Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126 results about "Vibration signal analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frequency analysis is the most commonly used method for analyzing a vibration signal. The most basic type of frequency analysis is an FFT, or Fast Fourier Transform, which converts a signal from the time domain into the frequency domain.

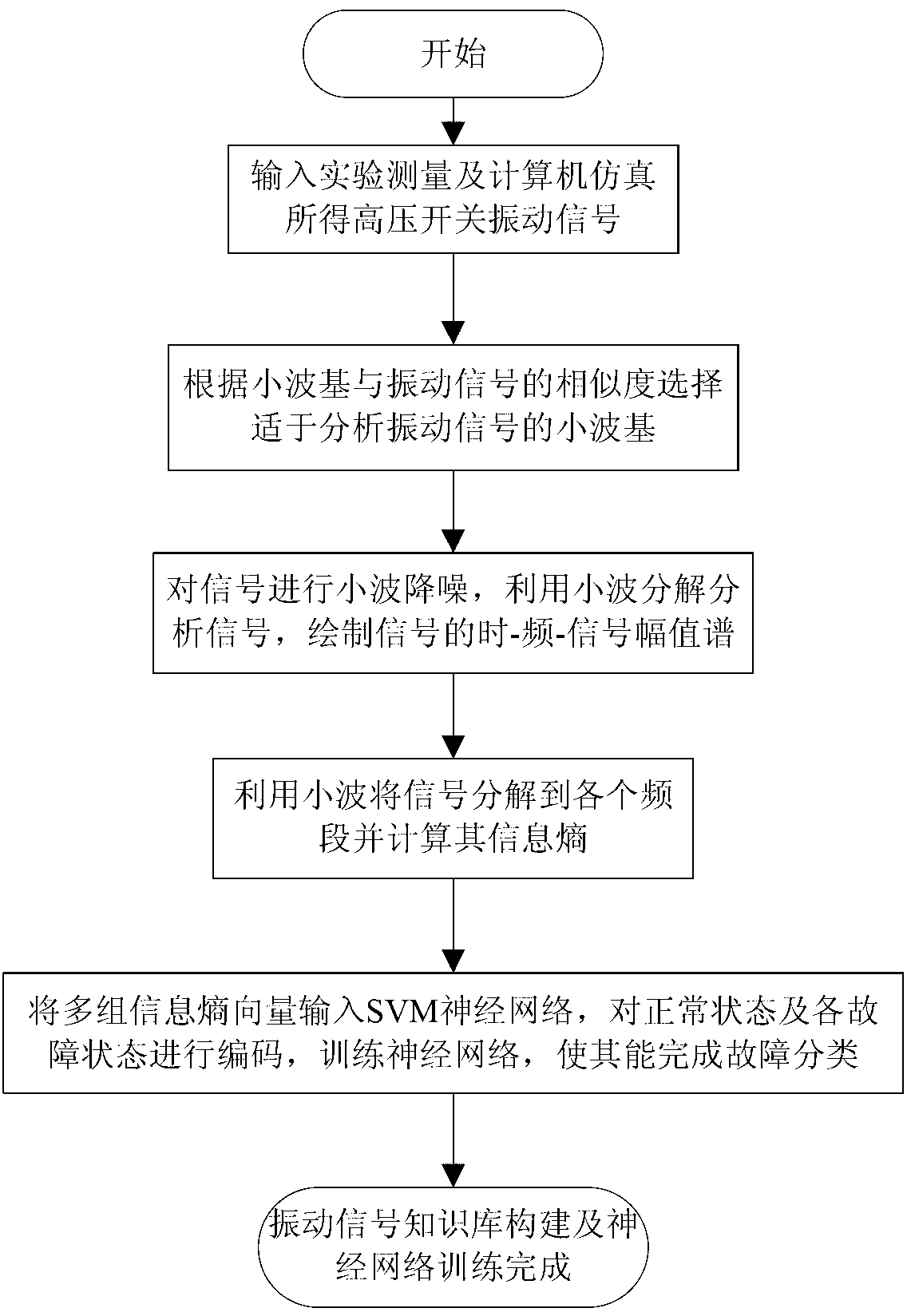

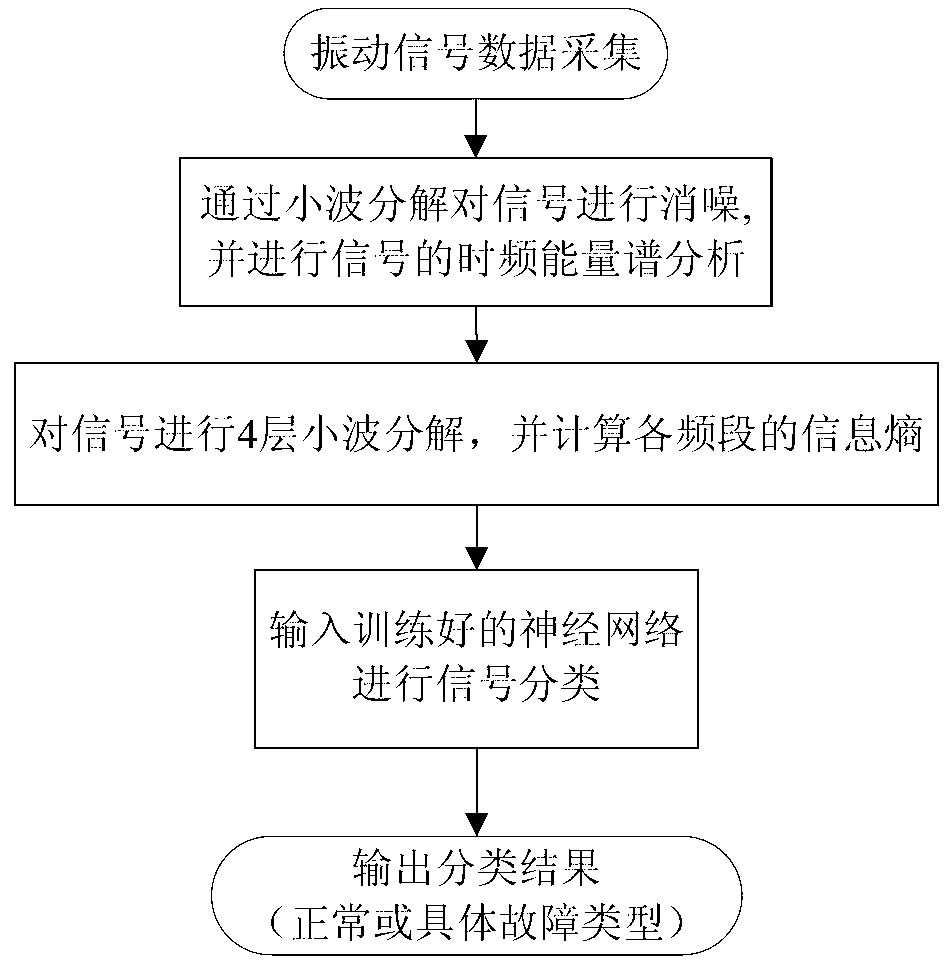

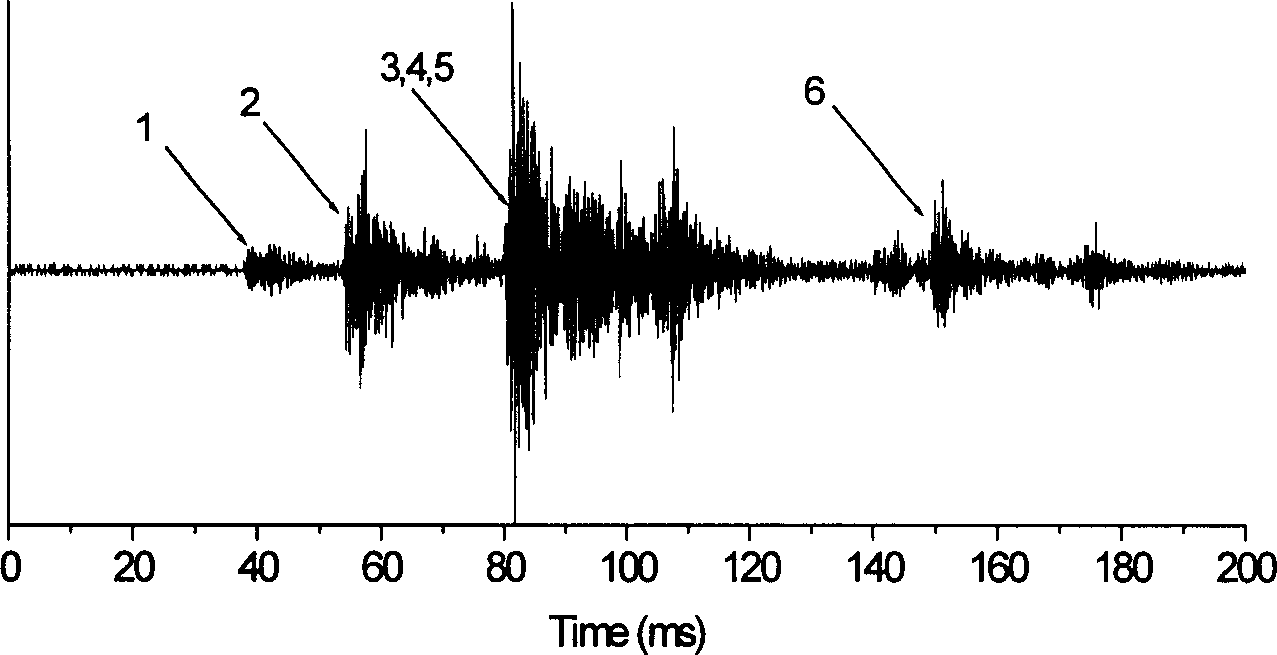

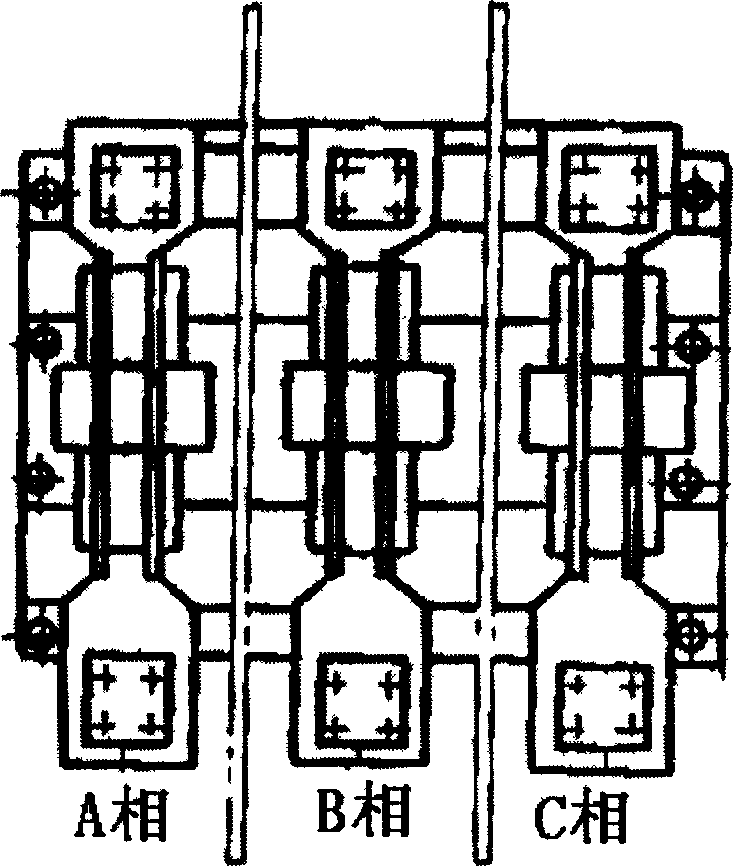

Vacuum breaker mechanical state detecting method based on vibration signal analysis

ActiveCN103308292AEffective noise cancellationEfficient decompositionMachine part testingSubsonic/sonic/ultrasonic wave measurementFeature vectorWavelet decomposition

The invention discloses a vacuum breaker mechanical state detecting method based on vibration signal analysis. The method comprises the following steps: 1), acquiring the vibration signal in the action process of a VS1 vacuum breaker; 2), performing wavelet decomposition to the vibration signal acquired in the step 1) in order to de-noise; 3), for the signal subjected to the wavelet decomposition, reconstructing the signal in each frequency band, drawing the reconstructed signal of each frequency band in a time-frequency-signal amplitude spectrum of the signal by mat lab, and calculating the information entropy of each frequency domain band and combining the information entropy of each frequency band of the vibration signal with each other to form a fault feature vector; and 4), inputting the fault feature vector calculated in the step 3) into a well trained neutral network and sort, so as to realize the state detection of the vacuum breaker.

Owner:STATE GRID CORP OF CHINA +2

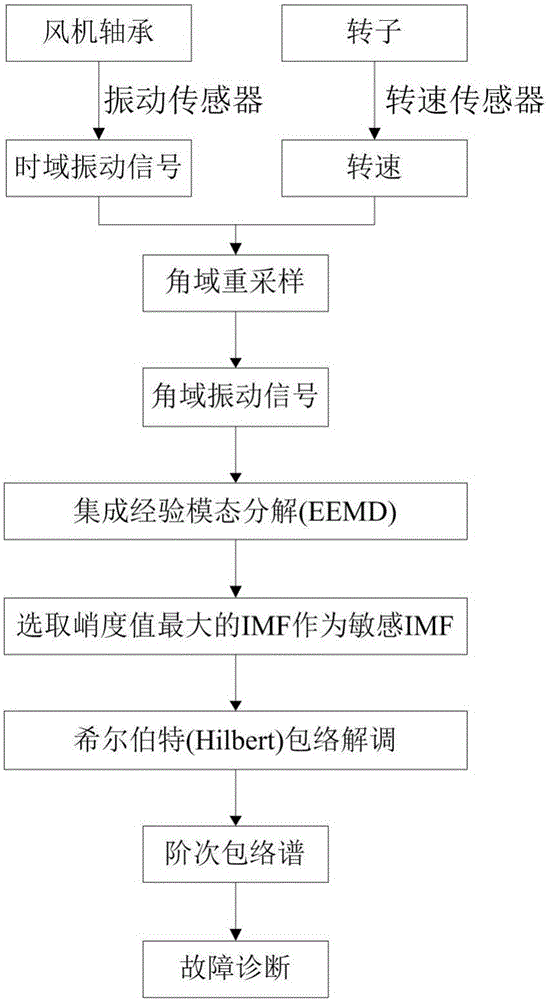

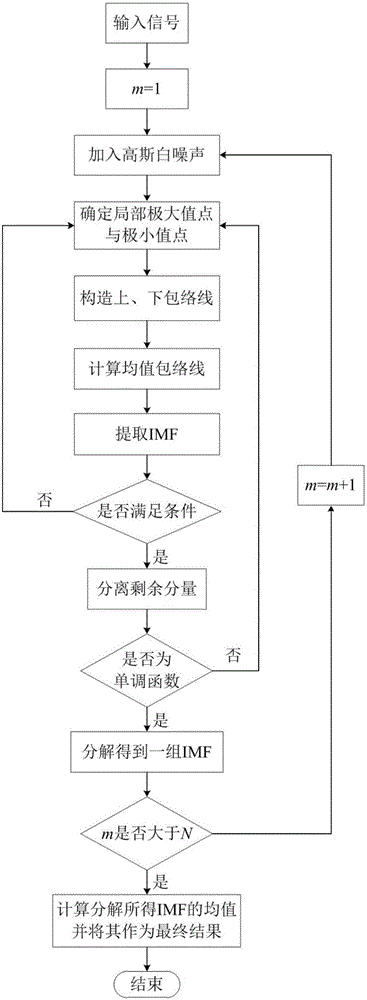

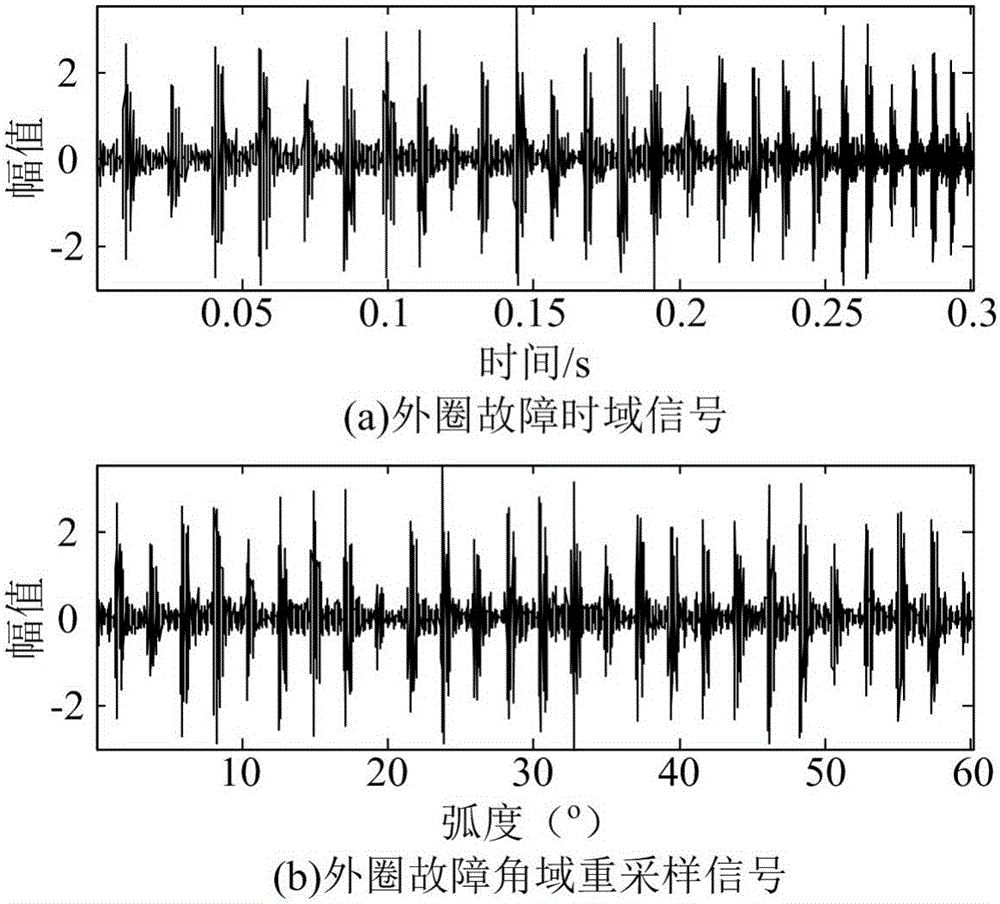

Wind turbine generator bearing fault diagnosis method under variable speed

InactiveCN105784366AEliminate the effects of analysisImprove accuracyMachine bearings testingElectricityBearing vibration

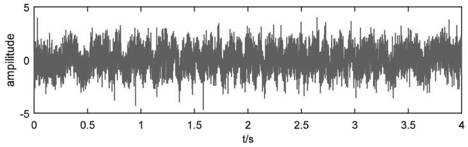

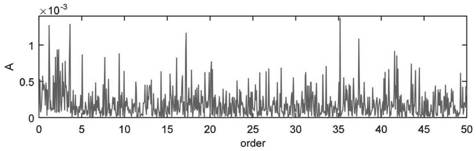

The invention discloses a wind turbine generator bearing fault diagnosis method under the variable speed. According to the method, a rotation angle change curve is drafted according to the bearing rotation speed; equal angle division for the rotation angle change curve is carried out, and an equal angle re-sampling time sequence is determined; interpolation for a bearing vibration signal is carried out according to the time sequence, a random Gauss white noise sequence is added to an angle domain vibration signal, and the signal added with the white noise is processed by utilizing an empirical mode decomposition (EMD) algorithm to acquire multiple sets of IMF; a kurtosis value of each IMF component is calculated; the IMF with the largest kurtosis value is selected and taken as a sensitive IMF; Hilbert envelope demodulation for the sensitive IMF is carried out to obtain an envelope signal, the envelope signal is processed by utilizing Fourier transform to obtain order envelope spectrum of the sensitive IMF, the fault characteristic frequency is extracted, and fault diagnosis on the wind turbine generator bearing is realized. The method is advantaged in that influence of rotation speed change on vibration signal analysis can be eliminated, and accuracy and validity of fault diagnosis can be improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

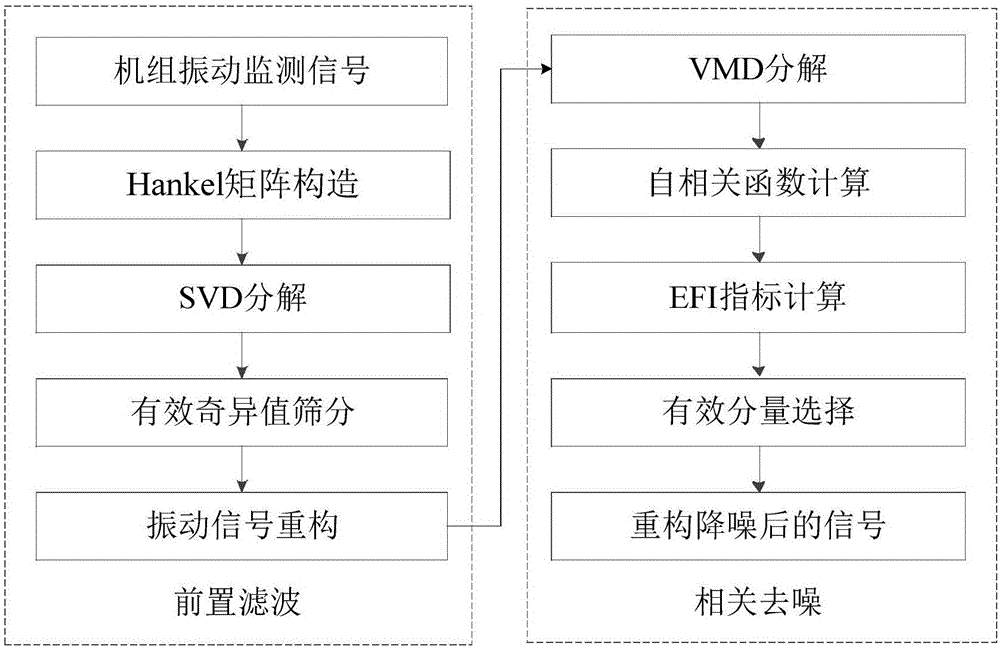

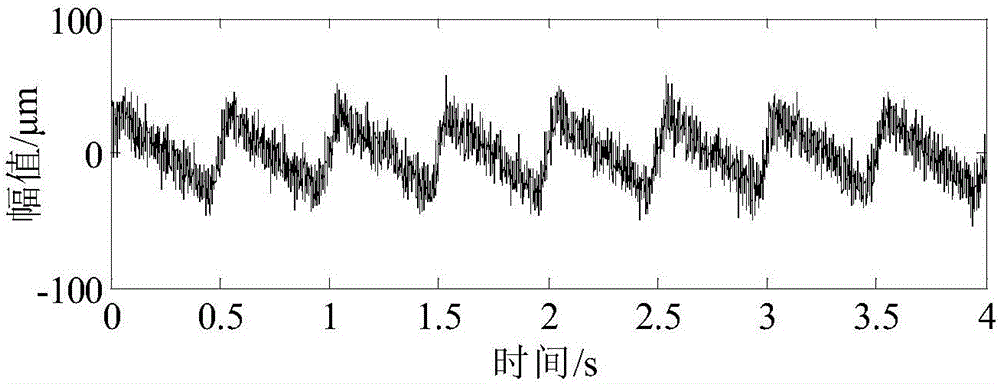

Hydroelectric generating set vibration signal noise reduction method based on mode autocorrelation analysis of SVD and VMD

InactiveCN106446829AEasy to separateEfficient screeningCharacter and pattern recognitionSingular value decompositionDecomposition

A hydroelectric generating set vibration signal noise reduction method based on mode autocorrelation analysis of SVD and VMD comprises the steps of constructing a Hankel matrix of a set vibration signal and performing singular value decomposition (SVD), selecting an effective singular value based on a mean value filtering strategy for reconstructing the signal, and realizing pre-filtering; performing decomposition through variational mode decomposition (VMD) for obtaining a series of mode functions, calculating an autocorrelation function of each mode component, selecting effective mode components according to an energy set of the autocorrelation function, and obtaining a signal after noise reduction through adding all effective mode components. According to the hydroelectric generating set vibration signal noise reduction method provided by the invention, a noise reduction experiment is carried out through simulation analysis and actual measurement of a vibration signal; and a result represents a fact that the method has relatively high noise reduction performance and can effectively improve hydroelectric generating set vibration signal analysis precision.

Owner:CHINA THREE GORGES UNIV

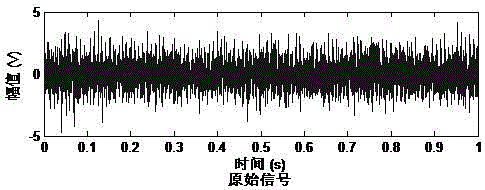

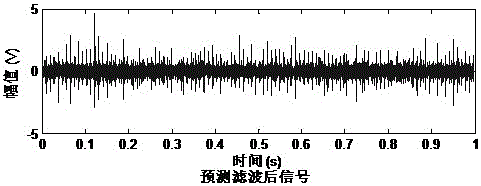

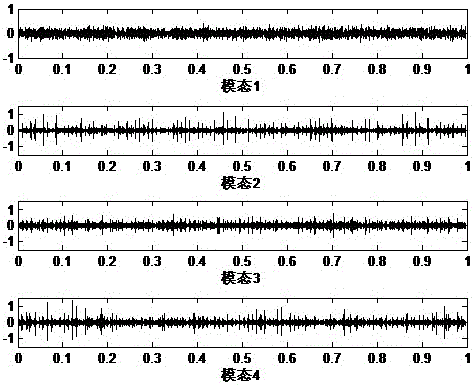

Rolling bearing fault diagnosis method based on variational mode decomposition

InactiveCN106017926ASuppress spectral noiseOptimal predictive filter orderMachine bearings testingCharacter and pattern recognitionFrequency matchingVariational mode decomposition

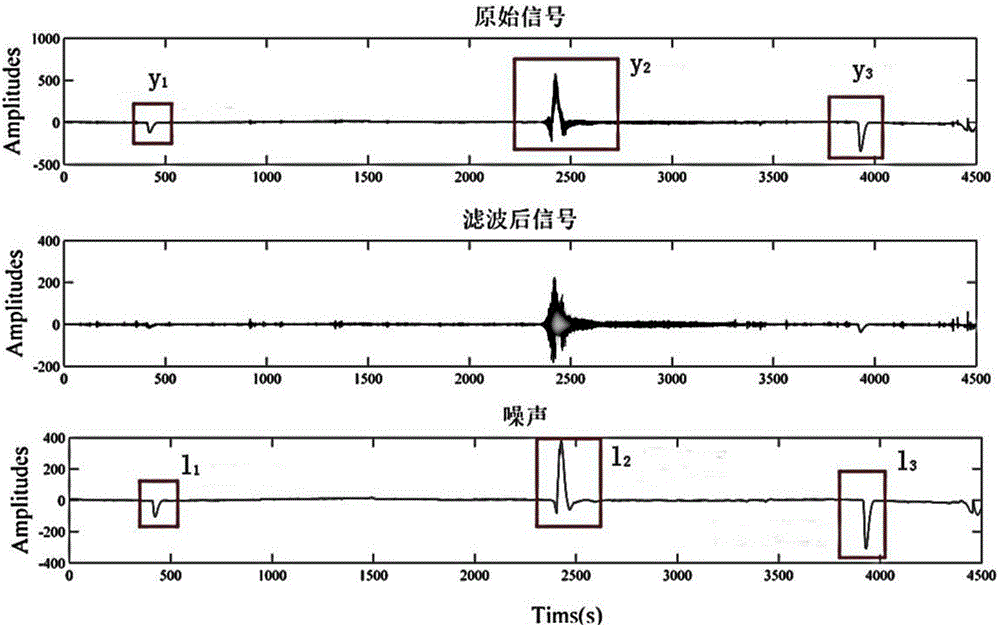

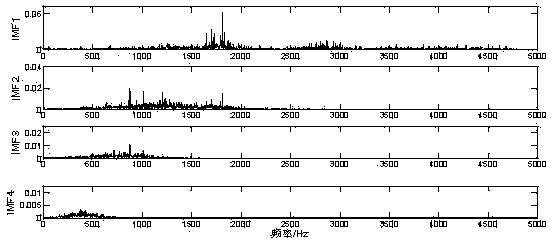

The invention discloses a rolling bearing fault diagnosis method based on variational mode decomposition, which is used to analyze a rolling bearing fault based on a vibration signal. First, fault information enhancement processing is performed on a signal collected by a sensor using a predictive filtering method; then, variational mode decomposition is performed on the filtered signal to get four modes; next, a mode most relevant to a rolling bearing fault is selected according to a fault information index; and finally, an envelope autocorrelation spectrum analysis of the filtered signal is made, and fault characteristic frequency matching is performed to get fault information.

Owner:SHANDONG UNIV OF TECH

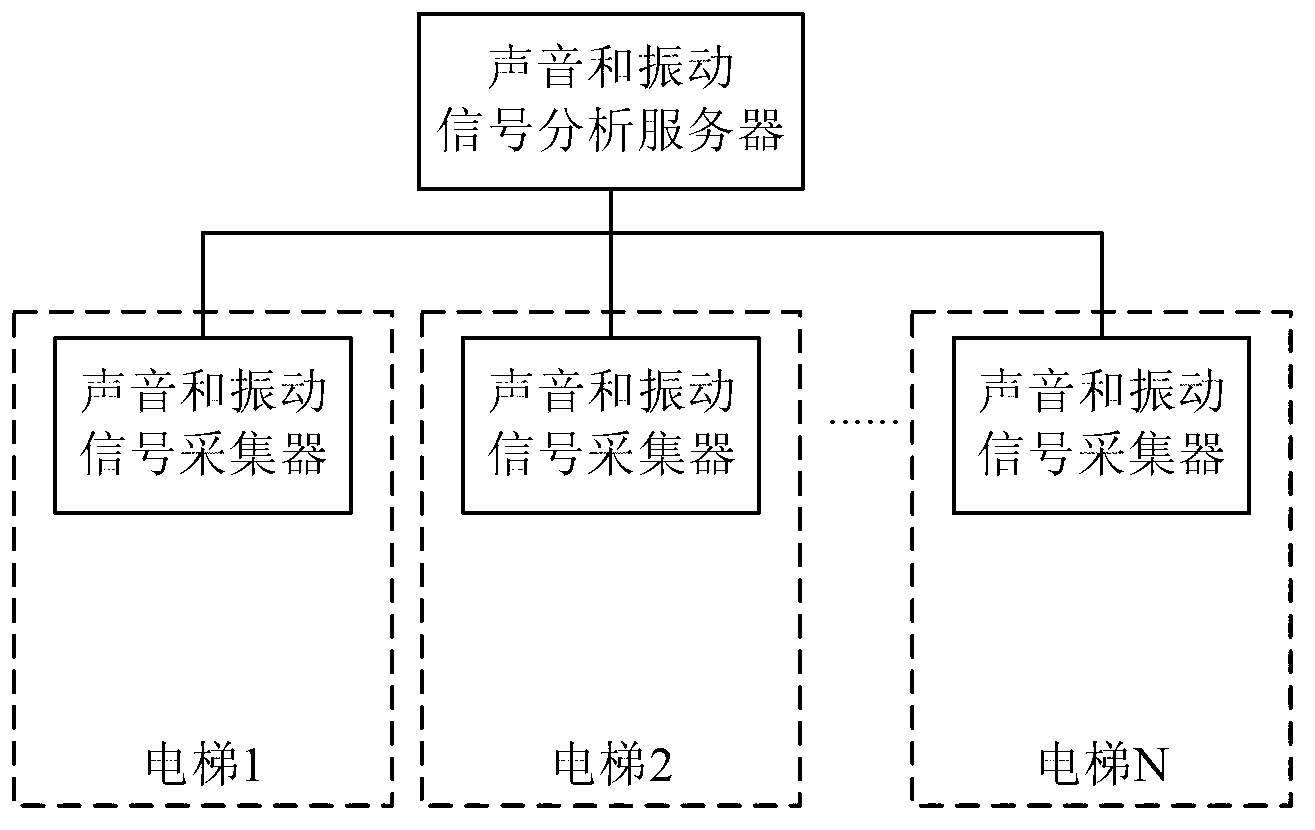

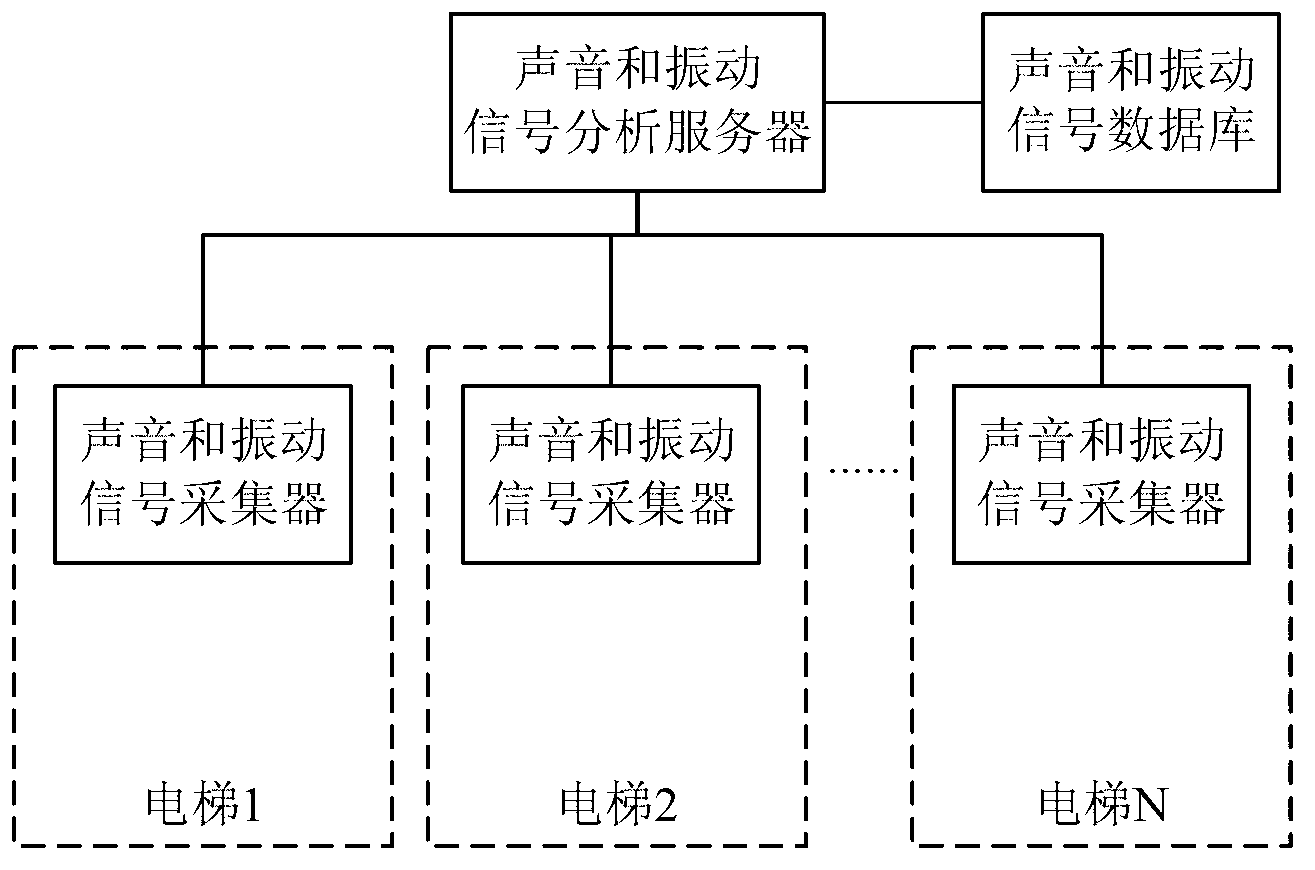

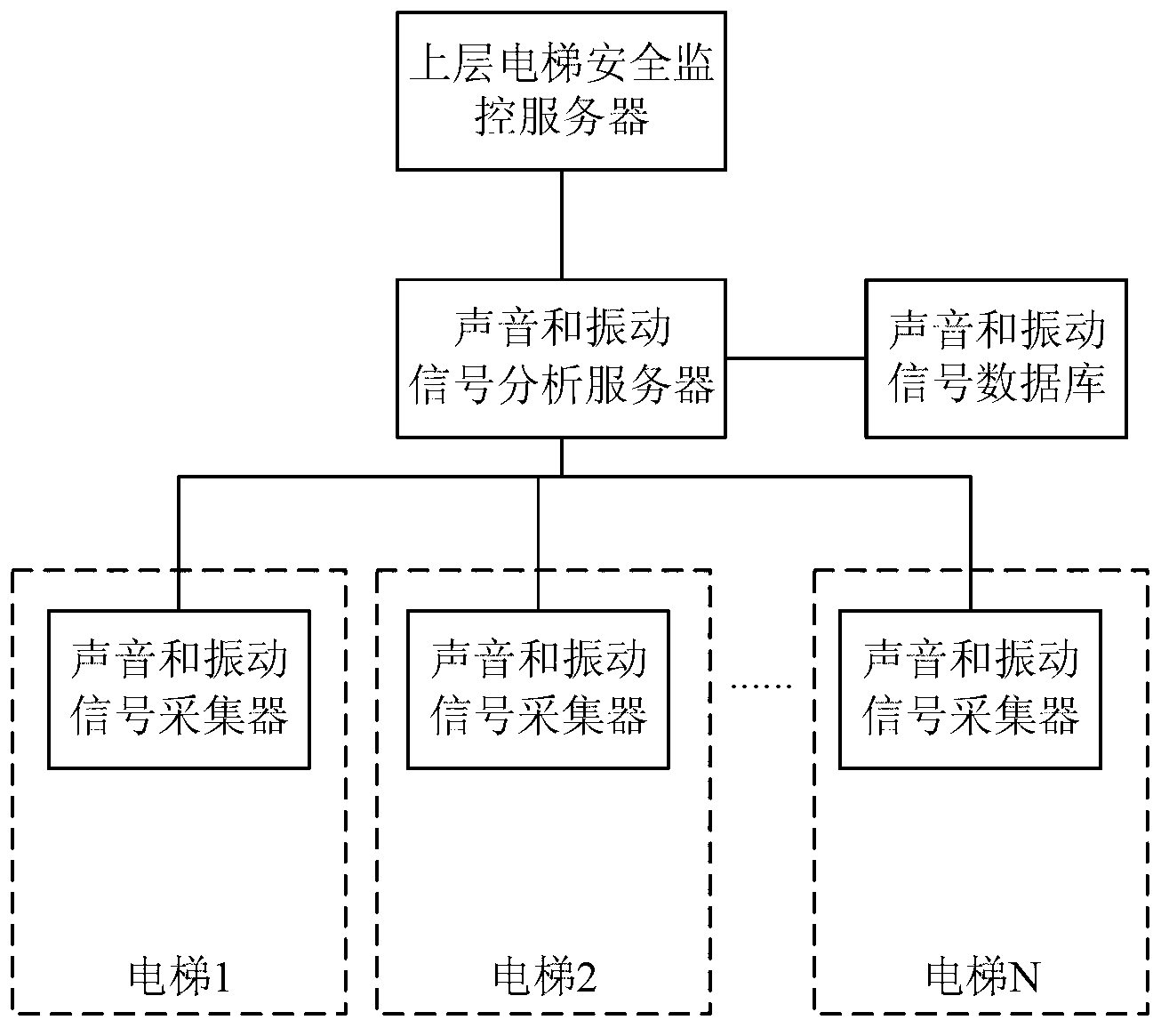

Diagnosis and early-warning system for elevator faults

The invention provides a diagnosis and early-warning system for elevator faults. The diagnosis and early-warning system comprises a sound and vibration signal acquirer and a sound and vibration signal analysis server, wherein the sound and vibration signal acquirer is arranged in an elevator car, connected with the sound and vibration signal analysis server and sends acquired sound signals and / or vibration signals to the sound and vibration signal analysis server; and the sound and vibration signal analysis server processes the sound signals and / or vibration signals. According to the diagnosis and early warning system for elevator faults, hidden faults of an elevator can be discovered as soon as possible, sufficient maintenance time is saved, and heavy losses are avoided. The running safety and reliability of elevators in an area range can be greatly improved once the diagnosis and early warning system is applied to the elevator Internet of Things field.

Owner:BEIJING JINGKE HUASHENG TECH

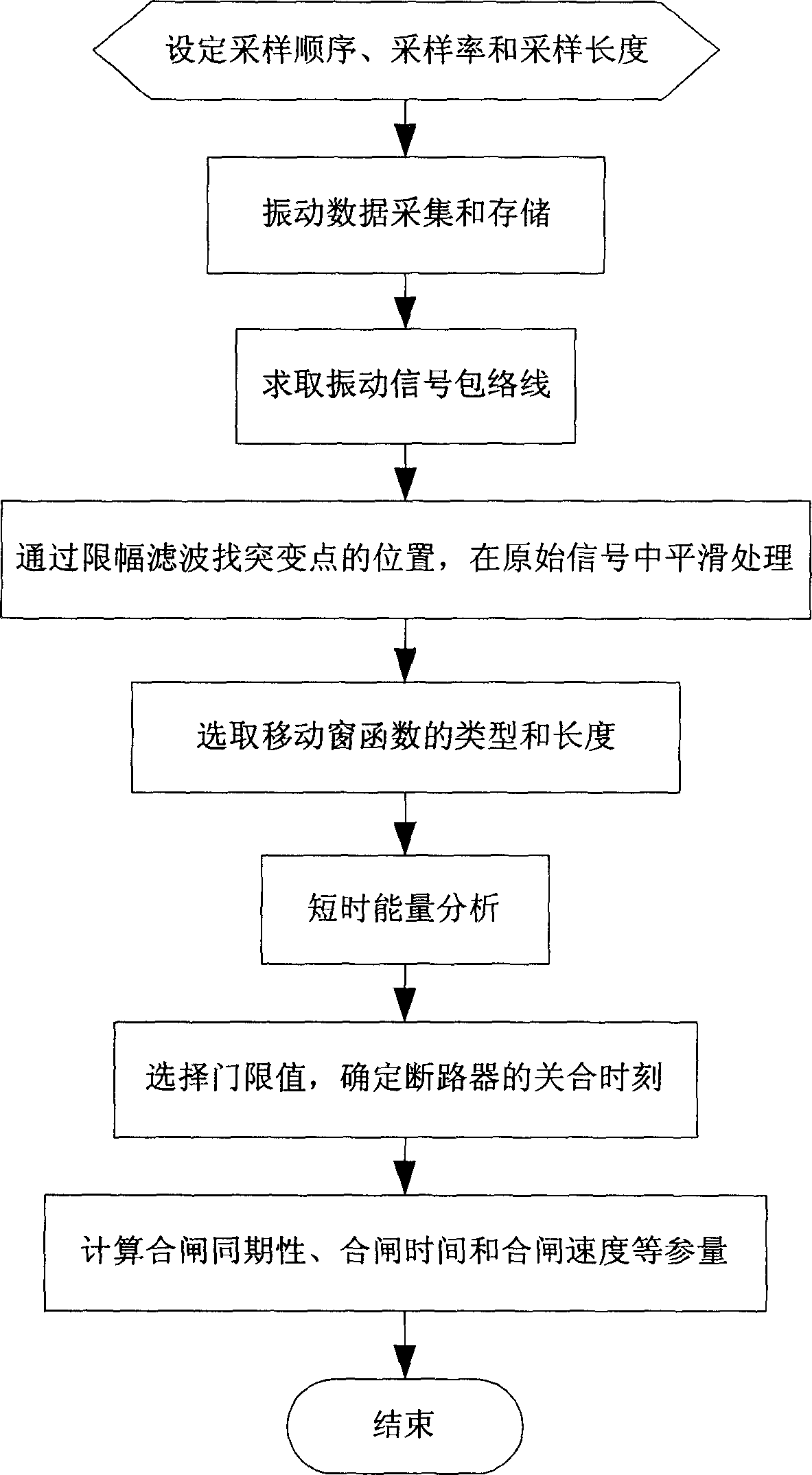

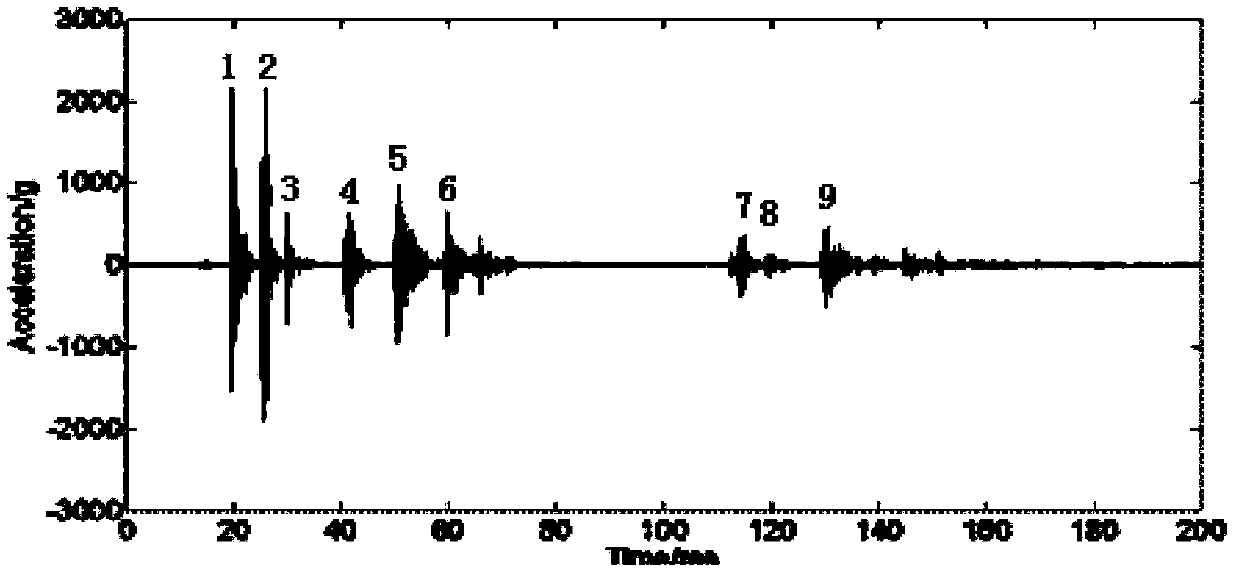

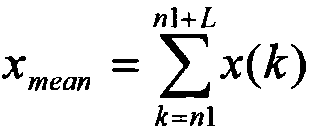

Online detection method for vacuum circuit breaker contact on-off time based on vibration analysis

InactiveCN1595188AExtension of timeImprove anti-interference abilityCircuit interrupters testingSample lengthFixed position

This invention discloses a vacuum breaker probes on or off moment on-line measurement method based on vibration analysis, which comprises the following steps: first to select the fix position and direction of the vibration sensor; second to set sample order, sample frequency, sample length and trigger means and to store the sample data; third to pre-process the vibration data; fourth to select moving window function type and length and adopt short-time energy calculation for further analysis; fifth to select threshold value to determine the on or off moments of triphase probes; sixth to calculate the closing term and closing time according to the on or off moments. This invention improves the affair resolution ability and anti-interference ability in the vibration signal analysis.

Owner:XI AN JIAOTONG UNIV

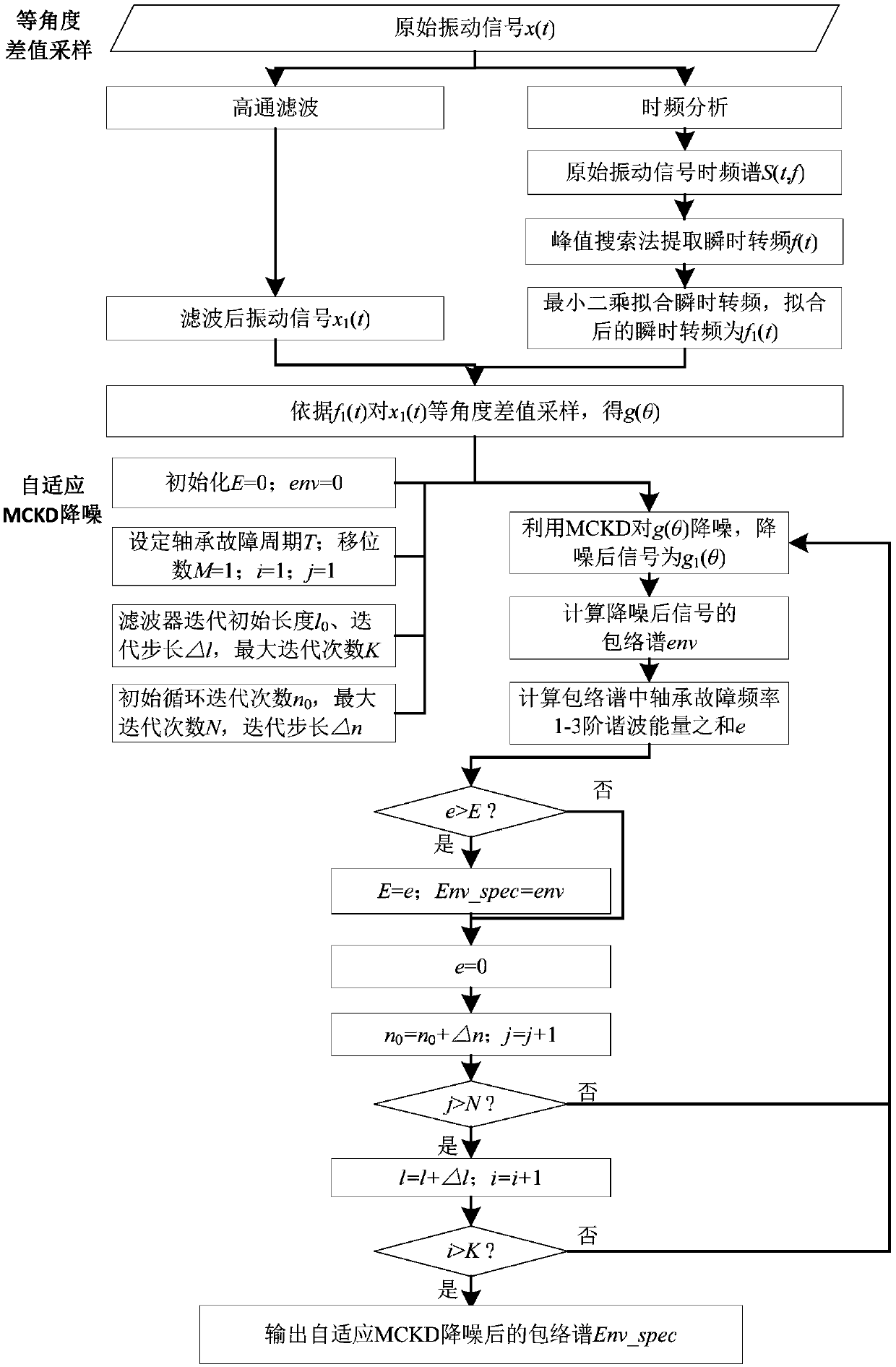

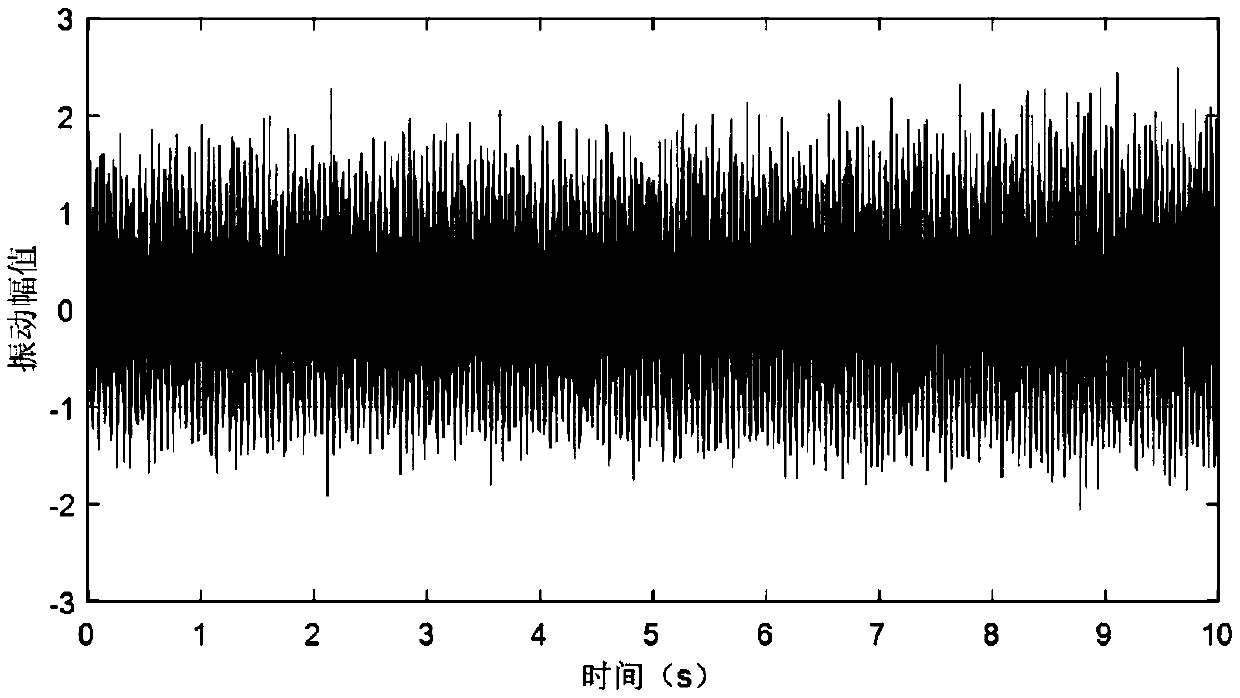

Early fault identification method of rolling bearing under variable rotating speed working condition

ActiveCN109682601AAvoid dependenceSolve the problem of being unable to process time-domain vibration signals under variable speed conditionsMachine part testingCharacter and pattern recognitionFrequency spectrumSignal-to-noise ratio (imaging)

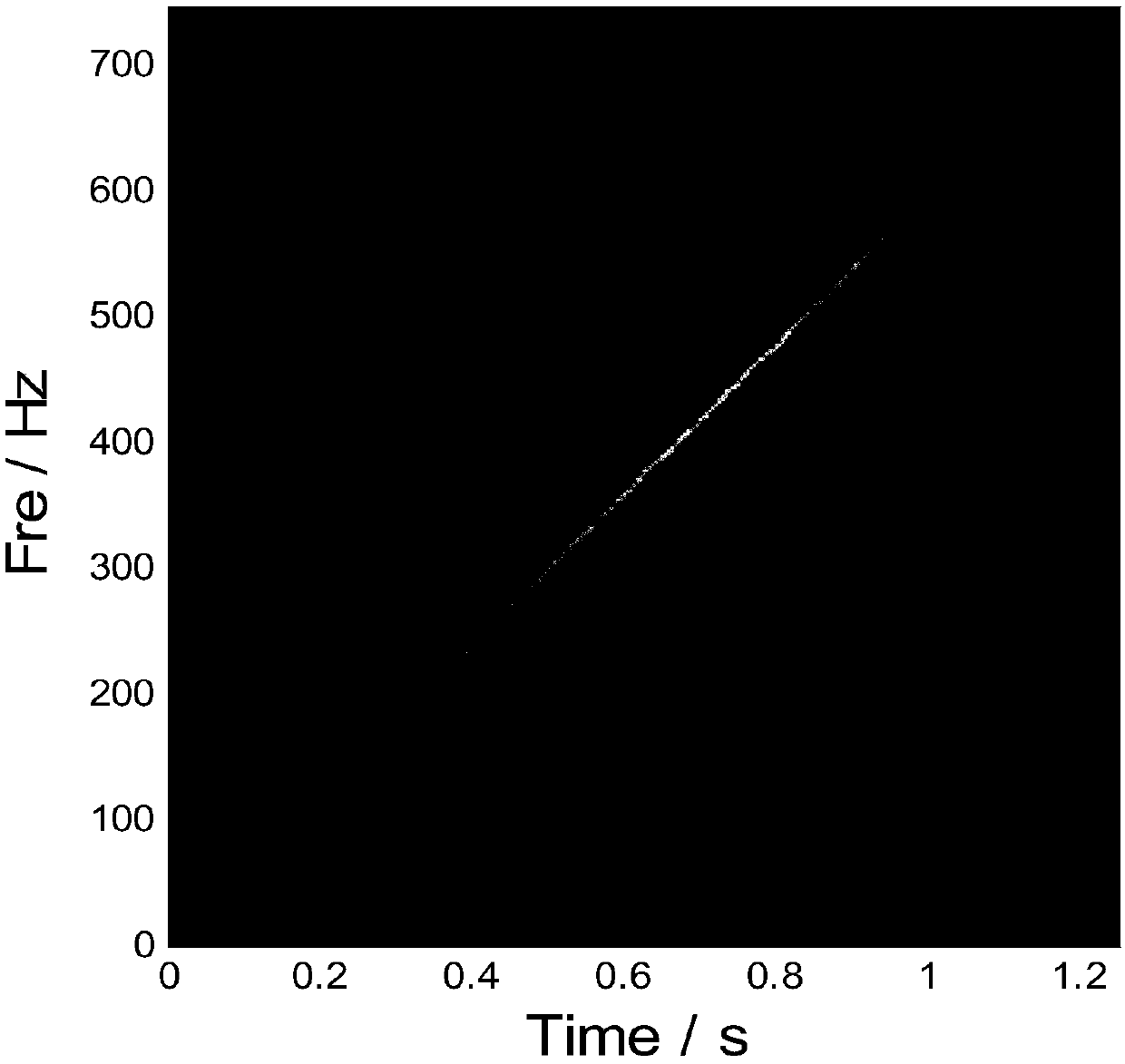

The invention relates to an early fault identification method of a rolling bearing under a variable rotating speed working condition. The method comprises the following steps that firstly, time-frequency analysis is carried out on a vibration signal of the rolling bearing to obtain a time-frequency spectrum; secondly, a peak value search method is adopted to extract an instantaneous frequency conversion in the time-frequency spectrum and data fitting is carried out; then high-pass filtering is carried out on an original vibration signal, and equal angle sampling is carried out on the originalvibration signal according to the instantaneous frequency conversion after data fitting to obtain an angle domain signal; finally, noise reduction processing is carried out on the original vibration signal and envelope spectrum analysis is carried out on the noise-reduced signal to identify faults of the rolling bearing. The method does not rely on a rotation speed sensor or human experience, andself-adaptively searches optimal parameters of the MCKD, moreover, the method is convenient and reliable, and is particularly suitable for vibration signal analysis of the rolling bearing with low signal-to-noise ratio under variable rotation speed working conditions.

Owner:CYBERINSIGHT TECH CO LTD

Vibration monitoring system of reactor and reactor internals

ActiveCN101685678AEasy to replaceRealize synchronous acquisitionNuclear energy generationNuclear monitoringVibration accelerationAccelerometer

The invention provides a vibration monitoring system of a reactor and reactor internals, solving the problems of reliability, compatibility, stability and maintenance convenience and comprising an accelerometer, a charge amplifier, signal conditioning equipment, vibration signal analyzing equipment, a display terminal, vibration monitor software and the like. In the signal conditioning equipment,a signal conditioning module carries out programmable amplification and low-pass filter on vibration signals, and a multi-channel selection module receives control signals of a self-check control module of the vibration signal analyzing equipment so as to realize system programmable self check; the vibration signal analyzing equipment comprises a PXI bus crate; the vibration monitor software calculates vibration characteristic frequency and amplitude of each channel as well as a CPSD value, a coherence value and a phase value of each channel pair and monitors vibration acceleration and amplitude of a pressure vessel of the reactor, a first order modal frequency and amplitude and a second order modal frequency and amplitude of a reactor fuel assembly, frequency and amplitude of a core barrel beam mode and a second order shell mode as well as swinging frequency and amplitude of the pressure vessel, and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

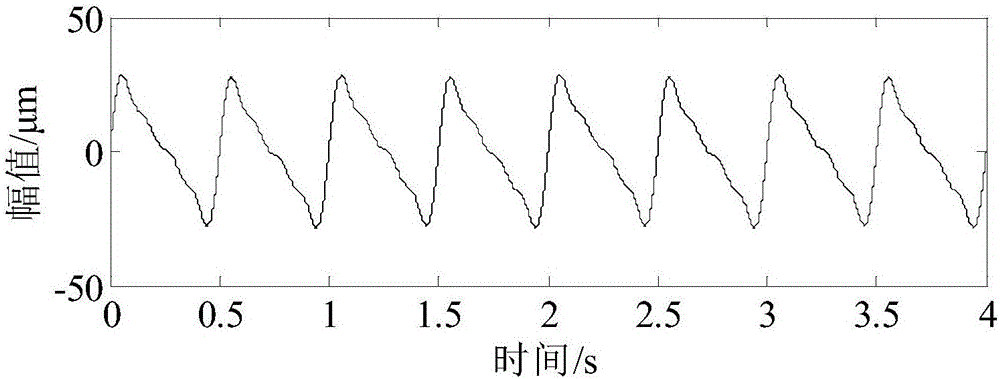

Device and method for automatically displaying vibration signal characteristics of turbo generator unit

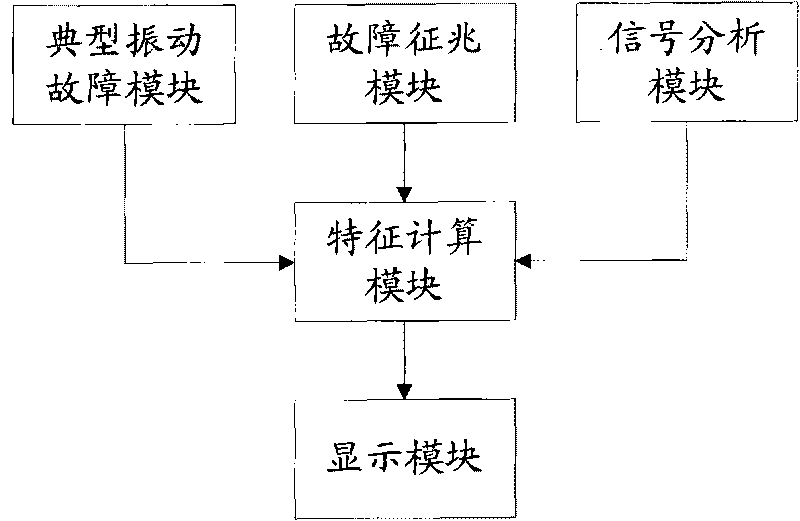

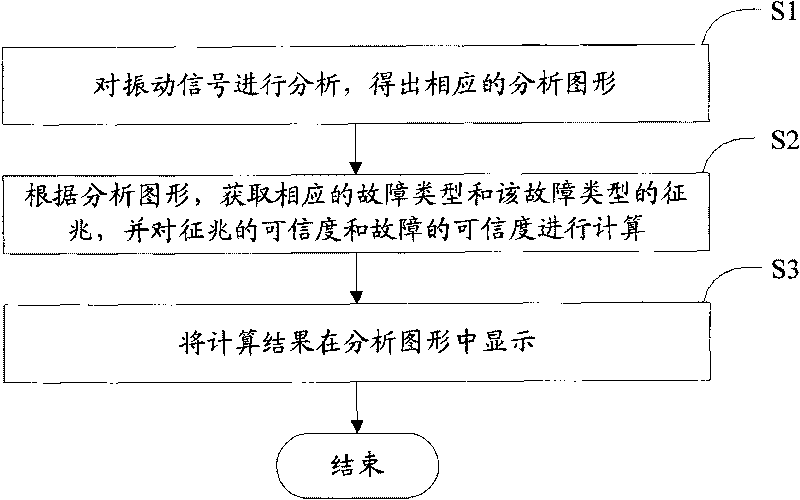

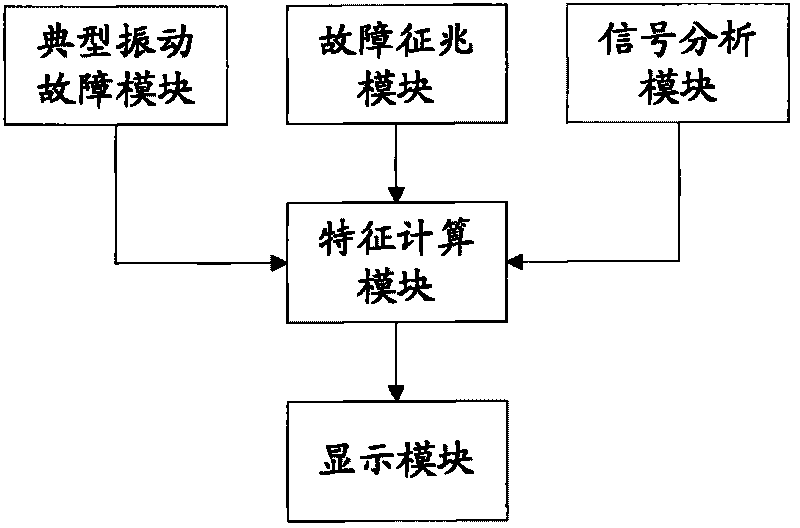

InactiveCN101706356AEnhance interestLower level requirementsEngine testingVibration testingGraphicsEngineering

The invention discloses a device and a method for automatically displaying vibration signal characteristics of a turbo generator unit, and relates to the field of machinery monitoring, which is used for helping a user understand a vibration signal analysis graphics. The device comprises a typical vibration fault module, a fault symptom module, a signal analysis module, a characteristic calculation module and a display module, wherein the signal analysis module is used for analyzing a vibration signal to acquire the corresponding analysis graphics; the characteristic calculation module is used for acquiring a corresponding fault type and a symptom of the fault type respectively from the typical vibration fault module and the fault symptom module according to the analysis graphics acquired by the signal analysis module, and calculating the credibility of the symptom and credibility of the fault; and the display module is used for displaying a calculation result of the characteristic calculation module in the analysis graphics. The method comprises the following steps of: analyzing the vibration signal to acquire the corresponding analysis graphics; acquiring the corresponding fault type and the symptom of the fault type according to the analysis graphics, and calculating the credibility of the symptom and the credibility of the fault; and displaying the calculation result in the analysis graphics.

Owner:BEIJING YINGHUADA SOFTWARE ENG

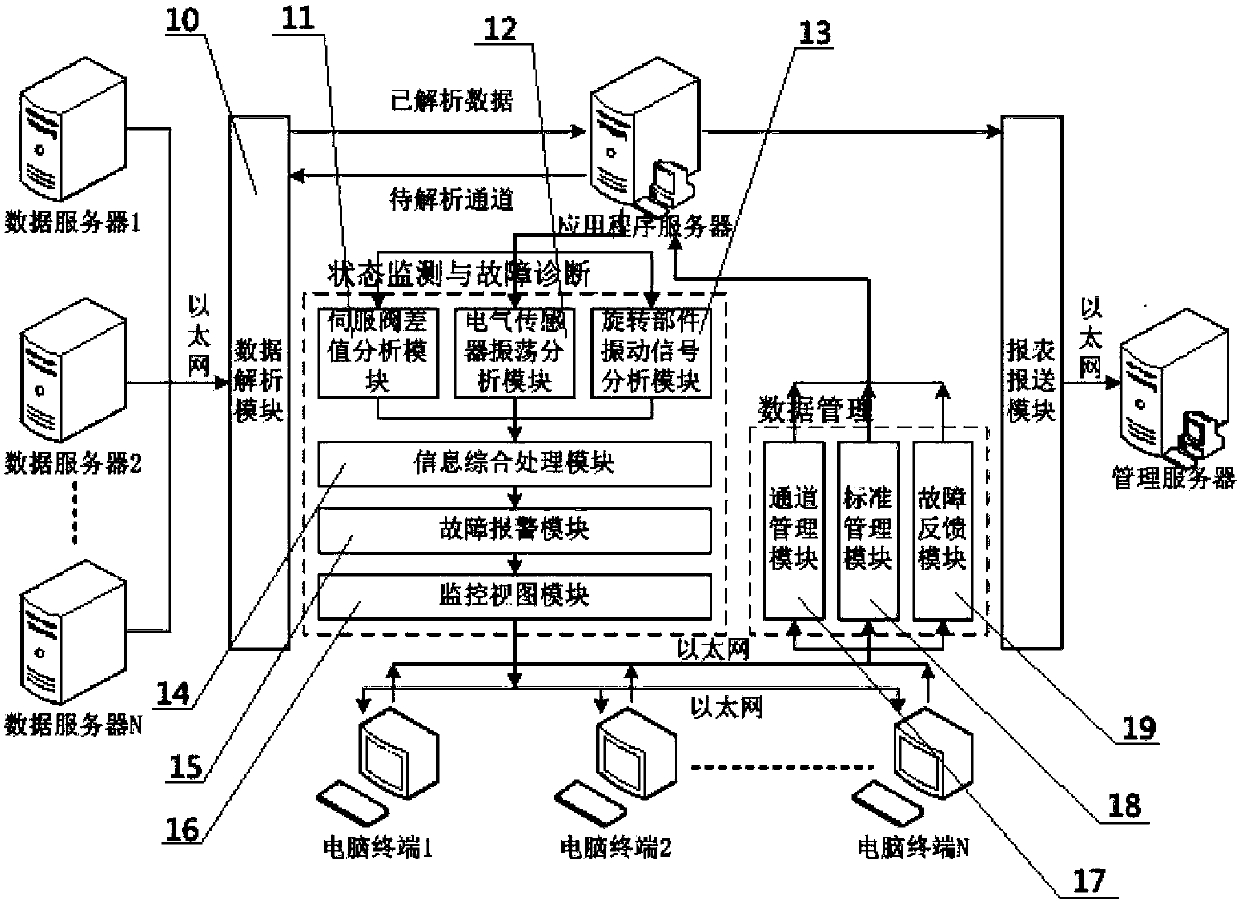

Rolling mill equipment state online monitoring and diagnosis system and monitoring and diagnosis method

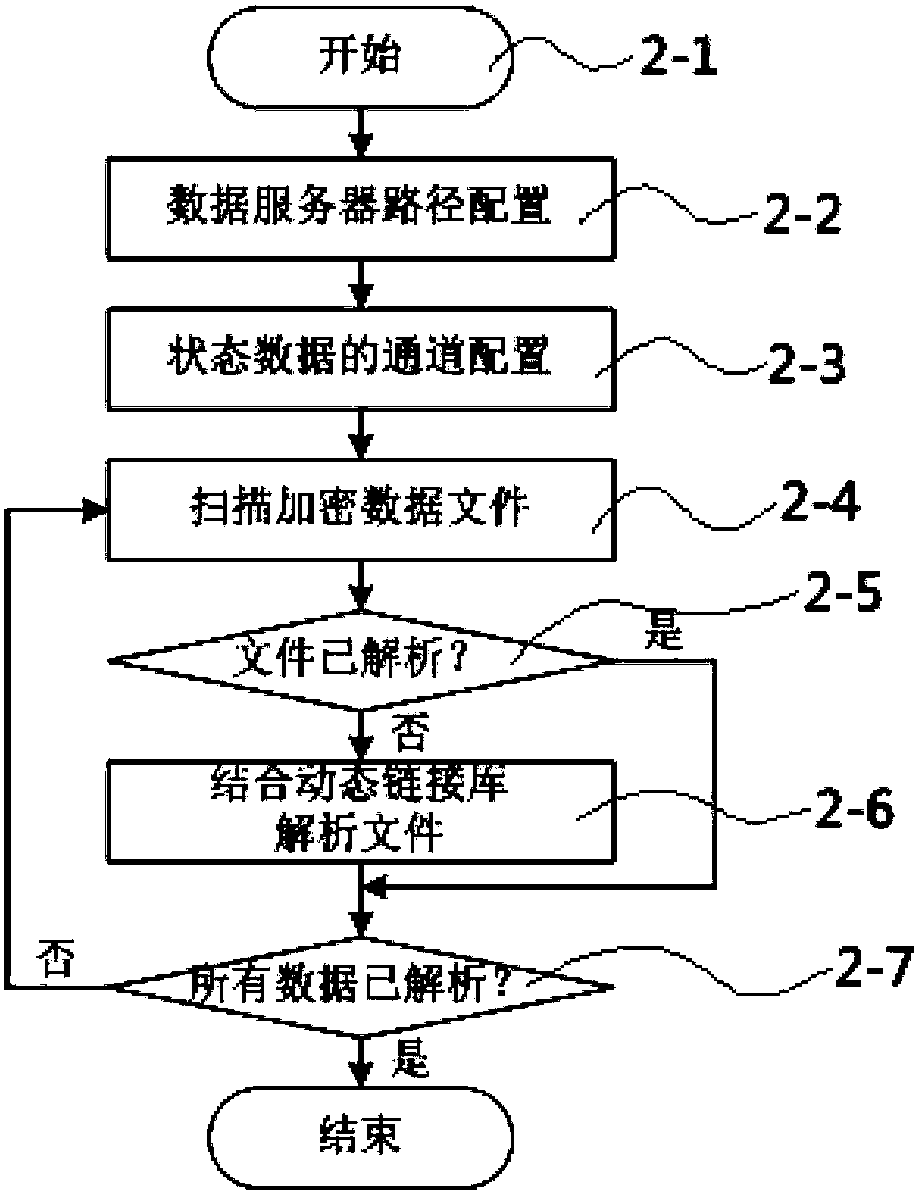

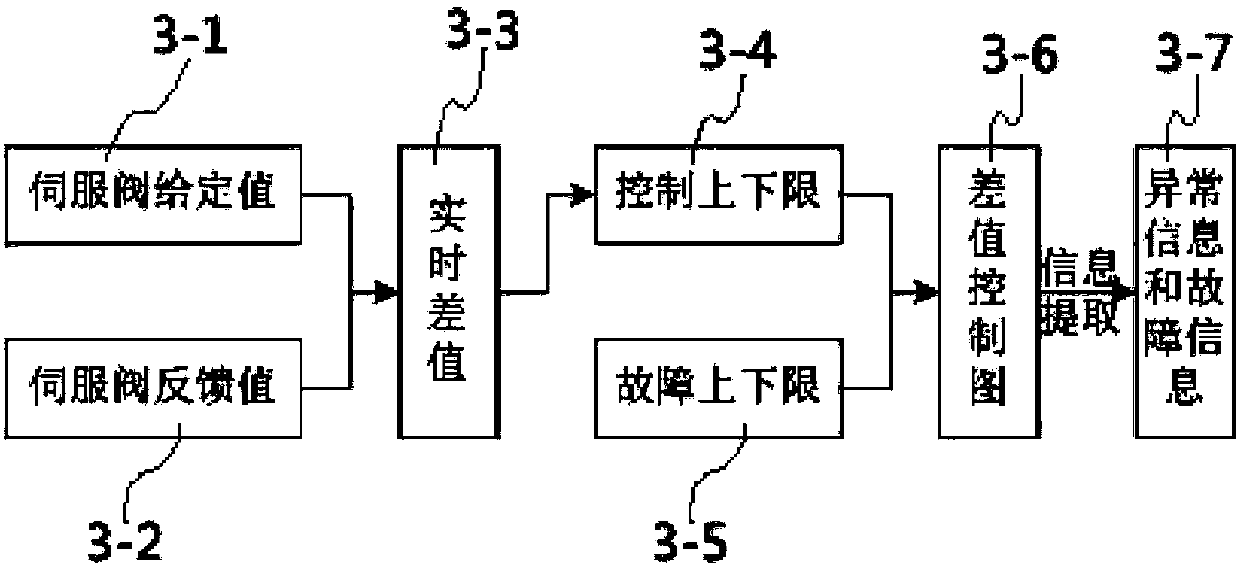

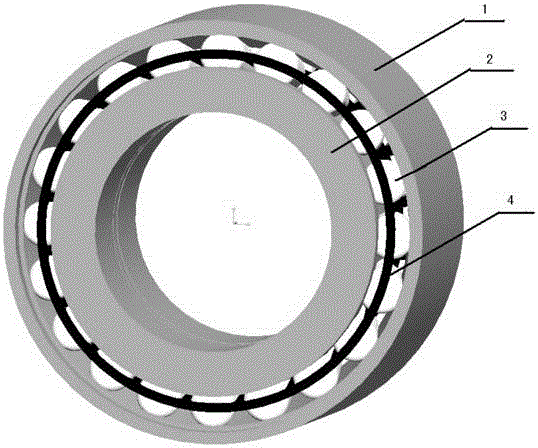

The invention provides a rolling mill equipment state online monitoring and diagnosis system and monitoring and diagnosis method. The rolling mill equipment state online monitoring and diagnosis system comprises a data analysis module, a servo valve difference value analysis module, an electric sensor oscillation analysis module, a rotary part vibration signal analysis module, an information comprehensive processing module, a fault alarming module, a monitoring view module, a channel management module, a standard management module and a fault feedback module. A large amount of encrypted production data files in the system are analyzed, so that the data storage space is greatly saved, and the fault data tracing and the big data-based deep analysis are facilitated; through extraction and analysis of different signal features of a servo valve, an electric sensor and a key rotary part, a rolling mill equipment state can be monitored and diagnosed online multi-dimensionally; and through therolling mill equipment state online monitoring and diagnosis system, the rolling stability and the product quality index control precision are improved.

Owner:科大集智数据科技(武汉)有限公司 +1

Sensitive feature selection and dimensionality reduction method for vibration signal analysis

InactiveCN109145706AIdeal Fault State Recognition EffectCharacter and pattern recognitionDimensionality reductionFeature selection

The invention discloses a sensitive feature selection and dimension reduction method for vibration signal analysis. The method comprises the following steps: the vibration signal is decomposed by MODWPT to obtain each frequency band coefficient and node signal; each node signal is reconstructed by a single branch and corresponding statistical features are calculated; the frequency band coefficientand node signal are decomposed by MODWPT. FSELM, a feature selection method based on extreme learning machine, is used to select the sensitive features, and NPEMMC is used to reduce the dimension ofthe selected sensitive features. The low-dimensional sensitive features are used as input space to train the classifier, and the trained classification model is used to complete the fault pattern recognition. The invention can achieve ideal rolling bearing fault state identification effect.

Owner:XUZHOU MEDICAL UNIV

Train rolling bearing fault and impurity vibration distinguishing method

ActiveCN106441893AEasy to classify and identifyImprove signal-to-noise ratioMachine bearings testingFrequency spectrumDecomposition

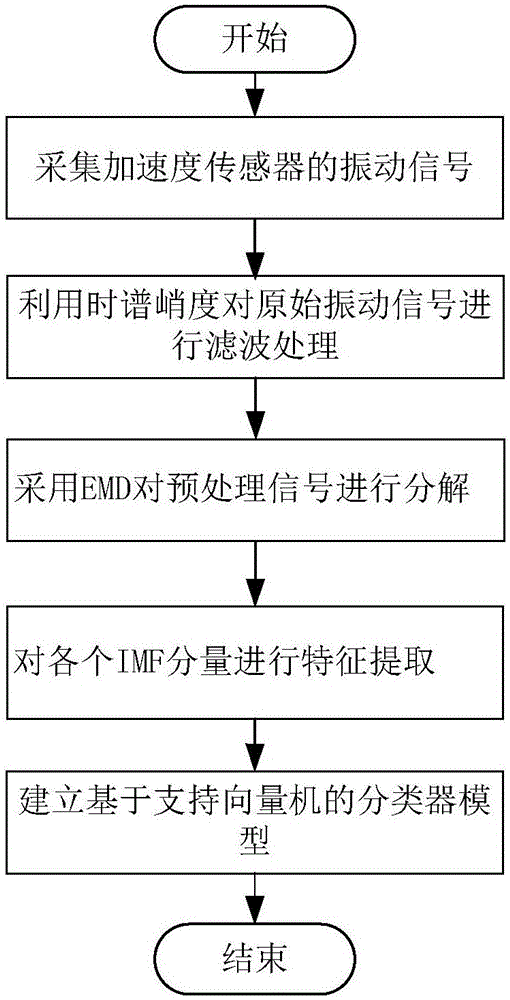

The invention discloses a train rolling bearing fault and impurity vibration distinguishing method. The method includes: utilizing spectral kurtosis to perform filtering processing on an original bearing vibration signal, and adopting an empirical mode decomposition technique to perform step-by-step decomposition on the preprocessed vibration signal to obtain intrinsic mode functions; subjecting the intrinsic mode functions to frequency spectrum and statistic characteristic analysis, extracting a feature vector composed of frequency spectrum center-of-gravity and characteristic frequency energy ratio as input, establishing a support vector machine based classifier model by training, and distinguishing whether a rolling bearing with abnormal noise is faulted or contains impurities in real time. The method is used for distinguishing the fault or impurity-containing state of the train rolling bearing based on vibration signal analysis, the method effectively improves accuracy in bearing fault identification, the problem of overhigh false alarm rate in the bearing vibration diagnosis method caused by impurities is solved, and good technical support is provided for engineering application of the vibration diagnosis method.

Owner:BEIJING UNIV OF POSTS & TELECOMM

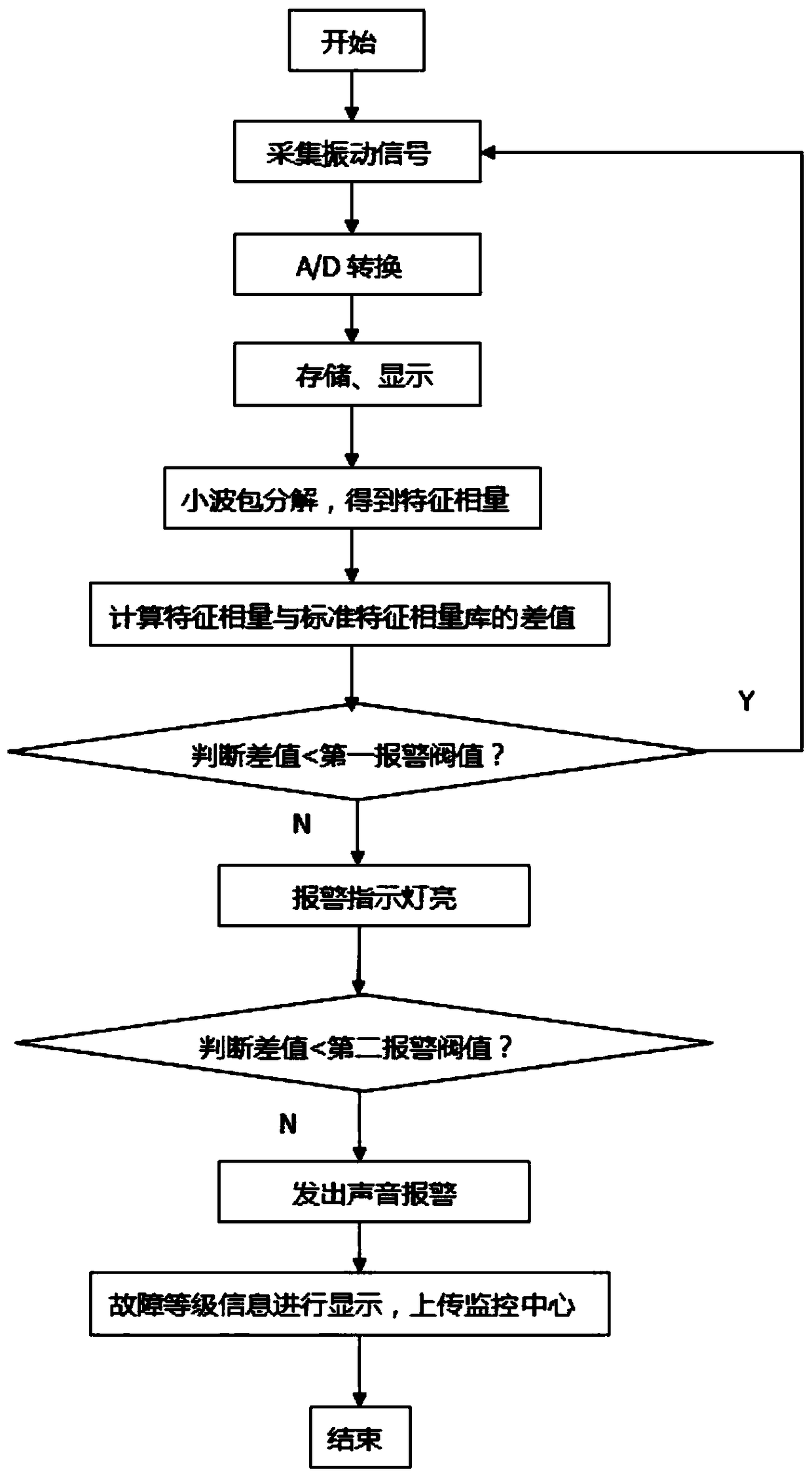

Transformer fault diagnosis system and diagnosis method based on vibration signal analysis

InactiveCN109443528ASubsonic/sonic/ultrasonic wave measurementTransformers testingCommunication unitDiagnosis methods

The invention provides a transformer fault diagnosis system based on vibration signal analysis. The fault diagnosis system comprises a vibration signal sensor, an A / D conversion unit, a control processing unit, a storage unit, a display unit, a key input unit, an alarm unit, and a communication unit. The fault diagnosis system analyzes and calculates collected vibration signals, determines whethera transformer is abnormal and vibrates, and further determines whether the transformer needs to be shut down for maintenance. If the transformer is abnormal, an alarm signal is emitted timely. The invention provides the transformer fault diagnosis system based on vibration signal analysis and a diagnosis method. The transformer to be detected and a normal operation transformer carry out parallelcomparison, and the state of a power transformer can be safely and reliably monitored.

Owner:JIANGSU ELECTRIC POWER CO +1

Method of fault diagnosis on ball socketed bearing of steel-making converter by comprehensive analysis

InactiveCN101726413ASmall attenuationEasy extractionVibration measurement in solidsMachine bearings testingBandpass filteringEngineering

The invention discloses a method of fault diagnosis on a ball socketed bearing of a steel-making converter by comprehensive analysis. The method carries out fault diagnosis on the ball socketed bearing of the steel-making converter by using vibration signal analysis and grease oil analysis. The method comprises the following steps of: firstly, selecting evenly distributed measuring points on the periphery of the outer ring of the bearing, and then punching bearing seats at the measuring points; carrying out resonance demodulation and wavelet noise reduction analysis on acquired bearing vibration signals; firstly, selecting centre frequency and bandwidth according to frequency bands generated in resonance peaks in a frequency spectrogram to carry out bandpass filtering, and then carrying out wavelet noise reduction and Hilbert demodulation treatment on the filtered signals; on the basis of detecting the conventional typical properties, carrying out qualitative and quantitative analysis on the components and the content of metal wearers in oil samples by using spectrum analysis and ferrographic analysis, and judging according to the detection result; and comparing and synthesizing two analysis results to make a fault diagnosis report. The invention can effectively increase the accuracy of fault diagnosis, thereby being beneficial to discovering fault hidden troubles as early as possible and avoiding major accidents happening.

Owner:BEIJING UNIV OF TECH

High-voltage circuit breaker mechanical failure diagnosis method based on vibration signal analysis

ActiveCN103743554AEasy to guide maintenance workSolve the problem that the criterion is too simple and the accuracy is lowVibration measurement in solidsMachine part testingEngineeringTime difference

The present invention relates to a high-voltage circuit breaker mechanical failure diagnosis method based on vibration signal analysis. The high-voltage circuit breaker mechanical failure diagnosis method based on the vibration signal analysis comprises the steps of measuring the time sequences and the time difference sequences of the occurrence moments of vibration events during the opening and closing processes of a circuit breaker under a normal working condition experiment and a typical fault experiment, and creating a time sequence feature library and a time difference sequence feature library; measuring a time sequence and a time difference sequence of the occurrence moments of the vibration events of an actually operated circuit breaker; comparing the time difference sequence of the occurrence moments of the vibration events during the opening and closing processes of the actually operated circuit breaker with the time difference sequences in the time difference sequence feature library to determine the types of faults; comparing a time sequence of the fault types under the faults of varying degrees in the time sequence feature library with the measured time sequence to determine the degrees of the faults. The method more visually solves the problems that the judgement of the conventional circuit breaker diagnosis method based on the vibration is too simple, and the accuracy is low, and can determine the degrees of the faults.

Owner:STATE GRID CORP OF CHINA +2

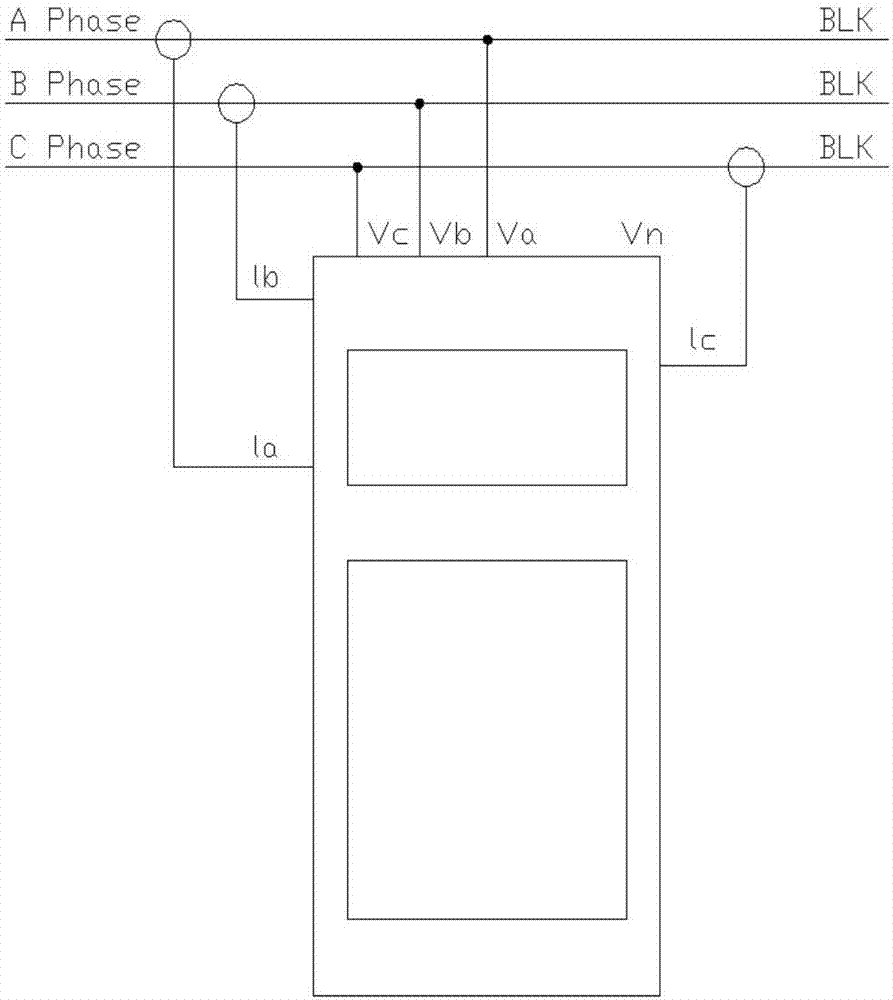

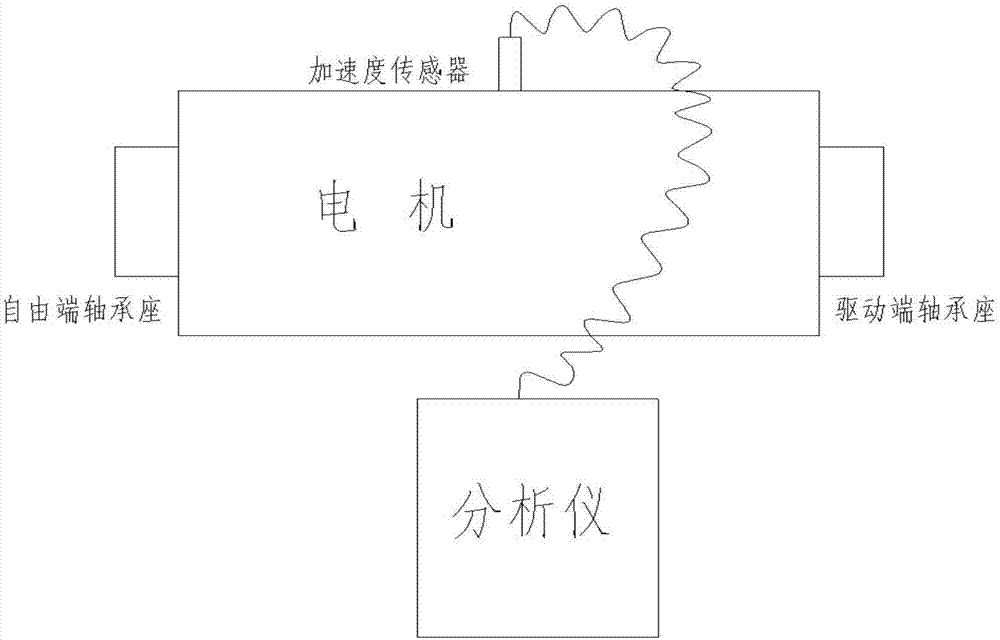

Asynchronous motor rotor broken bar fault judgment method with electric signals and vibration signals integrated

InactiveCN107544025ANot lostPrecise electrical signatureMachine part testingDynamo-electric machine testingFrequency spectrumVibratory signal

The invention discloses an asynchronous motor rotor broken bar fault judgment method with electric signals and vibration signals integrated, which belongs to the field of motor fault judgment. The method comprises the following steps: an acquisition instrument acquires voltage and current data through a current clamp and a voltage clamp, current spectrum analysis is carried out, if the current signals are normal, no broken bar fault happens to the motor rotor, and if the current signals are abnormal and when one side band appears at each position with a twice slip frequency difference from a power frequency, the next step is carried out; voltage spectrum analysis is carried out, if the voltage signals are normal, no broken bar fault happens to the motor rotor, if the voltage signals are abnormal and when one side band appears at each position with a twice slip frequency difference from the power frequency, vibration signal analysis is carried out, and whether broken bar fault happens to the motor is judged. In view of the problem that error judgment exists in a motor current signal analysis method in the asynchronous motor rotor broken bar fault in the prior art, a mode of sequentially judging the stator current, the stator voltage and the vibration signals is adopted, the rotor broken bar fault is detected, and the error judgment rate is reduced.

Owner:马鞍山马钢华阳设备诊断工程有限公司

Solid rocket engine fault diagnosis method

InactiveCN104406792AEfficient detectionPrecise frequency informationEngine testingFeature extractionDiagnosis methods

The invention relates to a solid rocket engine fault diagnosis method, and particularly relates to application of vibration signal analysis and a constant fault alarm detection algorithm in solid rocket engine fault diagnosis. The fault diagnosis method is based on a vibration signal analysis technology, and the constant fault alarm detection algorithm is applied to the feature extraction process to perform state identification on specific frequency points on the basis of a frequency fault diagnosis method so that sudden frequency signals submerged in clutter energy spectrum can be effectively detected and accurate frequency information can be obtained. The solid rocket engine fault diagnosis method has important meaning on engine fault decision and provides reliable reference and support for engine design personnel and test personnel.

Owner:内蒙航天动力机械测试所

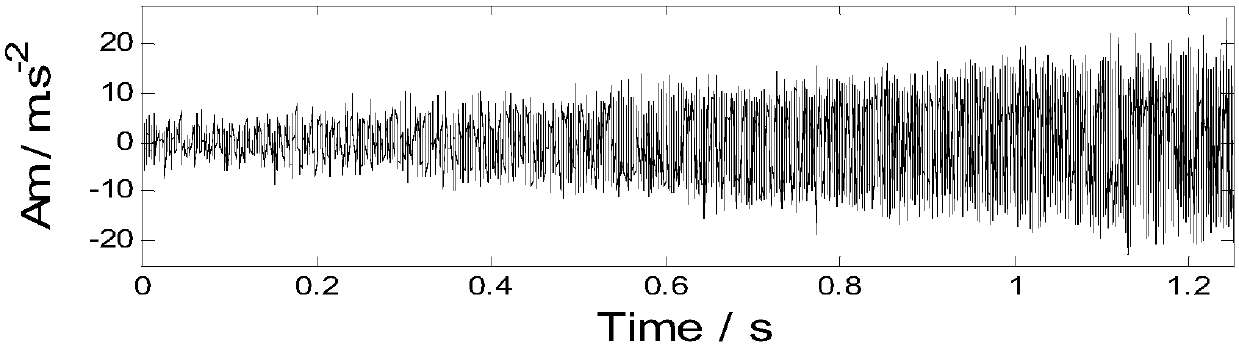

Bearing fault diagnosis method under strong noise variable speed condition based on energy weight method

InactiveCN111665051AEliminate the effects of analysisImprove featuresGeometric CADMachine part testingFrequency spectrumEnergy based

The invention relates to a bearing fault diagnosis method under a strong noise variable speed condition based on an energy weight method. The method comprises the steps: extracting a vibration signalorder through employing a time-frequency ridge feature point linear interpolation and masking algorithm method according to a time-frequency representation graph based on Gabor transformation; performing instantaneous frequency estimation and secondary fitting on the vibration signal by using a local extremum search algorithm and the extracted order; carrying out equal-angle resampling on the vibration signal by utilizing a key phase time scale method according to the fitted instantaneous frequency; performing Hilbert-Huang transformation of CEEMDAN on the resampled isometric domain signal toobtain an order-frequency spectrum of the signal; extracting an impact energy occurrence position in the order-frequency spectrum, and then carrying out binaryzation on the order-frequency spectrum; acquiring an energy weight order sequence capable of reflecting impacts through multi-scale binary spectrum analysis, and carrying out power spectrum analysis on the energy weight order sequence to obtain fault-related impact components. The influence of strong noise and variable rotating speed on vibration signal analysis can be eliminated, and the accuracy of rolling bearing fault diagnosis is improved.

Owner:TIANJIN UNIV

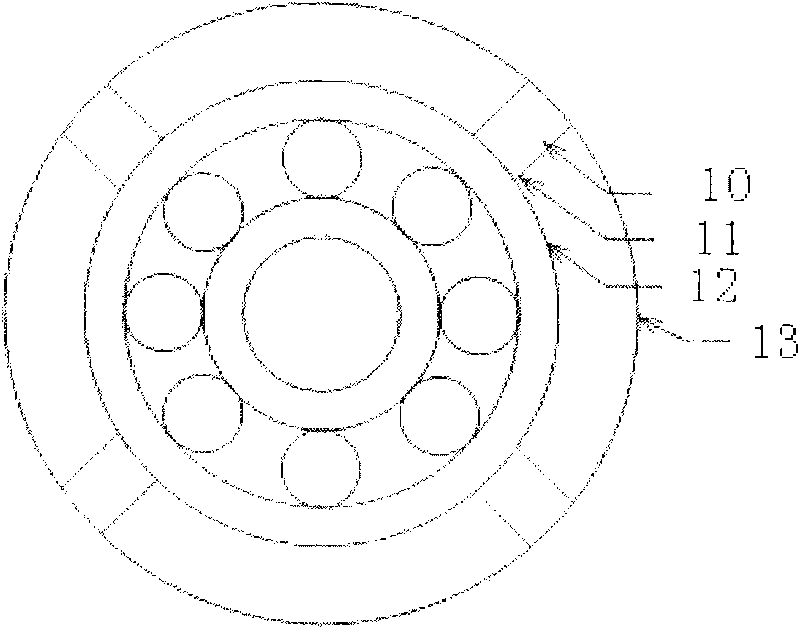

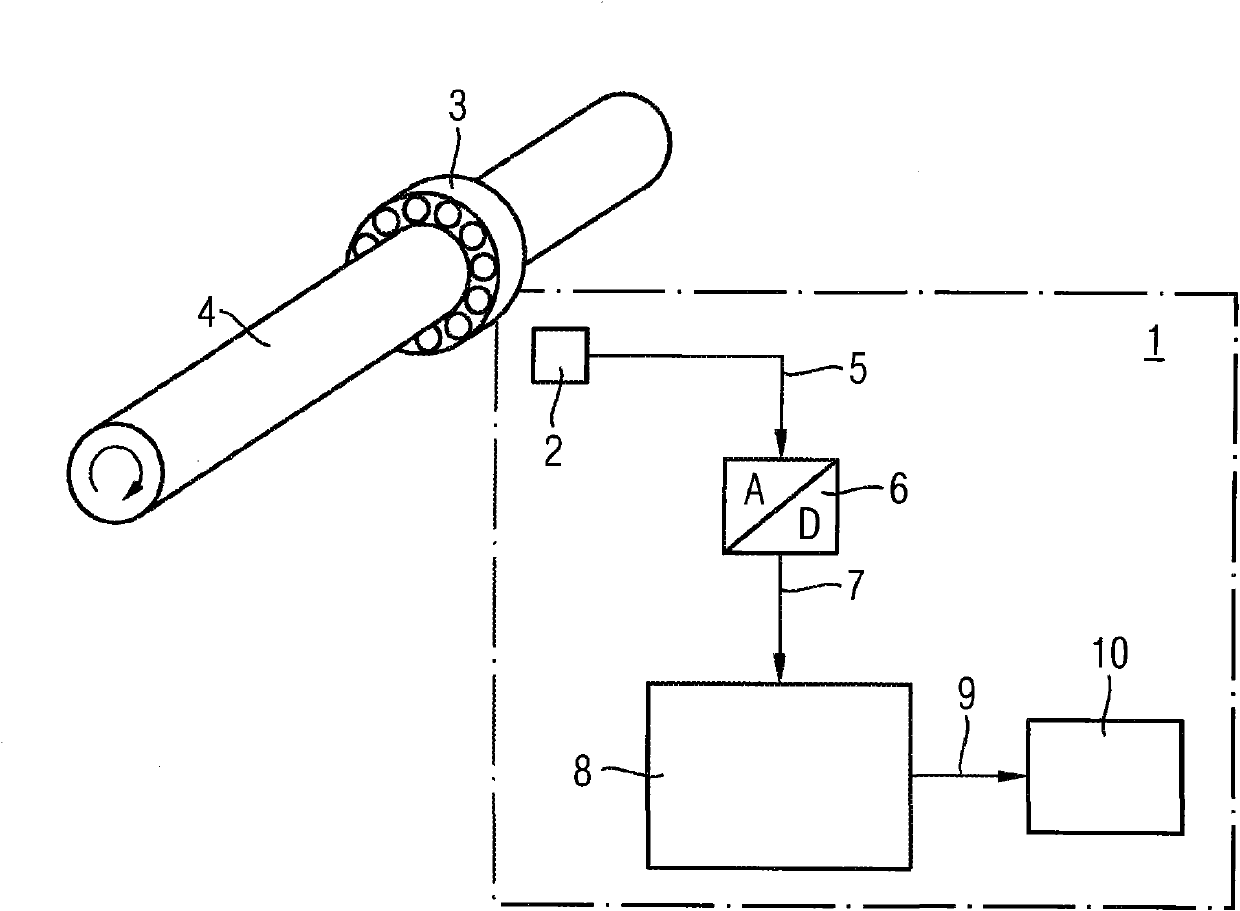

Method and device for recognizing bearing damage using oscillation signal analysis

InactiveCN102007403AIdentify damageVibration measurement in solidsVibration measurement in fluidElectricityFrequency spectrum

A device for recognizing bearing damage of a bearing (3), on which an object (4) which rotates at a rotational frequency is mounted, having at least one oscillation sensor (2) for converting an oscillation signal output by the bearing (3) into an electrical signal and having a calculation unit (8) for performing a first frequency transformation for multiple time windows of the oscillation signal to generate multiple time window spectra associated with the particular time windows and for performing a second frequency transformation for multiple frequency bands of the time window spectrograms to generate a multiband modulation spectrum, which, for modulation frequencies which are a function of the rotational frequency of the rotating object (4) because of bearing damage of the bearing (3), have signal amplitudes, the level thereof disclosing an extent of the bearing damage.

Owner:SIEMENS AG

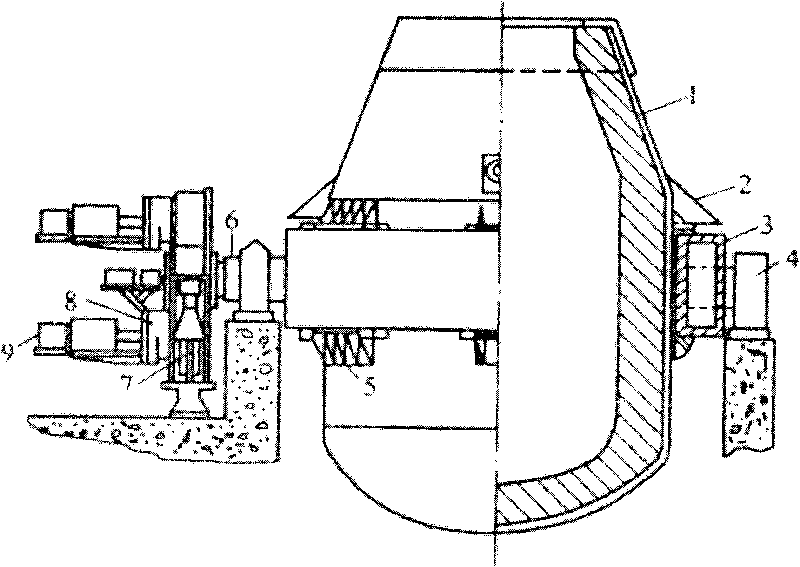

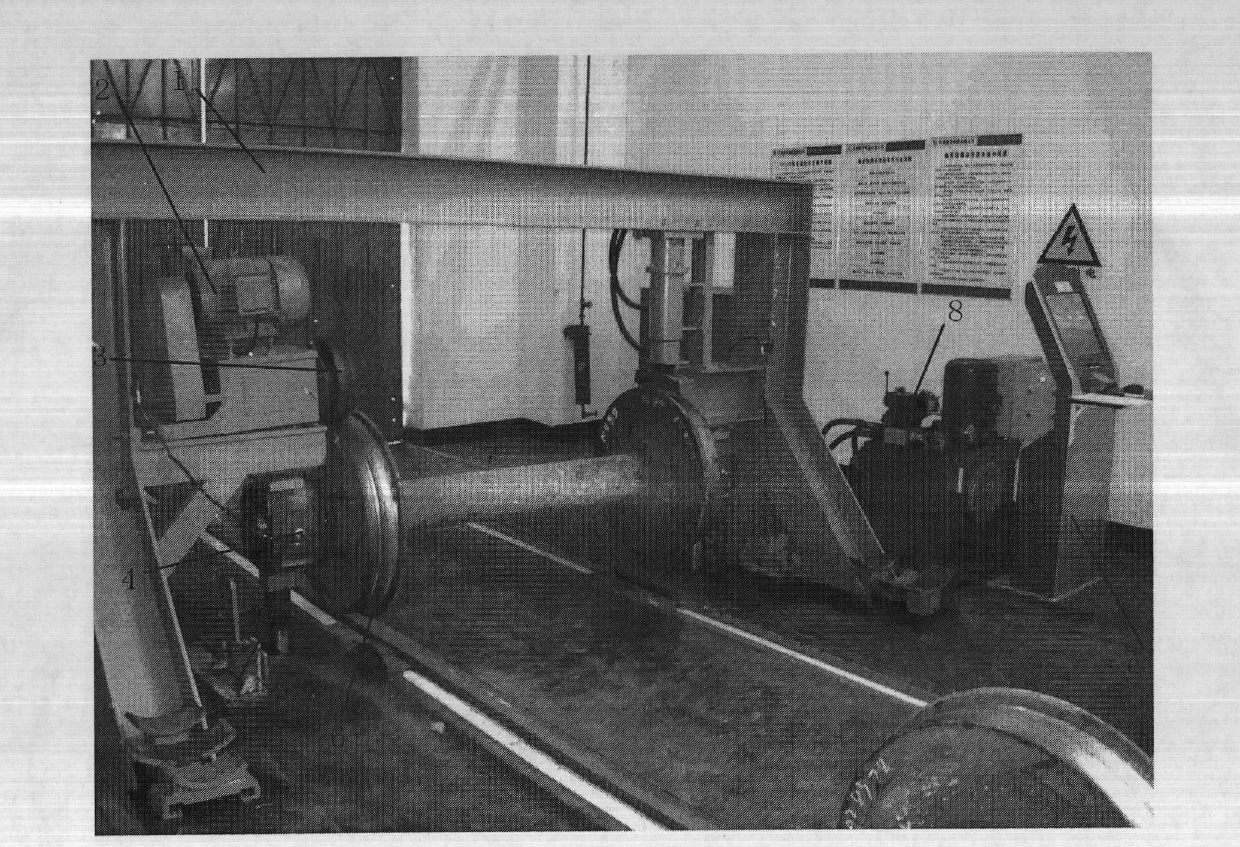

Intelligent detection system of special metallurgical vehicle wheel set bearings

ActiveCN102589881AEasy maintenanceEasy to manageMachine bearings testingVibration accelerationDisplay device

The invention relates to an intelligent detection system of special metallurgical vehicle wheel set bearings. The system comprises a rotating platform, a hydraulic pump, a touch display, a personal computer, a computer cabinet, a signal switchboard, a signal acquisition card, an 8-path relay output module, a vibration sensor, a rotating speed sensor, a hydraulic sensor, connecting wires for each part, a signal communication module, a driving control module, a data acquisition and processing module and a data warning and report generating module. A wheel set is placed on the rotating platform, the computer controls the wheel set to be lifted to a designated position, vibration acceleration sensors are placed at horizontal positions of bearing at both sides of the wheel set, and belt pulleys are driven by a motor to rub with the wheel set. When the rotating speed keeps constant, the wheels stay in the uniform rotation state, vibration signals are started to be collected, test data is stored after collection, and the wheel set is put back to the original position. The software can analyze whether the wheel set has bearing faults through the rotating speed, the current bearing model and the vibration signal. With the detection system, the accuracy rate and the real-time performance are effectively increased, the detection time is reduced, and the detection cost is reduced.

Owner:马鞍山马钢华阳设备诊断工程有限公司

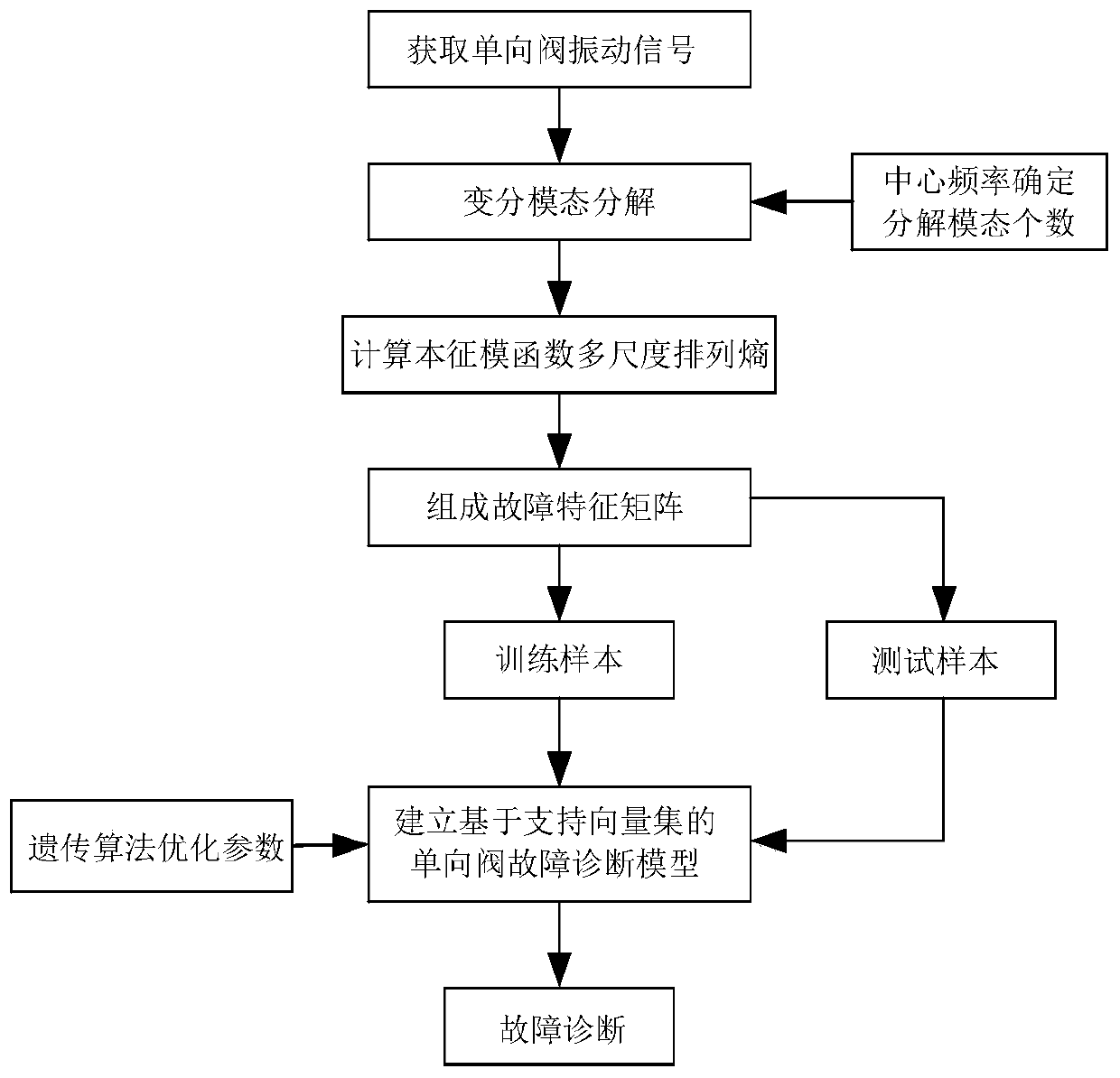

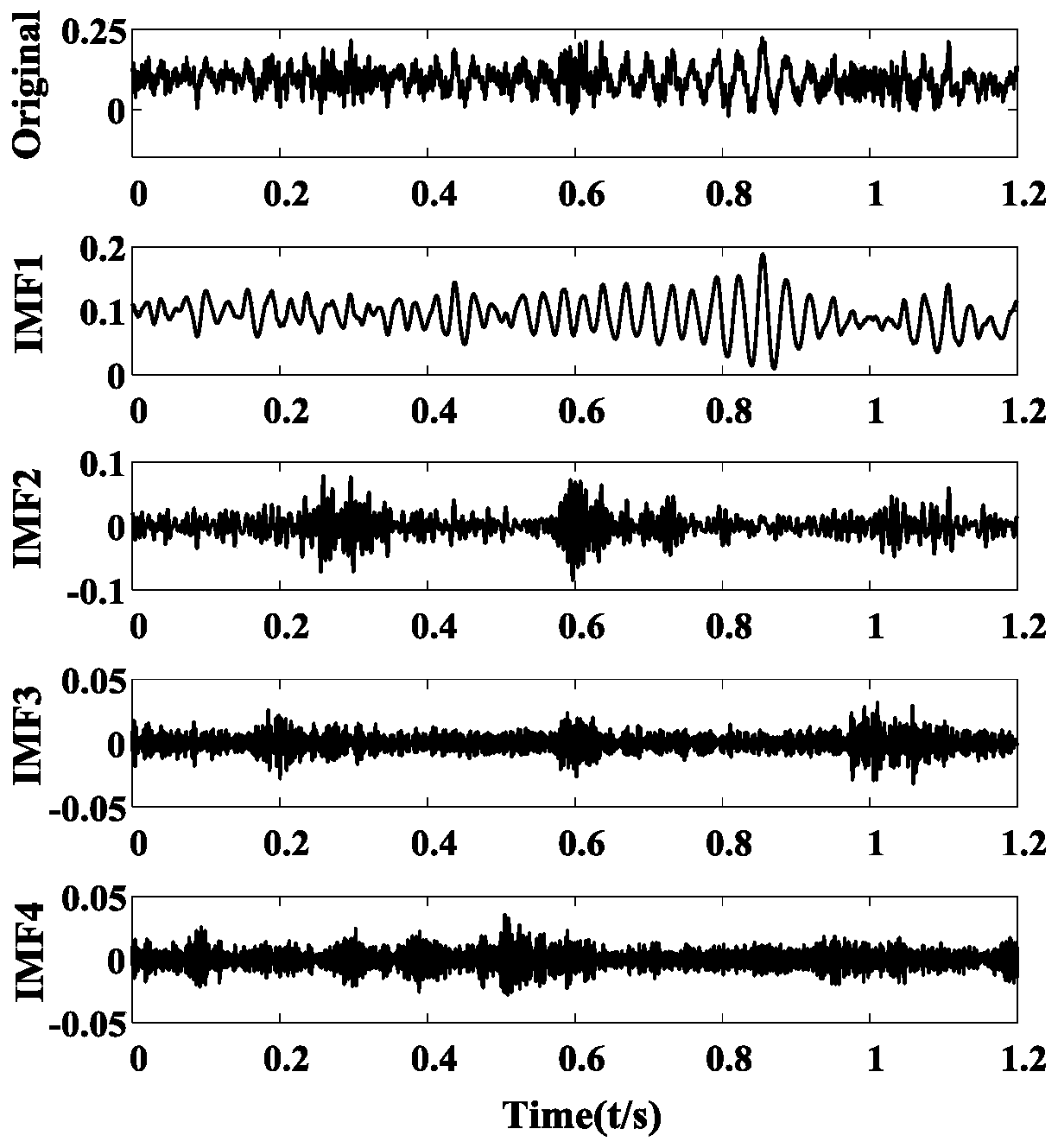

High-pressure diaphragm pump check valve fault diagnosis method based on vibration signal analysis

InactiveCN110044602AImprove the problem of poor vibration signal effectRich in detailsMachine valve testingVibration testingDecompositionEngineering

The invention relates to a high-pressure diaphragm pump check valve fault diagnosis method based on vibration signal analysis, and belongs to the field of mechanical fault diagnosis and signal processing. The high-pressure diaphragm pump check valve fault diagnosis method based on the vibration signal analysis comprises the following steps that firstly, VMD decomposition is carried out on a vibration signal of a check valve of a high-pressure diaphragm pump, and the number K of decomposition modes is determined through a center frequency to obtain K IMF components with physical significance; the MPE of the IMF components is then calculated to form a multi-scale complexity measure feature vector; and finally, a high-dimensional feature matrix is input into a classifier established by a support vector machine optimized based on a genetic algorithm to identify a working state of the check valve of the high-pressure diaphragm pump. According to the high-pressure diaphragm pump check valvefault diagnosis method based on the vibration signal analysis, the vibration signal of the check valve is denoised and decomposed into the IMF components without mode-mixing through a VMD algorithm, the multi-scale arrangement entropy of each IMF component is calculated to collect fault characteristic information distributed on multiple scales, the correct rate of fault identification of the checkvalve is improved, and higher practicability and engineering significance are achieved.

Owner:KUNMING UNIV OF SCI & TECH

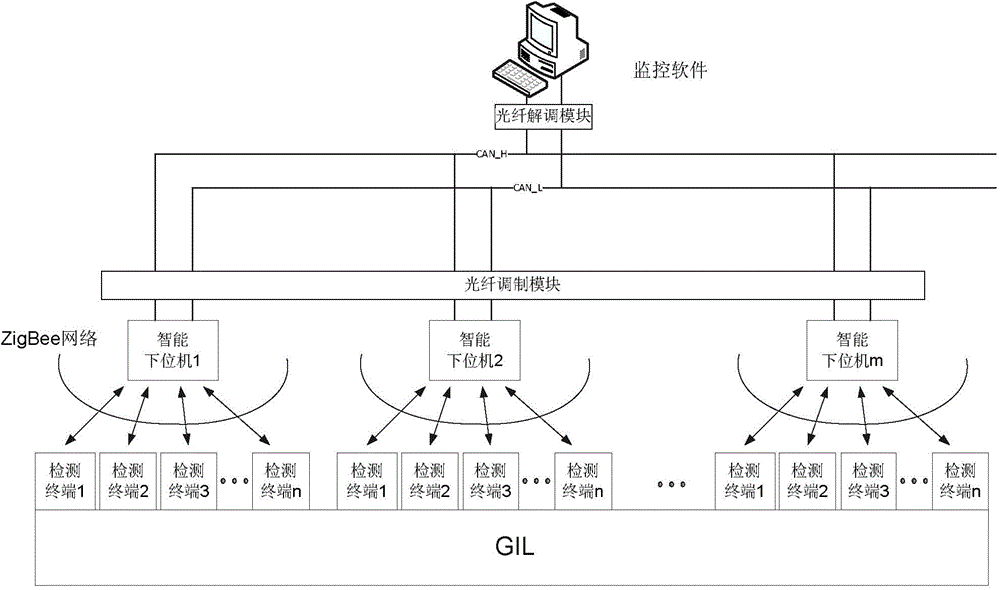

GIL (globalization, internationalization and localization) breakdown discharge positioning detecting system

InactiveCN104698354AImprove maintenance efficiencyExtend working lifeTransmission systemsTesting circuitsElectric power systemEngineering

The invention discloses a GIL (globalization, internationalization and localization) breakdown discharge positioning detecting system. A plurality of vibration detecting devices are adhered to GIL equipment at intervals of 10-20 meters, and if the outputting voltage of the vibration detecting devices is higher than a certain threshold value, the locations of the vibration detecting devices or positions close to the vibration detecting devices have breakdown discharge; and when the breakdown discharge is caused, the intensities of vibration signals acquired from the same GIL equipment are compared, and the distance from the location of the vibration detecting device which acquires the signals with the maximum intensity to the position of breakdown discharge is minimum. Advantages of the vibration signals are utilized sufficiently, by an advanced vibration signal analyzing method, the position and the intensity of breakdown discharge of the GIL equipment can be determined accurately, the overhaul efficiency of the GIL equipment is greatly improved, the service life of the GIL equipment is prolonged, the working reliability of the GIL equipment is improved, and the safety and the reliability on stable running of an electric system are guaranteed.

Owner:XI AN JIAOTONG UNIV

Fiber-optic gyroscope vibration signal analysis method based on improved LMD

ActiveCN105424057AImprove endpoint effect problemFast convergenceMeasurement devicesMoving averageFiber

The invention discloses a fiber-optic gyroscope vibration signal analysis method based on improved LMD, and belongs to the technical field of inertial navigation. The method includes the steps that time-frequency domain decomposition is performed on a vibration signal through the improved LMD method, and a series of harmonic signals corresponding to different frequency bands in the original signal are obtained; finally, construction is performed by eliminating light source fluctuation noise and gyroscopic drift caused by vibration, and an output signal with vibration noise removed is obtained. According to the improved LMD method, cubic spline interpolation is adopted for replacing a moving average method, meanwhile a mirror extension method is adopted for relieving possible end effect problems, and OC judgment with a higher convergence speed is introduced into decomposition ending conditions. A kernel principal component analysis method is used for analyzing component signals, an energy ratio method is used for separating and reflecting effective signals and noise generated under vibration influences, and finally effectiveness analysis of the fiber-optic gyroscope vibration signal is completed.

Owner:SOUTHEAST UNIV

Method for detecting and diagnosing faults of intermittent low-speed and heavy-load device

InactiveCN101900660AOvercome the disadvantage of being easily interfered by noise signalsFlow propertiesAnalysis by material excitationLow speedDevice status

The invention discloses a method for state monitoring and fault diagnosis of an intermittent large-scale low-speed and heavy-load production device, wherein the state monitoring and the fault diagnosis can not be effectively solved by utilizing the vibration signal analysis method, and the method is the technical method for carrying out the state monitoring and the fault analysis and diagnosis on the intermittent large-scale low-speed and heavy-load device through physical and chemical index detection, spectral analysis and ferrographic analysis of lubricating oil liquid (grease) used by the device. The invention provides an early wear fault diagnosis and maintenance scheme of the low-speed and heavy-load device, which can improve the accuracy of lubrication state monitoring of the low-speed and heavy-load device and the using management level of the lubricating oil (grease), save maintenance cost, prolong the service life of the device and create greater production value.

Owner:BEIJING UNIV OF TECH

Vibration signal analysis method for main bearing of wind power transmission system based on improved HHT and fuzzy entropy

The invention discloses a vibration signal analysis method for a main bearing of a wind power transmission system based on improved HHT and fuzzy entropy. The method comprises the steps of collectinga vibration signal, performing EMD decomposition on the vibration signal, screening a real IMF component by a relative entropy theory, and performing Hilbert spectrum analysis to obtain marginal spectrum through synthesis. According to the method, the fault characteristics of the main bearing of the wind power transmission system can be stably and effectively extracted, and the interference of thenoise to a characteristic frequency can be effectively filtered. A false eigenmode function component generated by empirical mode decomposition is eliminated with proposed improved Hilbert-Huang transform, the marginal spectrum synthesized by the real component is made, and the true frequency distribution of the signal is reflected. Combined with the fuzzy entropy theory, an eigenmode function which best reflects fault bearing characteristics is screened out.

Owner:SOUTHEAST UNIV

Bearing fault intelligent diagnosis method based on compressed sensing and correlation vector machine

PendingCN112287889AImprove efficiencyImprove accuracyMachine part testingCode conversionEngineeringSignal-to-noise ratio

The invention discloses a bearing fault intelligent diagnosis method based on compressed sensing and a correlation vector machine. According to the method, fault diagnosis is achieved through vibration signal analysis. The method comprises the steps of firstly selecting a Gaussian random matrix as a measurement matrix based on a compressed sensing theory to realize compressed sampling of signals,secondly constructing an over-complete redundant dictionary to perform sparse representation on the signals, then utilizing an orthogonal matching pursuit algorithm to realize signal reconstruction, and selecting a time domain index sensitive to fault features as a feature vector for the reconstructed signals; and finally, selecting a Gaussian function as a kernel function, dividing a training sample and a test sample by utilizing a feature vector, importing the training sample into an intelligent recognizer of a relevance vector machine model constructed by a relevance vector machine, and comparing a test result with an actual fault type and degree to obtain the effectiveness of the diagnosis model. According to the invention, the problems of difficult transmission and processing of massdata and low signal-to-noise ratio of bearing vibration signals can be solved, and qualitative and quantitative identification of bearing faults can be realized more accurately.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for extracting fault features of gantry crane lifting mechanism under variable speed

InactiveCN108120597AOvercome the flaw of inaccurate estimationMachine gearing/transmission testingFeature extractionTime–frequency analysis

The invention relates to a method for extracting fault features of a gantry crane lifting mechanism under the variable speed. The method comprises the steps of firstly collecting an original vibrationsignal of the gantry crane lifting mechanism under the variable speed, performing low-pass filtering and downsampling on the original vibration signal according to the speed of the lifting mechanism,then analyzing the undersampled vibration signal by using a time-frequency analysis method to obtain a time-frequency cloud map, extracting the instantaneous rotating frequency according to a frequency ridge extraction method, obtaining an estimated instantaneous rotating frequency curve through polynomial fitting, performing uniform angle sampling on the original vibration signal according to the estimated instantaneous rotating frequency curve, carrying out order ratio analysis by using the uniform angle sampled vibration signal to obtain an order ratio spectrum, and judging whether the gantry crane lifting mechanism breaks down or not according to the order ratio spectrum. The method solves a problem that it is difficult to extract fault features for the existing gantry crane lifting mechanism under the variable speed.

Owner:TIANJIN JINAN HEAVY IND

Fault diagnosis system and method for fuel delivery pump

InactiveCN104121178AImprove efficiencyImprove accuracyPump testingPositive-displacement liquid enginesSignal ConditionerInstrumentation

The invention provides a fault diagnosis system and method for a fuel delivery pump. The fault diagnosis system mainly comprises four piezoelectric acceleration transducers, five temperature sensors, a signal conditioner, a temperature measurement module, a data acquisition card and an industrial control computer. The four piezoelectric acceleration transducers are connected with the signal conditioner respectively. The signal conditioner, the data acquisition card and the industrial control computer are connected in sequence. The five temperature sensors are connected with the temperature measurement module respectively. The temperature measurement module, the data acquisition card and the industrial control computer are connected in sequence. The fault diagnosis method comprises the steps of (1) vibration signal acquisition, (2) signal conditioning, (3) data acquisition and (4) signal analysis. The fault diagnosis system can combine the virtual instrument technology, a traditional temperature signal analysis method, a traditional vibration signal analysis method and a modern vibration signal analysis method, thereby effectively improving efficiency and accuracy of fault diagnosis of the fuel delivery pump.

Owner:QINGDAO UNIV OF SCI & TECH

Vibration signal grading judgment recognition method, rockfall energy scale computing method and rockfall risk early warning method

ActiveCN106845429AImprove analysis accuracySolve the problem of vibration signal identificationCharacter and pattern recognitionComputing centerPattern recognition

The invention discloses a vibration signal grading judgment recognition method. On account of defects of lack of combination and using of multiple analysis methods and aiming at improving vibration signal analysis precision, the invention provides the vibration signal multistage recognition method achieving improving identification precision by adopting different signal analysis indexes and analysis methods on different identification stage layers and combining amplitude analysis, energy analysis and frequency analysis into one. According to the method, a computing center executes the steps of de-noising processing, signal I level identification of an amplitude index, signal II level identification based on FFT transformation and signal III level identification based on STFT transformation after subtracting an amplitude signal with an initial time, and finally judges whether target vibration occurs or not. The invention further discloses a rockfall energy scale computing method and a rockfall risk early warning method. The vibration signal grading judgment recognition method, the rockfall energy scale computing method and the rockfall risk early warning method have the advantages of being reliable in theory, scientific and simple in computing process, simple in implement apparatus, convenient to install, high in measuring result precision, and especially suitable for the demand of the engineering field.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI +1

Fault diagnosis method for gear of drive system based on vibration signal analysis

InactiveCN103472137ASolve the problem of modal aliasingEasy to troubleshootMaterial analysis using acoustic emission techniquesProcessing detected response signalDecompositionEngineering

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com