Electric automobile resonance power generation optimization method and structure based on lever principle

A technology based on the principle of electric vehicles and levers. It is applied in the direction of mechanisms, machines/engines, and mechanical equipment that generate mechanical power. It can solve the problem of wasting vibration energy, and achieve the effects of improving energy consumption, simplifying settings, and improving conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

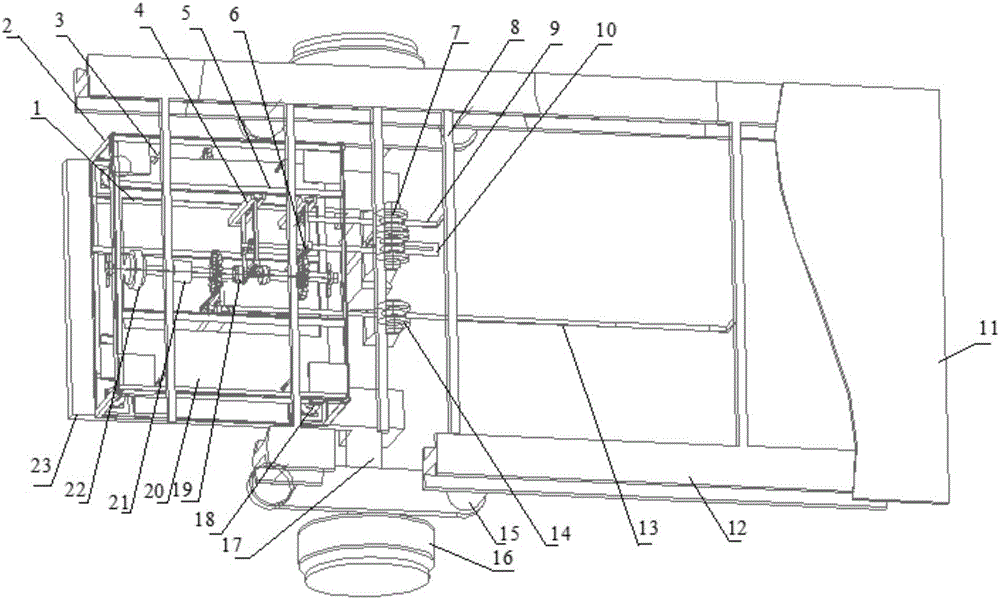

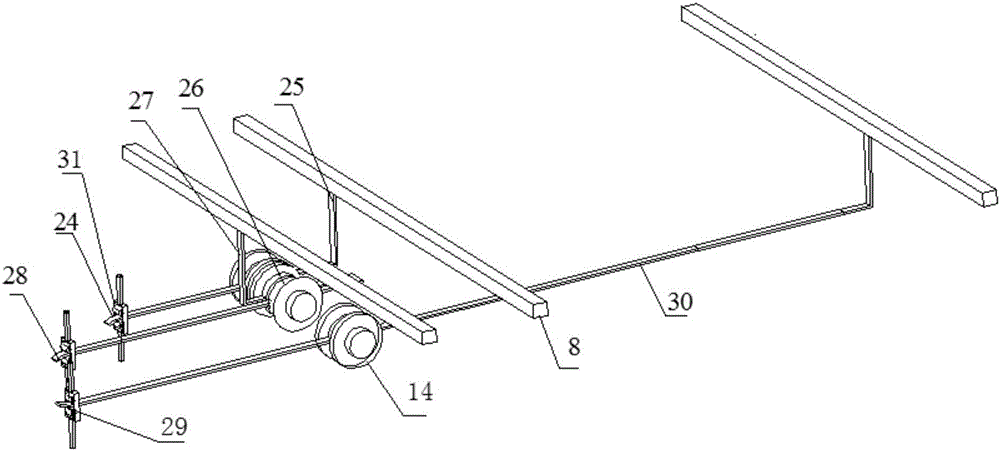

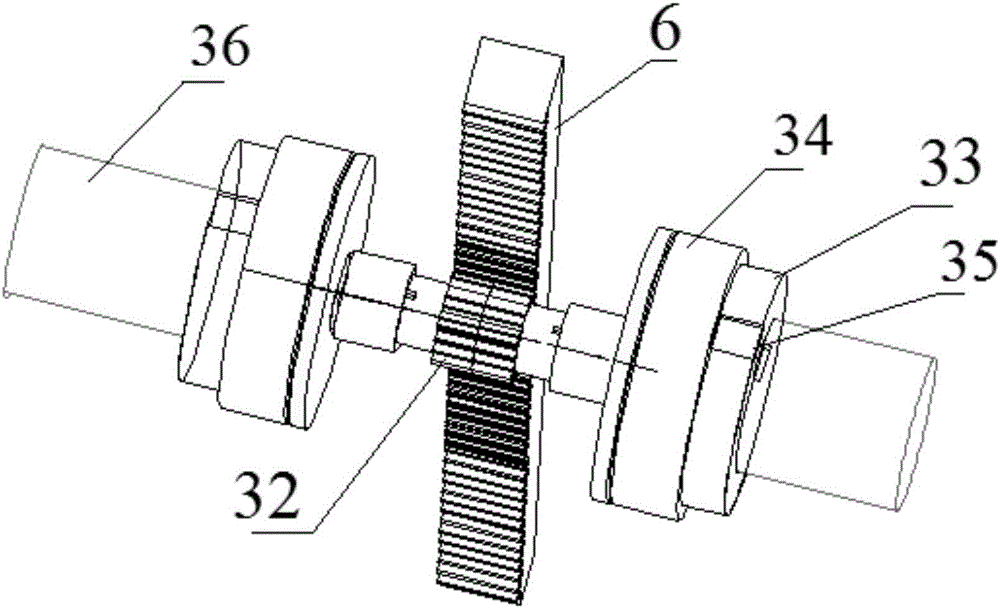

[0029] In the invention proposed by the applicant to apply frequency resonance to the method of automobile kinetic energy power generation, the sprung body with the vertical elastic system is used to vibrate freely at its natural frequency to excite the sprung body as the support. The same or similar natural frequency, also equipped with a vertical elastic system, the hollow weight pallet installed with the kinetic energy generating device generates frequency resonance or effective vibration, through the frequency resonance, the sprung body transfers the kinetic energy of vibration to the hollow weight The supporting plate realizes its own vibration reduction, and at the same time, the hollow heavy object supporting plate that is excited to resonate uses the absorbed kinetic energy of the sprung vehicle body and the kinetic energy of its own vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com