Intelligent detection system of special metallurgical vehicle wheel set bearings

A special vehicle and intelligent detection technology, which is applied in the detection field, can solve the problems of heavy disassembly and assembly work, axle damage, waste of resources, etc., and achieve the effects of convenient maintenance and management, reduced inspection costs, and reduced inspection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

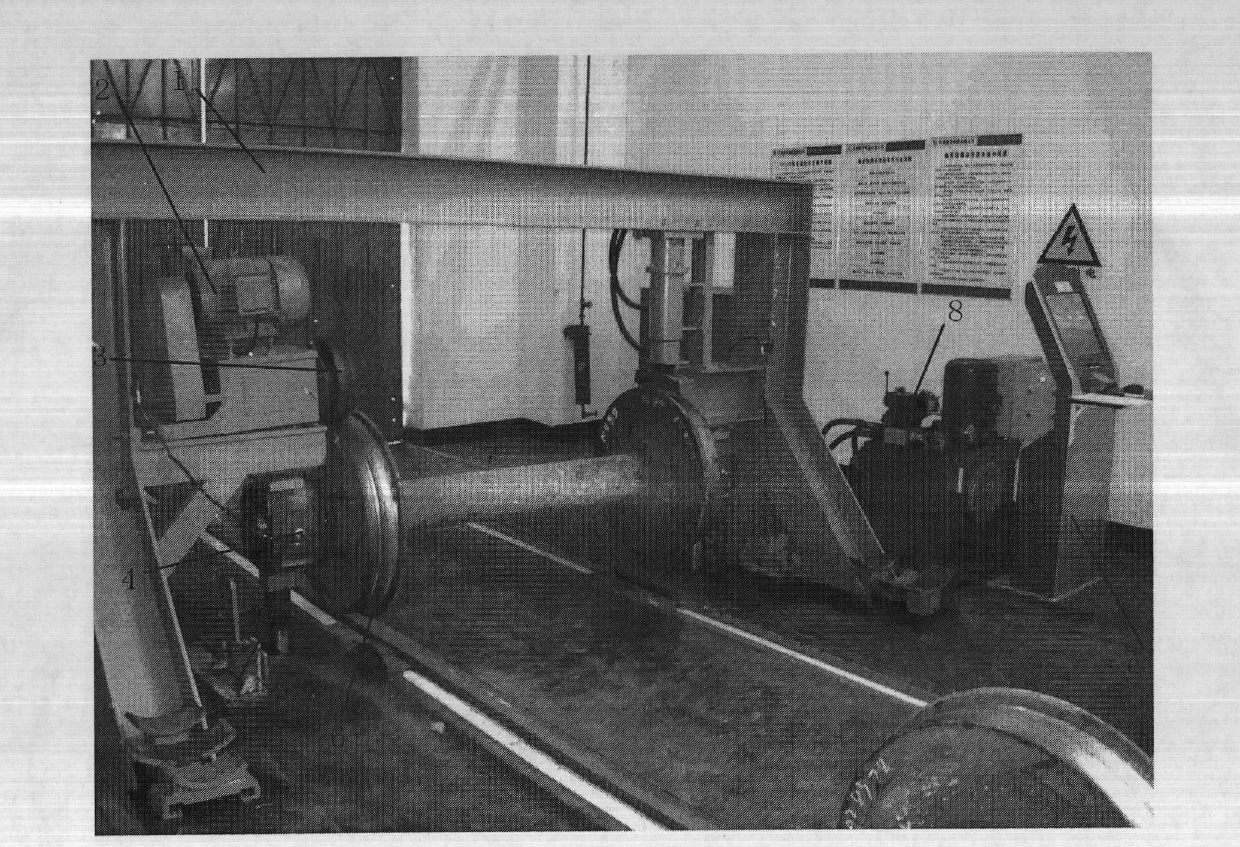

[0037] An intelligent detection system for wheel set bearing defects of metallurgical special vehicles with wheel diameters of 760 mm and 840 mm ( figure 1 , figure 2 ), consisting of a hardware part and a software part, the hardware part mainly consists of a rotating platform (1), a hydraulic pump (8), a touch display (7), a personal computer and a cabinet (7), a signal adapter board and a signal acquisition card, 8 Road relay output module, vibration sensor (4), speed sensor, hydraulic sensor and connecting lines of various parts; the software part is mainly composed of signal communication module, drive control module, data acquisition and processing module, data alarm and report generation module, etc. .

[0038] The two vibration sensors used in this system are the acceleration sensor 780A of Wellcome Corporation of the United States, which are used to detect the vibration of the two wheel bearings respectively, and the operation of the detected wheel set is obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com