Method of fault diagnosis on ball socketed bearing of steel-making converter by comprehensive analysis

A technology for steelmaking converters and trunnion bearings. It is applied in the direction of material analysis, material analysis, and mechanical bearing testing through optical means. It can solve problems such as equipment failure limitations, avoid major accidents, improve accuracy, and facilitate failures. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, a method of comprehensively using vibration signal analysis and oil (grease) analysis to diagnose the fault of the steelmaking converter trunnion bearing is as follows: respectively carry out vibration signal analysis and oil (grease) analysis on the steelmaking converter trunnion bearing ) analysis, and then integrate the results of the two for the final fault diagnosis.

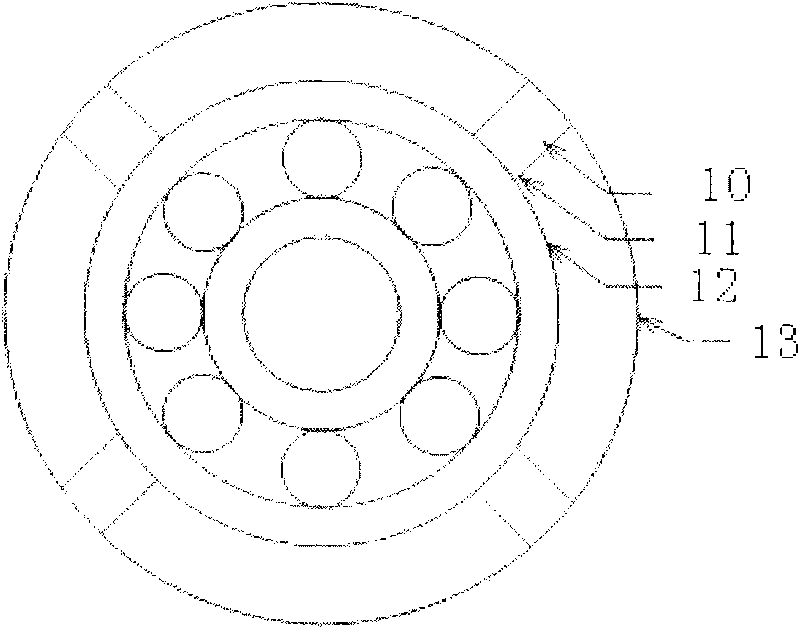

[0030] Such as figure 2 As shown, there are three main steps in vibration signal analysis:

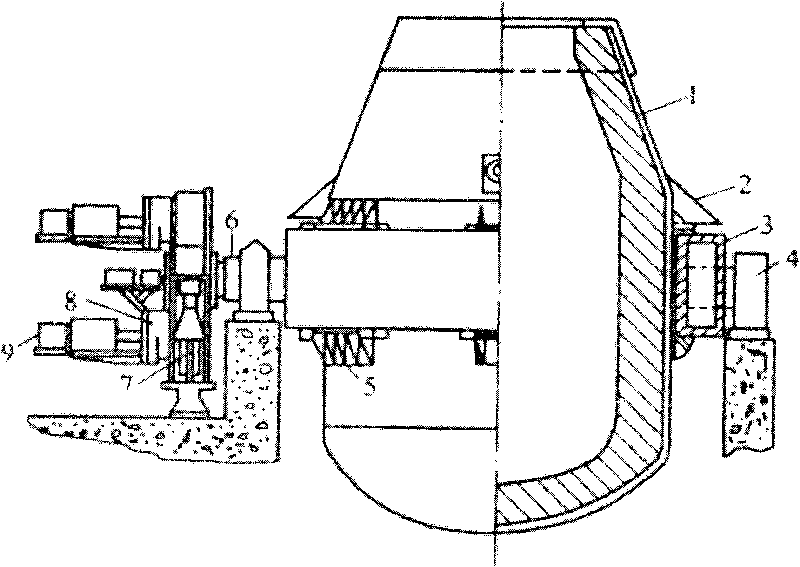

[0031] 1) Selection of measuring points, installation and fixation of sensors. image 3 It is the furnace structure diagram of the steelmaking converter. The number 4 in the figure is the trunnion bearing and the bearing seat. Since the trunnion rotates at a low speed and carries a large load, the trunnion bearing is a fault-prone part and becomes a key component for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com