Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1024results about How to "Polished evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

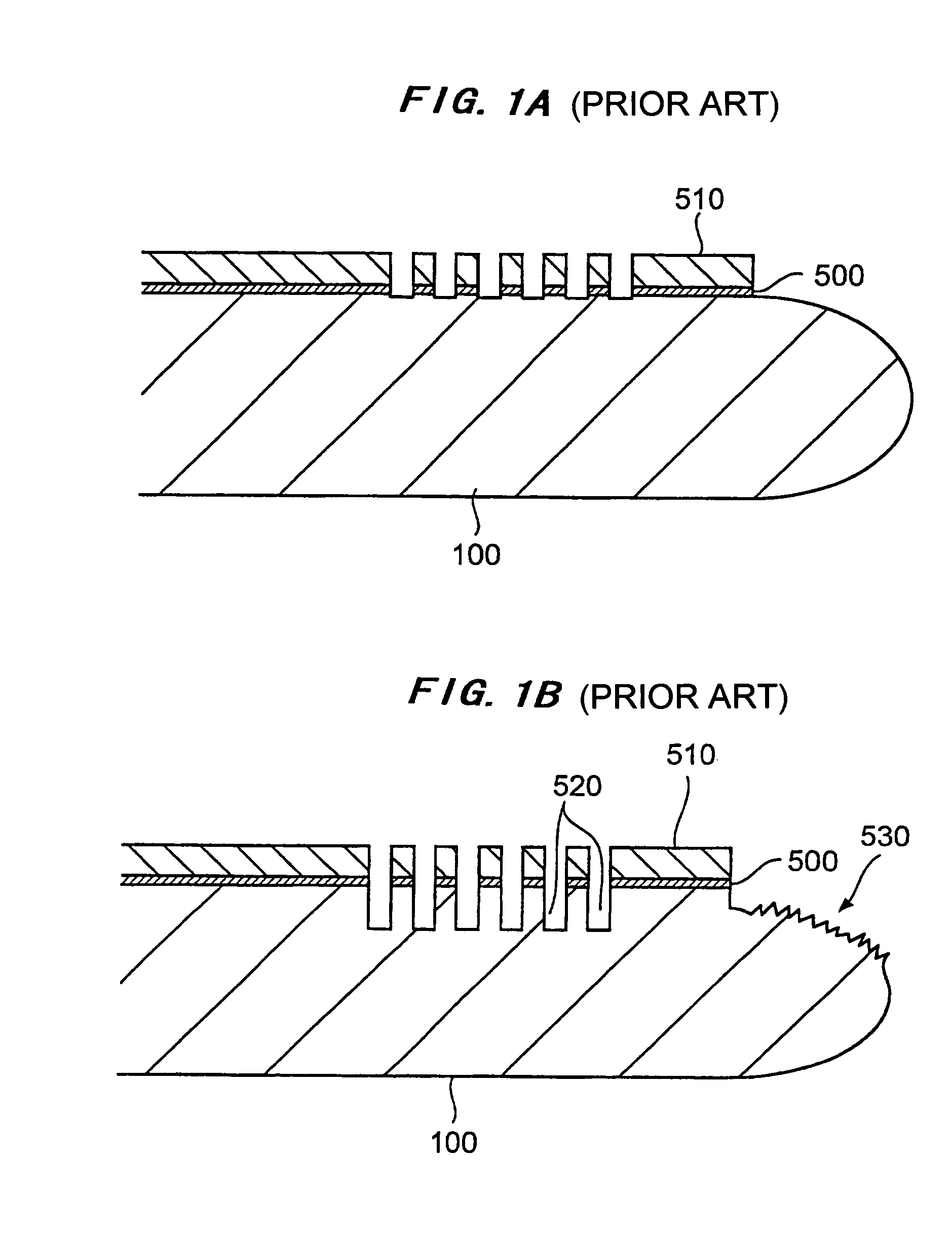

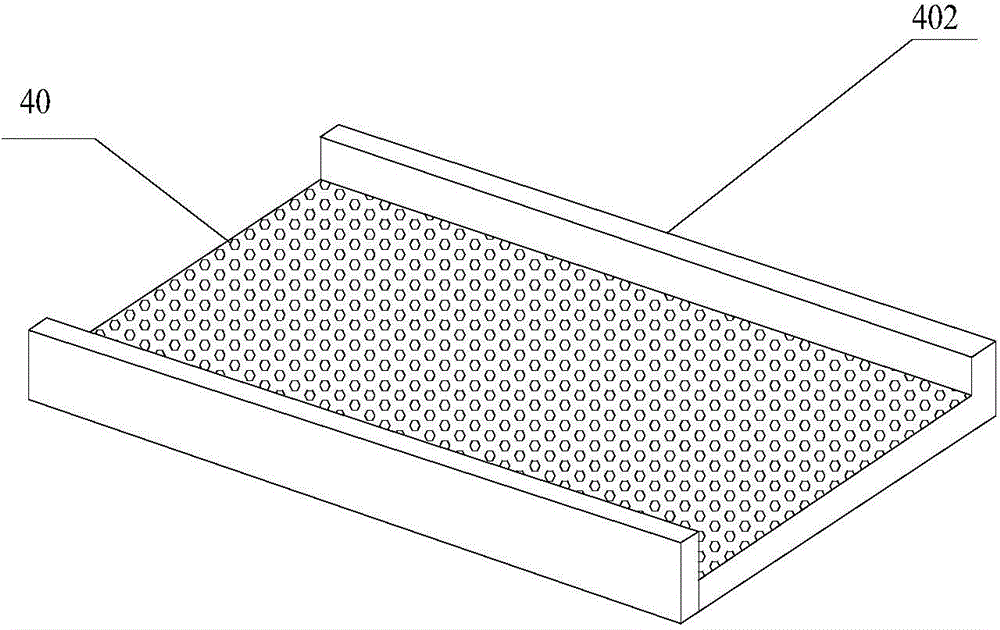

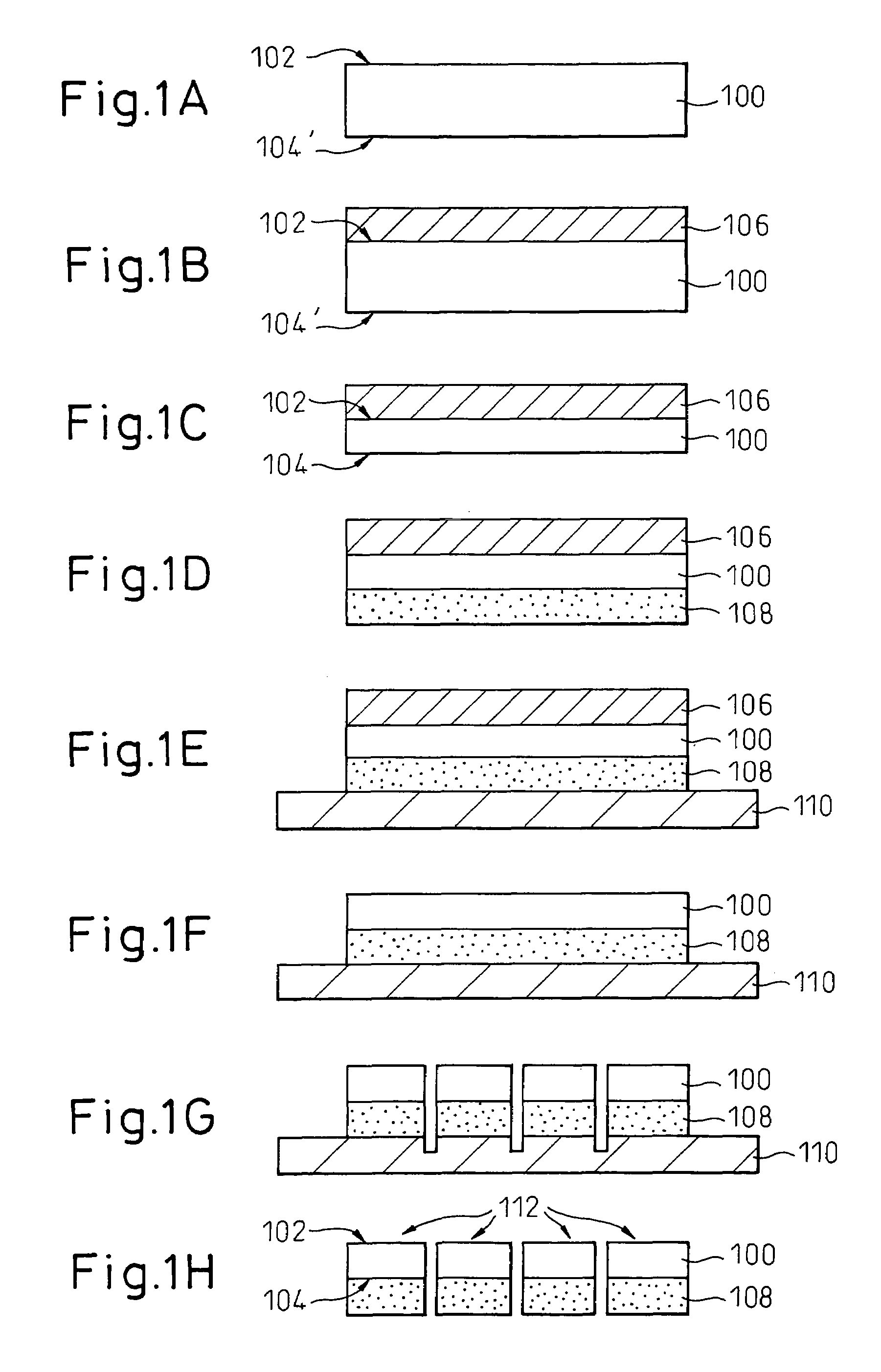

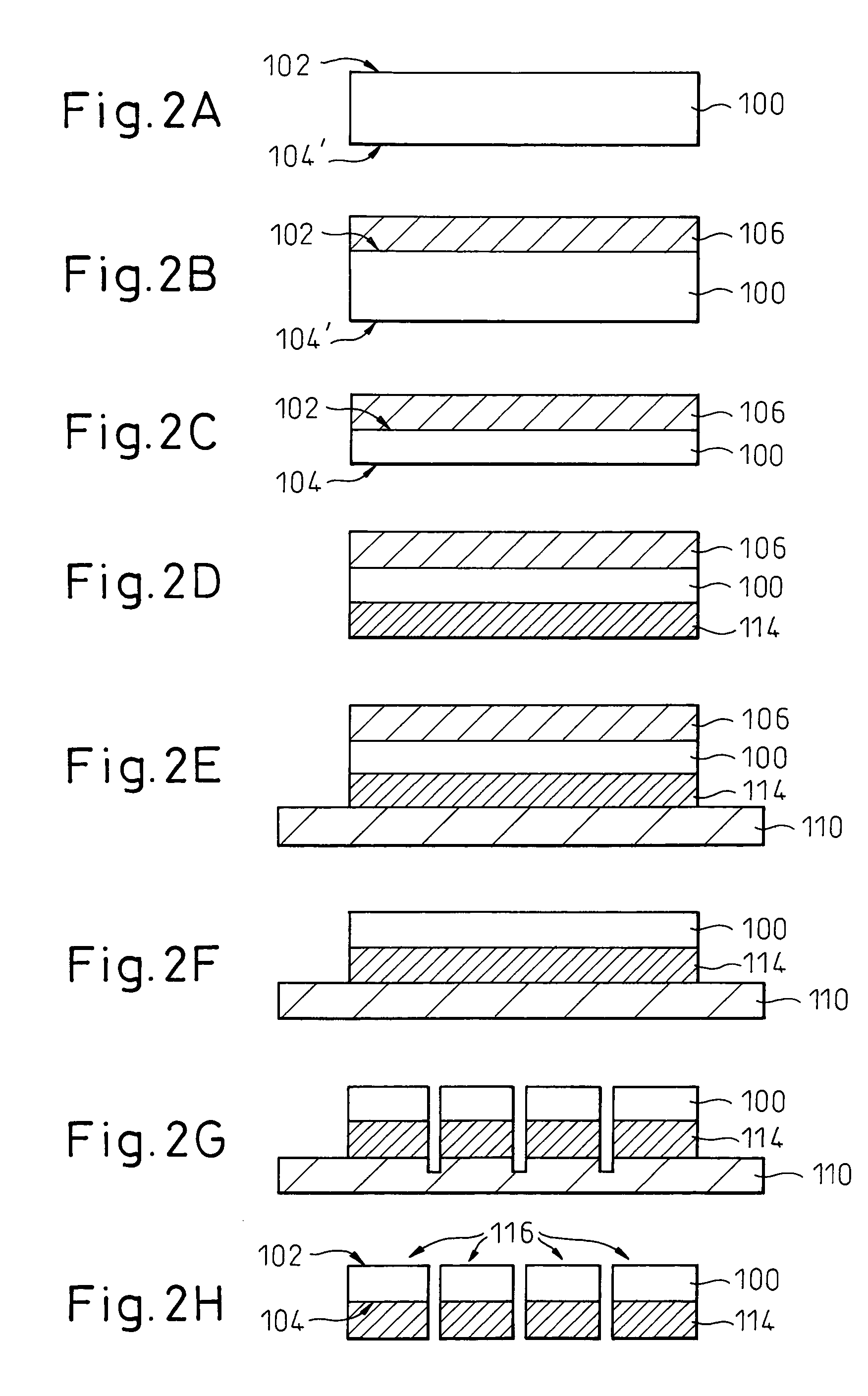

Abrasive bead coated sheet and island articles

InactiveUS20050118939A1Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedSlurry

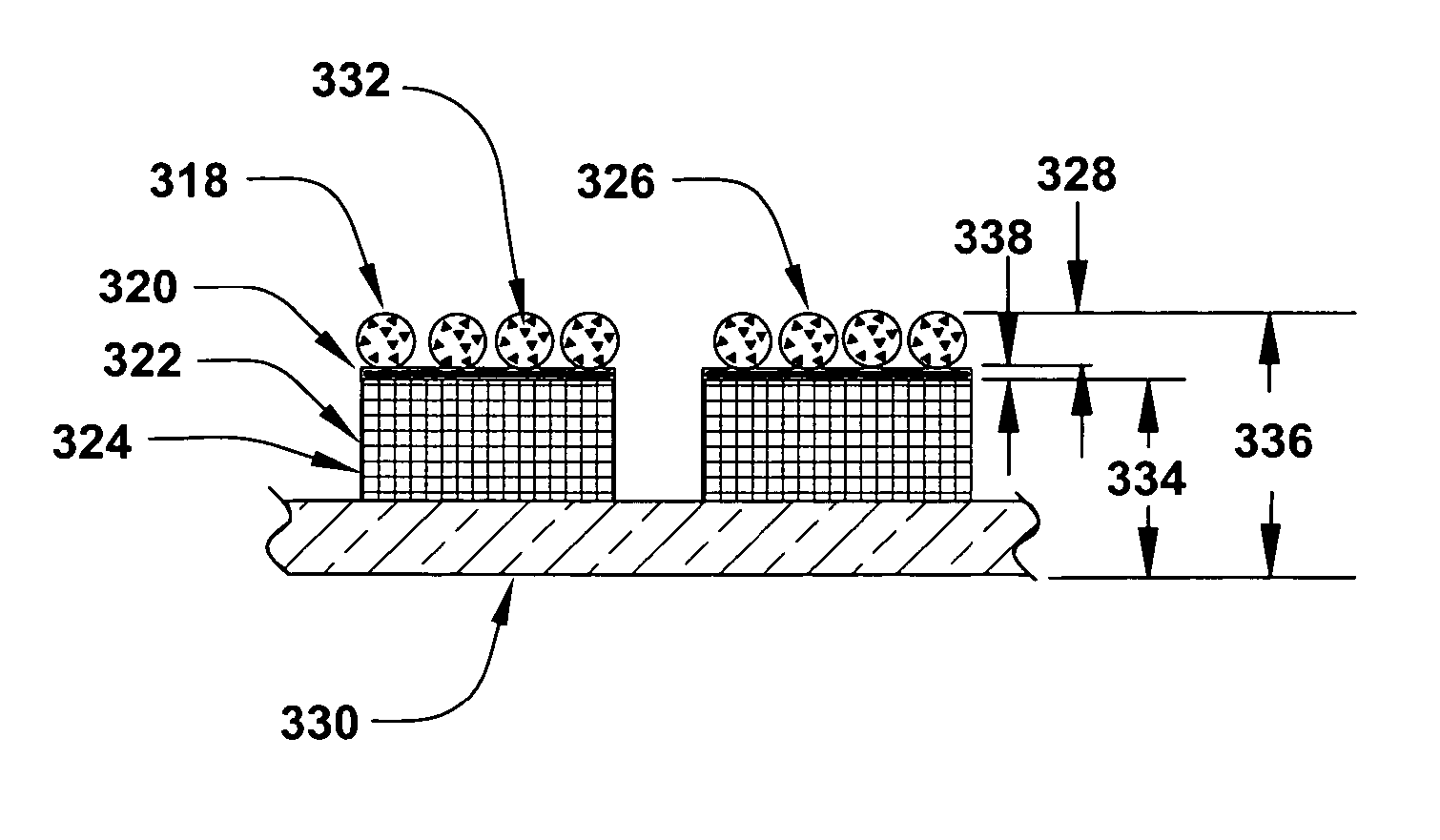

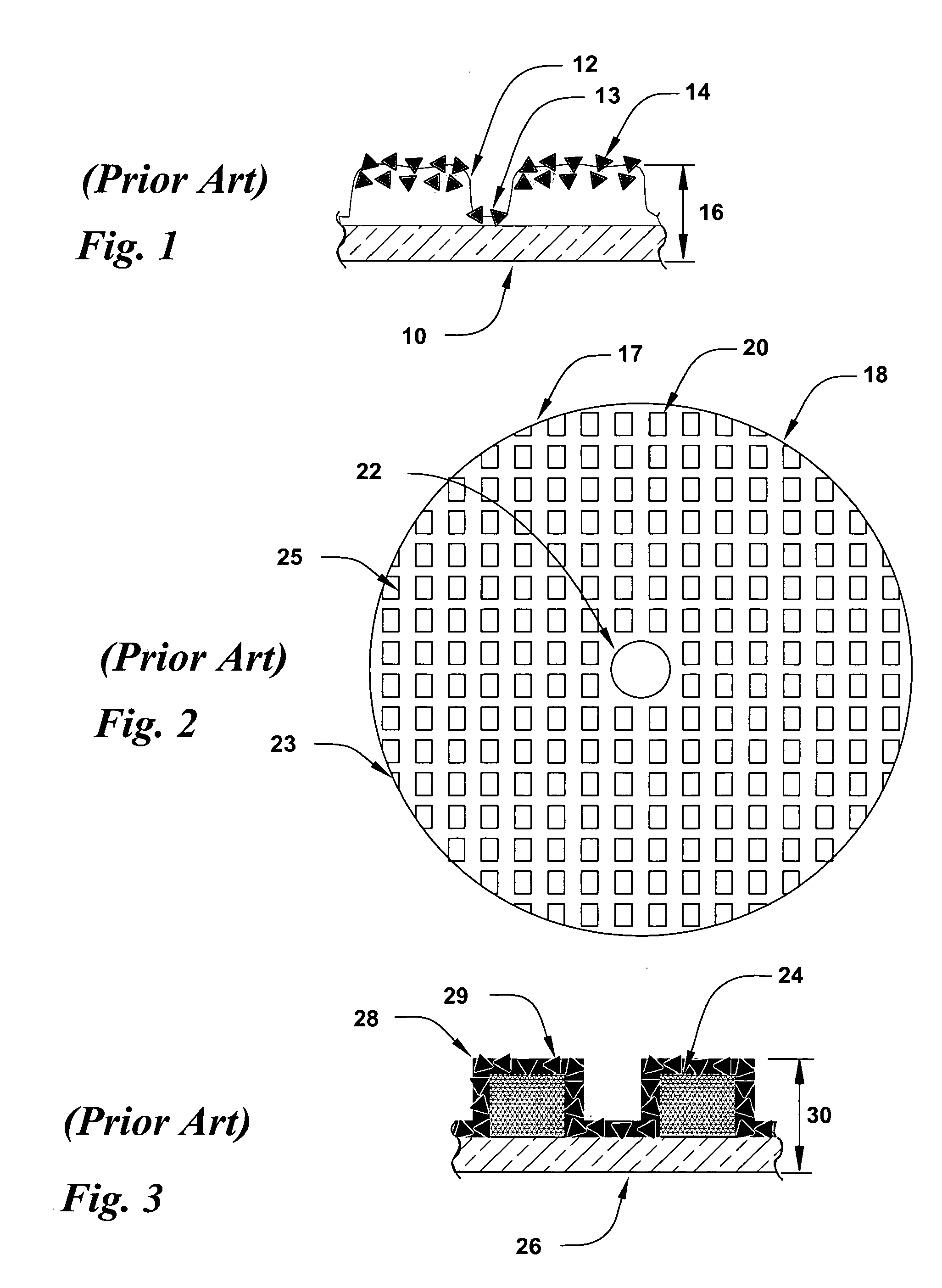

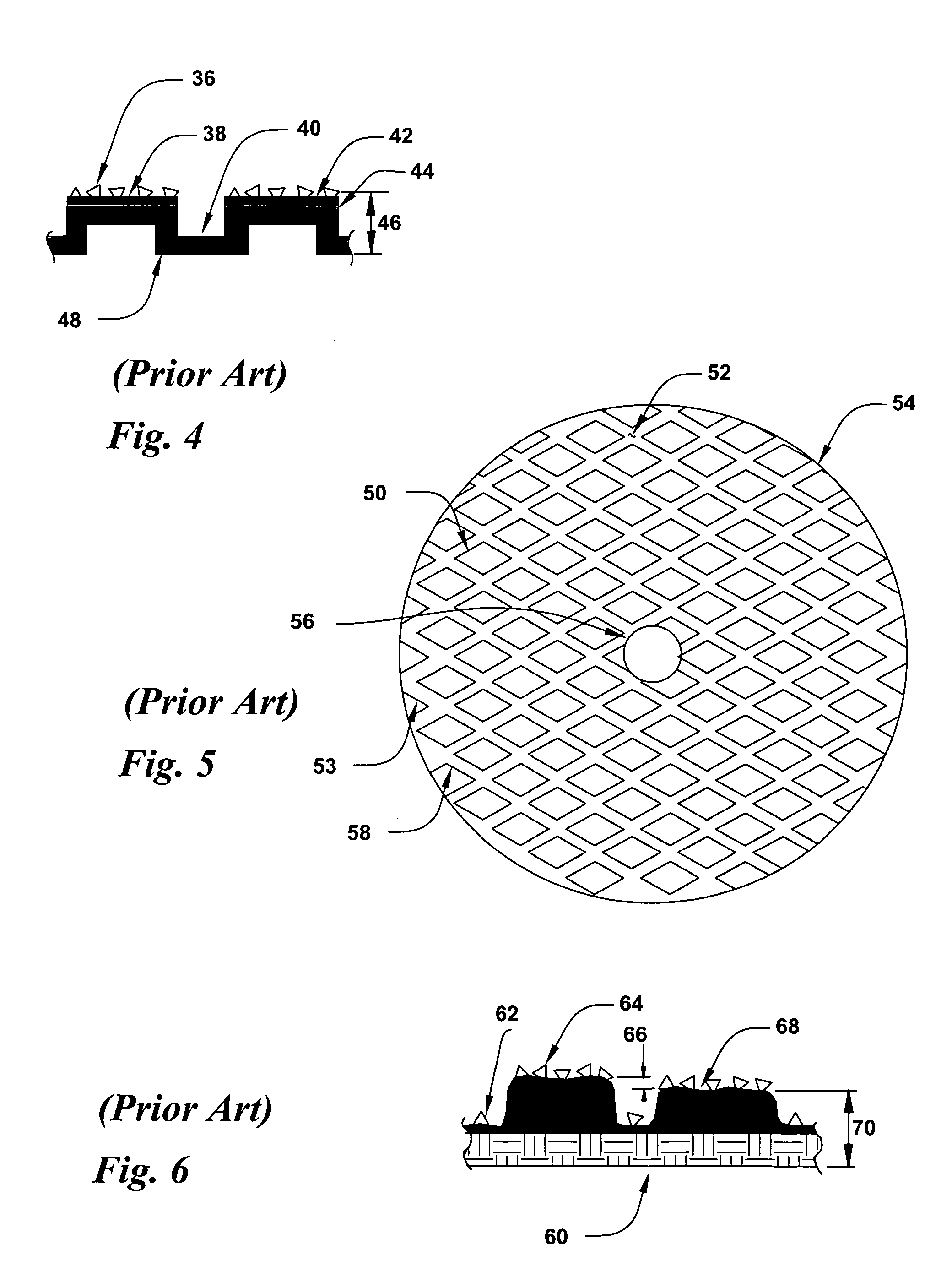

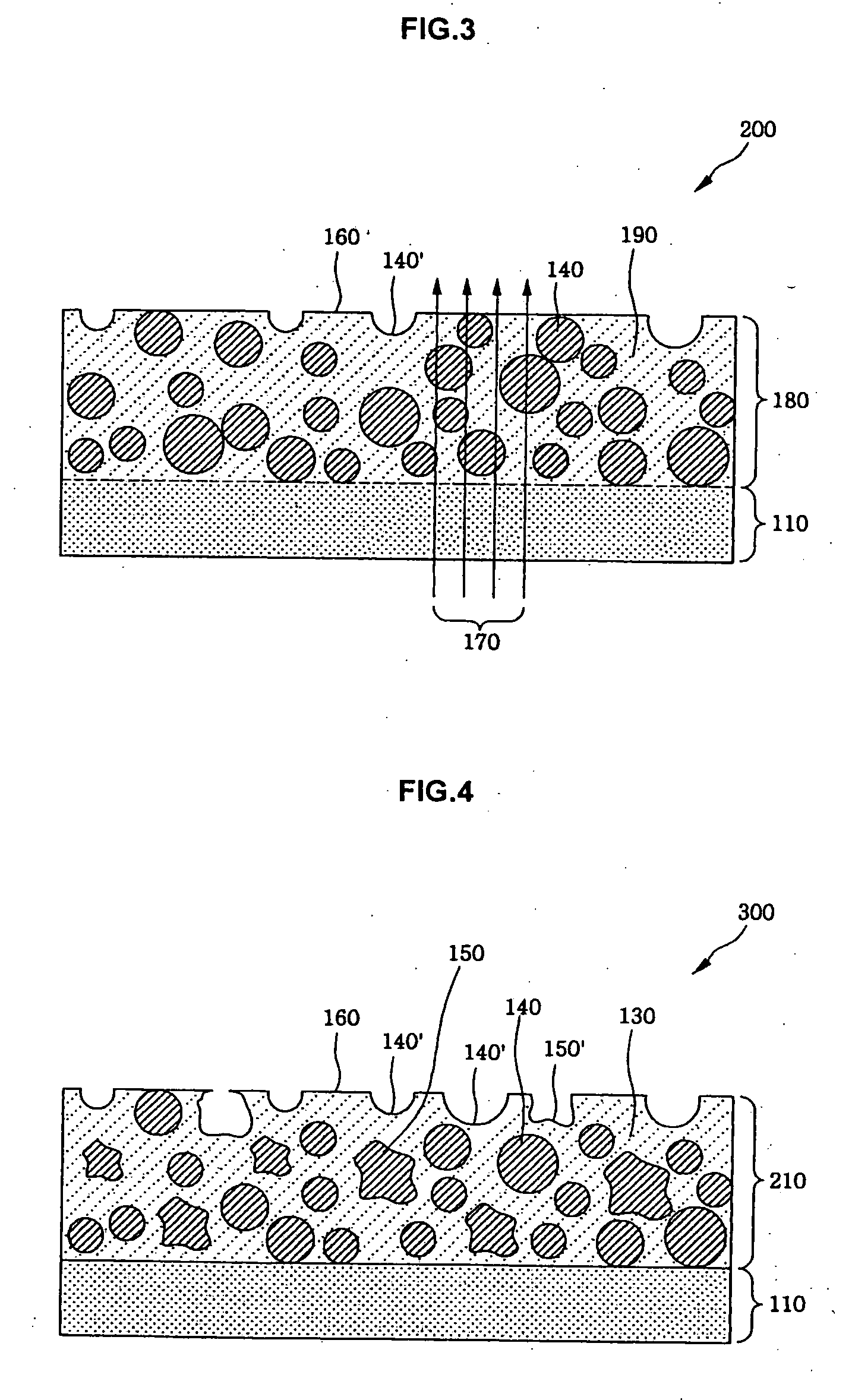

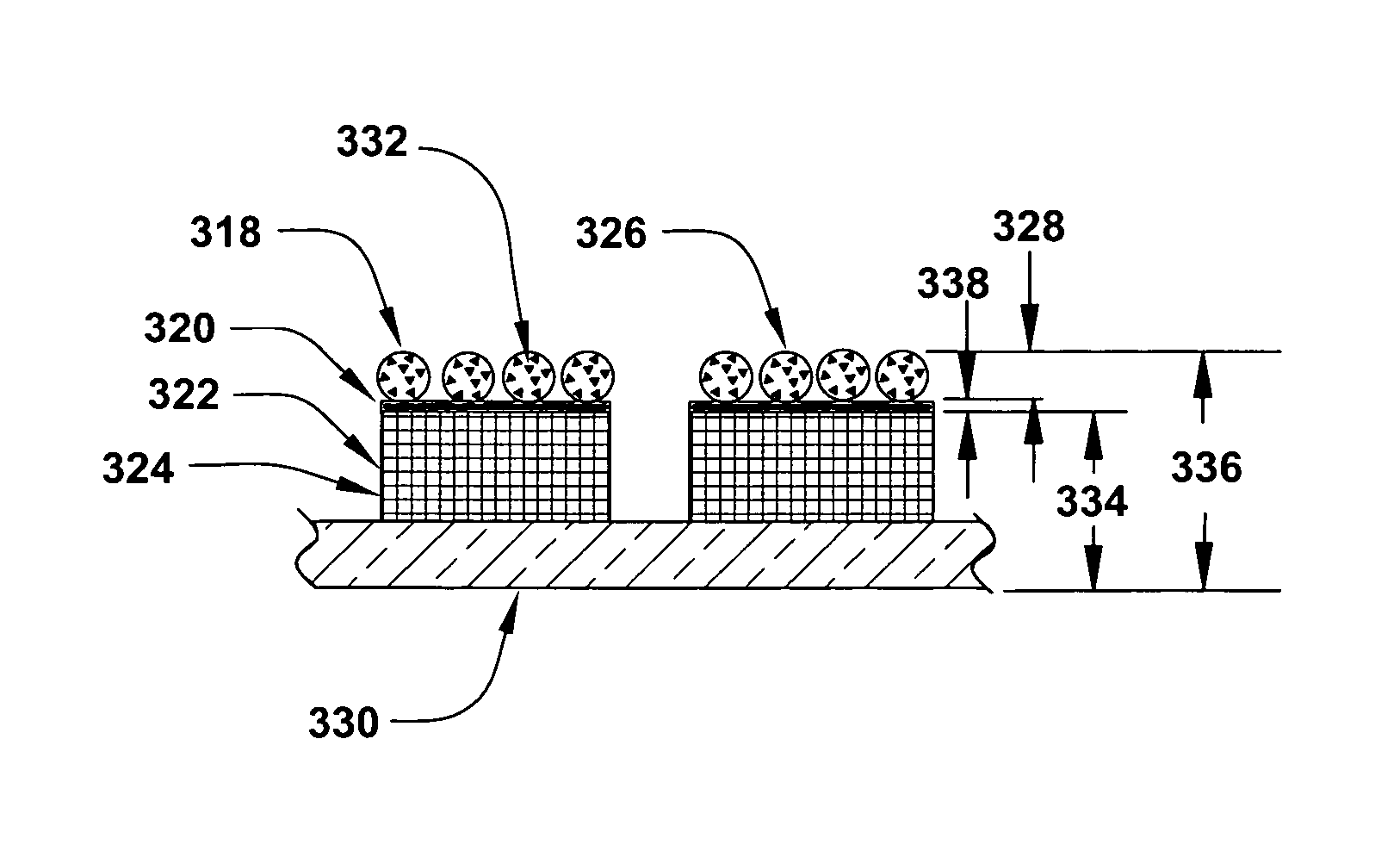

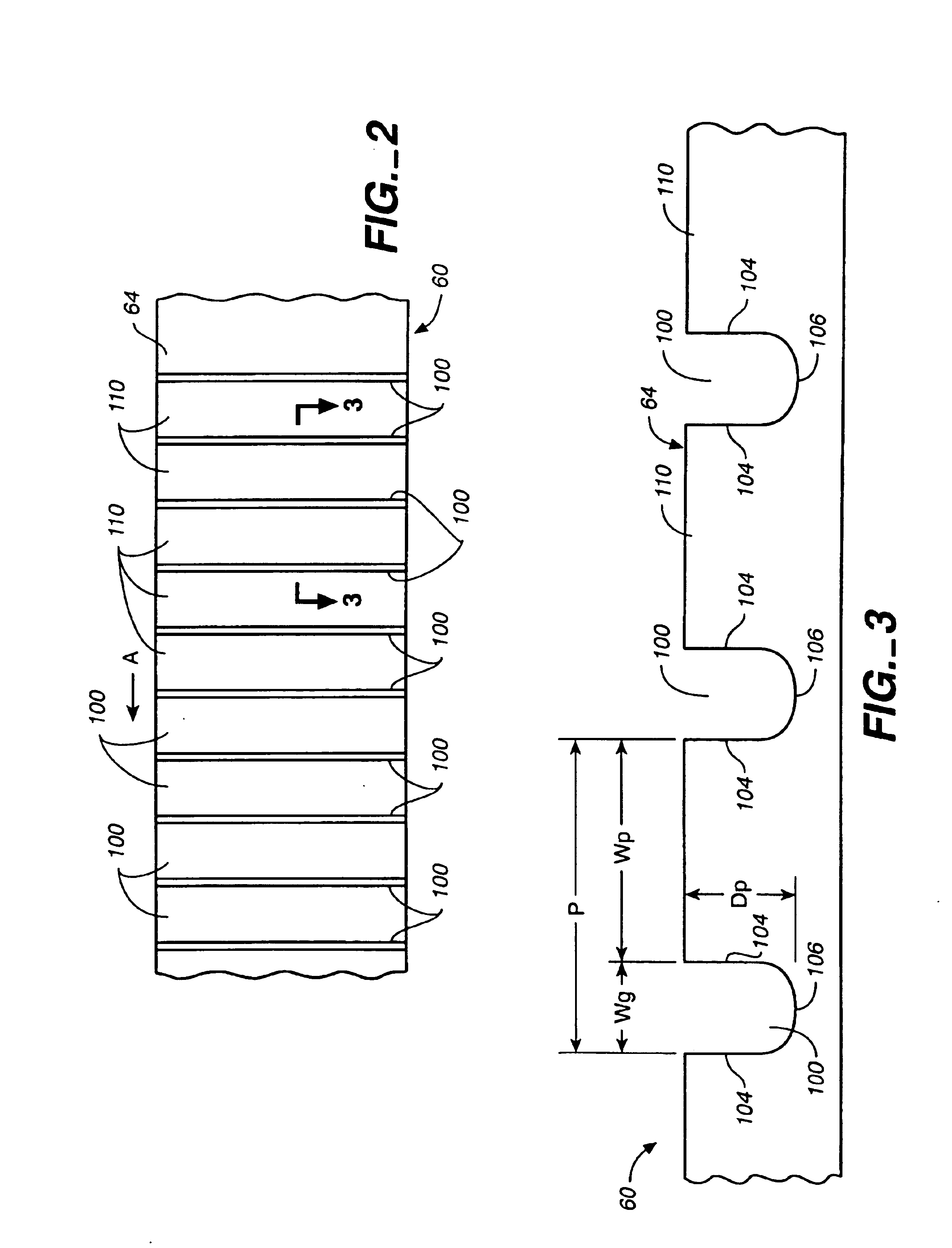

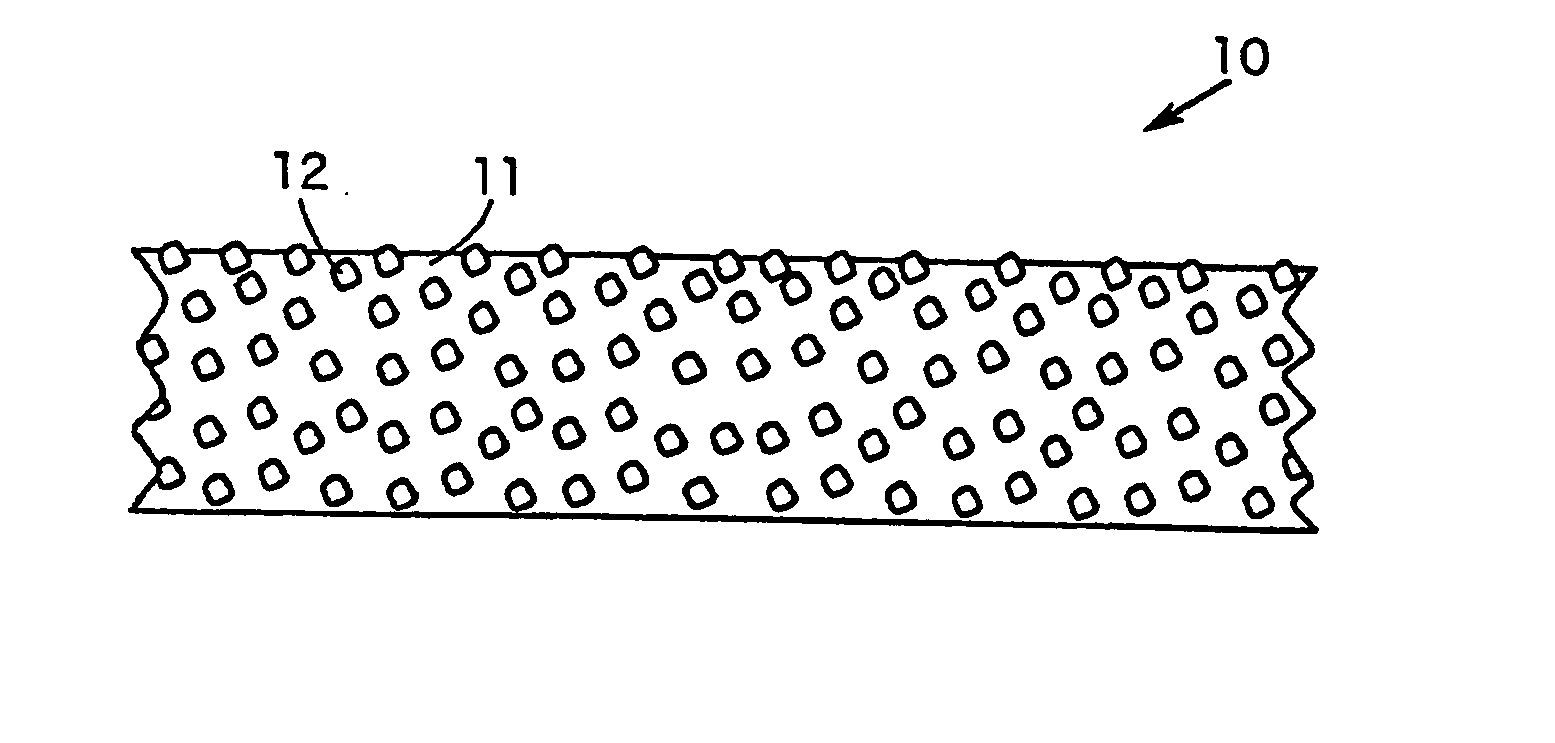

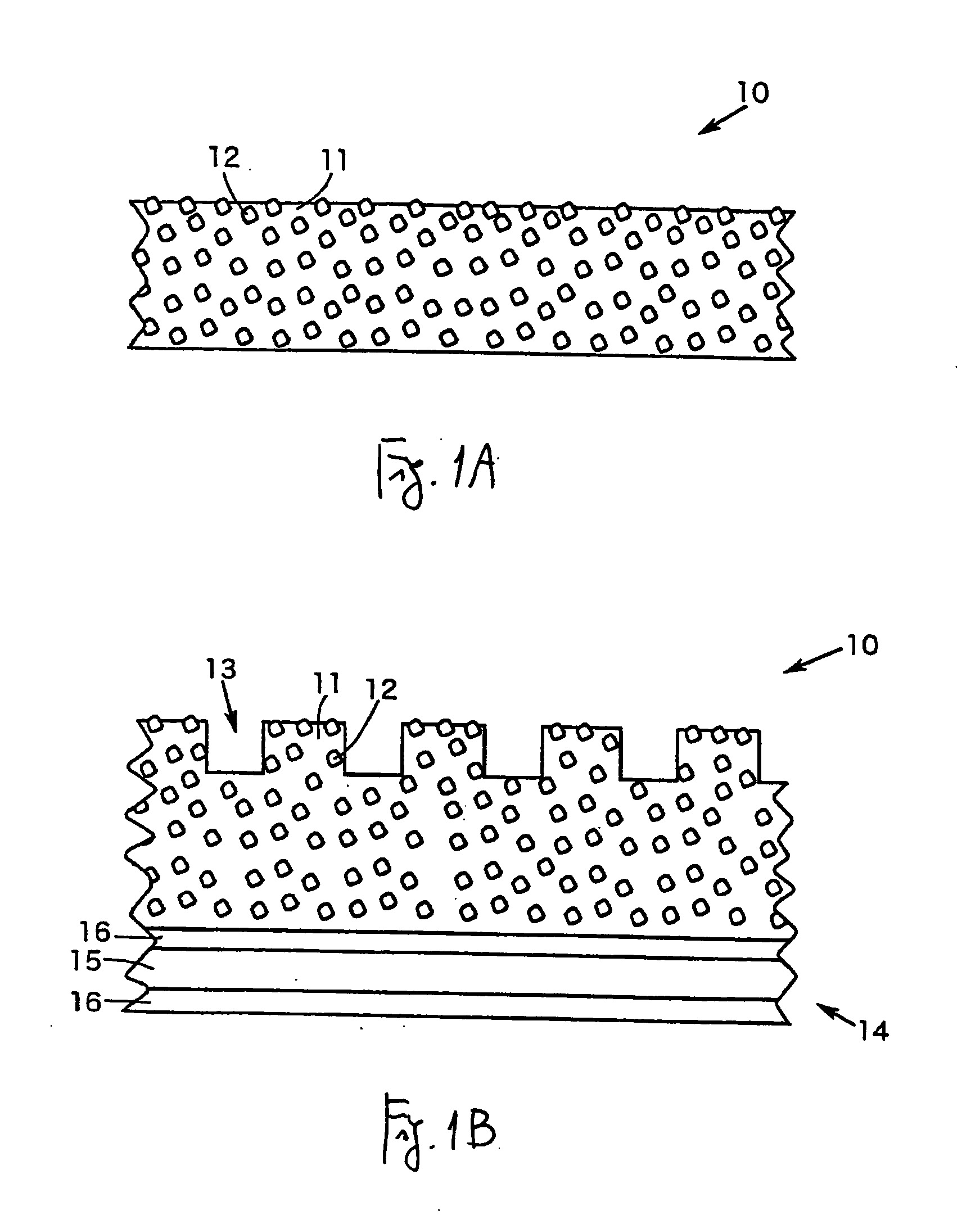

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

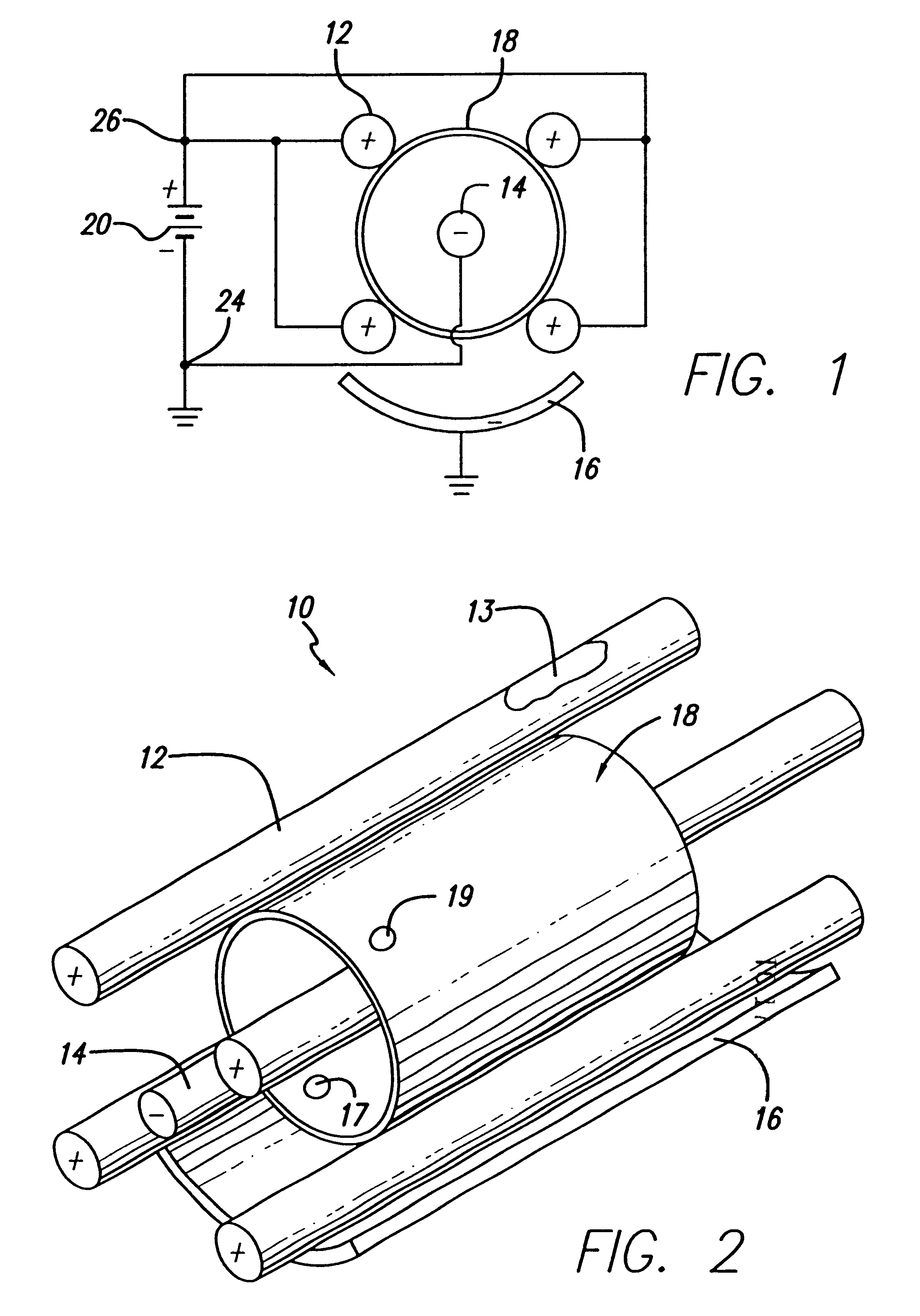

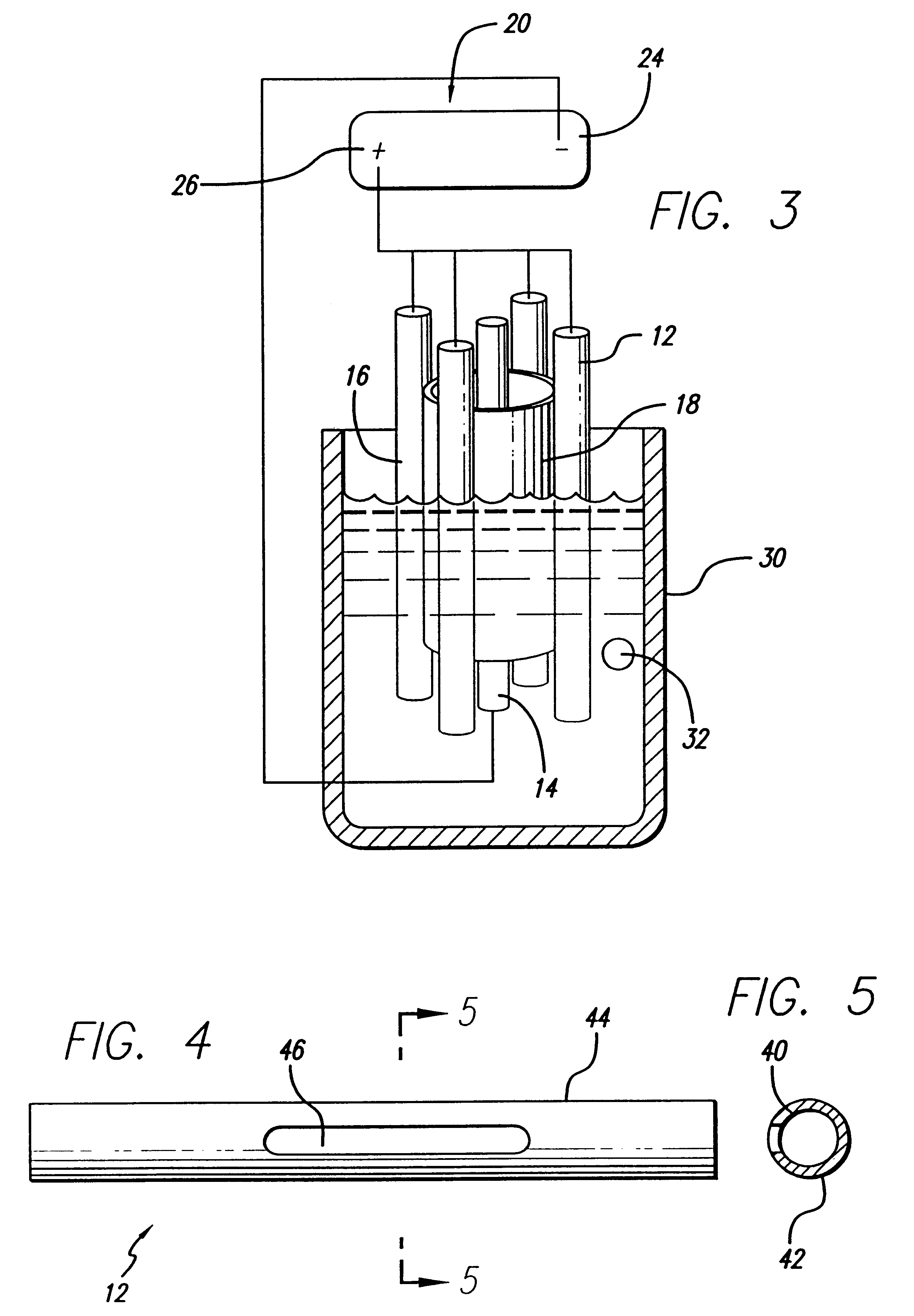

Electro-polishing fixture and electrolyte solution for polishing stents and method

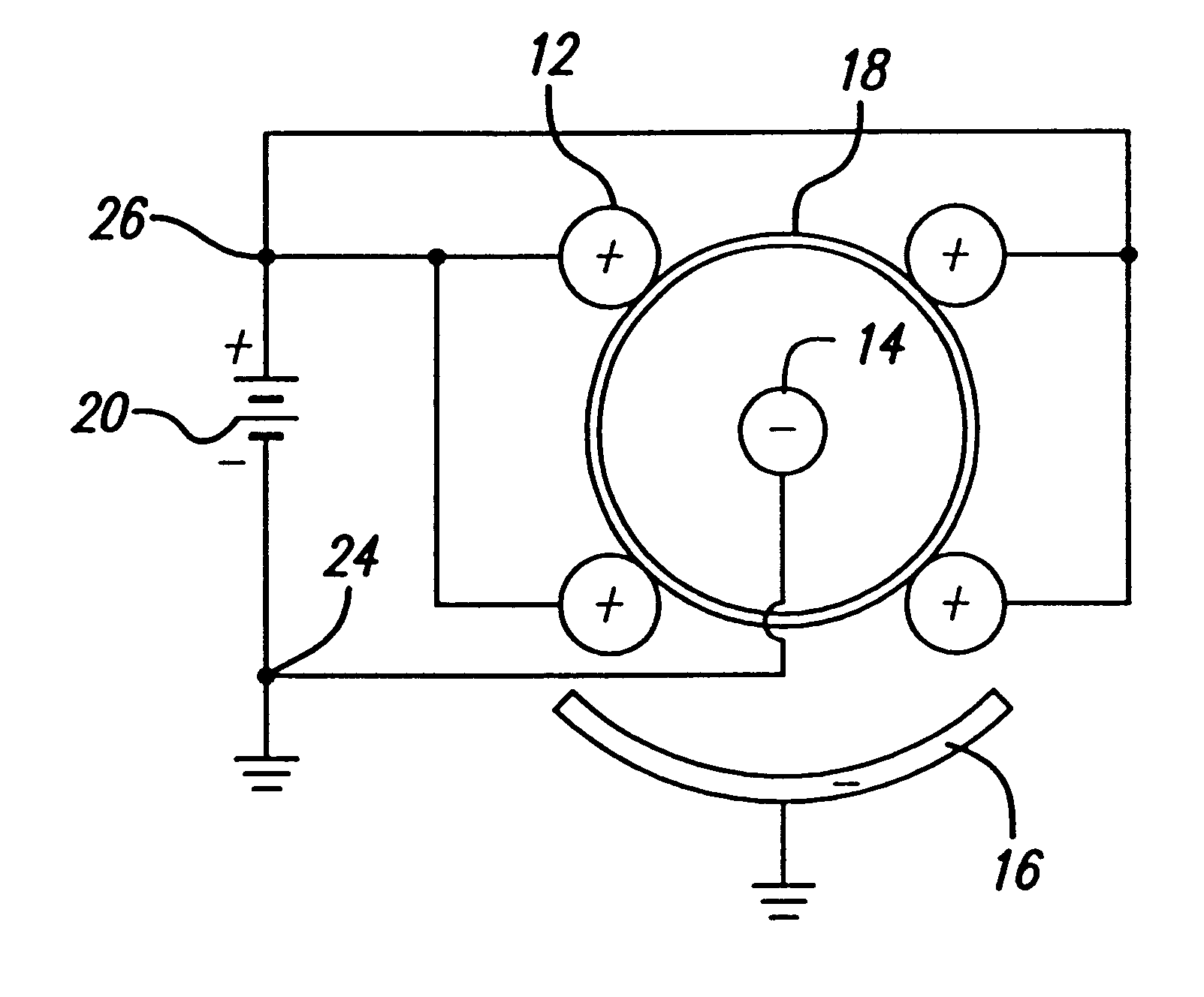

An electro-polishing fixture for polishing stents which incorporates multiple anodes in contact with the stent and a center cathode disposed coaxially within the interior of the stent and a curved exterior cathode disposed about the perimeter of the stent. The invention further includes an electrolyte solution adapted for polishing stents composed of nickel-titanium alloy and a method of using the electrolyte in combination with the electro-polishing fixture.

Owner:ABBOTT CARDIOVASCULAR

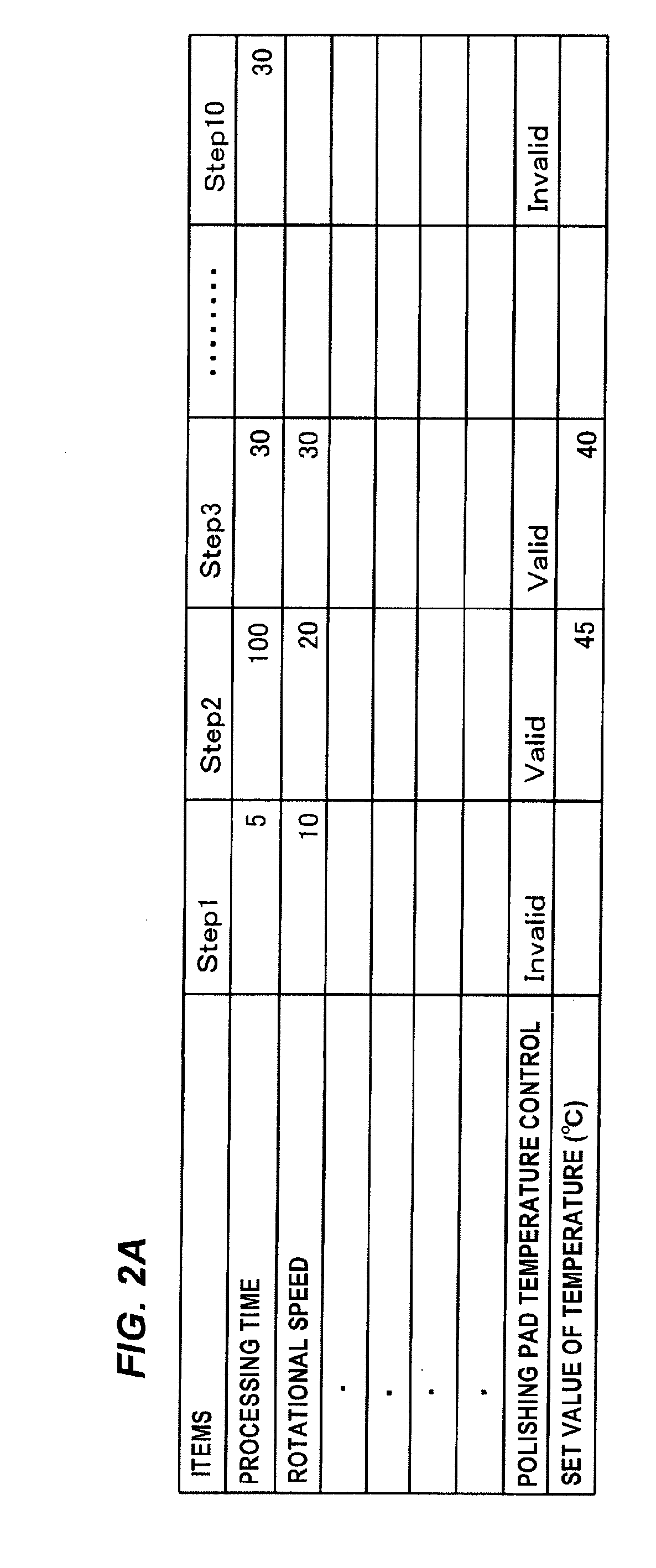

Substrate polishing apparatus, substrate polishing method, and apparatus for regulating temperature of polishing surface of polishing pad used in polishing apparatus

ActiveUS20110159782A1Polishing rate can be optimizedShorten polishing timeSemiconductor/solid-state device manufacturingLapping machinesTemperature controlEngineering

Owner:EBARA CORP

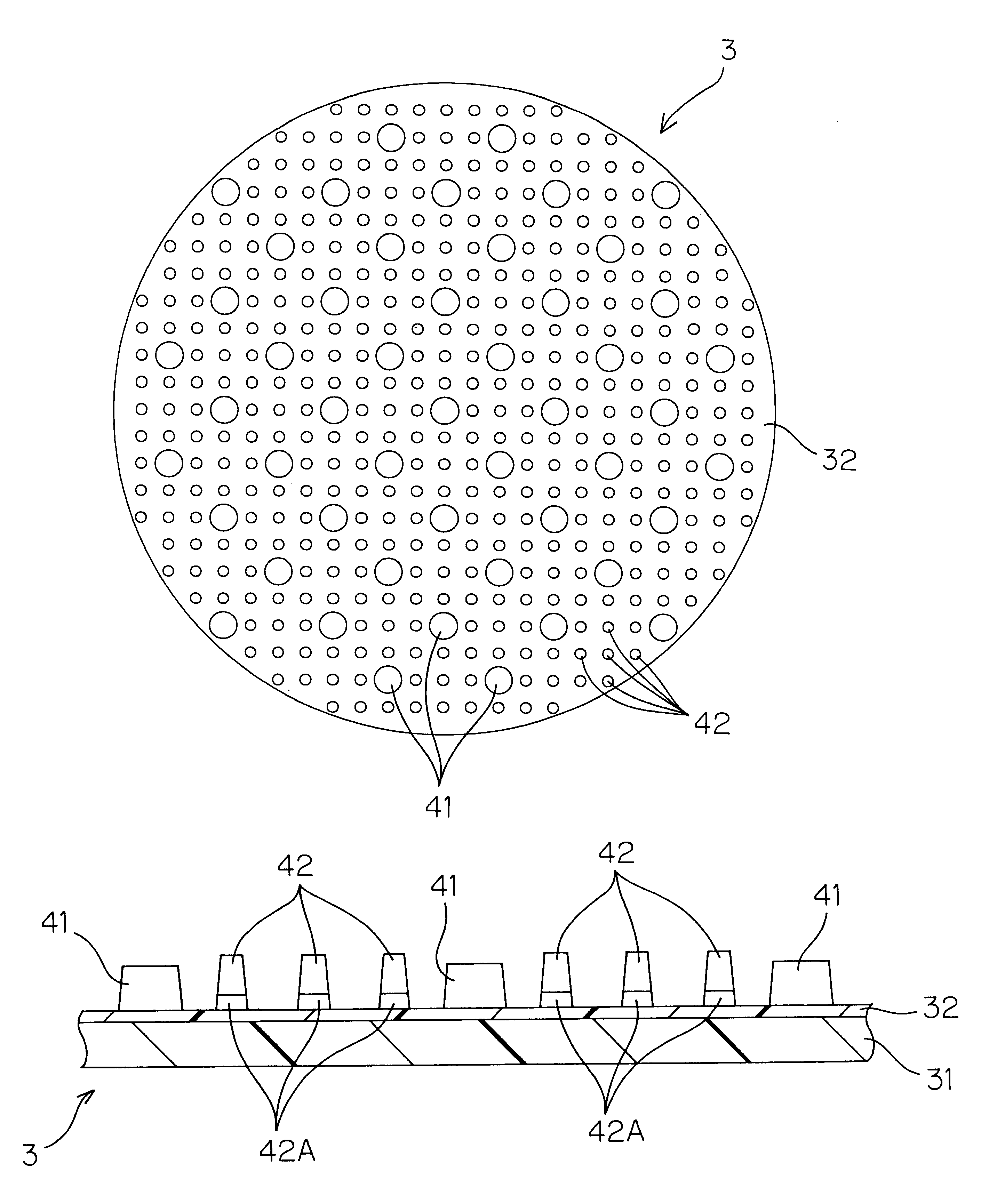

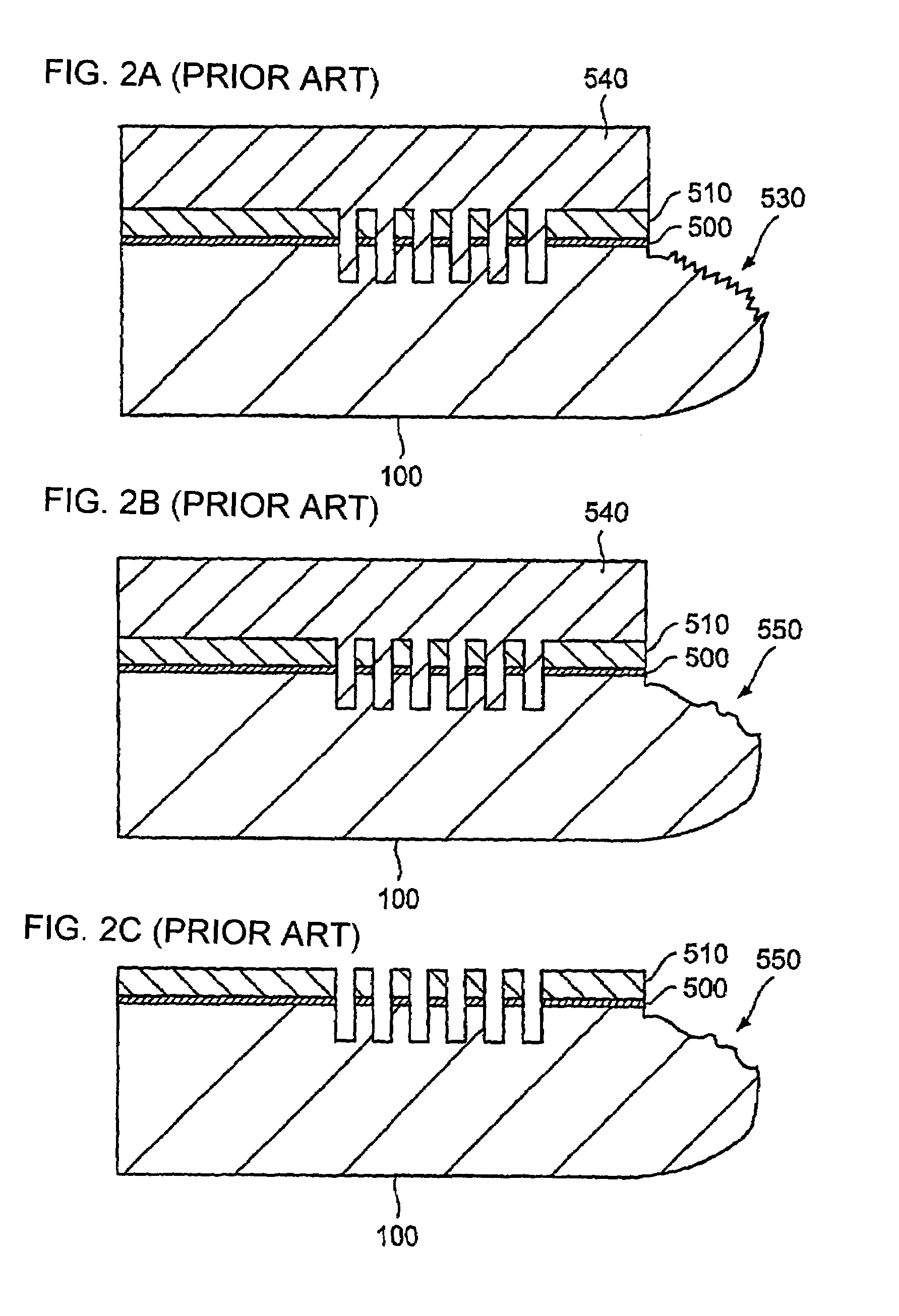

CMP polish pad and CMP processing apparatus using the same

InactiveUS6332832B1Improvement factorReduction factorSemiconductor/solid-state device manufacturingLapping machinesMechanical engineeringContact region

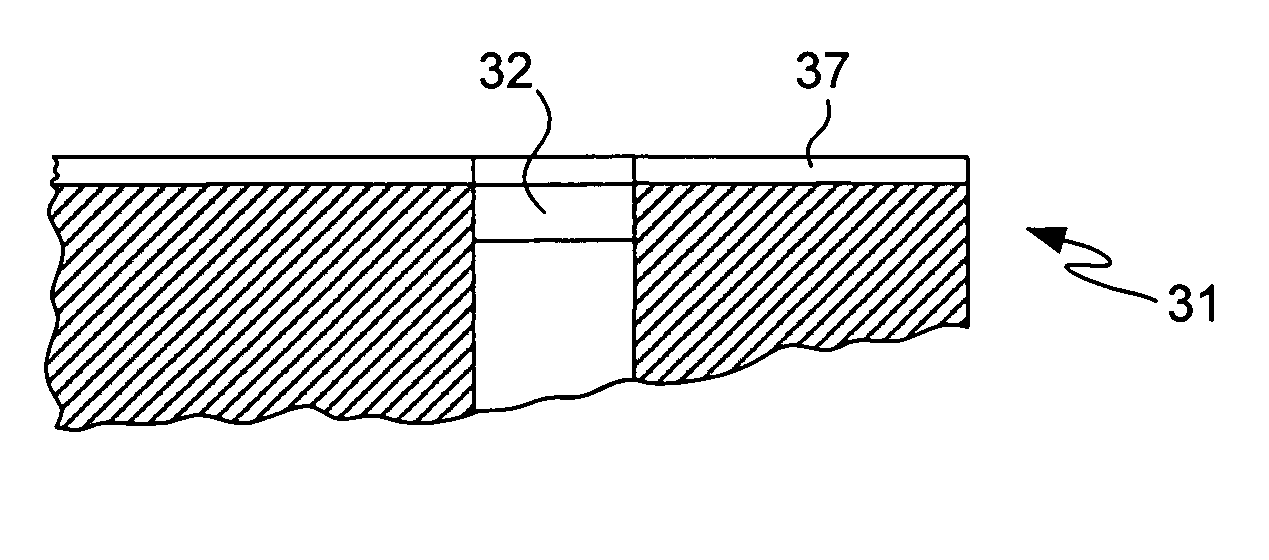

A CMP polish pad used to chemically and mechanically polish a work to be polished. The CMP polish pad has polishing portions of two or more types, that have different conditions of contact with the work, provided on the pad surface. For example, polishing portions of a plurality of types having different coefficients of elasticity with respect to compression in the direction of pressing against the work may be provided on the pad surface. Also polishing portions of a plurality of types having different areas of contact with the work may be provided on the pad surface. Further, polishing portions of a plurality of types having different heights above the pad surface may be provided on the pad surface.

Owner:ROHM CO LTD

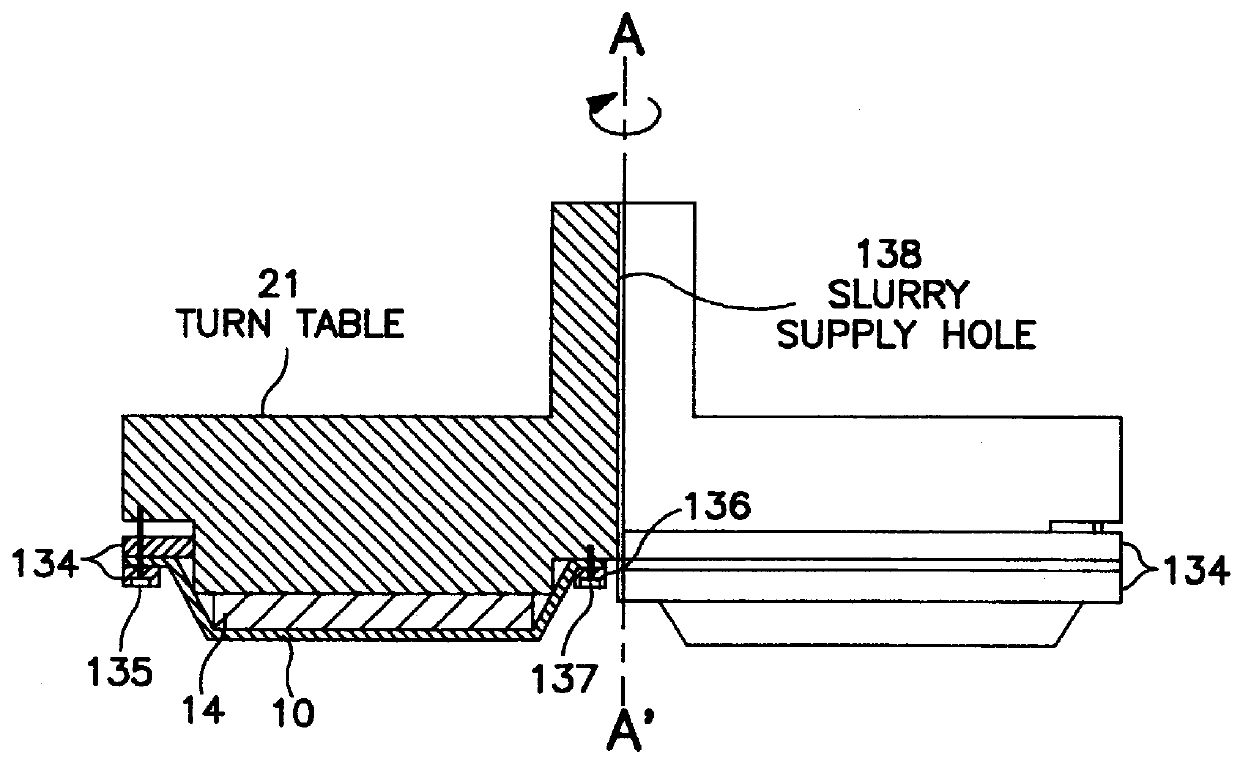

Polishing pad and apparatus for polishing a semiconductor wafer

An apparatus for polishing a semiconductor wafer includes a polishing pad to be in contact with the semiconductor wafer; a turn table which rotates the polishing pad; and an elastic member which is arranged between the turn table and the polishing pad. The polishing pad includes a polishing layer which is made of a material having a good characteristic of slurry holding; and a support layer which is made of a rigid material having an optimum thickness to prevent the polishing layer from loosening. The polishing pad is attached to the turn table by a stretch-holding technique without adhesive bonding.

Owner:TOKYO ELECTRON LTD

Substrate processing apparatus

InactiveUS7367873B2Eliminate surface roughnessShort timeEdge grinding machinesRevolution surface grinding machinesConstant forceEngineering

A substrate processing apparatus has a polishing tape and a polishing head for pressing the polishing tape against a peripheral portion of a semiconductor wafer. The substrate processing apparatus polishes the wafer due to sliding contact of the polishing tape and the wafer. The polishing head has an elastic body for supporting the polishing tape. The substrate processing apparatus has an air cylinder for pressing the polishing head so that the elastic body of the polishing head presses the polishing tape against the predetermined portion of the wafer under a constant force.

Owner:EBARA CORP +1

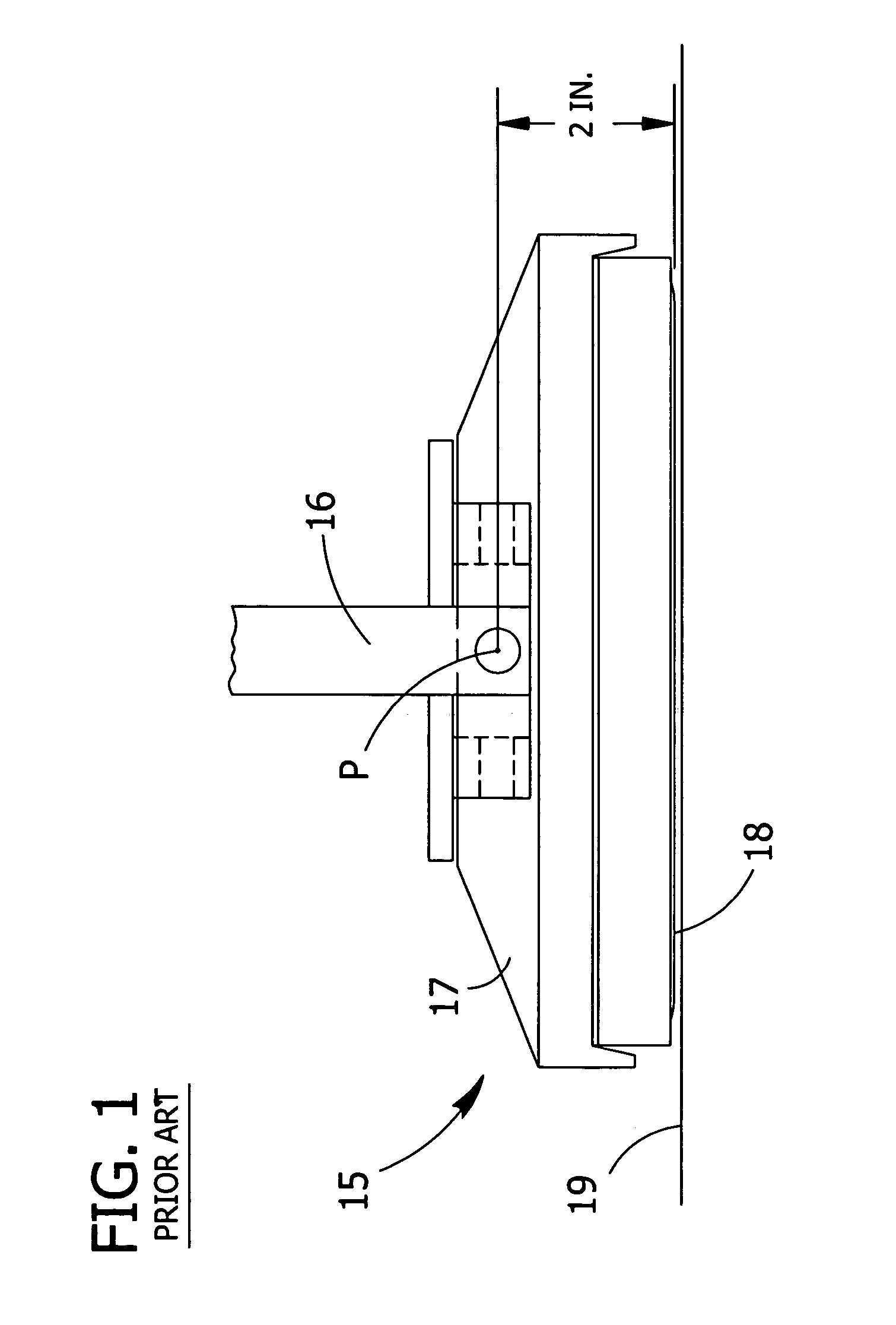

Wafer carrier with pressurized membrane and retaining ring actuator

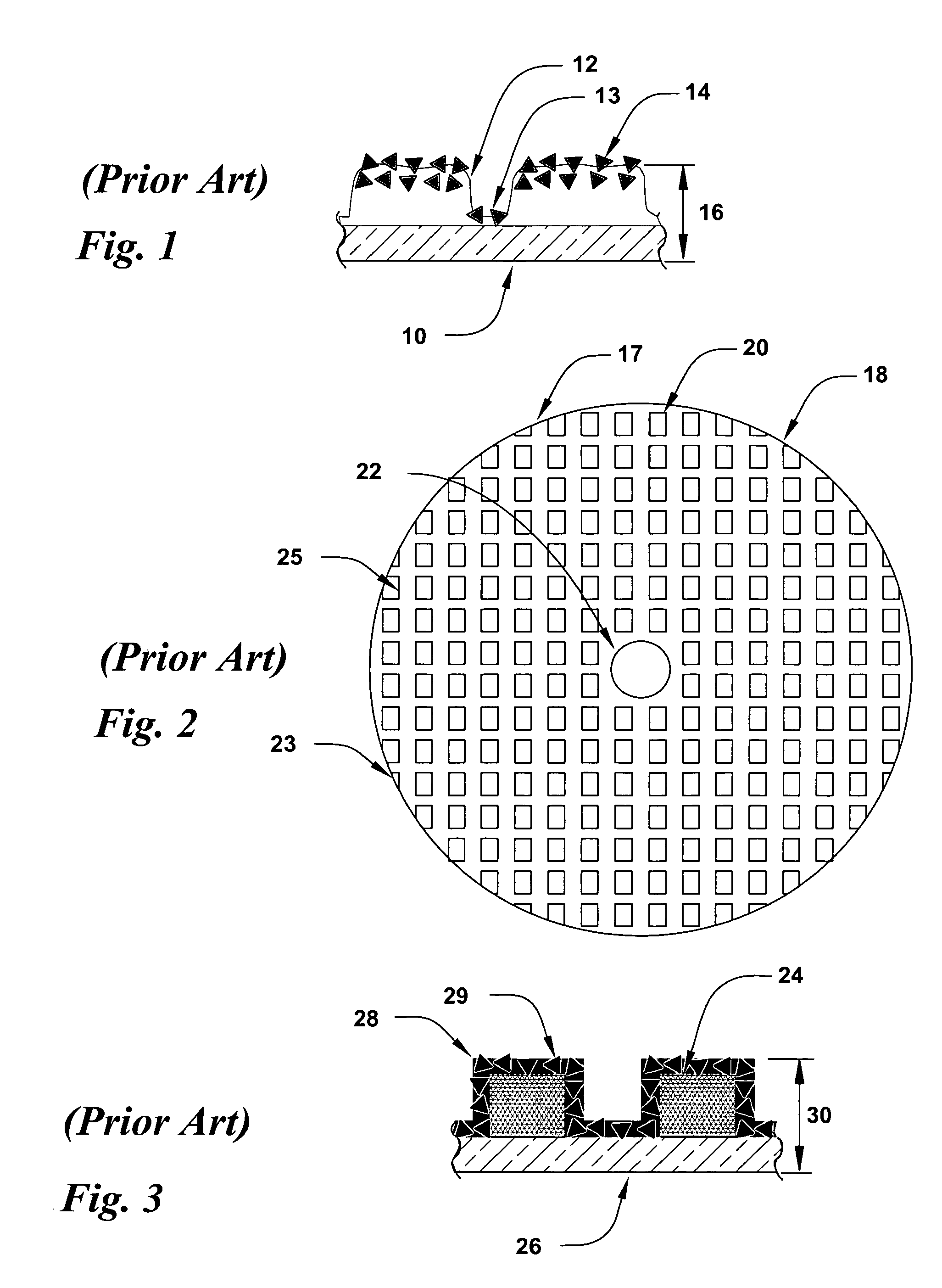

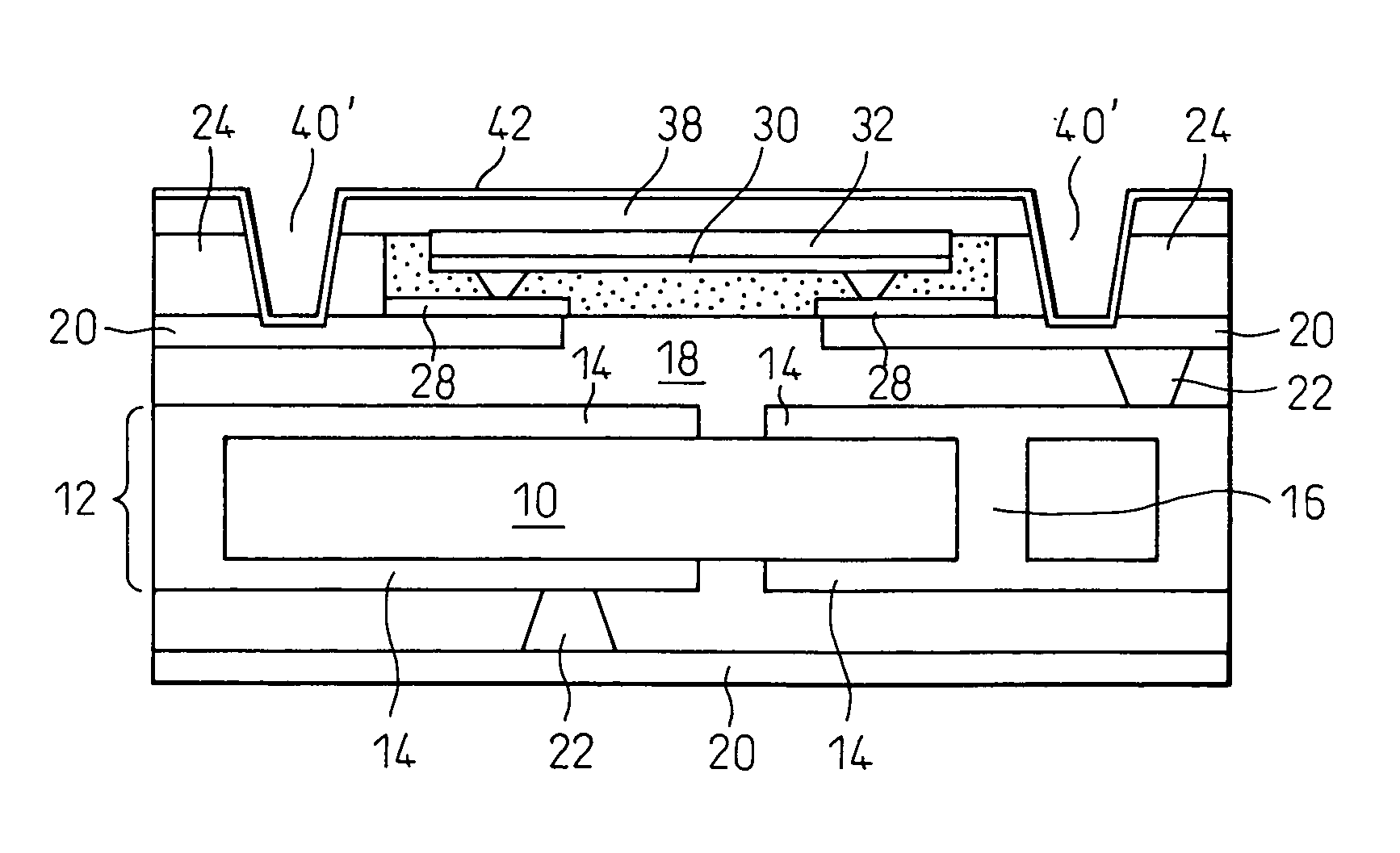

ActiveUS20050215182A1Reduce edge effectReduce edge effectsPolishing machinesRevolution surface grinding machinesChemical-mechanical planarizationRetaining ring

A wafer carrier for controlling downward force and edge effect during chemical mechanical planarization. A retaining ring actuator is disposed within the retaining ring to control the height of the retaining ring relative to the bottom surface of the wafer carrier. An inflatable membrane is disposed across the bottom surface of the wafer carrier such that pressure in the bladder is independently regulated to control the downward force acting on the wafer during CMP. In addition, an edge control bladder may also be disposed within the carrier such that if the pressure in the bladder is also regulated, the amount of force on the edge of the wafer changes. By regulating retaining ring actuator pressure, inflatable membrane pressure, and edge control bladder pressure, non-uniformities in the wafer surface and edge effect may be addressed during CMP.

Owner:REVASUM INC +1

Polishing pad containing embedded liquid microelements and method of manufacturing the same

ActiveUS20060125133A1Easy to manufactureImprove accuracySemiconductor/solid-state device manufacturingFlexible-parts wheelsMaterials scienceLiquid phase

A polishing pad is provided. The polishing pad includes a polishing layer composed of a polymeric matrix and liquid microelements embedded in the polymeric matrix. Open pores defined by the embedded liquid microelements are distributed across a surface of the polishing layer. Due to the microstructural open pores uniformly distributed across a surface of the polishing pad, a polishing operation can be performed at high precision. The polishing pad shows constant polishing performance during the polishing operation, can be stably used, and does not cause a wafer to be scratched. In addition, a method of manufacturing the polishing pad is provided. Since all components used to manufacture the polishing pad are in a liquid phase, manufacturing can be easily performed.

Owner:KPX CHEM

Method of forming a flexible abrasive sheet article

InactiveUS8545583B2Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedPrill

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

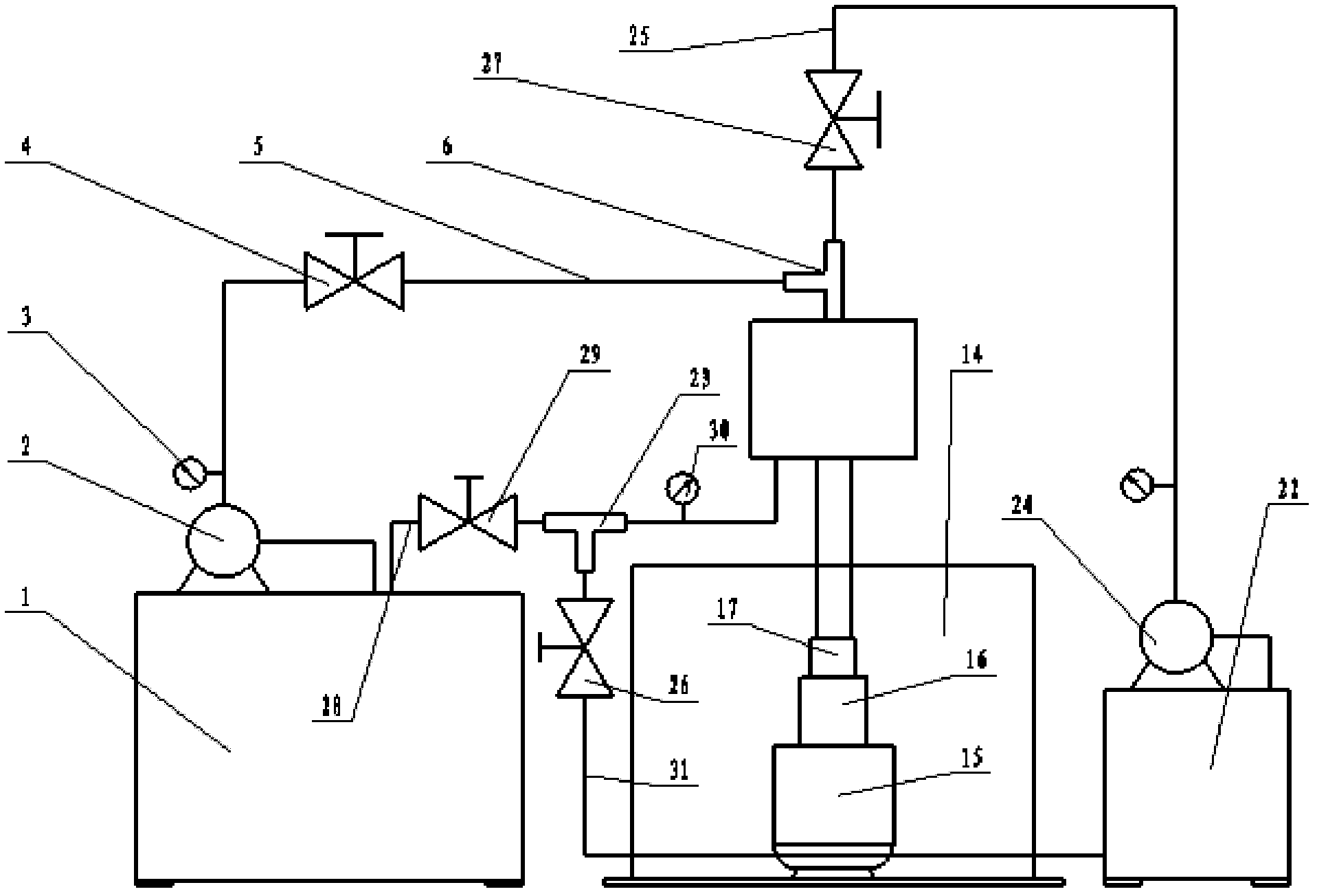

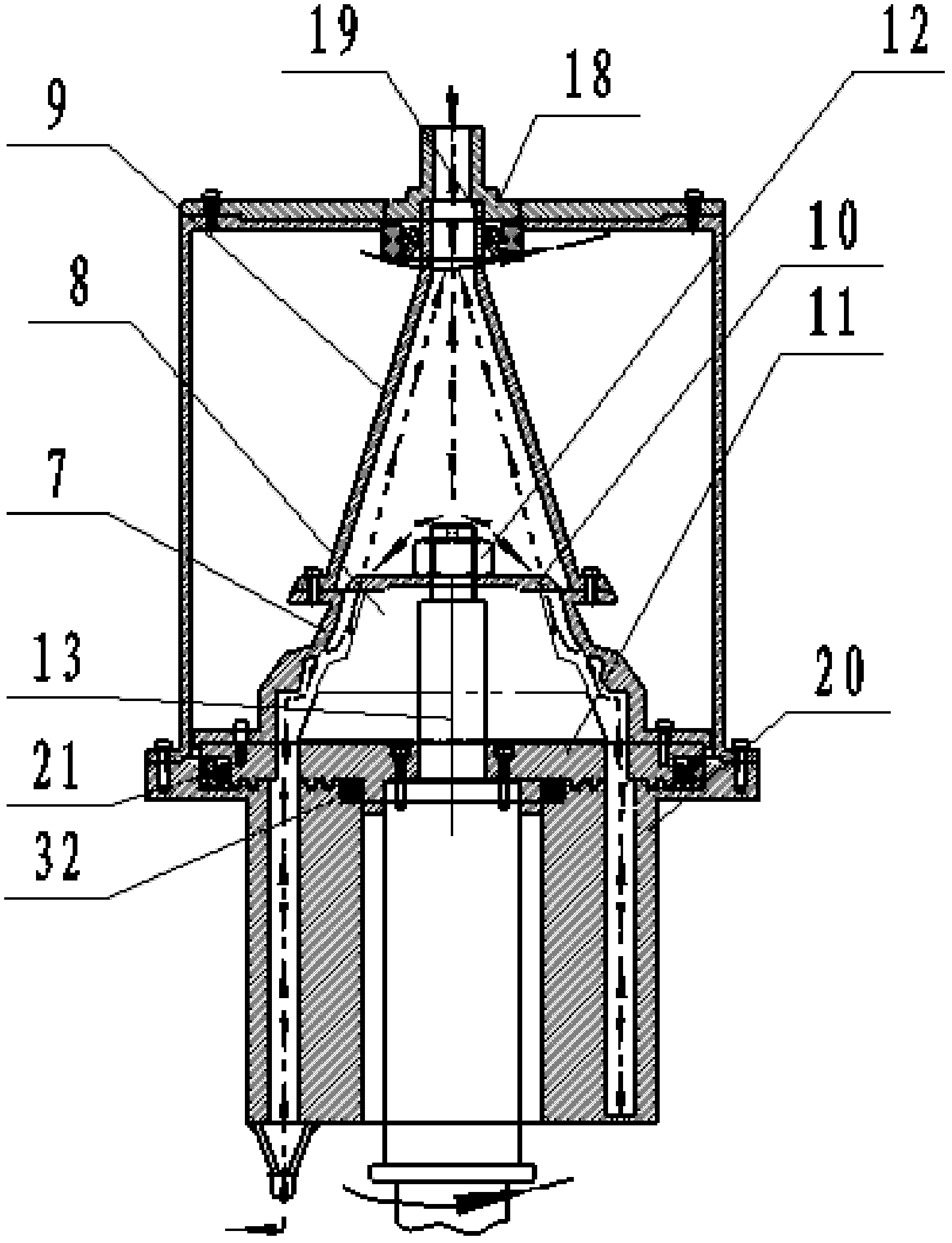

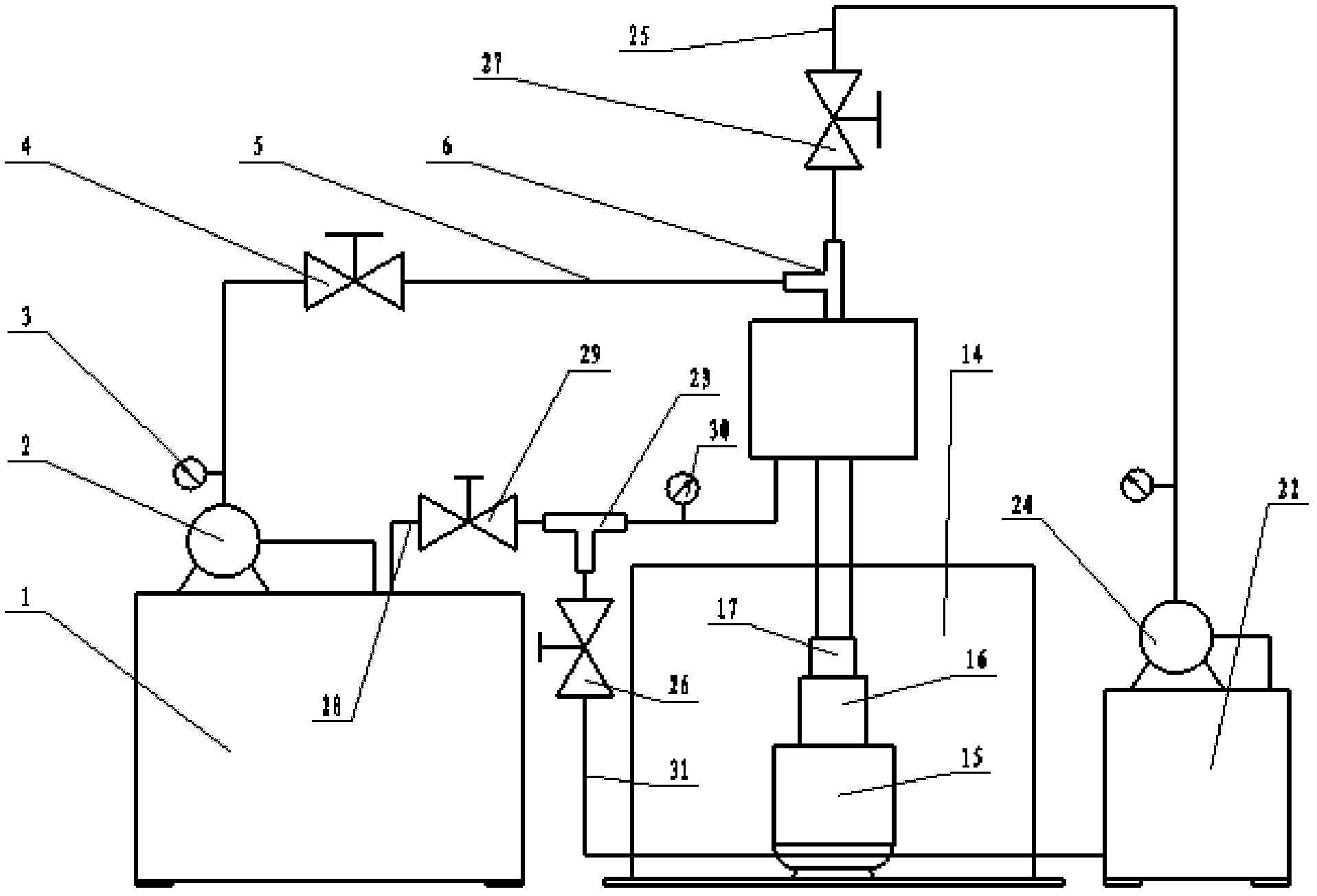

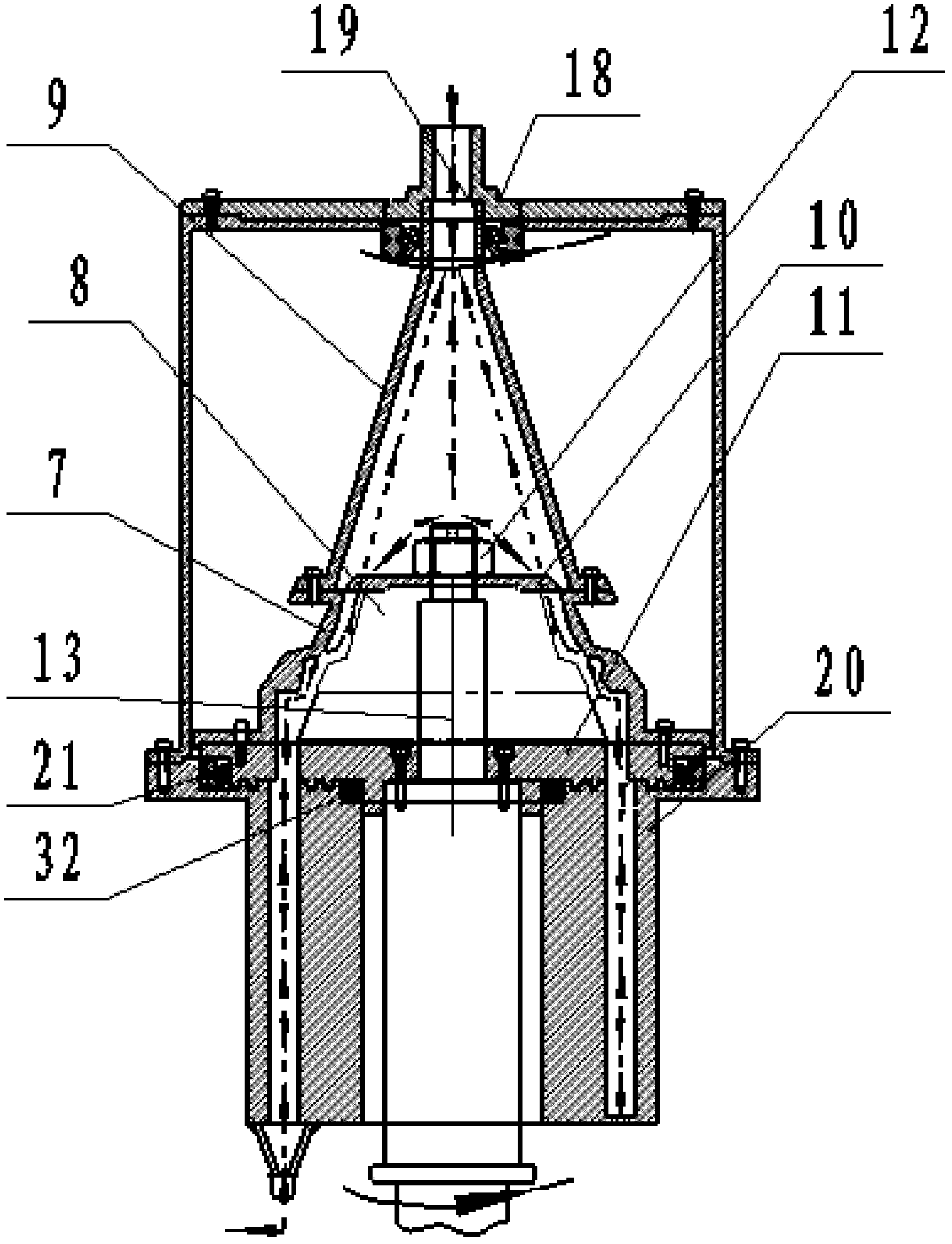

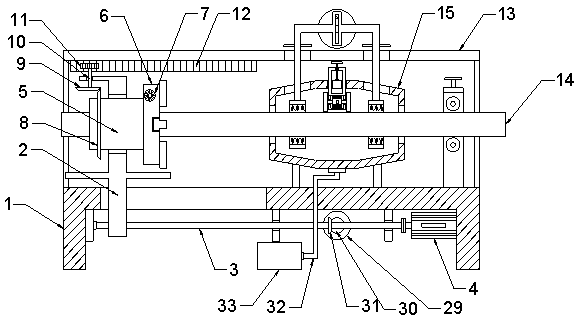

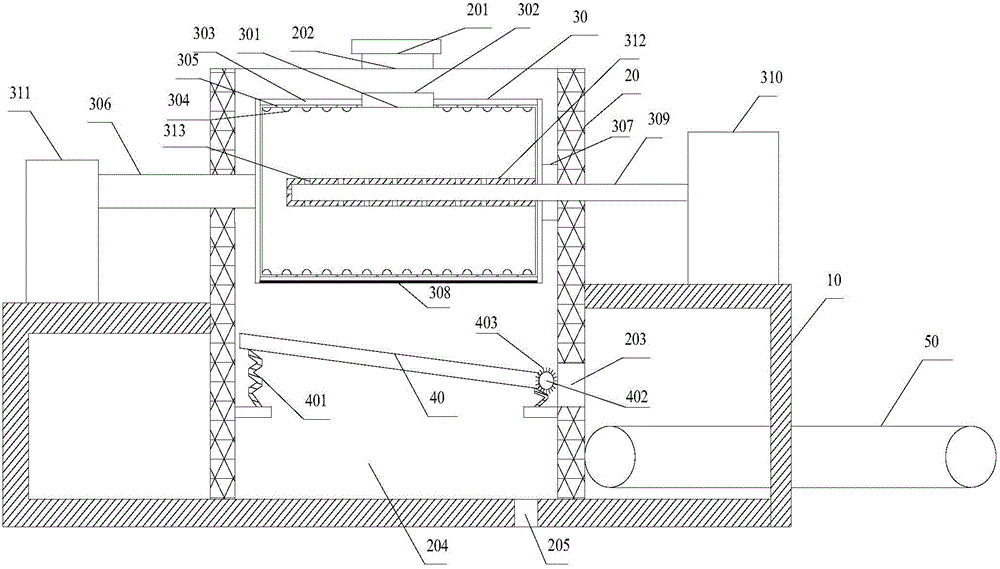

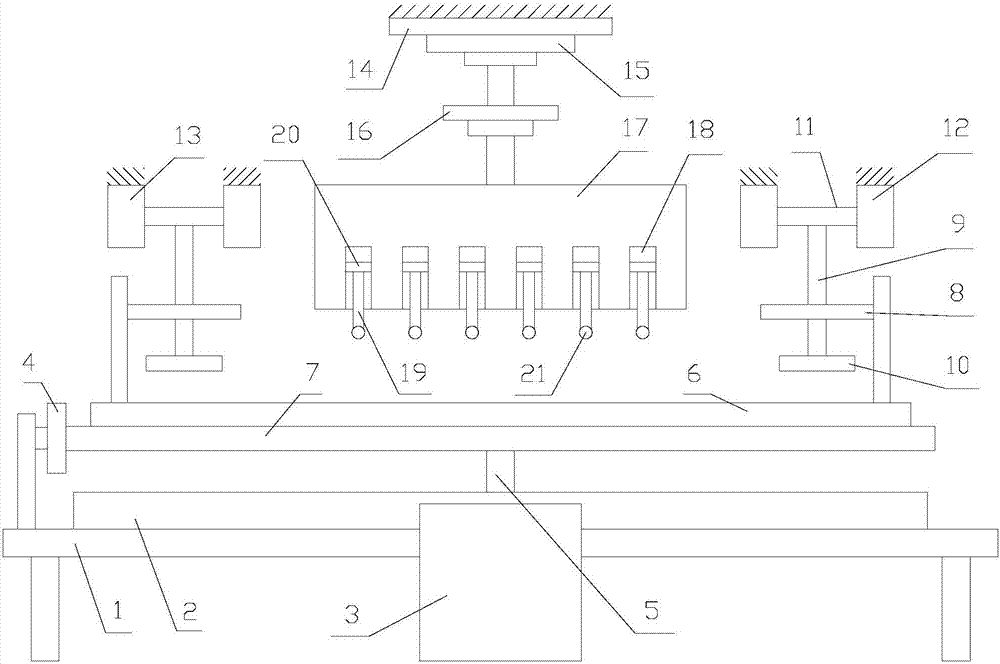

Rotary abrasive flow polishing device for integral impeller type parts

ActiveCN102601686AUniform abrasive flowUniform distribution of pressure fieldGrinding work supportsImpellerEngineering

A rotary abrasive flow polishing device for integral impeller type parts comprises a feeding system, a spindle system, a device body, a clamp cover, a guide structure and a cleaning system, wherein the feeding system is used for regular bidirectional feeding and controlling abrasive flow, the spindle system is capable of rotating positively and reversely and adjustable in rotation speed, the clamp cover clamps an impeller to form a closed cavity and protects non-polishing sides and upper and lower edges, the guide structure is used for guiding abrasives, and the cleaning system is used for realizing cleanness in ingoing and outgoing. The rotary abrasive flow polishing device solves the problems of easiness in interference, over-polishing of blades, chamfering, dead angles and nonuniform polishing in polishing of integral impeller type parts, the abrasives can bidirectioally cyclically flow to be recovered easily, machining efficiency is improved, and cleanness in ingoing and outgoing during machining can be realized by means of the cleaning system used after polishing is completed.

Owner:DALIAN UNIV OF TECH

Polishing method for rotating abrasive stream of entire impeller part

ActiveCN102615597AEvenly distributedUniform distribution of pressure fieldAbrasive machine appurtenancesAbrasive blasting machinesEngineeringHigh pressure water

The invention discloses a polishing method for rotating an abrasive stream of an entire impeller part. The polishing method is characterized by comprising the following steps of: firstly, protecting non-polished faces, such as upper and lower end faces of an impeller and outer edges of blades, by virtue of a special shape clamp cover, and integrally fixing with a workpiece; secondly, properly buffering and adjusting before the workpiece is polished by abrasive through an abrasive stream drainage device, so that a pressure field in a sealing cavity is uniformly distributed; thirdly, driving an equipment spindle and the workpiece to rotate by using a power system consisting of a motor and a speed reducer; and finally, converting to a high-pressure water cleaning system to wash the workpiece and an equipment pipeline after polishing. According to the polishing method provided by the invention, the problems in a polishing process of the entire impeller part of easiness of interference, excessive polished blades, chamfering, dead angle and uniform polishing can be solved; the abrasive circularly flows in double directions so as to be easy to recycle; the machining efficiency is improved; and clean-in and clean-out in a machining process can be realized through the water washing system after the polishing process.

Owner:DALIAN UNIV OF TECH

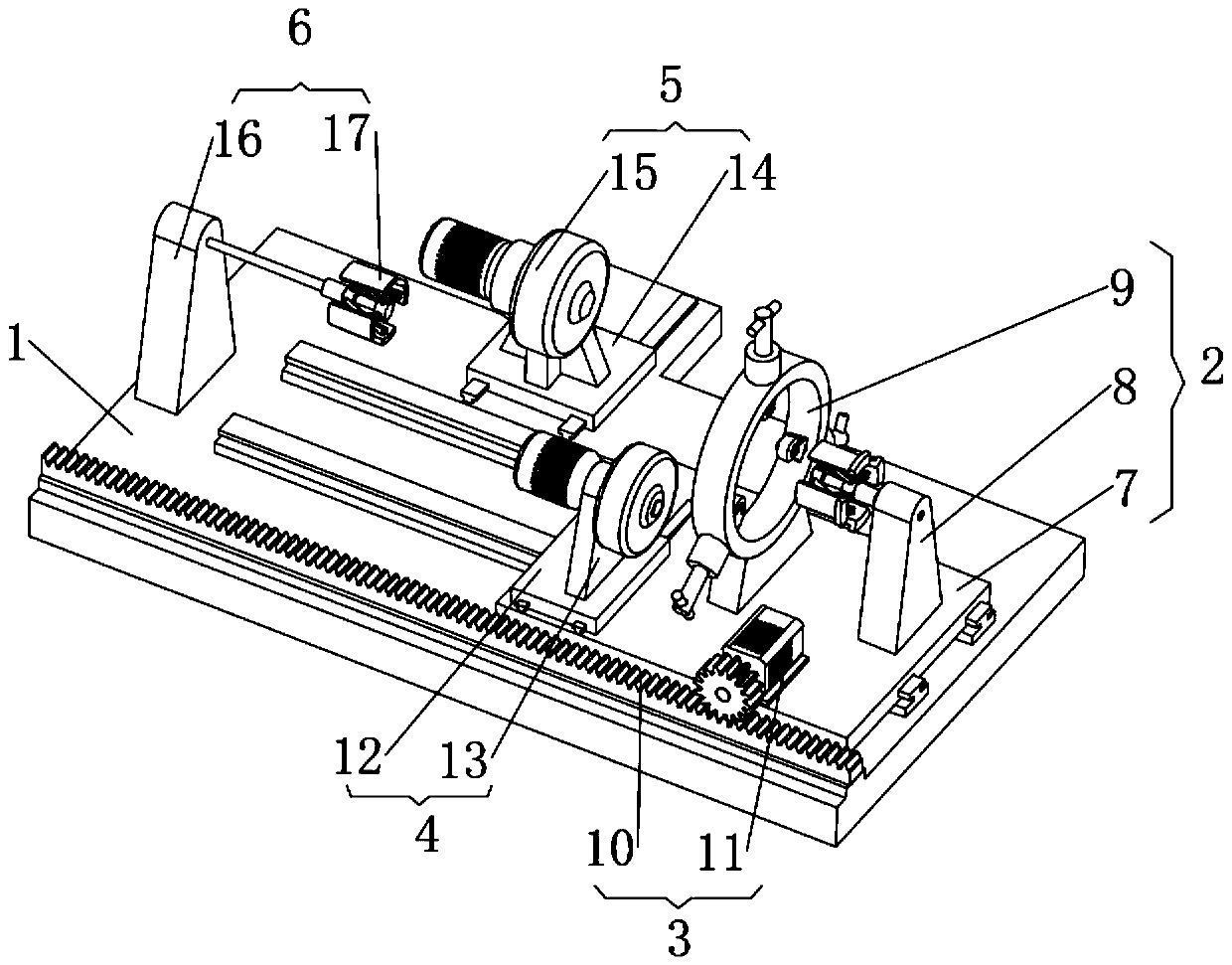

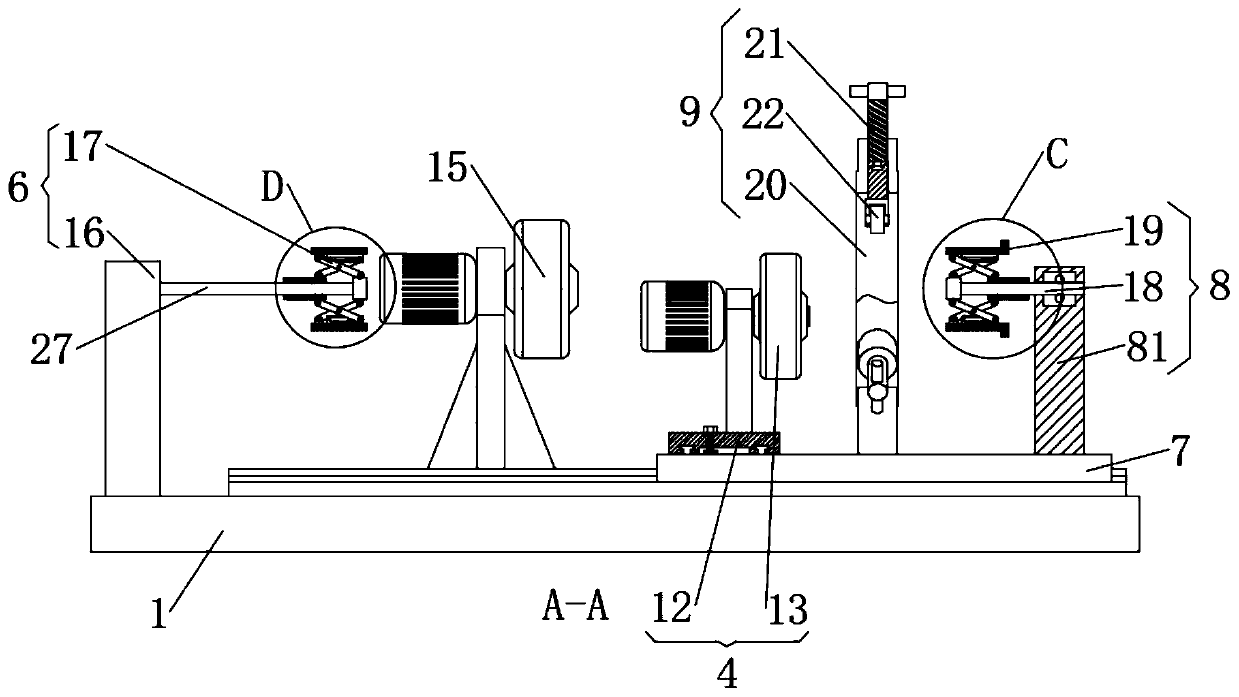

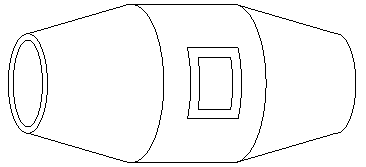

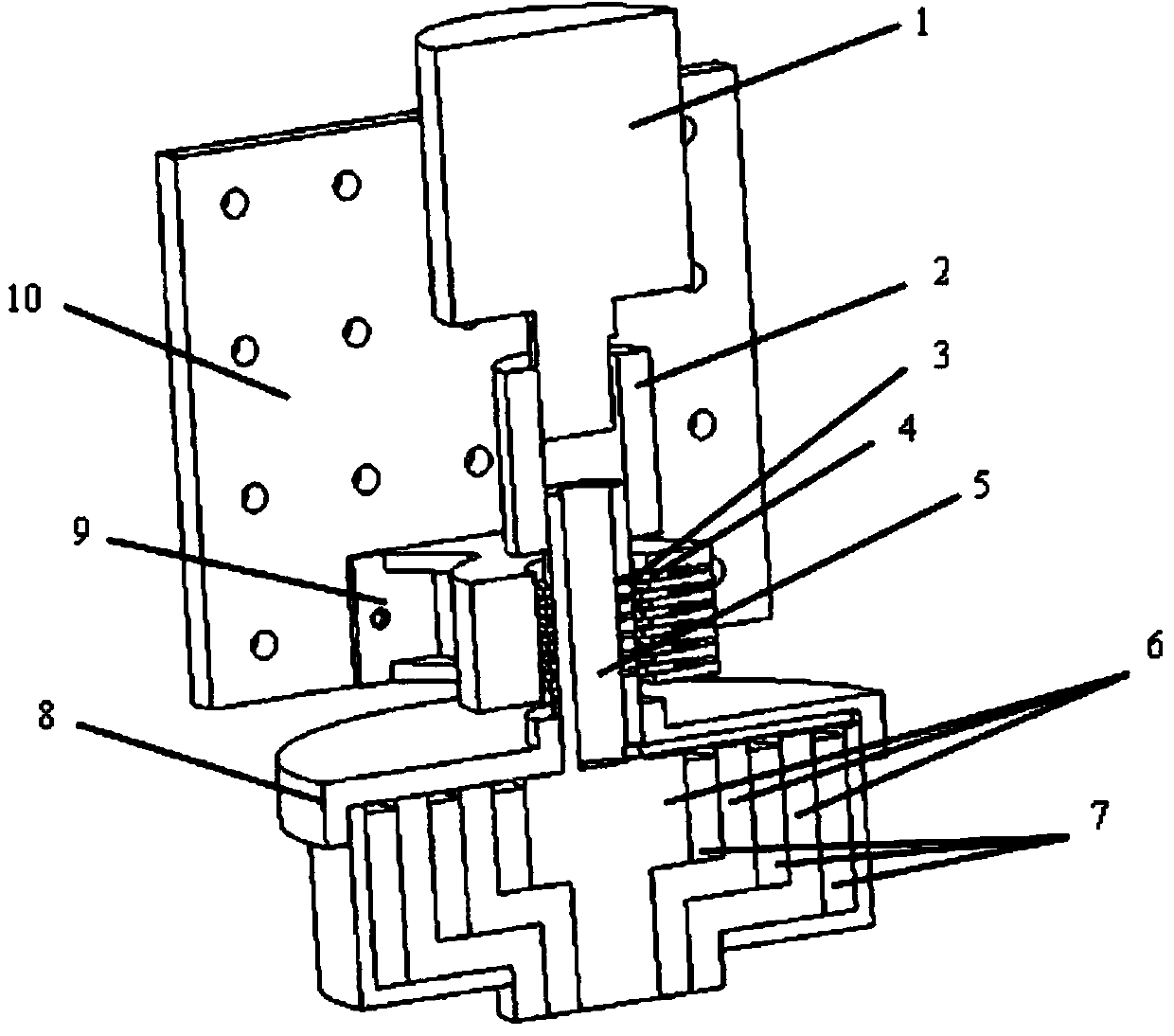

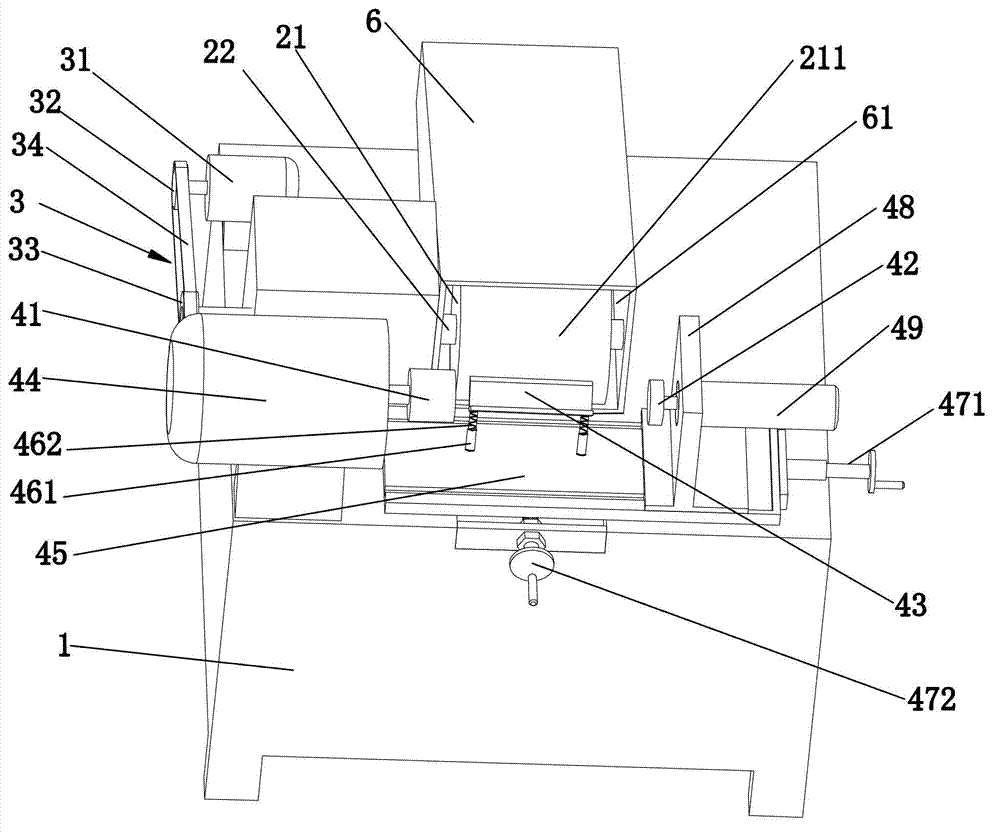

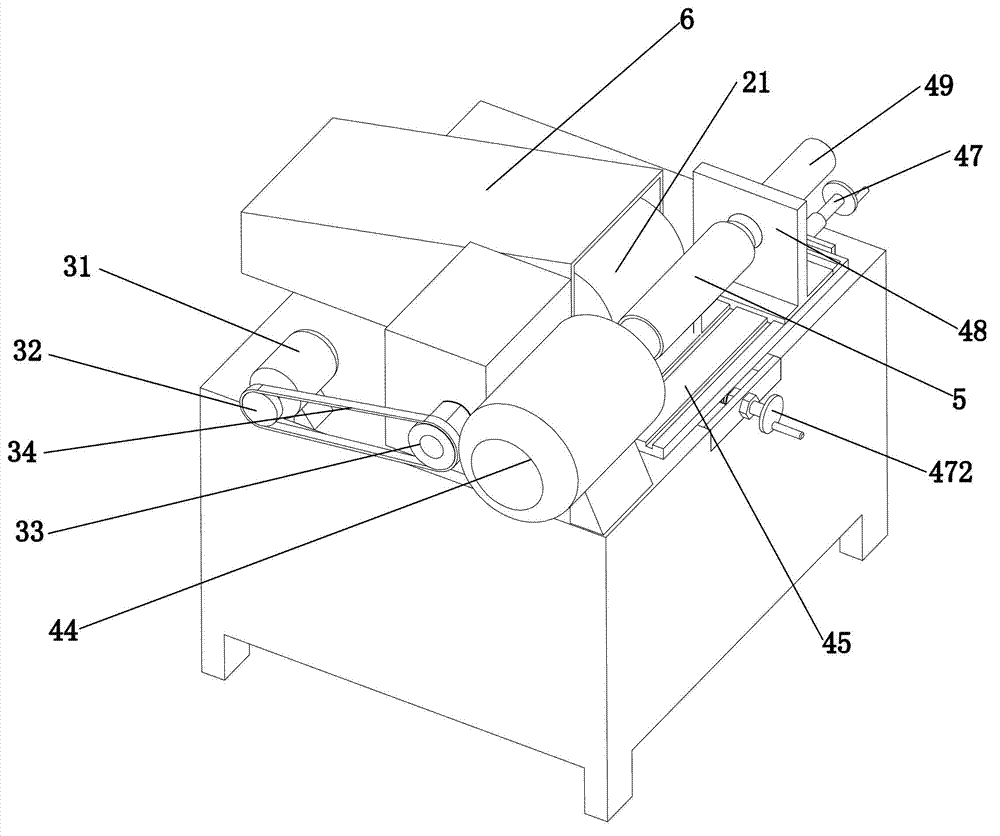

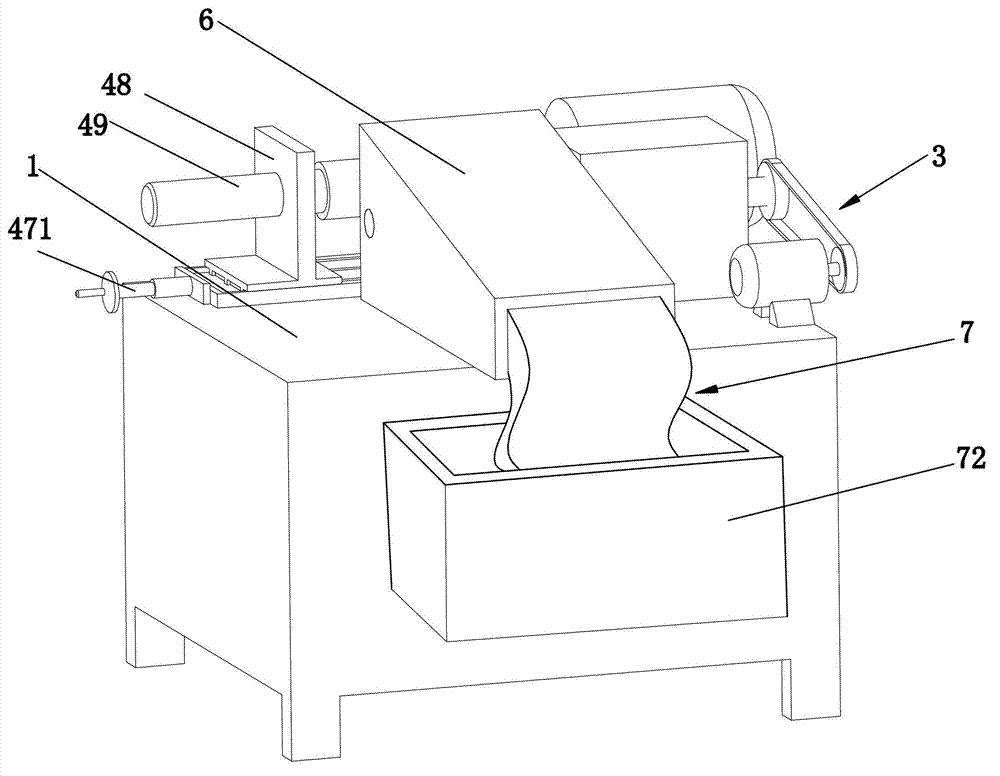

Mechanical part grinding fixing device

ActiveCN110000636ADouble clamping fixed and stableEasy to polishPolishing machinesRevolution surface grinding machinesMachine partsMechanical components

The invention discloses a mechanical part grinding fixing device, and relates to the field of mechanical part machining equipment. The mechanical part grinding fixing device comprises a base platform,a fixing device, an axial driving unit, a rotatable driving unit, an outer wall polishing unit and an inner wall polishing unit; the fixing device comprises a fixing device base, an inner wall fixingdevice and an outer wall limiting device; the axial driving unit comprises a rack and a servo motor; the outer wall polishing unit is arranged on the back side of the left portion of the upper surface of the base platform; and the inner wall polishing unit is arranged on the left side of the upper surface of the base platform. According to the mechanical part grinding fixing device, the fixing device base is driven by the axial driving unit to move to uniformly grind the outer wall of a round pipe type part by cooperating with the outer wall polishing unit, and meanwhile an inner wall polishing head in the inner wall polishing unit goes deep into the inner wall of the round pipe type part to grind the inner wall of the round pipe type part.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

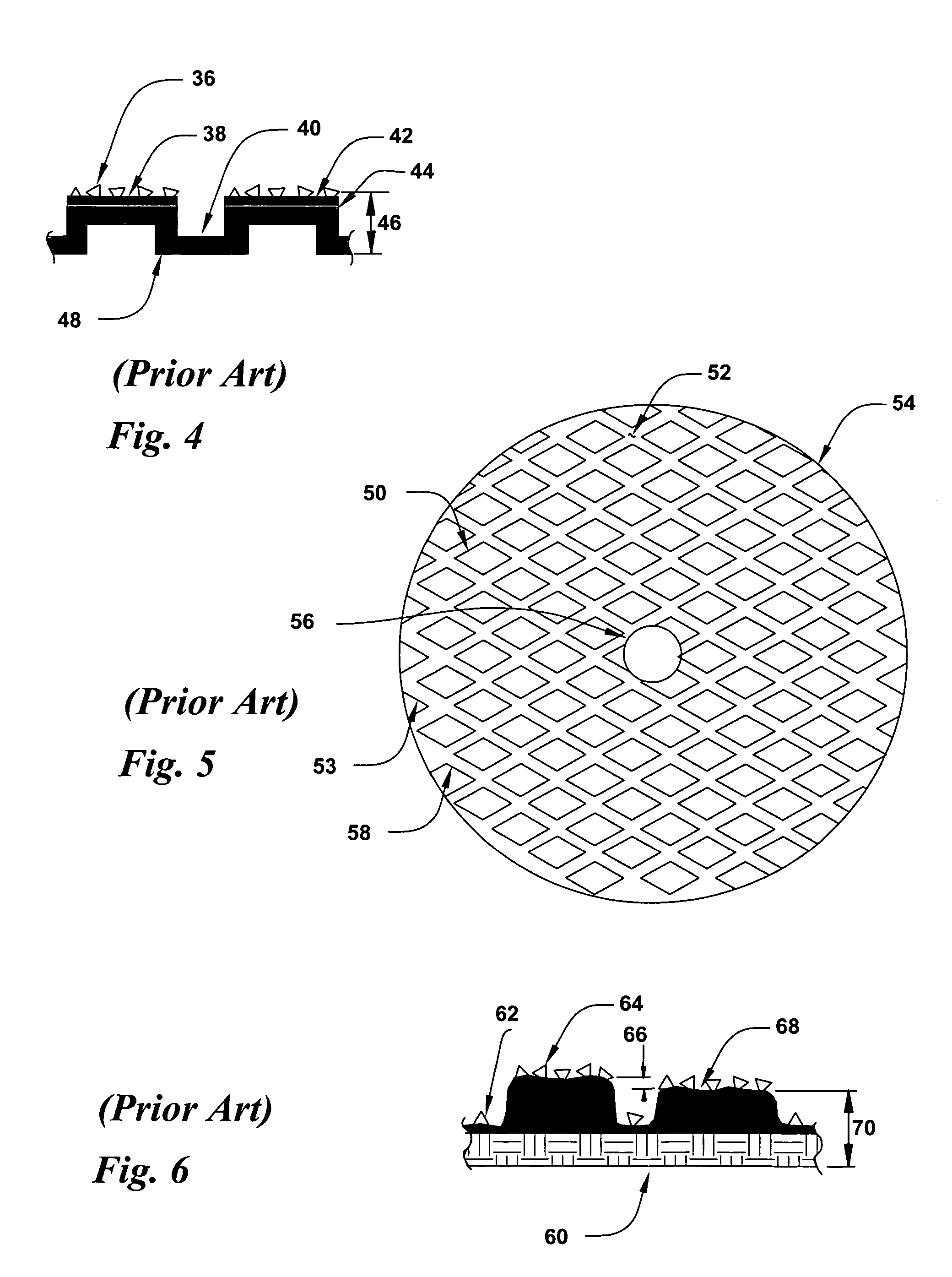

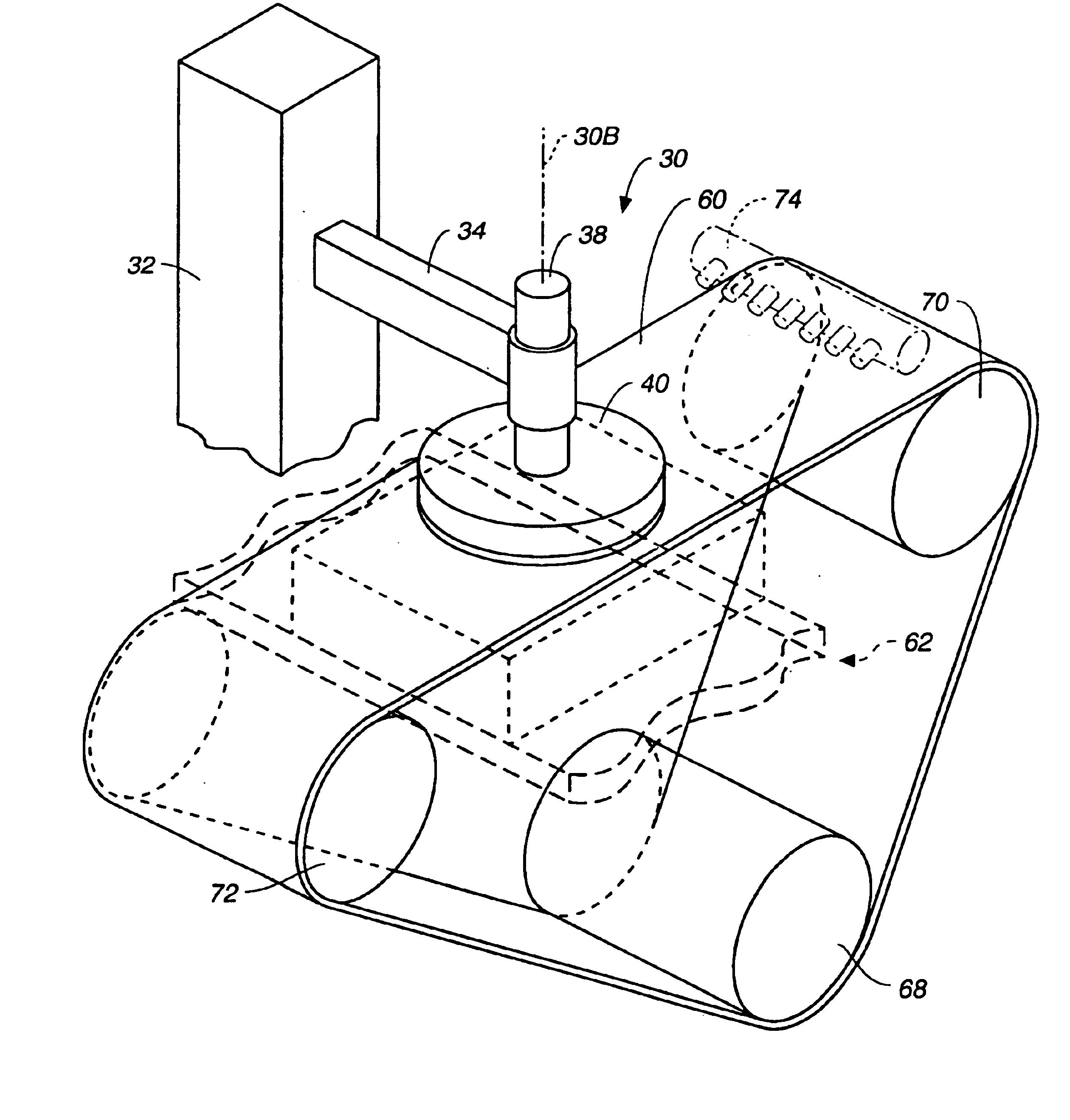

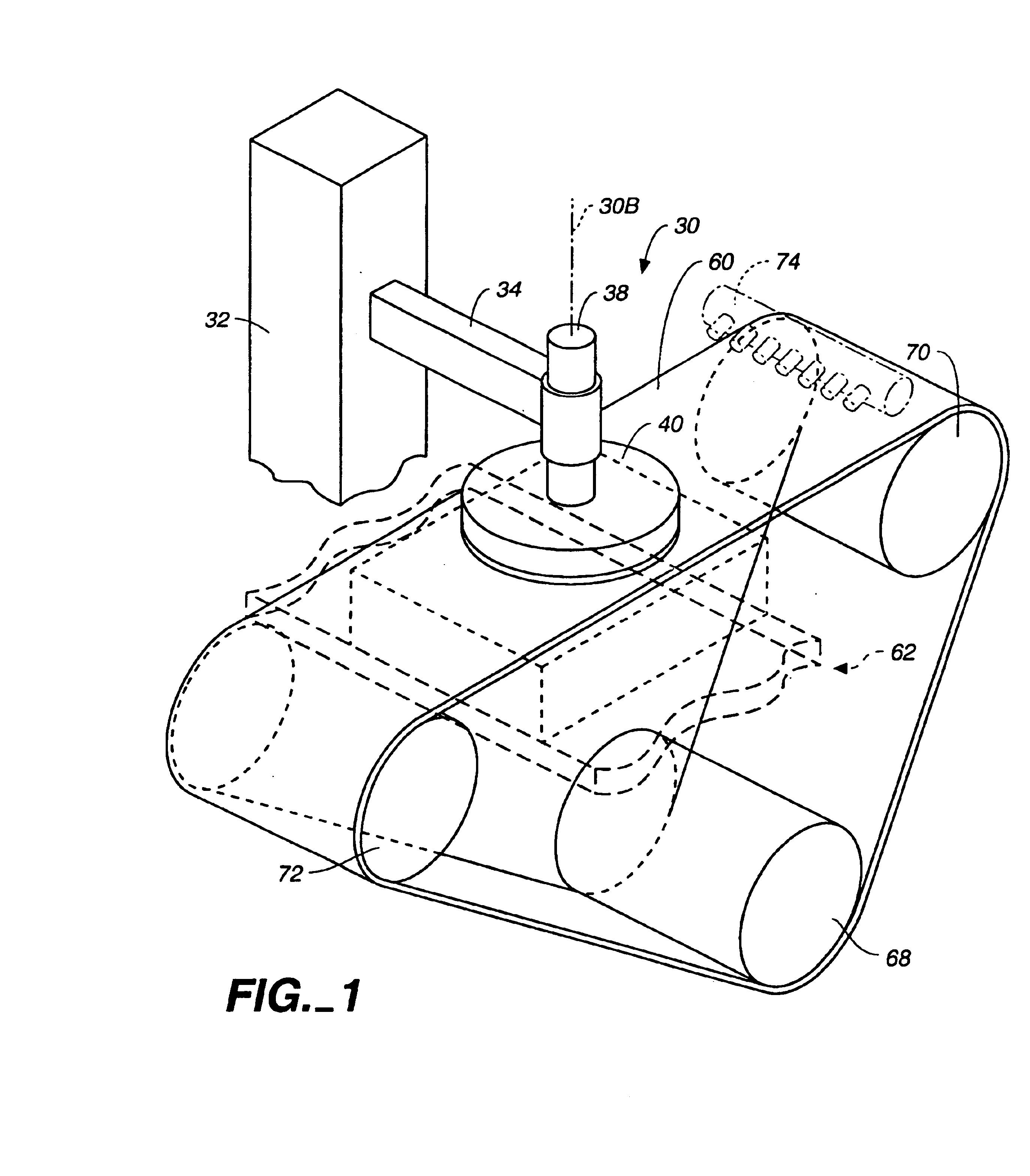

Chemical mechanical polisher with grooved belt

InactiveUS6837779B2Improve pad lifetimeEffective distributionPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

A chemical mechanical polishing apparatus has a substrate holder, a polishing belt, and a backing member positioned on a side of the polishing belt opposite the substrate holder. The polishing belt has a polishing surface to contact at least a portion of the substrate held by the substrate holder. The polishing belt is movable in a first direction in a generally linear path relative to the substrate. The polishing belt has a plurality of grooves formed therein.

Owner:APPLIED MATERIALS INC

Polishing apparatus, polishing method and pressing member for pressing a polishing tool

ActiveUS20110237164A1Accurate polishingUniform contact timeEdge grinding machinesGrinding drivesMechanical engineering

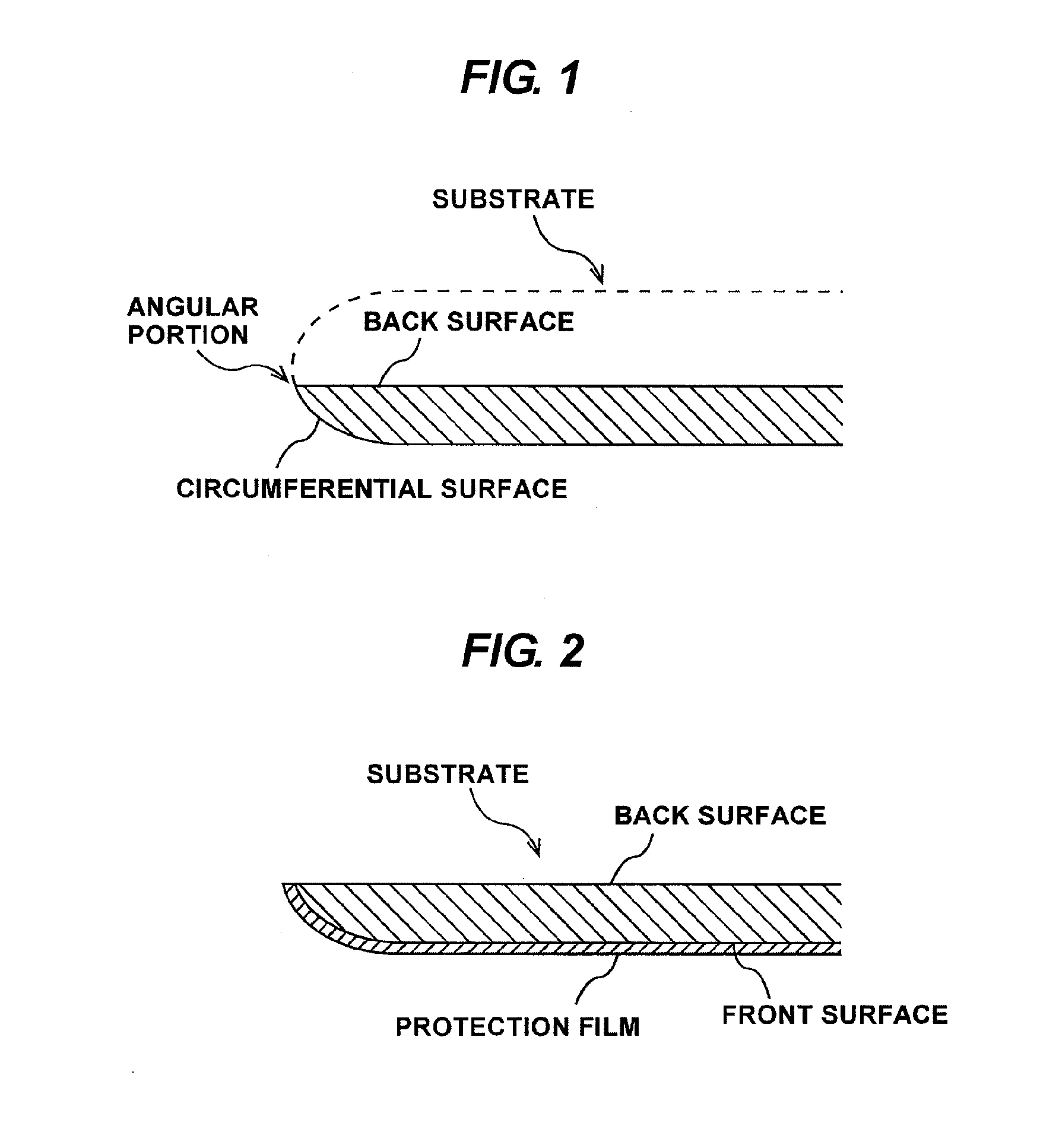

A polishing apparatus polishes a top edge portion and / or a bottom edge portion of a substrate accurately and uniformly. The polishing apparatus includes a rotary holding mechanism 3 configured to hold the substrate W horizontally and to rotate the substrate W; and at least one polishing head 30 disposed near the peripheral portion of the substrate. The polishing head 30 has at least one protrusion 51a, 51b extending along a circumferential direction of the substrate W, and the polishing head 30 is configured to press a polishing surface of a polishing tape 23 by the protrusion 51a, 51b against the peripheral portion of the substrate W from above or below.

Owner:EBARA CORP

Method and apparatus for polishing a substrate having a grinded back surface

ActiveUS20110136411A1Polish uniformityShorten timeEdge grinding machinesPolishing machinesEngineeringMechanical engineering

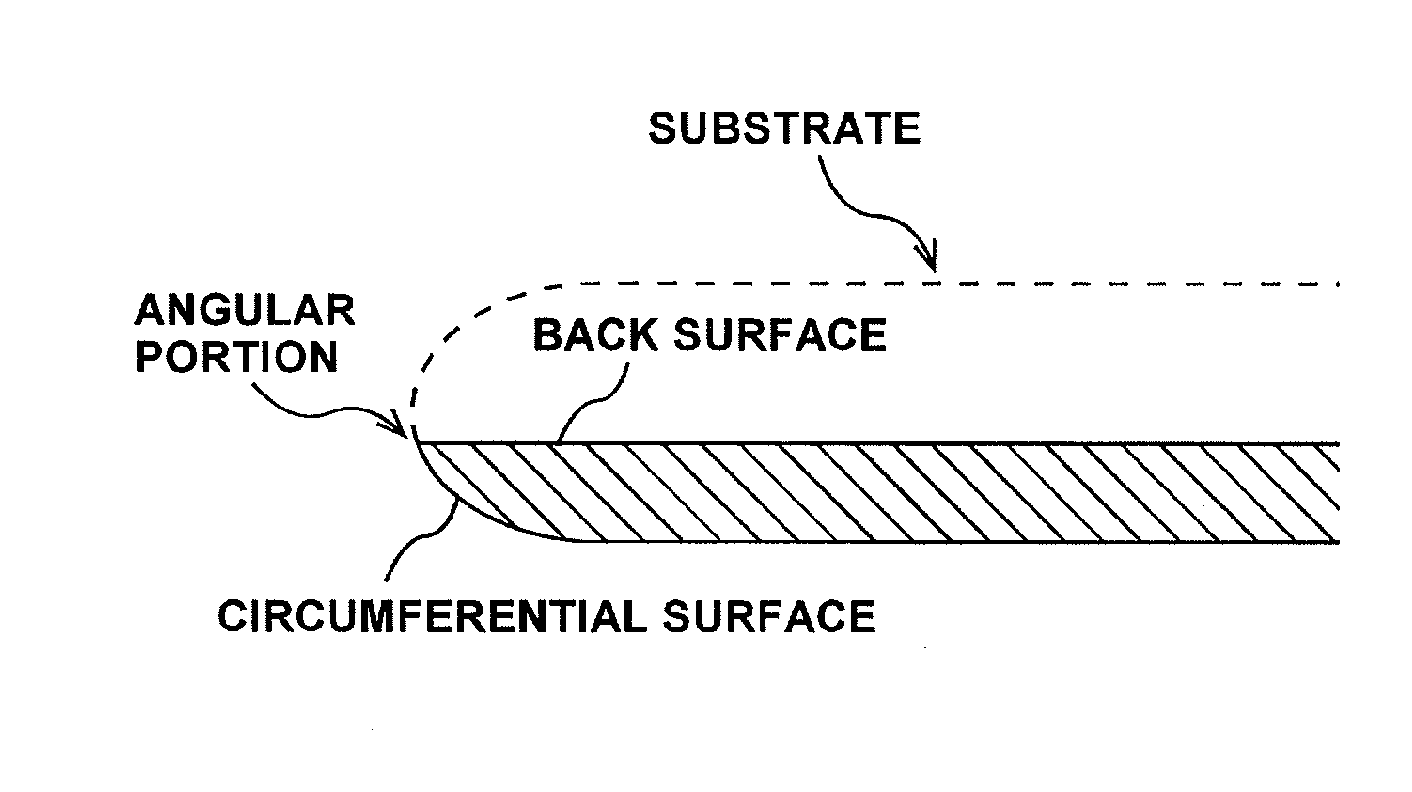

A method capable of quickly polishing an angular portion formed by a grinded back surface and a circumferential surface of a substrate without causing damages on the thin substrate is provided. The method includes rotating the substrate about its center, and pressing a polishing tape against the angular portion formed by the back surface and the circumferential surface of the substrate to polish the angular portion.

Owner:EBARA CORP

Steel pipe grinding device for machining

PendingCN109571162AAchieve rotationEasy to polishRevolution surface grinding machinesGrinding drivesBristleEngineering

The invention discloses a steel pipe grinding device for machining. The steel pipe grinding device comprises a base, a steel pipe and a rust removal barrel fixedly connected with the base. A moving frame is arranged above the base, a rotation barrel is embedded in the moving frame, and one side of the rotation barrel is fixedly connected with a three-jaw chuck. Symmetric grinding abrasive wheels are arranged at the middle position of the rust removal barrel. Through the arrangement of the rotation barrel embedded in the moving frame and rotationally connected with the moving frame, a bevel gear ring, a rolling gear and a rack plate, self-rotation during transverse steel pipe feeding is achieved, and subsequent steel pipe circumference face comprehensive grinding and scrubbing cleaning areconvenient. Through the arrangement of a swinging frame, a first rust removal brush barrel with steel wire bristles and a second rust removal brush barrel with soft bristles, the spindle-shaped rust removal barrel and an industrial dust collector are matched, so that iron scraps are conveniently collected in a centralized manner, and operation environment pollution is avoided.

Owner:HUNAN UNIV OF SCI & ENG

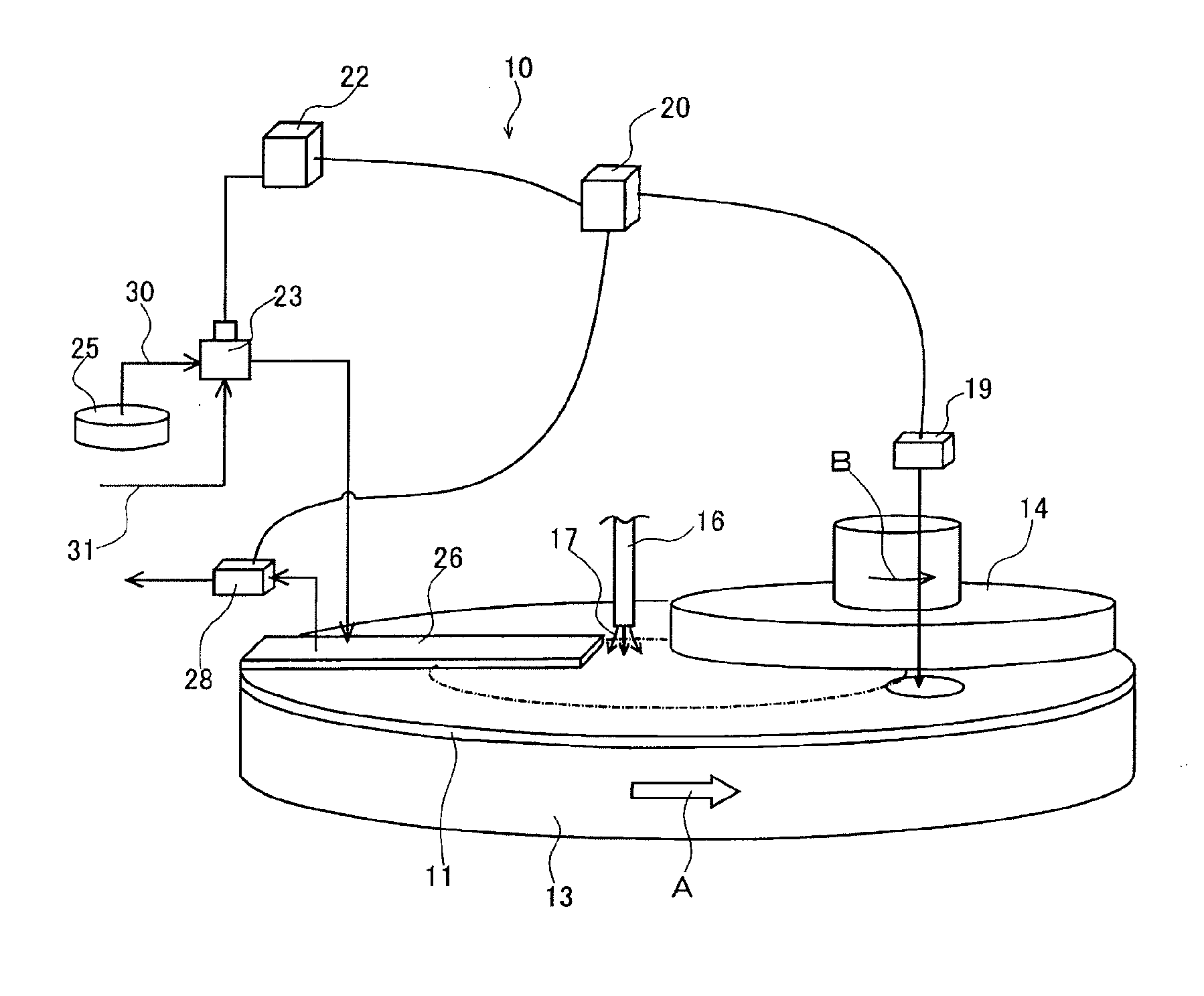

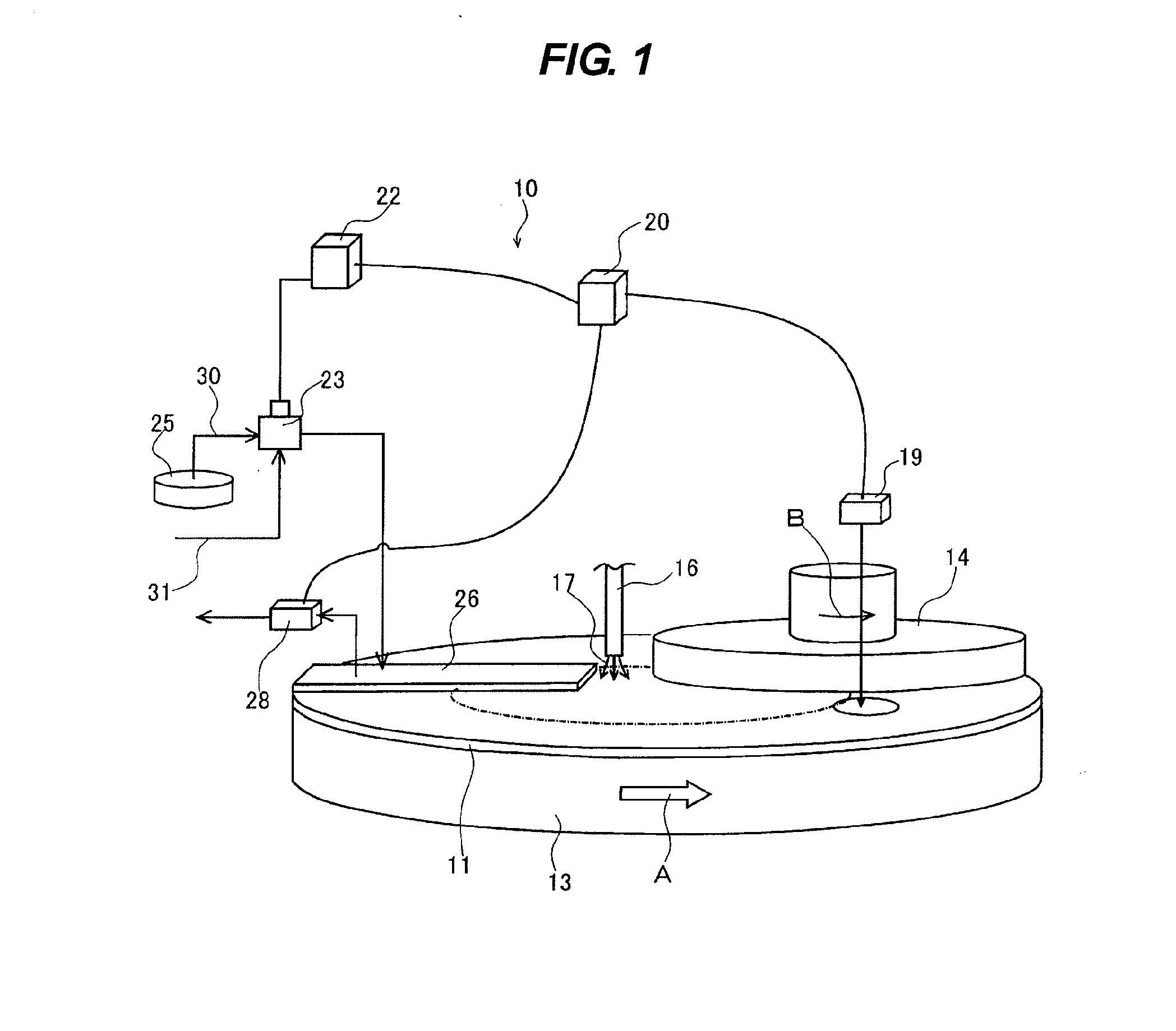

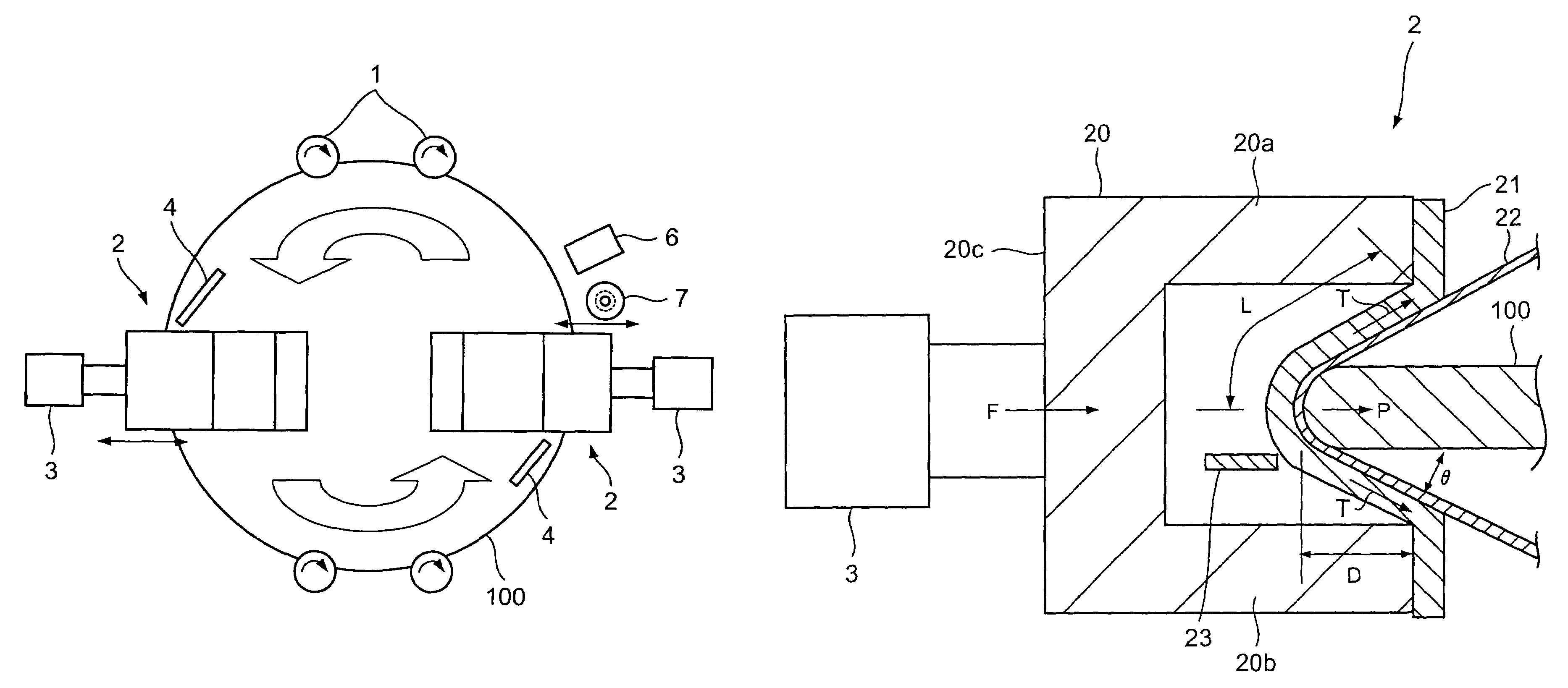

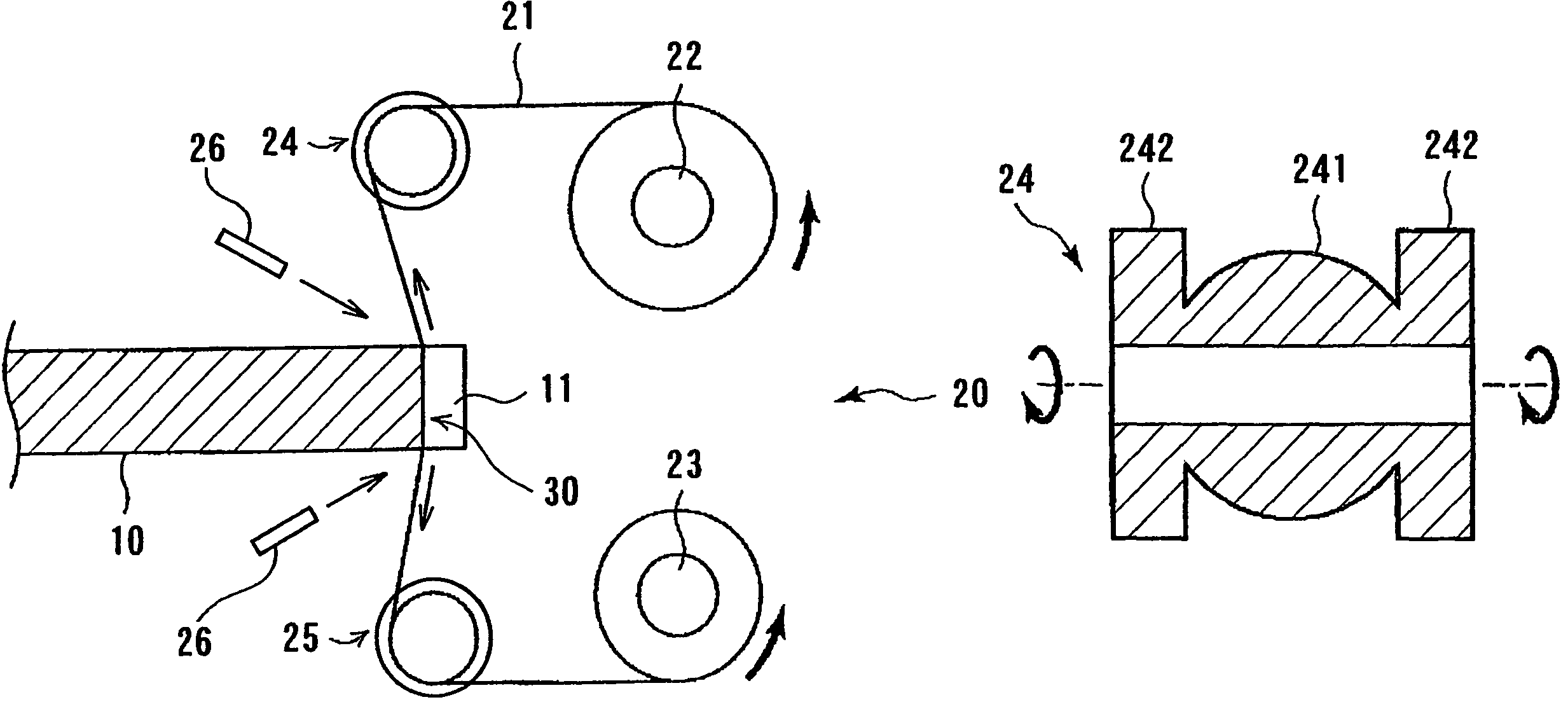

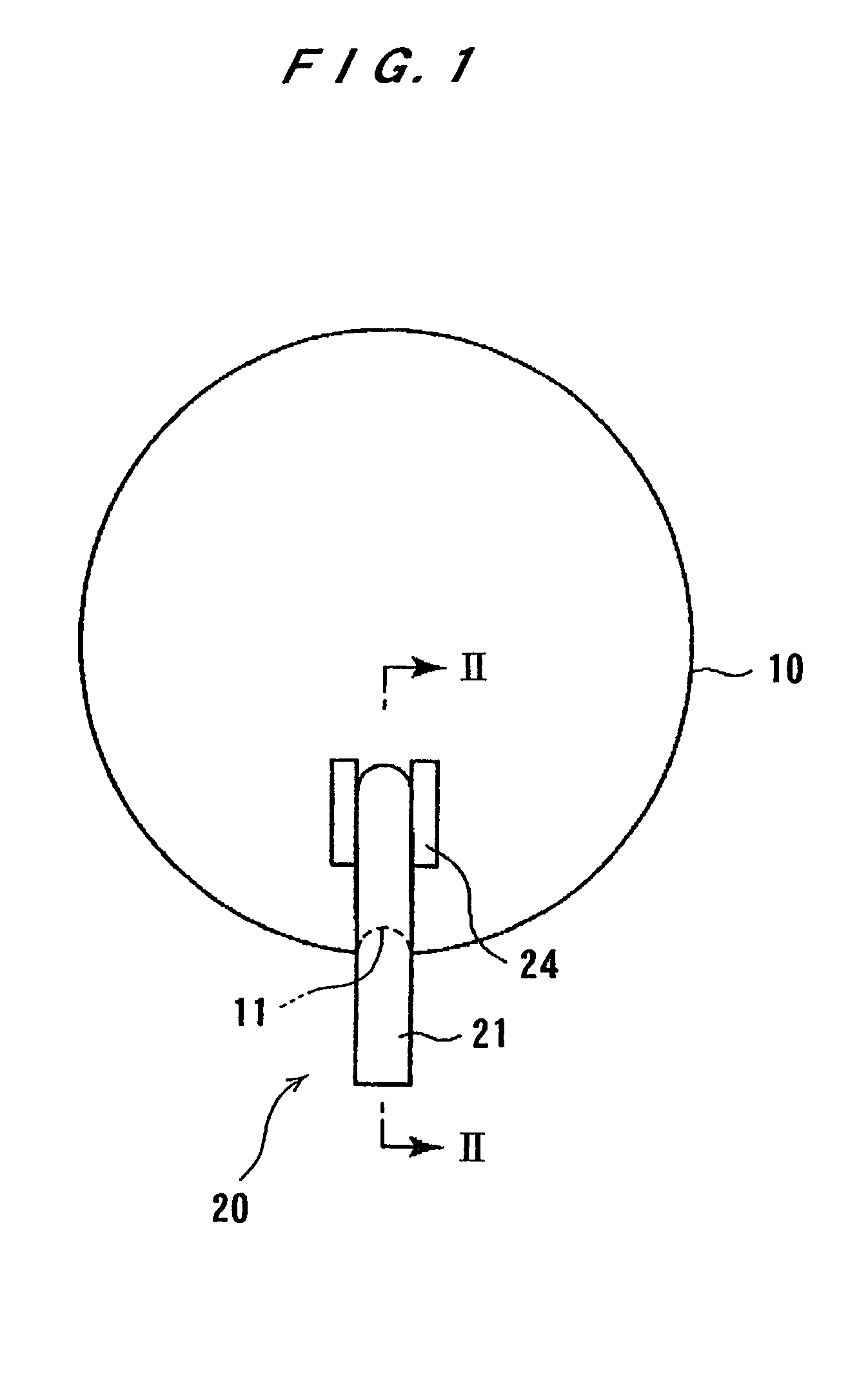

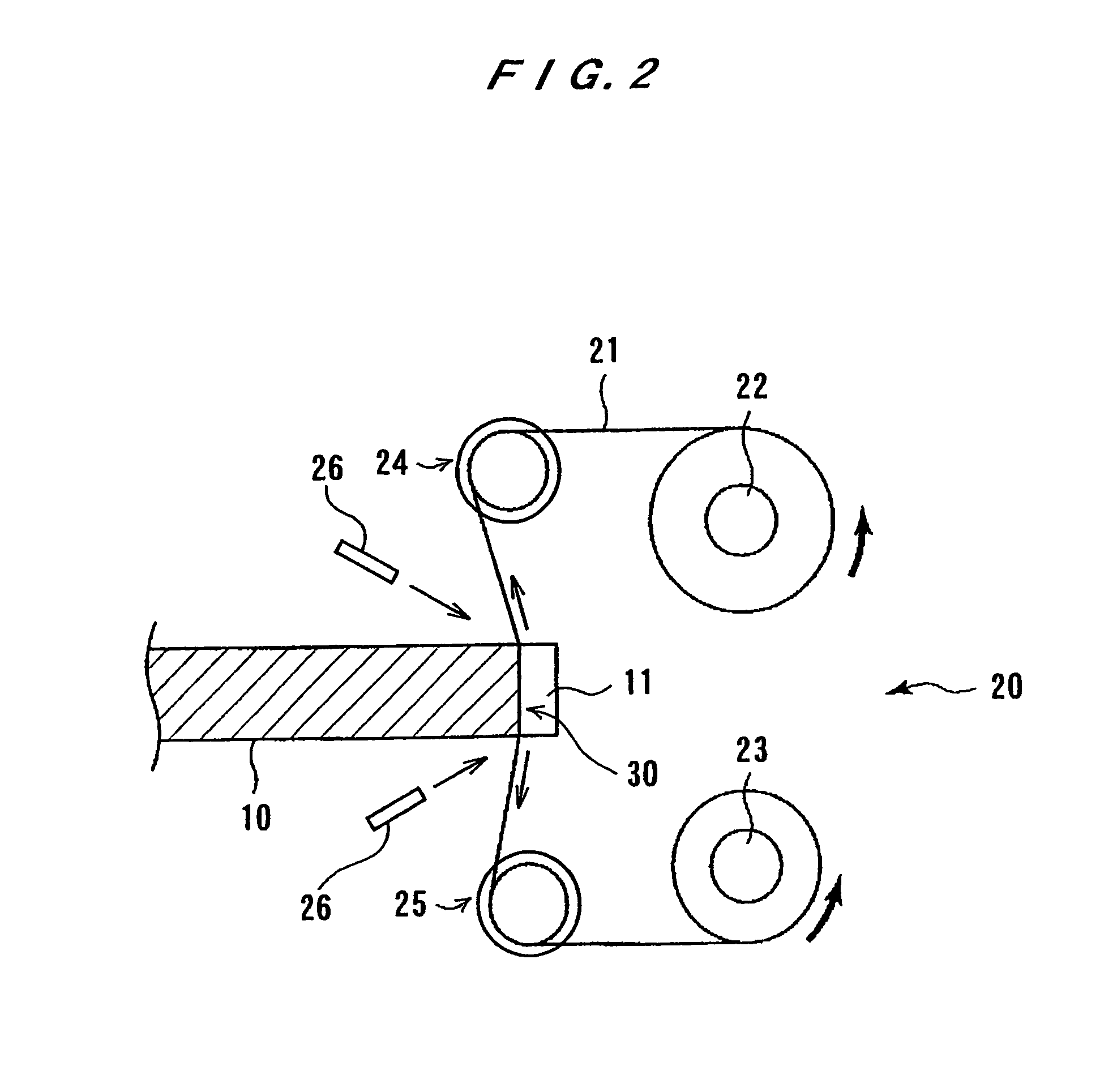

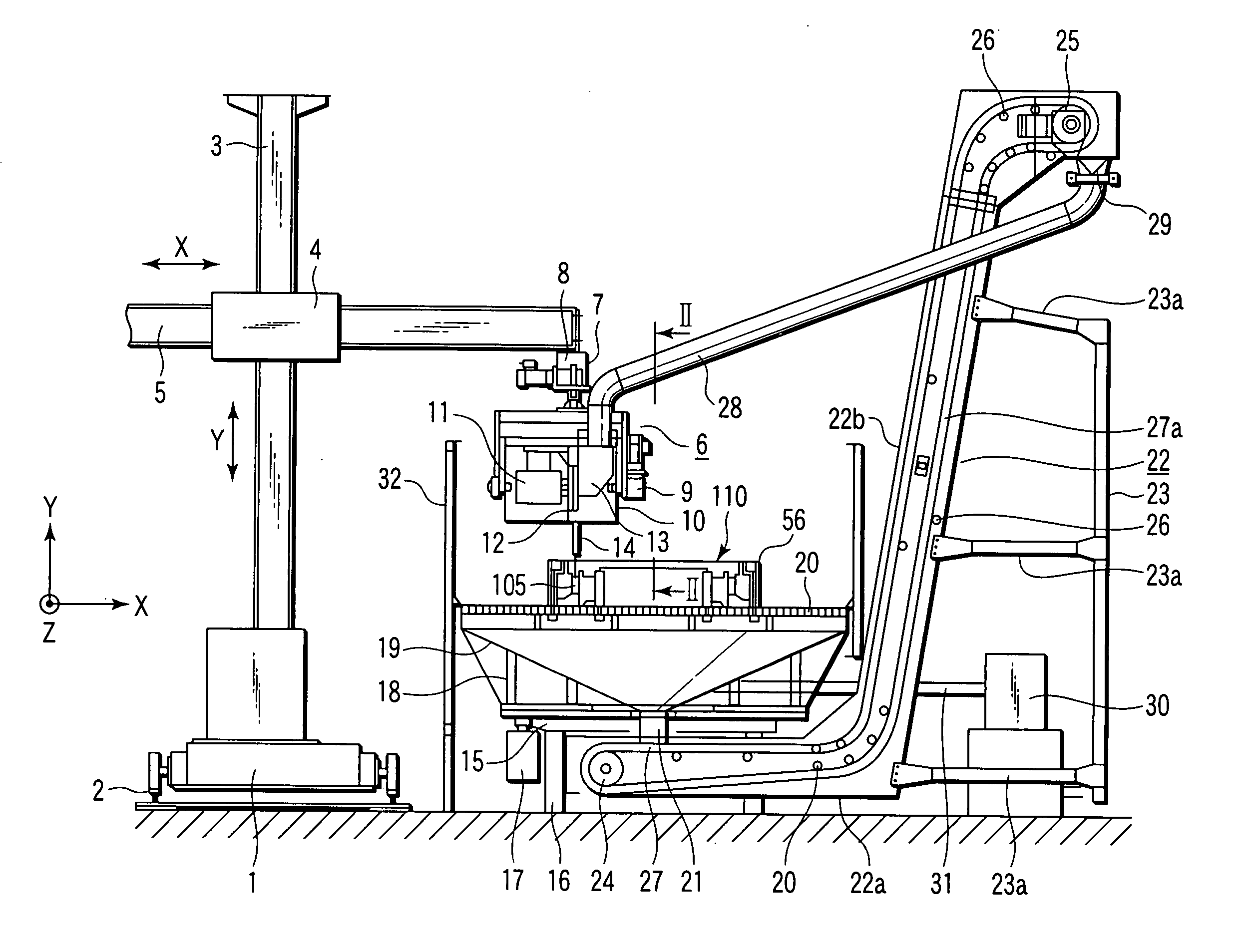

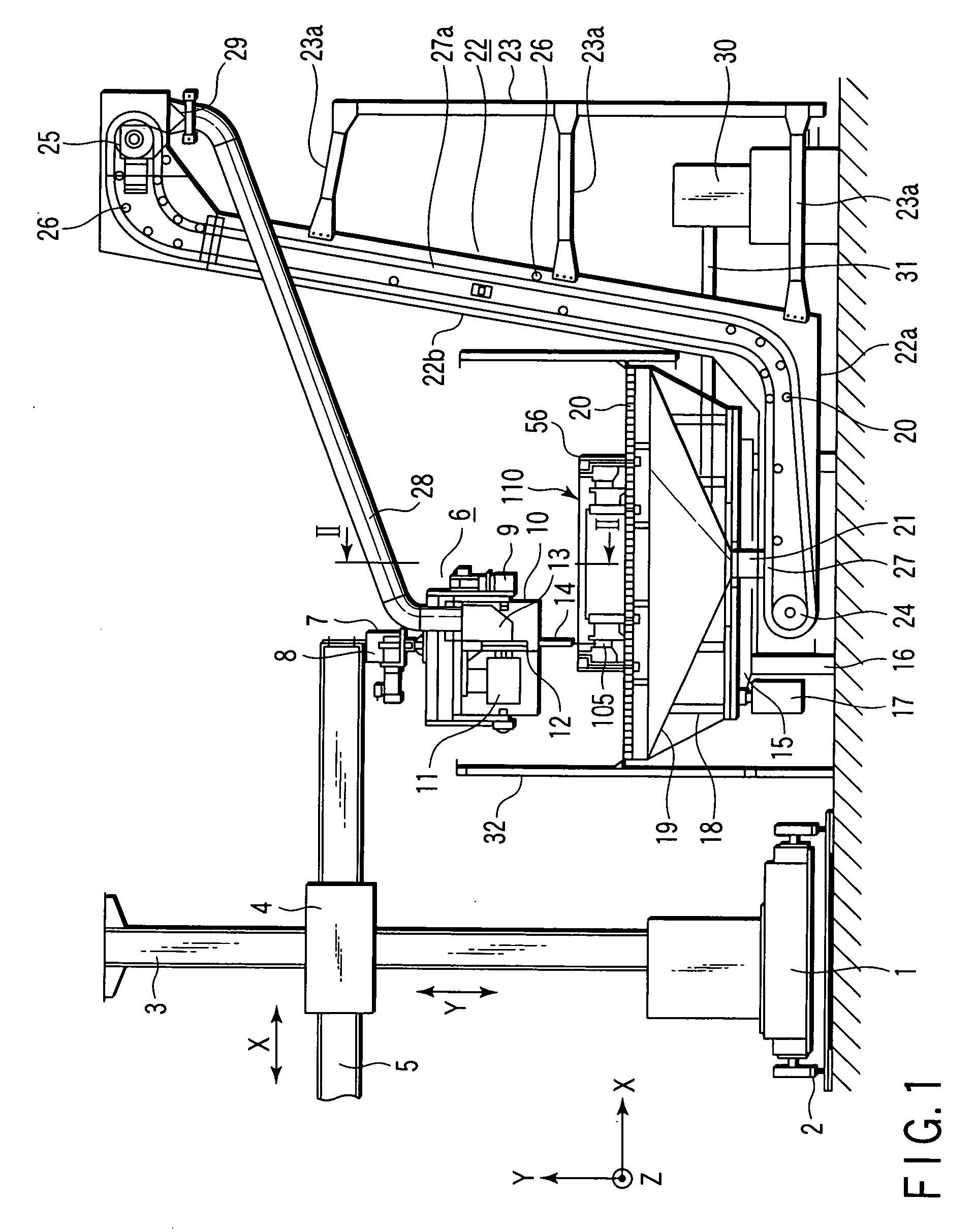

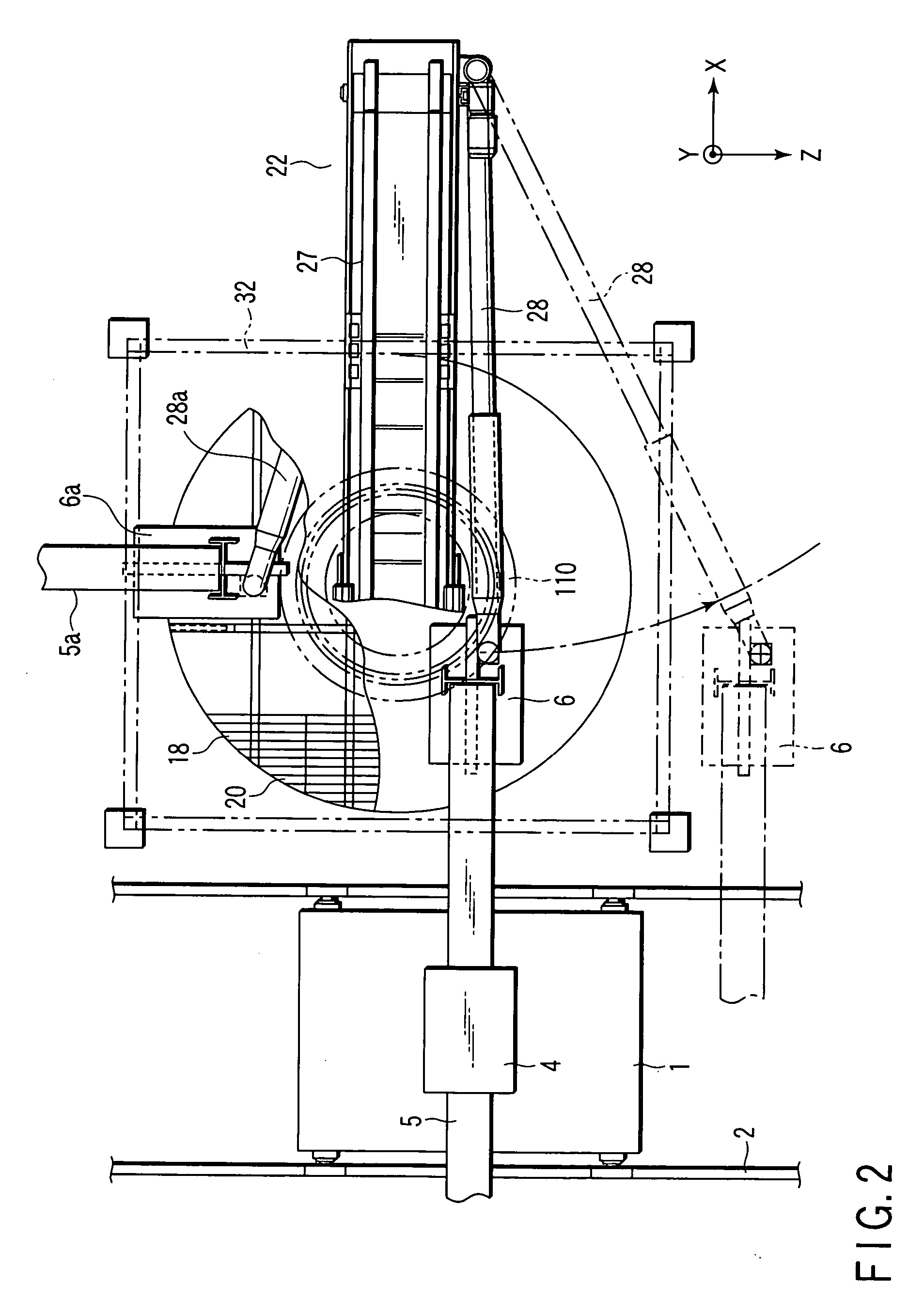

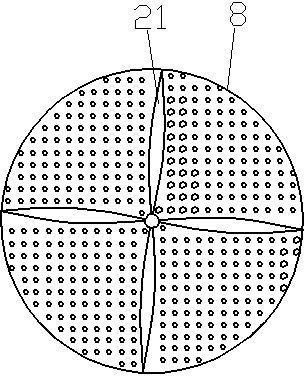

Polishing apparatus and polishing method

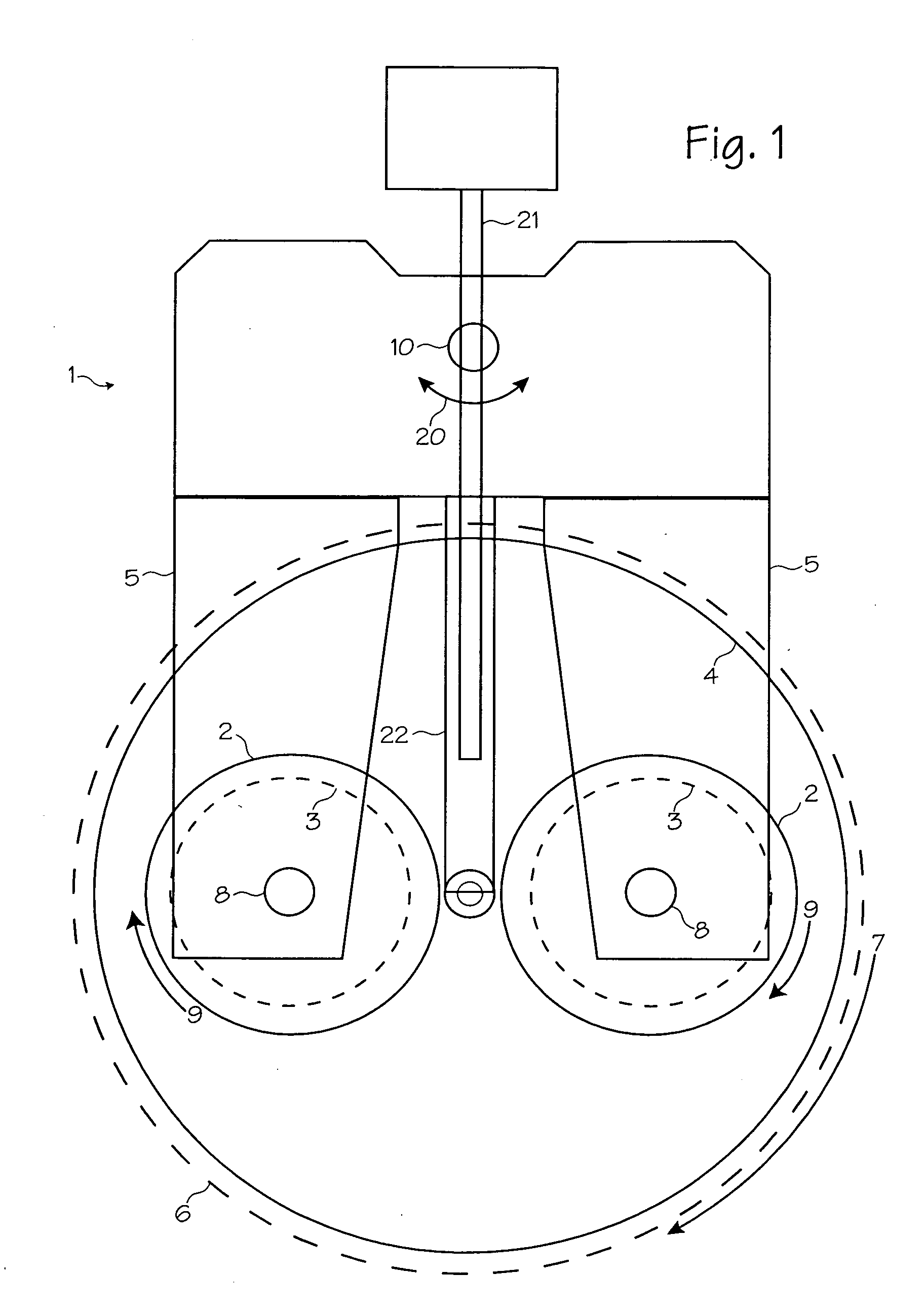

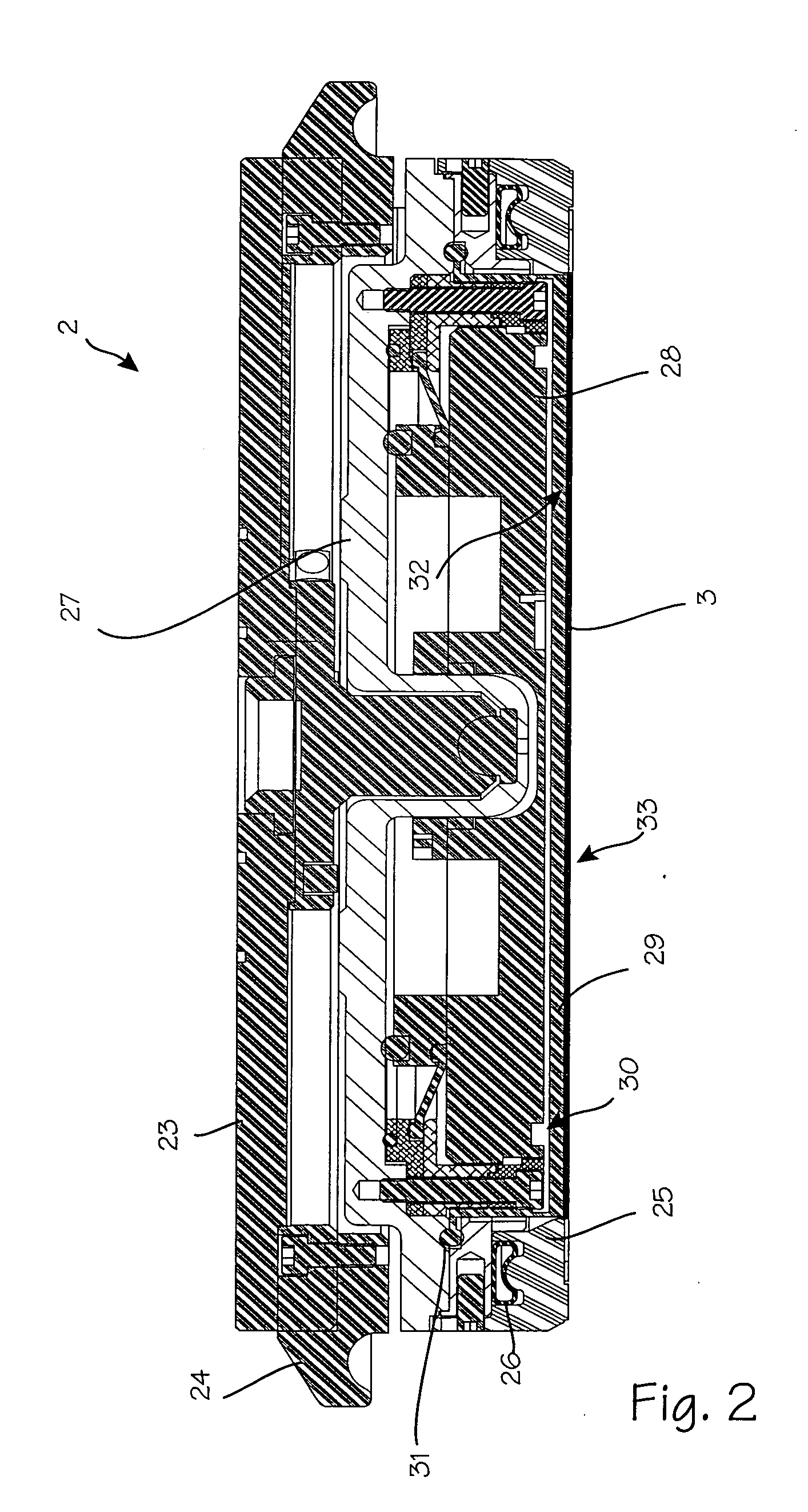

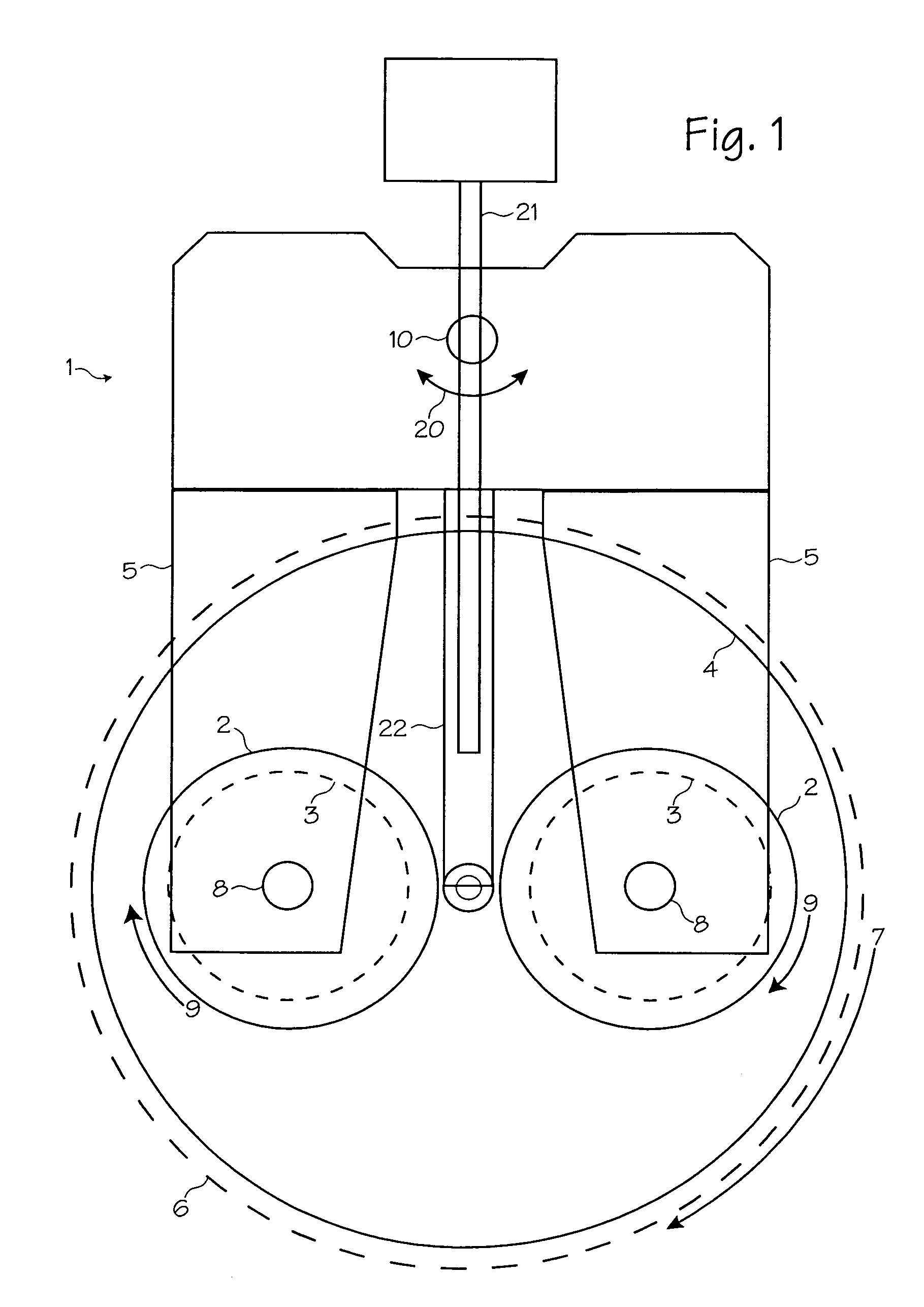

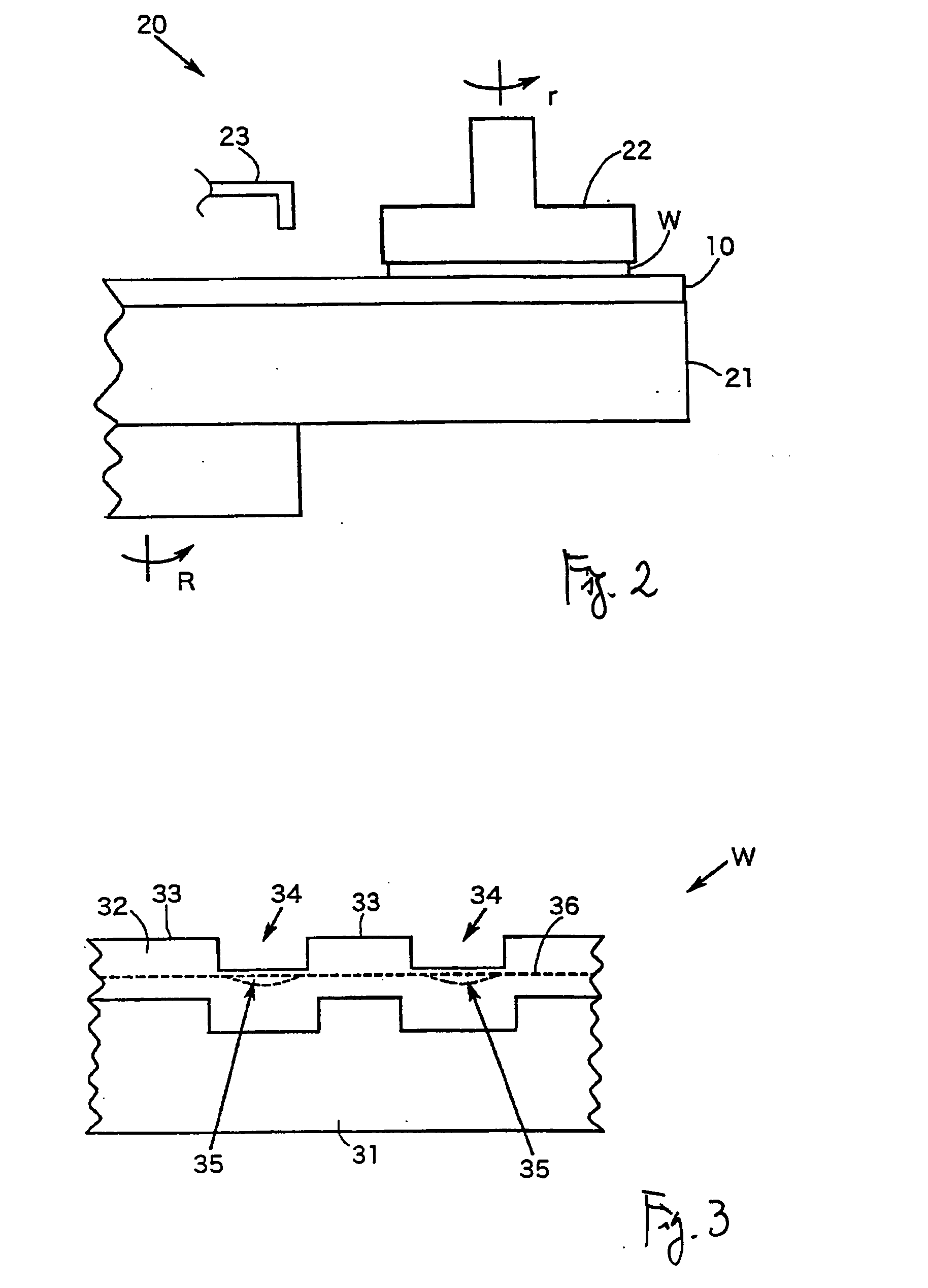

ActiveUS7744445B2Increase speedPolished evenlyEdge grinding machinesBelt grinding machinesMechanical engineeringEngineering

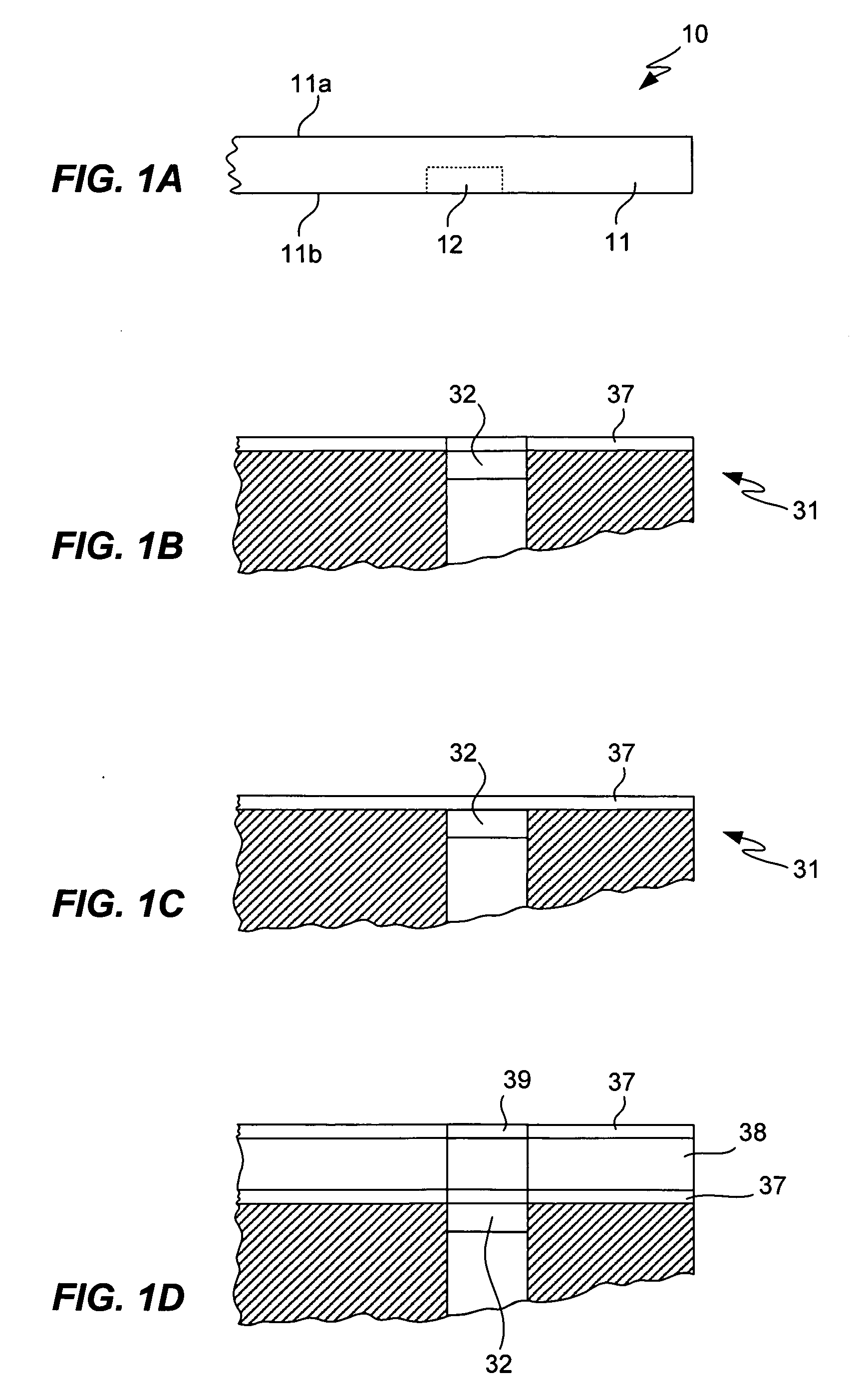

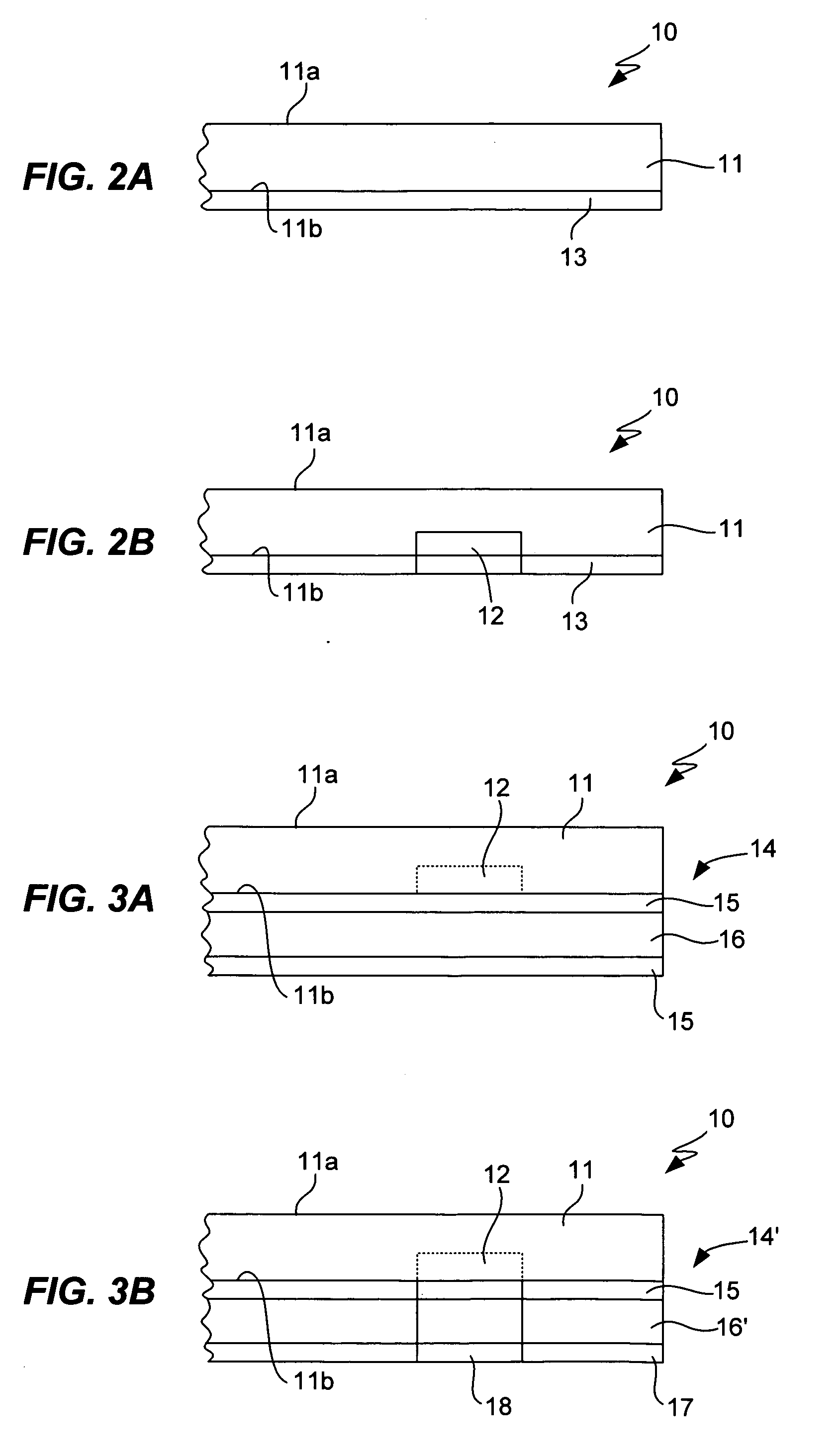

A polishing apparatus has a polishing tape (21), a supply reel (22) for supplying the polishing tape (21) to a contact portion (30) at which the polishing tape (21) is brought into contact with a notch portion (11) of a substrate (10), and a take-up reel (23) for winding up the polishing tape (21) from the contact portion (30). The polishing apparatus also has a first guide portion (24) having as guide surface (241) for supplying the polishing tape (21) directly to the contact portion (30), and a second guide portion (25) having a guide surface for supplying the polishing tape (21) tot the take-up reel (23). The guide surface (241) of the first guide portion (24) and / or the guide surface of the second guide portion (25) has a shape corresponding to a shape of the notch portion (11) of the substrate (10).

Owner:EBARA CORP +1

Chemical mechanical polishing composite of stainless steel surface polishing

InactiveCN101654599ASuppression of surface defectsFacilitates mechanical polishing capabilitiesPolishing compositions with abrasivesPseudoboehmiteHydrated alumina

The invention relates to a chemical mechanical polishing composite of stainless steel surface polishing; the polishing composite is composed of grinding material, oxidizer, polishing accelerant, metalchelator, penetrant, and surfactant; the invention is characterized in that: aluminum oxide sol, namely hydrated alumina dispersed in acidic aqueous solution in sol state, is added, the hydrated alumina can be boehmite, fake boehmite, diaspore or gibbsite.

Owner:JIANGSU HAIXUN IND GROUP SHARE

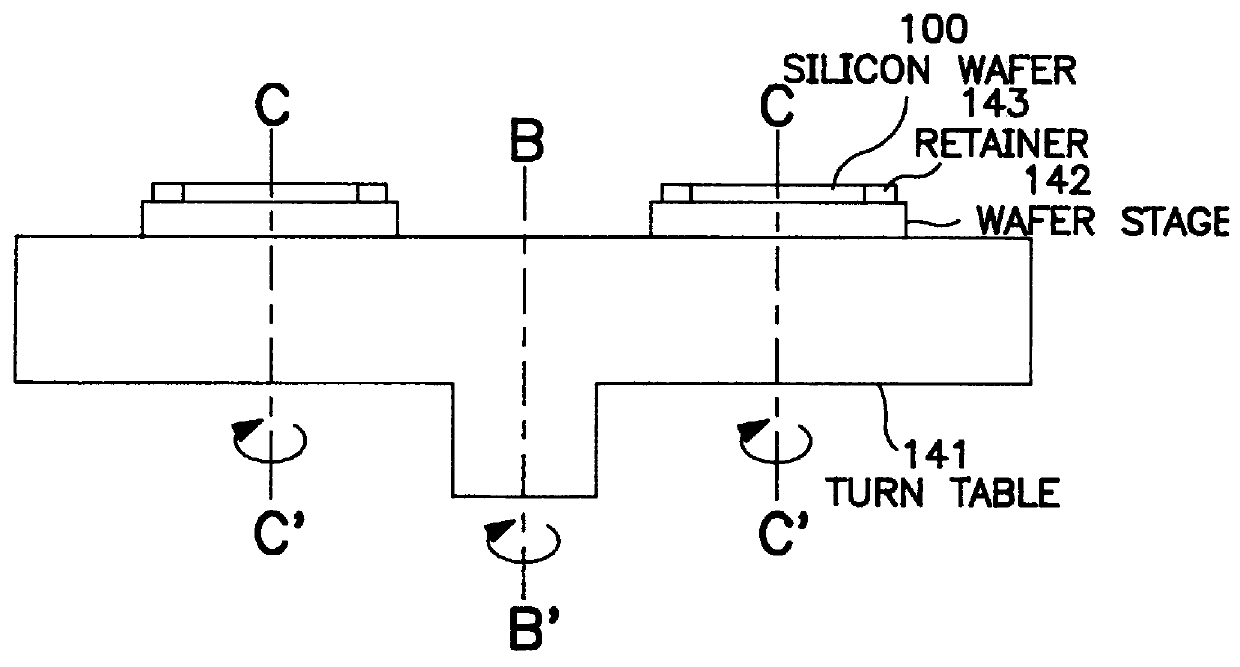

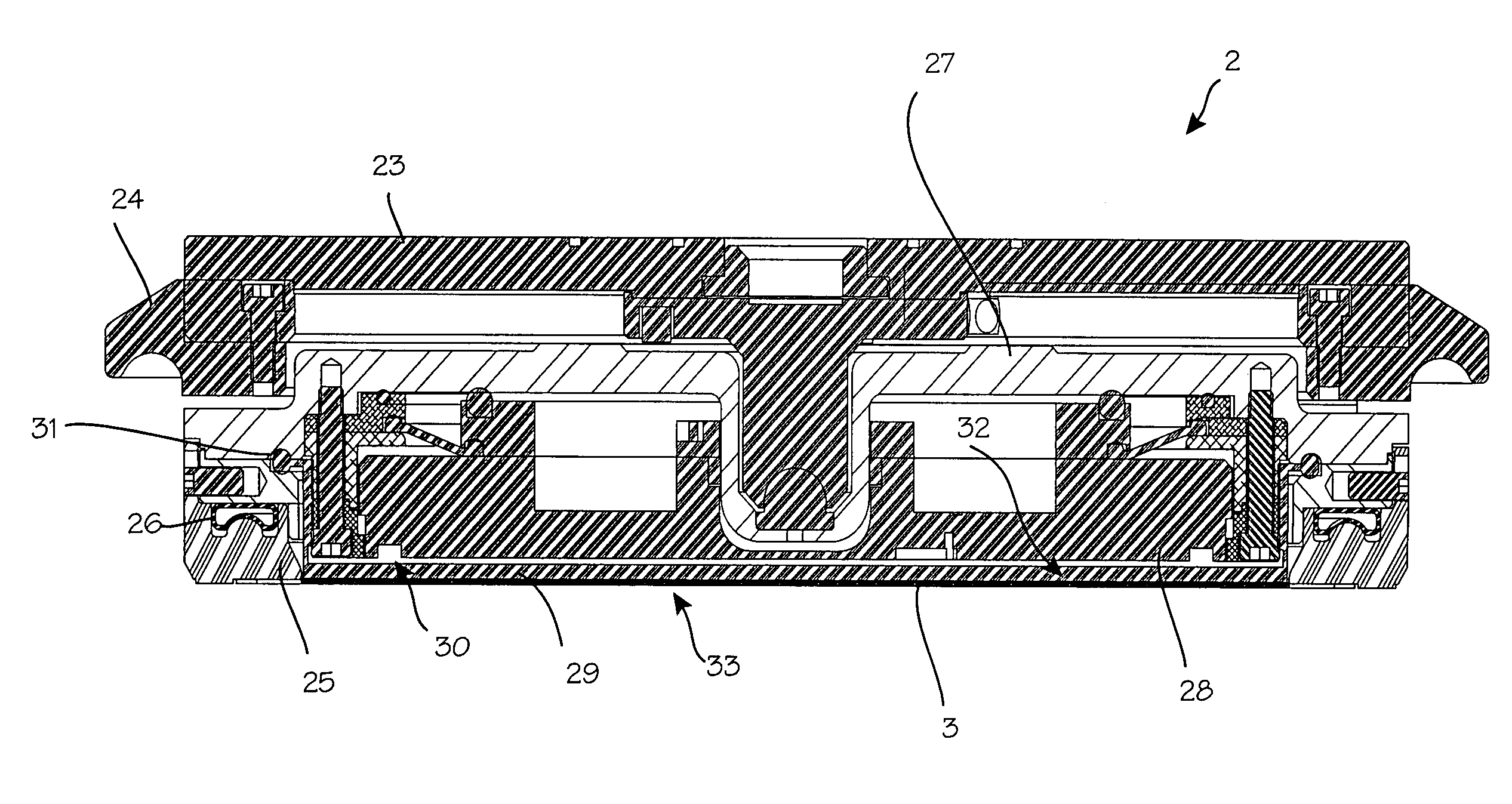

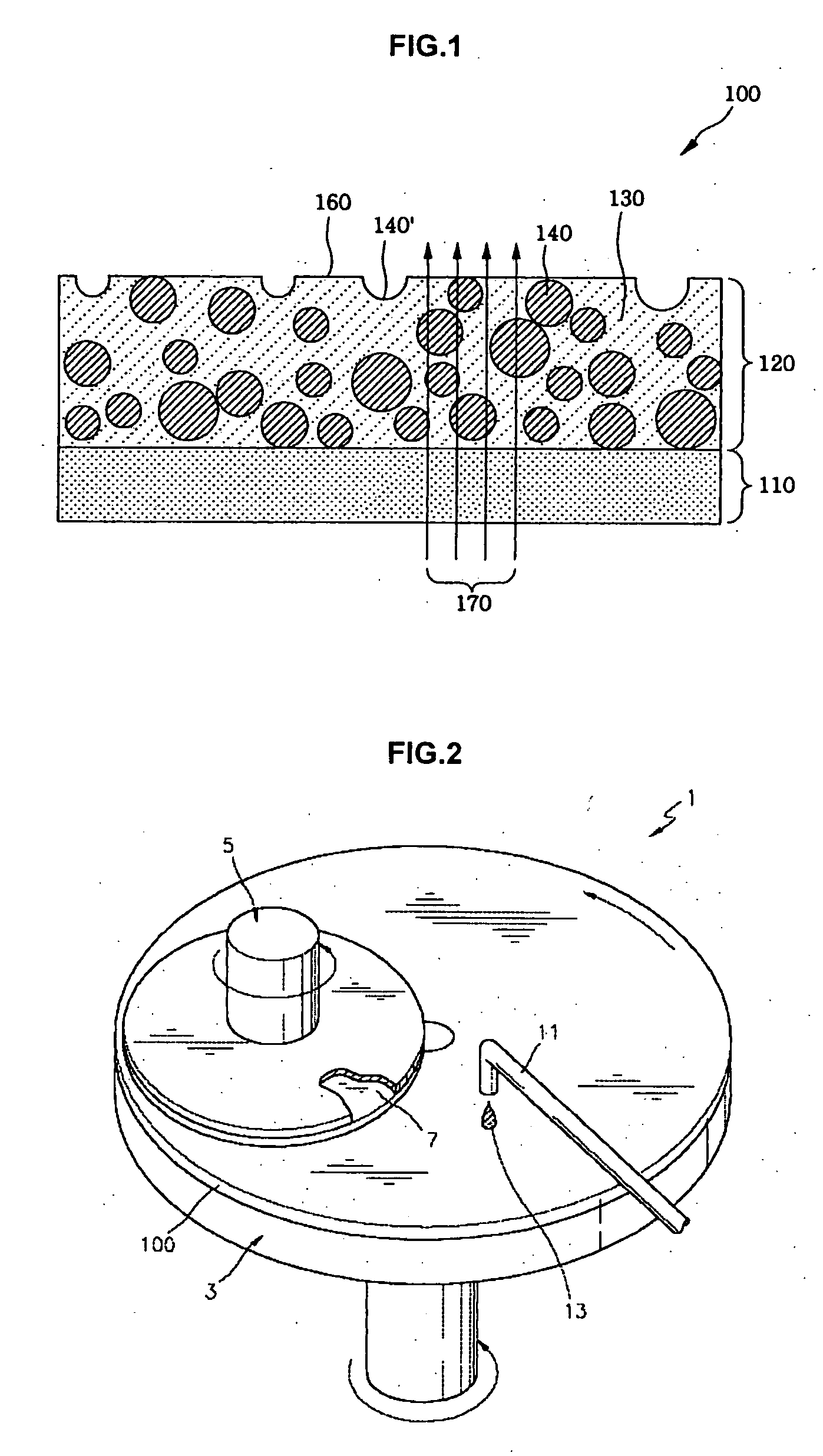

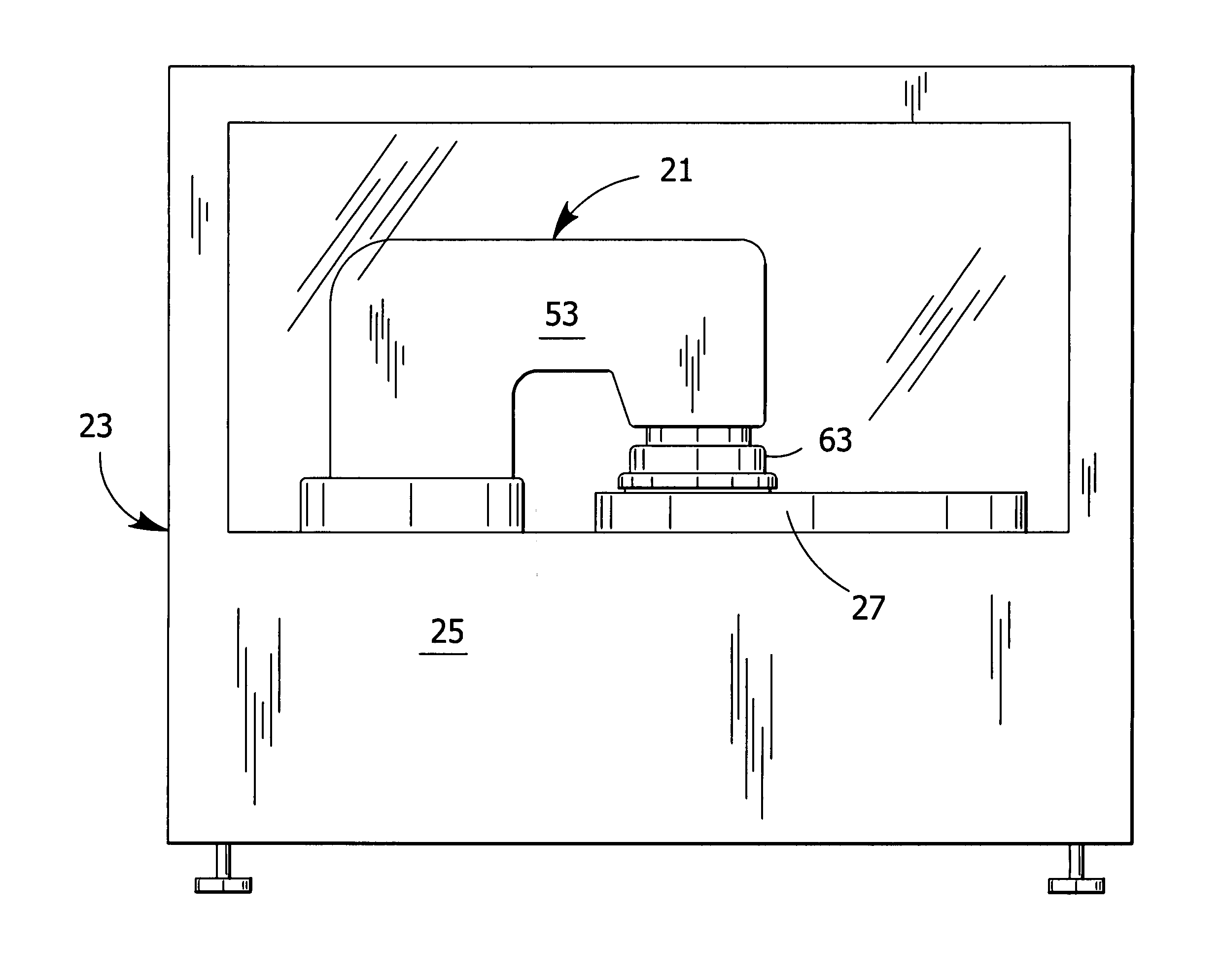

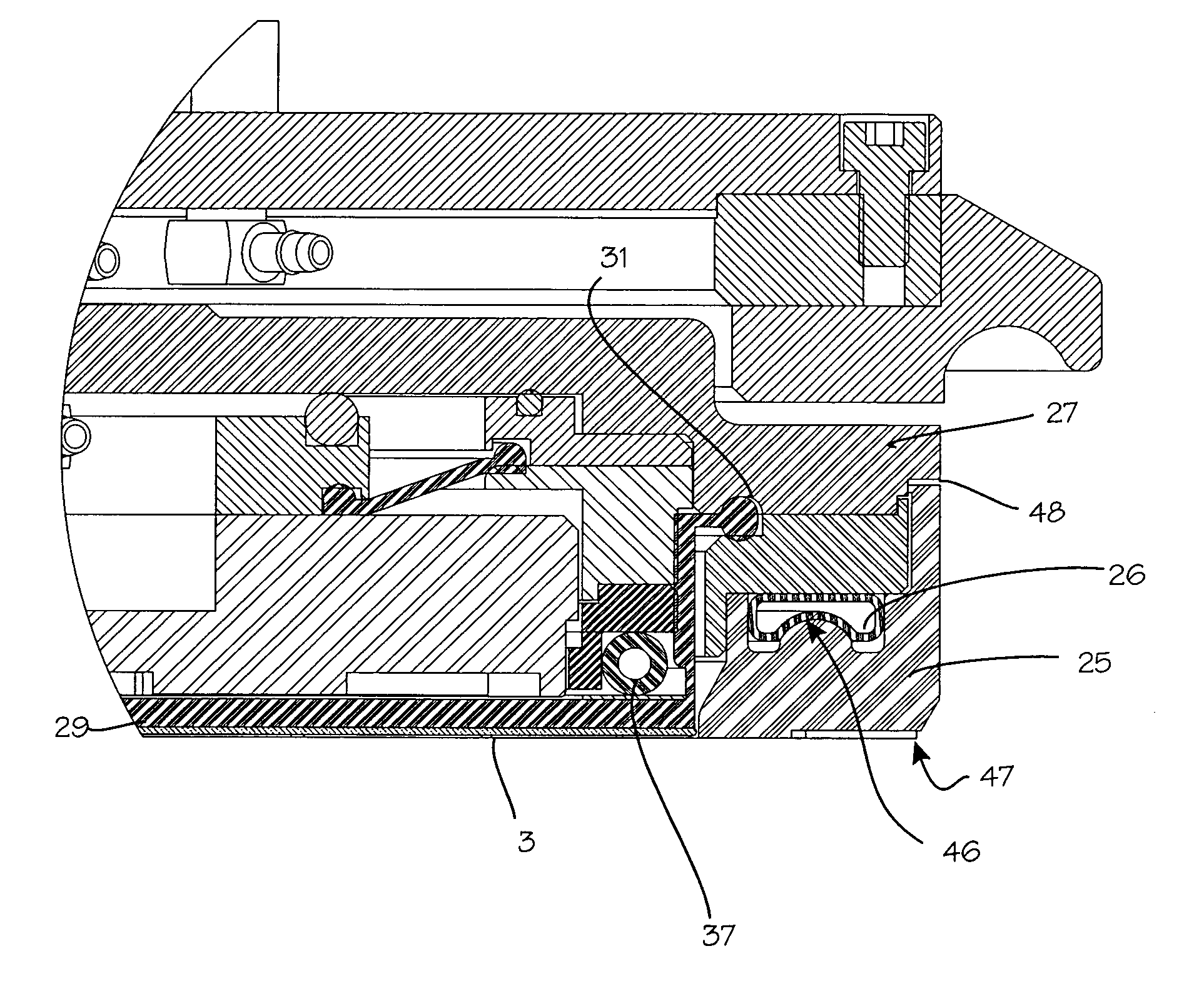

Semiconductor wafer, polishing apparatus and method

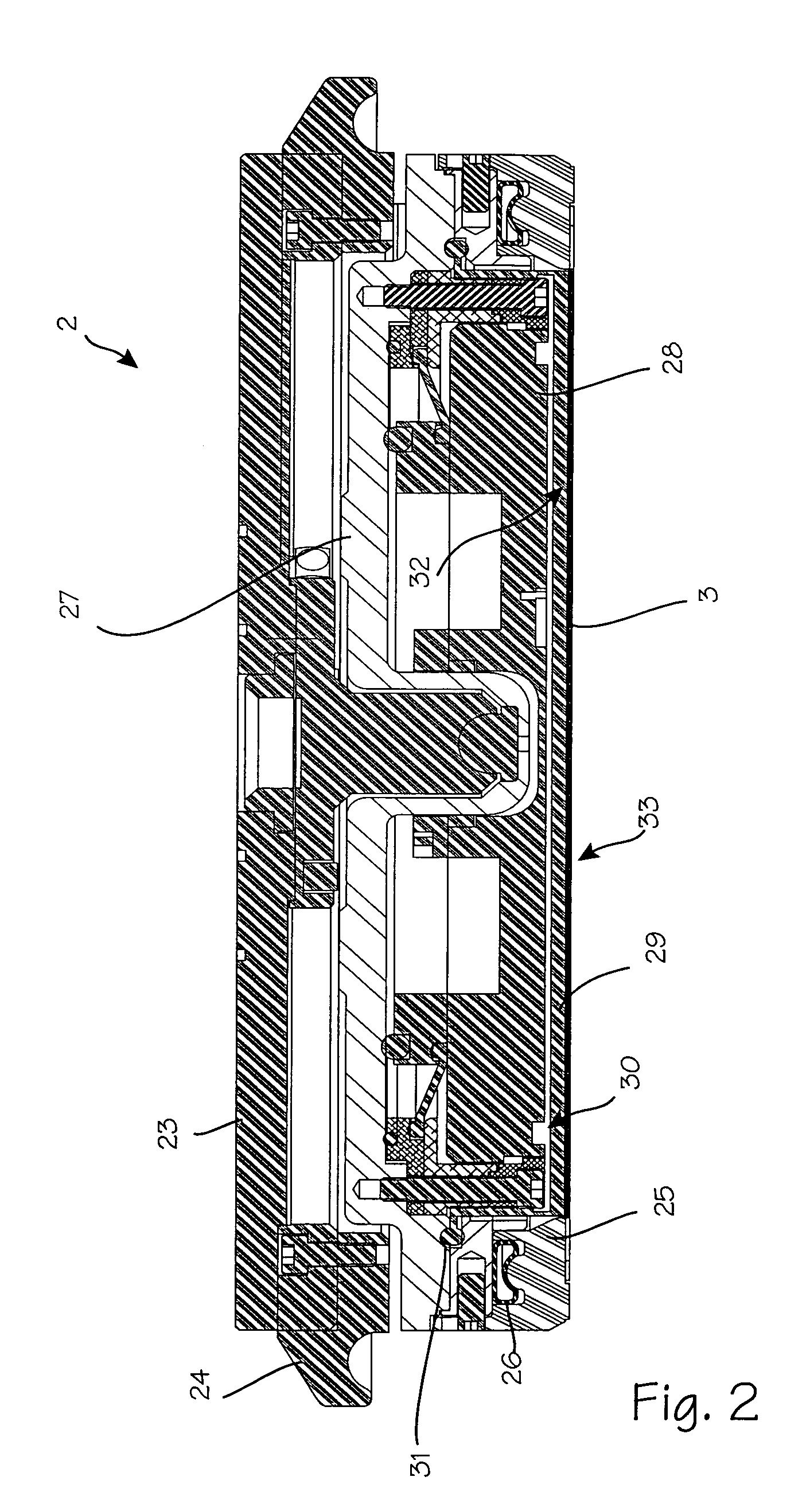

InactiveUS7137874B1Improve flatnessReduces wafer edge roll-offPolishing machinesRevolution surface grinding machinesSpherical bearingEngineering

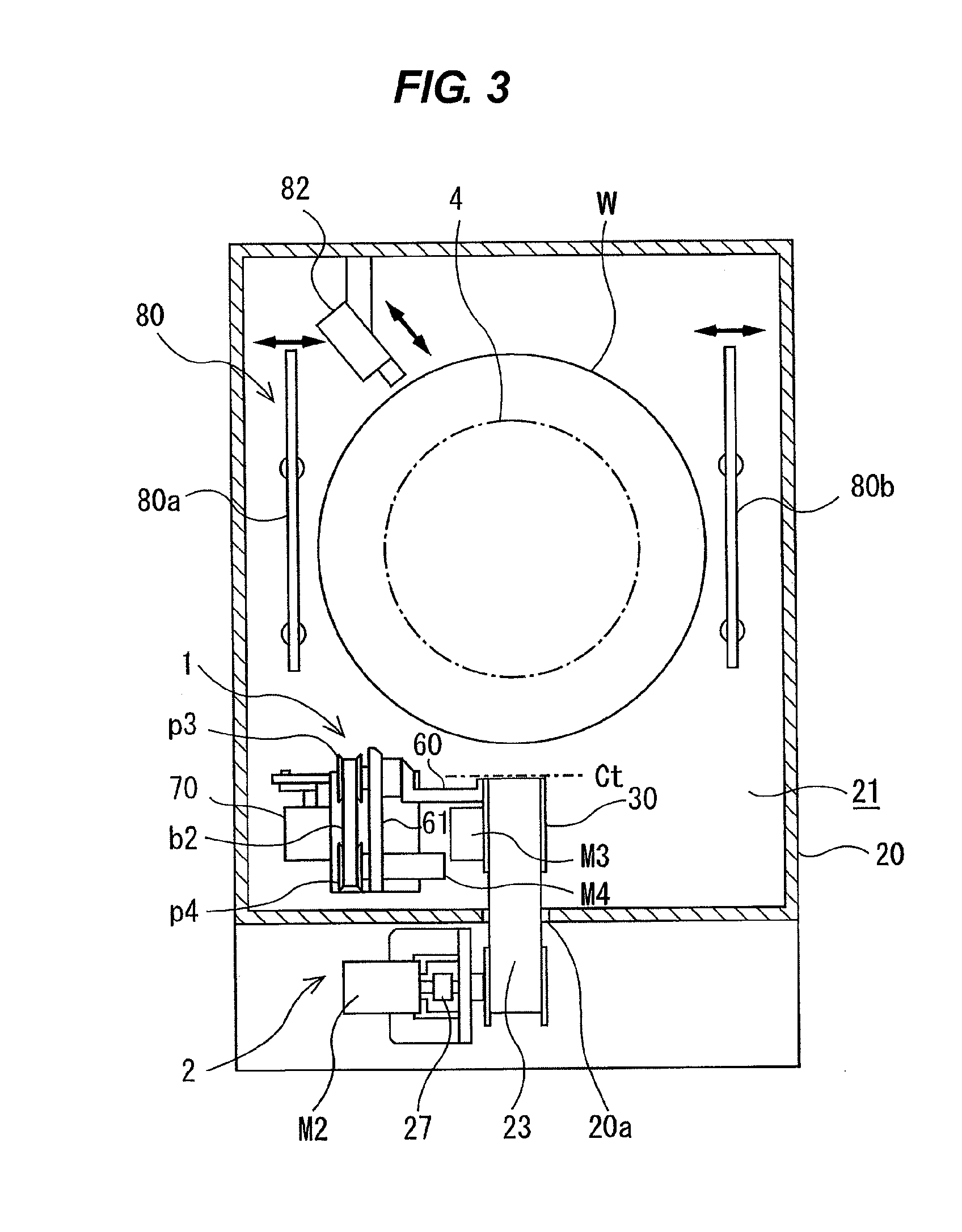

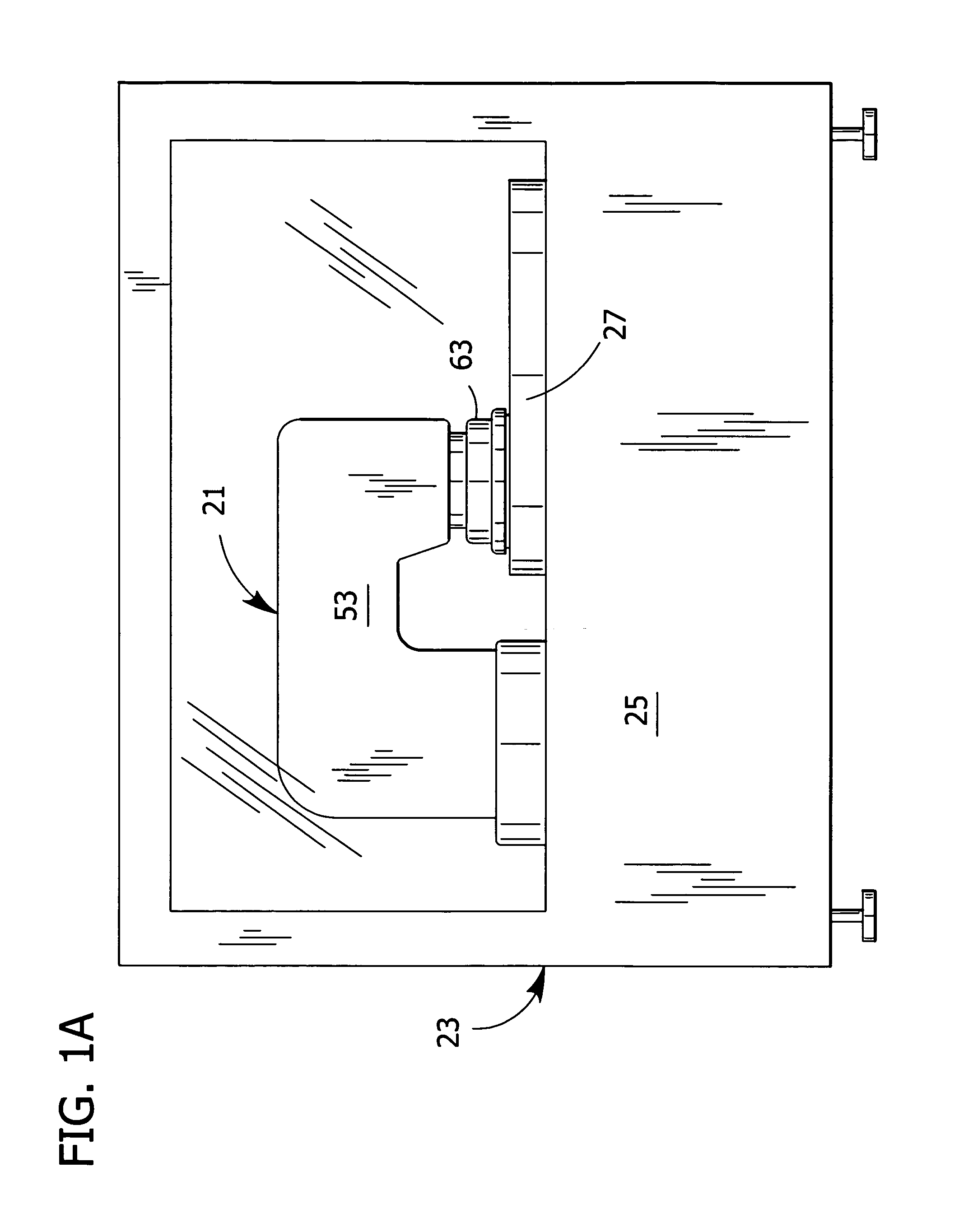

A wafer polishing apparatus for polishing a semiconductor wafer. The polisher comprises a base (23), a turntable (27), a polishing pad (29) and a drive mechanism (45) for driven rotation of a polishing head (63). The polishing head is adapted to hold at least one wafer (35) for engaging a front surface of the wafer with a work surface of the polishing pad. A spherical bearing assembly (75) mounts the polishing head (63) on the drive mechanism for pivoting of the polishing head about a gimbal point (p) lying no higher than the work surface when the polishing head holds the wafer in engagement with the polishing pad. This pivoting allowing the plane of the front surface of the wafer to continuously align itself to equalize polishing pressure over the front surface of the wafer, while rotation of the polishing head is driven by the driving mechanism. This maintains the front surface and work surface in a continuously parallel relationship for more uniform polishing of a semiconductor wafer, particularly near the lateral edge of the wafer. A cassette of wafers and method of polishing are also disclosed.

Owner:GLOBALWAFERS CO LTD

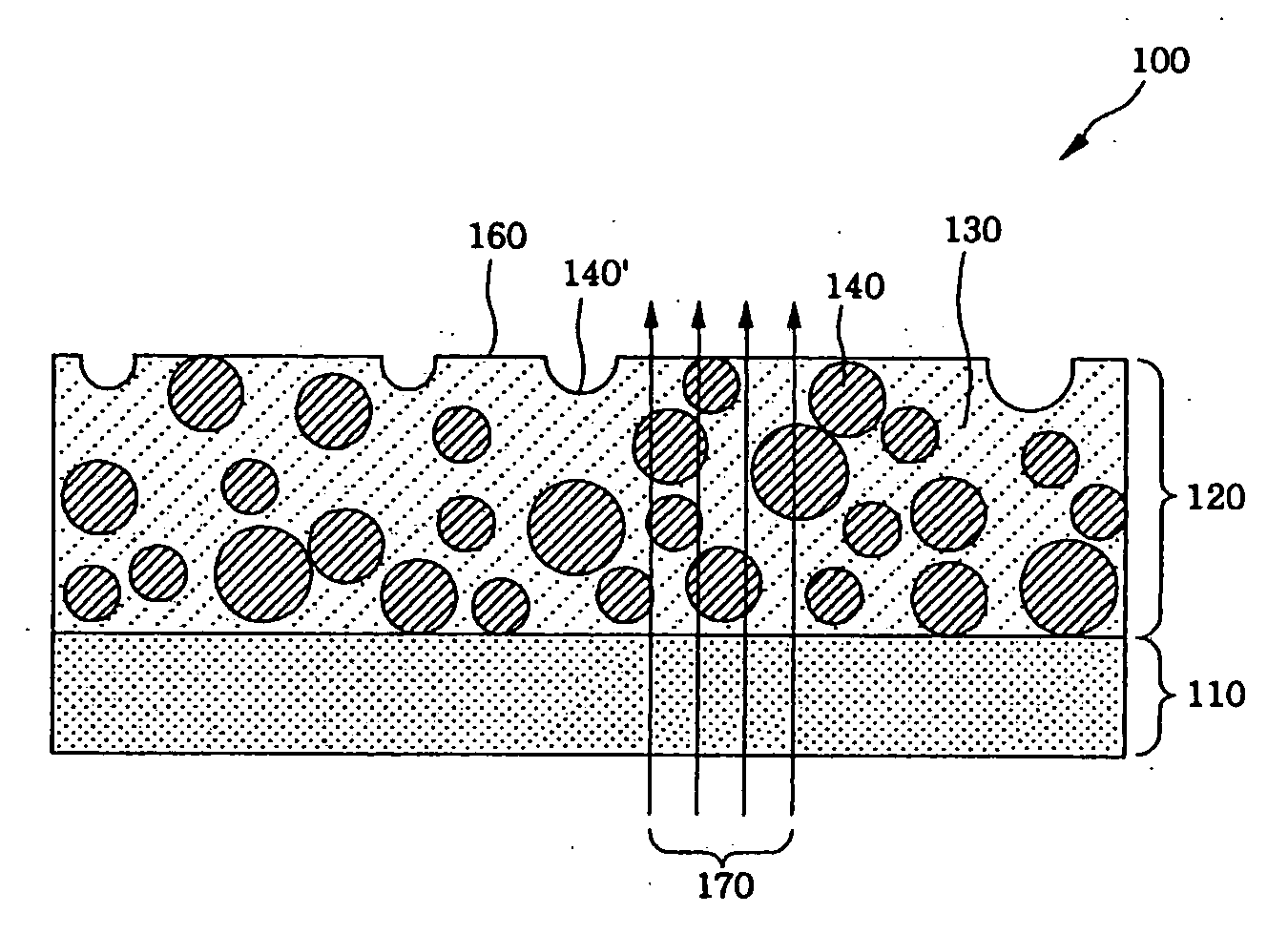

Polishing pad and method of producing same

InactiveUS20050142996A1Stably polishing the surface of a target object evenly and smoothlyHigh transparencySemiconductor/solid-state device manufacturingFlexible-parts wheelsSurface roughnessLength wave

A transparent pad having a polishing surface with an average surface roughness of 5 μm or less is used as a polishing pad. An indentation is formed on the back surface of the transparent pad such that its rate of light transmission is locally changed. The transparent pad has a rate of light transmission equal to or greater than 10% or preferably 30% for light of at least one wavelength in the range of 350 nm-900 nm.

Owner:NIHON MICRO COATING

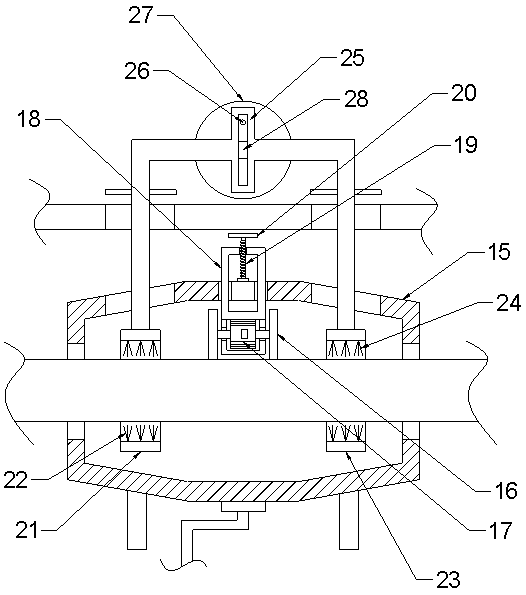

Large part polishing apparatus and polishing method

InactiveUS20060111025A1Reduce surface roughnessPolish surfaceImpeller wheelsRotor bladesImpellerDrive motor

The present invention comprises a turntable which holds a turbine part at a predetermined position, the turn table being rotatably supported by a support member, and rotated and driven by a driving motor, an abrasive feeding unit which feeds an abrasive particle having an elastic material as a core to a predetermined position as an abrasive, and a polishing head including an impeller which is rotated and driven by an impeller driving motor at high speed and applies rotary energy to the abrasive particle to be supplied from the abrasive feeding unit, the polishing head injecting the abrasive particle flying from the tangential direction of the impeller at a predetermined speed toward a surface to be polished of the turbine part held on the turntable, and an abrasive recovery unit which recovers the abrasive particle provided for polishing of the turbine part from the polishing head, and feeding into the abrasive feeding unit.

Owner:KK TOSHIBA

Wafer carrier with pressurized membrane and retaining ring actuator

ActiveUS7033252B2Reduce edge effectsPolished evenlyPolishing machinesRevolution surface grinding machinesEdge effectsEngineering

Owner:REVASUM INC +1

Building construction pipeline end surface processing device capable of conveniently fixing different sizes

ActiveCN109702578AImprove stabilityAdjustable grinding rangeEdge grinding machinesGrinding carriagesArchitectural engineeringSurface processing

The invention discloses a building construction pipeline end surface processing device capable of conveniently fixing different sizes. The building construction pipeline end surface processing devicecapable of conveniently fixing the different sizes comprises a bottom plate, a first telescopic rod is fixedly mounted on the upper surface of the left end of the bottom plate, a supporting plate is fixedly connected to the top end of the first telescopic rod, a first toothed disc is fixedly mounted at the right end of a handle, a rotary rod is movably connected into the upper end of the supporting plate, a movable barrel is connected to the middle of the rotary rod through bolts, a motor is fixedly connected to the upper end of a second telescopic rod, a second polishing block is fixedly mounted on the outer surface of a first polishing block, and third telescopic rods are connected to the outer surface of the right end of the rotary rod in an equal angle mode. According to the building construction pipeline end surface processing device capable of conveniently fixing the different sizes, polishing is comprehensive and uniform, the polishing degree and effect of an annular end surfacecan be controlled manually, a round supporting structure is arranged in a pipeline, the height and a clamping range of a pipeline clamping structure are convenient to adjust, and a device for integrally connecting sweeps is arranged.

Owner:RIZHAO POLYTECHNIC

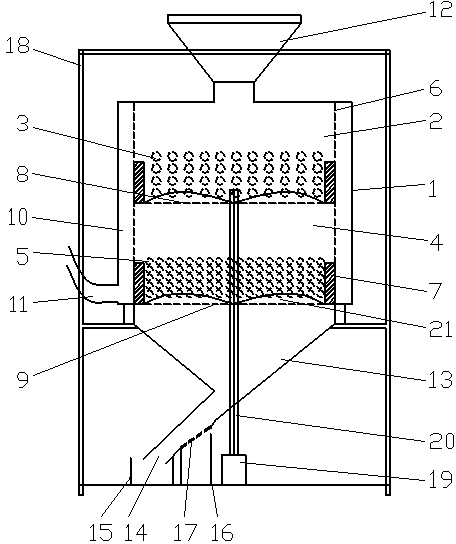

Processing and polishing device for steel ball production

ActiveCN104858762AEasy dischargeIncrease contact areaEdge grinding machinesSievingEngineeringSteel ball

The invention discloses a processing and polishing device for steel ball production. The processing and polishing device comprises a bracket, an external box body, an internal barrel body and a sieve plate, wherein the external box body is arranged on the bracket; the internal barrel body and the sieve plate are arranged in the external box body; the internal barrel body adopts a double-layer structure; a circular passage is formed between the outer wall and the inner wall; bulges are arranged on the inner wall of the internal barrel body; through holes are formed between the bulges; an elastic connecting piece is arranged at the lower end of the sieve plate; a material outlet is formed in the part, near the lower end of the sieve plate, of the external box body. Steel balls to be polished are added into the internal barrel body; the internal barrel body is driven to rotate through a driving device; the steel balls collide and rub with the bulges on the inner wall of the internal barrel body; powdered scrap generated during the steel ball polishing process enters the circular passage from the through holes. The device is good in polishing effect and high in working efficiency; the powdered scrap generated during the steel ball polishing can be timely separated from the steel balls; the impurity on the surfaces of the steel balls can be immediately removed after steel ball polishing is finished.

Owner:芜湖市永帆精密模具科技有限公司

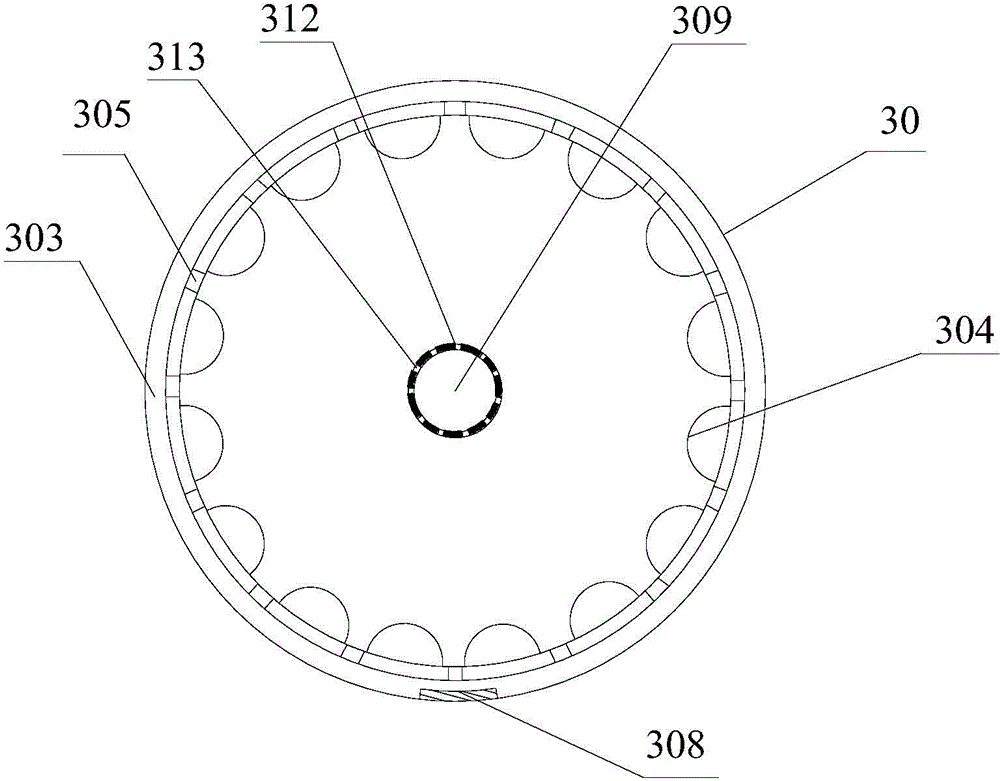

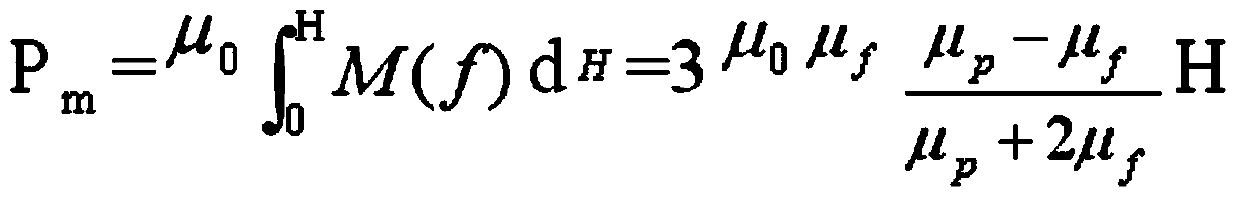

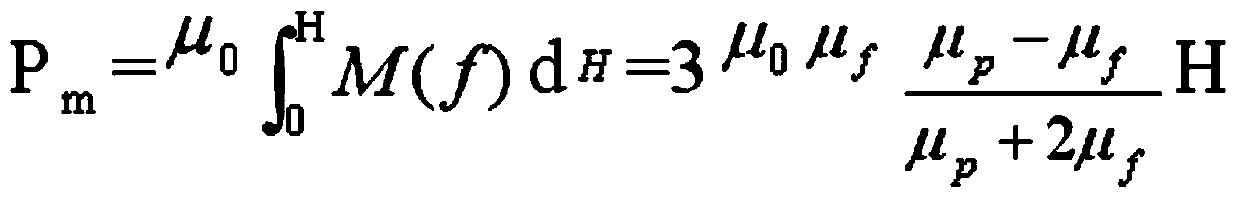

Magneto-rheological polishing method and tool

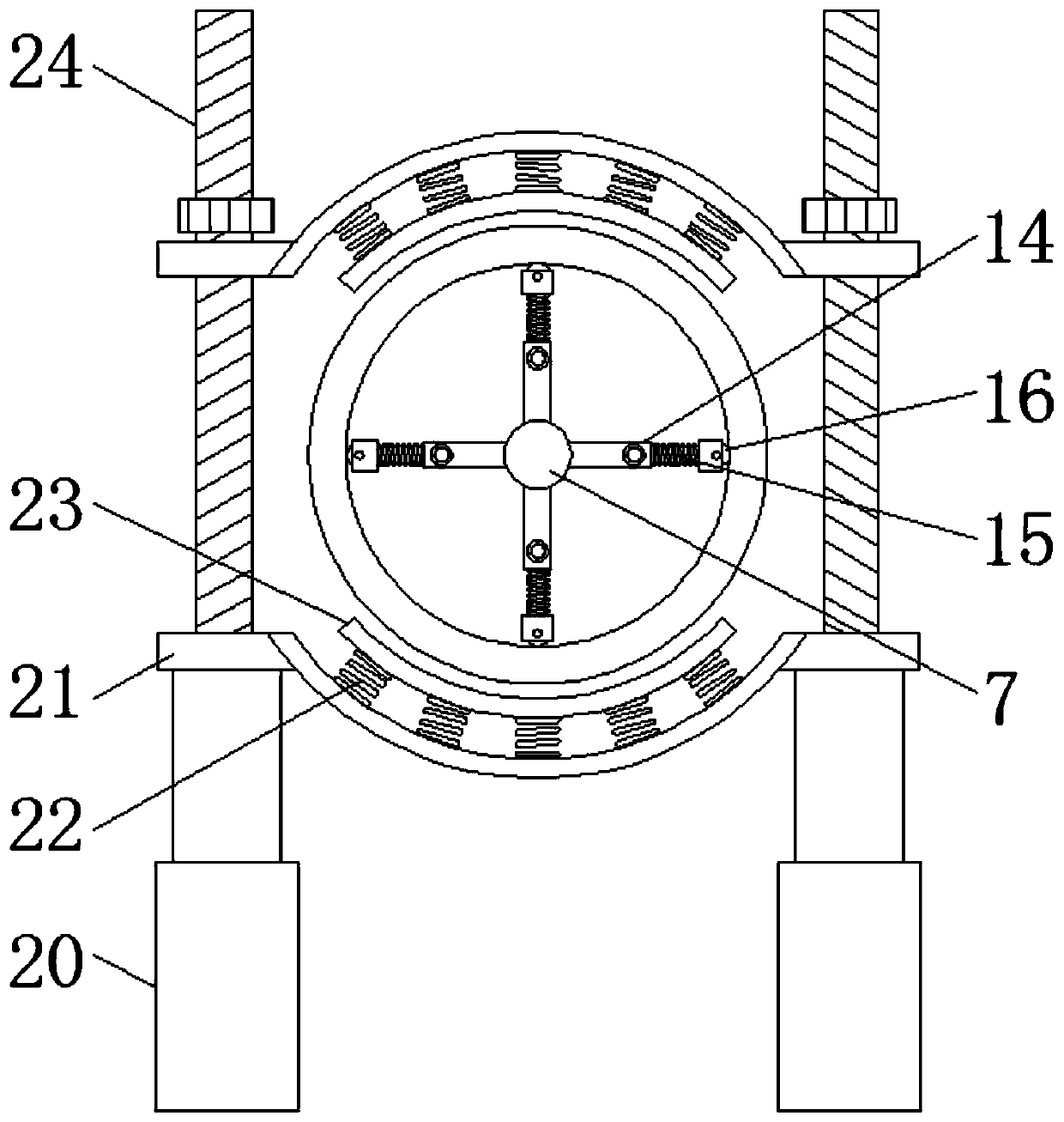

ActiveCN104191318AIndividual control of magnetic field strengthPolished evenlyMagnetic currentSurface type

The invention discloses a magneto-rheological polishing method and device. The magneto-rheological polishing method comprises the steps that surface type information of a workpiece is known; the position and polishing interval of the polishing tool are determined; the polishing interval is filled with magneto-rheological fluid; according to surface shape information of a polishing area and linear velocity distribution of all points in the polishing area, polishing pressure distribution is calculated when the removal rate is even; magnetic field distribution is obtained according to the pressure distribution through inverse solution; according to the obtained magnetic field distribution model, coil voltages of three layers of concentric circular electromagnets are changed respectively, so that magnetic field distribution in the radius direction meets the requirement; polishing is carried out. According to the magneto-rheological polishing method, the concentric circular electromagnets are of a nested structure and supply power to a collecting ring respectively, and therefore the purposes that magnetic fields at the same radius are the same in intensity and intensity of magnetic fields at different radii can be controlled separately are achieved.

Owner:ZHEJIANG FUSIDA TOOLS

Cup body polisher

InactiveCN102848296AReduce labor intensityImprove work efficiencyPolishing machinesGrinding drivesMechanical engineeringLinkage concept

The invention discloses a cup body polisher for polishing the outer surface of a cup, and aims at providing the cup body polisher capable of effectively reducing the labor intensity of an operator, improving the working efficiency, and realizing the uniform polishing. The key points of the technical scheme are as follows: the cup body polisher comprises a stander, wherein a polishing assembly and a polishing driving assembly for driving the polishing assembly to work are arranged on the stander, the polishing assembly comprises a polishing member, a polishing face is arranged on the polishing member, and the polishing member is in linkage connection with the polishing driving assembly; and a clamping assembly for clamping the cup body is arranged on the stander, the clamping assembly and the polishing face of the polishing member are arranged in parallel, and the clamping assembly comprises a clamping member for holding the cup body and abutting the cup body with the polishing face of the polishing member.

Owner:苍南县灵泉抛光机床制造有限公司

Polishing pad, method of producing same, and polishing method

InactiveUS20050020188A1Prevents from becoming easily cloggedHigh precisionSemiconductor/solid-state device manufacturingBonded abrasive wheelsSurface roughnessEngineering

Owner:NIHON MICRO COATING

Method of production of multilayer circuit board with built-in semiconductor chip

ActiveUS7134195B2Improve adhesionPolished evenlyPrinted circuit assemblingSubstation/switching arrangement detailsInsulation layerSemiconductor chip

A method of production of a multilayer circuit board comprised of a multilayer structure circuit formed by a plurality of interconnect layers and insulation layers stacked together and a semiconductor chip included therein, including the steps of placing a semiconductor chip having a polished back surface, with its active surface facing downward, on an already formed lower interconnect layer and forming an insulation layer over the layer on which the semiconductor chip has been placed, the method further including the step of treating the polished back surface of the semiconductor chip to improve its bondability with the insulation layer before the step for formation of the insulation layer.

Owner:SHINKO ELECTRIC IND CO LTD

Continuous production equipment

InactiveCN107263230ASimple structureEasy to useEdge grinding machinesPlane surface grinding machinesEngineeringMachining

The invention discloses continuous production equipment. The continuous production equipment is used for machining metal plates and at least comprises a machining table, guide tracks, a machining plate, a driving mechanism, a clamping portion and a machining portion. The guide tracks are horizontally mounted on the machining table, the machining plate is mounted on the guide tracks in a sliding mode, and the driving mechanism is used for driving the machining plate to move in the length direction of the guide tracks. The clamping portion comprises a plurality of clamping mechanisms and first gear racks, and the multiple clamping mechanisms are arranged in sequence in the length direction of the guide tracks. Each clamping mechanism comprises a supporting shaft, a bottom plate, a first gear, supporting plates, screw rods and pressing plates, wherein the supporting shaft is vertically mounted on the machining plate; the bottom plate is horizontally and rotationally mounted on the supporting shaft; the first gear is mounted on the bottom plate, and the center line of the first gear coincides with the center line of the supporting shaft; the supporting plates are arranged horizontally and connected with the bottom plate; threaded holes are formed in the supporting plates; and the screw rods are disposed in the threaded holes and matched with the threaded holes.

Owner:铜陵市得盛机电制品有限责任公司

Polishing grain type rice polishing machine

ActiveCN104258920APolished evenlyEfficient polishingGrain huskingGrain polishingBroken riceEngineering

The invention relates to the field of rice machining, in particular to a polishing grain type rice polishing machine. The polishing grain type rice polishing machine comprises a polishing barrel, a to-be-polished rice inlet, a polishing barrel hopper chamber and a polishing rice outlet, wherein the to-be-polished rice inlet is arranged above the polishing barrel, the polishing barrel hopper chamber is arranged below the polishing barrel, and the polishing rice outlet is arranged below the polishing barrel hopper chamber. The polishing chamber comprises an upper polishing chamber, coarse-grain polishing grains, a lower polishing chamber and fine-grain polishing grains, the upper polishing chamber and the lower polishing chamber are arranged on the upper portion and the lower portion of the polishing barrel respectively, and the coarse-grain polishing grains and the fine-grain polishing grains are filled in the upper polishing chamber and the lower polishing chamber respectively. The polishing grain type rice polishing machine can well polish rice uniformly, and broken rice rate is decreased.

Owner:南雄市香溢工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com