Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

639 results about "Bearing vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

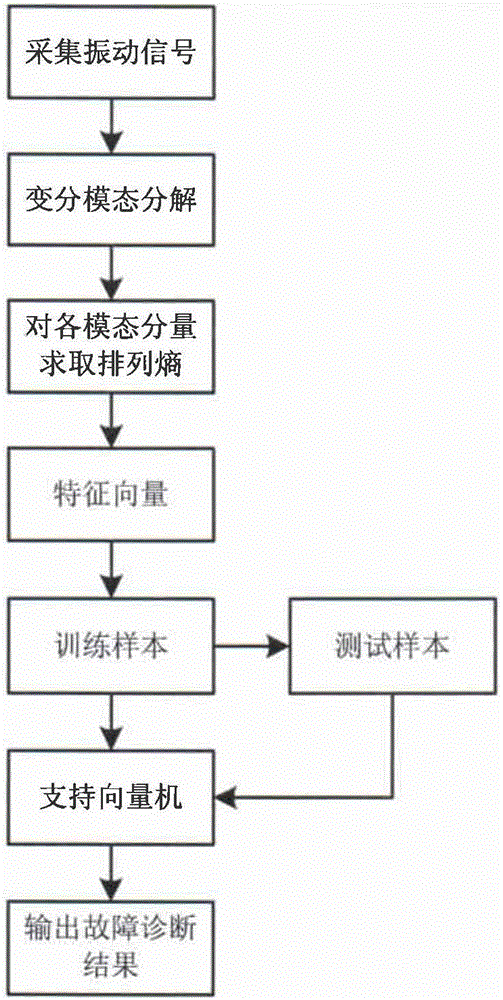

Rolling bearing fault diagnosis method based on variation mode decomposition and permutation entropy

InactiveCN105758644AImplement fault diagnosisImprove recognition accuracyMachine bearings testingCharacter and pattern recognitionSupport vector machineDecomposition

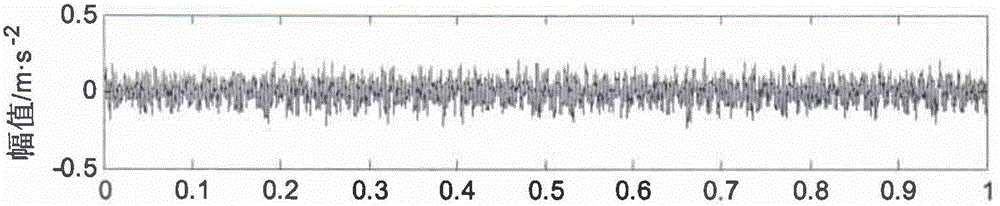

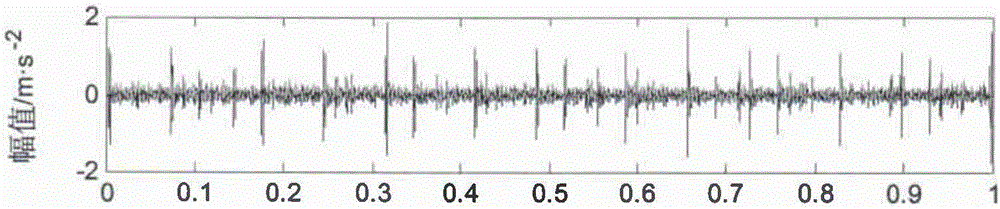

The invention relates to a rolling bearing fault diagnosis method based on variation mode decomposition and permutation entropy. Vibration signals are decomposed with a variation mode decomposition method, so that reactive components and mode aliasing are effectively reduced, all the mode components include characteristic information of different time scales of original signals, and effective multi-scale components are provided for subsequent signal characteristic extraction. With the combination of the features that permutation entropy is simple in calculation, high in noise resisting ability and the like, bearing fault characteristics of all the mode components are extracted from multi-scale angles. Compared with single permutation entropy analysis of rolling bearing vibration, the characteristic information of the signals can be more comprehensively represented through the permutation entropy characteristic extracting method based on multiple scales, the recognition accuracy of a support vector machine is improved, and fault diagnosis of rolling bearings is better achieved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

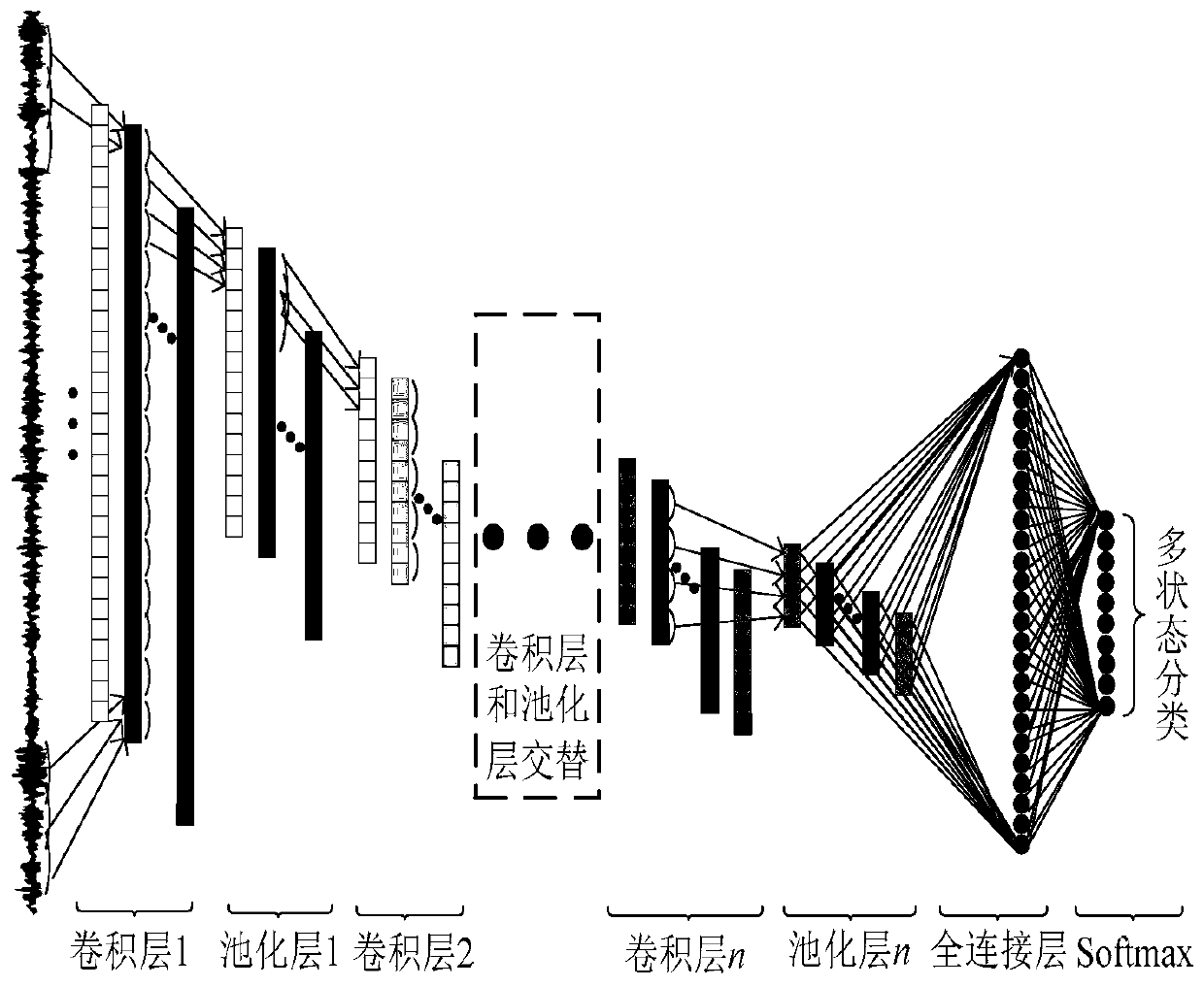

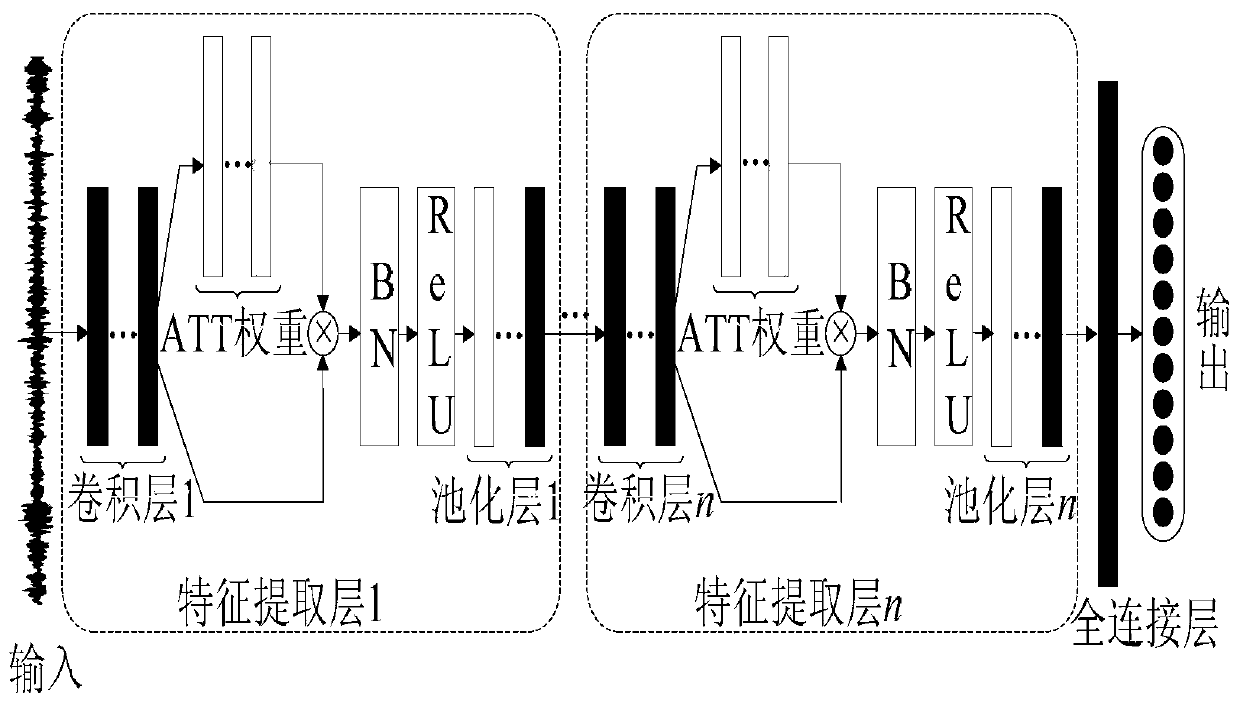

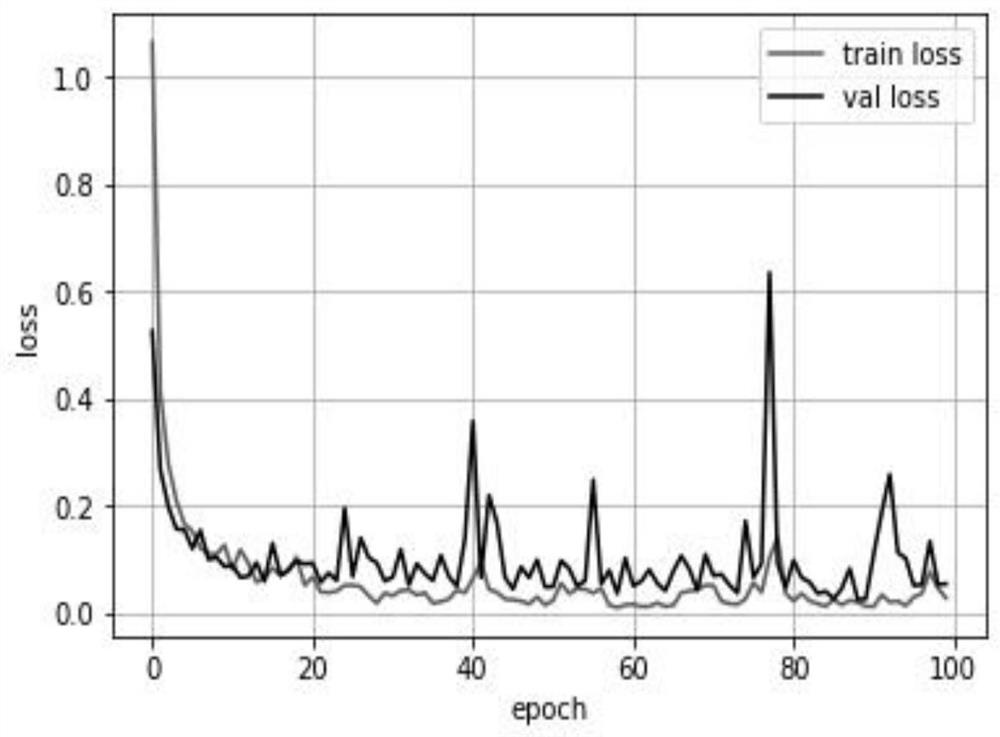

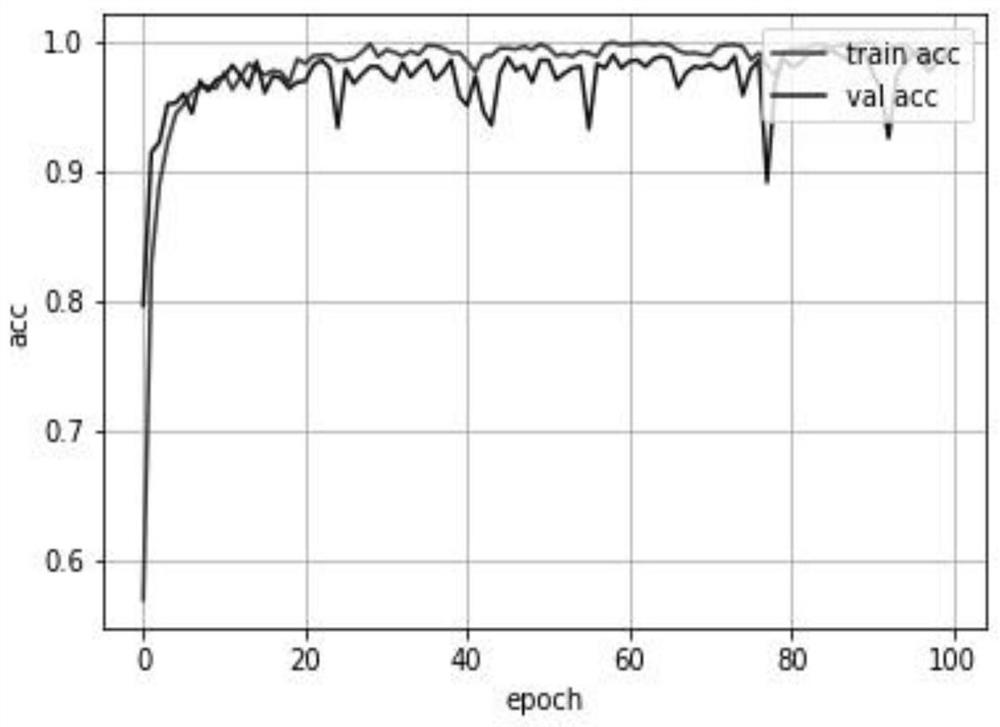

A rolling bearing fault identification method under variable working conditions based on ATT-CNN

ActiveCN109902399ASolve the fault identification problemIncreased sensitivityMachine bearings testingNeural architecturesAlgorithmBearing vibration

The invention discloses a rolling bearing fault identification method under variable working conditions based on ATT-CNN, and relates to a rolling bearing fault identification technology. The problemthat the generalization ability of an existing rolling bearing fault recognition method under variable working conditions is limited to a certain extent for a complex classification problem is solved.The method comprises the following steps: firstly, mapping vibration data to a nonlinear space domain through a convolutional neural network (CNN), and adaptively extracting rolling bearing fault characteristics under variable working conditions by utilizing the characteristic that the CNN has invariance on micro displacement, scaling and other distortion forms of an input signal; Secondly, an attention mechanism (ATT) thought is put forward to be fused into a CNN structure, and the sensitivity of bearing vibration characteristics under variable working conditions is further improved; And meanwhile, more abundant and diverse training samples are obtained through a data enhancement method, so that the network can be learned more fully, and the robustness is improved. The proposed fault diagnosis model based on the attention mechanism CNN (ATT-CNN) can realize multi-state recognition and classification of the rolling bearing under variable working conditions, and compared with other methods, higher accuracy can be obtained.

Owner:HARBIN UNIV OF SCI & TECH

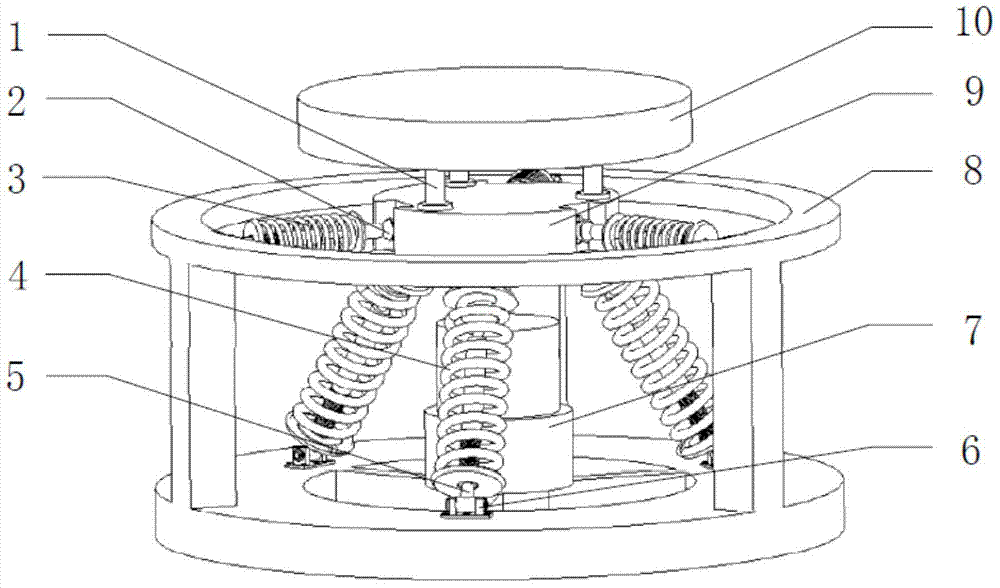

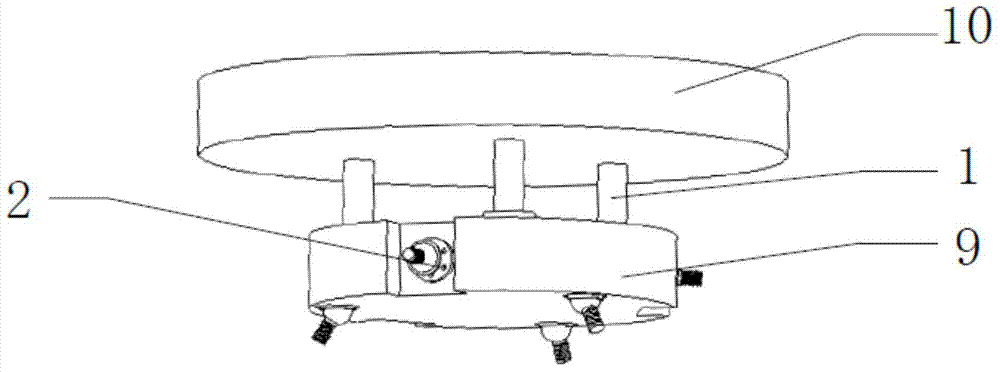

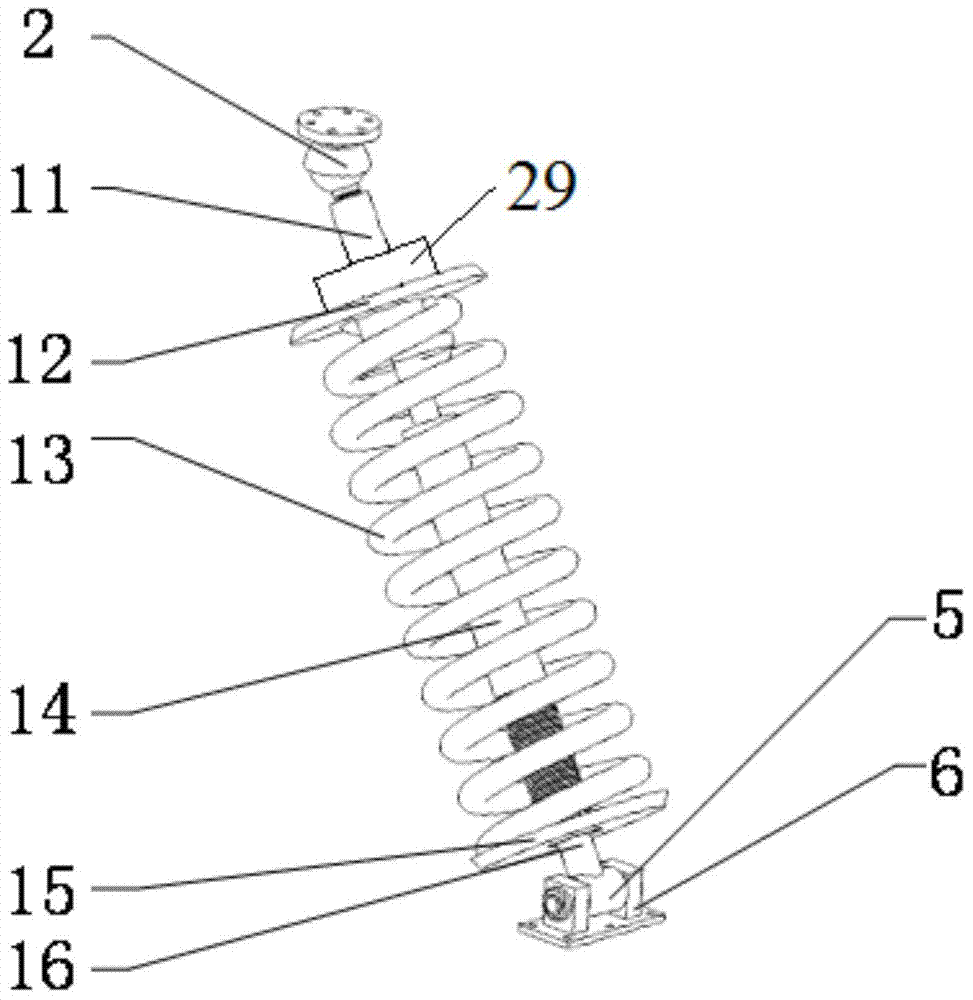

Damping-adjustable vibration isolation platform with quasi-zero stiffness

ActiveCN103899704ASolve the problem of isolating low frequencySolve the problem of ultra-low frequency vibrationNon-rotating vibration suppressionSemi activeBearing vibration

The invention discloses a damping-adjustable vibration isolation platform with quasi-zero stiffness. The damping-adjustable vibration isolation platform comprises a bearing assembly, a fixed platform frame and damping assemblies. The bearing assembly is used for bearing vibration isolation objects. The fixed platform frame is provided with an open end and a cavity which is communicated with the open end, and the bearing assembly and the damping assemblies are contained in the cavity. The damping assemblies comprise the damping-adjustable upper damping assembly and the damping-adjustable lower damping assembly which are arranged in the cavity in the longitudinal direction, and the bearing assembly is connected with the fixed platform frame through the upper damping assembly and the lower damping assembly. The vibration isolation platform solves the difficulty existing when a traditional linear vibration isolation system isolates low frequency or ultra-low frequency vibration, and also overcomes the defects that an active or semi-active control vibration isolation device is complex in structure, high in manufacturing cost, high in energy consumption and the like; the vibration isolation platform is simple in structure, applicable to wide-frequency-domain vibration isolation, capable of being widely applied to precise equipment with strict vibration isolation requirements and has good engineering adaptability. Besides, damping is simple and convenient to adjust.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

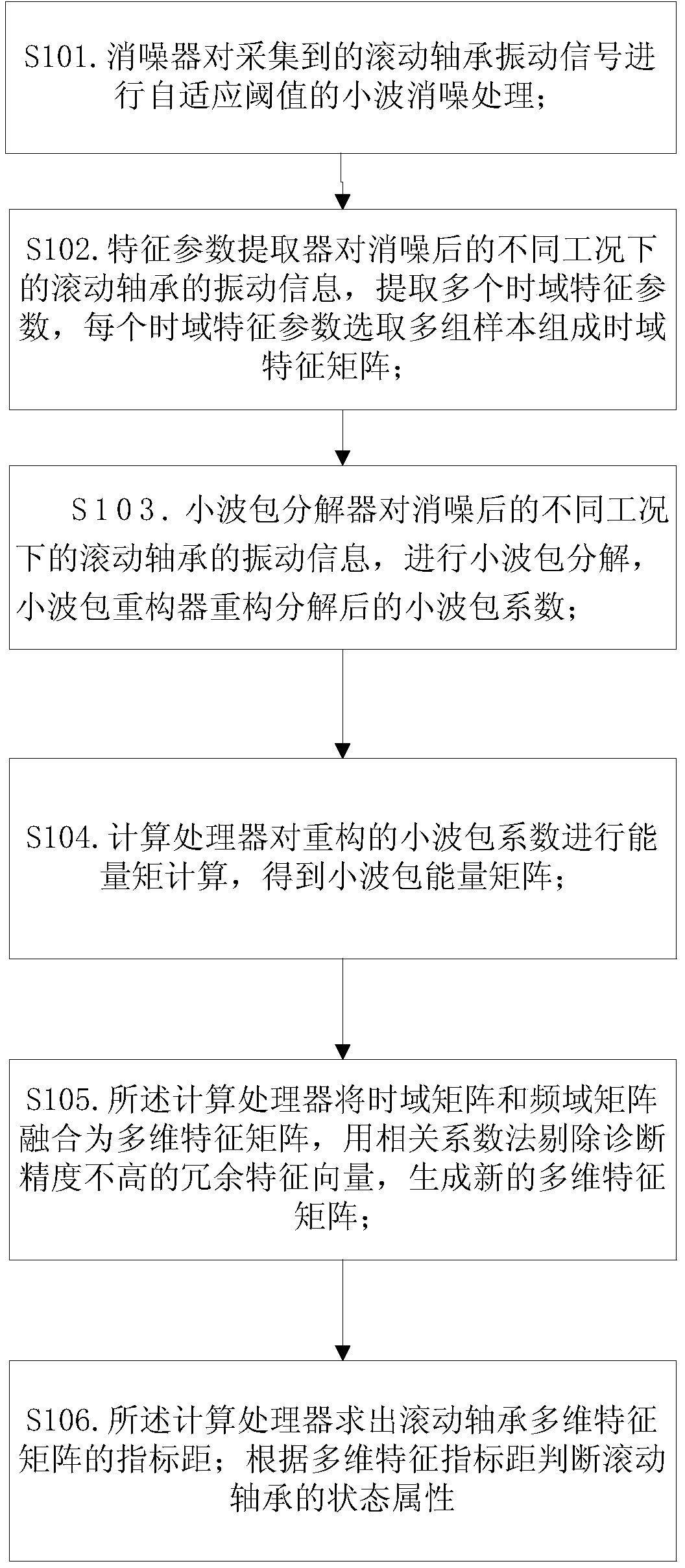

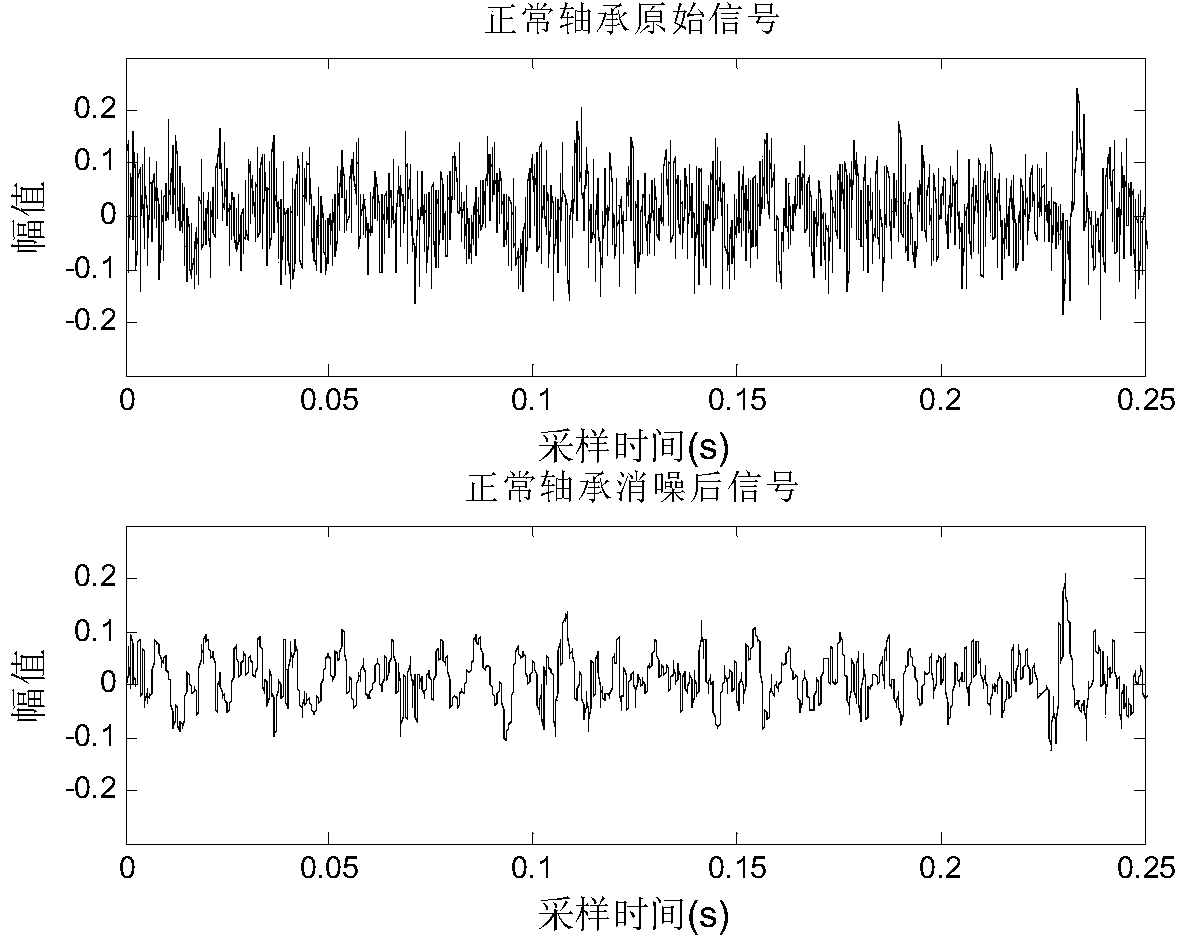

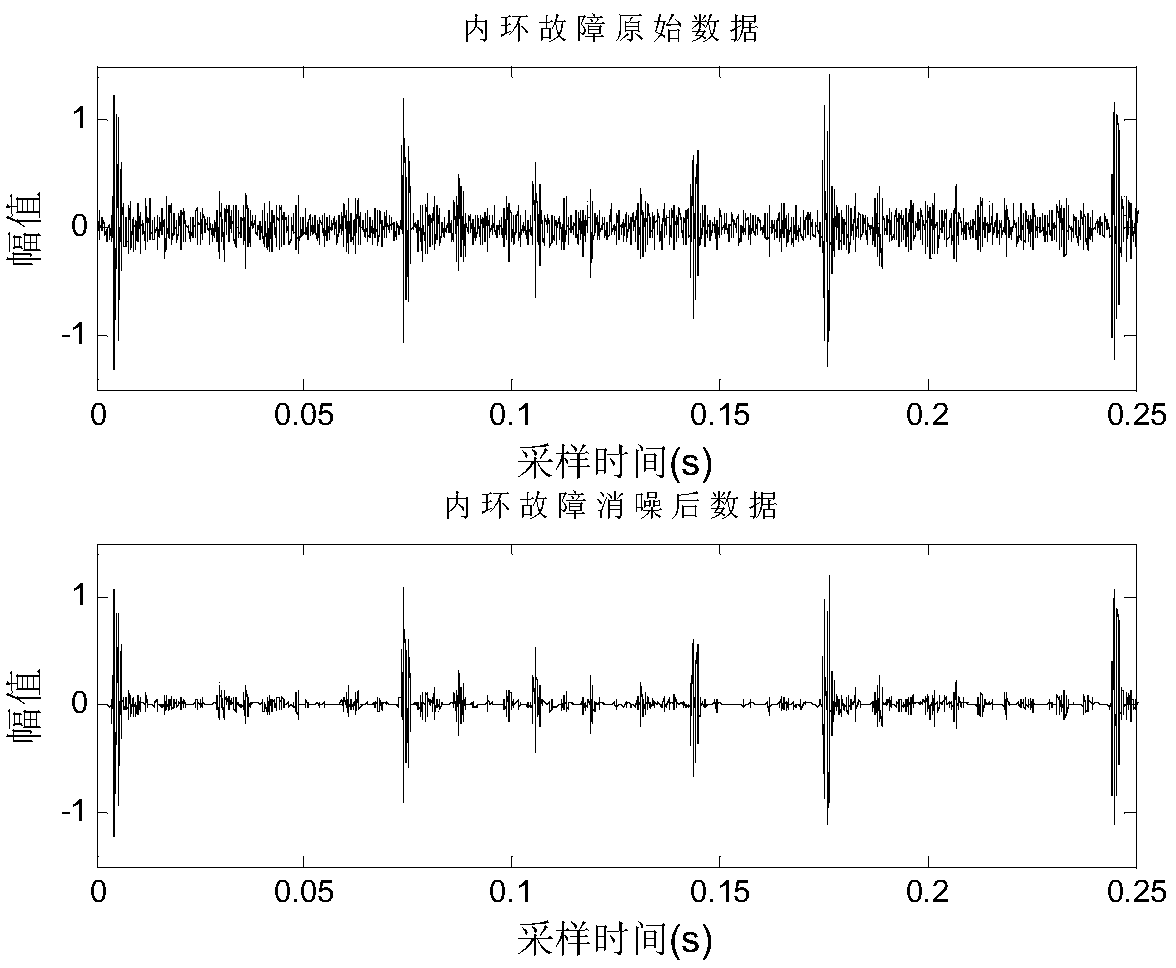

Rolling bearing fault diagnosis method based on time-frequency domain multidimensional vibration feature fusion

ActiveCN104655423AIncrease computational time complexityImprove diagnostic accuracyMachine bearings testingEngineeringEuclidean vector

The invention provides a rolling bearing fault diagnosis algorithm based on time-frequency domain multidimensional fault feature fusion. Aiming at the respective features of vibration signals of a rolling bearing in a normal state, a roller fault state, an inner ring fault state and an outer ring fault state in a time-frequency domain, through extraction of time domain and frequency domain features, redundancy removal and re-fusion, fault features are described in an optimal way to obtain an intelligent judgment result. First, wavelet de-noising is performed on extracted original rolling bearing vibration data; then, time domain feature vectors are extracted to form a time domain feature matrix, and coefficient energy moments after wavelet packet decomposition and reconstruction are extracted to form a frequency domain feature matrix; and the time and frequency domain matrixes are further fused to obtain a time-frequency domain multidimensional fault feature matrix. Redundancy of the multidimensional feature matrix is eliminated to obtain a new multidimensional feature matrix. Then, information of multidimensional features is fused with a weighted feature index distance, and a state judgment result of the rolling bearing is obtained through the feature index distance obtained through fusion.

Owner:BEIJING JIAOTONG UNIV +1

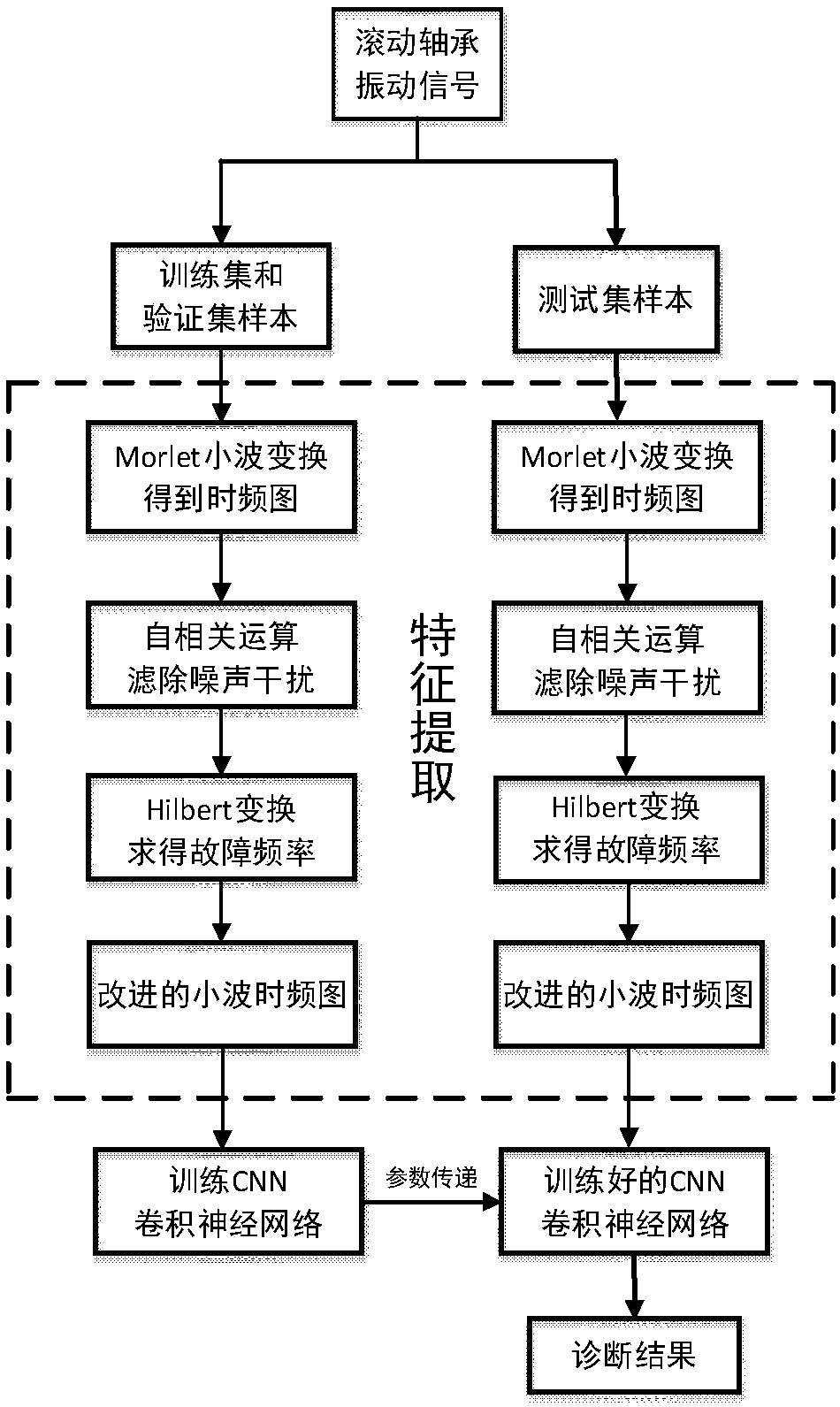

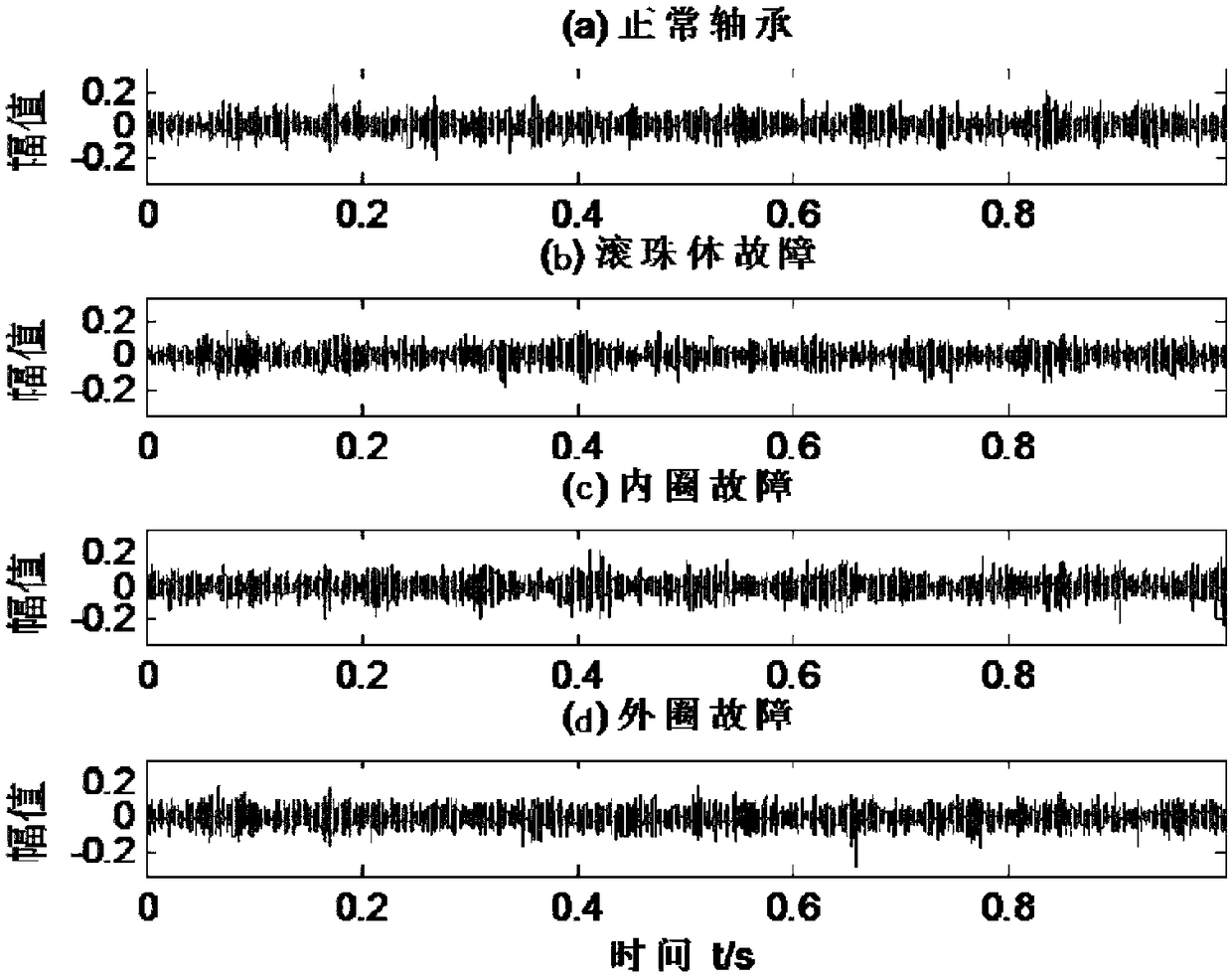

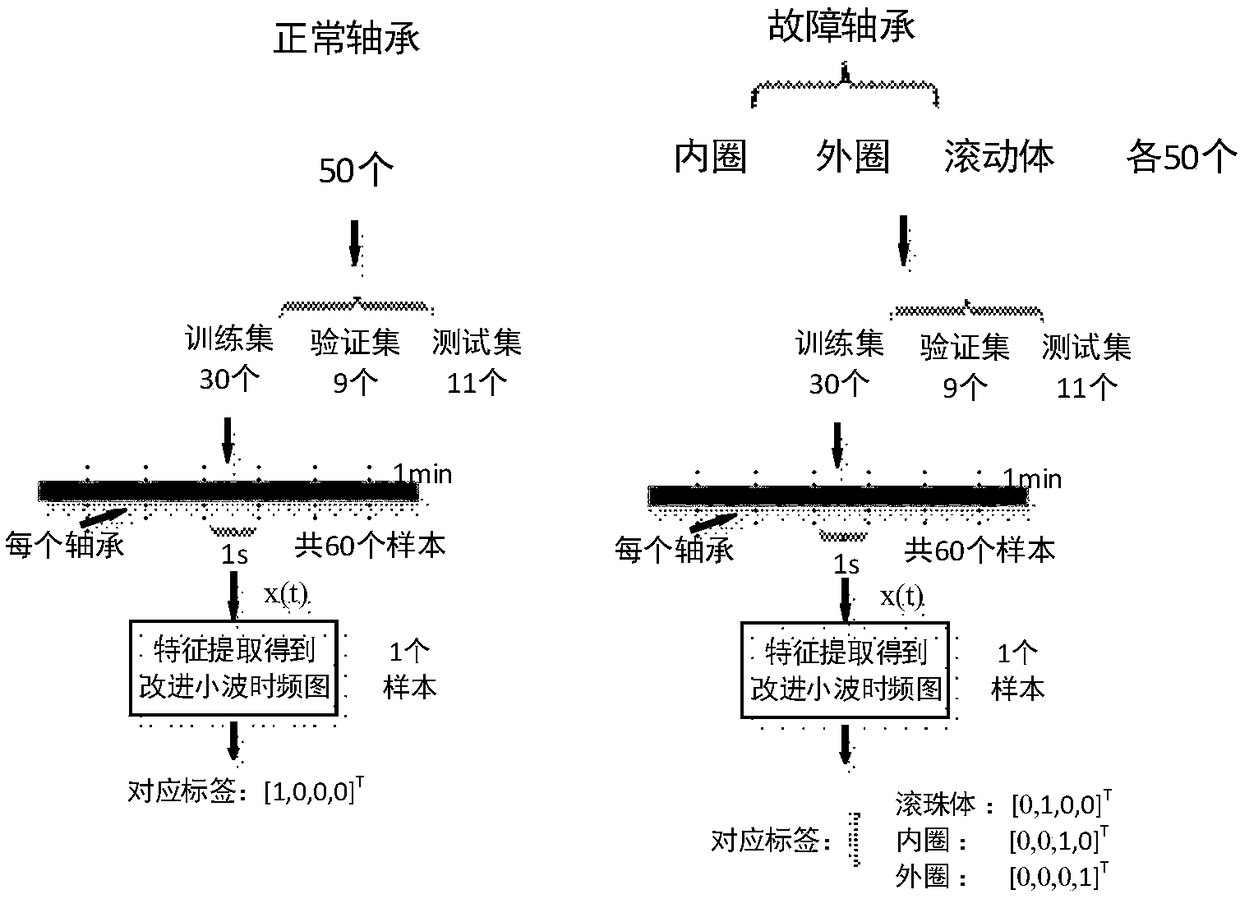

Wavelet transformation and deep learning-based rolling bearing weak fault diagnosis method

The invention discloses a wavelet transformation and deep learning-based rolling bearing weak fault diagnosis method. The method comprises the following steps: a rolling bearing vibration signal is obtained, and the acquired vibration signal is subjected to continuous wavelet transformation to obtain a time-frequency diagram; autocorrelation operation is performed on wavelet coefficients corresponding to each frequency on the time-frequency diagram to filter out noise interference and extract periodic fault components; the Hilbert transformation is used to perform envelope demodulation to obtain a fault characteristic frequency; a processed time-frequency diagram is input as a feature diagram, and categories of early faults are determined by training a deep learning classification model. Theoretical and experimental results show that fault categories can be determined accurately at an early stage when weak fault of a rolling bearing occur based on an improved wavelet time-frequency diagram used as the classification model for input training, right determination results can be given when the method is applied to different bearings, high training speed can be realized, and high actual application value can be achieved.

Owner:绍兴声科科技有限公司

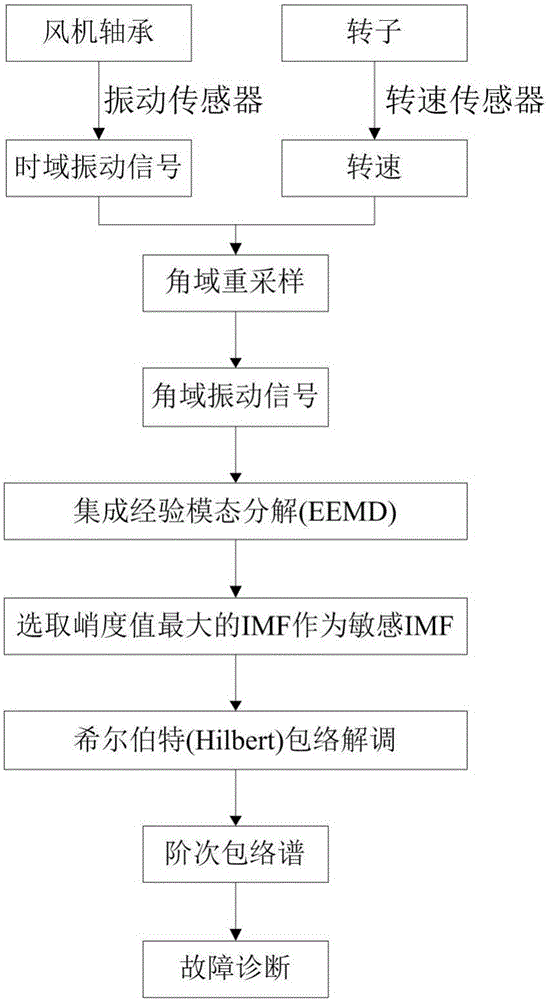

Wind turbine generator bearing fault diagnosis method under variable speed

InactiveCN105784366AEliminate the effects of analysisImprove accuracyMachine bearings testingElectricityBearing vibration

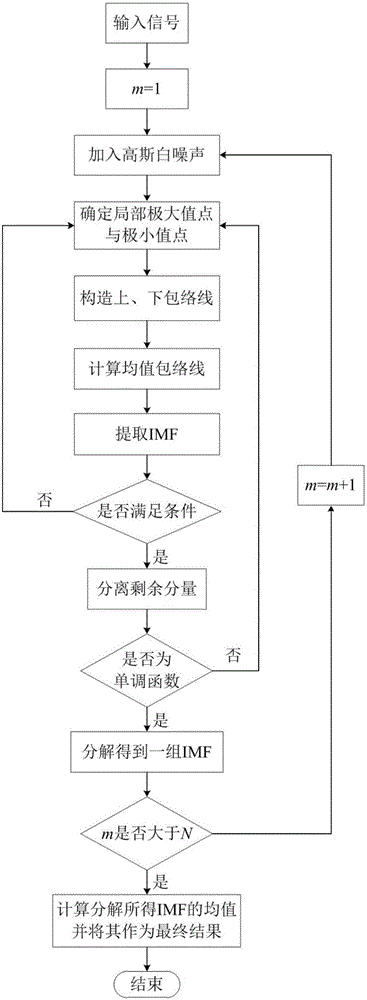

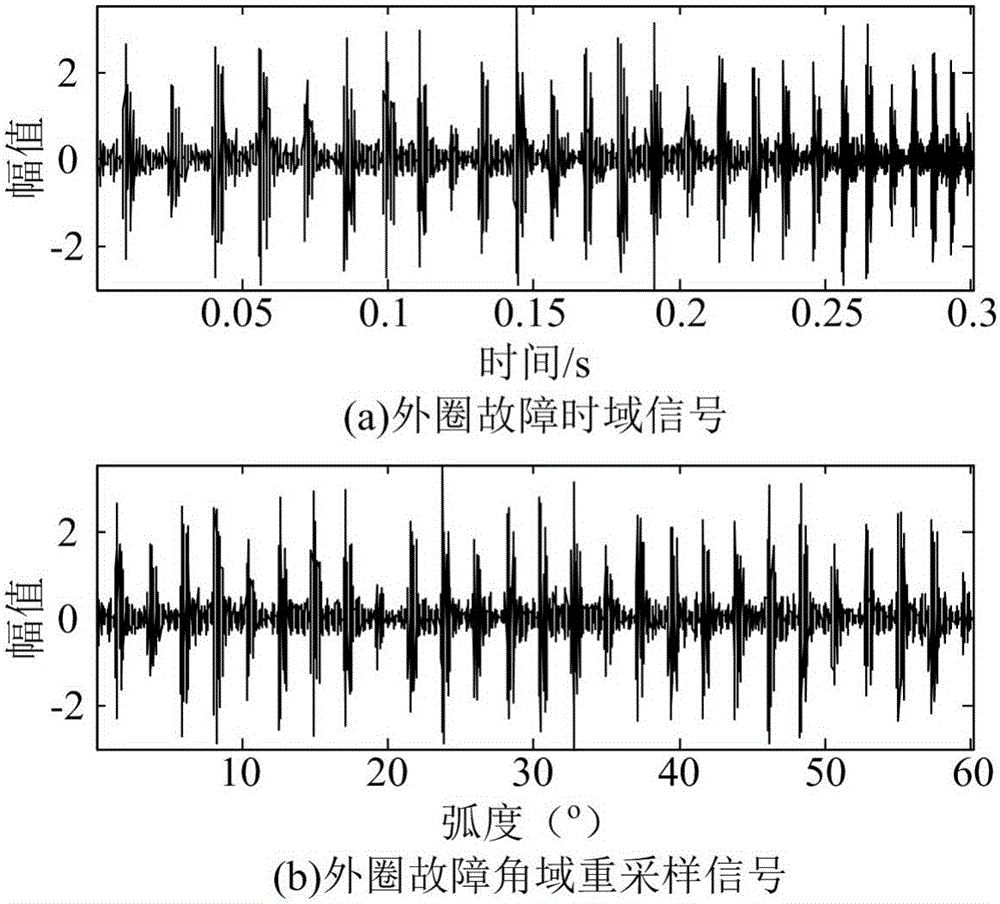

The invention discloses a wind turbine generator bearing fault diagnosis method under the variable speed. According to the method, a rotation angle change curve is drafted according to the bearing rotation speed; equal angle division for the rotation angle change curve is carried out, and an equal angle re-sampling time sequence is determined; interpolation for a bearing vibration signal is carried out according to the time sequence, a random Gauss white noise sequence is added to an angle domain vibration signal, and the signal added with the white noise is processed by utilizing an empirical mode decomposition (EMD) algorithm to acquire multiple sets of IMF; a kurtosis value of each IMF component is calculated; the IMF with the largest kurtosis value is selected and taken as a sensitive IMF; Hilbert envelope demodulation for the sensitive IMF is carried out to obtain an envelope signal, the envelope signal is processed by utilizing Fourier transform to obtain order envelope spectrum of the sensitive IMF, the fault characteristic frequency is extracted, and fault diagnosis on the wind turbine generator bearing is realized. The method is advantaged in that influence of rotation speed change on vibration signal analysis can be eliminated, and accuracy and validity of fault diagnosis can be improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Rolling bearing remaining life prediction method based on feature fusion and particle filtering

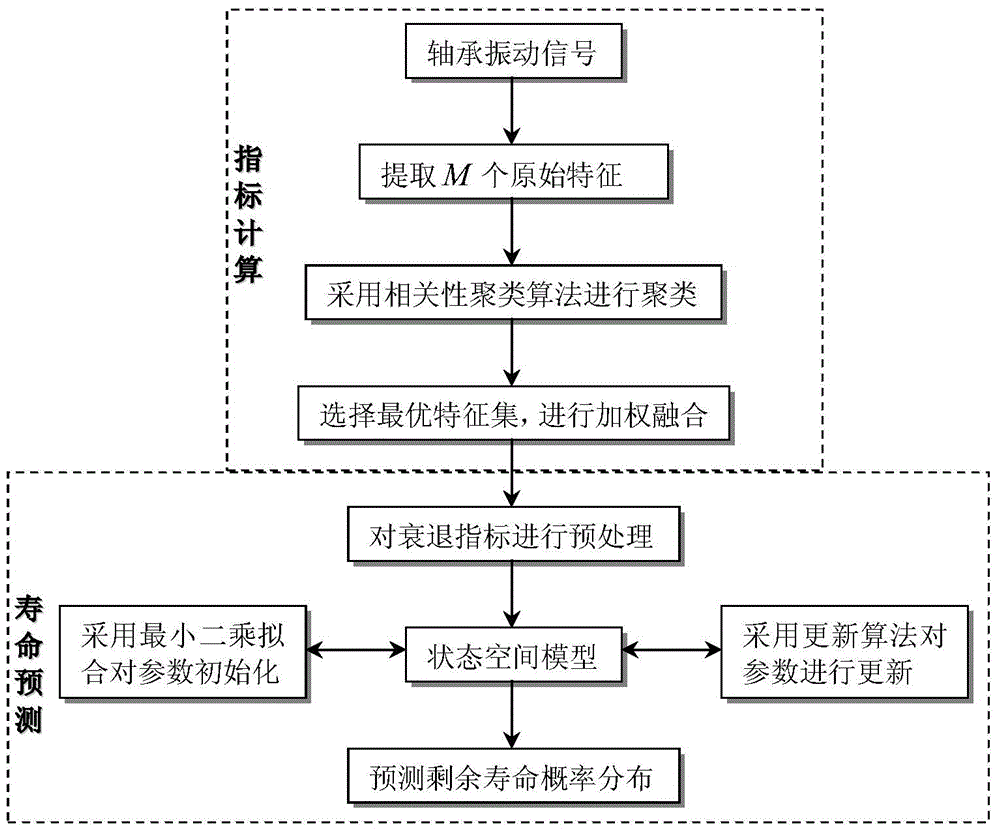

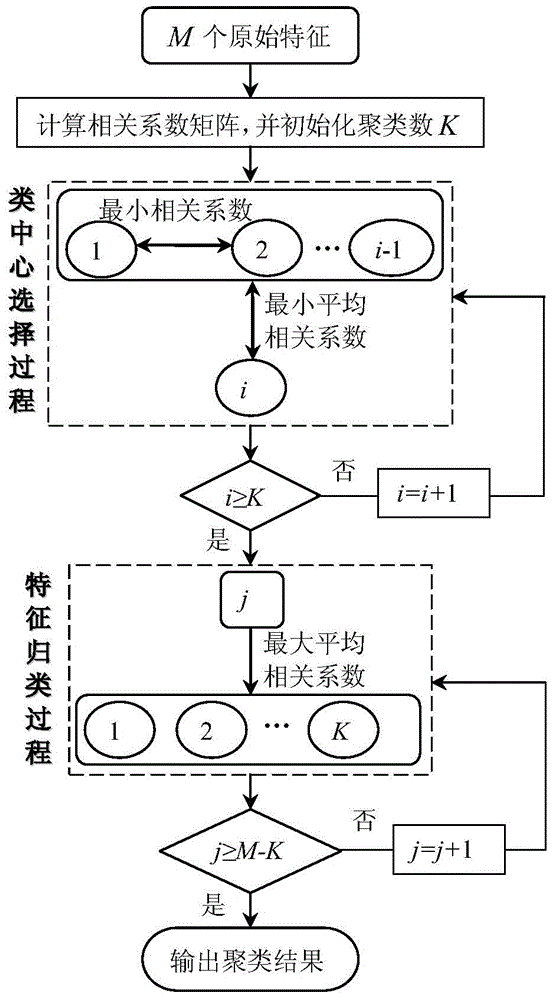

Disclosed is a rolling bearing remaining life prediction method based on feature fusion and particle filtering. According to an index calculation process, firstly, original features are extracted from bearing vibration signals, the extracted original features are clustered by the adoption of a relevance clustering method, then, one typical feature is selected from each cluster to form optimal feature sets, and finally the feature sets are fused by the adoption of a weight fusion method into a final recession index. According to a life prediction process, firstly, smoothing and resampling are carried out on the recession index, the time interval is adjusted to be an expected value, state-space model initial parameters are calculated by the adoption of least square fitting, then, model parameters are updated in real time according to new observation data, and finally the remaining life of a bearing can be predicted. According to the rolling bearing remaining life prediction method based on feature fusion and particle filtering, the difference between the life prediction result and a true value is small, and the application effect is good.

Owner:CHANGXING SHENGYANG TECH CO LTD

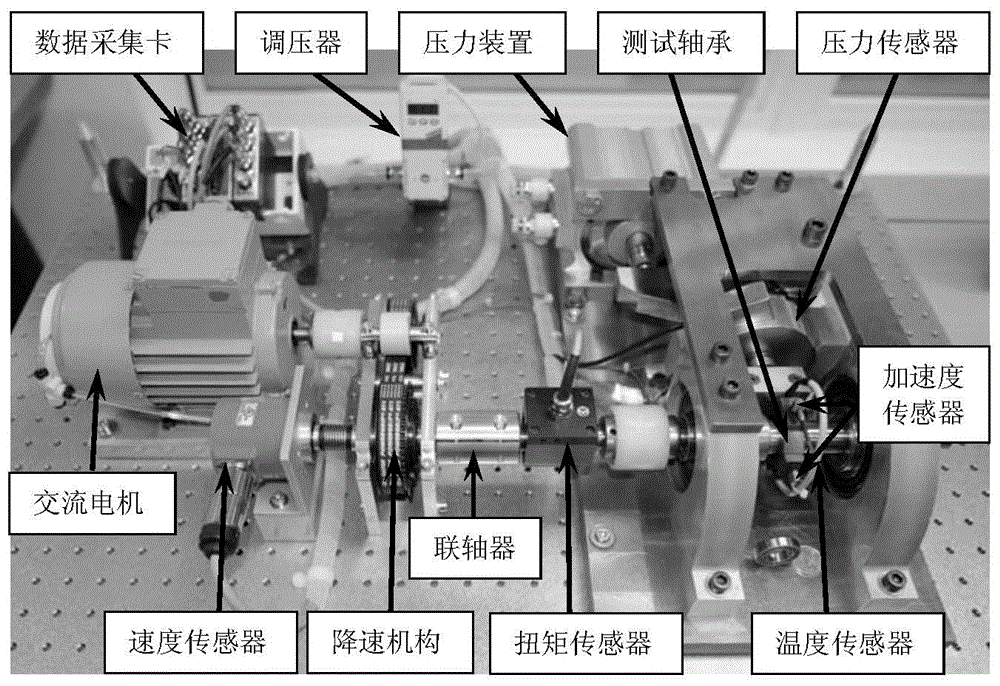

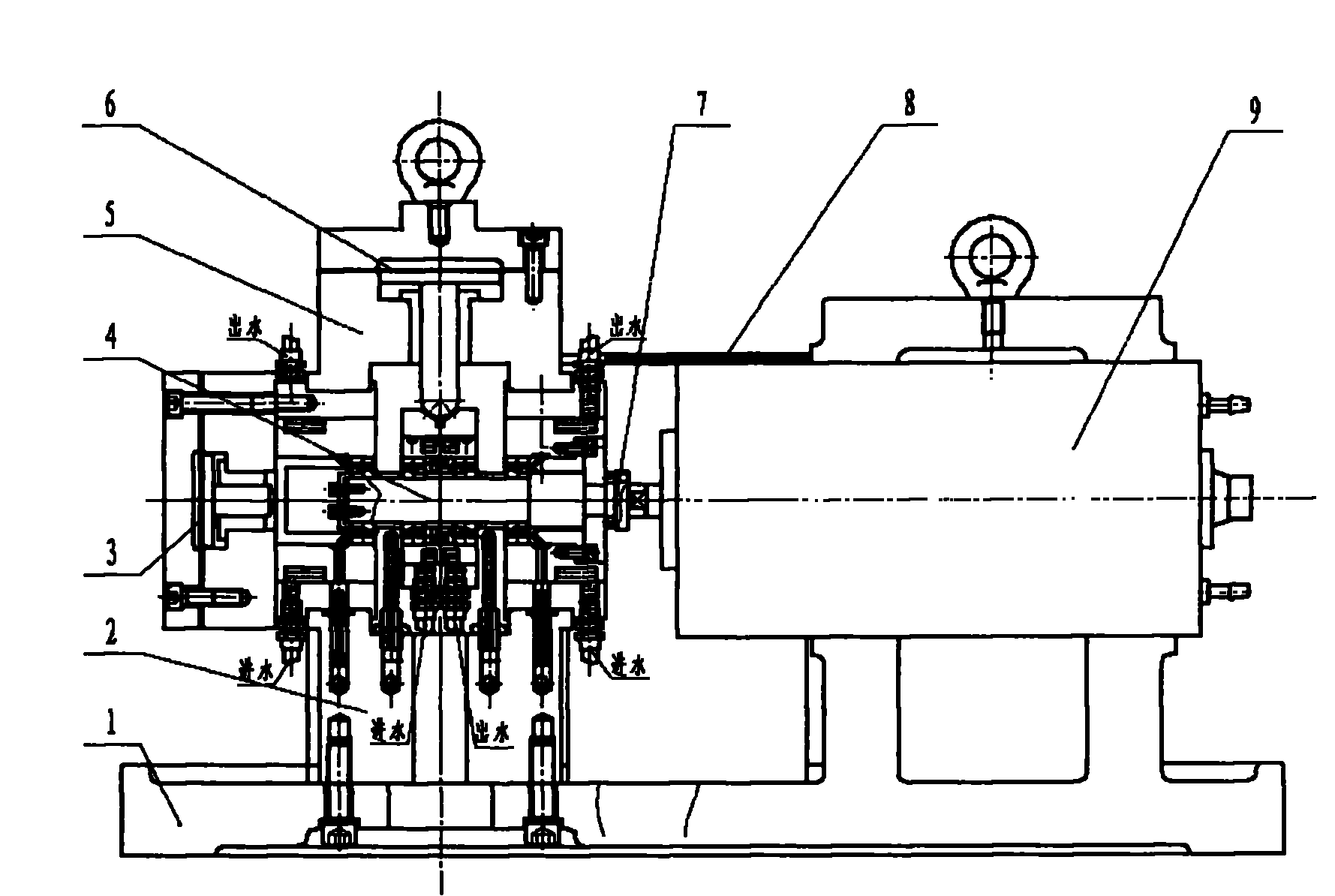

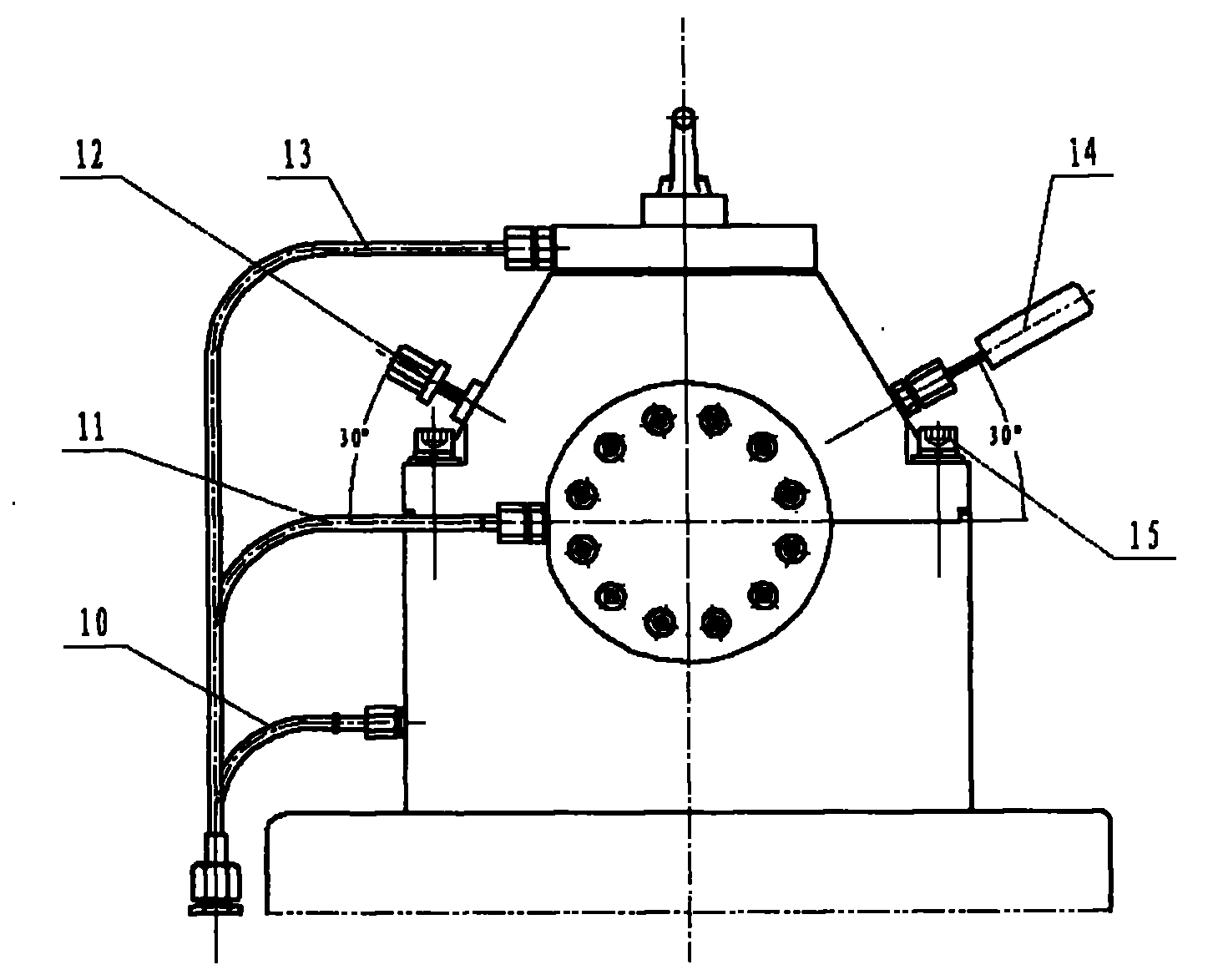

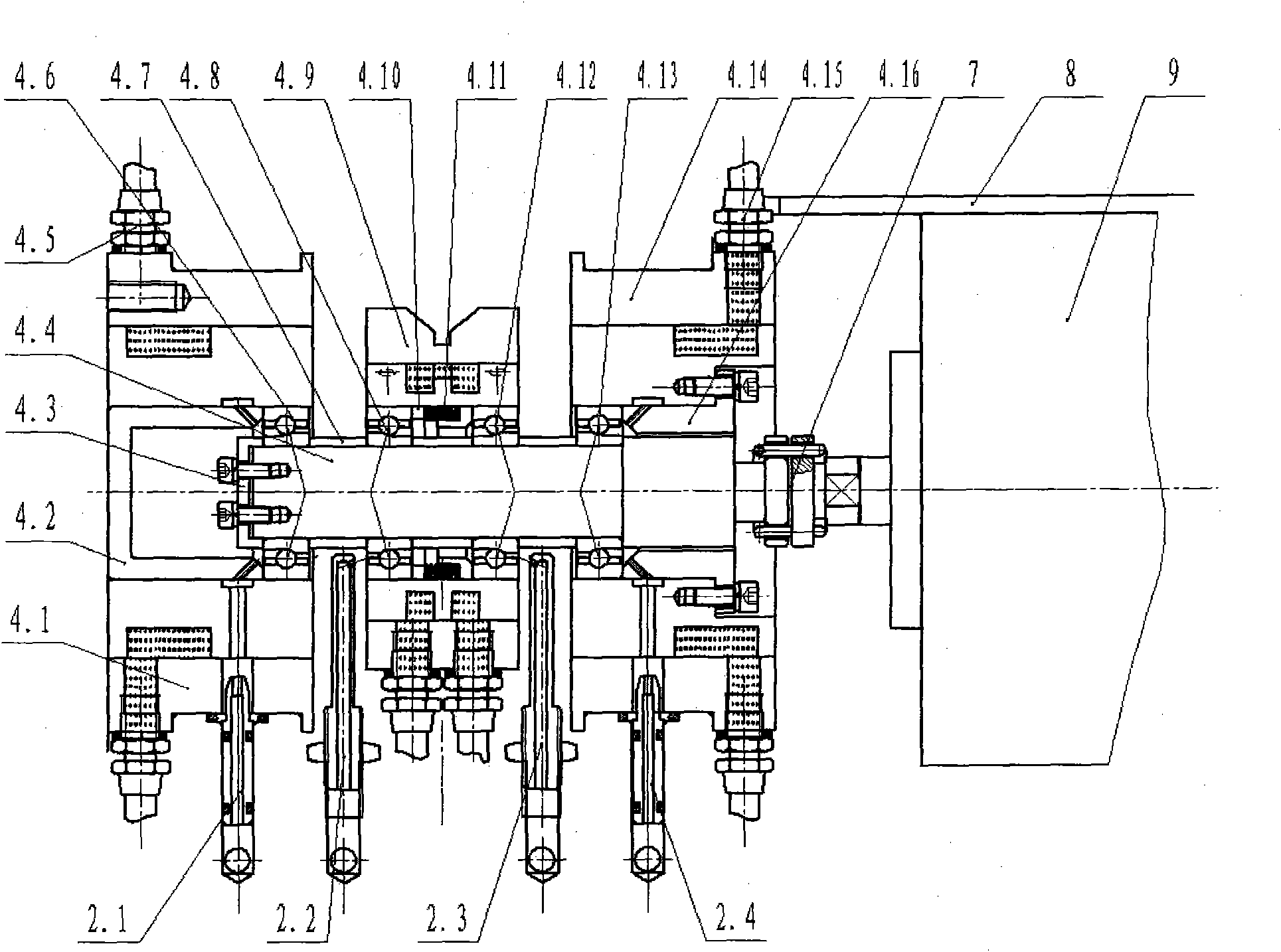

High-speed dynamic simulation test method for electric mainshaft bearing

ActiveCN101975659AEasy to achieve high speedRealize stepless speed regulationMachine bearings testingComputer databasePetroleum engineering

The invention relates to a high-speed dynamic simulation test method used for an electric mainshaft bearing. The electric mainshaft bearing comprises a frame, a main body pedestal, an axial loading cylinder, a test head assembly, a main body gland, a radial loading cylinder, a shaft coupling, a protecting hood, an electric mainshaft, a lubricating oil pipe, an axial loading oil pipe, a vibration sensor, a radial loading oil pipe and a temperature sensor and also a final assembly of all the parts. A hydraulic loading system is started to provide pressure oil to the axial loading cylinder and the radial loading cylinder, the electric mainshaft drives a test mainshaft to rotate, the radial loading cylinder exerts radial force on a first test accompanying bearing and a second test accompanying bearing through a radial loading sleeve, and the radial loading cylinder exerts axial force on a first test bearing and a second test bearing through an axial loading sleeve. The entire test is controlled by a computer to display parameters of the rotating speed, the axial load and the radial load, the oil pressure, the cooling water temperature, the bearing temperature, the bearing vibration, the power current of the electric mainshaft and the test time, and the parameters are saved in a computer database and analyzed.

Owner:国创(洛阳)轴承产业技术研究院有限公司

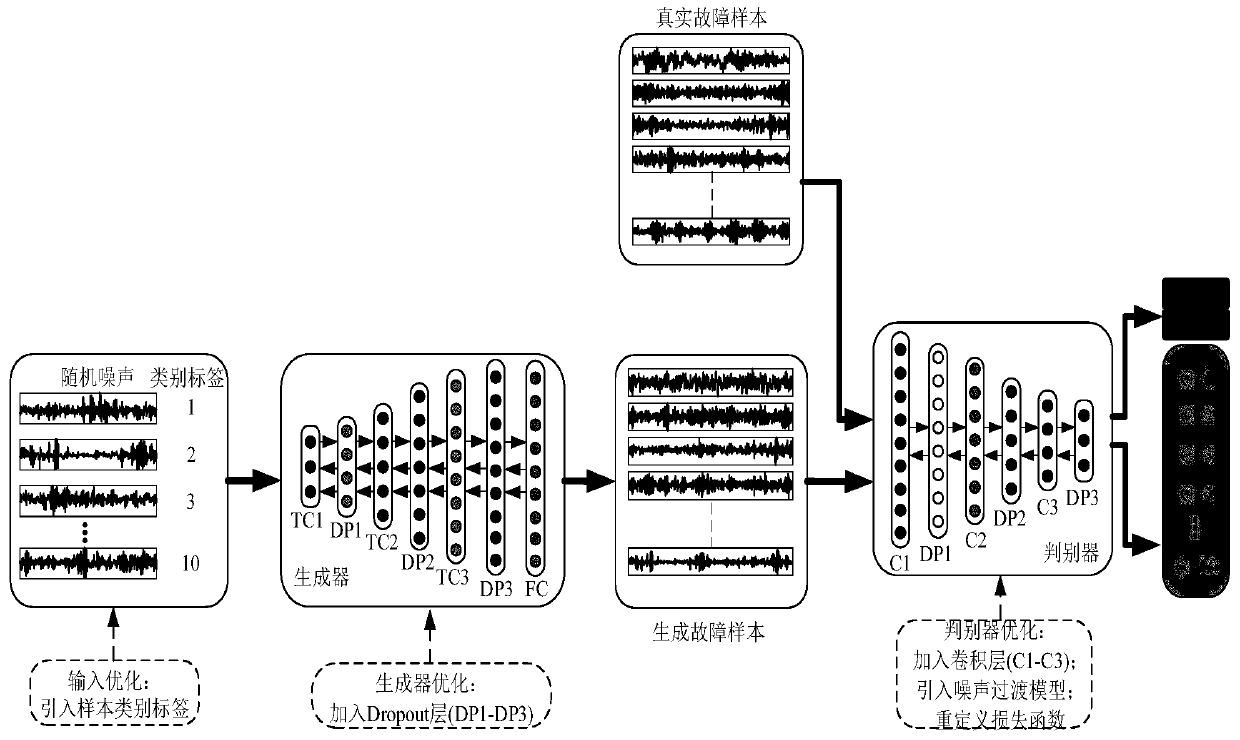

Deep adversarial diagnosis method for fan bearing fault under non-equilibrium small sample scene

ActiveCN110567720AEasy to identifyEffective data augmentationMachine bearings testingCharacter and pattern recognitionElectricitySmall sample

The invention provides a deep adversarial diagnosis method for a fan bearing fault under a non-equilibrium small sample scene. The deep adversarial diagnosis method is characterized by comprising thefollowing steps of acquiring wind turbine bearing vibration signals, building an improved AC-GAN (Generative Adversarial Networks) model, building an improved AC-GAN sample, generating a wind turbinebearing vibration signal sample, and diagnosing wind turbine bearing faults under various scenes. The deep adversarial diagnosis method solves the problems of complex vibration signal noise interferences, fewer fault samples, and unbalanced number of samples between categories in the fan fault diagnosis based on the vibration signals, improves the fault identification accuracy under a small samplenon-equilibrium scene, has good fault identification accuracy under complex scenes such as high noise interferences, insufficient number of samples and nonequilibrium of different types of sample training set scales, has the advantages of being scientific and reasonable, strong in adaptability, high in practical value, and can provide references for fan research and development, wind farm operation and maintenance, wind turbine research and other related personnel.

Owner:NORTHEAST DIANLI UNIVERSITY

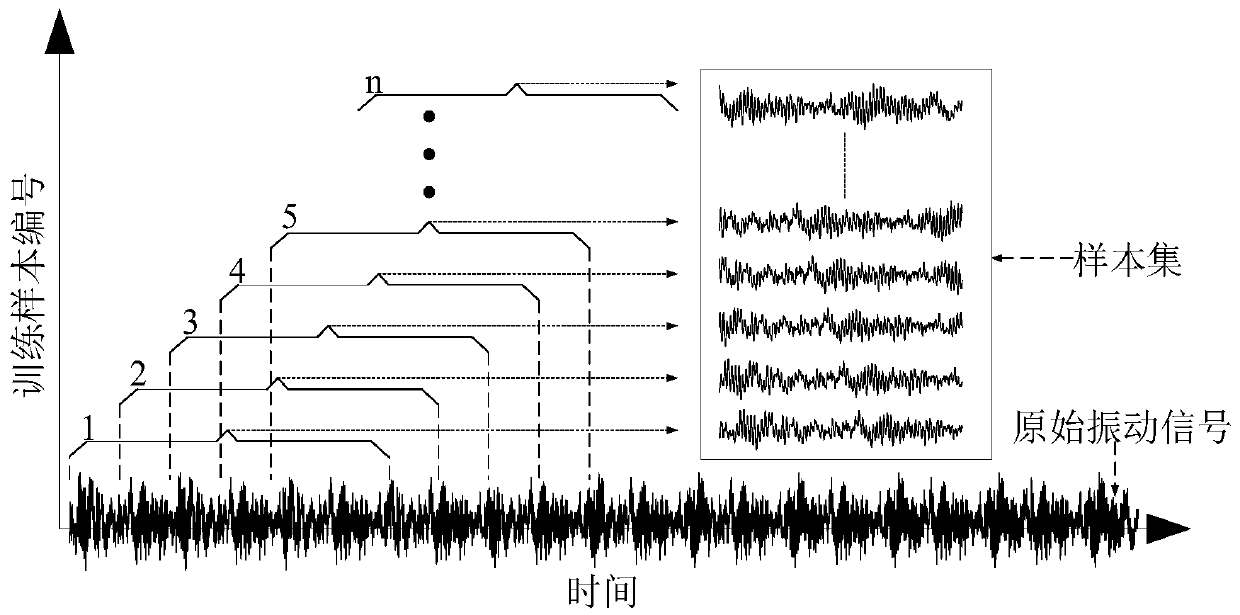

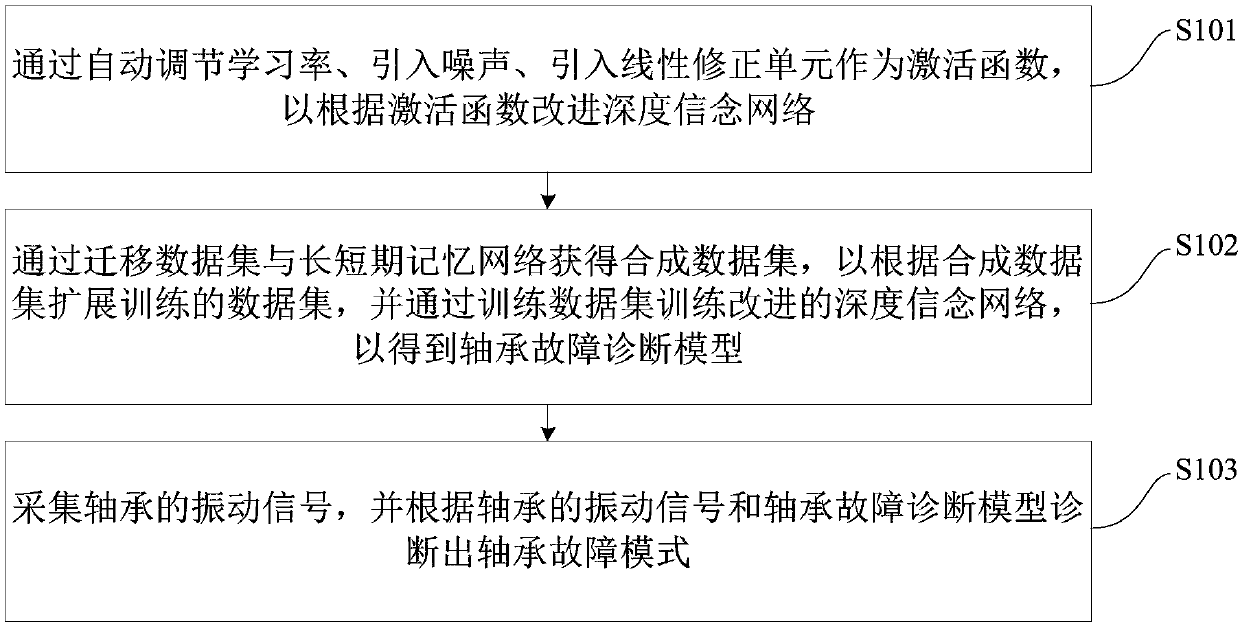

Bearing fault mode diagnosis method and system based on deep learning

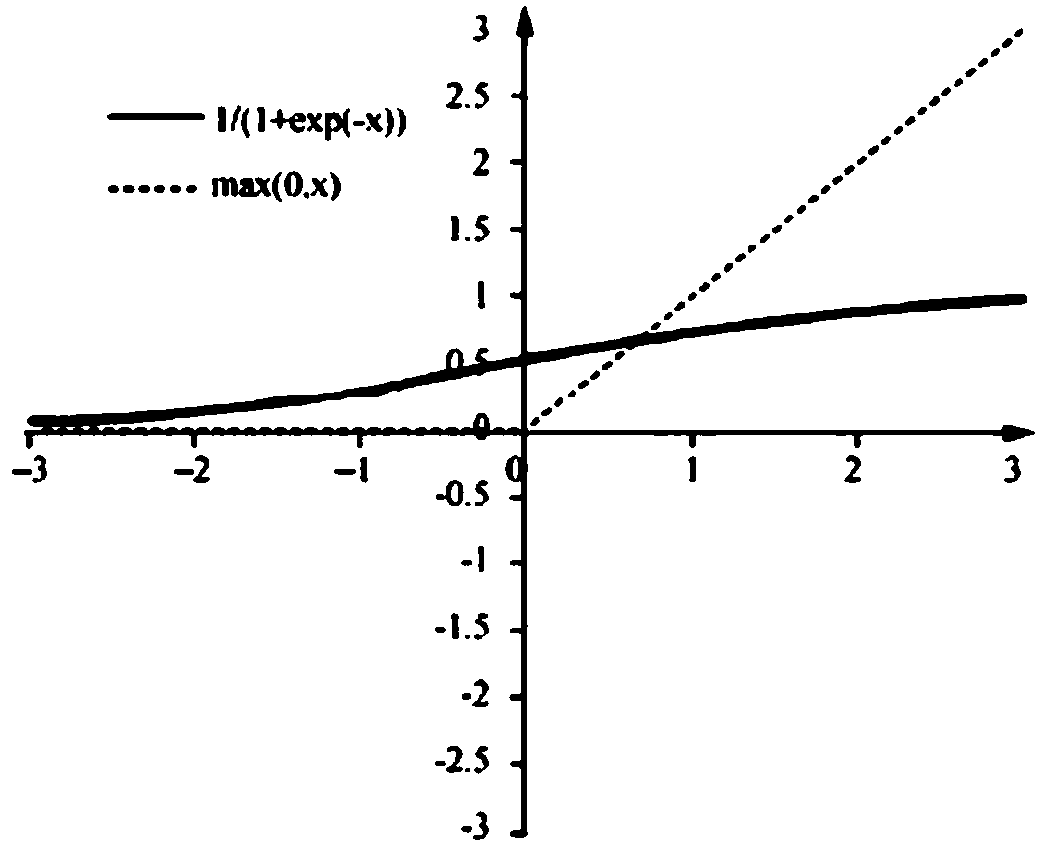

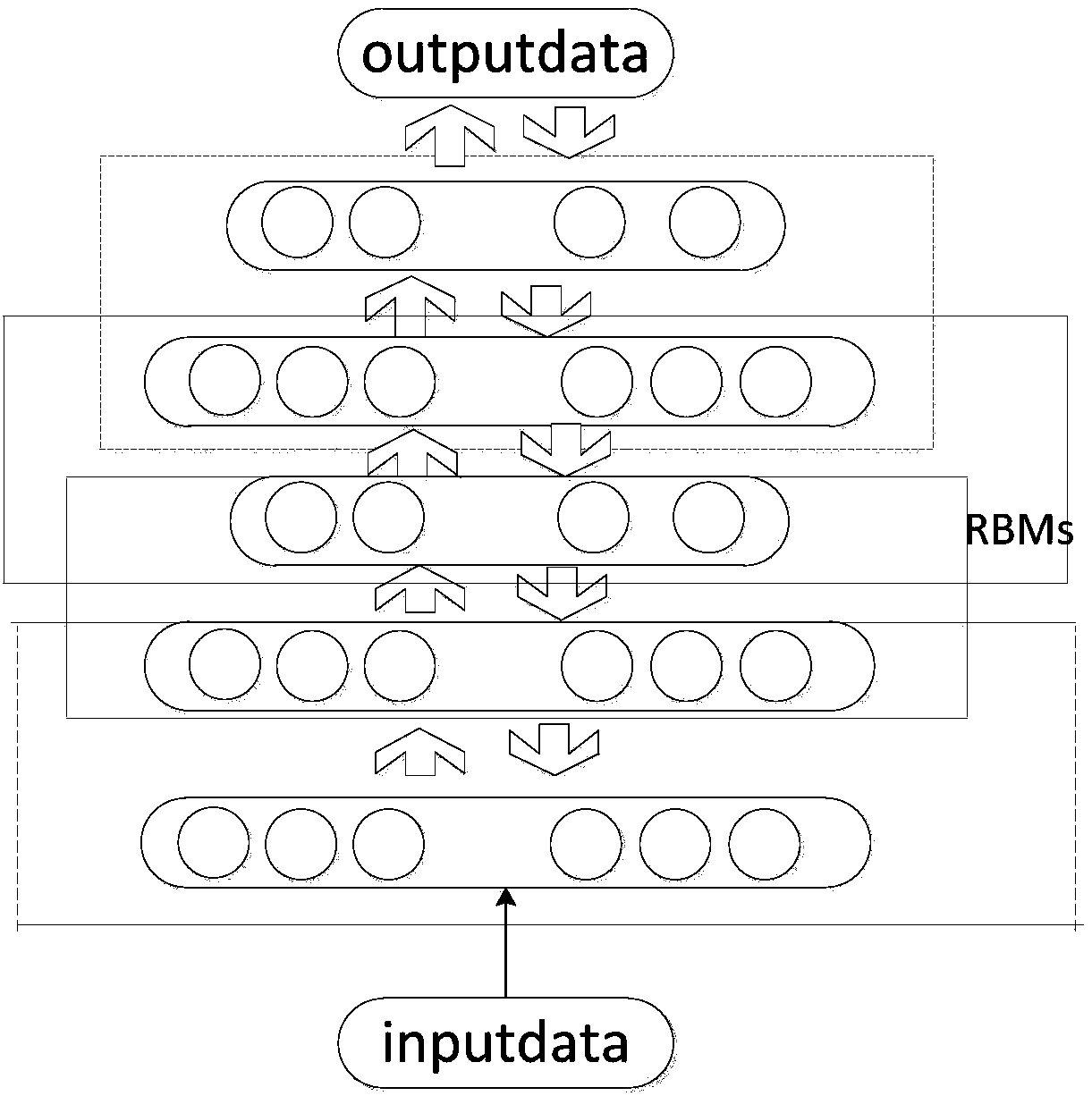

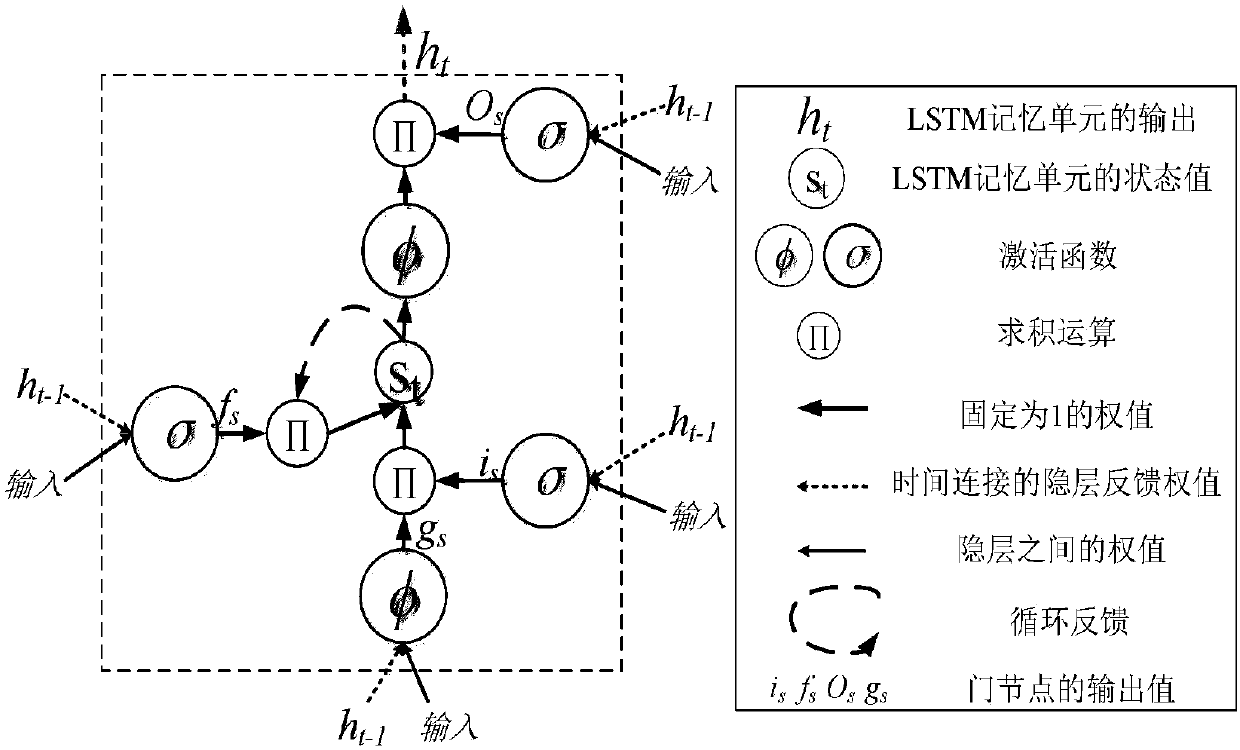

InactiveCN108304927ASolve problemsAccurate Fault Diagnosis AccuracyMachine bearings testingNeural architecturesDeep belief networkActivation function

The invention discloses a bearing fault mode diagnosis method and system based on deep learning. The method comprises: a learning rate is adjusted automatically, noises are introduced, and a linear correction unit is introduced as an activation function, and thus a deep belief network is improved based on the activation function; a data set and long- and short-term memory networks are migrated toobtain a synthetic data set, a trained data set is extended based on the synthetic data set, and the improved deep belief network is trained based on training data set training to obtain a bearing fault diagnosis model; and a vibration signal of the bearing is collected and a bearing failure mode is diagnosed based on the bearing vibration signal and the bearing fault diagnosis model. On the basisof combination of a semi-supervised learning and a migration learning algorithm, the diagnostic accuracy is improved while no insufficient data are provided.

Owner:TSINGHUA UNIV

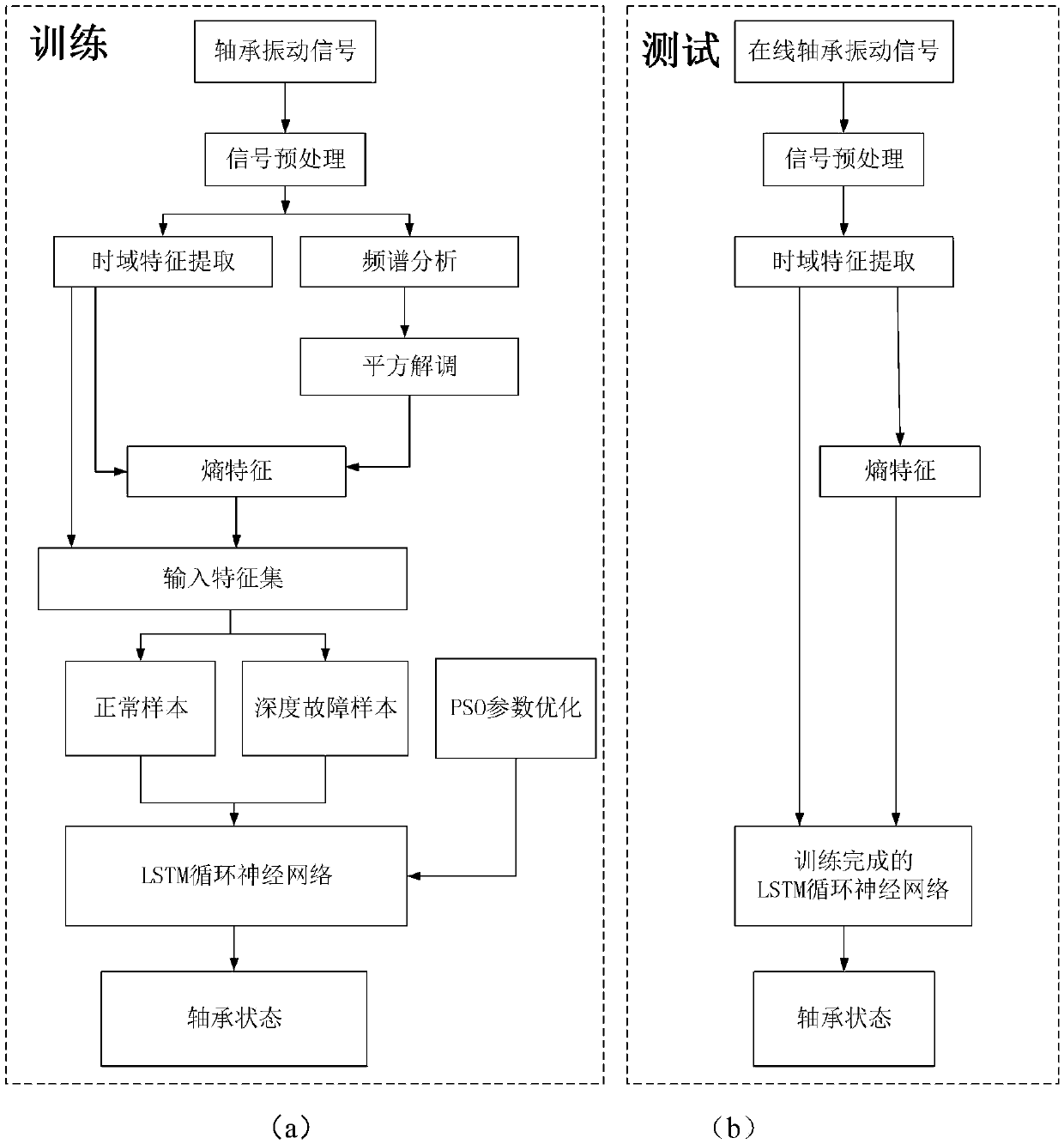

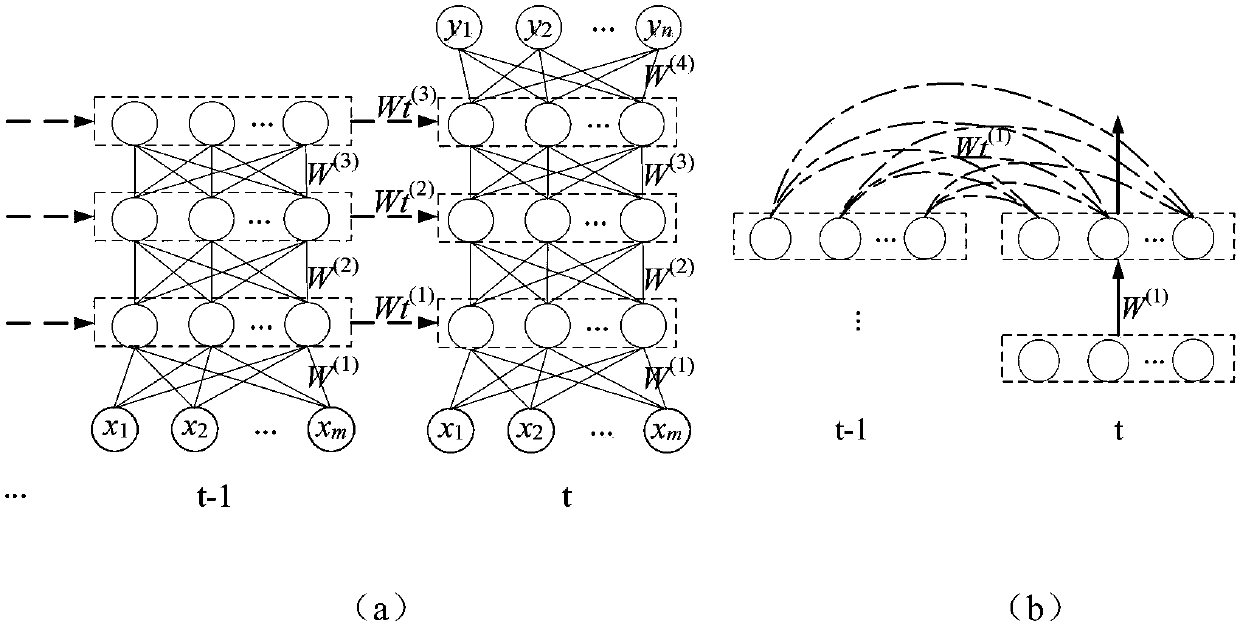

Method for recognizing early fault of bearing based on long and short-term memory recurrent neural network

ActiveCN108303253AEfficient use ofAccurately identify the moment of failureMachine bearings testingNeural architecturesTime domainData set

The invention discloses a method for recognizing an early fault of a bearing based on a long and short-term memory recurrent neural network, which comprises the steps of collecting full life vibrationsignals of the bearing, and then extracting common time domain characteristics; constructing waveform entropy characteristics, and verifying the validity of the waveform entropy according to a squaredemodulation method; building a characteristic data set by using the time domain characteristics and the entropy characteristics, and selecting a normal data set and a deep fault data set; taking thenormal data set and the deep fault data set to serve as training samples to train the LSTM (Long and Short-Term Memory) recurrent neural network; and performing time domain characteristic and entropycharacteristic extraction on an online bearing vibration signal, and then inputting the online bearing vibration signal into the trained LSTM recurrent neural network so as to recognize the fault occurrence time. The traditional characteristics and the entropy characteristics of the vibration signals are combined, so that the current state of the bearing is accurately reflected under the condition of ensuring the physical meaning of the vibration characteristics. The adopted recurrent neural network can effectively apply the degraded historical data so as to perform effective recognition on the fault occurrence time of the bearing.

Owner:SOUTH CHINA UNIV OF TECH

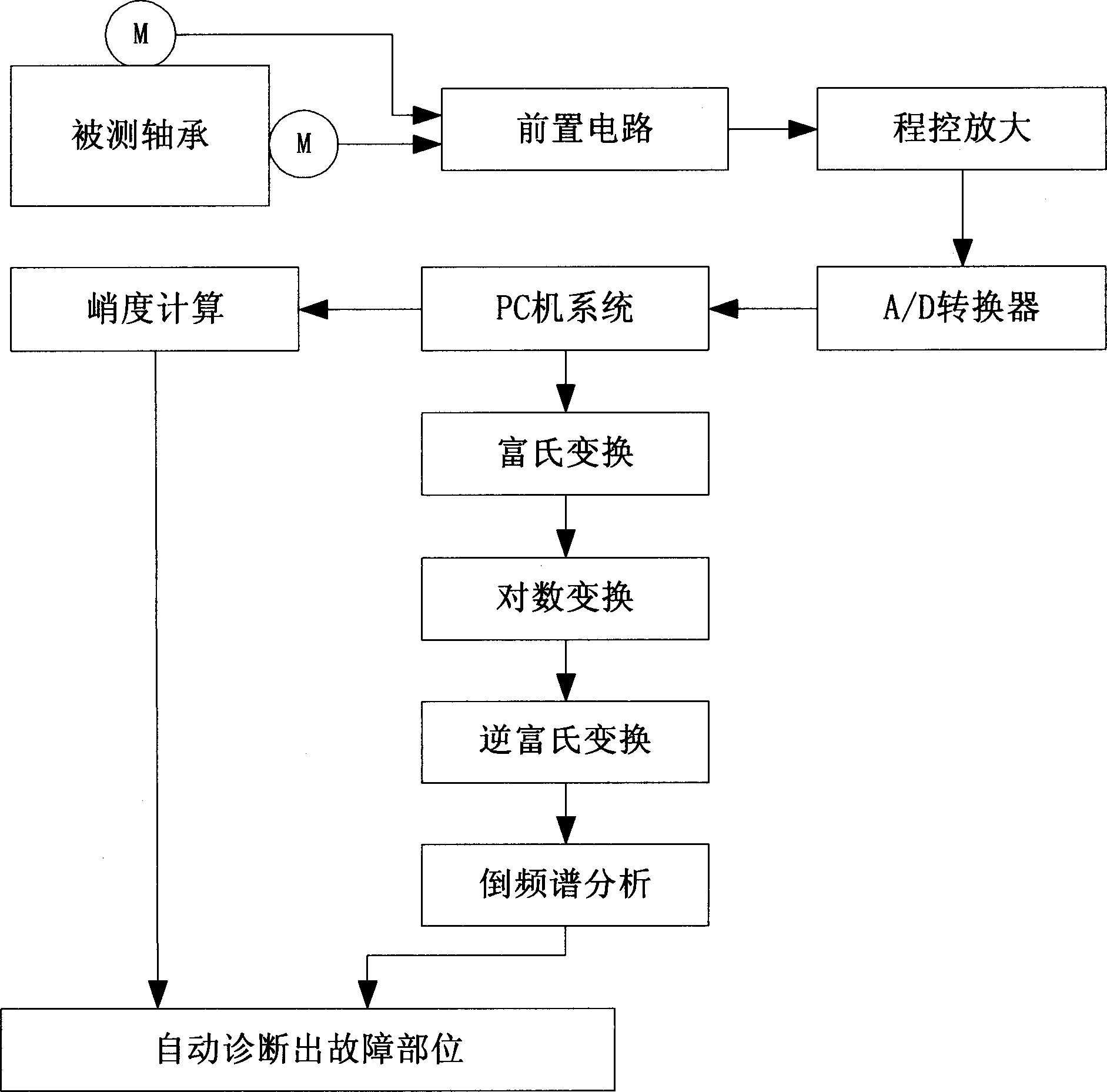

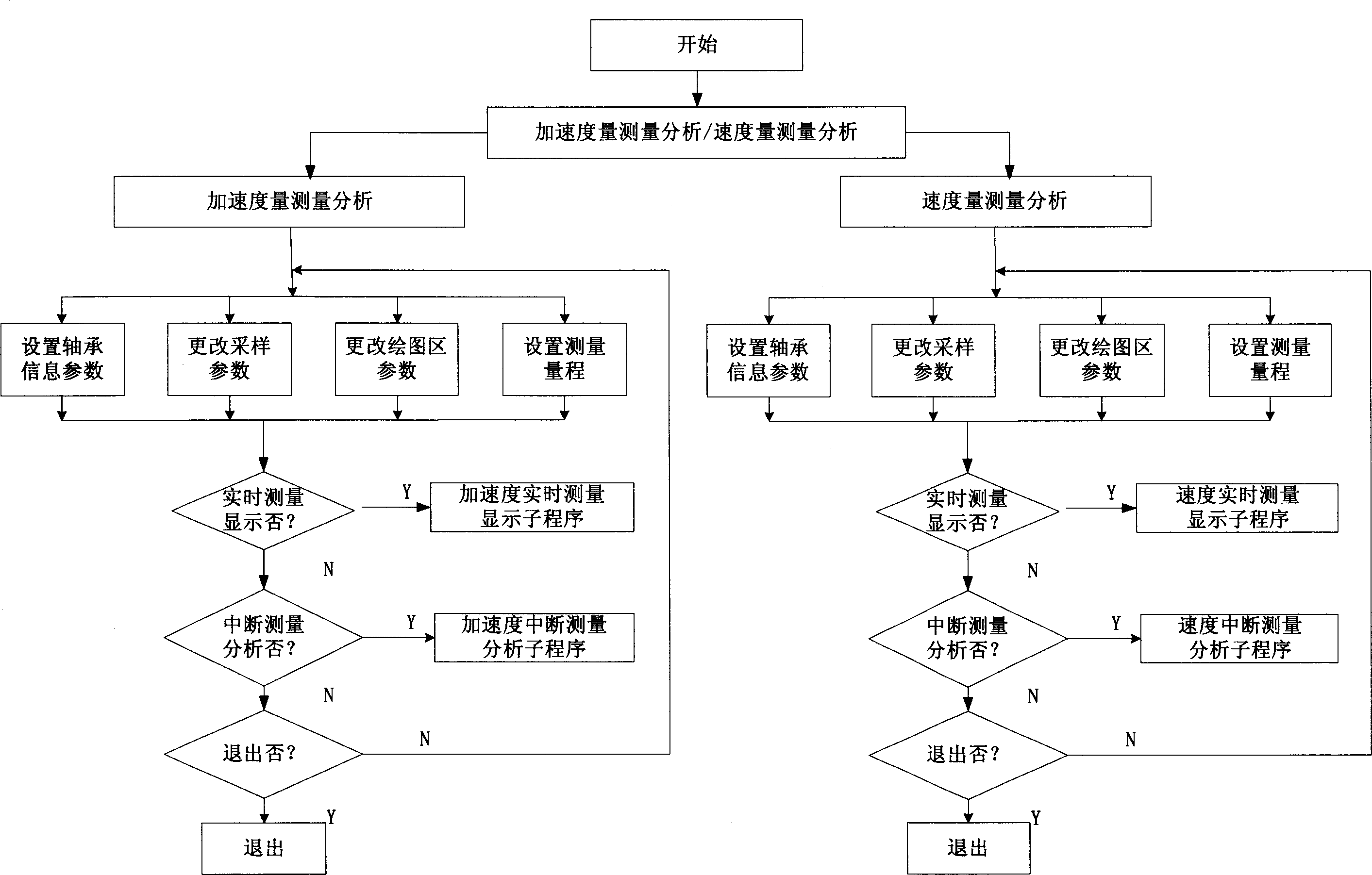

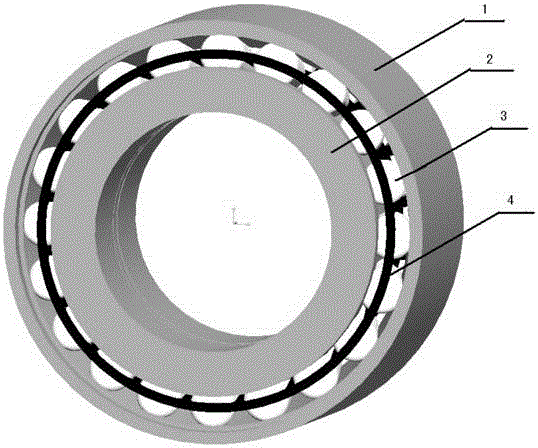

Automatic diagnosing system for rolling bearing fault

InactiveCN1825082AEasy to debugEasy maintenanceMachine bearings testingVibration testingDigital signal processingVibration acceleration

The invention relates to a rolling bearing error auto diagnose system. It takes testing analysis and kurtosis analysis to the bearing vibration, and calculates the kurtosis by virtual device and DSP, analyzes and compares the spectral configuration to accurately measure the acceleration and speed of bearing vibration, and achieve accurate analysis to automatically judge the place of the error.

Owner:LUOYANG BEARING SCI & TECH CO LTD

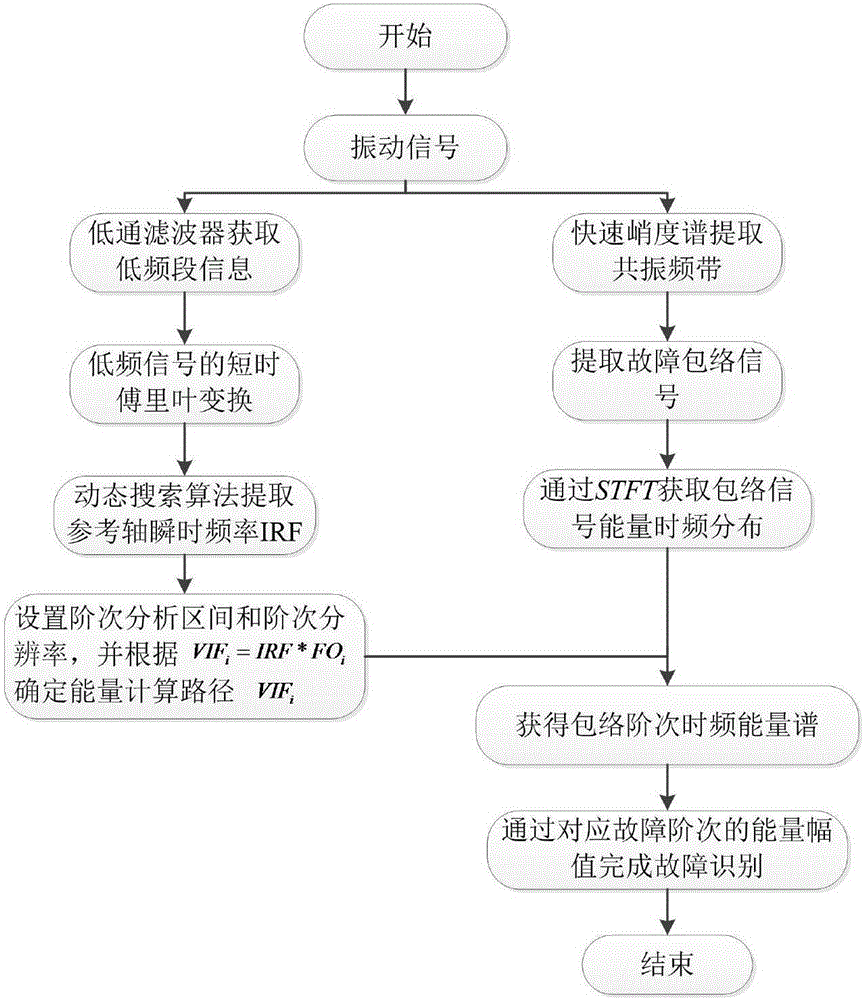

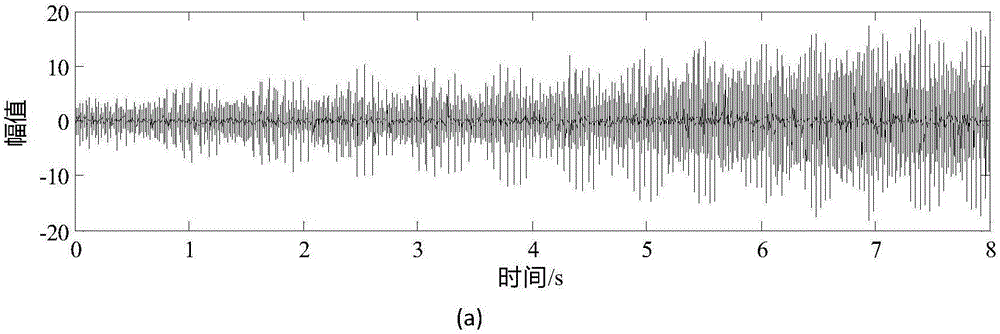

Variable-speed rolling bearing fault recognition method based on order enveloping time-frequency energy spectrum

ActiveCN106769033AReduce hardware costsRealize real-time monitoringMachine bearings testingFrequency spectrumTime spectrum

The invention discloses a variable-speed rolling bearing fault recognition method based on an order enveloping time-frequency energy spectrum. Short time Fourier transform is carried out on low-band signals in acquired rolling bearing vibration signals under a variable speed to acquire a short time spectrum, and in combination of a peak search method, instantaneous rotating frequency estimation for a bearing reference axis harmonic component is acquired; then, through a fast kurtosis spectrum technique, the optimum resonance frequency band pass parameters of the vibration signals are determined, the band pass signals after band pass filtering are subjected to Hilbert transform to acquire enveloping signals, and through short time Fourier transform, an enveloping time-frequency energy matrix is obtained; and an extraction interval is set, an order enveloping energy calculation path is obtained, order enveloping time-frequency energy in different orders is calculated through the energy calculation path and the enveloping time-frequency energy matrix, an order enveloping time-frequency energy spectrum is acquired, and through comparison between the order corresponding to the maximum order enveloping time-frequency energy and a fault order, bearing fault recognition is realized. The method has the advantages that the calculation efficiency is high, and requirements of real-time monitoring in actual engineering application can be met.

Owner:XI AN JIAOTONG UNIV

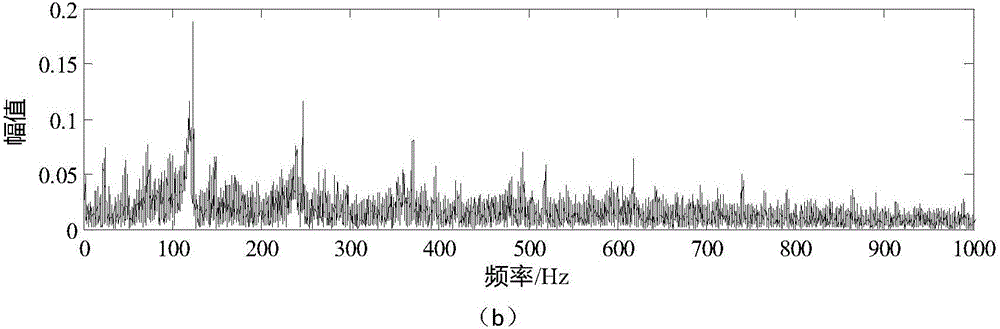

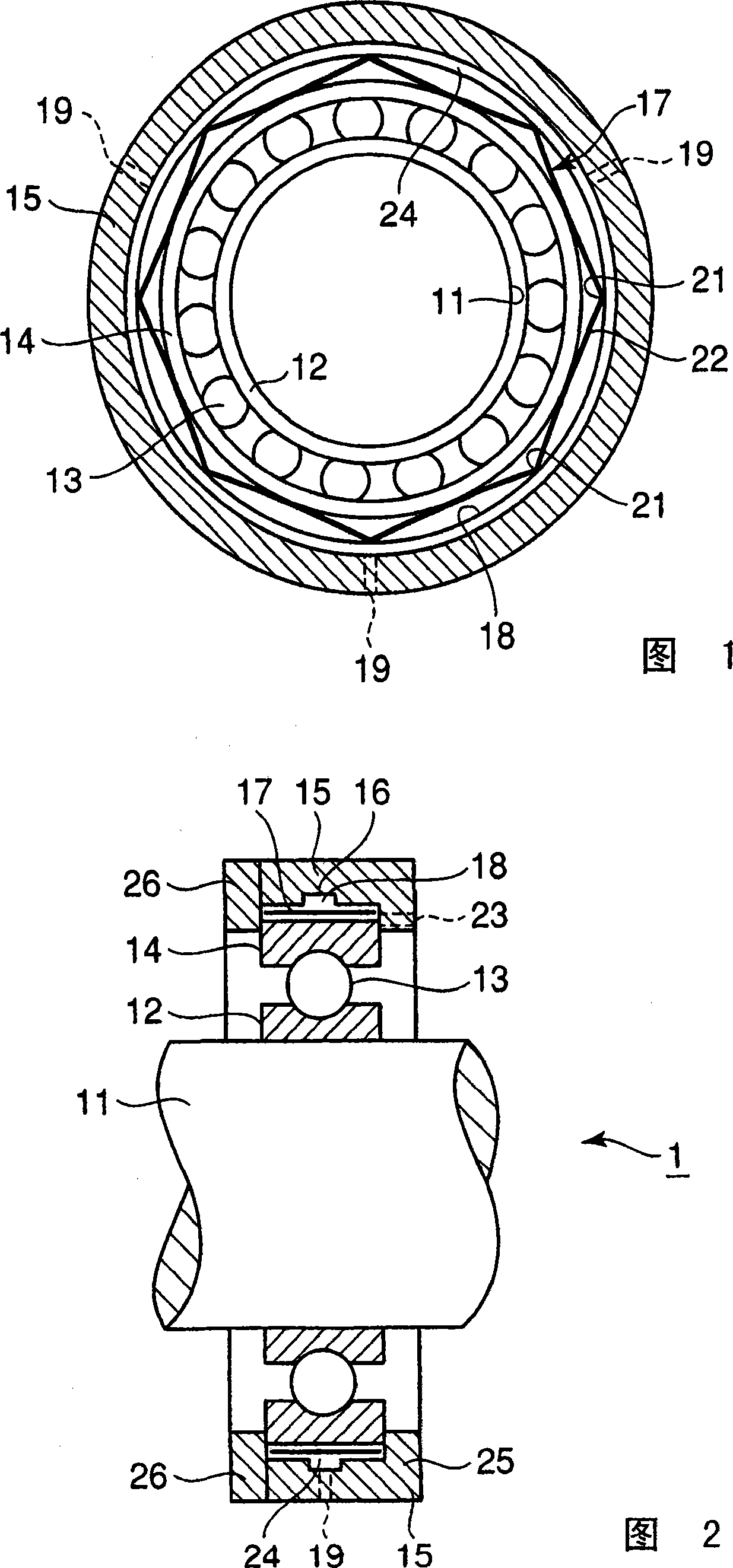

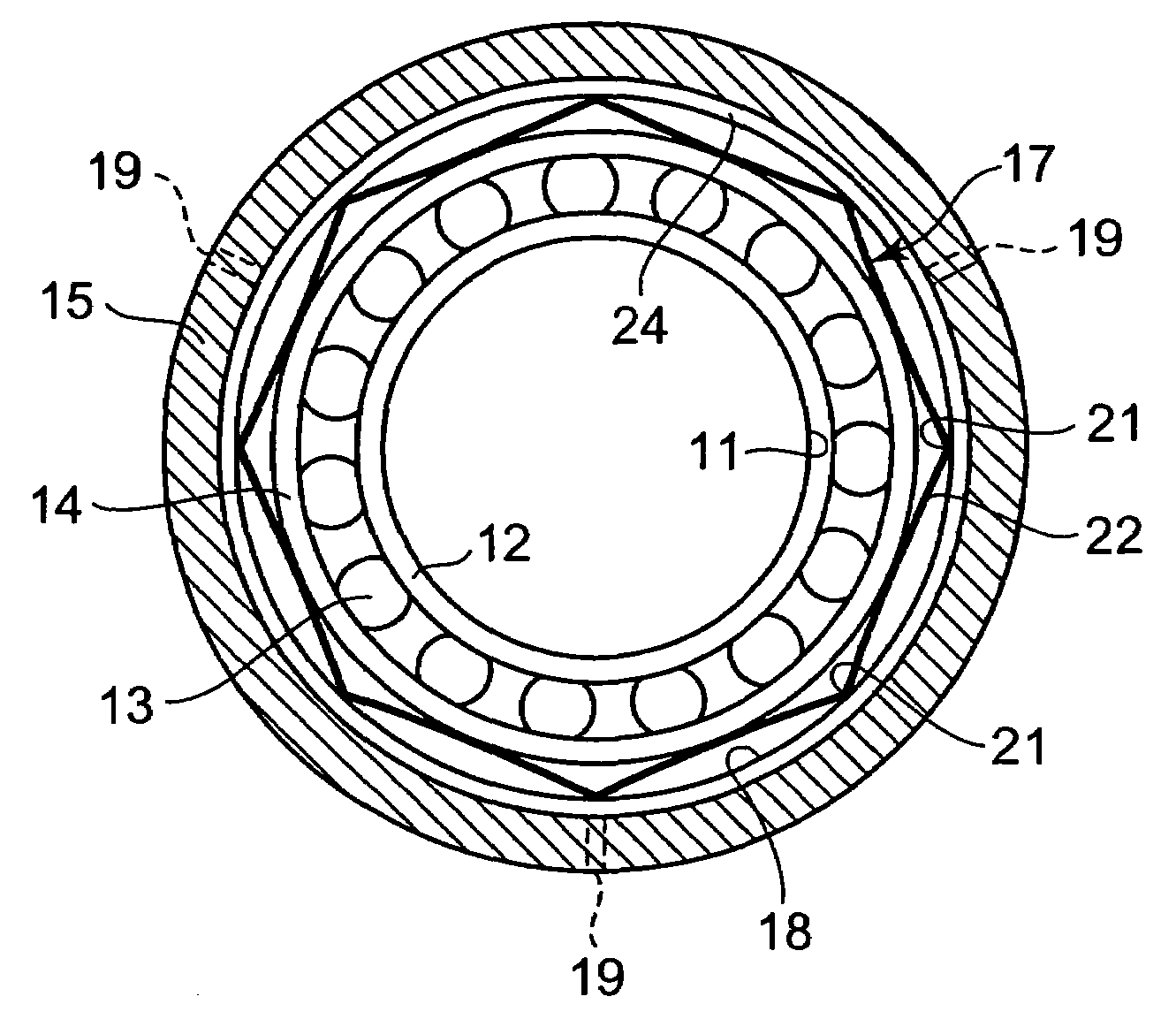

Vibration damping mechanism for bearing

ActiveCN101010521AInhibit sheddingInhibition releaseLeaf springsShaftsRolling-element bearingEngineering

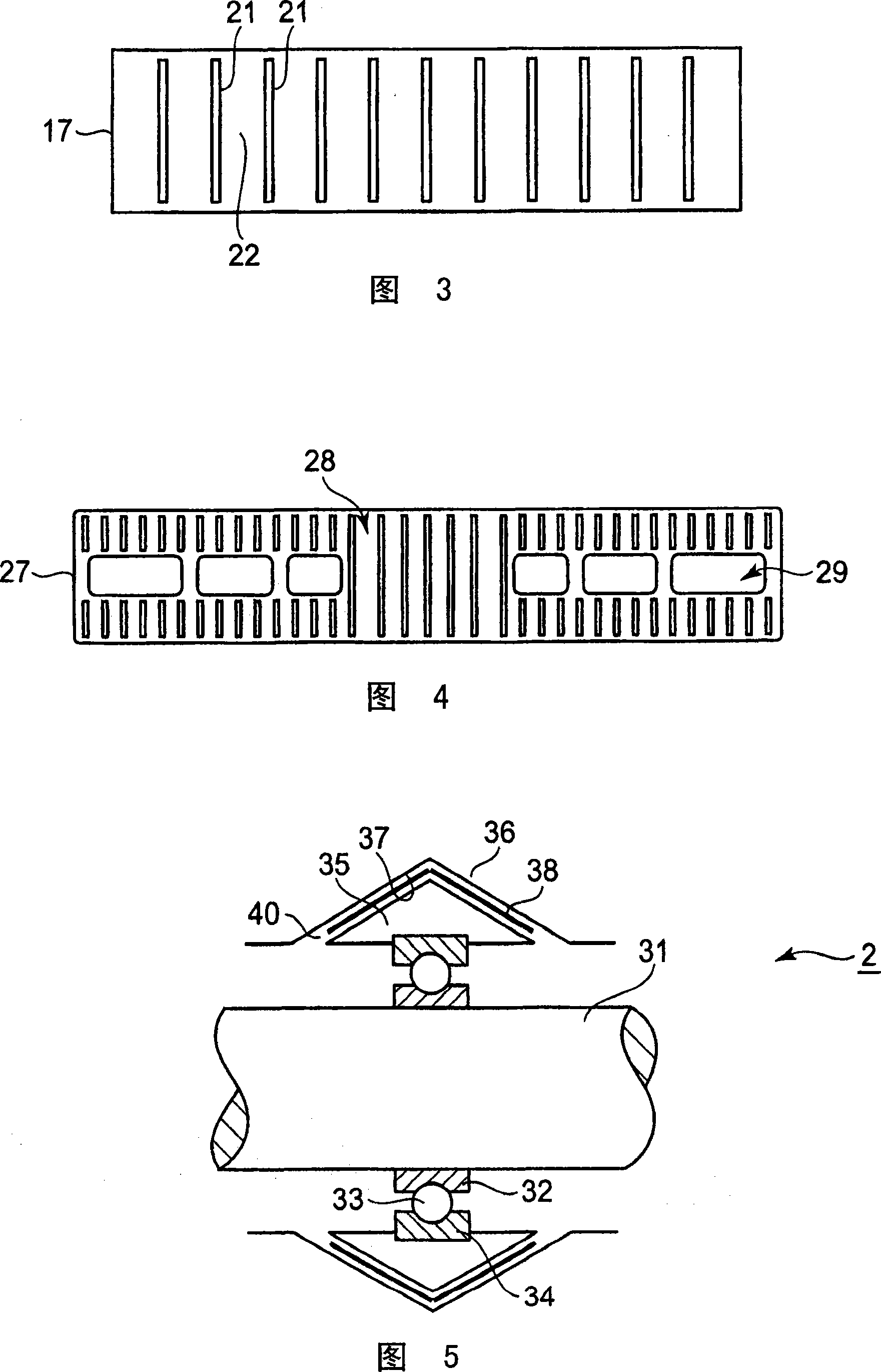

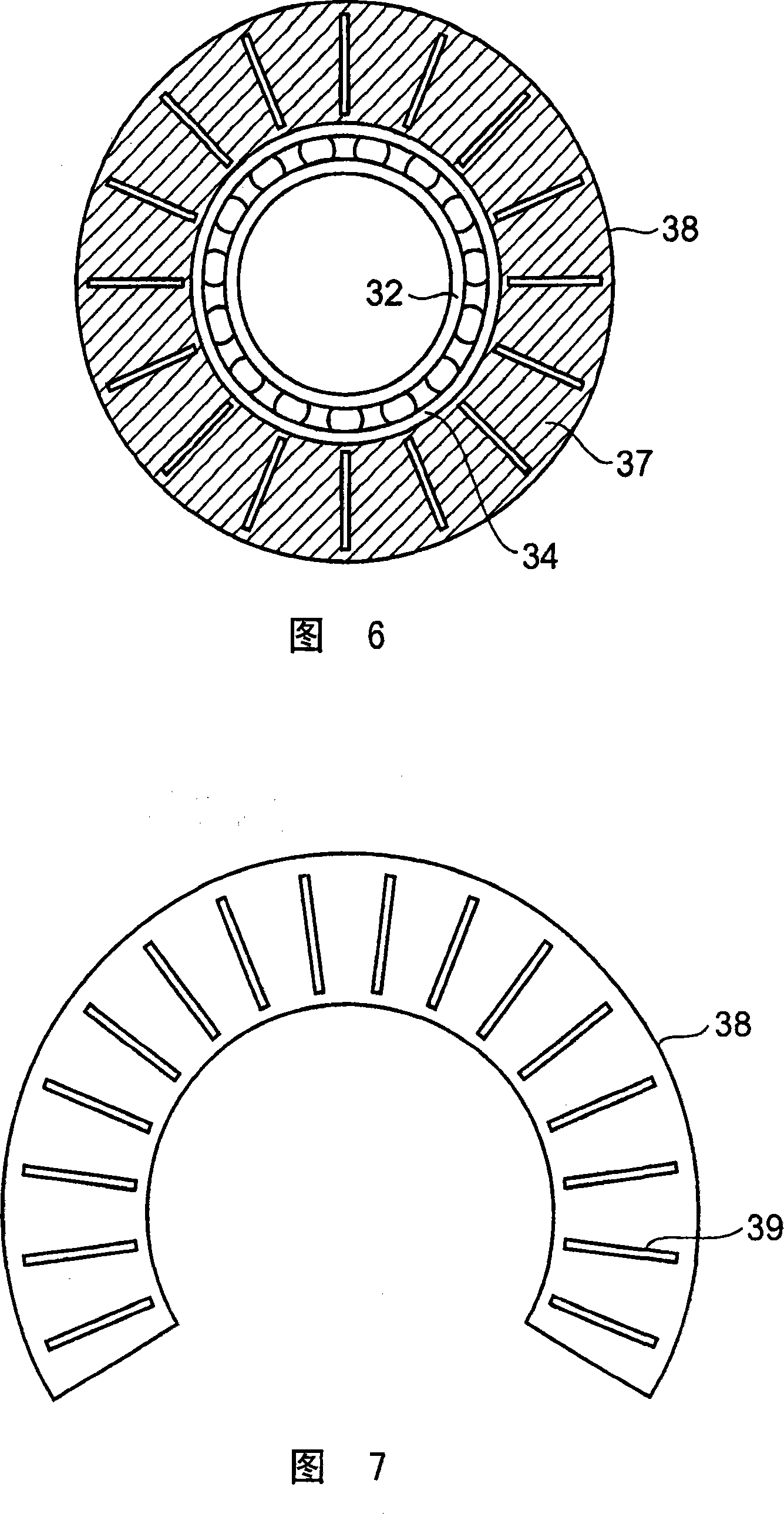

A squeeze film damper bearing easily manufacturable, having excellent productivity, and reduced in size and a vibration damping mechanism for the rolling bearing capable of having an effect on loads in two of radial and thrust directions. In the vibration damping mechanism (1) for the rolling bearing, a storage hole (16) having a diameter larger than the diameter of the outer periphery (14) of the bearing is formed on the inside of a housing (15) and an oil supply hole (19) supplying an oil into the storage hole is formed in the wall of the housing (15), the bearing is inserted into the storage hole to form an annular clearance (18) on the outer periphery of the bearing, and a thin flat plate (17) having a plurality of slits is inserted into the annular clearance along the circumferential direction. The portions of the thin flat plate held by the slits are formed in an elastic beam to elastically support the bearing at a center position, and the vibration of the bearing is damped by a squeeze film action caused by an oil film generated by supplying the oil into the annular clearance.

Owner:KAWASAKI JUKOGYO KK

Sparse representation and dictionary learning-based bearing fault classification method

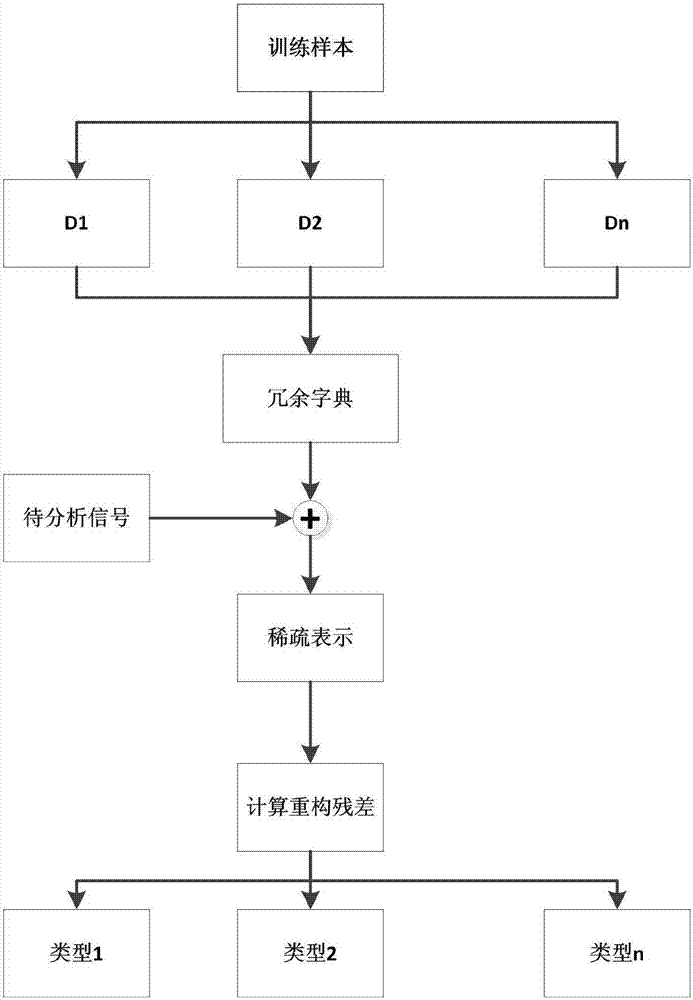

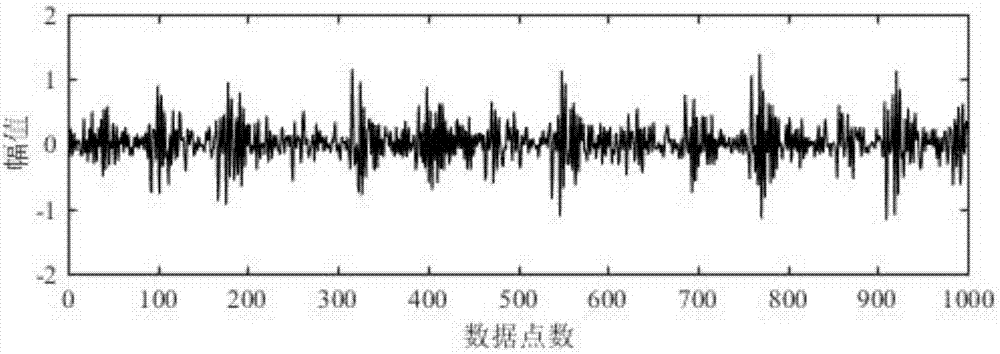

ActiveCN107368809AEnhance expressive abilityQuality assuranceCharacter and pattern recognitionDictionary learningDecomposition

The invention discloses a sparse representation and dictionary learning-based bearing fault classification method. The method is characterized by comprising the following steps of: preprocessing acquired history bearing vibration signals to obtain vibration signals under different working states, respectively constructing corresponding sub-dictionaries and combining the sub-dictionaries into a redundant dictionary; and online acquiring a bearing vibration signal by using a sensor, solving a sparse coefficient of the signal under the redundant dictionary by using a generalized orthogonal matching pursuit algorithm, and classifying the vibration signal through a reconstruction error so as to identify the bearing working state. According to the method, relatively good classification effect can be obtained, the dictionary training process can be accelerated and the ability, of being adapted to target signals, of the dictionary is improved, so that the method is capable of realizing the sparse decomposition of complex vibration signals more efficiently and is used for fault identification.

Owner:HEFEI UNIV OF TECH

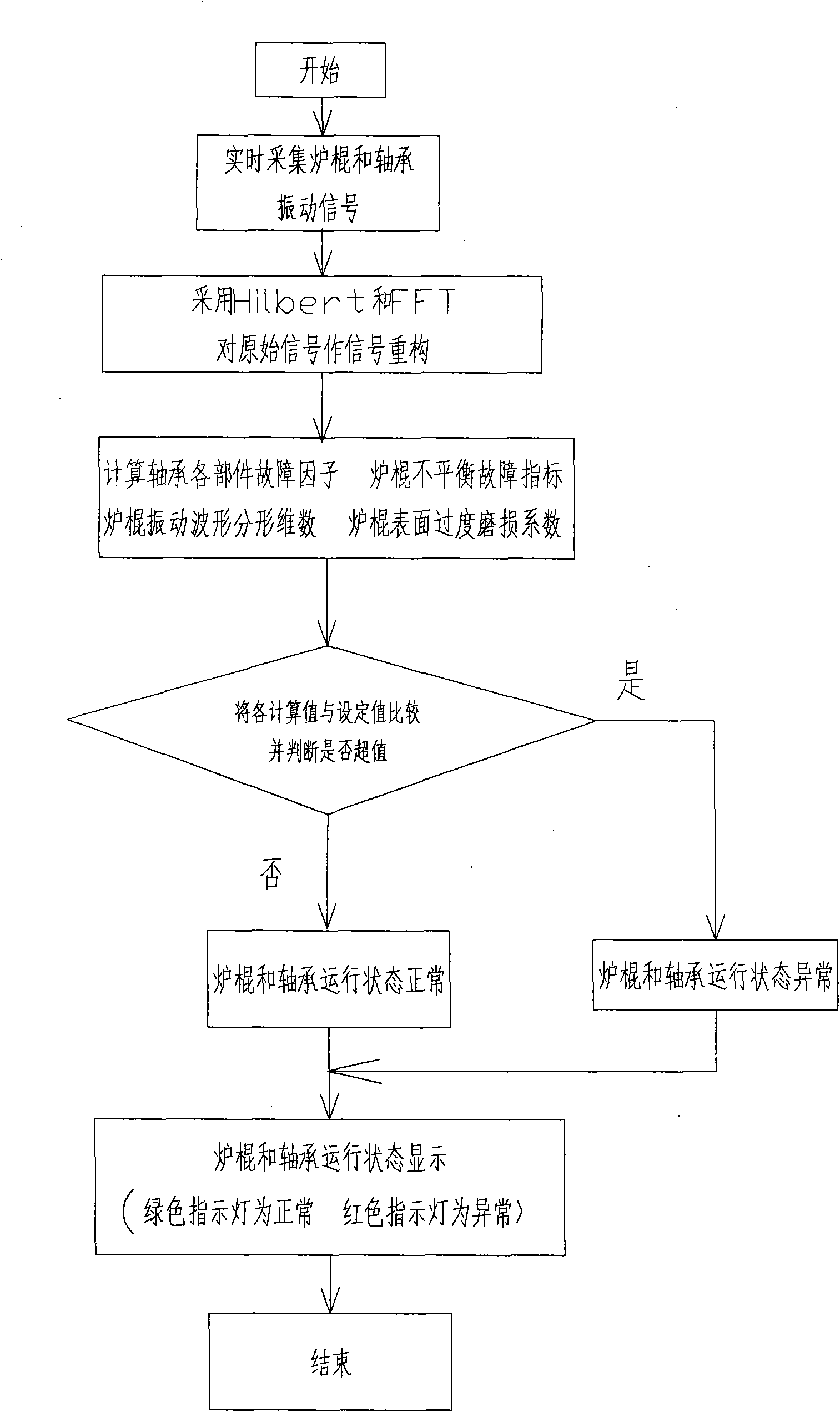

On-line monitoring method of cold rolled heating furnace roller running state

ActiveCN101685042AReal-time monitoring of running statusGuaranteed uptimeVibration measurement in solidsFurnace componentsVibration amplitudeFrequency spectrum

The invention discloses an on-line monitoring method of cold rolled heating furnace roller running state. The method comprises the following steps: using a vibration sensor to collect vibration signalof the furnace roller and bearing, performing signal reconstruction to the vibration signal to obtain a vibration characteristic signal of the furnace roller and bearing, wherein the characteristic signal comprises the vibration frequency spectrum of each part of the bearing and the rotary frequency of the furnace roller in every frequency multiplication; calculating failure factor of each part of the bearing to compare with a set value and judge bearing failure; calculating total vibration value of the furnace roller, comparing the value with vibration amplitude values of the rotary frequency of the furnace roller in 1 and 2 frequency multiplication to judge whether the furnace roller is abnormal; building vibration waveform aggregate to the original vibration signal to obtain the fractal dimension of furnace roller vibration, obtaining the conclusion that the furnace roller is abnormal when the fractal dimension changes violently; and finally judging whether the furnace roller surface is over abrasion by comparing the basic furnace roller vibration amplitude value with the on-line furnace roller total vibration value.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

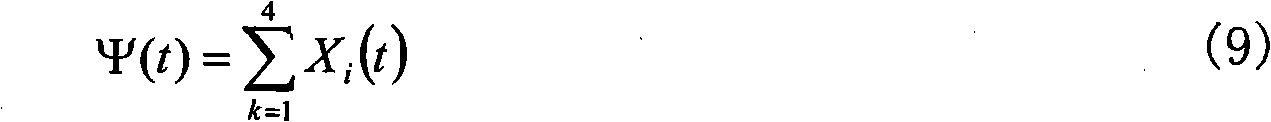

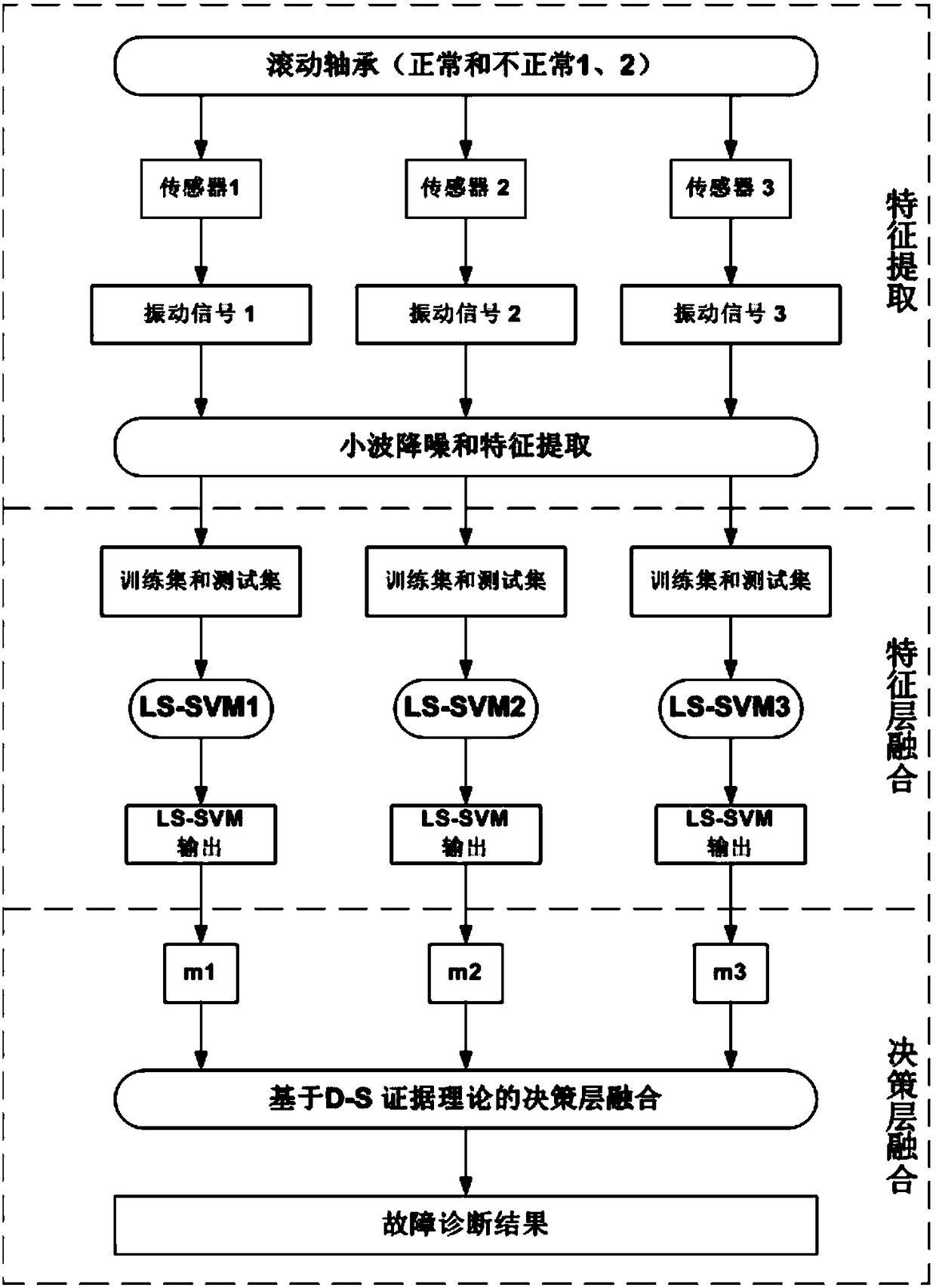

Bearing fault diagnosis method based on LS-SVM and D-S evidence theory

InactiveCN108332970AImprove reliabilityHigh precisionMachine bearings testingCharacter and pattern recognitionLeast squares support vector machineInformation integration

The invention discloses a bearing fault diagnosis method based on an LS-SVM and the D-S evidence theory. Through a multi-level information fusion method, the least squares support vector machine (LS-SVM) is adopted in a feature layer, and the D-S evidence theory is adopted in a decision-making layer to solve the problems that the single sensor fault diagnosis accuracy is low and the sensitive features are difficult to extract. Firstly, the wavelet noise reduction technology is used to improve the signal-to-noise ratio of a rolling bearing vibration signal, and eight parameters in the time domain and the frequency domain are introduced as feature parameters of the bearing vibration. Secondly, the bearing is fault identified by the LS-SVM. Thirdly, the LS-SVM feature output is used as the D-S evidence theory input, and the D-S evidence theory is used for fault decision making. The method can effectively improve the accuracy of rolling bearing fault diagnosis. The invention has certain significance for improving the fault diagnosis accuracy of the rolling bearing and the reliability of the diagnostic system.

Owner:CHINA RAILWAYS CORPORATION +1

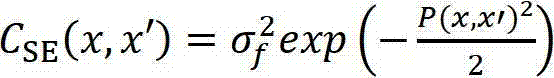

Method for predicting bearing fault based on Gaussian process regression

InactiveCN102831325AImprove usage management capabilitiesIncrease computing speedSpecial data processing applicationsTime domainTime range

The invention discloses a method for predicting a bearing fault based on Gaussian process regression. The method comprises the following five steps of: step 1, setting prediction system parameters, initializing a Gaussian process regression model; step 2, collecting a bearing vibration signal regularly, extracting characteristics of a vibration signal to obtain time domain characteristic parameters of the bearing vibration signal, and carrying out fault symptom judgment; step 3, judging whether a fault symptom exists; step 4, calculating and storing the characteristic parameters, and carrying out dynamic updating of the Gaussian process regression model; and step 5, predicting the fault of a bearing. According to an actual use condition of a product, small amount of data is collected, time that the product possibly has the fault is given quantificationally, a calculation speed and prediction accuracy are improved by using the Gaussian process regression, a whole life cycle of the bearing is divided into three time ranges, such as a health time range, a sub-health time range and a fault time range by use of an idea of health management, fault prediction is carried out in the sub-health state, usage management capacity of the bearing is improved.

Owner:BEIHANG UNIV

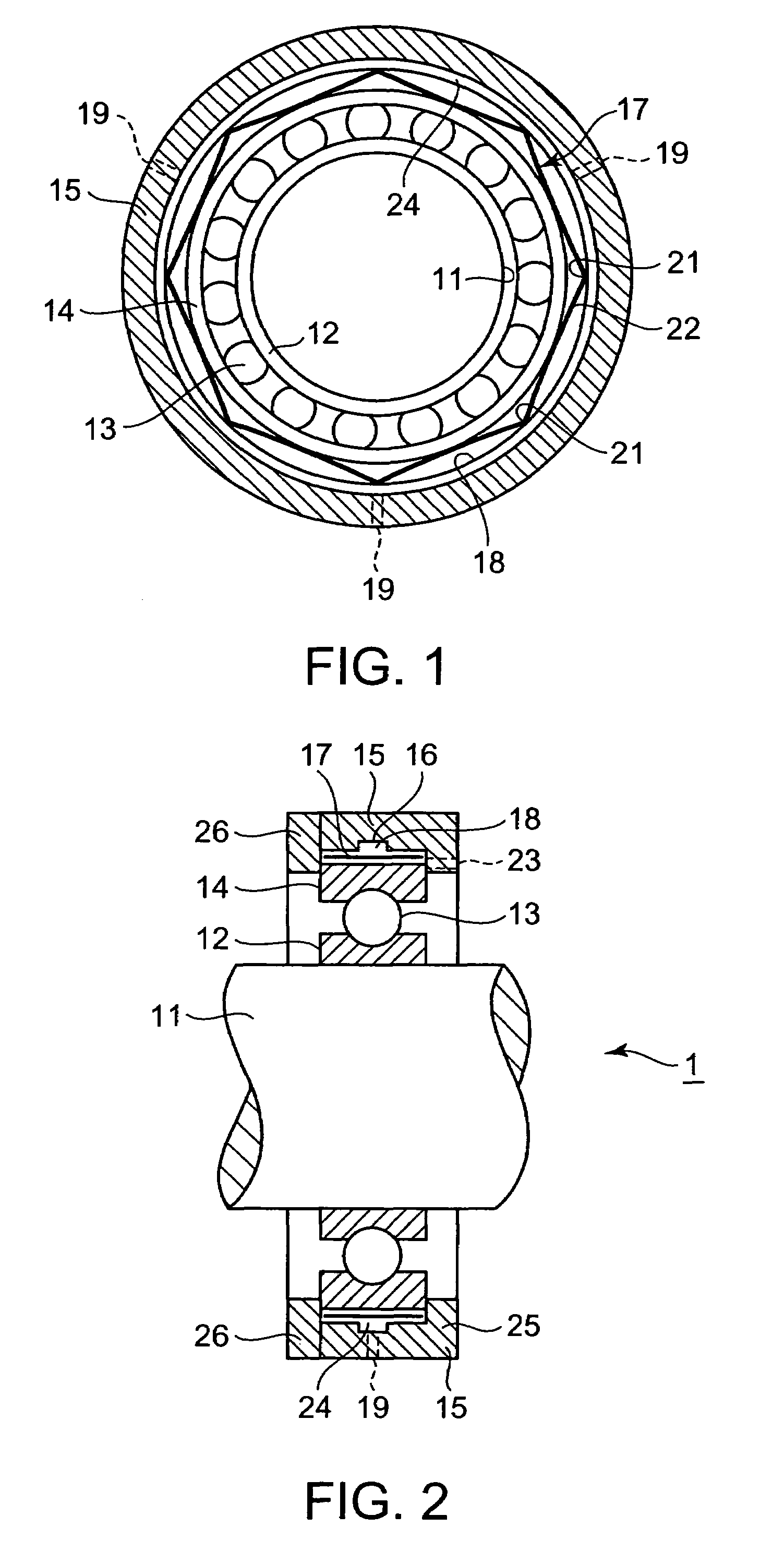

Bearing vibration damping mechanism

ActiveUS7628542B2Easy to produceReduce vibrationLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper for a bearing and a vibration damping mechanism capable of damping the vibration of a rolling bearing are provided. The squeeze film damper is small in construction and can be easily made by mass production. The vibration damping mechanism is capable of damping both radial and axial vibrations. A bearing housing 15 is provided with a bearing holding bore 16 of a diameter greater than the outside diameter of the outer ring 14 of a bearing, and an oil hole 19 through which oil is supplied into the bearing holding bore 16. A vibration damping mechanism 1 is formed by inserting a thin, flat sheet 17 provided with slits into an annular space formed between the inner wall of the bearing holding bore 16 and the outside surface of a bearing held in the bearing holding bore 16 so as to surround the bearing. Parts of the thin, flat sheet extending between the adjacent slits serve as elastic beams. The elastic beams center the bearing and support the centered bearing elastically. The vibration of the bearing is damped by the squeeze film effect of an oil film formed by supplying oil into the annular space.

Owner:KAWASAKI HEAVY IND LTD

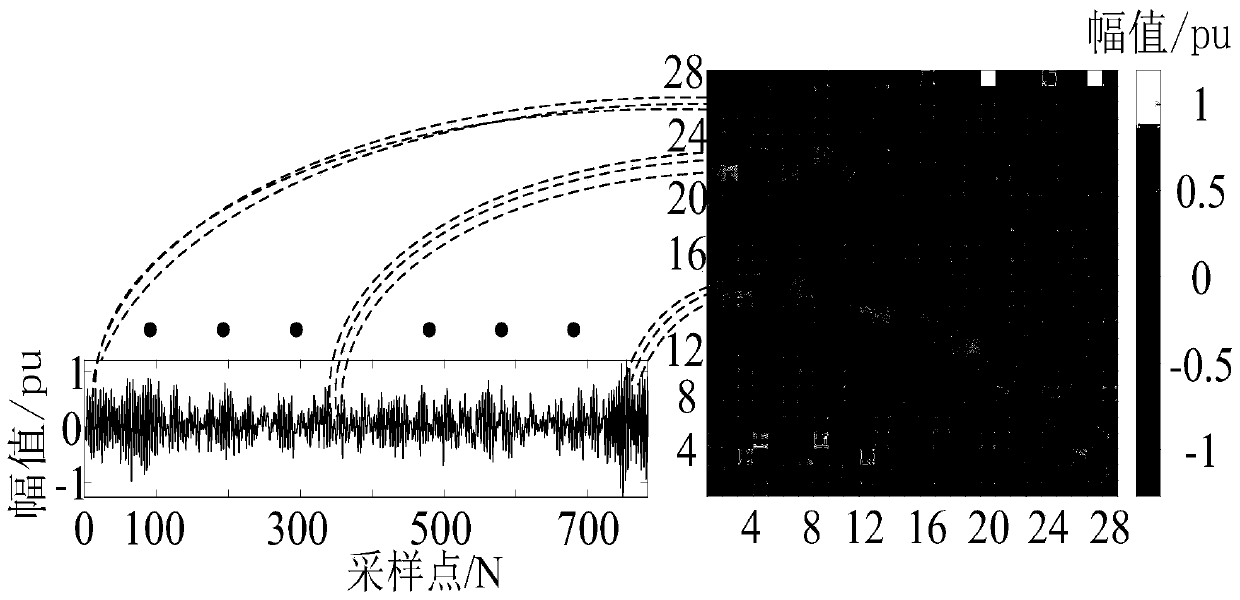

Performance evaluation method for rolling bearing under multiple operating conditions based on geometric measurement

InactiveCN106289777AData stabilityGeometry stabilityMachine bearings testingSingular value decompositionControl theory

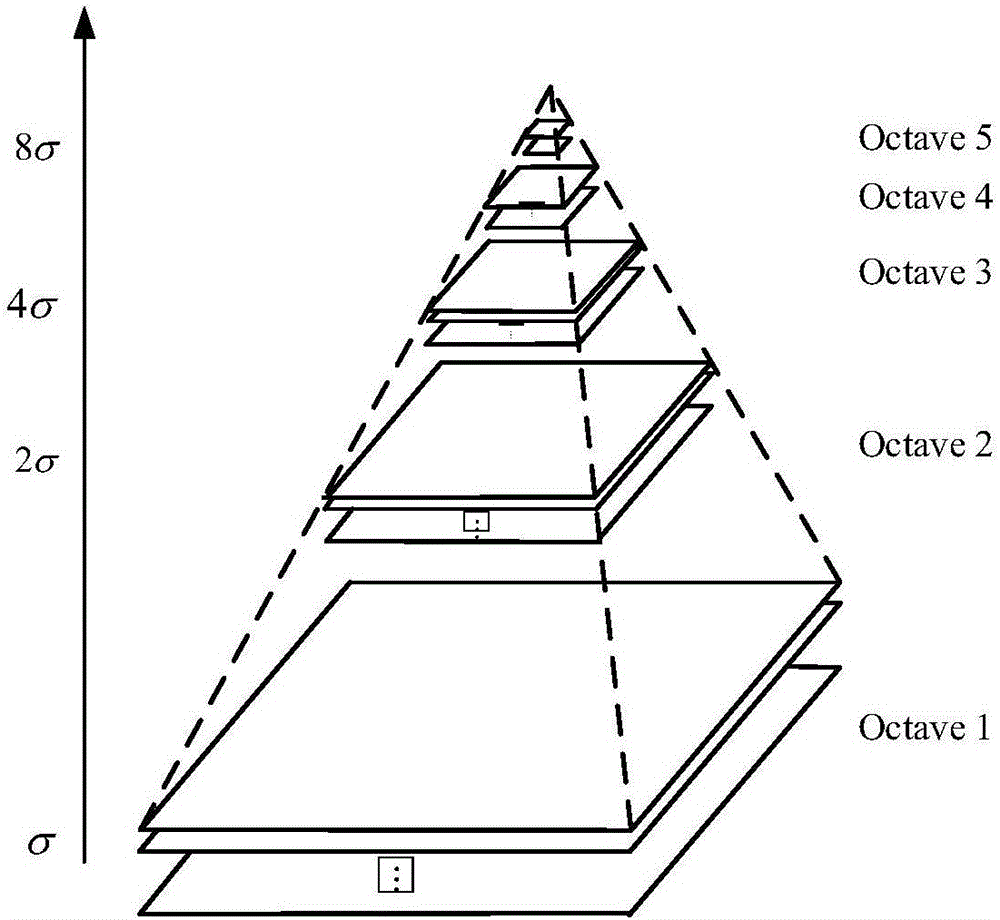

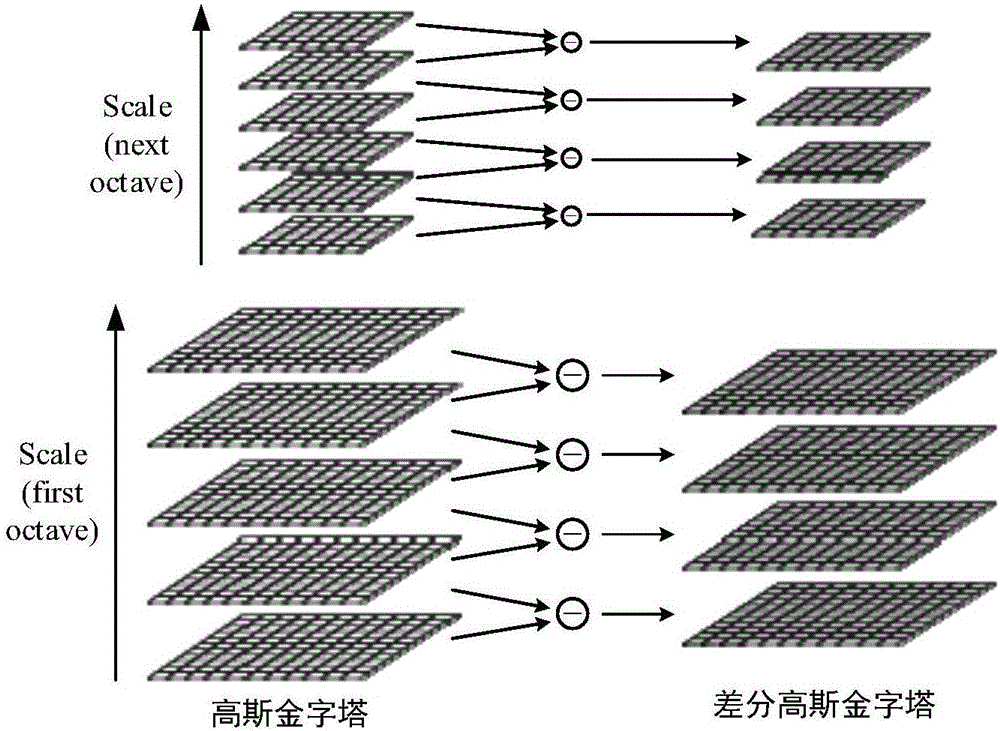

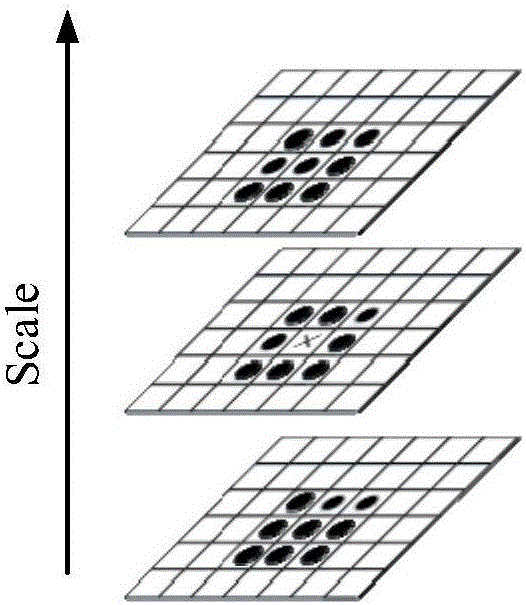

The invention relates to a performance evaluation method for a rolling bearing under multiple operating conditions based on geometric measurement. The performance evaluation method comprises the steps of firstly converting rolling bearing vibration signals with different fault degrees under different operating conditions into a recurrence plot, then stable extracting geometric features of the converted recurrence plot by using scale invariant feature transform method, carrying out singular value decomposition on the geometric features extracted from the bearing signals to acquire feature curves of the rolling bearing with different fault degrees under the different operating conditions, and then calculating the similarity of different feature curves by using dynamic time warping so as to work out a health degree of the rolling bearing. Case verification is carried out by using bearing data of the Case Western Reserve University in the United States, and an experimental result shows that the performance evaluation method can evaluate the health degree of the rolling bearing under multiple operating conditions effectively.

Owner:北京恒兴易康科技有限公司

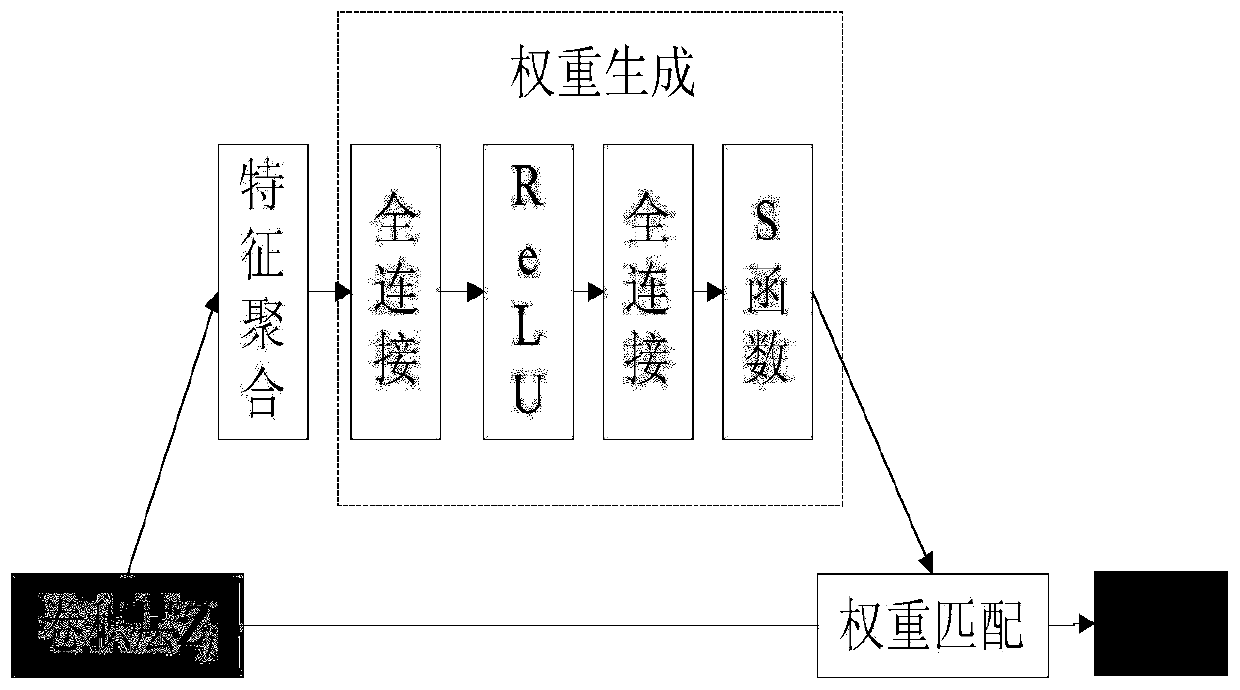

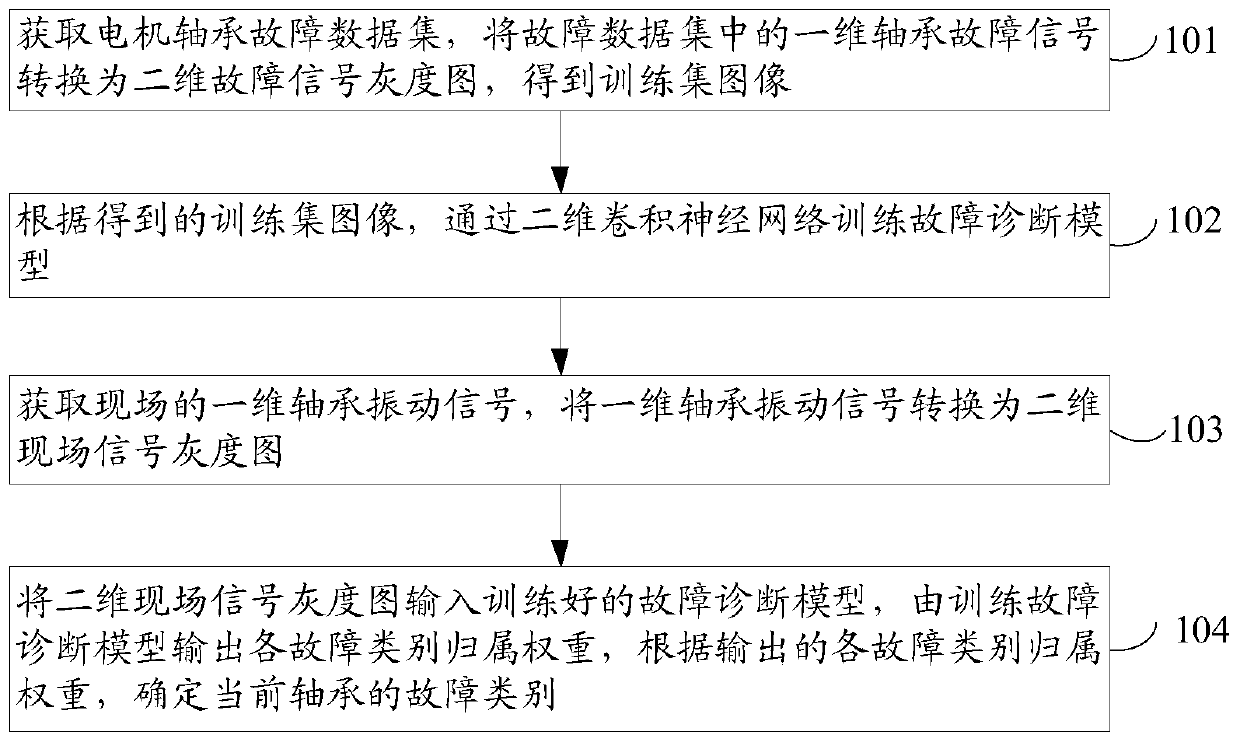

Motor bearing fault diagnosis method and device

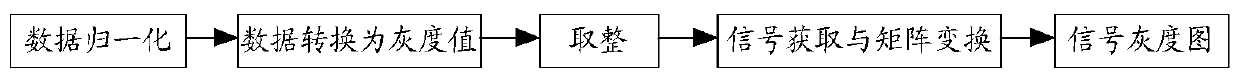

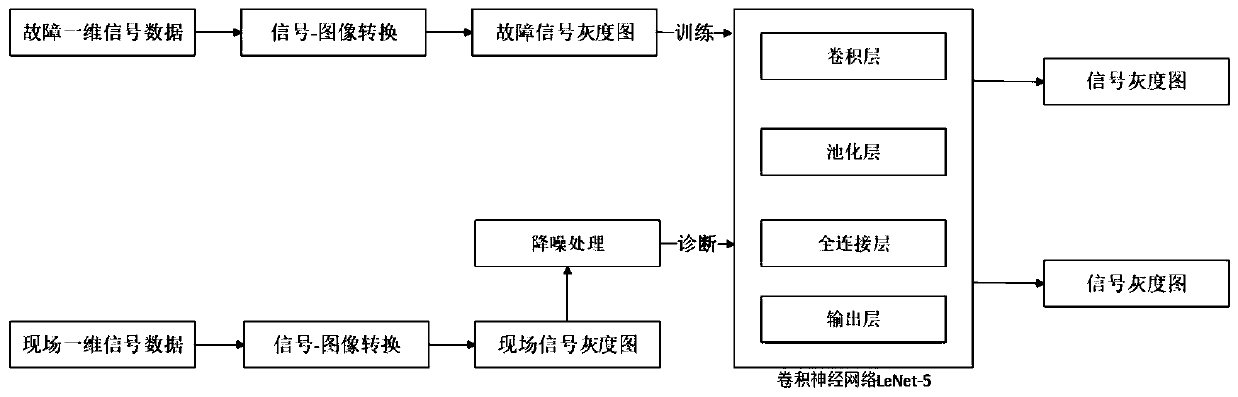

The invention provides a motor bearing fault diagnosis method and device which can convert a one-dimensional vibration signal of a bearing into a two-dimensional gray-scale map by adopting a sample-image conversion method and reduce complexity of a structure of a two-dimensional convolutional neural network. The method comprises the steps of: acquiring a motor bearing fault data set, converting aone-dimensional bearing fault signal in the fault data set into a two-dimensional fault signal gray-scale map to obtain a training set image; according to the obtained training set image, training a fault diagnosis model by the two-dimensional convolutional neural network; acquiring a one-dimensional bearing vibration signal in the field, and converting the one-dimensional bearing vibration signalinto a two-dimensional field signal gray-scale map; and inputting the two-dimensional field signal gray-scale map into the trained fault diagnosis model, outputting each fault category affiliation weight by the trained fault diagnosis model, and according to each output fault category affiliation weight, determining a fault category of a current bearing. The motor bearing fault diagnosis method and device are applicable to the field of motor bearing fault diagnosis.

Owner:UNIV OF SCI & TECH BEIJING

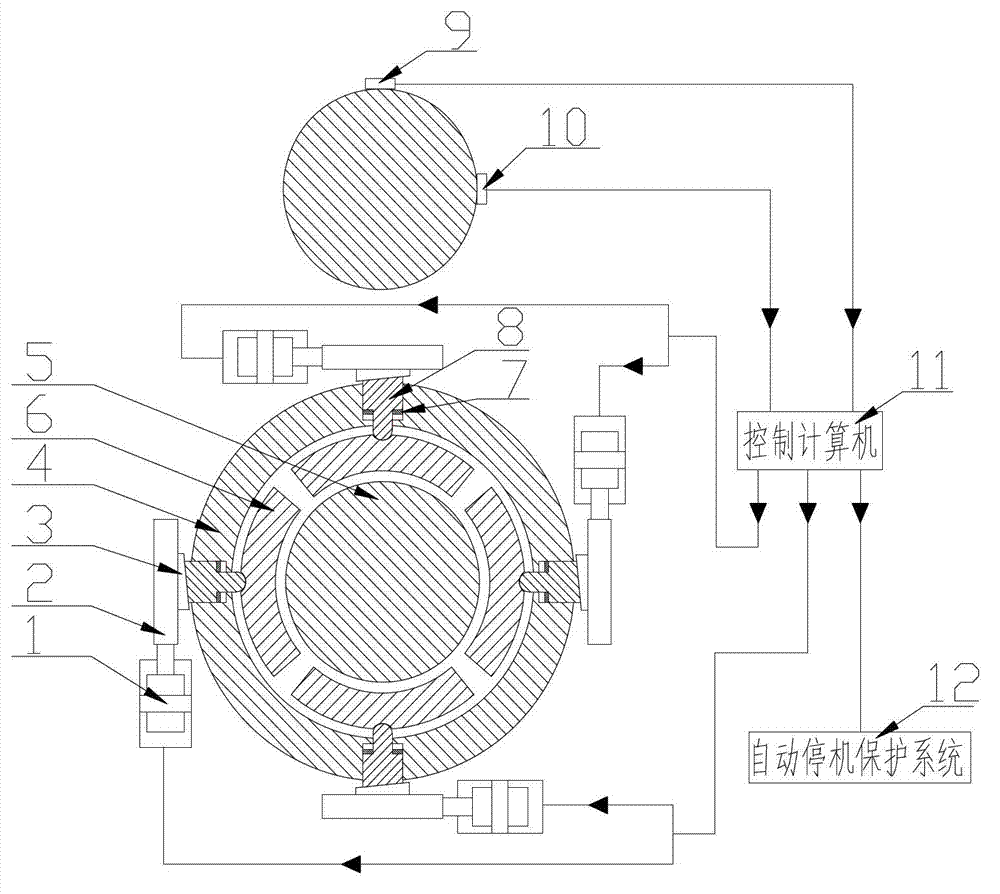

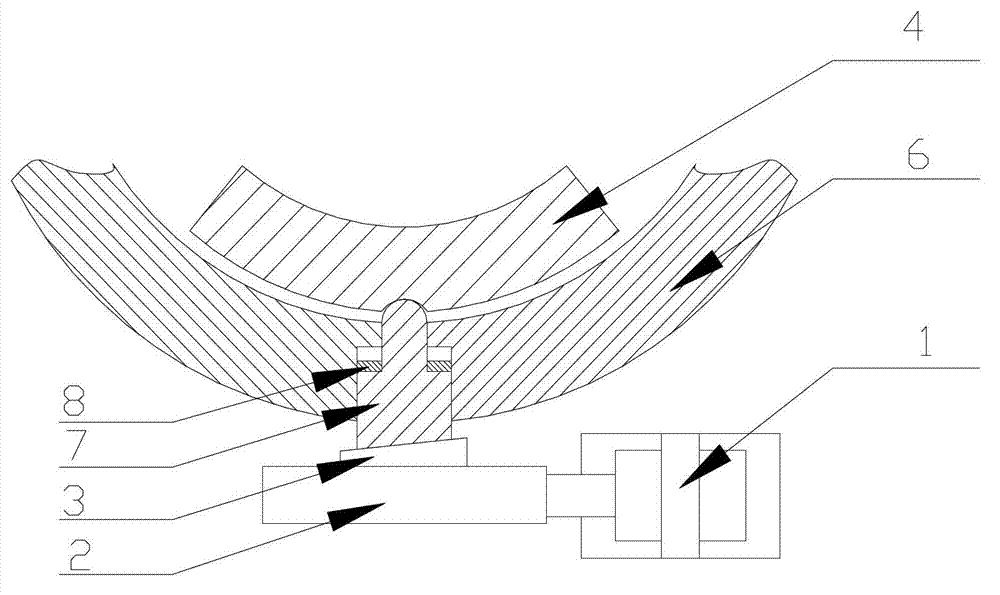

Online vibration control tilting-pad radial sliding bearing device

InactiveCN103089810AImprove working conditionSelect Radial Displacement AccuracySliding contact bearingsVibration controlRadial position

Owner:XI AN JIAOTONG UNIV

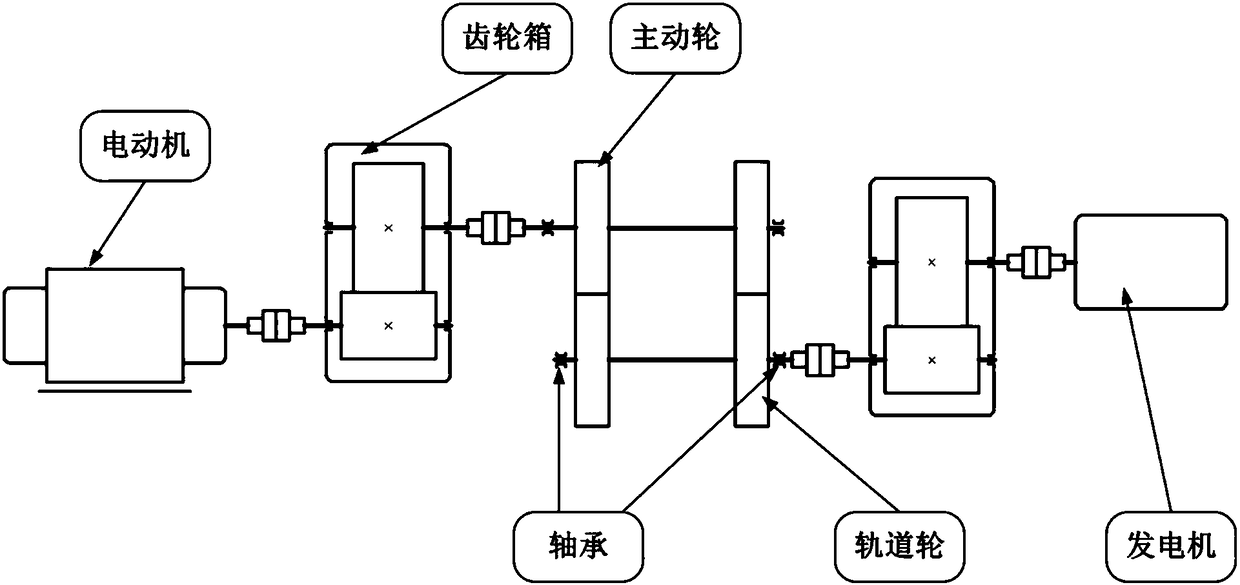

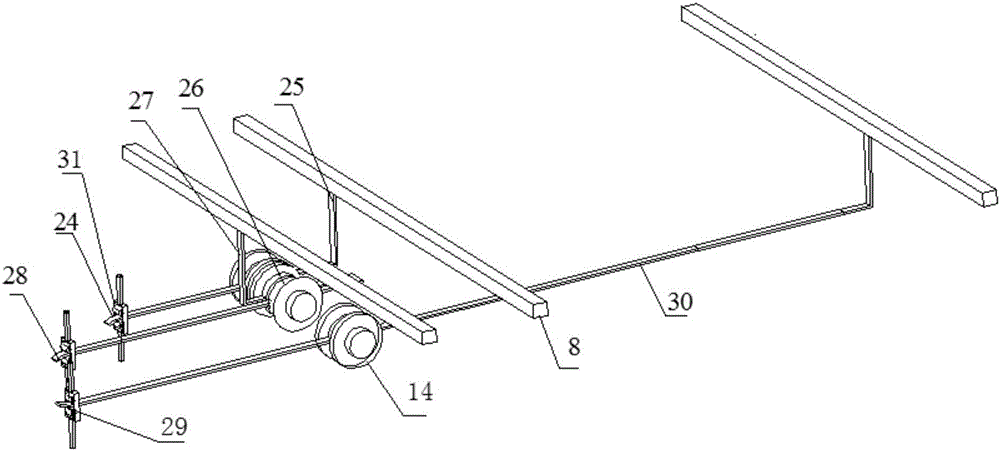

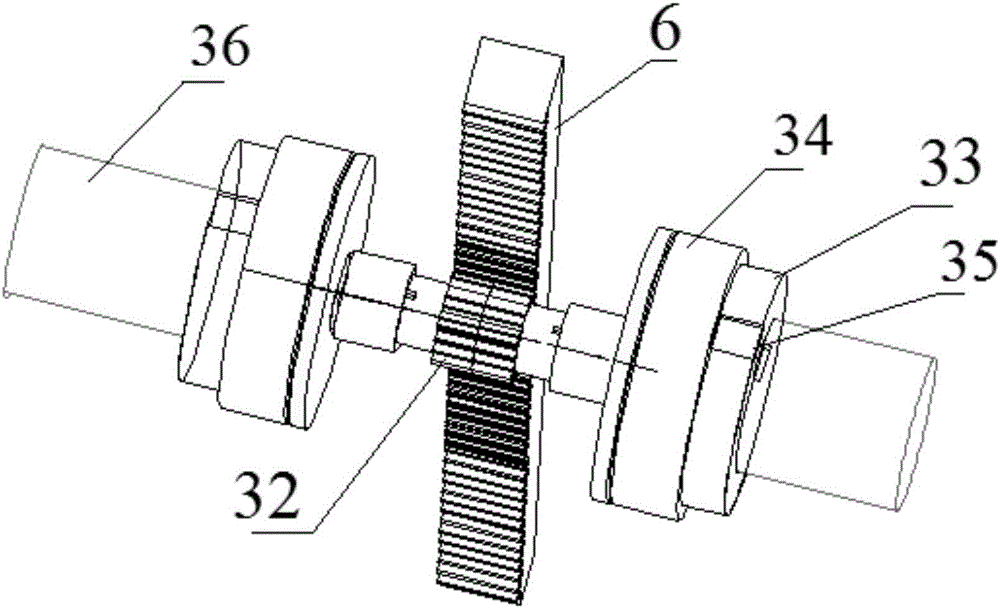

Electric automobile resonance power generation optimization method and structure based on lever principle

ActiveCN105971834AImprove capture efficiencyPlay a role in suppressing vibrationMachines/enginesMechanical power devicesElectricityGear wheel

The invention relates to a method and structure for generating power through automobile kinetic energy, and belongs to the field of automobiles. An electric automobile resonance power generation optimization structure based on the lever principle comprises a kinetic energy power generation device on a hollow weight supporting plate, wherein the hollow weight supporting plate is arranged on an above-spring automobile body and is provided with a vertical elastic system; the method is characterized in that the hollow weight supporting plate and the above-spring automobile body have the same inherent frequency, straight racks are driven by a lever, the supporting point of the lever is arranged on an axle, the power end of the lever bears vibration force of the above-spring automobile body, and the resistance end of the lever drives the straight racks to vertically move along a sliding rail vertically fixed to a vibration guide frame; and in the compression and rebound stroke of the above-spring automobile body, the lever drives the different straight racks, gears engaged with the straight racks are driven, a center shaft of an electric generator generates the same-direction continuous torsional force, the torsional force and resonance action force generated by the hollow weight supporting plate during automobile body vibration are superposed, and the electric generator generates electricity.

Owner:杨亦勇

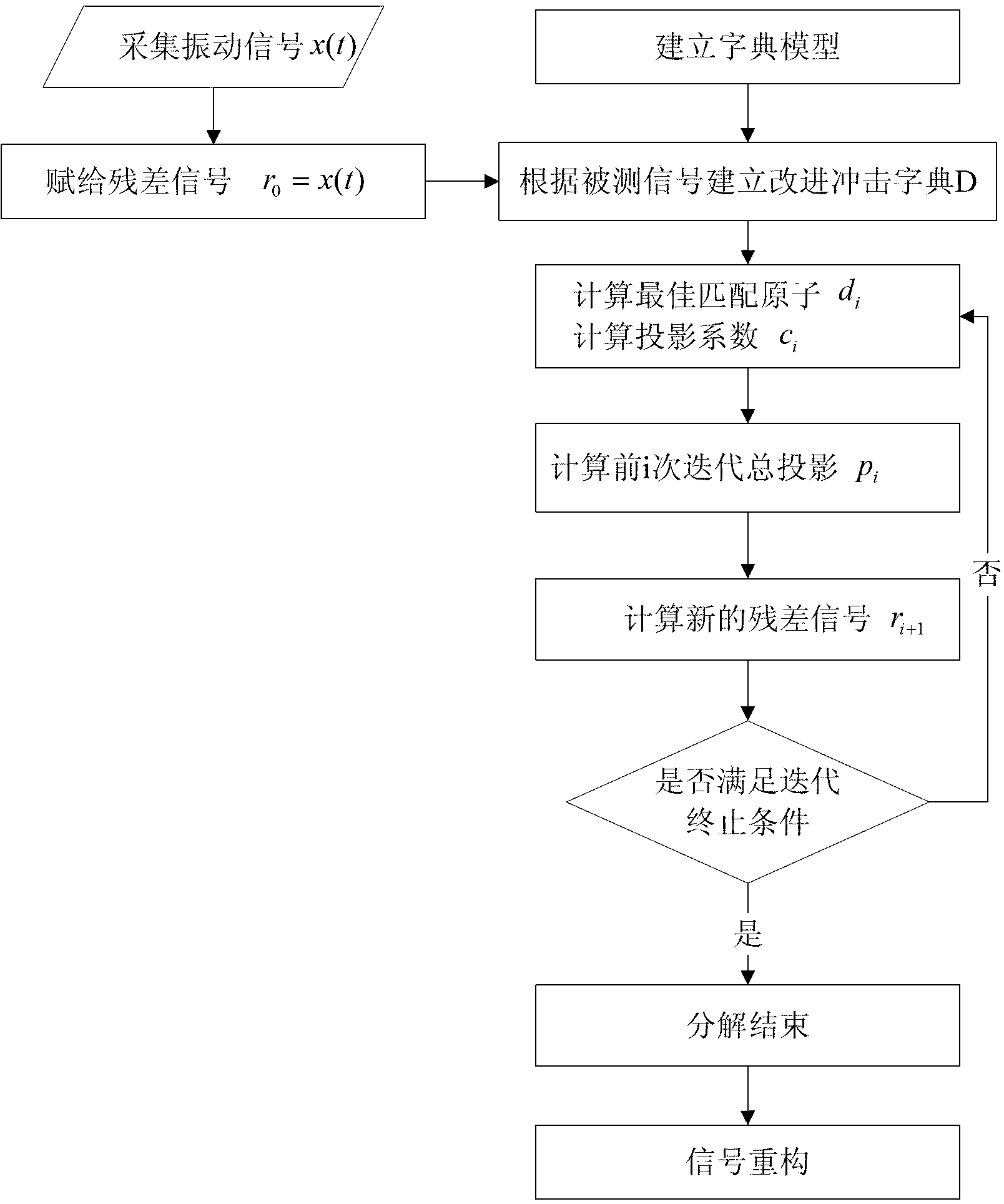

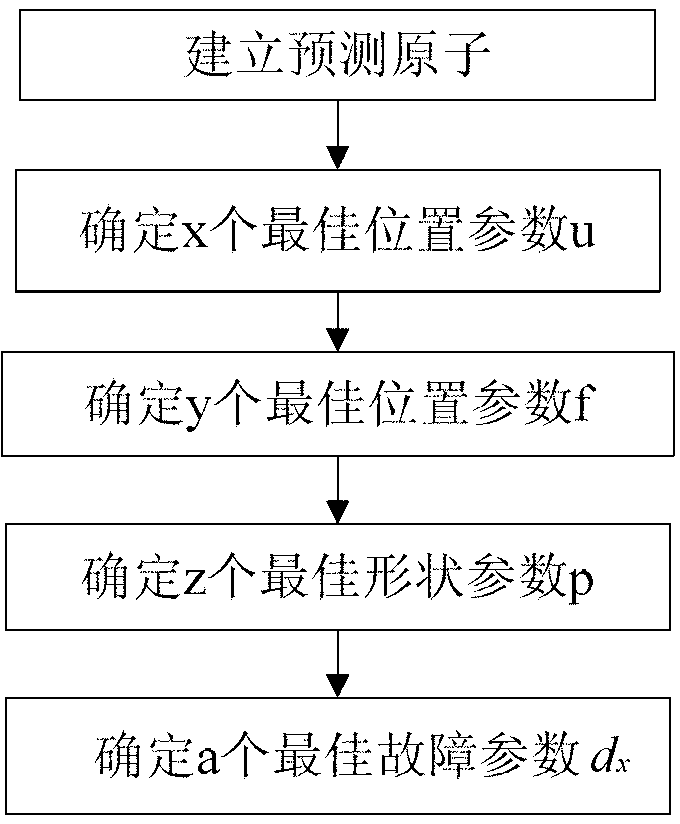

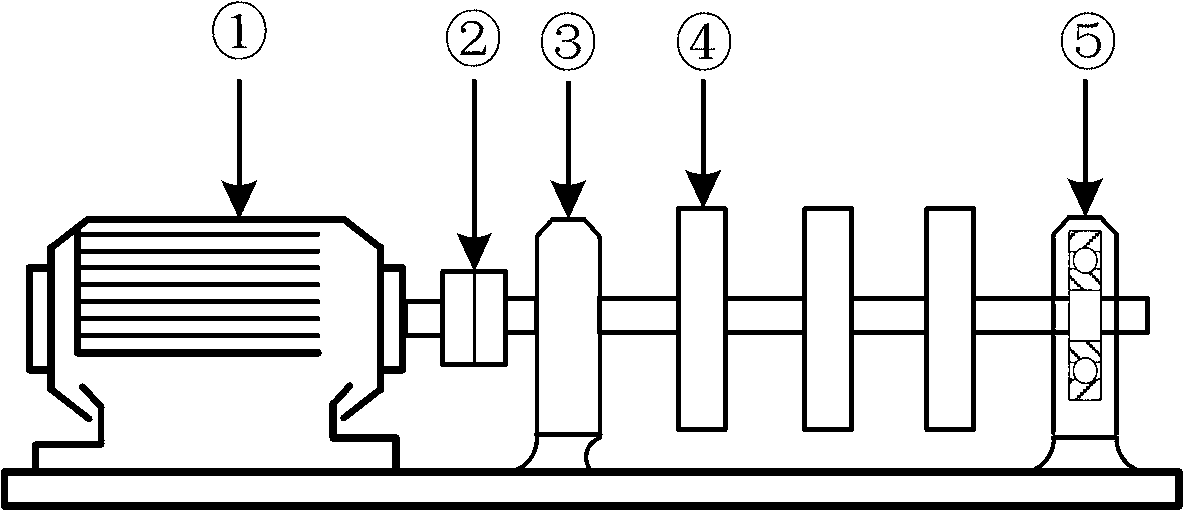

Bearing combined failure diagnosis method based on improved impact dictionary matching pursuit

ActiveCN103018044AImplement fault diagnosisImprove search speedMachine bearings testingBearing vibrationEngineering

The invention discloses a bearing combined failure diagnosis method based on improved impact dictionary matching pursuit. According to the method, a bearing vibration signal is iterated and decomposed successively to be a linear combination based on an i-item atom of an improved impact model dictionary; an improved model is established according to the type of an analyzed bearing, and can very accurately indicate out an impact signal of a fault bearing in the running process; a position parameter u in the improved model is used as a preferentially changing parameter according to the cycle characteristic of a bearing failure signal, an atom base with relatively low redundancy is established by using a method of gradually changing the parameters, and the search speed of an optimal atom is greatly improved; a analyzed signal is cut in the signal decomposing process, the optimal atom is searched from atoms in the atom base, and a corresponding impact signal component can be obtained by impact component reconfiguration; and then the failure characteristic frequency of a bearing is obtained by time-frequency transform, and thus the failure diagnosis of the bearing is achieved.

Owner:BEIJING UNIV OF TECH

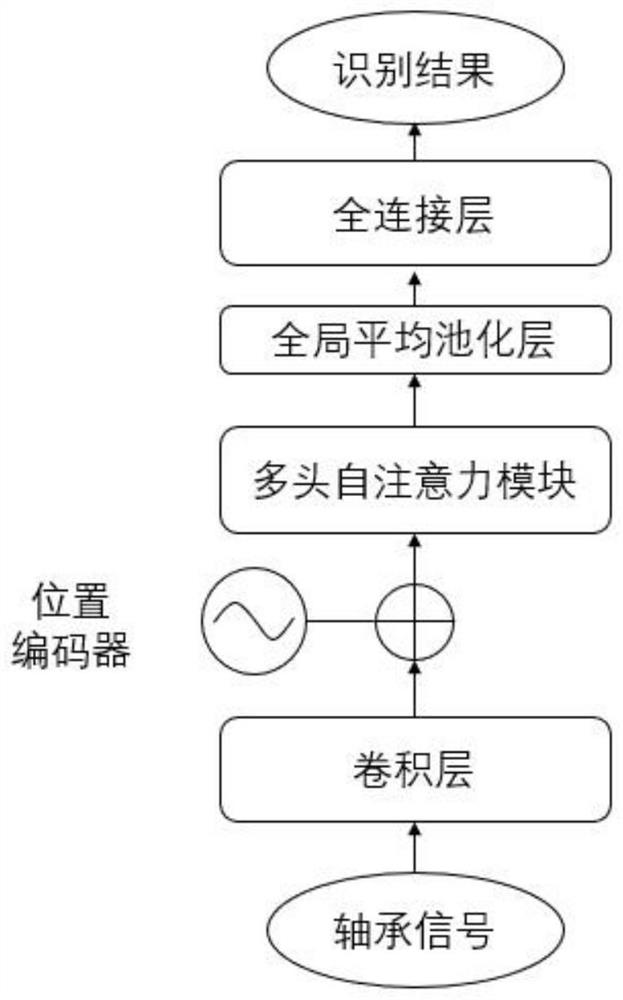

Bearing fault detection method based on convolution multi-head self-attention mechanism

ActiveCN111721535ARealize intelligent detectionAccurate identificationMachine part testingCharacter and pattern recognitionData setAlgorithm

The invention discloses a bearing fault detection method based on a convolution multi-head self-attention mechanism. The detection method comprises the following steps: acquiring and preprocessing a fault bearing vibration signal; generating a bearing fault data set; and constructing a convolutional multi-head self-attention mechanism network, and performing training to obtain a bearing fault detection result. The convolution multi-head self-attention mechanism network comprises a convolution layer, a position encoder, a multi-head self-attention module, a global average pooling layer and a full connection layer; the convolution layer extracts bearing signal initial features; the position encoder performs position encoding on the initial characteristics of the bearing; the multi-head self-attention module learns the initial features; the global average pooling layer regularizes the network to prevent overfitting; and the full connection layer outputs different fault types of the bearing. An efficient and accurate method is provided for bearing fault detection, so that normal operation of mechanical equipment is effectively maintained.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

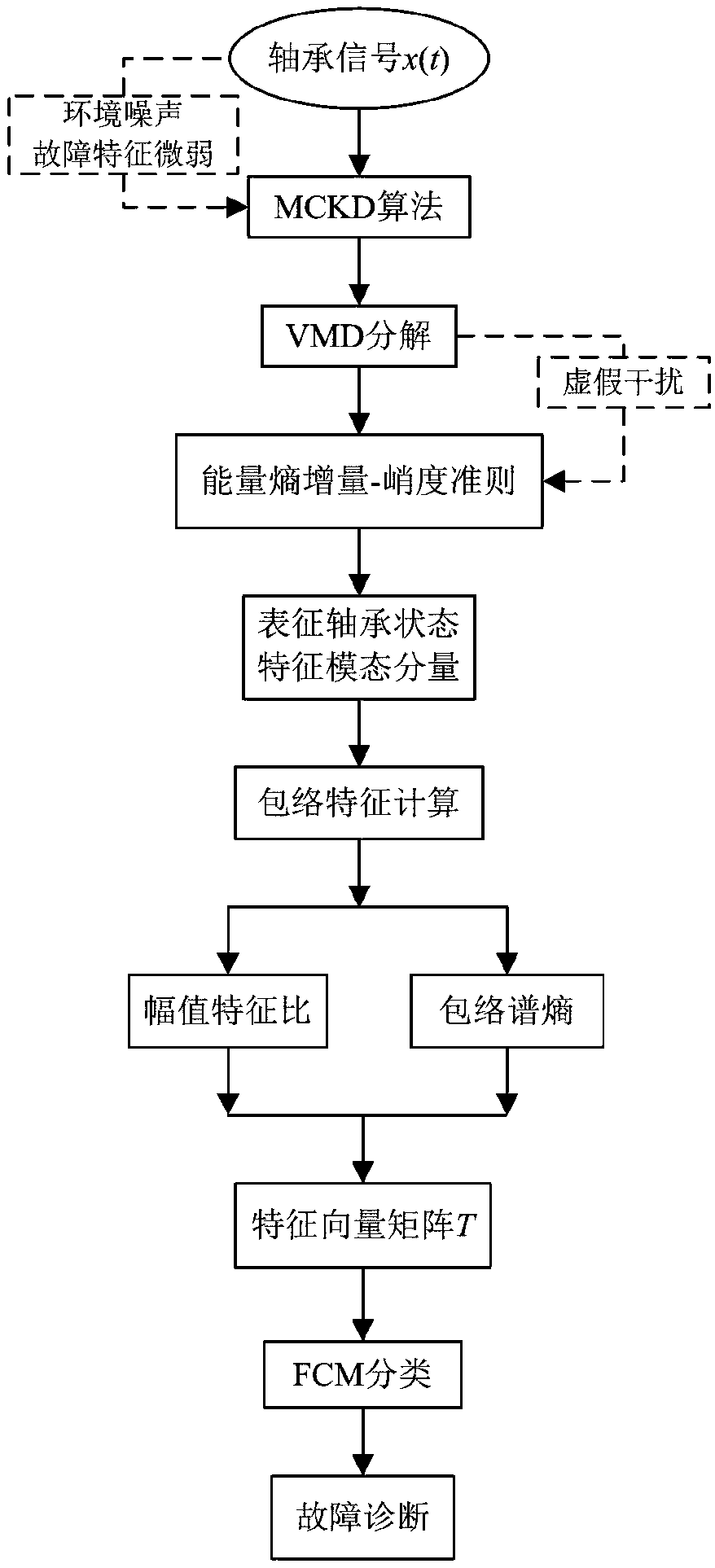

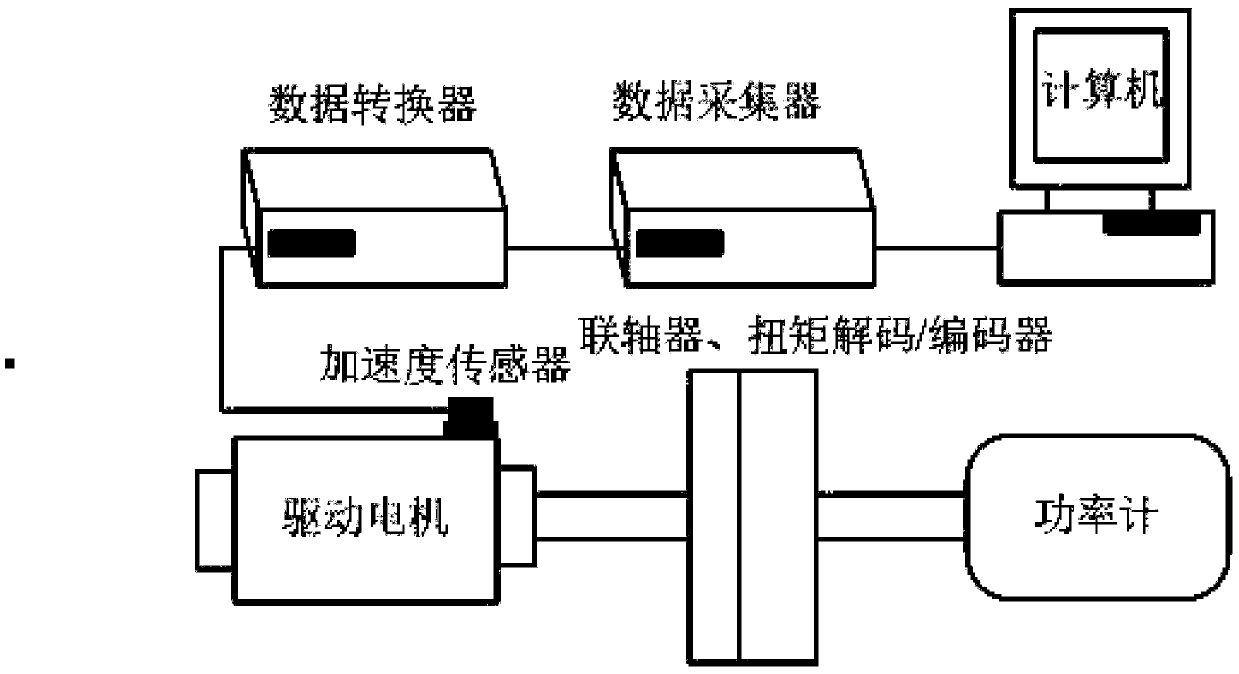

Rolling bearing fault diagnosis method based on deconvolution and envelope spectrum

InactiveCN109612732AEffectively distinguish working statusEffectively distinguish fault typesMachine part testingCluster algorithmDiagnosis methods

The invention discloses a rolling bearing fault diagnosis method based on deconvolution and an envelope spectrum. In order to study influence on classification and identification results of rolling bearing working states under different damage degrees, rolling bearing rolling body fault signals are analyzed, the rotating speed of a rotating shaft is 1800r / min, the sampling frequency is 12000Hz, and the damage degrees are divided into a mild degree, a moderate degree and a severe degree according to diameters of damage points. According to the rolling bearing fault diagnosis method based on thedeconvolution and the envelope spectrum, the structure is scientific and reasonable, and the usage is safe and convenient. The rolling bearing fault diagnosis method based on the deconvolution and the envelope spectrum comprises the steps that firstly, a fault feature of a rolling bearing vibration signal is enhanced by using MCKD algorithm; the enhanced signal is carried out VMD decomposing; IMFcomponents containing main fault feature information are selected based on energy entropy increment and a kurtosis criterion; an envelope spectrum feature amplitude ratio and envelope spectrum entropy of each sensitive IMF component are extracted to better reflect and quantify the fault feature information; and a fault state is identified by using fuzzy C-means clustering algorithm to realize thediagnosis of a working state and a fault type of a rolling bearing.

Owner:BEIHUA UNIV

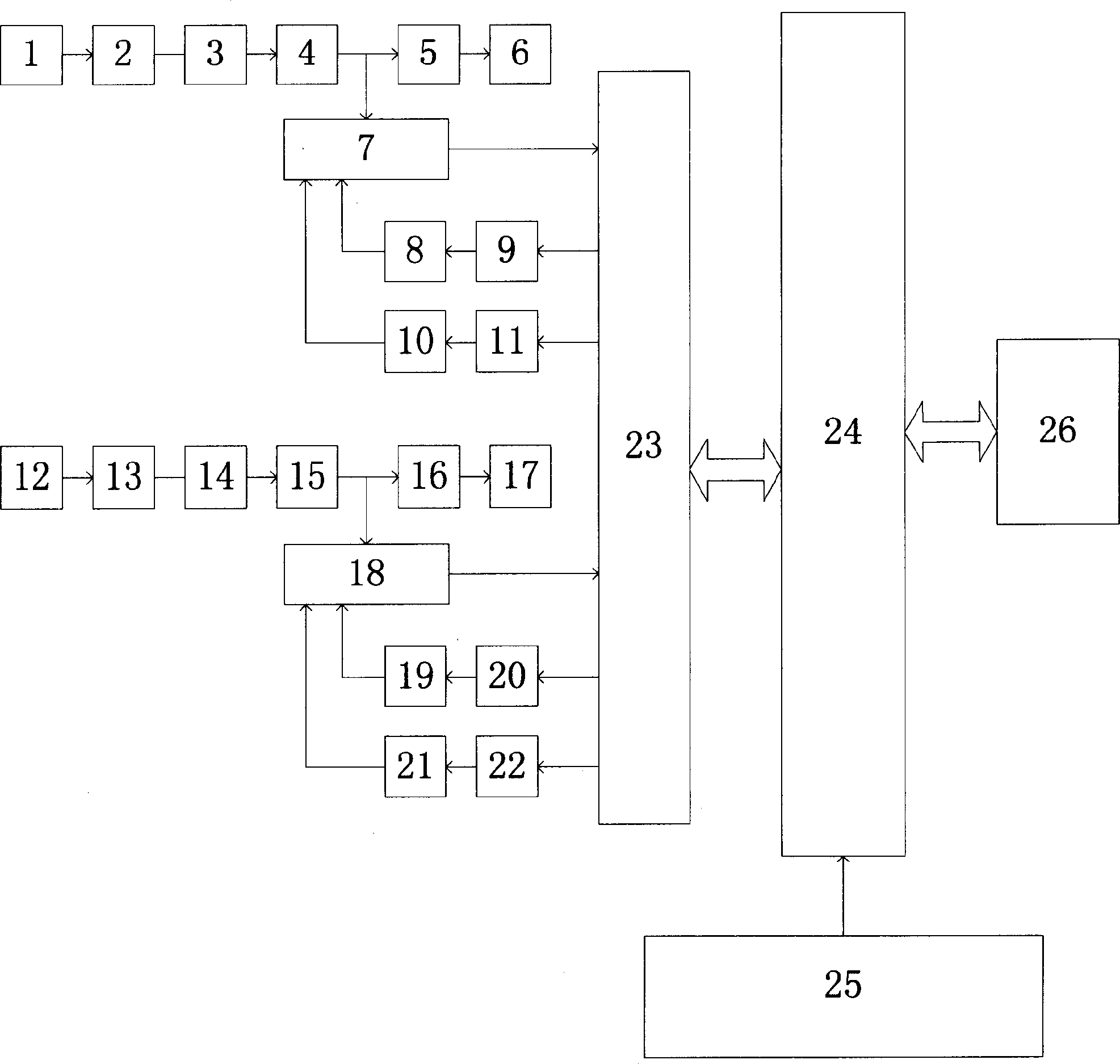

Full-automatic bearing vibration survey instrument and method thereof

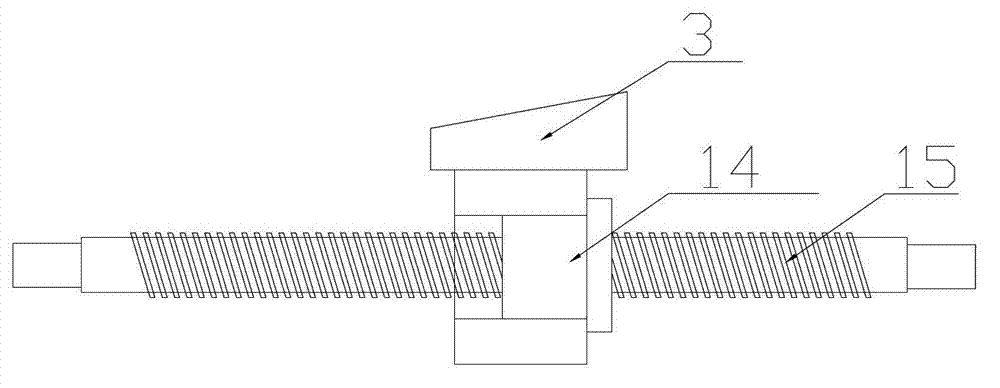

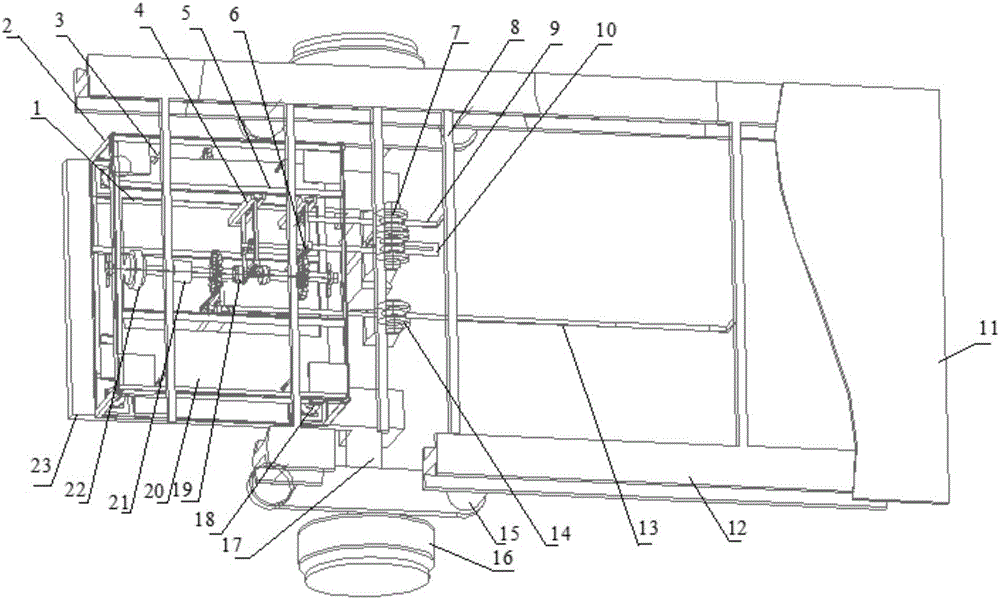

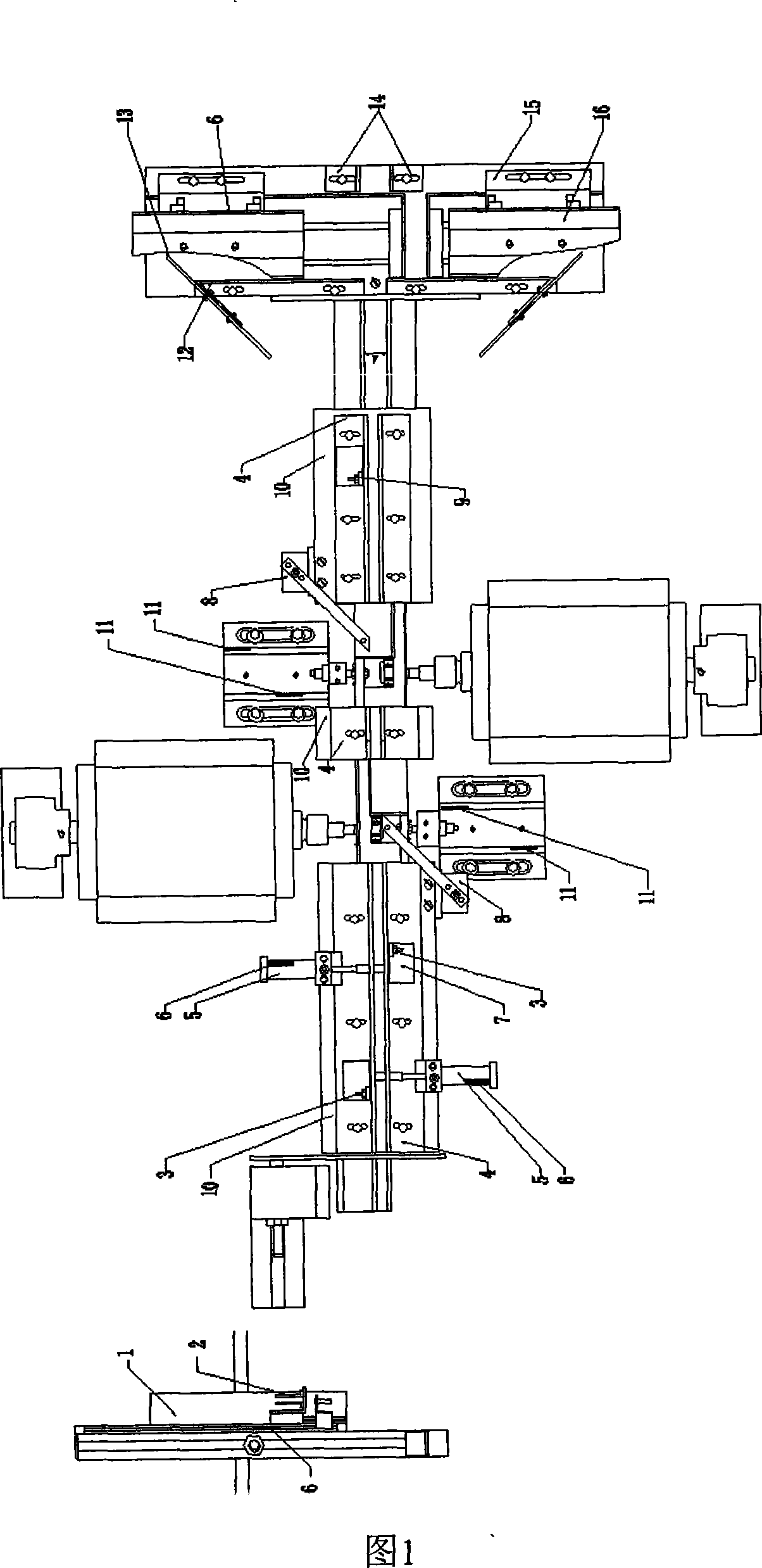

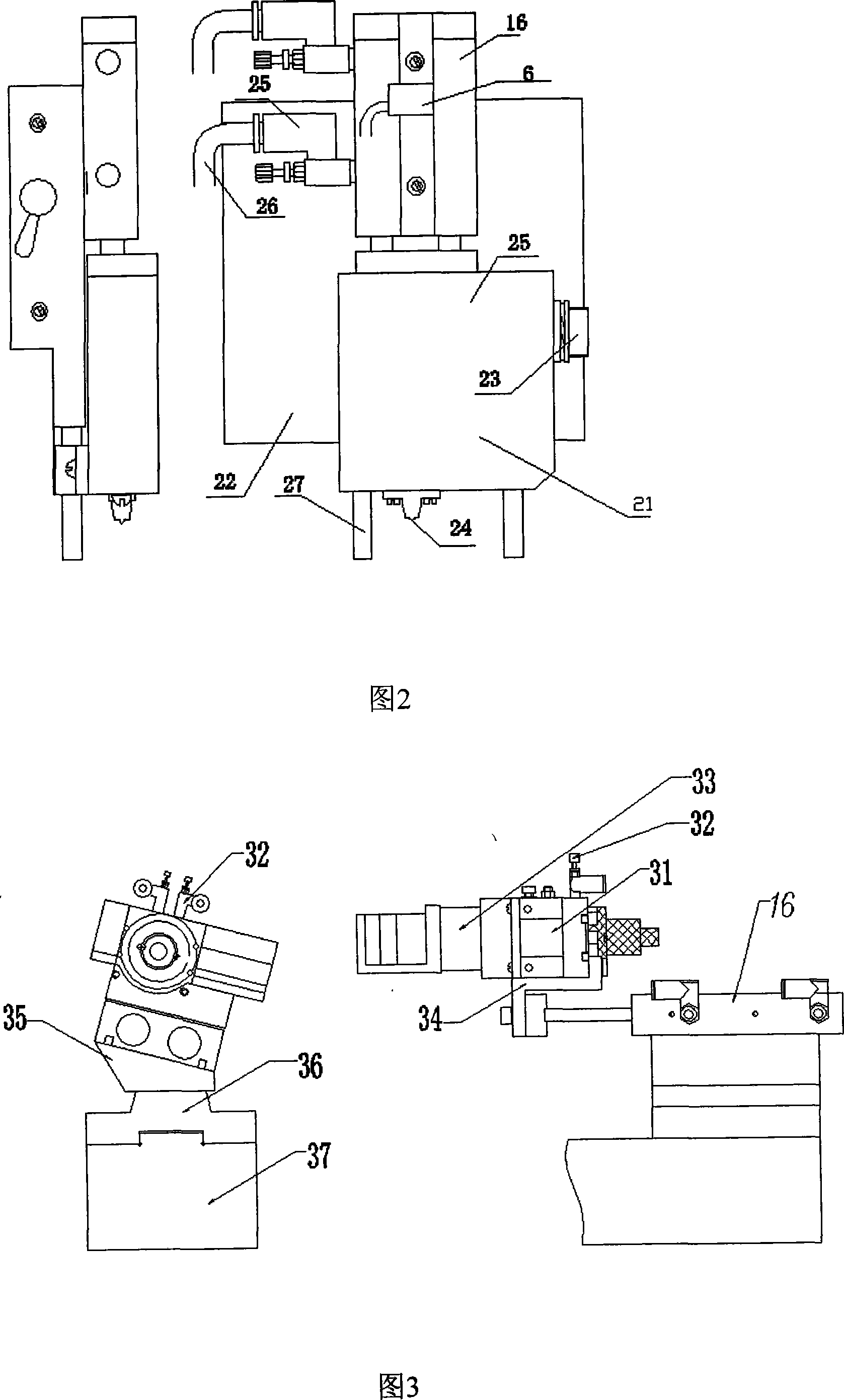

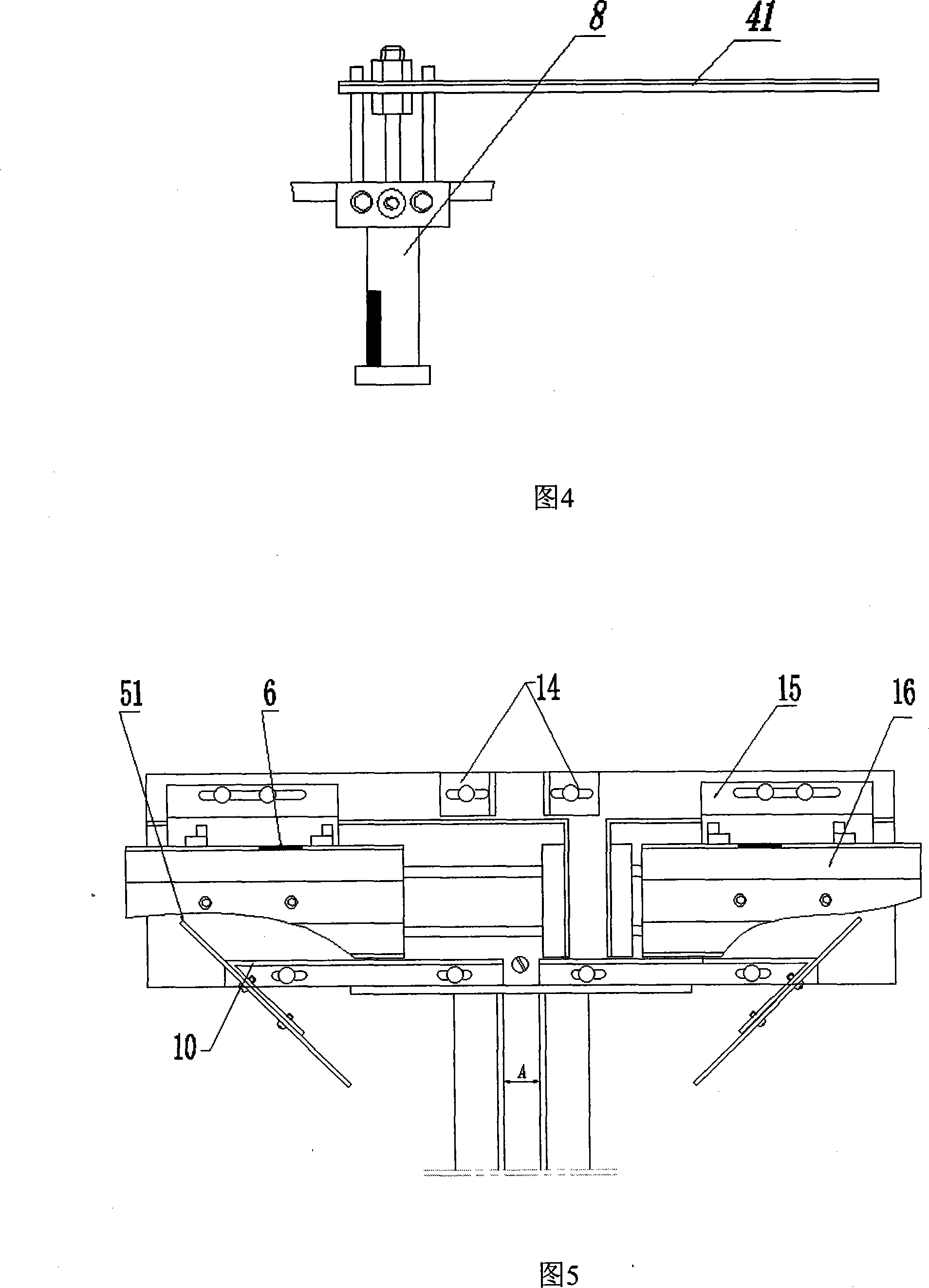

InactiveCN101246046AExcellent material structureGood material structureSubsonic/sonic/ultrasonic wave measurementMachine bearings testingSurvey instrumentBearing vibration

The invention discloses a full-automatic bearing vibration measuring device and the measuring method thereof, the measuring device comprises the following components: a measuring head lifting mechanism, a measuring mechanism, a protecting mechanism and a material-distributing mechanism, the invention is characterized in that the bearing to be measured is placed to a corresponding station with the lifting mechanism, then the bearing to be measured is conveyed to the measuring mechanism with the driving mechanism of the station, and afterwards the bearing to be measured enters the material-distributing mechanism according to the signal of the measuring mechanism after detecting. The invention realizes the automatic lifting of the measuring head, the automatic three-point measuring of the bearing to be measured, preventing to the distortion of the baring and the automatic material distributing to the excellent, good and inferior products in bearing measuring.

Owner:孙连贵

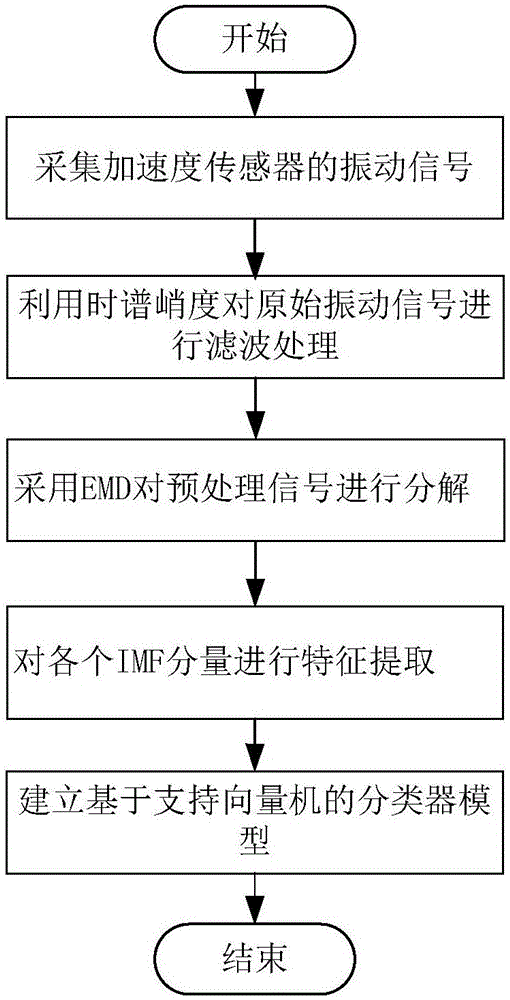

Train rolling bearing fault and impurity vibration distinguishing method

ActiveCN106441893AEasy to classify and identifyImprove signal-to-noise ratioMachine bearings testingFrequency spectrumDecomposition

The invention discloses a train rolling bearing fault and impurity vibration distinguishing method. The method includes: utilizing spectral kurtosis to perform filtering processing on an original bearing vibration signal, and adopting an empirical mode decomposition technique to perform step-by-step decomposition on the preprocessed vibration signal to obtain intrinsic mode functions; subjecting the intrinsic mode functions to frequency spectrum and statistic characteristic analysis, extracting a feature vector composed of frequency spectrum center-of-gravity and characteristic frequency energy ratio as input, establishing a support vector machine based classifier model by training, and distinguishing whether a rolling bearing with abnormal noise is faulted or contains impurities in real time. The method is used for distinguishing the fault or impurity-containing state of the train rolling bearing based on vibration signal analysis, the method effectively improves accuracy in bearing fault identification, the problem of overhigh false alarm rate in the bearing vibration diagnosis method caused by impurities is solved, and good technical support is provided for engineering application of the vibration diagnosis method.

Owner:BEIJING UNIV OF POSTS & TELECOMM

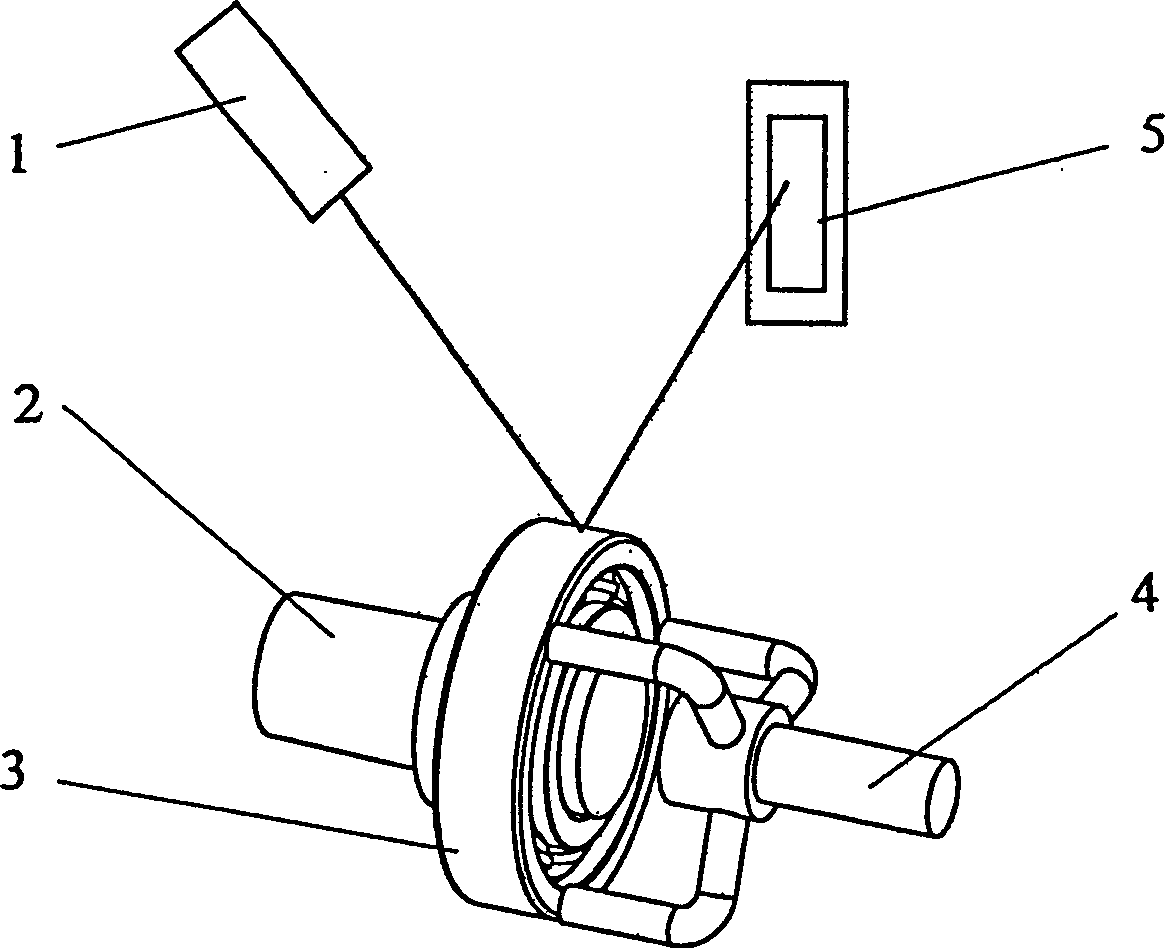

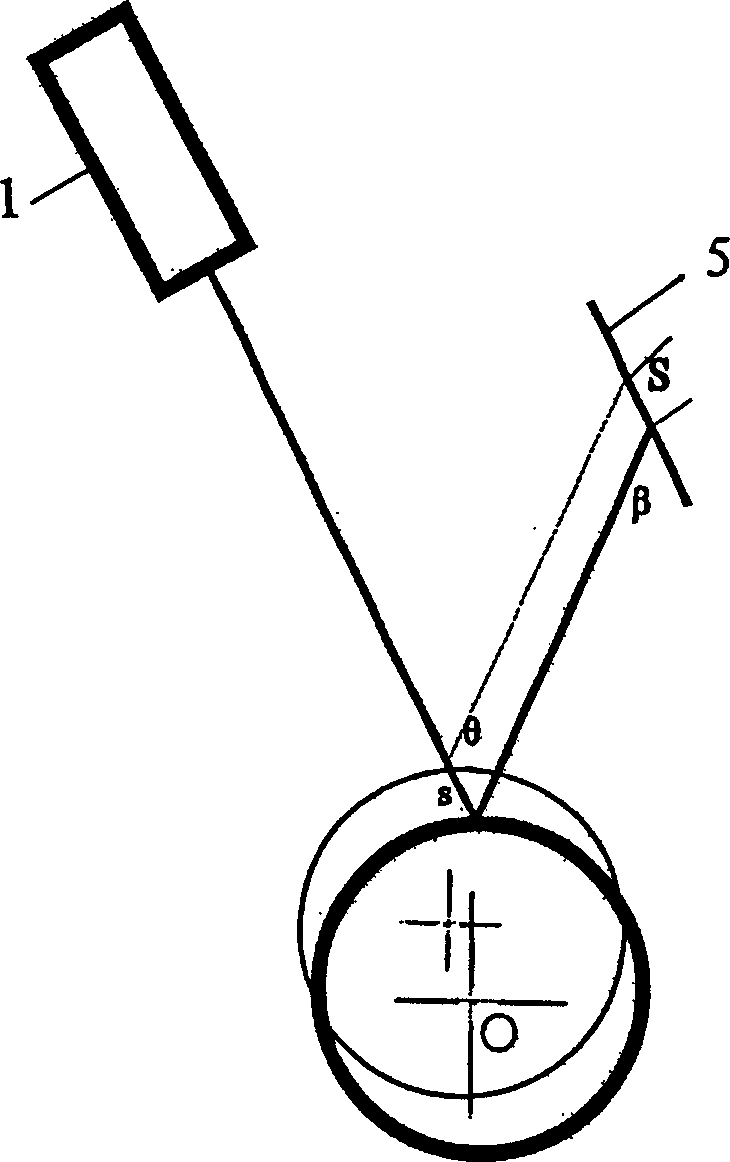

Laser method for measuring vibration displacement of rolling bearing

InactiveCN1687720AAvoid instabilityEasy to installSubsonic/sonic/ultrasonic wave measurementMachine bearings testingRolling-element bearingEngineering

The invention discloses the laser testing method of the roller bearing vibration displacement. Equip the bearing on the spin axis of the test bed; makes use of the reflection of the laser through the bearing surface to arrive the PSD sensor surface; the PSD position sensor gives the facula position. The internal loop and the main axis of the bearing can be viewed as the rigid body because the radial force carried by the external loop of the bearing. When the spin axis spins, the inner and the external loops and the roller bring about the vibration and reflect the displacement s of certain point of the bearing surface by the PSD sensor. The invention has simple structure, clear principle and high precision.

Owner:ZHEJIANG UNIV

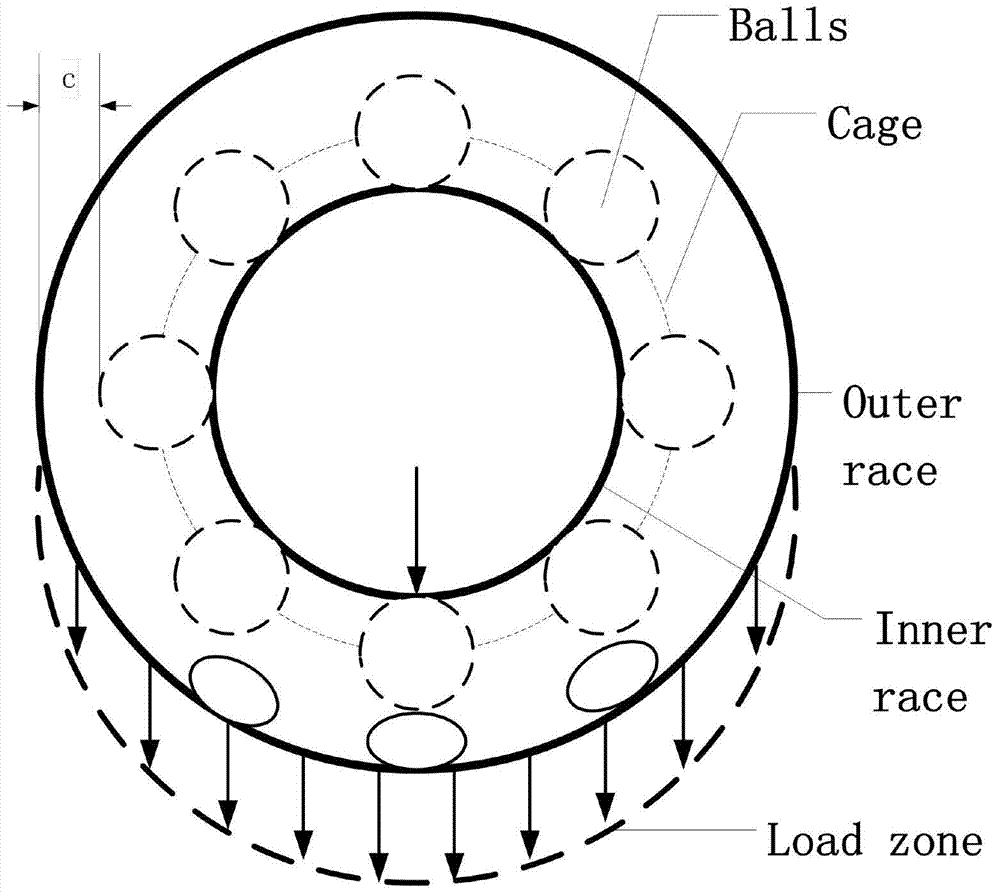

Vibration response simulation analyzing method for rolling bearing with single-point failures

ActiveCN103927414ASolve the problem of long cycle and high costSpecial data processing applicationsEngineeringMATLAB

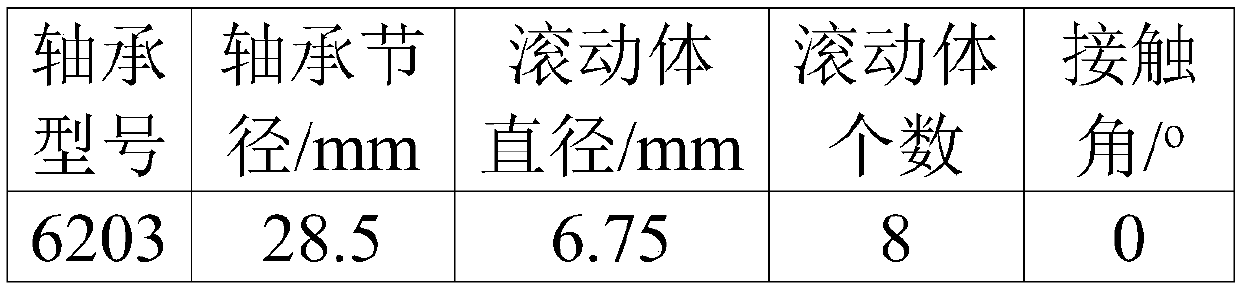

The invention relates to a vibration response simulation analyzing method for a rolling bearing with single-point failures. On the basis of a Hertz contact theory, related knowledge about kinematics and kinetics are utilized to establish a five-degree-of-freedom nonlinear vibration mode of a rolling bearing and kinetic differential equations of the rolling bearing while influencing factors like slipping of rolling balls, oil slick rigidity and the like are taken into consideration, according to that the rolling balls change due to contact deformation is caused when the rolling balls roll through partial failures, a partial failure model of the rolling bearing is introduced into the kinetic differential equations of the rolling bearing, and the single-point failures of the rolling bearing are classified according to length-width ratios of the failures and size ratios between the failures and the rolling balls so as to establish different failure shape functions; the differential equations are solved by an ode solver in MATLAB (matrix laboratory) software, and vibration responses of the rolling bearing are simulated when an inner ring, an outer ring and the rolling balls of the rolling bearing are suffered from the single-point failures. By the aid of the vibration response simulation analyzing method, vibration responses of the bearings with failures in different sizes can be simulated. Compared with traditional methods for acquiring vibration responses of failed bearings, the vibration response simulation analyzing method has the advantages that an experimental period is short and experimental cost is saved. The computation for the vibration responses for the failed rolling bearings can lay the foundation of late failure diagnosis for the rolling bearings.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com