Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "Uneven wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

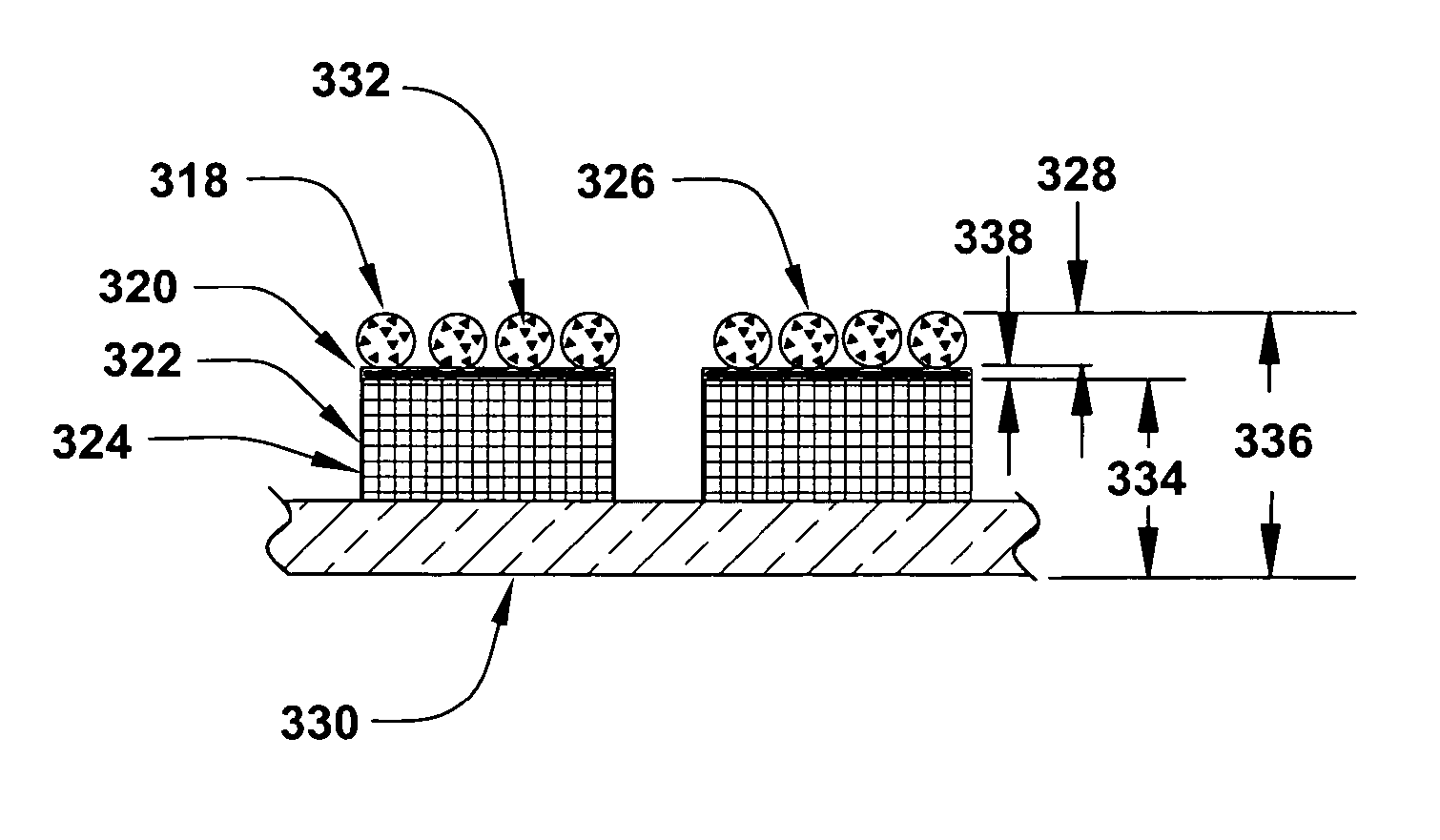

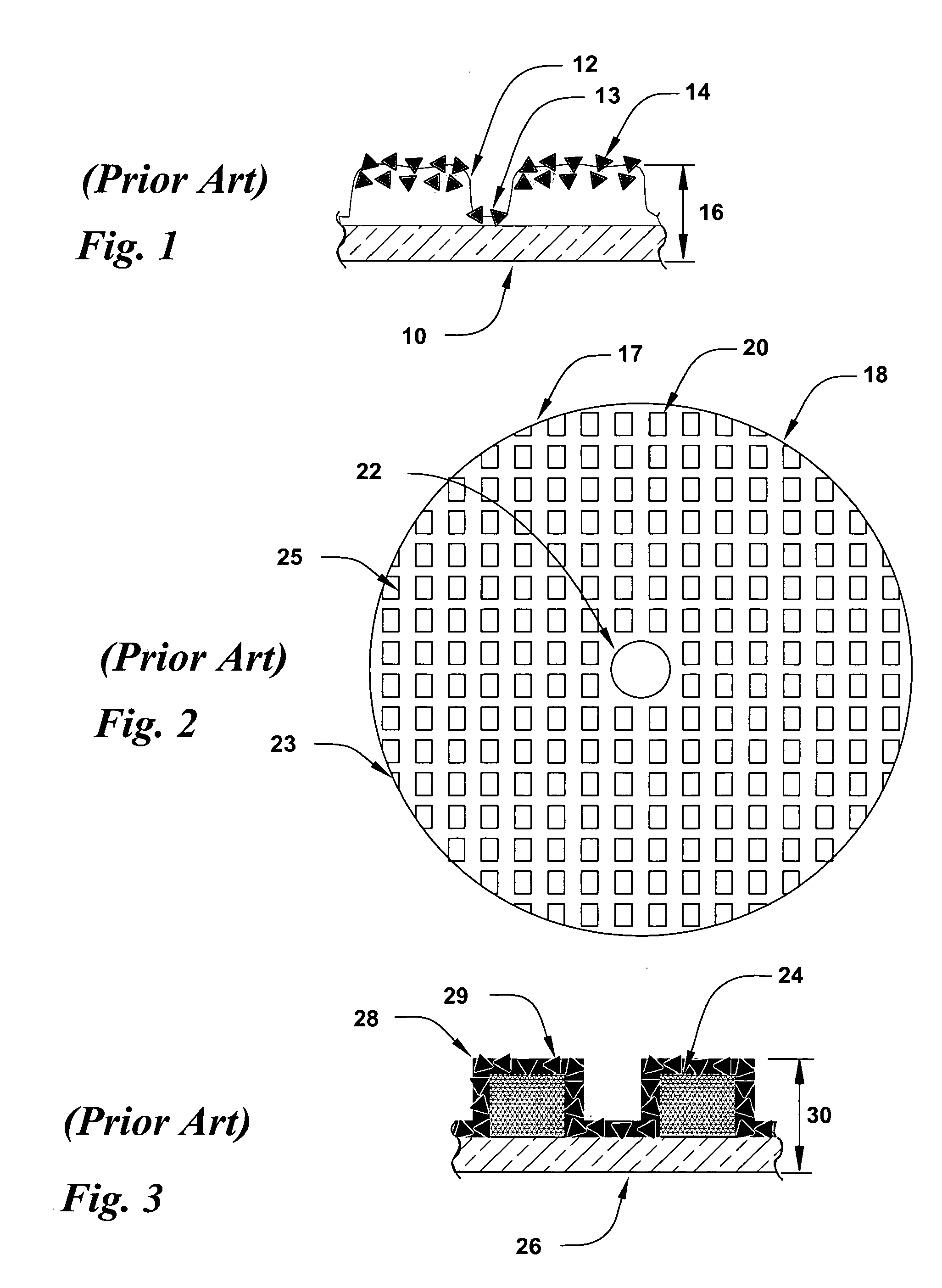

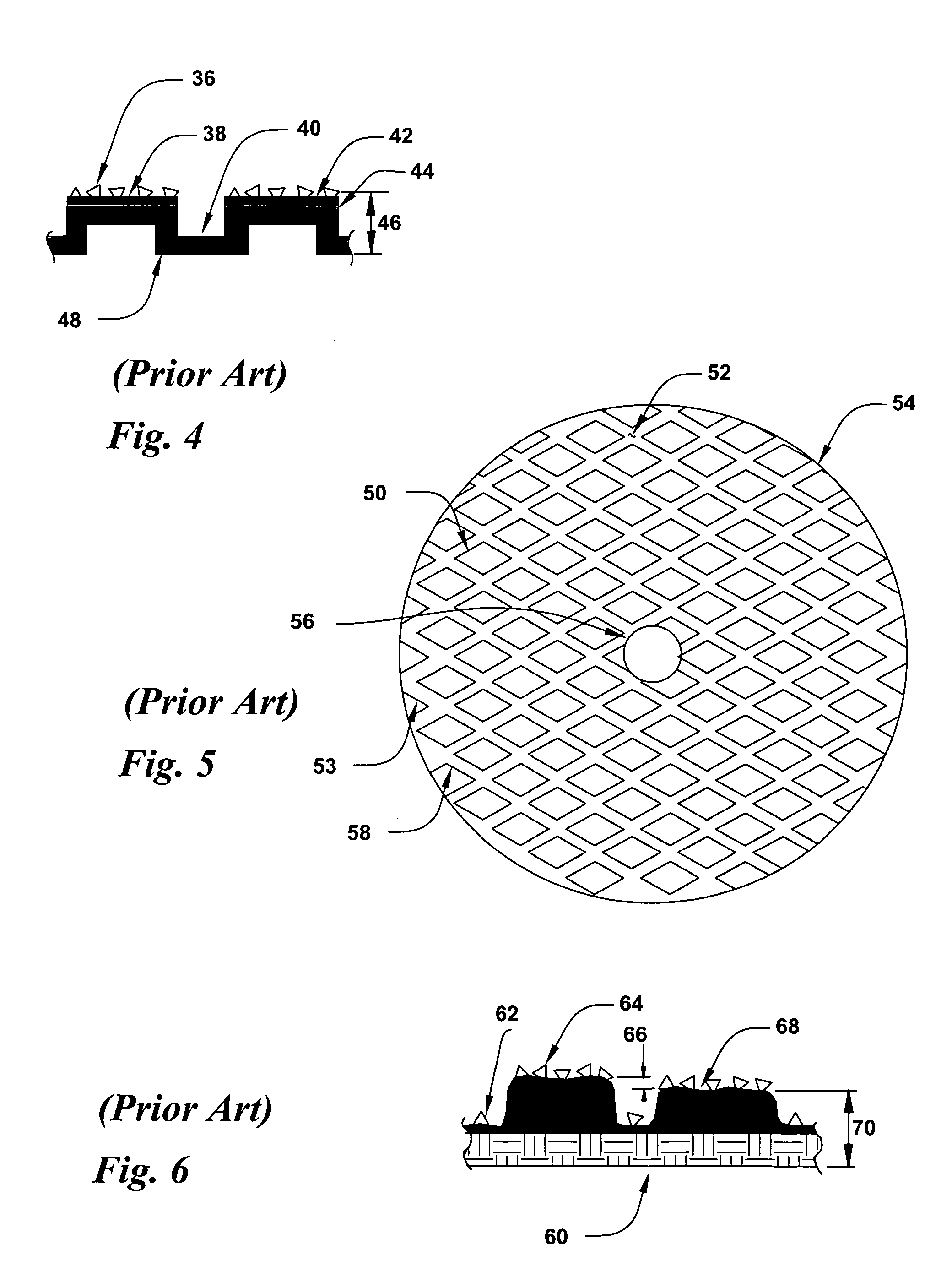

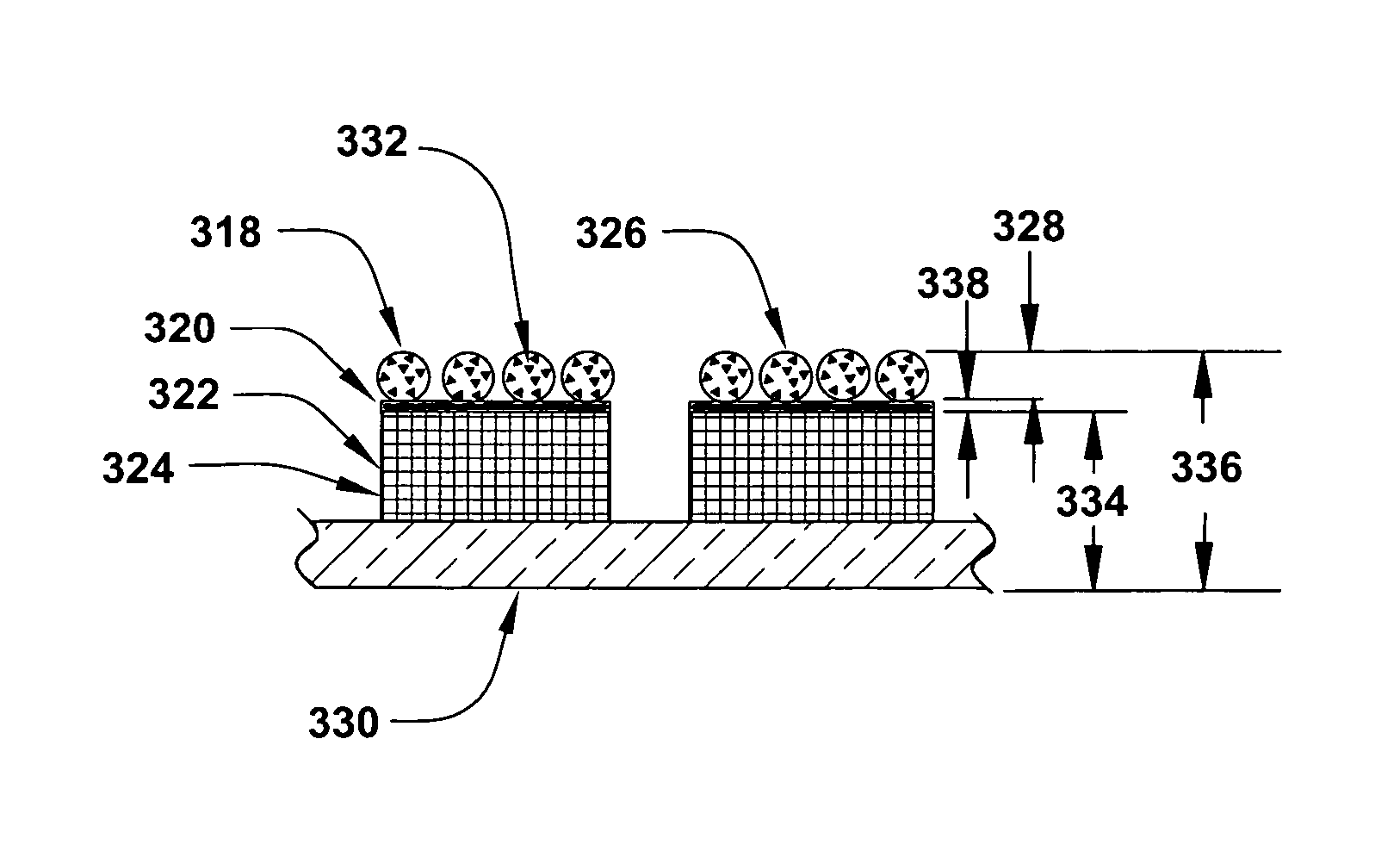

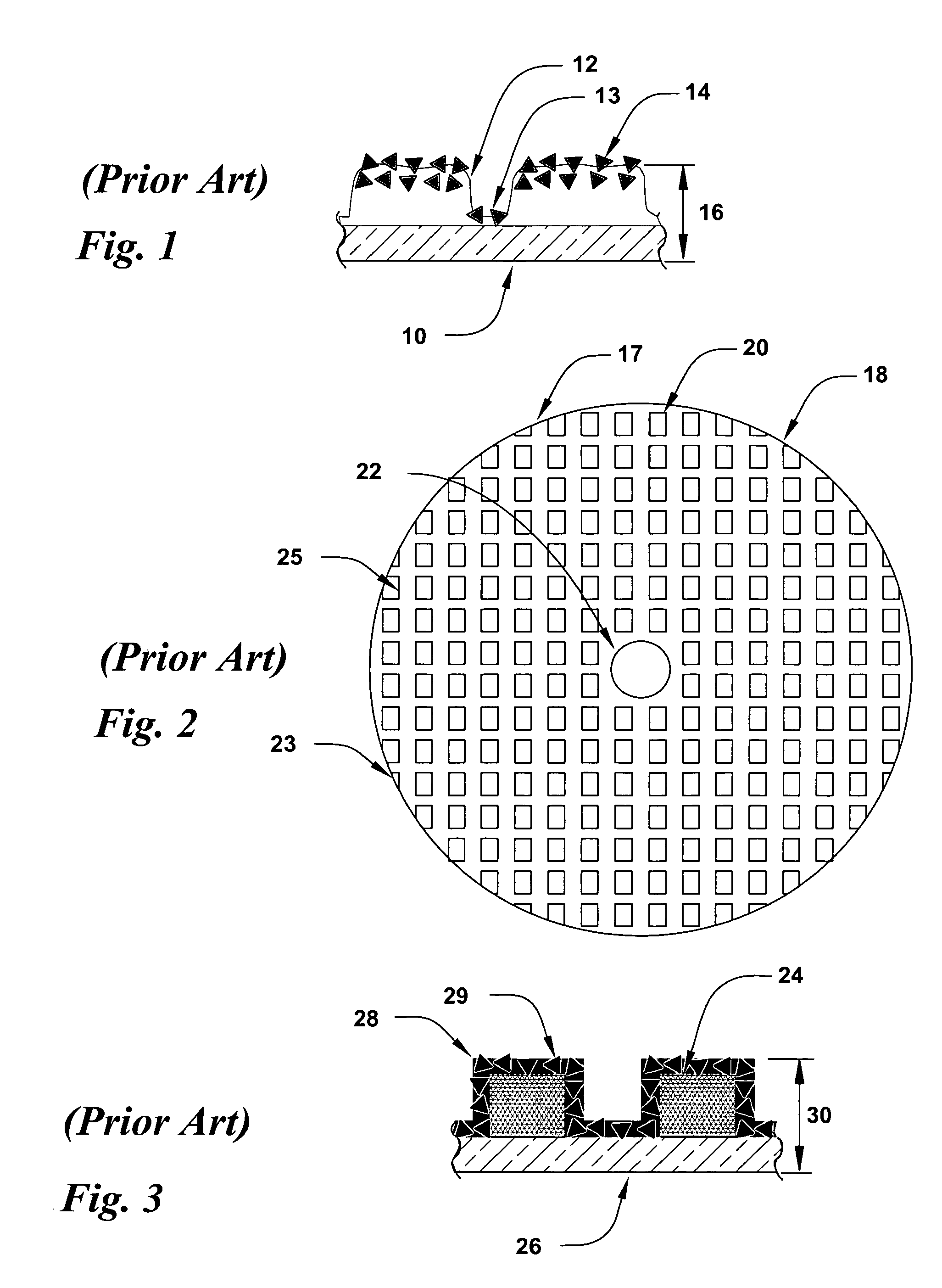

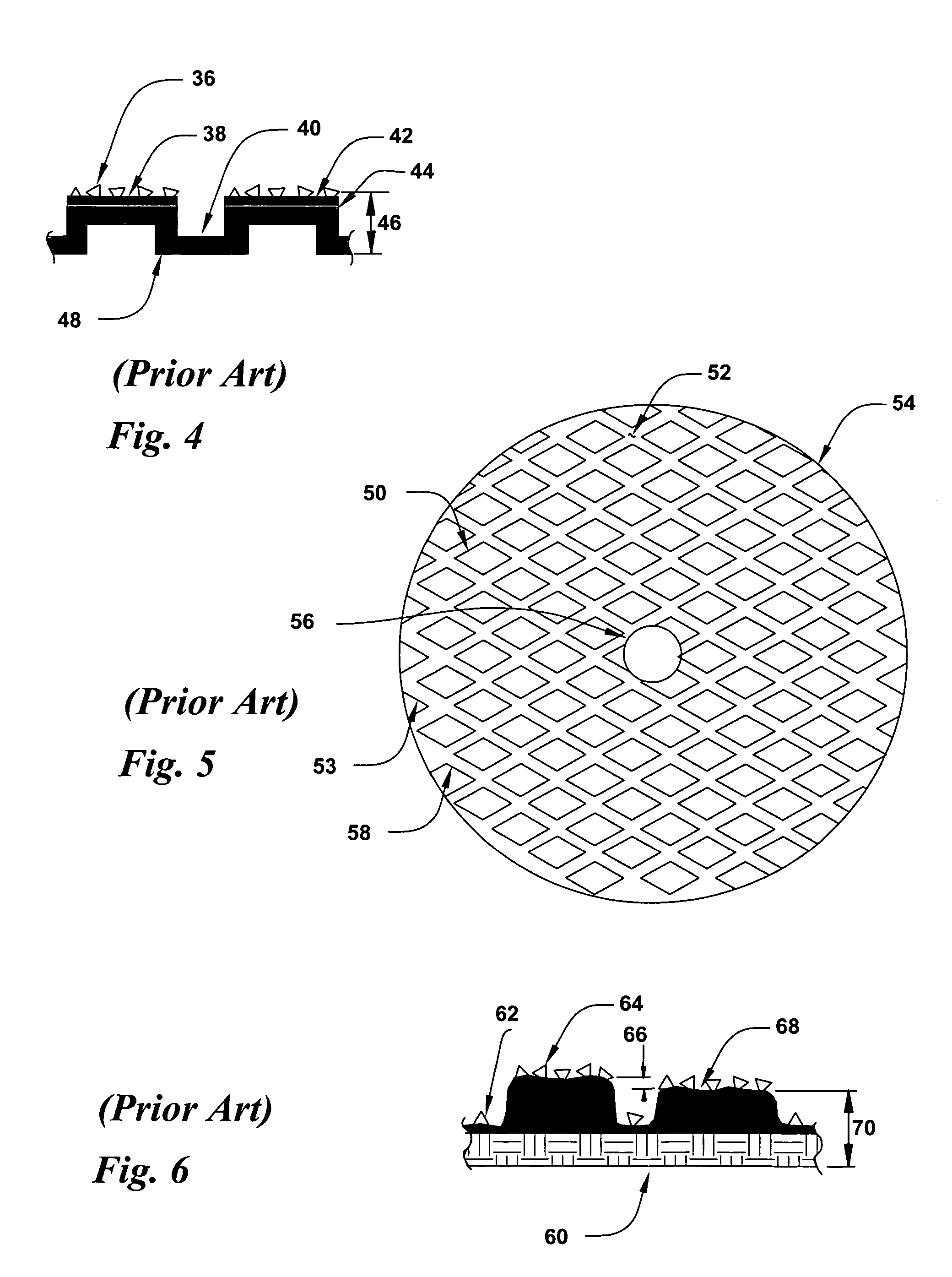

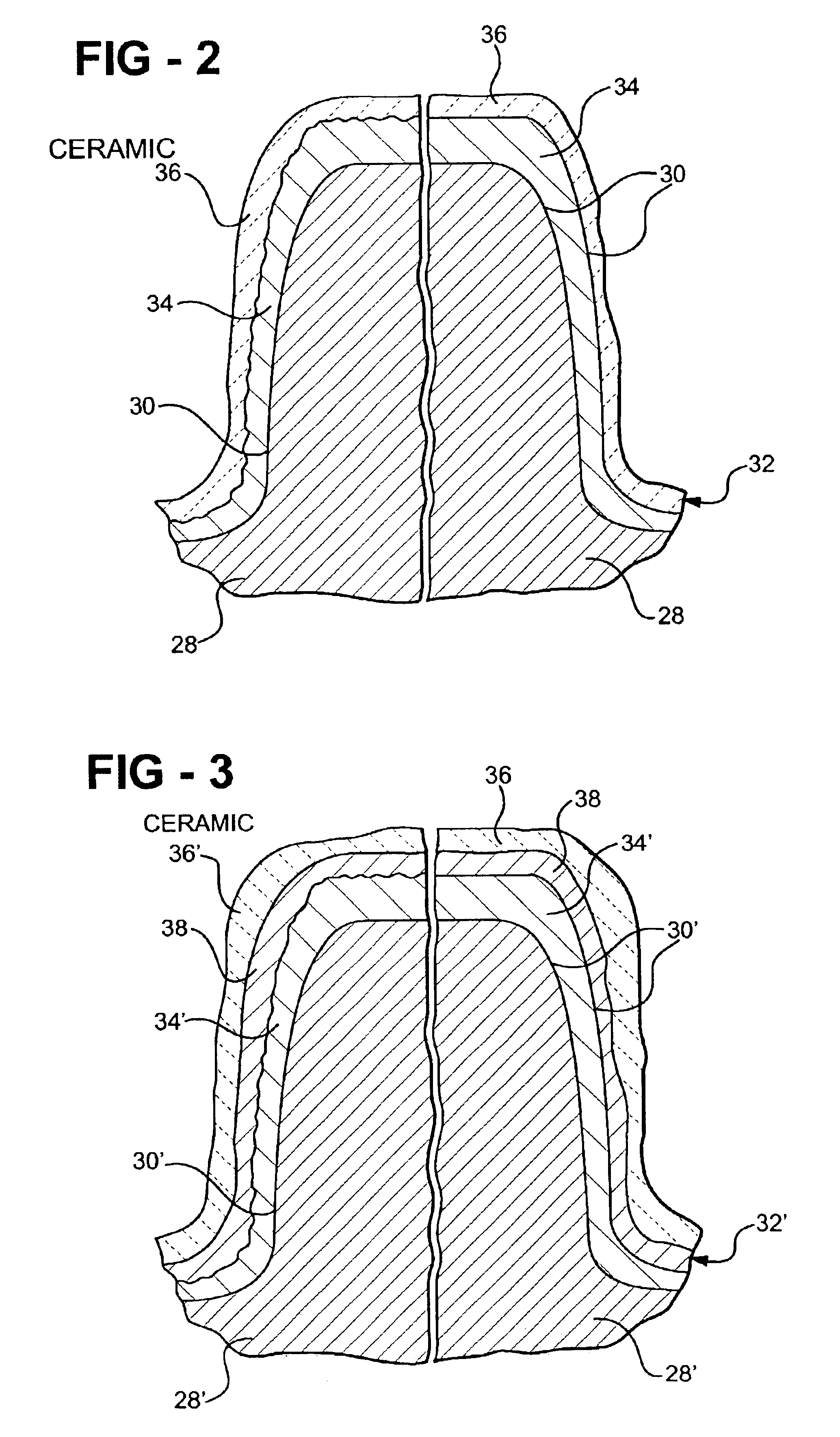

Abrasive bead coated sheet and island articles

InactiveUS20050118939A1Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedSlurry

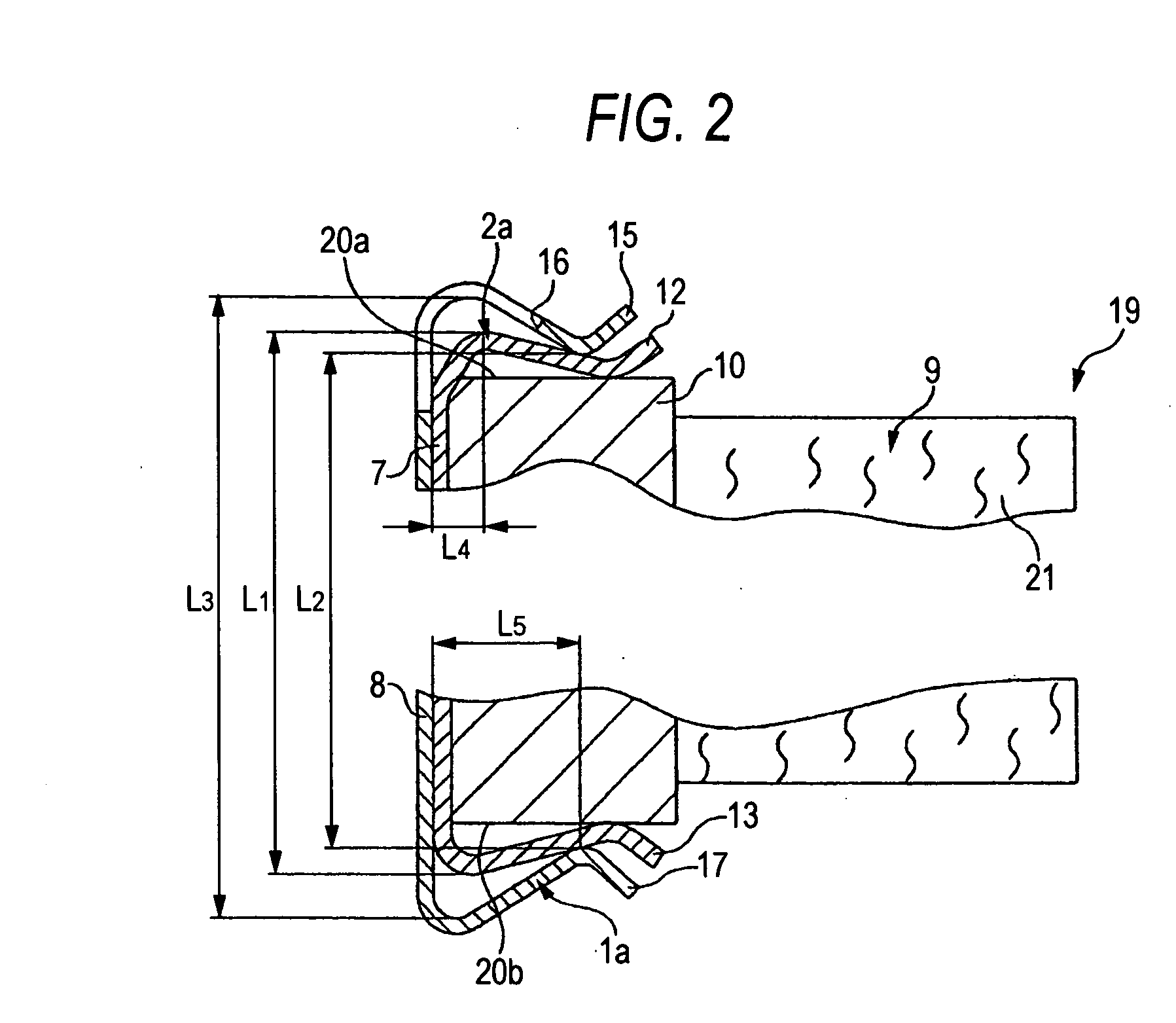

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

Method of forming a flexible abrasive sheet article

InactiveUS8545583B2Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedPrill

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

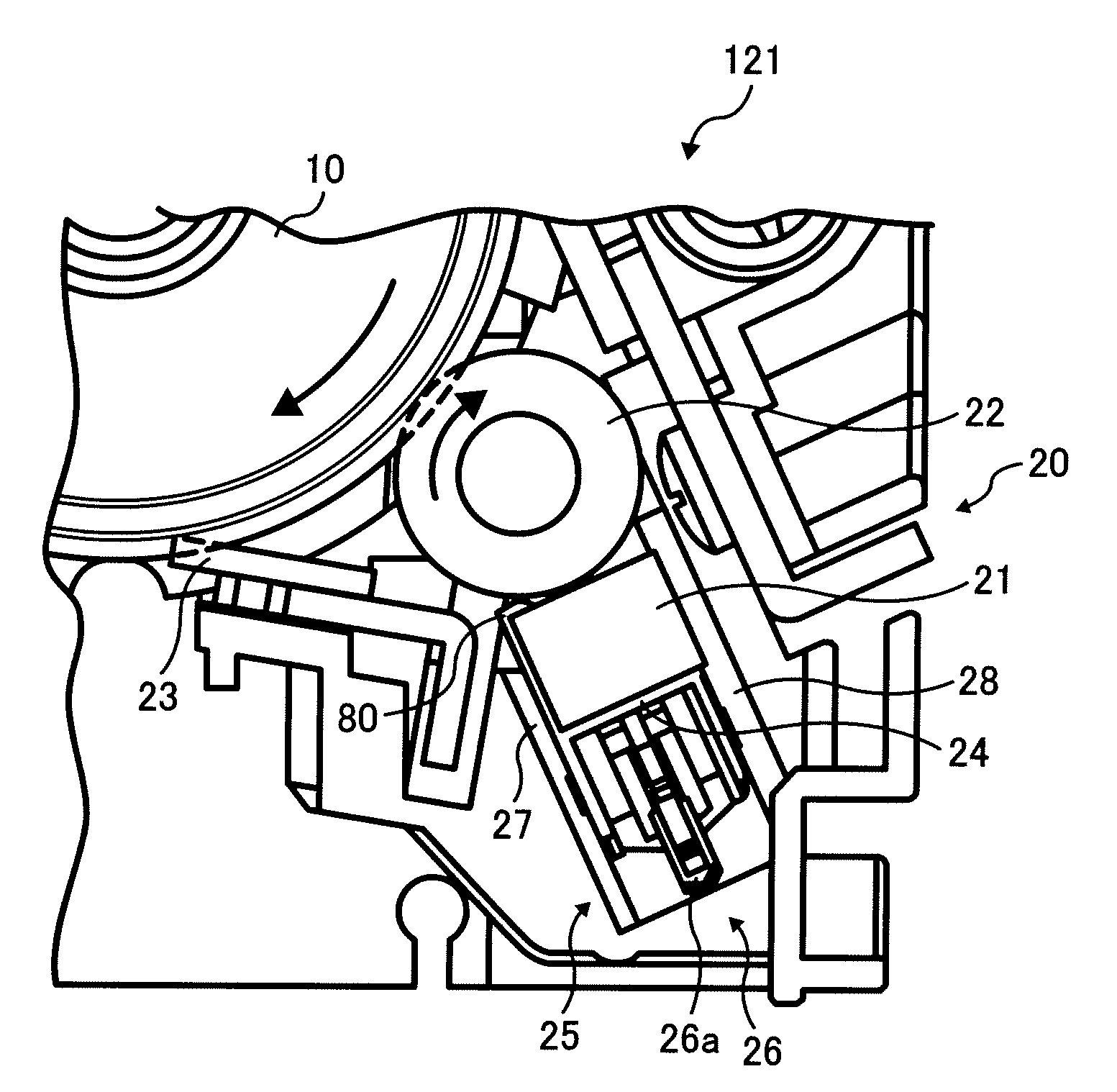

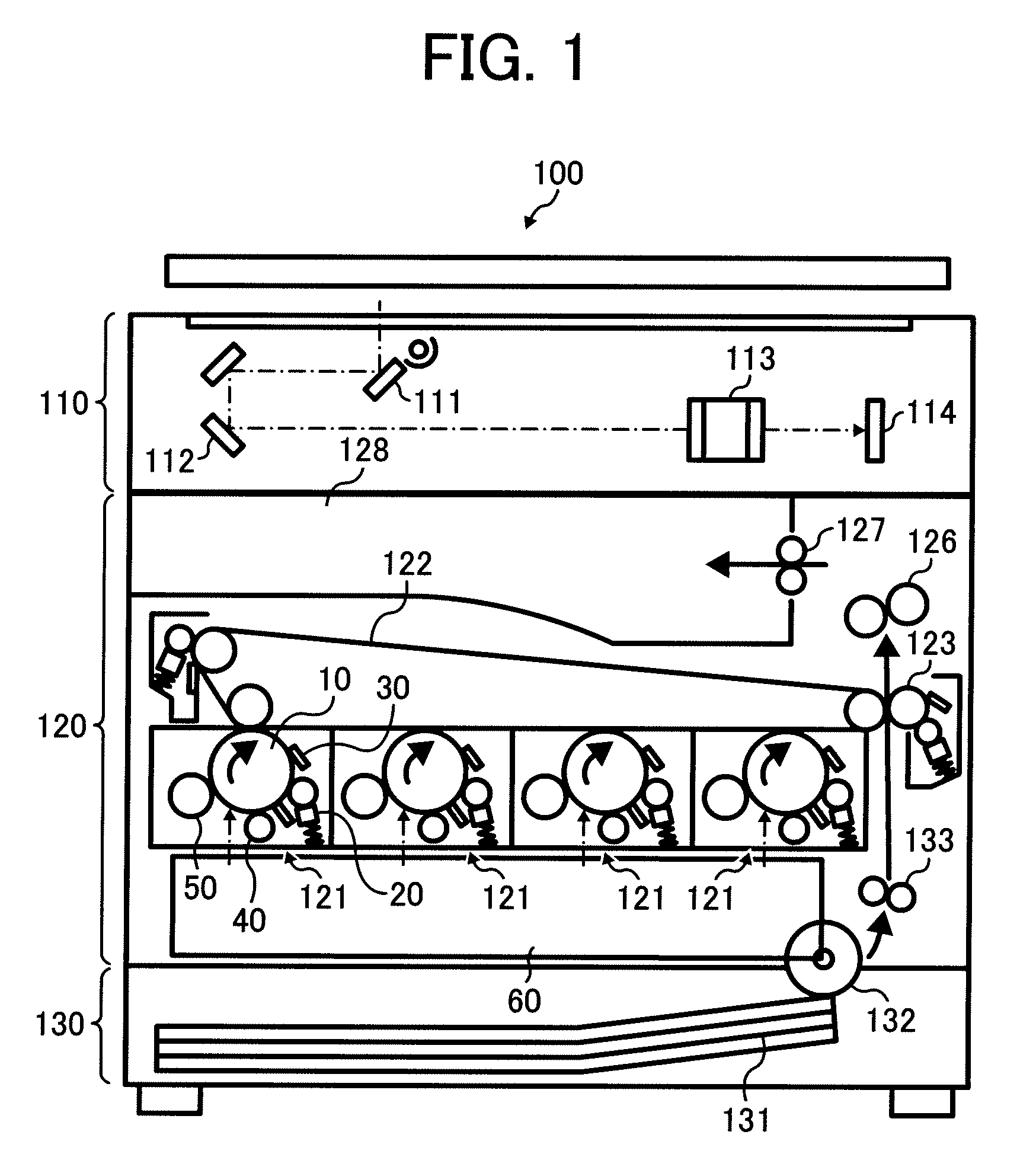

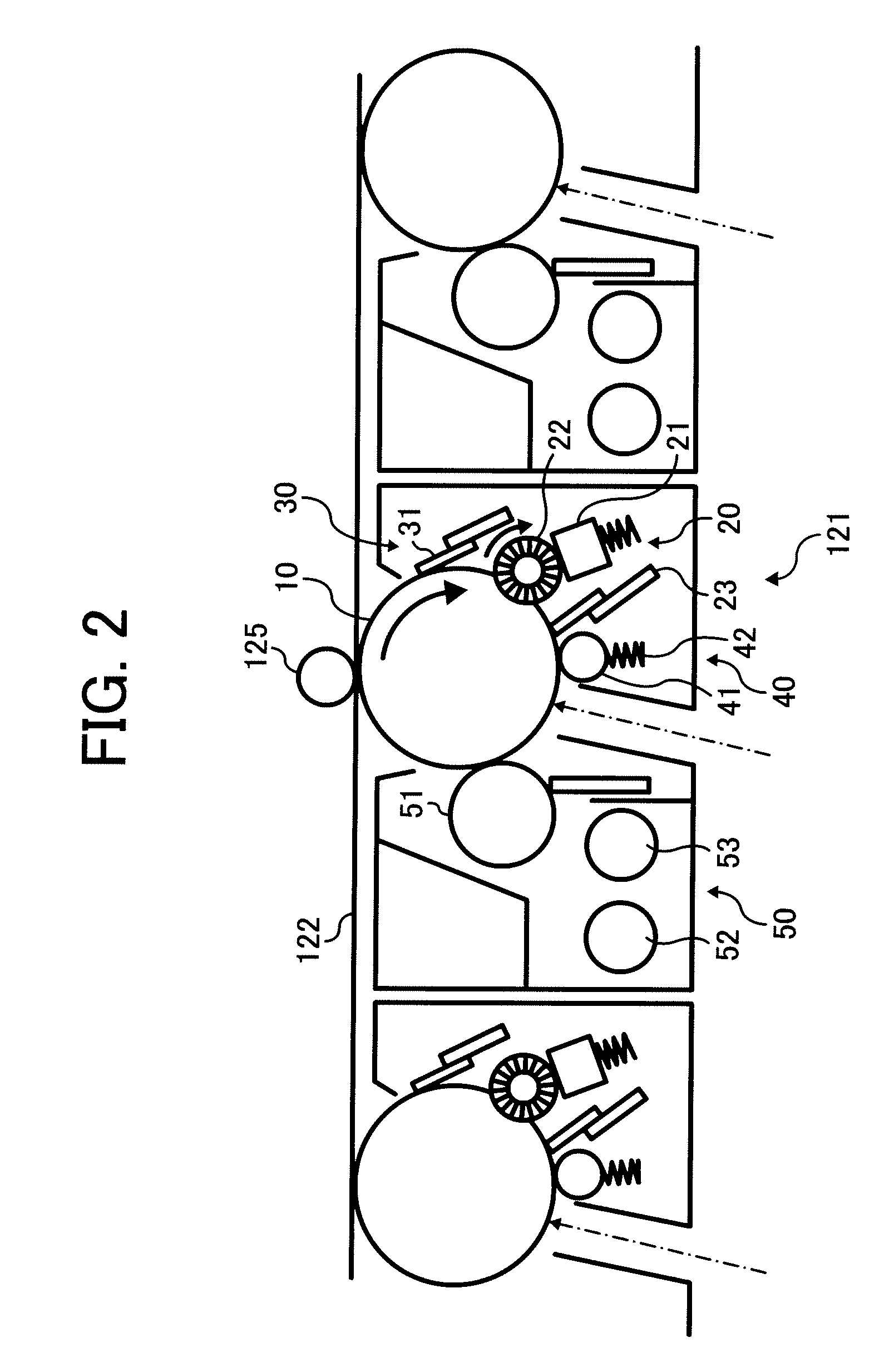

Lubricant applying unit, a process cartridge including the same, and an image forming apparatus provided with the process cartridge including the same

InactiveUS20070172273A1Produce some attenuationFrictional resistanceElectrographic processSliding contactLubricant

A lubricant applying unit, included in a process cartridge provided in an image forming apparatus, includes a solid lubricant, a lubricant supporting unit to support the solid lubricant, a lubricant holder to accommodate the solid lubricant supported by the lubricant supporting unit, a pressing mechanism located between the lubricant supporting unit and the lubricant holder and designed to press the solid lubricant against a lubricant applying member, and a frictional resistance reducing member to reduce a frictional resistance produced at sliding contact portions between the lubricant supporting unit and internal surfaces of the lubricant holder.

Owner:RICOH KK

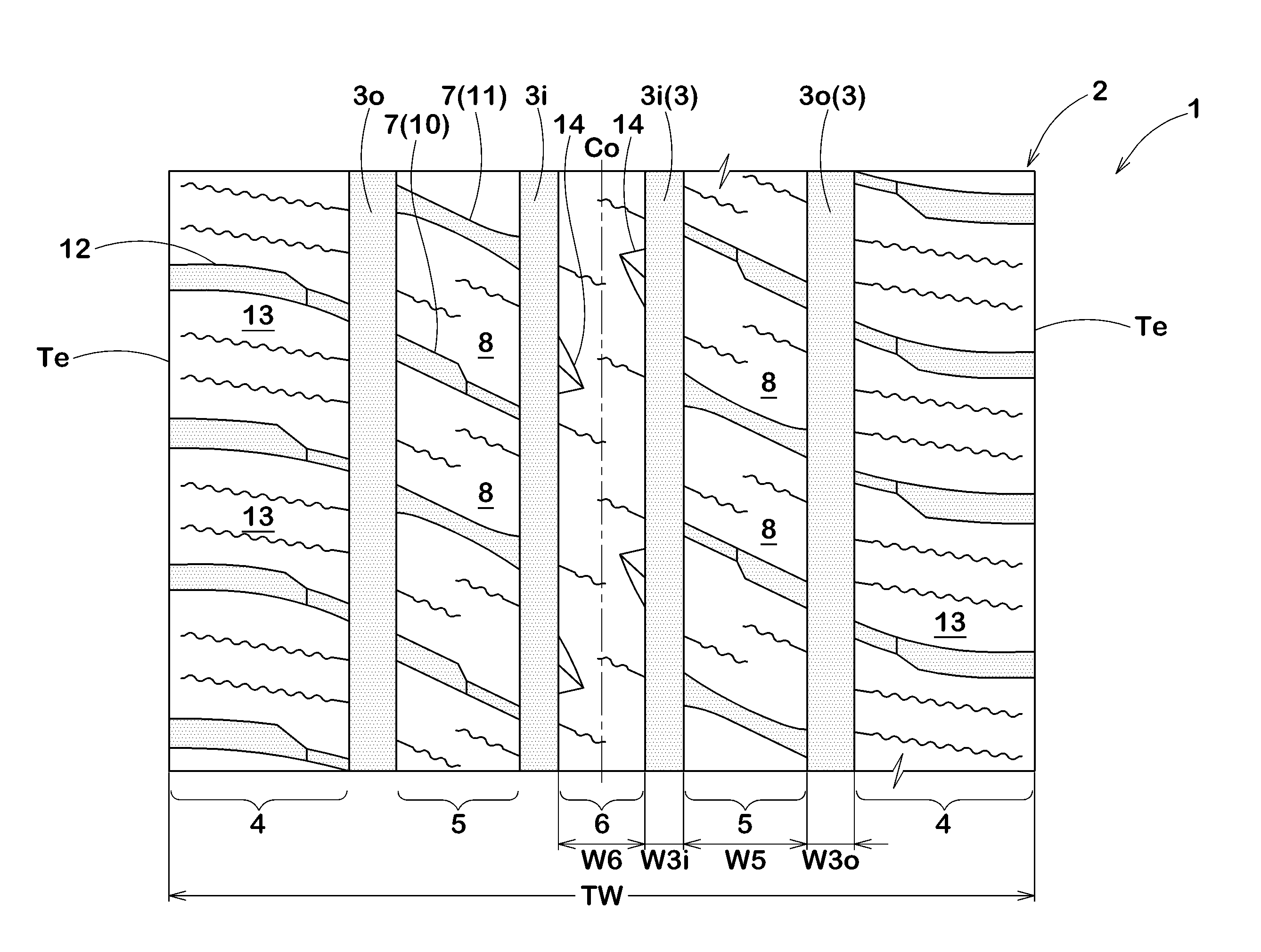

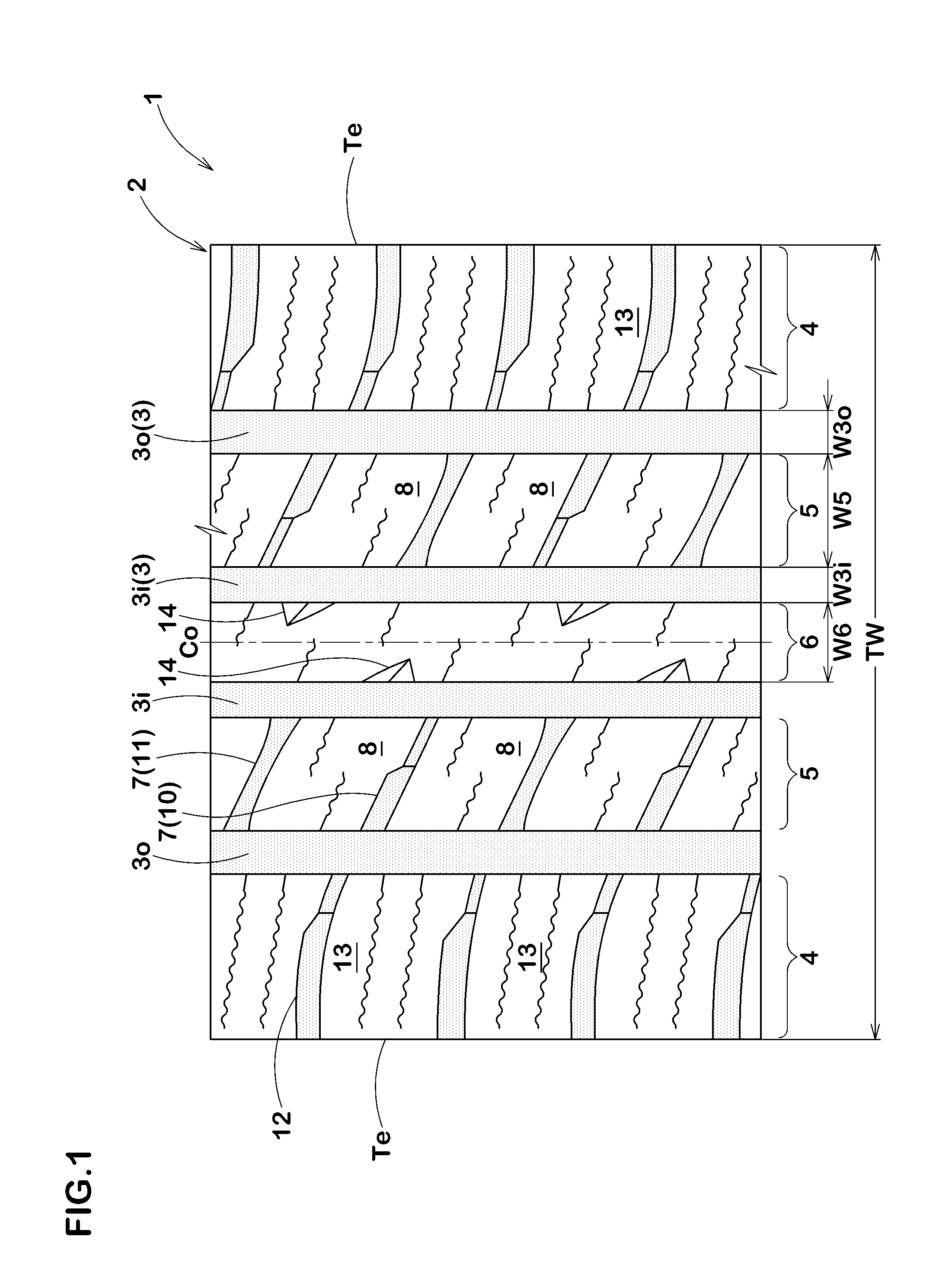

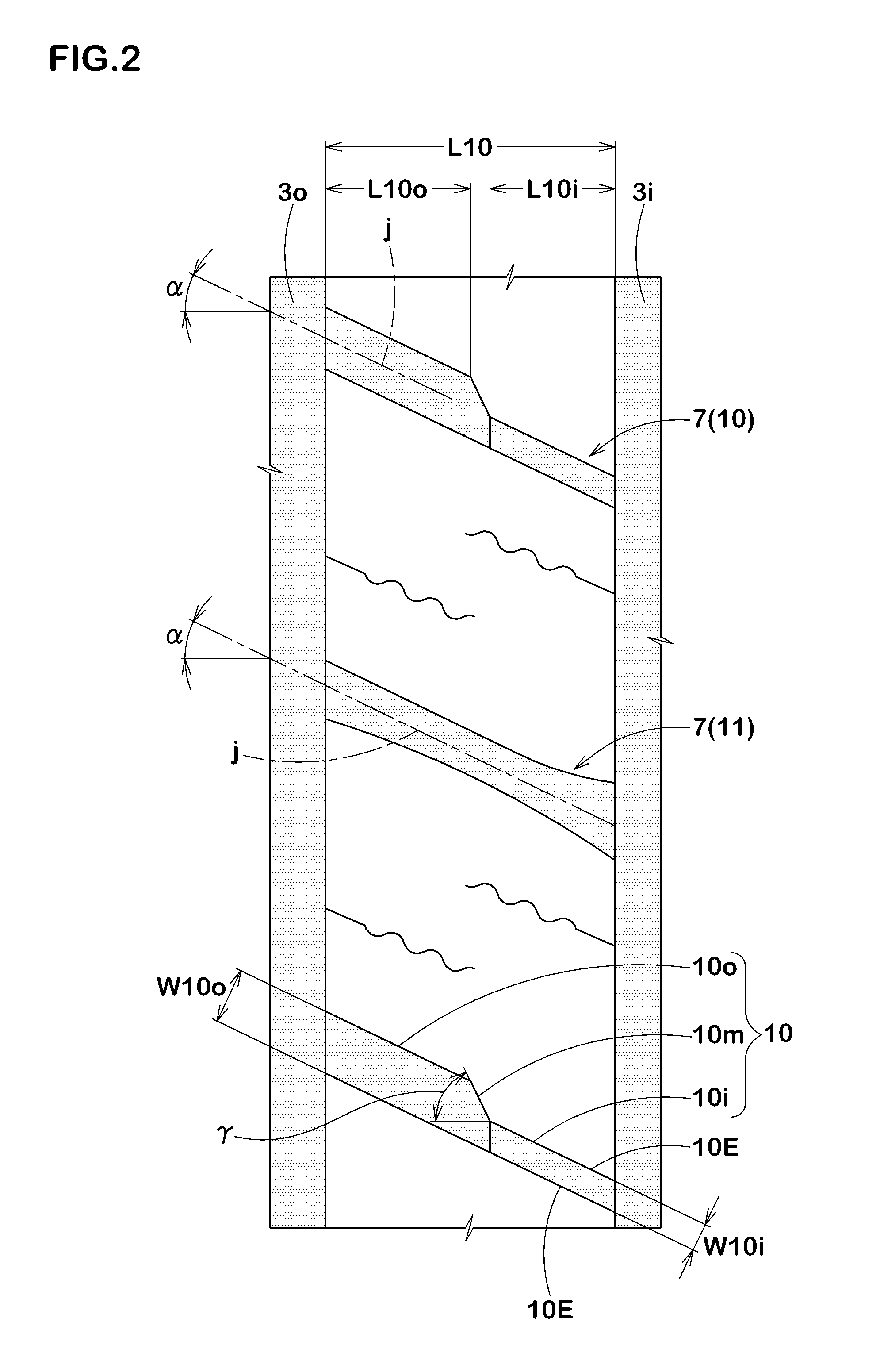

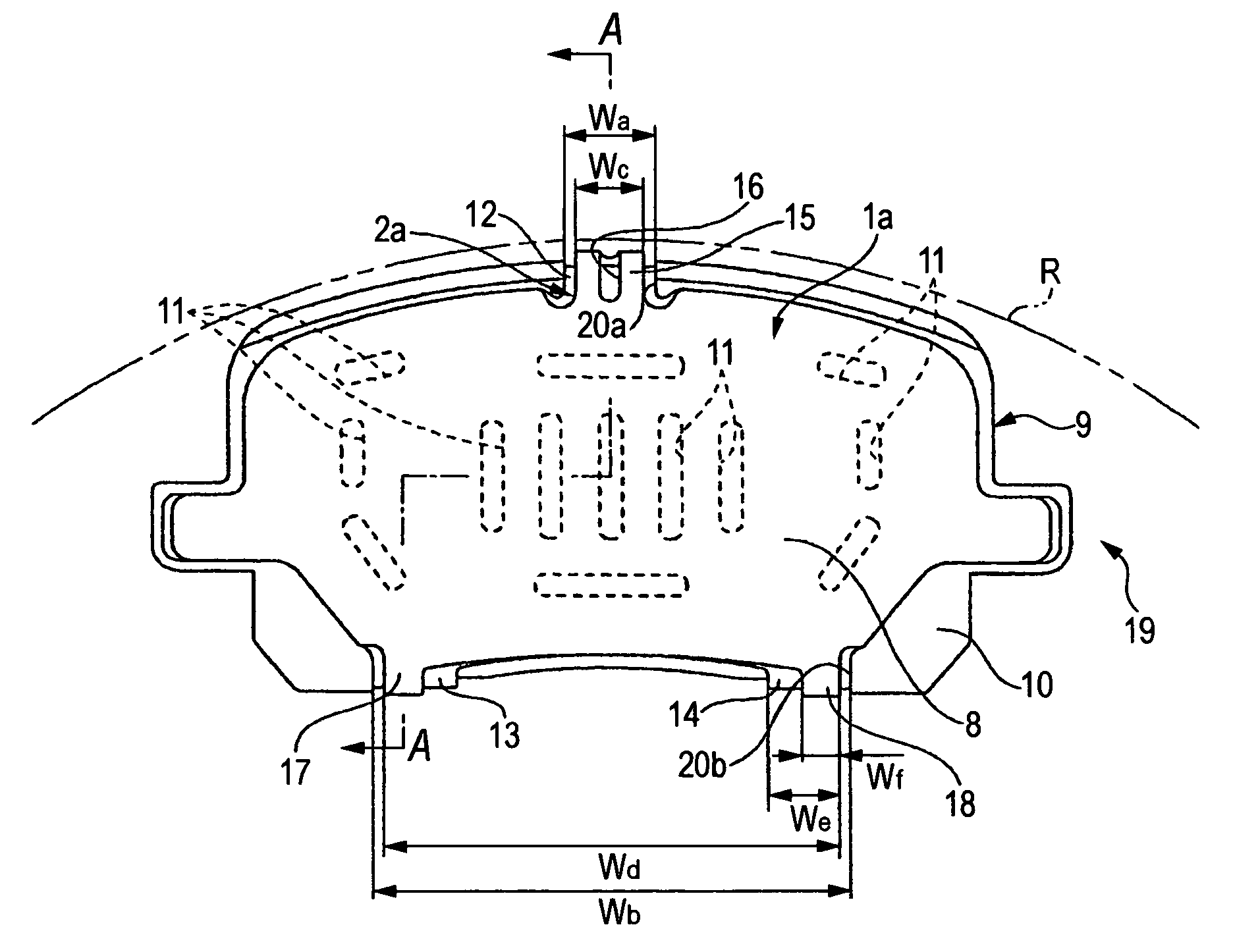

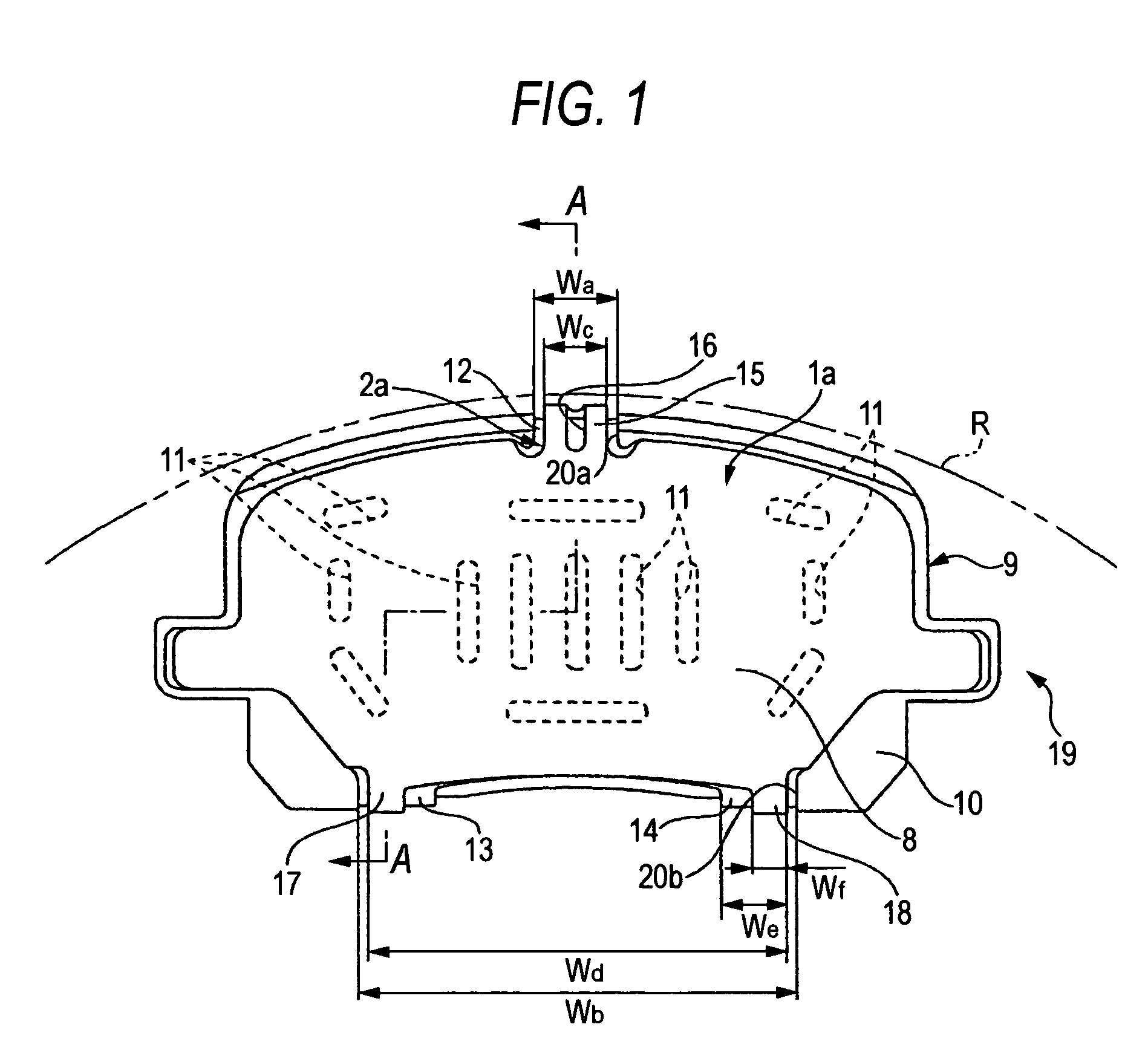

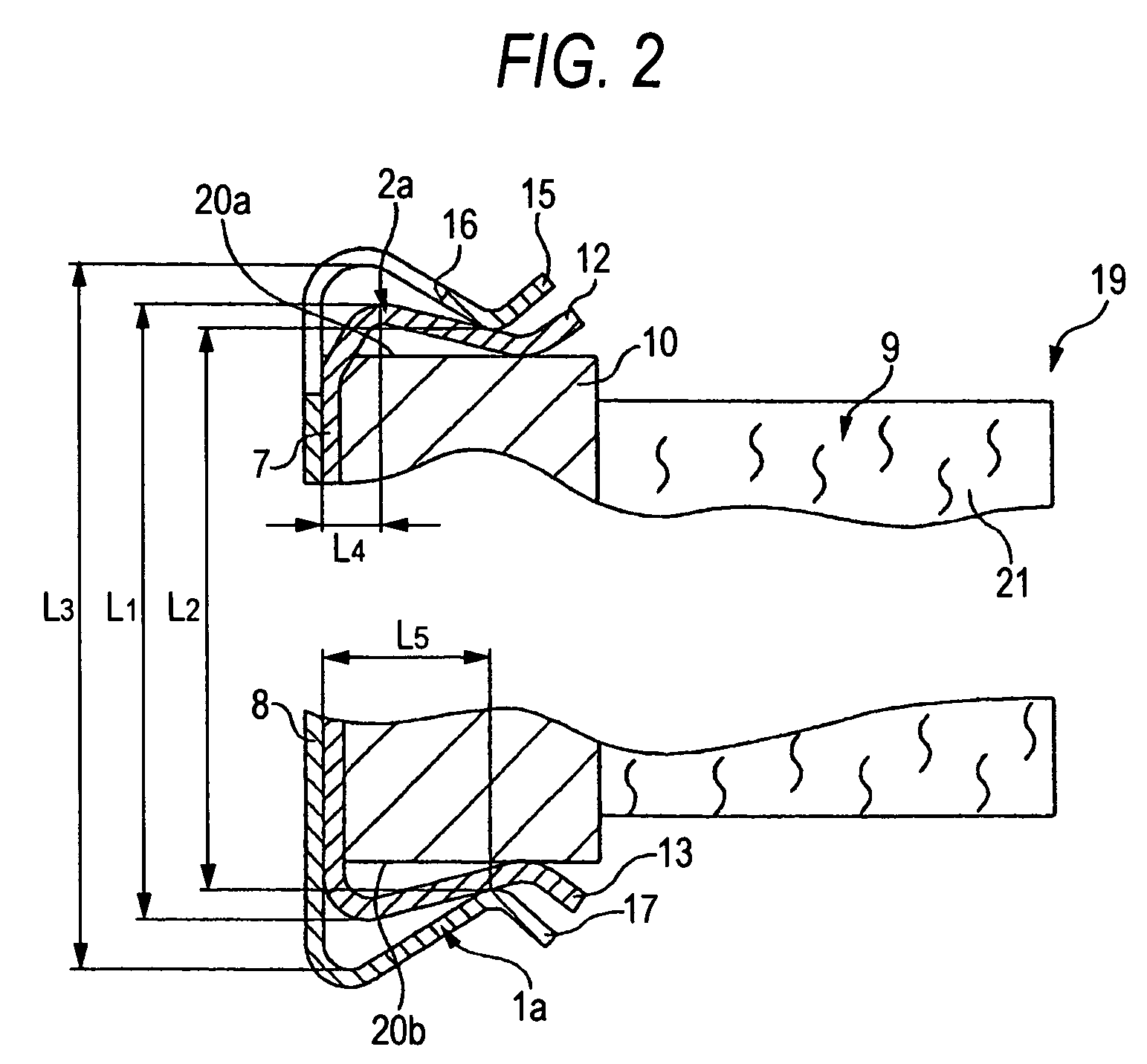

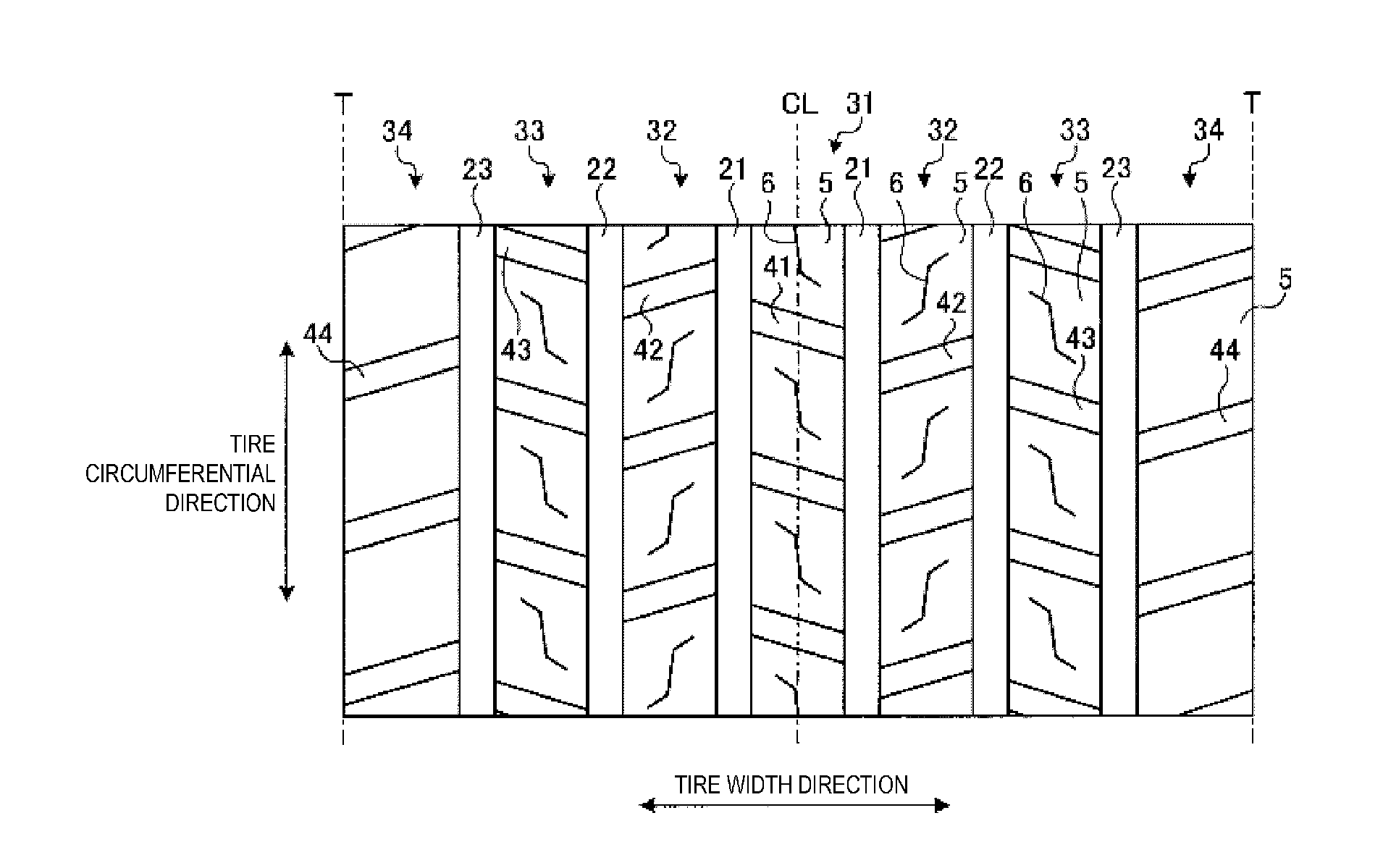

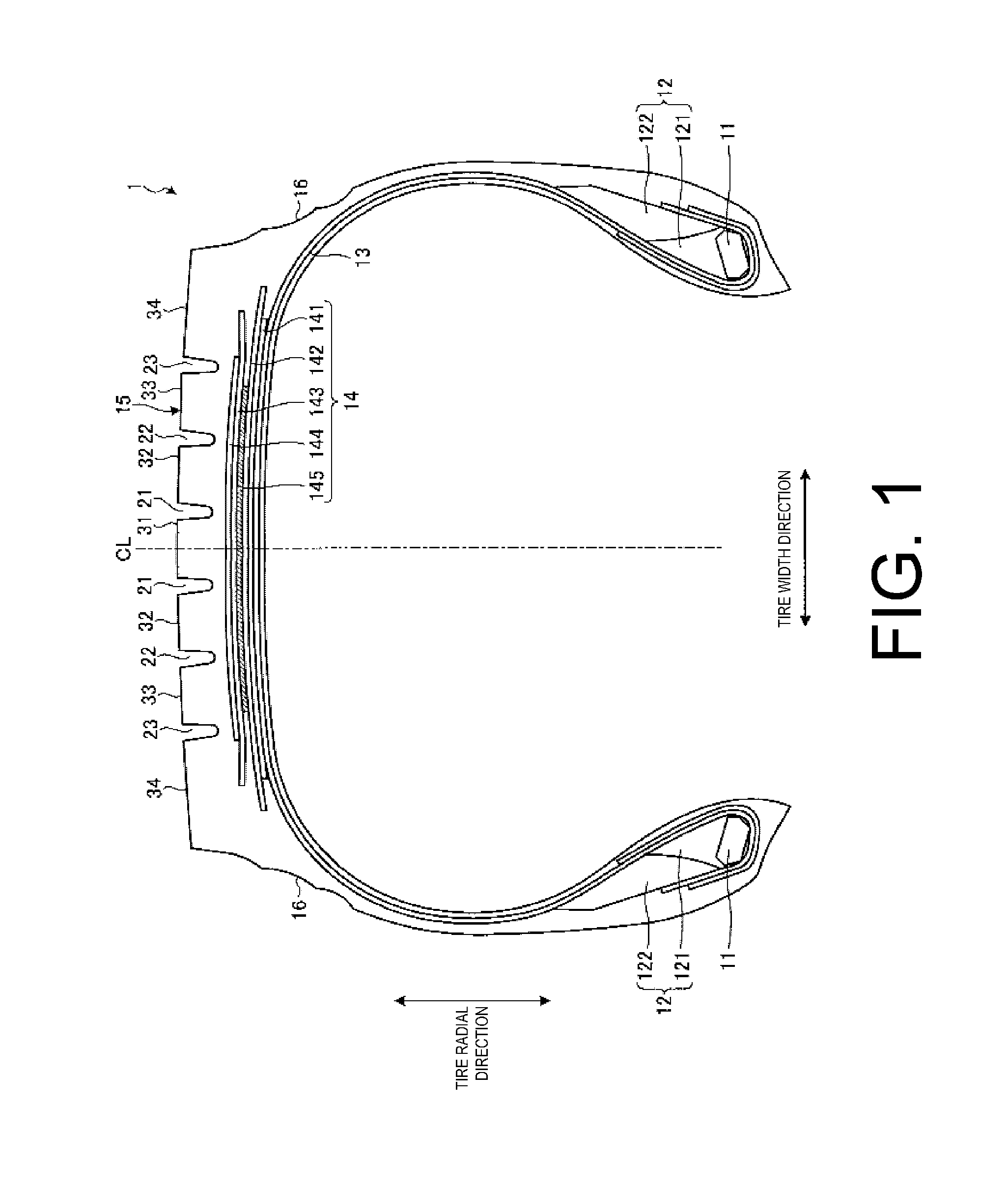

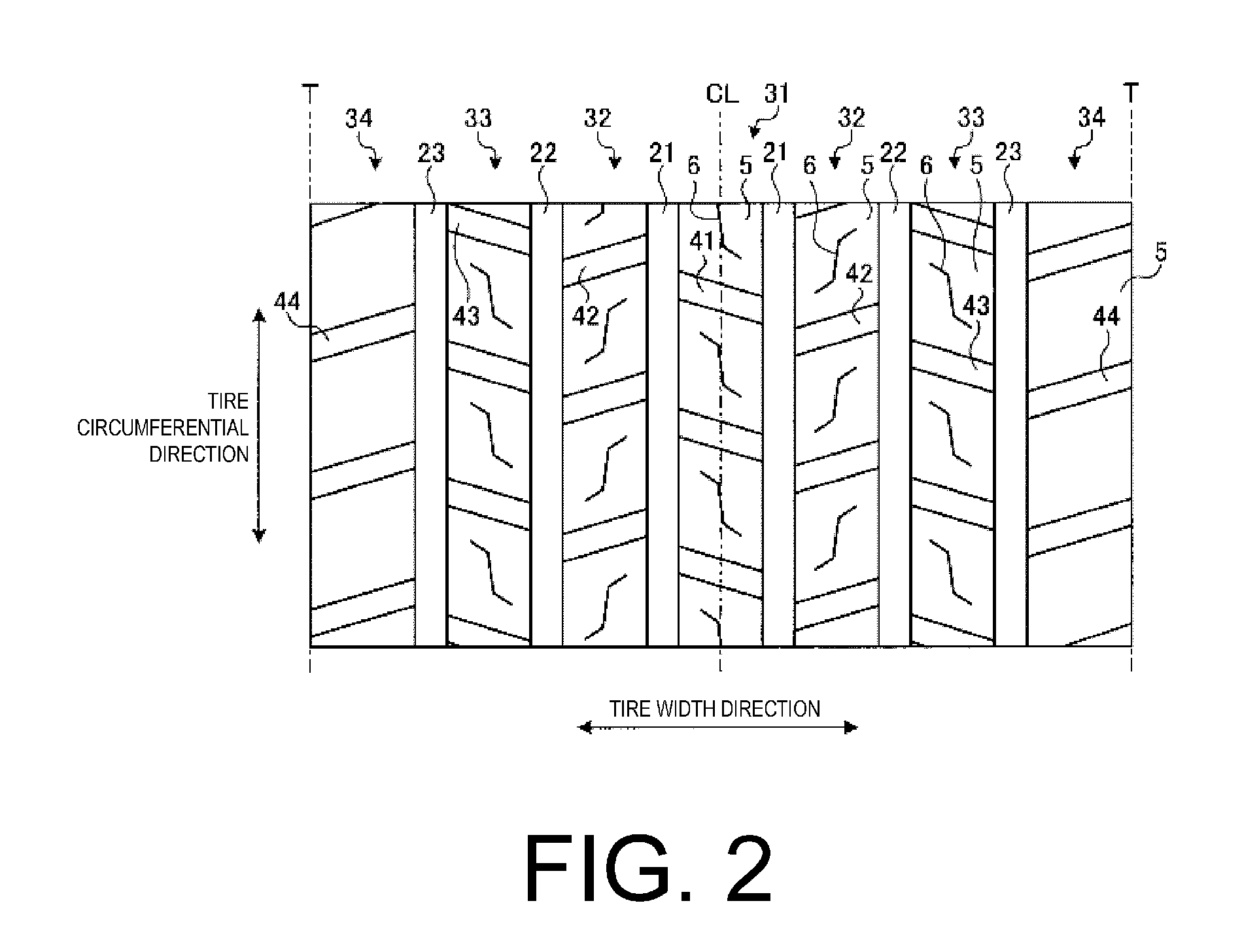

Pneumatic tire

ActiveUS20130192731A1Improve rigidityAvoid uneven wearTyre tread bands/patternsNon-skid devicesGround contactMarine engineering

A tread portion of a pneumatic ti re includes inner land portions between outer circumferential main grooves disposed most on tread ground-contact end sides and at least one inner circumferential main groove on the inner side thereof. The inner land portions are divided into inner blocks by inner lateral grooves inclined at an angle α of 10 to 40°. The inner lateral grooves consist of first inner lateral grooves and second inner lateral grooves which are alternately arranged in a circumferential direction. The first inner lateral grooves include a wide-width part connecting to the outer circumferential main groove and a narrow-width part connecting to the inner circumferential main groove.

Owner:SUMITOMO RUBBER IND LTD

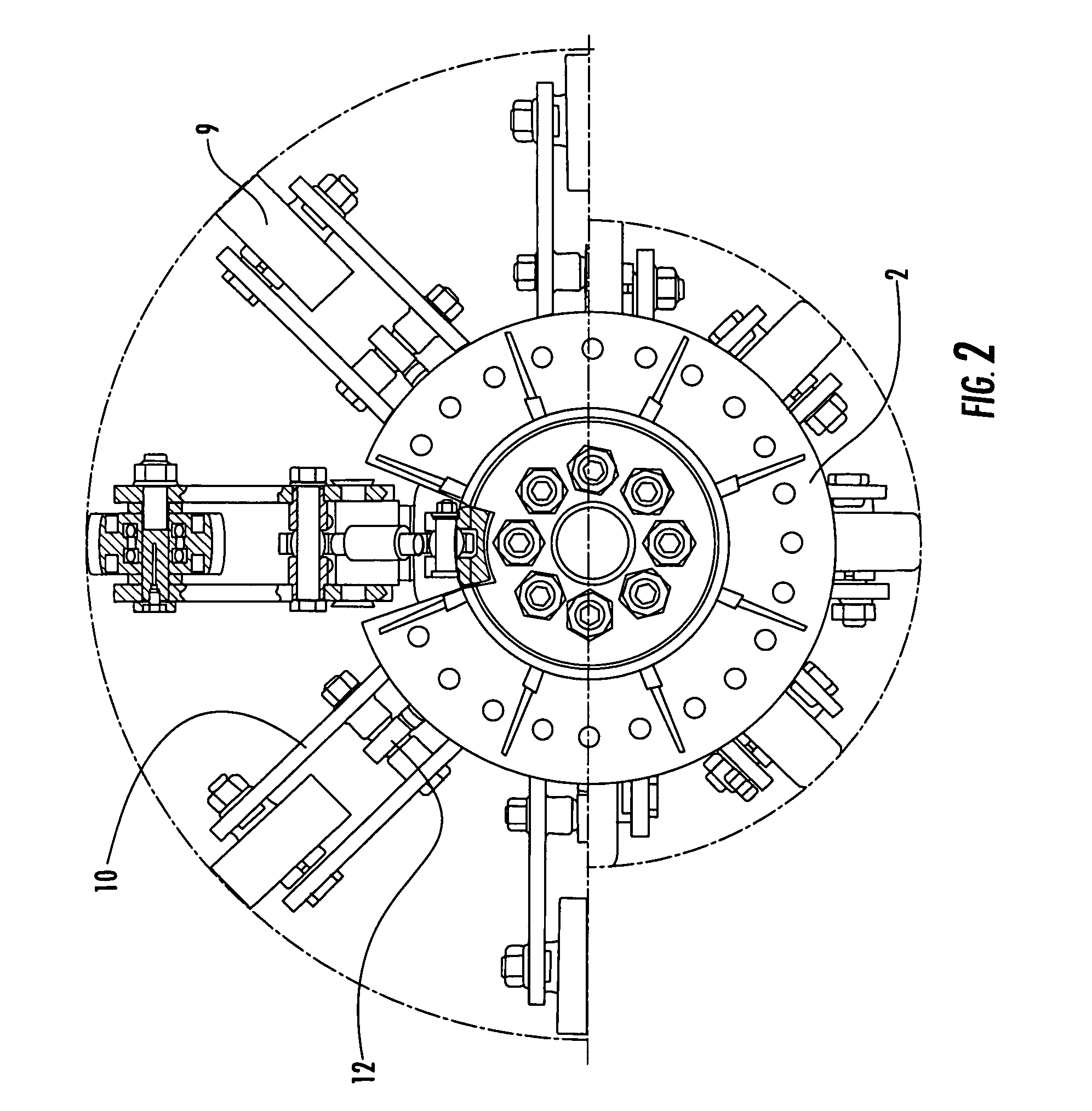

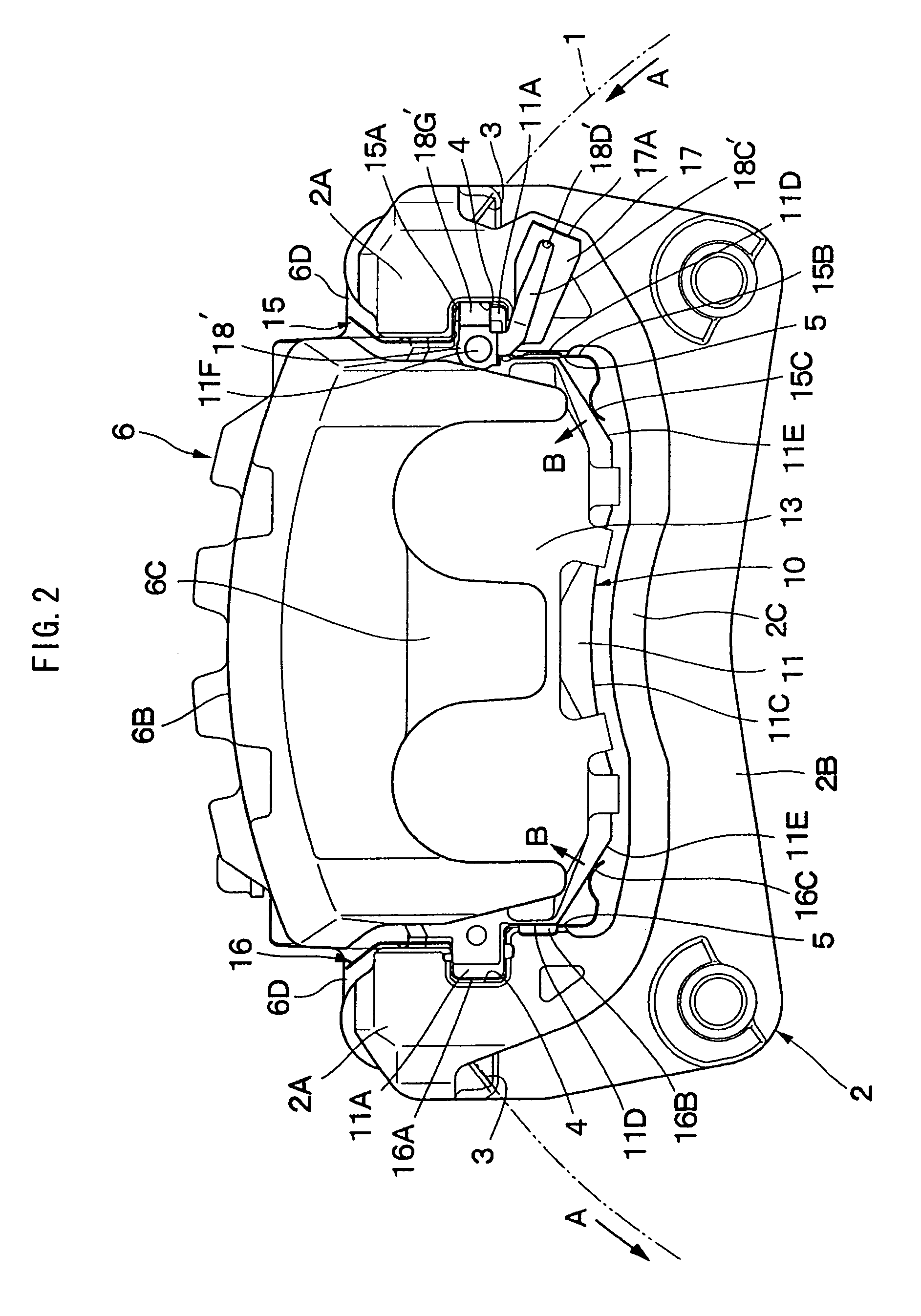

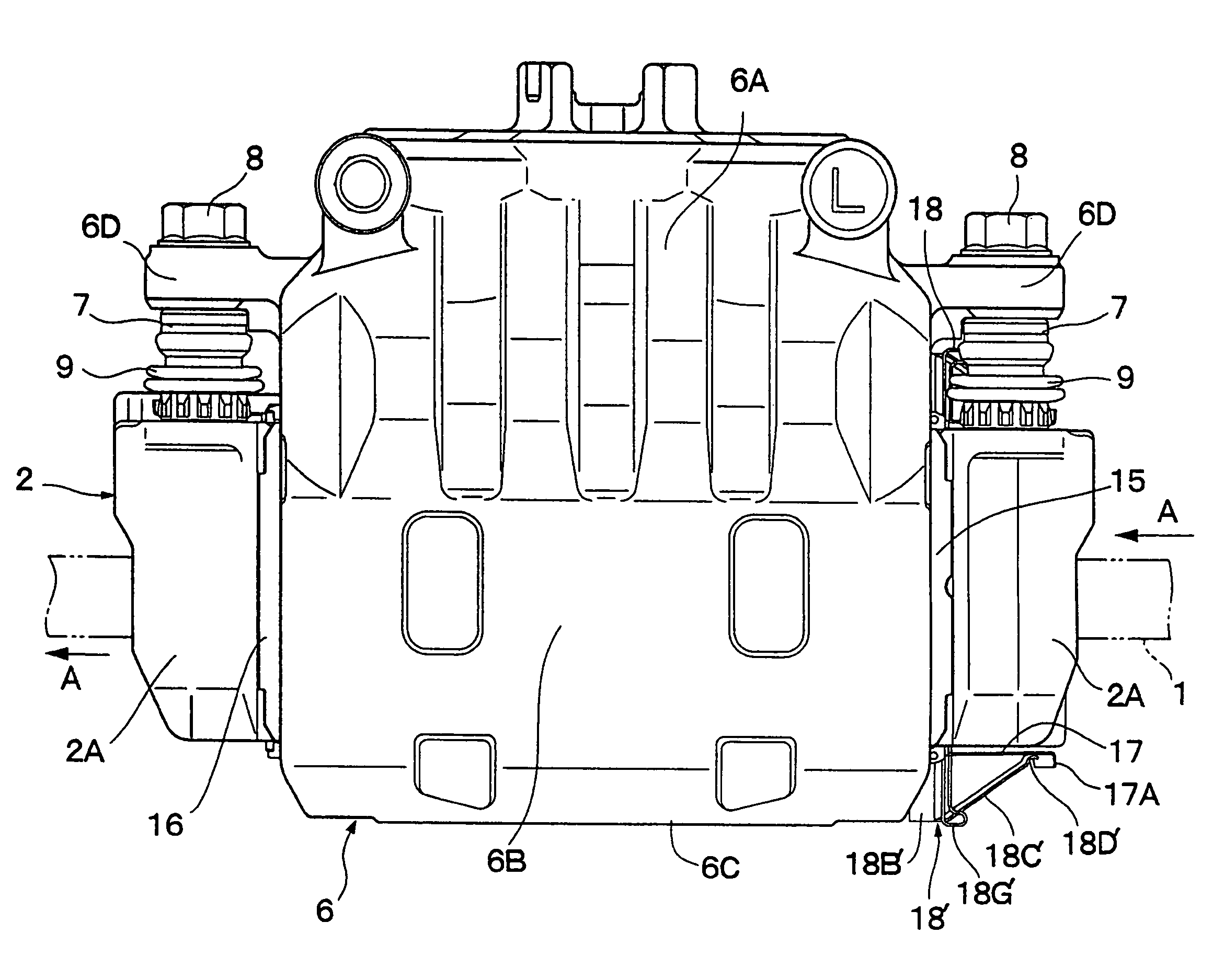

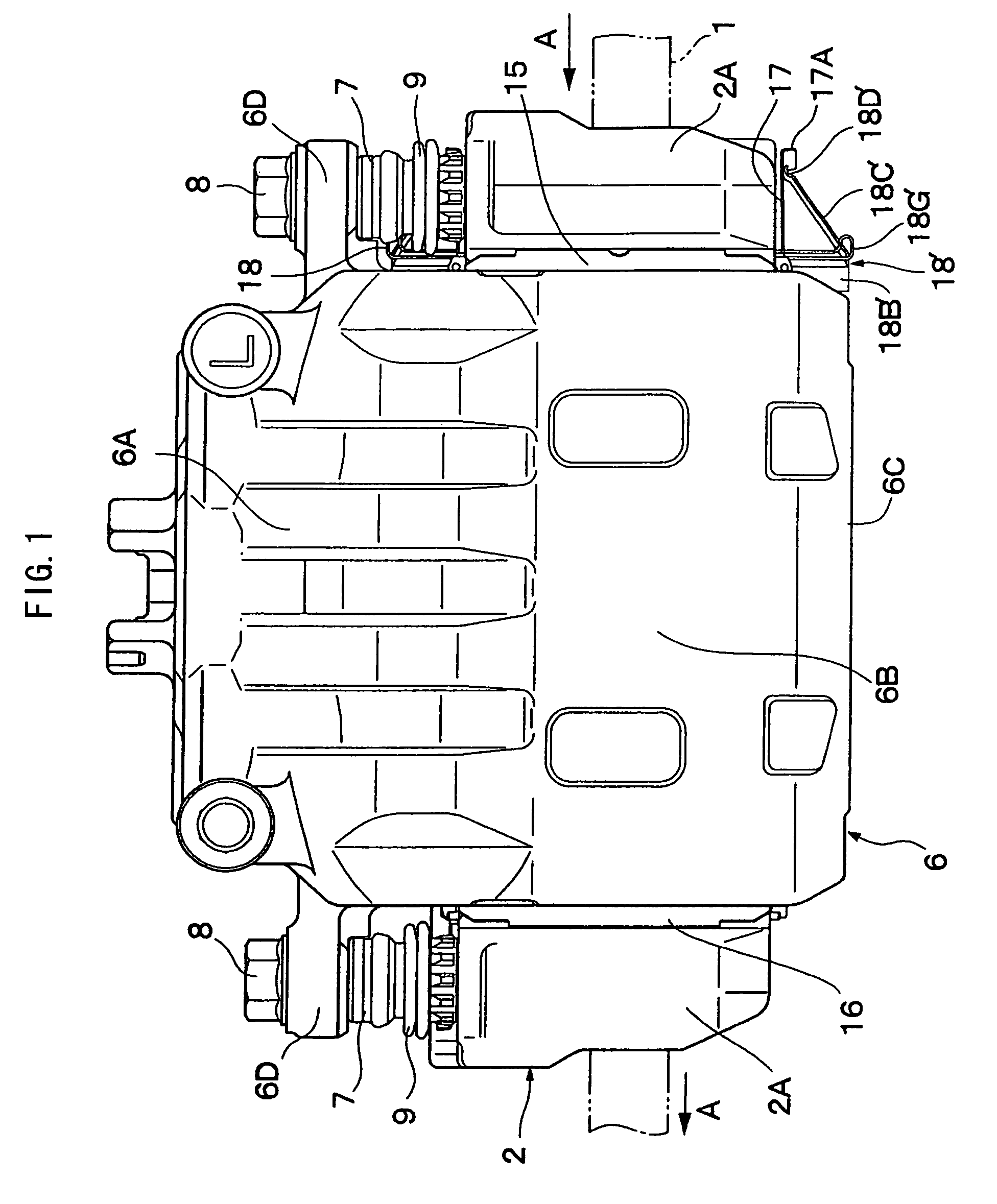

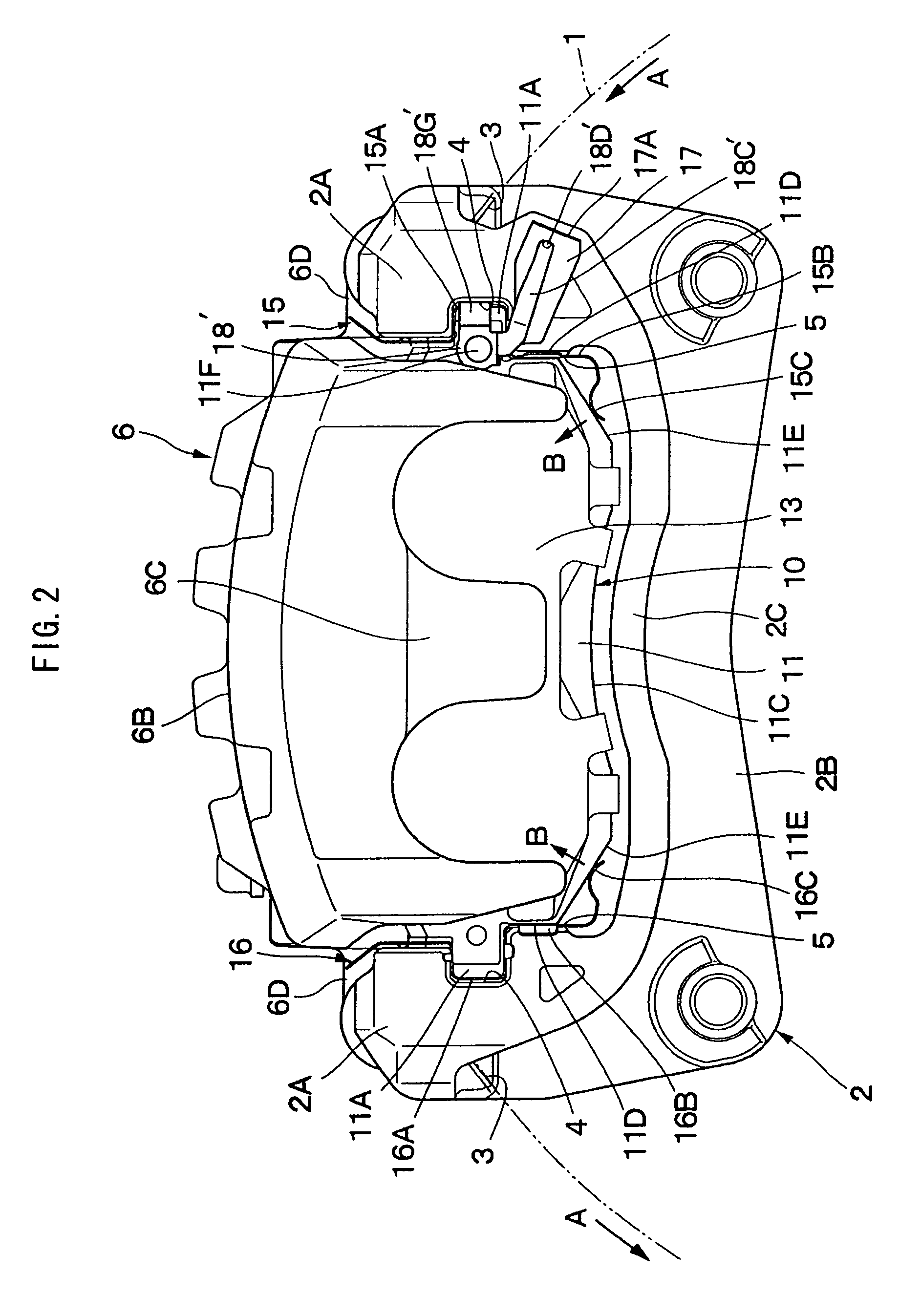

Pad assembly for disc brake

ActiveUS20060157307A1Smooth slidingSmooth movementBraking membersSlack adjustersEngineeringMechanical engineering

Owner:AKEBONO BRAKE IND CO LTD

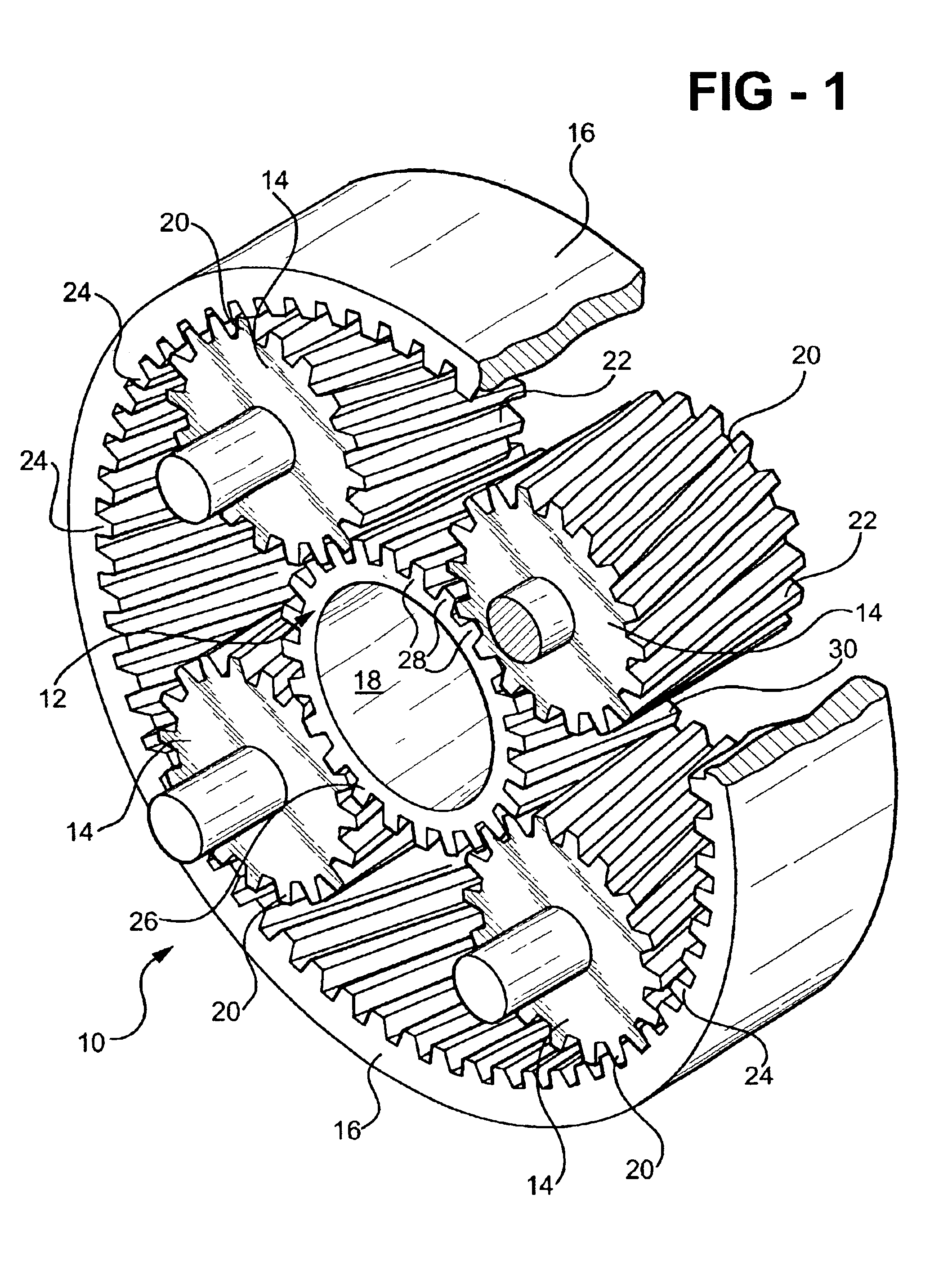

Planetary gearset with multi-layer coated sun gear

InactiveUS6846261B2Improve lubrication conditionsFlat surfaceMetal-working apparatusGear lubrication/coolingGear toothCoating

A planetary gearset includes a sun gear member having a sun gear body made of a steel material and an outer periphery with a plurality of teeth formed thereon. Each of the sun gear teeth has at least one mating surface for engaging mating surfaces on complementary teeth on at least one planet gear. A fatigue-resistant coating is applied to the mating surfaces of the sun gear teeth. The coating is harder and more abrasive than the mating surfaces of the planet gear teeth.

Owner:GENERAL MOTORS COMPANY

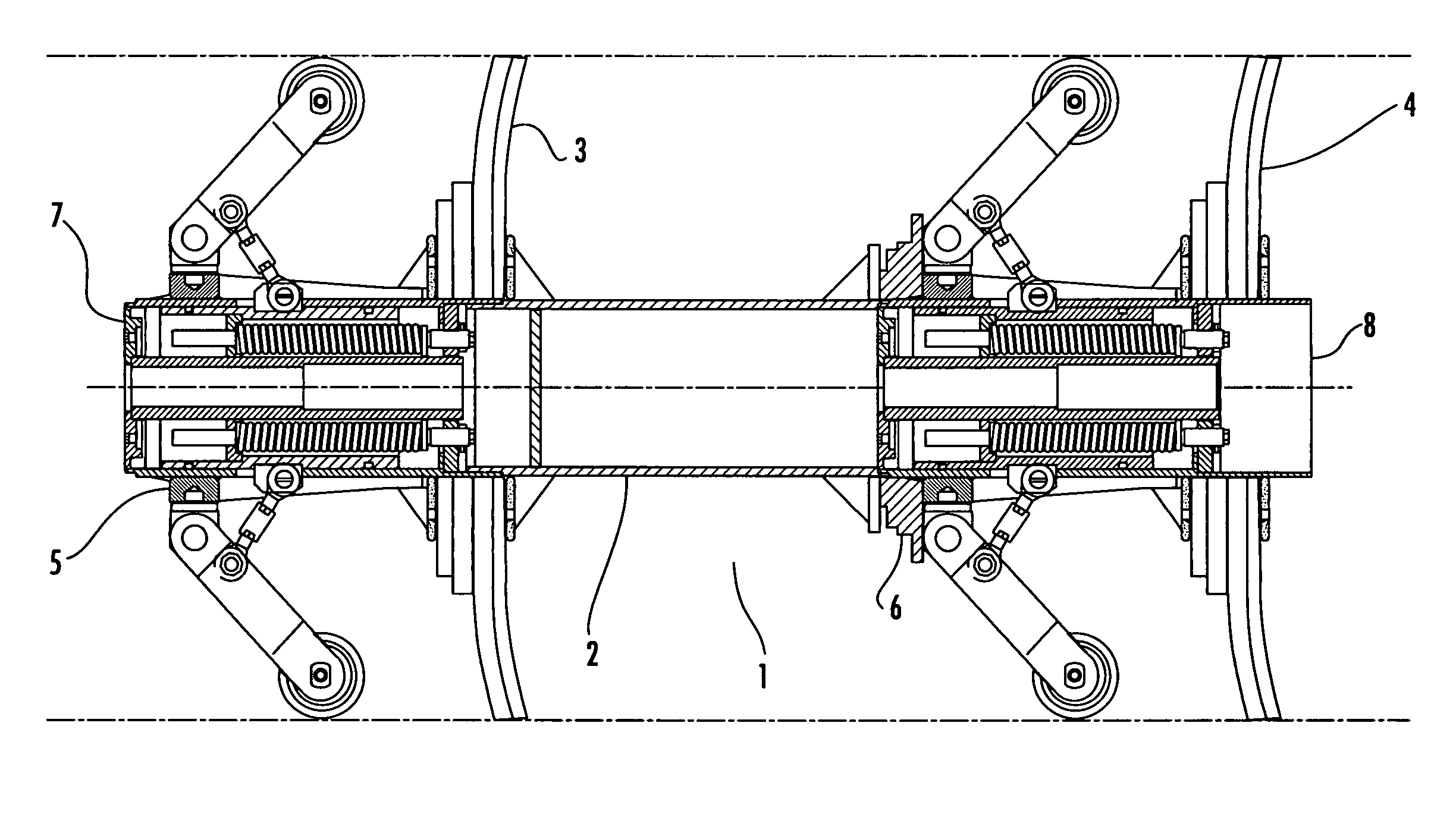

Centre line multidimensional suspension system

InactiveUS7328475B2Uneven wearHollow article cleaningCleaning using toolsMonitoring systemEngineering

There is described a novel apparatus for use in connection with pipe cleaning and monitoring systems. The apparatus is a suspension system adapted to fit a pipeline pig shaft, the pig being provided with a plurality of wheels. The wheels are concentrically mounted around a biasing means which is operable in a direction coplanar with the pig shaft. There is also described a pipeline pig comprising the suspension system and a method of cleaning a pipeline.

Owner:FTL SEALS TECH

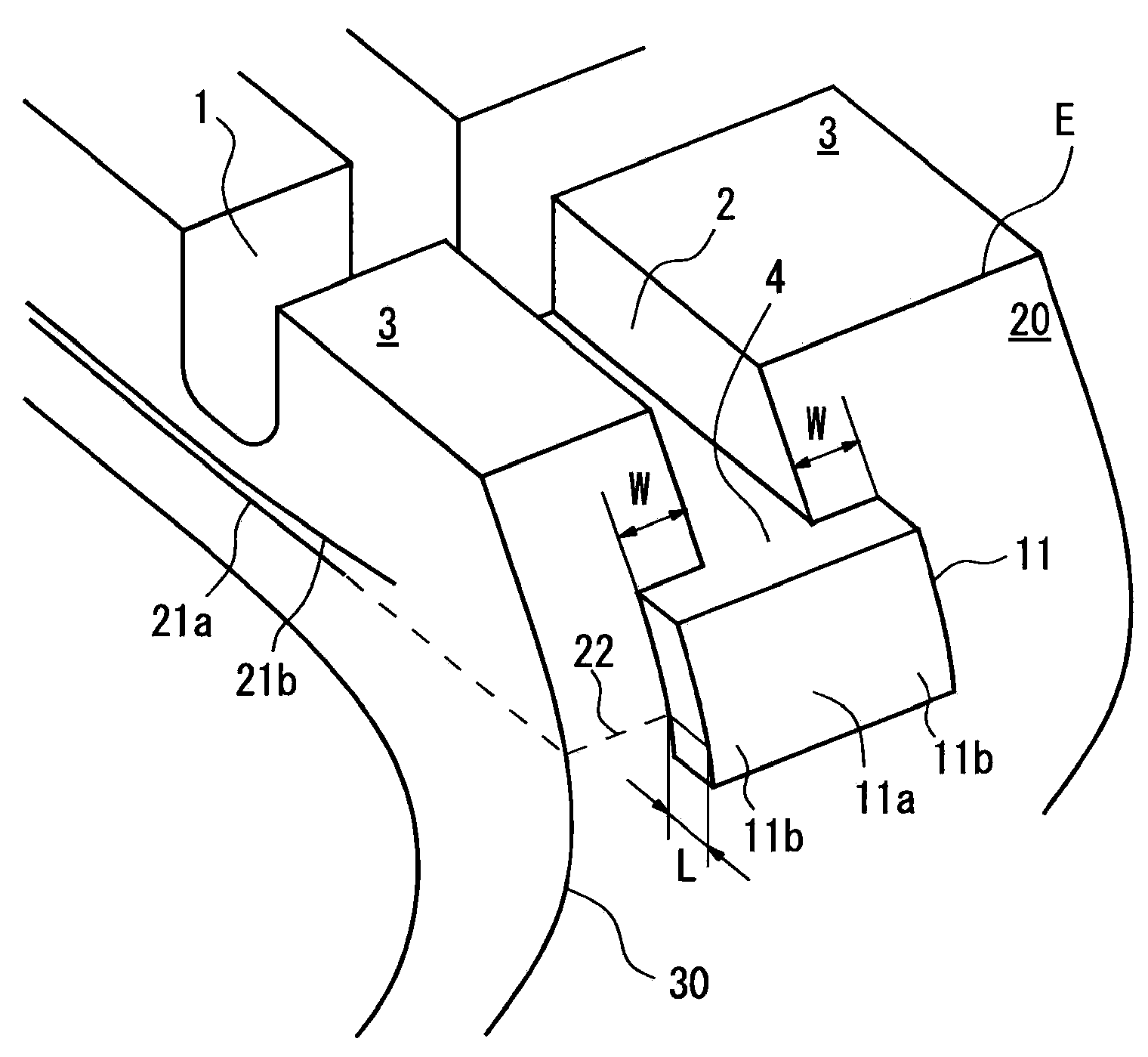

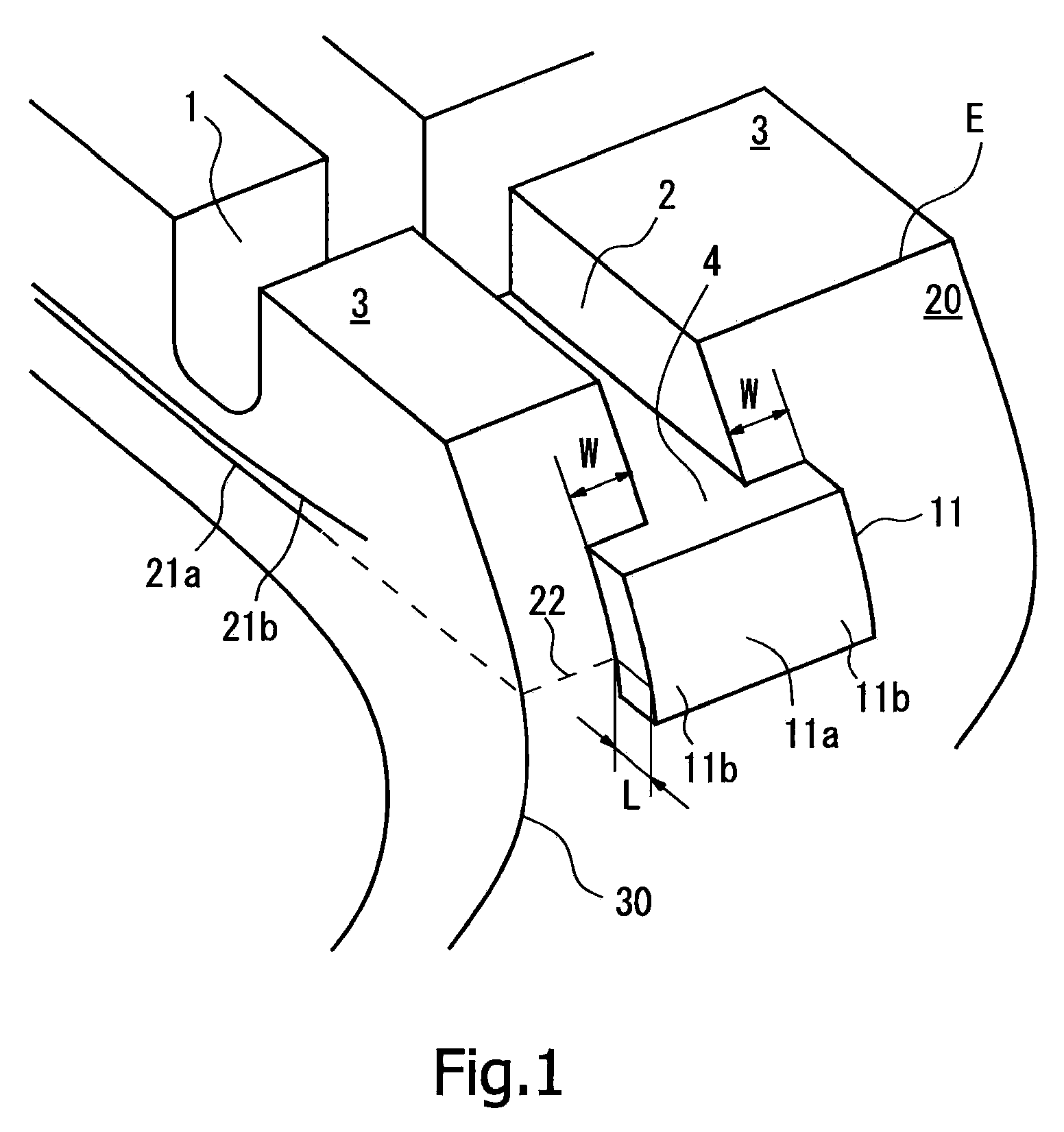

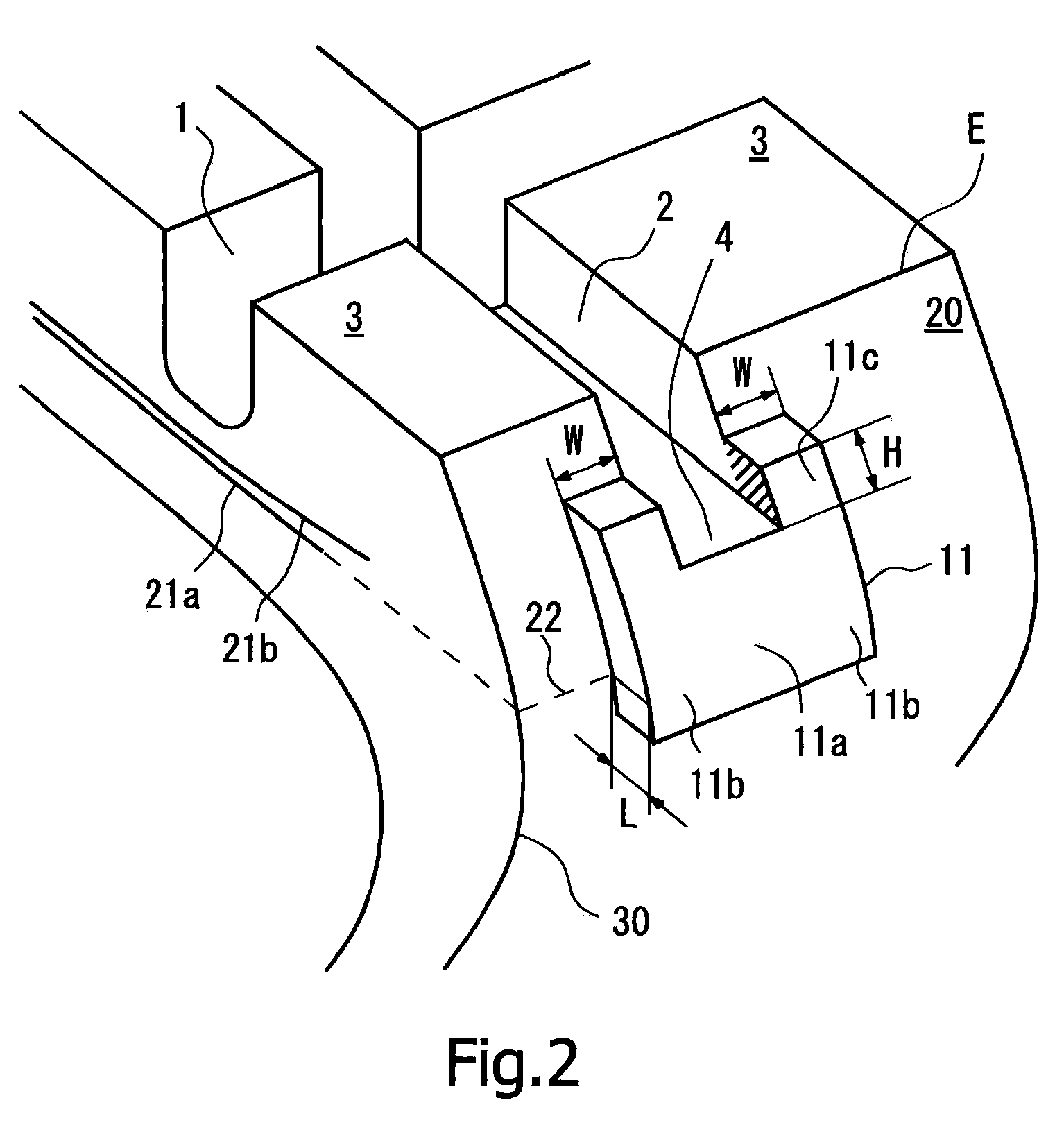

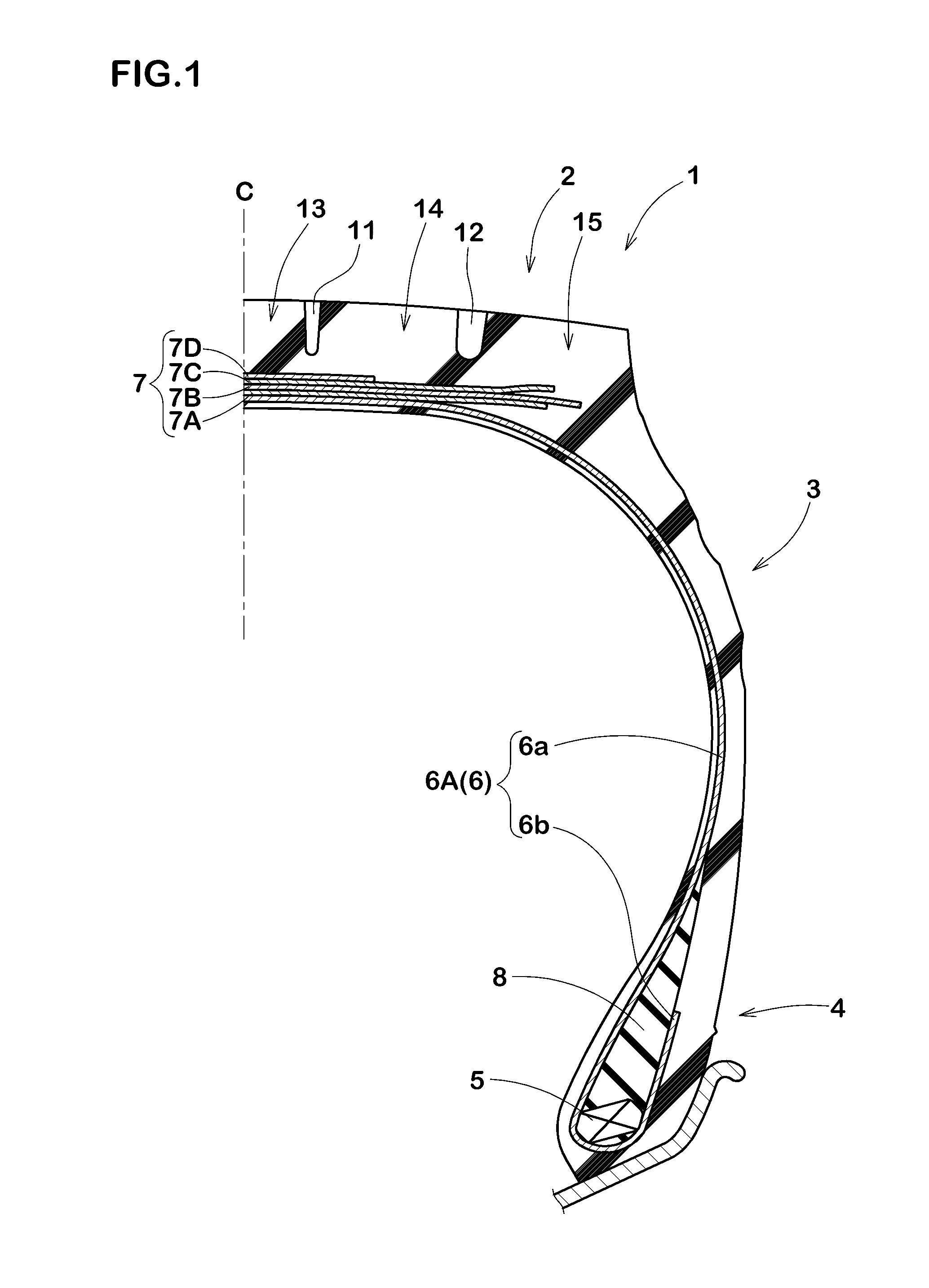

Pneumatic Tire

ActiveUS20090159166A1Improves stability and handlingReduce depthInflatable tyresTyre tread bands/patternsRotational axisBiomedical engineering

Protrusions 11 are provided in a buttress portion 20, the protrusions 11 are composed of a center portion 11a extending from the groove bottom 4 of the transverse grooves 2 toward the tire rotational axis and side portions 11b, the center portion 11a and the side portions 11b are integrally formed, the side portions 11b extend from the same cross-sectional height as, that of the center portion toward the tire rotational axis, the protrusions 11 extend at least to a virtual line 22 in which the inner most belt layer 21a is virtually extended to the buttress portion 20, and the width W of the side portions 11b is 7% to 30% of the depth D of the transverse grooves 2, and the thickness L of the protrusions 11 on the virtual line 22 is 1 mm to 10 mm.

Owner:TOYO TIRE & RUBBER CO LTD

Polycrystalline diamond

InactiveUS20100146865A1Uneven wearStable jobMaterial nanotechnologyBurnersPolycrystalline diamondScriber

An object is to provide polycrystalline diamond applicable to diverse applications; and a water jet orifice, a stylus for gravure printing, a scriber, a diamond cutting tool, and a scribing wheel that include such polycrystalline diamond. This object is achieved by polycrystalline diamond obtained by converting and sintering non-diamond carbon under an ultrahigh pressure and at a high temperature without addition of a sintering aid or a catalyst, wherein sintered diamond grains constituting the polycrystalline diamond have an average grain diameter of more than 50 nm and less than 2500 nm and a purity of 99% or more, and the diamond has a D90 grain diameter of (average grain diameter+average grain diameter×0.9) or less.

Owner:SUMITOMO ELECTRIC IND LTD +1

Pneumatic tire with rib having widthwise sipes and circumferential sipe

ActiveUS7836926B2Improve uneven wear resistanceImprove wettabilityHeavy duty tyresHeavy duty vehicleEngineeringTread

A circumferential sipe extends continuously in the circumferential direction of the tire in the center region of the tread surface section of a rib defined between circumferential grooves. Widthwise sipes are disposed at prescribed intervals in the circumferential direction of the tire in the tread surface section, the widthwise sipes extending in the widthwise direction of the tire in crossing relationship to the circumferential sipe, the widthwise sipes each having opposing terminal ends open to the circumferential grooves. The circumferential sipe changes in depth periodically in such a manner that the circumferential sipe is shallow between adjacent widthwise sipes. The widthwise sipes changes in depth in such a manner that they are greater in depth in the center region and end regions of the tread surface section.

Owner:THE YOKOHAMA RUBBER CO LTD

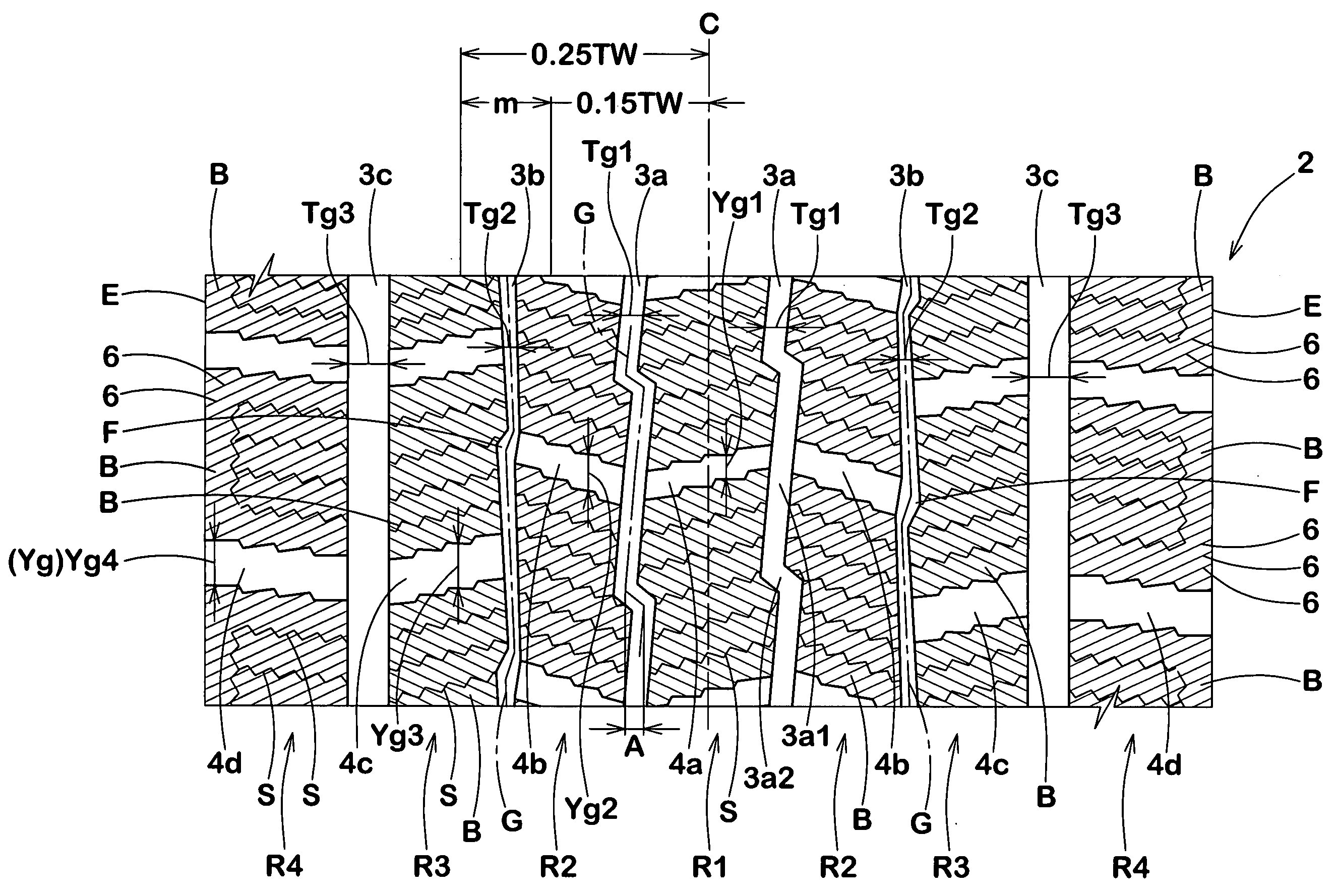

Studless tire

InactiveUS20080202658A1Reduce coefficient of frictionIncrease friction forceTyre tread bands/patternsNon-skid devicesGround contactShoulder region

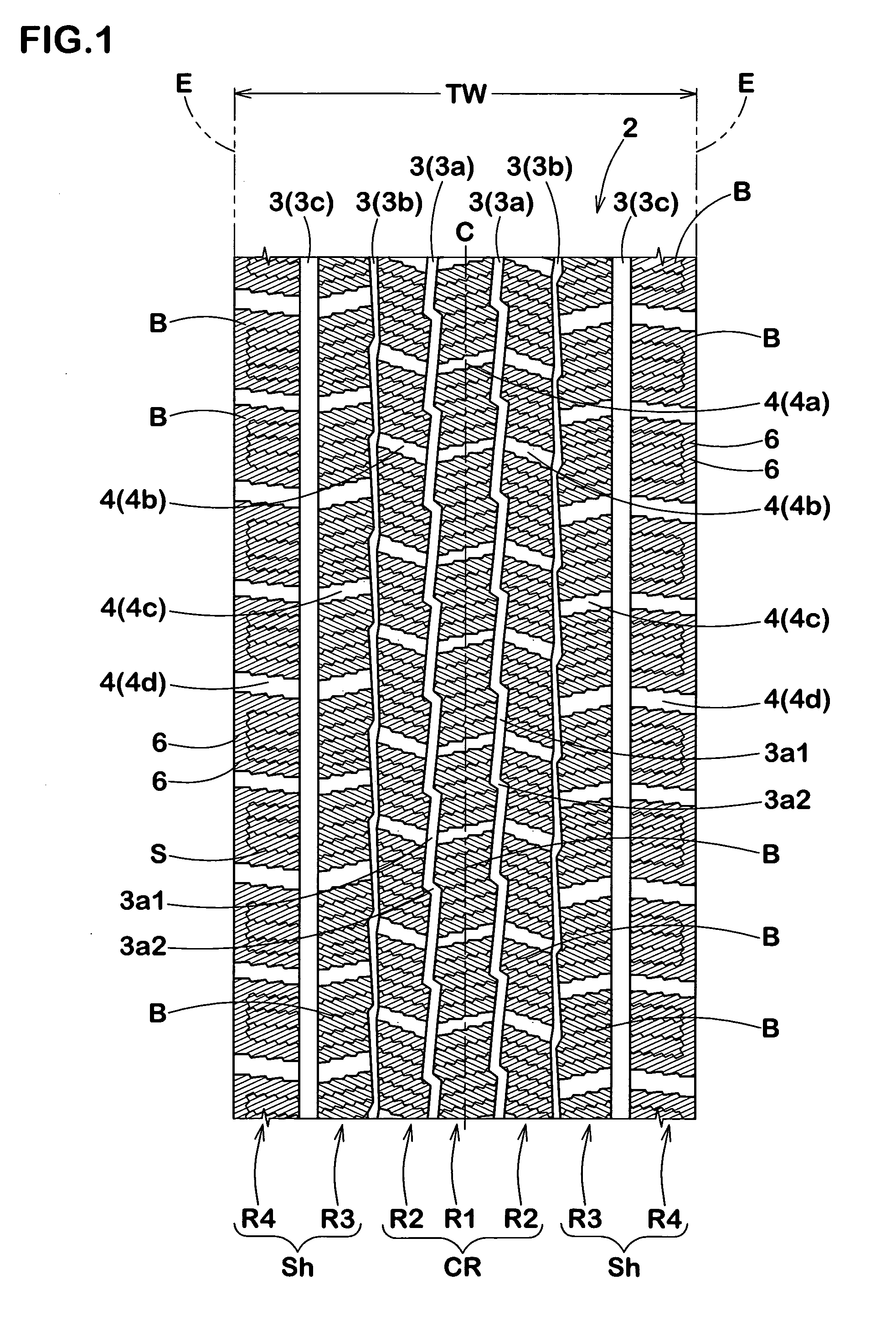

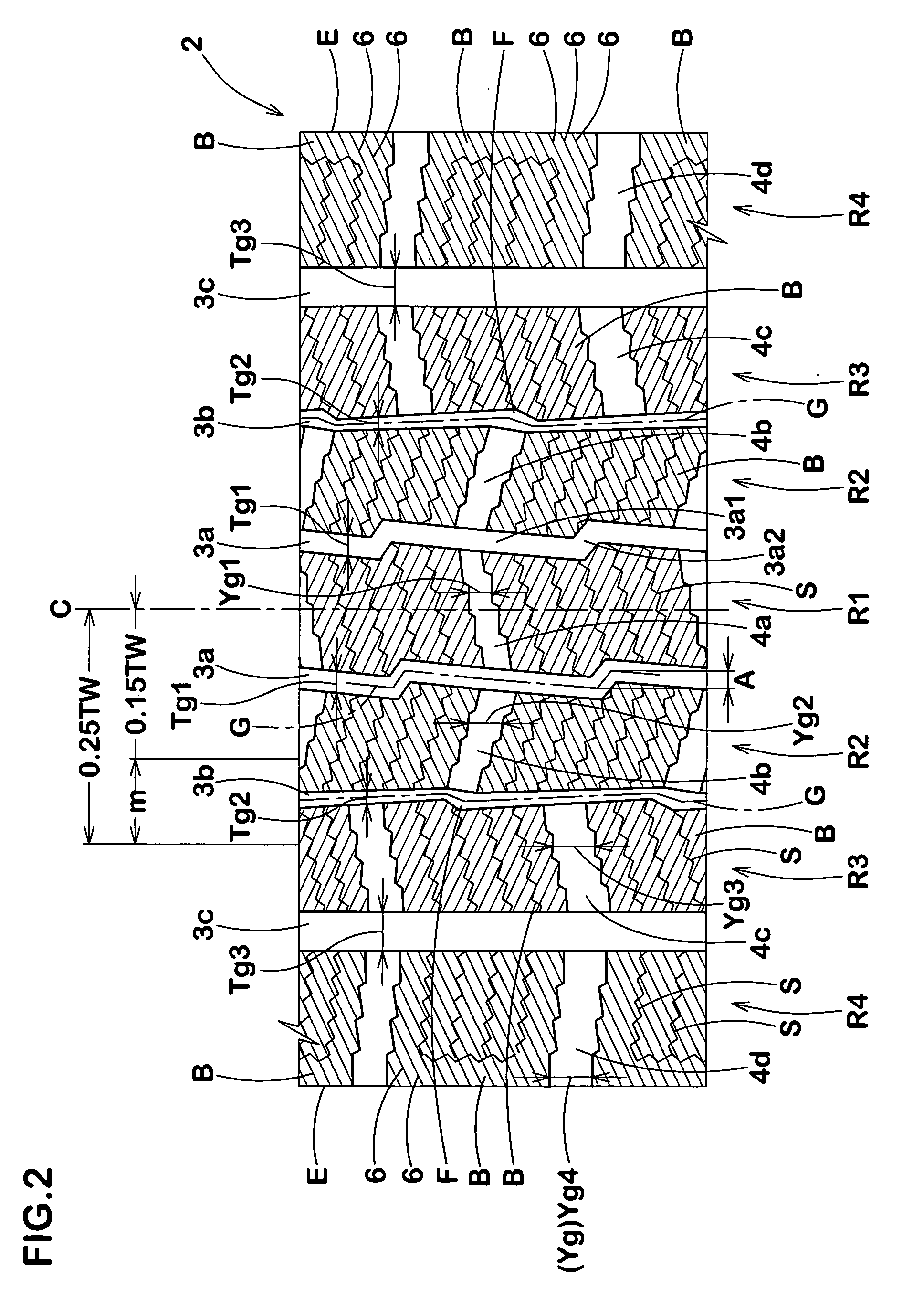

A studless tire capable of exhibiting excellent performances on both icy road and snow-covered road, including tread portion 2 having a pair of middle circumferential grooves 3b each extending in a region between 15% and 25% of tread width TW from tire equator C to provide crown region CR between the middle grooves 3b and a pair of shoulder regions Sh between the middle groove 3b and ground contact edge E, wherein the crown region CR includes rows R1, R2 of blocks B having sipes S and defined by zigzag inner circumferential grooves 3a and crown lateral grooves 4a, 4b, each shoulder region Sh includes rows R3, R4 of blocks B having sipes S and defined by linear outer circumferential grooves 3c and shoulder lateral grooves 4c, 4d, and groove area rate Gs (%) of shoulder regions Sh is larger than groove area rate Gc (%) of crown region CR so that the difference (Gs−Gc) is from 3 to 7%.

Owner:SUMITOMO RUBBER IND LTD

Rubber crawler traveling device

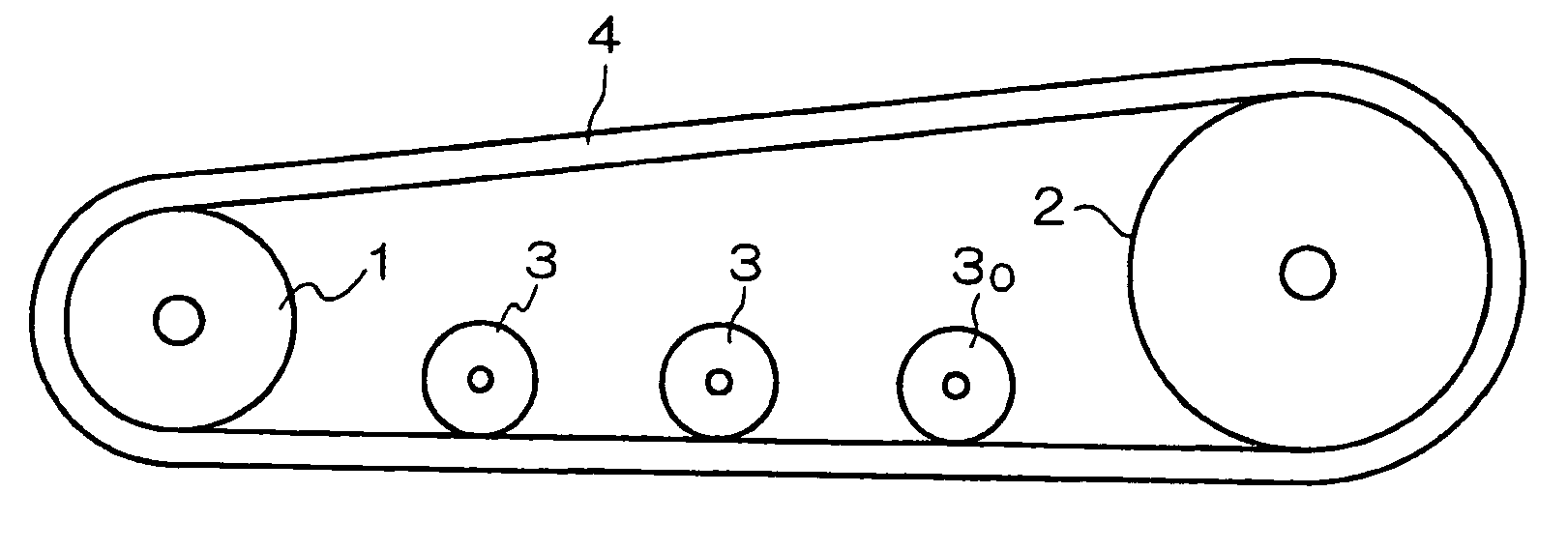

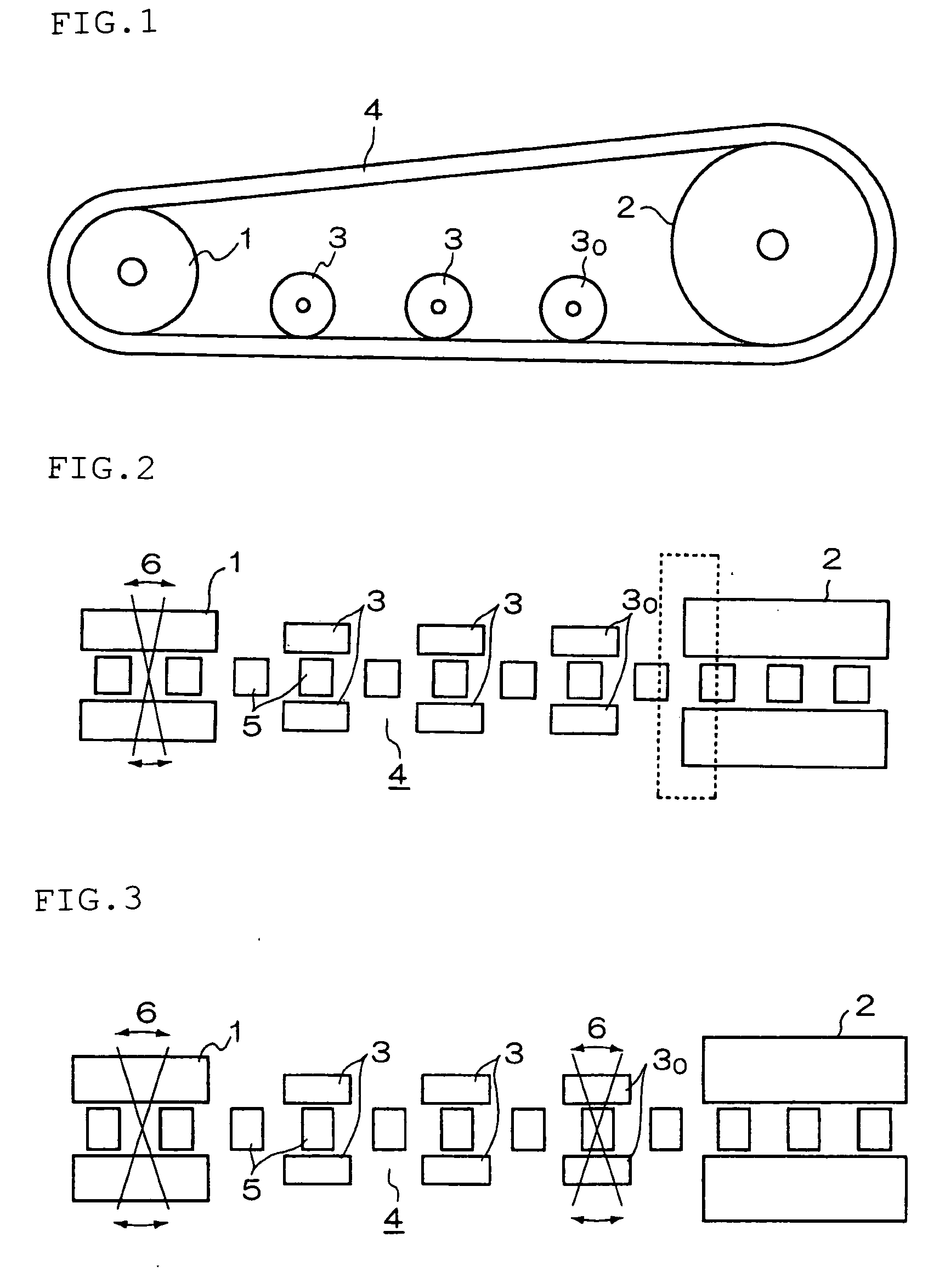

InactiveUS20060220456A1Uneven wearProlong lifeSuperstructure subunitsVehicle cleaningGround contactDrive wheel

The present invention relates to a rubber track traveling device, which adjusts contact between a guide and a drive wheel to a normal state by adjusting the direction, meandering and the like of a rubber track particularly in relation to the drive wheel. The rubber track traveling device comprises: an idler wheel provided at a vehicle; a drive wheel; a wheel provided between the idler wheel and the drive wheel on a ground-contact surface side; and a rubber track entrained around the idler wheel, the drive wheel and the wheel, wherein an adjustment mechanism for orienting the direction of the rubber track to the direction of the vehicle is provided at the idler wheel and / or the wheel.

Owner:BRIDGESTONE CORP

Pneumatic tire

ActiveUS20070284026A1Moderate shear strainUneven wearHeavy duty tyresHeavy duty vehicleEngineeringTread

A circumferential sipe extends continuously in the circumferential direction of the tire in the center region of the tread surface section of a rib defined between circumferential grooves. Widthwise sipes are disposed at prescribed intervals in the circumferential direction of the tire in the tread surface section, the widthwise sipes extending in the widthwise direction of the tire in crossing relationship to the circumferential sipe, the widthwise sipes each having opposing terminal ends open to the circumferential grooves. The circumferential sipe changes in depth periodically in such a manner that the circumferential sipe is shallow between adjacent widthwise sipes. The widthwise sipes changes in depth in such a manner that they are greater in depth in the center region and end regions of the tread surface section.

Owner:THE YOKOHAMA RUBBER CO LTD

Pad assembly for disc brake

ActiveUS7481304B2Smooth slidingSmooth movementBraking membersFriction liningEngineeringMechanical engineering

Owner:AKEBONO BRAKE IND CO LTD

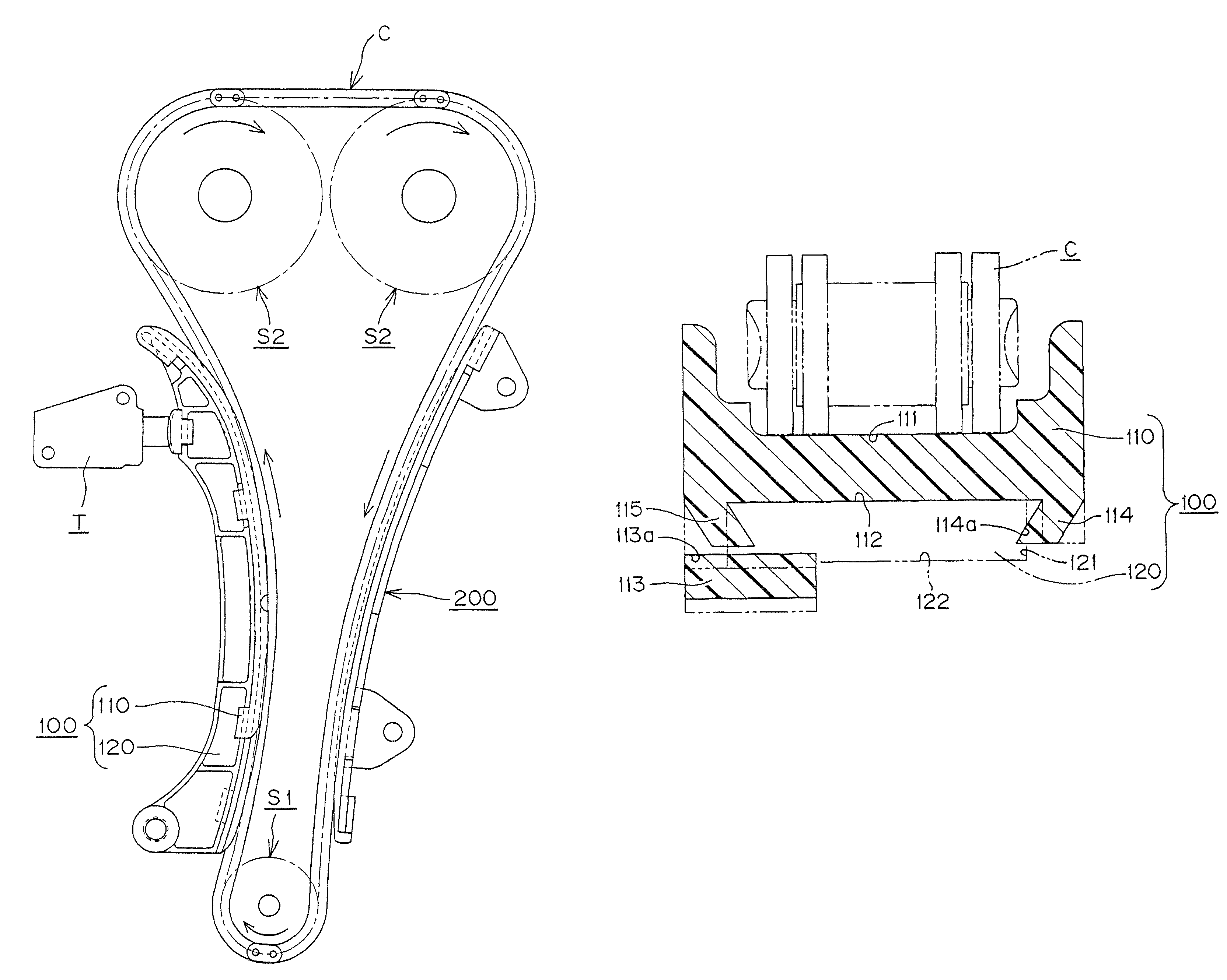

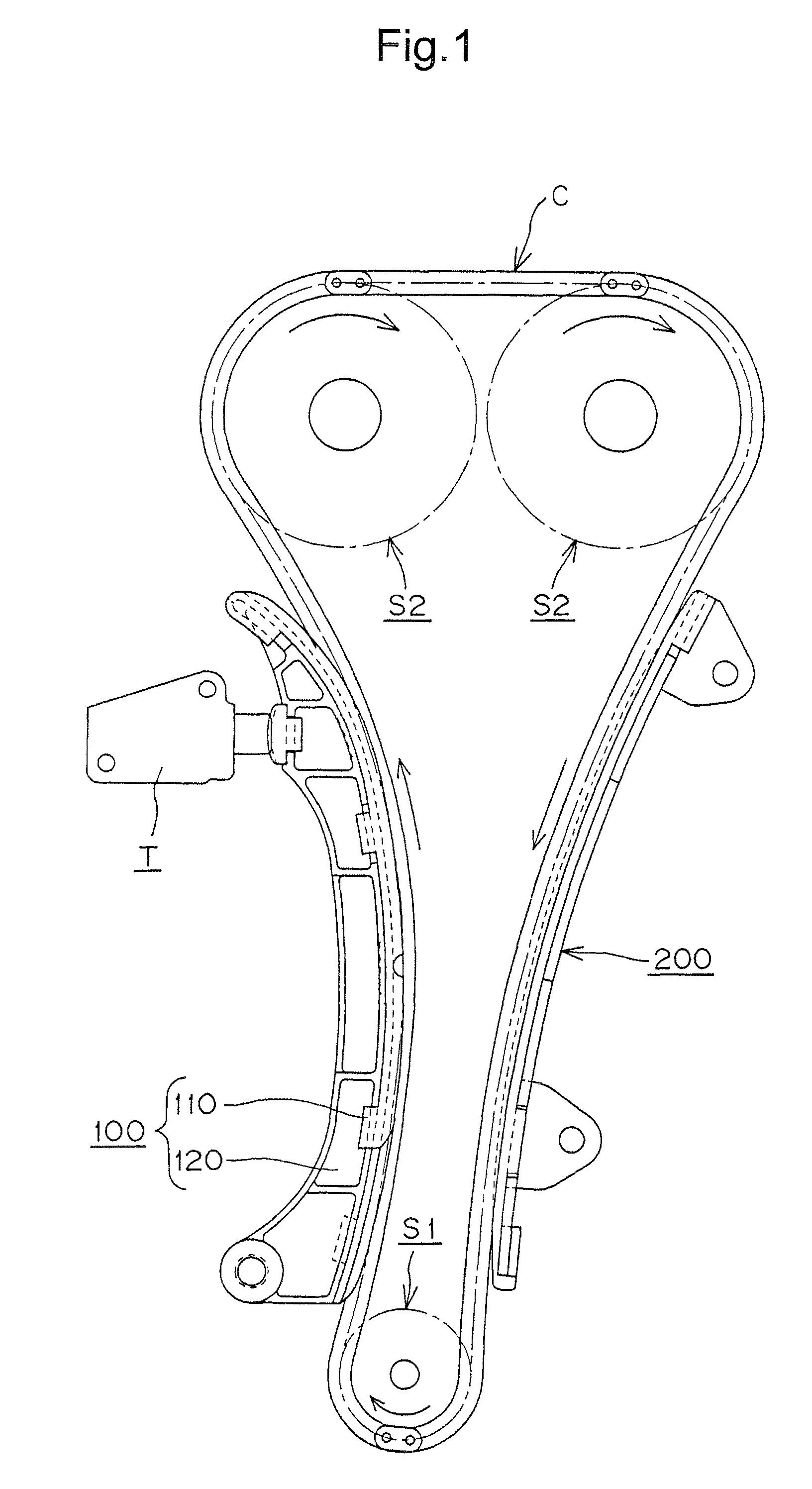

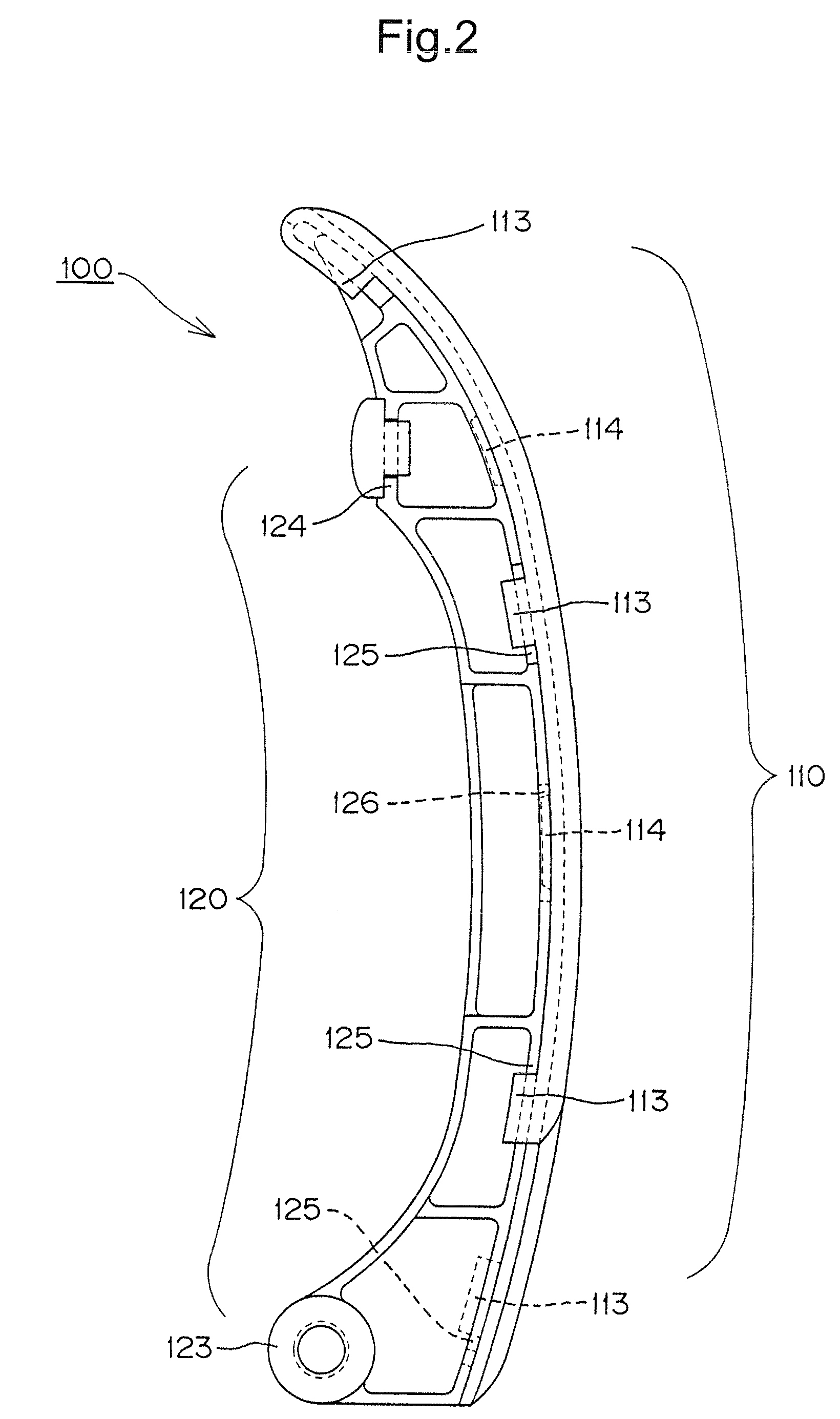

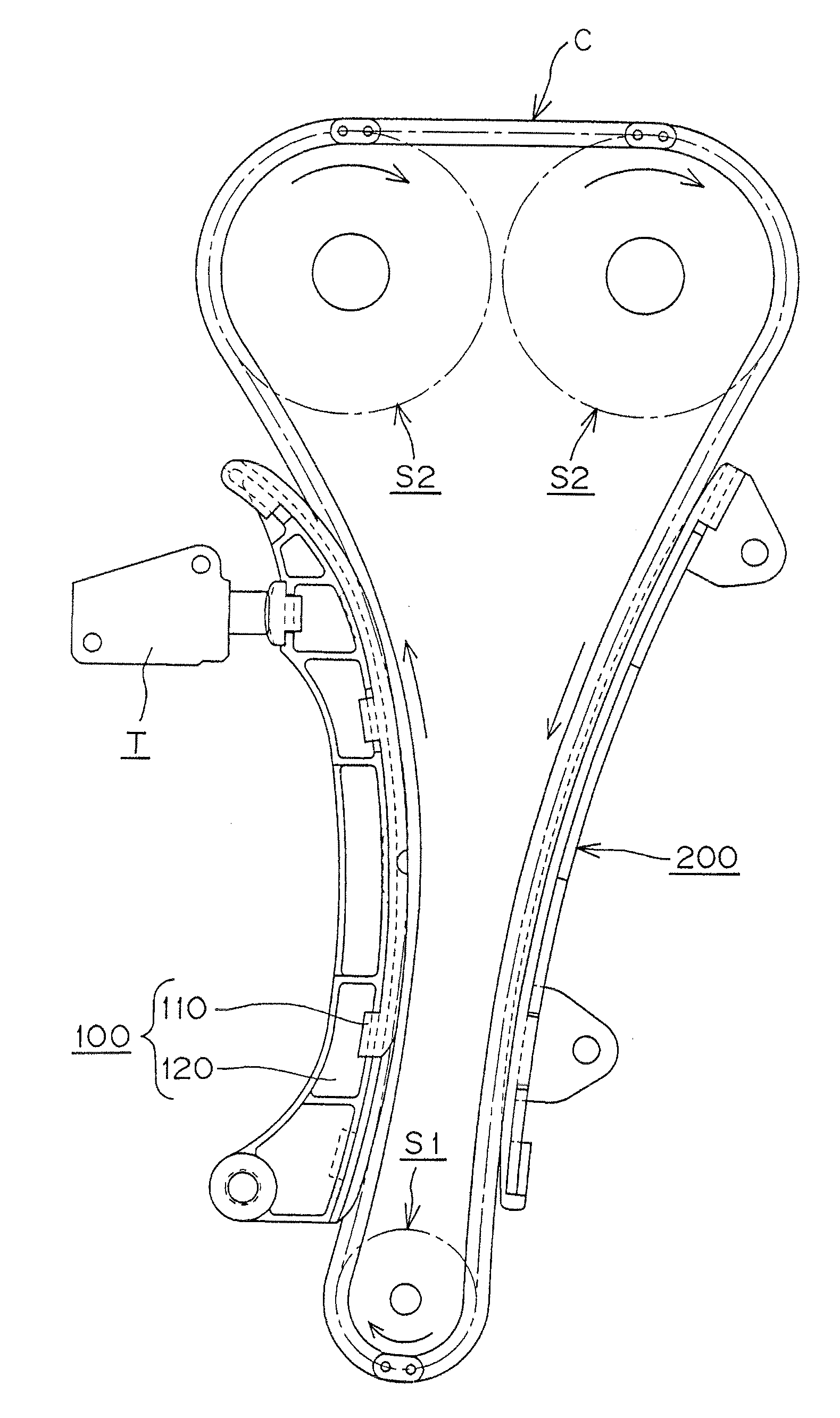

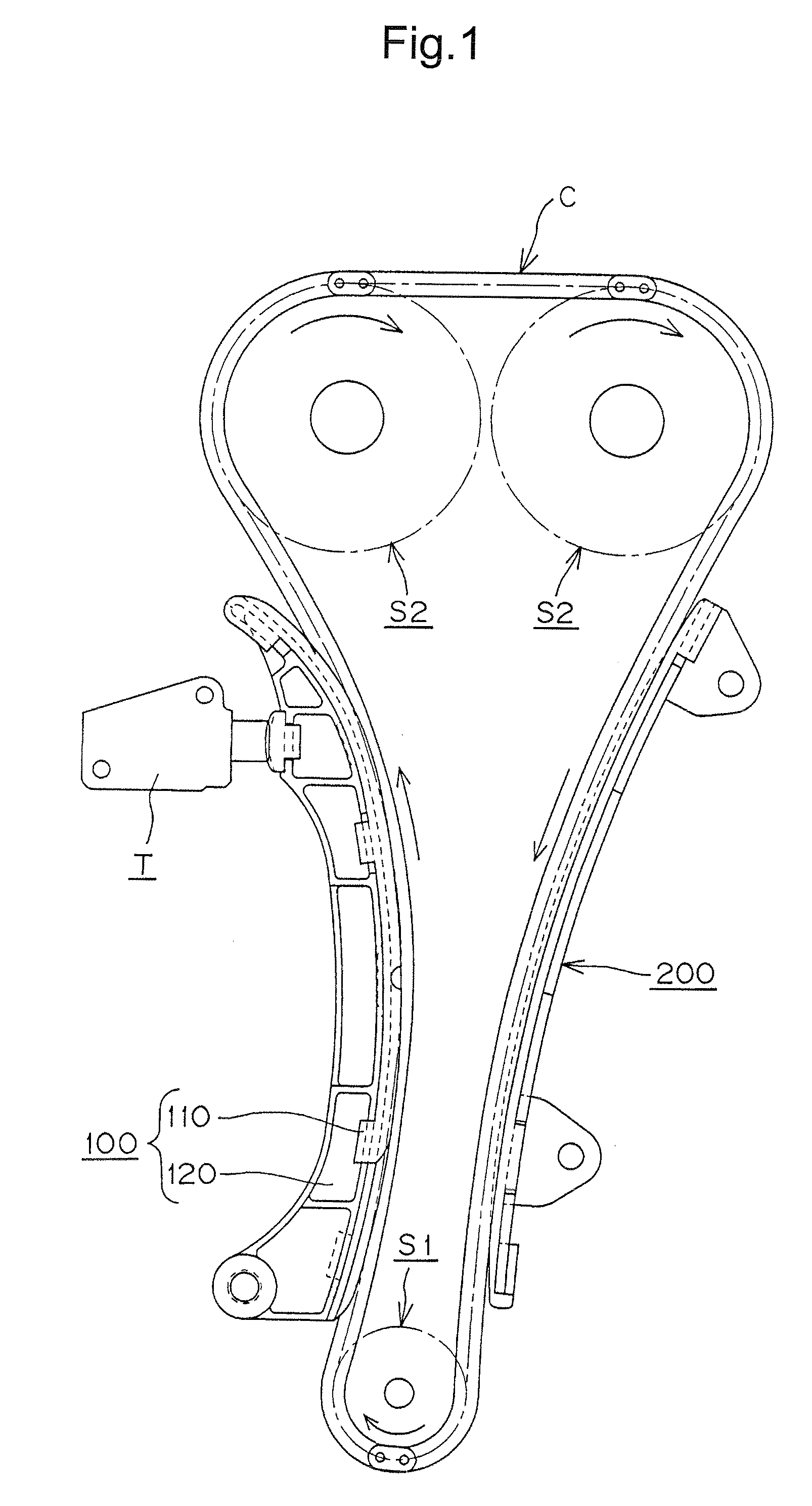

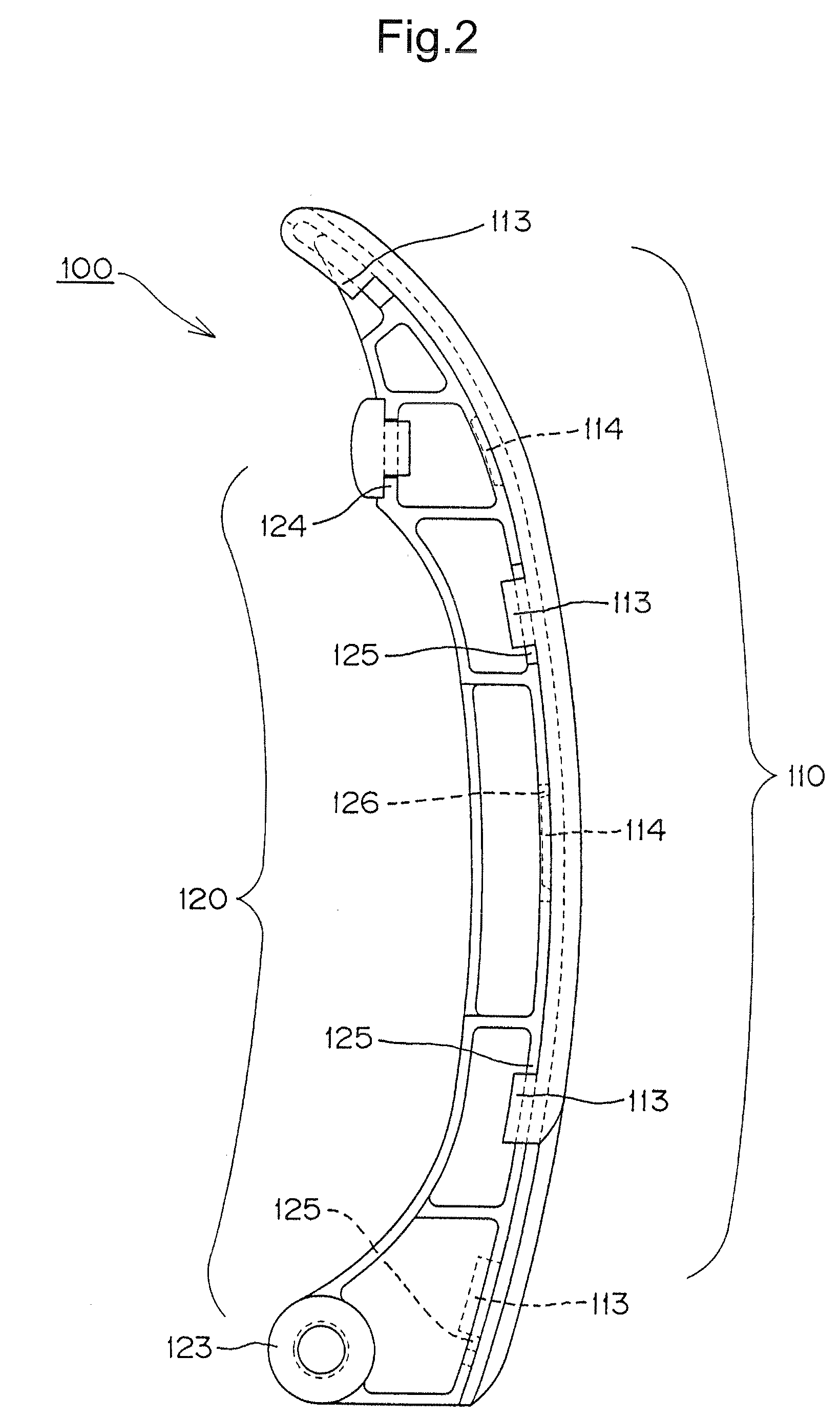

Guide for transmission device

In an engine timing chain guide composed of a synthetic resin shoe supported on a frame by L-shaped and strip-shaped engagement members integrally molded as unitary parts of the shoe, the L-shaped members are formed with oblique tongues that resiliently engage side edges of the frame member, and the strip-shaped engagement members include surfaces that extend obliquely toward, and resiliently engage, a side edge of the frame member. Laterally extending legs of the L-shaped members are also formed with bulged portions, and the frame member is sandwiched between the bulged portions and a back side of the shoe.

Owner:TSUBAKIMOTO CHAIN CO

Disk brake

ActiveUS20100187050A1Easy to findReduce frictionAxially engaging brakesSlack adjustersCalipersDisc brake

There is provided a disk brake comprising: a mounting member axially extending over a disk periphery, the mounting member including a pad guide where a friction pad travels; a caliper; and a return spring between the friction pad and the mounting member and urges the friction pad into a return direction separating from the disk, wherein the return spring includes: a first extended portion where a base end side thereof is fixed to a back plate of the friction pad while a top end side thereof extends separating from the disk; and a second extended portion folded from the top end side of the first extended portion toward the mounting member, a top of the second extended portion extending to elastically abut to the side of the mounting member, and a plate thickness direction of the first extended portion extends to be approximately a radial direction of the disk.

Owner:HITACHI ASTEMO LTD

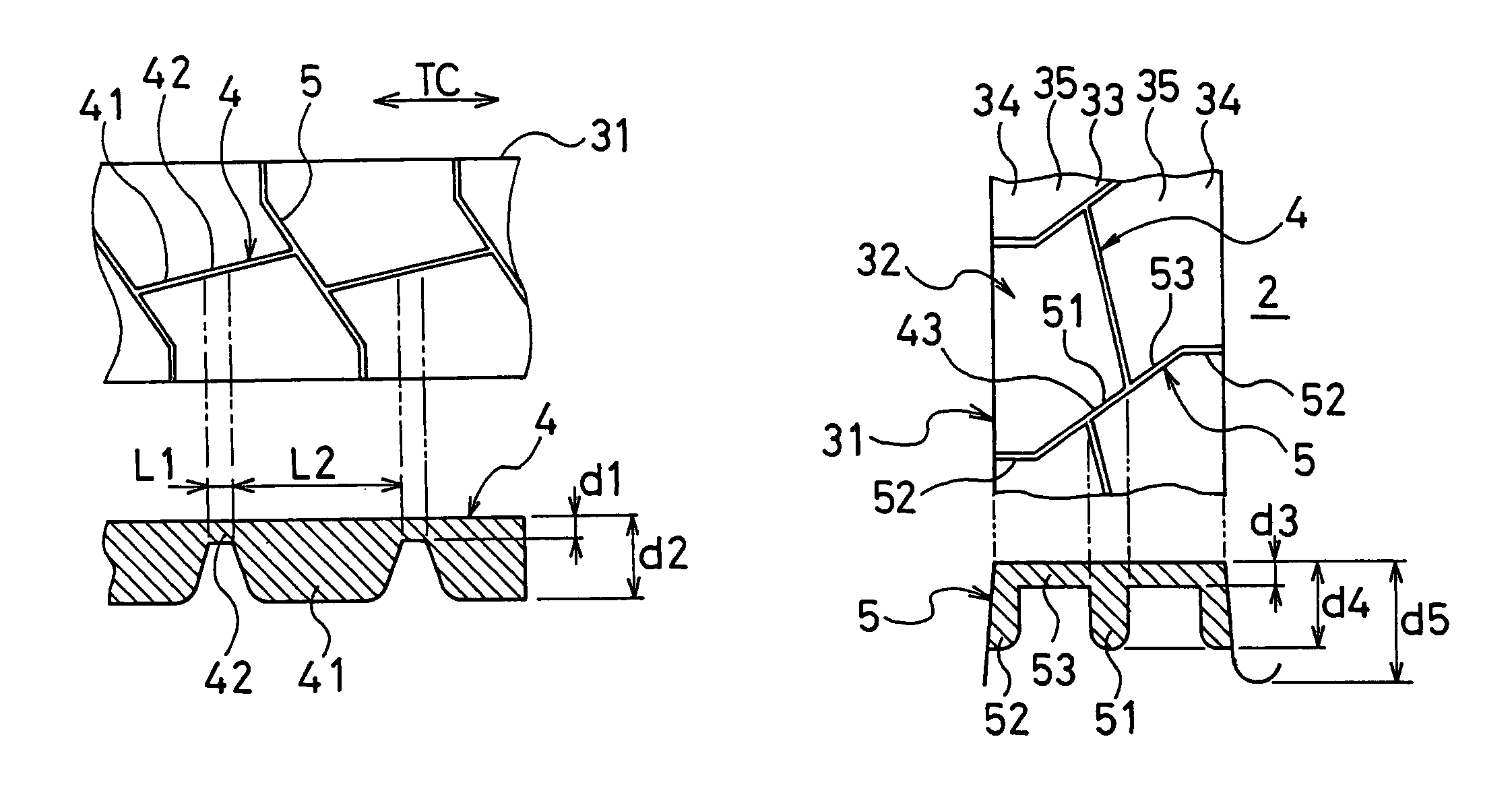

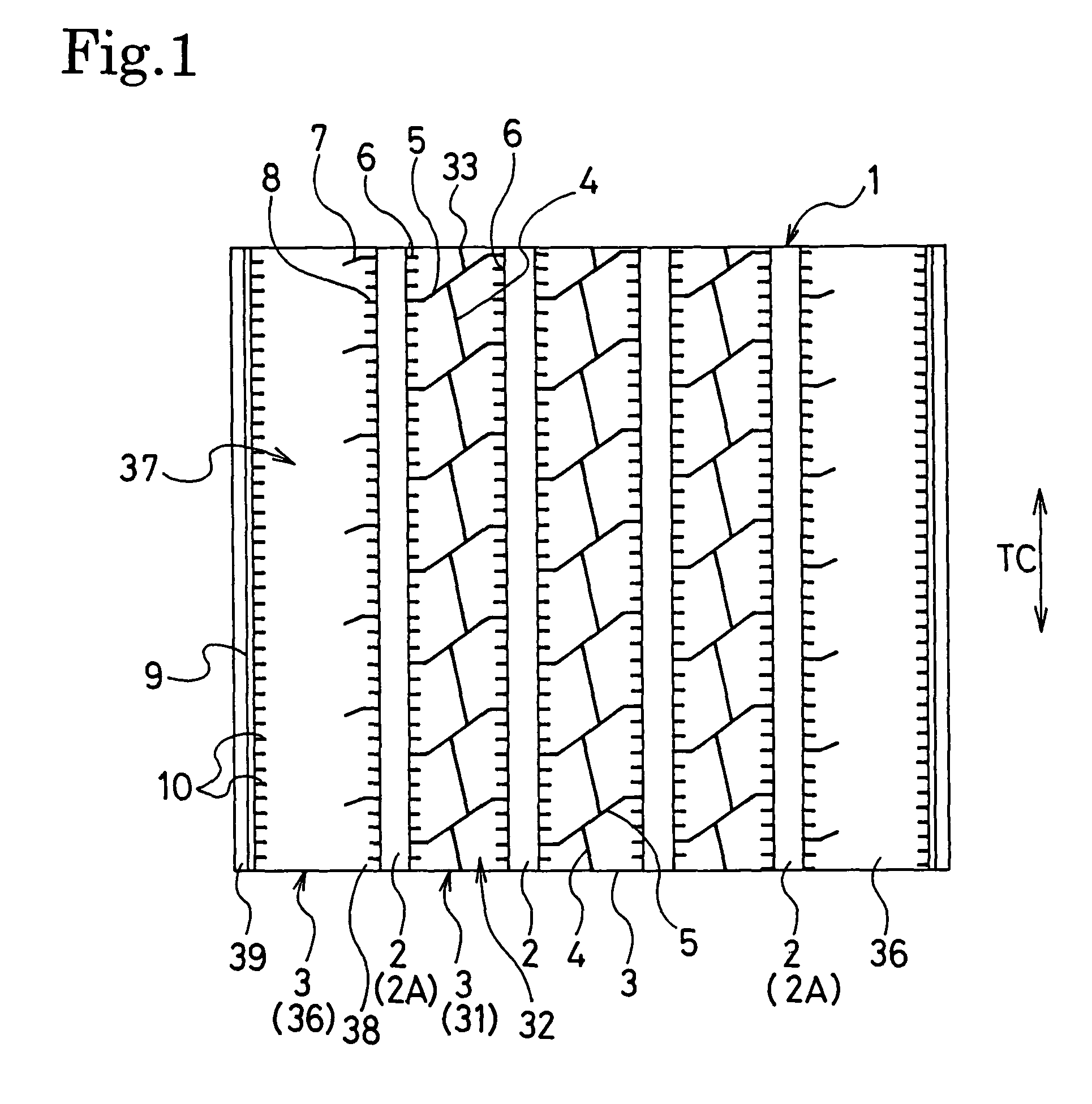

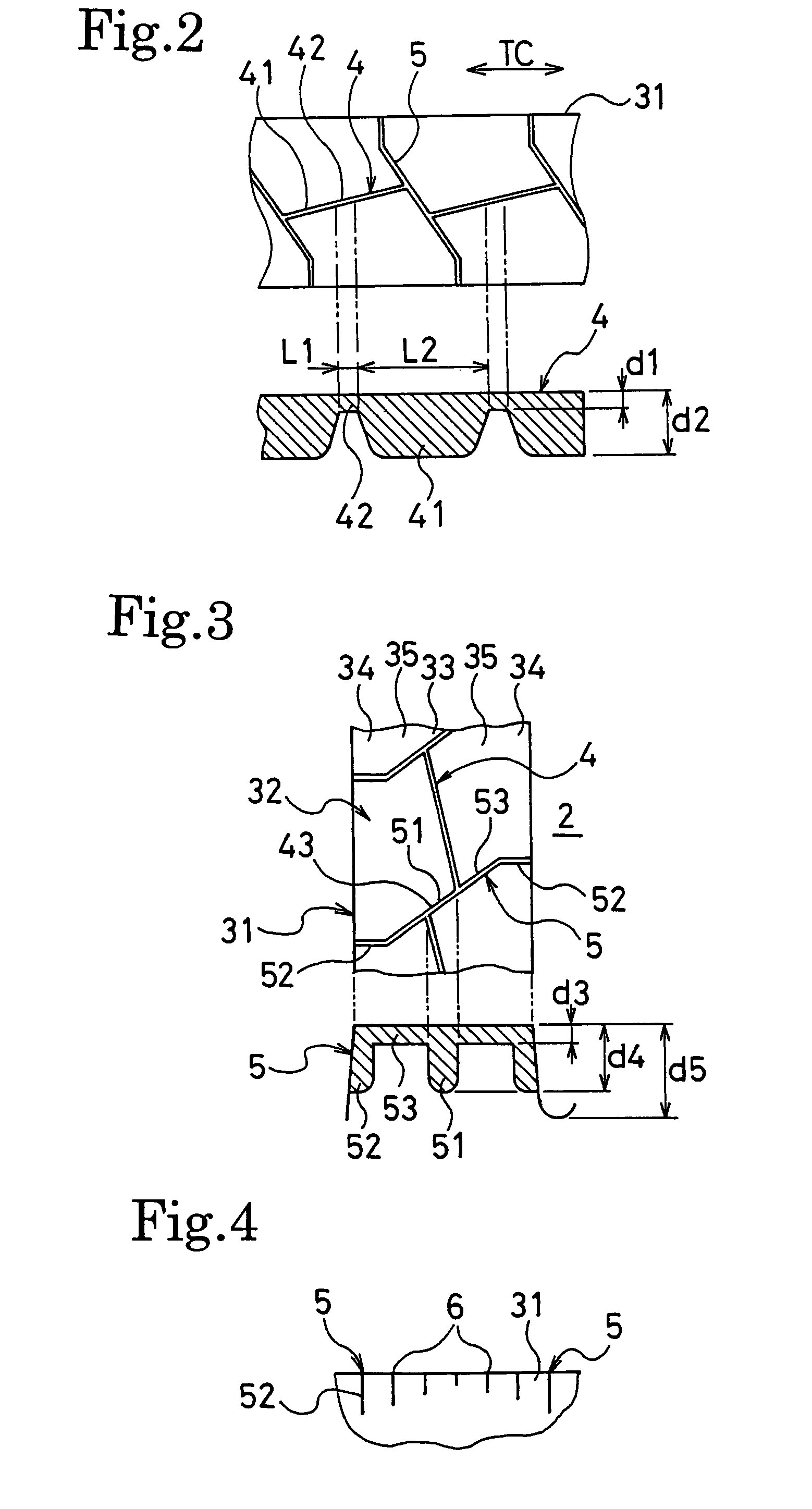

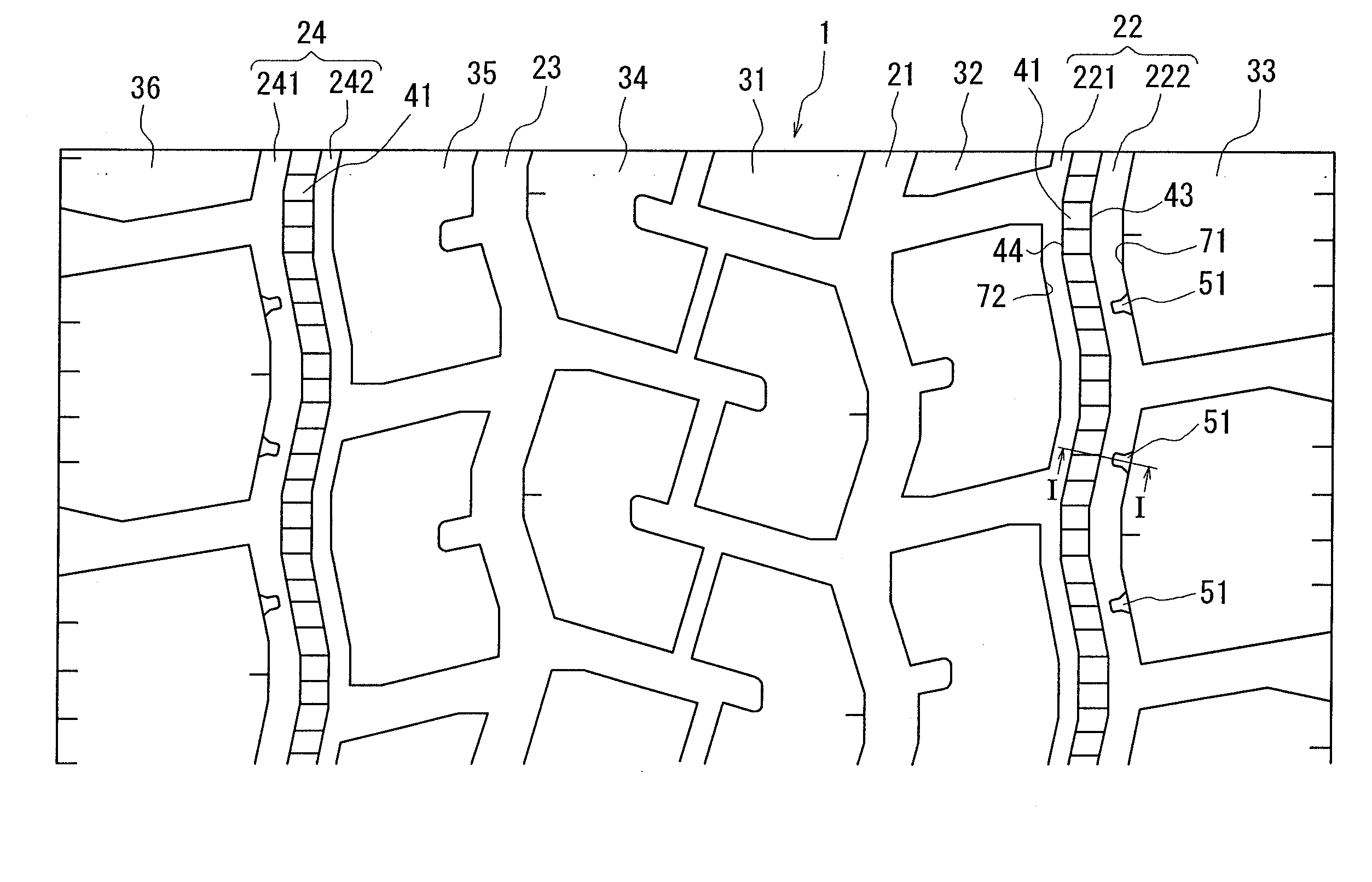

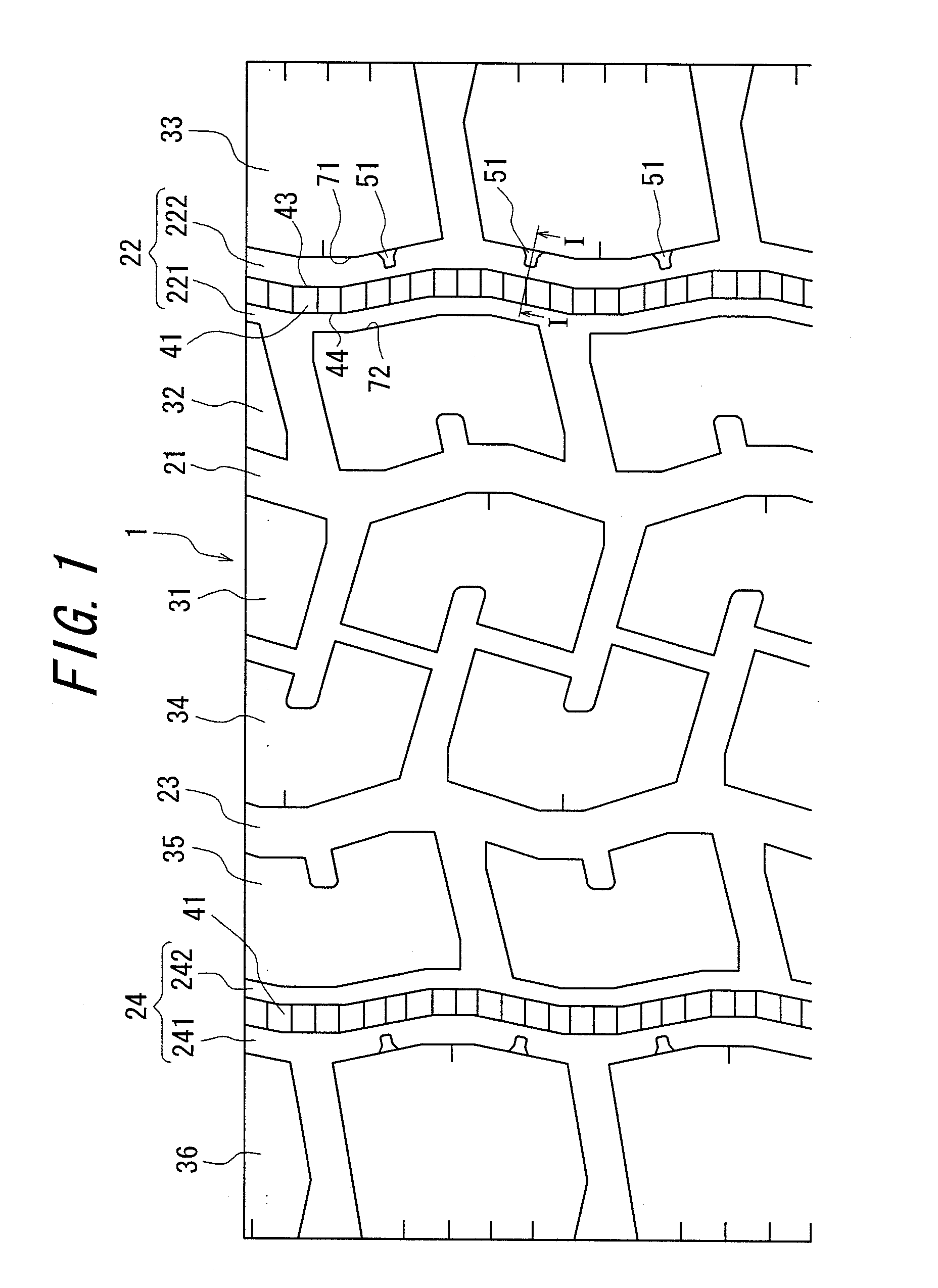

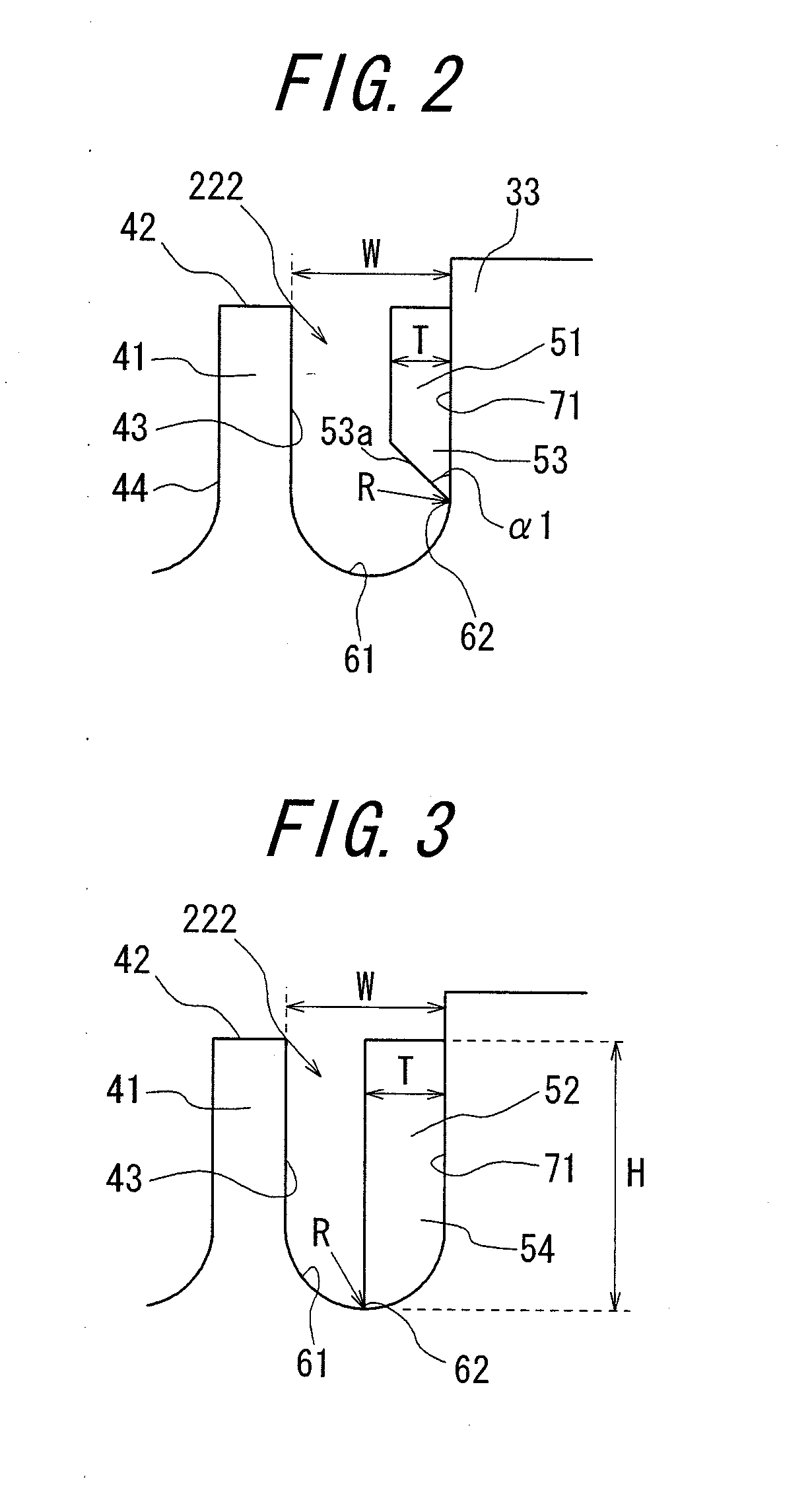

Tire and method of producing the same

InactiveUS20110126952A1Reduce noiseUneven wearTyre tread bands/patternsNon-skid devicesVulcanizationEngineering

An object of the invention is to provide a tire and a method of producing the tire, in which tire breakage of a groove fence in vulcanization molding and generation of cracks at a groove bottom can be suppressed, noise is relatively low and uneven wear is less likely to occur. At least one of a groove wall 71 surface of the circumferential groove 222 and a side wall 43 surface of a stepped land portion 41 is provided with a groove fence 51 which are formed in the extending direction of the circumferential groove at a predetermined intervals therebetween such that the groove fence protrudes in the groove widthwise direction of the circumferential groove. The groove fence 51 is characterized in that: it has a thin wall portion 53 having a shape in which a portion 61 thereof on the side of the groove bottom of the circumferential groove has been notched in a section orthogonal to the circumferential groove 22; and an angle formed by a notched face 53a of the thin wall portion 53 with respect to the at least one of the wall surfaces 71 provided with the groove fence 51 is set at 70° or smaller.

Owner:BRIDGESTONE CORP

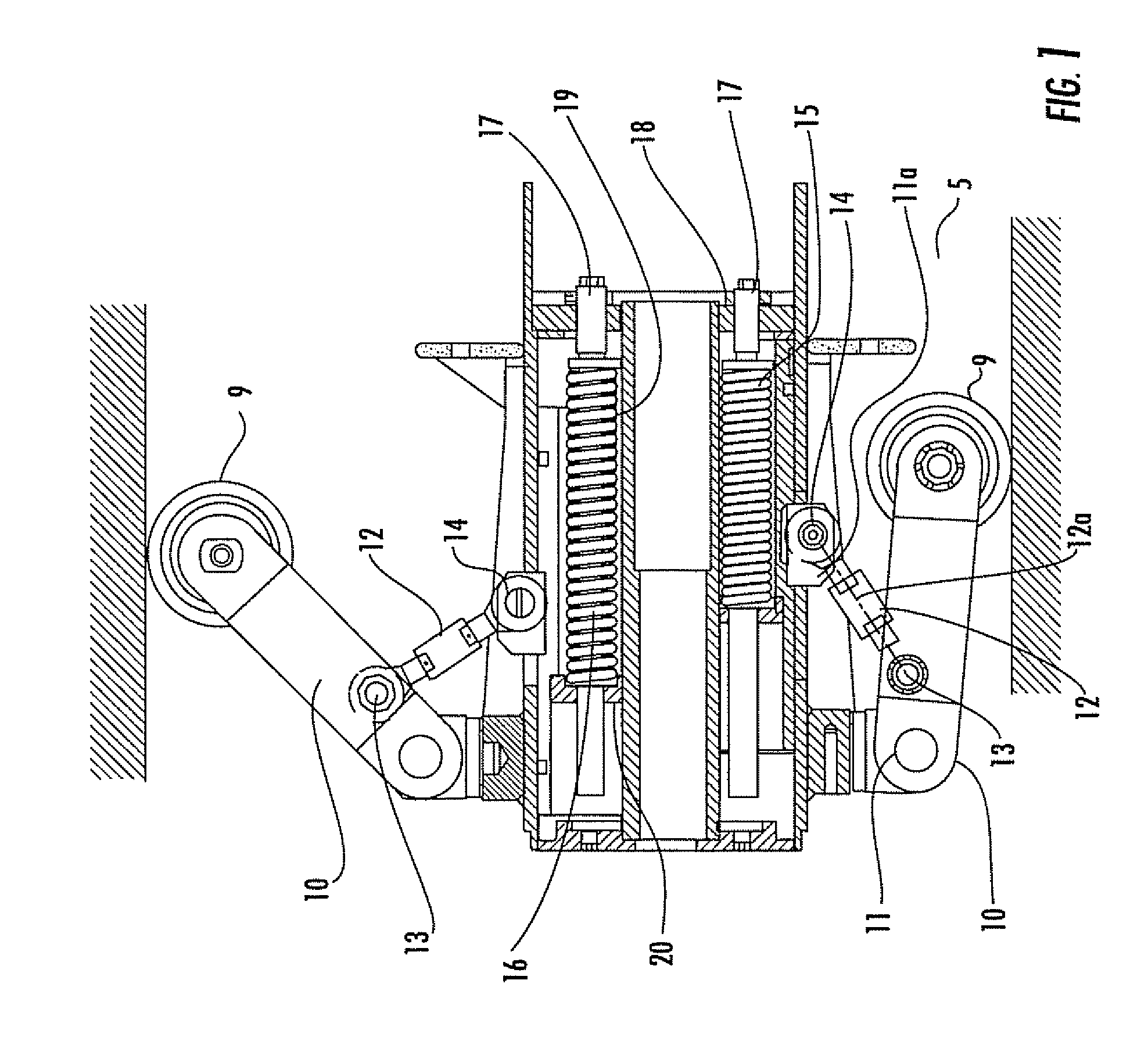

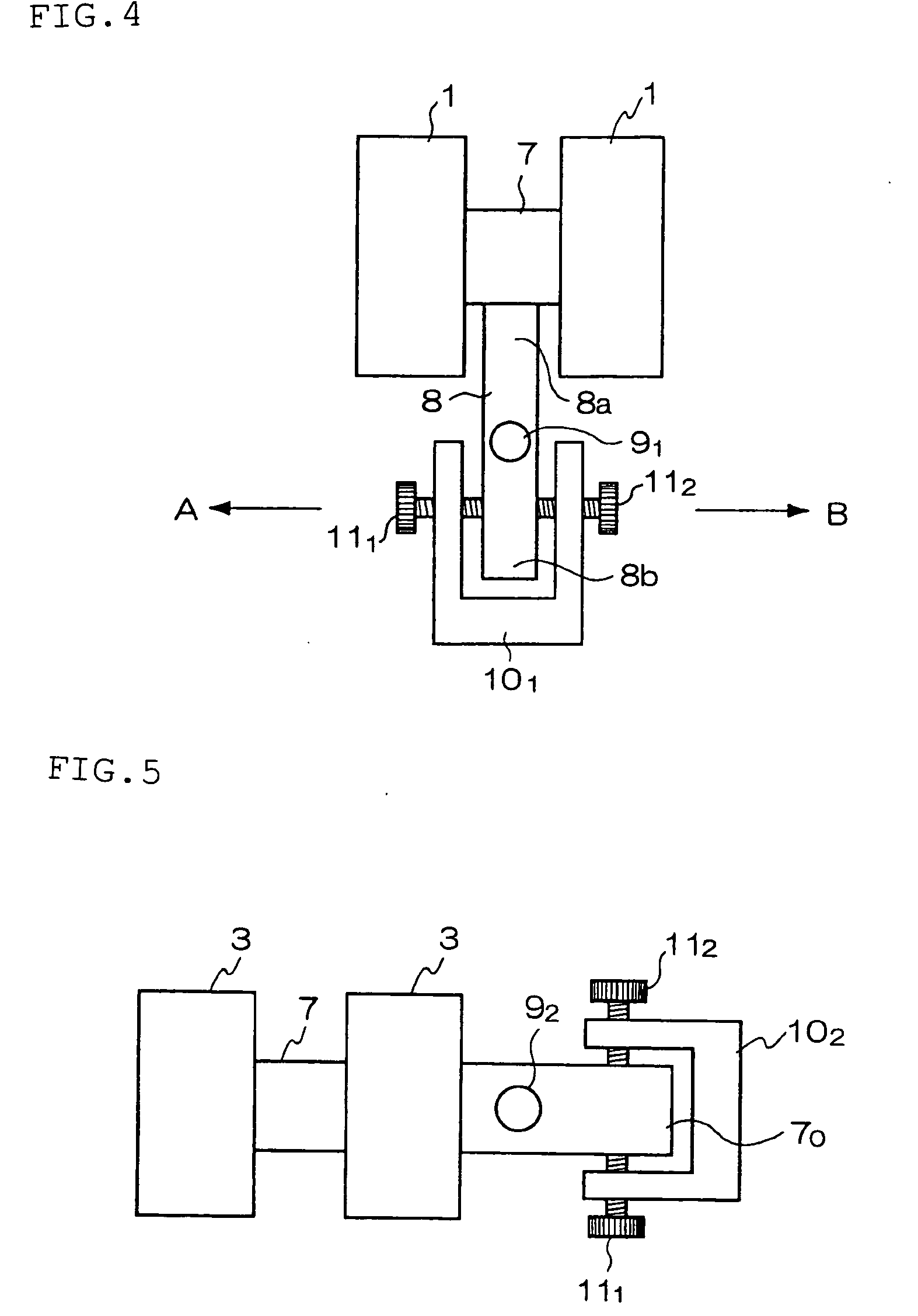

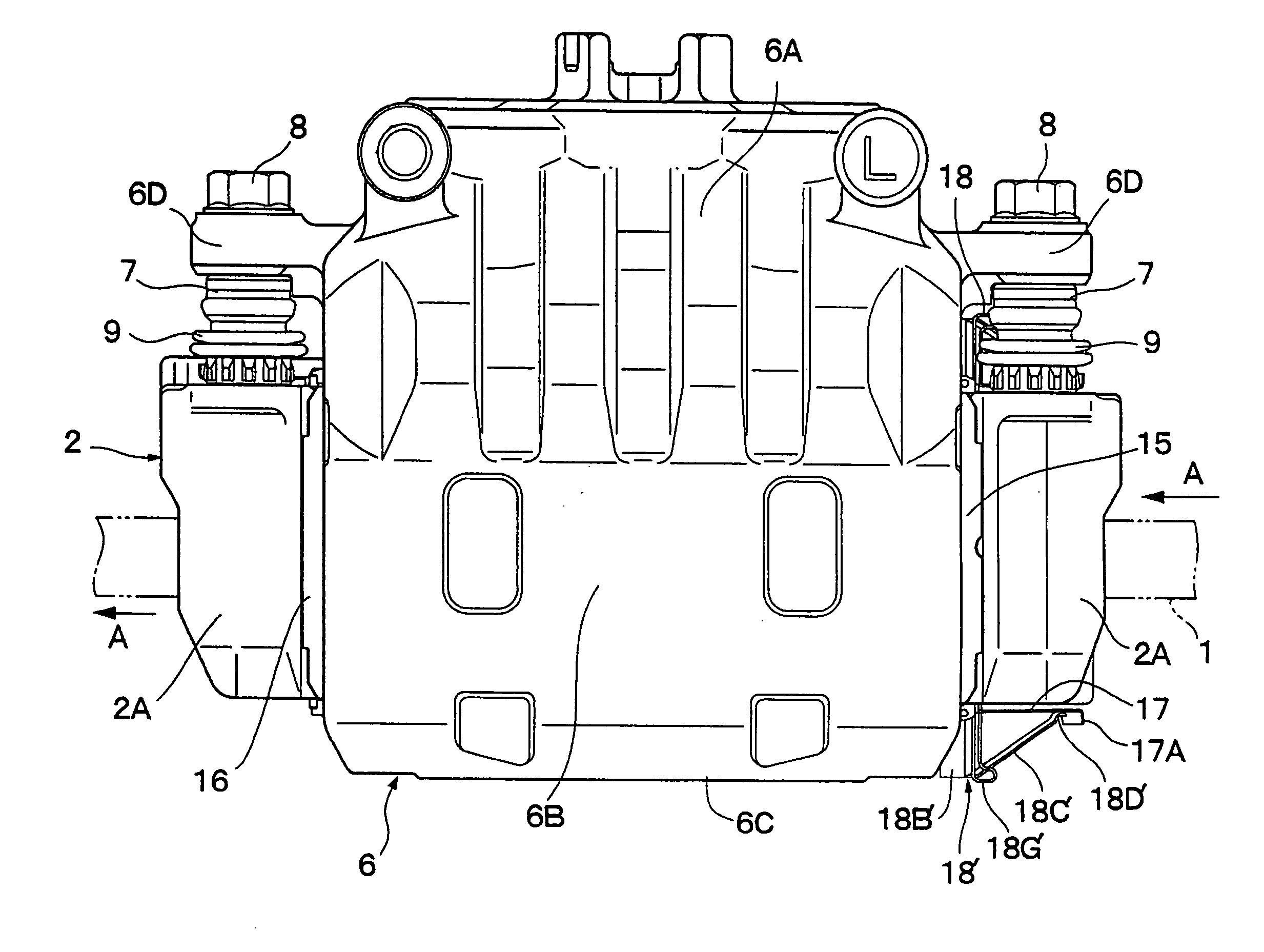

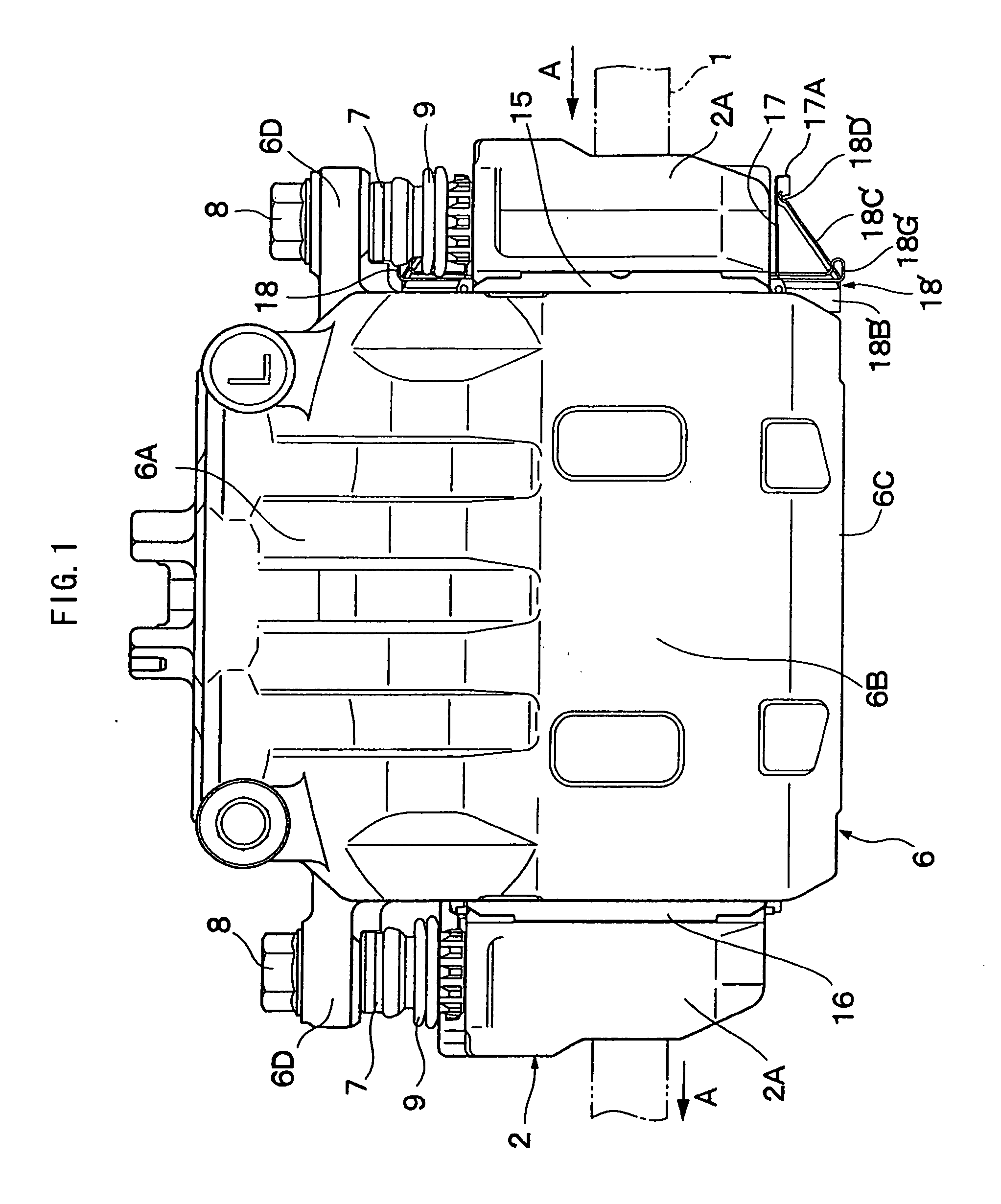

Electromagnetic reciprocating compressor with spring assembly mounted around piston

InactiveUS6015273AShorten the lengthReduce lateral forceEngine sealsPiston pumpsReciprocating motionPiston Guide

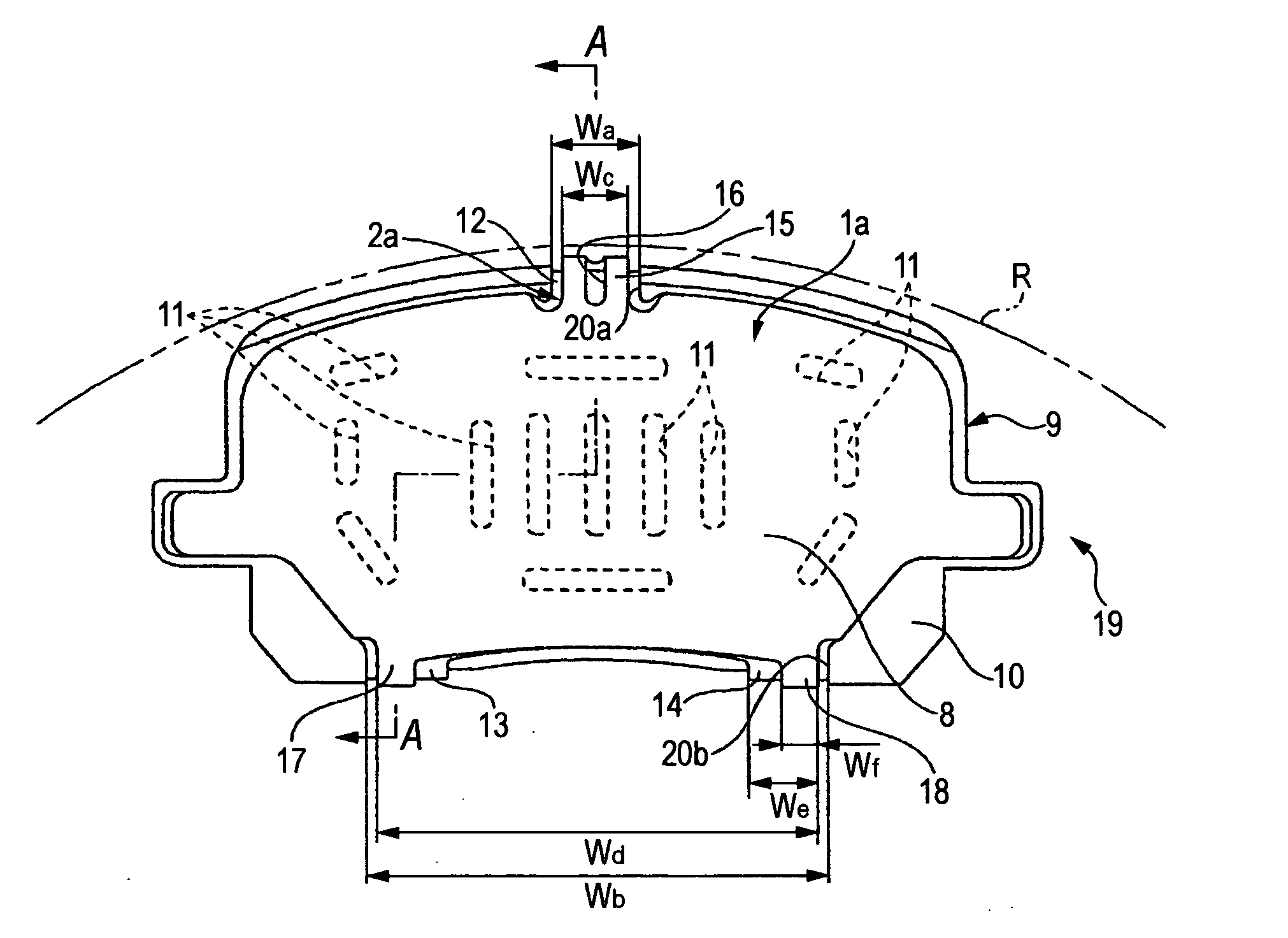

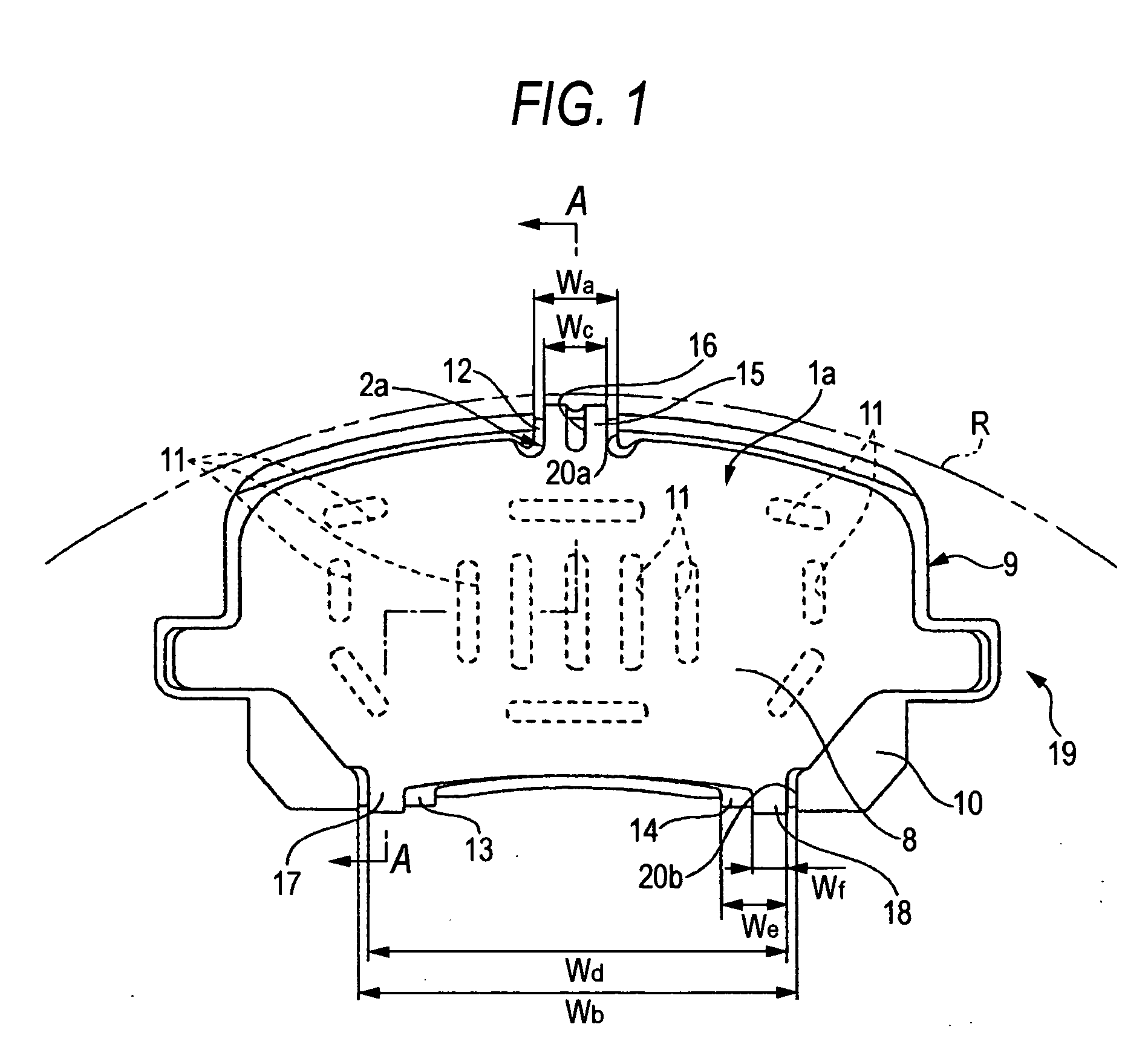

PCT No. PCT / GB95 / 02901 Sec. 371 Date Jul. 10, 1997 Sec. 102(e) Date Jul. 10, 1997 PCT Filed Dec. 8, 1995 PCT Pub. No. WO96 / 18037 PCT Pub. Date Jun. 13, 1996An electromagnetic reciprocating compressor has a body (1, 2), a piston (10) reciprocating in the body, and an electromagnetic drive (22, 23, 24) for the piston. The piston has a piston head (11) which slides in a cylinder (12) in the body to effect compression of fluid in the cylinder during operation of the compressor and, axially spaced from the piston head, a piston guide member (13) slidingly movable on a guide surface (14) provided by the body. The compressor has a compression spring arrangement (20) comprising at least one helical compression spring (20a, b) acting to drive the piston axially. The spring (20a, b) is mounted around the piston and is at least partly located within the cylinder during at least part of the piston stroke but is outside the working volume of fluid undergoing compression.

Owner:PEGASUS

Pneumatic Tire

InactiveUS20080128063A1Improve wear resistanceImprove rigidityTyre tread bands/patternsNon-skid devicesGround contactEngineering

A pneumatic tire is provided which can realize an increase in stone-catching resistance while suppressing uneven wear such as river wear in a tread portion. In a pneumatic tire in which a center rib and intermediate ribs which are defined by four straight-line main grooves, which extend continuously in a circumferential direction of the tire and shoulder ribs which are defined by the main grooves which are situated closer to shoulders of the tire and straight-line thin grooves which extend continuously in the circumferential direction of the tire in the vicinity of tread ground-contacting edges are formed on the surface of a tread of the tire, inclination angles of a shoulder side groove wall of the main groove which defines the shoulder rib and a tire's equator line side groove wall of the thin groove are both such an angle that the shoulder side groove wall and the tire's equator line side groove wall are inclined at an angle of not more than five degrees in a direction in which the width of a proximal portion of the rib is expanded relative to normal lines to the tread.

Owner:TOYO TIRE & RUBBER CO LTD

Disk brake

ActiveUS8540060B2Reduce frictionEasy to fixAxially engaging brakesSlack adjustersCalipersEngineering

There is provided a disk brake comprising: a mounting member axially extending over a disk periphery, the mounting member including a pad guide where a friction pad travels; a caliper; and a return spring between the friction pad and the mounting member and urges the friction pad into a return direction separating from the disk, wherein the return spring includes: a first extended portion where a base end side thereof is fixed to a back plate of the friction pad while a top end side thereof extends separating from the disk; and a second extended portion folded from the top end side of the first extended portion toward the mounting member, a top of the second extended portion extending to elastically abut to the side of the mounting member, and a plate thickness direction of the first extended portion extends to be approximately a radial direction of the disk.

Owner:HITACHI ASTEMO LTD

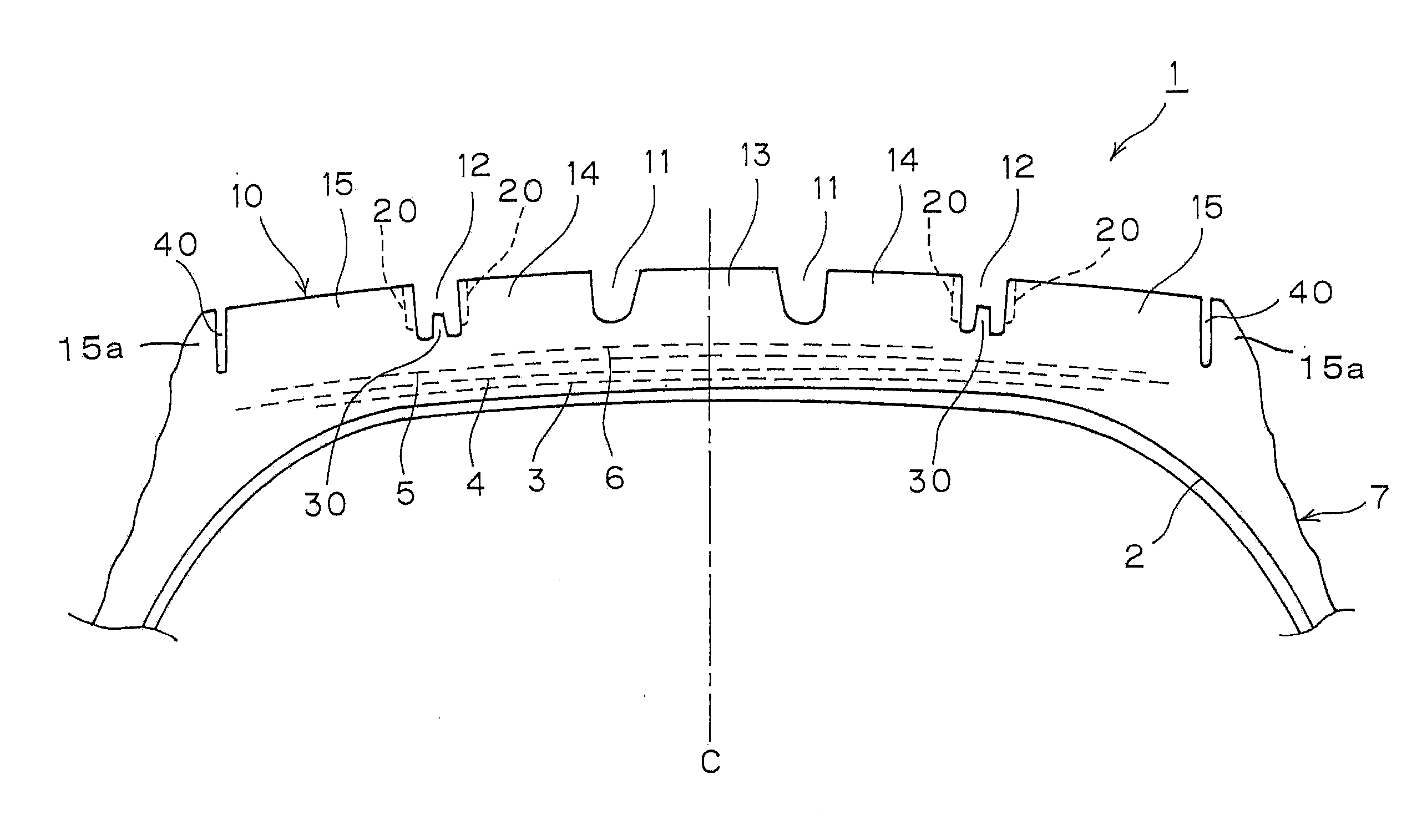

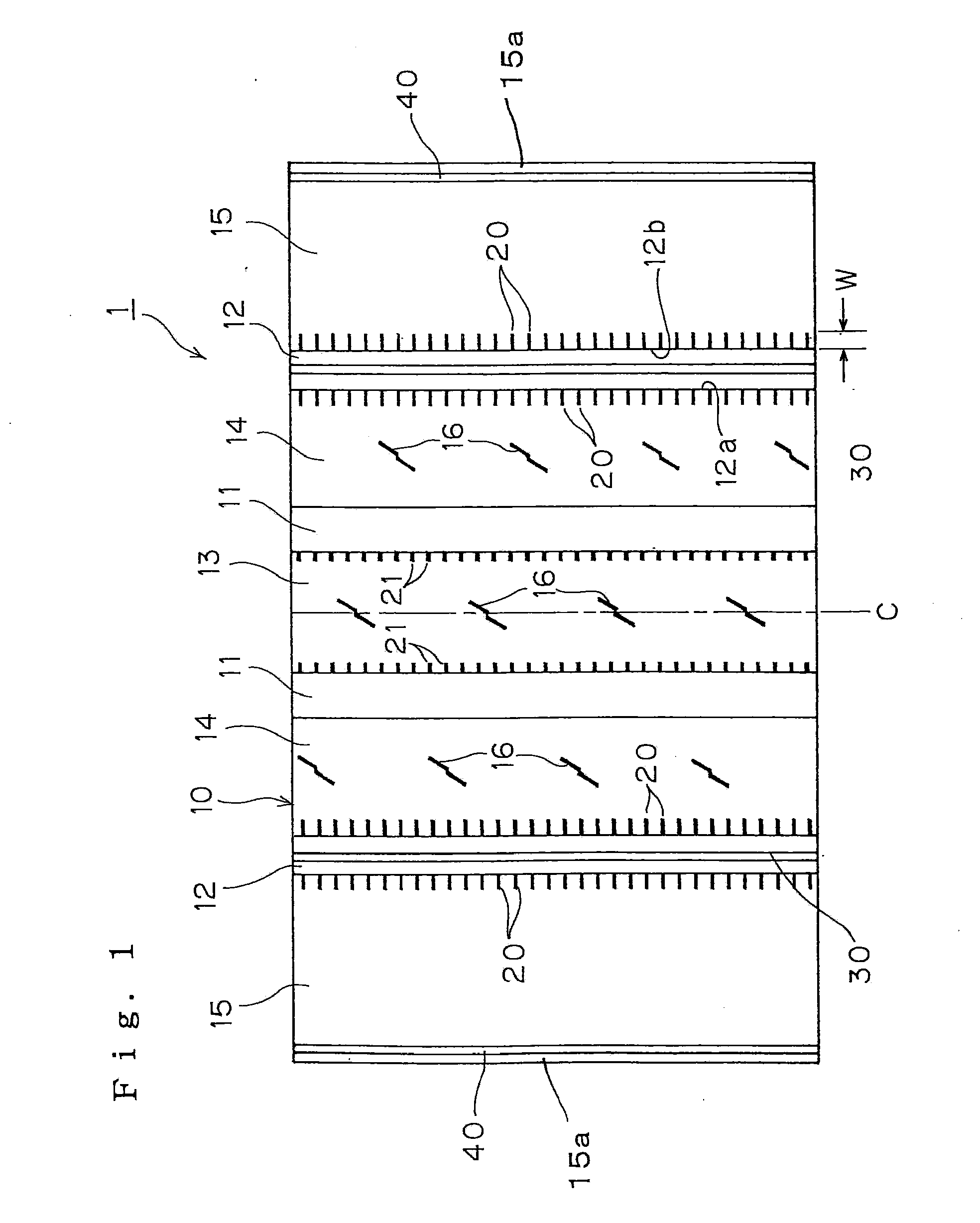

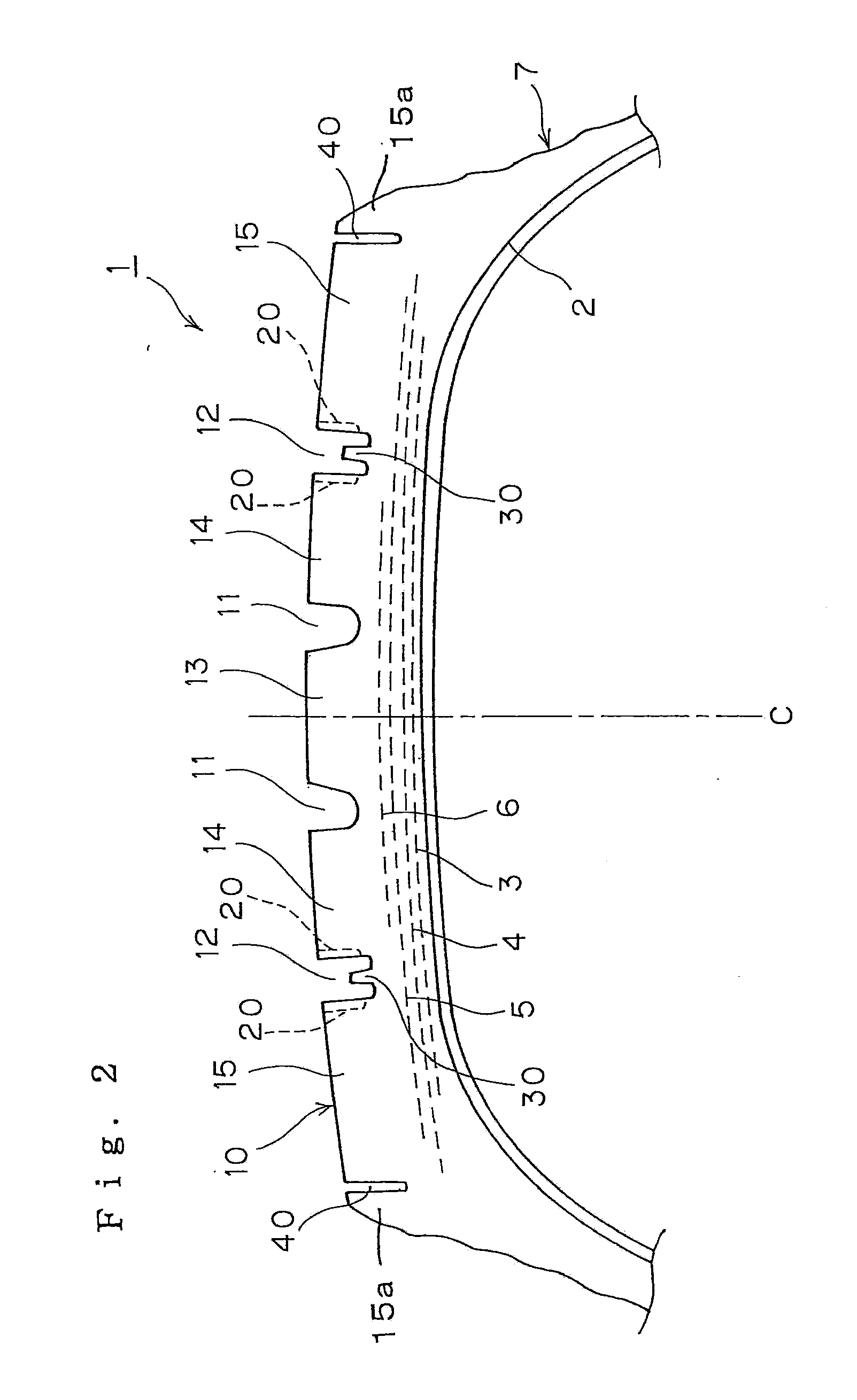

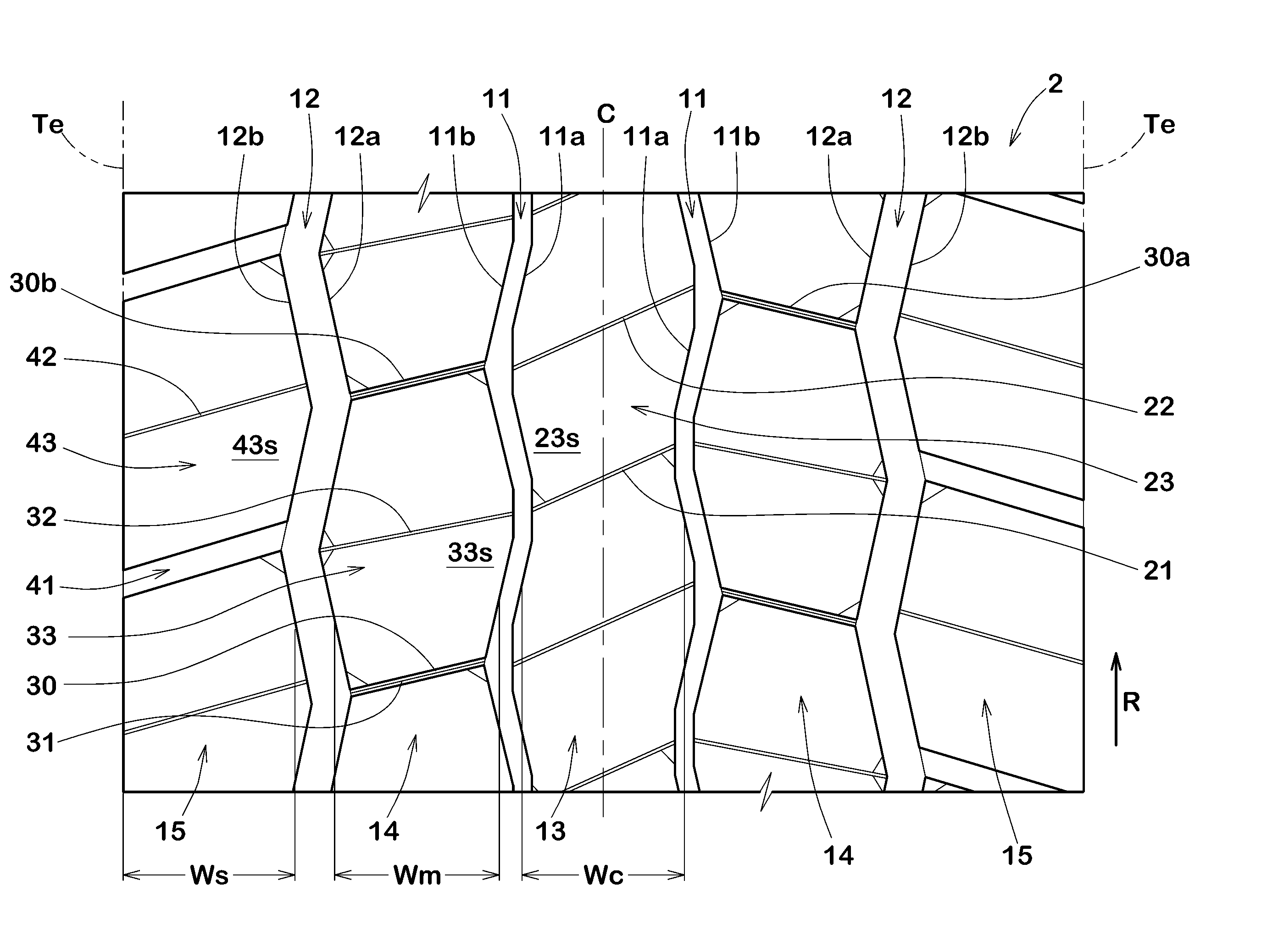

Heavy-duty tire

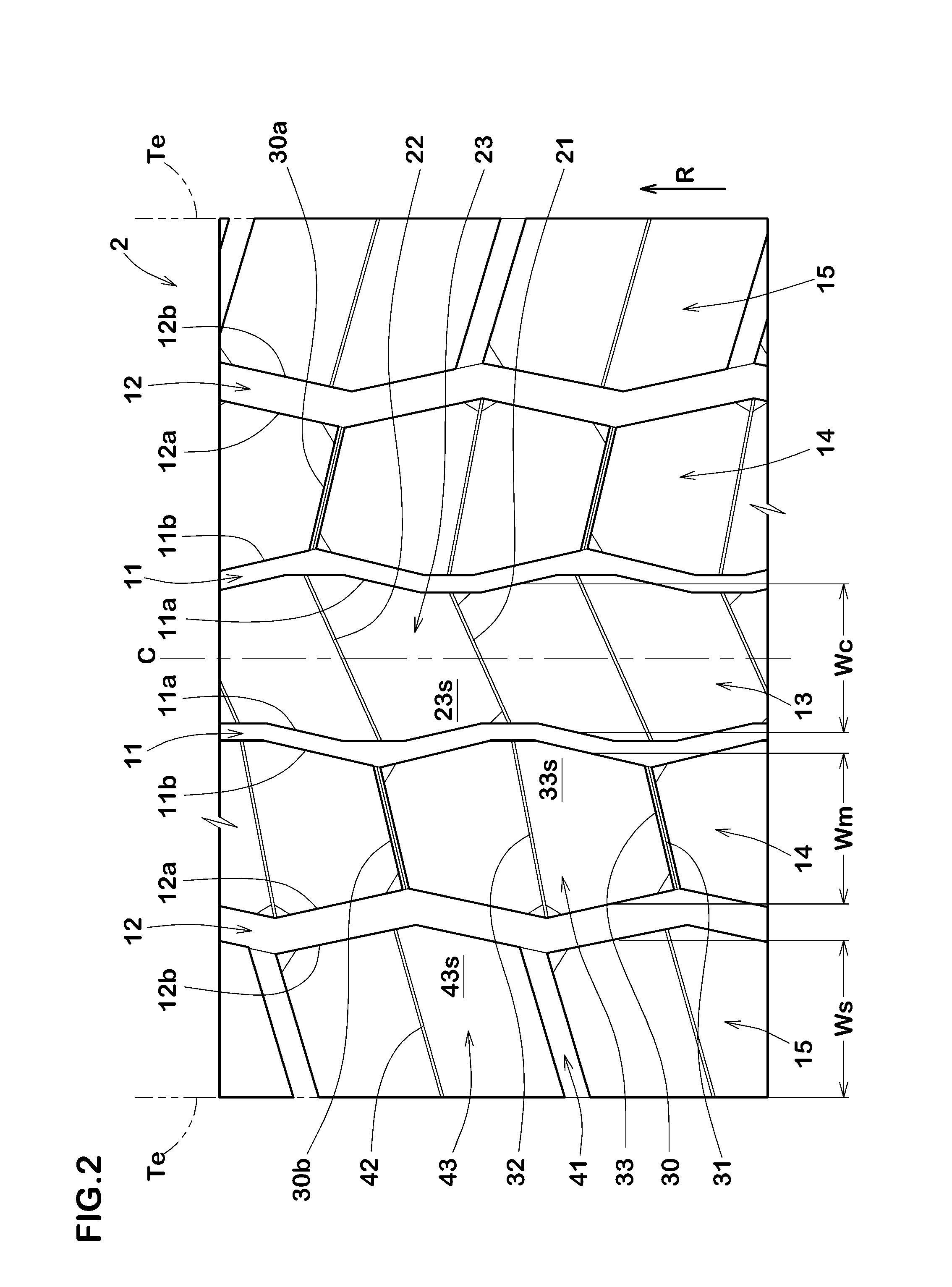

ActiveUS20160159158A1Improve rigiditySmall rolling resistanceHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

A tread portion (2) has a pair of center main grooves (11) extending zigzag and continuously in a tire circumference direction, a pair of shoulder main grooves (12), a center land portion (13), a pair of middle land portions (14), and a pair of shoulder land portions (15). The center main groove (11) has a first groove edge (11a) on the tire equator side and a second groove edge (11b) on the tread edge side. The shoulder main groove (12) has a third groove edge (12a) on the tire equator side and a fourth groove edge (12b) on the tread edge side. The middle land portion (14) is provided with a plurality of middle lateral shallow grooves (30) connecting between apex portions (11h) on the most tread edge side of the second groove edge (11b) and apex portions (12c) on the most tire equator side of the third groove edge (12a); and a plurality of first middle lateral sipes (31) extending along the middle lateral shallow grooves (30) at the groove bottoms of the middle lateral shallow grooves (30) and connecting between the center main groove (11) and the shoulder main groove (12).

Owner:SUMITOMO RUBBER IND LTD

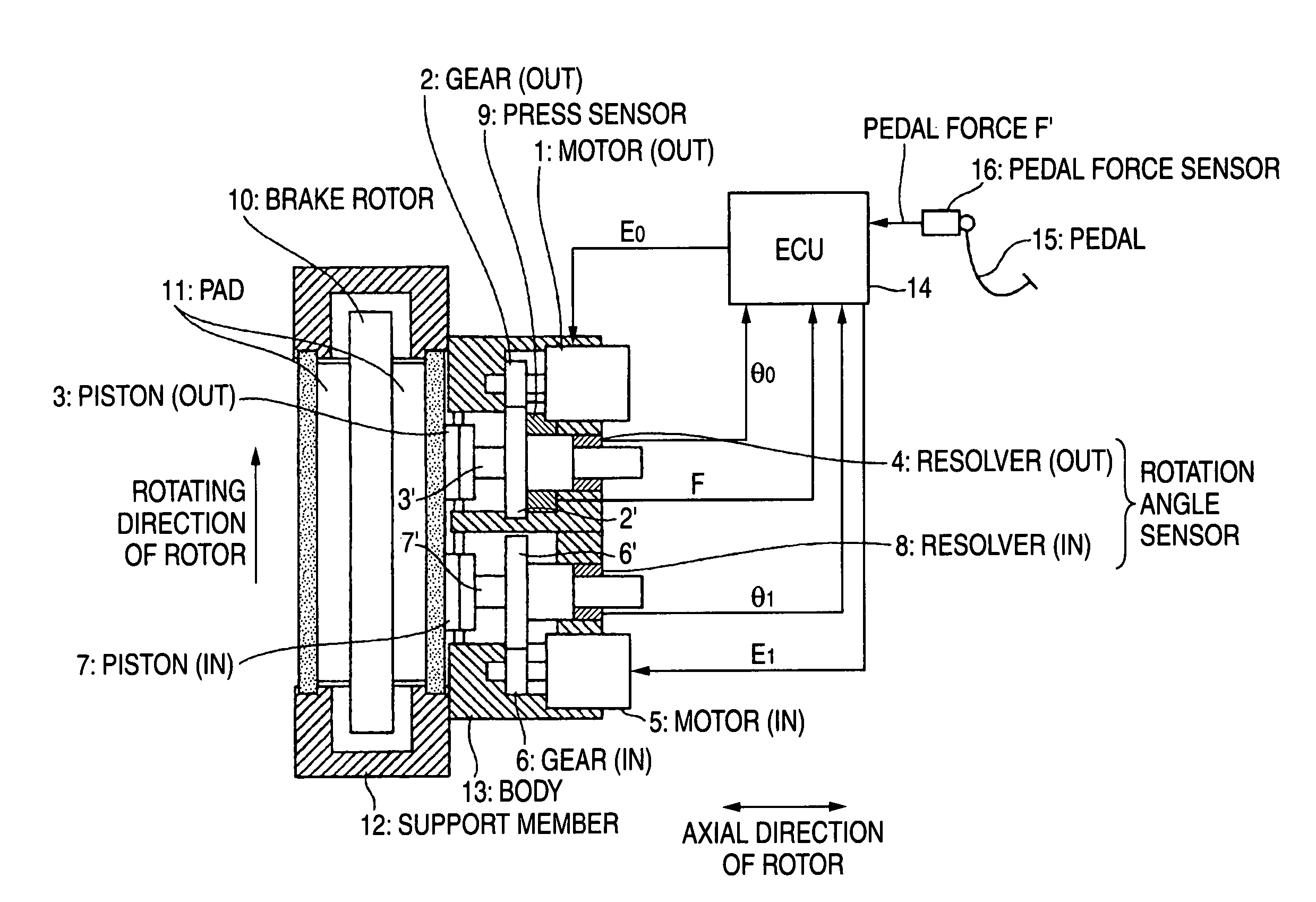

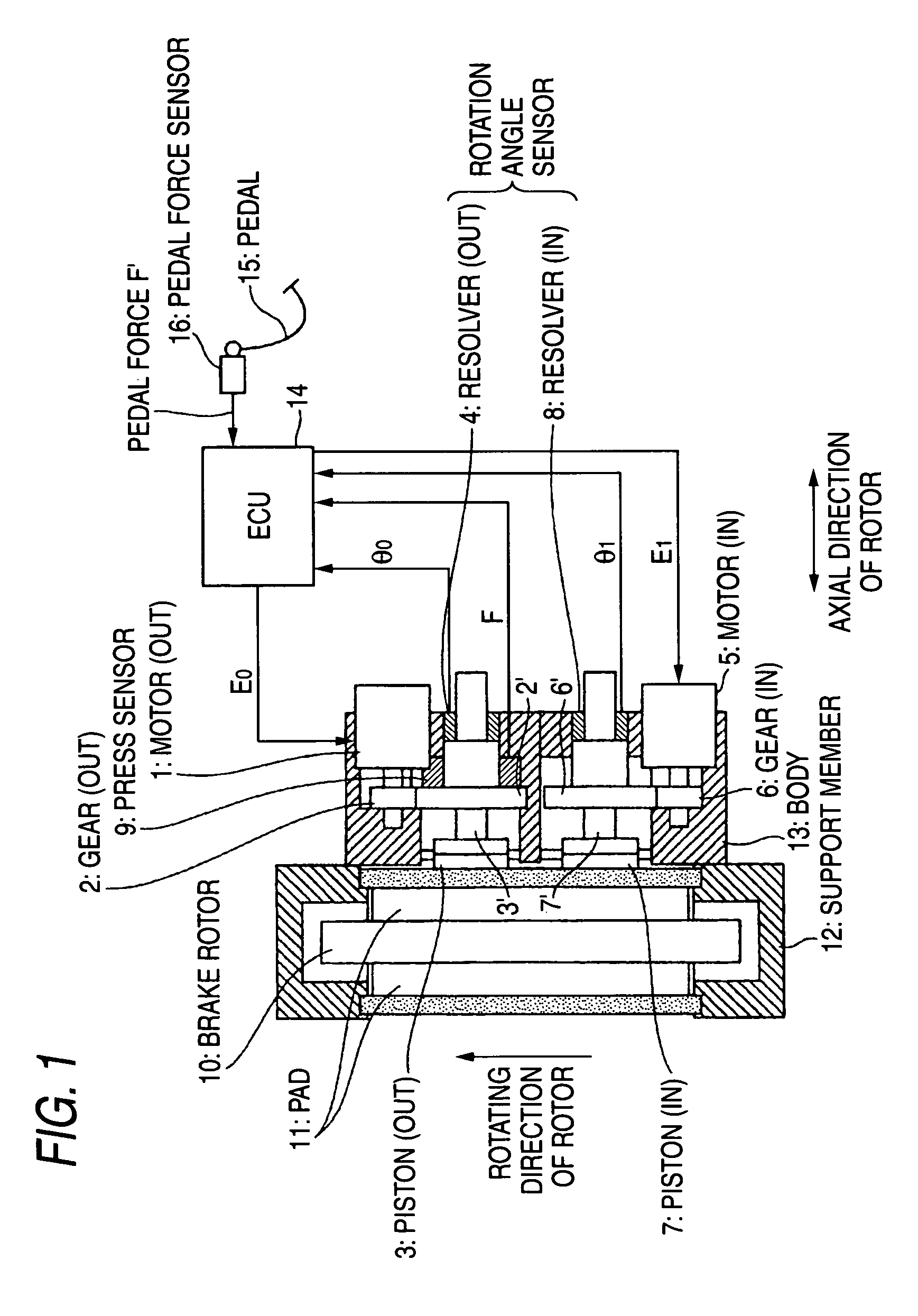

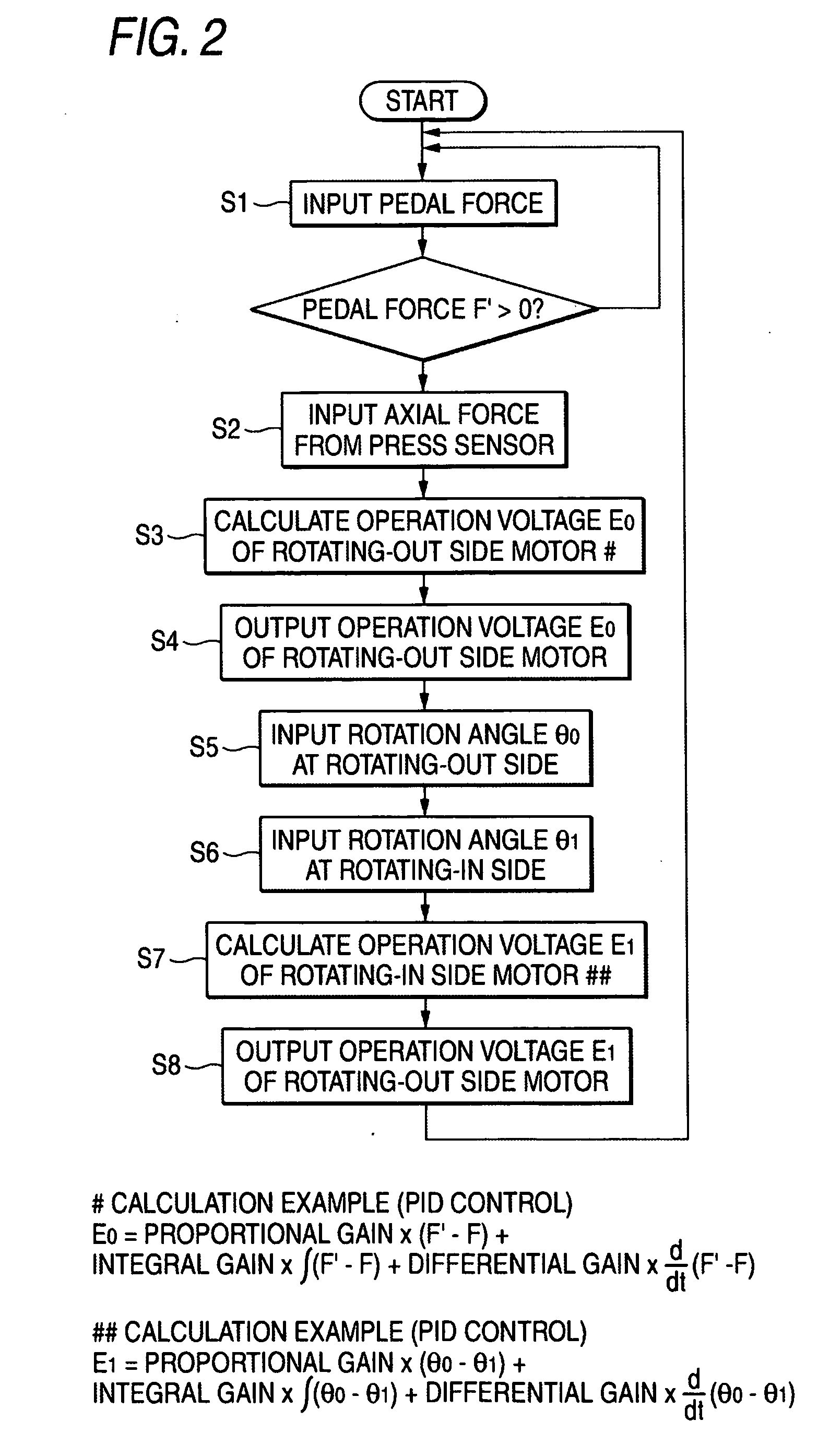

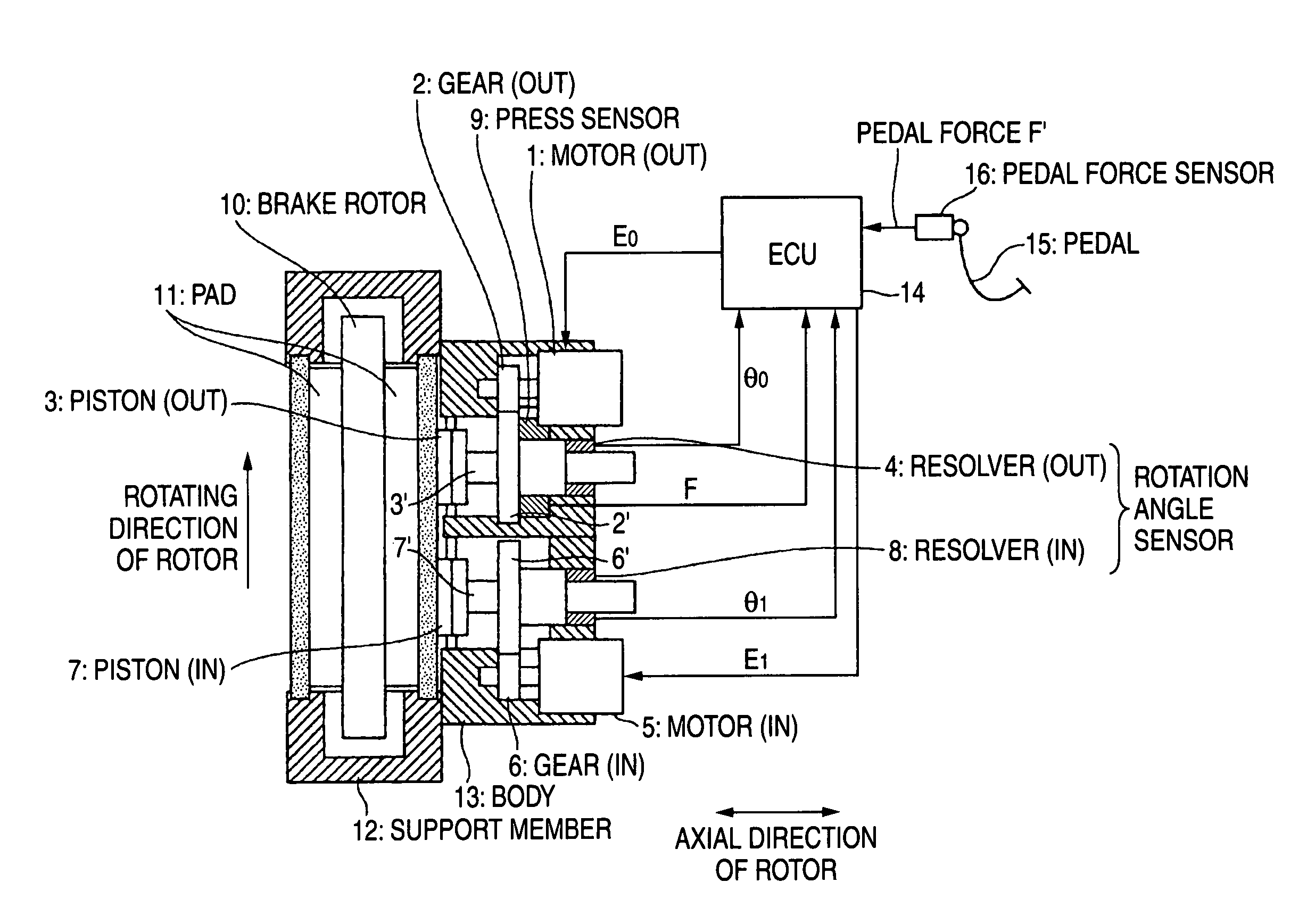

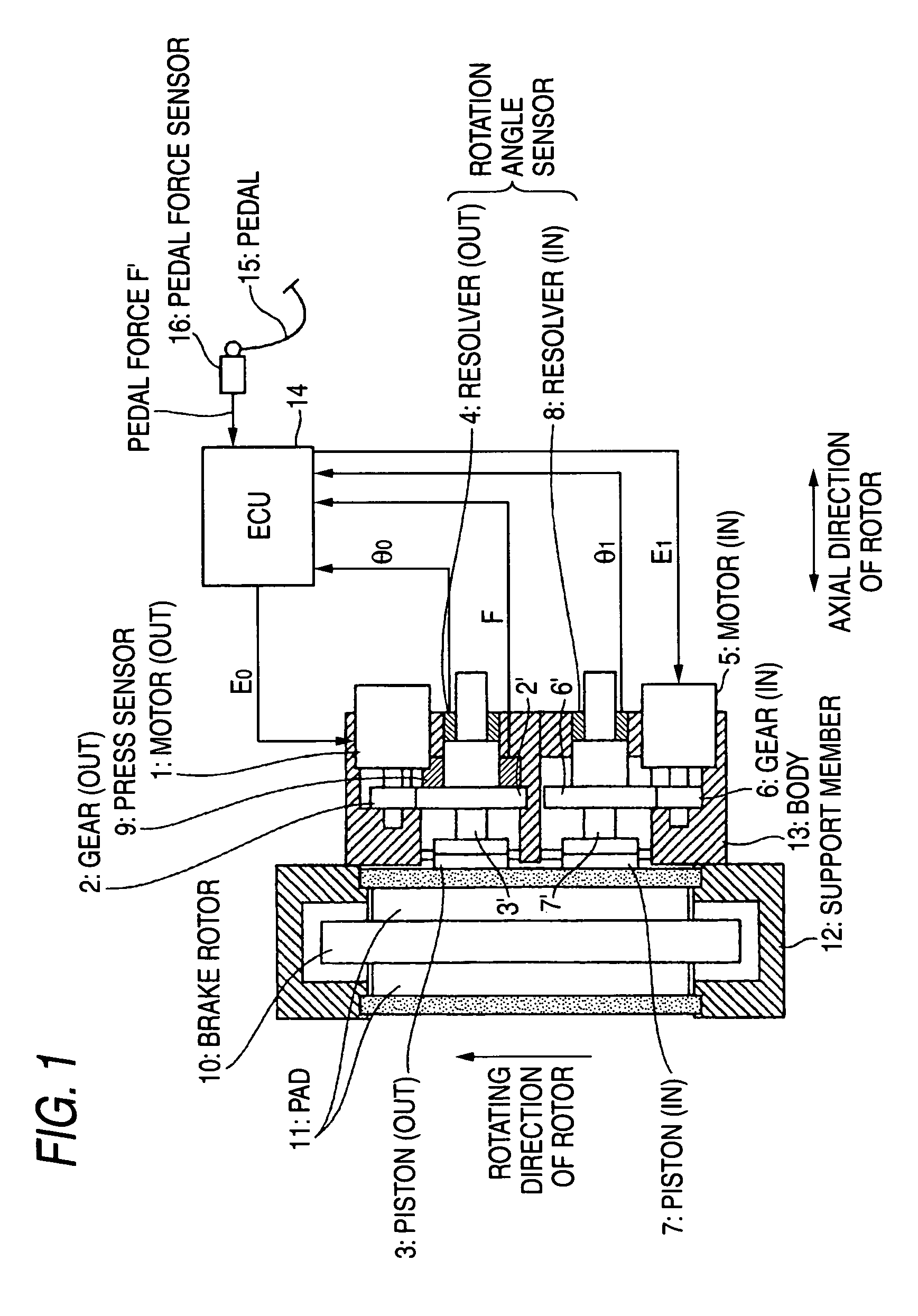

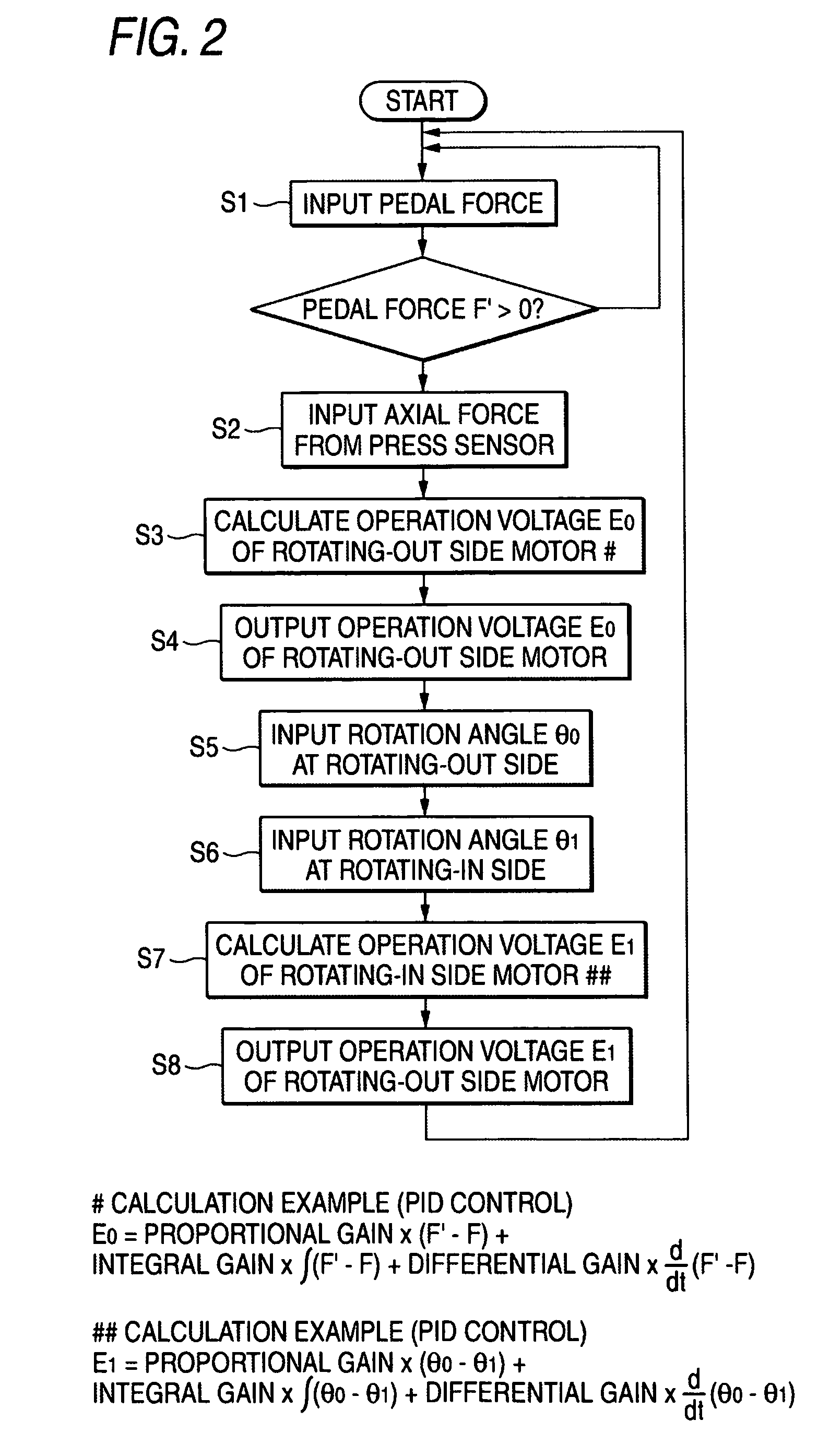

Electric brake

InactiveUS20070062764A1Avoid uneven wearInhibits uneven wearDynamo-electric brakes/clutchesElectrodynamic brake systemsPosition controlPiston

Pistons 3 and 7 are pressed to a friction member 11 at two points that are positioned at a rotating-in side and a rotating-out side in a rotating direction of a brake rotor 10. An axial force control is performed for the piston 3 on the rotating-out side, and a position control based on the position of the piston 3 on the rotating-out side is performed for the piston 7 on the rotating-in side.

Owner:AKEBONO BRAKE IND CO LTD

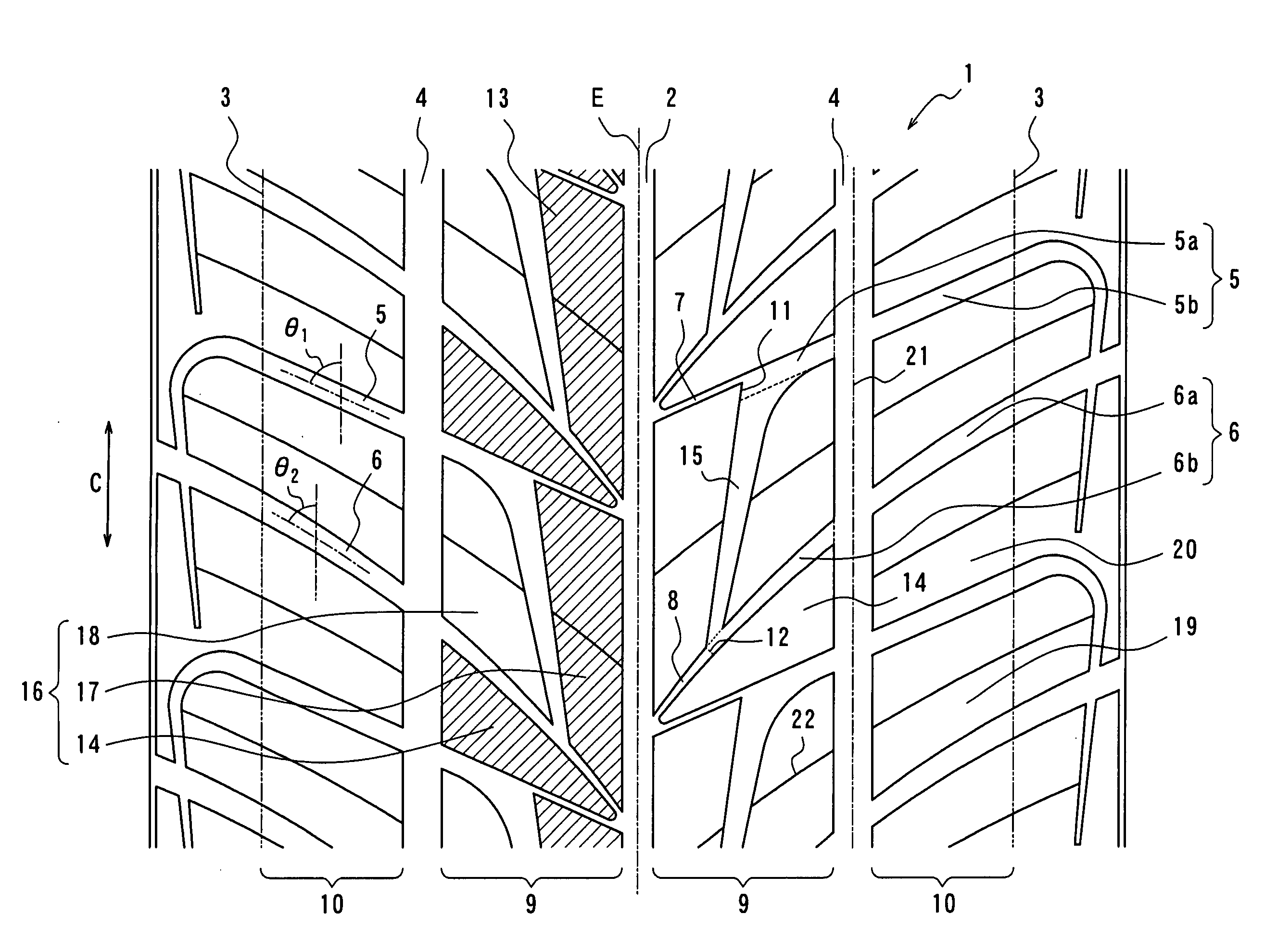

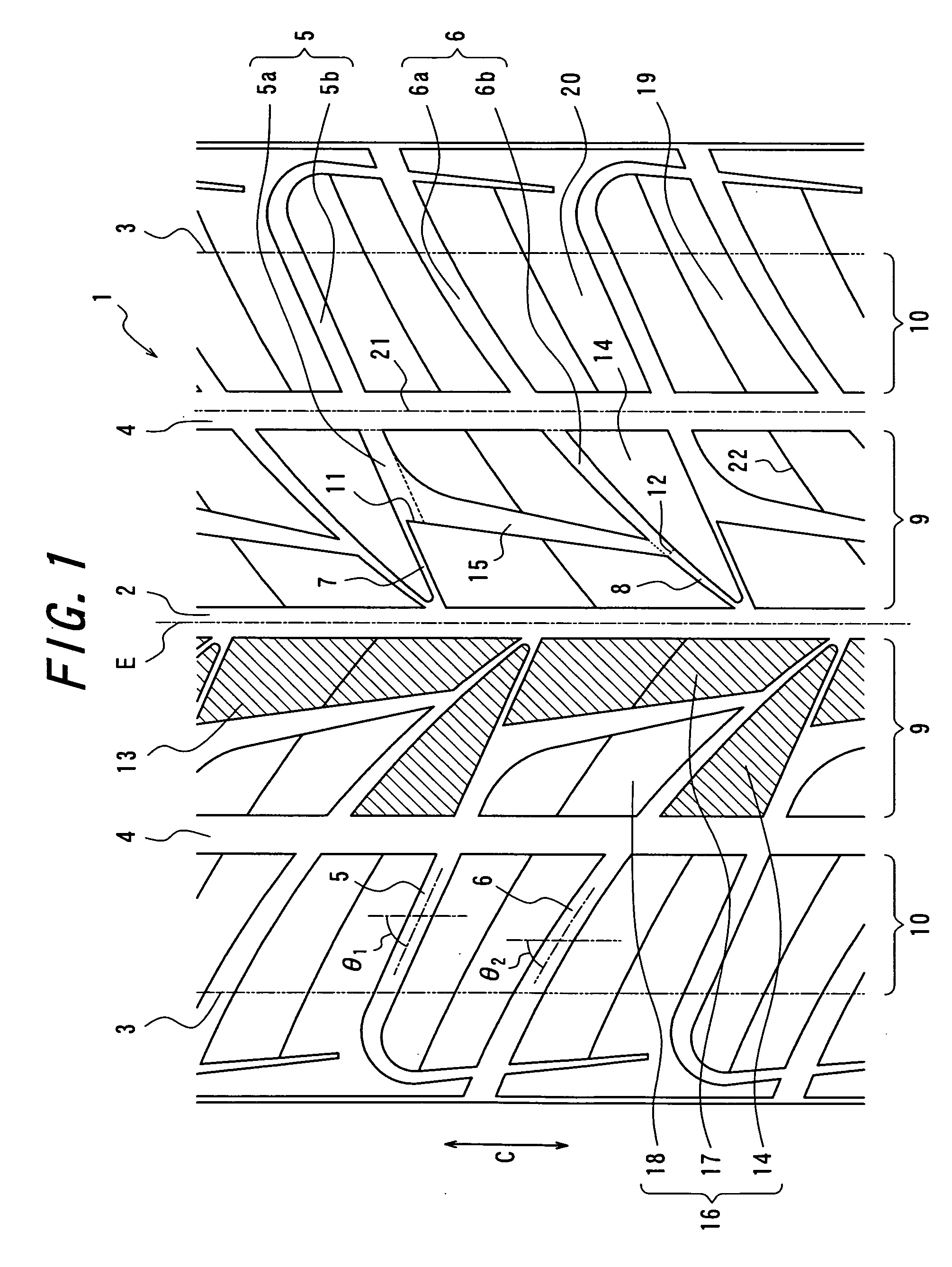

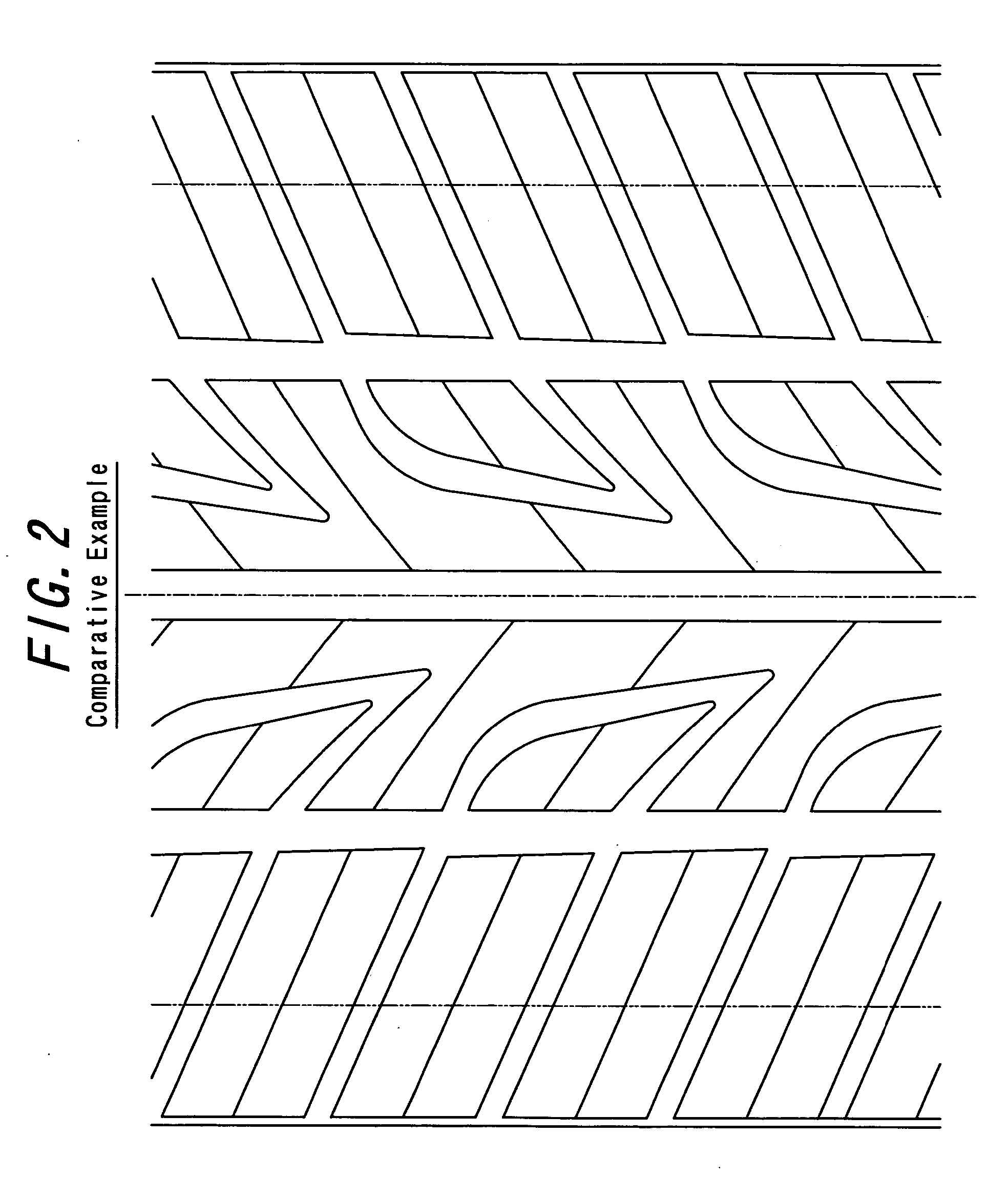

Pneumatic tire

InactiveUS20070131324A1Excellent drainage propertyImprove performanceTyre tread bands/patternsNon-skid devicesEngineeringTread

In a pneumatic tire having excellent drainage property and performances on snow, a central main groove 2 and a side main groove 4 and first and second gently slant grooves 5, 6 are arranged in a tread portion 1, and the first and second gently slant grooves 5, 6 are terminated in a central land portion 9 between the central main groove 2 and the side main groove 4, and first and second fine grooves 7, 8 are further arranged so as to extend from terminal ends 11, 12 of the first and second gently slant grooves 5, 6 toward the central main groove 2 and open thereto, respectively.

Owner:BRIDGESTONE CORP

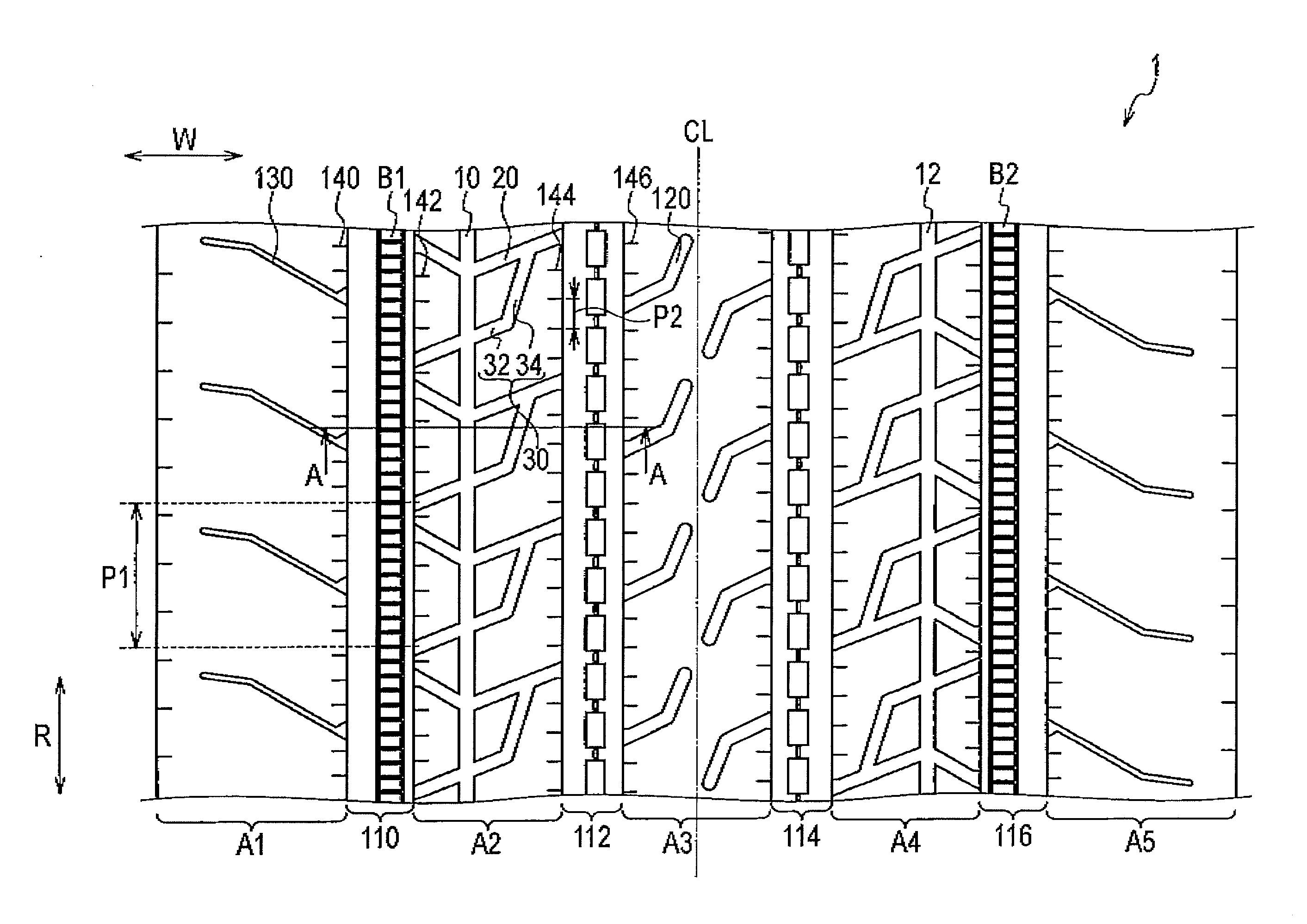

Heavy duty tire

InactiveUS20120168048A1Inhibits uneven wearImprove wettabilityHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

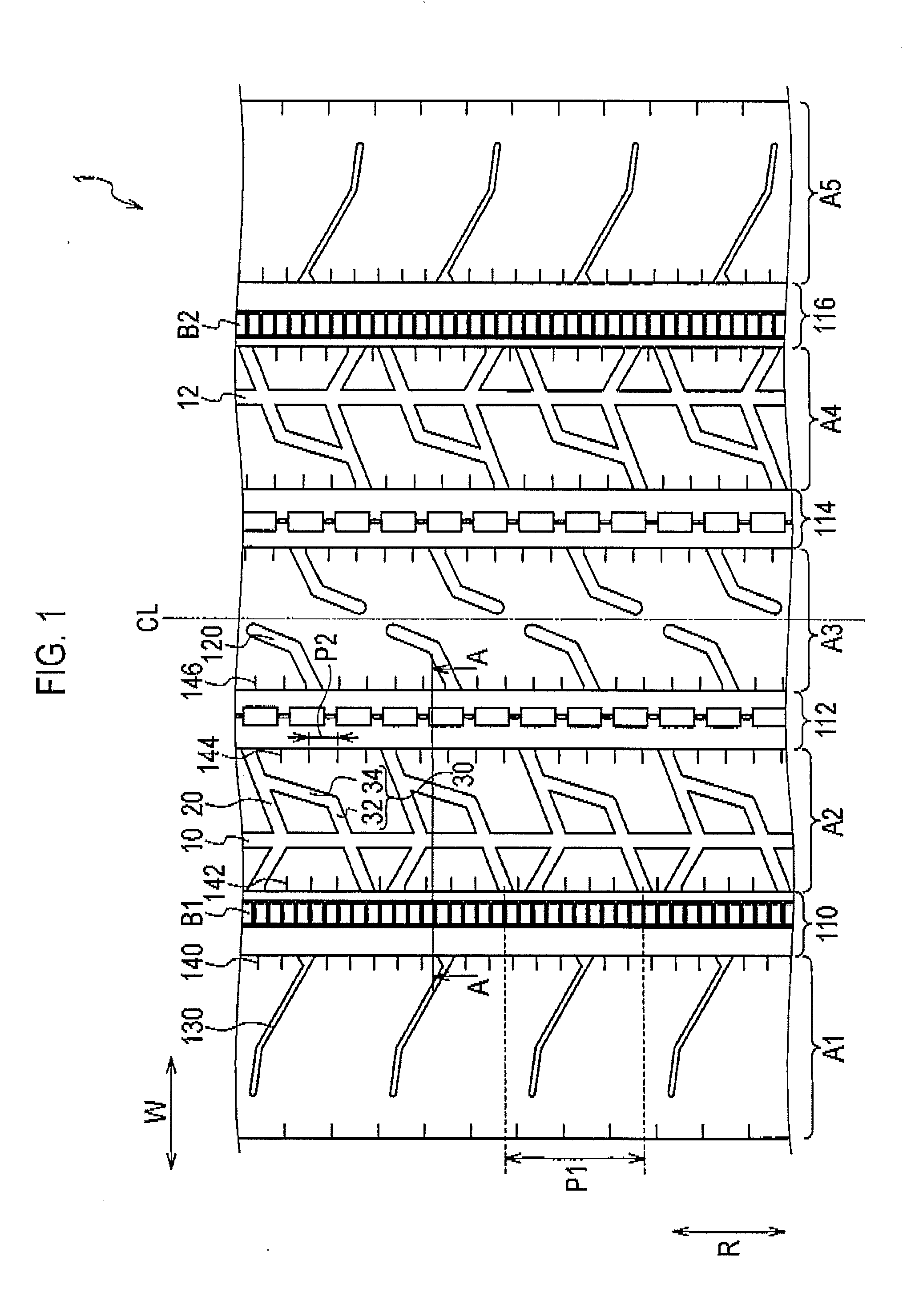

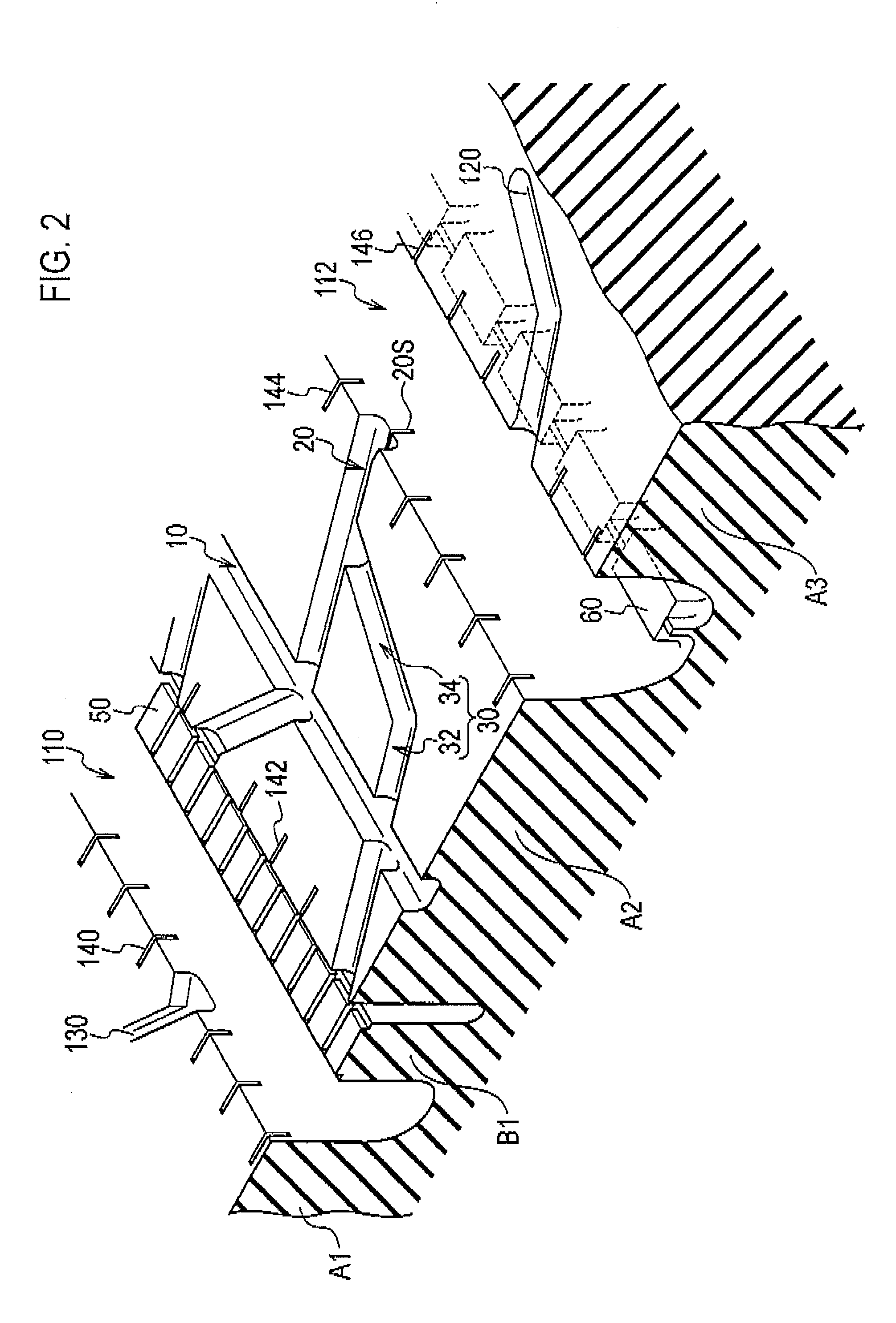

A heavy duty tire comprising: a shoulder rib (A1) (shoulder rib (A5)) which is provided to a tread shoulder unit; a second rib (A2) (second rib (A4)) which is adjacent to the shoulder rib (A1) with a circumferential groove (110) (circumferential groove (116)) interposed therebetween and is provided further toward the tire equator side than the shoulder rib (A1); and an uneven wear absorbing rib (B1) (uneven wear absorbing rib (B2)) provided within the circumferential groove (110) and located further toward the inside in the tire radial direction than the tread surfaces of the shoulder rib (A1) and of the second rib (A2). Circumferential narrow grooves (10, 12) having a smaller width than the circumferential grooves (110, 116) are formed in the second ribs (A2, A4). Each circumferential narrow groove (10, 12) is formed in such a manner that, when the tire is mounted on the vehicle, the circumferential groove (10, 12) is located on the outer side of the tire with reference to the center of the second rib (A2, A4) in the tread width direction.

Owner:BRIDGESTONE CORP

Guide for transmission device

In an engine timing chain guide composed of a synthetic resin shoe supported on a frame by L-shaped and strip-shaped engagement members integrally molded as unitary parts of the shoe, the L-shaped members are formed with oblique tongues that resiliently engage side edges of the frame member, and the strip-shaped engagement members include surfaces that extend obliquely toward, and resiliently engage, a side edge of the frame member. Laterally extending legs of the L-shaped members are also formed with bulged portions, and the frame member is sandwiched between the bulged portions and a back side of the shoe.

Owner:TSUBAKIMOTO CHAIN CO

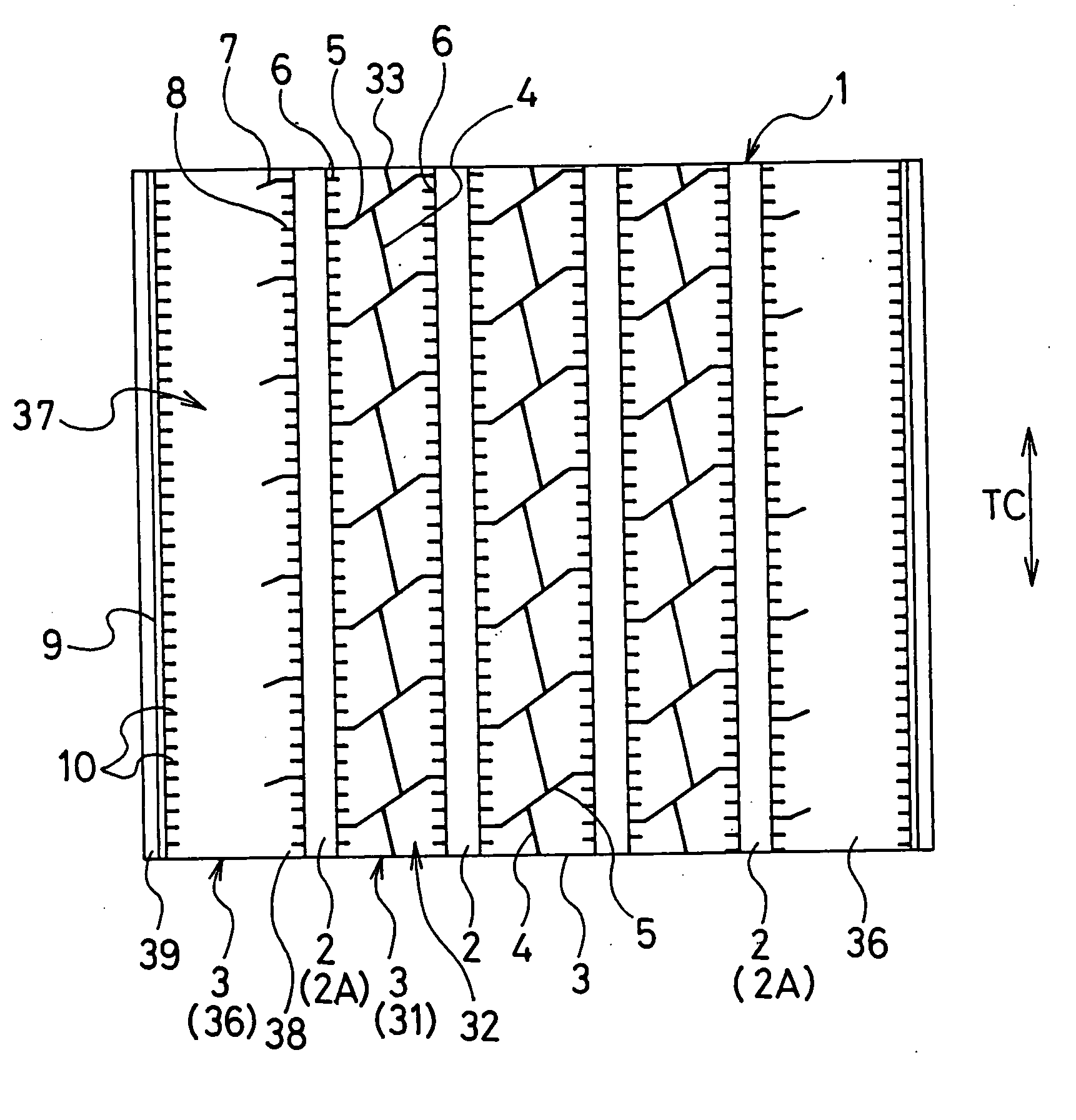

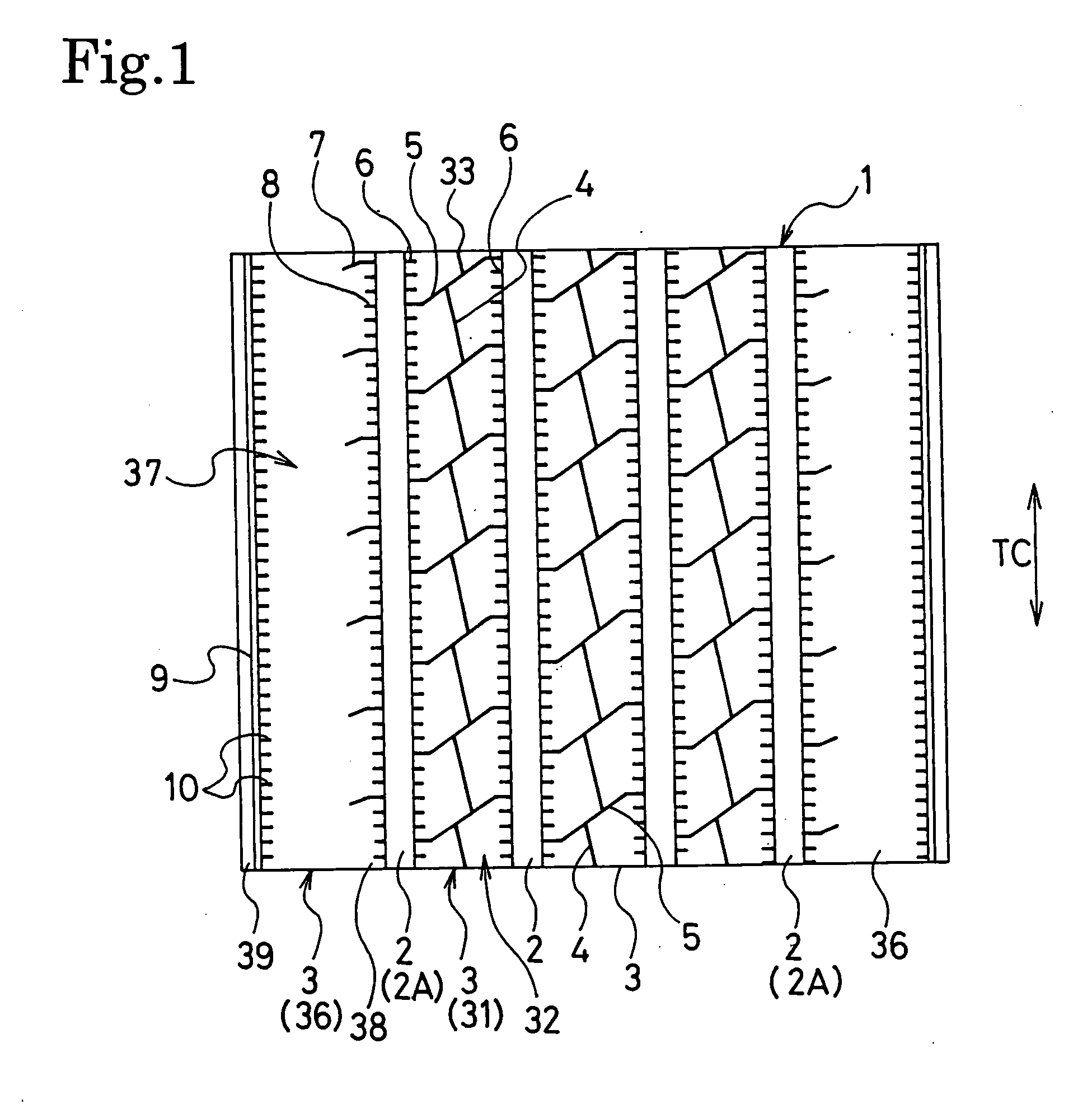

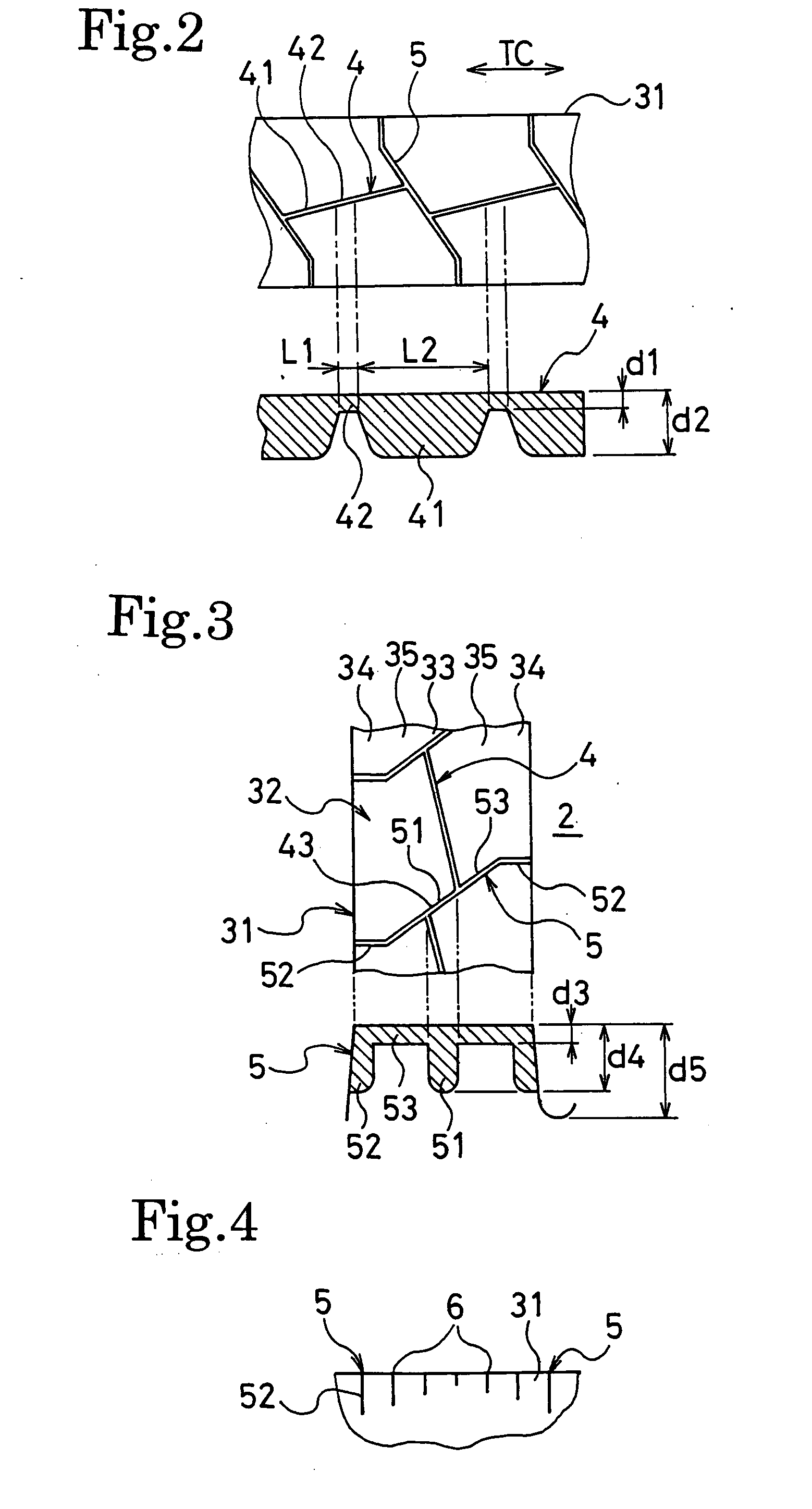

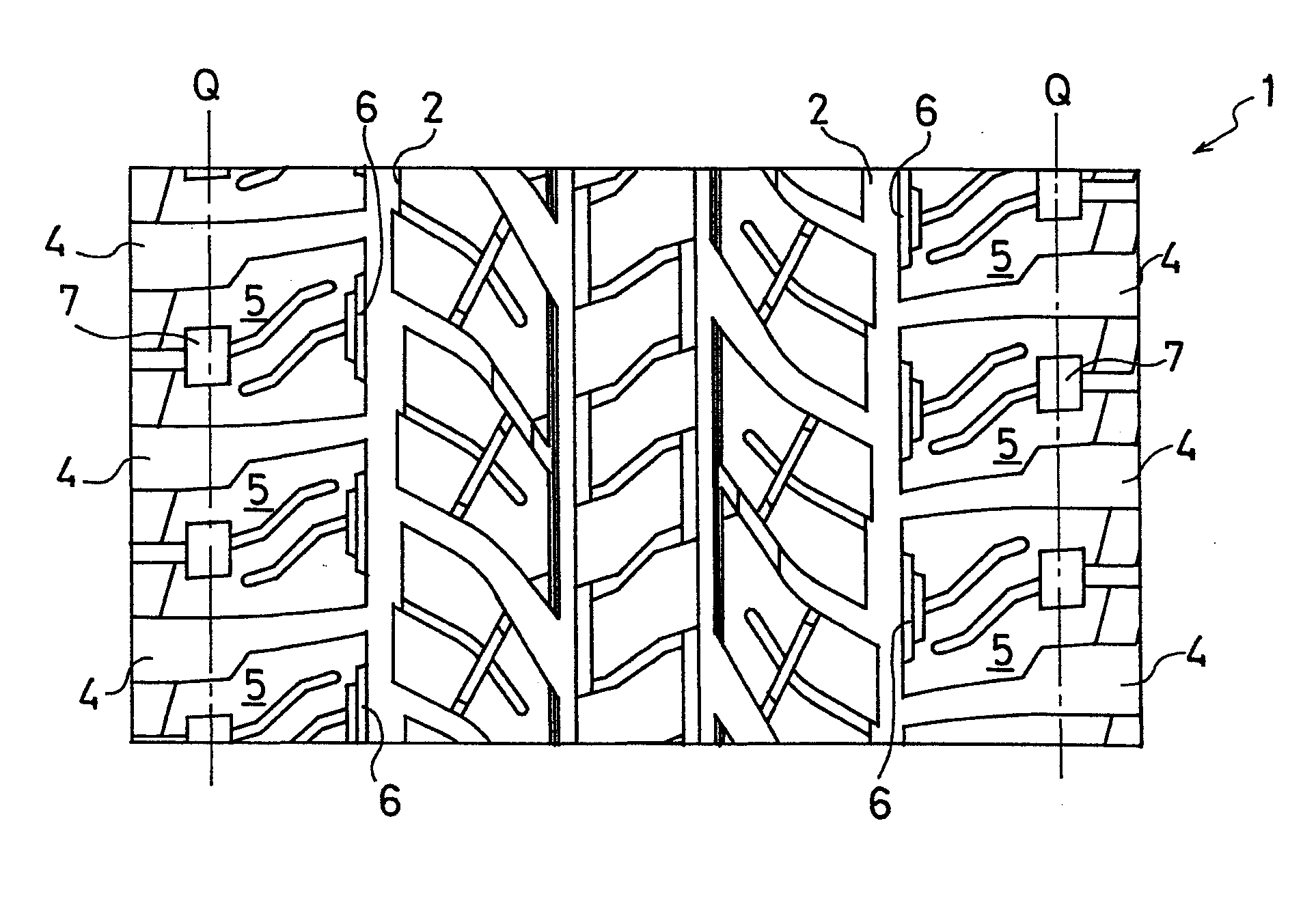

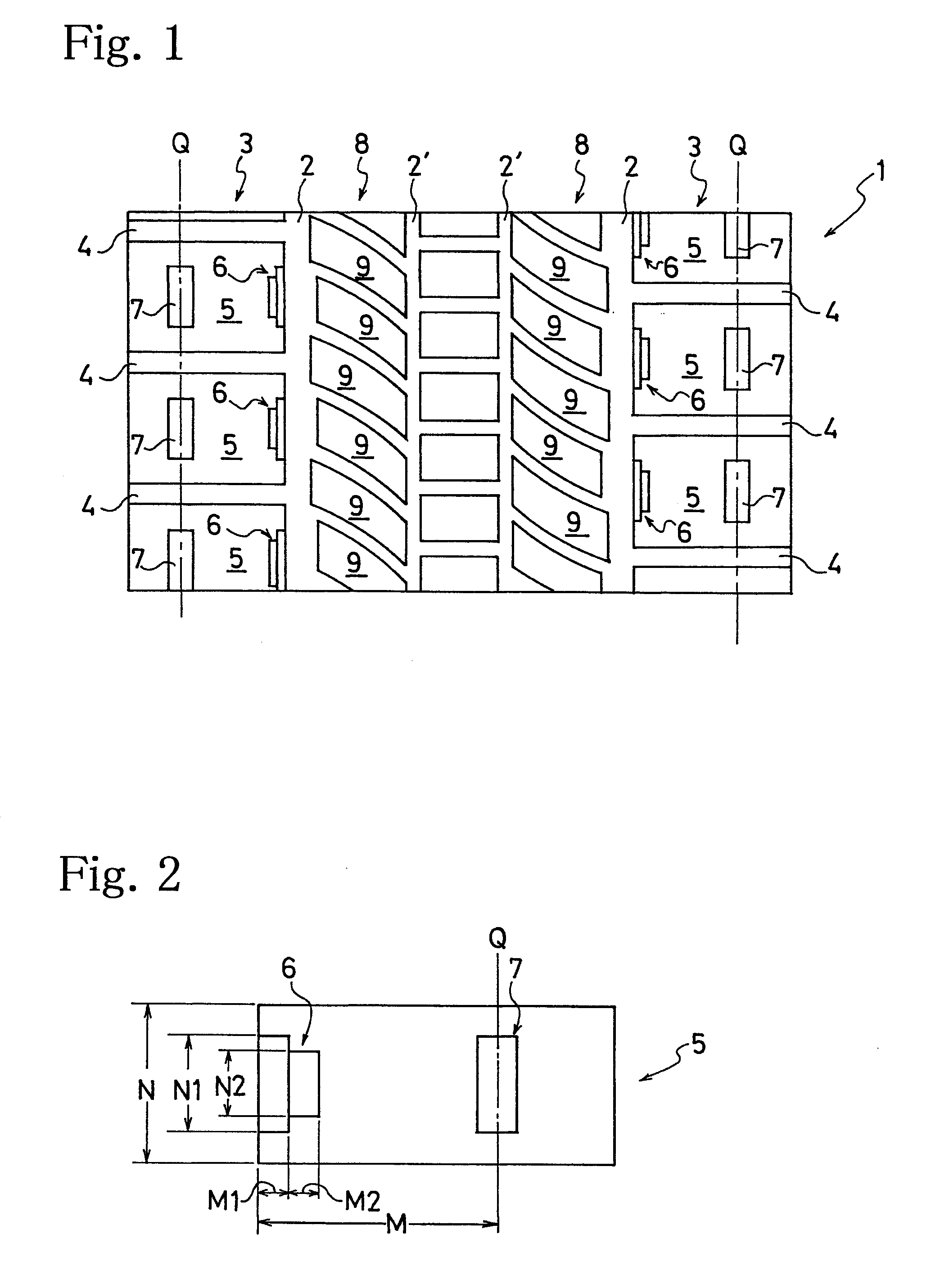

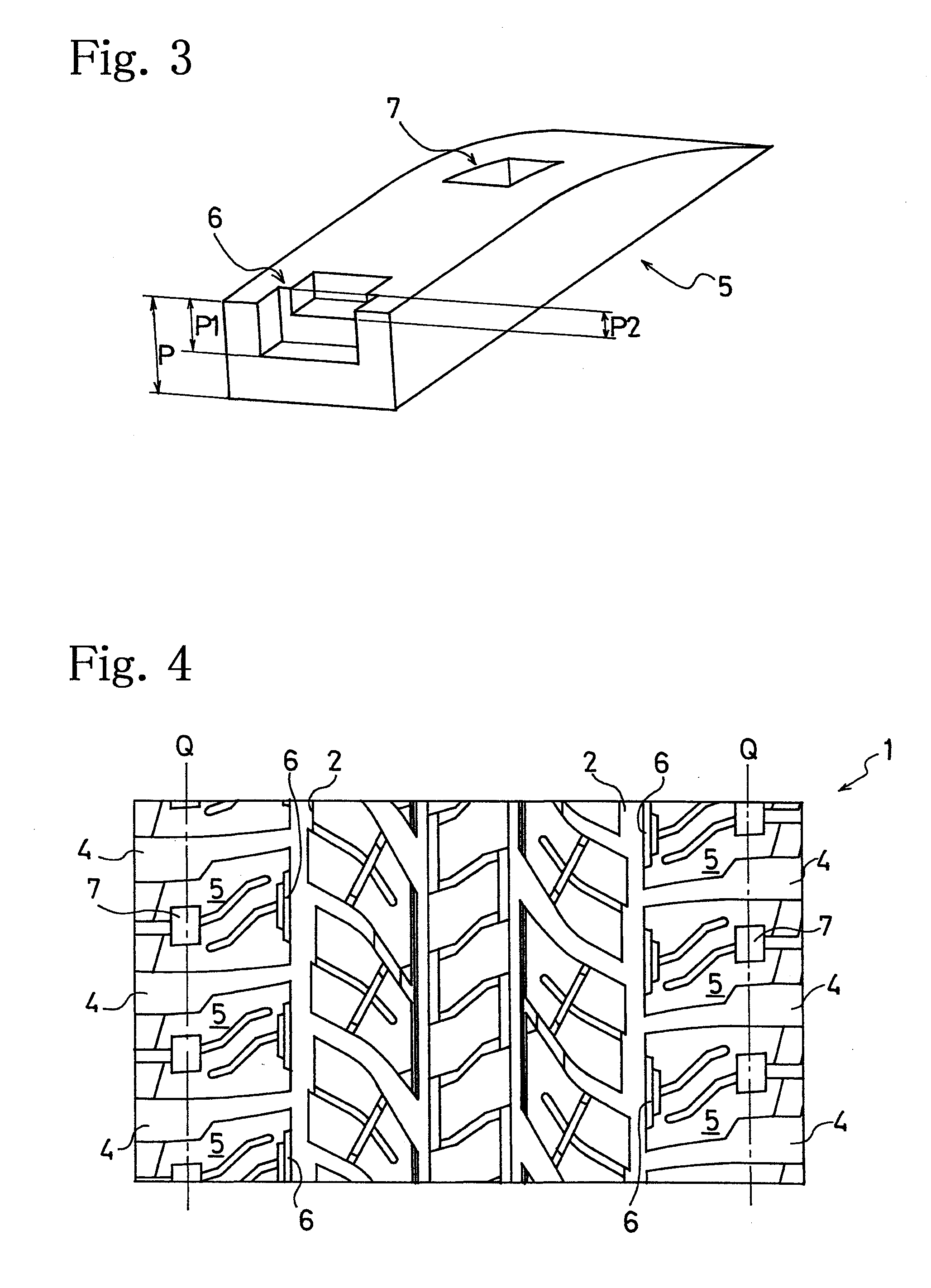

Pneumatic tire

InactiveUS20090272473A1Block stiffness is not substantially deterioratedAdequate levelTyre tread bands/patternsNon-skid devicesAerospace engineeringWear resistance

Provided is a pneumatic tire having a tread surface (1) with a tread pattern having: at least two circumferential grooves (2) extending in the tire circumferential direction to define land sections (3) on the outer sides in the tire width direction; and lateral grooves (4) extending in the tire width direction to partition the land sections (3) into a large number of blocks (5). In addition, in each of the blocks (5), a cutout (6) is formed in the center region of an edge portion of the block (5), the edge facing the corresponding circumferential groove (2). The cutout (6) has plural steps in the tire width direction. This structure improves the performance of running on a muddy ground with the resistance to uneven wear and the driving stability on general road surfaces maintained respectively at sufficient levels.

Owner:YOKOHAMA RUBBER CO LTD

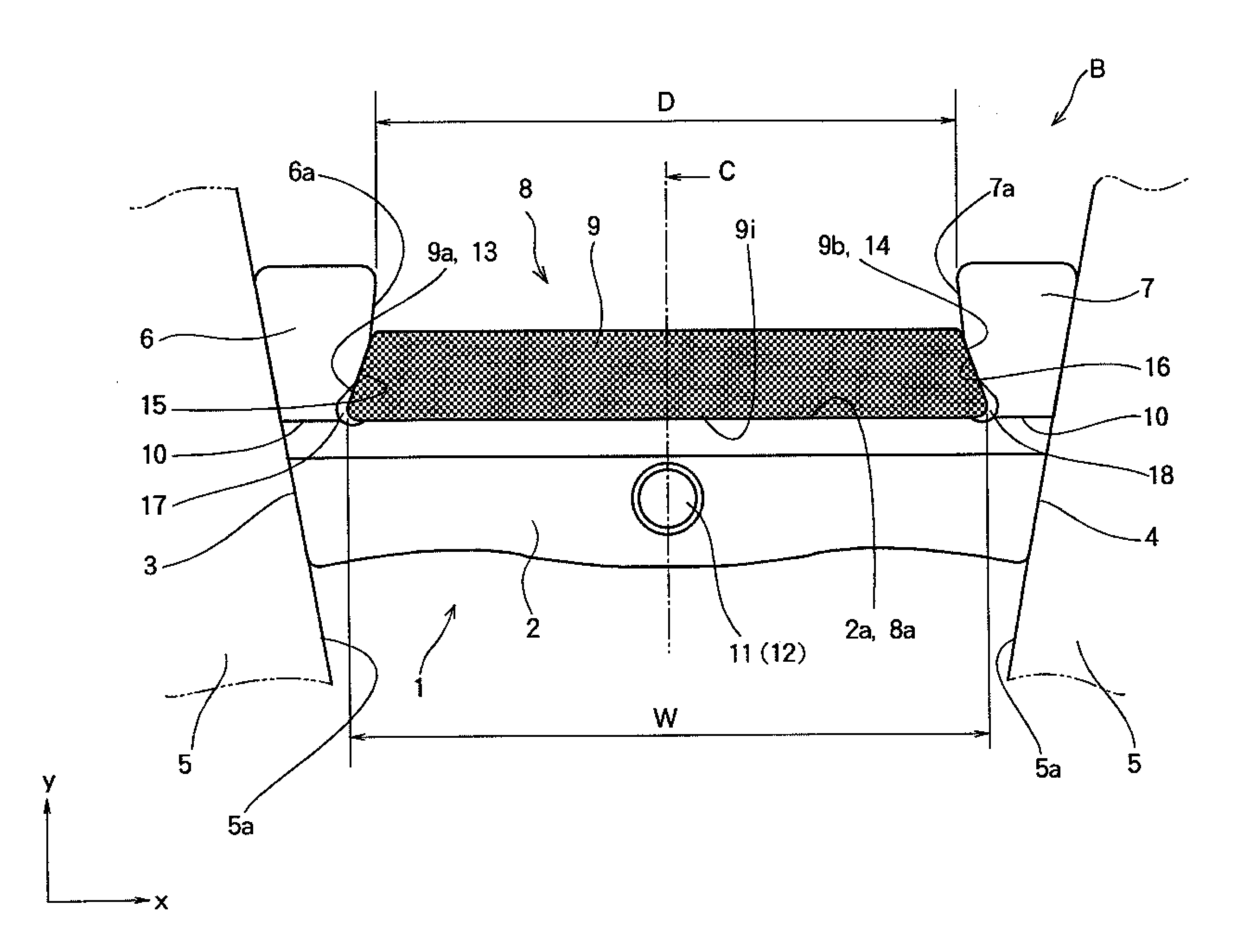

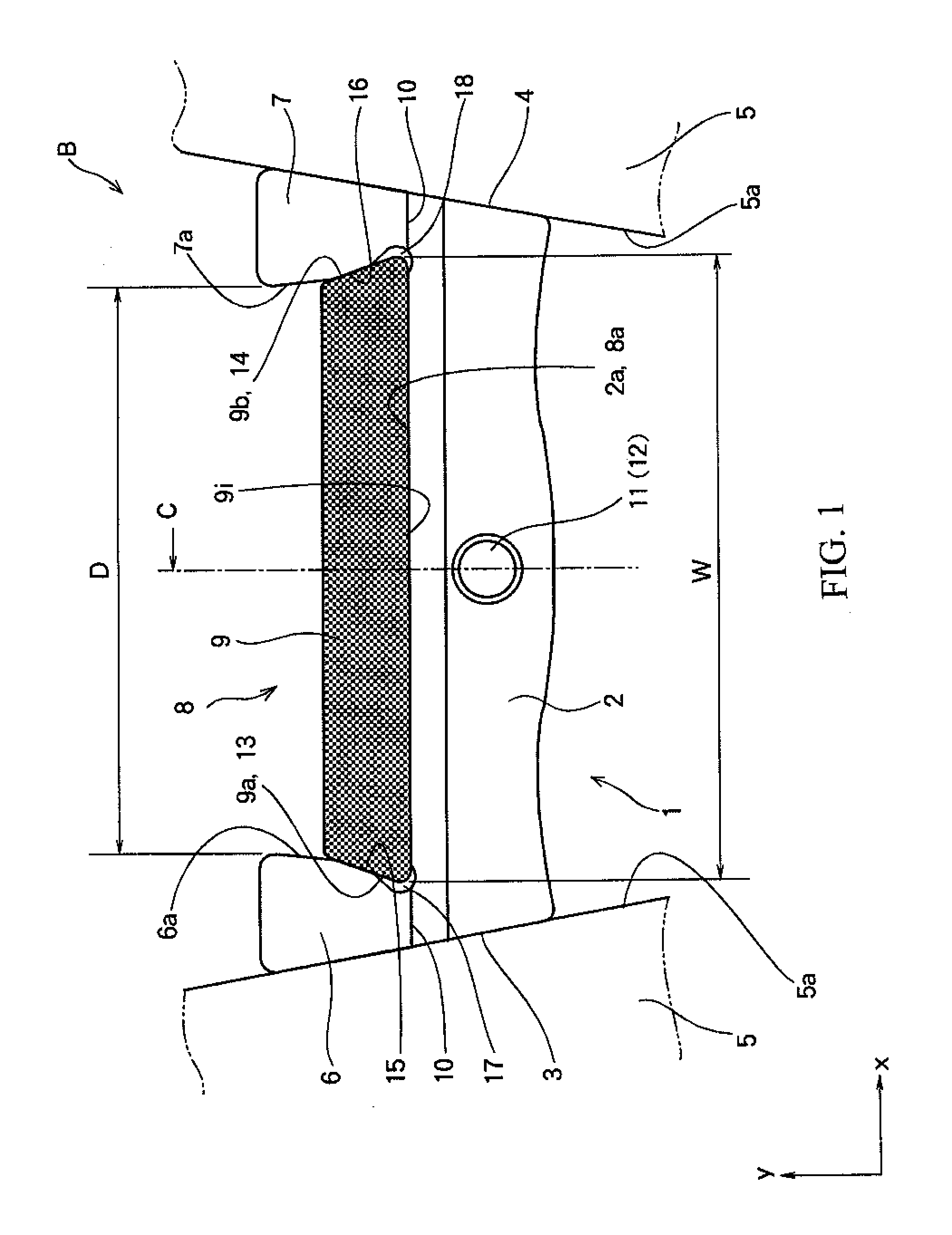

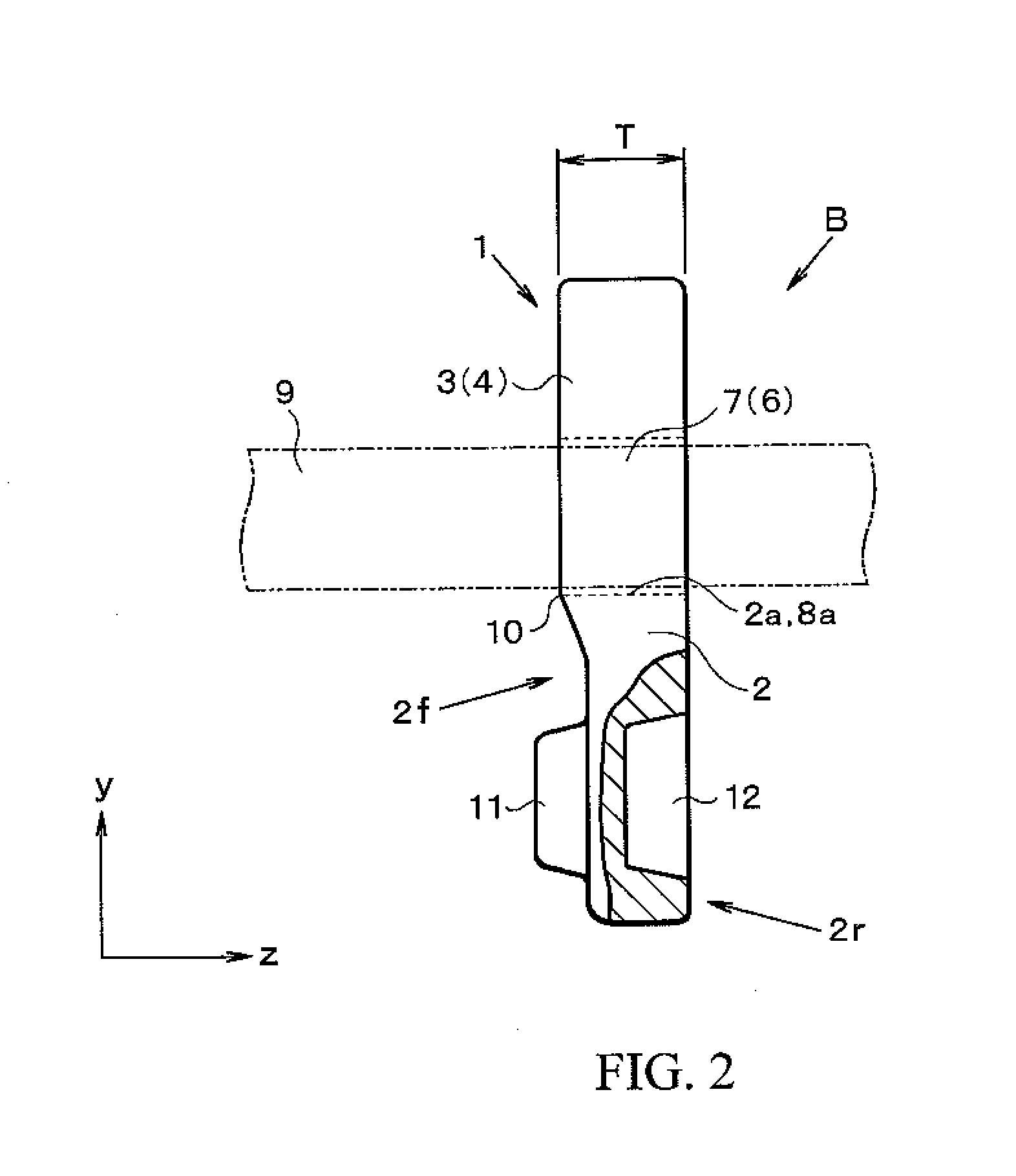

Push type driving belt

InactiveUS20110237376A1Uneven of in durabilityUneven wearV-beltsDriving beltsEngineeringTransmission loss

To provide a push type driving belt, which is capable of preventing uneven wear of the ring and deterioration in durability of the ring, by preventing a transmission loss resulting from an internal slippage of the ring, and by positioning the ring properly with respect to the element.The push-type driving belt B comprises: an element 1, in which a recess 8 opening toward a diametrically outer circumferential side is formed in a width center thereof; and a ring 9, which is formed of single layer in its thickness direction using elastic material, and which is fitted into the recess 8 of the element 1 to fasten the elements 1 juxtaposed in a circular manner. In the push-type driving belt B, inclined faces 13 and 14 are formed on side faces 9a and 9b of the ring 9 plane symmetrically across a width center plane C; and contact faces 15 and 14 each inclination thereof is identical to that of the inclined faces 13 and 14 and each area thereof is smaller than that of the inclined face 13 and 14 are formed on the inner wall 6a and 7a of width end of the recess 8.

Owner:TOYOTA JIDOSHA KK

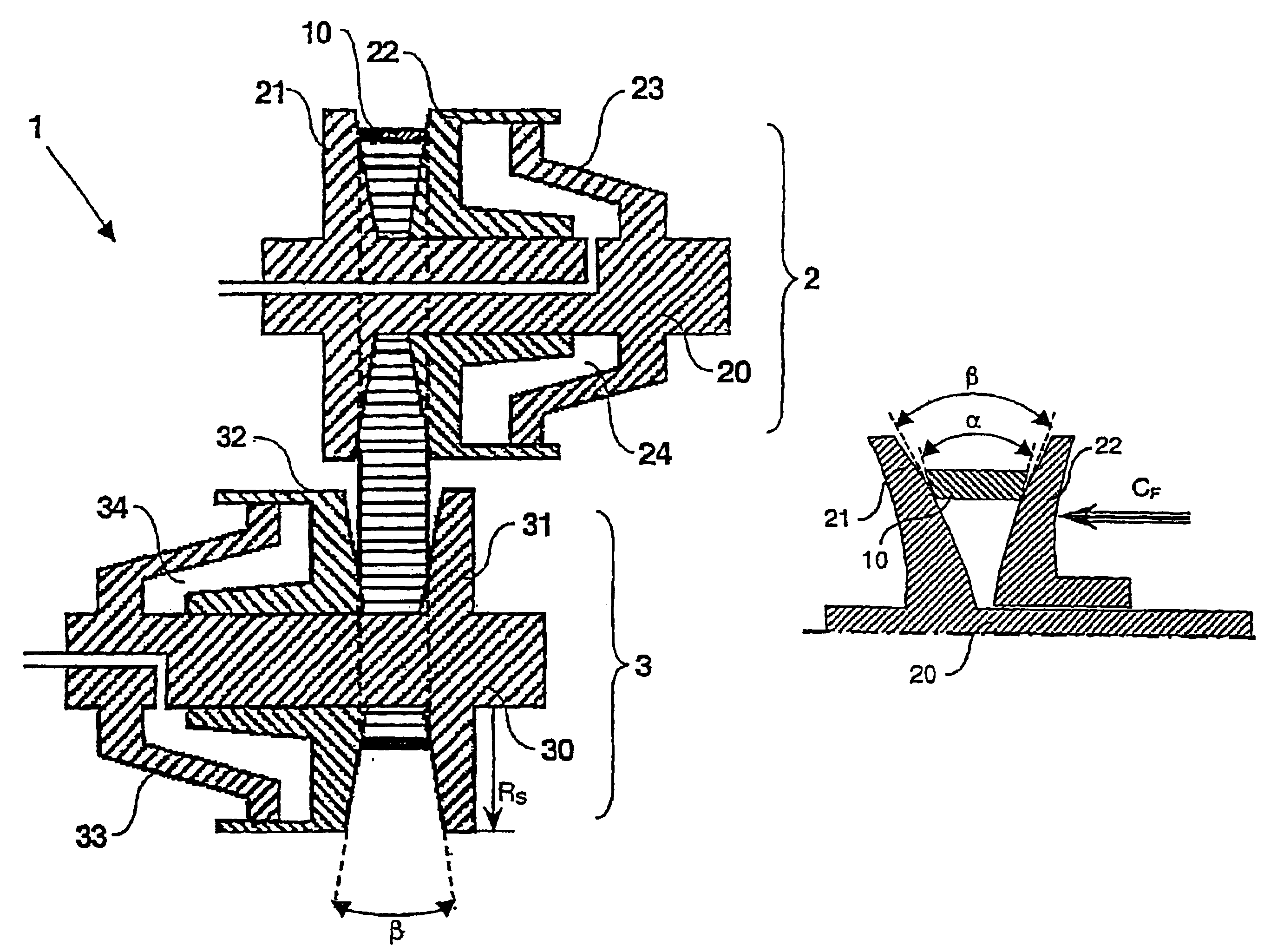

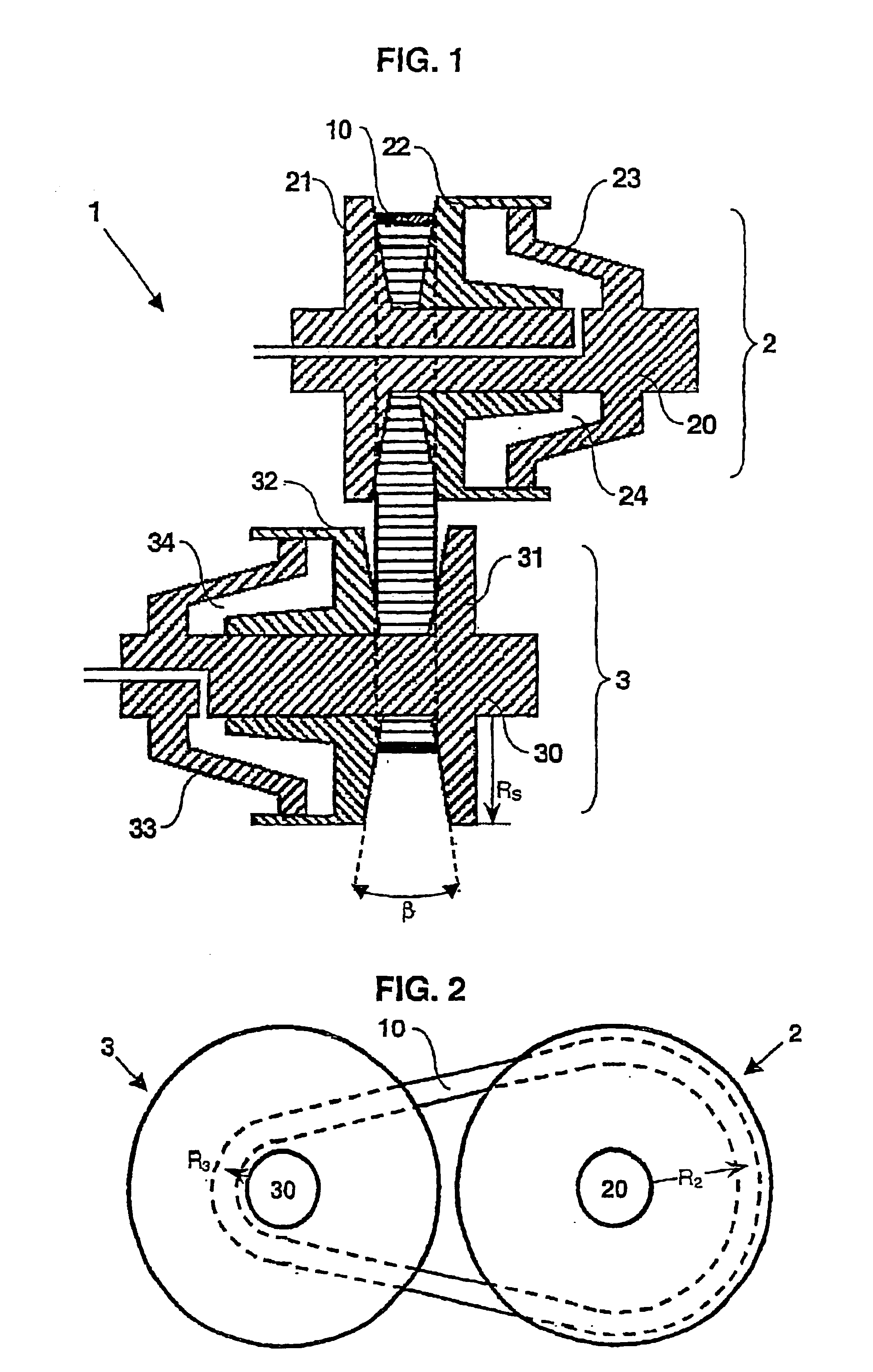

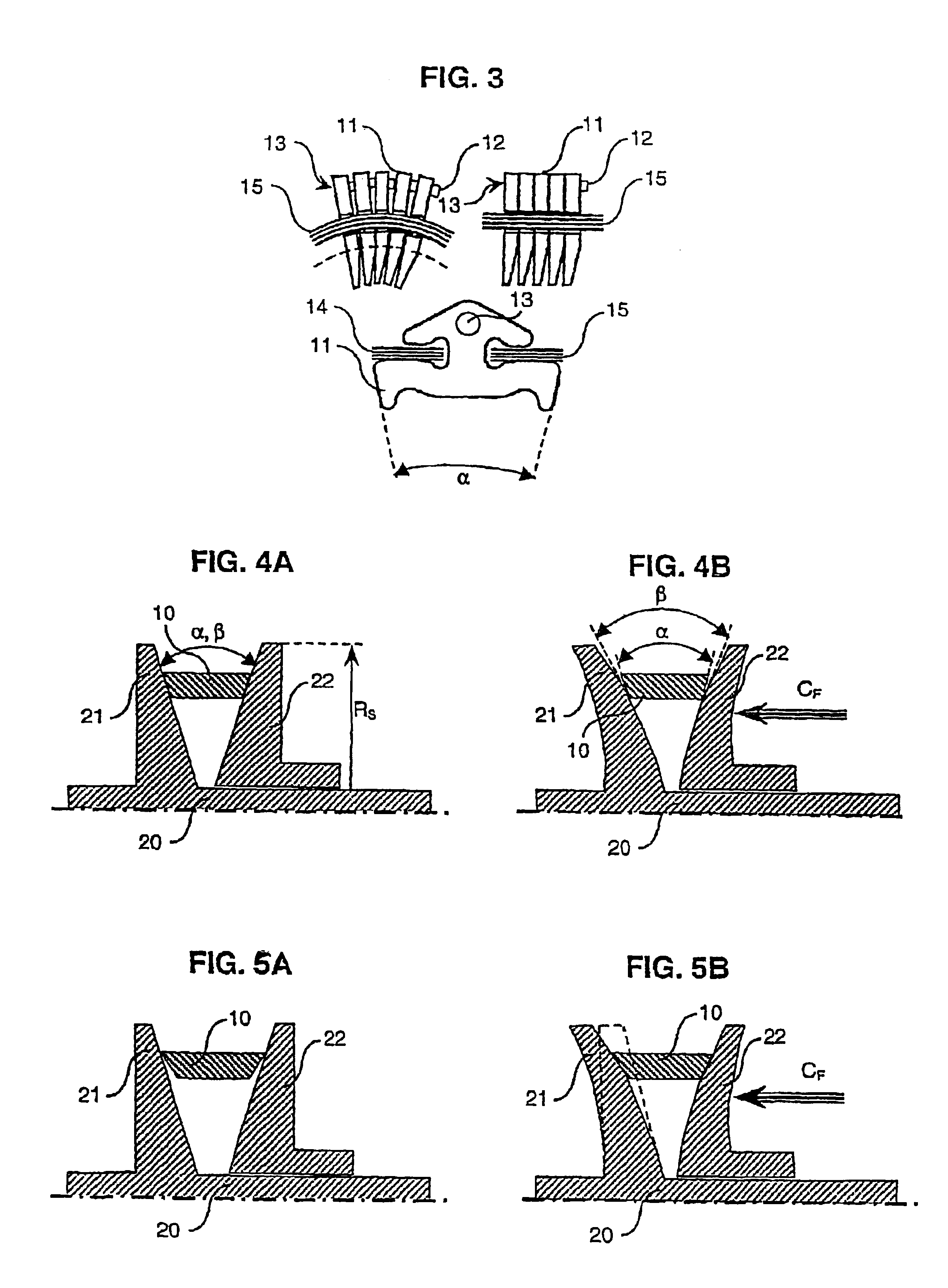

Continuously variable transmission, endless flexible belt for torque transmission and adjustable pulley

A continuously variable transmission, provided with two adjustable pulleys, each pulley comprising a pair of mutually displaceable essentially frusto-conical pulley sheaves having a radial dimension provided on a pulley shaft, each sheave having a sheave face, whereby the sheave faces of a pulley are mutually oriented at a pulley angle, and with an endless flexible belt for transmitting torque comprising two lateral side faces, which are mutually oriented at a belt angle (alpha) such that the flexible belt tapers radially inwardly and which are intended for interacting with the sheave faces of a pulley under the influence of a clamping force to be exerted on the flexible belt by the sheaves. The belt angle is marginally, but notionally, larger than the pulley angle (beta) of at least one pulley for at least a substantial part of the radial dimension of the pulley sheaves.

Owner:VAN DOORNES TRANSMISSIE BV

Electric brake

InactiveUS7806241B2Avoid uneven wearInhibits uneven wearDynamo-electric brakes/clutchesAxially engaging brakesPosition controlPiston

Owner:AKEBONO BRAKE IND CO LTD

Pneumatic Tire

ActiveUS20140326381A1Improve uneven wear resistanceUneven wearHeavy duty tyresHeavy duty vehicleEngineering

Owner:YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com