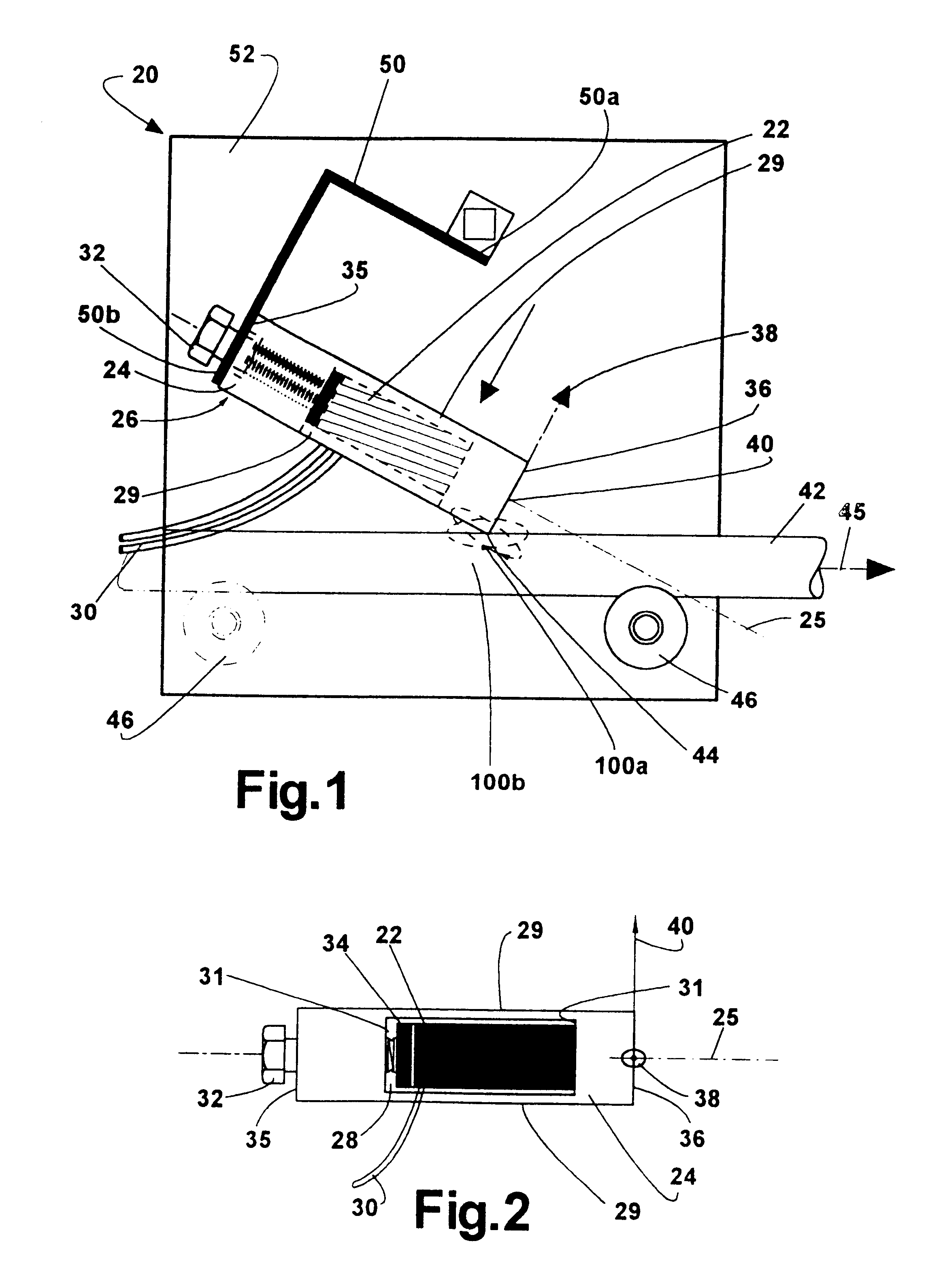

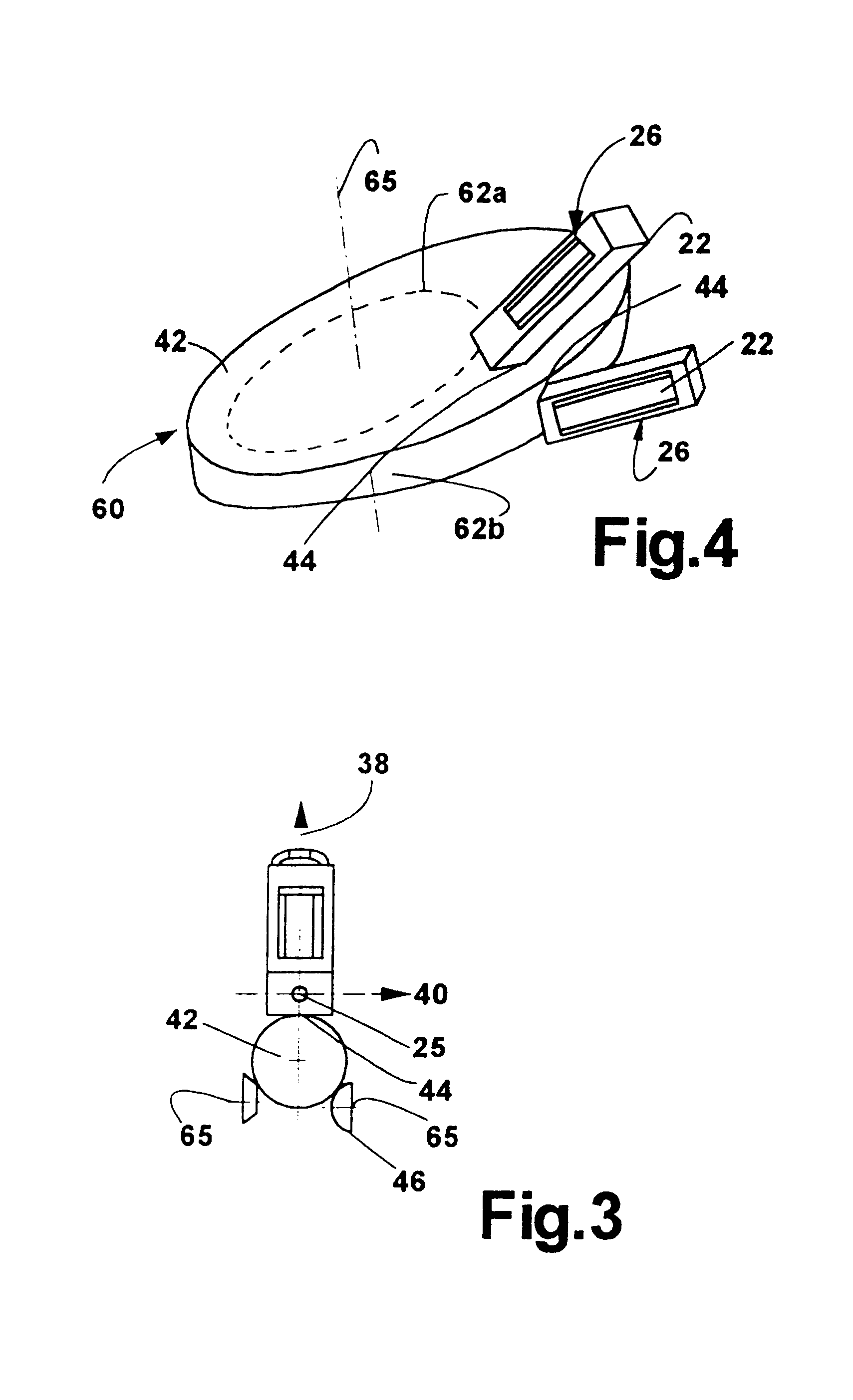

Vibratory motors and methods of making and using same

InactiveUS6870304B2Easy crimpingPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesVibratory signalAcoustics

A single piezoelectric is excited at a first frequency to cause two vibration modes in a resonator producing a first elliptical motion in a first direction at a selected contacting portion of the resonator that is placed in frictional engagement with a driven element to move the driven element in a first direction. A second frequency excites the same piezoelectric to cause two vibration modes of the resonator producing a second elliptical motion in a second direction at the selected contacting portion to move the driven element in a second direction. The piezoelectric is preloaded in compression by the resonator. Walls of the resonator are stressed past their yield point to maintain the preload. Specially shaped ends on the piezoelectric help preloading. The piezoelectric can send or receive vibratory signals through the driven element to or from sensors to determine the position of the driven element relative to the piezoelectric element or resonator. Conversely, the piezoelectric element can receive vibration or electrical signals passed through the driven element to determine the position of the driven element. The resonator is resiliently urged against the driven element, or vice versa. Plural resonators can drive common driven elements.

Owner:ELLIPTEC RESONANT ACTUATOR

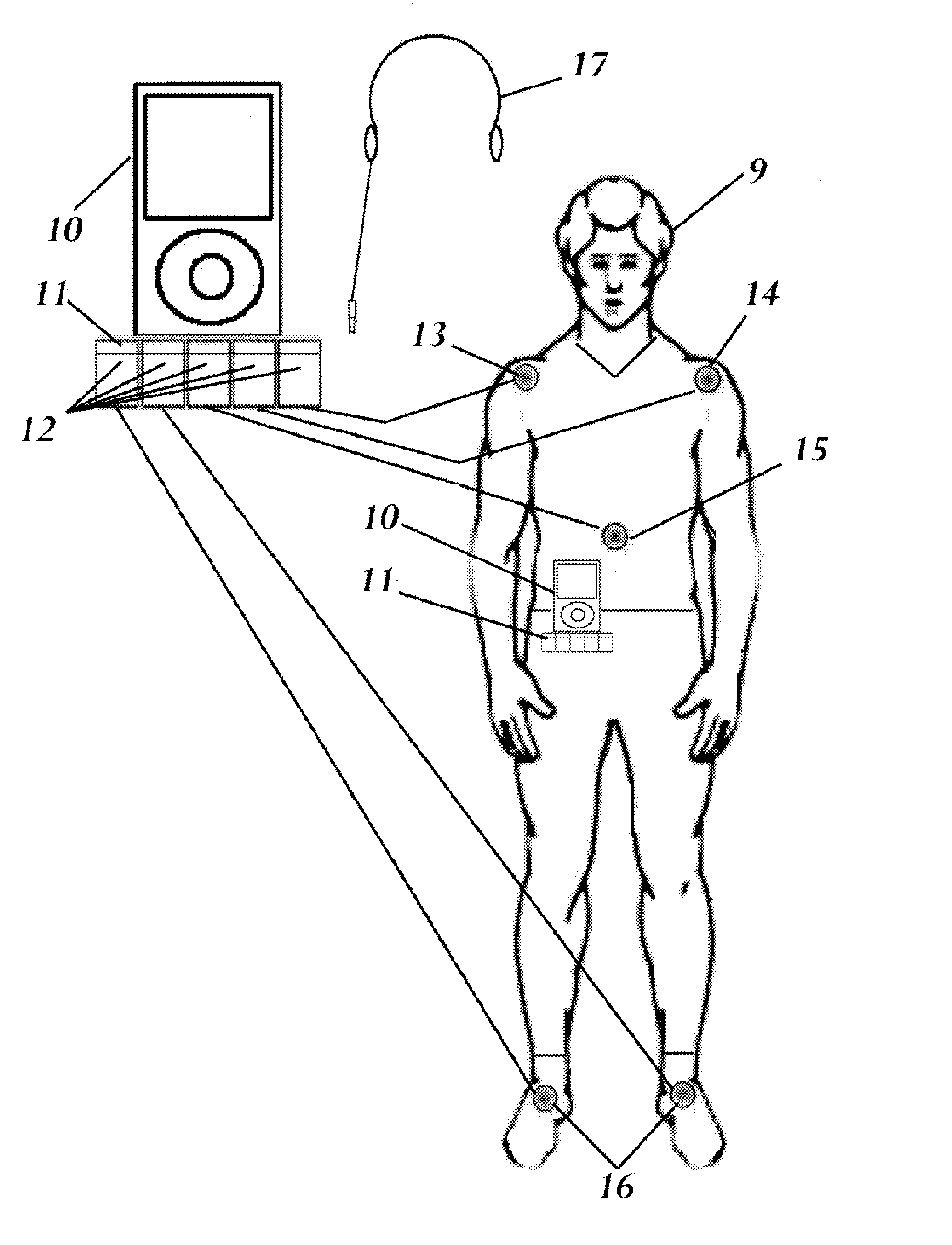

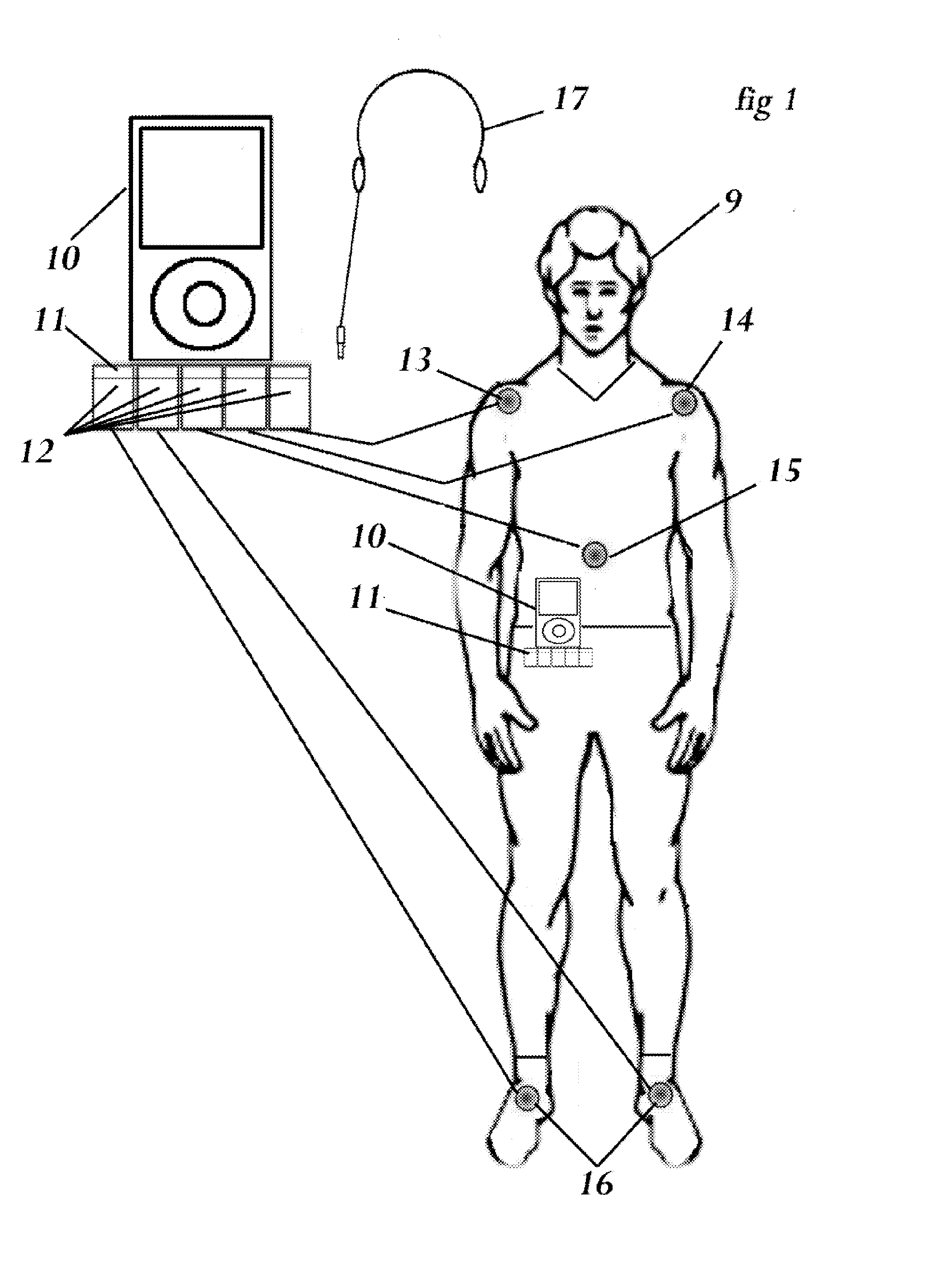

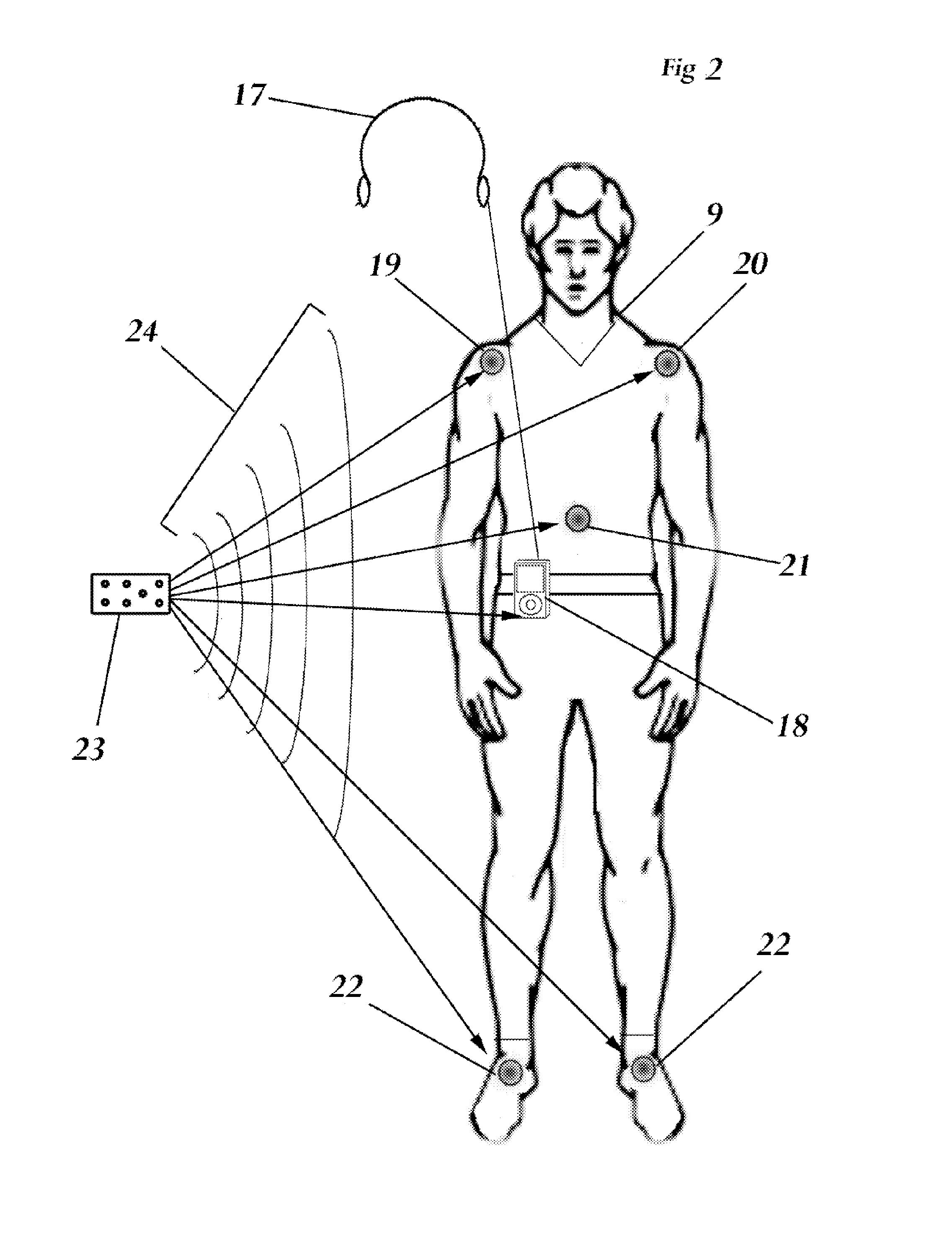

Multi-channel audio vibratory entertainment system

ActiveUS20100217413A1Improve entertainment experienceMaximize separationDocking-station type assembliesMicrophonesVibratory signalVocal tract

An entertainment system according to an embodiment of the present application includes a portable media device configured to produce an audible output signal, and a plurality of individual vibratory output signals representative of individual recorded tracks of a musical piece and a plurality of actuators positioned at various locations on a user's body, each actuator configured and operable to receive one of the plurality of individual vibratory signals and to vibrate based on the received vibratory signal.

Owner:HAPTECH HLDG INC

Method for predicting service life of screw pair of numerical control machine on basis of performance degradation model

InactiveCN101870075APrecise real-timeAccurate predictionMachine gearing/transmission testingMeasurement/indication equipmentsNumerical controlVibratory signal

The invention provides a method for predicting the service life of a screw pair of a numerical control machine on the basis of a performance degradation model. The method comprises the following steps of: acquiring vibration signals, carrying out time-frequency domain analysis, extracting the sensitive characteristic data vectors of the performance degradation of the screw pair, and forming a sensitive characteristic matrix in a time-sequence manner; calculating the load Pi of the screw pair and recording the operating time ti at the same time; calculating the rated life time Lhi, the total time t' that the screw pair has run under the current working condition, and the expected residual life LDi according to Pi, and forming an expected residual life vector T of the expected residual life in a time-sequence manner; and fitting the mapping relation between the inputted sensitive characteristic matrix and the expected residual life vector by using a degradation model formed by a double-layer dynamic fuzzy neural network, and outputting the prediction result of the service life. By taking the impact on the performance degradation of the screw pair caused by the load change thereof under various working conditions of the numerical control machine into consideration, the method of the invention can achieve the prediction of the residual life when the screw pair is used, and ensure the high prediction accuracy and high value in actual application.

Owner:SOUTHWEST JIAOTONG UNIV

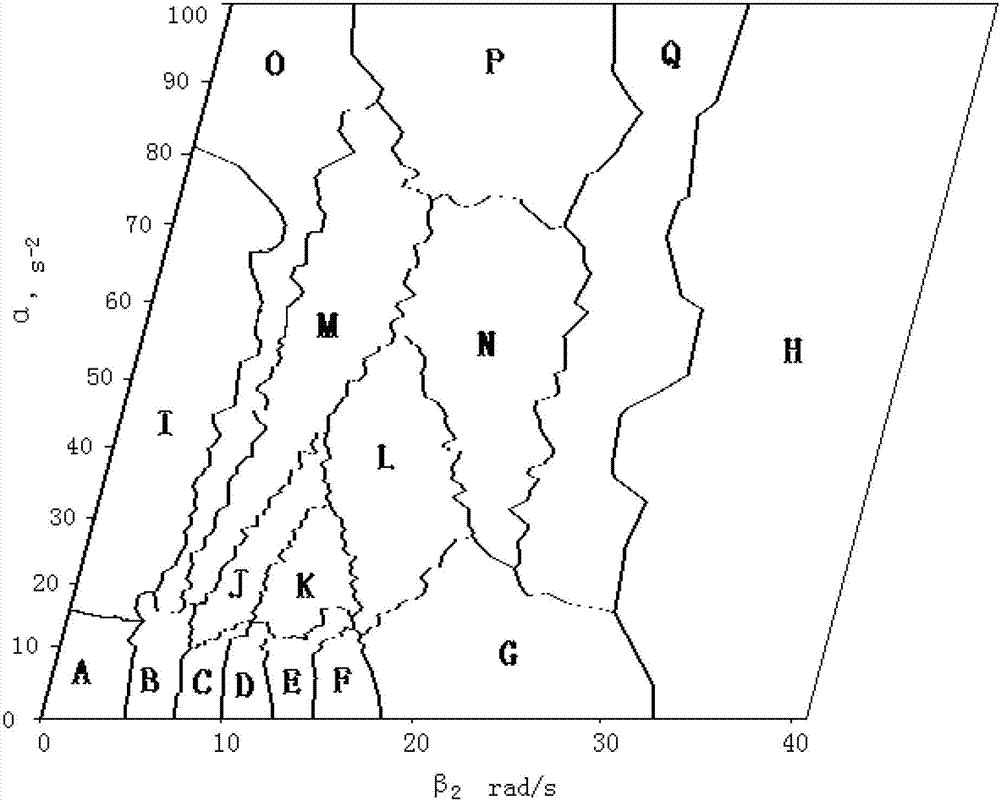

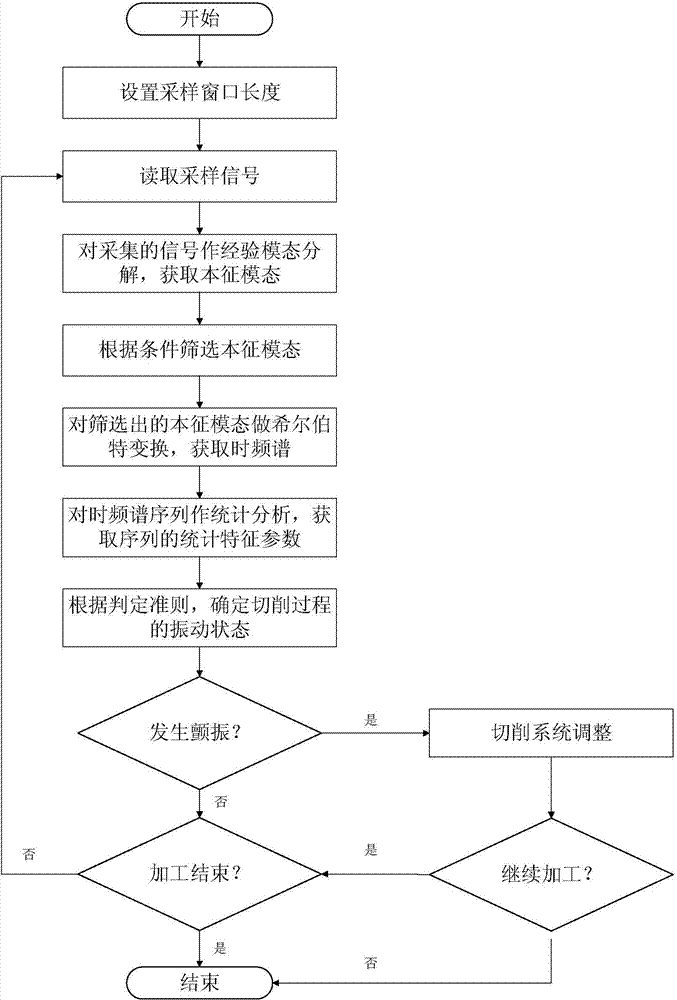

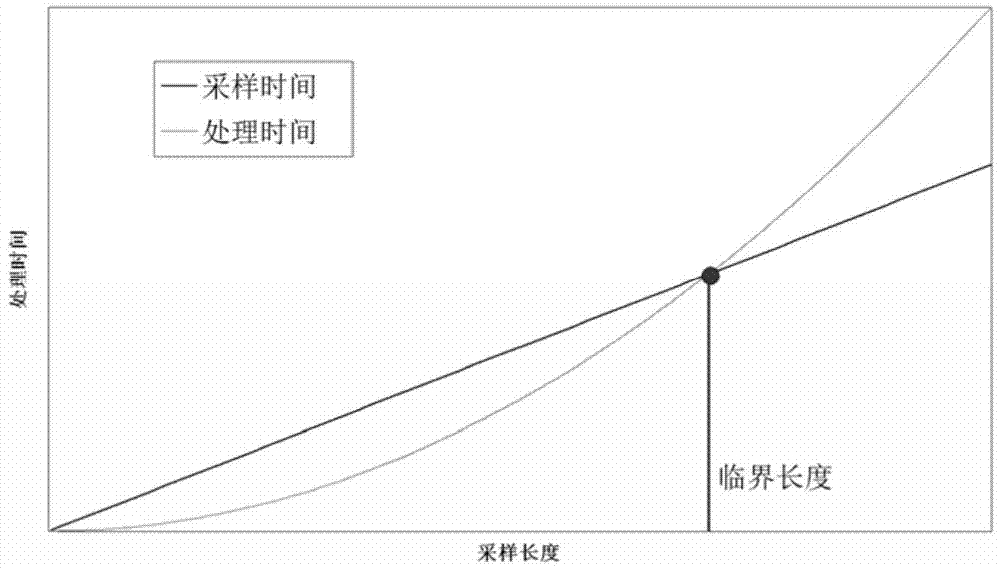

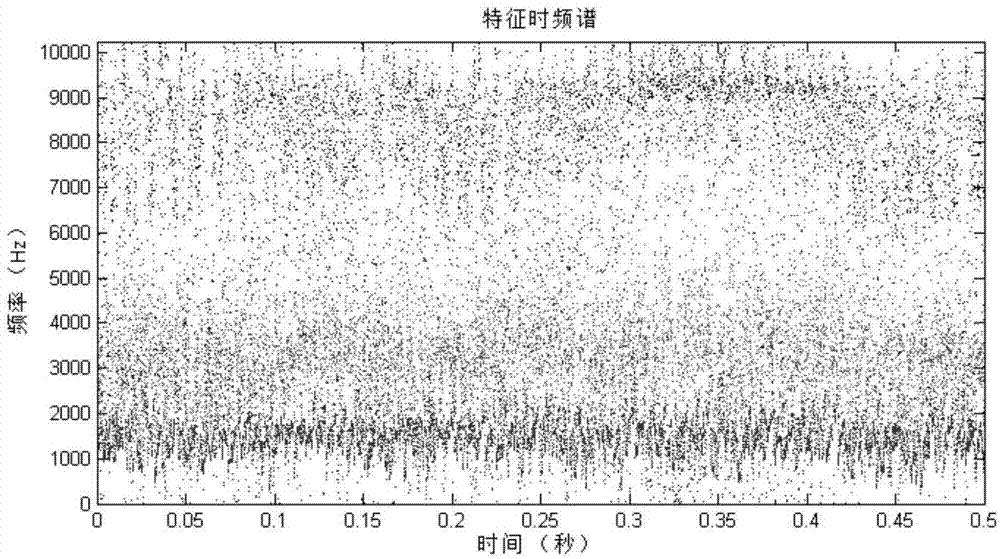

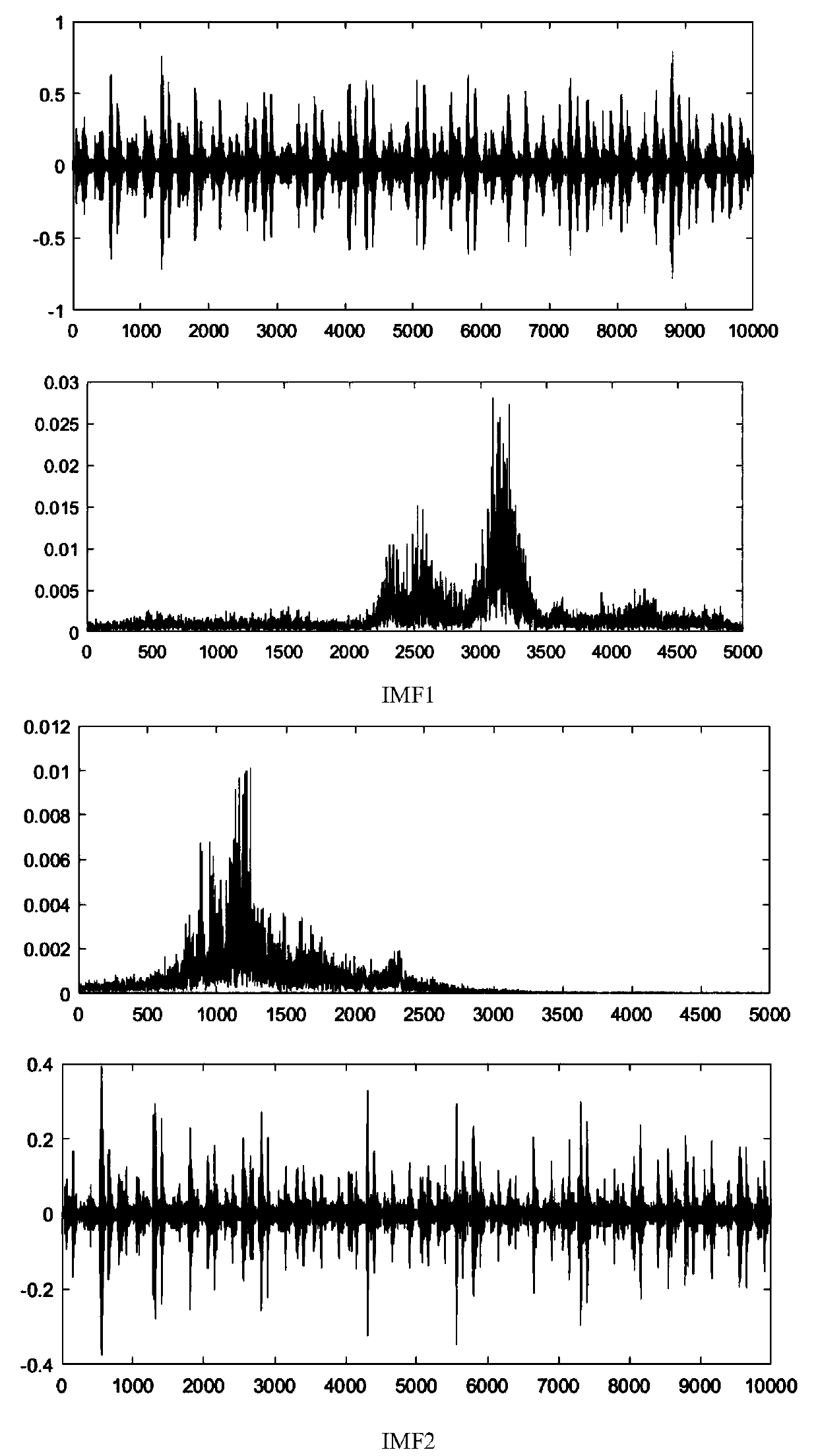

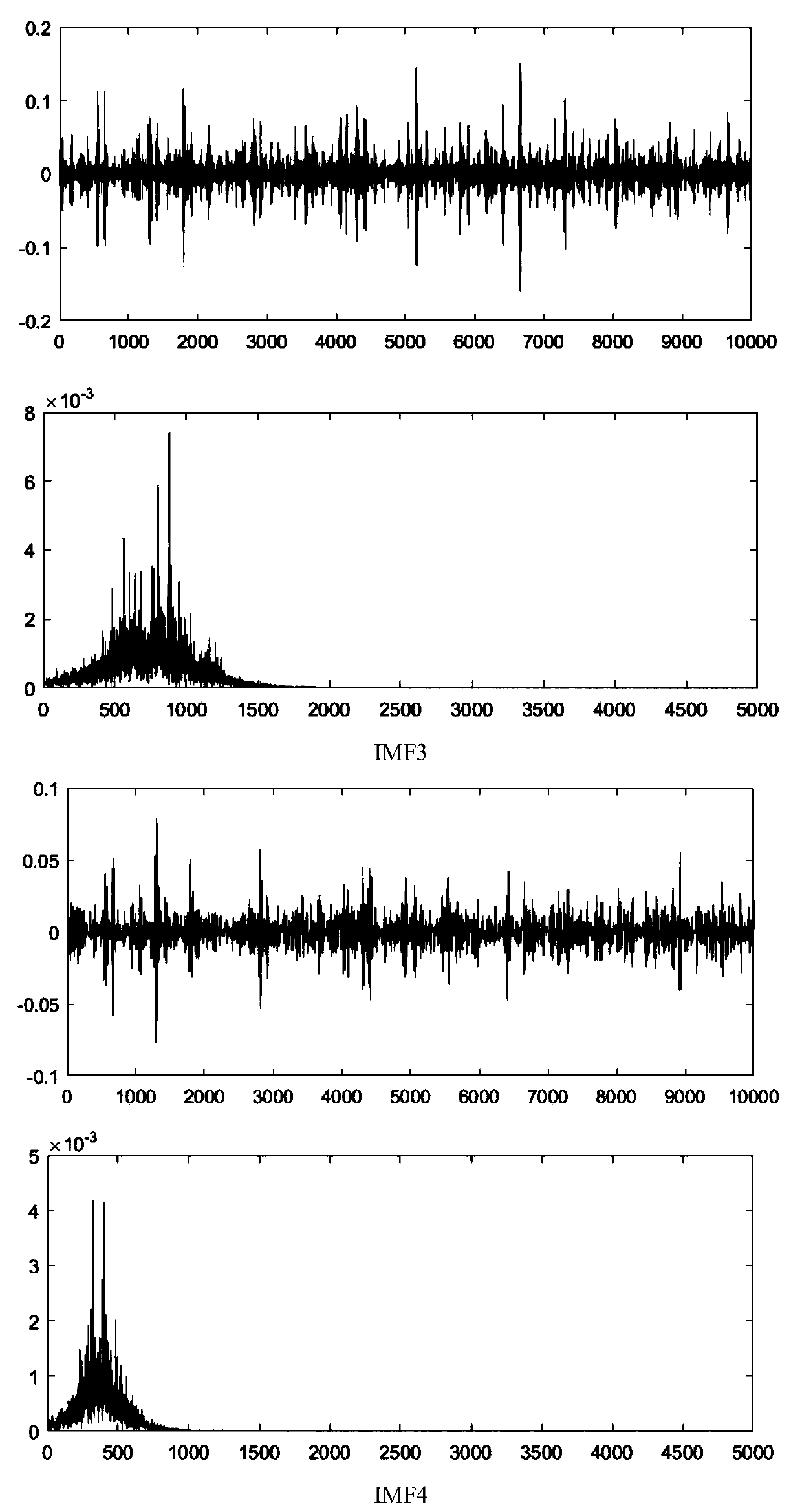

Flutter online monitoring method for machining equipment

ActiveCN103786069AIntuitive imageAccurate judgmentMeasurement/indication equipmentsDiagnostic Radiology ModalityFrequency spectrum

The invention discloses a flutter online monitoring method for machining equipment. The method comprises the steps that a proper sampling window is selected; empirical mode decomposition is carried out on sampled vibration signals; decomposed eigen modalities are screened to obtain a characteristic eigen modality; Hilbert transformation is carried out on the characteristic eigen modality to obtain a time-frequency spectrum; statistical pattern analysis is carried out on the time-frequency spectrum to obtain characteristic parameters; the statistical characteristic parameters are compared with a set characteristic threshold value and the statistical characteristic parameter of a historical adjacent signal, and the vibration state of a system is judged. The flutter online monitoring method aims to solve the problems that a flutter detecting method is strong in sample dependency and poor in generalization ability, threshold value measurement is difficult, and judgment is not carried out in time, the method combining Hilbert-Huang transformation and statistical pattern recognition is provided, statistical modeling and clustering analysis are carried out on the time-frequency spectrum of the vibration signal based on the aggregation character of energy on frequency in the fluttering process, the characteristic parameters are utilized, the physical characteristic of cutting flutter is represented essentially, the cutting vibration state is effectively monitored in real time, and the judgment result is accurate and visual.

Owner:HUAZHONG UNIV OF SCI & TECH

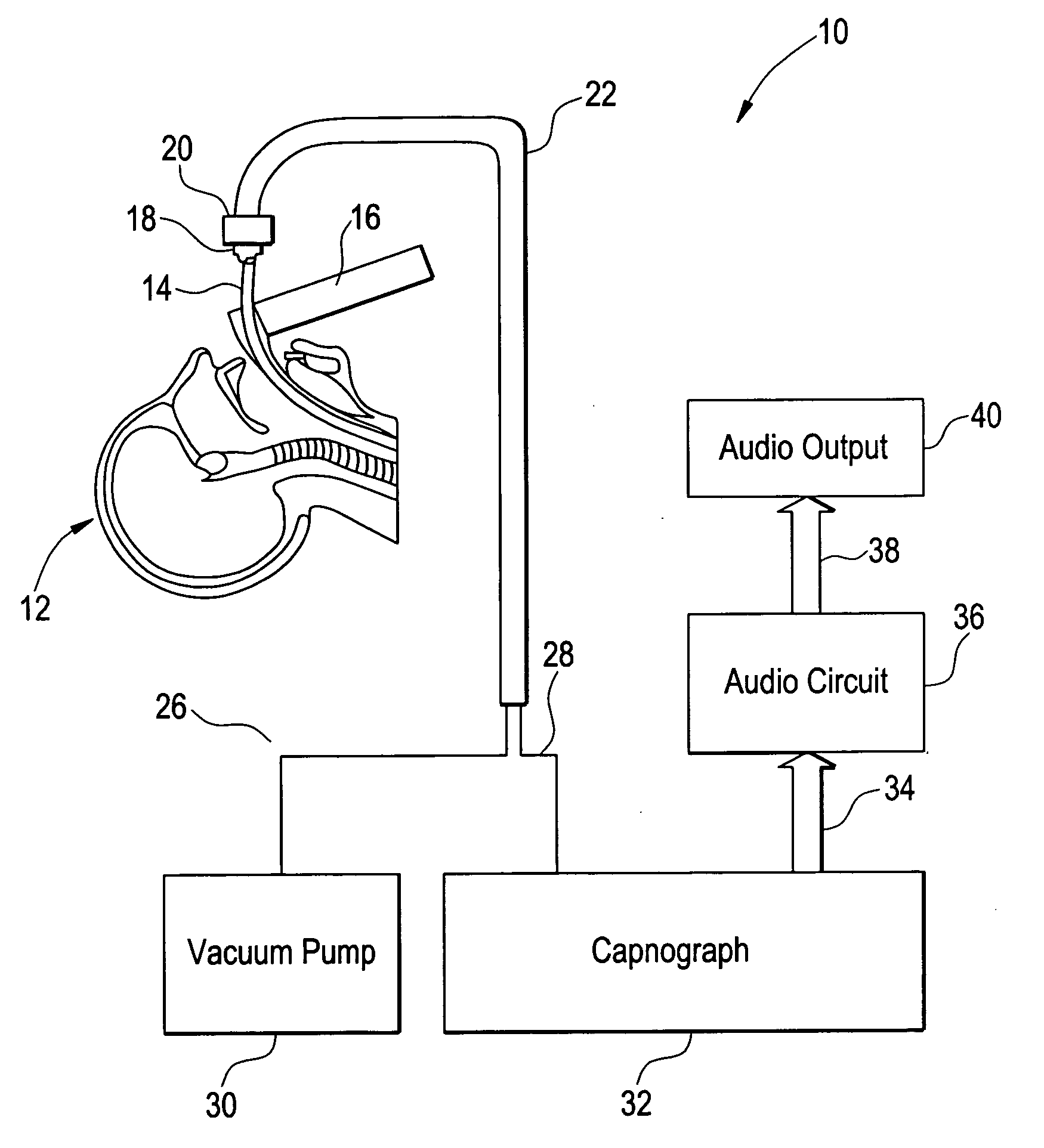

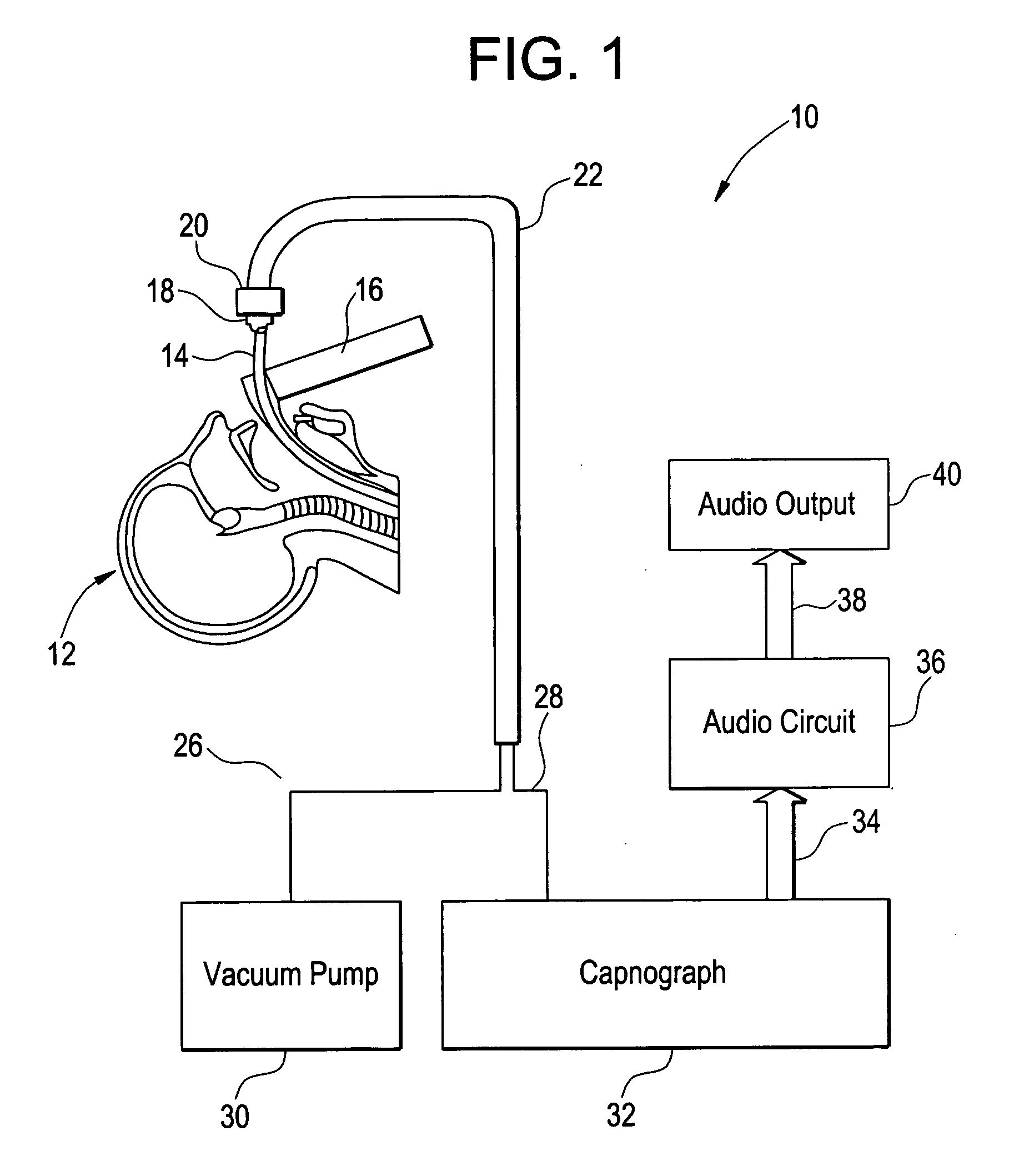

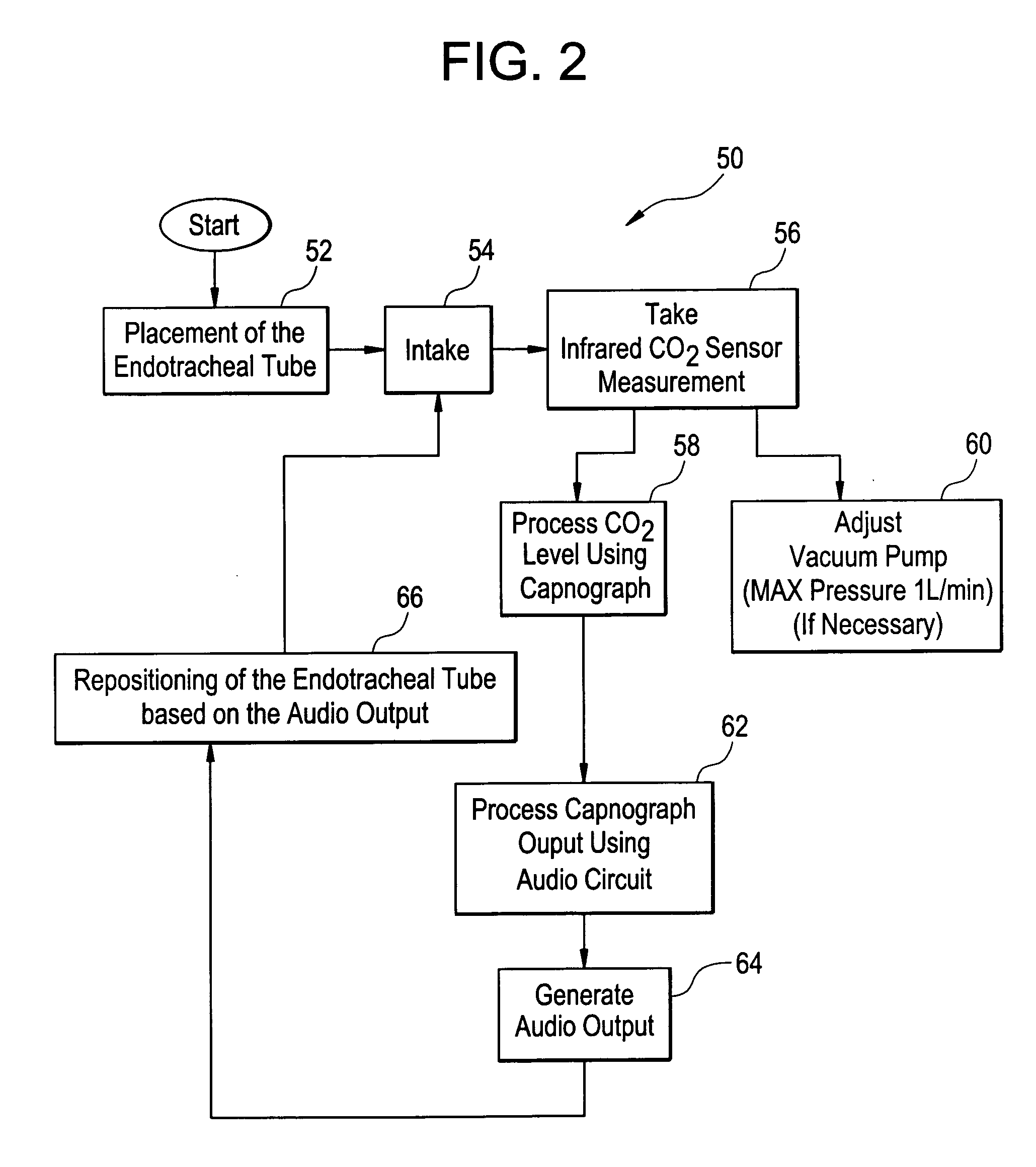

Method and apparatus for capnography-guided intubation

InactiveUS20080251070A1Easy to transportSimplified managementTracheal tubesRespiratory device testingVibratory signalOmni directional

A method and apparatus for qualitative sensory signal, capnography-guided intubation is provided. A qualitative sensory signal, such as an audible signal, is generated during intubation of a patient to provide an audible indication of carbon dioxide levels, so as to facilitate proper placement of an intubation tube. The frequency of the audible signal corresponds to measured carbon dioxide levels, thereby providing a simple, easy-to-interpret, audible indication of the current position of an endotracheal tube during intubation, as well as confirmation of proper placement of the tube. Alternatively, the qualitative sensor signal may be an omni-directional visual signal or a palpable vibratory signal.

Owner:UNIV OF MEDICINE & DENTISTRY OF NEW JERSEY +1

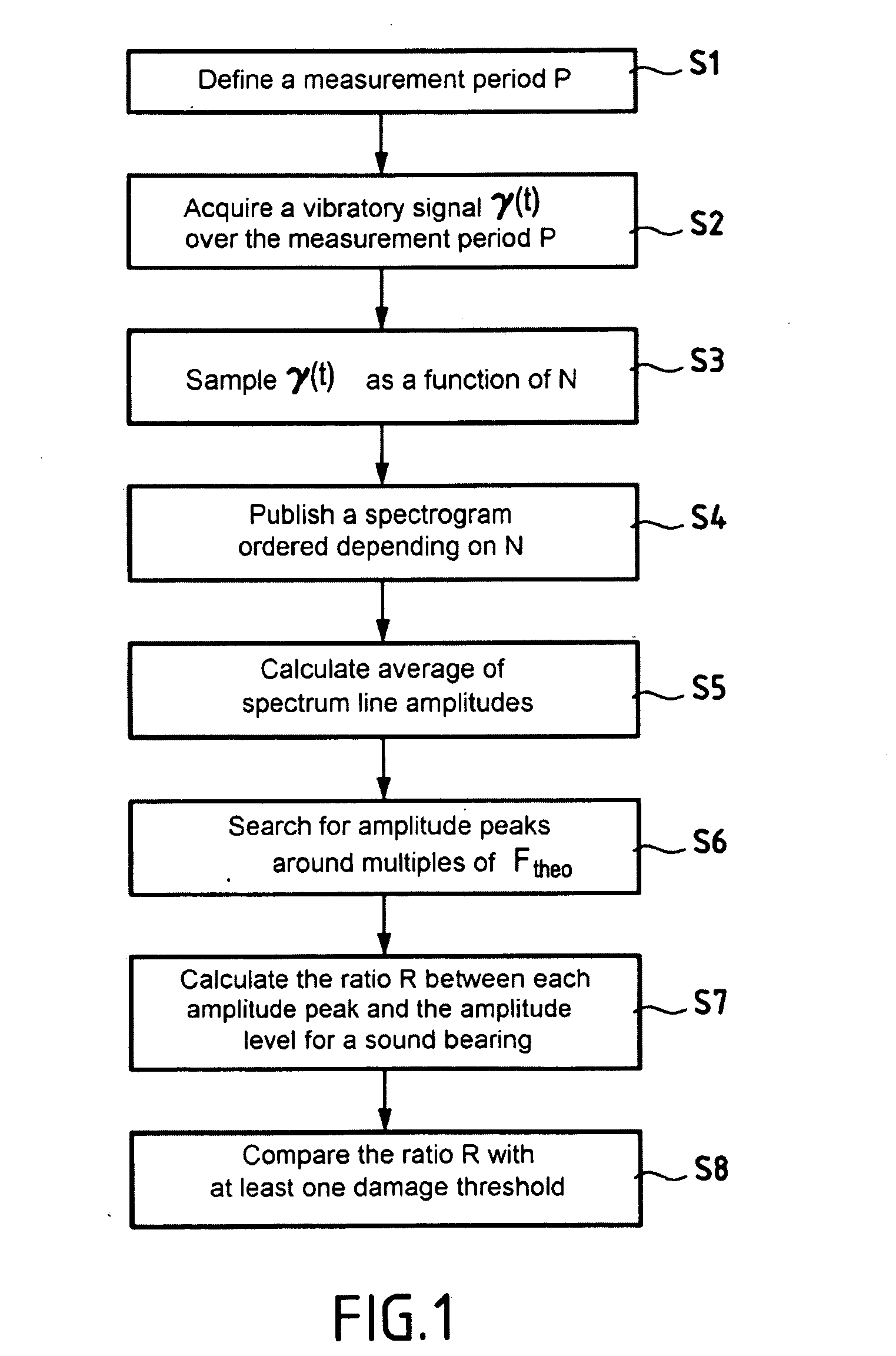

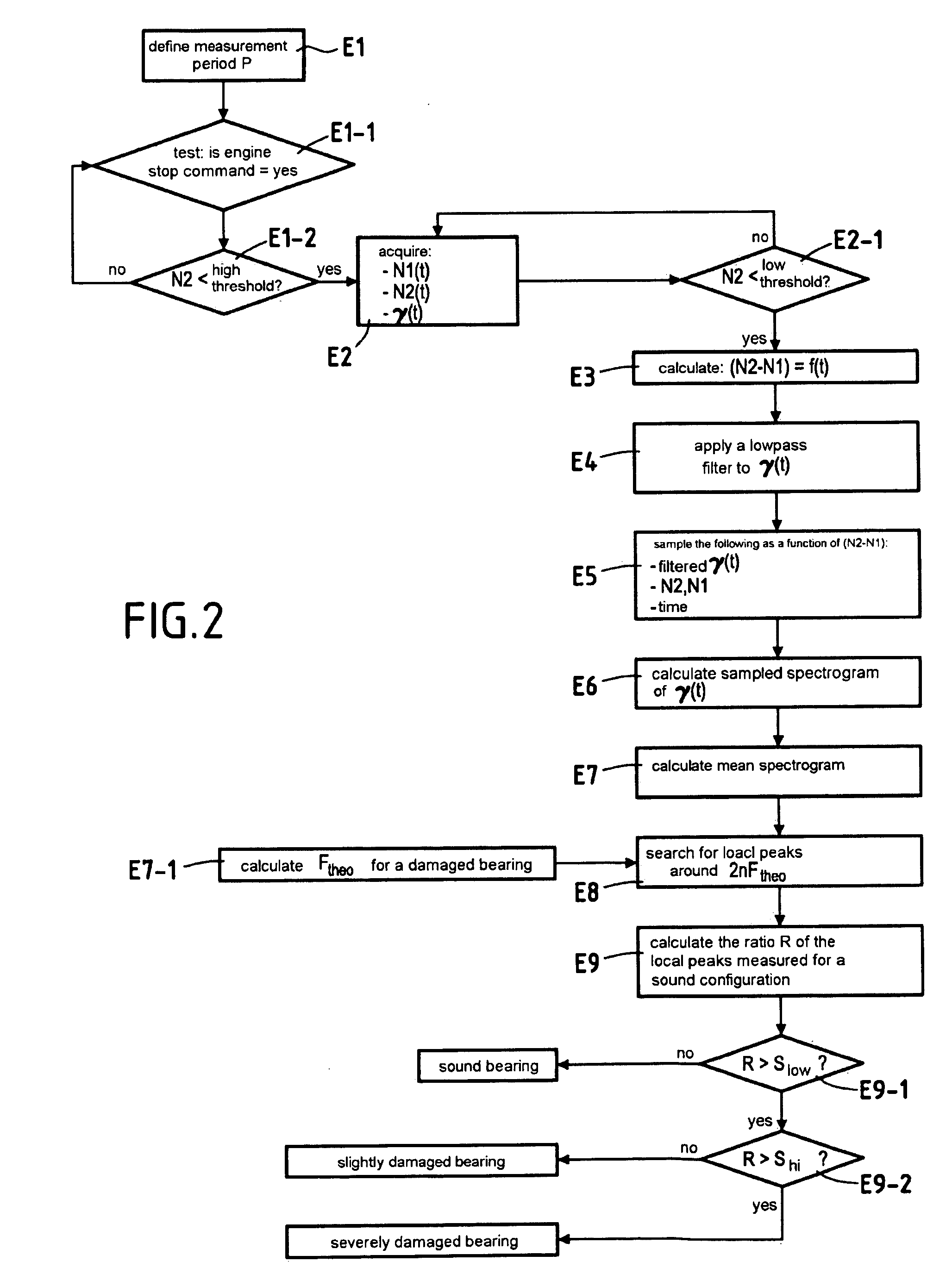

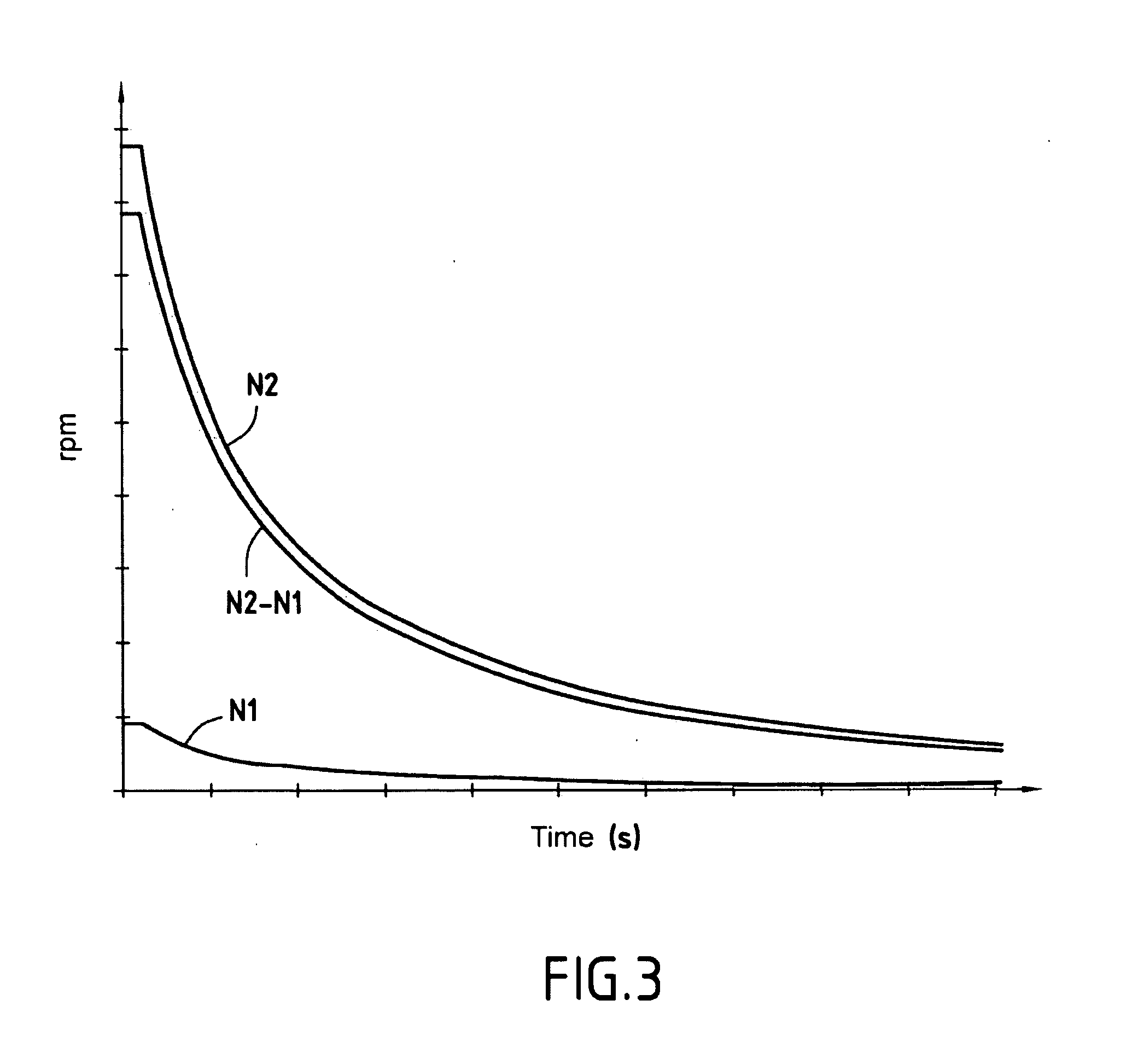

Method of detecting damage to an engine bearing

ActiveUS20080223135A1Mitigate such drawbackLess polluted by noiseVibration measurement in solidsMachine part testingLow speedFrequency spectrum

The invention relates to a method of detecting damage in a bearing supporting at least one rotary shaft of an engine in rotation, the method consisting in: defining a measurement period corresponding to a range of speeds of rotation of the shaft during renewable activity at low speeds of operation of the engine; acquiring over the entire measurement period a vibratory signal representative of acceleration of components of the engine; sampling the vibratory signal as a function of the speed of rotation of the shaft during the measurement period; transforming the sampled vibratory signal into a frequency signal to obtain frequency spectrum lines as a function of the speed of rotation of the shaft; calculating the mean of the amplitudes of the spectrum lines; determining amplitude peaks around multiples of the theoretical frequency of a damaged roller; calculating the ratio between each amplitude peak and the amplitude level determined for a sound bearing; and comparing the ratio that is obtained with at least one predetermined damage threshold.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

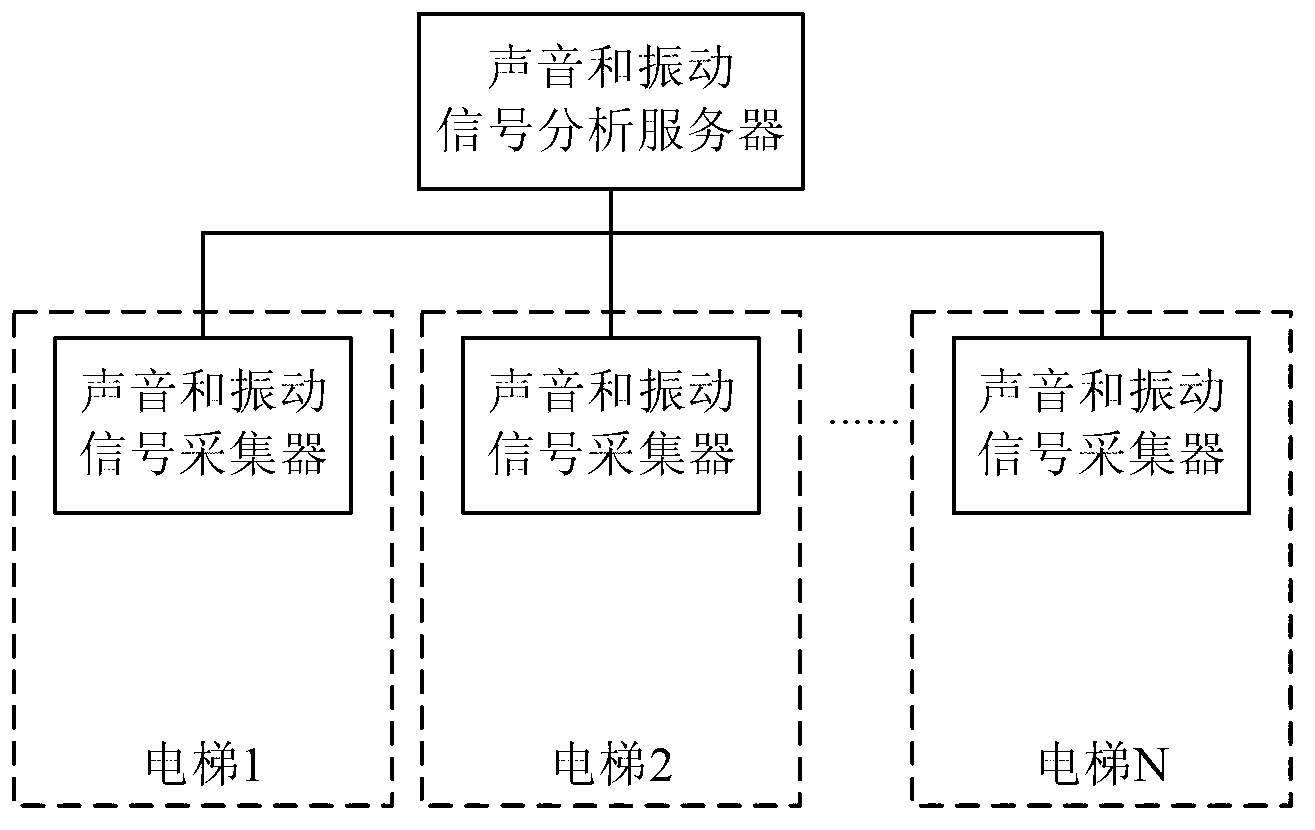

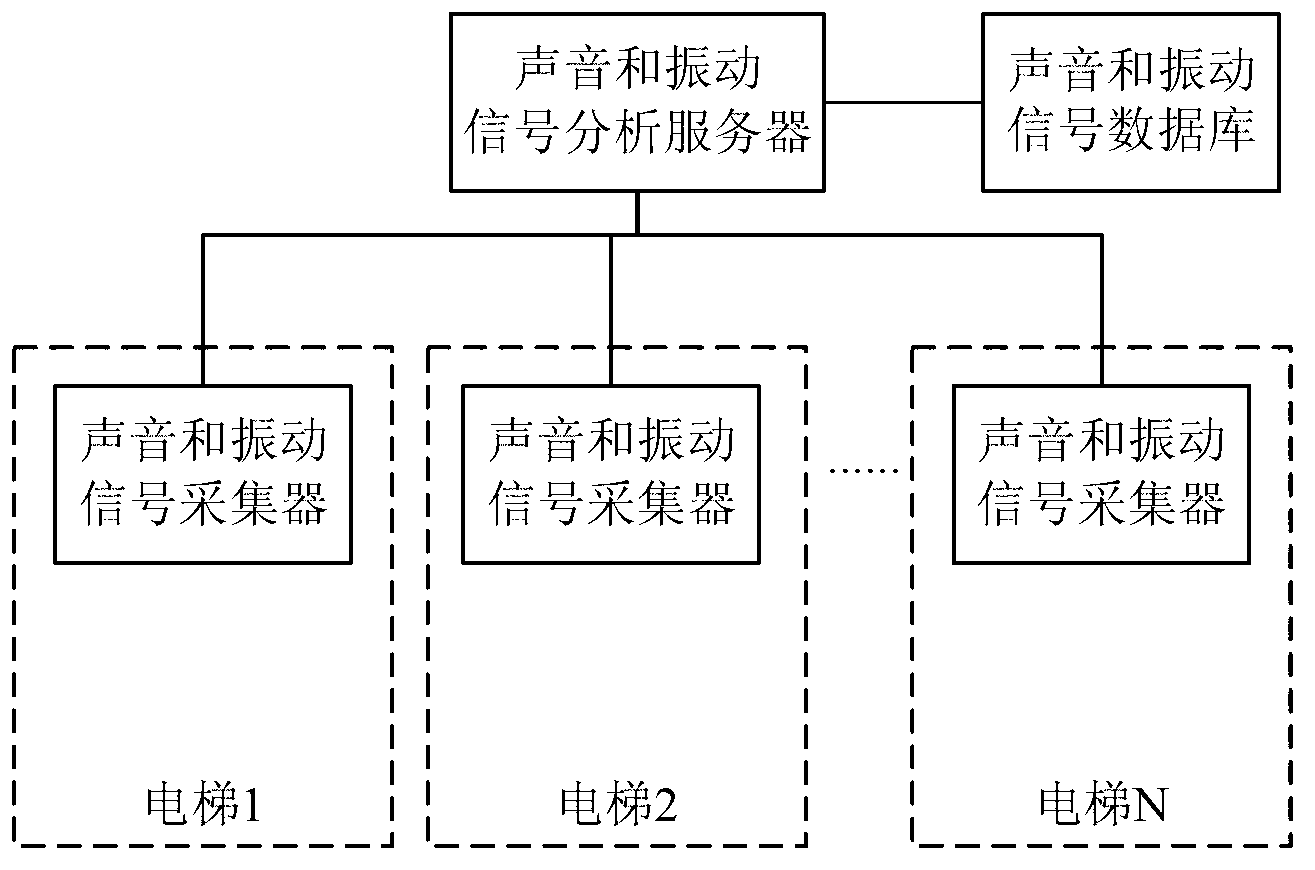

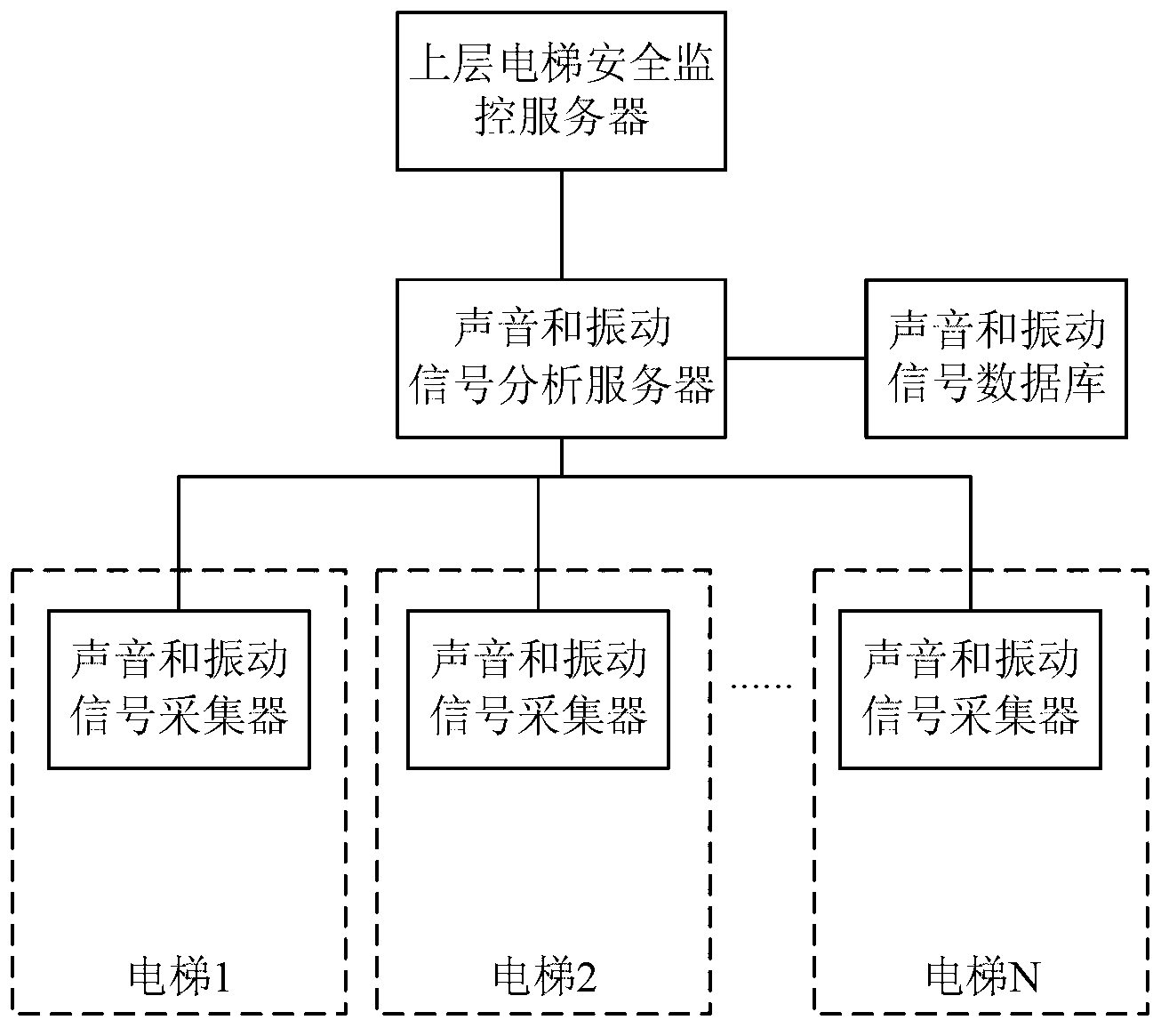

Diagnosis and early-warning system for elevator faults

The invention provides a diagnosis and early-warning system for elevator faults. The diagnosis and early-warning system comprises a sound and vibration signal acquirer and a sound and vibration signal analysis server, wherein the sound and vibration signal acquirer is arranged in an elevator car, connected with the sound and vibration signal analysis server and sends acquired sound signals and / or vibration signals to the sound and vibration signal analysis server; and the sound and vibration signal analysis server processes the sound signals and / or vibration signals. According to the diagnosis and early warning system for elevator faults, hidden faults of an elevator can be discovered as soon as possible, sufficient maintenance time is saved, and heavy losses are avoided. The running safety and reliability of elevators in an area range can be greatly improved once the diagnosis and early warning system is applied to the elevator Internet of Things field.

Owner:BEIJING JINGKE HUASHENG TECH

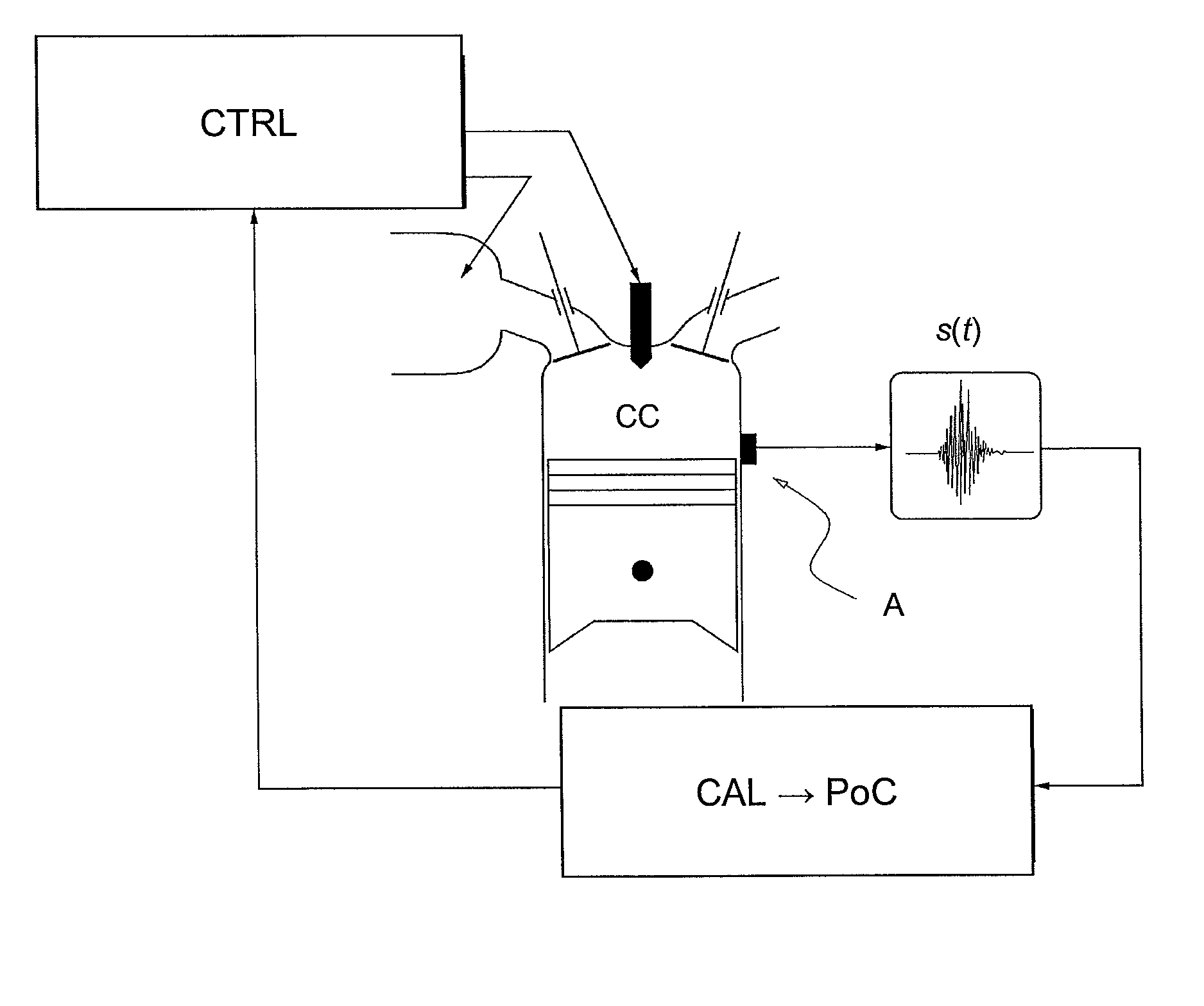

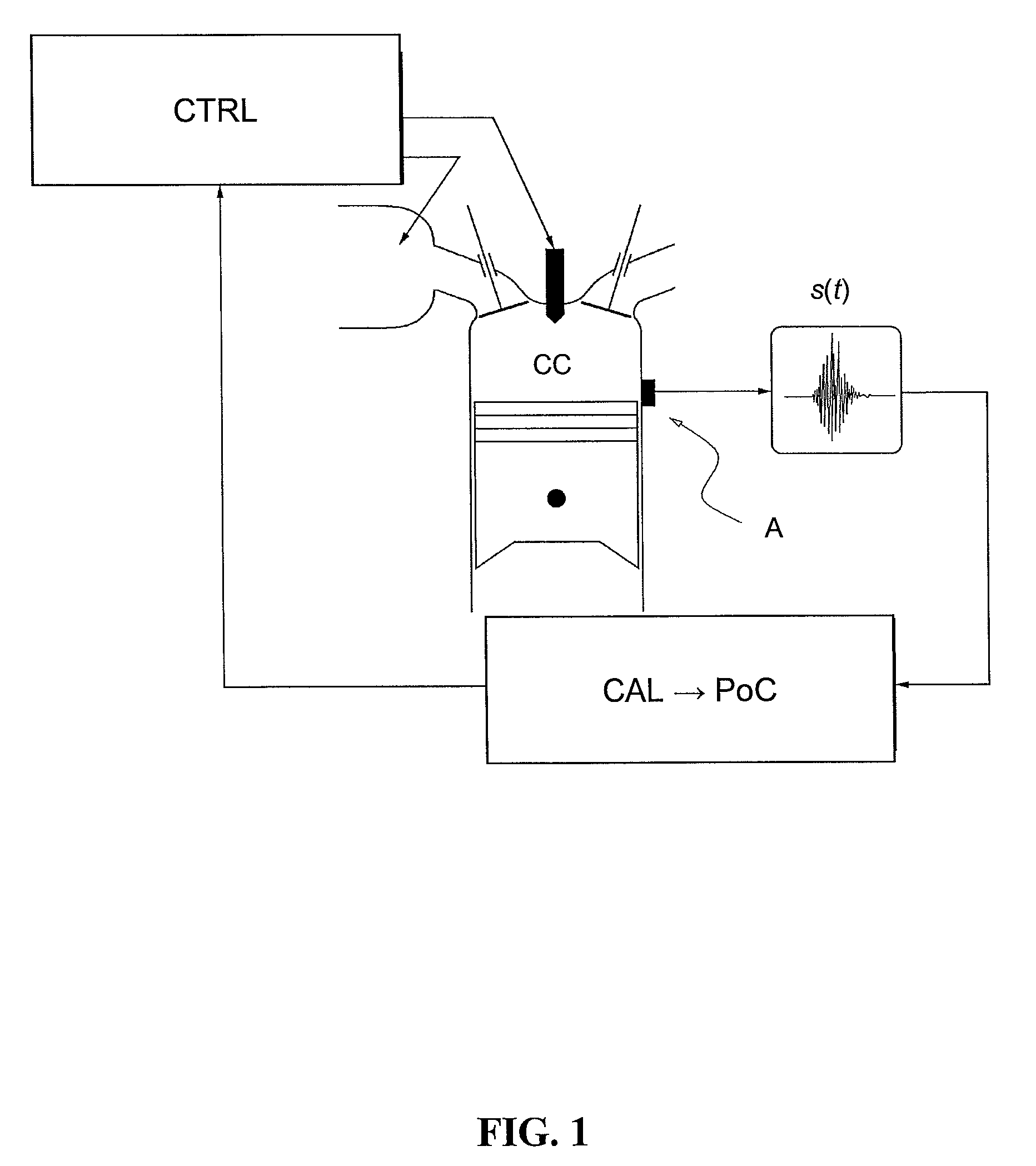

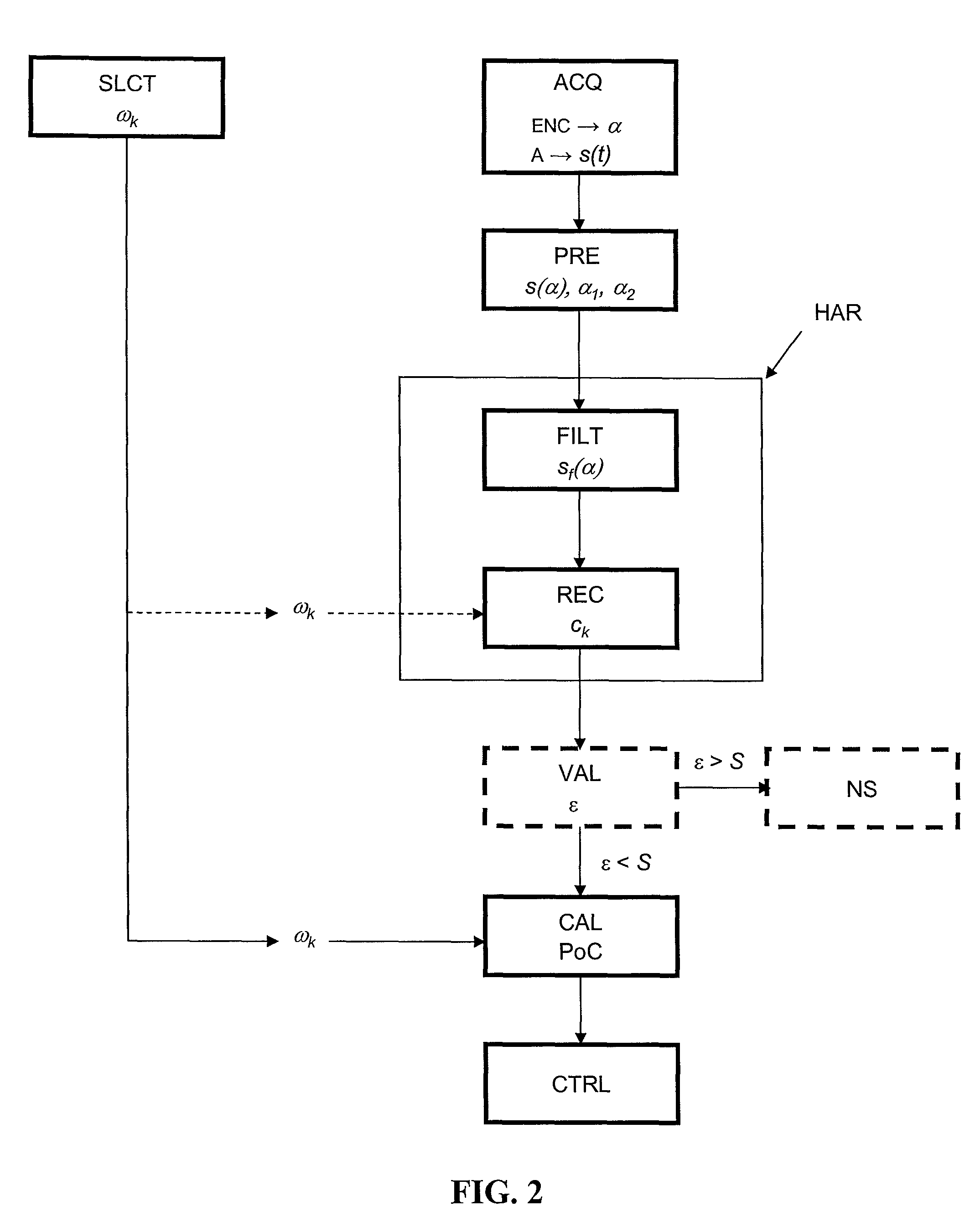

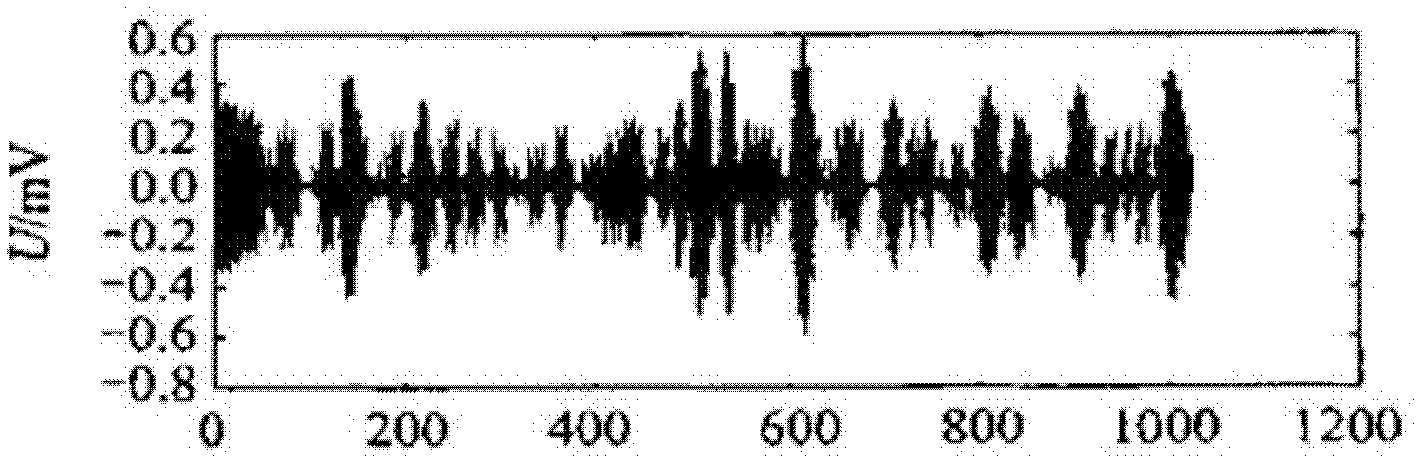

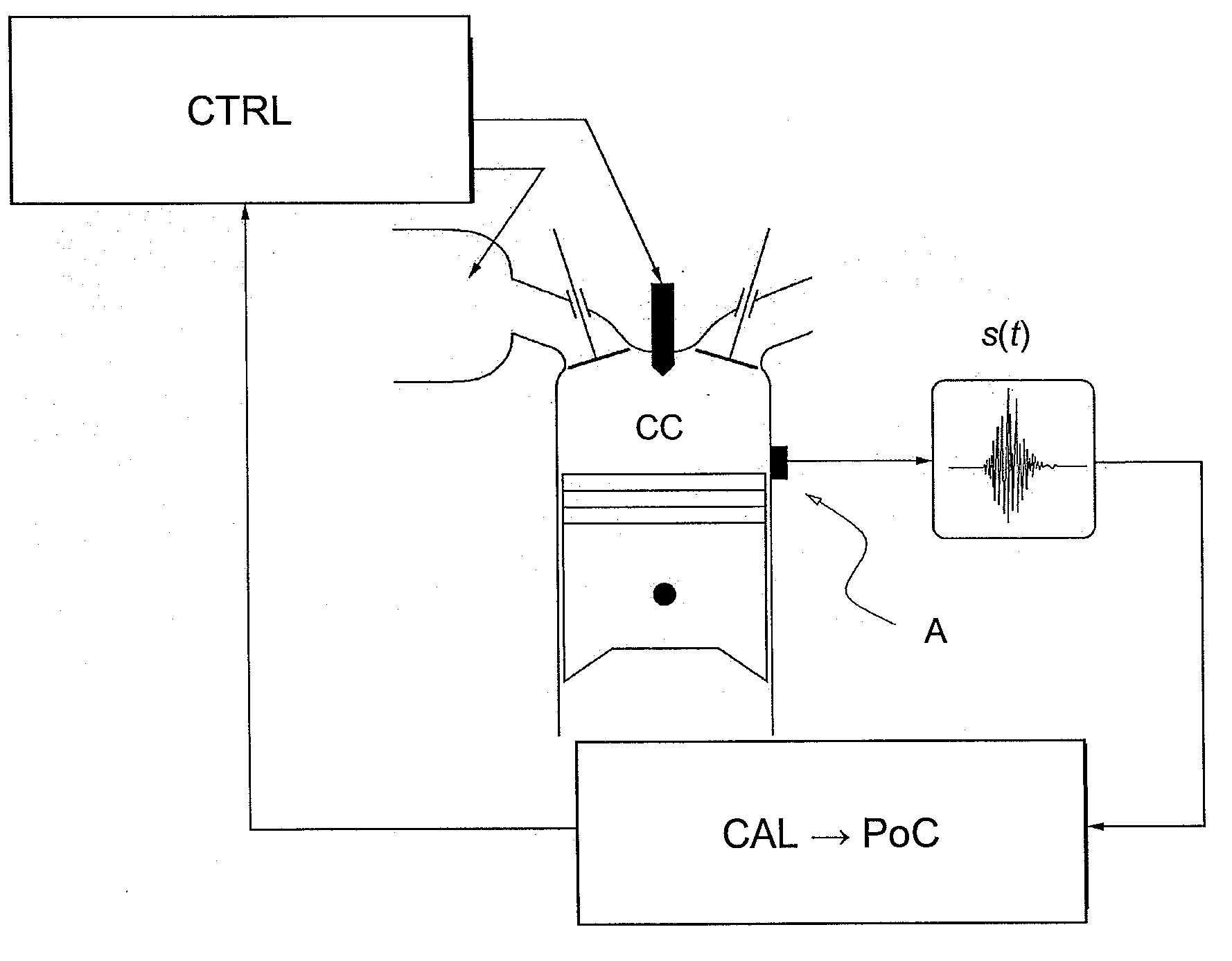

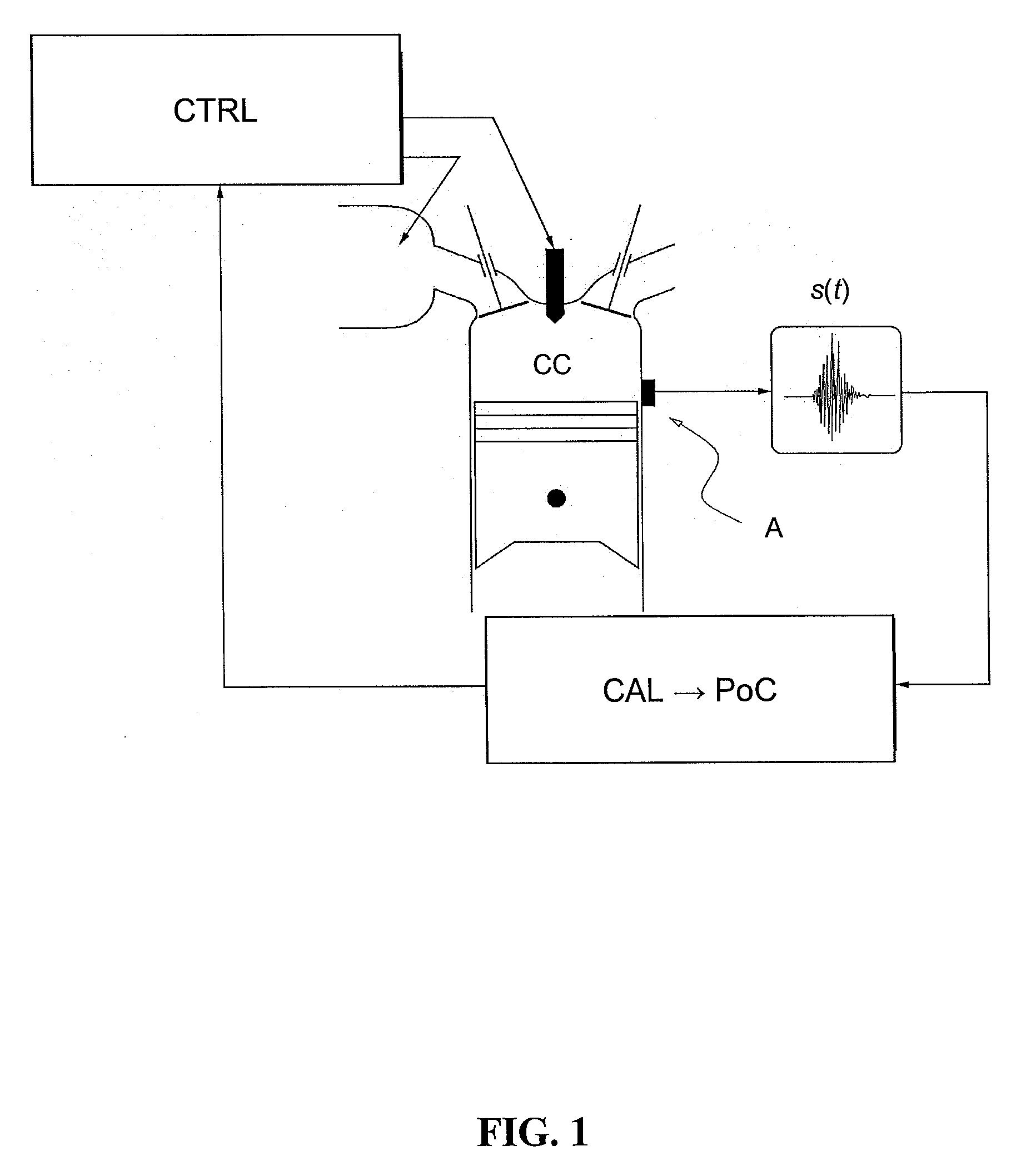

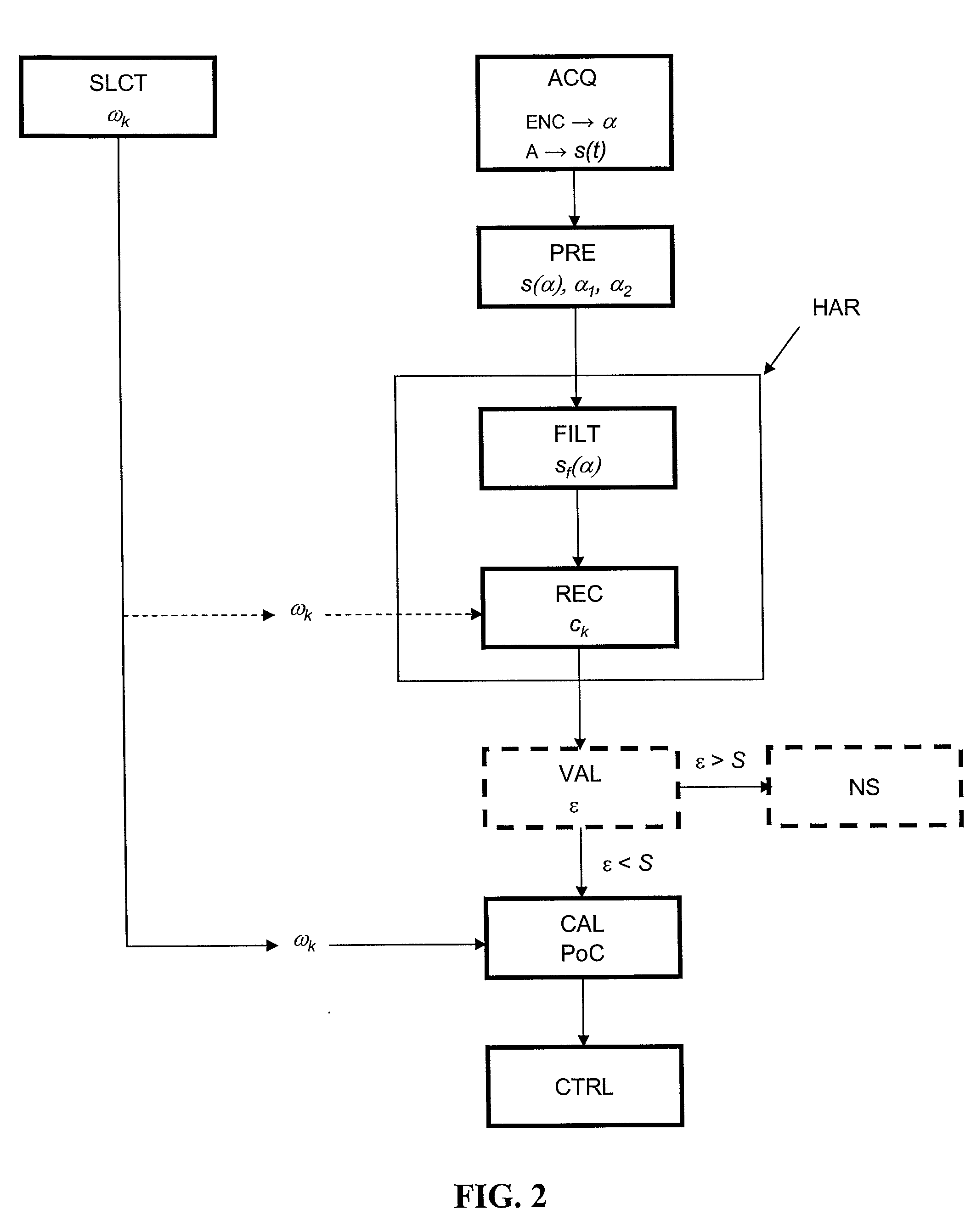

Method for real-time estimation of engine combustion parameters from vibratory signals

InactiveUS7747380B2Analogue computers for vehiclesInternal-combustion engine testingCombustionVibratory signal

The invention relates to a method having application to combustion control of an internal-combustion engine for real-time estimation of engine combustion parameters from vibratory signals. A vibratory signal representative of the engine vibrations is continuously acquired as a function of the crank angle, from a vibration detector. Real-time filtering of this vibratory signal and real-time estimation of the Fourier decomposition coefficients for the acquired vibratory signal is carried out by inverting the dynamics of the filter which is used. Finally, real-time estimation of combustion parameters allowing the combustion to be qualified is carried out from these coefficients.

Owner:INST FR DU PETROLE

Characteristic-signal-based elevator safety checking device and elevator safety checking method

The invention relates to a characteristic-signal-based elevator safety checking device and an elevator safety checking method. The elevator safety checking device comprises a signal detection unit, a data acquisition unit and a microprocessor, which are connected in turn, wherein the signal detection unit is used for detecting the vibration information and noise information of the elevator; the data acquisition unit is used for acquiring a signal from the signal detection unit; the microprocessor is used for extracting the characteristic signals of the vibration information and the noise information under different working conditions of the elevator and processing the signals; and the signal detection unit is arranged on an elevator tractor unit. The device is widely applied, and can effectively give a fault alarm or early warning for elevators of different specifications and from different manufacturers. According to the elevator safety checking method based on the device, the characteristics of the vibration signal are extracted by using wavelet transform, the set working conditions of the elevator can be identified, an expert policy knowledge library can be built, consequently the functions of noncontact remote monitoring, fault diagnosis and the like can be realized, and the safety of the elevator can be improved.

Owner:阳西县电梯配件有限公司

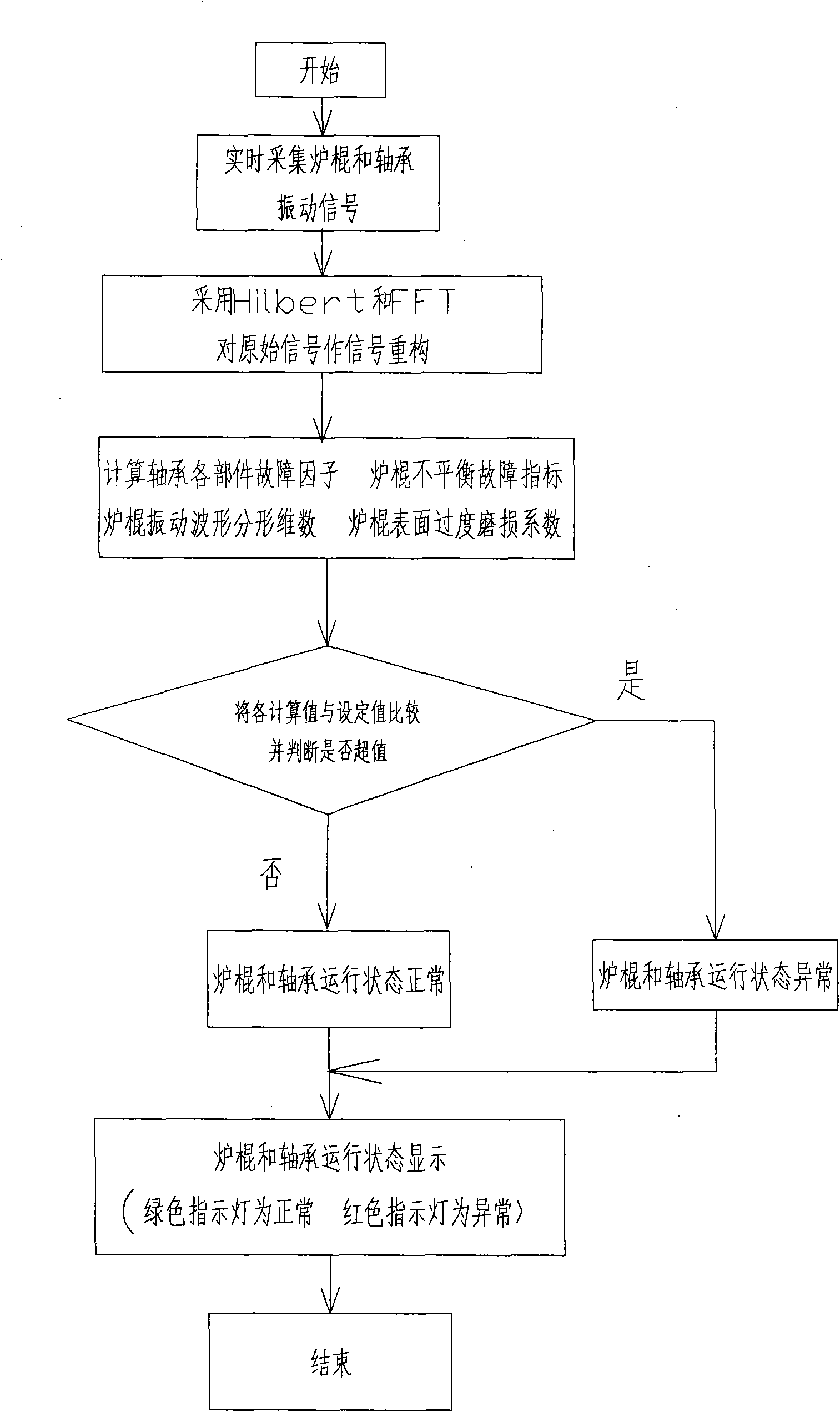

On-line monitoring method of cold rolled heating furnace roller running state

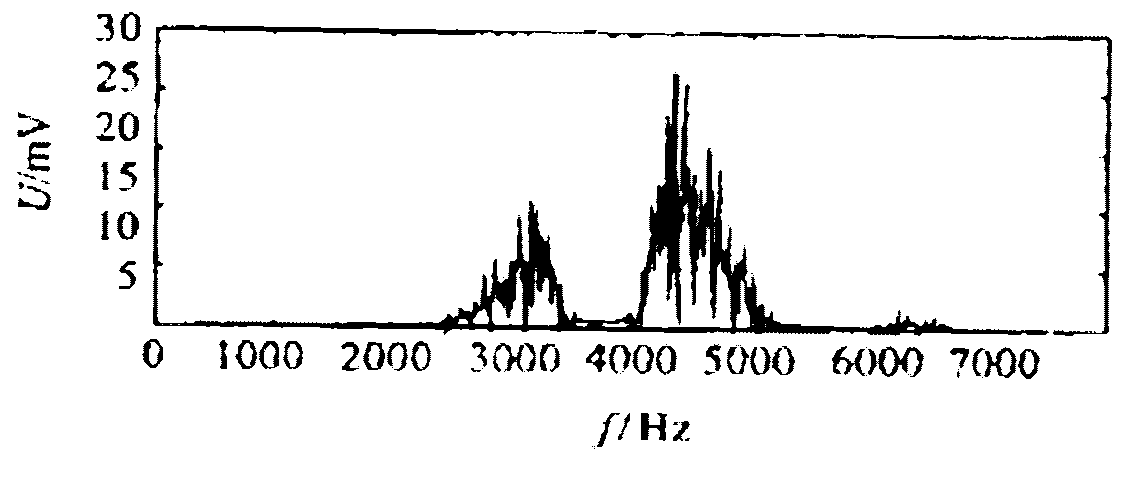

ActiveCN101685042AReal-time monitoring of running statusGuaranteed uptimeVibration measurement in solidsFurnace componentsVibration amplitudeFrequency spectrum

The invention discloses an on-line monitoring method of cold rolled heating furnace roller running state. The method comprises the following steps: using a vibration sensor to collect vibration signalof the furnace roller and bearing, performing signal reconstruction to the vibration signal to obtain a vibration characteristic signal of the furnace roller and bearing, wherein the characteristic signal comprises the vibration frequency spectrum of each part of the bearing and the rotary frequency of the furnace roller in every frequency multiplication; calculating failure factor of each part of the bearing to compare with a set value and judge bearing failure; calculating total vibration value of the furnace roller, comparing the value with vibration amplitude values of the rotary frequency of the furnace roller in 1 and 2 frequency multiplication to judge whether the furnace roller is abnormal; building vibration waveform aggregate to the original vibration signal to obtain the fractal dimension of furnace roller vibration, obtaining the conclusion that the furnace roller is abnormal when the fractal dimension changes violently; and finally judging whether the furnace roller surface is over abrasion by comparing the basic furnace roller vibration amplitude value with the on-line furnace roller total vibration value.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

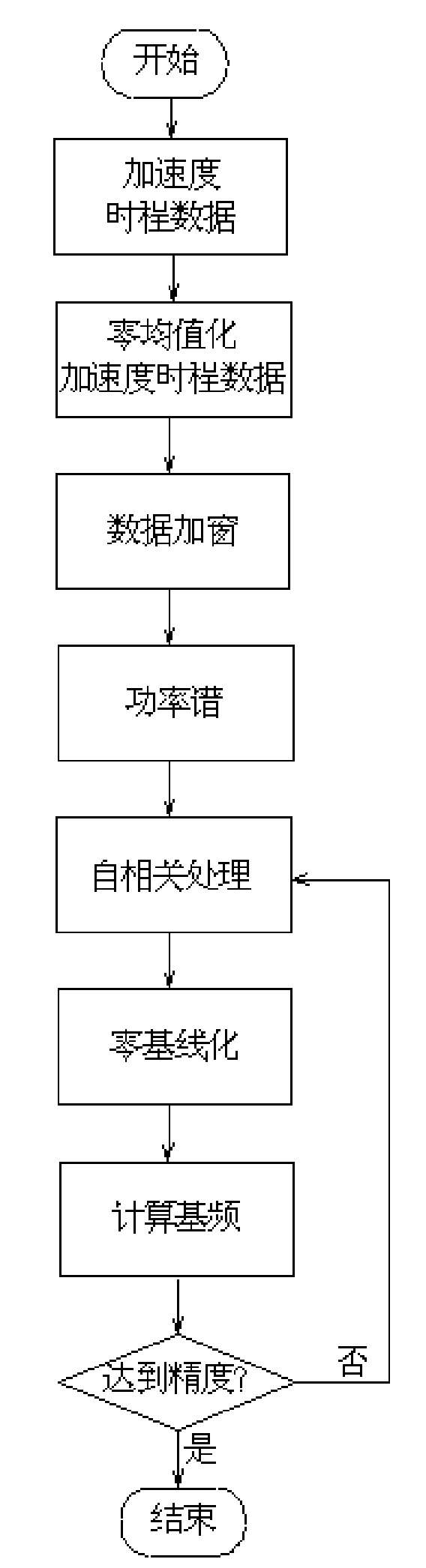

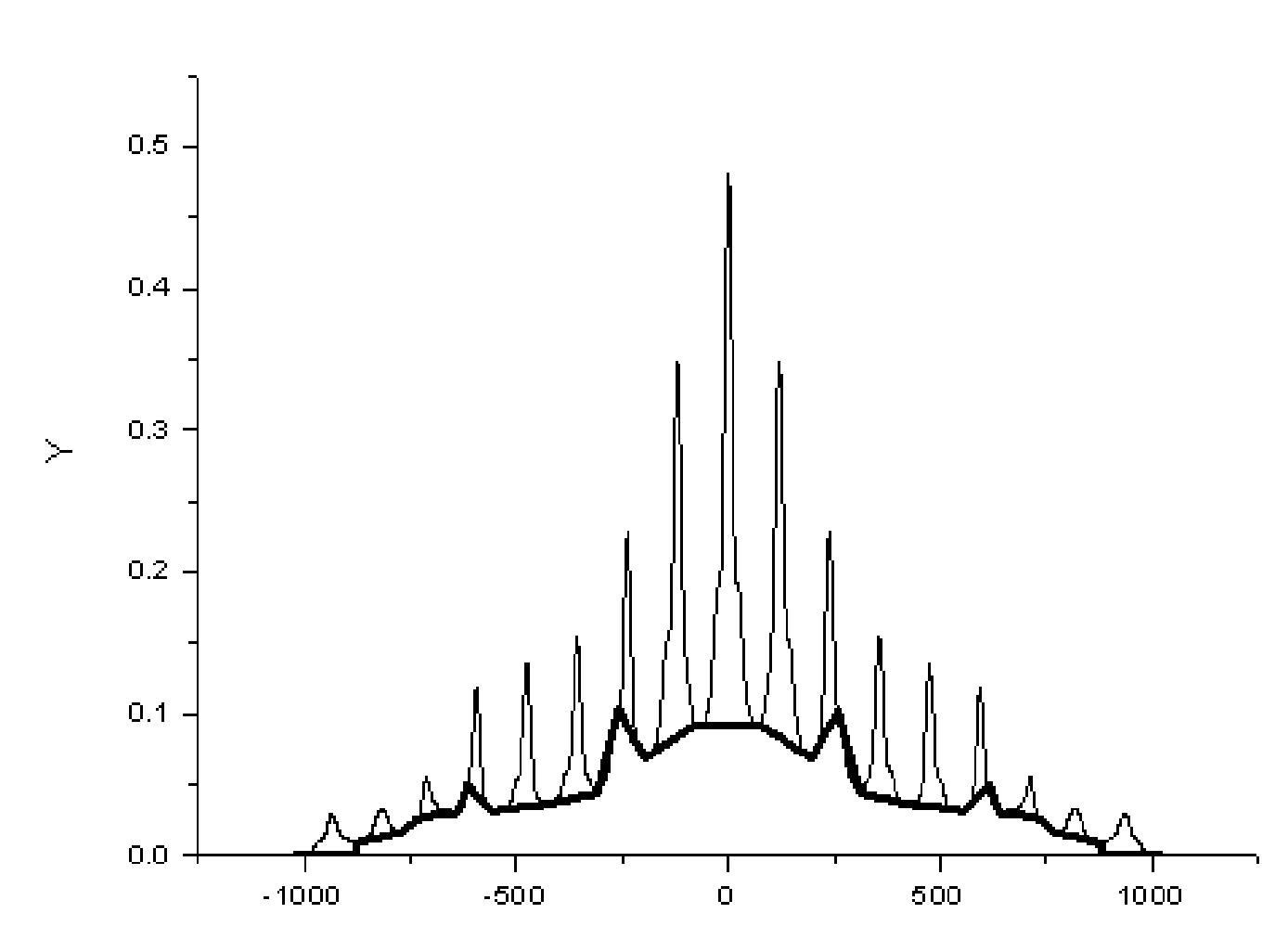

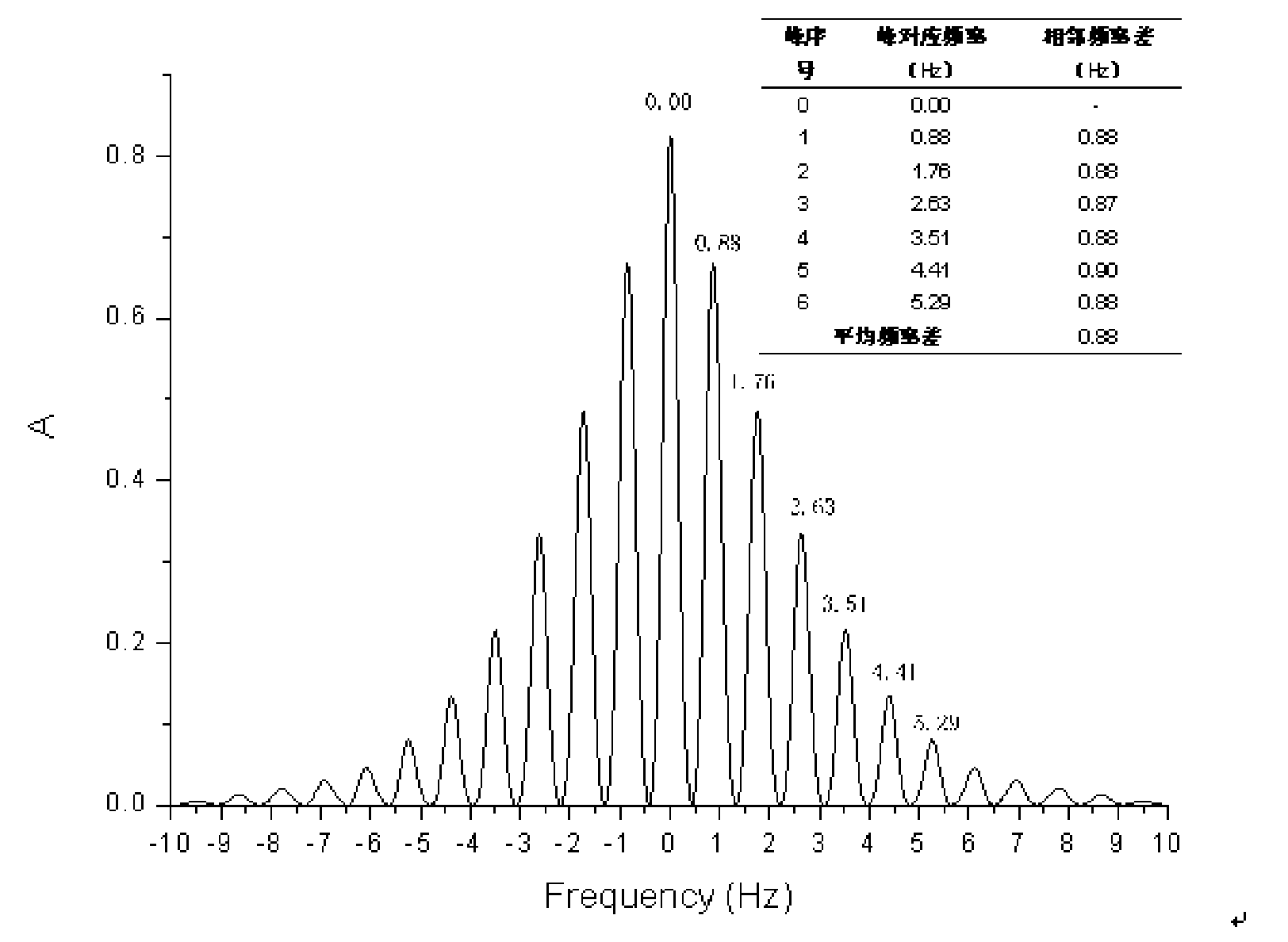

Method for calculating guy cable vibrating base frequency

InactiveCN101586997AAccurate calculationRaise the level of automaticTension measurementVibration accelerationVibratory signal

The present invention discloses a method for calculating the guy cable vibrating base frequency, including collecting the vibration acceleration data of the guy cable to implement a zero mean and window adding operation to calculate a power spectrum of the vibration acceleration; based on the power spectrum of the vibration acceleration, extracting near periodic spectrum peaks from the power spectrum of the vibration acceleration by autocorrelation calculation, and processing the autocorrelation calculated result by a zero base line operation; then calculating the base frequency and implementing a plurality of iteration operations until the error of the base frequency calculated results is less than 0.01Hz, the final base frequency value is the base frequency of the guy cable. The invention is capable of calculating the vibrating base frequency of the inclined guy cable accurately to meet the precision requirement for measuring a cable force, improving the base frequency recognition precision effectively, and calculating the vibrating base frequency of the guy cable accurately when the guy cable vibrating signal contains an environment vibration noise signal, thus the invention has good robustness and accuracy.

Owner:GUIZHOU NORMAL UNIVERSITY

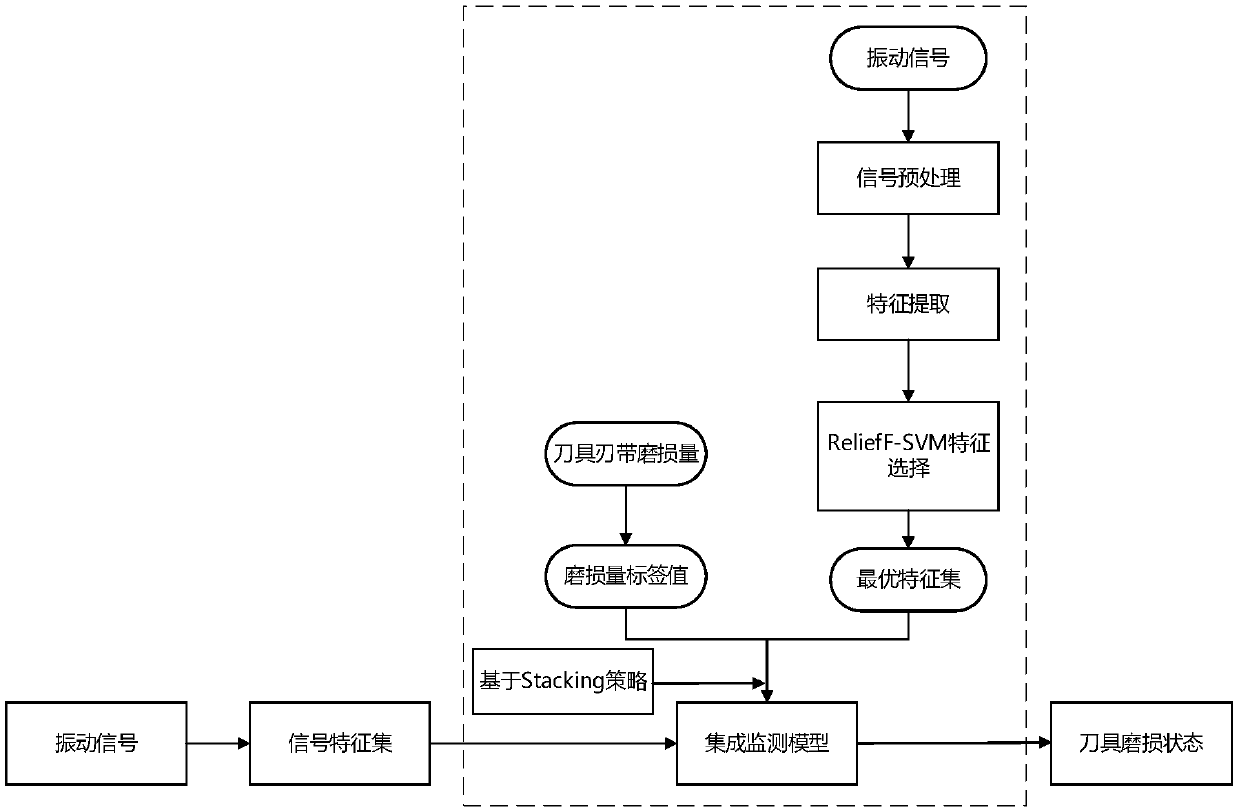

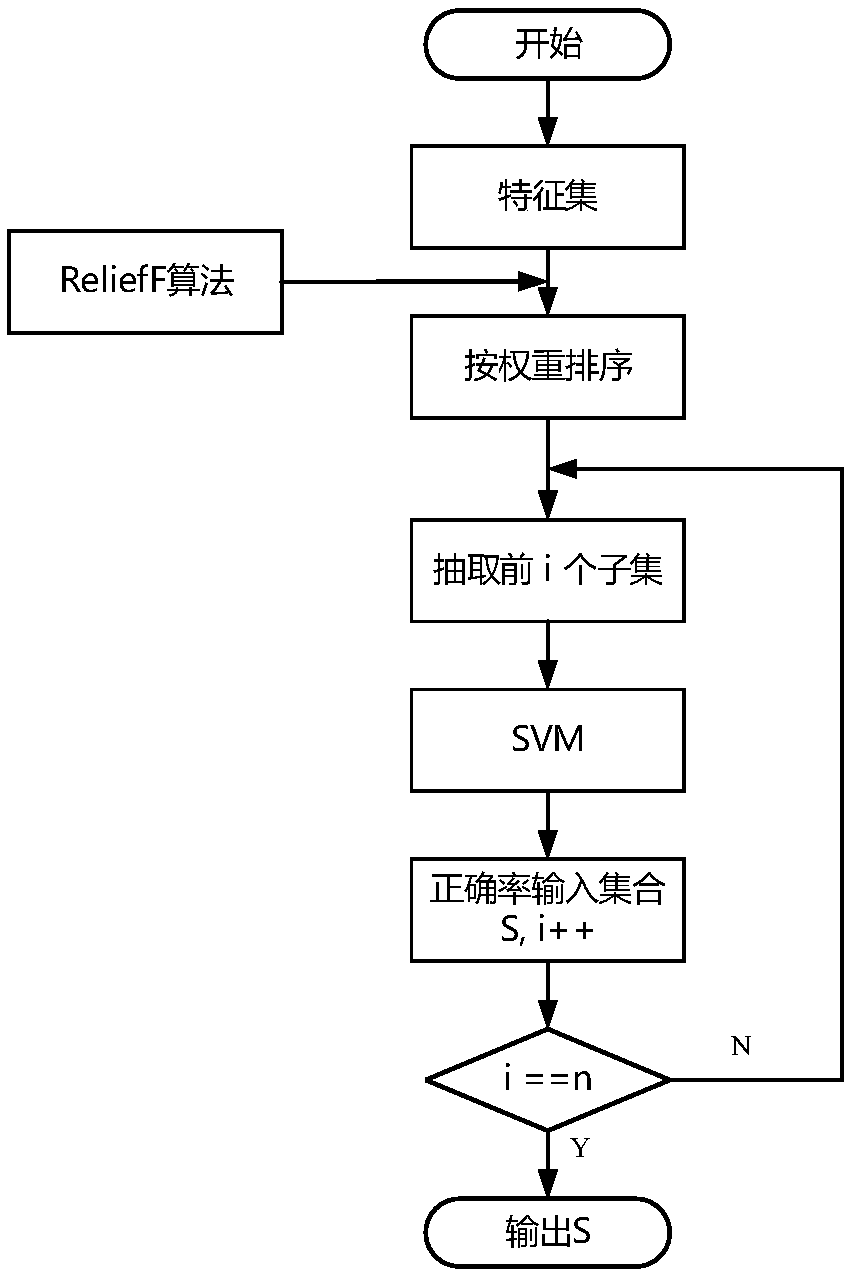

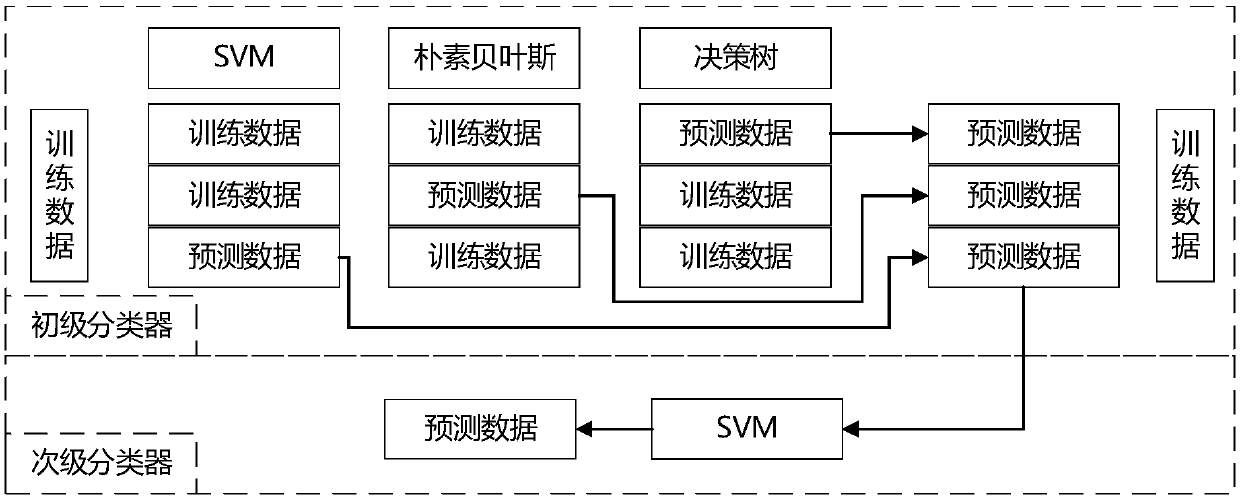

Tool abrasion state monitoring method based on vibration signal and Stacking ensemble model

ActiveCN109514349AEnable wear monitoringSolving Wear Condition Monitoring ChallengesMeasurement/indication equipmentsTime domainFeature set

The invention discloses a tool abrasion state monitoring method based on a vibration signal and a Stacking ensemble model. The vibration signal of a machine tool spindle in the machining process is utilized, and the vibration signal is subjected to feature extraction through time-domain analysis, frequency-domain analysis and ensemble empirical mode decomposition (EEMD); then extracted features are screened through a Relief F-SVM algorithm to obtain an optimal feature set; the width of a tool abrasion blade belt serves as the abrasion label value, and an ensemble monitoring model is built based on a Stacking ensemble strategy through the optimal feature set and the abrasion label value; and after the model is built, the vibration signal in the machining process is monitored and processed to obtain the signal feature set to be input into the ensemble monitoring model, and the tool abrasion label value, namely the tool abrasion state is obtained. The tool abrasion state can be monitoredbased on the vibration signal and the Stacking ensemble model.

Owner:XI AN JIAOTONG UNIV

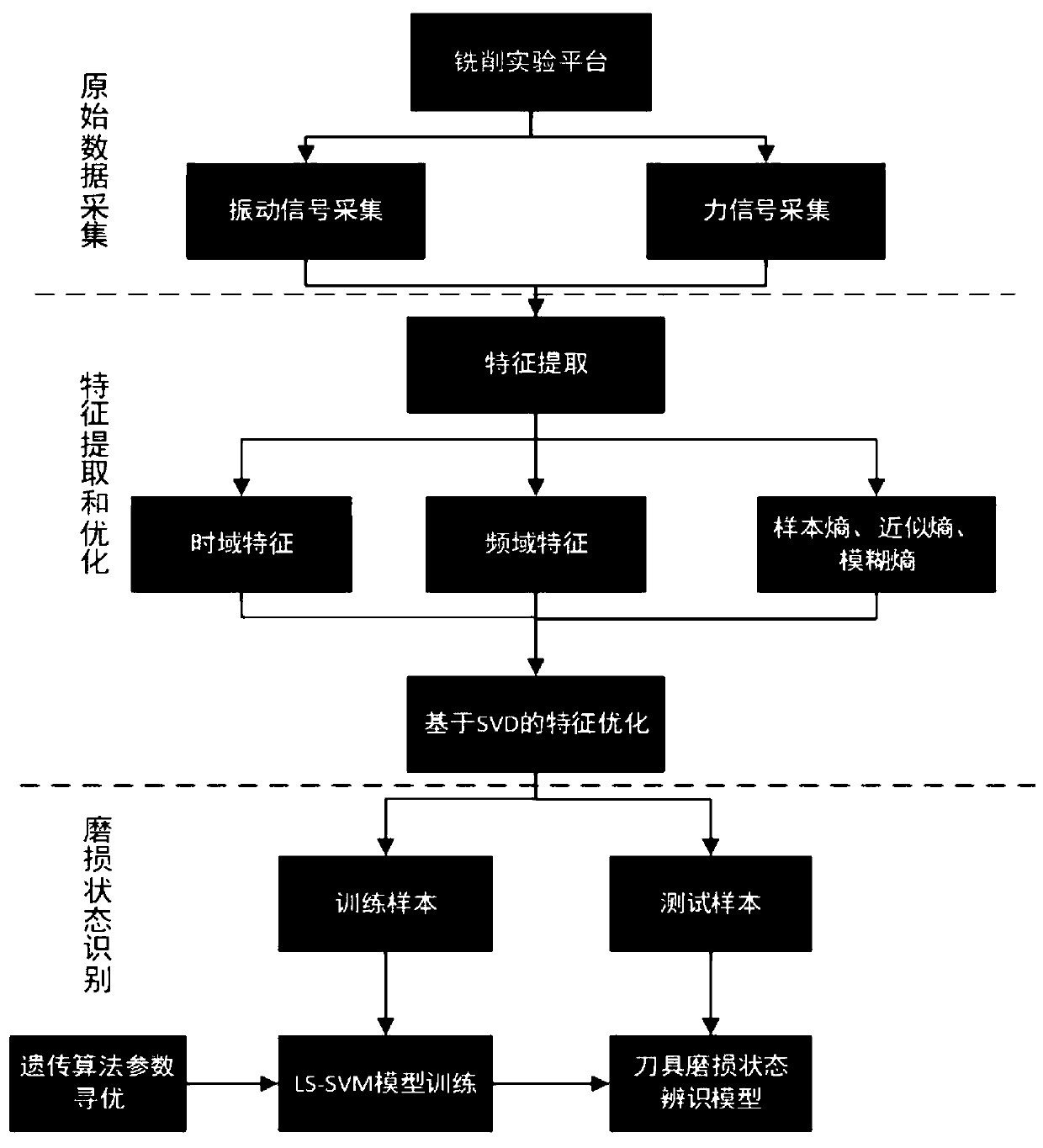

Tool abrasion state identification method based on multi-feature fusion

ActiveCN110153801AImprove recognition efficiencyImprove anti-interference abilityMeasurement/indication equipmentsVibration accelerationFeature set

The invention relates to a tool abrasion state identification method based on multi-feature fusion. A plurality of methods are utilized for extracting feature information of vibration acceleration signals and cutting force signals, optimization is conducted on a feature set based on singular value decomposition, and the tool abrasion state identification precision is improved. According to the tool abrasion state identification method, mainly, the cutting force signals and the vibration signals are fused for feature extraction, the feature set is optimized through the singular value decomposition method, then, the feature set is input into a least squares support vector machine tool abrasion state identification model optimized on the basis of the genetic algorithm for identification, andthe tool abrasion state is output. According to the tool abrasion state identification method based on multi-feature fusion, the cutting force signals and the vibration acceleration signals are fusedfor feature extraction to serve as input, and the tool abrasion state identification precision is improved.

Owner:SOUTHWEST JIAOTONG UNIV

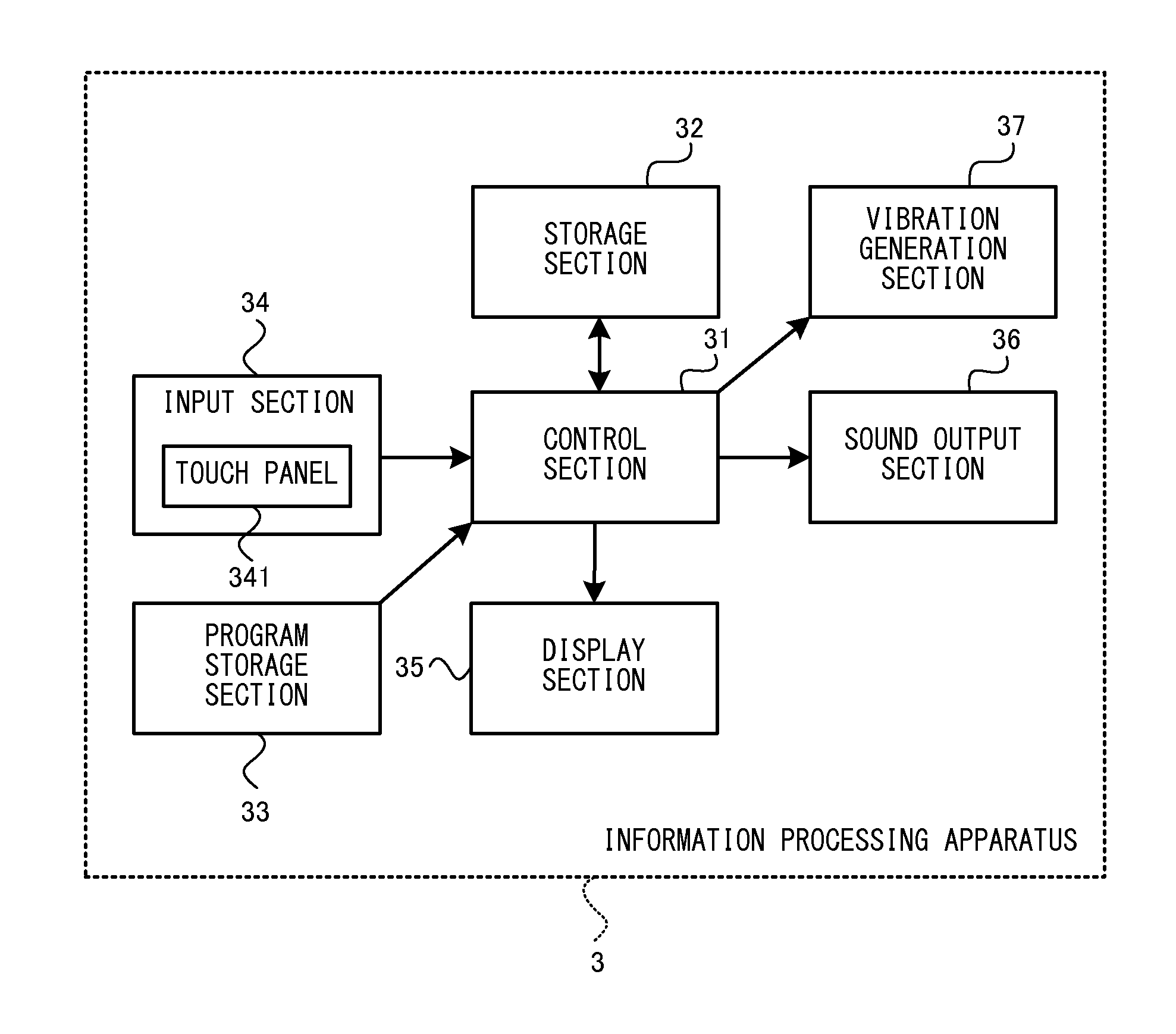

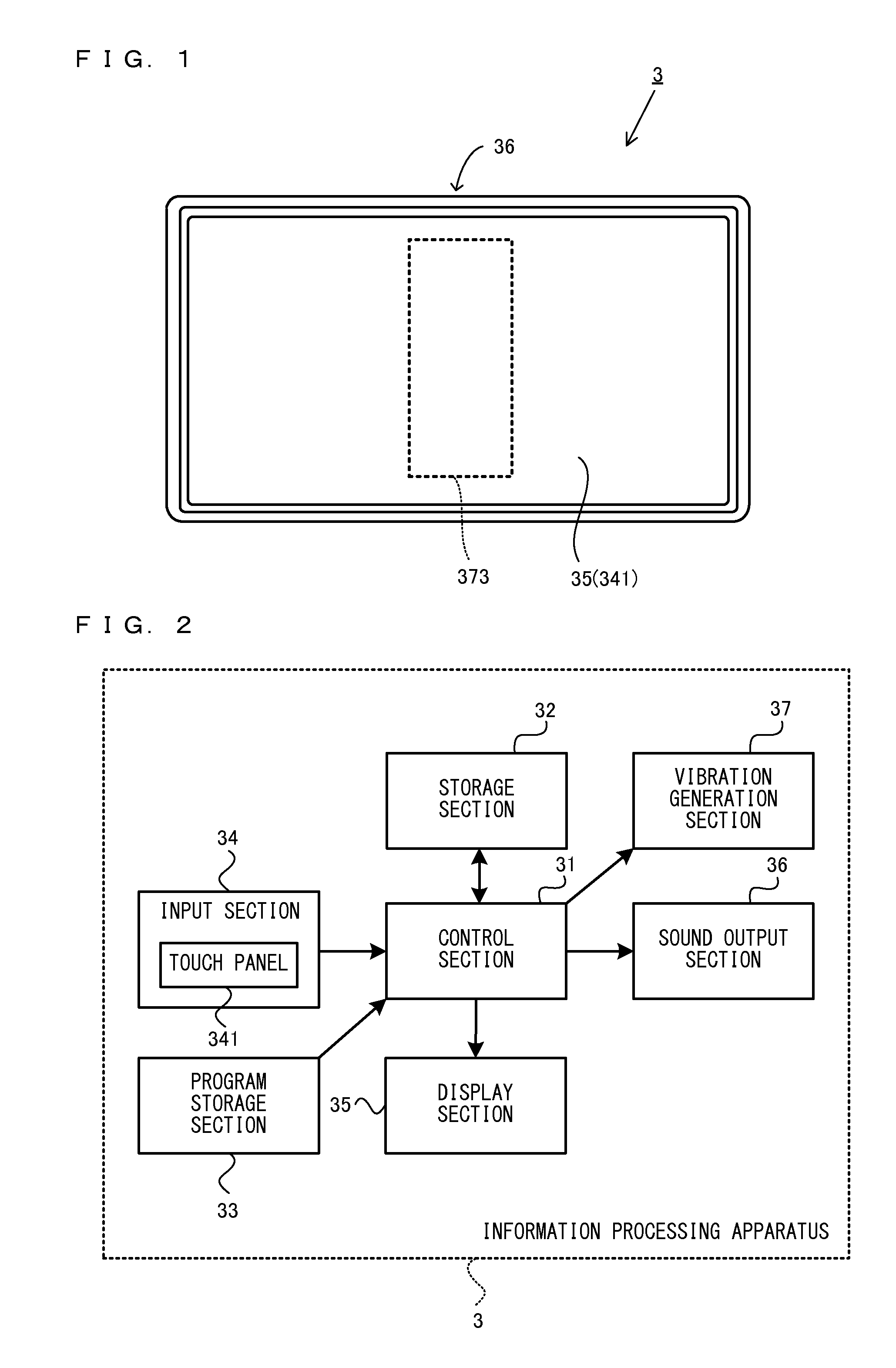

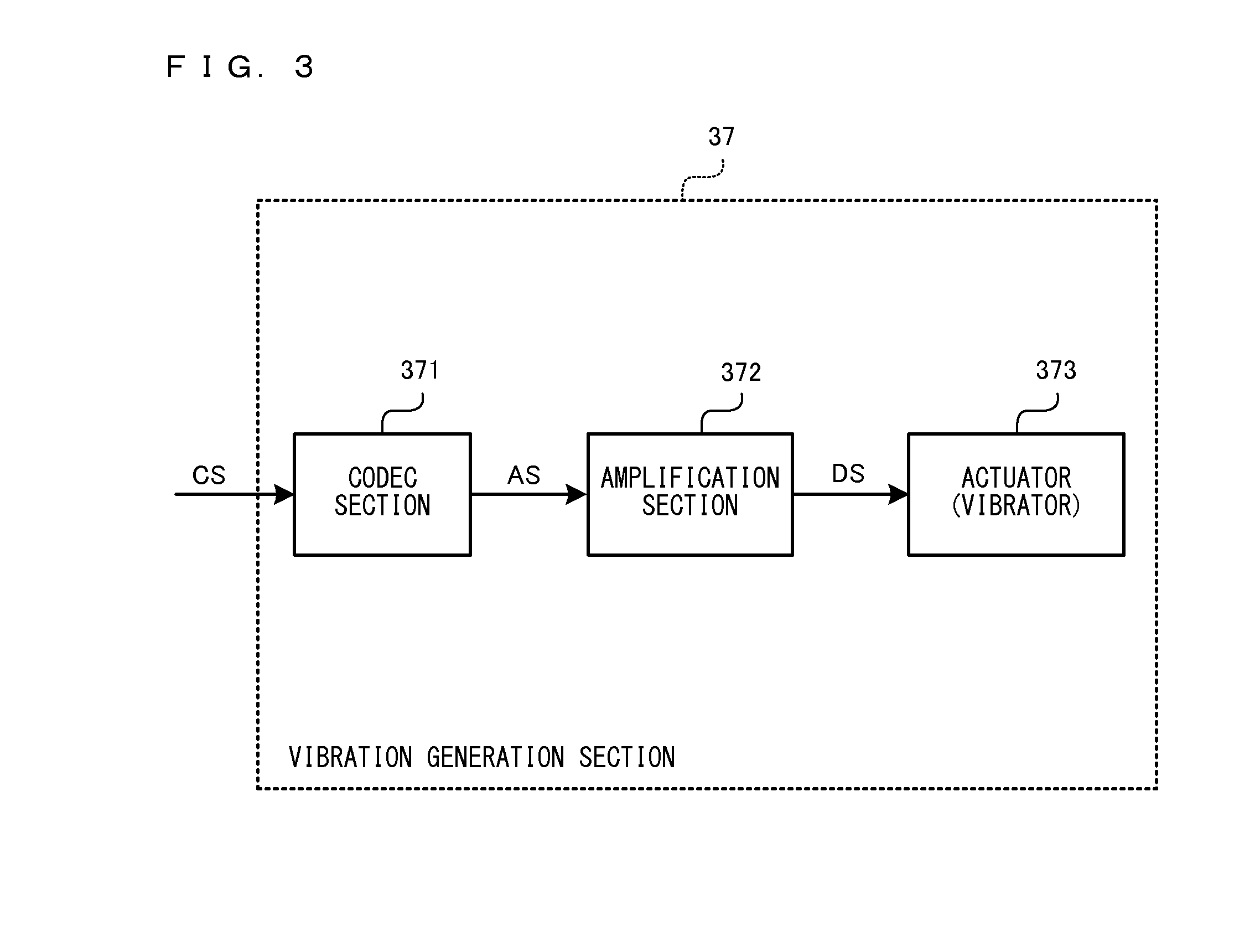

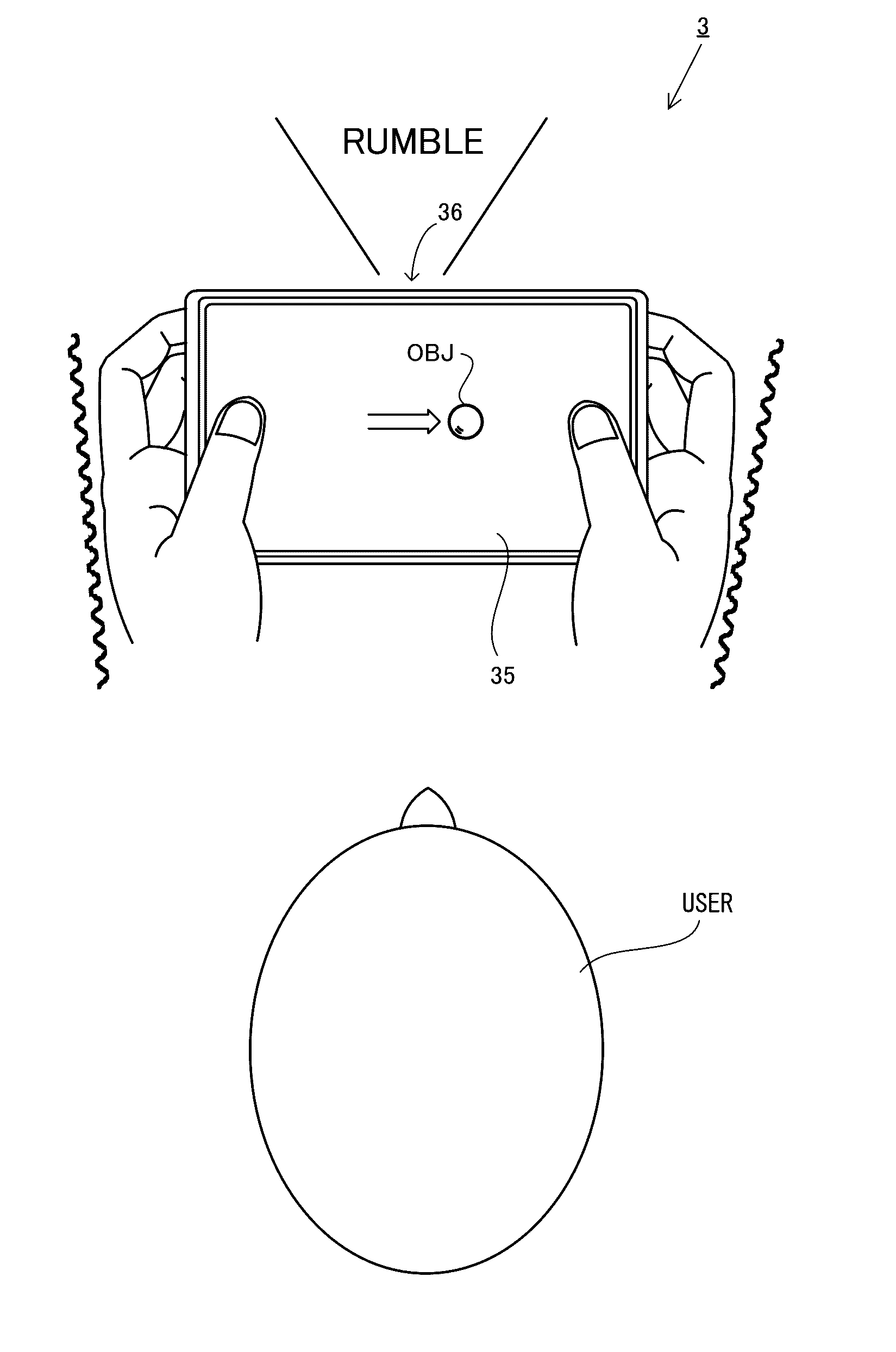

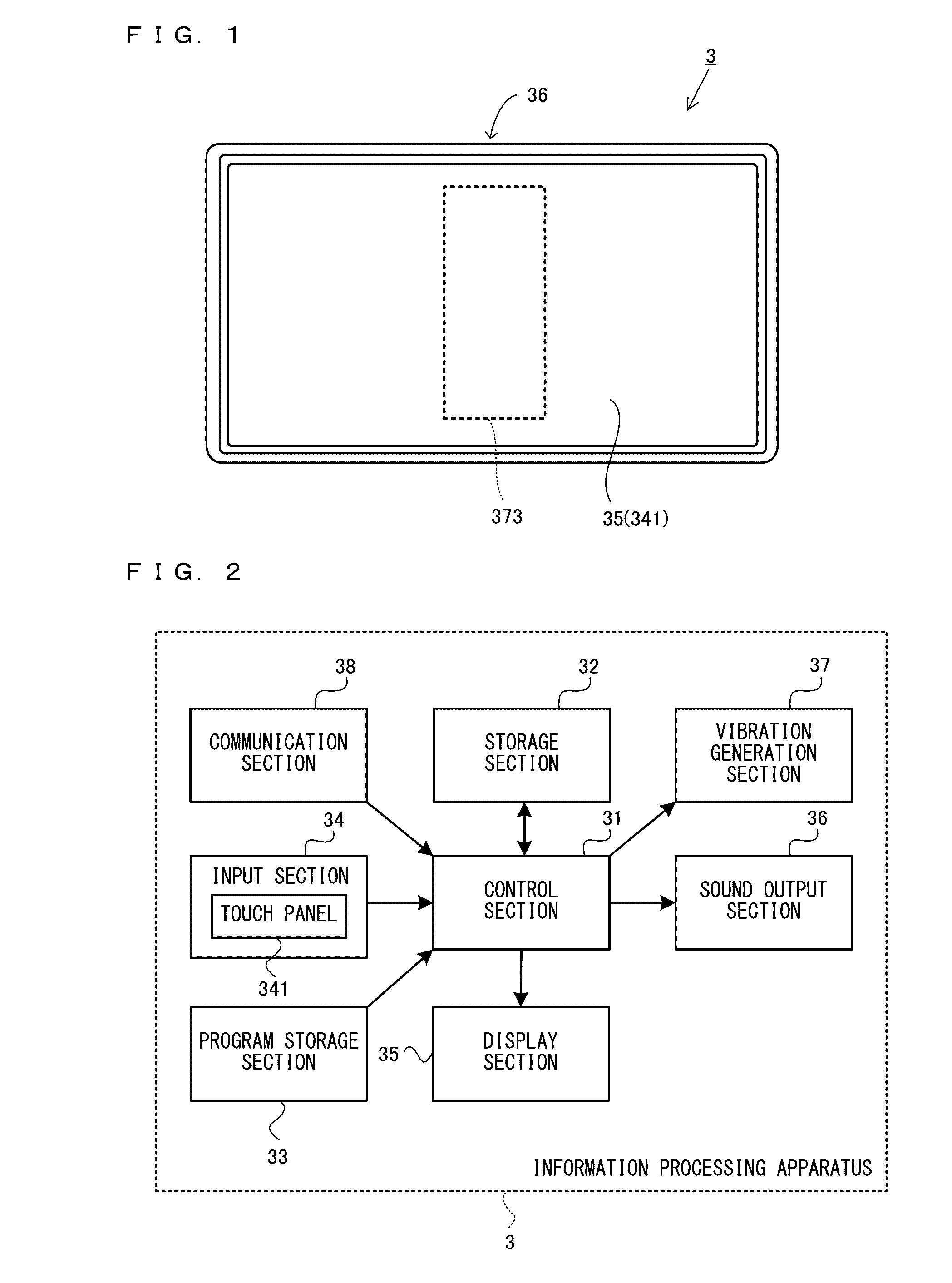

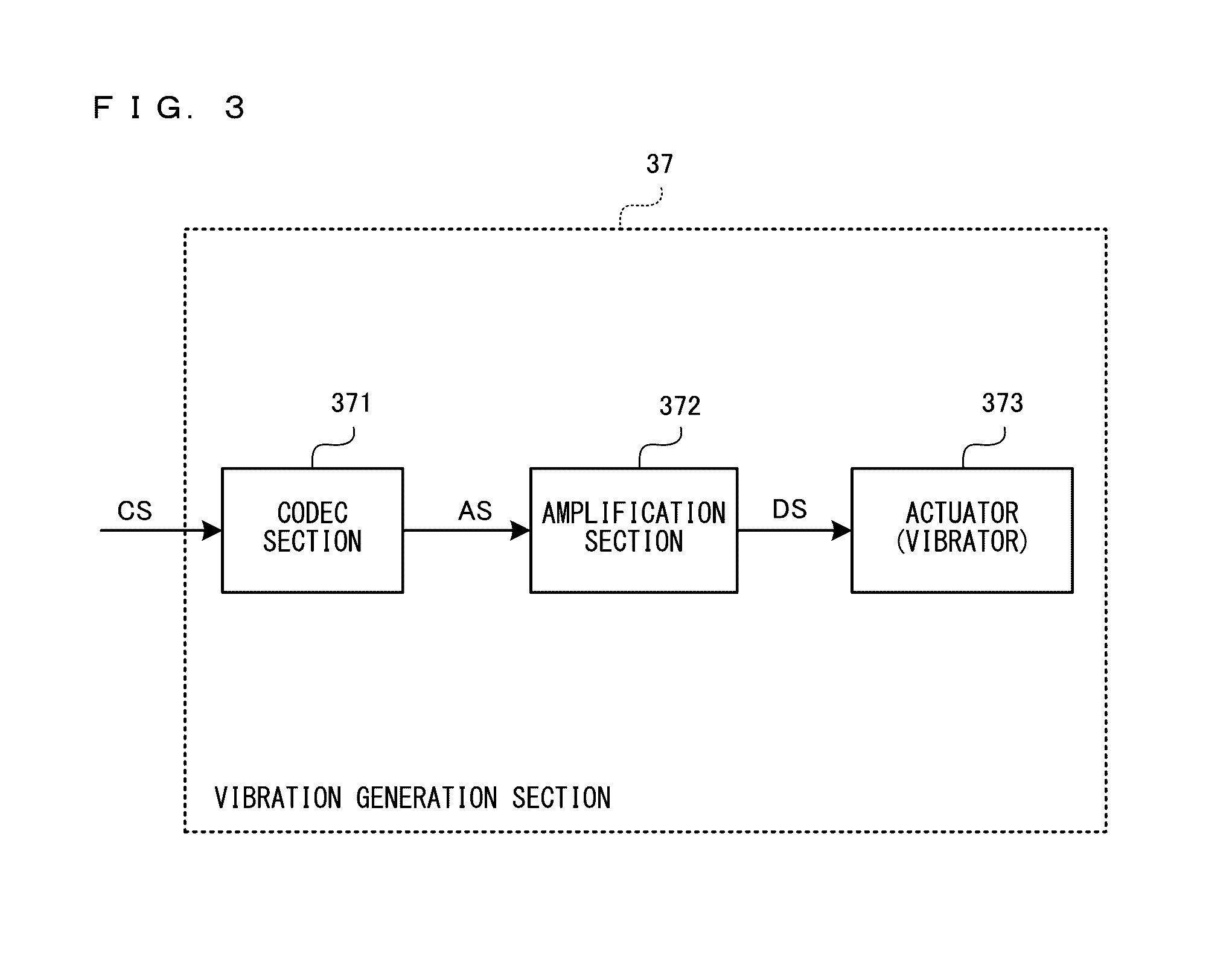

Vibration generation system, vibration generation apparatus, storage medium having stored therein vibration signal generation program, and vibration generation method

Owner:NINTENDO CO LTD

Storage medium having stored therein vibration signal generation program, vibration signal generation system, vibration signal generation apparatus, vibration signal generation method, and storage medium having stored therein data output program

A vibration signal for vibrating a vibration apparatus is generated, and data obtained by encoding amplitude modulation information indicating a change in an amplitude and / or frequency modulation information indicating a change in a frequency are acquired. Then, the acquired data is decoded, and the vibration signal is generated using the decoded amplitude modulation information and / or frequency modulation information.

Owner:NINTENDO CO LTD

Method for predicting service life of guide pair of numerical control machine on basis of performance degradation model

InactiveCN101870076AAccurate predictionFit closelyMachine gearing/transmission testingMeasurement/indication equipmentsNumerical controlVibratory signal

The invention provides a method for predicting the service life of a guide pair of a numerical control machine on the basis of a performance degradation model. The method comprises the following steps of: acquiring vibration signals, carrying out time-frequency domain analysis, extracting the sensitive characteristic data vectors of the performance degradation of the guide pair, and forming a sensitive characteristic matrix in a time-sequence manner; calculating the load Pi of the guide pair and recording the operating time ti at the same time; calculating the rated life time Lhi, the total time t' that the guide pair has run under the current working condition, and the expected residual life LDi according to Pi, and forming an expected residual life vector T of the expected residual life in a time-sequence manner; and fitting the mapping relation between the inputted sensitive characteristic matrix and the expected residual life vector T by using a degradation model formed by a double-layer dynamic fuzzy neural network, and outputting the prediction result of the service life. By taking the impact on the performance degradation of the guide pair caused by the load change thereof under various working conditions of the numerical control machine into consideration, the method of the invention can achieve the prediction of the residual life when the guide pair is used, and ensure the high prediction accuracy and high value in actual application.

Owner:SOUTHWEST JIAOTONG UNIV

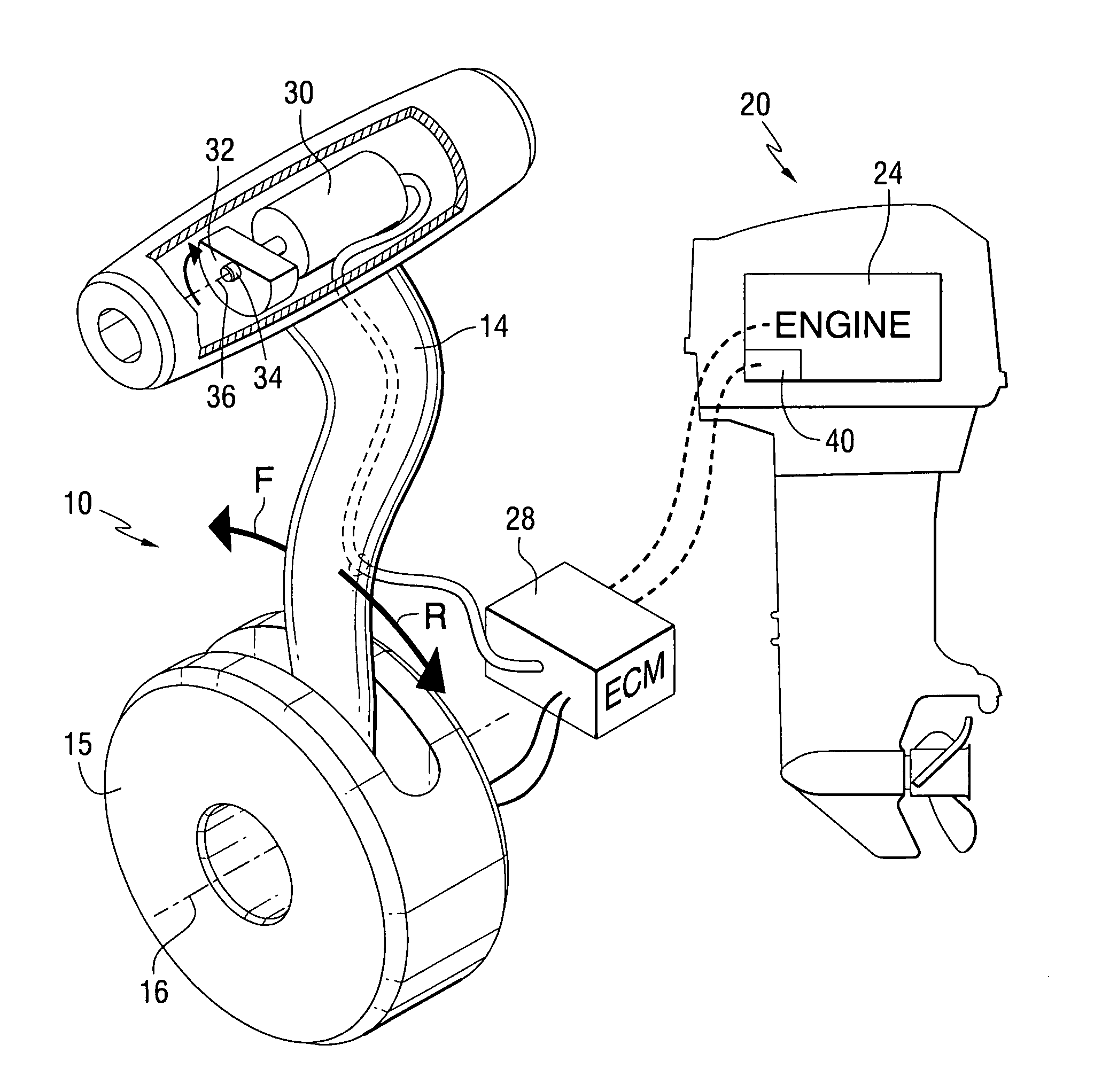

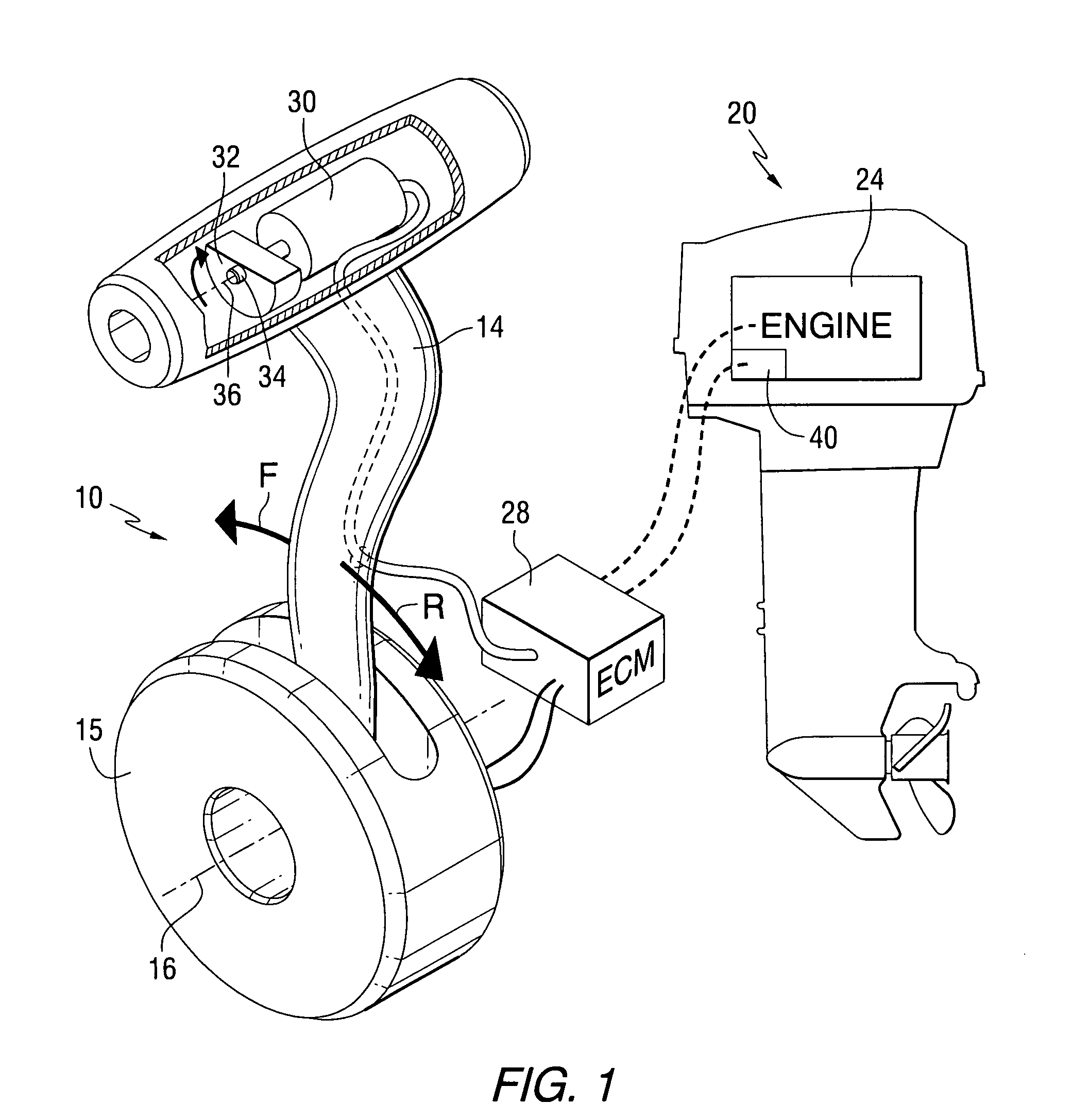

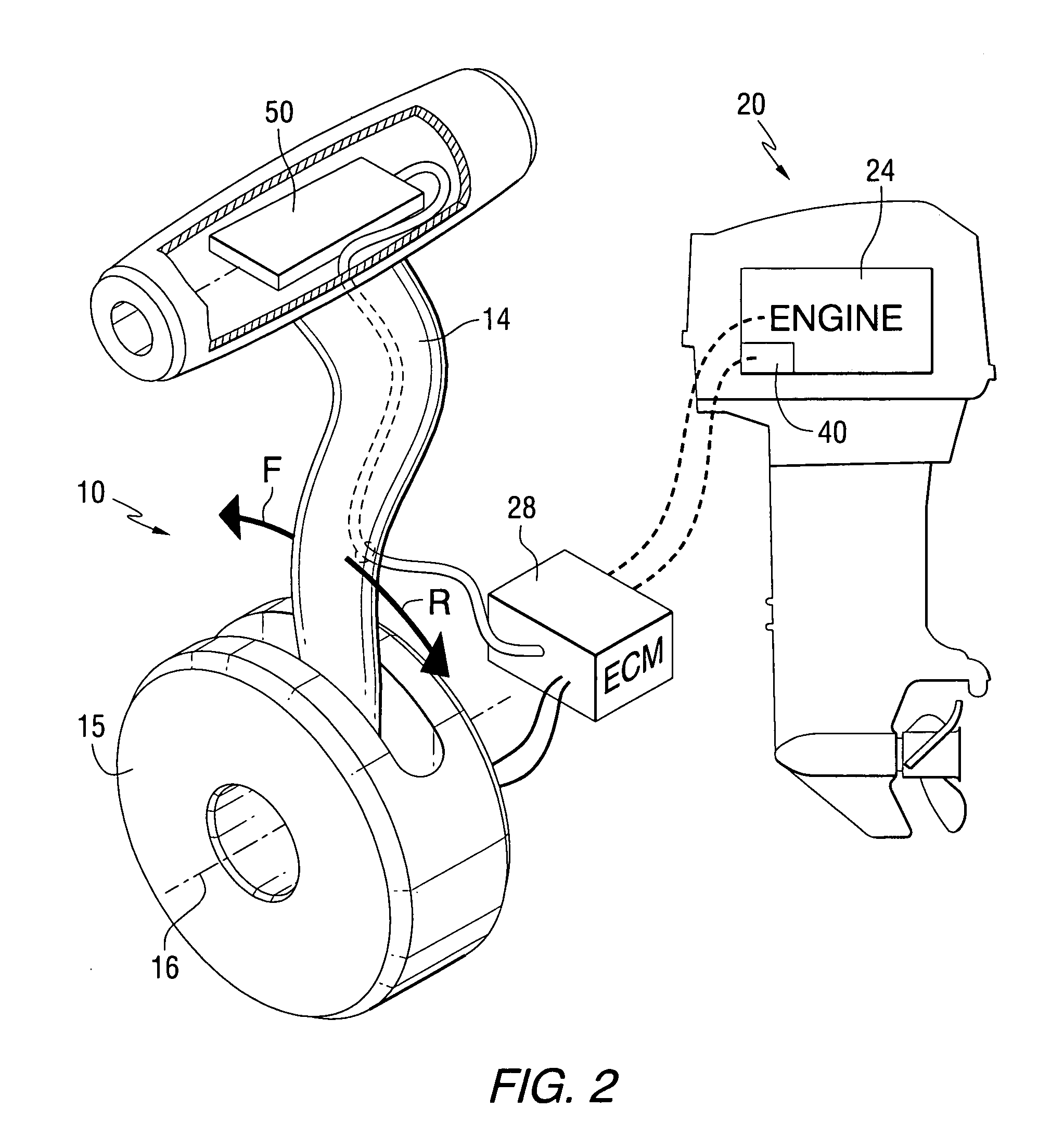

Throttle control mechanism with haptic feedback

A haptic throttle control mechanism includes a vibrating element that is connected in vibration transmitting relation with the control mechanism. The vibrating element can be a motor with an eccentric weight attached to its shaft or a piezoceramic component. The vibrating signal can be used to provide information to the operator of the marine vessel relating to the actual operating speed of the engine or, alternatively, it can be used to alert the operator of an alarm condition.

Owner:BRUNSWICK CORPORATION

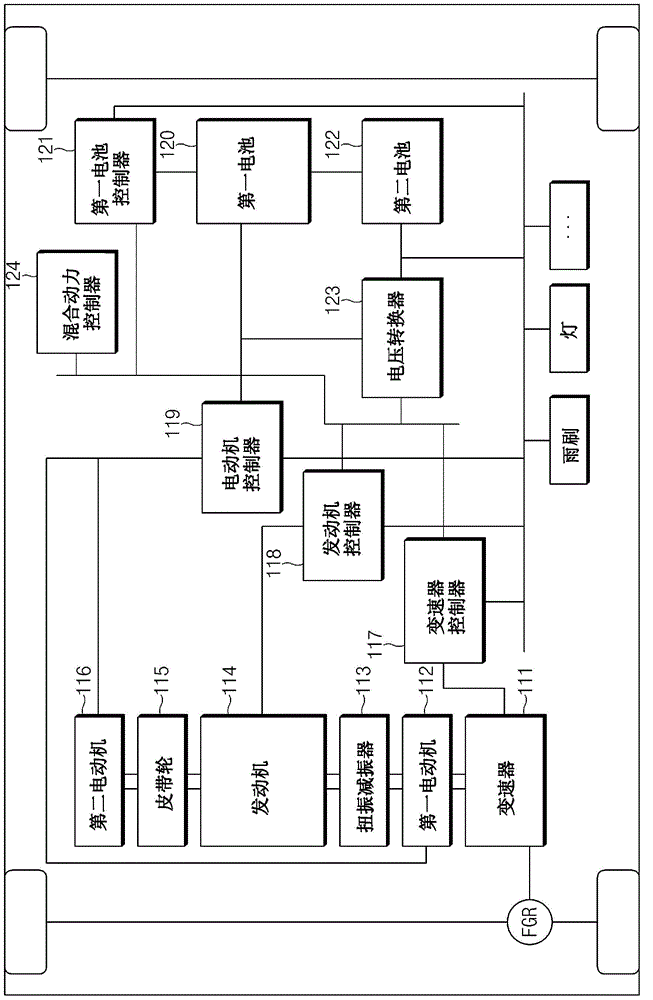

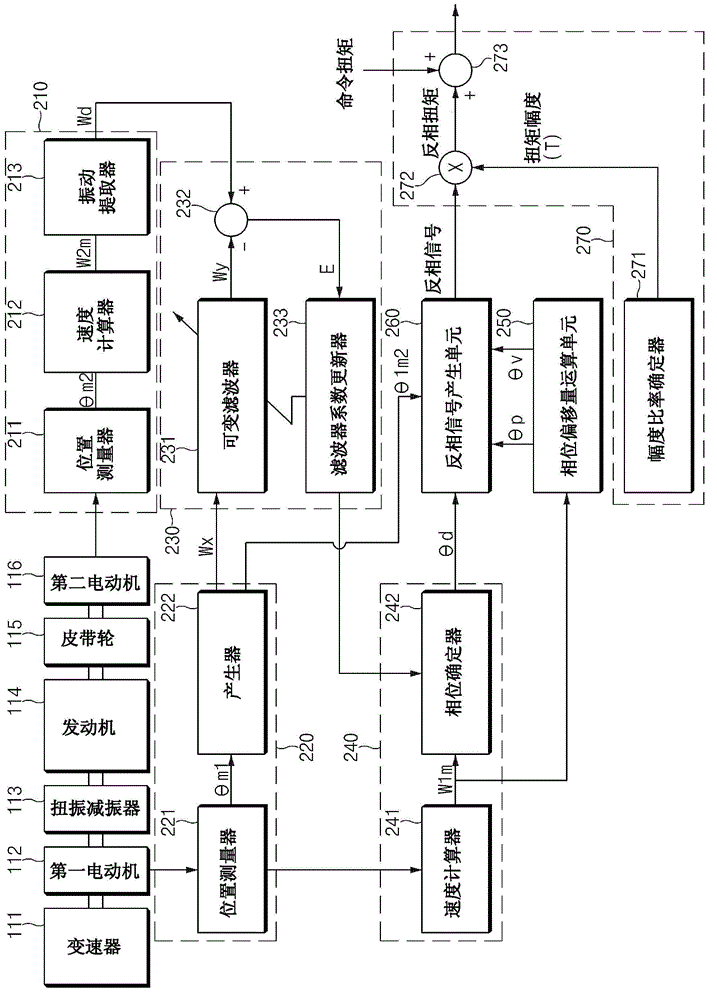

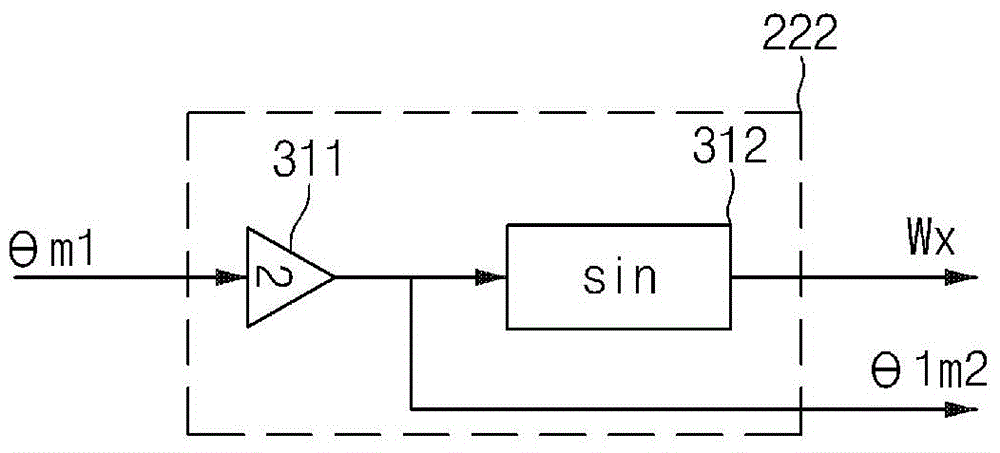

Active vibration reduction control apparatus and method of hybrid vehicle

An active vibration reduction control apparatus and method of a hybrid vehicle are provided to generate a reference signal of a first motor that corresponds a vibration signal extracted from a second motor. An amplitude and phase of the reference signal is adjusted based on frequency characteristic of a drive system transfer function to generate vibration reduction torque of a first motor within the hybrid vehicle. The first motor, a torsional damper, an engine, a connector (a belt-pulley, a chain, a gear, and so on), and the second motor are sequentially connected within the hybrid vehicle.

Owner:HYUNDAI MOTOR CO LTD +1

Optical fibre grating accelerometer based on cantilever beam deflection

InactiveCN101285846AHigh sensitivityLarge strainTelevision system detailsImpedence networksCantilevered beamAccelerometer

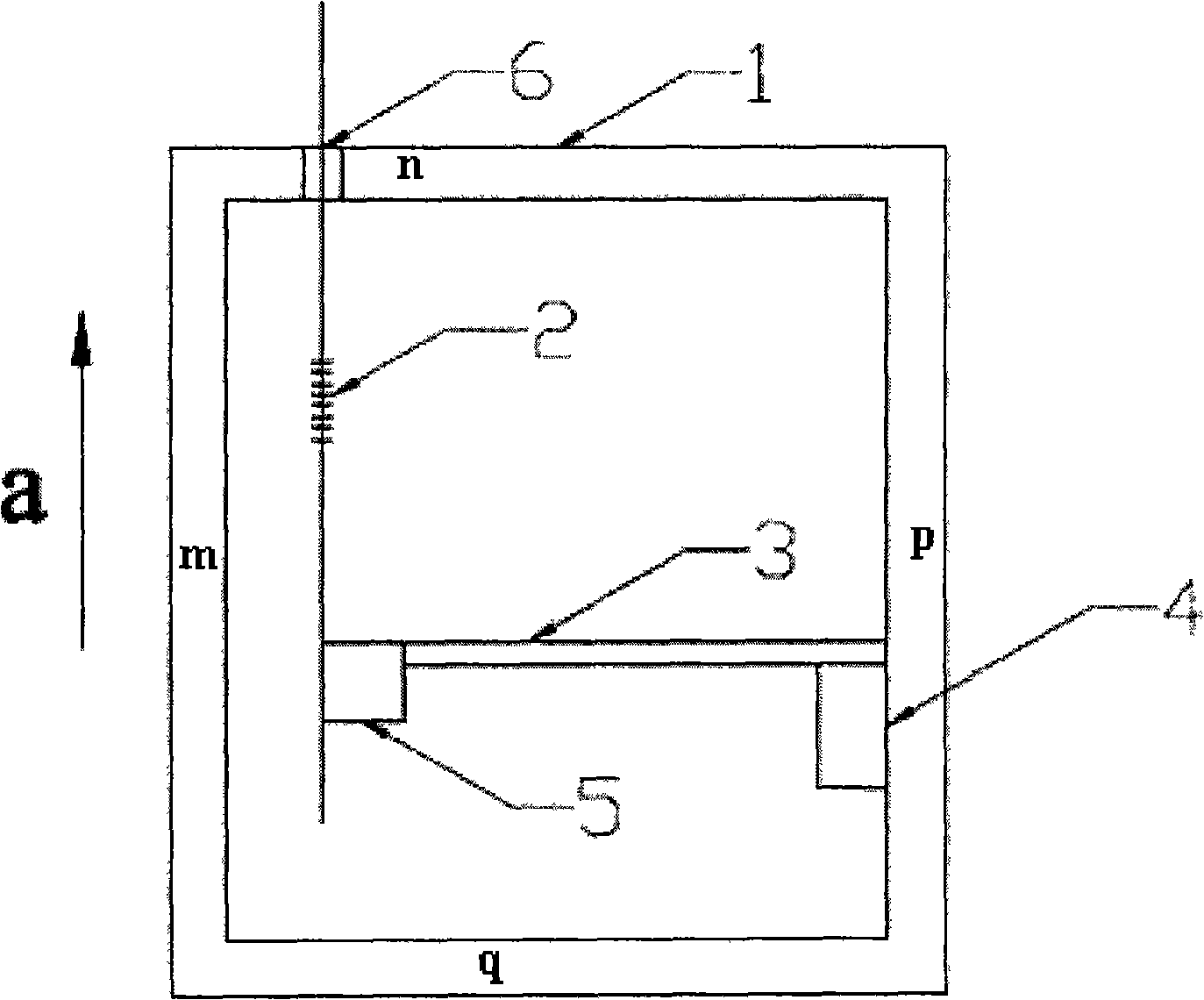

The invention relates to the optical fiber sensor technical field, disclosing an optical fiber grating accelerometer based on cantilever beam deflection. The accelerometer comprises an outer casing 1 used as a support structure of the accelerometer, an optical fiber grating 2 used to measure acceleration, a cantilever beam 3 with one end horizontally fixed on the third sidewall p of the accelerometer and a mass block 5 fixed at the other end of the cantilever beam 3, wherein the outer casing 1 has a first sidewall m, a second sidewall n, a third sidewall p and a fourth sidewall q; one end of the optical fiber grating 2 is fixed with the mass block 5, while the other end is parallel to the first sidewall m and passes through the hole 6 on the second sidewall n of the accelerometer to extend outside the accelerometer; the cantilever beam 3 is used to send vibration signal to the optical fiber grating 2; and the mass block 5 is used to adjust the sensitivity and the natural vibration frequency of the accelerometer. The optical fiber grating accelerometer increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

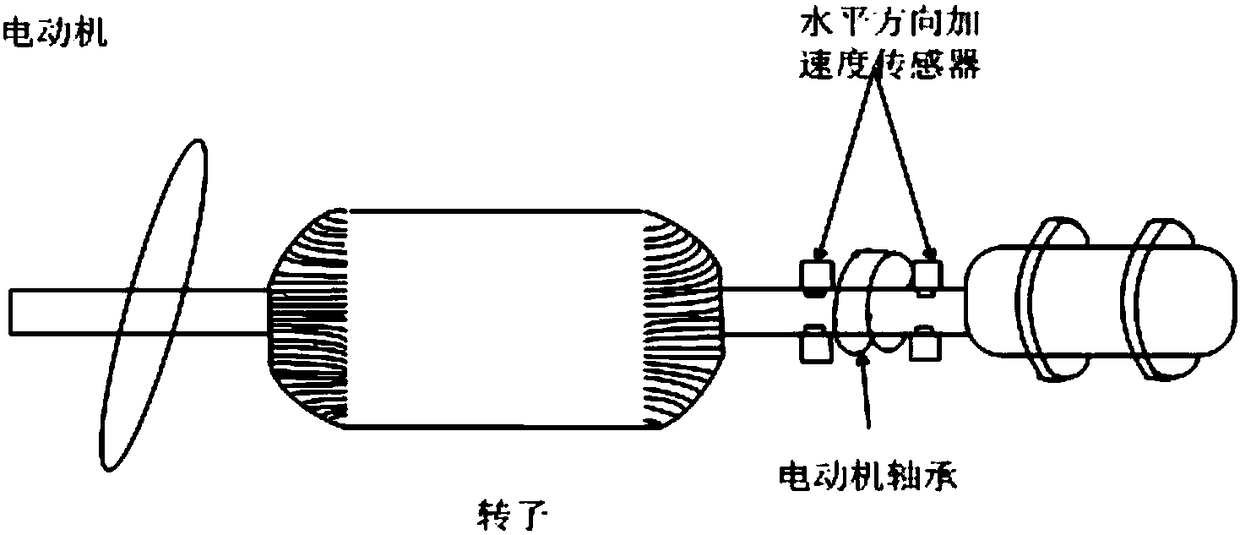

Robot vibration suppression method based on acceleration sensor

ActiveCN107433589AHigh precisionReduce the difficulty of implementationProgramme-controlled manipulatorTime lagVibratory signal

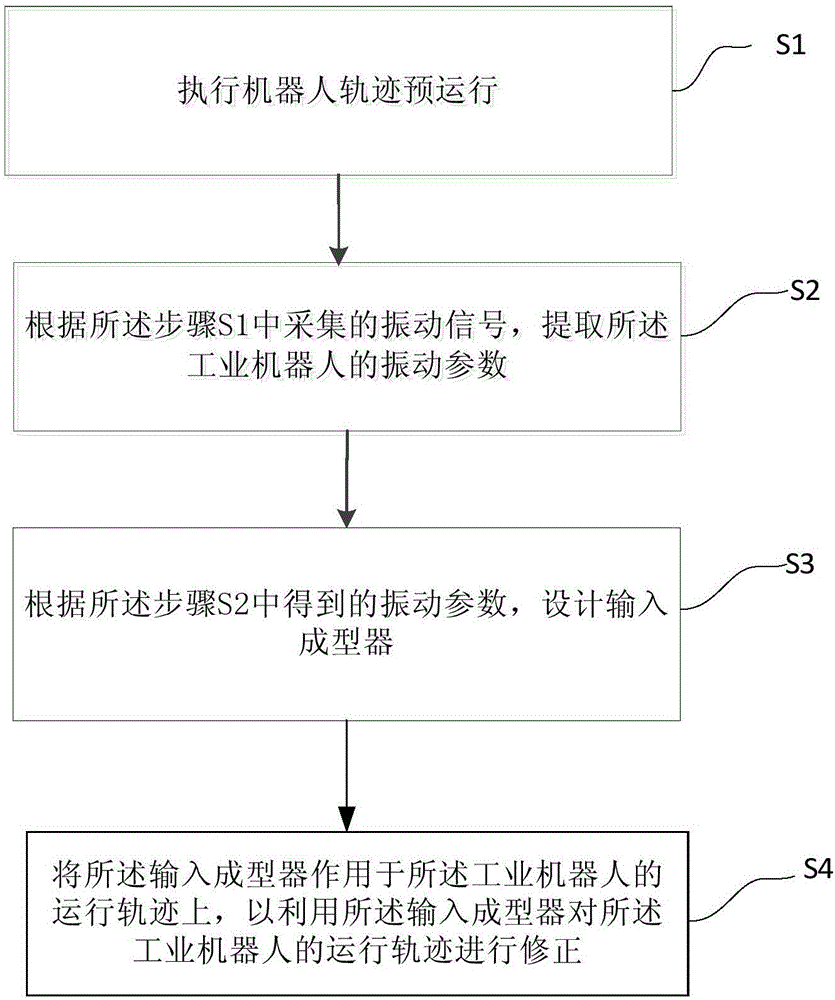

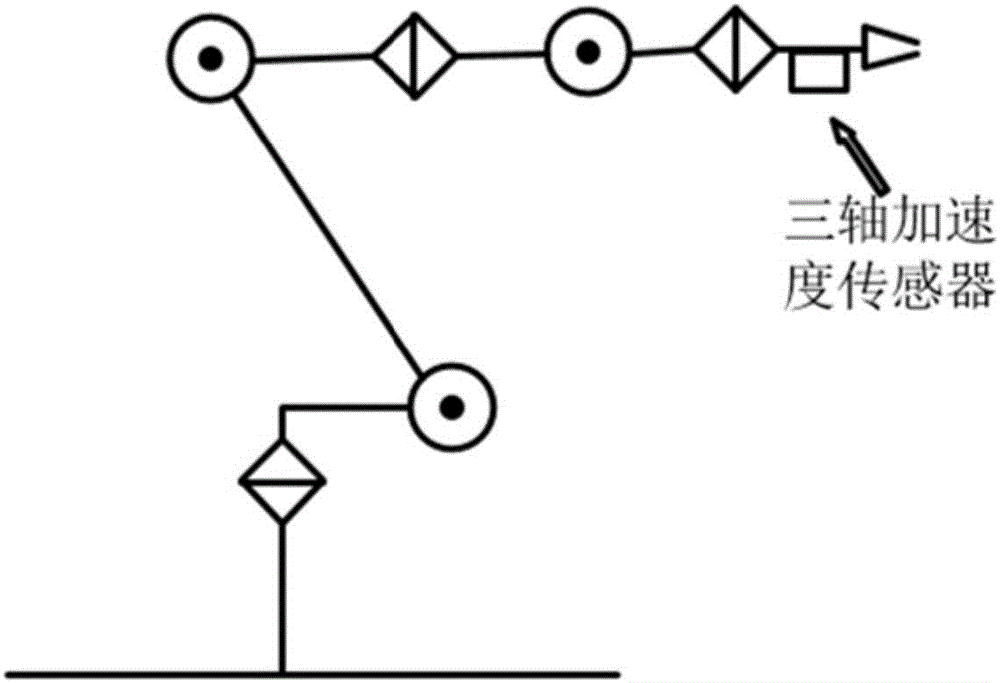

The invention provides a robot vibration suppression method based on an acceleration sensor. The robot vibration suppression method comprises the steps that robot track pre-operation is executed, specifically, the three-shaft acceleration sensor is mounted at the tail end of a robot, and vibration signals in three directions in the mounting position during pre-operation of the robot are collected; vibration parameters of the industrial robot are extracted according to the collected vibration signals; an input forming device is designed according to the obtained vibration parameters; and the input forming device acts on the operation track of the industrial robot so as to correct the operation track of the industrial robot through the input forming device. Through the method of applying input shaping to the industrial robot, the problems that input shaping parameters are difficult to obtain, and shafts move asynchronously due to the input shaping time lag are solved, vibration of the industrial robot can be suppressed, and track precision and positioning precision are improved.

Owner:ROKAE SHANDONG INTELLIGENT TECH CO LTD

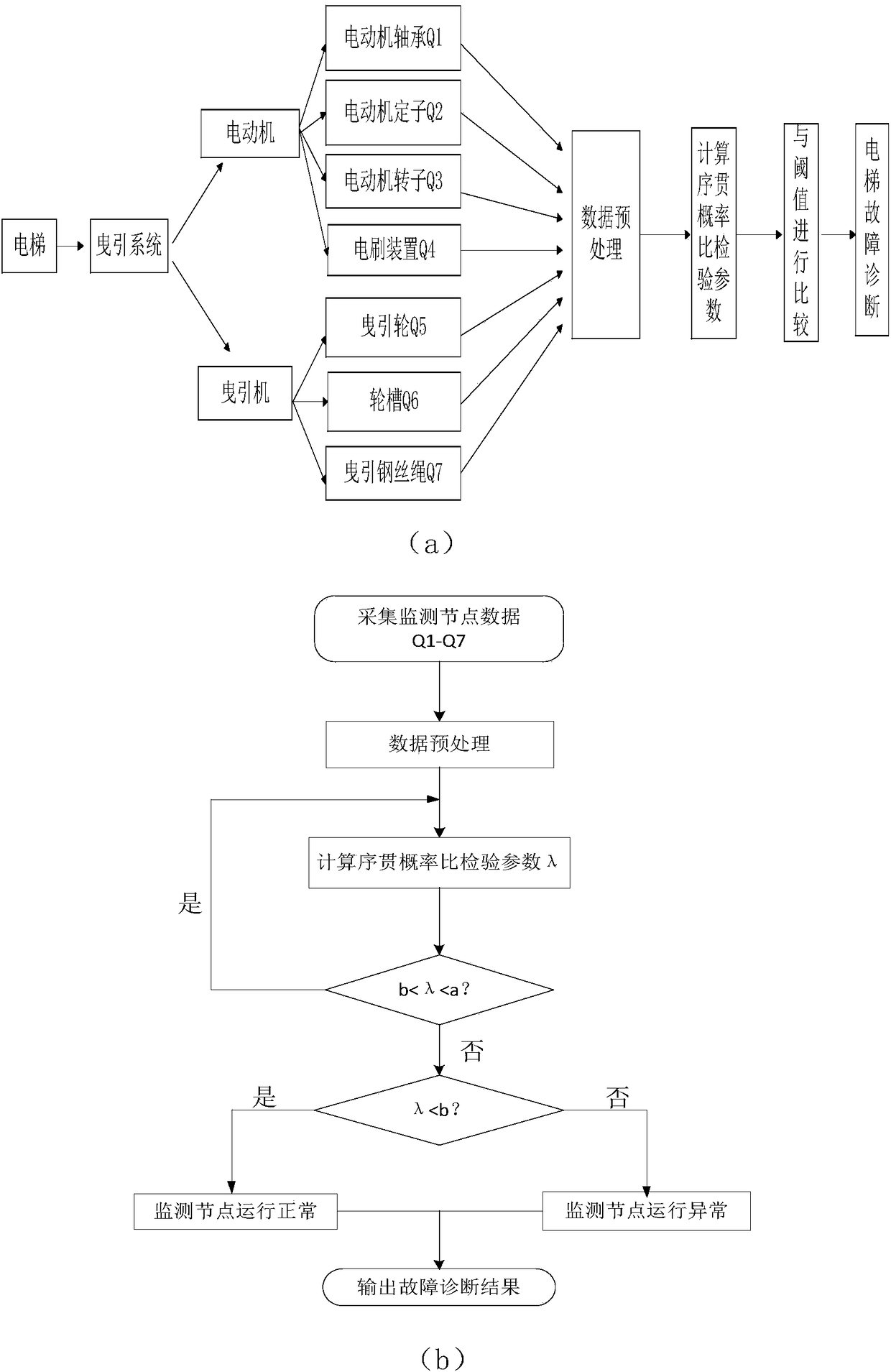

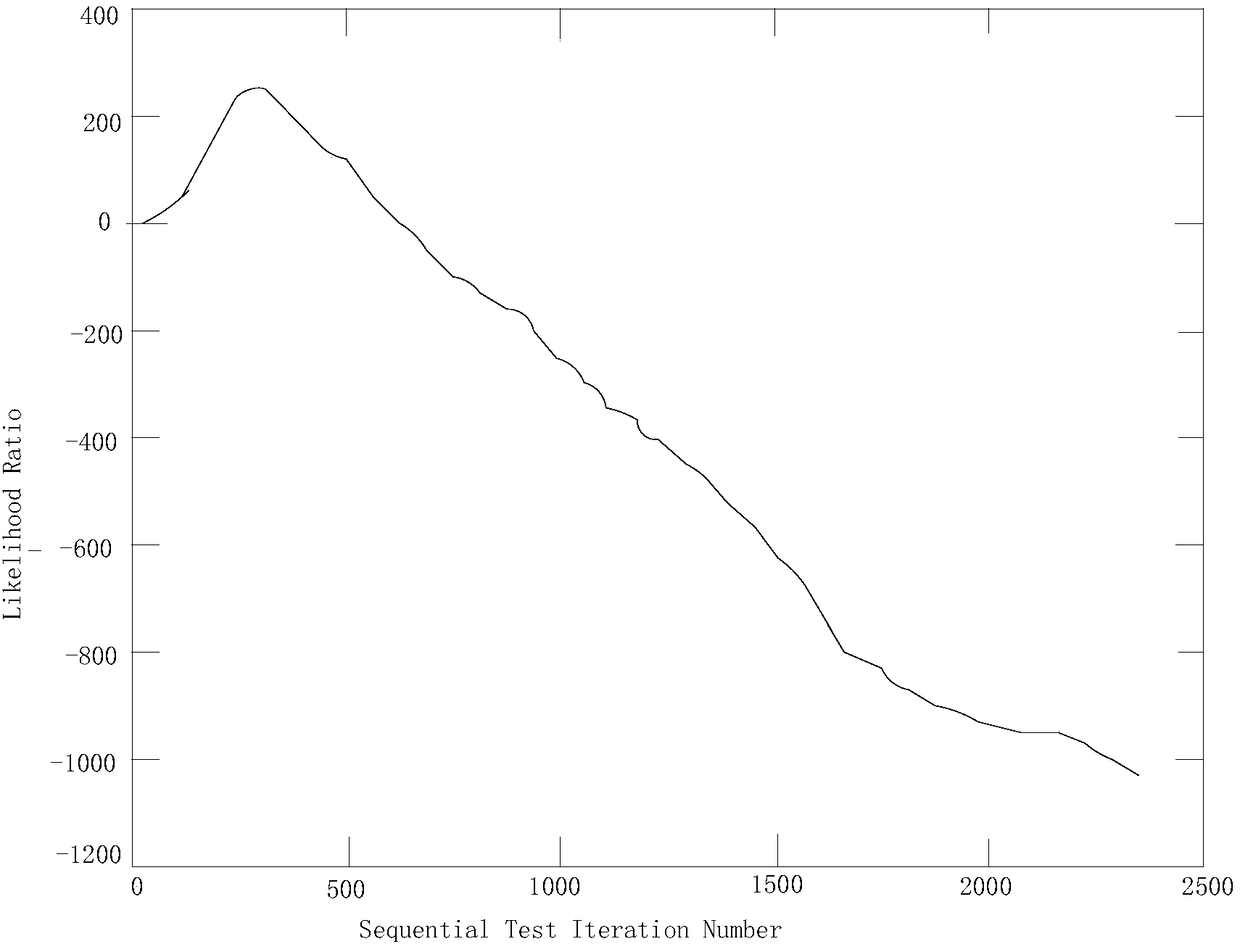

Escalator fault diagnosis method based on sequential probability

ActiveCN108069308AReduce noiseImprove signal-to-noise ratioDesign optimisation/simulationElevatorsVibratory signalDiagnosis methods

The invention discloses an escalator fault diagnosis method based on the sequential probability. The escalator fault diagnosis method based on the sequential probability comprises the steps that vibration signals of key components of an escalator are collected through accelerator sensors mounted on the components of the escalator in vertical direction and the horizontal direction; the vibration signals are treated, and the peak values of the processed signals are used for characteristic values, namely indicator data of the actual operating state of the escalator; the indicator data are calculated through a sequential probability ratio algorithm to obtain a likelihood ratio; and the likelihood ratio is compared with the threshold value of a monitoring node, and fault diagnosis of an escalator mechanical system is conducted. According to the escalator fault diagnosis method based on the sequential probability, a wavelet packet algorithm is used for achieving smoothening and noise reduction of escalator data at different frequencies; and for the escalator in different operating states, the characteristic parameters are calculated through the sequential probability ratio algorithm, andthus differences caused by different operating states of the escalator are eliminated. In the detection process, the number of samples used for diagnosis does not need to be preset, the influence ofsample deficiencies or sample redundancy on the diagnosis result is avoided, the checking efficiency and accuracy are improved, and safety operation of the escalator is ensured.

Owner:JINAN UNIVERSITY

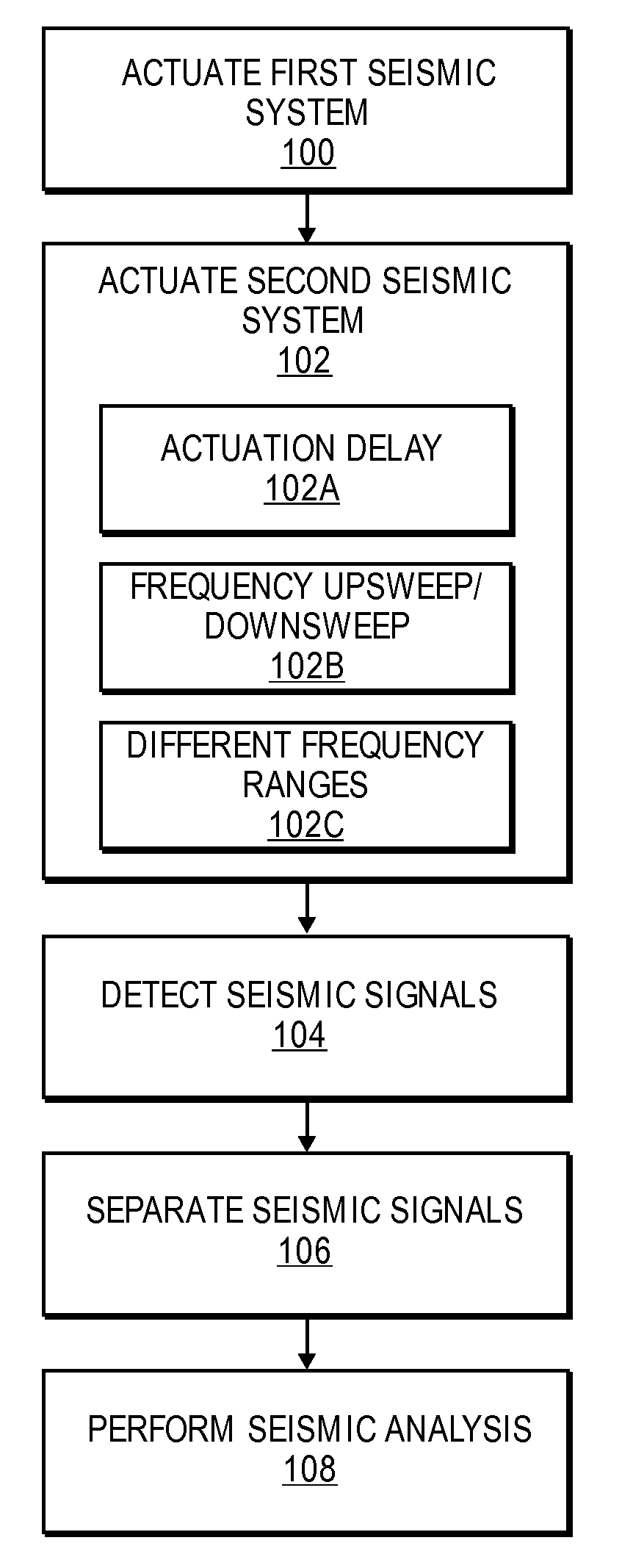

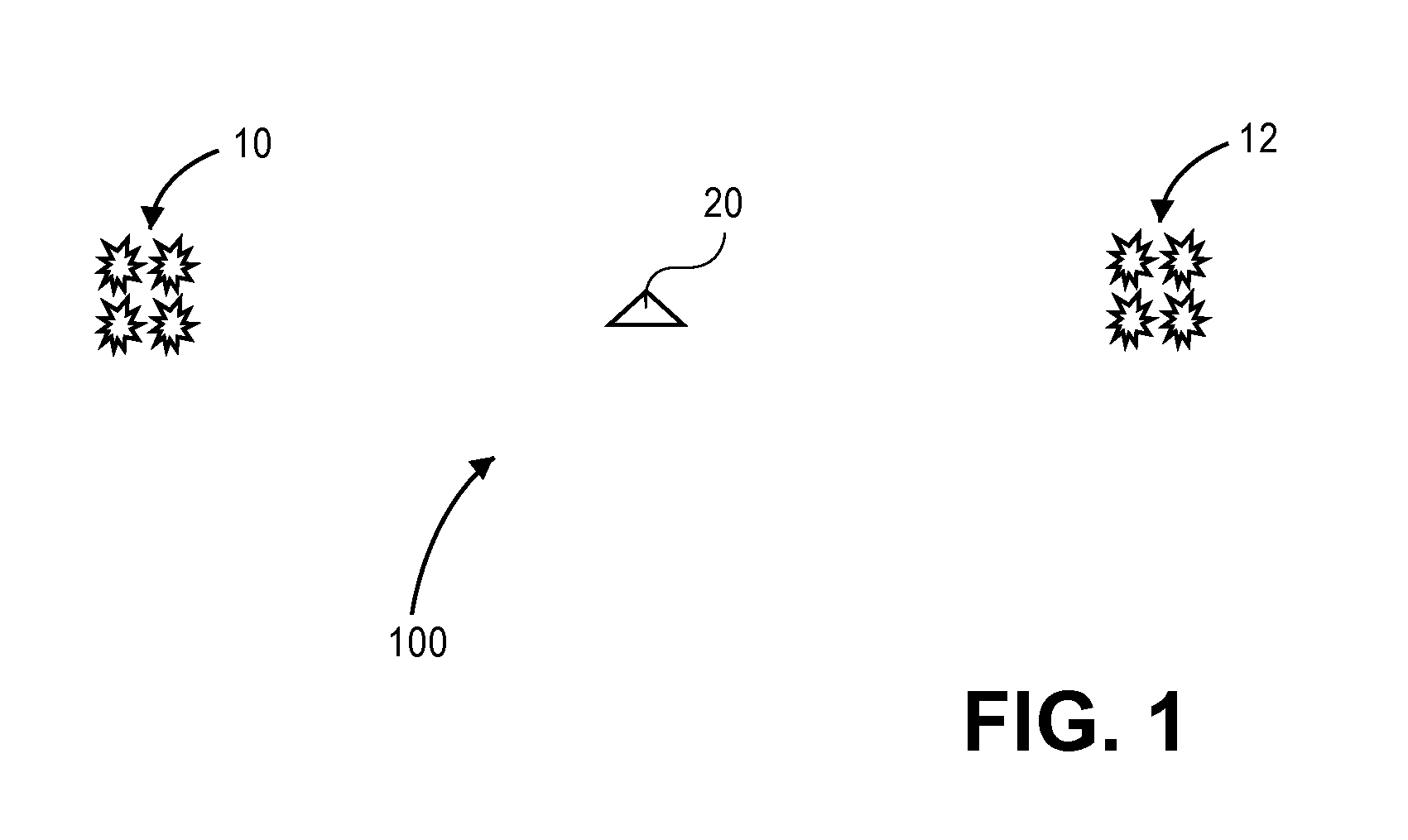

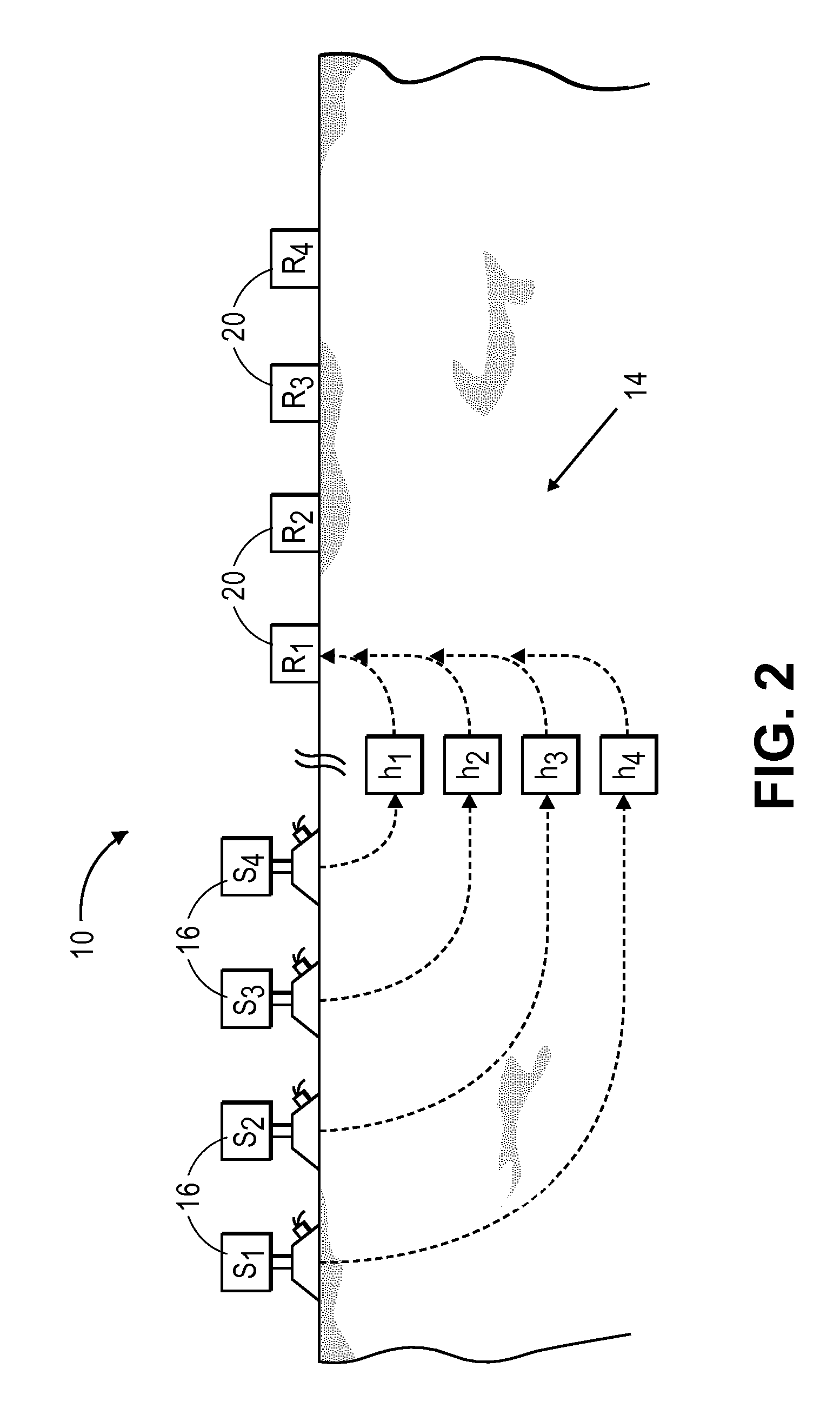

Method and apparatus for minimizing interference between seismic systems

A method and apparatus for minimizing interference between seismic systems. The method may generally include: (a) actuating a plurality of first sources associated with a first seismic system to generate a first plurality of phase-encoded vibratory signals; (b) actuating a plurality of second sources associated with a second seismic system to generate a second plurality of phase-encoded vibratory signals that are at least partially frequency separated from the first plurality of phase-encoded vibratory signals generated in (a); and (c) detecting the first and second plurality of phase-encoded vibratory signals utilizing a first receiver positioned at a location remote from the first and second sources.

Owner:CONOCOPHILLIPS CO

Method for Real-Time Estimation of Engine Combustion Parameters from Vibratory Signals

InactiveUS20090030593A1Analogue computers for vehiclesInternal-combustion engine testingCombustionVibratory signal

The invention relates to a method having application to combustion control of an internal-combustion engine for real-time estimation of engine combustion parameters from vibratory signals. A vibratory signal representative of the engine vibrations is continuously acquired as a function of the crank angle, from a vibration detector. Real-time filtering of this vibratory signal and real-time estimation of the Fourier decomposition coefficients for the acquired vibratory signal is carried out by inverting the dynamics of the filter which is used. Finally, real-time estimation of combustion parameters allowing the combustion to be qualified is carried out from these coefficients.

Owner:INST FR DU PETROLE

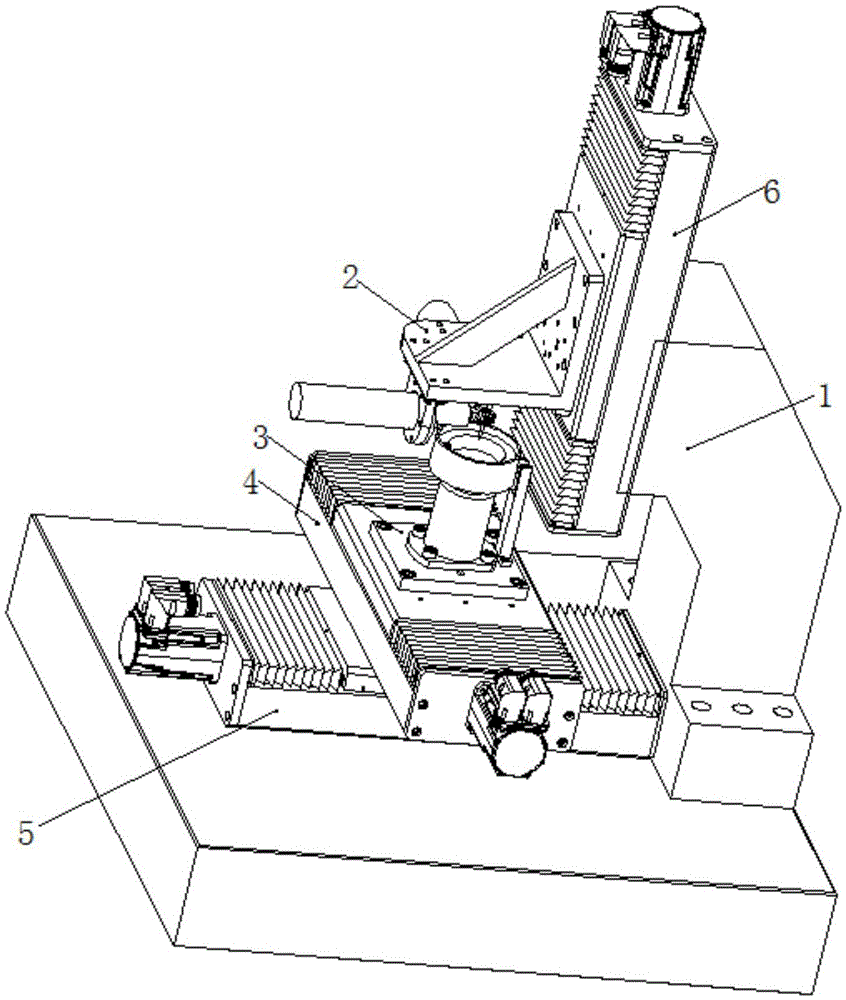

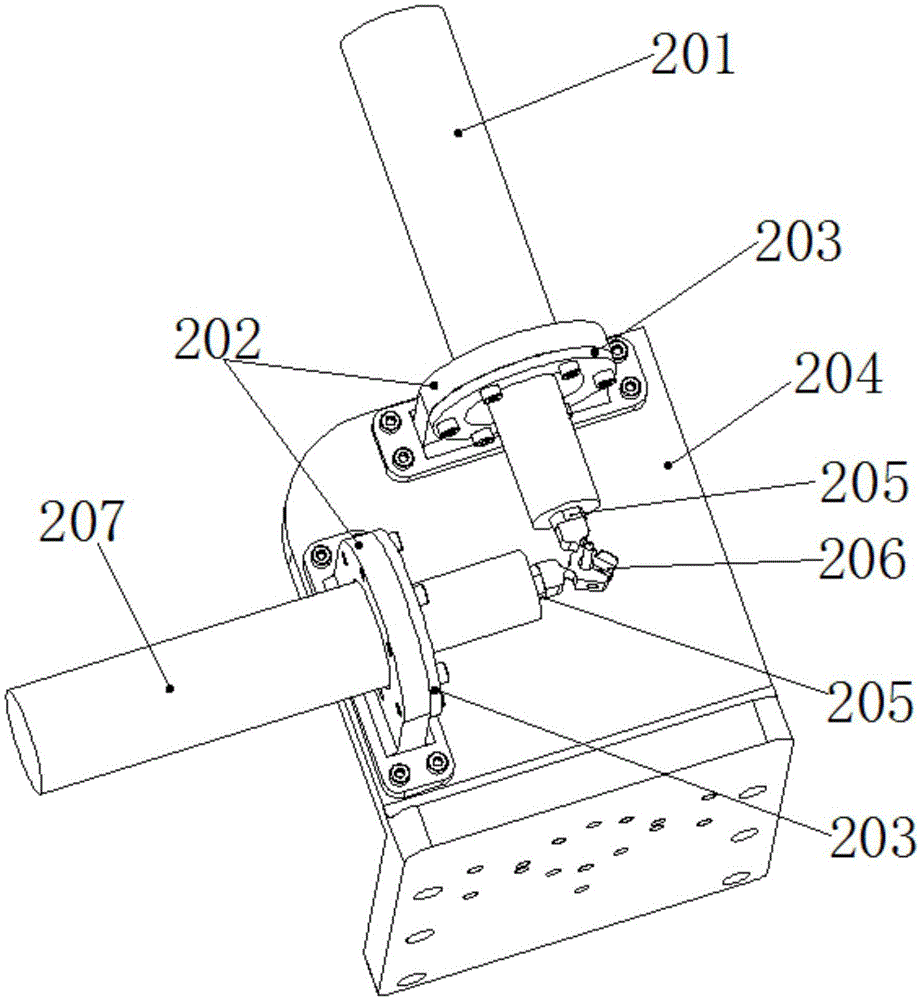

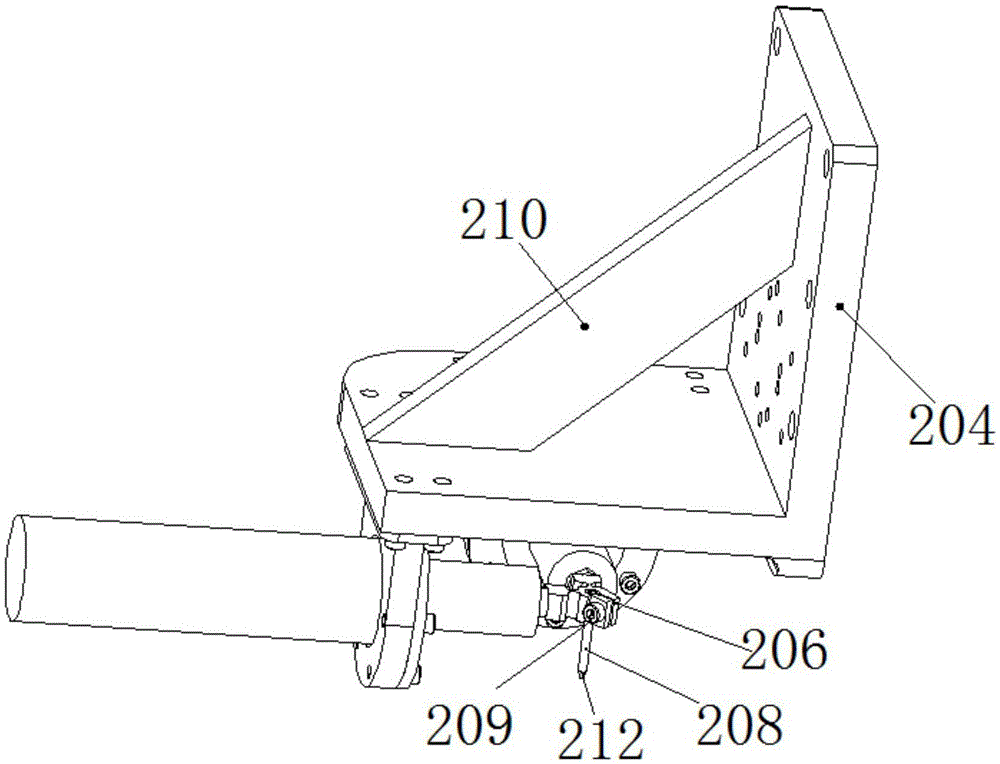

Two-dimensional ultrasonic vibration polishing device and method

InactiveCN105619187AIdeal Instantaneous Random Motion TrajectoryStrong profiling abilityVibratory signalEngineering

The invention relates to a two-dimensional ultrasonic vibration polishing device and a two-dimensional ultrasonic vibration polishing method, and belongs to the technical field of machine manufacturing. A two-dimensional ultrasonic vibration polishing tool is fastened to the z-axis of a machine tool by screws; a workpiece fixture is fastened to the x-axis of the machine tool by the screws; and the x-axis, the y-axis and the z-axis of the machine tool are fixedly connected with a machine tool main body after debugging. The two-dimensional ultrasonic vibration polishing device provides elliptical vibration in a polishing tangent plane, vibration signals of an x-direction ultrasonic vibrator and a y-direction ultrasonic vibrator are coupled to form two-dimensional vibration at a pivoting joint, and are output to a polishing head, the polishing head acquires a perfect instantaneous random motion track in a processing area, and motion composited by the vibration is polishing primary motion, so that a polishing force can be controlled to be stable on the premise that no polishing head rotates; the polishing head has high profile modeling capability, so that various complicated curved surfaces can be processed; deterministic polishing is realized; stable and uniform removal of a polishing material is realized; and high-efficiency and high-quality polishing can be realized simply by controlling the polishing force.

Owner:JILIN UNIV

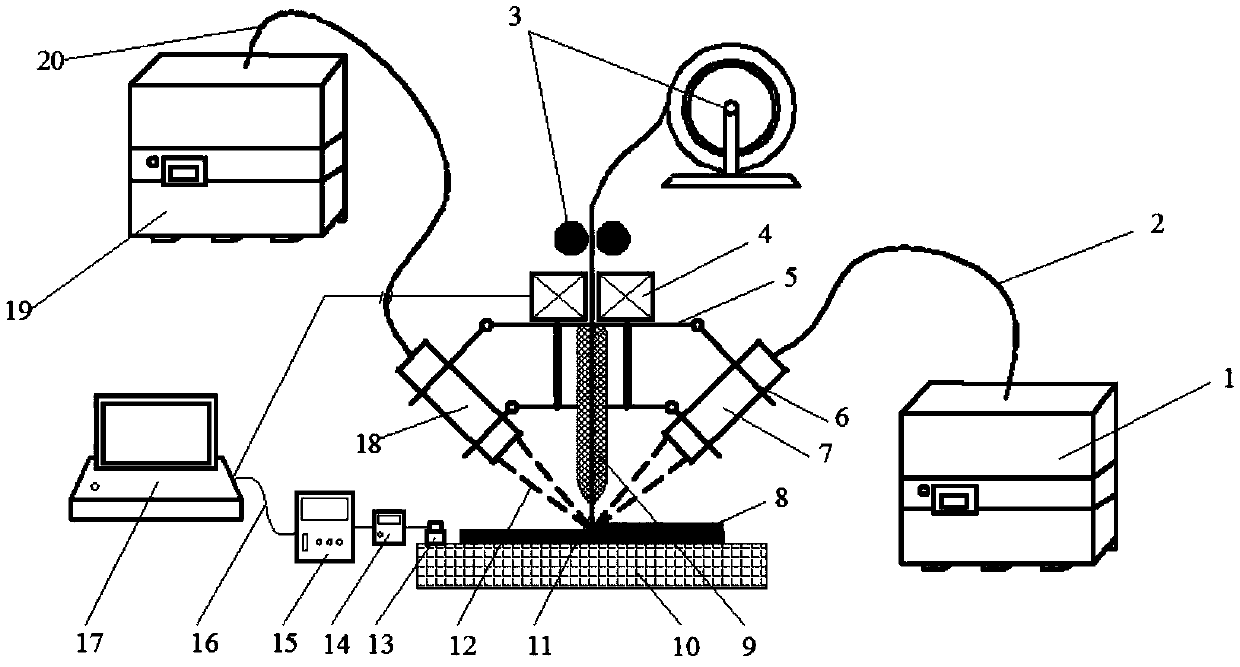

Ultrasonic-assisted multi-beam laser wire-melting type additive manufacturing equipment and method

ActiveCN109530919AIncrease flexibilityAvoid interferenceLaser beam welding apparatusFiberVibratory signal

The invention discloses ultrasonic-assisted multi-beam laser wire-melting type additive manufacturing equipment. The equipment comprises a laser device, a wire feeding mechanism, a base plate, a wireguide head, an electromagnetic ultrasonic generator, an electromagnetic ultrasonic probe, a controller and a protective gas protection box, wherein the laser device comprises a laser light source, anoptical fiber and a laser head, the laser light source is connected with the laser head through the optical fiber, the electromagnetic ultrasonic generator is arranged at an inlet of the wire guide head, the electromagnetic ultrasonic probe is arranged on the base plate, and is used for receiving a vibration signal of an accumulated body and transmitting the vibration signal to the controller so that monitoring of a droplet transfer state in the additive manufacturing process can be realized, and the base plate, the wire guide head, the electromagnetic ultrasonic generator and the electromagnetic ultrasonic probe are all located in the protective gas protection box. According to the equipment, the flexibility of the additive manufacturing process can be greatly improved so that the accumulated layers are not prone to collapse, then the mechanical property of the accumulated body can be improved, the deformation can be inhibited, and the speed of the additive process can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

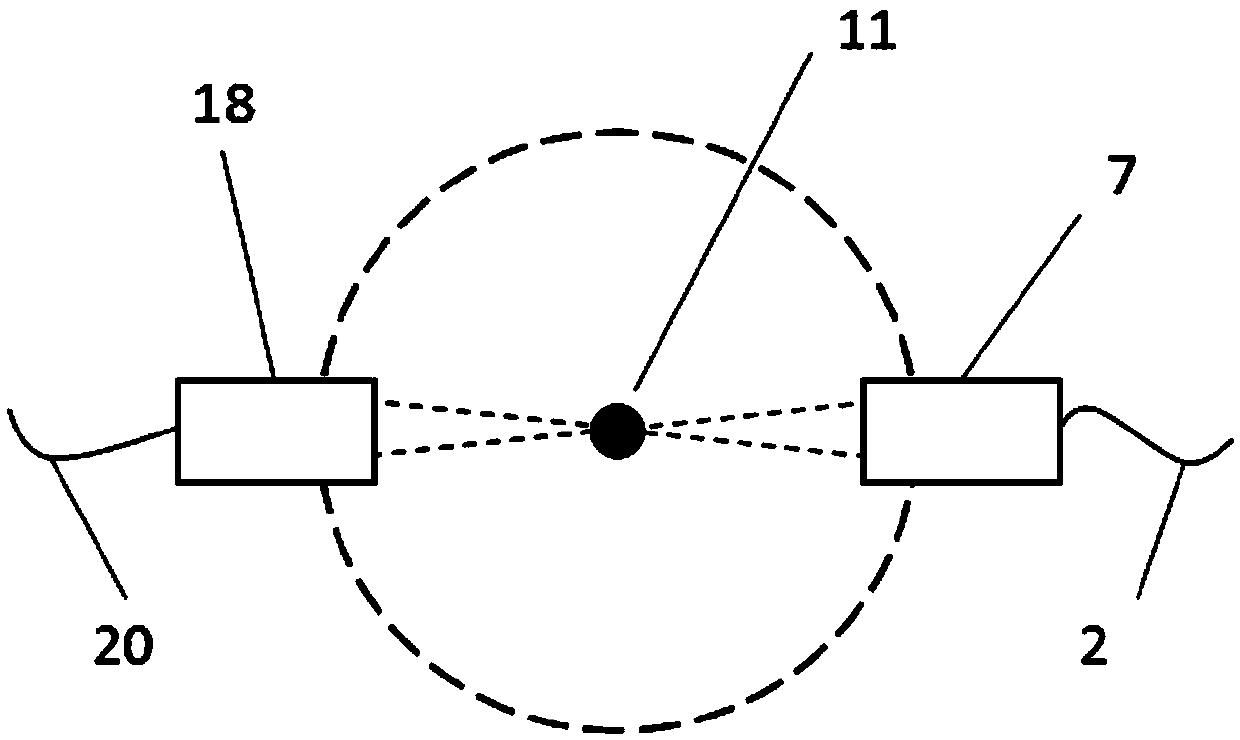

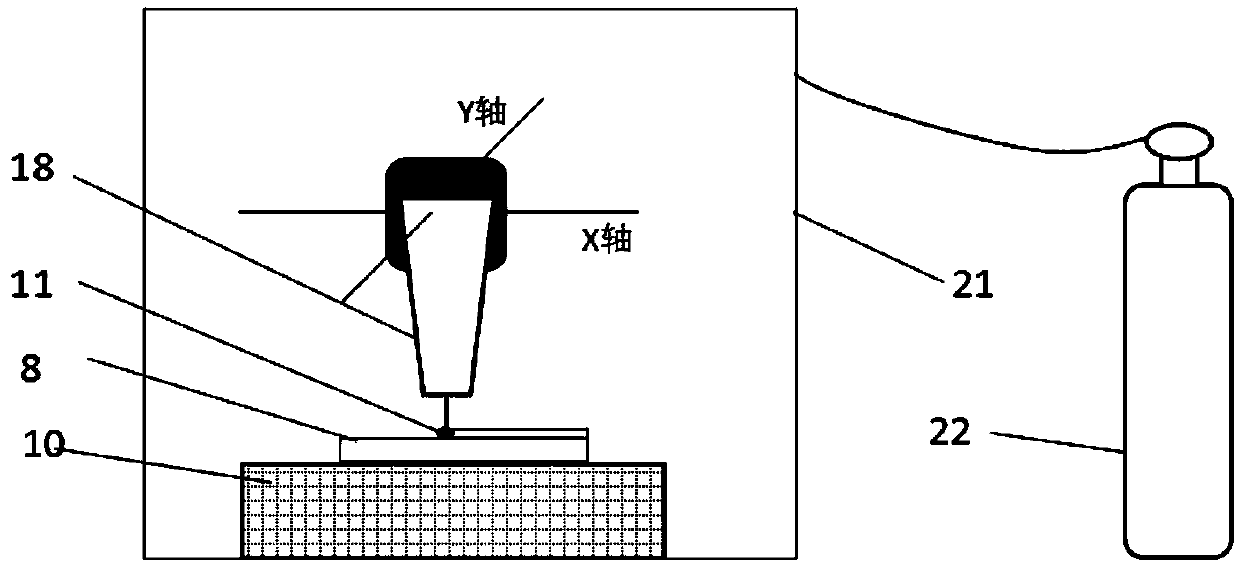

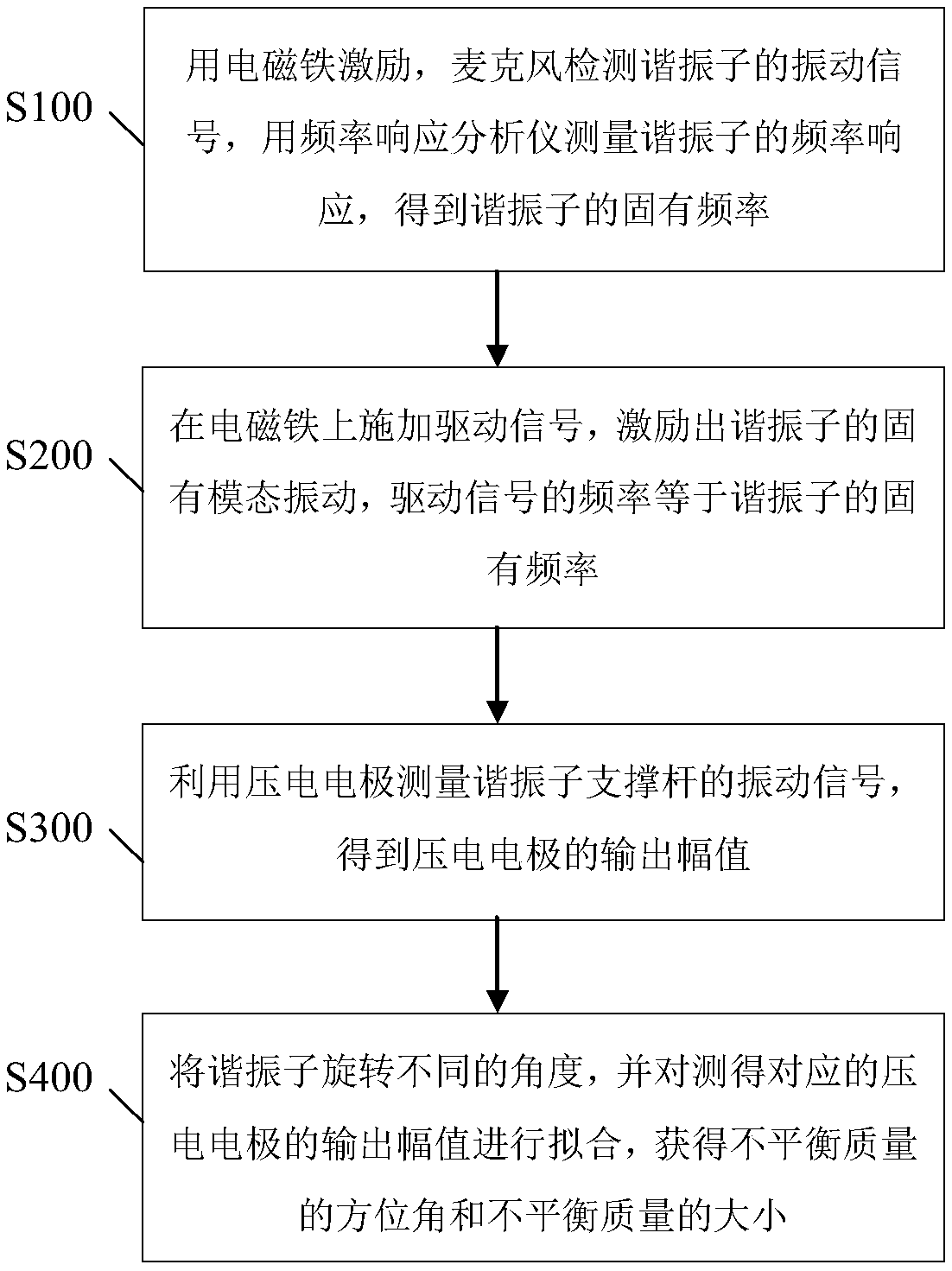

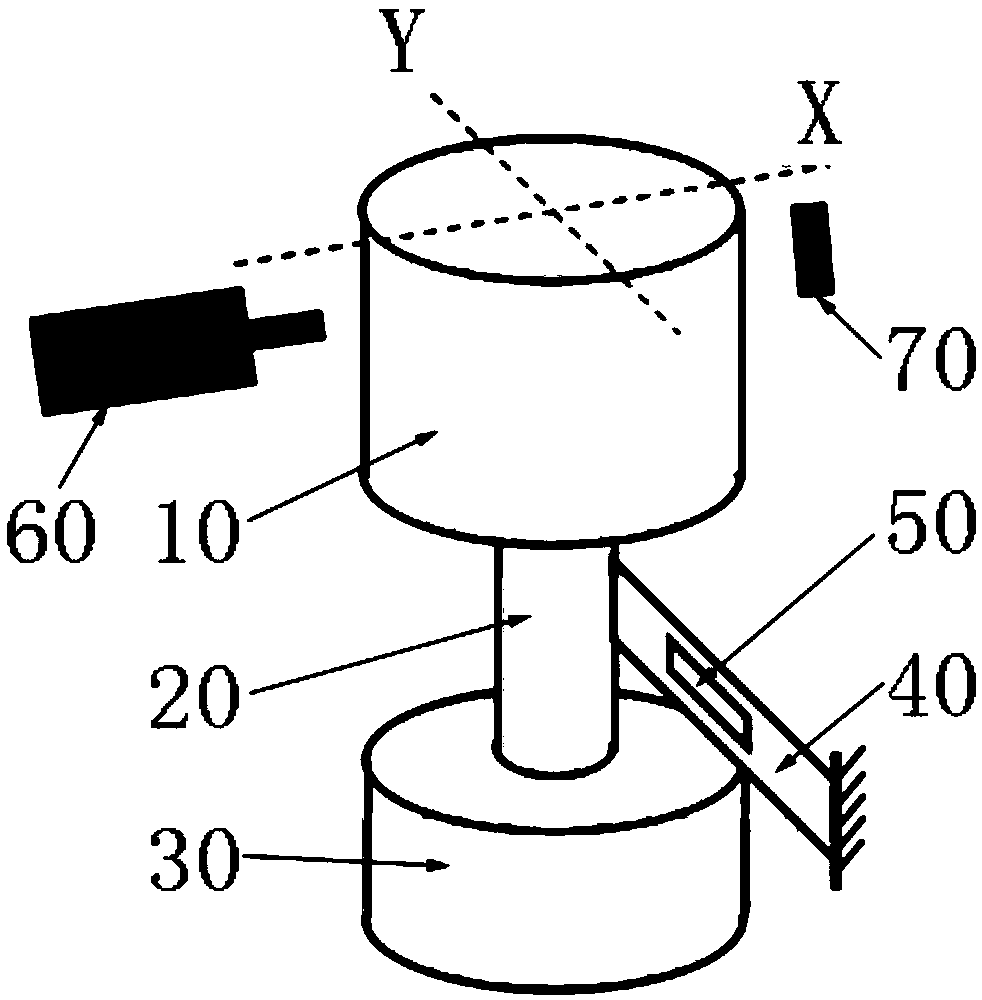

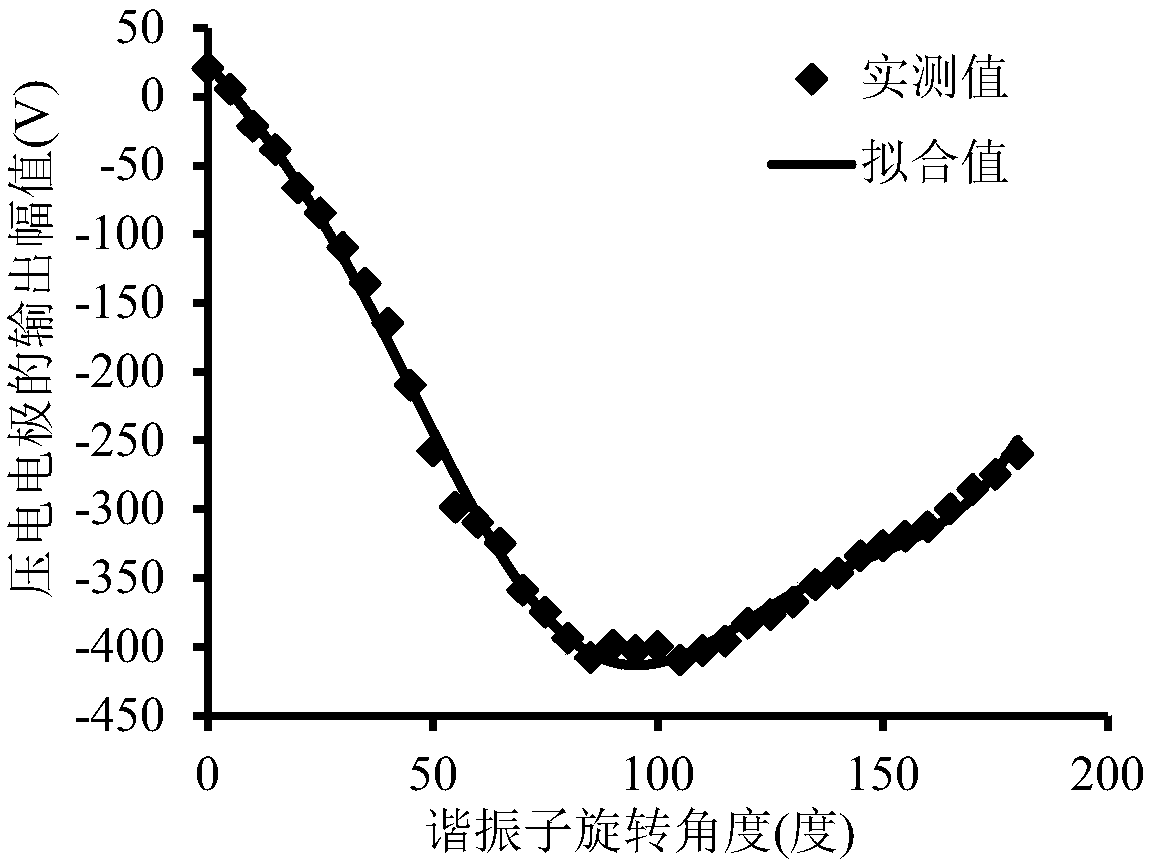

Determination method and system for unbalance mass of cylindrical shell gyroscope harmonic oscillator

ActiveCN108844555AImprove discriminationLow costSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeVibratory signal

The invention discloses a determination method and system for the unbalance mass of a cylindrical shell gyroscope harmonic oscillator. The method comprises the following steps: A, applying a driving signal to an electromagnet to excite the natural mode of vibration of oscillator, wherein the frequency of the driving signal is equal to the inherent frequency of the oscillator; B, measuring a vibrating signal of an oscillator supporting rod by means of an piezoelectric electrode to obtain an output amplitude of the piezoelectric electrode; and C, rotating the vibrator at different angles, and fitting the output amplitude of the corresponding piezoelectric electrode to obtain an azimuth angle of the unbalance mass and the amplitude of the unbalance mass. By exciting the natural mode of vibration of oscillator, the vibrating amplitude of the supporting rod at different angles is measured, and fitting analysis is performed on the measured data, so that the azimuth of the unbalance mass andthe amplitude of the unbalance mass can be judged conveniently and rapidly, and the cost is extremely low.

Owner:NAT UNIV OF DEFENSE TECH

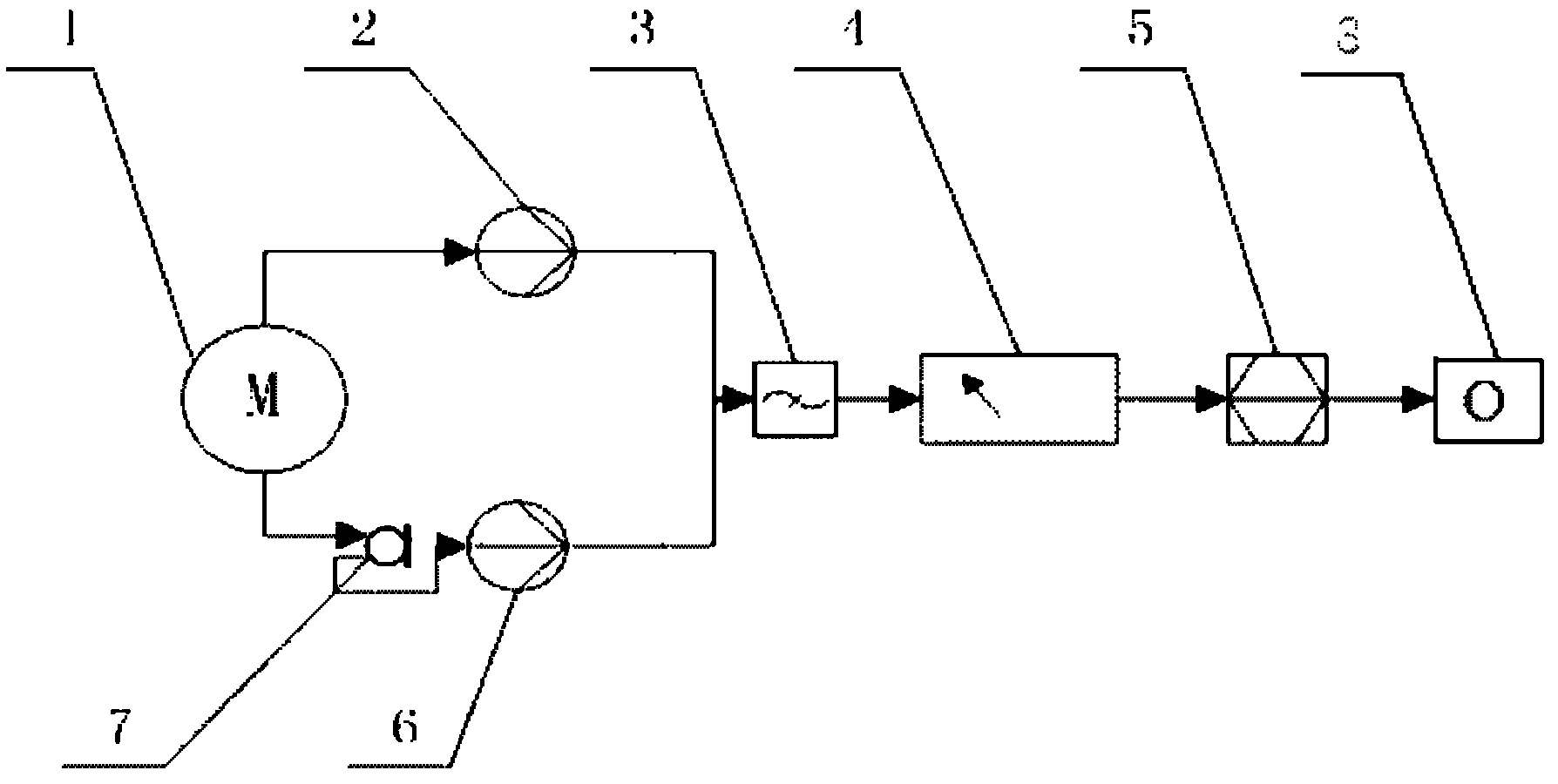

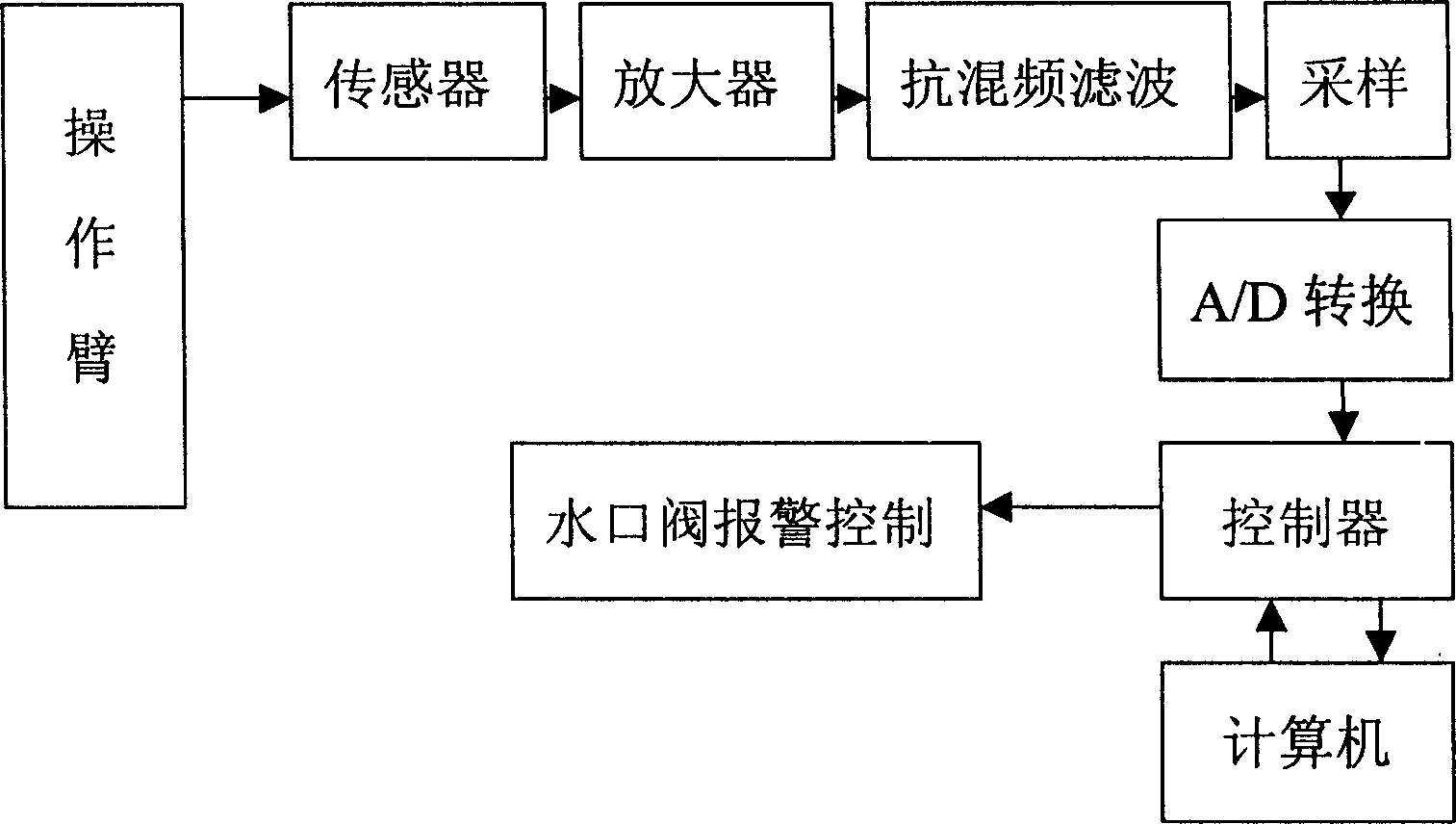

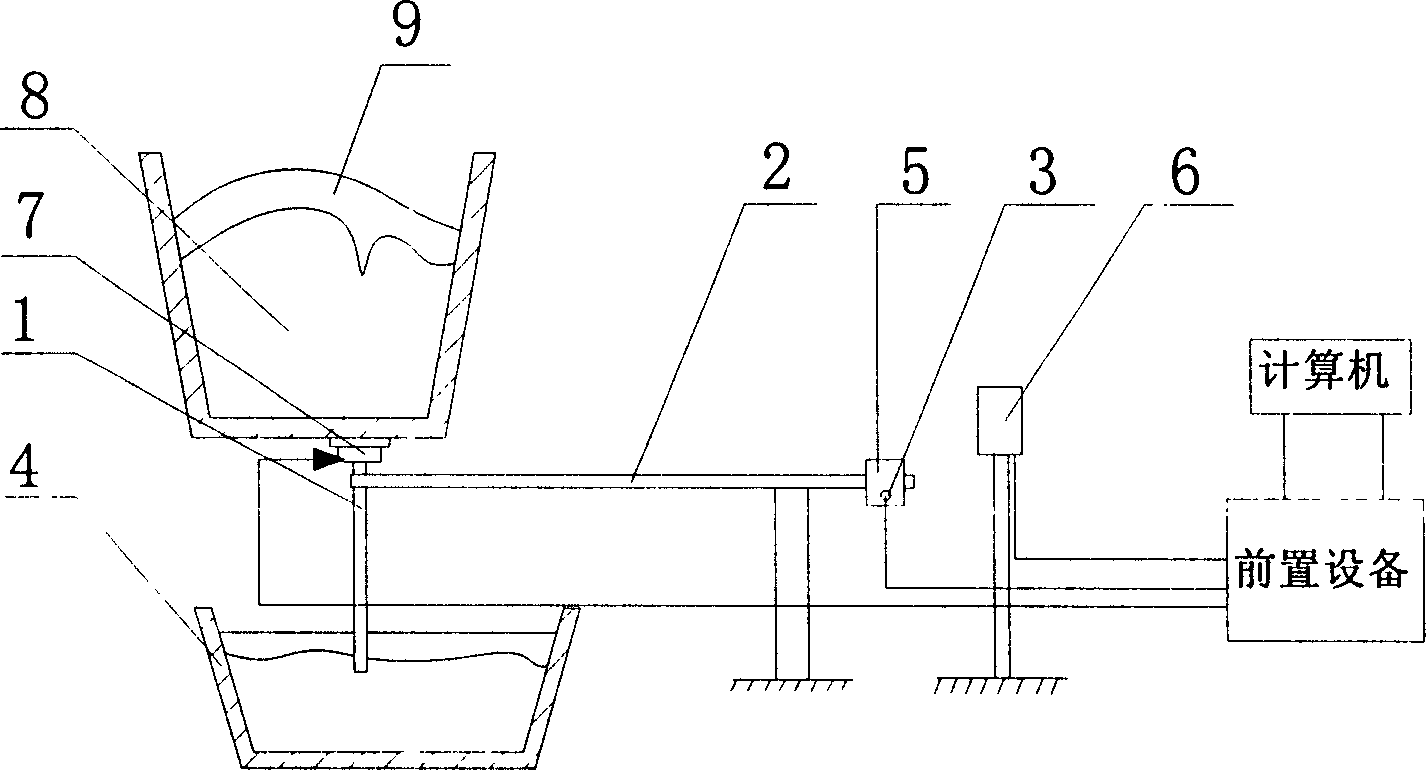

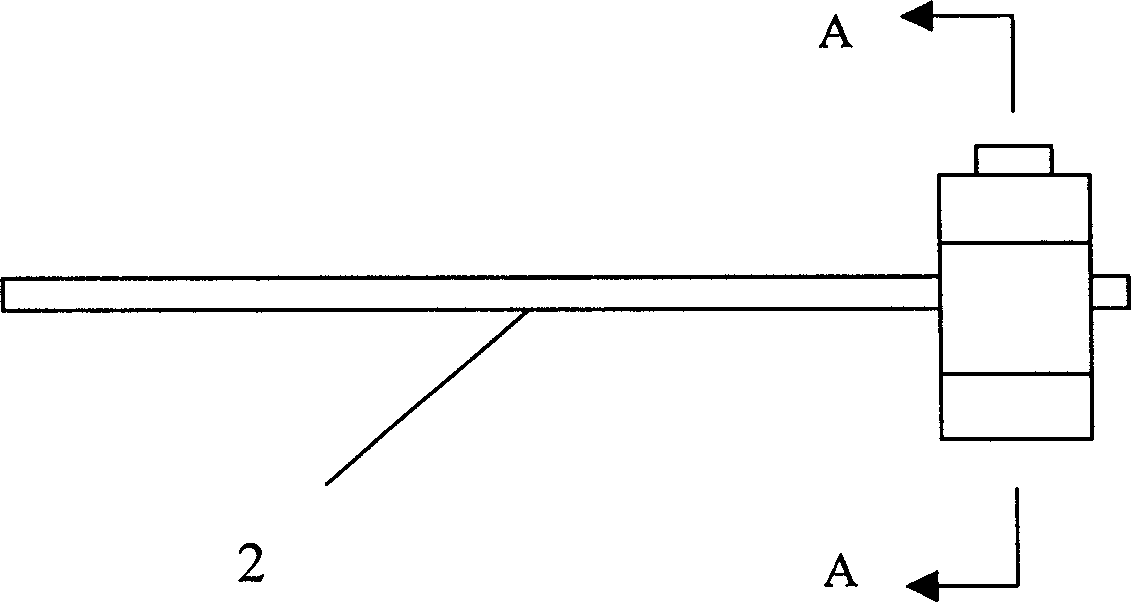

Continuous casting roughing slag inspection method and device based on vibration monitoring

InactiveCN1701877AAccurate and effective captureSolve the problem that the opening cannot be adjustedVibratory signalSlag

This invention relates to continuous casting dross detection method and device based on vibration detection. On section if the end of motion arm far away the long nozzle, assemble multiple vibration sensors with different directions to collect vibration signals of different directions; form sampled signal after amplifying, filtering, sampling and A / D transform; take off-line process for the ,mass collected signals to form norm eigen vector; use effective vector quantization algorithm to train codebook corresponding to all states used as codebook KB of all casting states when recognizing on line; by wavelet analysis method, obtain eigen vector of sampled signals; through the search and calculation for code word, decide which codebook that current state belongs to and give dross information. The advantage of this invention is that it needs just to set multiple vibration sensors on motion arm and treat the signal real time, and needs no other auxiliary device.

Owner:杭州谱诚泰迪实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com