Wheel and belt polishing device and machine tool for inner and outer surfaces and free-form surfaces of high-steepness parts

A technology for inner and outer surfaces and polishing devices, applied in belt grinders, grinding/polishing equipment, grinders, etc. Effective polishing, difficult to correct intermediate frequency errors, etc., to achieve effective polishing, good polishing effect, and good surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

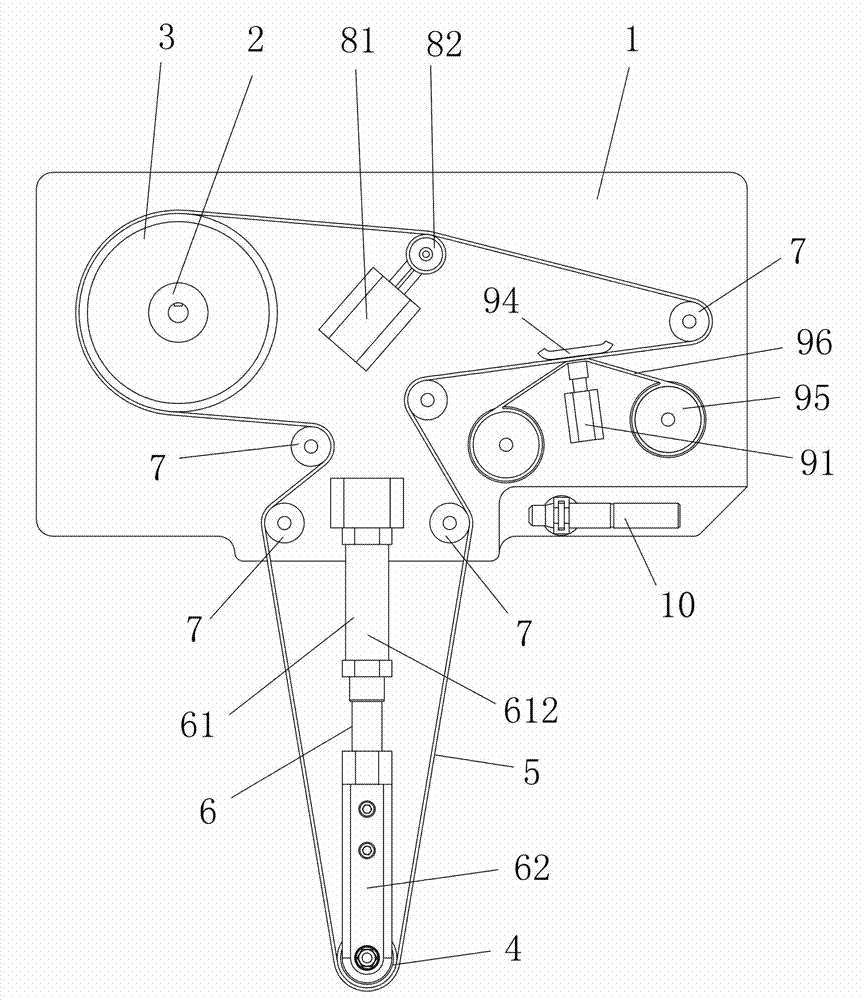

[0043] Such as figure 1As shown, an embodiment of a tire polishing device for inner and outer surfaces of high-steep parts and free-form surfaces of the present invention, the tire polishing device includes a mounting platen 1, a driving mechanism 2, a driving wheel 3, a contact wheel 4, and a polishing belt 5 and the long-armed support arm 6. The driving mechanism 2 is installed on the installation platform 1 . The driving wheel 3 is connected to the output end of the driving mechanism 2, and the polishing belt 5 is wound on the driving wheel 3 and the contact wheel 4. During processing, the polishing belt 5 wound on the contact wheel 4 acts on the workpiece with a certain pressure The surface is polished. The outer edge of driving wheel 3 and contact wheel 4 is all covered with the rubber material of certain thickness, plays the effect of cushioning and preventing polishing belt 5 from slipping. One end of the support arm 6 is fixed on the installation table 1, and the ot...

Embodiment 2

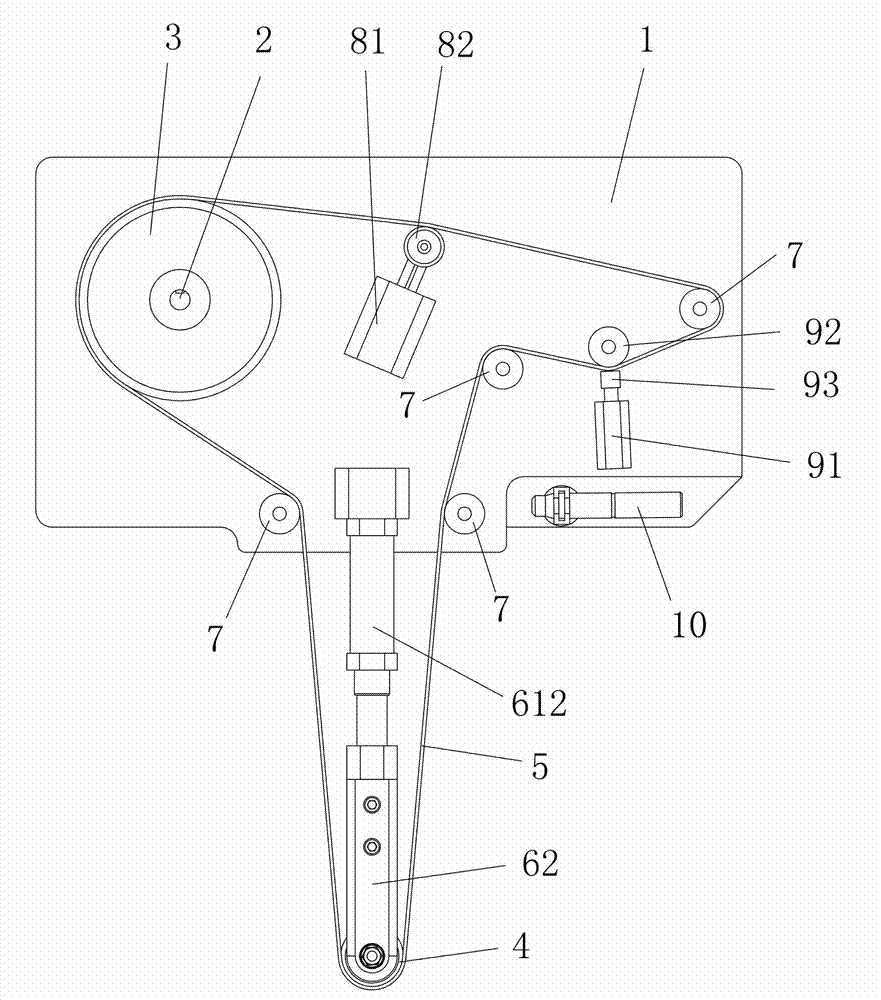

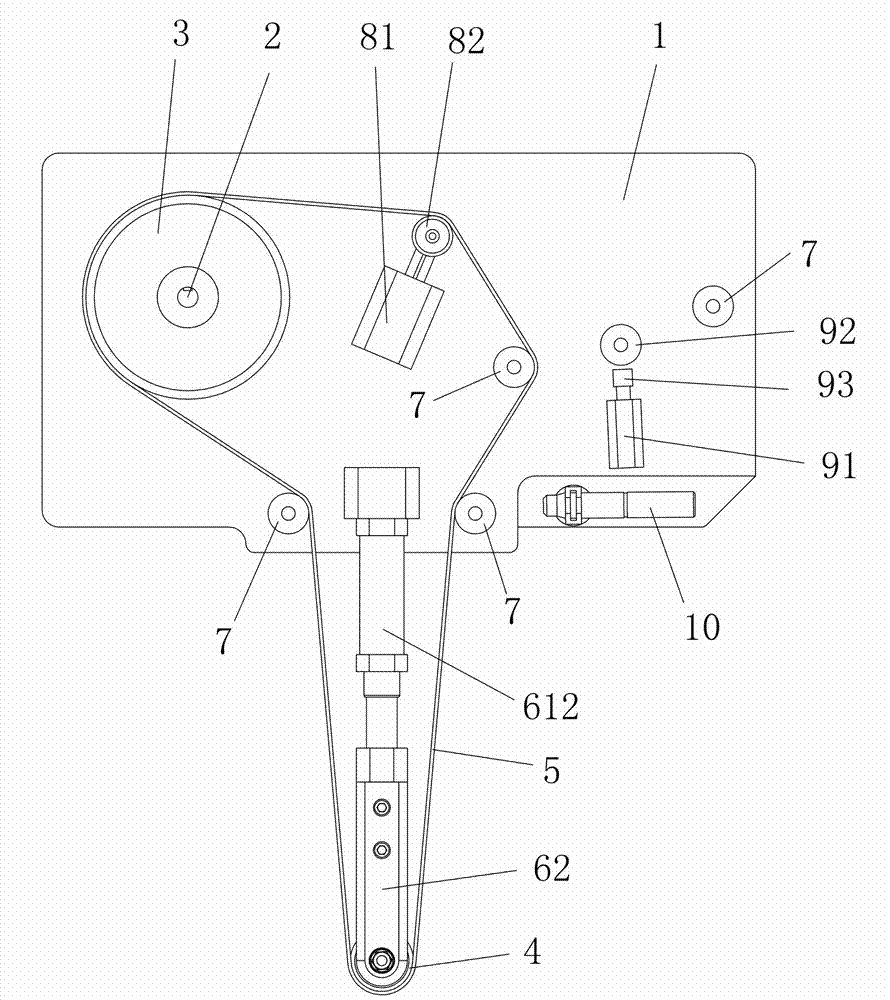

[0053] Such as figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the trimming mechanism includes a second driving cylinder 91 and a trimming wheel 92 installed on the mounting platen 1, and the driving end of the second driving cylinder 91 The end is provided with a trimming block 93 with consolidated abrasives. During trimming, the polishing belt 5 is wound around the dressing wheel 92, and the second driving cylinder 91 pushes the trimming block 93 to be compressed on the polishing belt 5 to realize sharpening; the guide wheel 7 is 4, and the installation position of guide wheel 7 and the winding way of polishing belt 5 have done corresponding change. When the polishing belt 5 does not need to be sharpened, the winding method of the polishing belt 5 is as follows: image 3 shown.

Embodiment 3

[0055] Such as Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the trimming mechanism and the in-position measuring part 10 are removed; the guide wheel 7 is one, and the driving wheel 3, the guide wheel 7 and the tension mechanism The installation position and the winding way of the polishing belt 5 have been changed accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com