Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Improve uneven wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

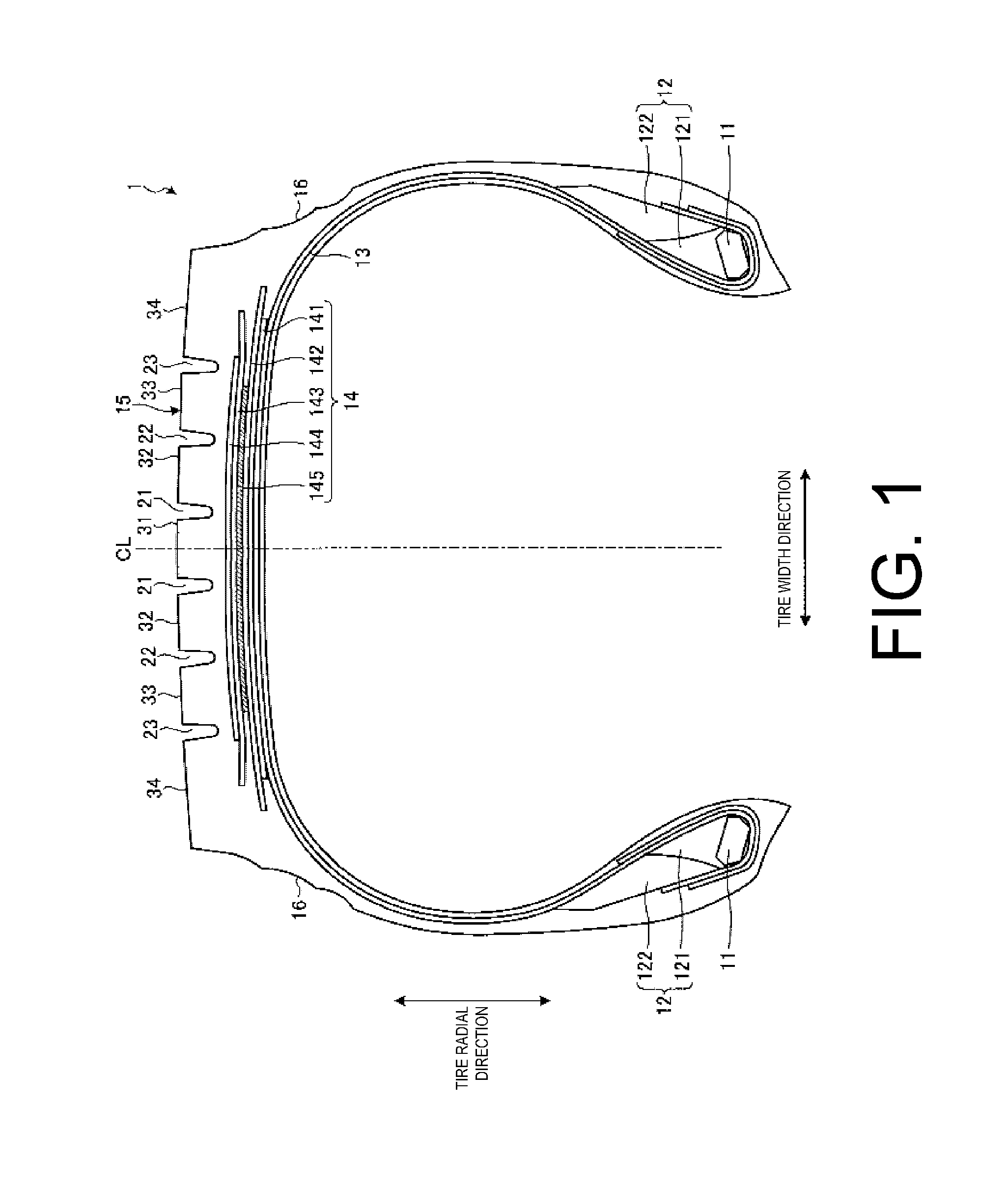

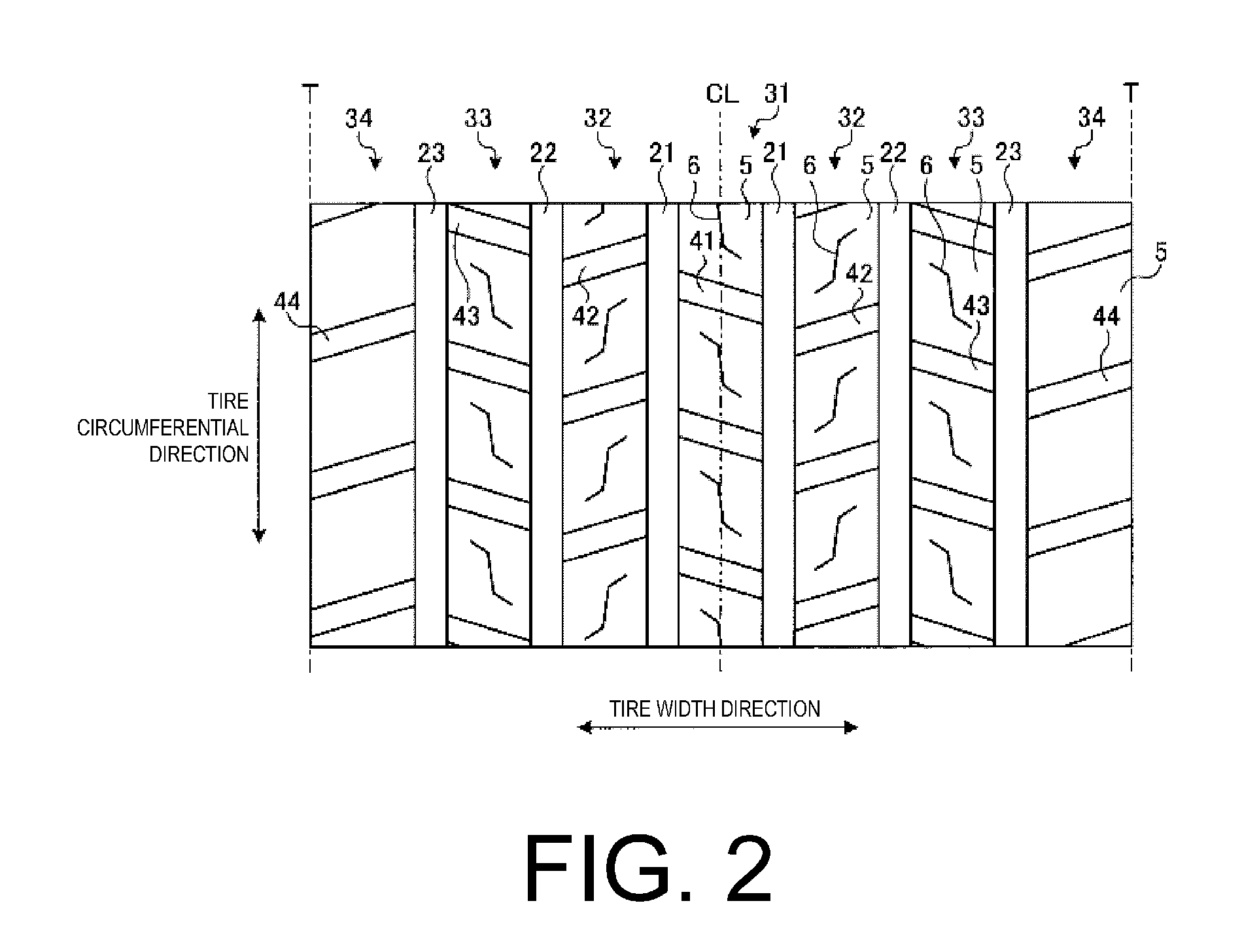

Pneumatic tire

ActiveUS20130192731A1Improve rigidityAvoid uneven wearTyre tread bands/patternsNon-skid devicesGround contactMarine engineering

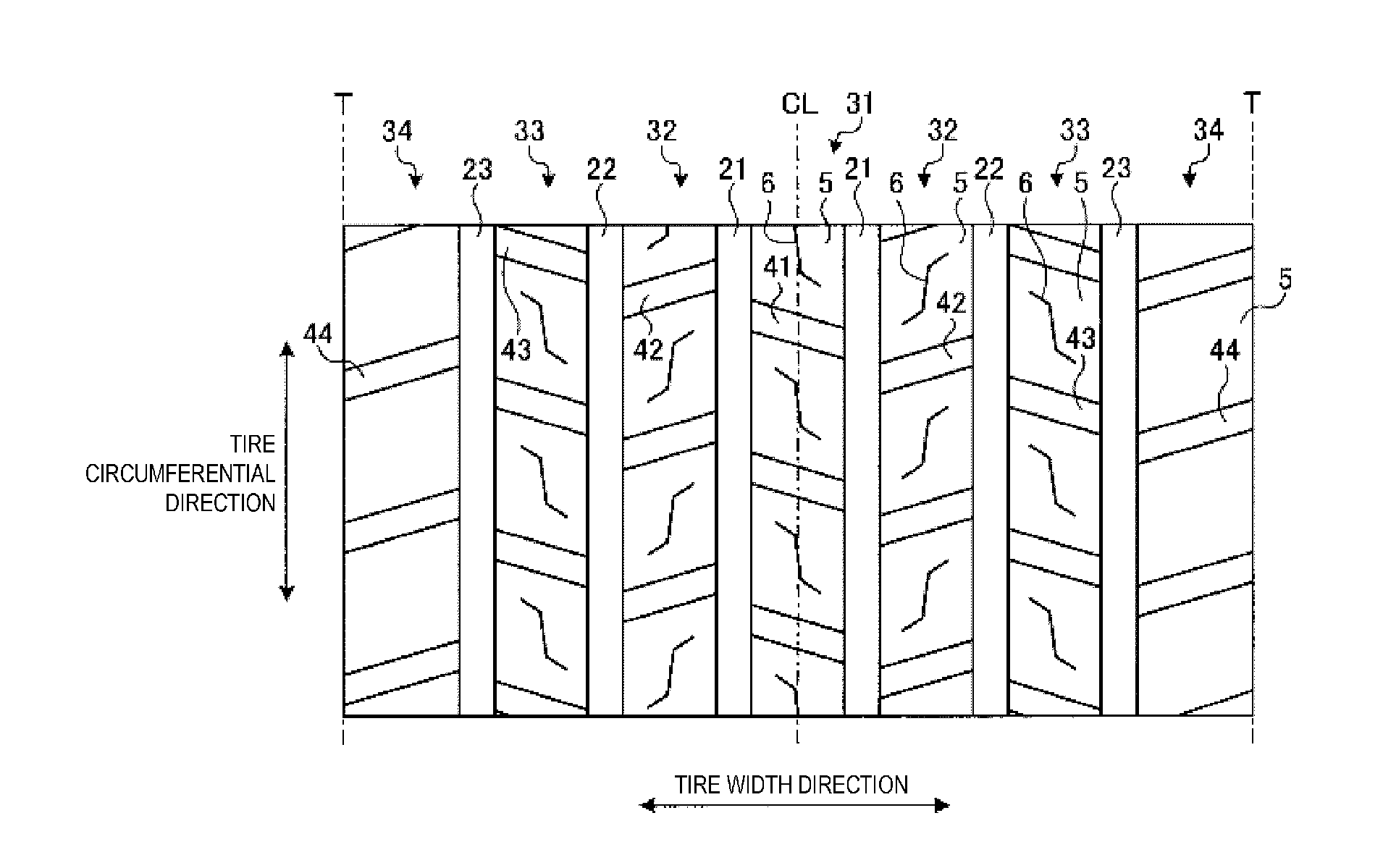

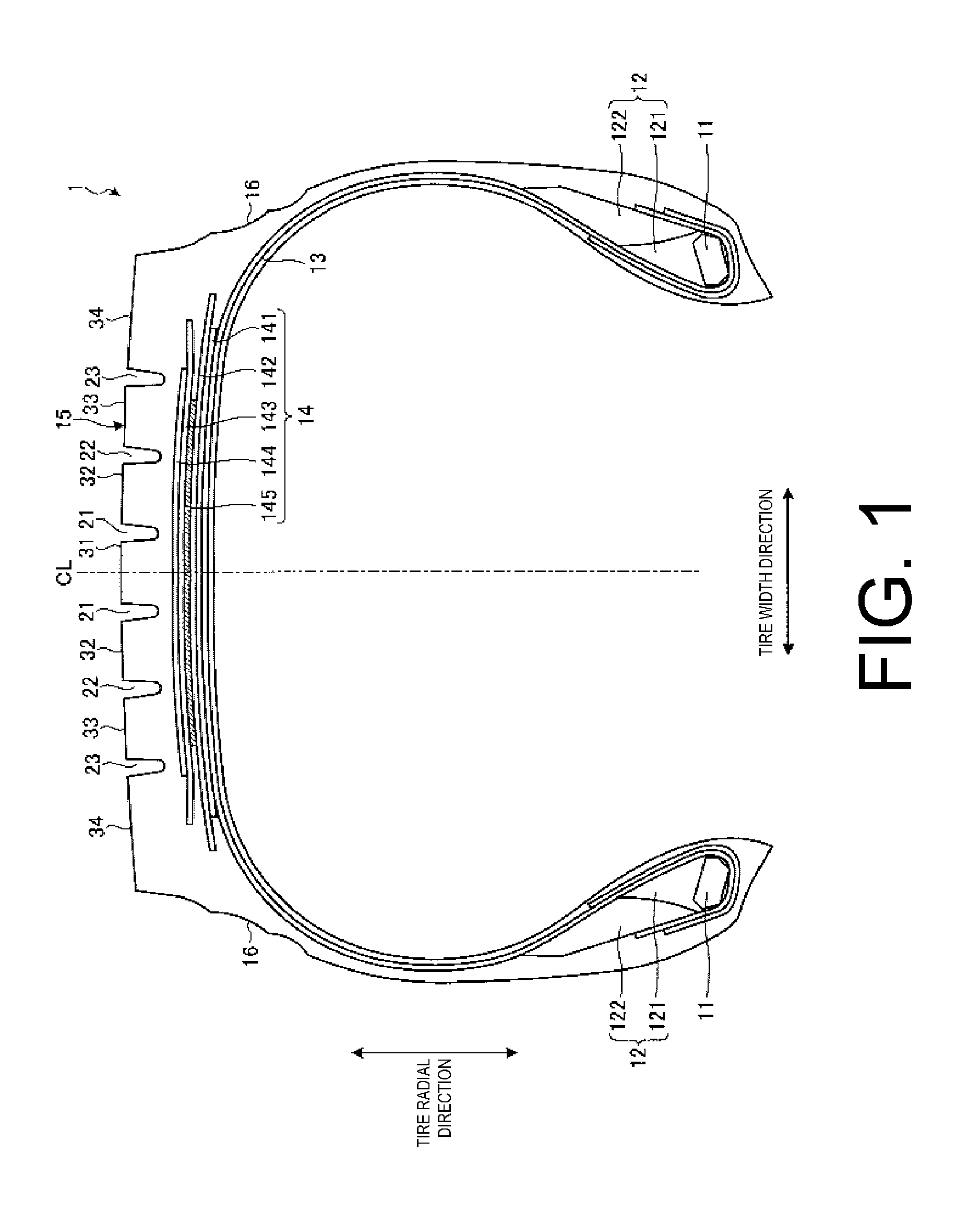

A tread portion of a pneumatic ti re includes inner land portions between outer circumferential main grooves disposed most on tread ground-contact end sides and at least one inner circumferential main groove on the inner side thereof. The inner land portions are divided into inner blocks by inner lateral grooves inclined at an angle α of 10 to 40°. The inner lateral grooves consist of first inner lateral grooves and second inner lateral grooves which are alternately arranged in a circumferential direction. The first inner lateral grooves include a wide-width part connecting to the outer circumferential main groove and a narrow-width part connecting to the inner circumferential main groove.

Owner:SUMITOMO RUBBER IND LTD

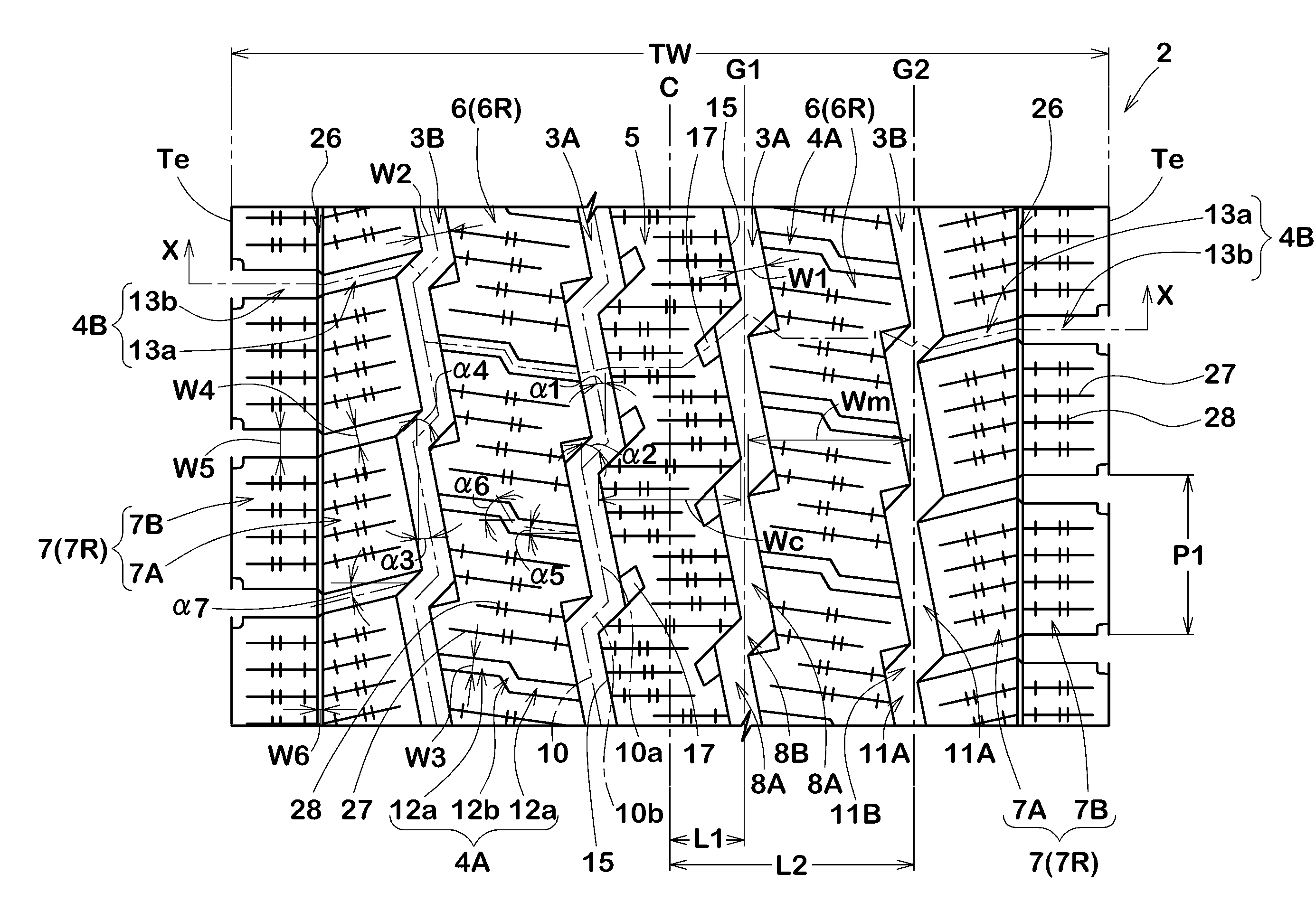

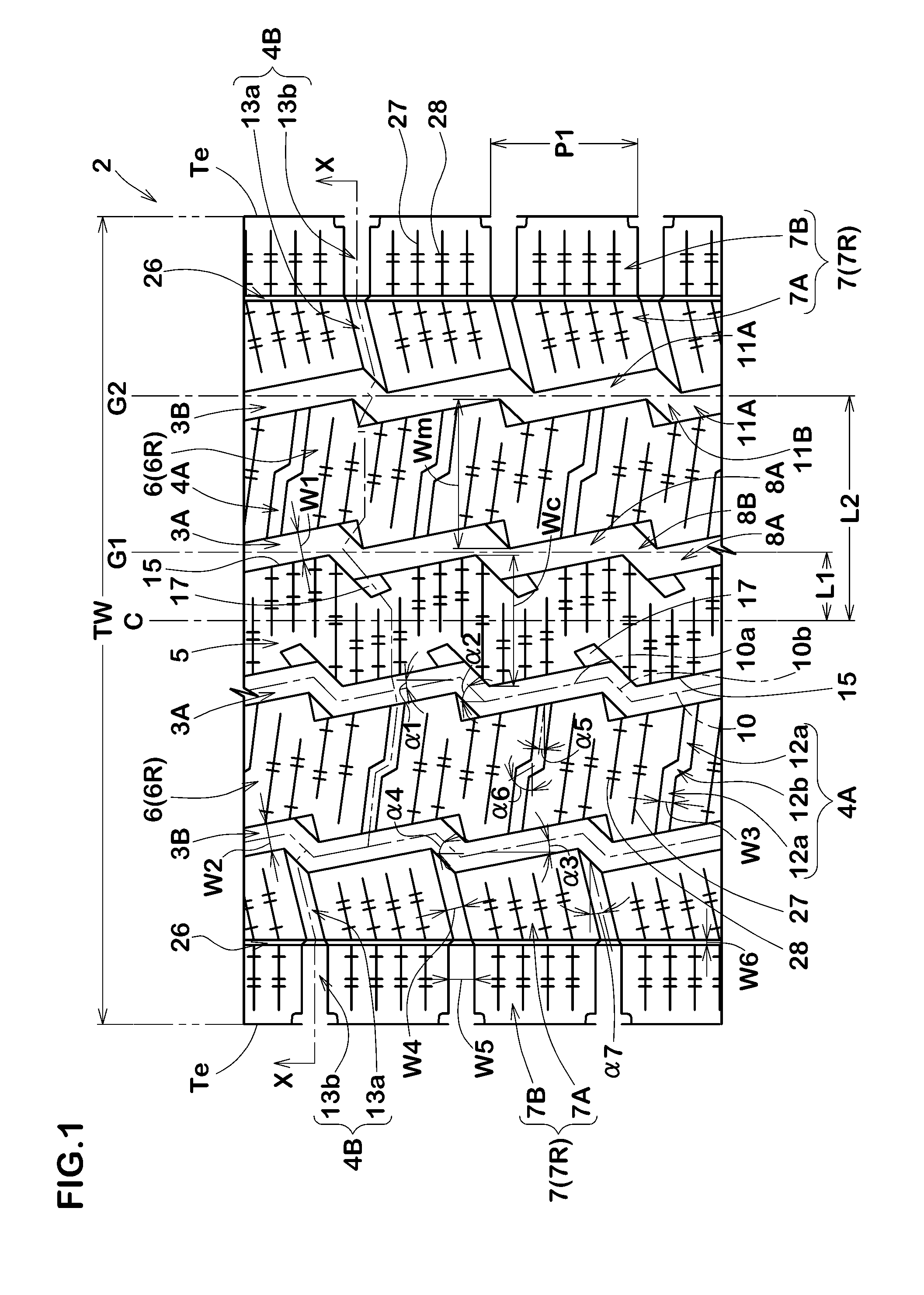

Pneumatic tire

ActiveUS20120118455A1Improve uneven wear resistanceMaintain performanceTyre tread bands/patternsNon-skid devicesEngineeringWear resistance

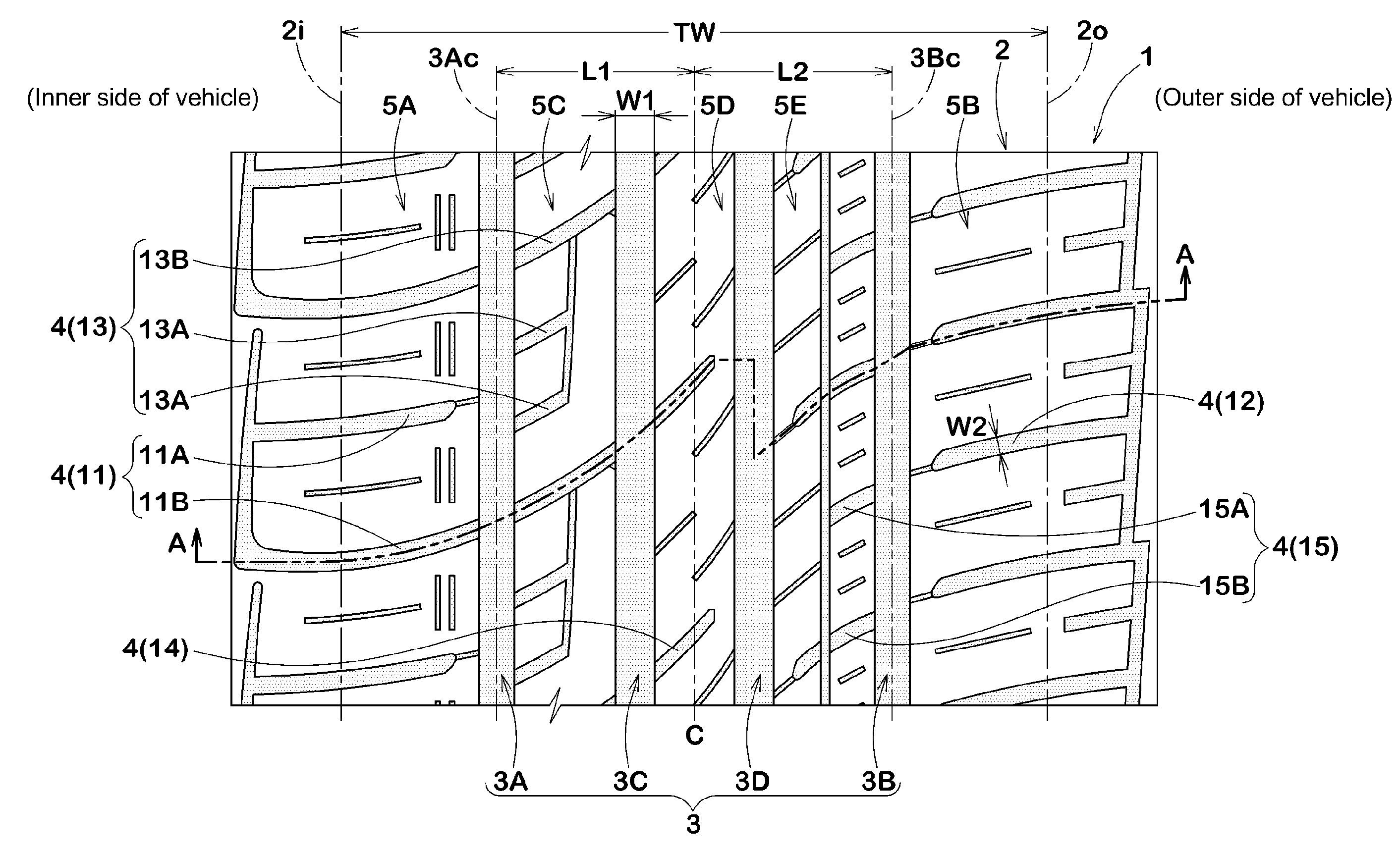

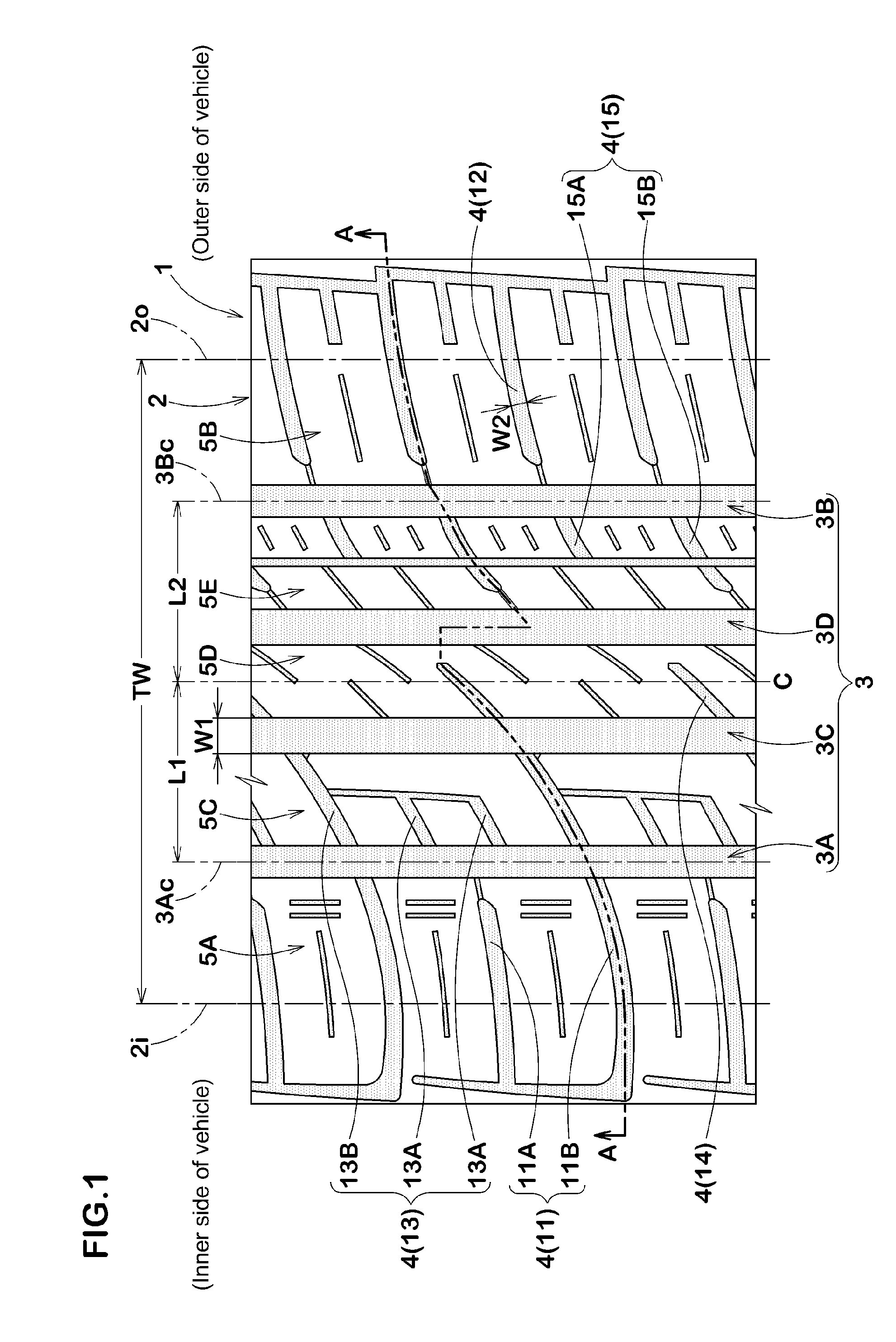

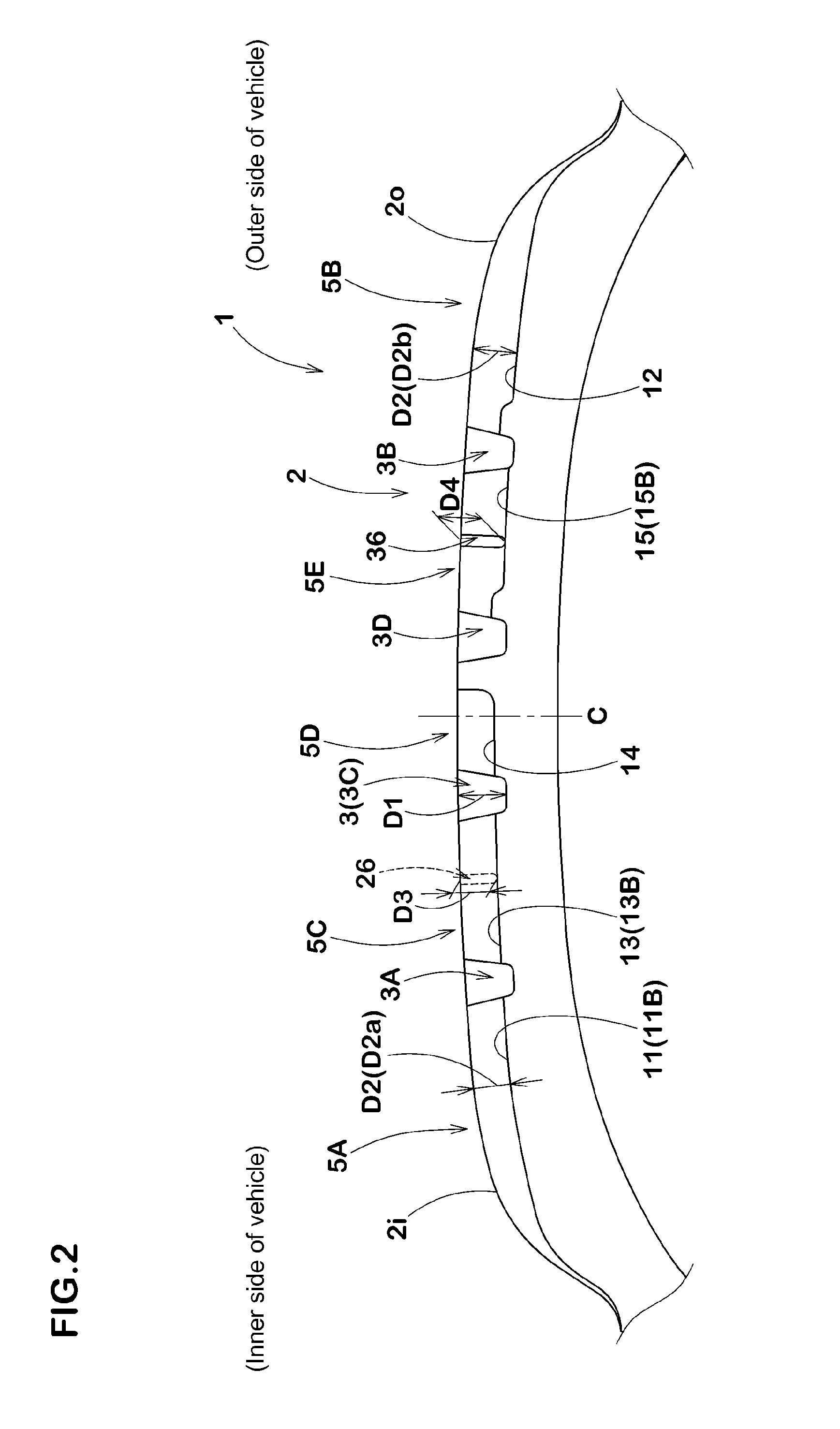

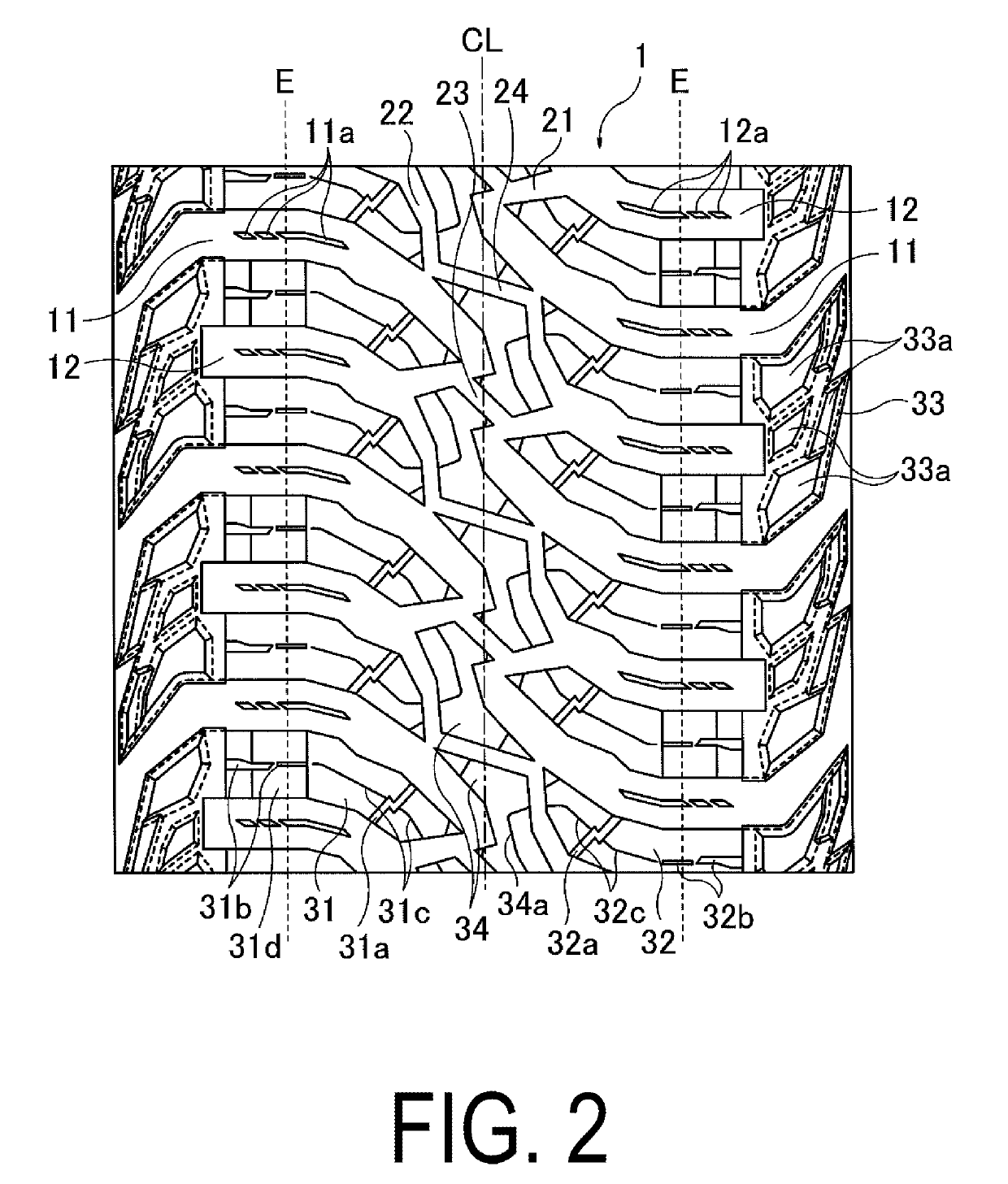

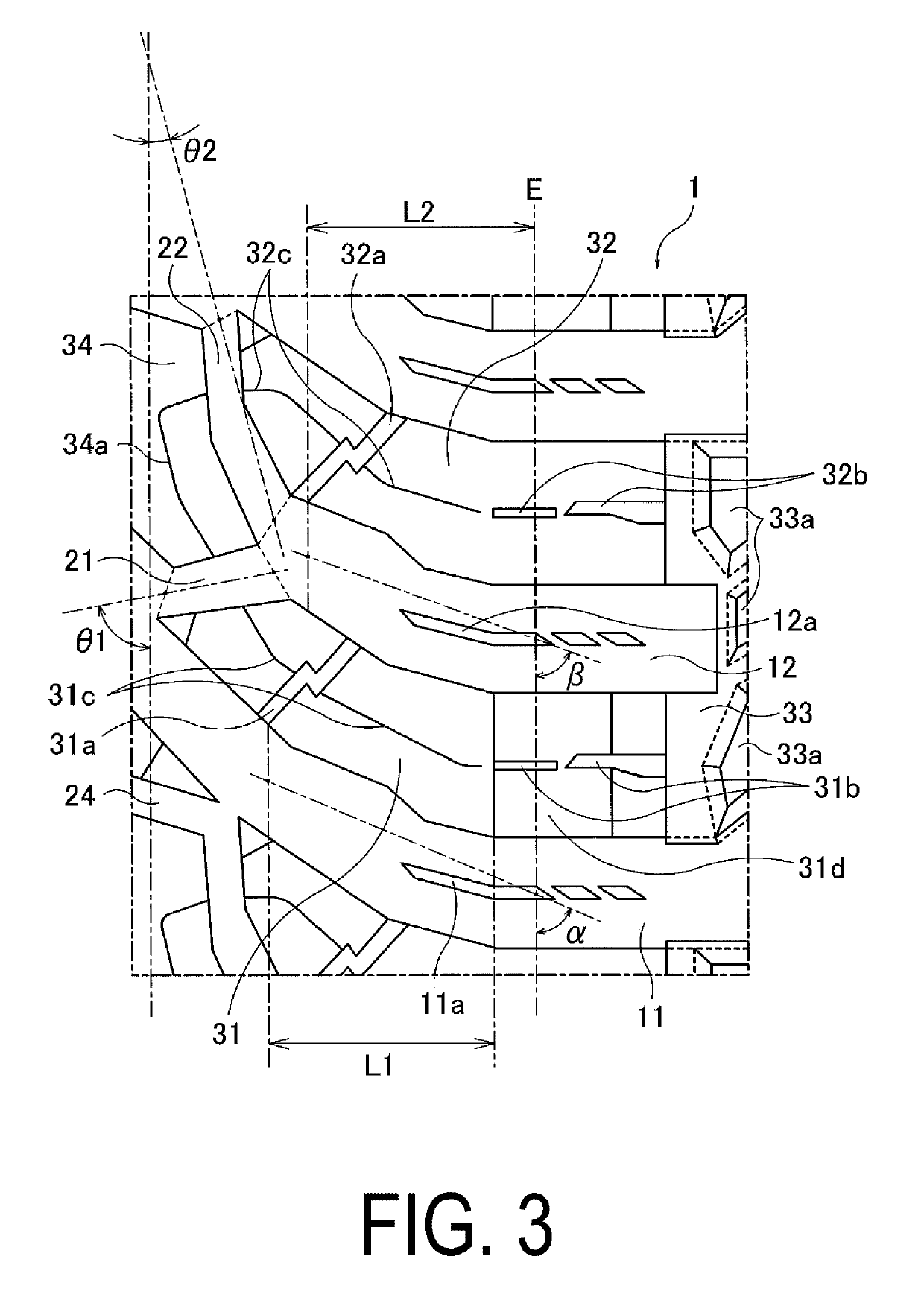

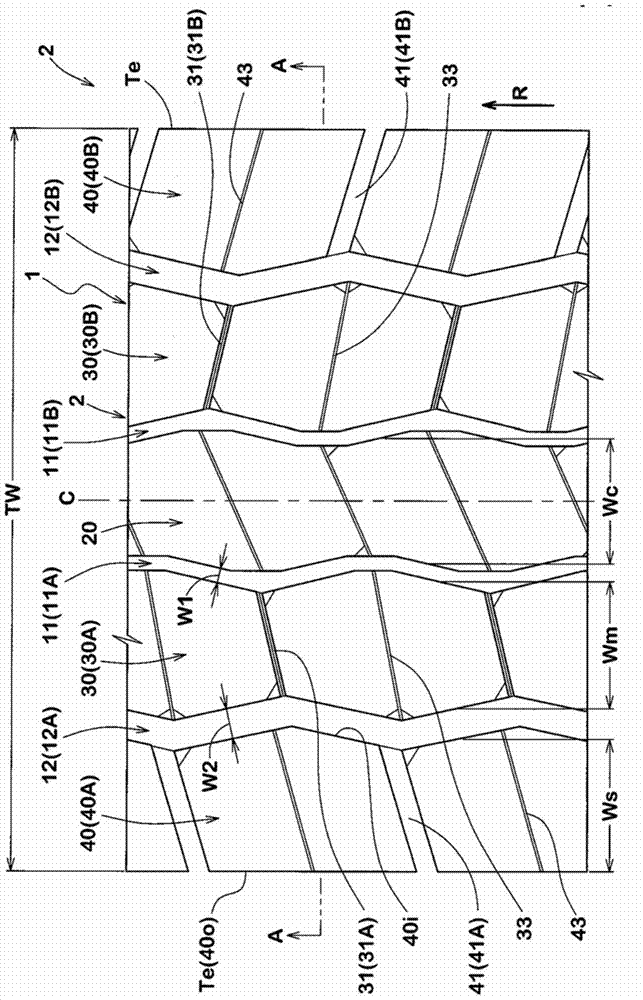

To make it possible to enhance uneven wear resistance while maintaining drainage performance, a pneumatic tire includes a left-right asymmetric tread pattern having a designated mounting orientation with respect to a vehicle. Vertical grooves include an inner shoulder circumferential groove disposed on an innermost side of the vehicle, and an outer shoulder circumferential groove disposed on an outermost side of the vehicle. Lateral grooves include inner shoulder lateral grooves and outer shoulder lateral grooves. The inner shoulder lateral groove includes a first inner shoulder lateral groove which extends inward in a tire axial direction from an outer side of a vehicle-inner side tread edge and terminates without reaching the inner shoulder circumferential groove, and a second inner shoulder lateral groove which extends inward in the tire axial direction from an outer side of the vehicle-inner side tread edge and opens in the inner shoulder circumferential groove.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

InactiveUS20080121326A1Improve wear resistanceImprove the immunityTyre tread bands/patternsNon-skid devicesEngineeringTread

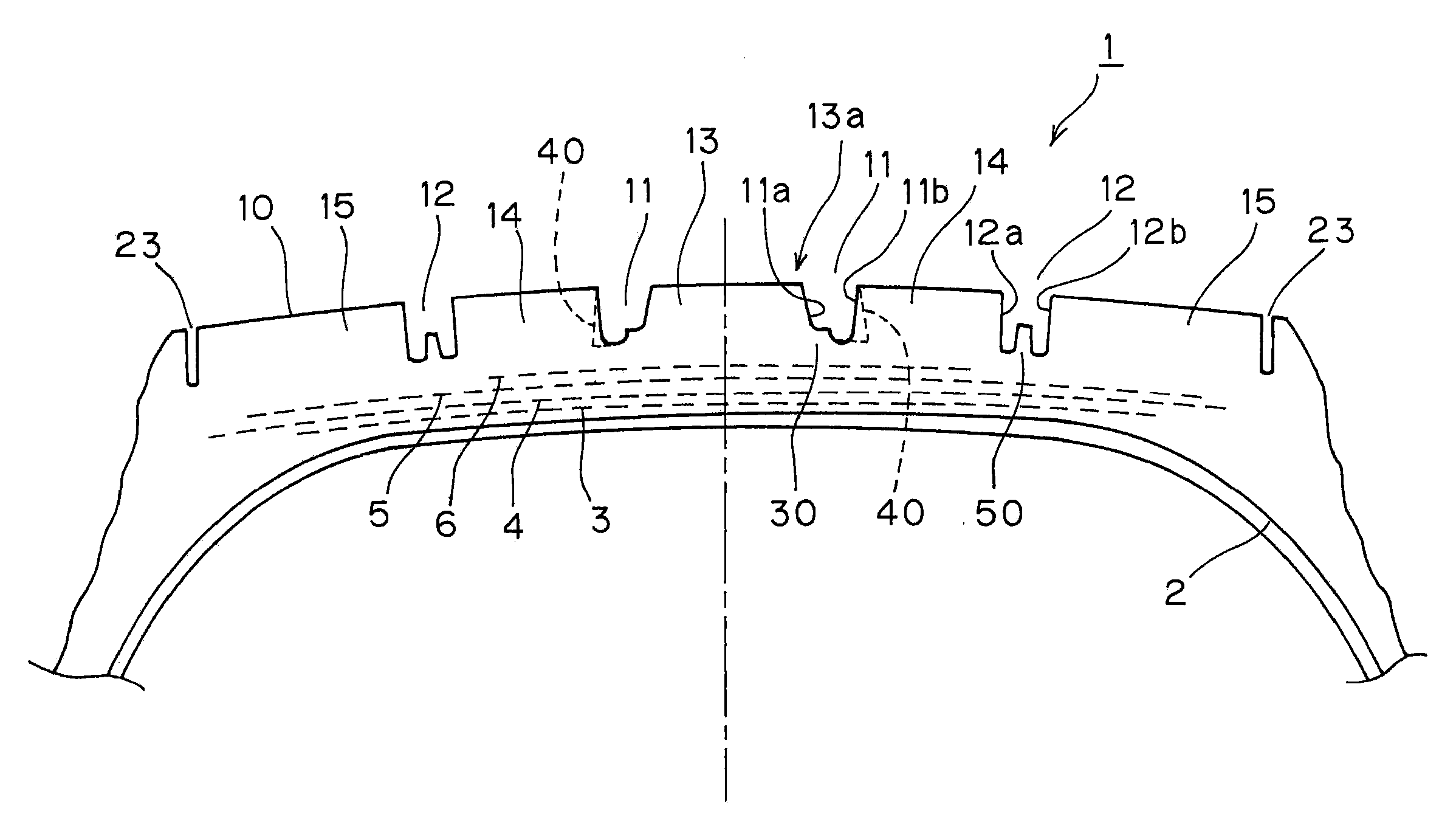

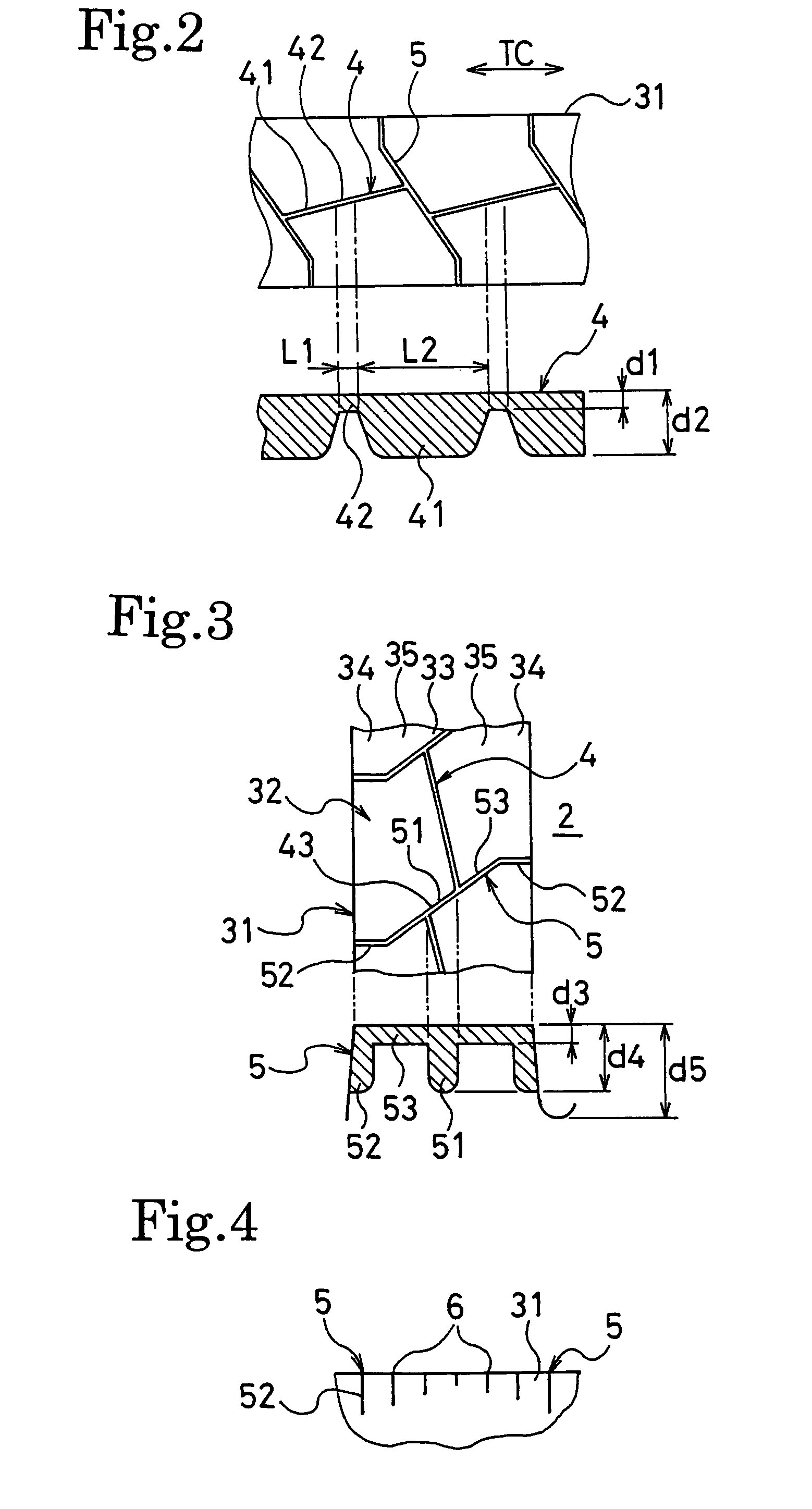

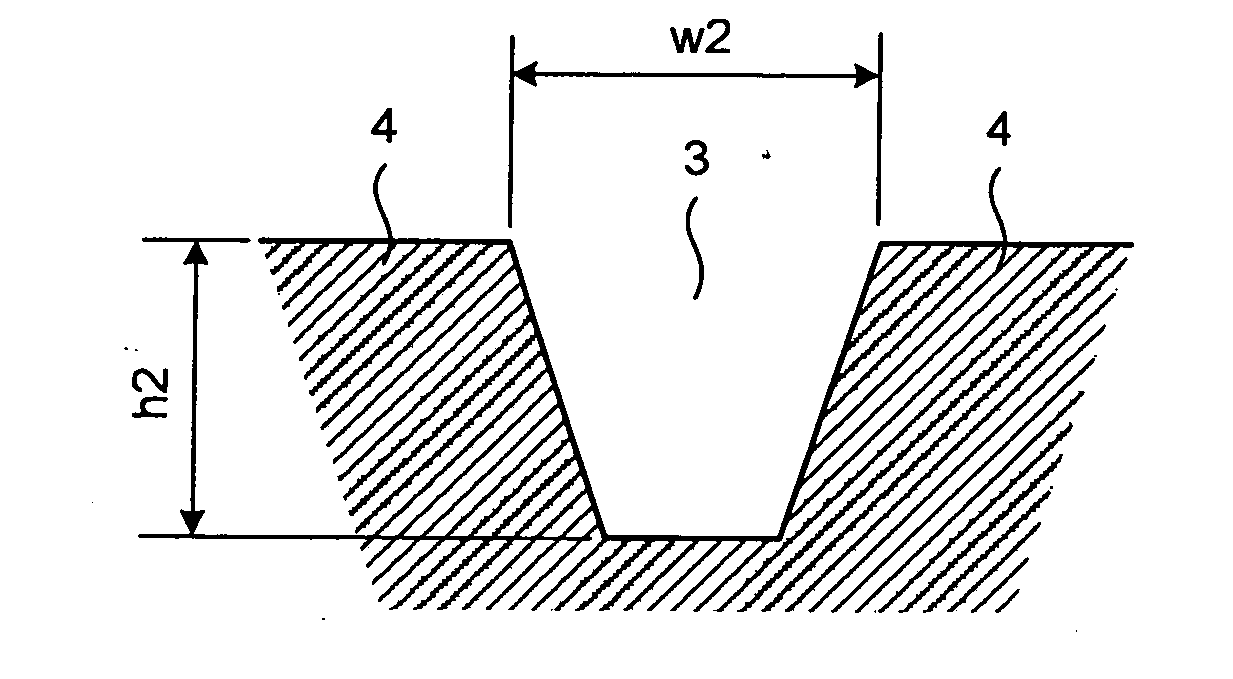

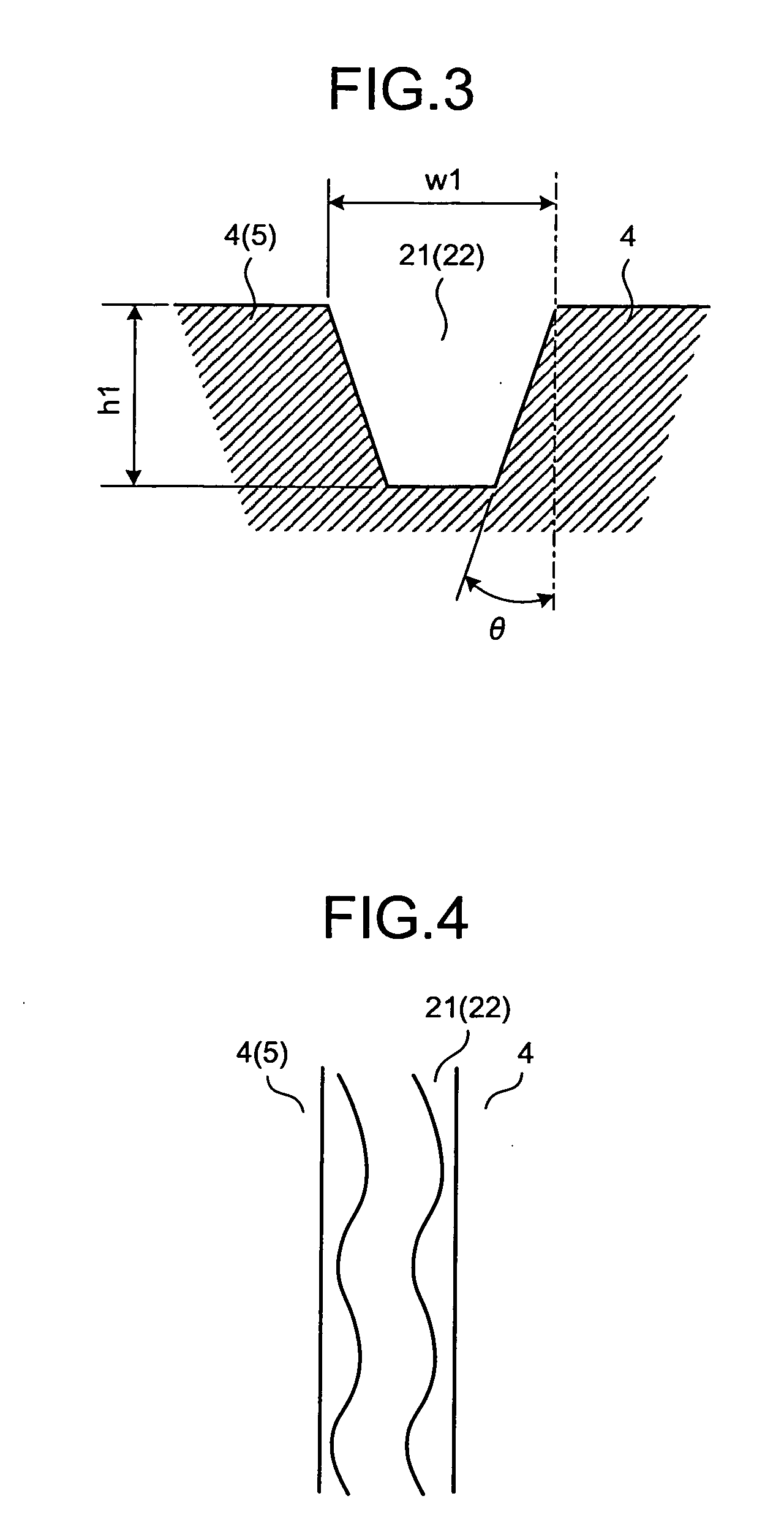

A pneumatic tire of the invention includes: a stepped-shaped raised area provided in the main groove positioned at a center area of the tire so as to be continued circumferentially of the tire, connected to either the main groove walls, and raised from the groove bottom; and a ridge lower than a tread surface of the tire in each of the main grooves on both outsides of the main groove at the center area of the tire so as to be raised from the center of the groove bottom continuously along the length thereof without being joined with the groove walls, and the angle of inclination of the main groove walls with respect to the normal line of the tangential line on the tread surface of the main groove portion is parallel to each other or is 5° or smaller.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire with rib having widthwise sipes and circumferential sipe

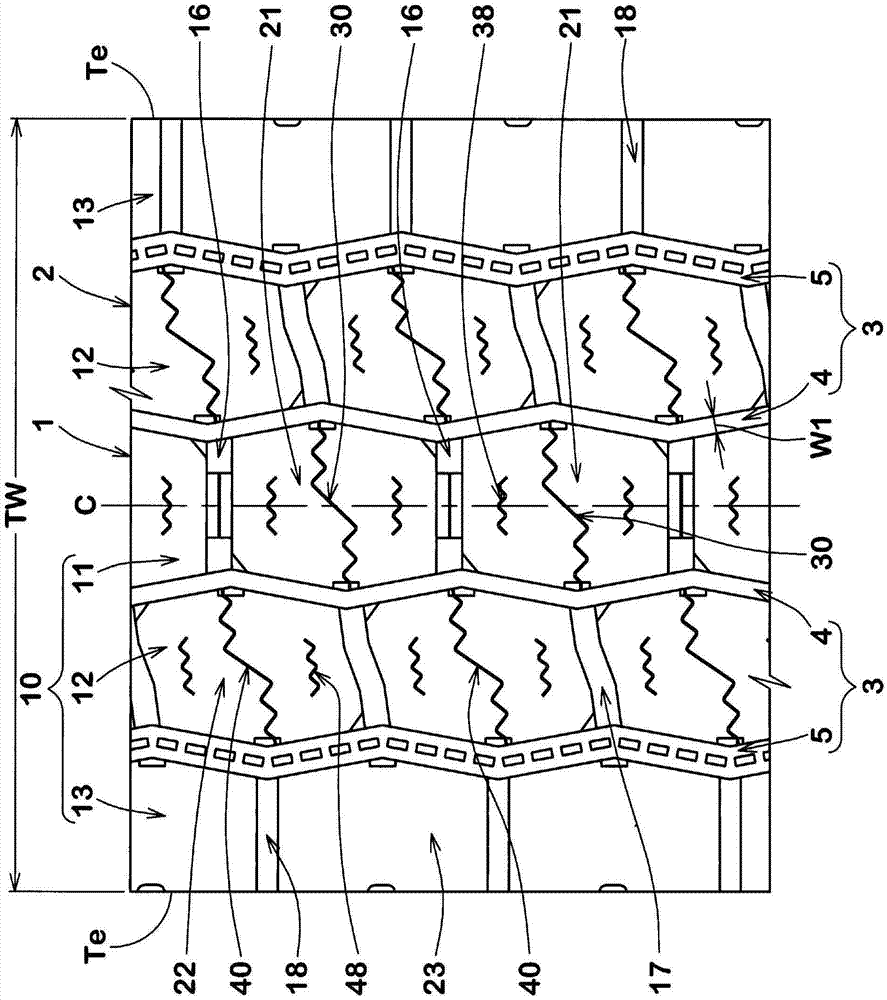

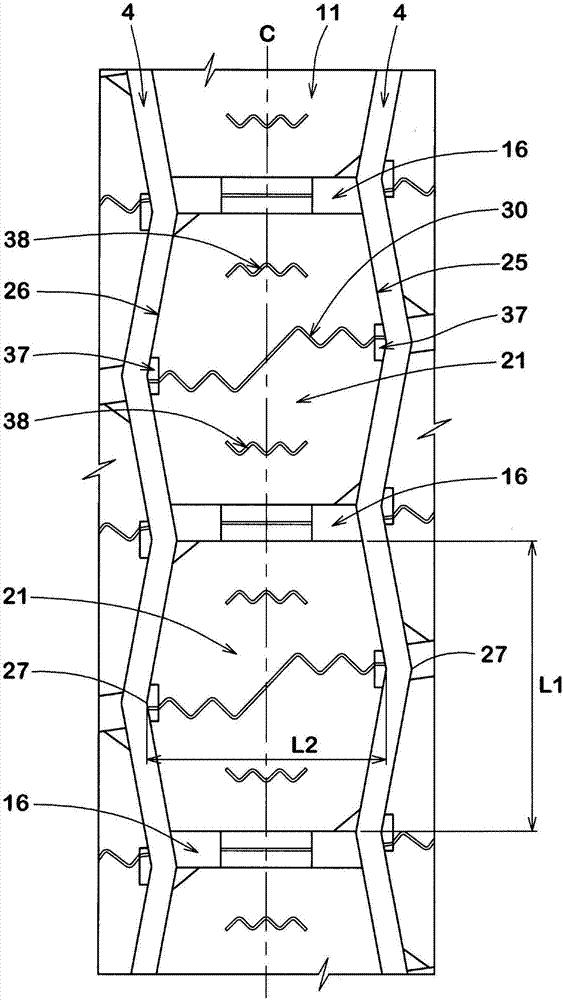

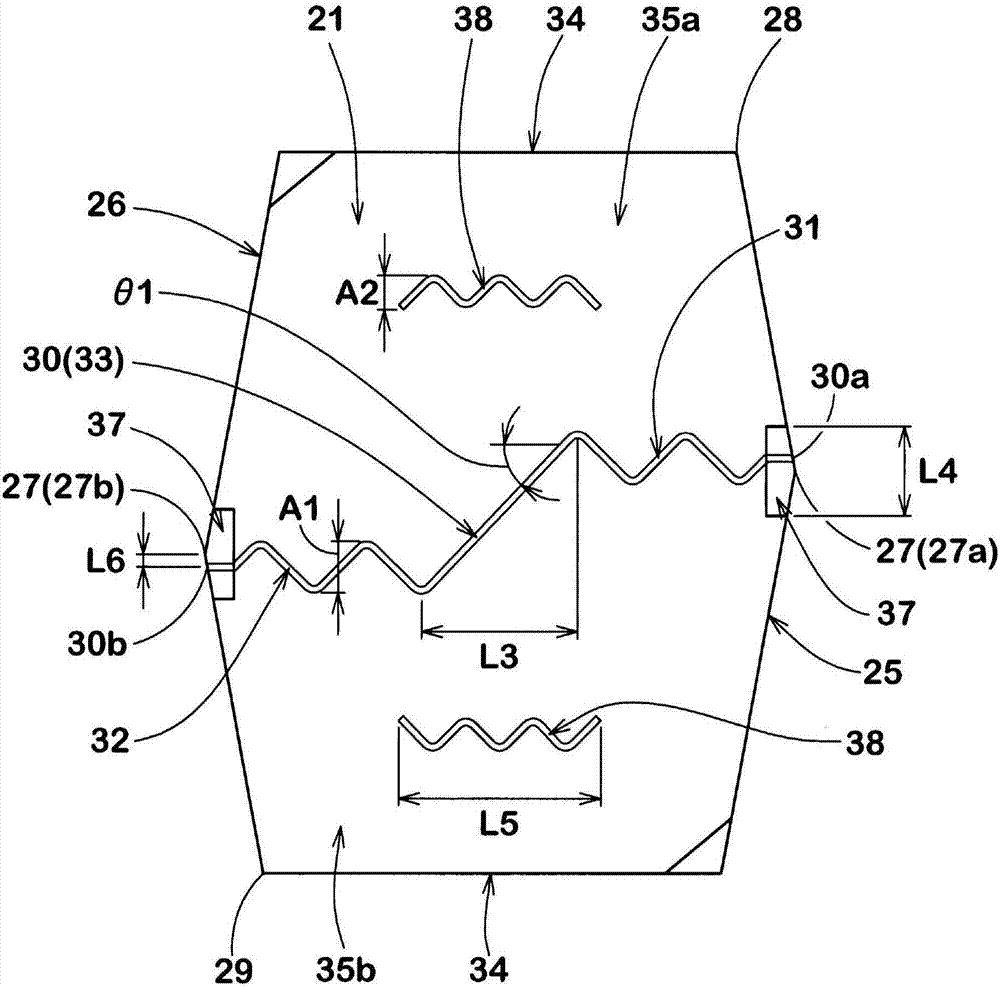

ActiveUS7836926B2Improve uneven wear resistanceImprove wettabilityHeavy duty tyresHeavy duty vehicleEngineeringTread

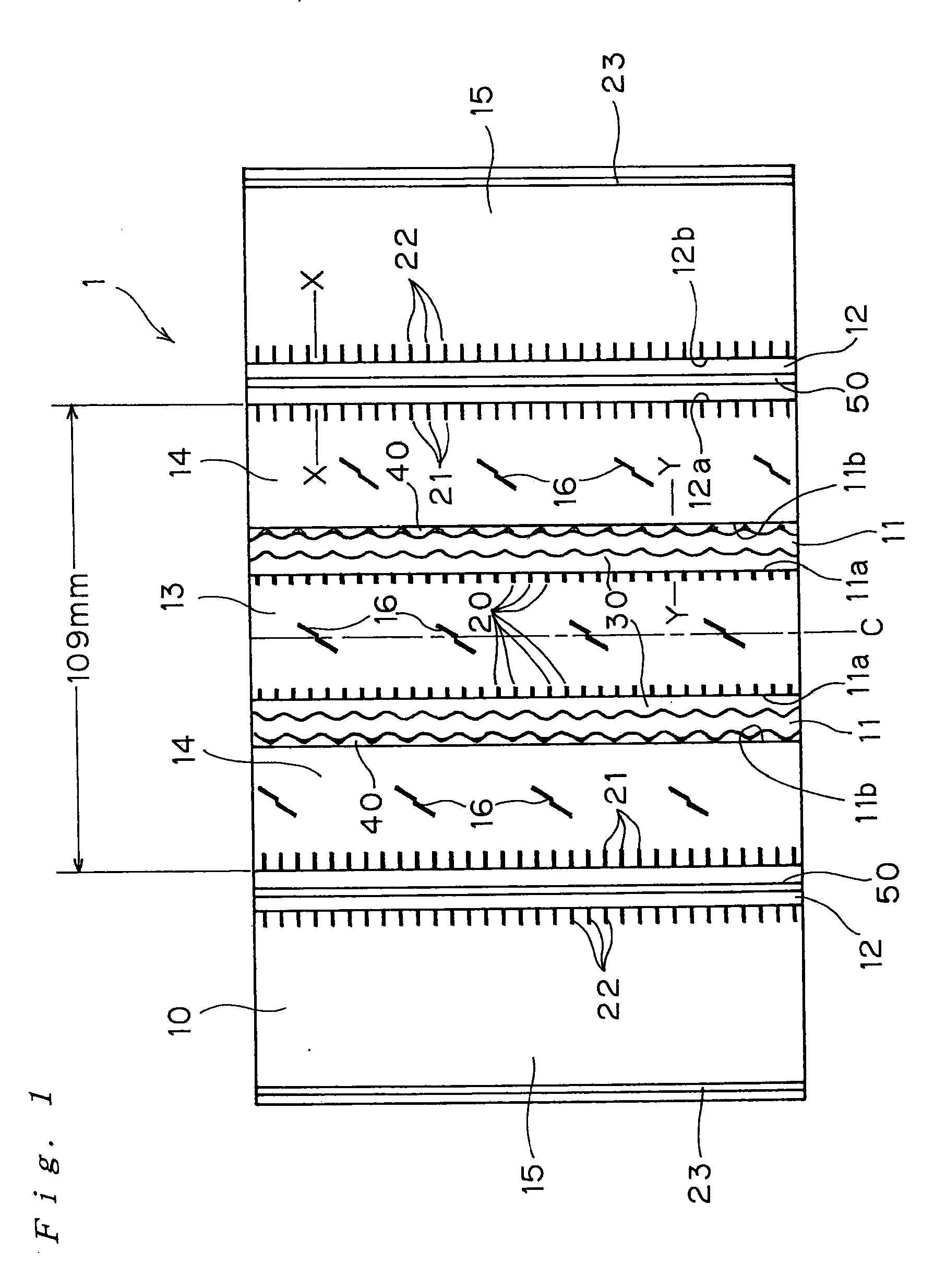

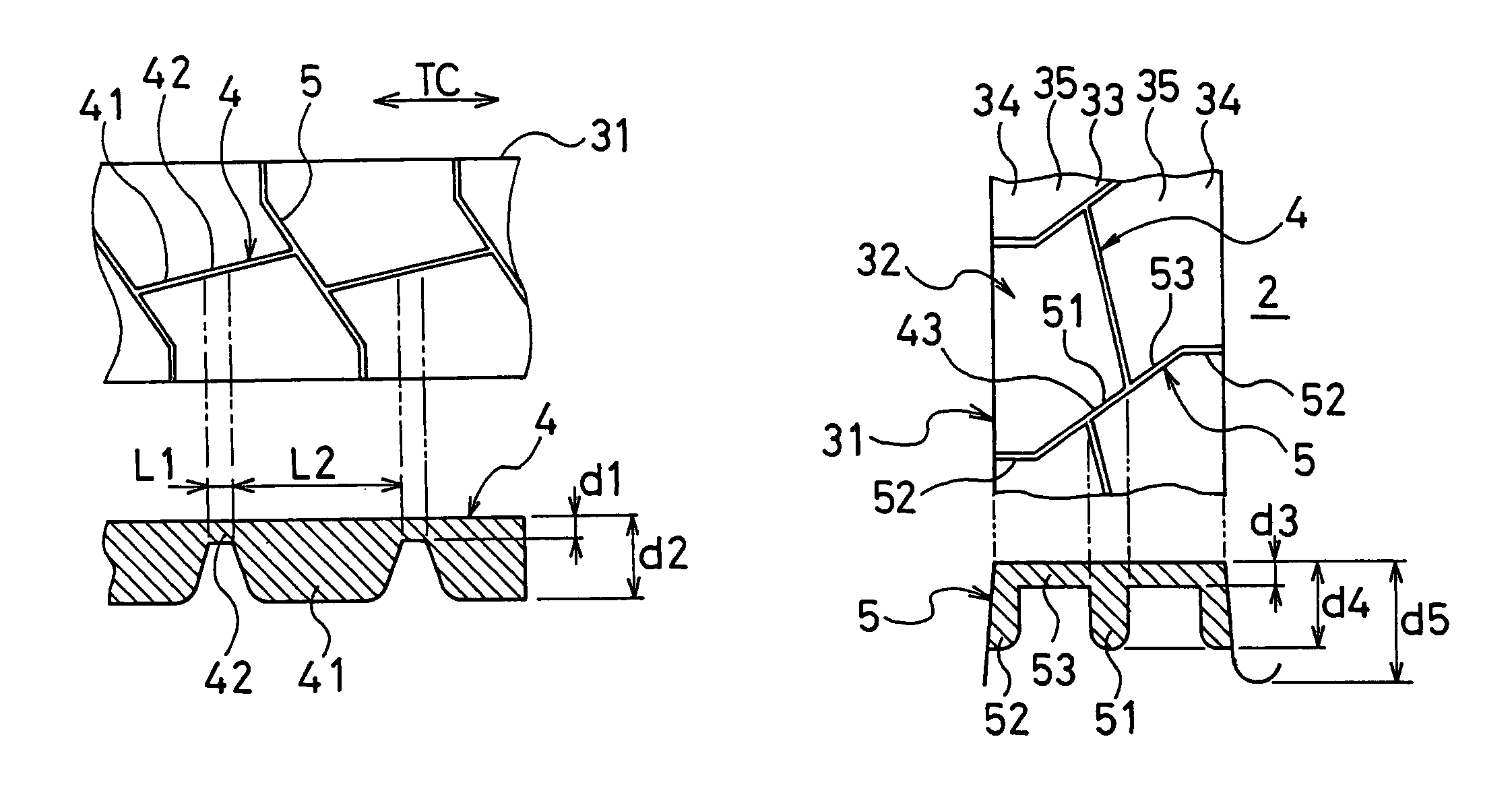

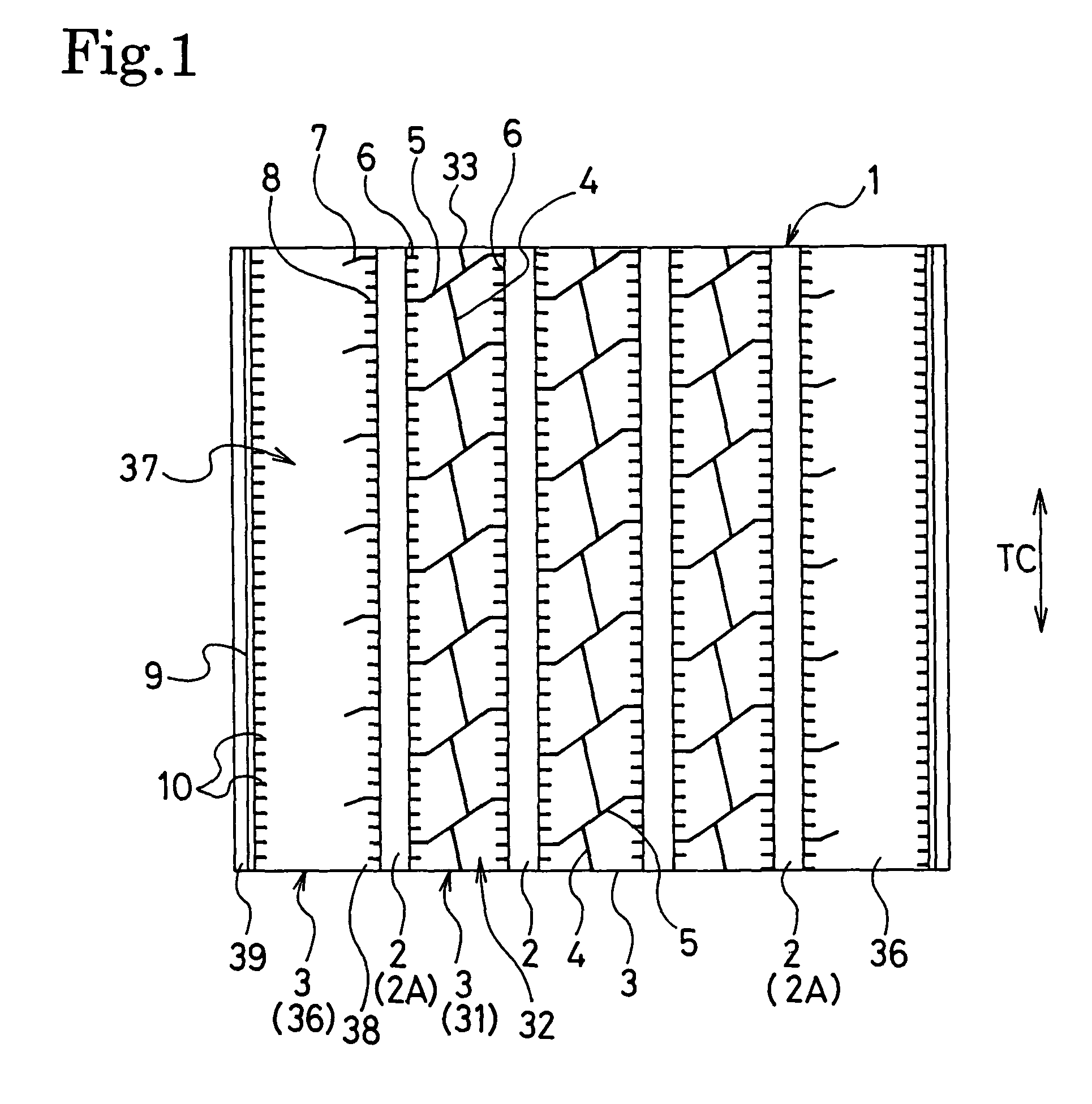

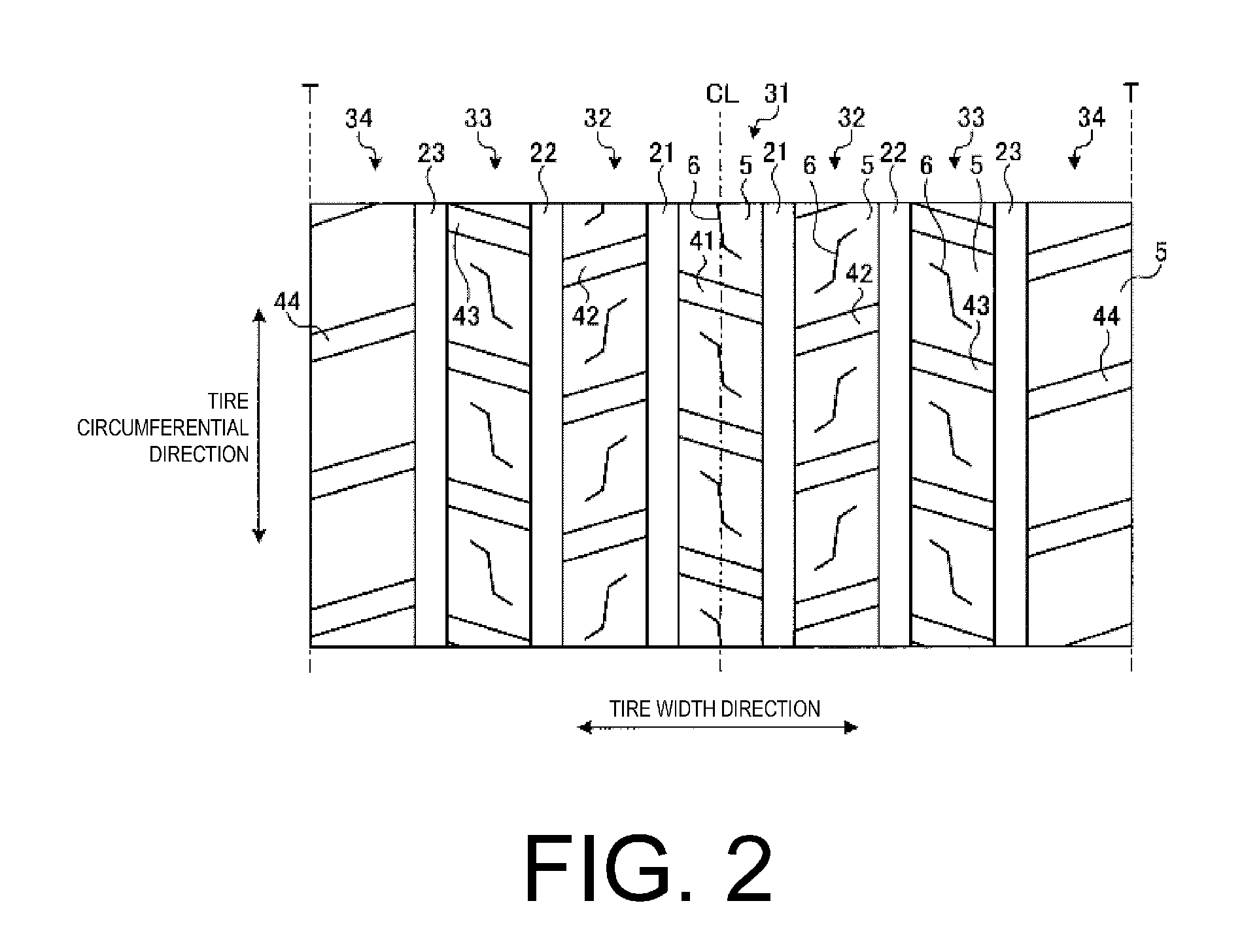

A circumferential sipe extends continuously in the circumferential direction of the tire in the center region of the tread surface section of a rib defined between circumferential grooves. Widthwise sipes are disposed at prescribed intervals in the circumferential direction of the tire in the tread surface section, the widthwise sipes extending in the widthwise direction of the tire in crossing relationship to the circumferential sipe, the widthwise sipes each having opposing terminal ends open to the circumferential grooves. The circumferential sipe changes in depth periodically in such a manner that the circumferential sipe is shallow between adjacent widthwise sipes. The widthwise sipes changes in depth in such a manner that they are greater in depth in the center region and end regions of the tread surface section.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS20070284026A1Moderate shear strainUneven wearHeavy duty tyresHeavy duty vehicleEngineeringTread

A circumferential sipe extends continuously in the circumferential direction of the tire in the center region of the tread surface section of a rib defined between circumferential grooves. Widthwise sipes are disposed at prescribed intervals in the circumferential direction of the tire in the tread surface section, the widthwise sipes extending in the widthwise direction of the tire in crossing relationship to the circumferential sipe, the widthwise sipes each having opposing terminal ends open to the circumferential grooves. The circumferential sipe changes in depth periodically in such a manner that the circumferential sipe is shallow between adjacent widthwise sipes. The widthwise sipes changes in depth in such a manner that they are greater in depth in the center region and end regions of the tread surface section.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

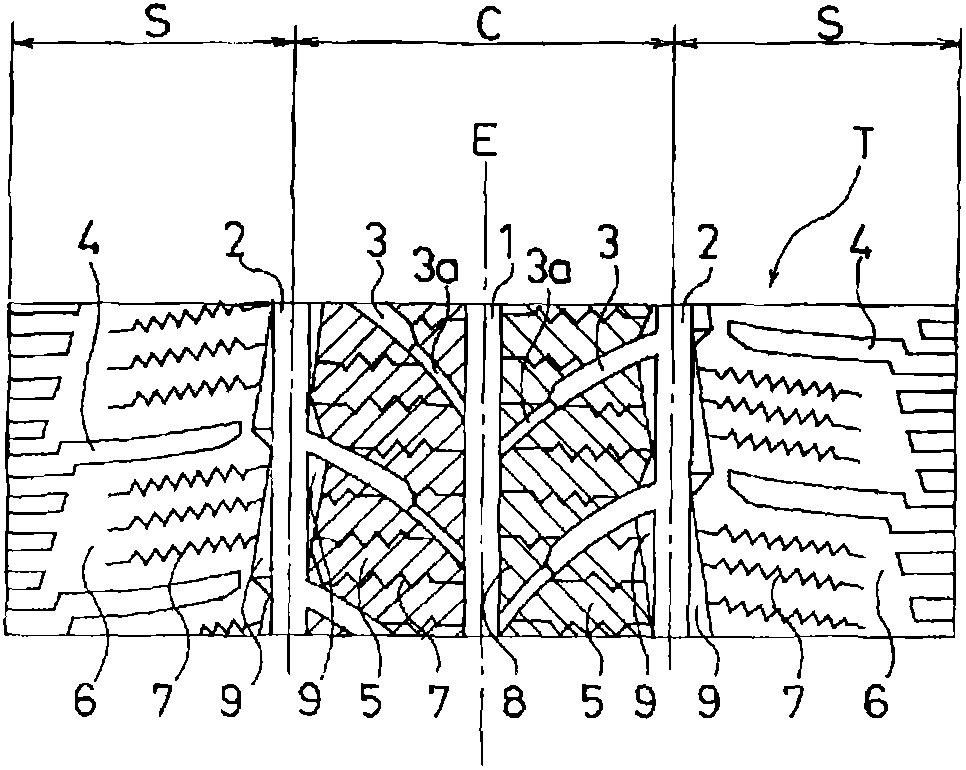

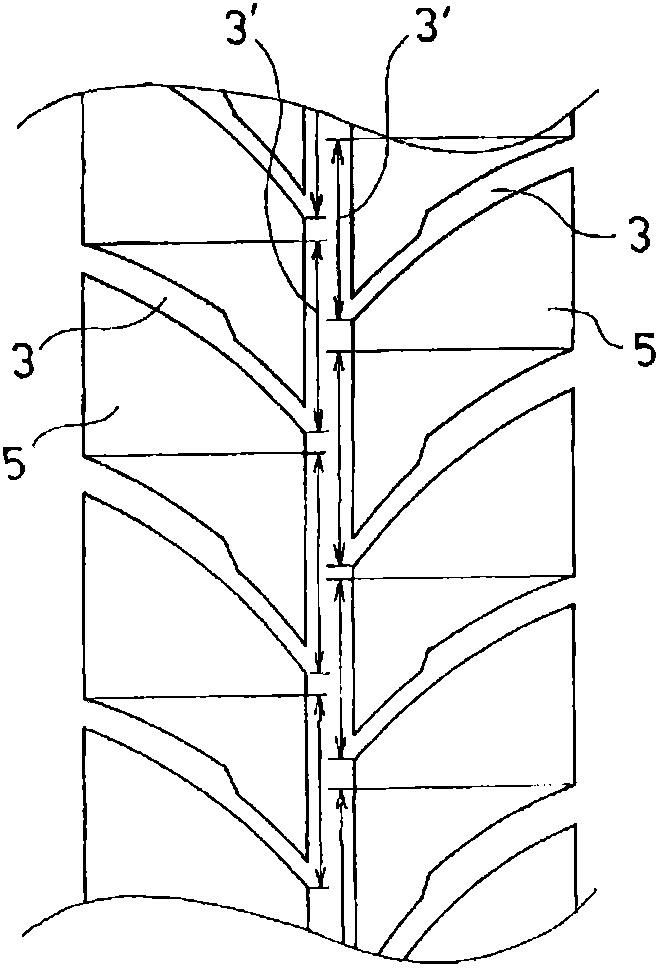

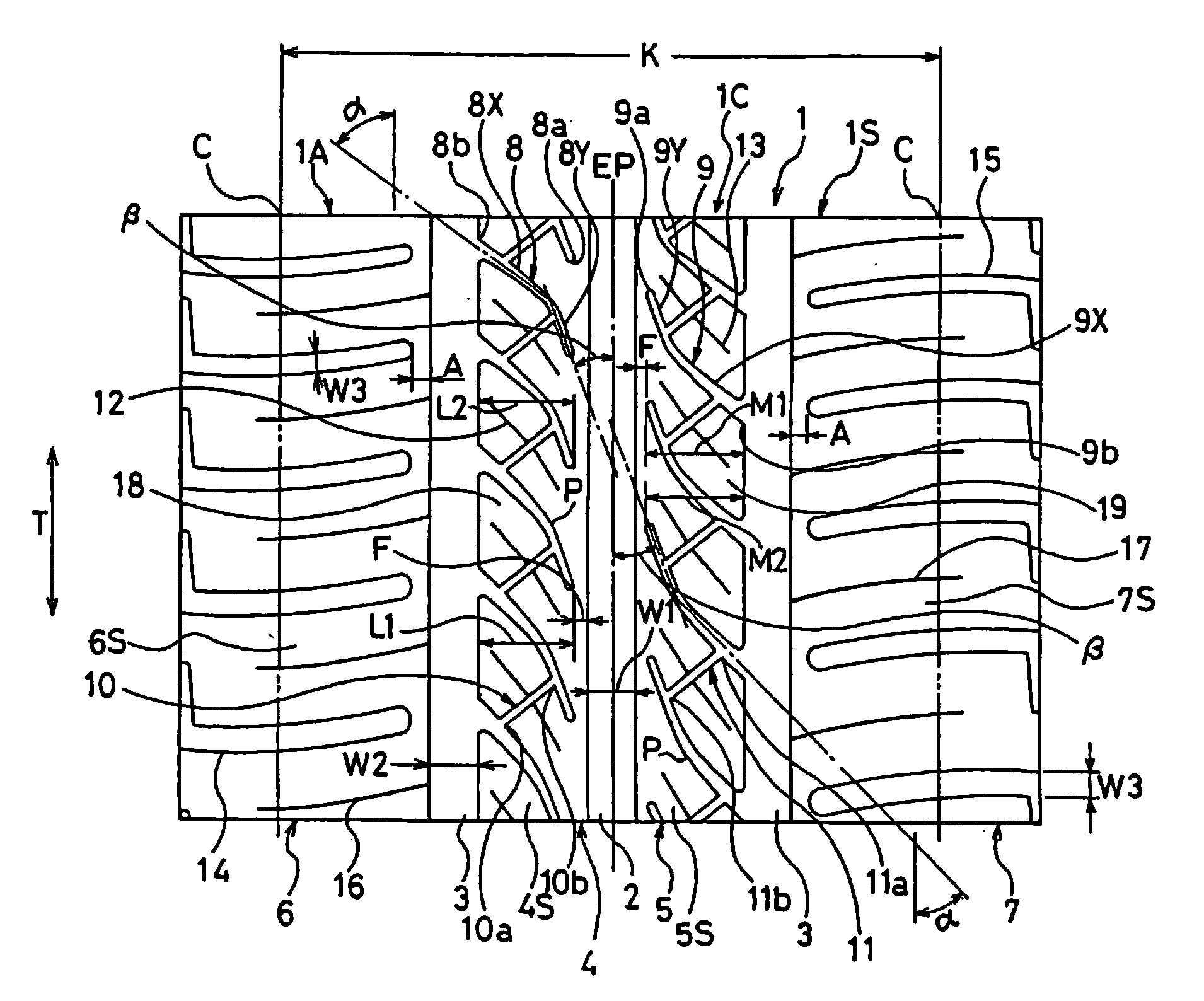

ActiveCN102310723AImprove wetting performanceImprove snow performanceSpecial tyresTyre tread bands/patternsAcute angleTransverse groove

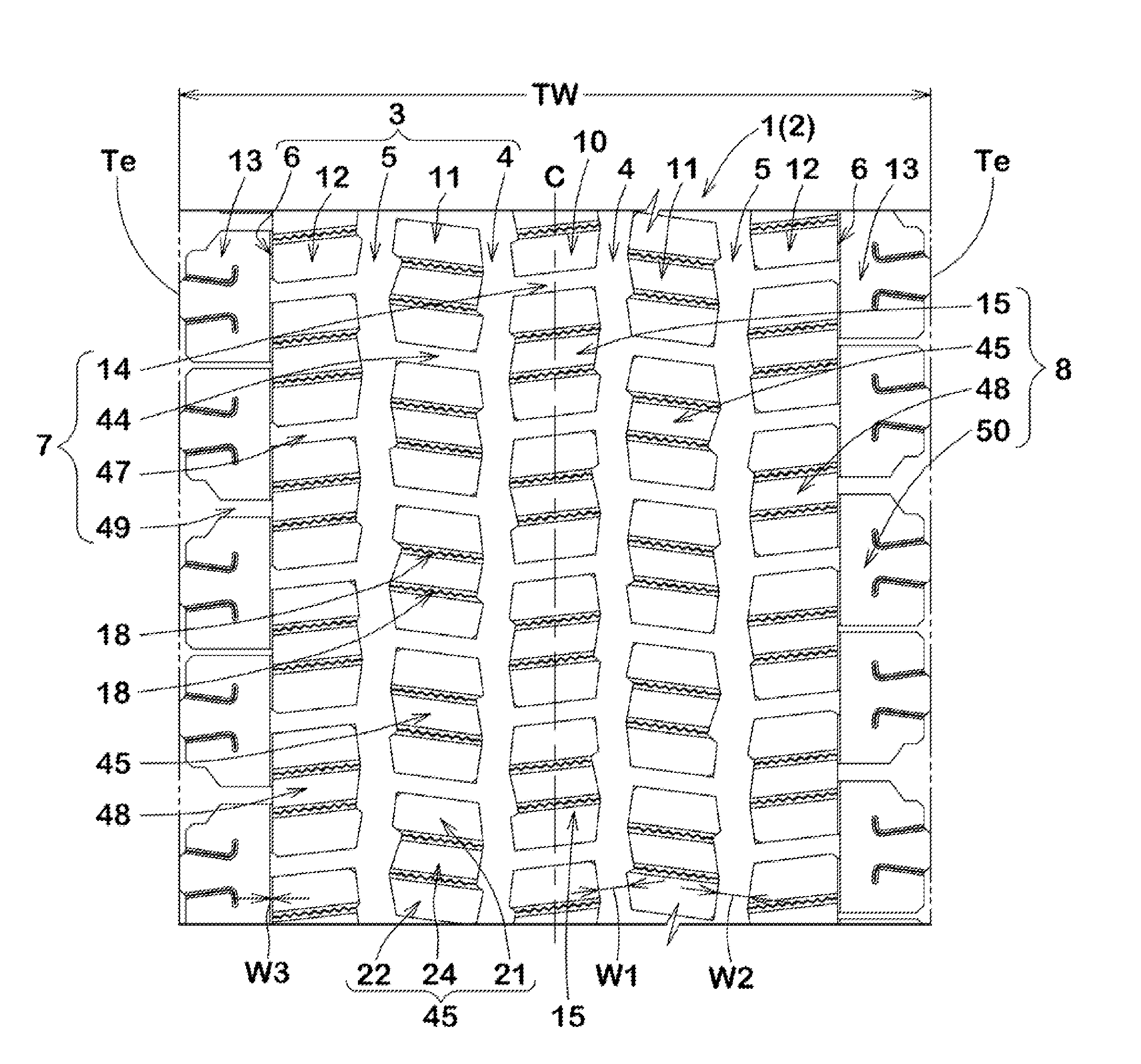

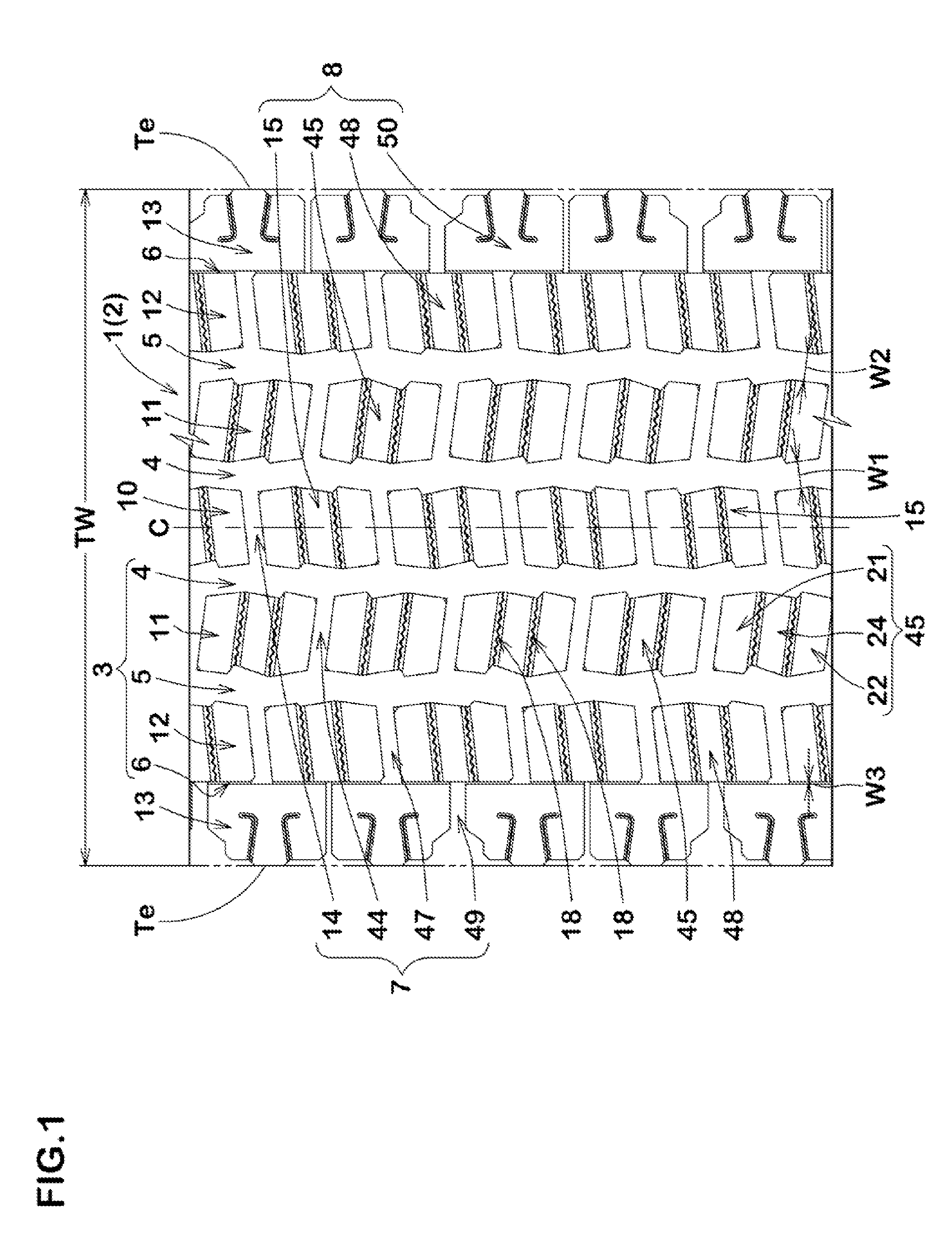

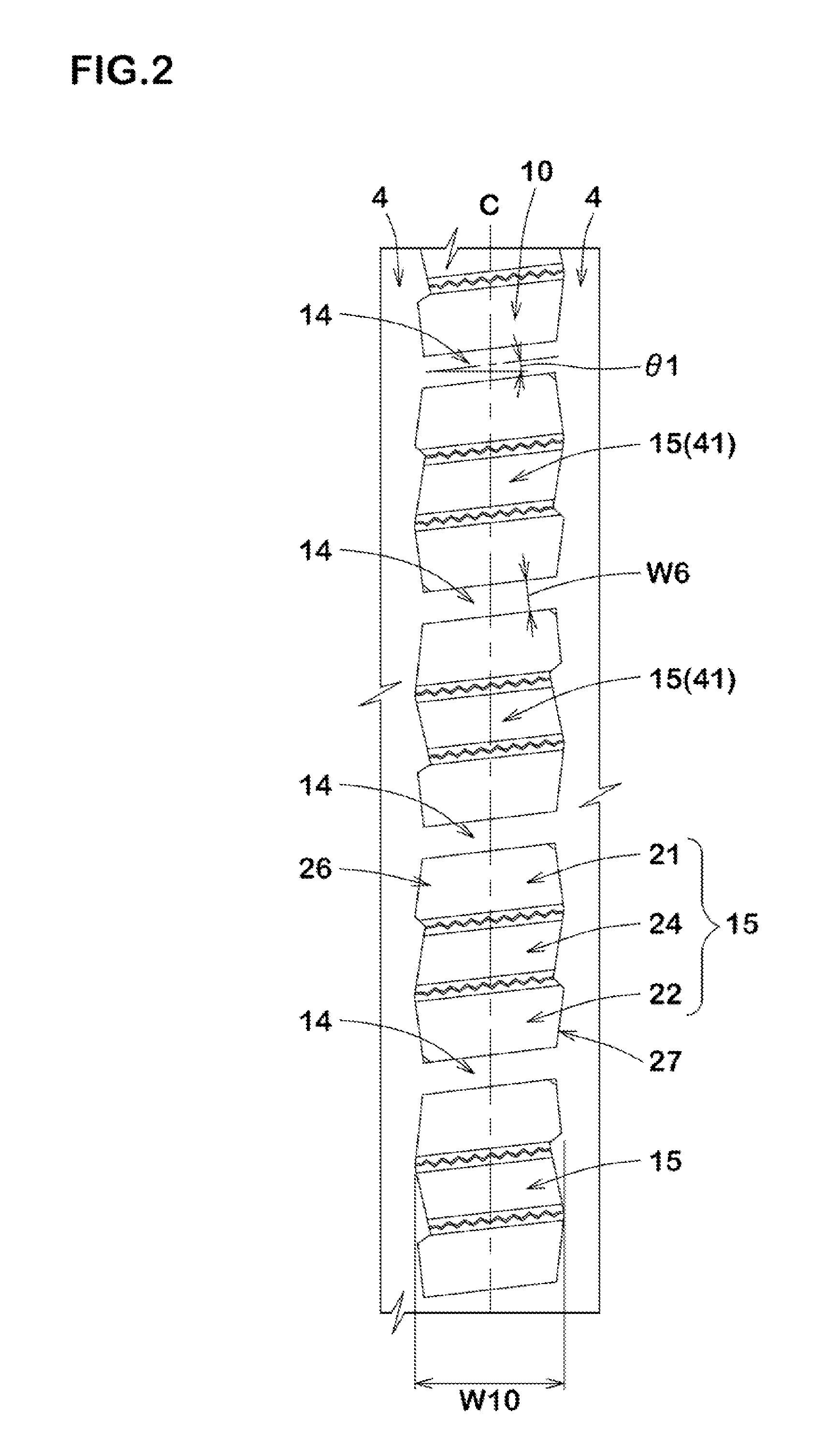

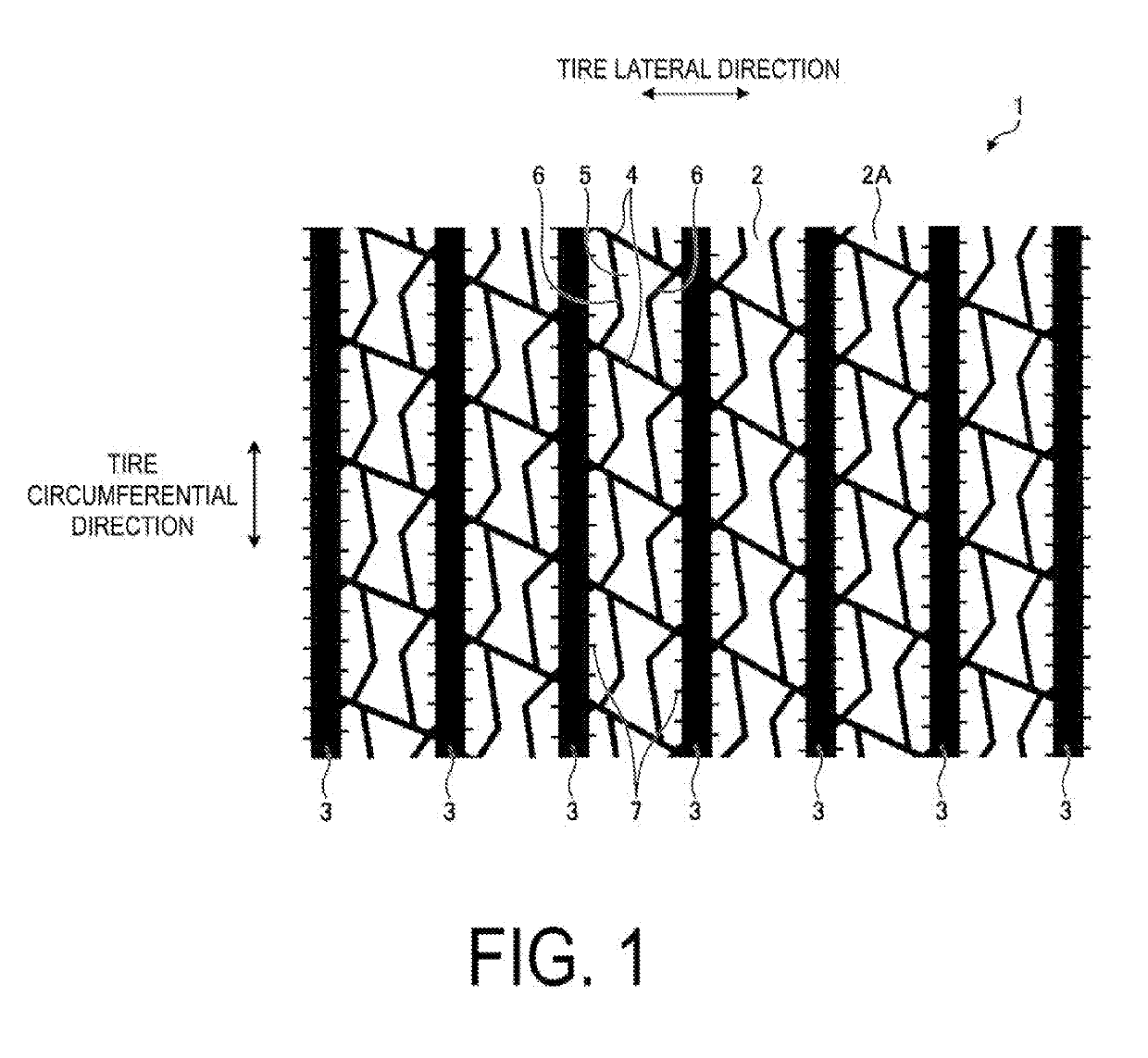

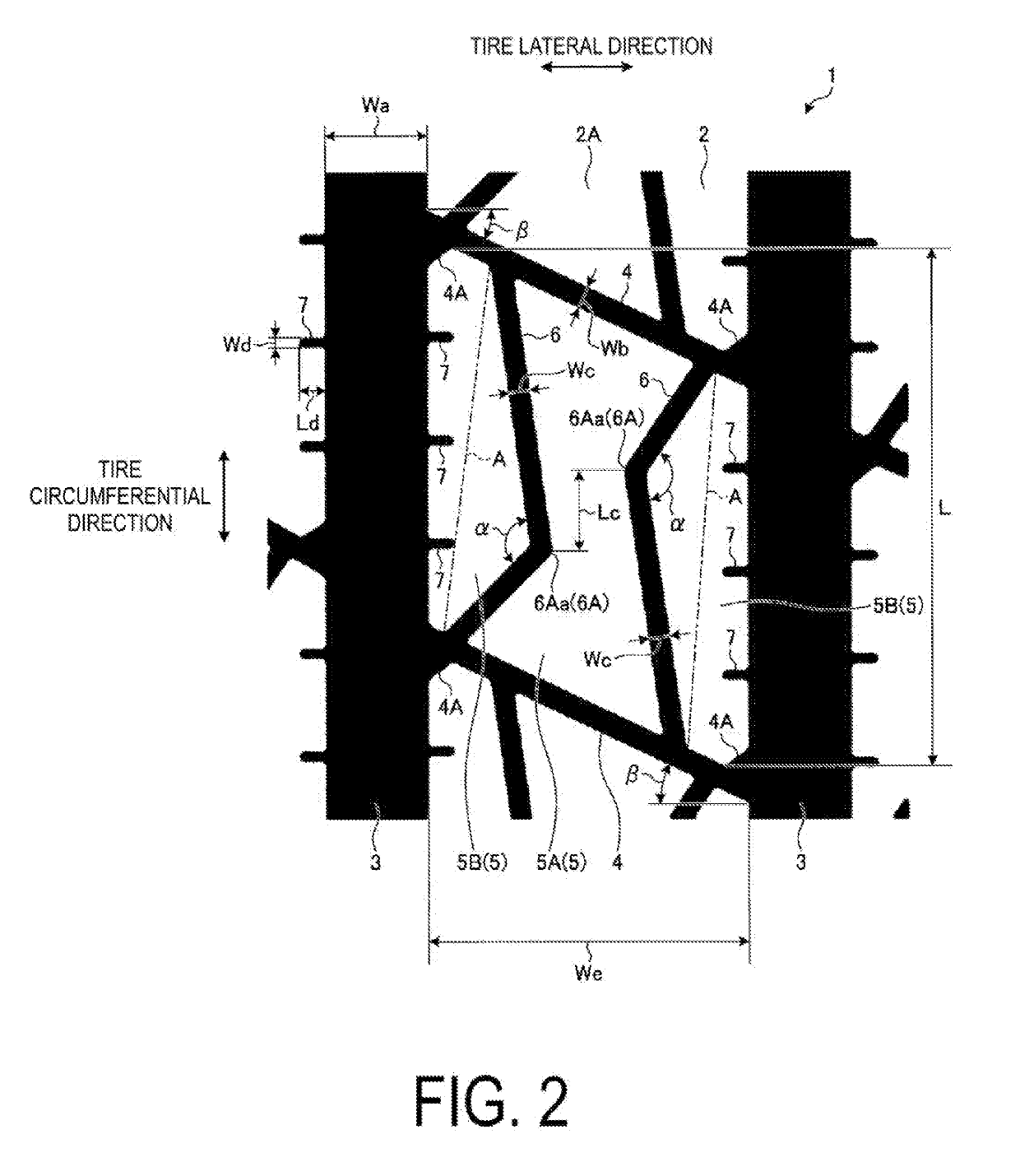

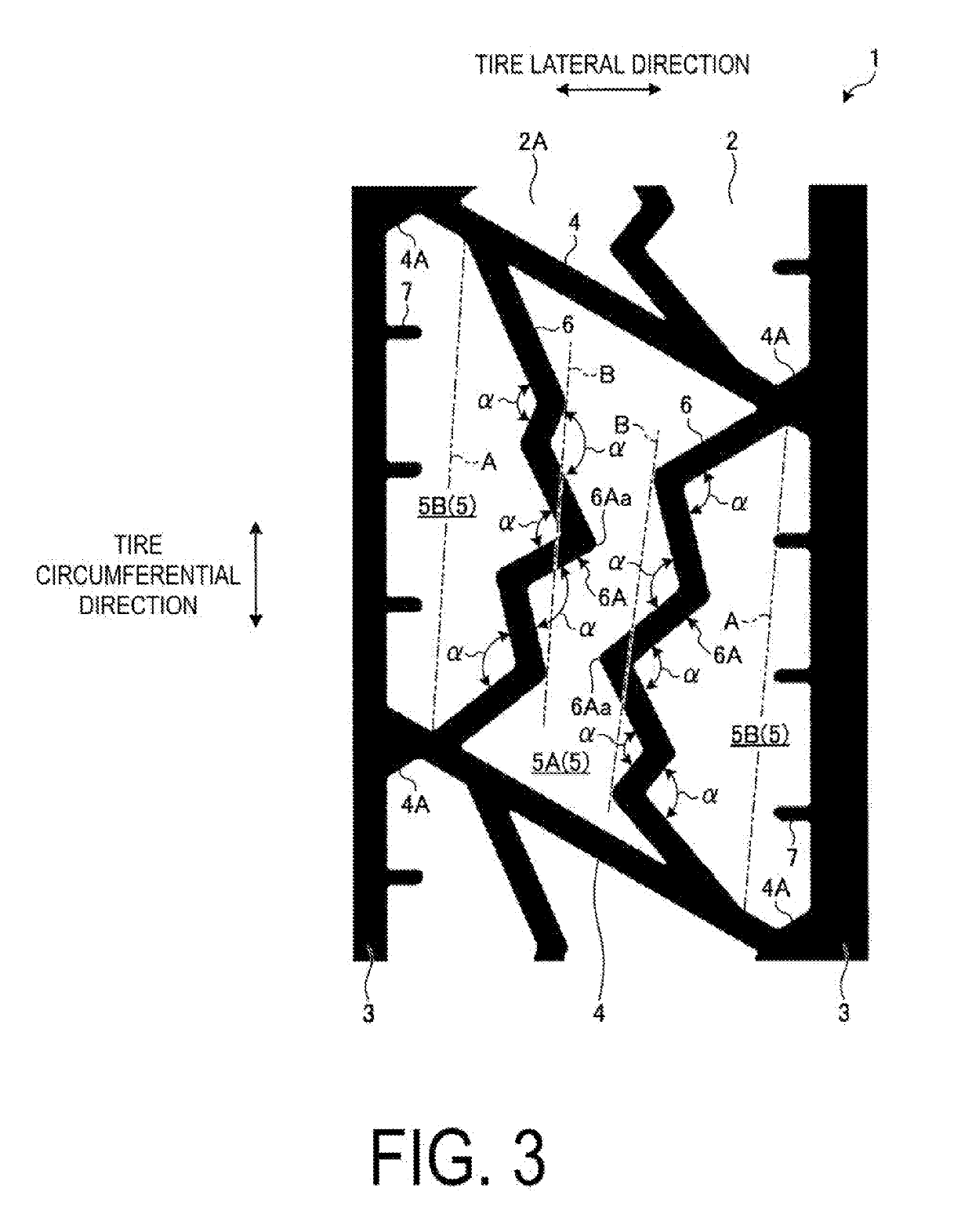

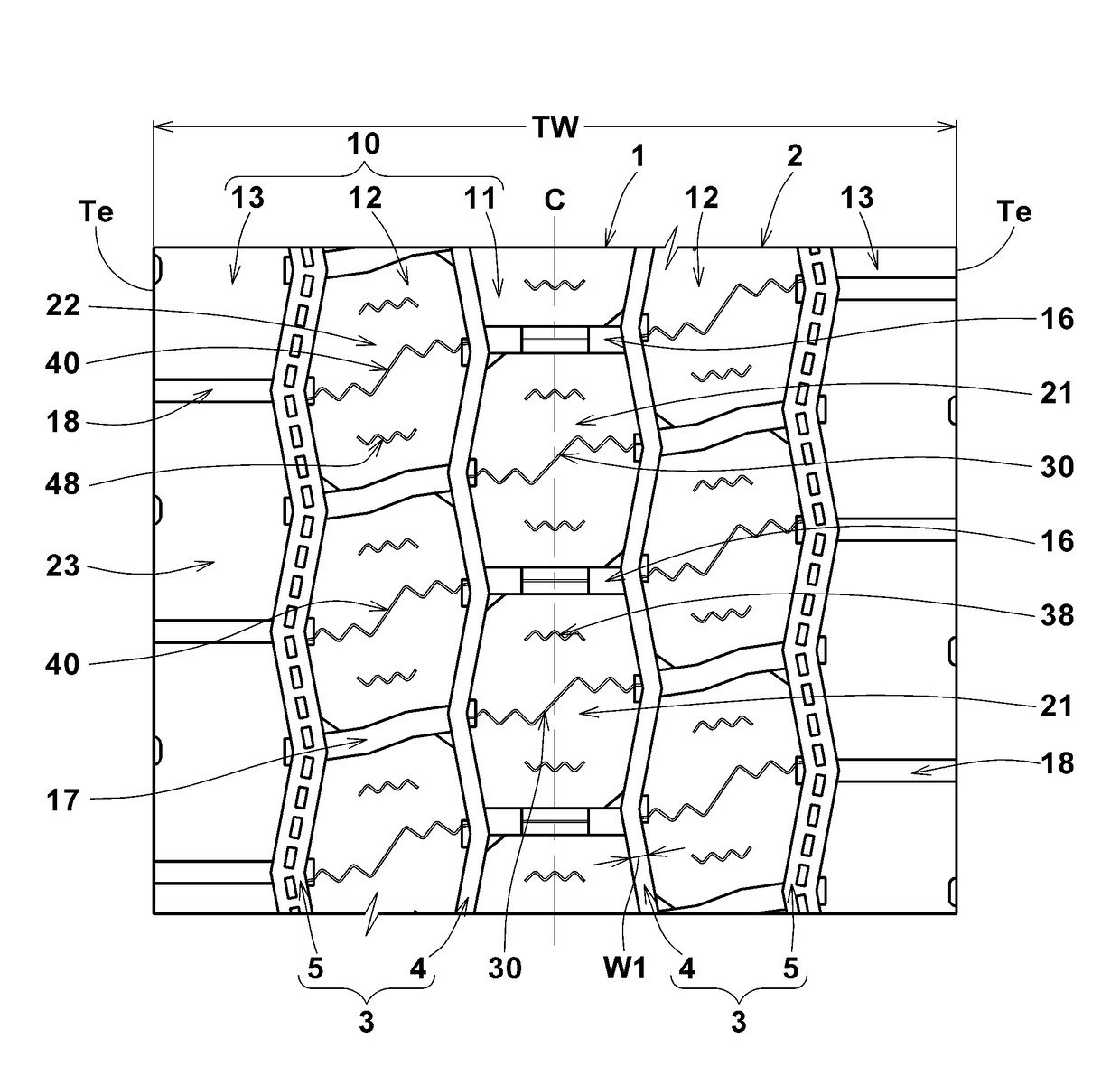

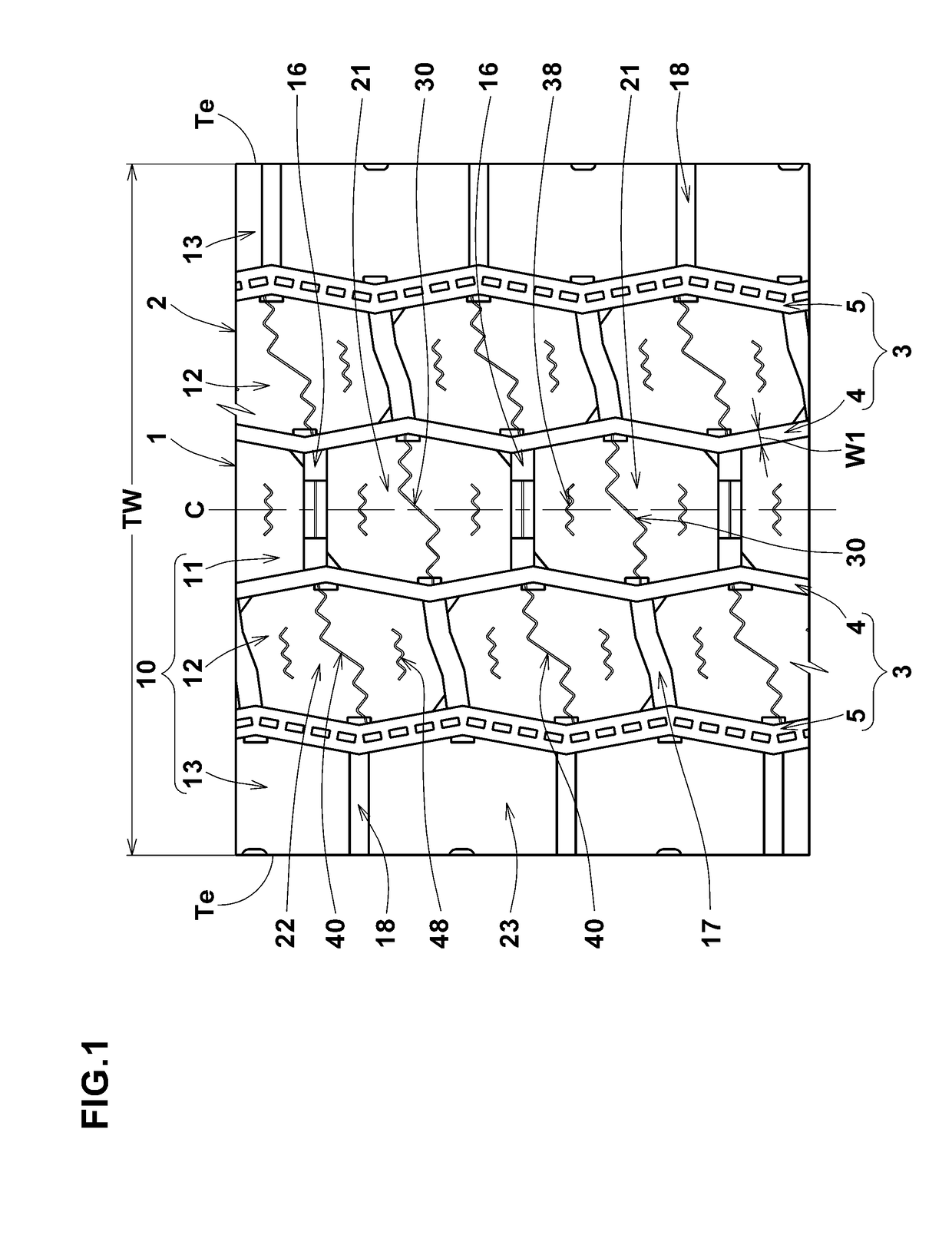

The invention provides a pneumatic tire, which has directional patterns and achieves improved wet performance, snow performance and nonuniform wear resistance. The central portion (C) of the pneumatic tire is divided into multiple pattern blocks (5) via a central main groove (1), outer main grooves (2) and transverse grooves (3). Meanwhile, the strip-shaped patterns (5) at the tire shoulder portion (S) is provided with shoulder pattern grooves (4). The patterns of the pneumatic tire are directional patterns. The transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and is reversely inclined relative to the tire equator, wherein the central inclined angle Theta1 of the transverse grooves (3) is an acute angle. Meanwhile, the transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and the tire circumferential direction in a staggered manner such that the circumferential portion (3') formed by upward projection of the transverse grooves (3) in the tire circumferential direction is provided at the periphery of the tire. In addition, sipes (7) are provided at the pattern blocks (5) and the strip-shaped patterns (6).

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

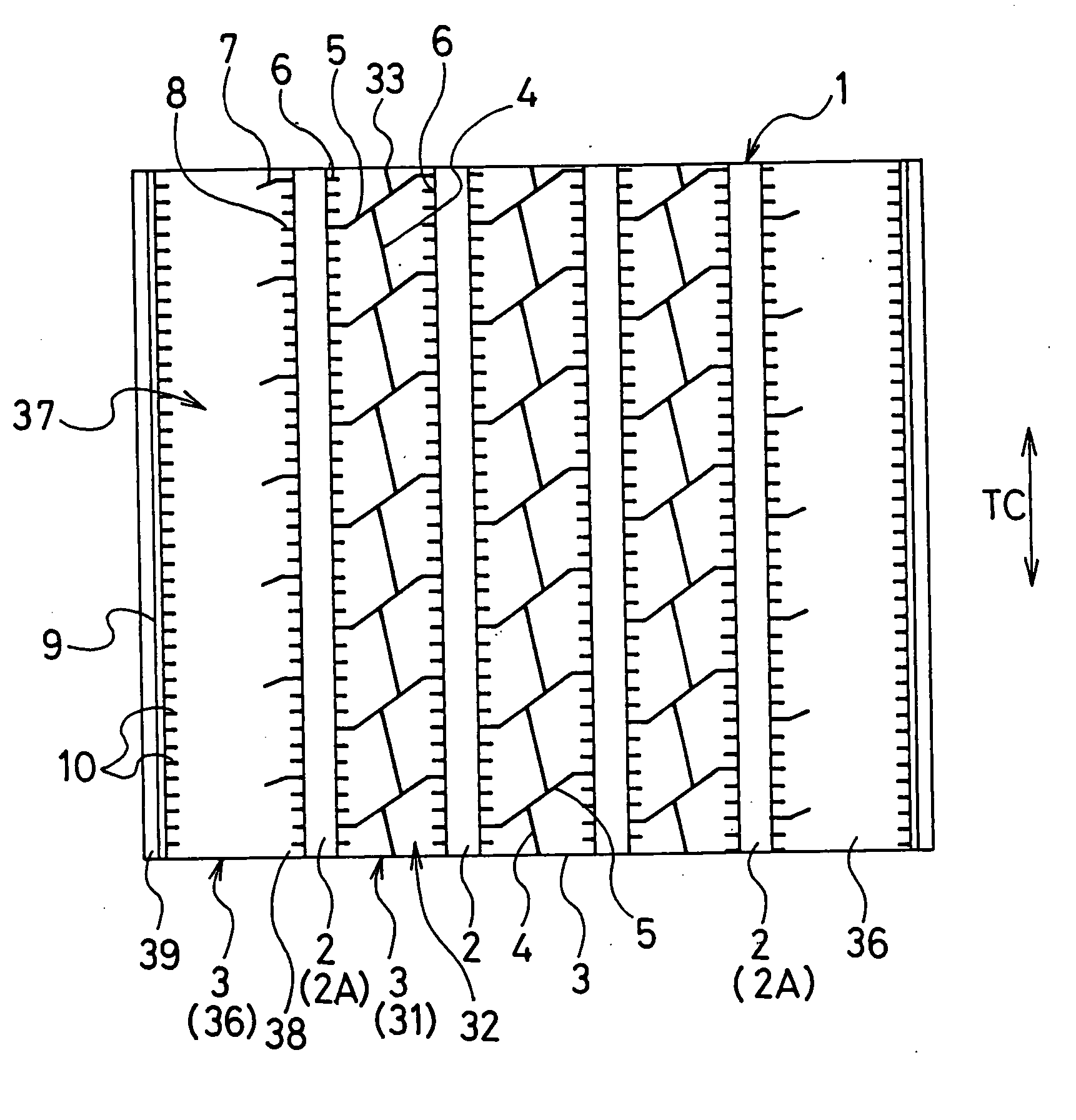

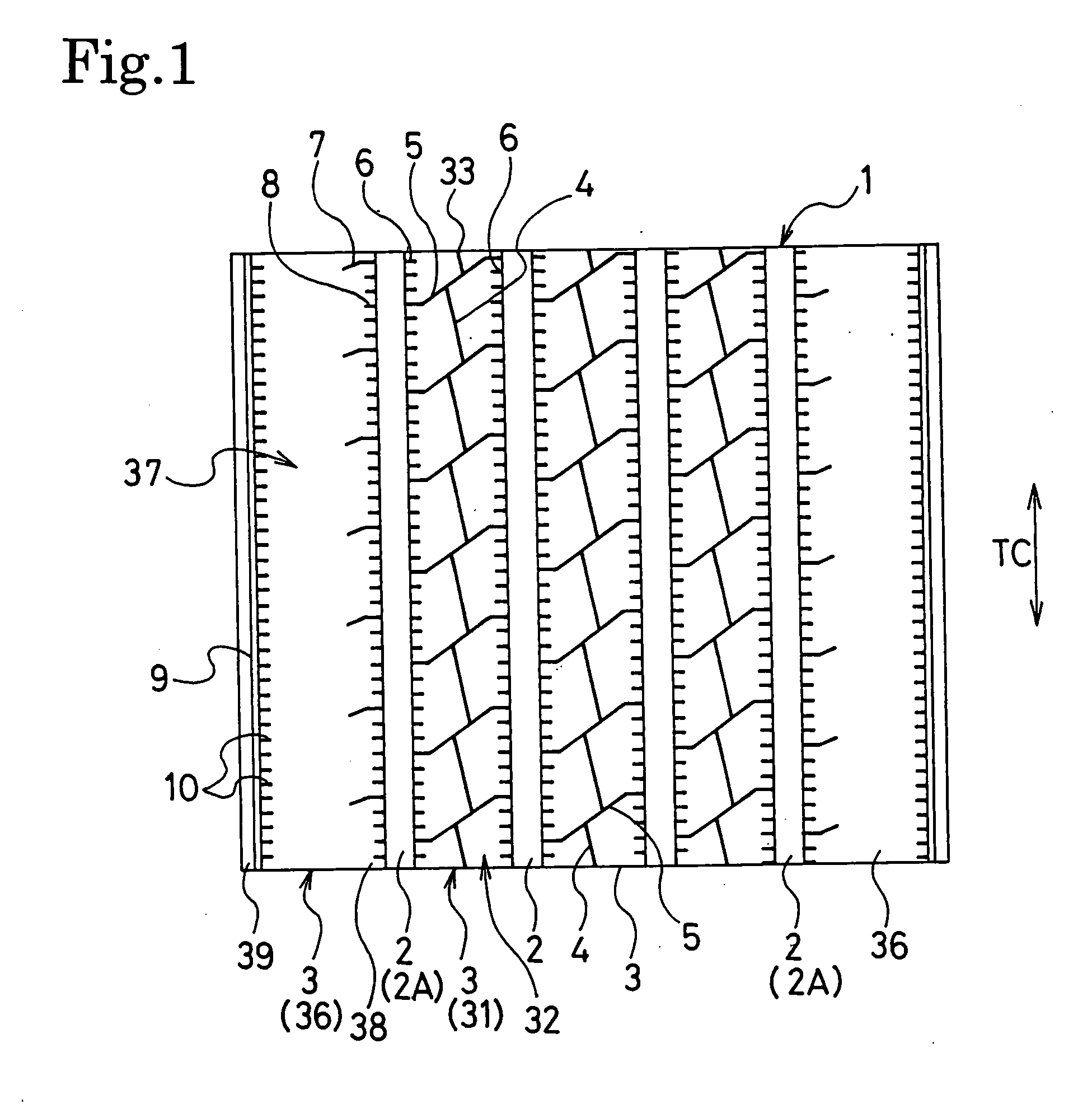

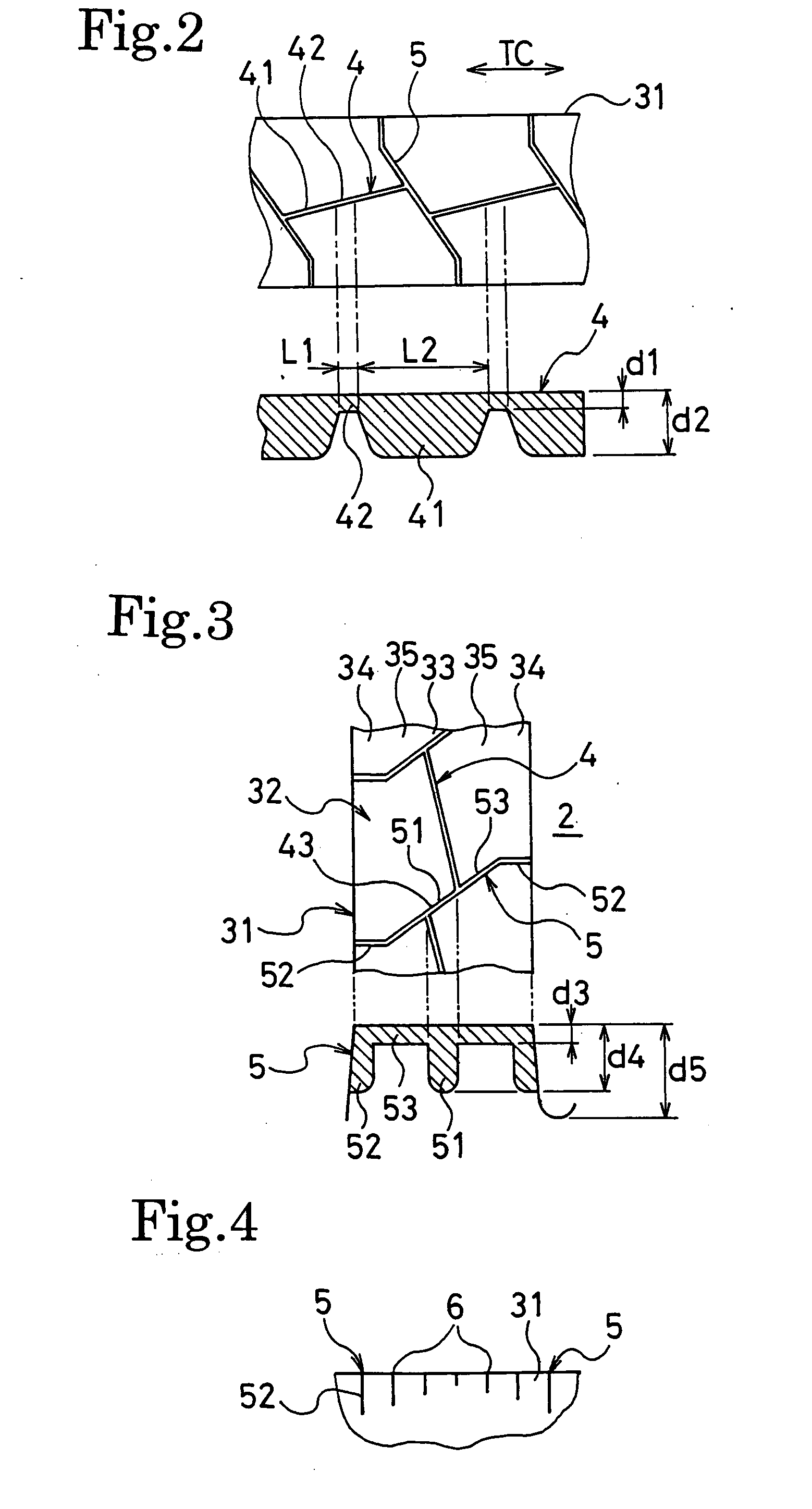

ActiveUS20110005651A1Improve uneven wear resistanceHeavy duty tyresHeavy duty vehicleMaximum depthEngineering

The present invention provides a pneumatic tire in which the tread pattern is optimized to improve wear resistance. The pneumatic tire has a tread portion embedding belt layer therein, wherein the tread portion has plural rows of lag grooves extending from the tread end to a tire equatorial plane and a narrow groove connecting the end of two lag grooves clipping the tire equatorial plane, wherein the narrow groove will be closed when contacting the road surface, wherein said lag groove is composed of a first lag groove portion located on the outer side in the tire widthwise direction and a second lag groove portion located on the inner side in the tire widthwise direction, wherein the maximum depth of the second lag groove portion is larger than the maximum depth of the first lag groove portion, wherein the second lag groove portion, in a sectional view in the tire circumferential direction, is composed of a shallow groove portion and deep groove portion having a larger depth than the shallow groove portion notching a part of the shallow groove portion, wherein the length in the tire circumferential direction of the deep groove portion is smaller than the length in the tire circumferential direction of the shallow groove portion.

Owner:BRIDGESTONE CORP

Pneumatic tire

ActiveUS20140230983A1Improve balanceGuaranteed uptimeTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

A pneumatic tire is provided in the tread portion with a central land portion between two crown main grooves. The central land portion is provided with notches each having a depth of 55% to 65% of the depth of the crown main groove and having a closed end and an open end opening to the crown main groove.The maximum axial length of the central notch is 10% to 15% of the maximum axial length of the central land portion, and the circumferential length of the opening is 10% to 15% of one circumferential pitch of the shoulder block row 7R.The circumferential length of the opening is 15% to 25% of one circumferential pitch of the central notches.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire with tread having circumferential main grooves

InactiveUS8006730B2Improve uneven wear resistanceInhibit the generation of cracksTyre tread bands/patternsNon-skid devicesEngineeringTread

A pneumatic tire of the invention includes: a stepped-shaped raised area provided in the main groove positioned at a center area of the tire so as to be continued circumferentially of the tire, connected to either the main groove walls, and raised from the groove bottom; and a ridge lower than a tread surface of the tire in each of the main grooves on both outsides of the main groove at the center area of the tire so as to be raised from the center of the groove bottom continuously along the length thereof without being joined with the groove walls, and the angle of inclination of the main groove walls with respect to the normal line of the tangential line on the tread surface of the main groove portion is parallel to each other or is 5° or smaller.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic Tire

ActiveUS20140326381A1Improve uneven wear resistanceUneven wearHeavy duty tyresHeavy duty vehicleEngineering

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

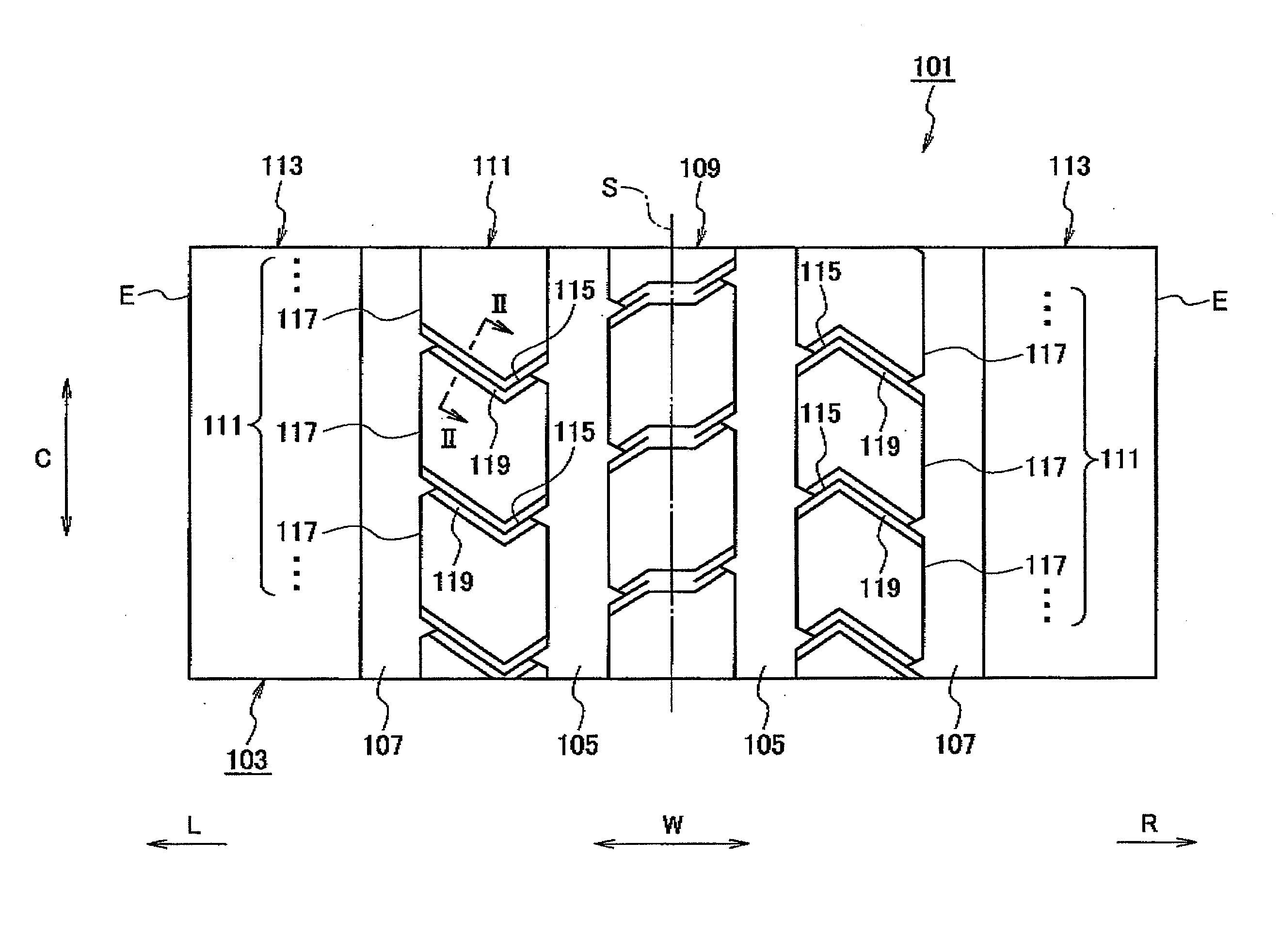

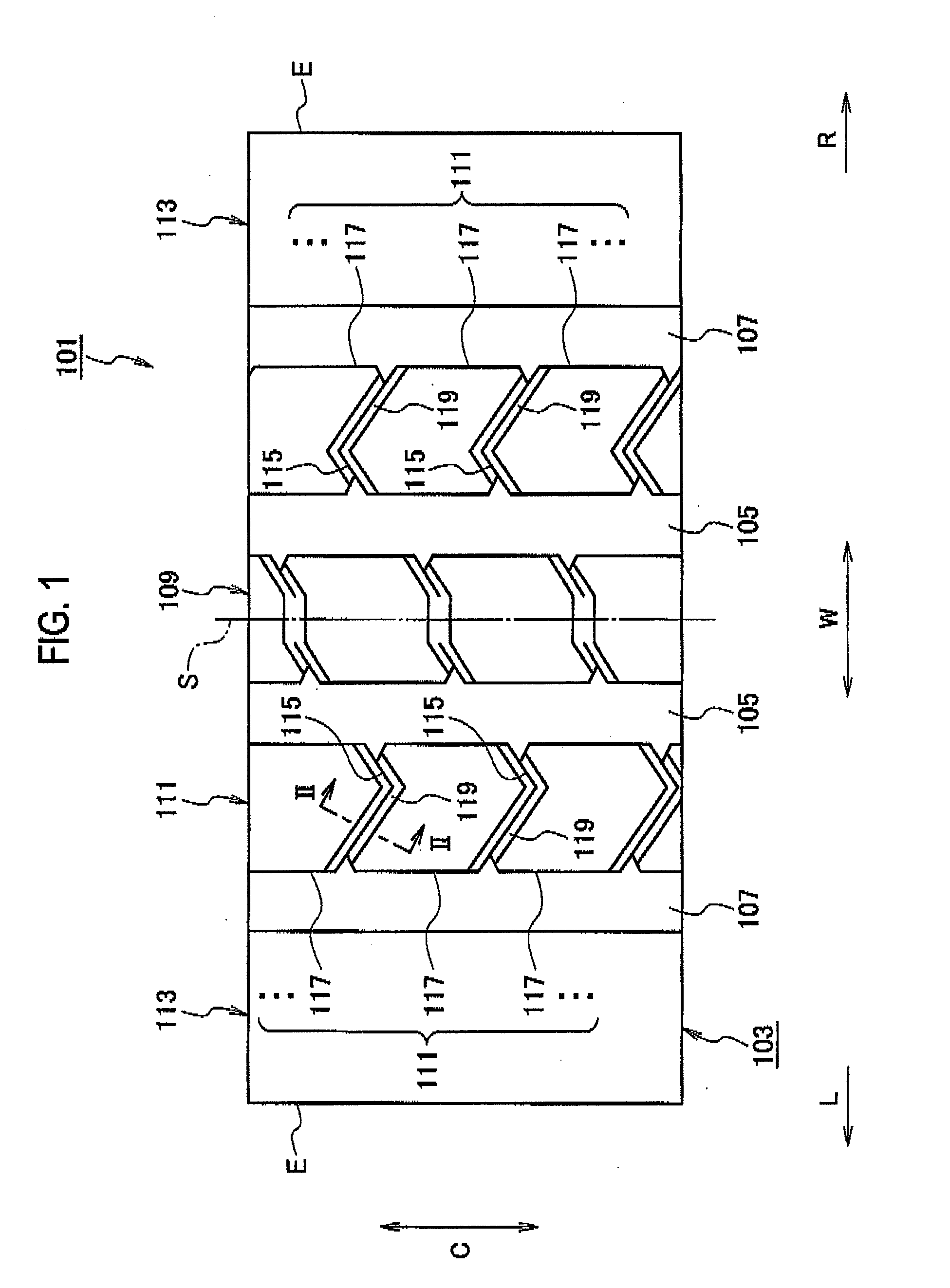

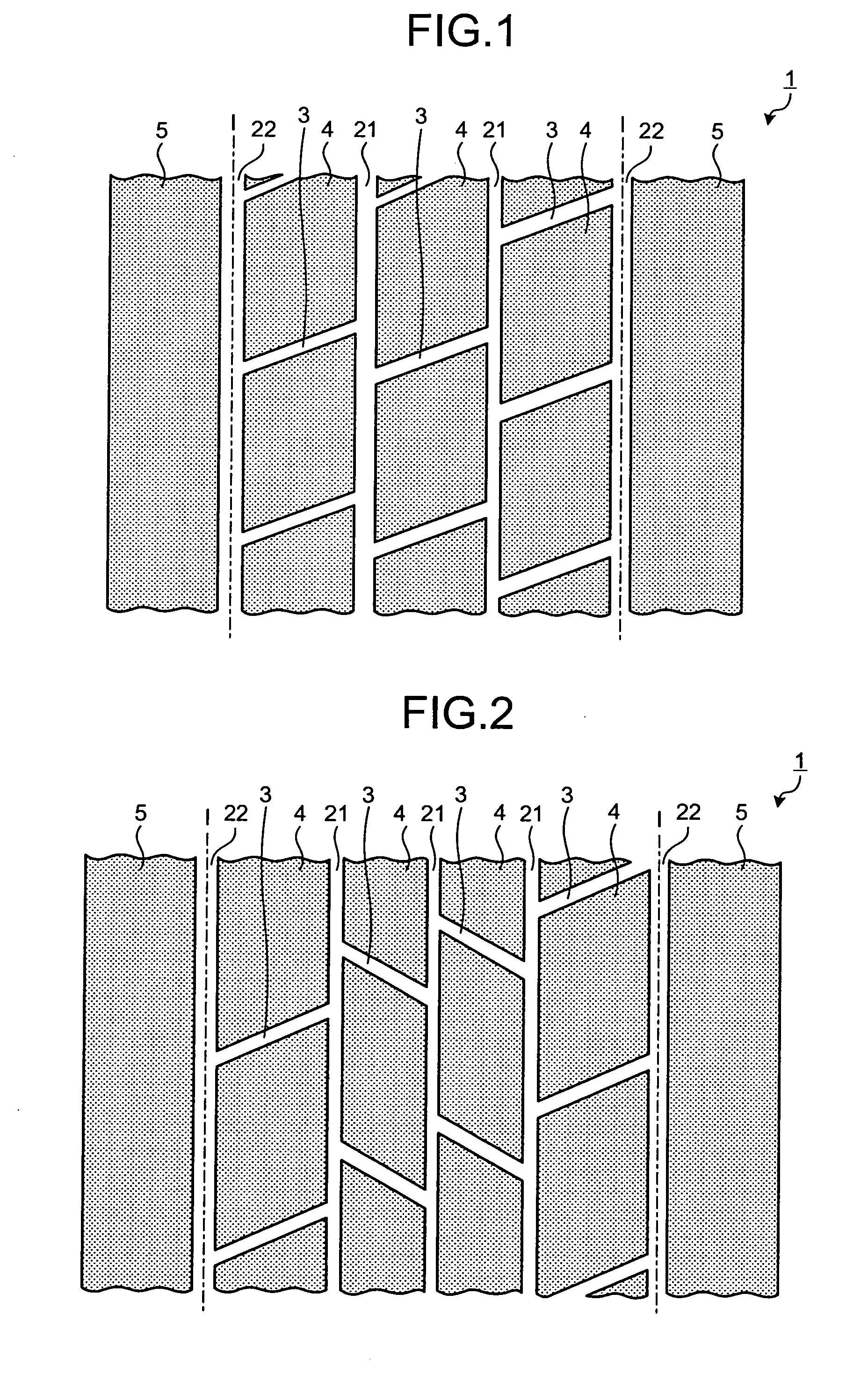

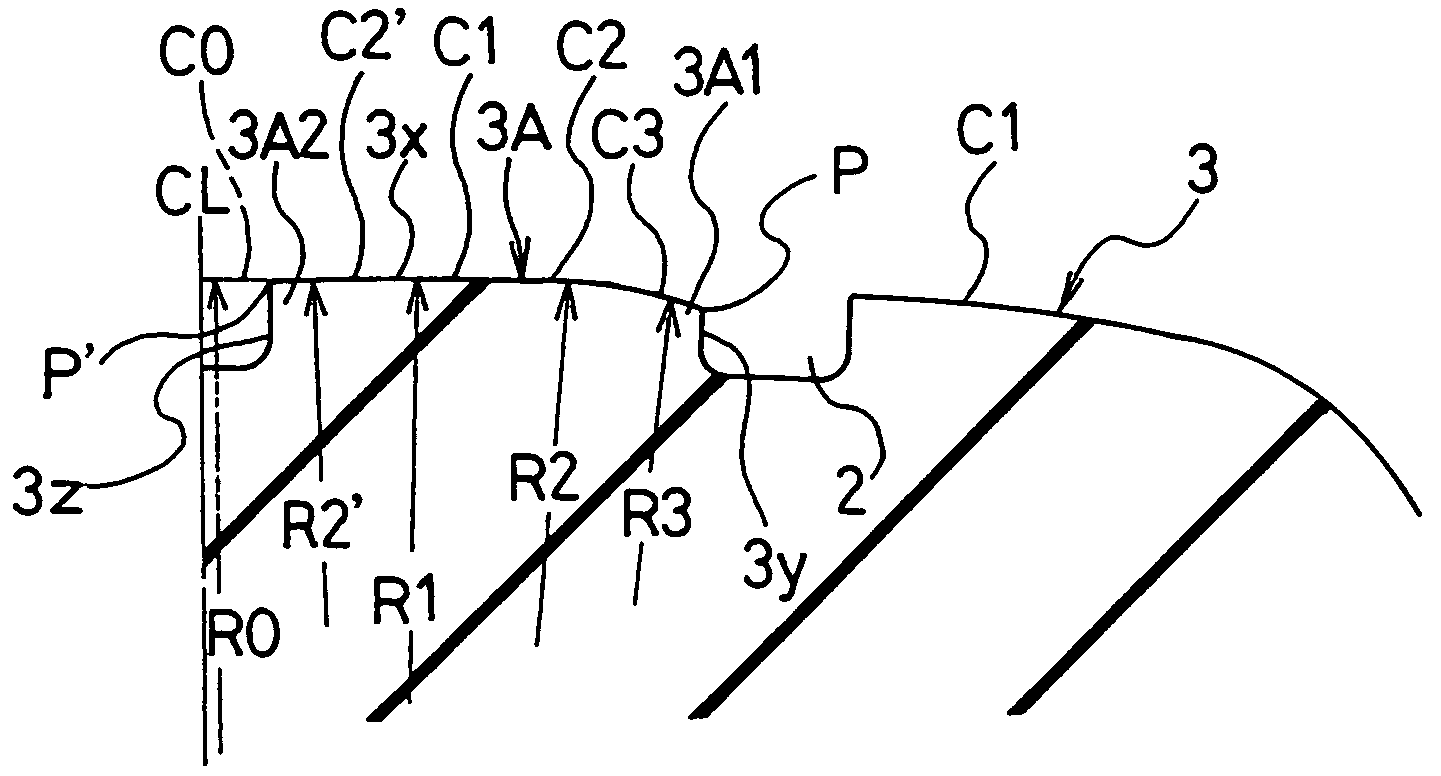

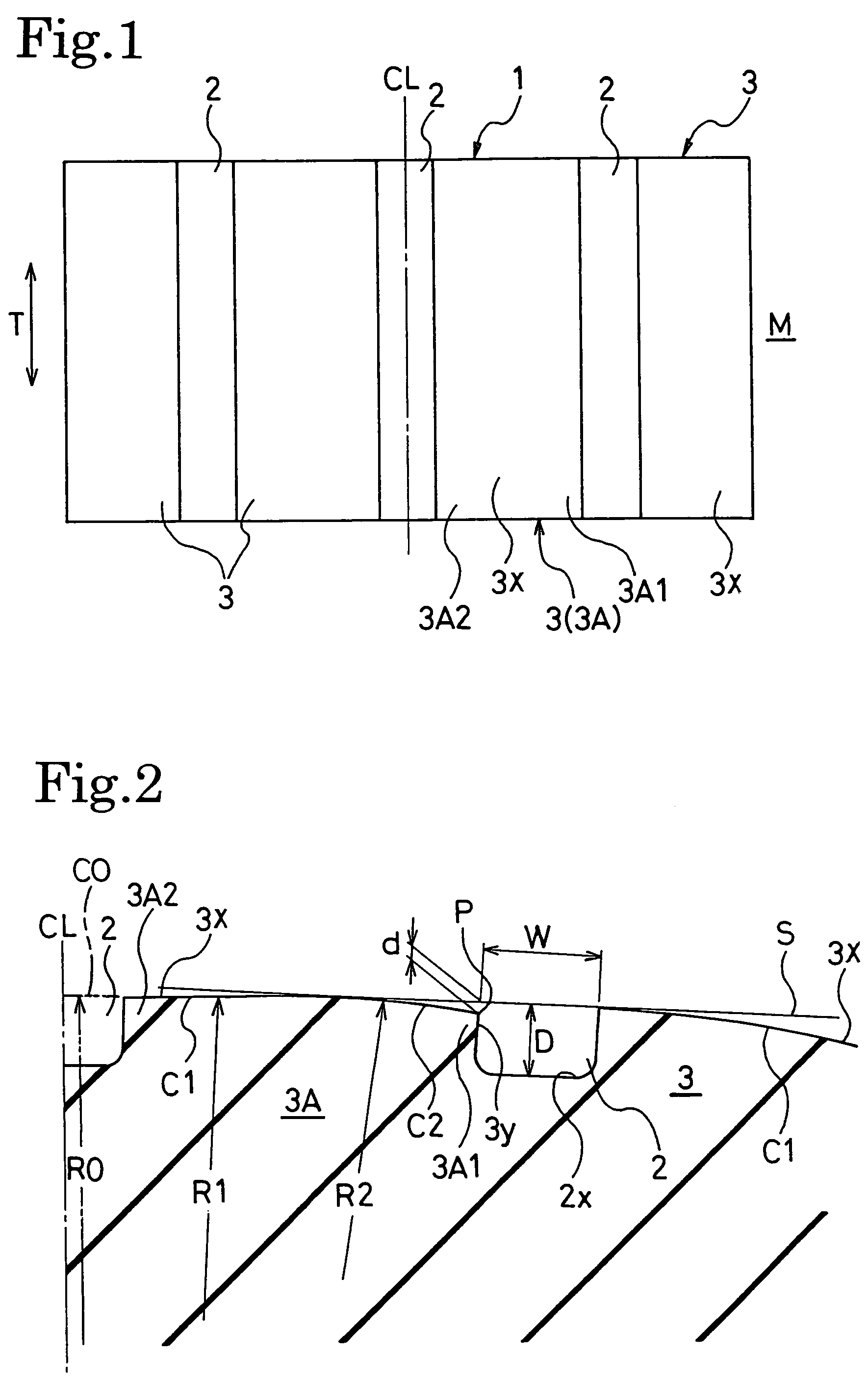

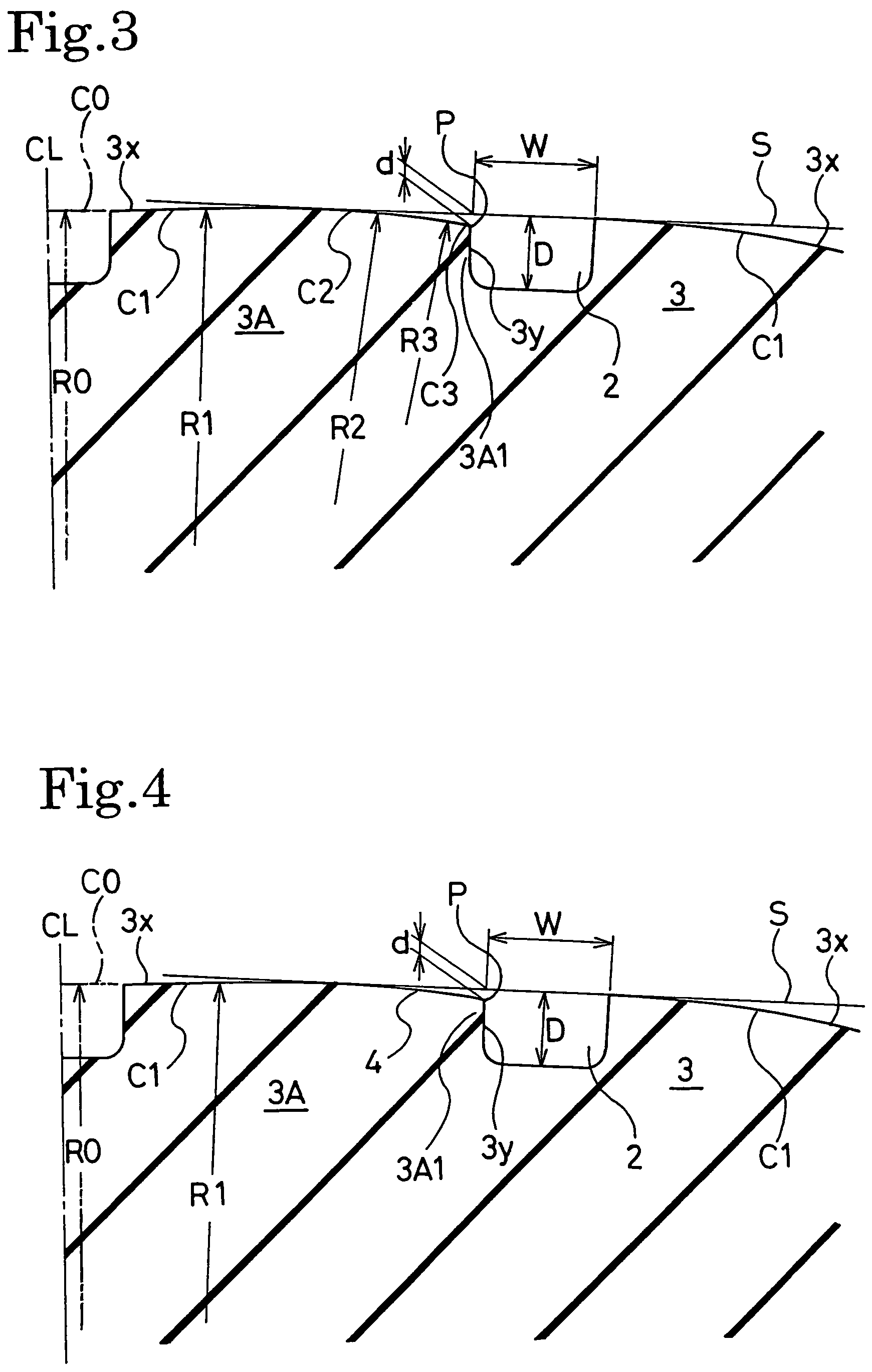

InactiveUS20100154951A1Enhance the edge effectGood drainageHeavy duty tyresHeavy duty vehicleEngineeringElectrical and Electronics engineering

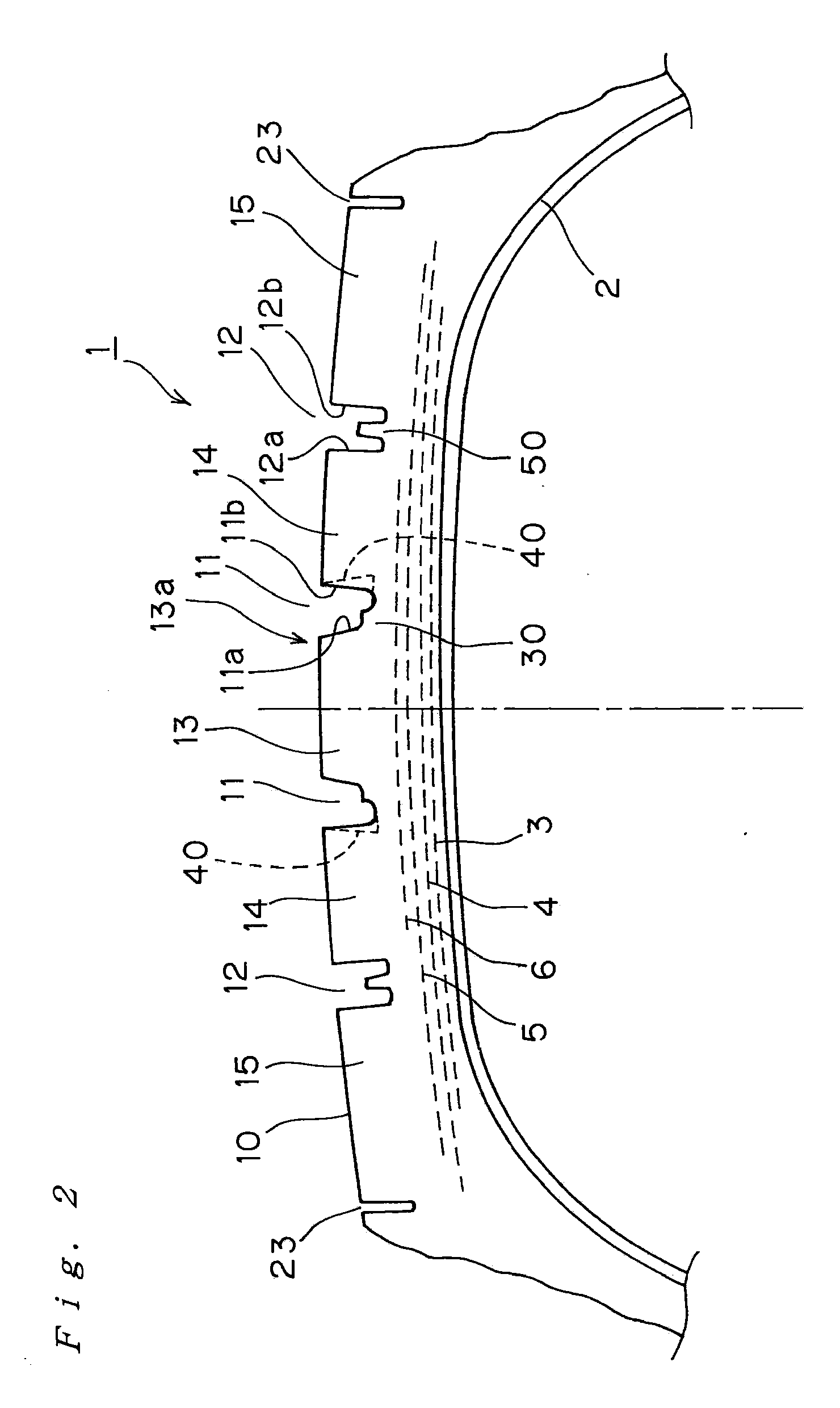

A plurality of ribs (9, 11 and 18) extending in a tire circumferential direction (C) are defined in a tire width direction (W) by a plurality of circumferential main grooves (5 and 7). In two or more second ribs (11), a plurality of sipes (19) are formed so as to be spaced apart in the tire circumferential direction (C) and to cut across the ribs. By the plurality of sipes (19), the two or more second ribs (11) are divided into a plurality of divided ribs (21). All intersection angle portions on one side in the tire circumferential direction (C) in each of the divided ribs (21) are formed to have obtuse angles. Only on one side in the tire circumferential direction (C) in each of the divided ribs (21), a runner groove (23) communicated with the corresponding sips (19) is formed so as to cut across the second rib (11).

Owner:BRIDGESTONE CORP

Pneumatic tire

ActiveUS20090114323A1Good drainage performanceGood noise performanceTyre tread bands/patternsNon-skid devicesWave shapeMechanical engineering

Disclosed is a pneumatic tire including a straight main groove and two wave-shaped main grooves arranged in the center area of a tread, and diagonal grooves arranged in each shoulder area ranging from each wave-shaped main groove to the outer side of the tire, and extending obliquely outward from the wave-shaped main groove to a direction reverse to the tire rotational direction, the rotational direction being specified for the tire. Each diagonal groove is formed to have a convex protruding toward the outer side of the tire, and the extending end portion of the diagonal groove terminates in the shoulder area. Thus, each shoulder area is provided with a non-block pattern in which a land section continues in the tire circumferential direction. Thereby, the pneumatic tire has increased driving stability and uneven wear resistance while substantially maintaining good drainage performance and noise performance against columnar resonance.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic Tire

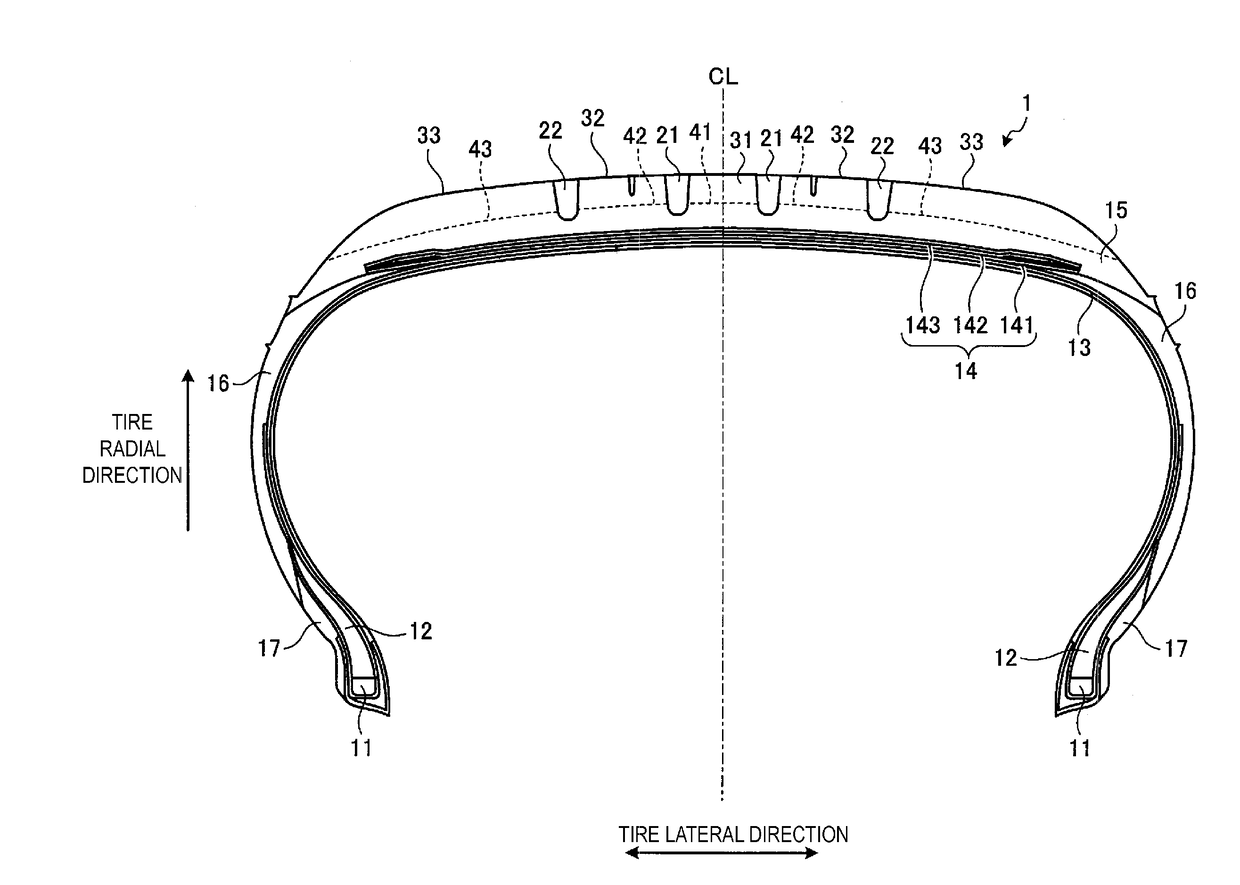

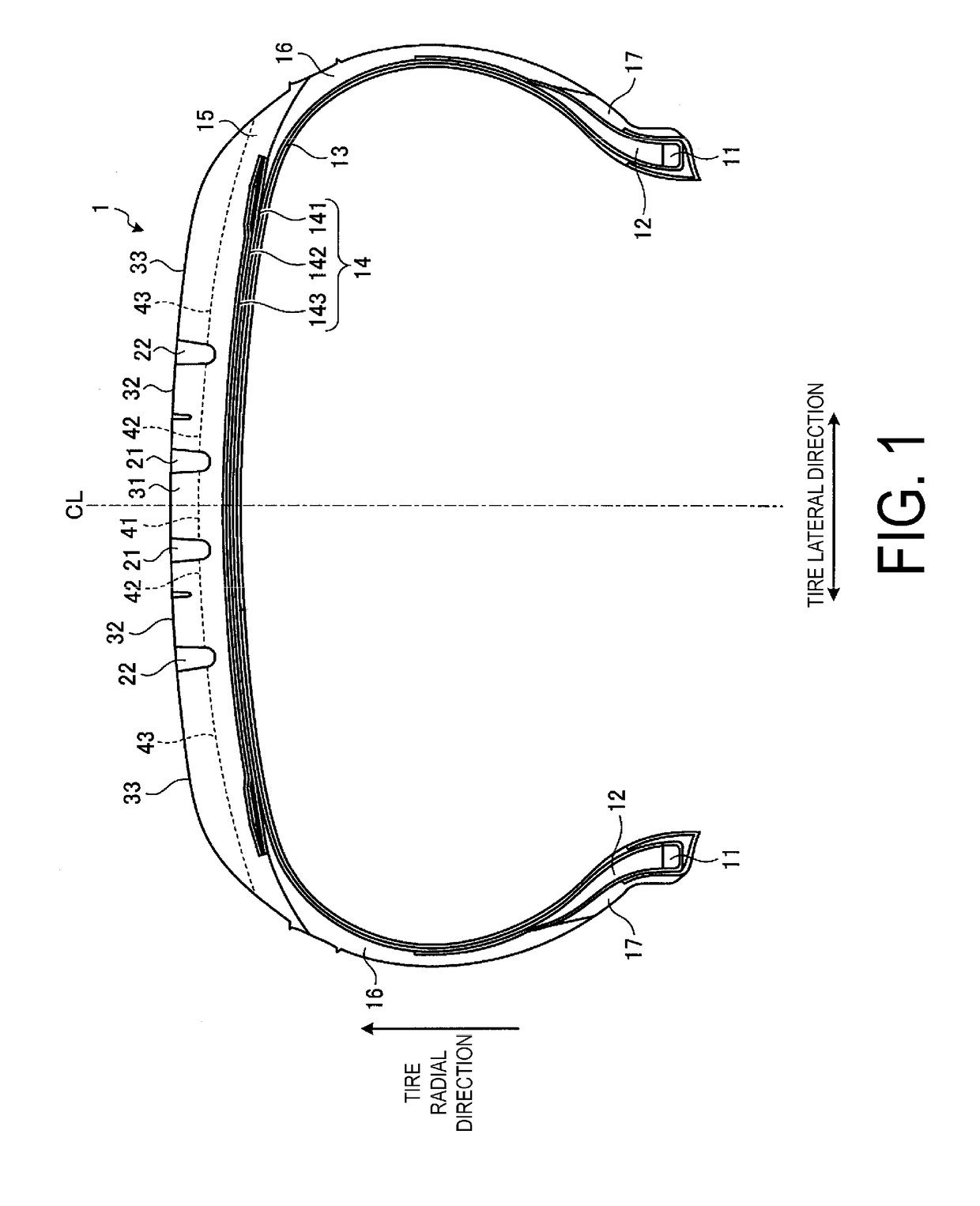

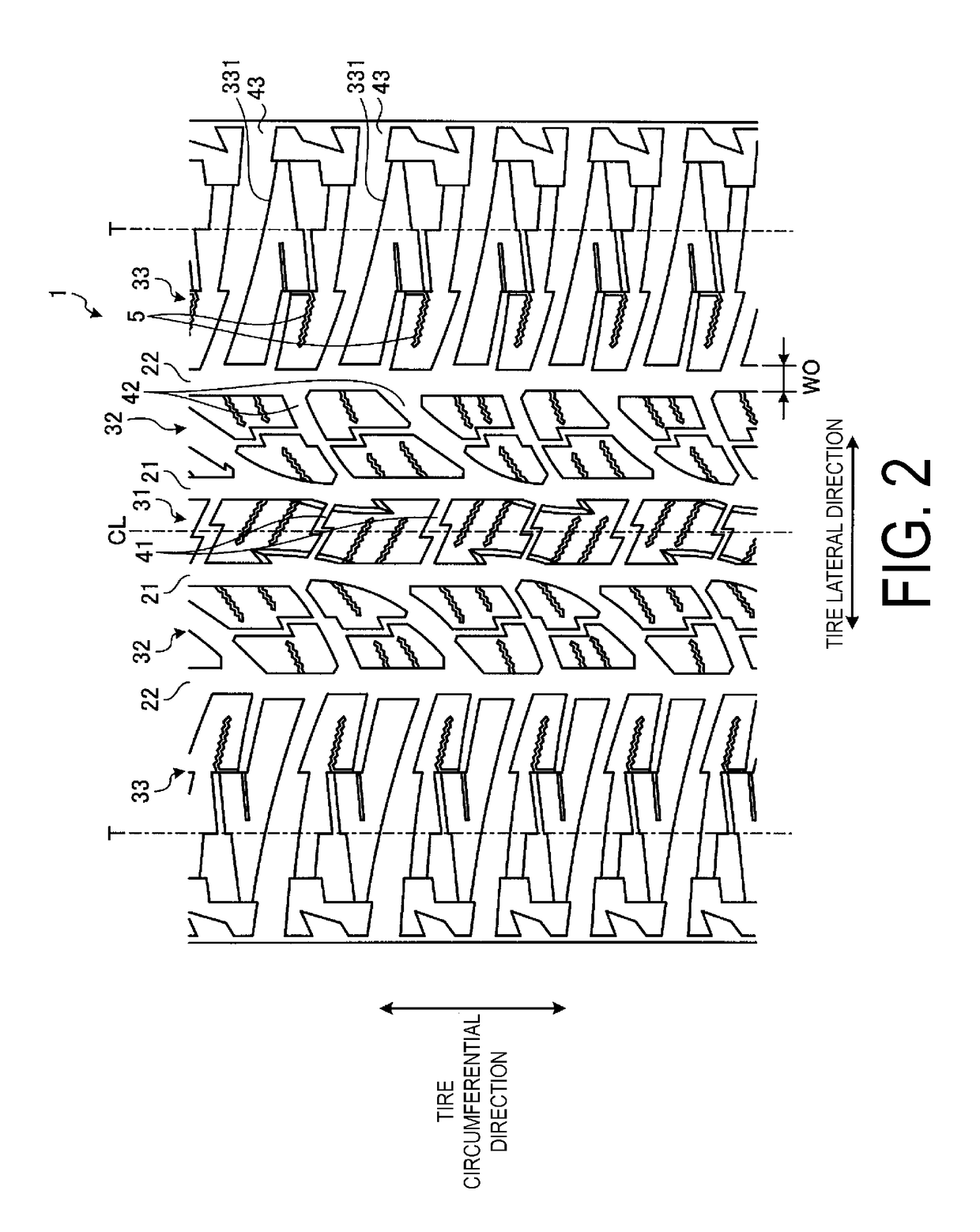

ActiveUS20170305201A1Improved snow performance and wear resistance performanceImprove tire performanceTyre tread bands/patternsGround contactMechanical engineering

A pneumatic tire comprises a plurality of blocks arranged on a tire ground contact edge. The plurality of blocks each comprise at least one main sipe that comprises: a two-dimensional sipe portion extending in a tire circumferential direction, and a three-dimensional sipe portion extending in a tire lateral direction that connects to the two-dimensional sipe portion.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic Tire

InactiveUS20190176531A1Improve driving performanceImprove uneven wear resistanceOff-road vehicle tyresTyre tread bands/patternsShoulder regionEngineering

A pneumatic tire includes first lug grooves and second lug grooves shorter than the first lug grooves provided alternately along a circumferential direction in a shoulder region of a tread section, a first connection groove that connects the second lug groove and a tip end part of the first lug groove, and a second connection groove that connects the first lug groove and a tip end part of the second lug groove. An angle of the first connection groove is greater than an angle of the second connection groove, and an inner end portion in the lateral direction of each of first shoulder blocks, each defined by the first lug groove, the second lug groove, and the first connection groove, is disposed closer to the equator side than an inner end portion in the lateral direction of each of second shoulder blocks.

Owner:THE YOKOHAMA RUBBER CO LTD

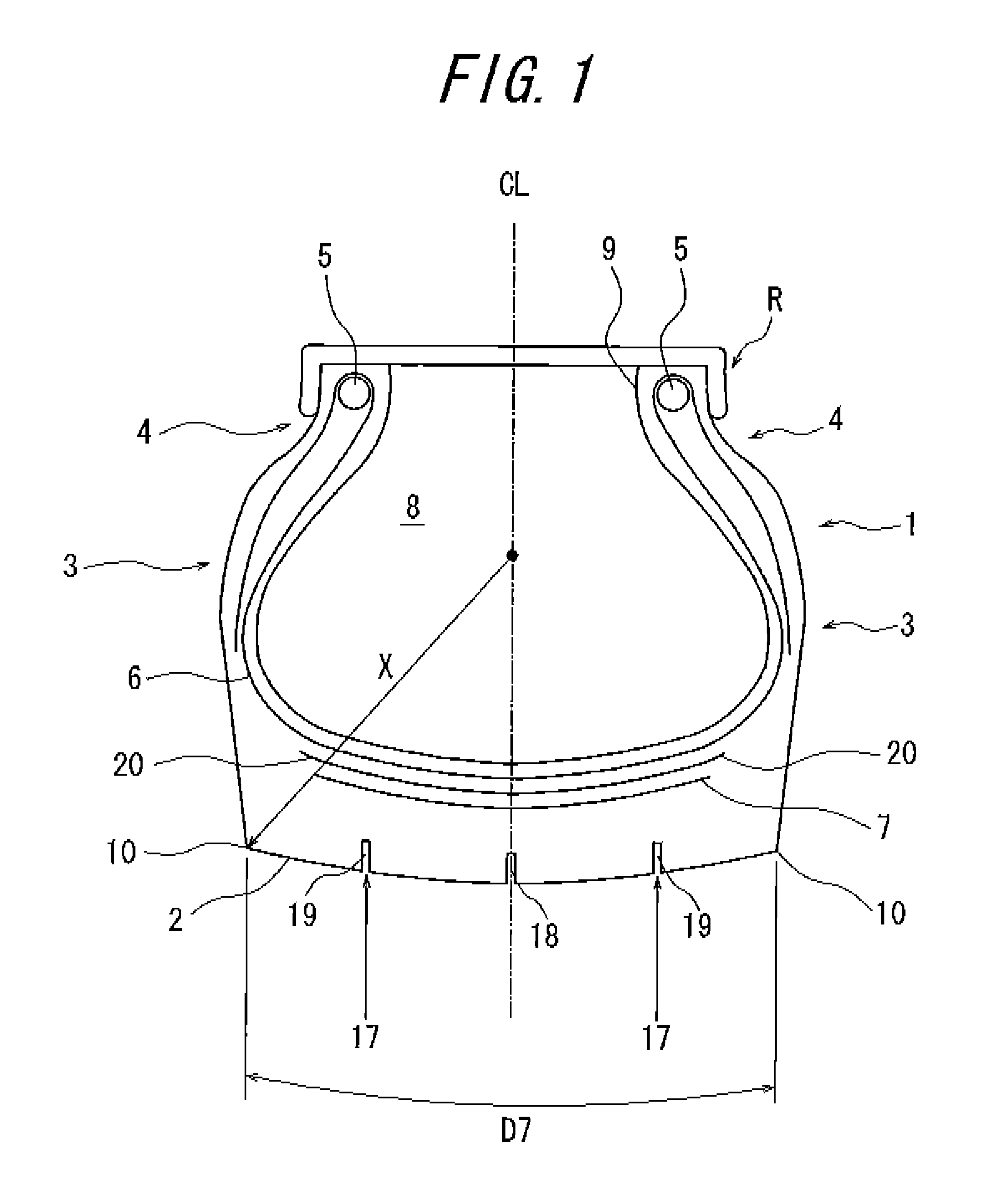

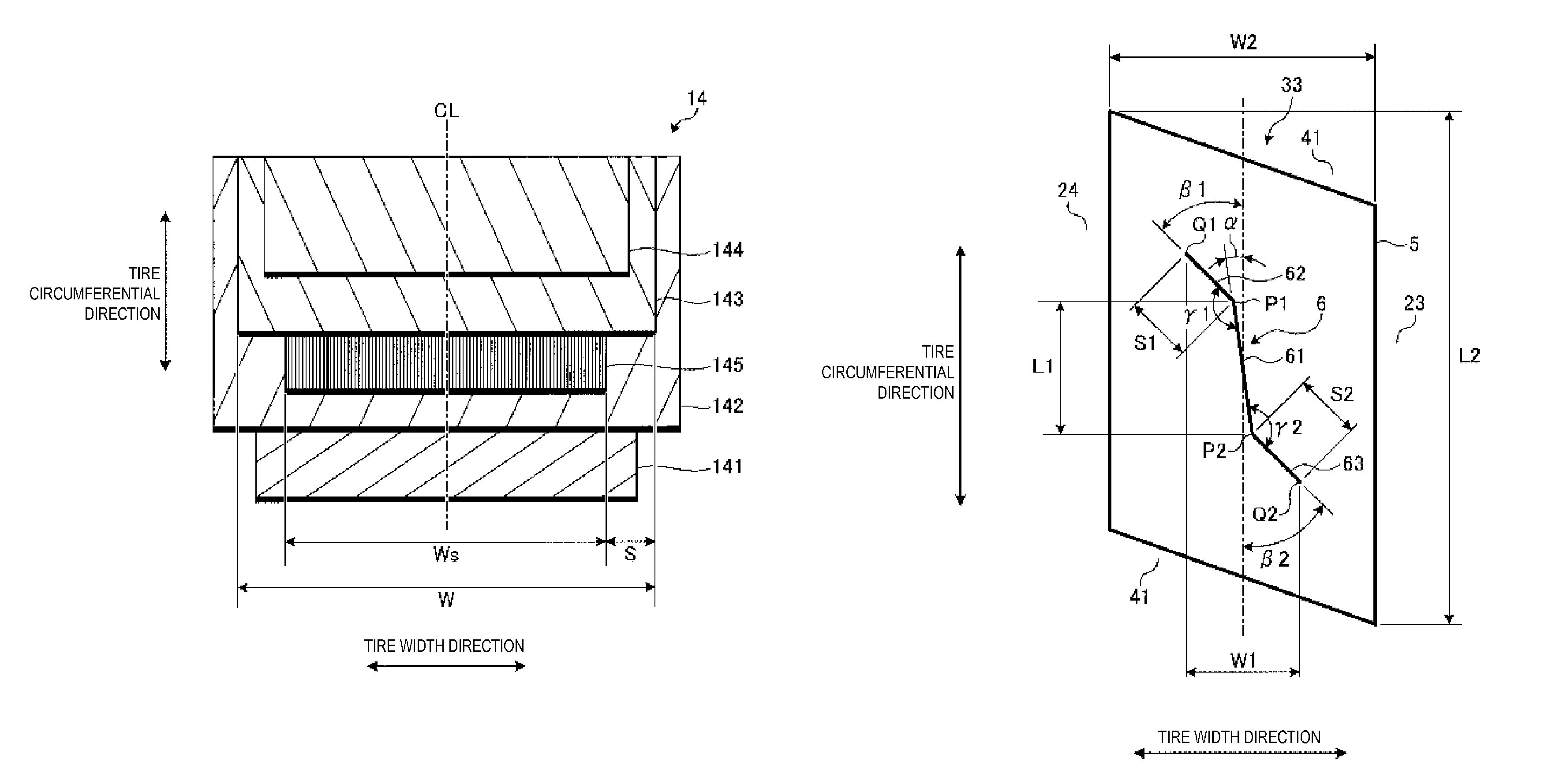

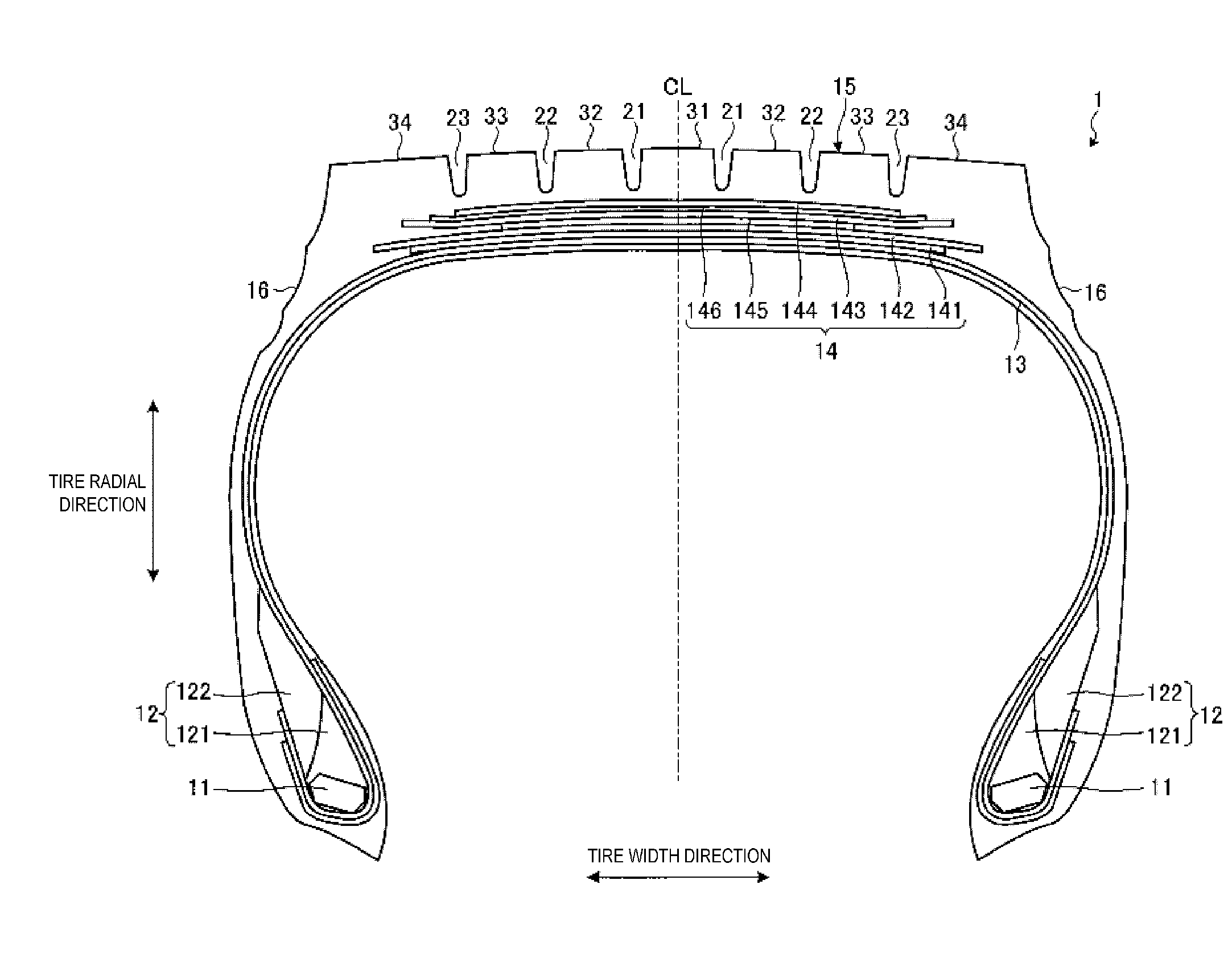

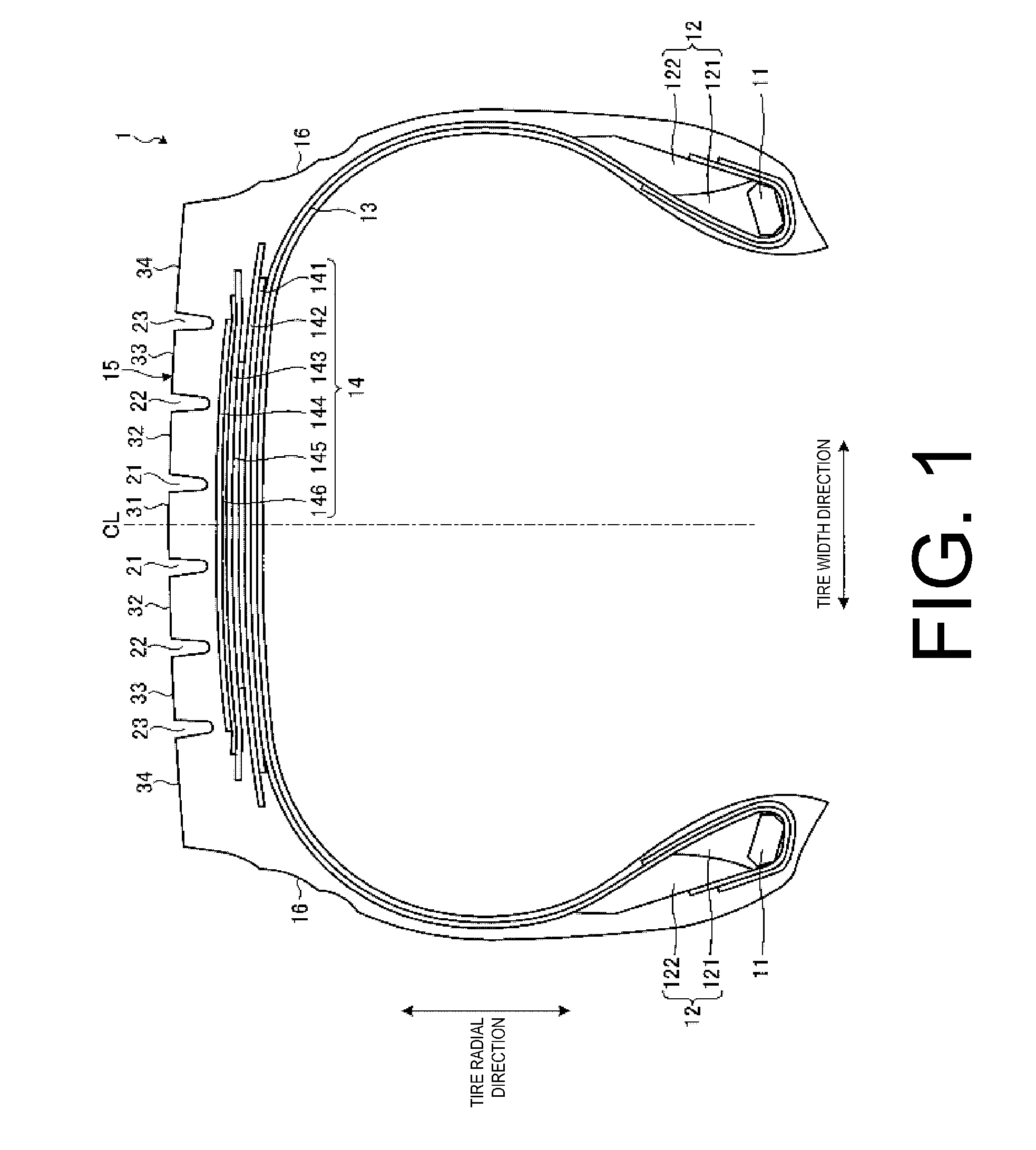

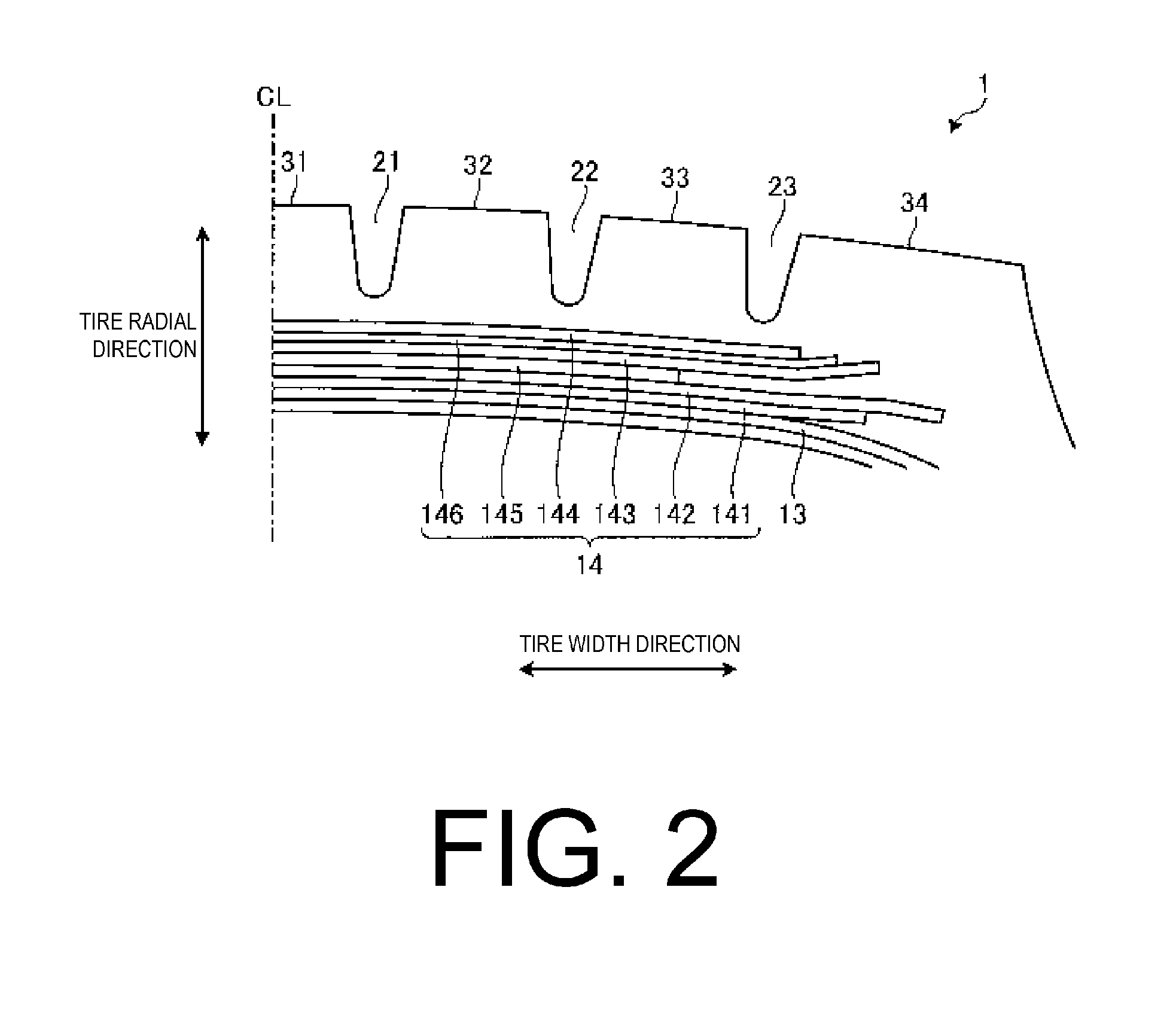

Pneumatic radial tire for a passenger vehicle

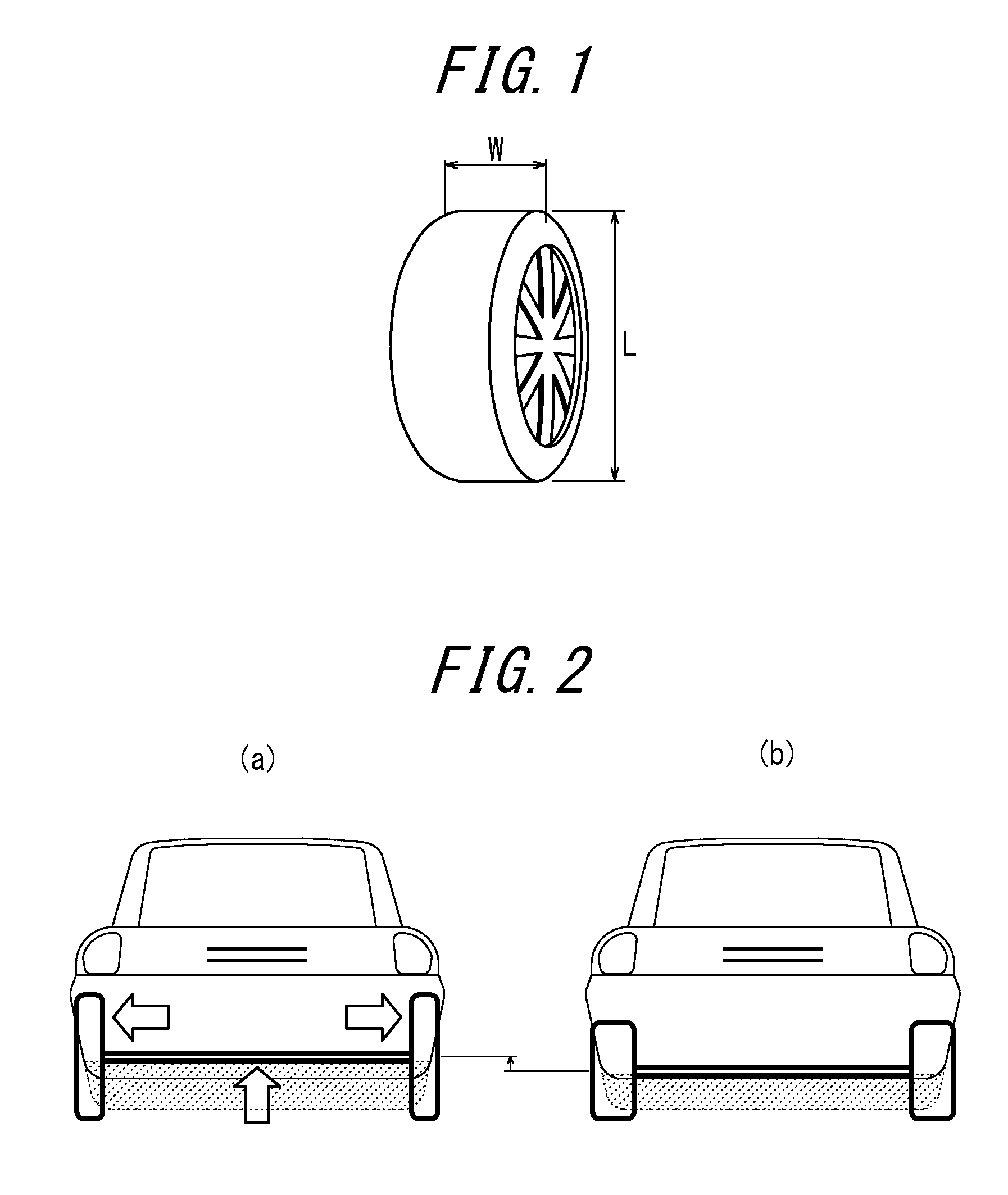

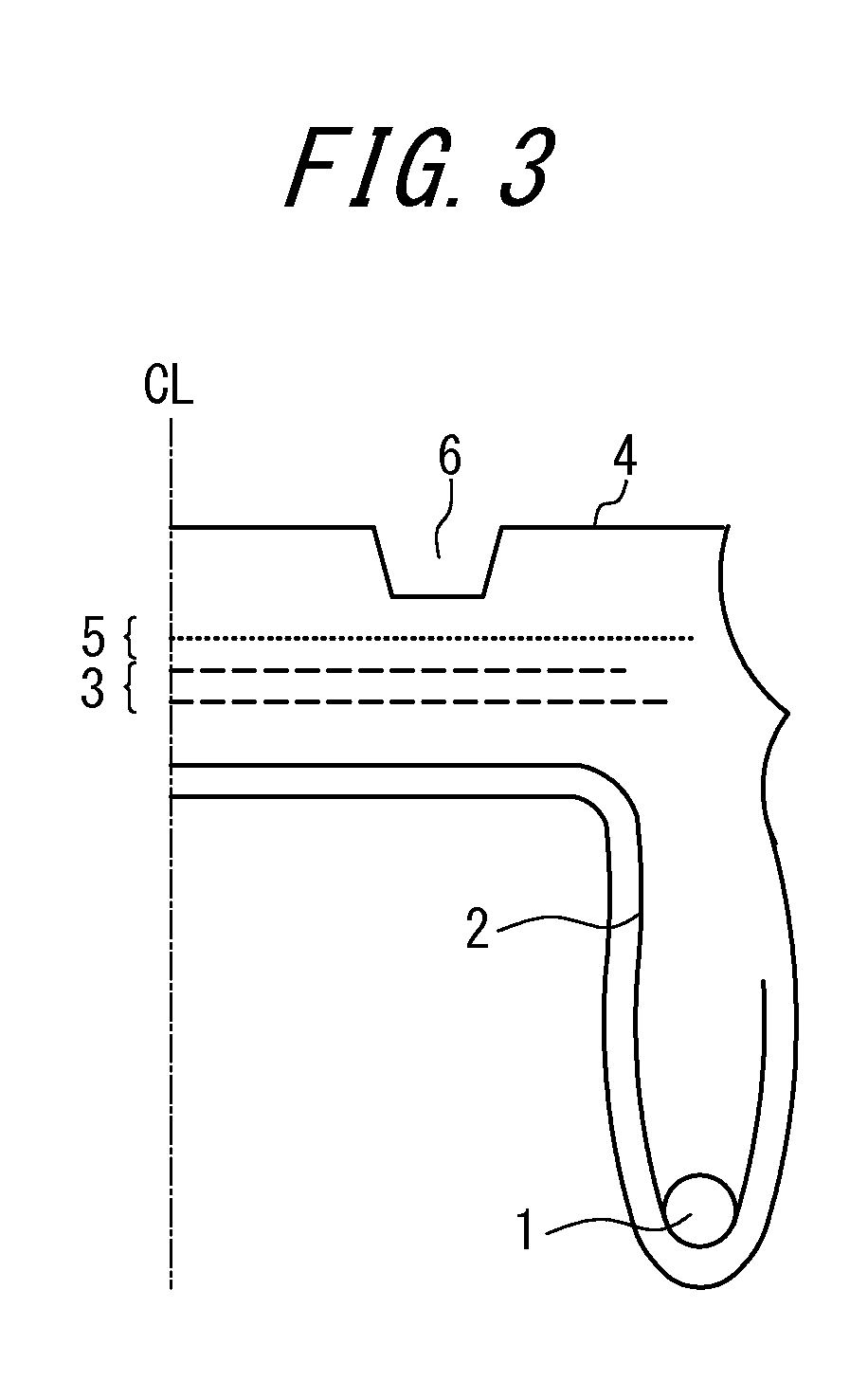

InactiveUS20130168000A1Reduce fuel consumptionUneven wear resistanceSpecial tyresPneumatic tyre reinforcementsEngineeringRadial tire

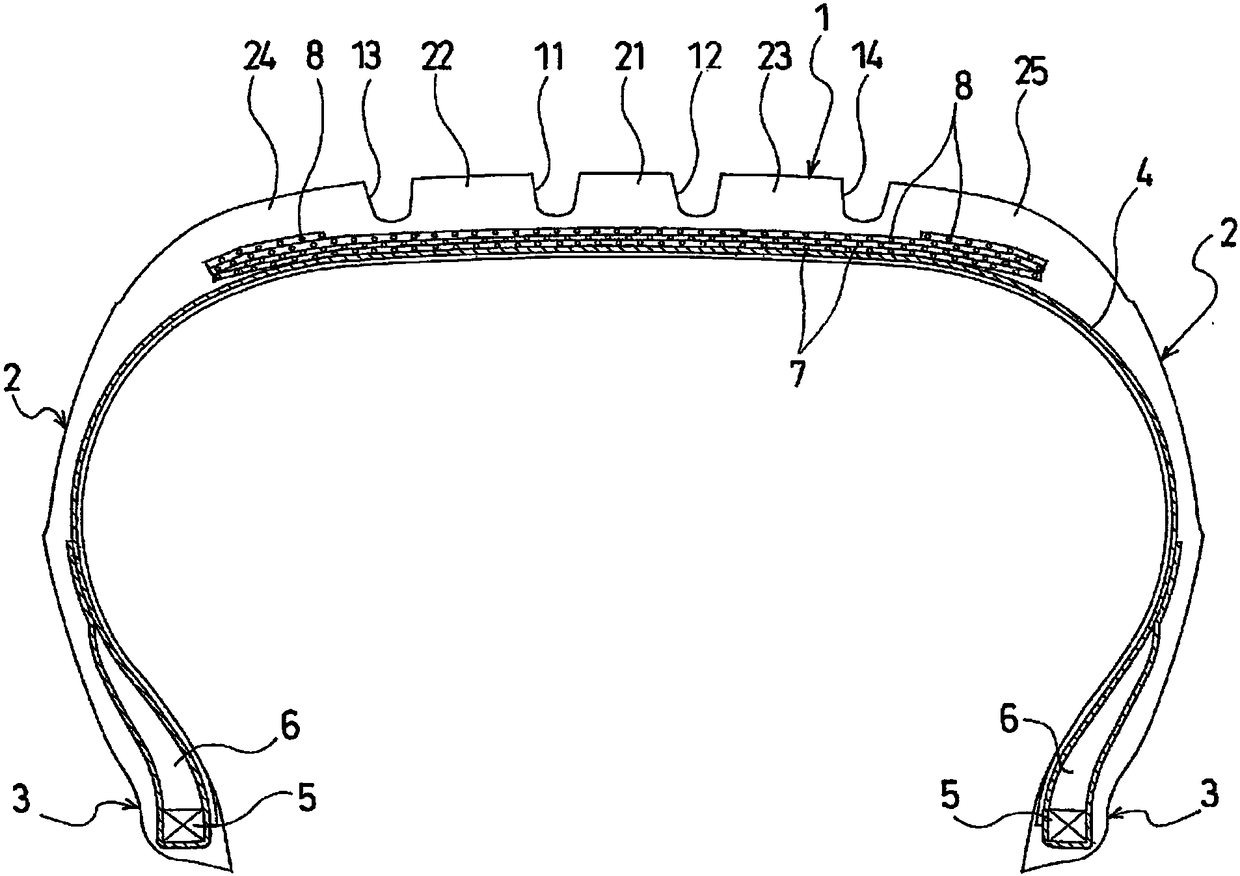

A pneumatic radial tire for a passenger vehicle has a ratio W / L where W is a cross-sectional width and L is an outer diameter. The tire also has a belt-reinforcing layer having a high rigidity and disposed between a belt and a tread.

Owner:BRIDGESTONE CORP

Pneumatic tire including slant main grooves and sipes

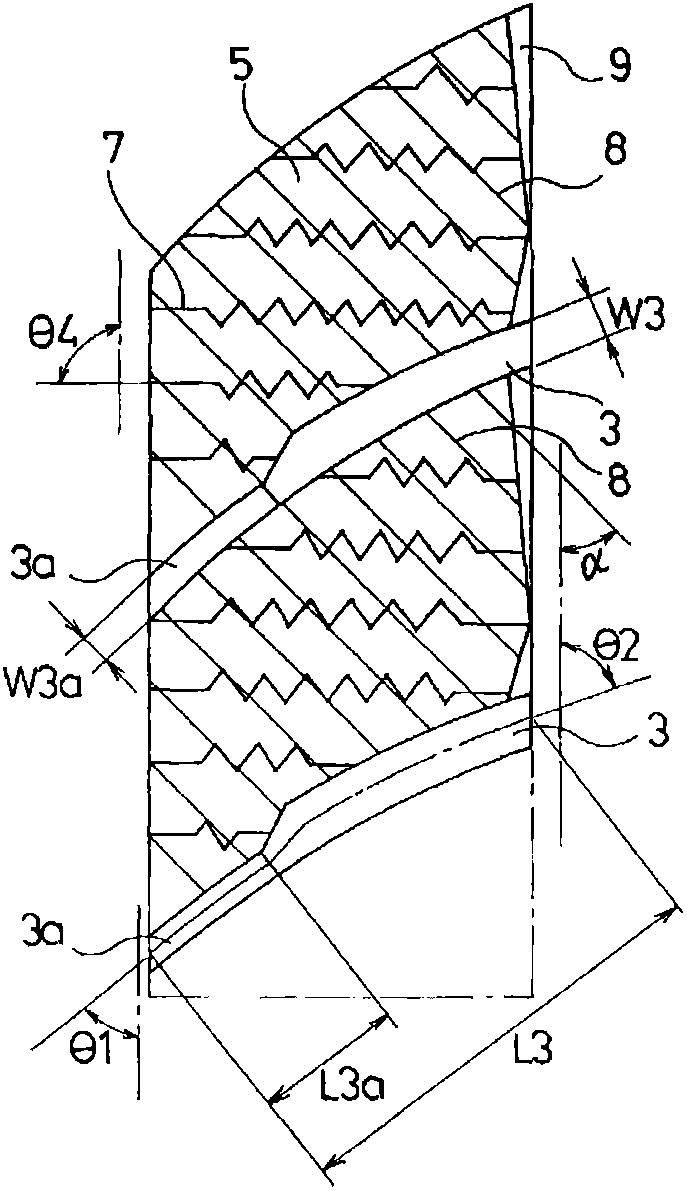

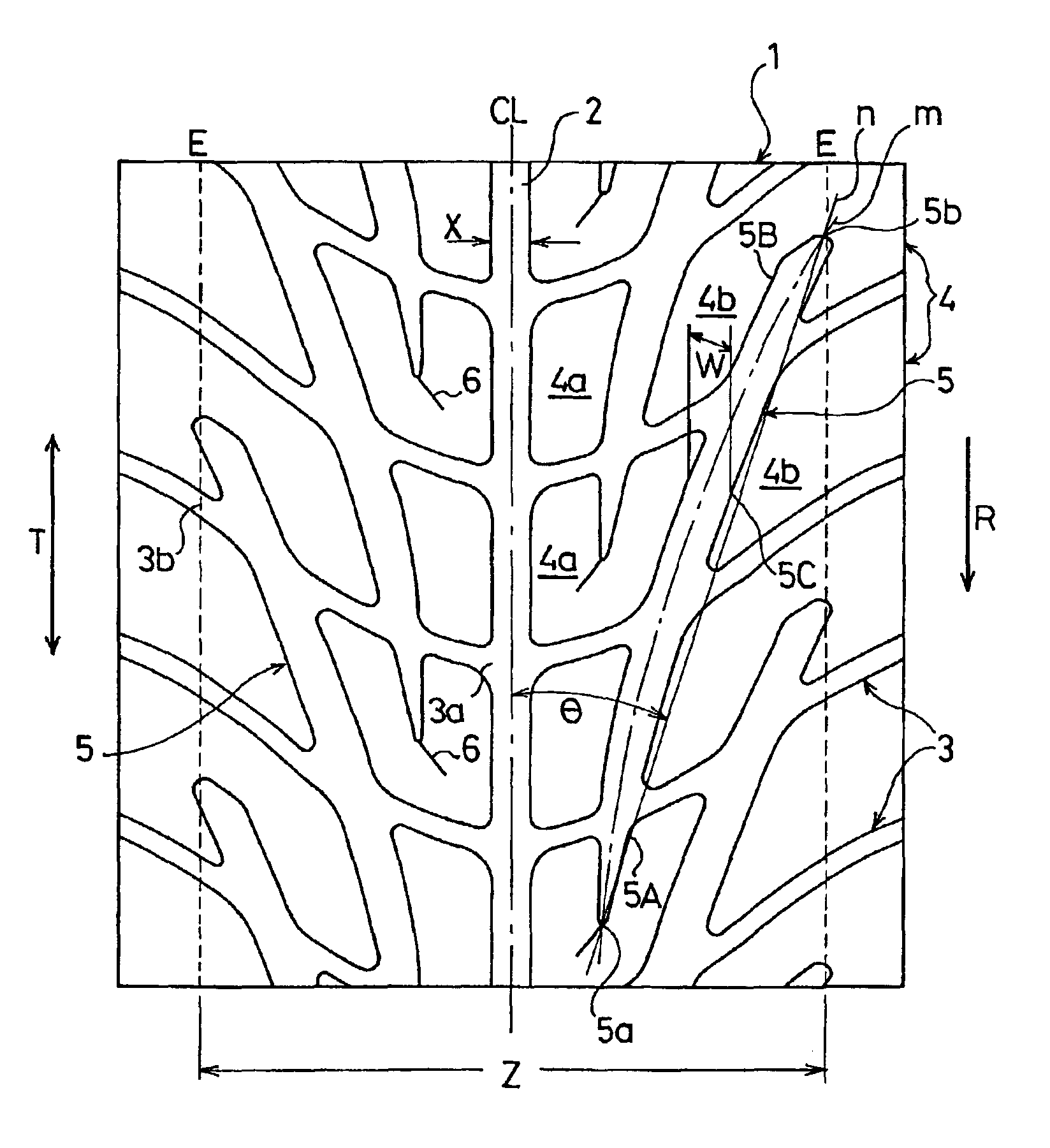

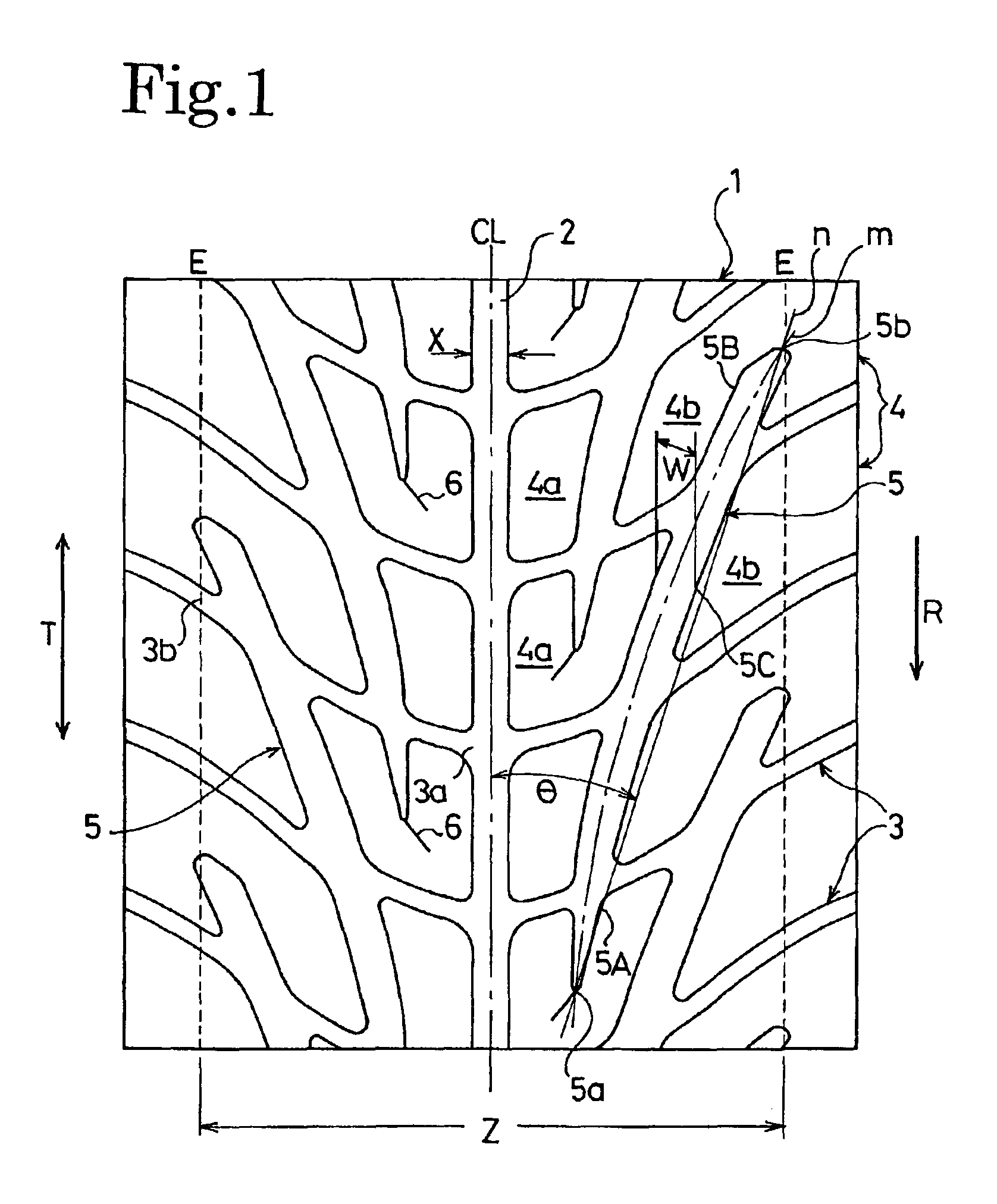

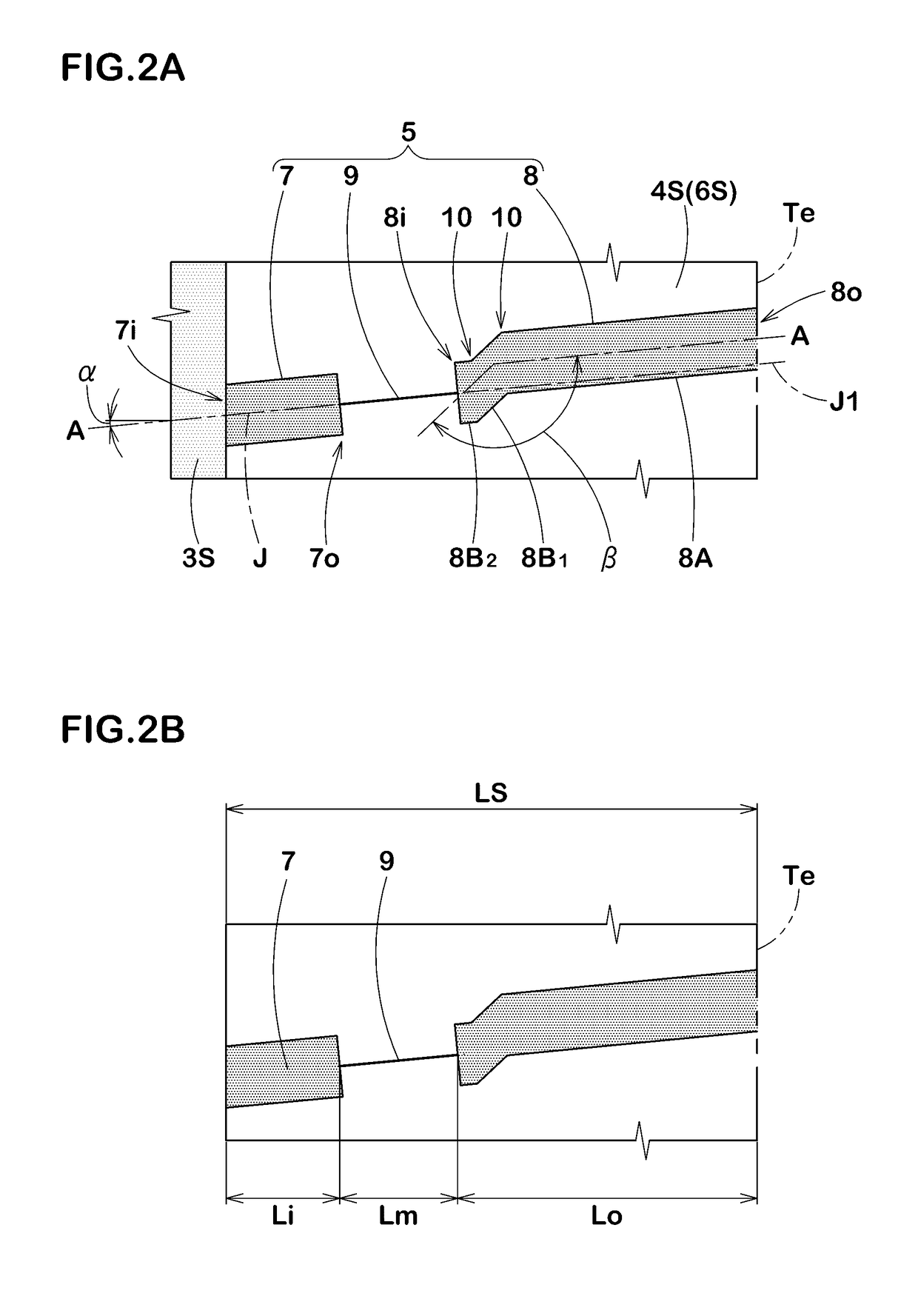

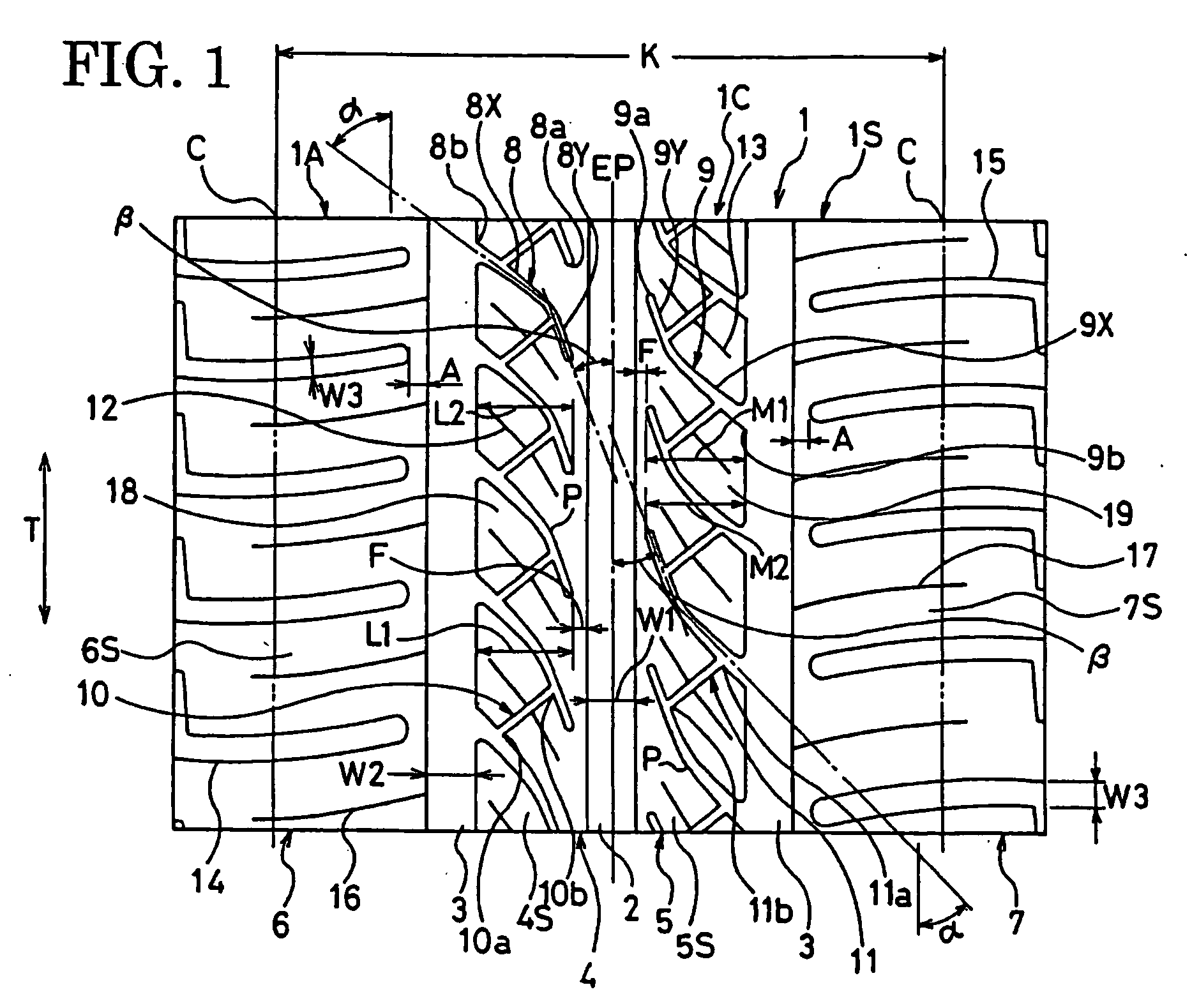

InactiveUS6935392B2PerformanceImprove uneven wear resistanceTyre tread bands/patternsNon-skid devicesGroove widthEngineering

A pneumatic tire according to the present invention includes a tread surface having a tire rotation direction designated in one direction. The tread surface has a straight main groove extending in a circumferential direction of the tire in the center, and lateral grooves obliquely extending in a width direction of the tire on both sides thereof, defining blocks thereon. On both sides of the straight main groove, left and right slant main grooves are arranged to cross three or more lateral grooves. Both ends of-the slant main grooves are positioned within the blocks, and the groove width thereof is gradually enlarged from both end portions toward the center portion of the slant main groove. The inclination angle of the slant main grooves relative to the tire circumferential direction is set in a range of 10 to 45°, and the maximum groove width thereof is set to 80 to 110% of the groove width of the straight main groove.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

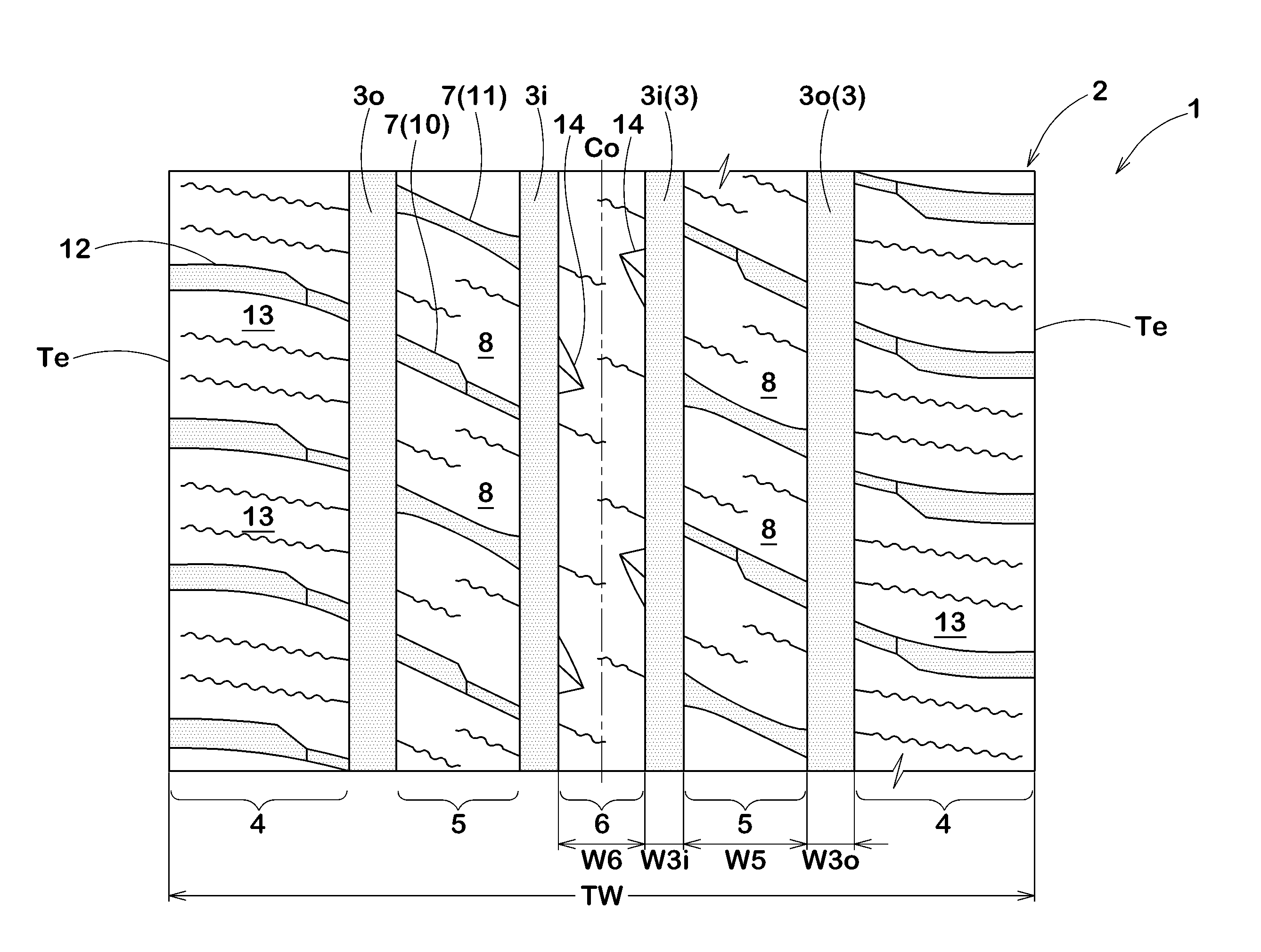

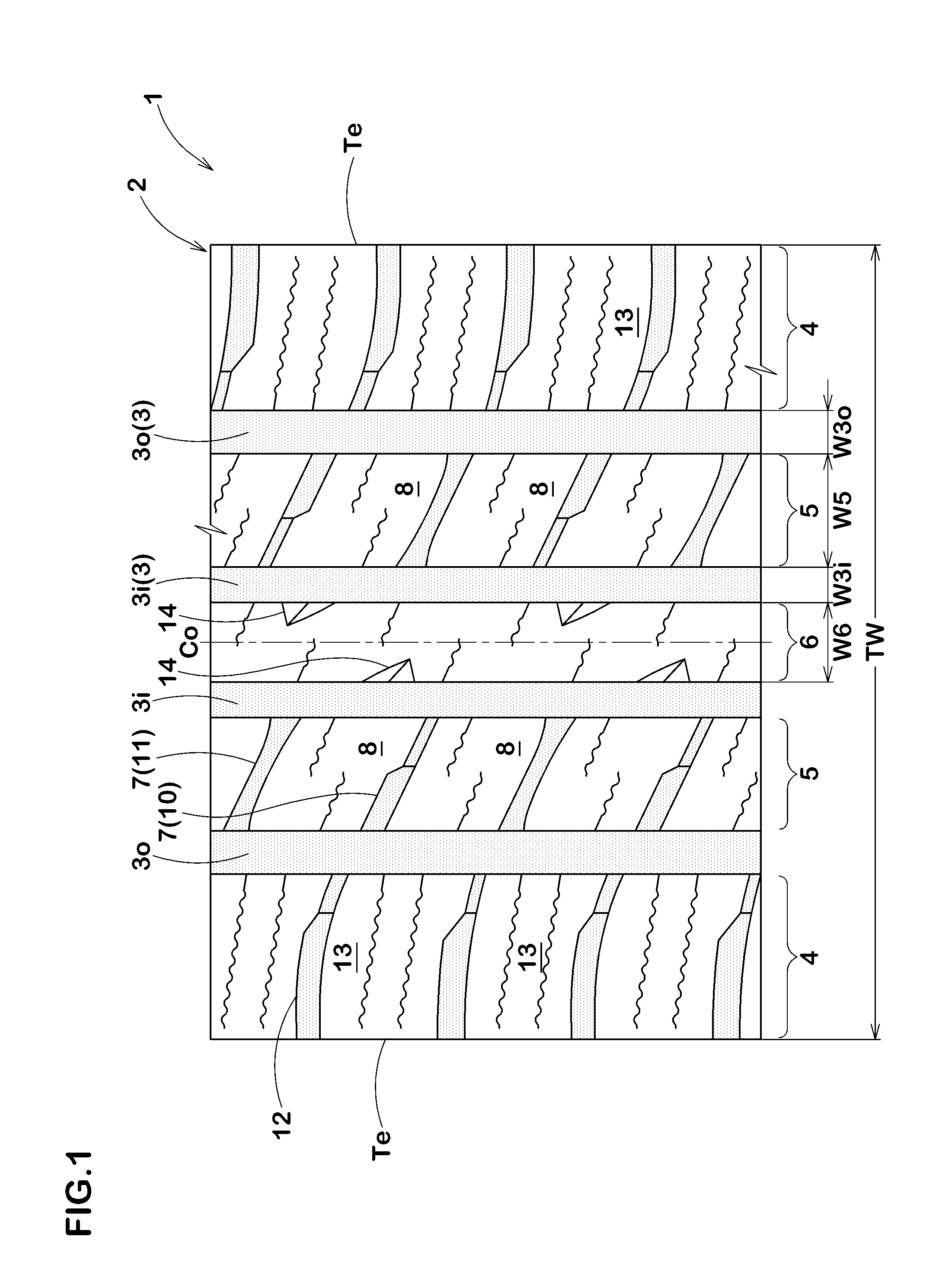

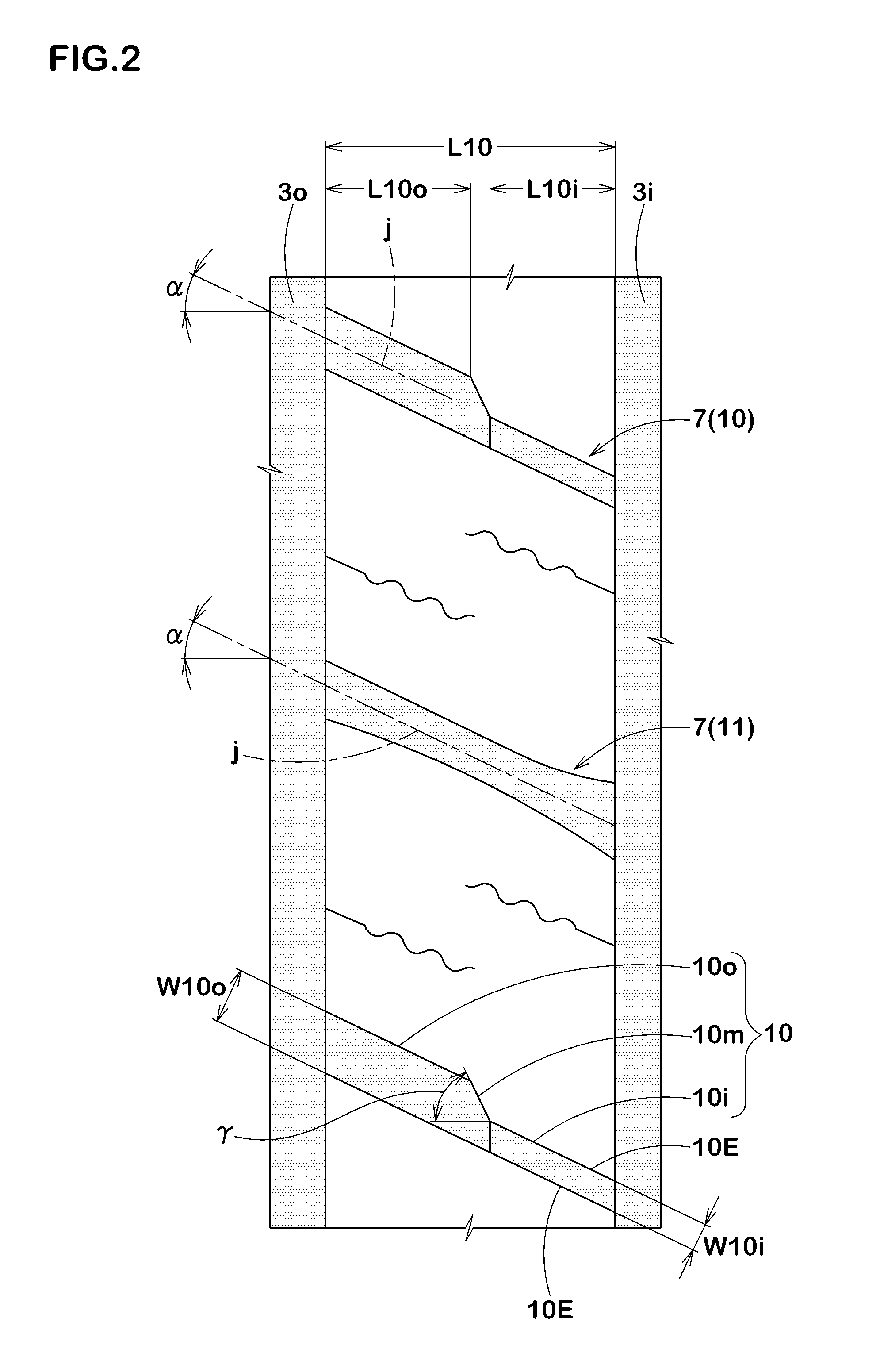

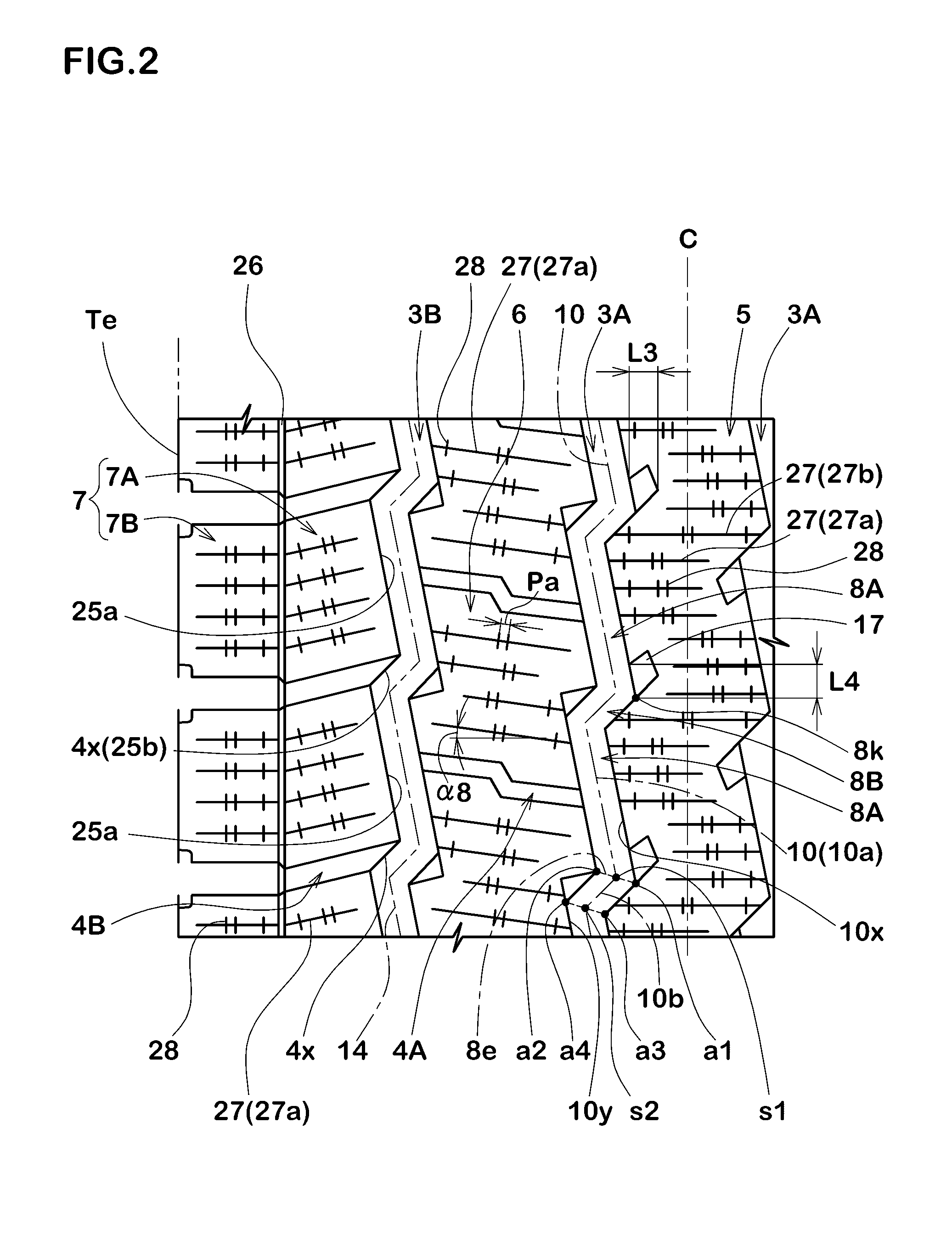

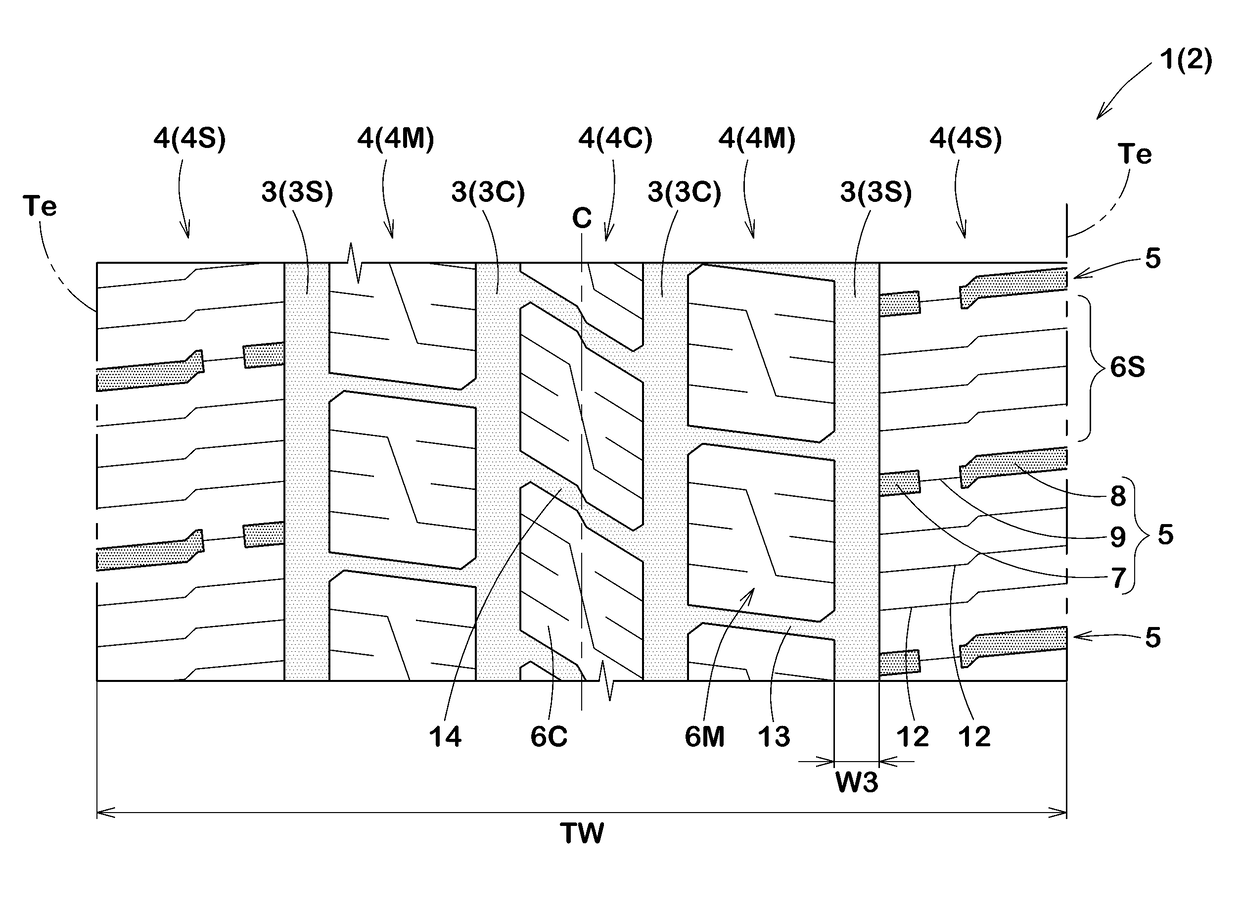

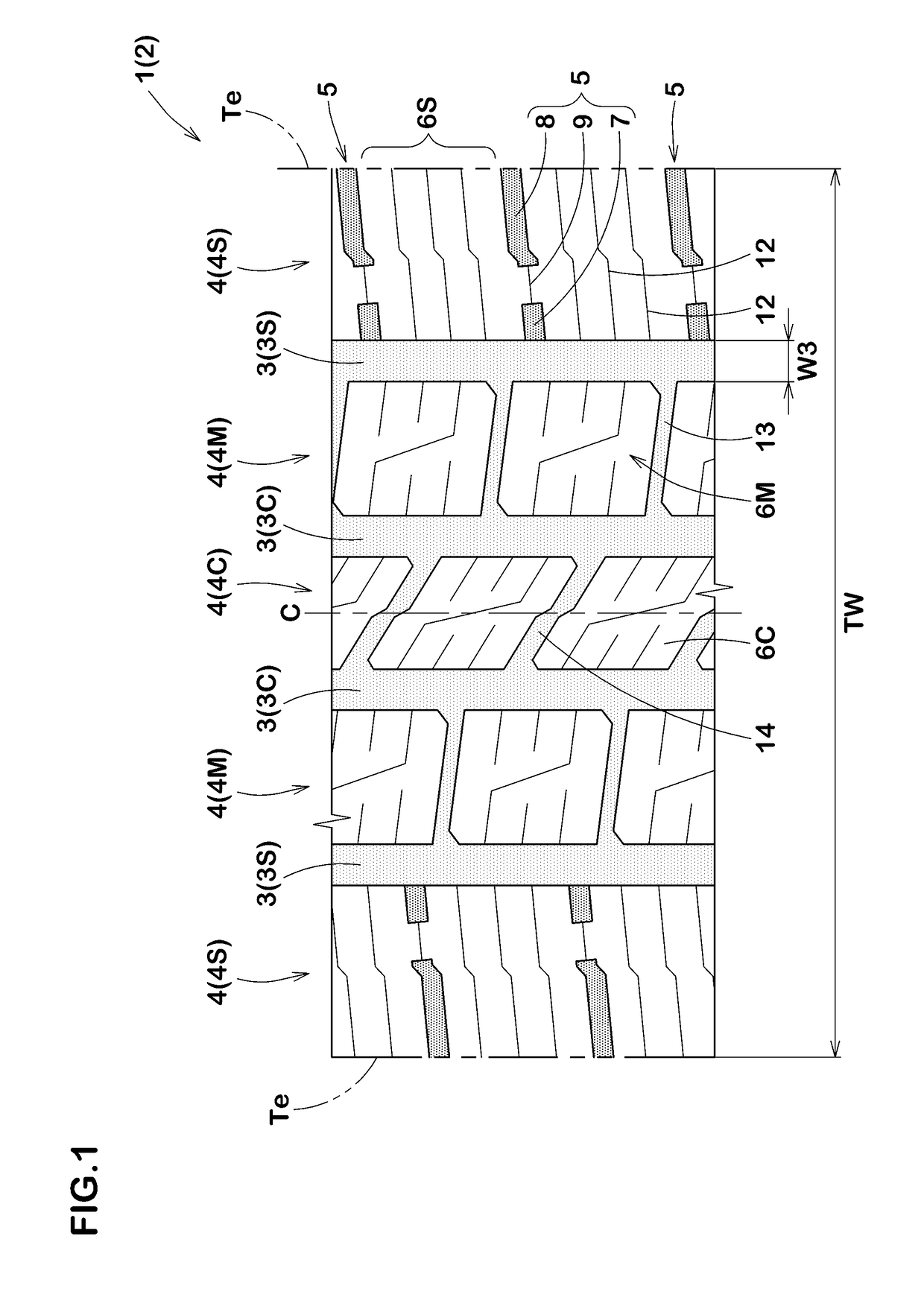

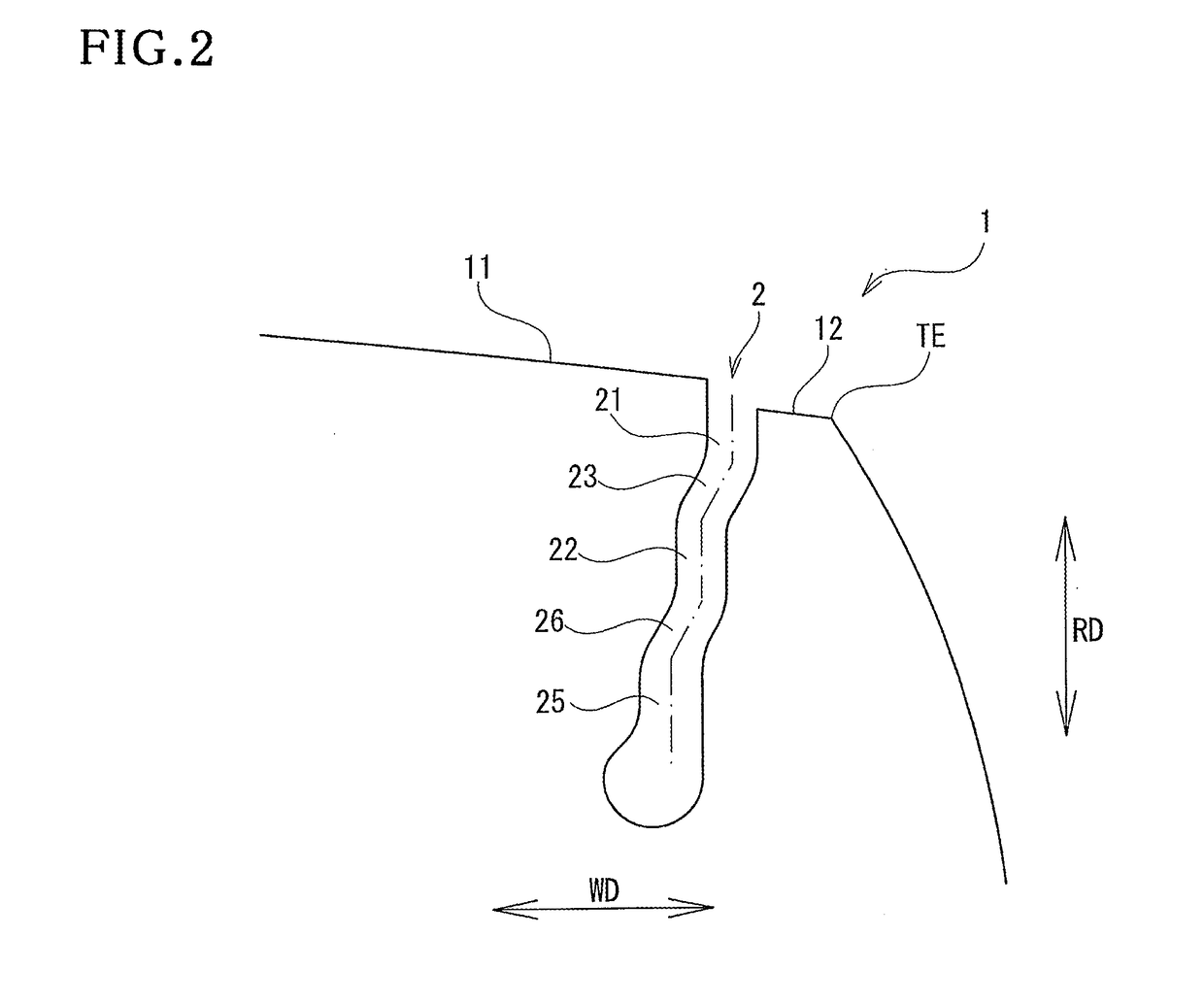

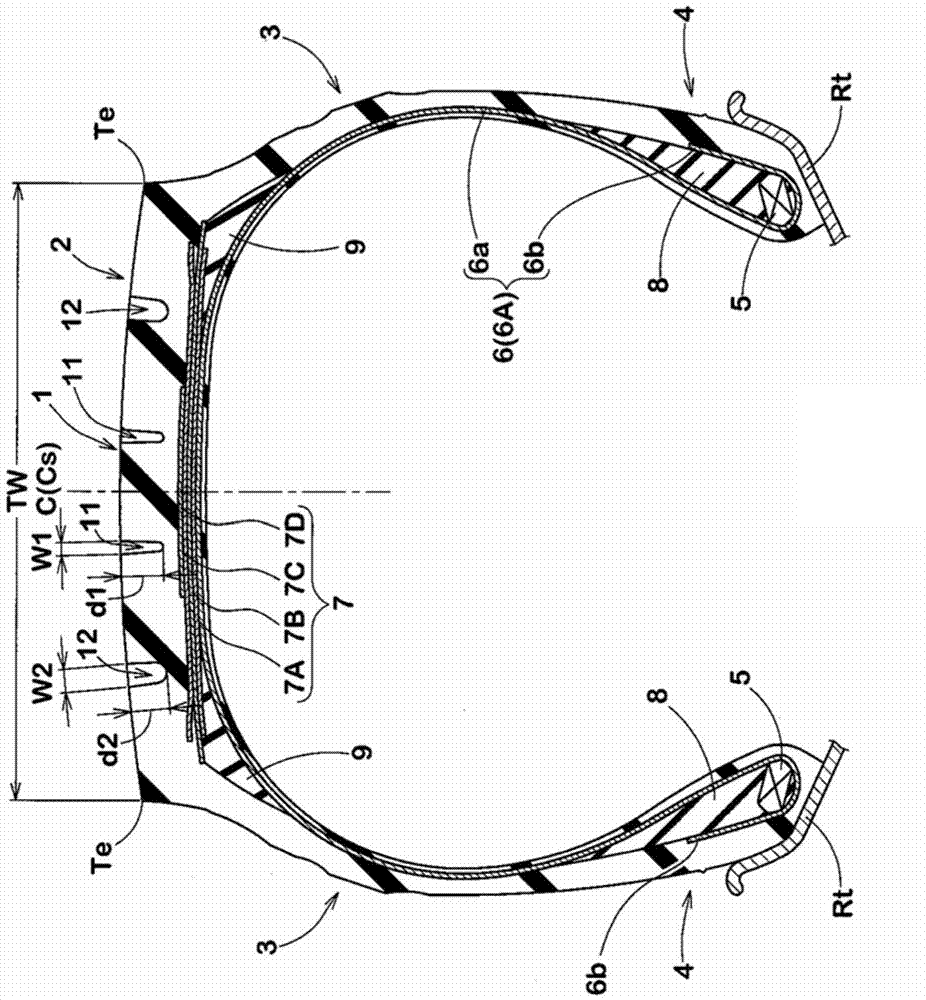

ActiveUS20180290498A1Improve uneven wear resistanceUneven wear resistance performance can be improvedHeavy duty tyresHeavy duty vehicleEngineeringTread

A shoulder lateral groove 5 comprises an inner lateral groove portion 7 intersecting a shoulder main groove 3S, an outer lateral groove portion 8 intersecting a tread edge (Te), and a sipe portion 9 connecting between the inner lateral groove portion 7 and the outer lateral groove portion 8. The outer lateral groove portion 8 has a bent portion 10 and extends so as to connect between the tread edge (Te) and the sipe portion 9.

Owner:SUMITOMO RUBBER IND LTD

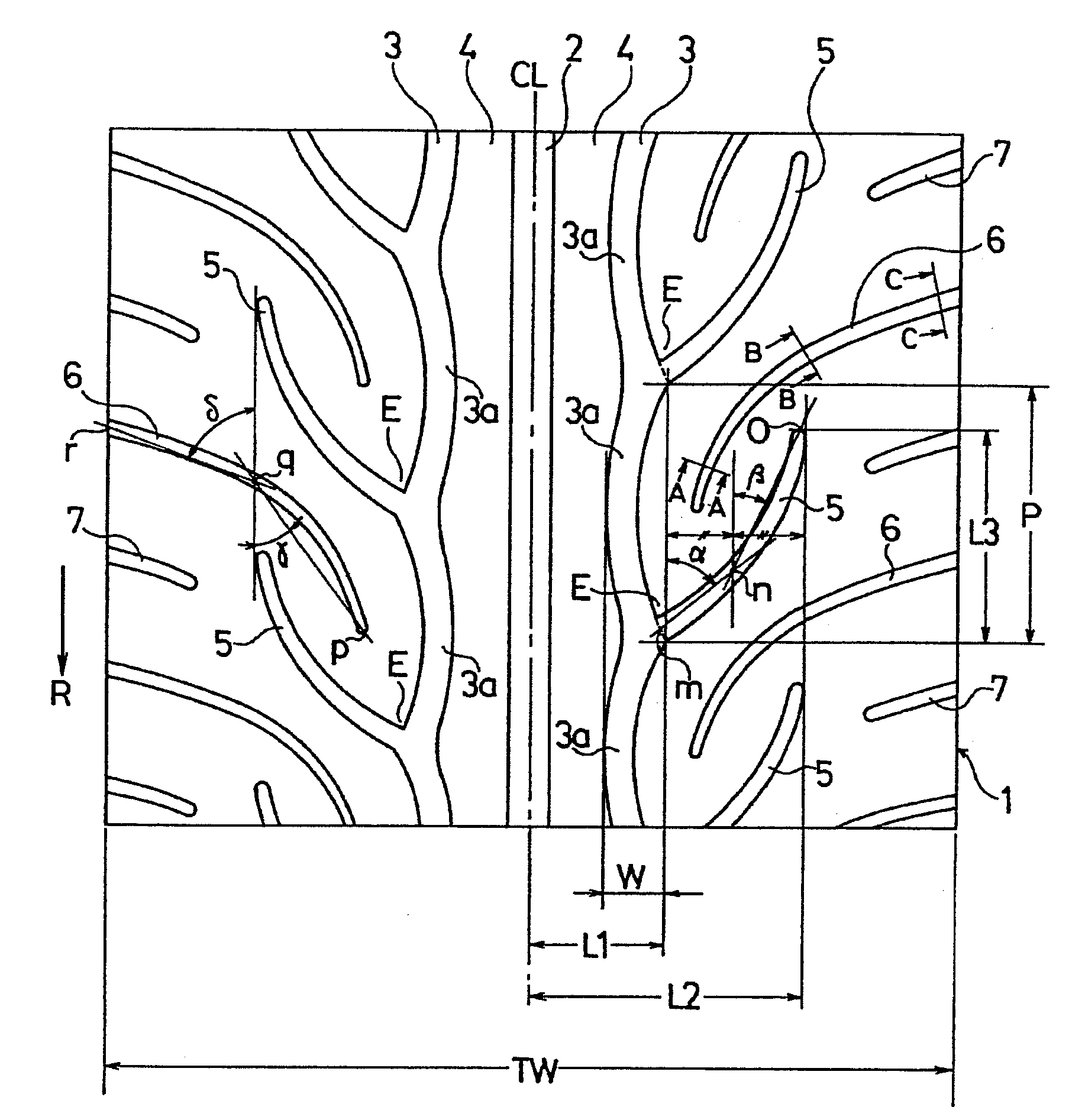

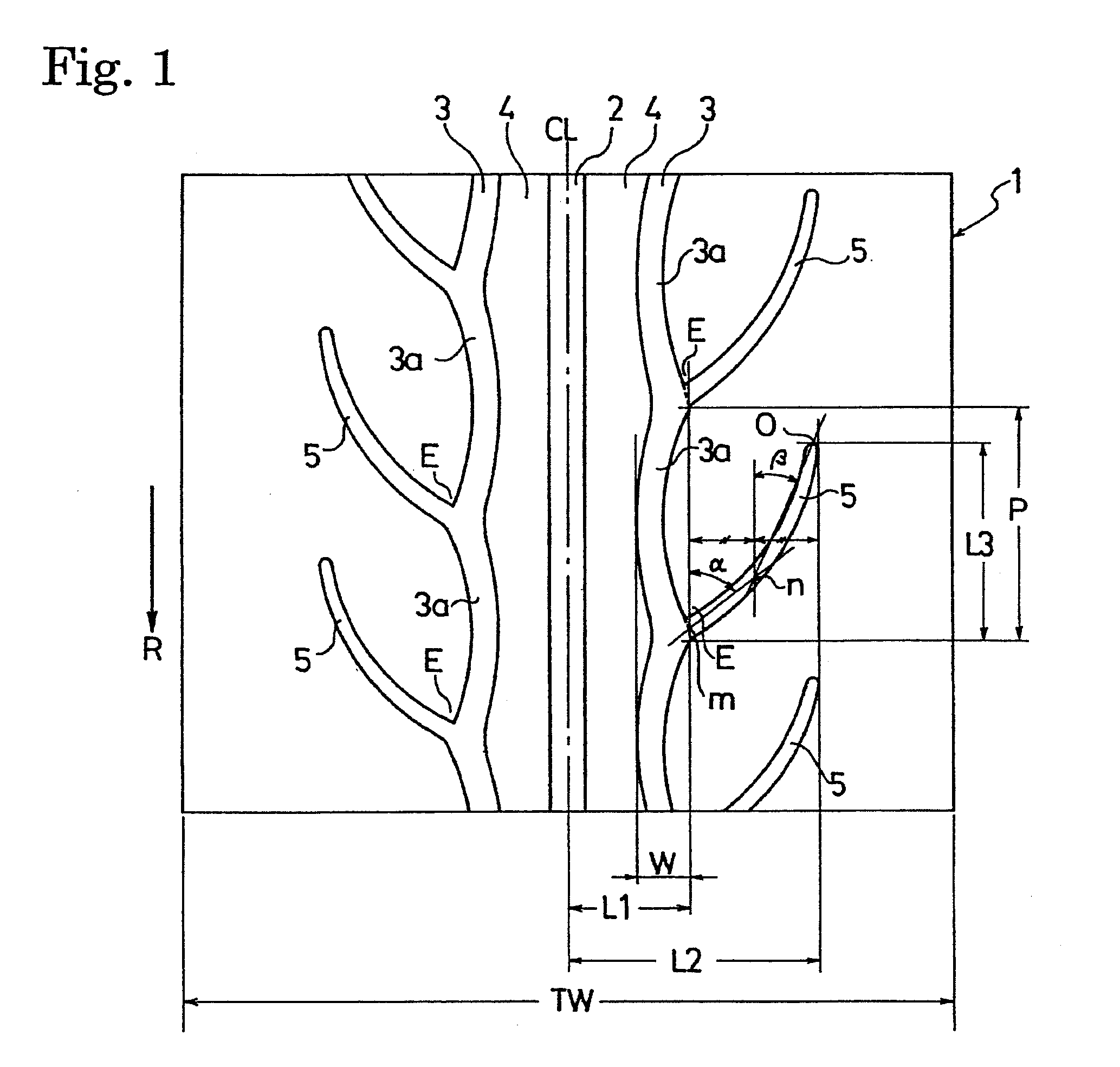

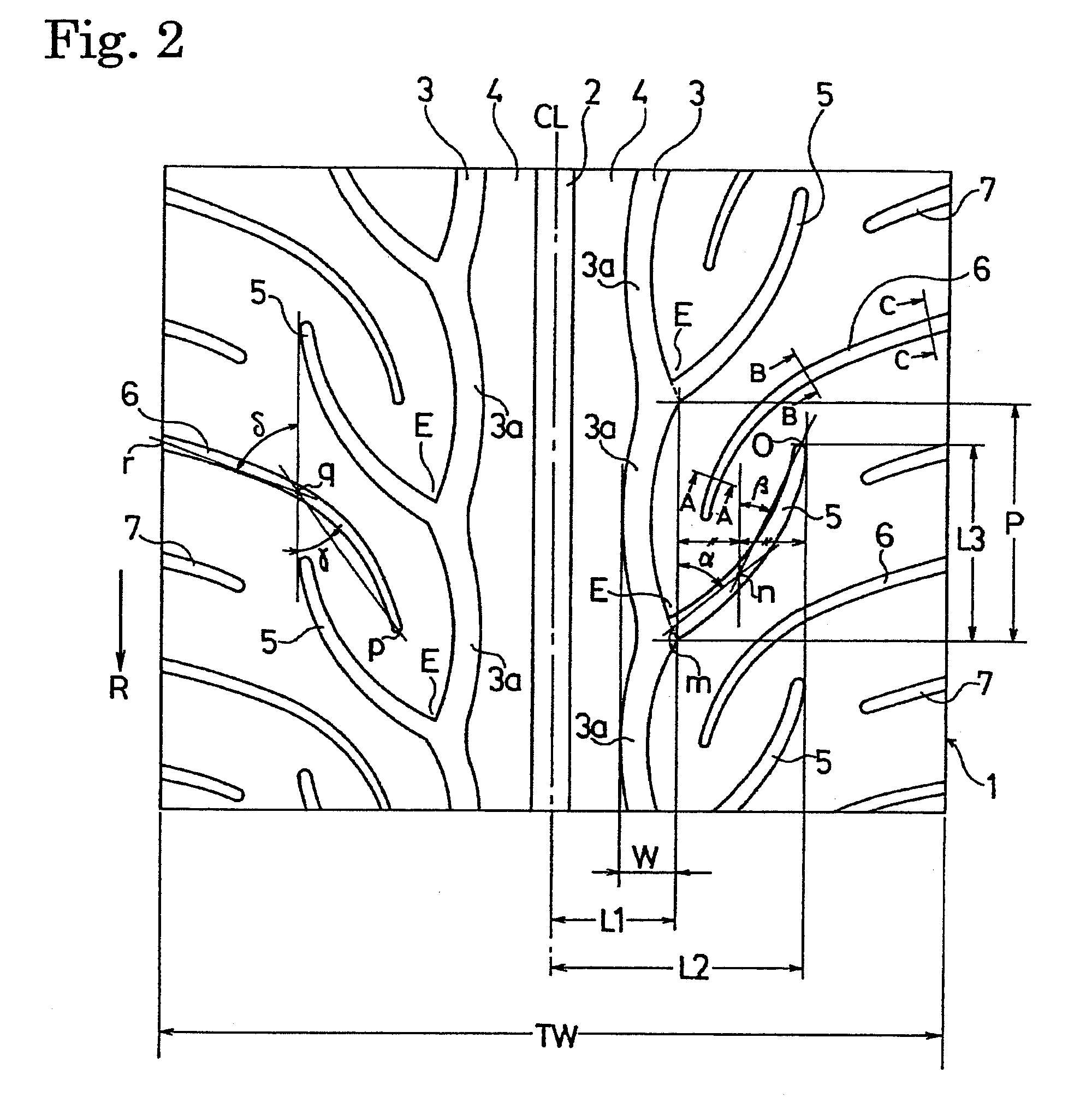

Pneumatic Tire

InactiveUS20080035256A1Improve drainage characteristicsMaintaining drainage characteristicTyre tread bands/patternsWheelsEngineeringTread

A pneumatic tire includes a tread surface having a middle rib defined by a first circumferential groove and a second circumferential groove in its center region. Middle lateral grooves, that obliquely extend in the widthwise direction of the tire, are disposed at predetermined intervals in the tire circumferential direction in the middle rib; only one terminal end of each middle lateral groove communicates with one circumferential groove of the first and second circumferential grooves. An assistant groove is provided between each of adjacent middle lateral grooves; the assistant groove extends in such an inclined manner that the inclination direction thereof with respect to the tire circumferential direction is opposite to that of the middle lateral grooves; a block is defined by the assistant groove, middle lateral grooves and one circumferential groove. The middle lateral grooves each include a first inclined groove portion having an inclination angle a ranging from 35 degrees to 60 degrees and a second inclined groove portion having an inclination angle β ranging from 0 degree to 30 degrees. One terminal end of the assistant groove is located at a position ranging from 20% to 30% of the tire-widthwise length of one middle lateral groove of the adjacent middle lateral grooves from the one terminal end of the one middle lateral groove toward the other terminal end side of the one middle lateral groove in the tire widthwise direction. The other terminal end of the assistant groove is located at a position ranging from 20% to 30% of the tire-widthwise length of the other middle lateral groove of the adjacent middle lateral grooves from the other terminal end of the other middle lateral groove toward the one terminal end side of the other middle lateral groove in the tire widthwise direction.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

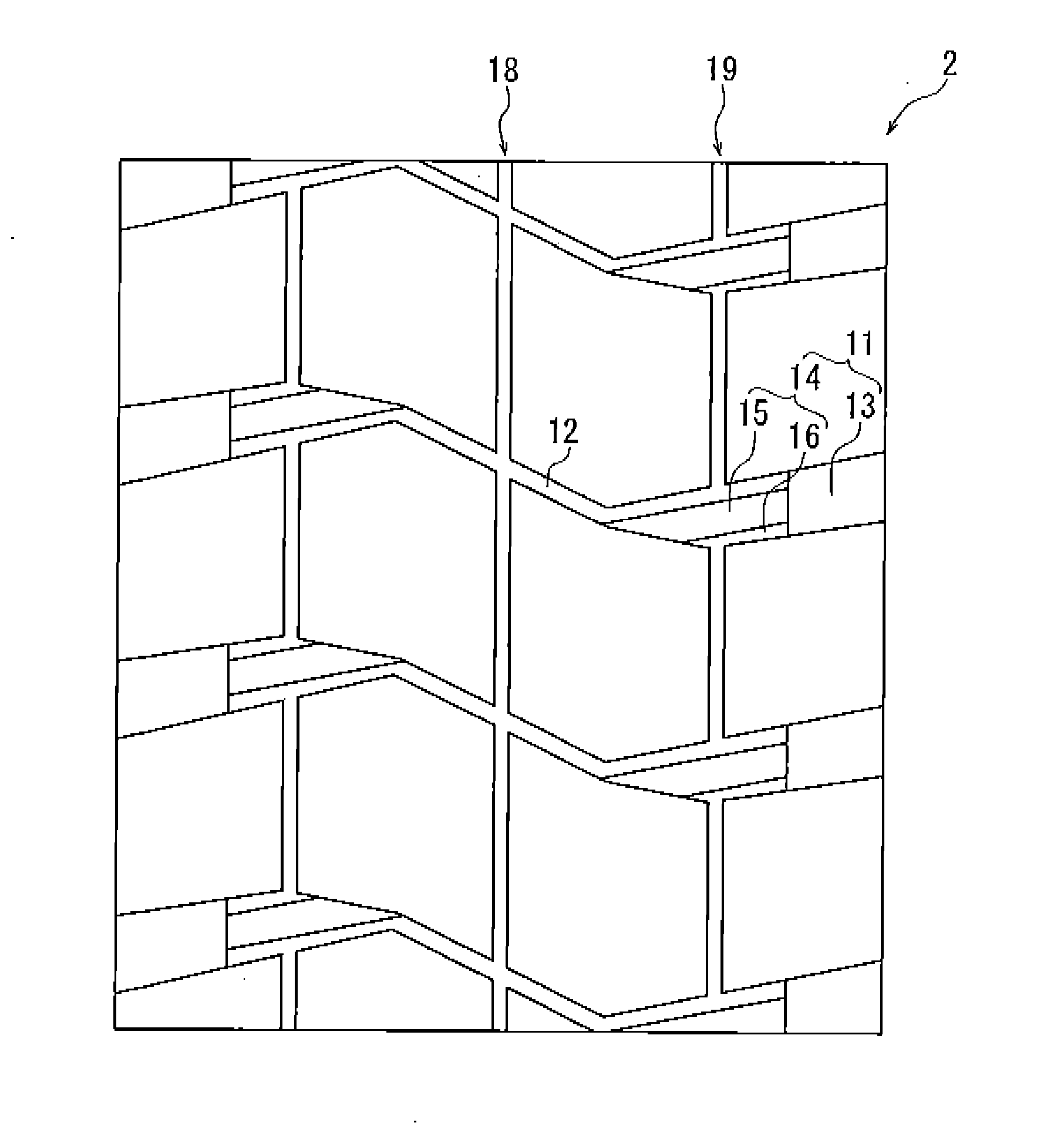

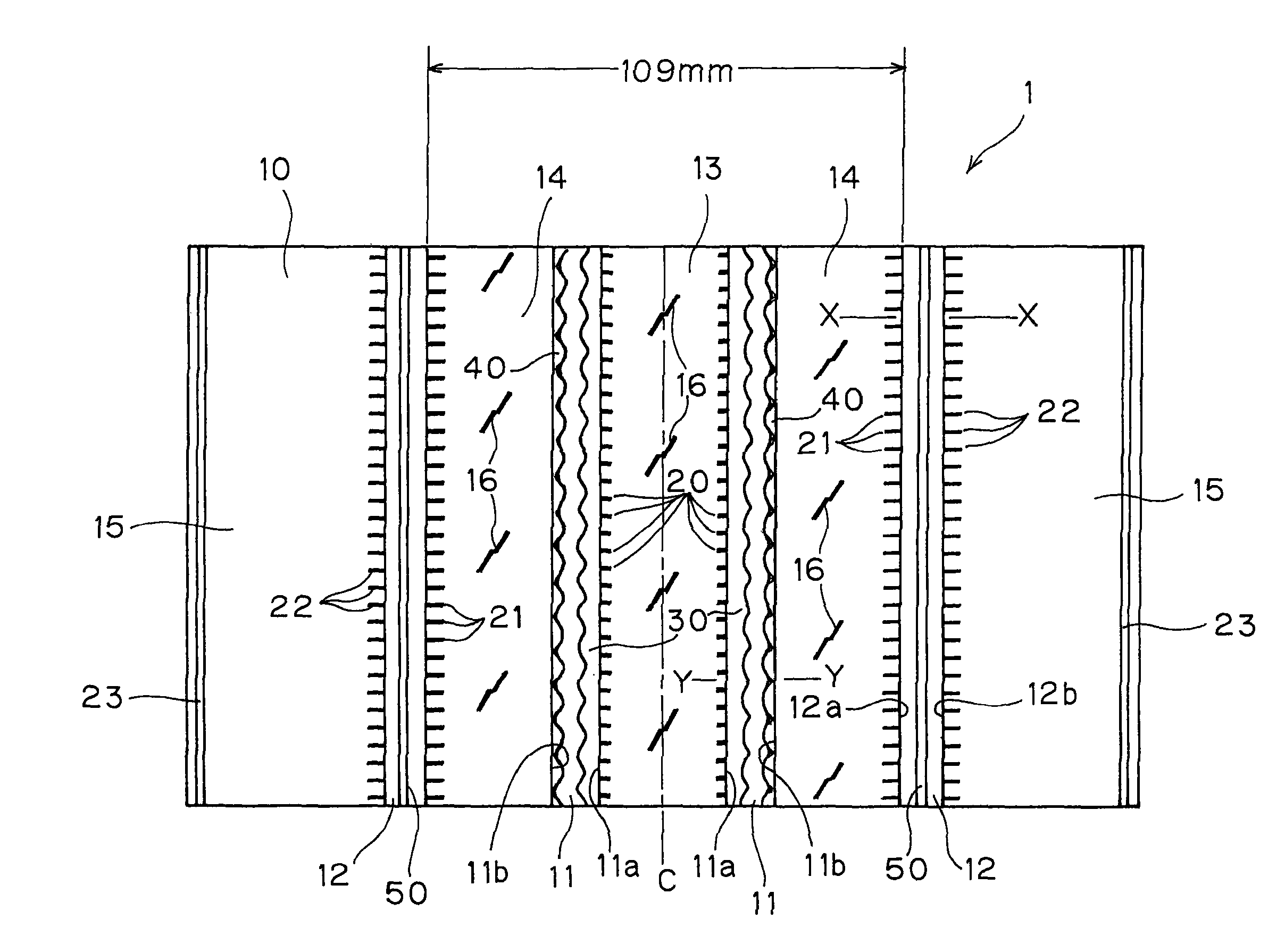

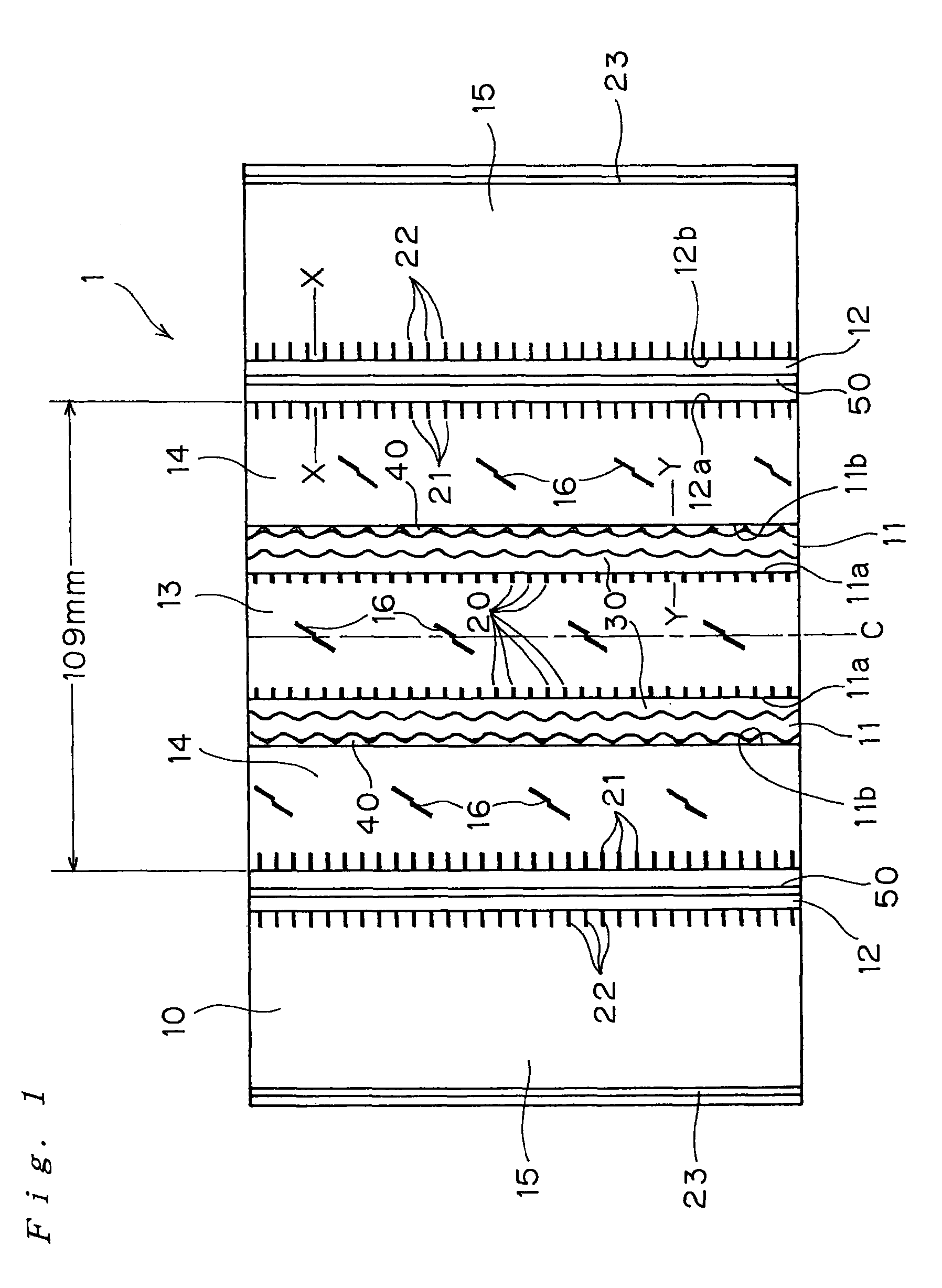

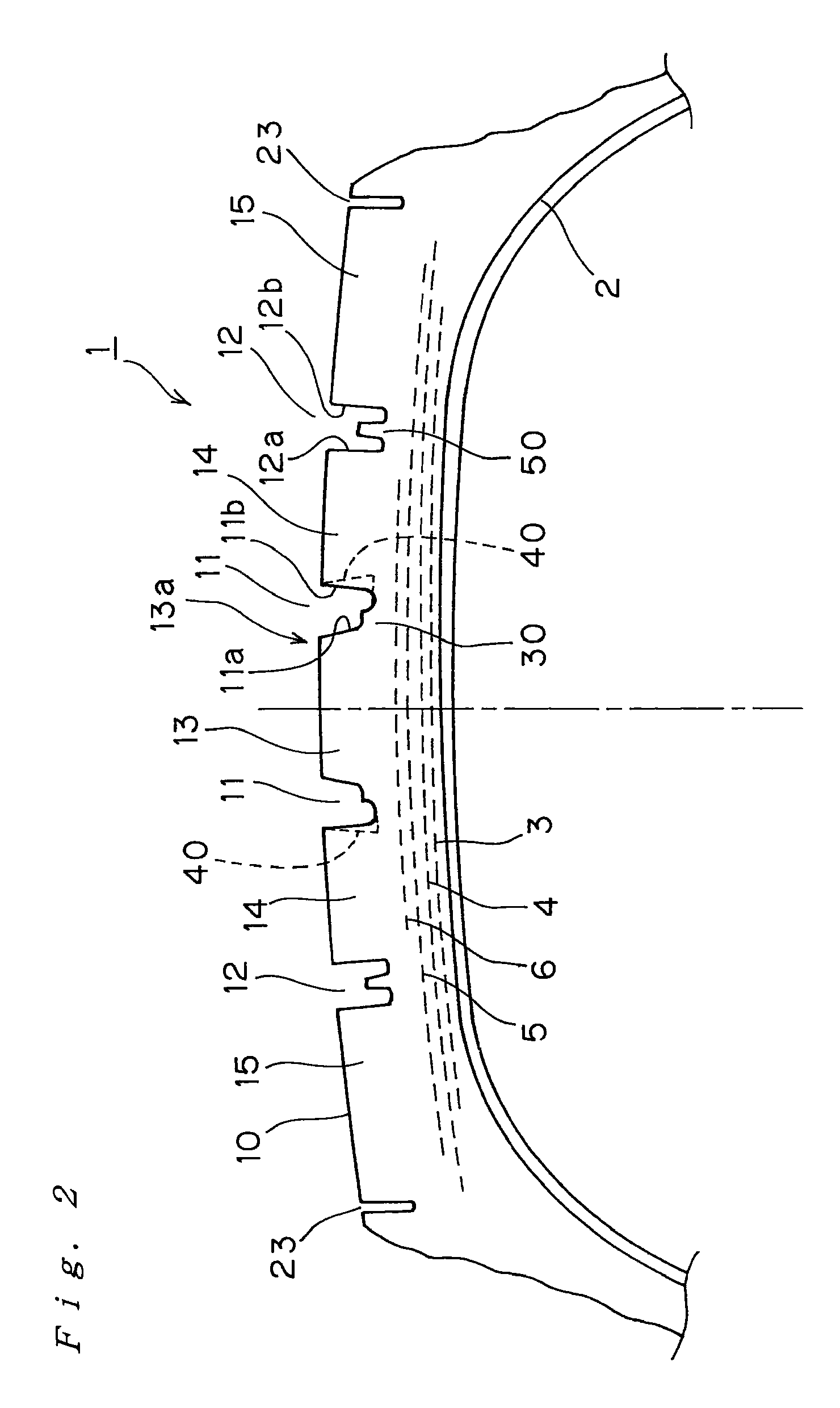

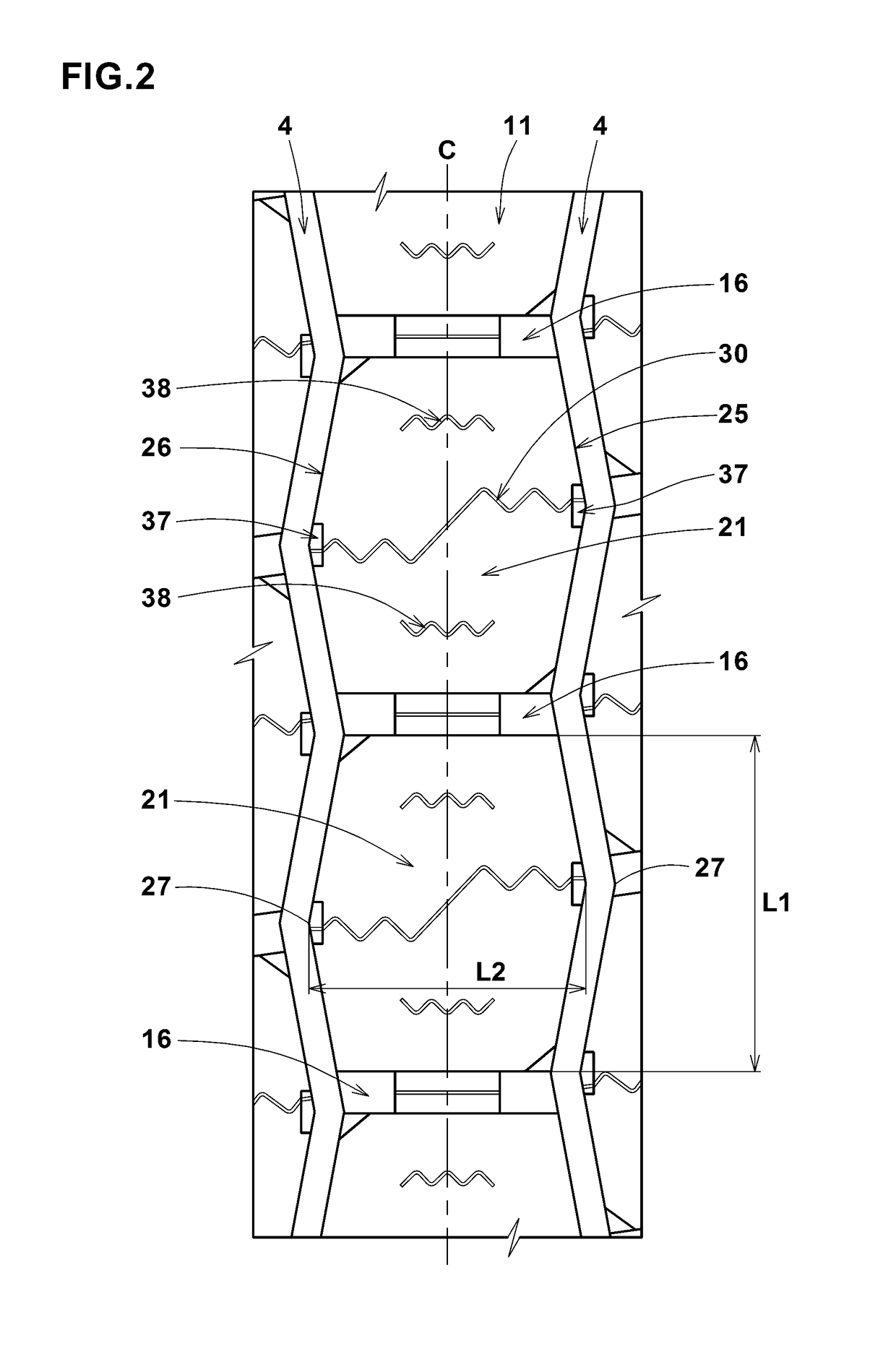

ActiveCN106985617AImprove uneven wear resistanceInhibits uneven wearHeavy duty tyresHeavy duty vehicleMechanical engineeringTread

A pneumatic tire is provided and has improved resistance to uneven abrasiveness of center blocks. The pneumatic tire (1) comprises a tread portion (2) provided with crown main grooves (4), a plurality of center axial grooves (16) and a plurality of center blocks (21). The center blocks (21) include a first block side wall (25), a second block side wall (26) and a first sipe (30). The first block side wall (25) and the second block side wall (26) are substantially V-shaped protruding from a vertex (27) respectively. At least a part of the first sipe (30) extends in a waveform manner. One end at the tire axial direction of the first sipe (30) is at one side in the tire circumferential direction of the vertex of the first block side wall (25), and the other end of the first sipe (30) at the tire axial direction is positioned on other side in the tire circumferential direction of the vertex of the second block side wall (26).

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

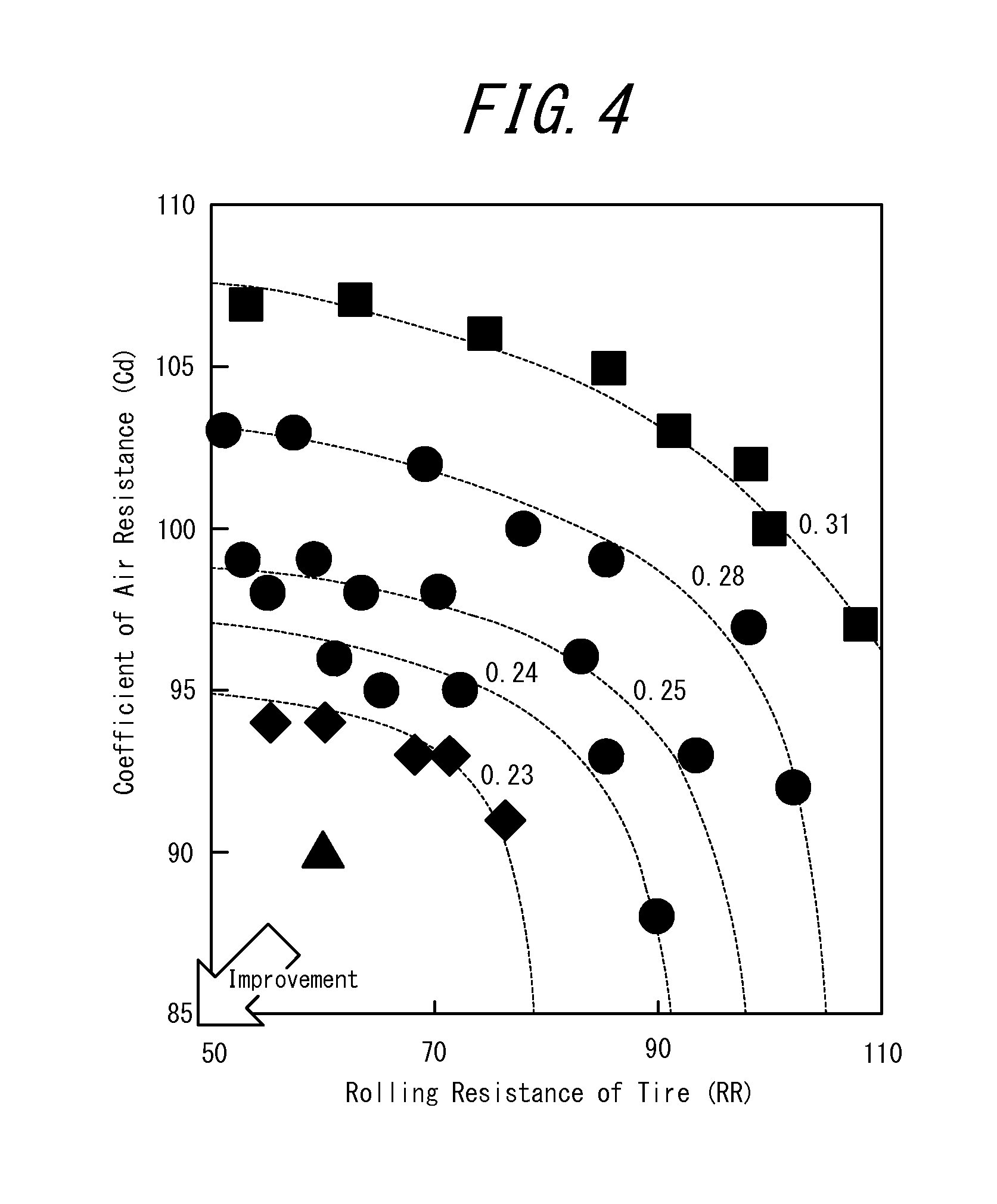

ActiveUS20110180189A1Reduce rolling resistanceMaintains snow traction performanceHeavy duty tyresHeavy duty vehicleEngineeringTread

A pneumatic tire includes a tread portion; three or more circumferential direction grooves; width direction grooves; and lines of land portions. When a tread center area and tread shoulder areas are sectioned at centerlines of the circumferential direction grooves in outermost sides in the tire width direction, a ratio G=(A+B) / X of a sum A+B of a groove area A of the circumferential direction grooves and a groove area B of the width direction grooves to a contact area X of the tread portion is in a range of G≦0.25, a ratio S=B / (A+B) of the groove area B to the sum A+B is in a range of 0.25<S<0.45, a ratio Gs=C / Y of a groove area C of the tread shoulder areas to a contact area Y of the tread shoulder areas is in a range of Gs<0.20, and the ratio G and the ratio Gs have a relation of Gs<G.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic heavy-duty tire having circumferential reinforcing layer and sipes

ActiveUS9108472B2Uneven wearImprove uneven wear resistanceHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

Owner:THE YOKOHAMA RUBBER CO LTD

Heavy duty pneumatic tire

ActiveUS20160152089A1Prevent excessive deformationImprove uneven wear resistanceTyre tread bands/patternsNon-skid devicesEngineeringHeavy duty

A heavy duty pneumatic tire includes a tread portion including a plurality of blocks separated by a plurality of circumferentially extending main grooves and a plurality of lateral grooves. At least one of the blocks is provided with two axially extending sipes to divide the block into a first end portion, a second end portion and a middle portion between the first end portion and the second end portion. The first end portion includes a first projected portion that protrudes outwardly in a block-width direction from the middle portion so as to form a steplike side, and the second end portion includes a second projected portion that protrudes outwardly in an opposite block-width direction to the first projected portion from the middle portion so as to form a steplike side.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire with ground contact surface of land portion having circular arcs

ActiveUS7478657B2Improve performanceIncrease resistanceSpecial tyresTyre tread bands/patternsGround contactEngineering

A pneumatic tire includes a tread surface having a plurality of main grooves extending straight in a circumferential direction of the tire. The plurality of main grooves defines land portions extending in the tire circumferential direction. The land portions each have a ground contact surface comprising a first circular are having a single curvature radius in tire meridian cross section. The ground contact surface of at least the land portion which is located second when counted from the outer side of a vehicle when the tire is mounted thereon, is arranged so as to have the first circular are and at least a second circular are connected thereto on the vehicle outer side thereof. The circular are located closer to the vehicle outer side has a smaller curvature radius and is positioned more inwardly away from the tread surface. The ratio d / D of the depth d of an intersection of the circular are located closest to the vehicle outer side with a vehicle outer sidewall surface of the at least second land portion to the groove depth D of the main groove facing to the vehicle outer sidewall surface is 0.02 to 0.1.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic Tire

ActiveUS20190092100A1Easy to blockDifference in rigidityHeavy duty tyresHeavy duty vehicleGroove widthEngineering

A pneumatic tire includes circumferential grooves aligned in a lateral direction and extending in a circumferential direction, lateral grooves aligned in the circumferential direction and extending to cross the circumferential direction, communicating at ends with the circumferential grooves and defining a block-shaped land portion between the circumferential grooves, two narrow grooves aligned in the lateral direction and extending in the circumferential direction, communicating at ends with a lateral groove and dividing the land portion defined by each of the circumferential grooves and each of the lateral grooves into small land portions, the narrow grooves having a smaller groove width than the circumferential grooves and being formed with a bent portion in an intermediate portion, the bent portion being disposed inward in the lateral direction, and bend points of the bent portions being disposed at positions offset from one another in the circumferential direction.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

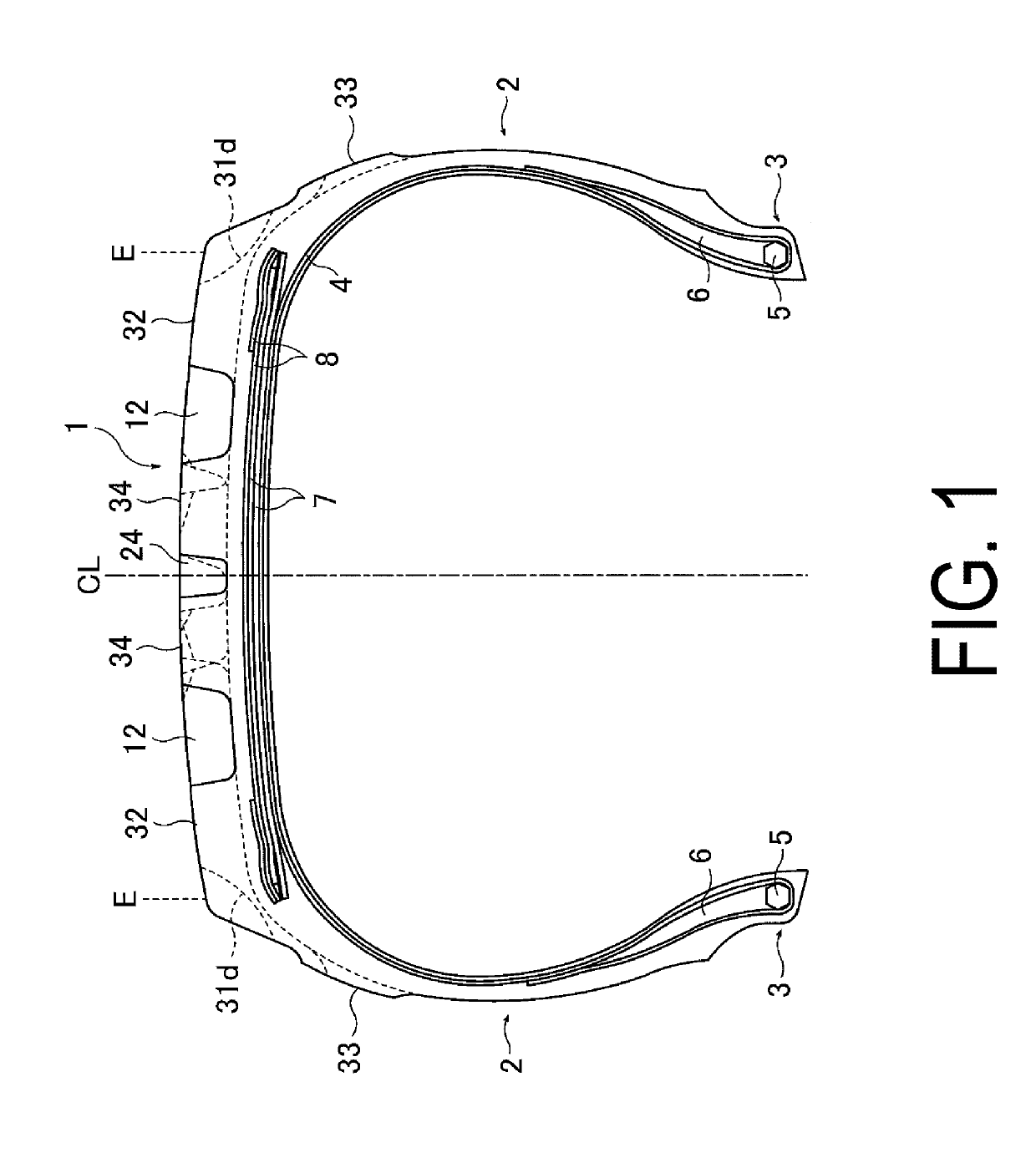

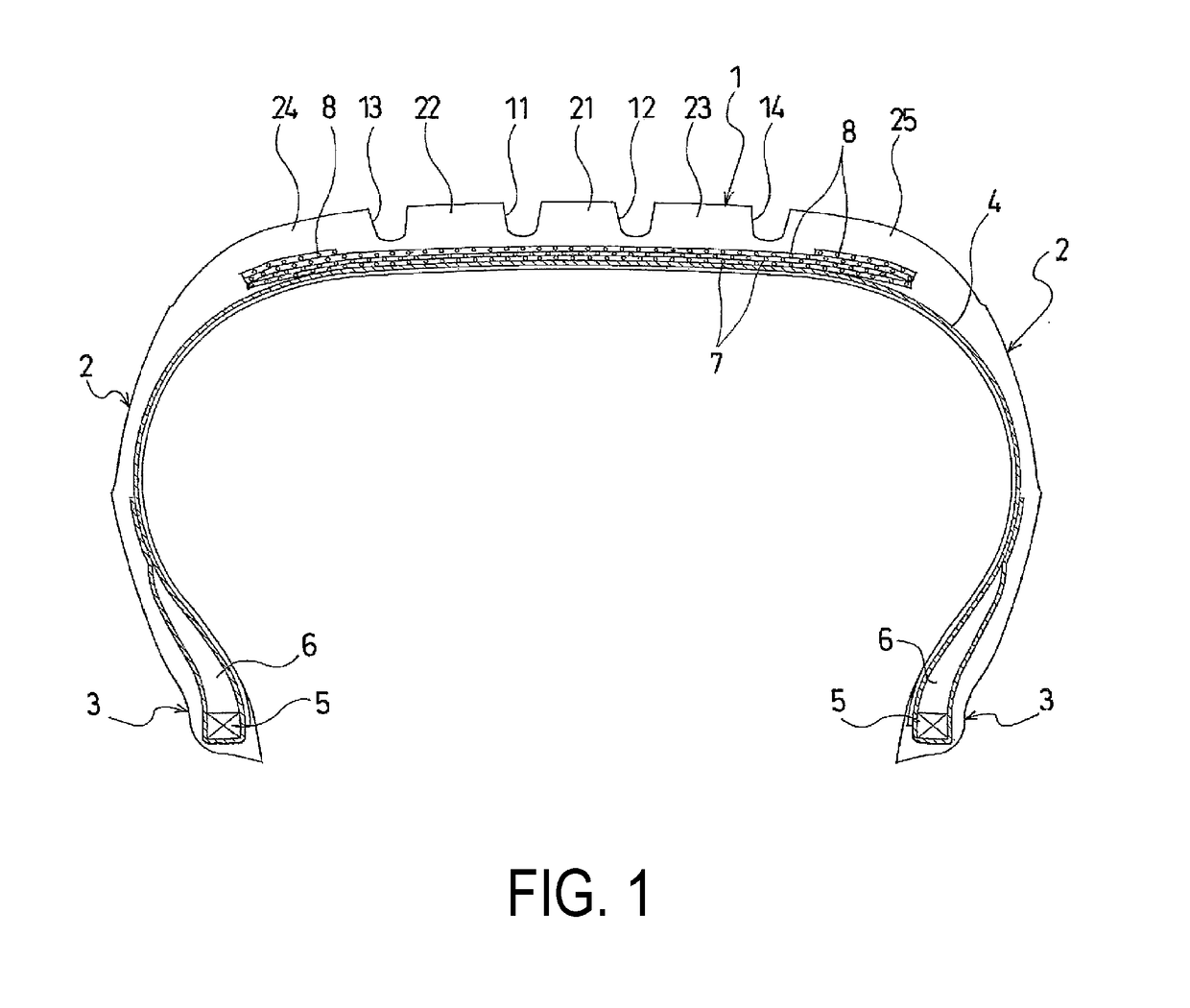

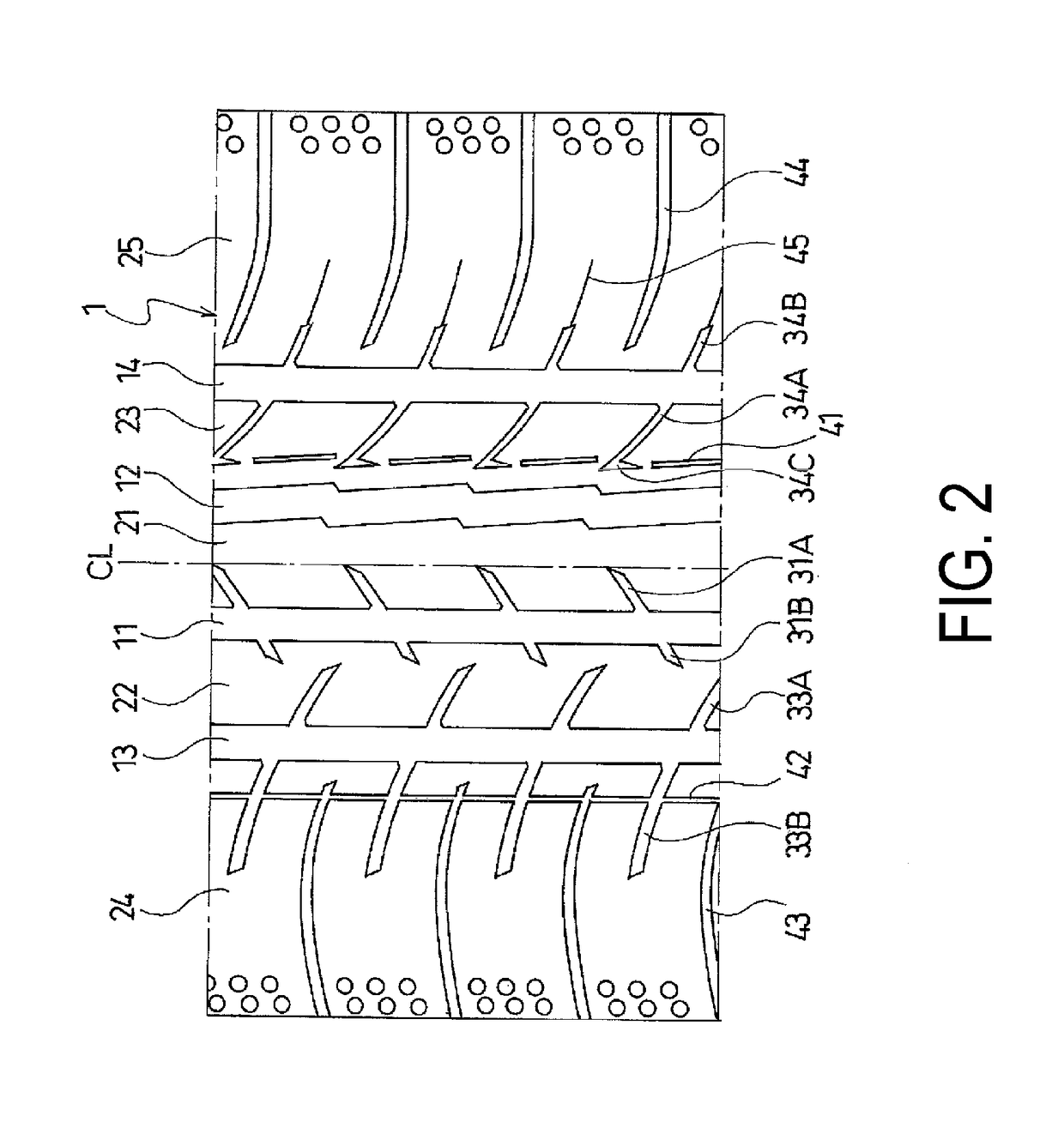

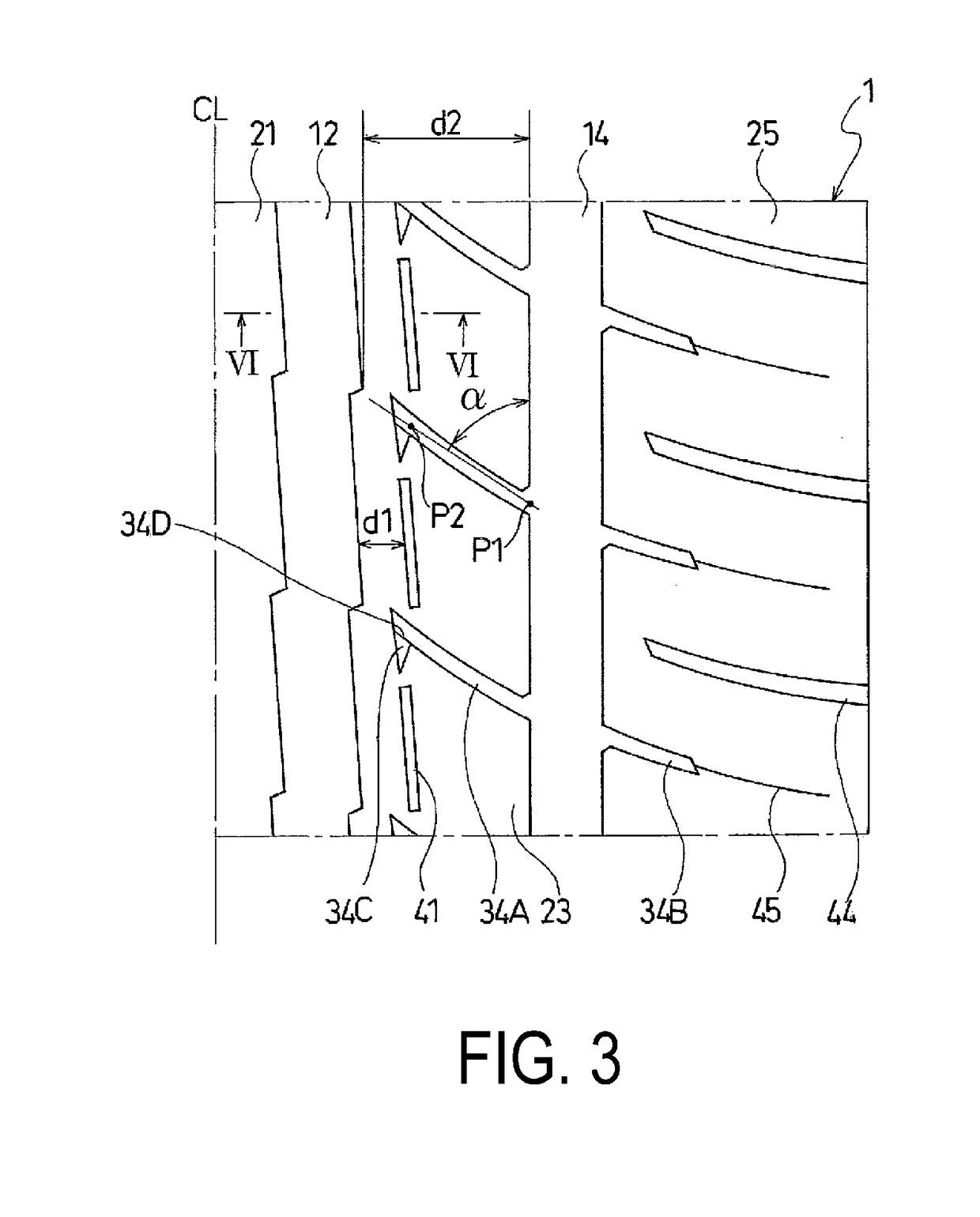

ActiveCN108349329AEnsure driving stabilityGuaranteed rigidityTyre tread bands/patternsEngineeringMechanical engineering

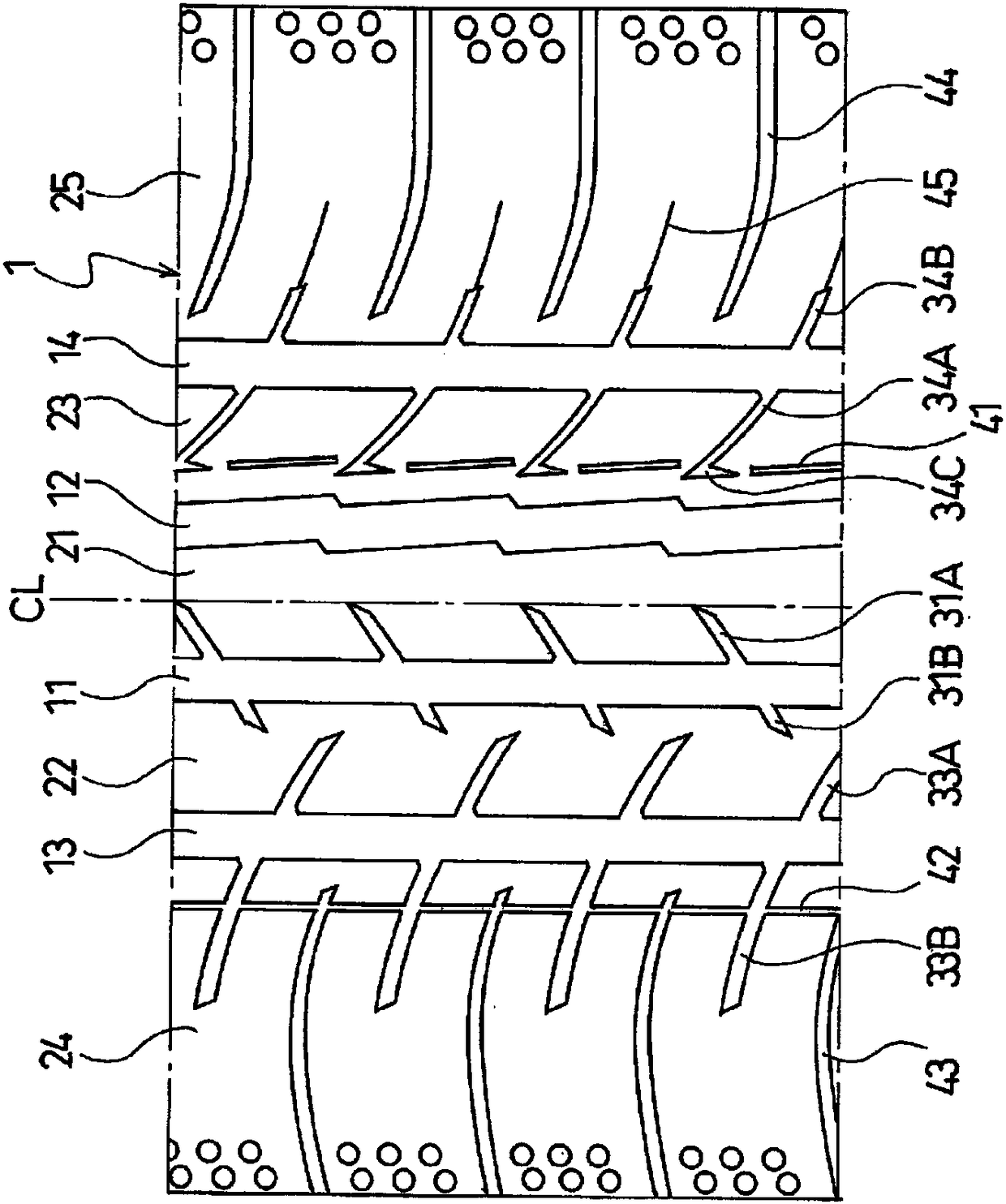

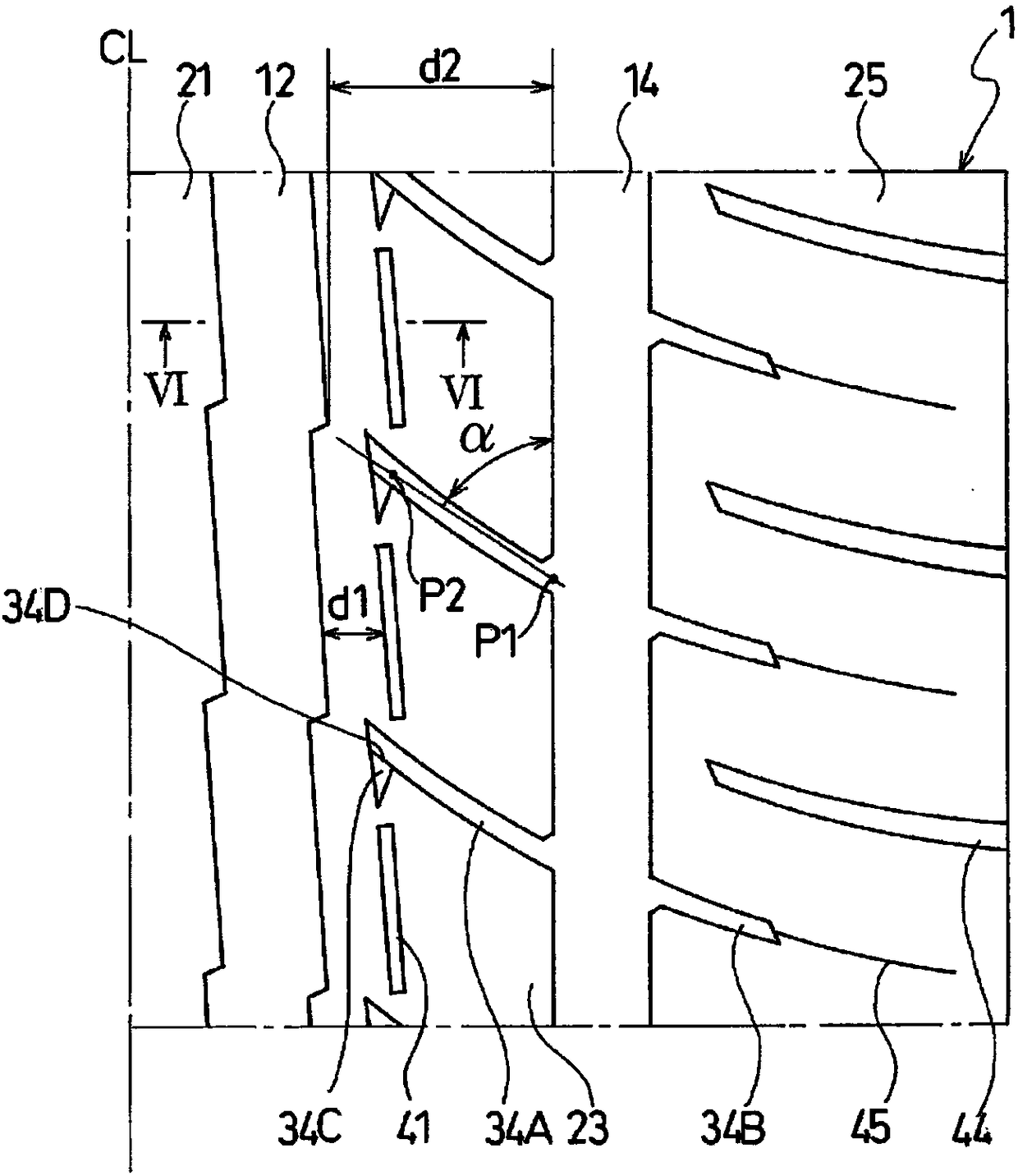

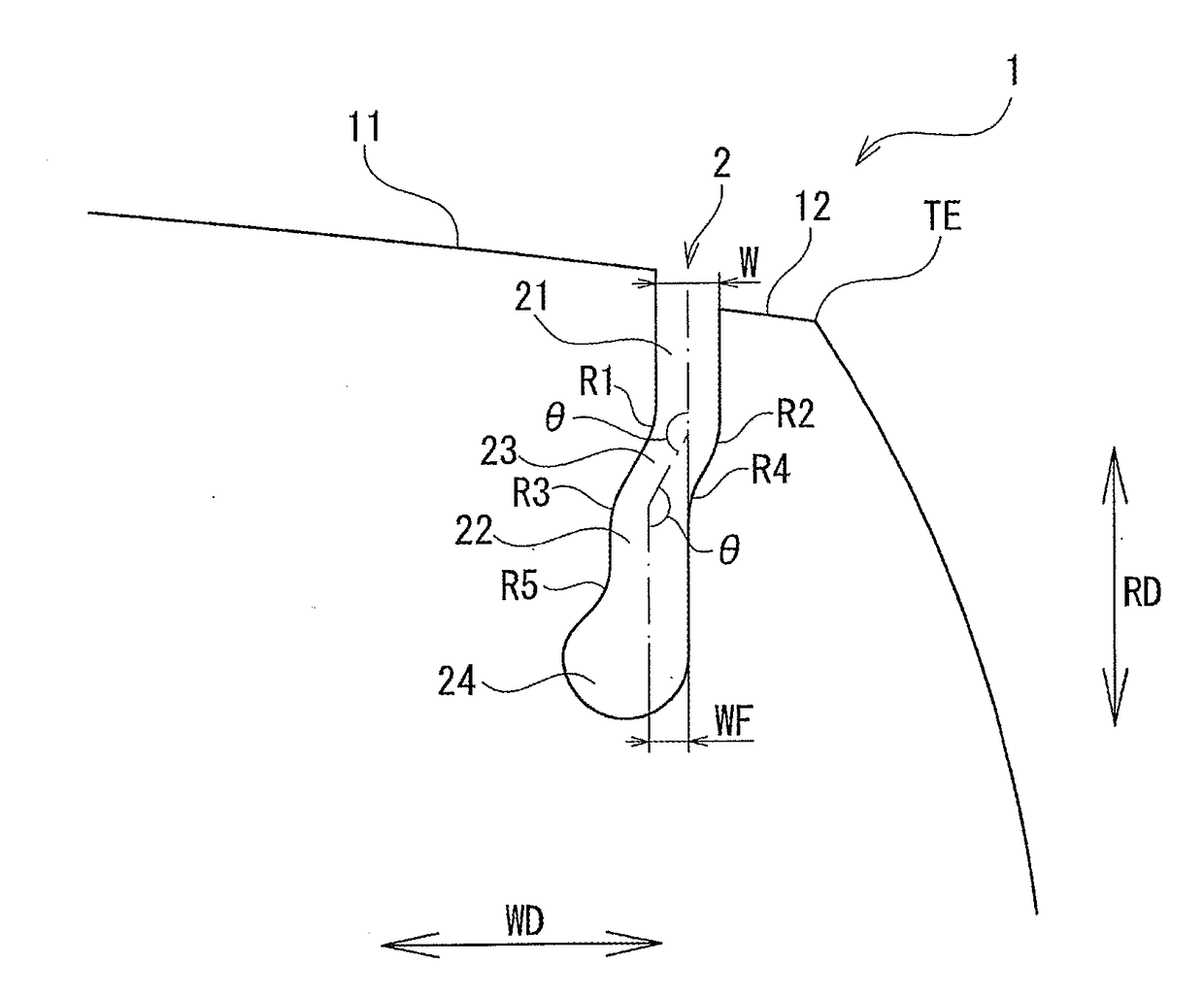

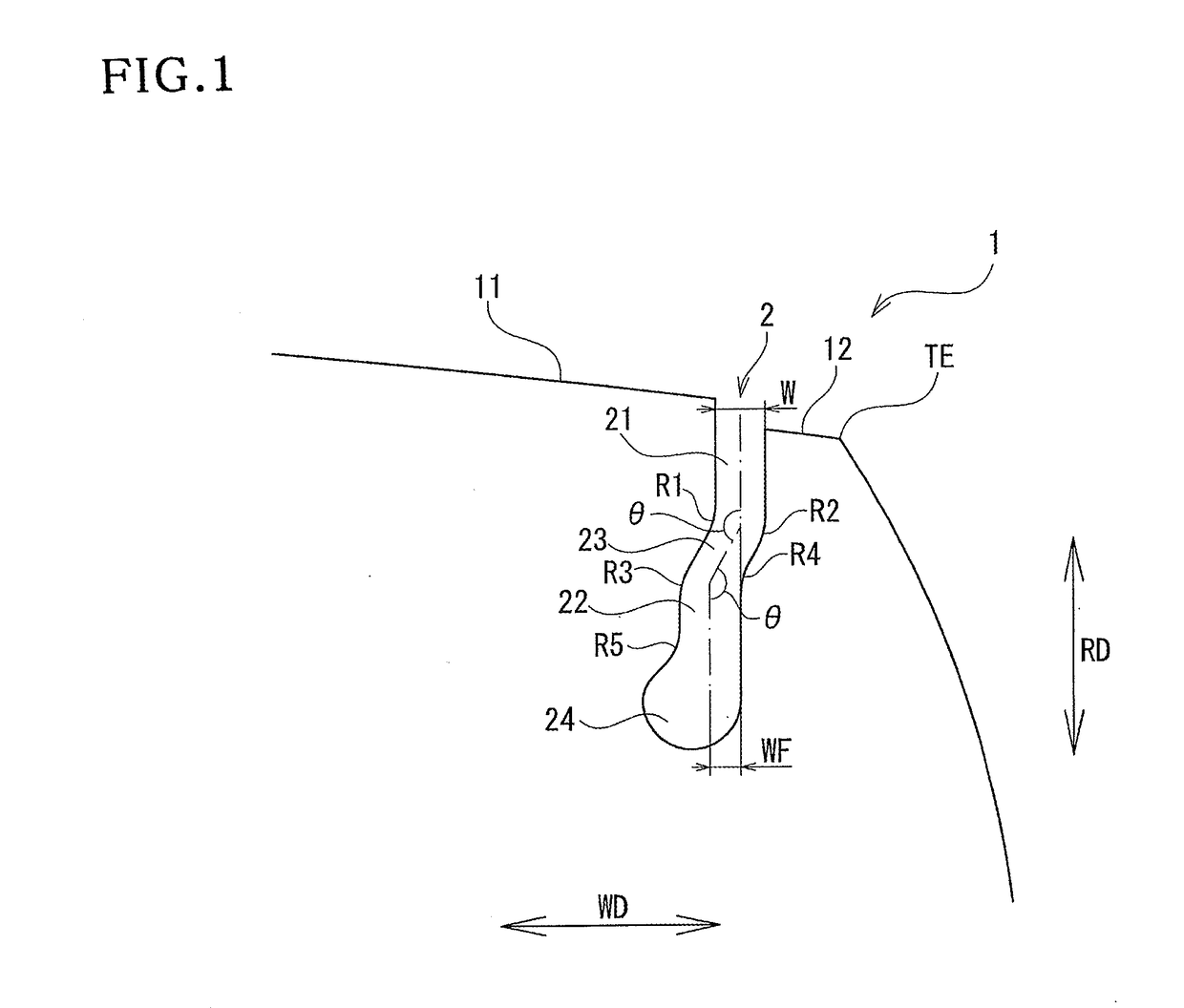

Provided is a pneumatic tire with which uneven wear resistance can be further improved while maneuvering stability on both dry roads and wet roads is achieved. This pneumatic tire is provided with a tread part (1), a side wall part (2), and a bead part (3), wherein the tread part (1) has a center main groove (12) extending in in the tire circumference direction and a shoulder main groove (14) extending in the tire circumference direction on the outer side of the center main groove (12), a land part (23) is sectioned between the center main groove (12) and the shoulder main groove (14), the land part (23) has a plurality of lug grooves (34A) extending inward with respect to the tire width direction from the shoulder main groove (14) and ending without communicating with the center main groove (12), the ending sides of the lug grooves (34A) have curved parts (34C) that curve to one side in the tire circumference direction, and the curved parts (34C) have raised bottom parts (34D) that form level differences with the lug grooves (34A) and that are shallower than the lug grooves (34A).

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

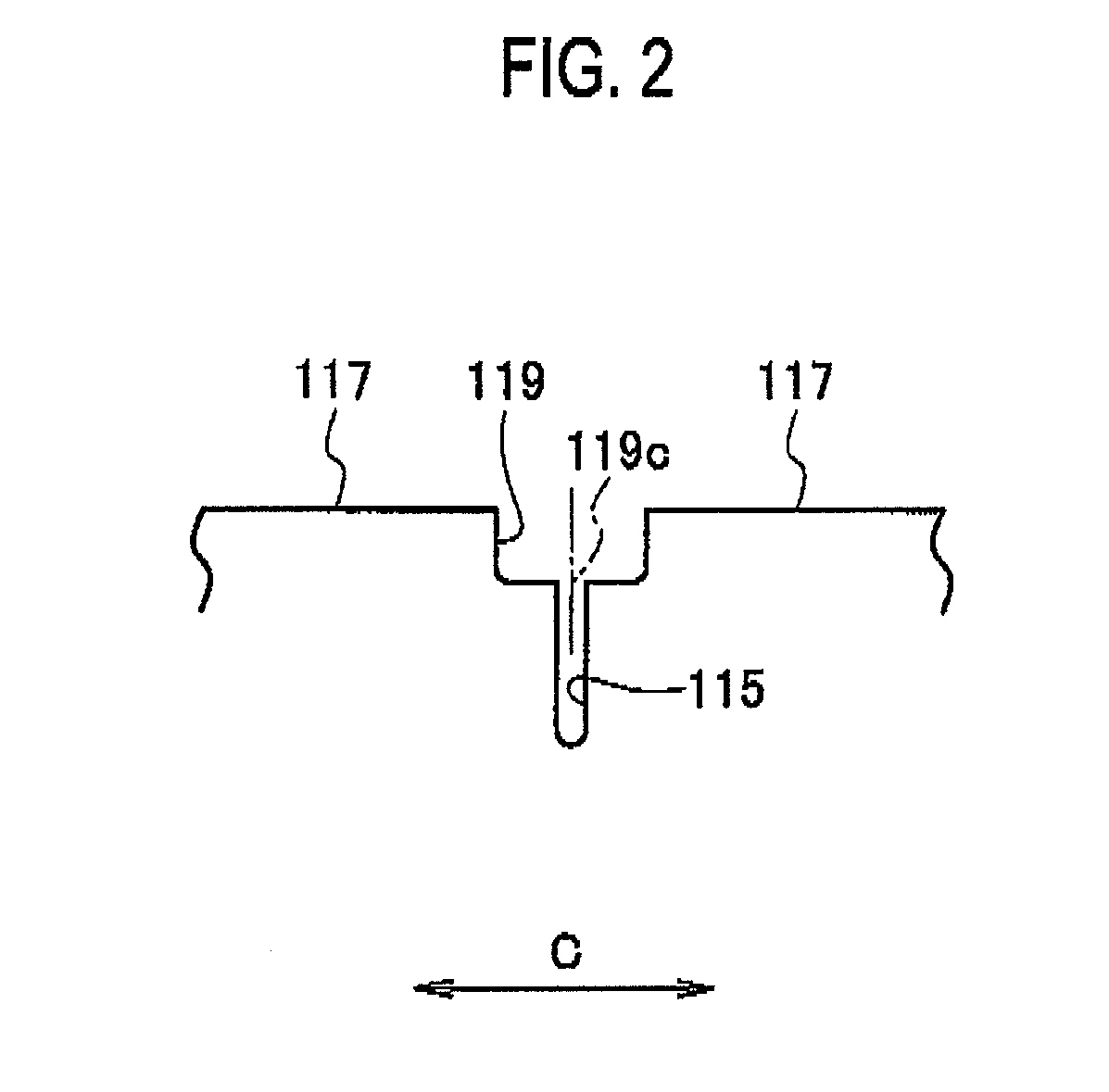

InactiveUS20180134091A1Improve wear resistanceEnhanced inhibitory effectTyre tread bands/patternsCouplingEngineering

A pneumatic tire includes a shoulder land portion and a narrow groove in a tread surface. The narrow groove extends in the tire circumferential direction and sections the shoulder land portion into a main land portion and a sub land portion. A first groove portion extends from the tread surface toward an inner side in the tire radial direction in parallel to the tire equatorial plane. A second groove portion is provided closer to the inner side in the tire radial direction and the tire equatorial plane side than the first groove portion and extends in parallel to the tire equatorial plane. A coupling portion is connected to an end portion of the first groove portion in the inner side in the tire radial direction and an end portion of the second groove portion in the tread surface side.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic Tire

ActiveUS20190030957A1Ensuring steering stabilityImprove steering stabilityTyre tread bands/patternsEngineeringMechanical engineering

A pneumatic tire is provided, the pneumatic tire including a tread portion, sidewall portions, and bead portions, and the pneumatic tire includes, in the tread portion, a center main groove extending in a tire circumferential direction and a shoulder main groove extending in the tire circumferential direction on the outside of the center main groove; a land portion between the main grooves; lug grooves extending inward in a tire lateral direction from the shoulder main groove and terminating without communicating with the center main groove; a bent portion bending toward one side in the tire circumferential direction, at a terminating end of each of the lug grooves; and a raised bottom portion included in the bent portion, creating a level difference with respect to a lug groove, and being shallower than the lug groove.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS20170106700A1Improve uneven wear resistanceUneven wear resistanceHeavy duty tyresHeavy duty vehicleMechanical engineeringTread

A pneumatic tire comprises a tread portion provided with crown main grooves, center axial grooves and center blocks including a siped center block with a first sipe. The siped center block has a pair of substantially v-shaped opposite first and second block side walls each having an outwardly protruding vertex. The first sipe has a wavy configuration at least partially. One end of the first sipe is positioned on one side in the tire circumferential direction of the vertex of the first block side wall, whereas the other end of the first sipe is positioned on other side in the tire circumferential direction of the vertex of the second block side wall.

Owner:SUMITOMO RUBBER IND LTD

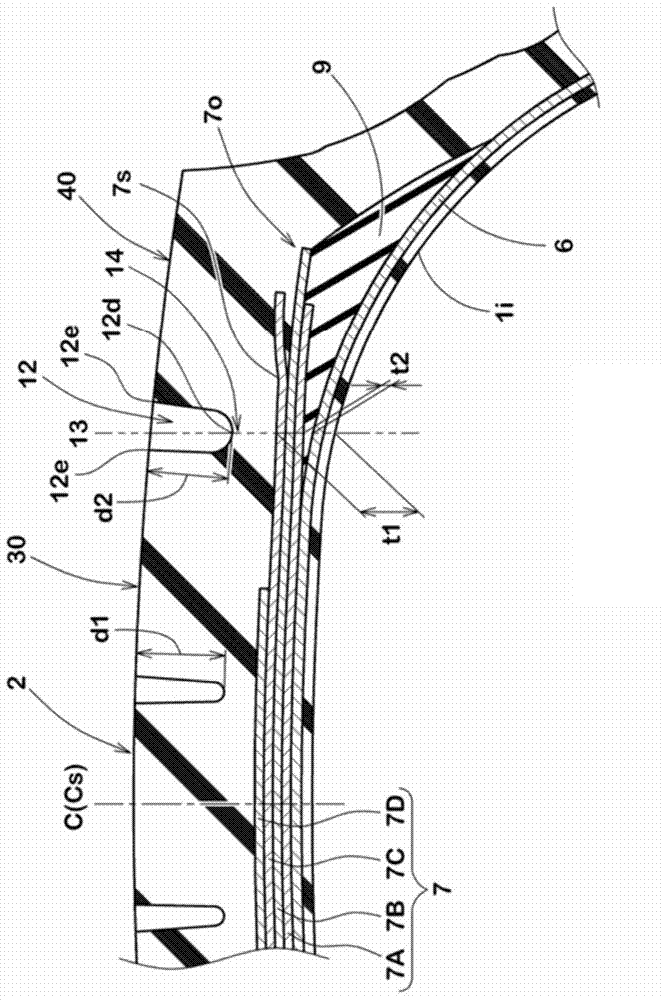

Heavy duty tire

InactiveCN104723798ACurb bendingInhibits uneven wearHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

Heavy duty tire, wherein a distance t1 from the radially outer surface of a belt layer (7) to the tire's inner surface is 15 to 23 mm when measured along a tire radial direction line (13) passing through the bottom of a shoulder main groove (12); the width of the shoulder main groove (12) is more than the width of a center main groove (11); the ratio Wc: Wm: Ws of the average width Wc of a center land portion (20), the average width wm of a middle land portion (30), and the average width Ws of a shoulder land portion (40) is 1.00 : 1.00 to 1.08: 1.03 to 1.13; the middle land portion (30) is provided with a plurality of middle axial grooves (31); the shoulder land portion (40) is provided with a plurality of shoulder axial grooves (41); the width of the shoulder axial groove (41) is more than the width of the middle axial groove (31); the angle ¸s of the shoulder axial groove (41) is more than the angle ¸m of the middle axial groove (31) with respect to the tire axial direction.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS9290056B2Reduce variationReduce load capacityHeavy duty tyresHeavy duty vehicleElectrical and Electronics engineeringEngineering

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com