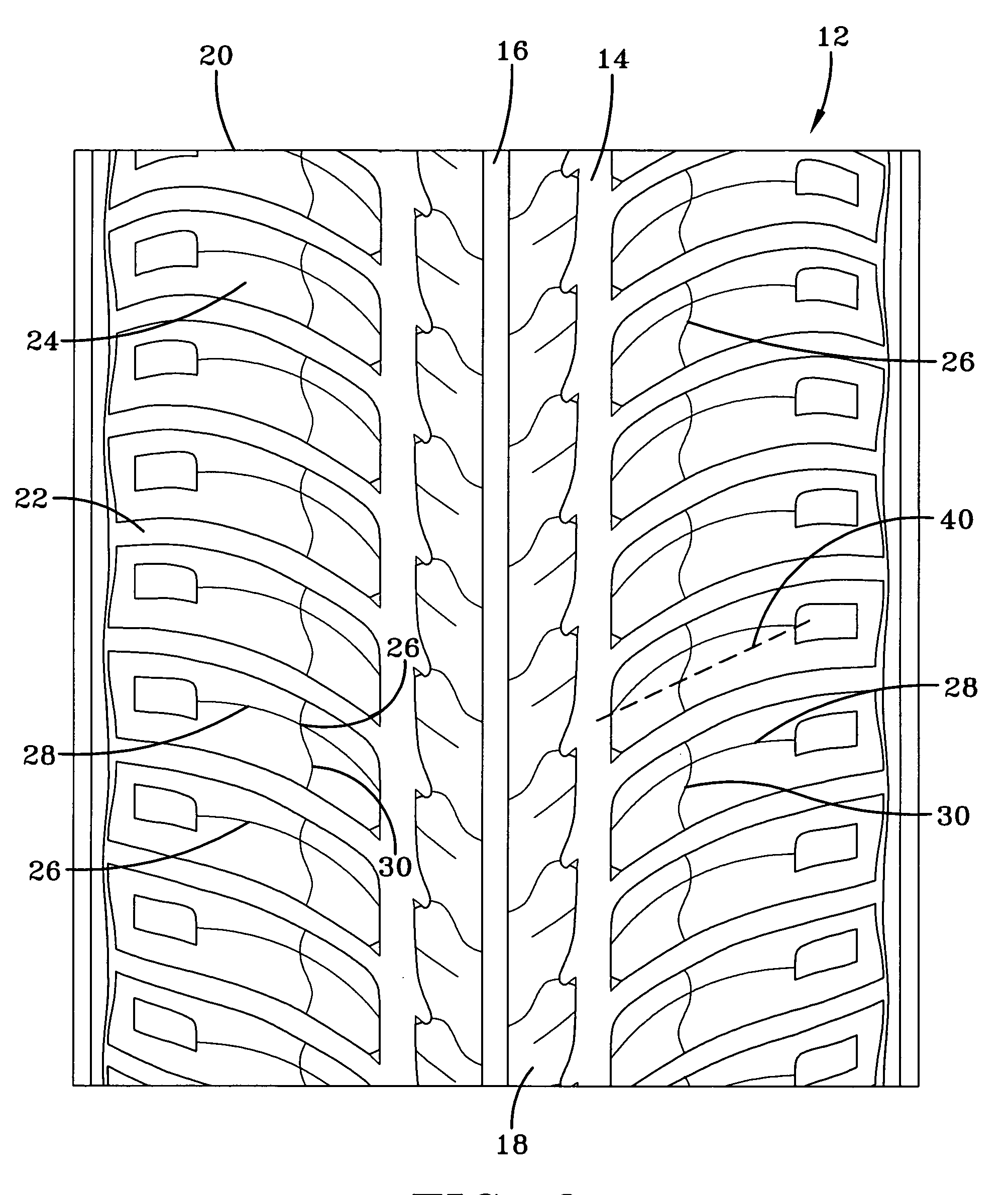

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Improve tire performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

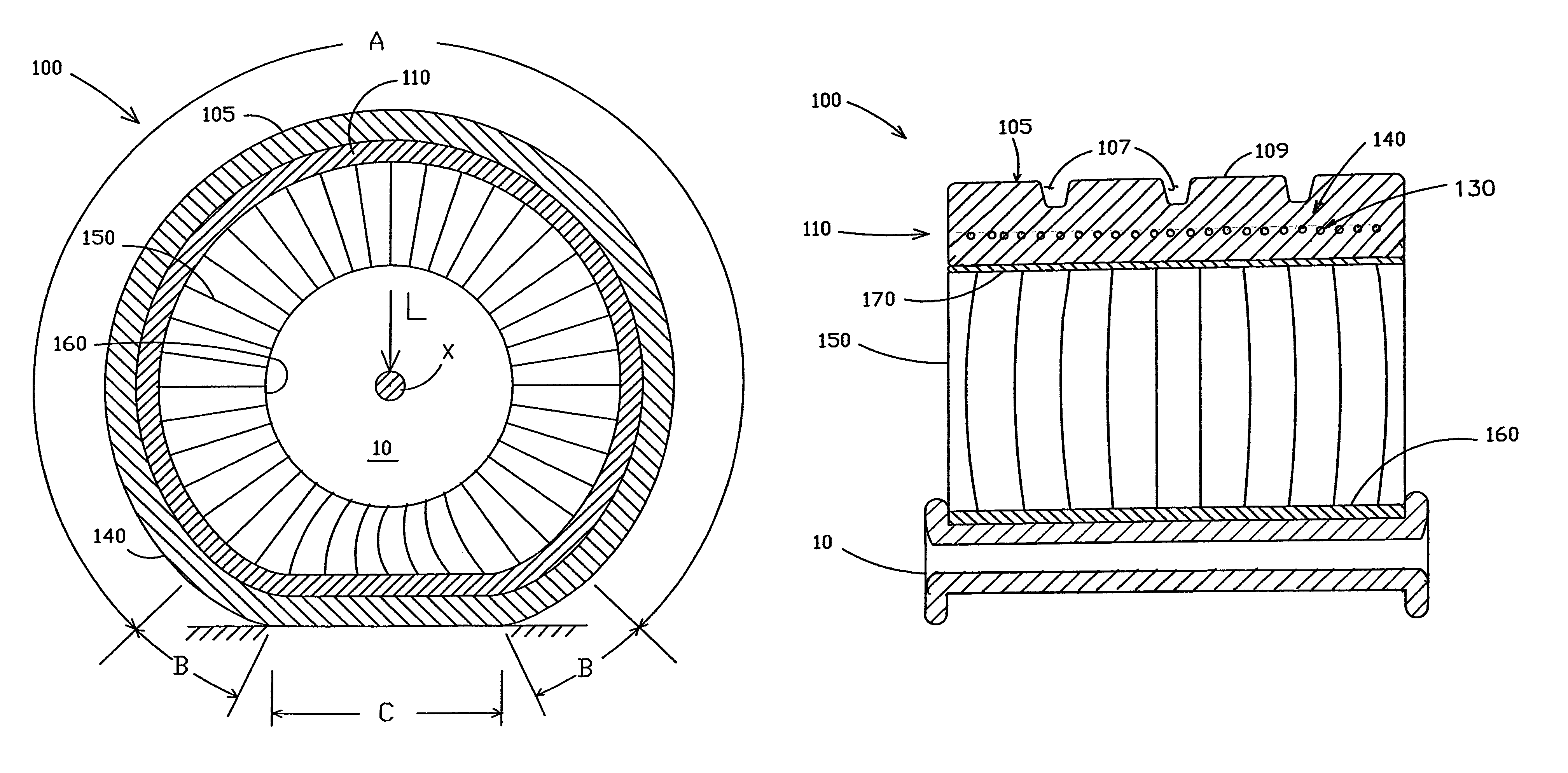

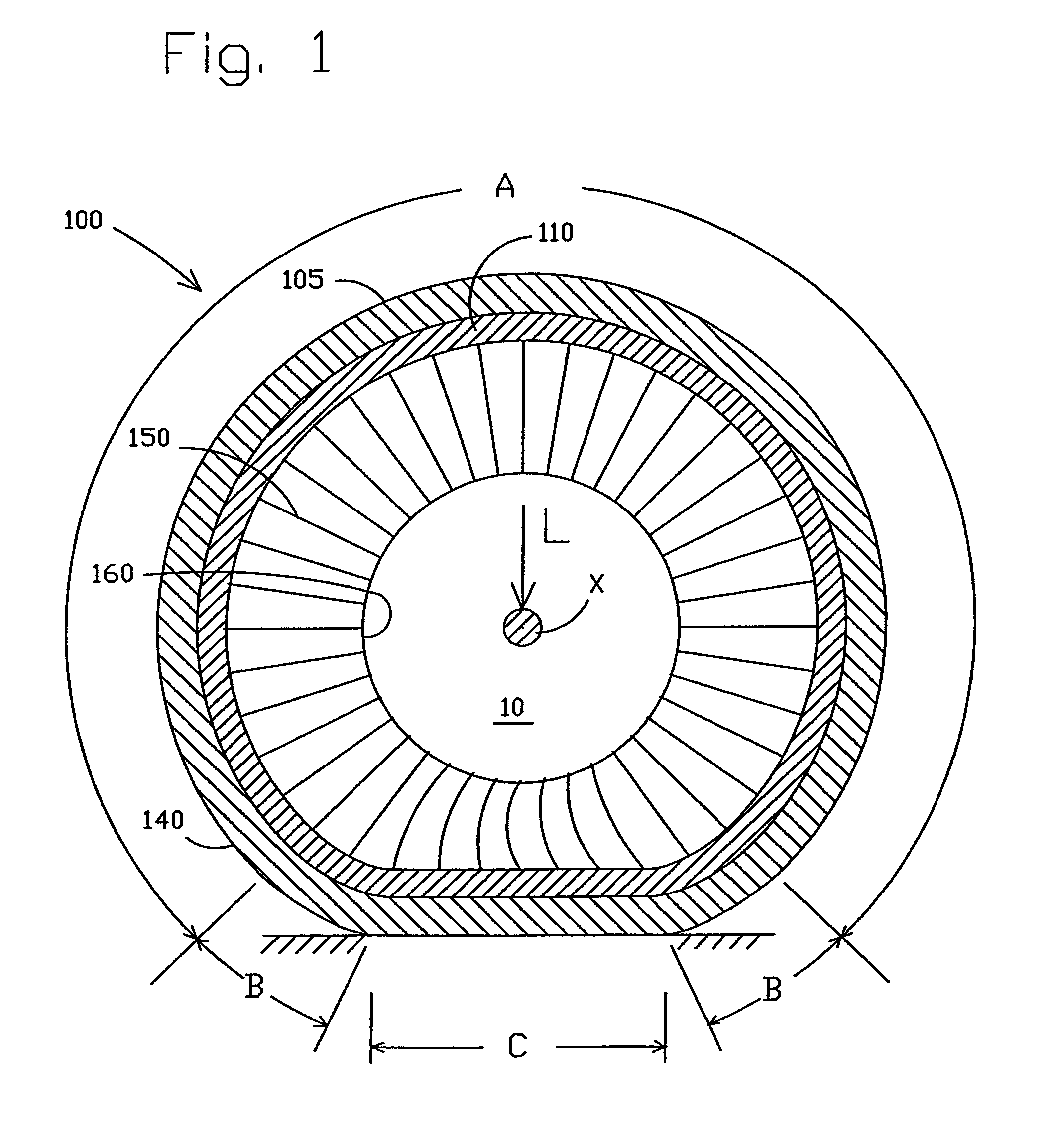

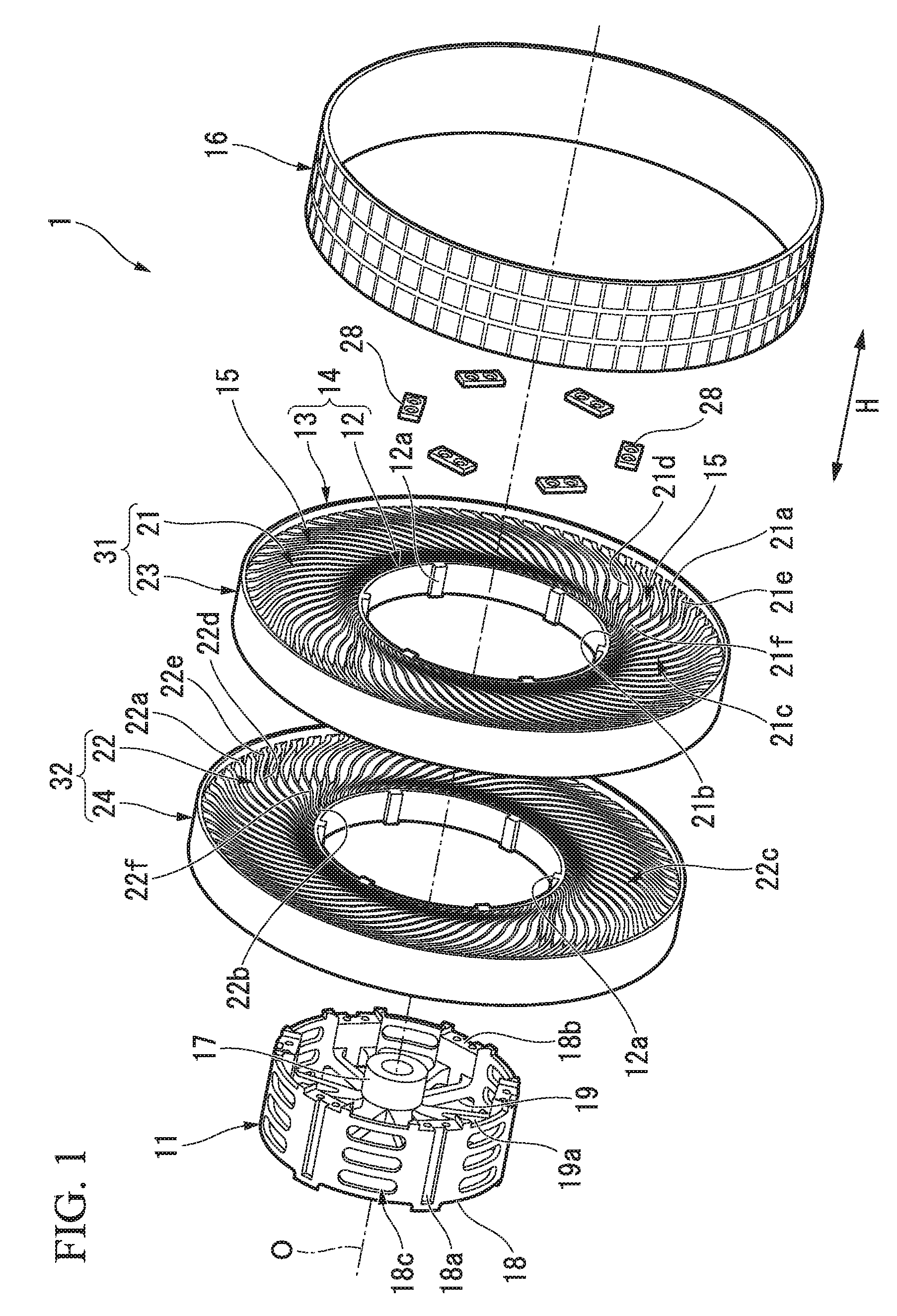

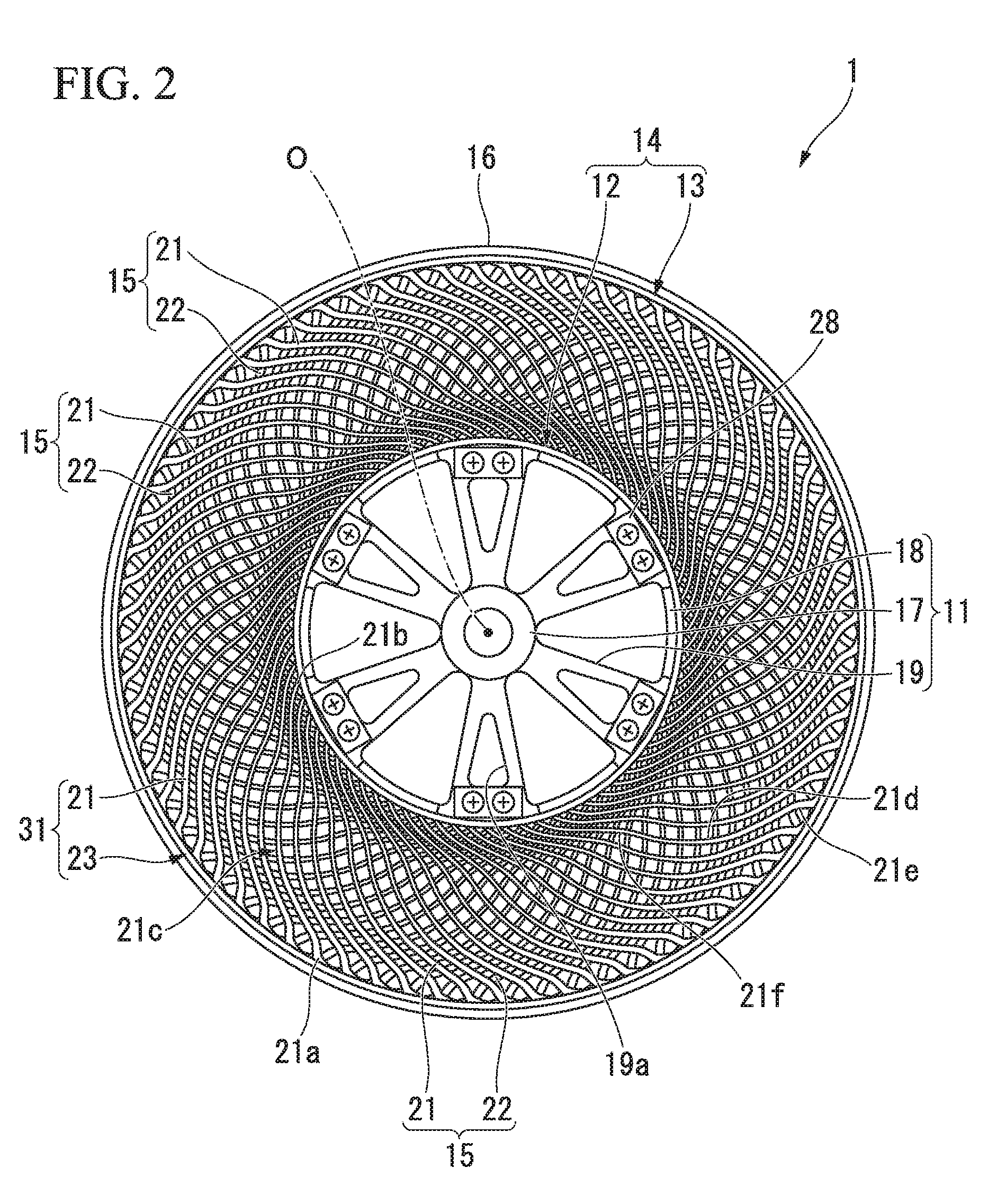

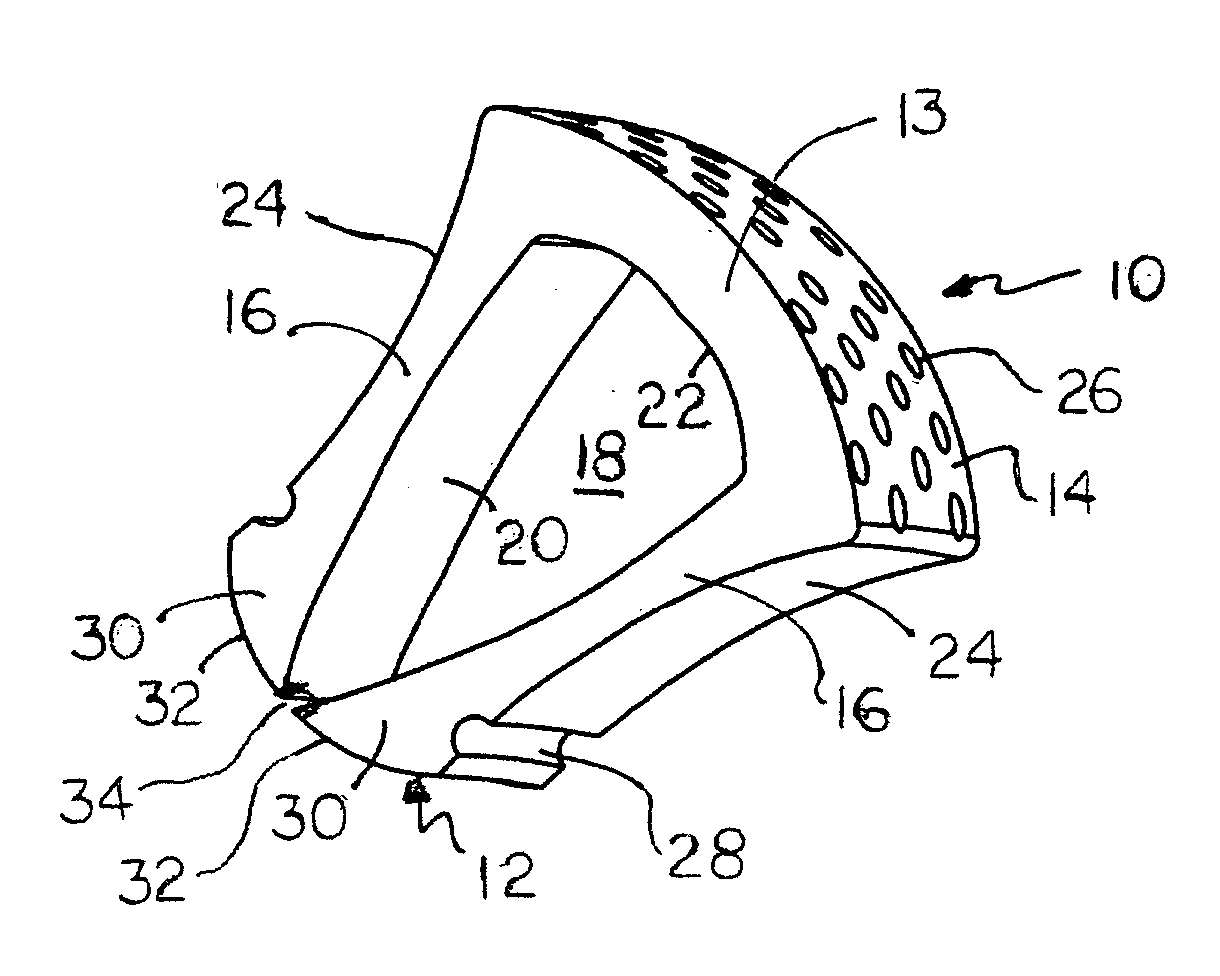

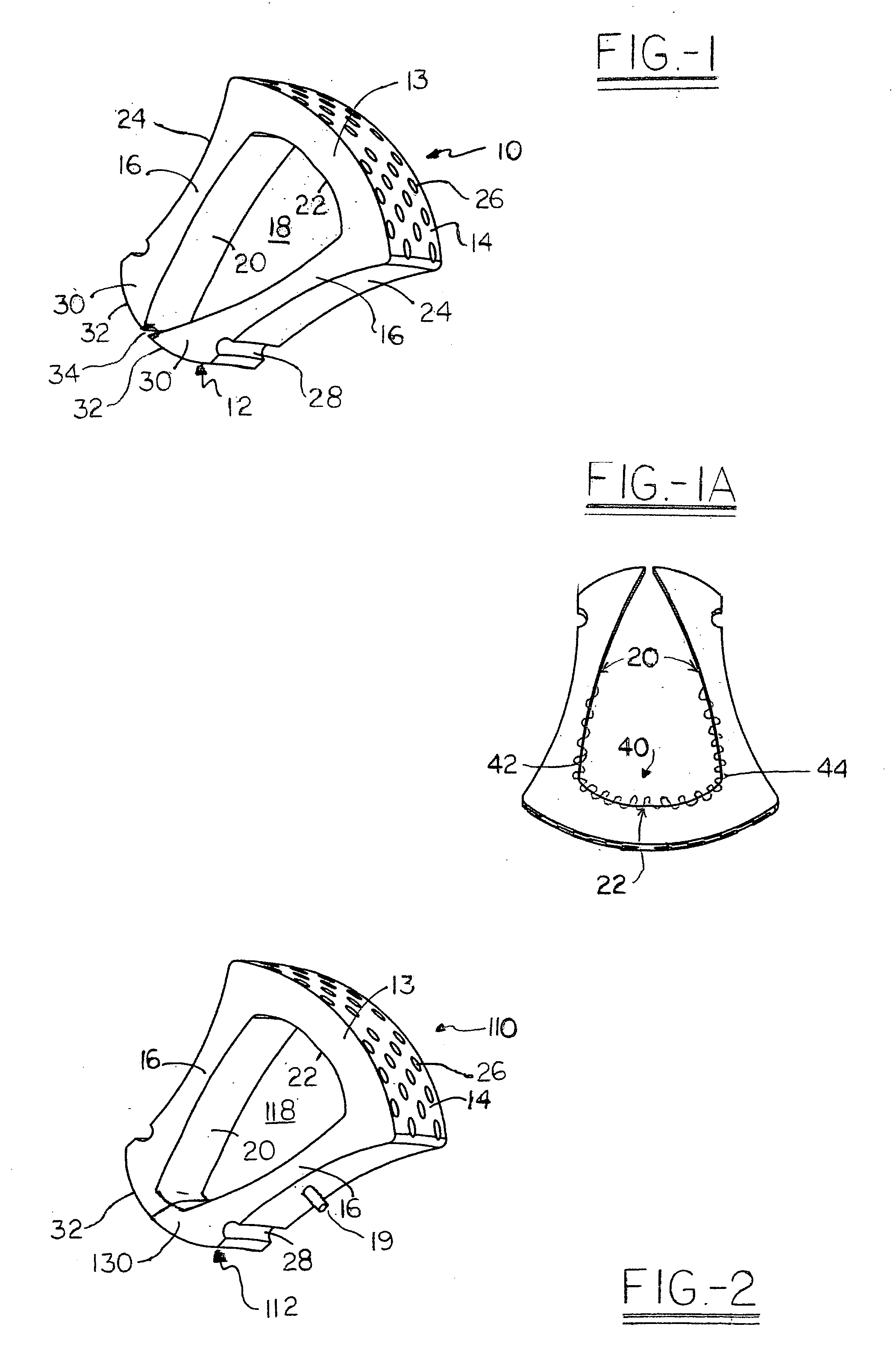

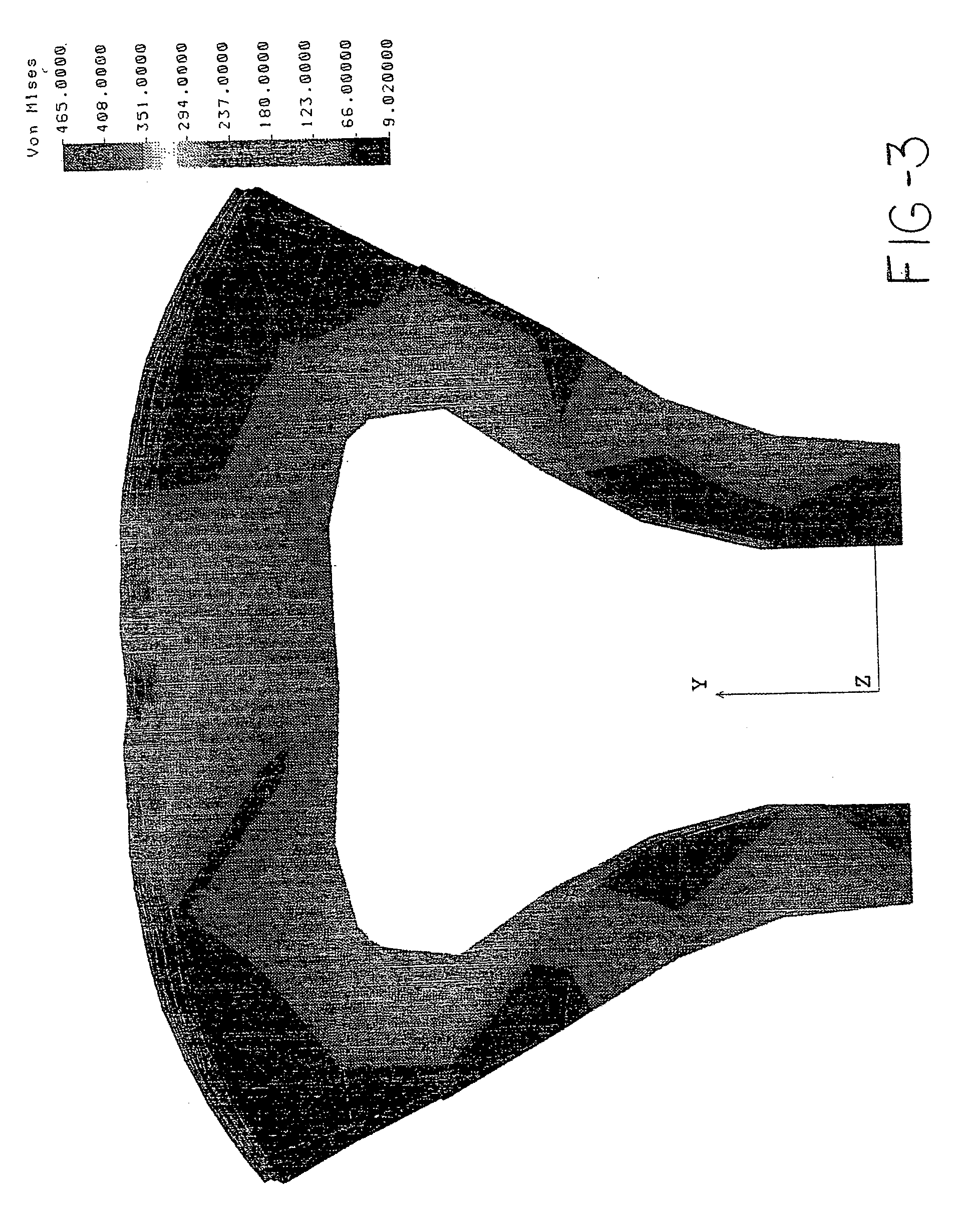

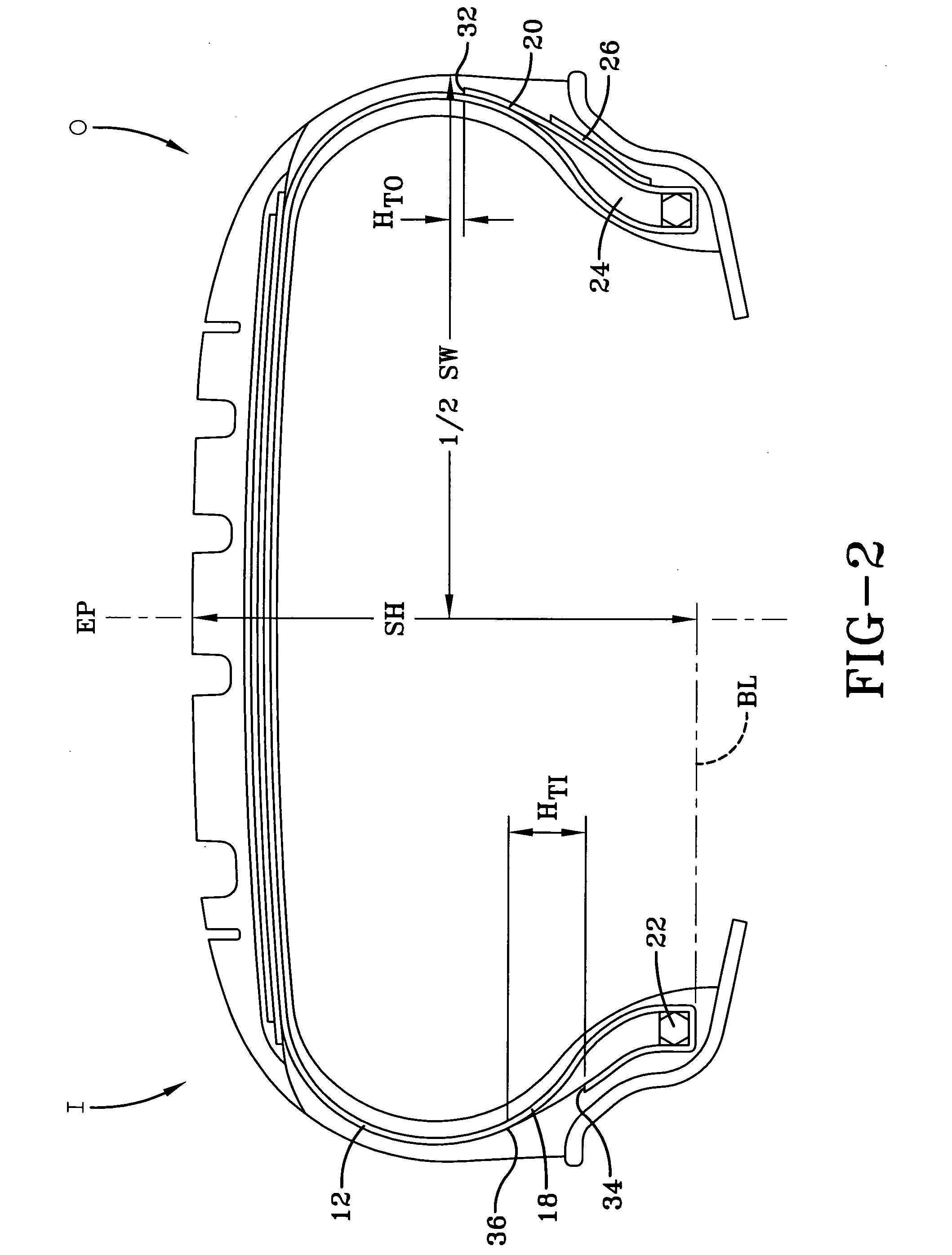

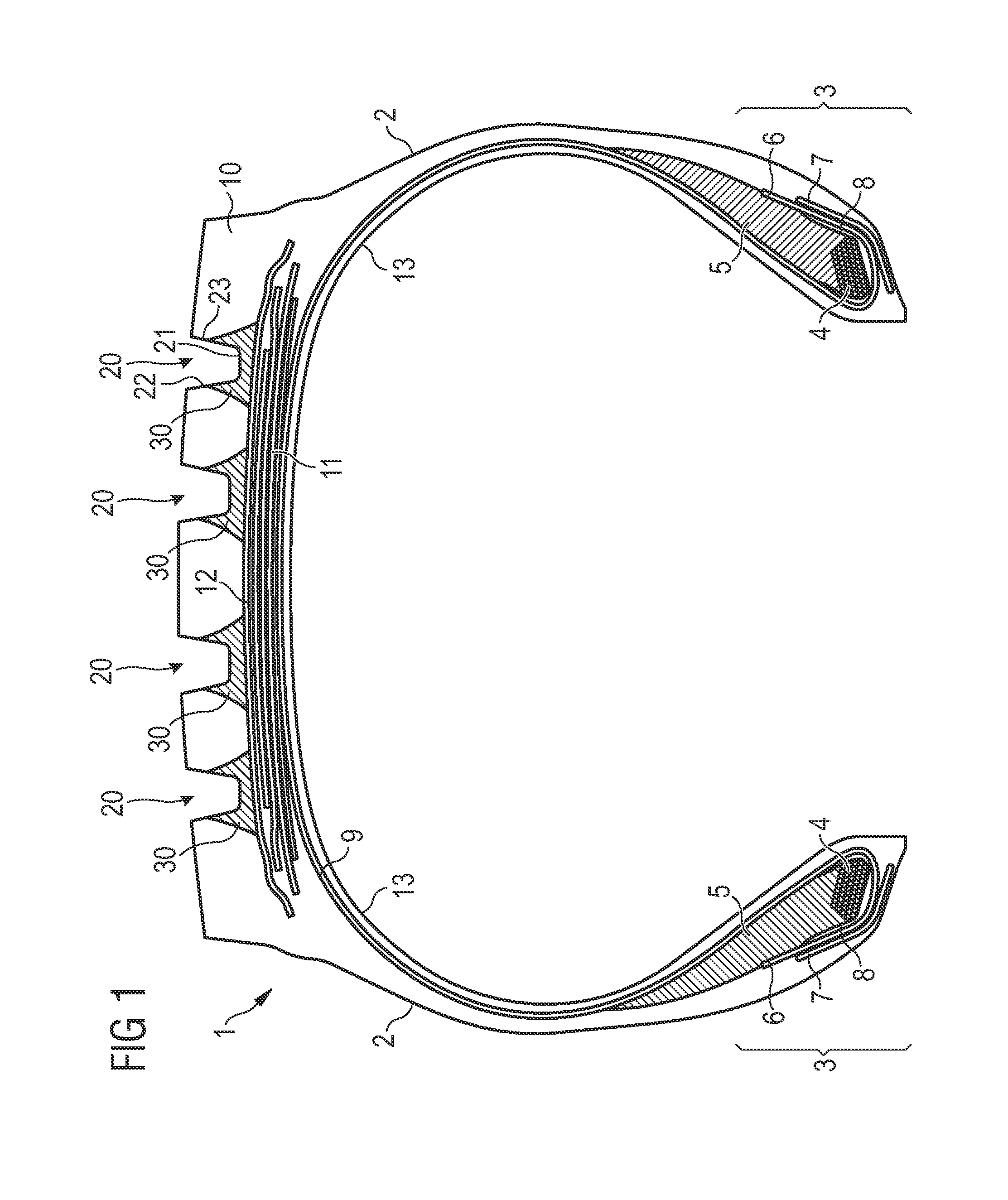

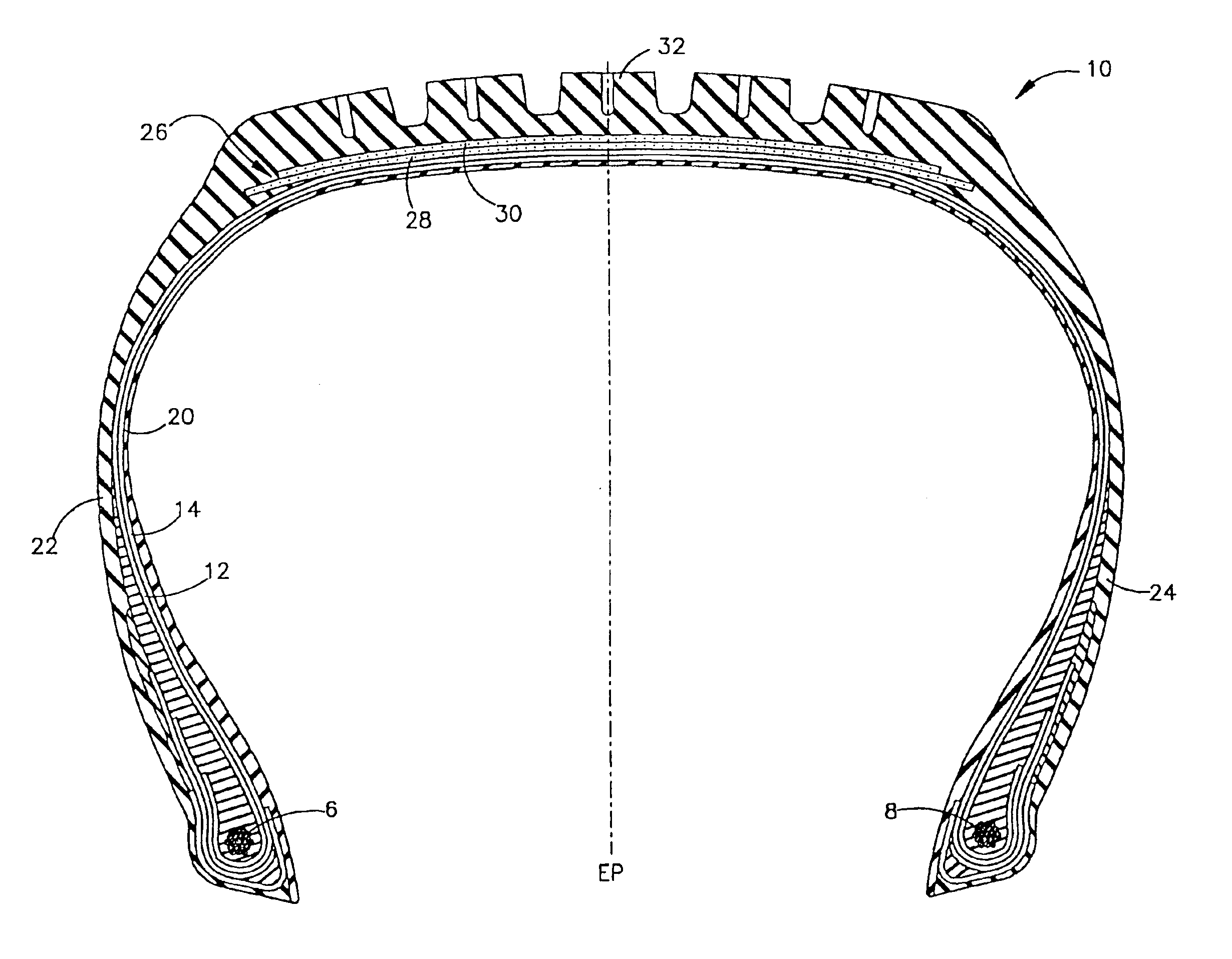

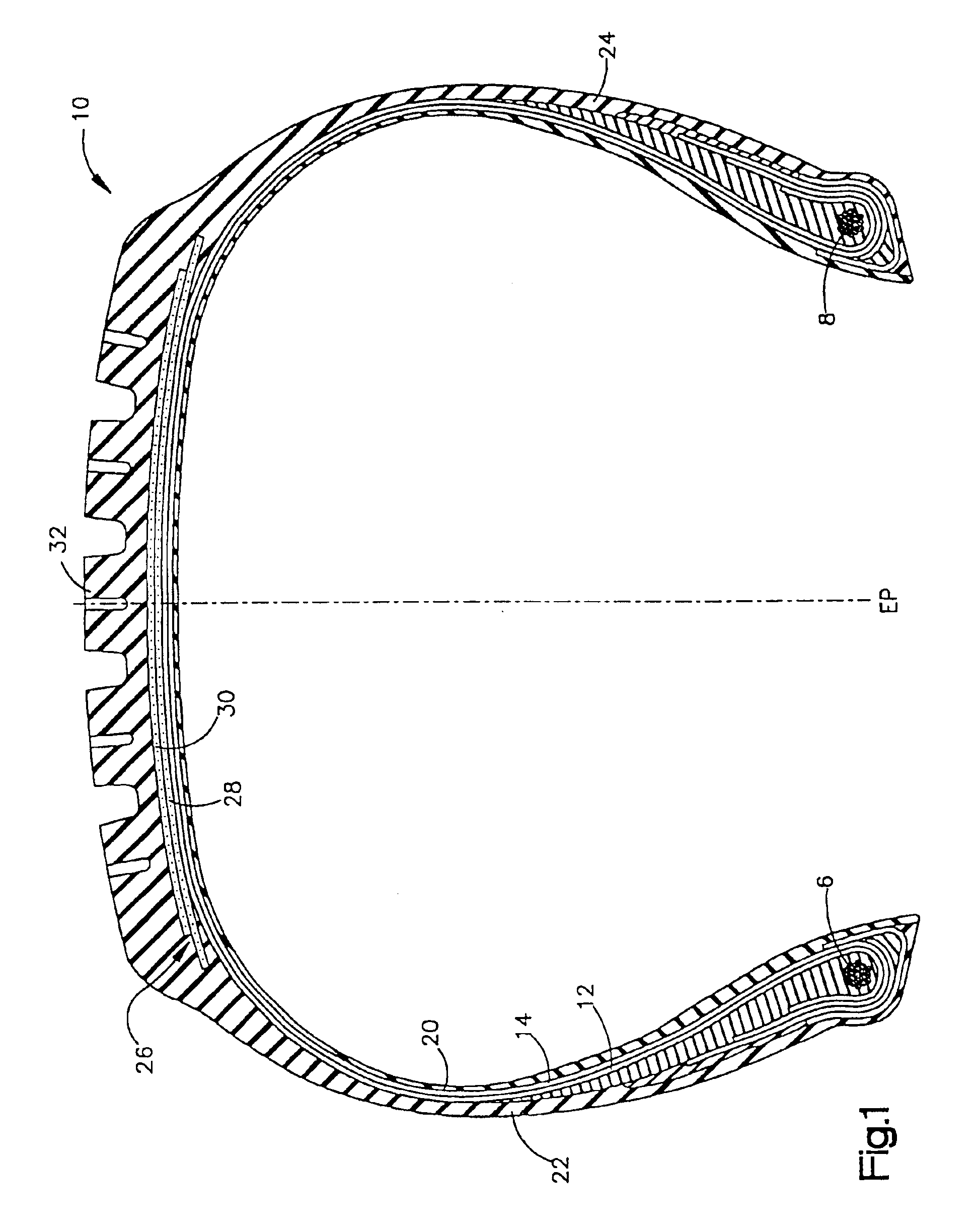

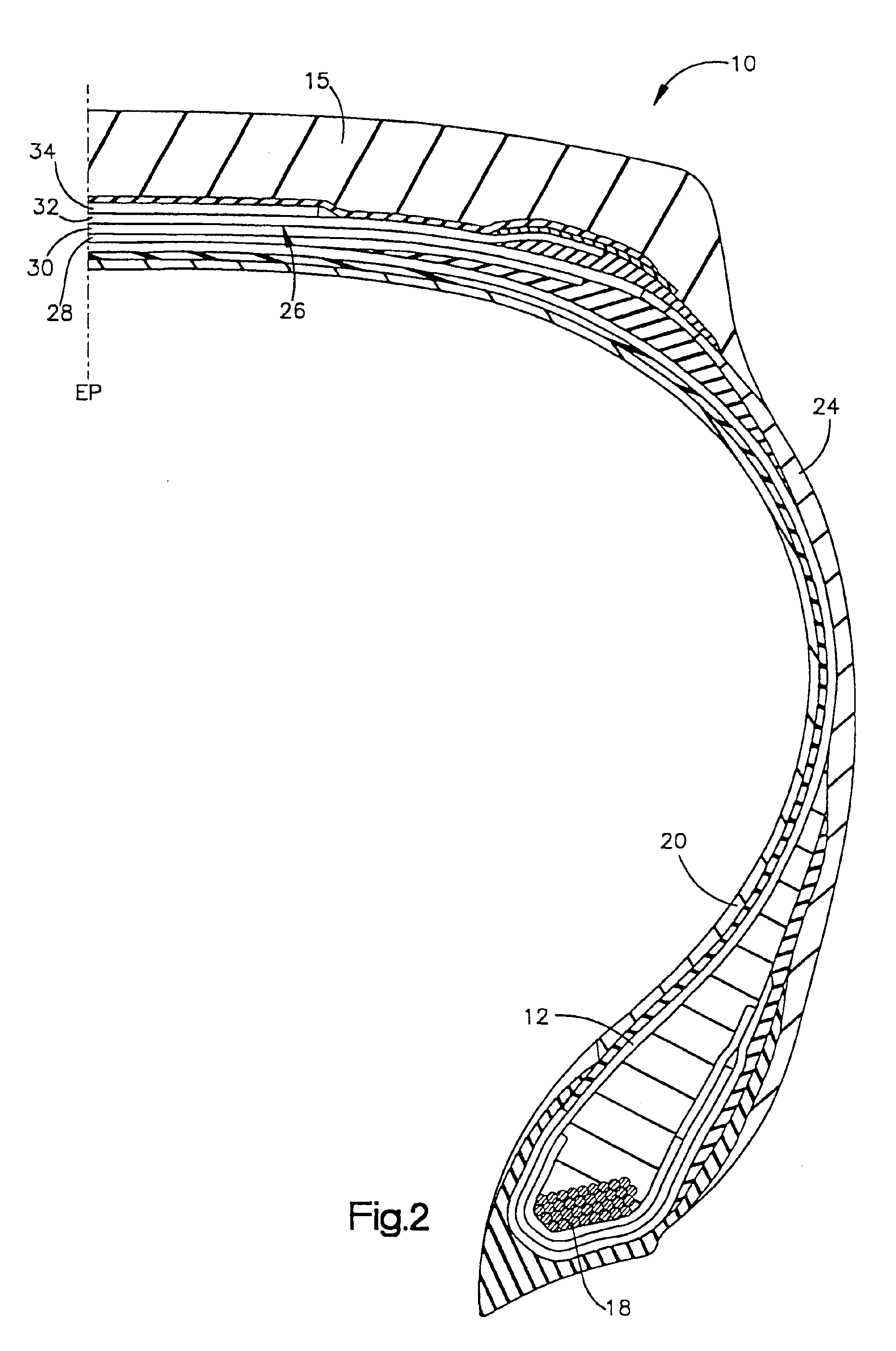

Compliant wheel

InactiveUS7013939B2High effective stiffness in tensionLow effective stiffness in compressionNon-inflatable tyresWheel manufactureBand bendingGround contact

A compliant wheel includes a compliant band and a plurality of web spokes extending transversely across and inward from the reinforced compliant band for attachment to a hub. The compliant band bends to comply with a contact surface and to envelope obstacles. The web spokes transmit load forces between the compliant band and the hub through tension in the web spokes not connected to the ground contacting portion of the wheel. The outer surface of the compliant band may be formed to include a tread, or a separate tread band may be attached.

Owner:MICHELIN RECH & TECH SA

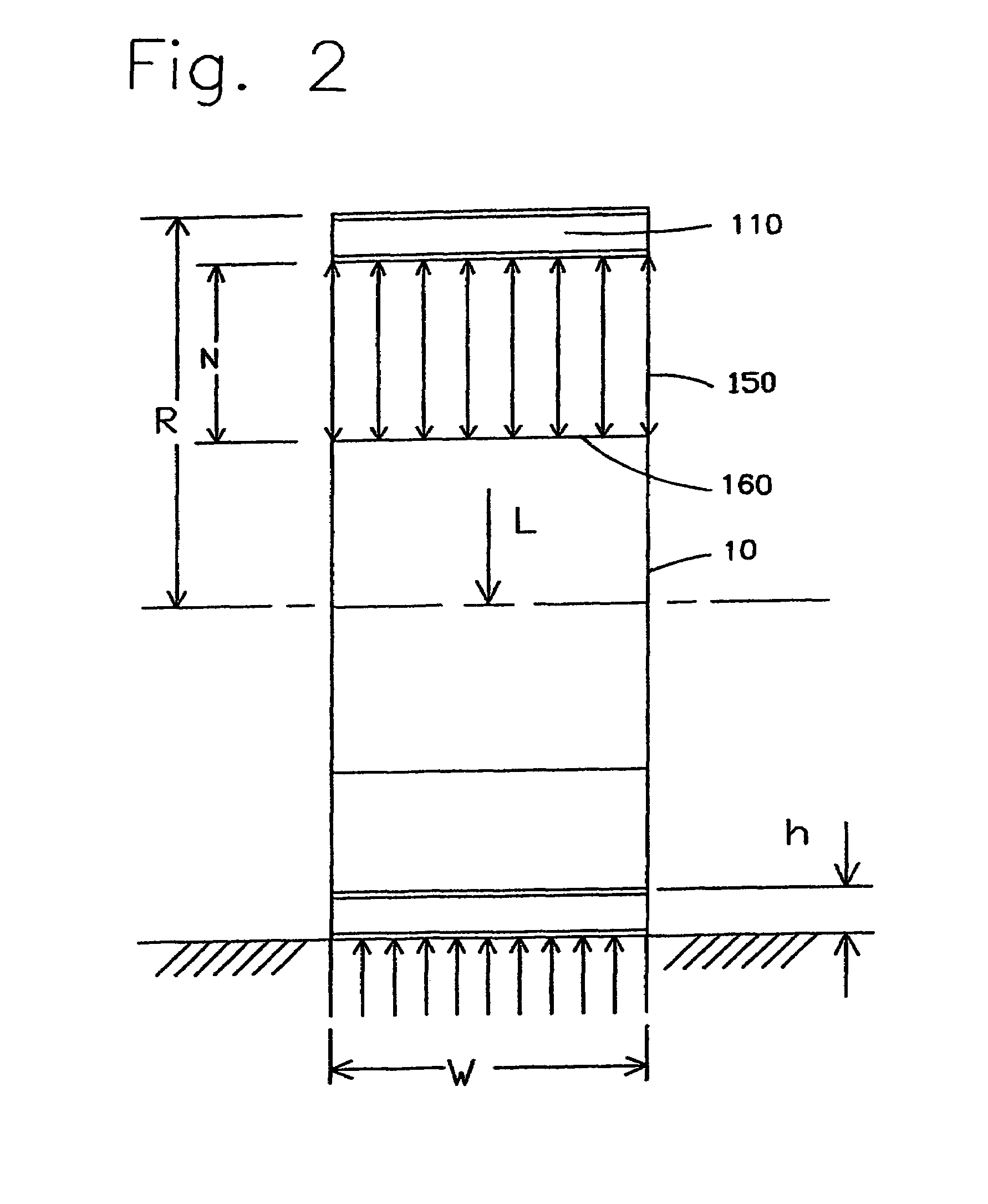

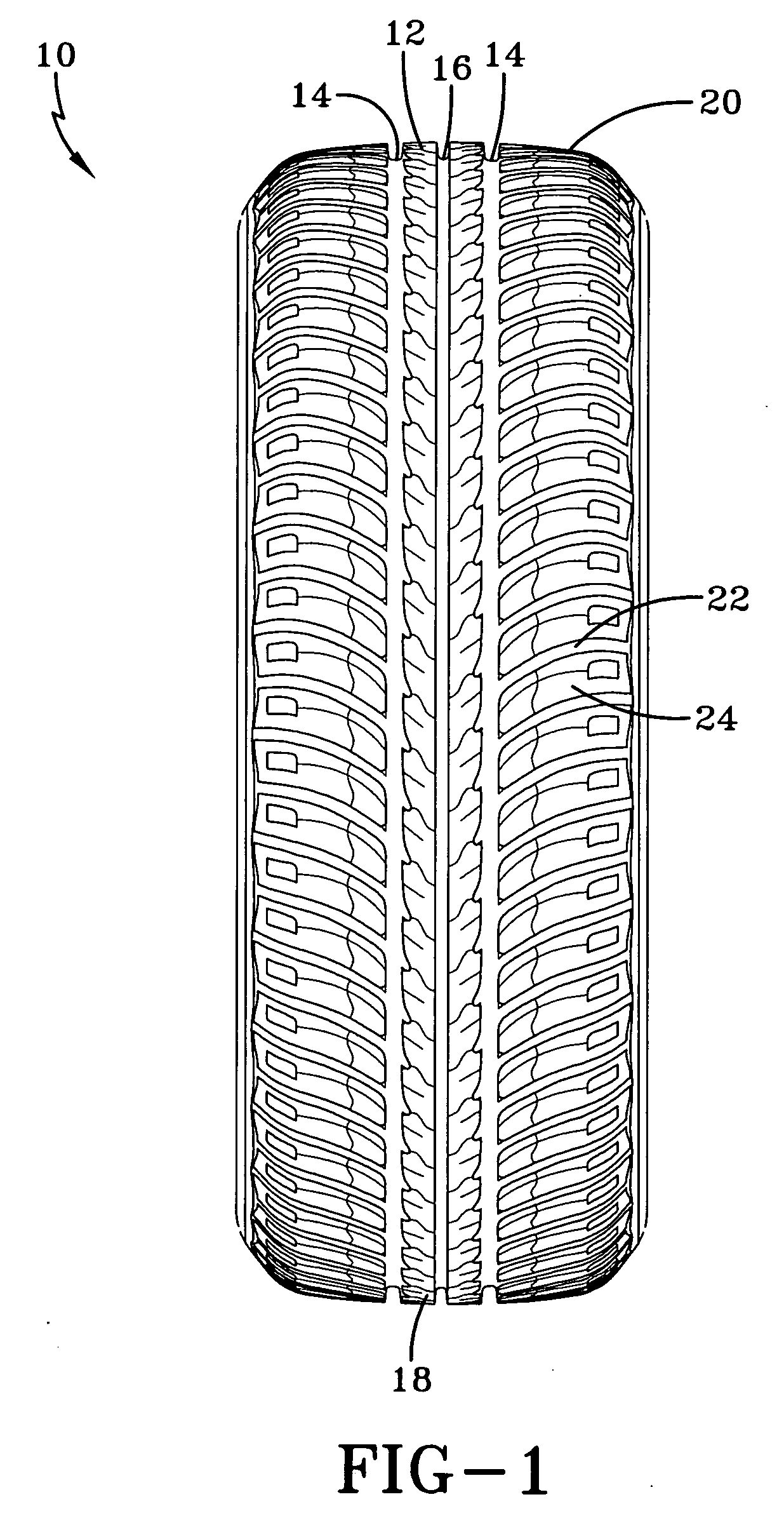

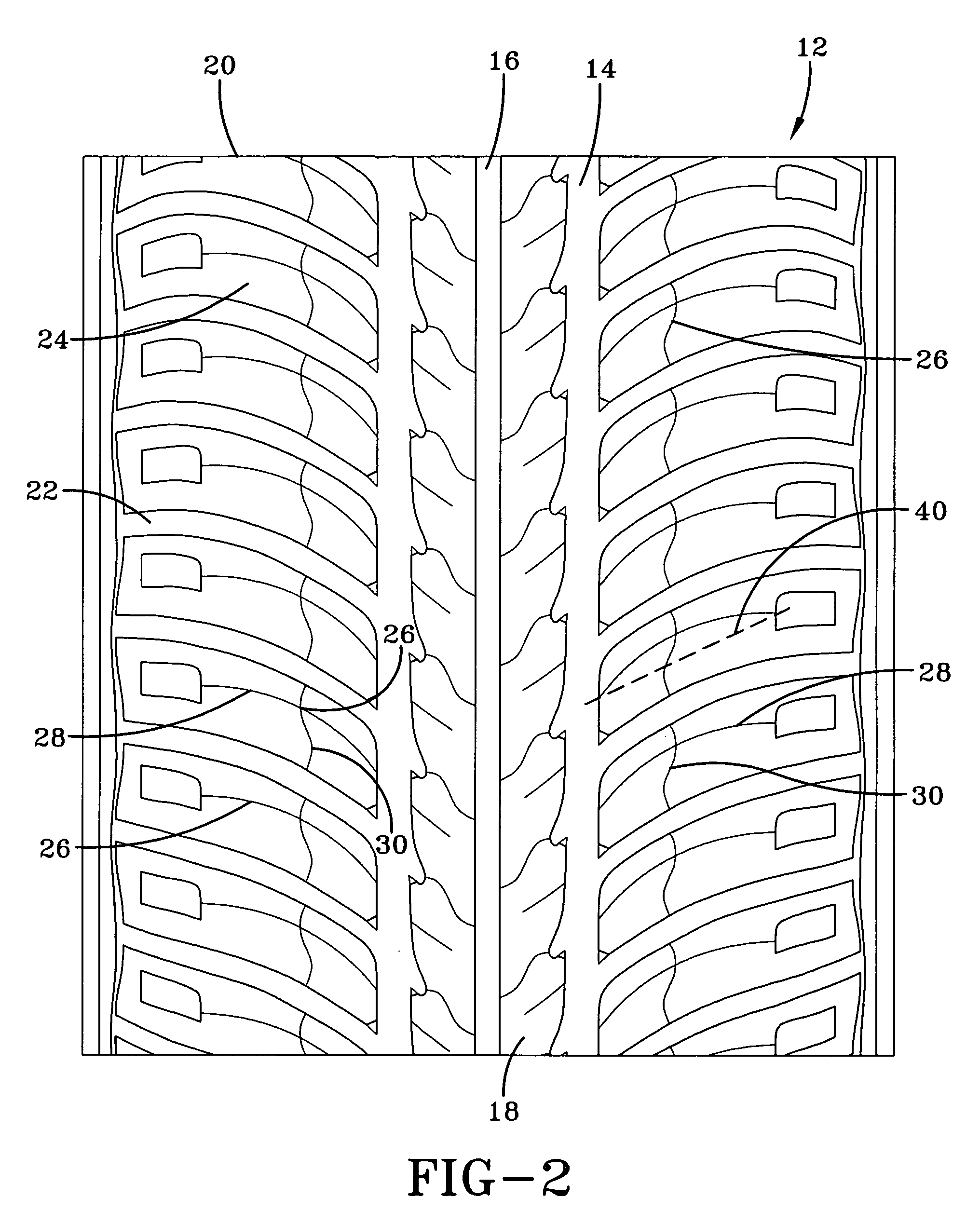

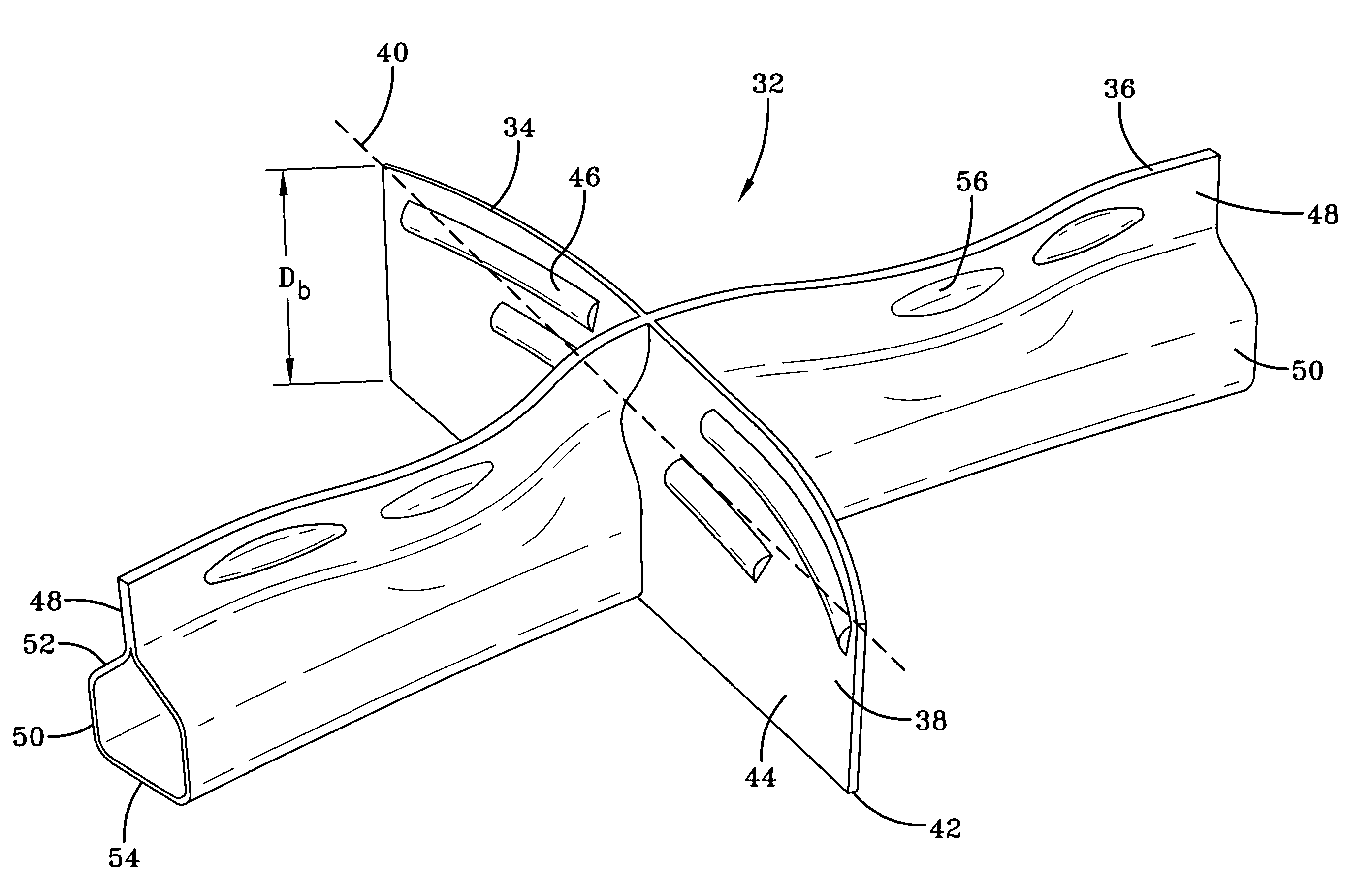

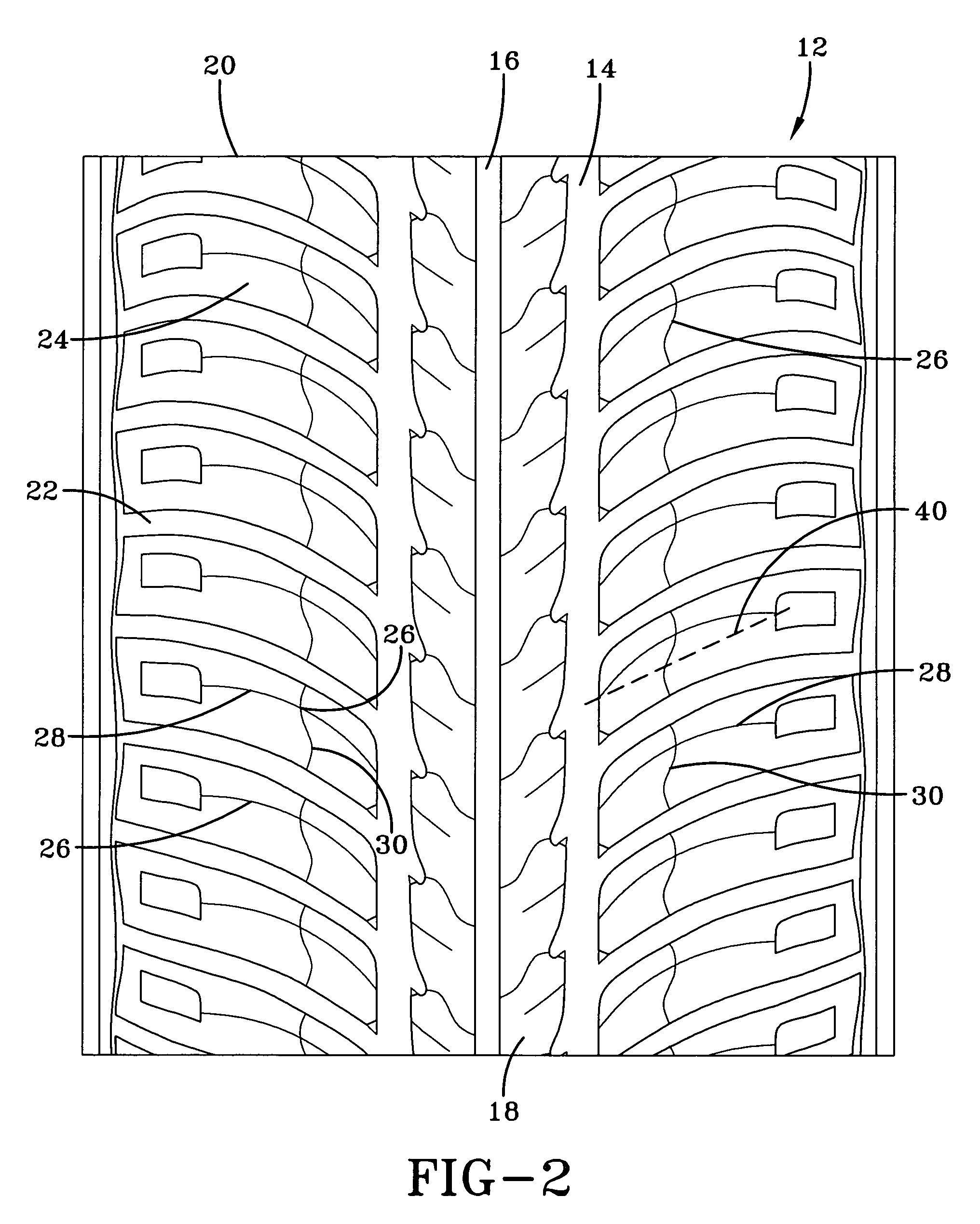

Tire with tread having sipes and sipe blades for tires

InactiveUS20070295434A1Good traction characteristicsImprove tire performanceTyresTyre tread bands/patternsLinear configurationTread

A tire has a tread with a plurality of ground engaging tread elements. In at least one of the tread elements is a sipe having a depth in the radial direction of the tire. The sipe has a crossed configuration comprised of two sipes. At least one of the sipes of the crossed sipe has a radially outer portion having three dimensional elements and a radially innermost portion have a substantially linear configuration. A blade useful for manufacturing the sipe has a crossed blade configuration with a configuration corresponding to the formed sipe.

Owner:THE GOODYEAR TIRE & RUBBER CO

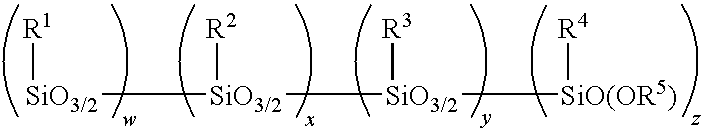

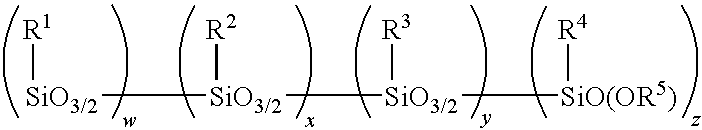

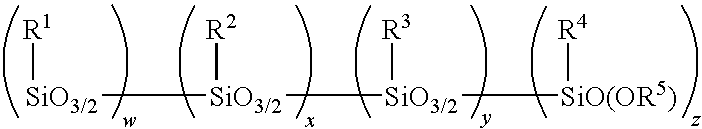

Amino alkoxy-modified silsesquioxanes in silica-filled rubber with low volatile organic chemical evolution

ActiveUS20100071818A1Improve propertiesHigh modulusGlass/slag layered productsCoatingsElastomerPolymer science

A vulcanizable rubber composition is presented that comprises an elastomer; a reinforcing filler selected from silica, carbon black, and mixtures thereof, a cure agent; and an amino alkoxy-modified silsesquioxane (AMS) comprising one or more compounds selected from the group consisting of an amino AMS, an amino / mercaptan co-AMS, an amino / blocked mercaptan co-AMS, mixtures thereof, and weak acid-neutralized solid and aqueous solutions thereof. Addition of such compounds to the rubber composition provides improved dynamic viscoelastic and mechanical properties of the vulcanized rubber compound and predict that tire components, especially tread stocks, will provide tires having improved snow traction, lower rolling resistance but equal wet traction, increased rebound, decreased hysteresis, and a general improvement in tire performance.

Owner:BRIDGESTONE CORP

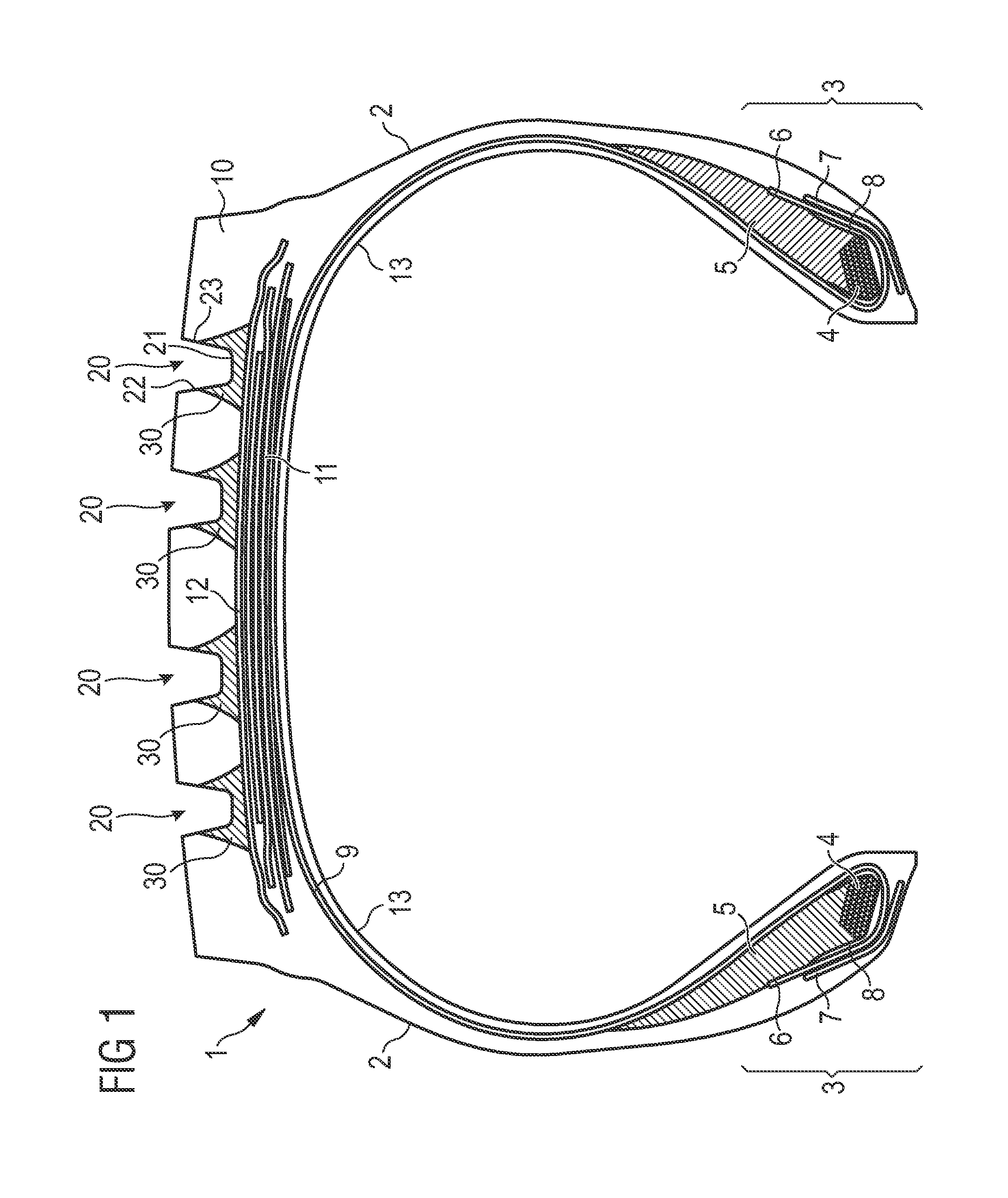

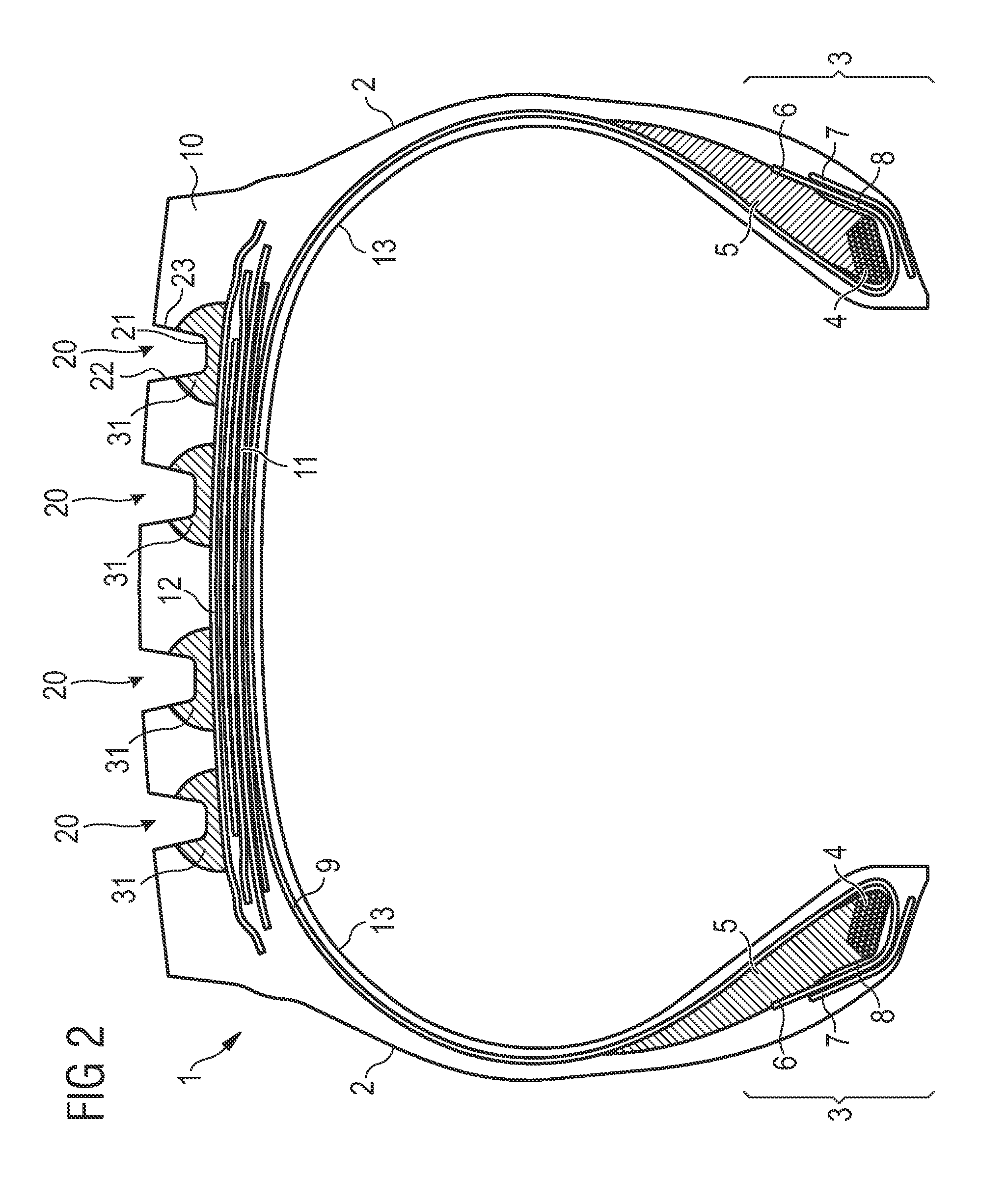

Tire tread with groove reinforcement

ActiveUS20140069561A1Reduce distortionStable structureSpecial tyresTyre tread bands/patternsEngineeringTread

The present invention relates to a tire tread comprising a plurality of circumferential grooves separating circumferential ribs, each groove comprising a bottom and two sidewalls, and a plurality of laterally separated reinforcements, wherein one reinforcement is arranged adjacent each circumferential groove, and wherein each reinforcement extends from the radially inner surface of the tread in a radial direction at least to the bottom of an adjacent circumferential groove to form the bottom of that groove. Further, the invention relates to a tire comprising a tread in accordance with the present invention.

Owner:THE GOODYEAR TIRE & RUBBER CO

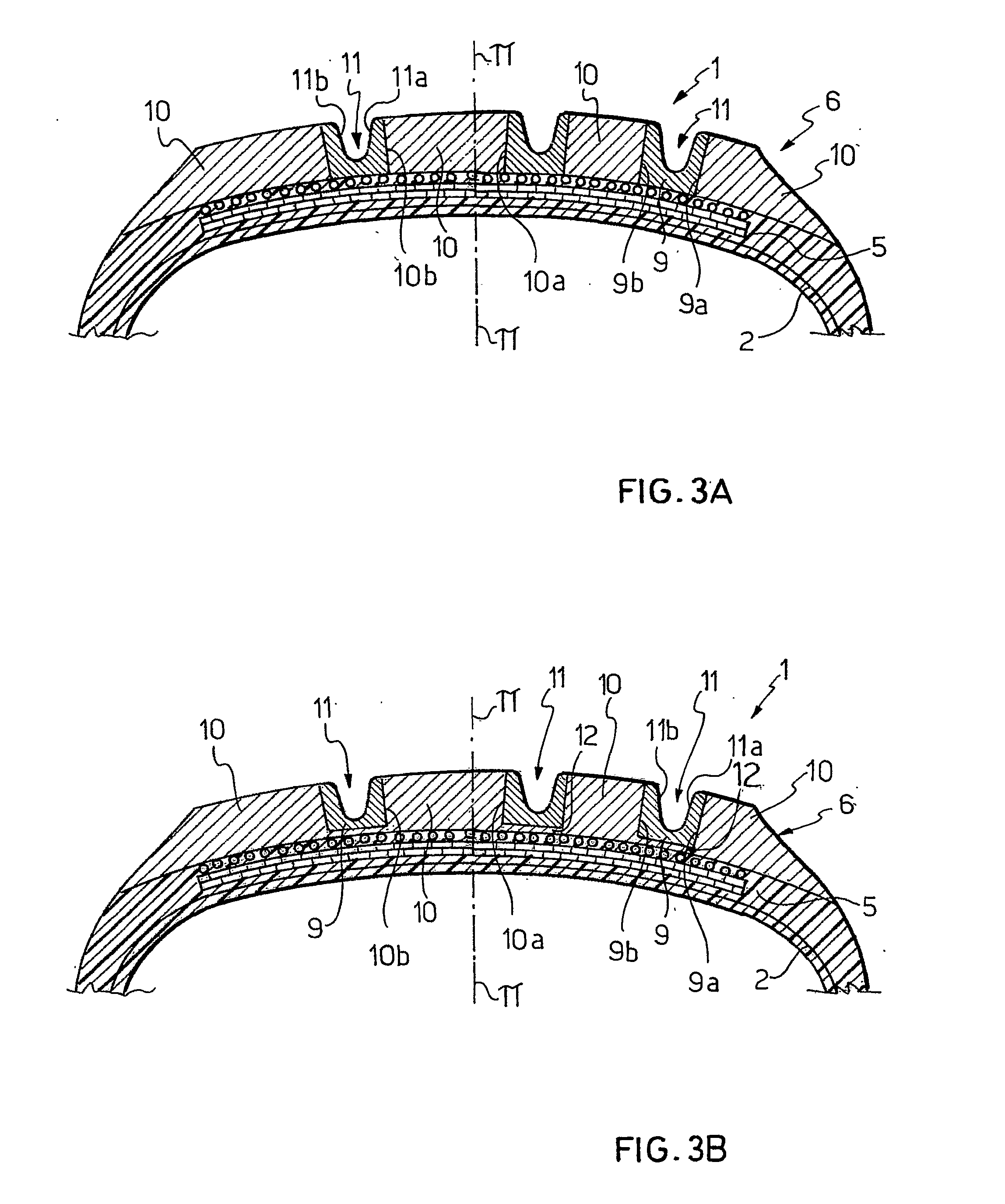

Pneumatic tire

ActiveUS20060169377A1Excellent travel performanceAvoid failure in mold releaseTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

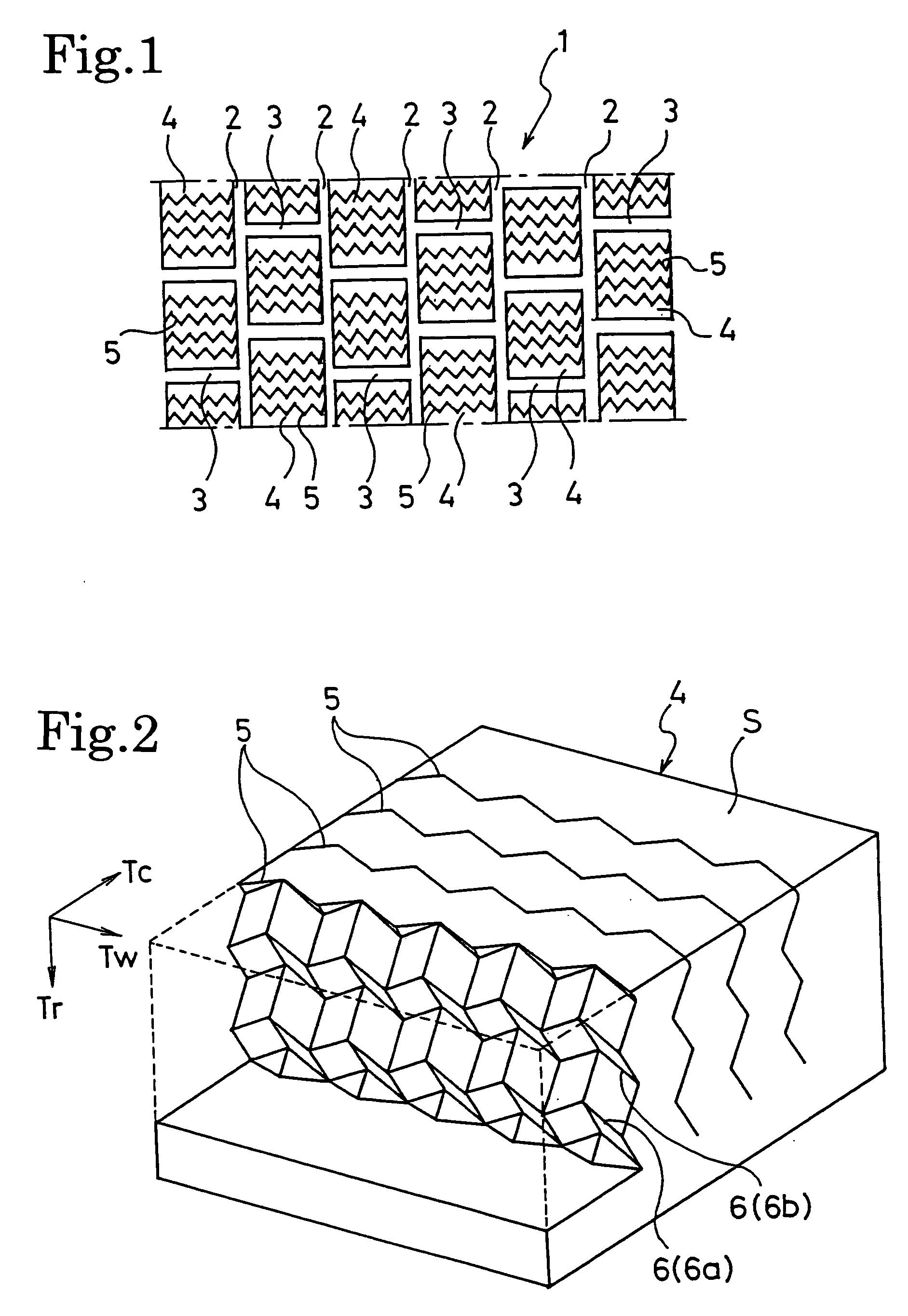

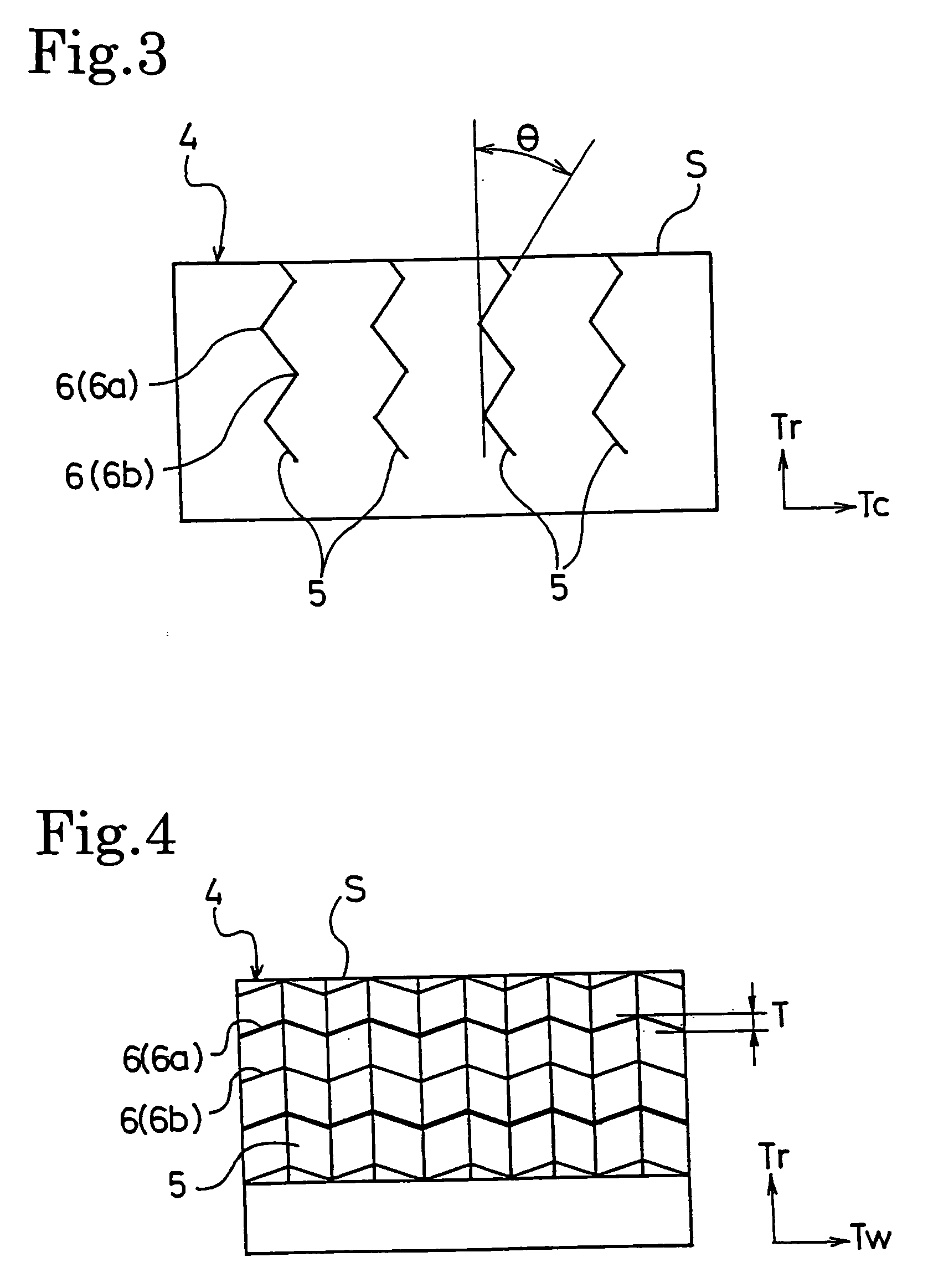

Disclosed is a pneumatic tire which is allowed to increase block stiffness not only during braking and driving but also during cornering, and is allowed thereby to compatibly enhance tire performances both during braking and driving and during cornering. The pneumatic tire of the present invention is one where a plurality of longitudinal grooves extending in a tire circumferential direction and a plurality of lateral grooves extending in a tire widthwise direction are provided in a tread portion, a plurality of blocks are defined by these longitudinal and lateral grooves, and a plurality of sipes extending in the tire widthwise direction are provided to each of the blocks, wherein, with regard to each of the sipes, a zigzag shape is formed on a tread surface, bent portions ranging in the tire widthwise direction while bent in the tire circumferential direction are formed inside the block at at least two positions in the tire radial direction, and a zigzag shape with an amplitude in the tire radial direction is formed in each of the bent portions.

Owner:YOKOHAMA RUBBER CO LTD

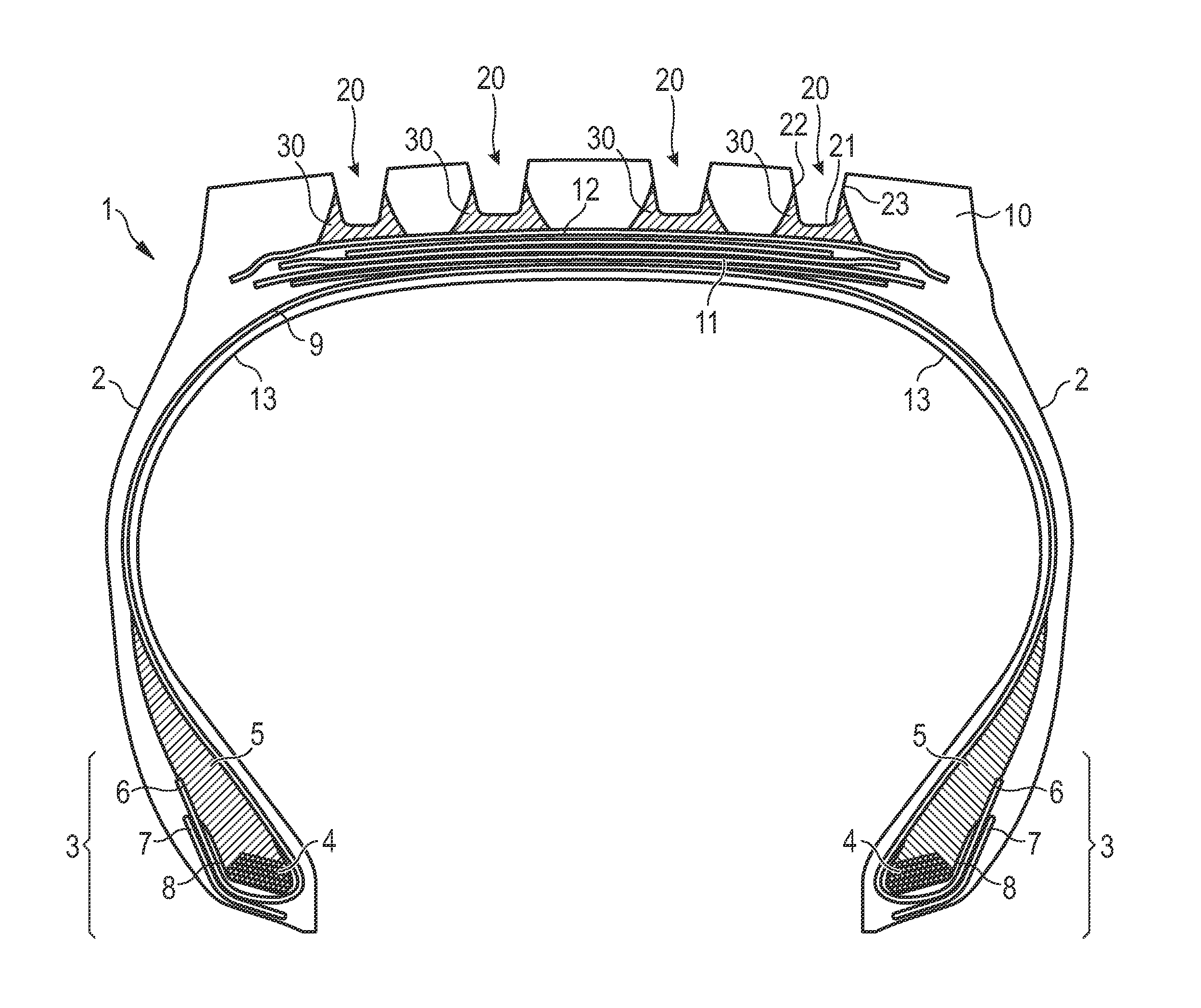

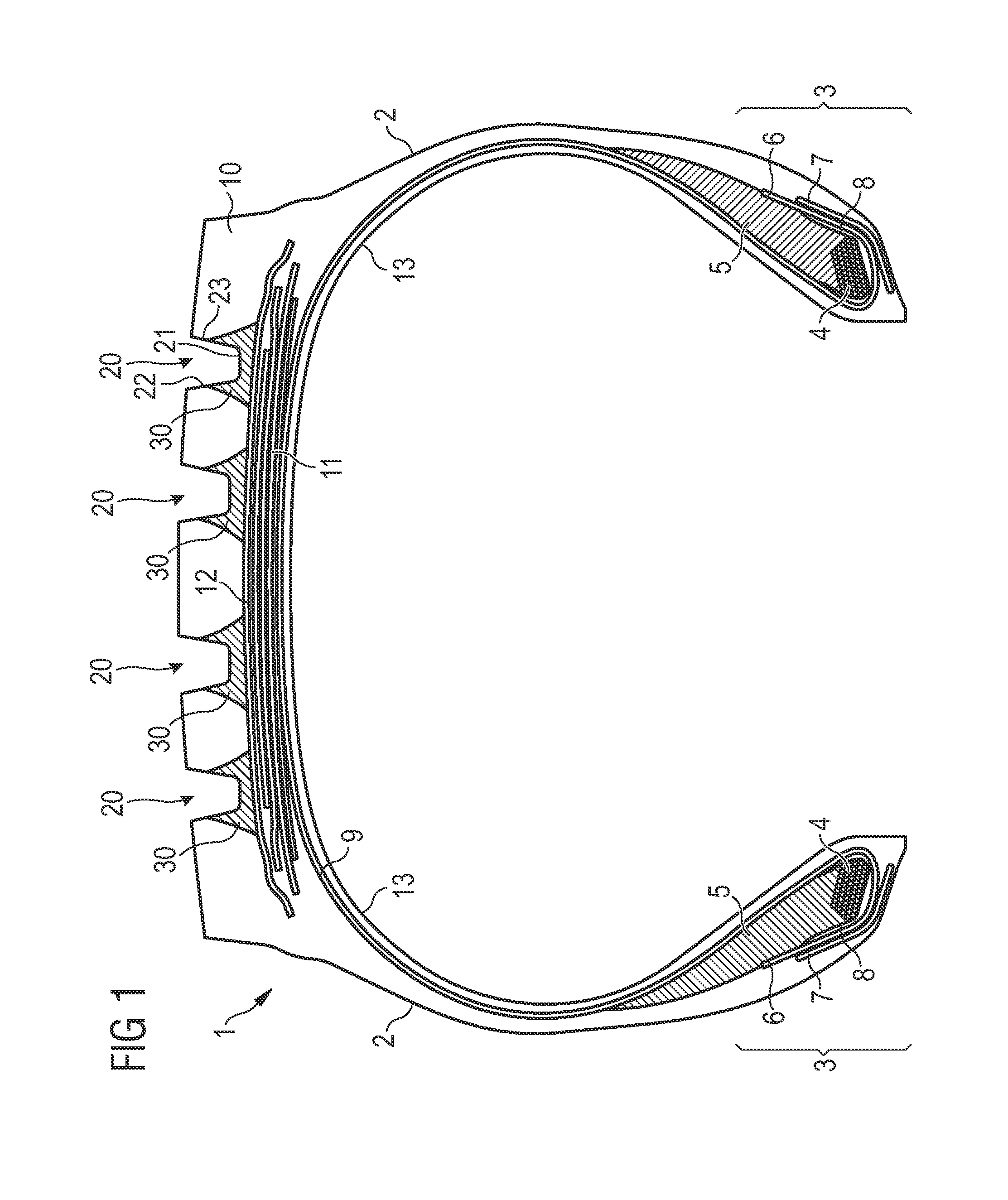

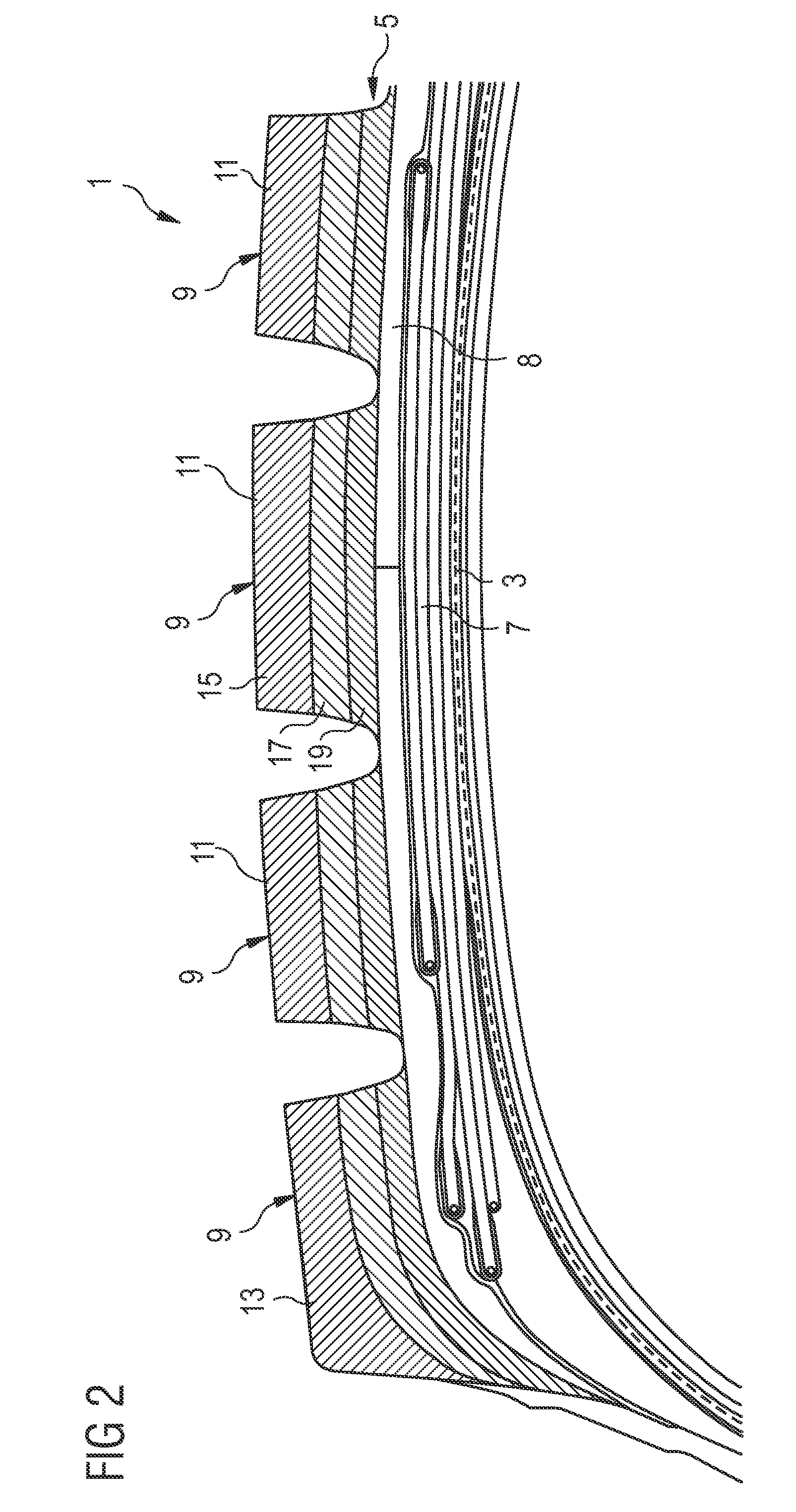

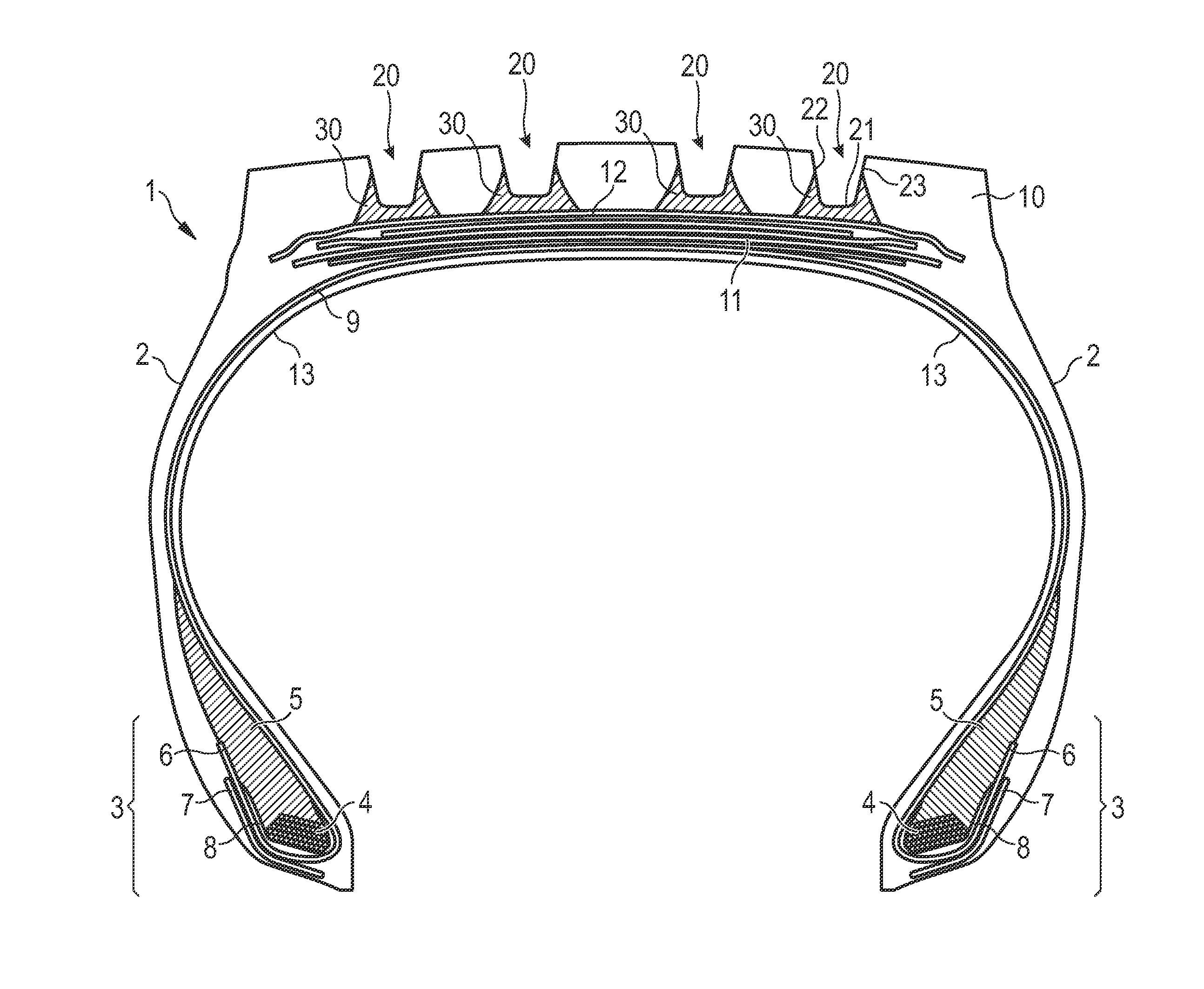

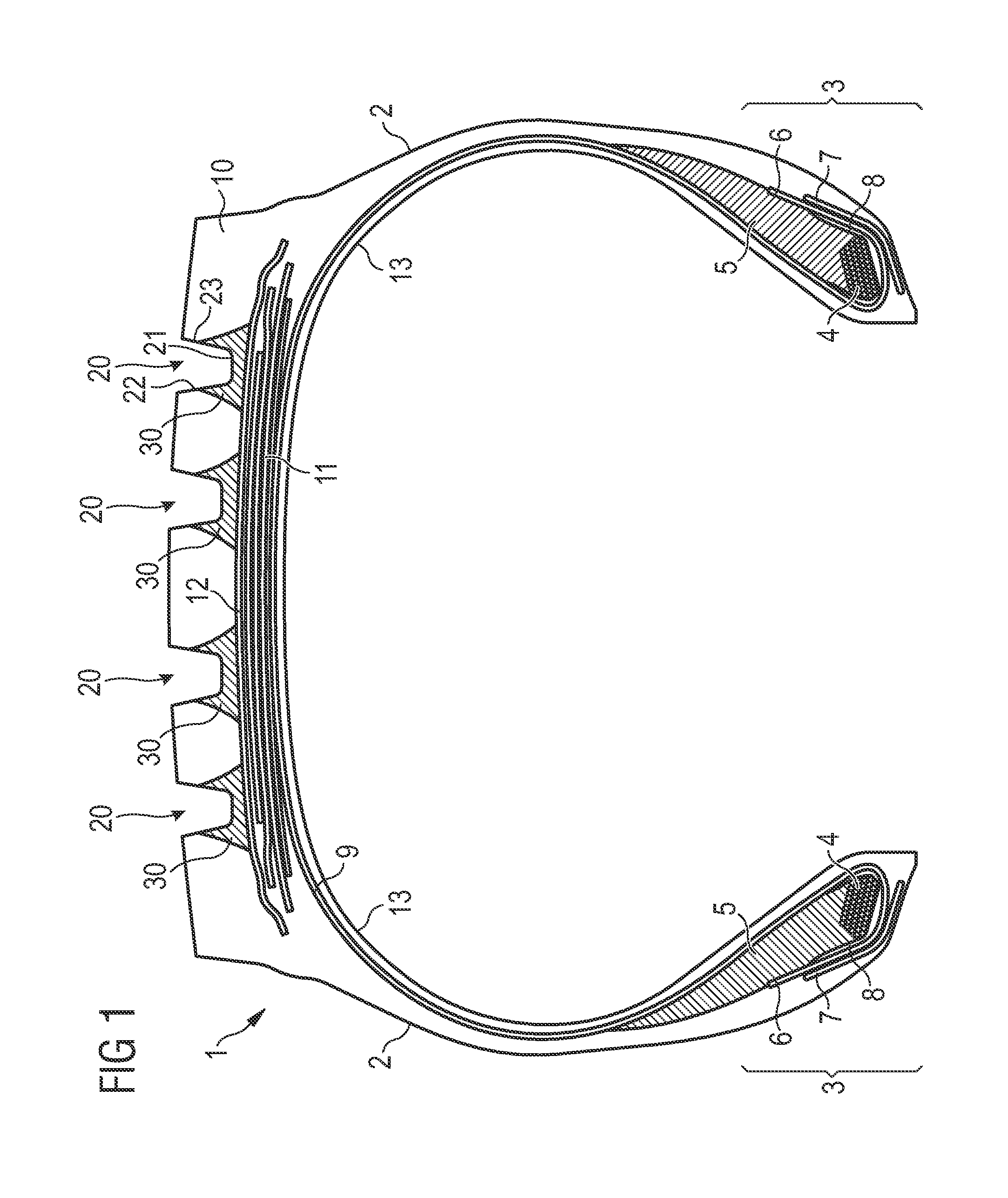

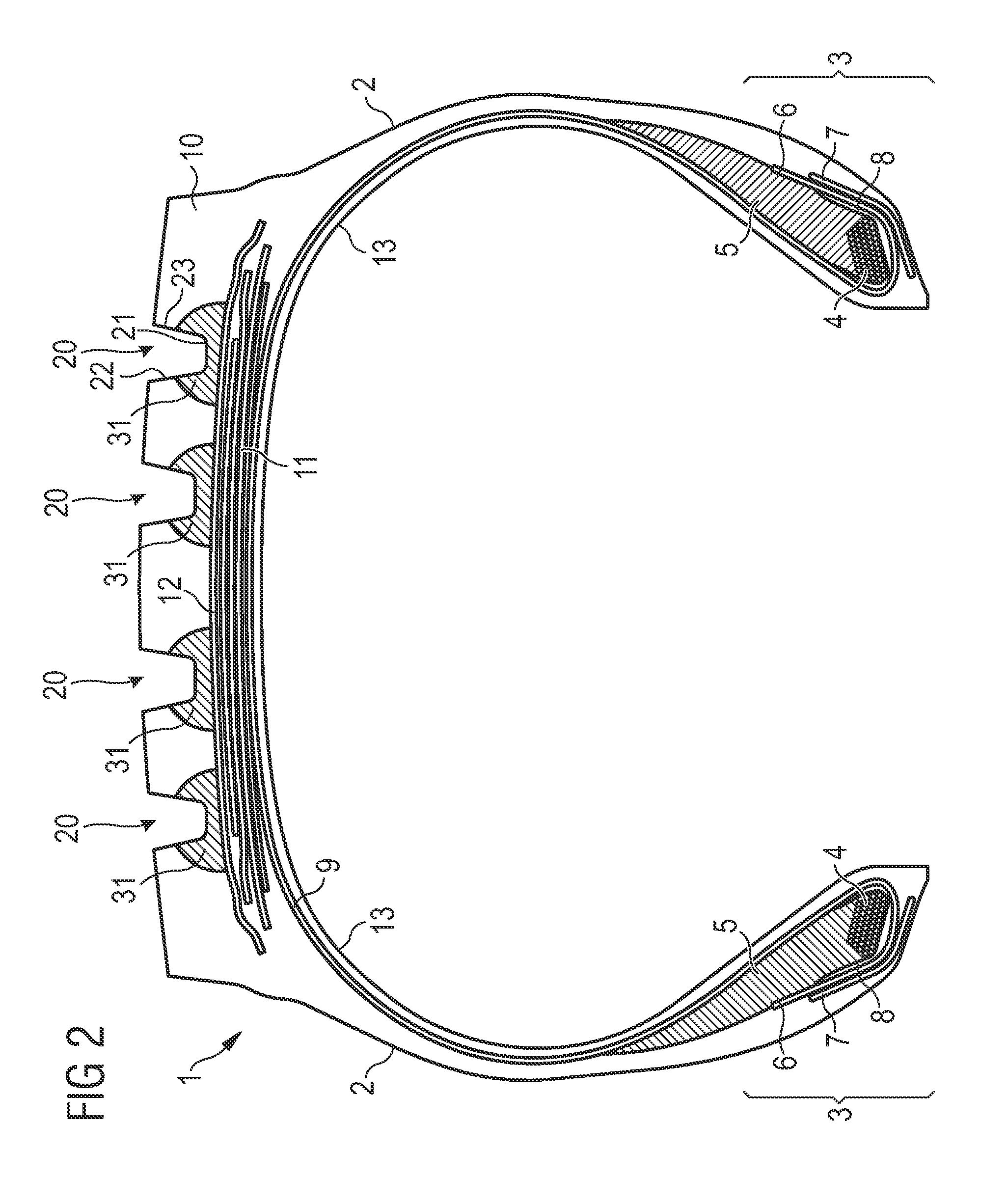

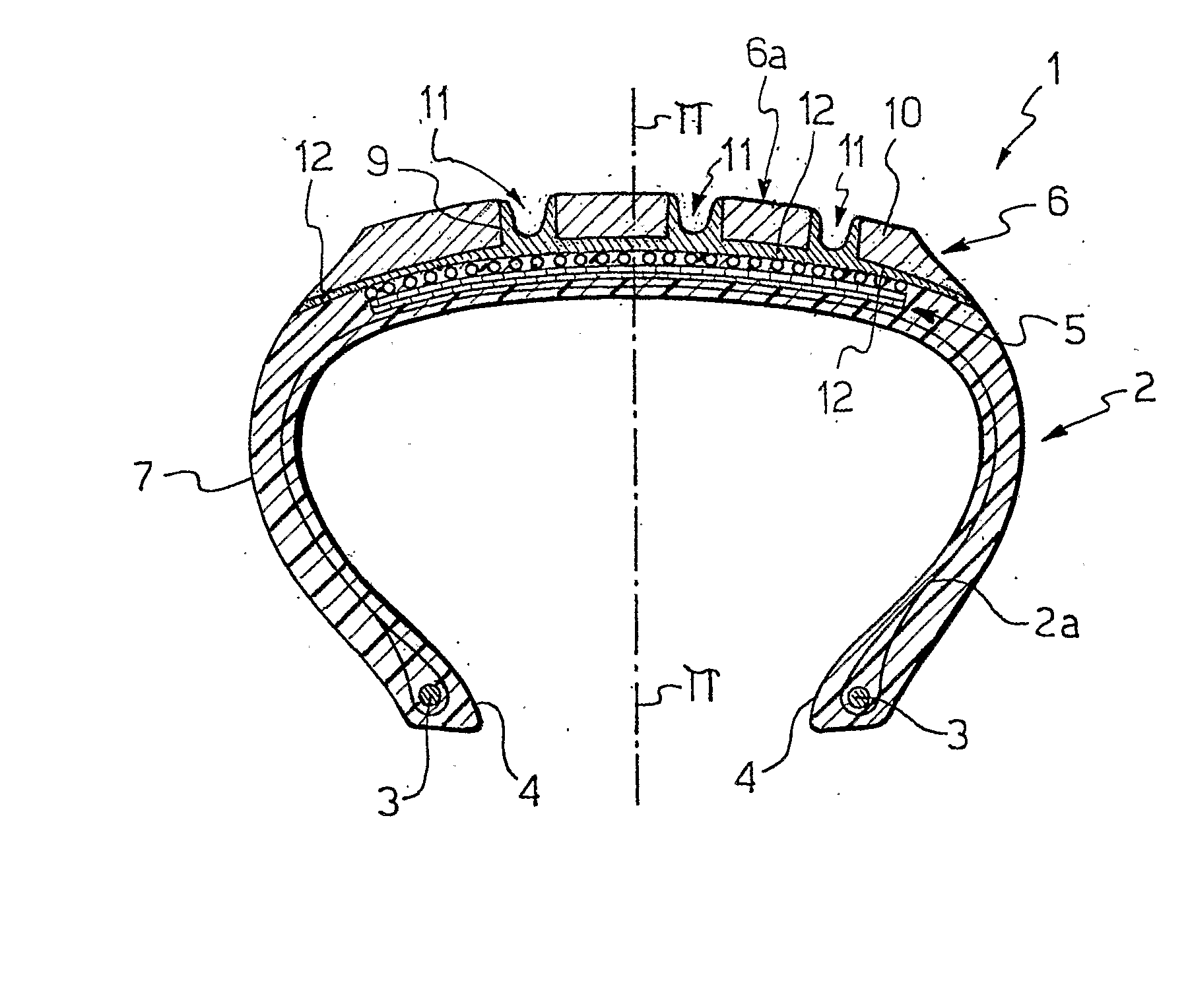

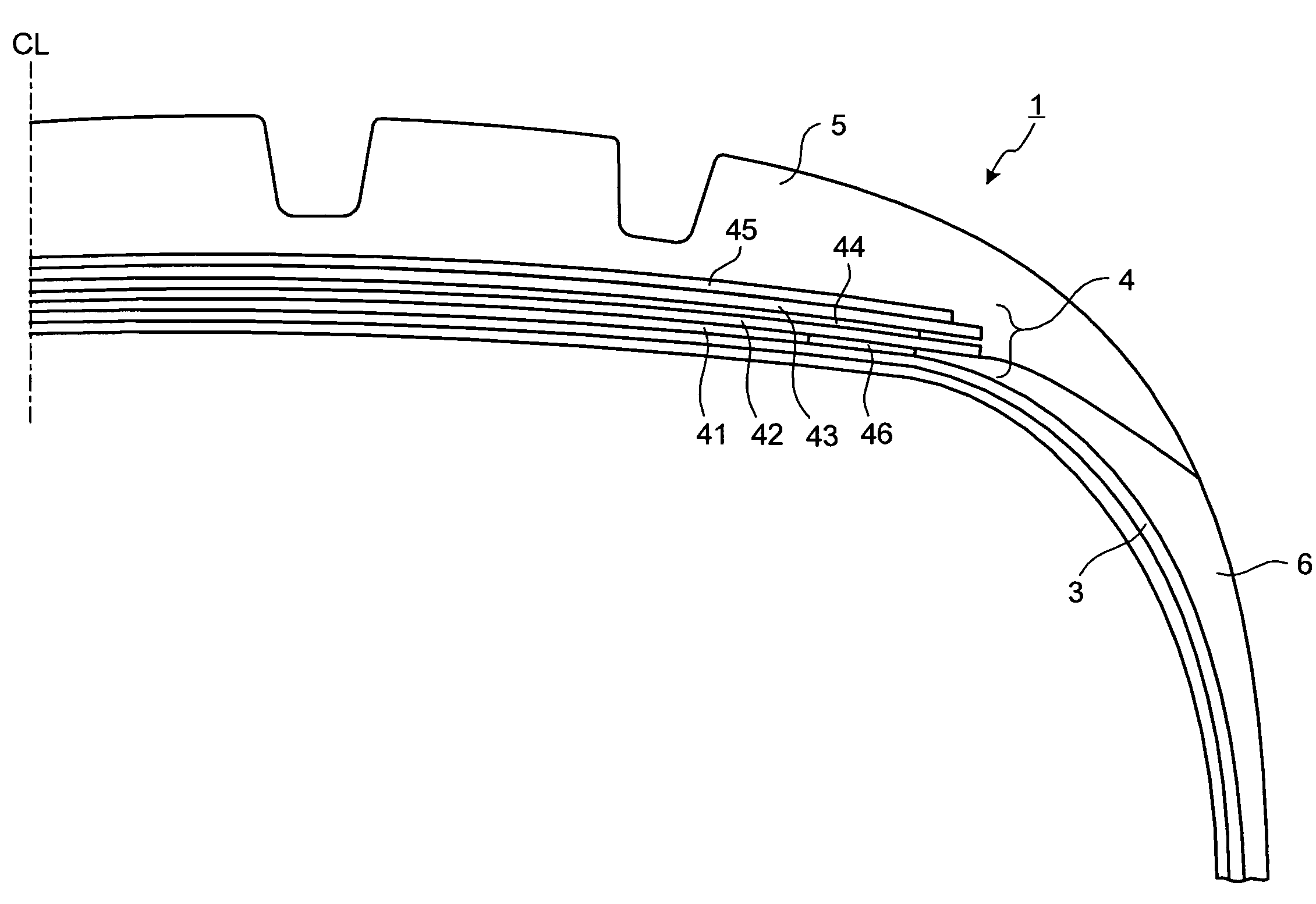

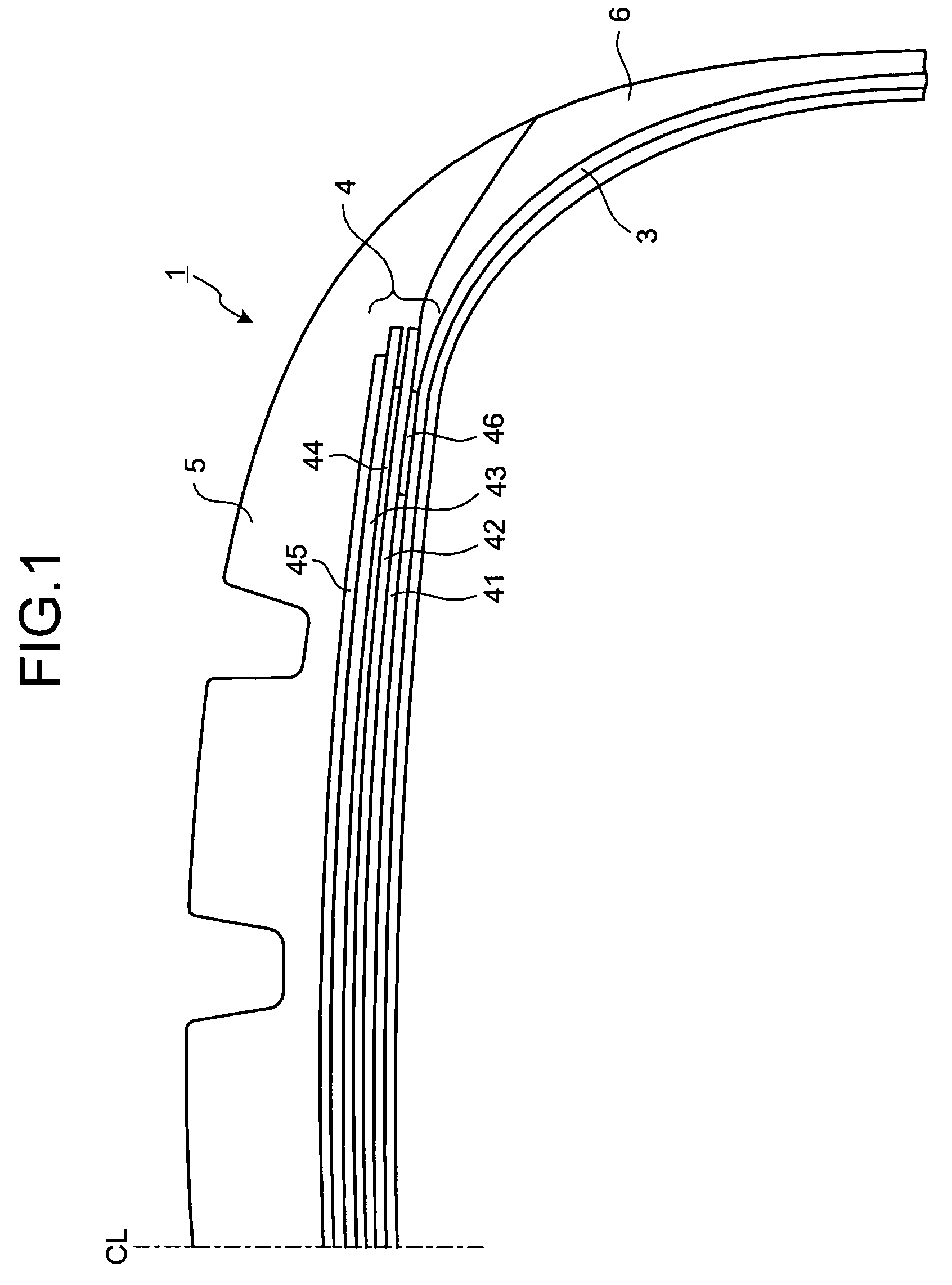

Pneumatic tire

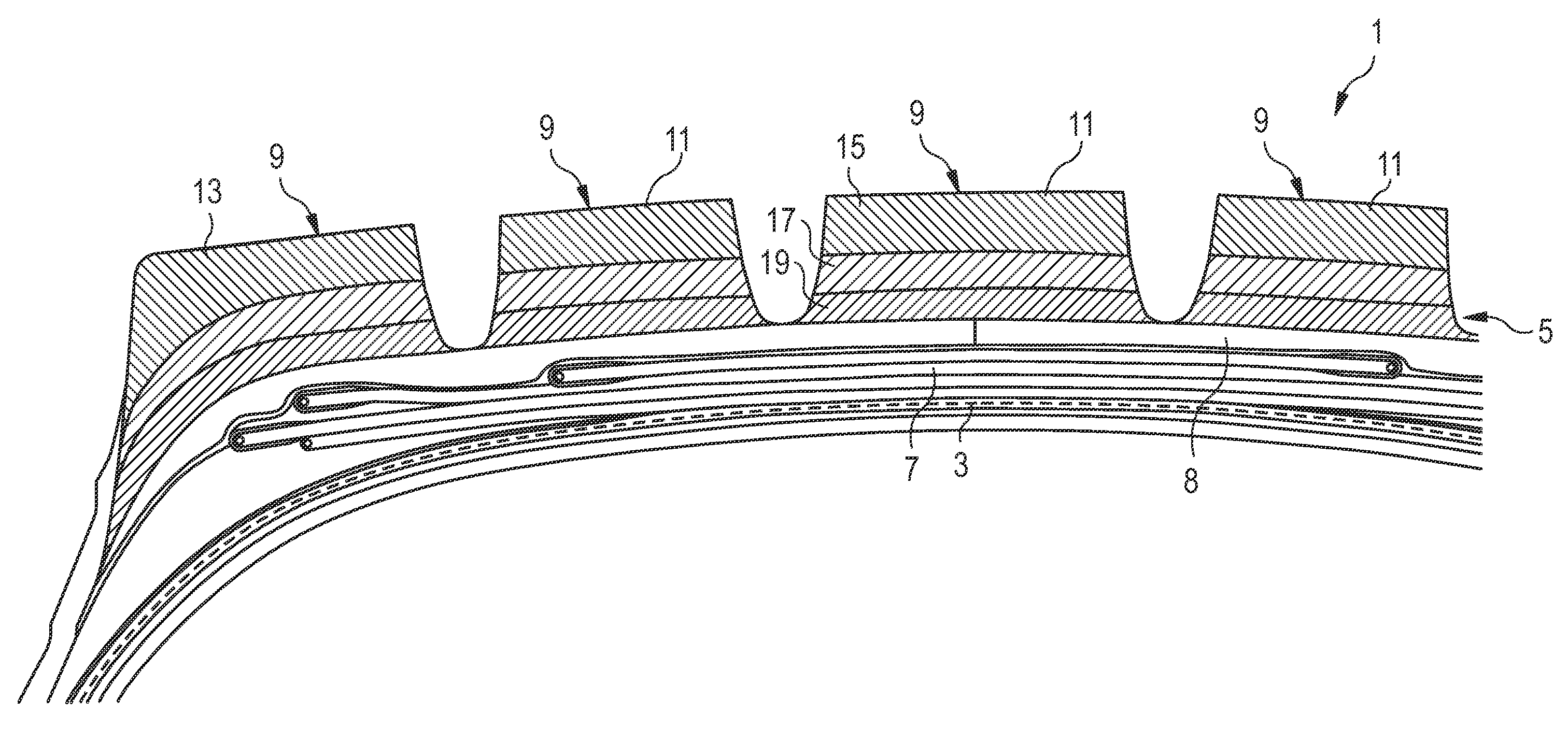

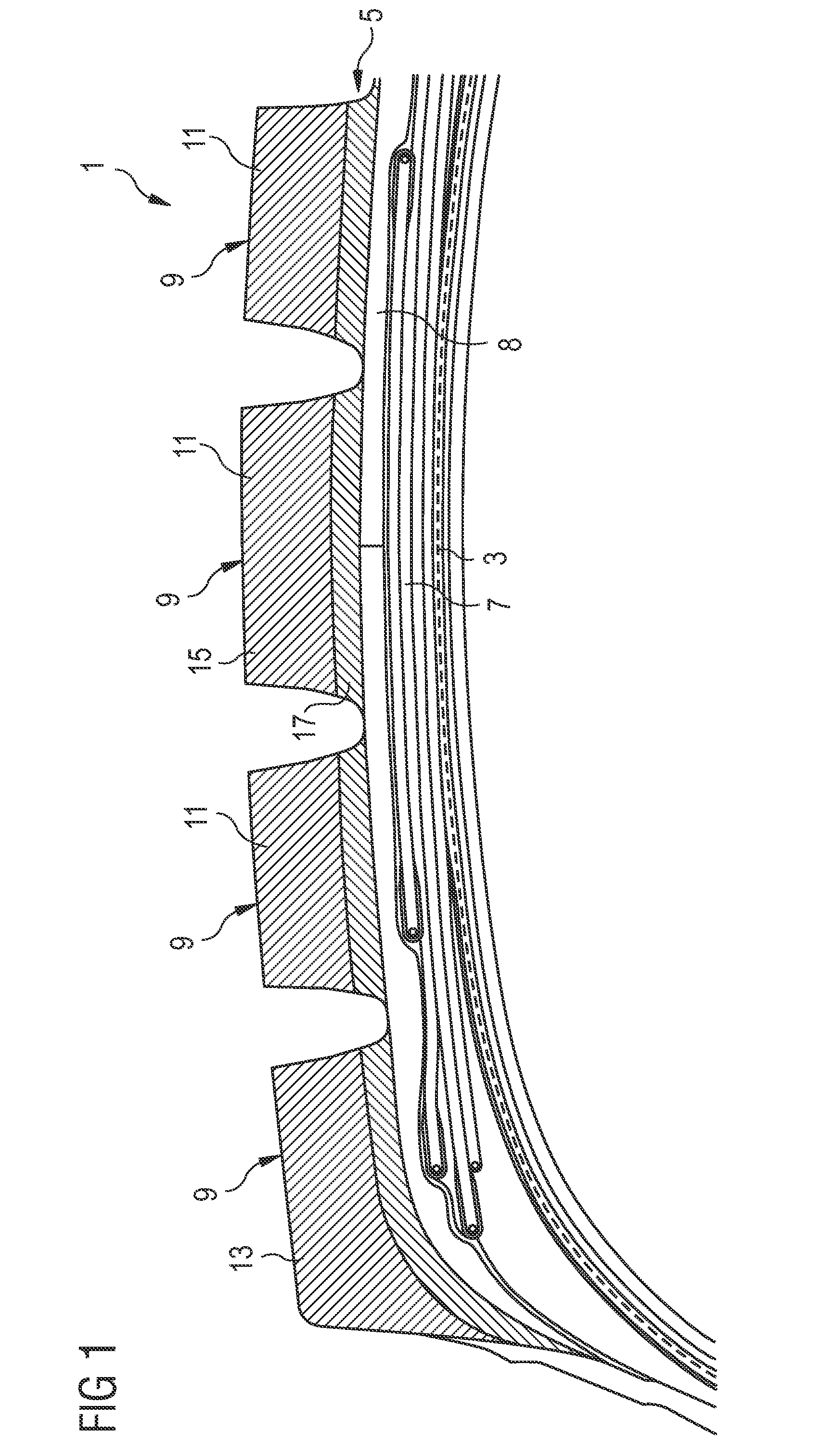

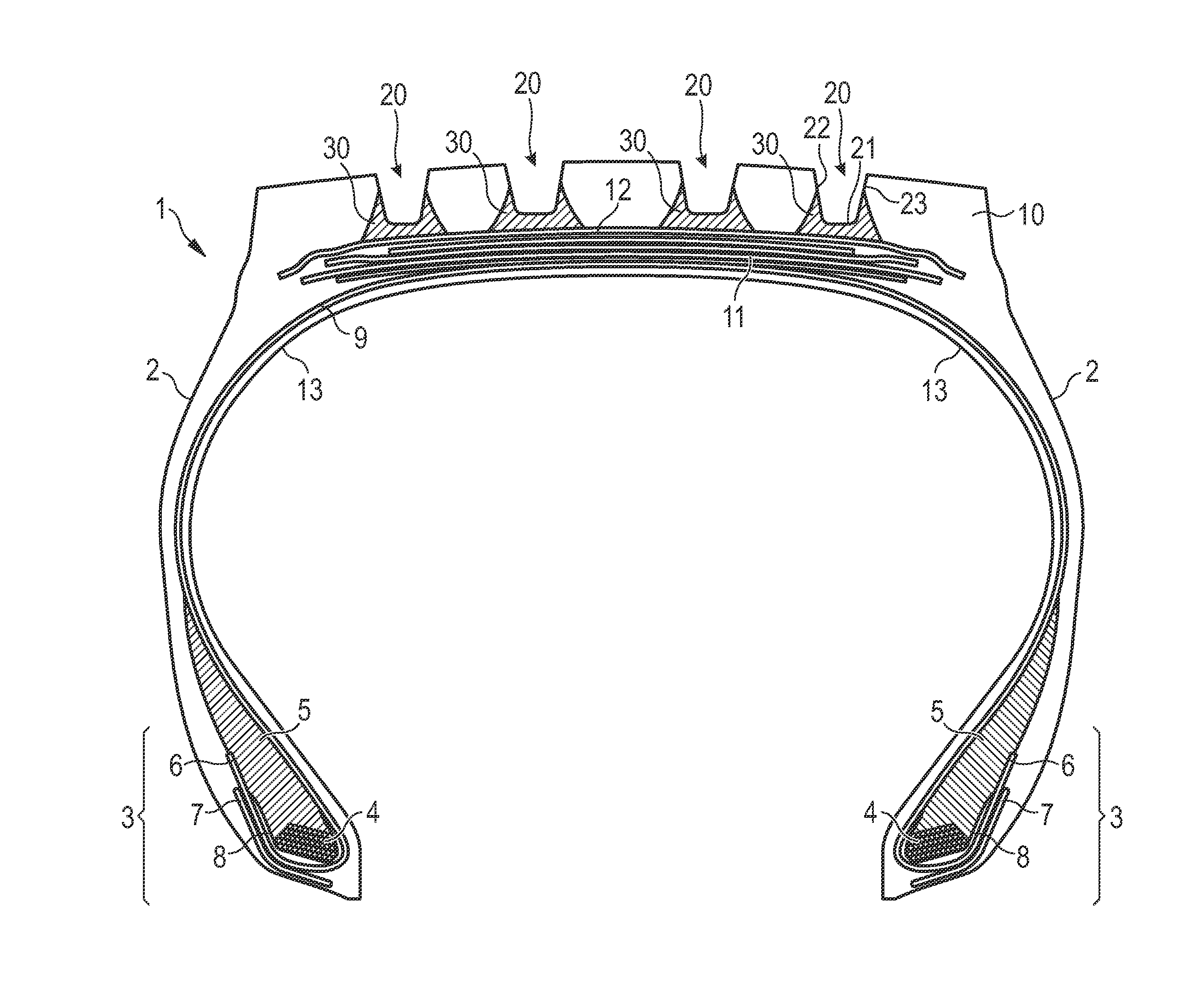

ActiveUS20120132331A1Easy to adjustStable and controllable performanceHeavy duty tyresHeavy duty vehicleMechanical engineeringTread

The present invention is directed to a pneumatic tire 1 comprising at least one pair of parallel annular beads; at least one carcass ply 3 wrapped around said beads; a tread 5; and first and second sidewalls disposed between said tread and one of said at least one pair of beads; as well as a belt portion 7 between the carcass ply 3 and the tread 5. In accordance with the invention, the tread 5 comprises a tread base layer 8 and a plurality of tread blocks 9, wherein the tread blocks 9 comprise at least two different rubber layers 15, 17, 19 arranged radially above each other, whereas the rubber layers 15, 17, 19 of different tread blocks are axially separate from each other.

Owner:THE GOODYEAR TIRE & RUBBER CO

Rubber composition for tread groove reinforcement

ActiveUS20140069560A1Reduce distortionStabilize crown structureSpecial tyresTyre tread bands/patternsEngineeringHigh surface area

The present invention relates to a rubber composition comprising at least one rubber component, between about 50 phr and about 120 phr of a filler, wherein at least 20 phr of the filler is a high surface area carbon black. Further, the composition comprises between 10 phr and 30 phr of a phenolic resin. The present invention is further directed to a tire tread or a tire comprising such a composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

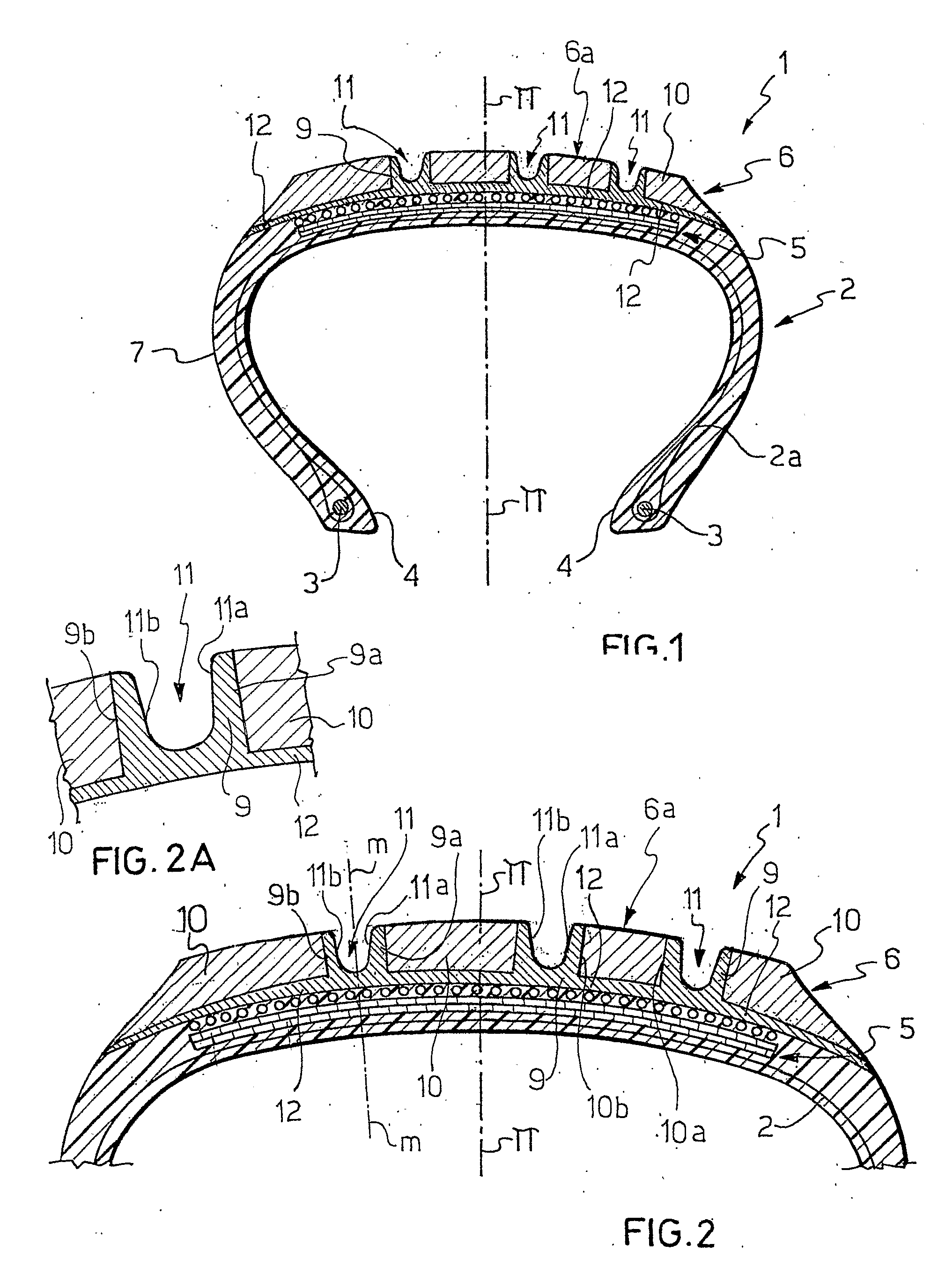

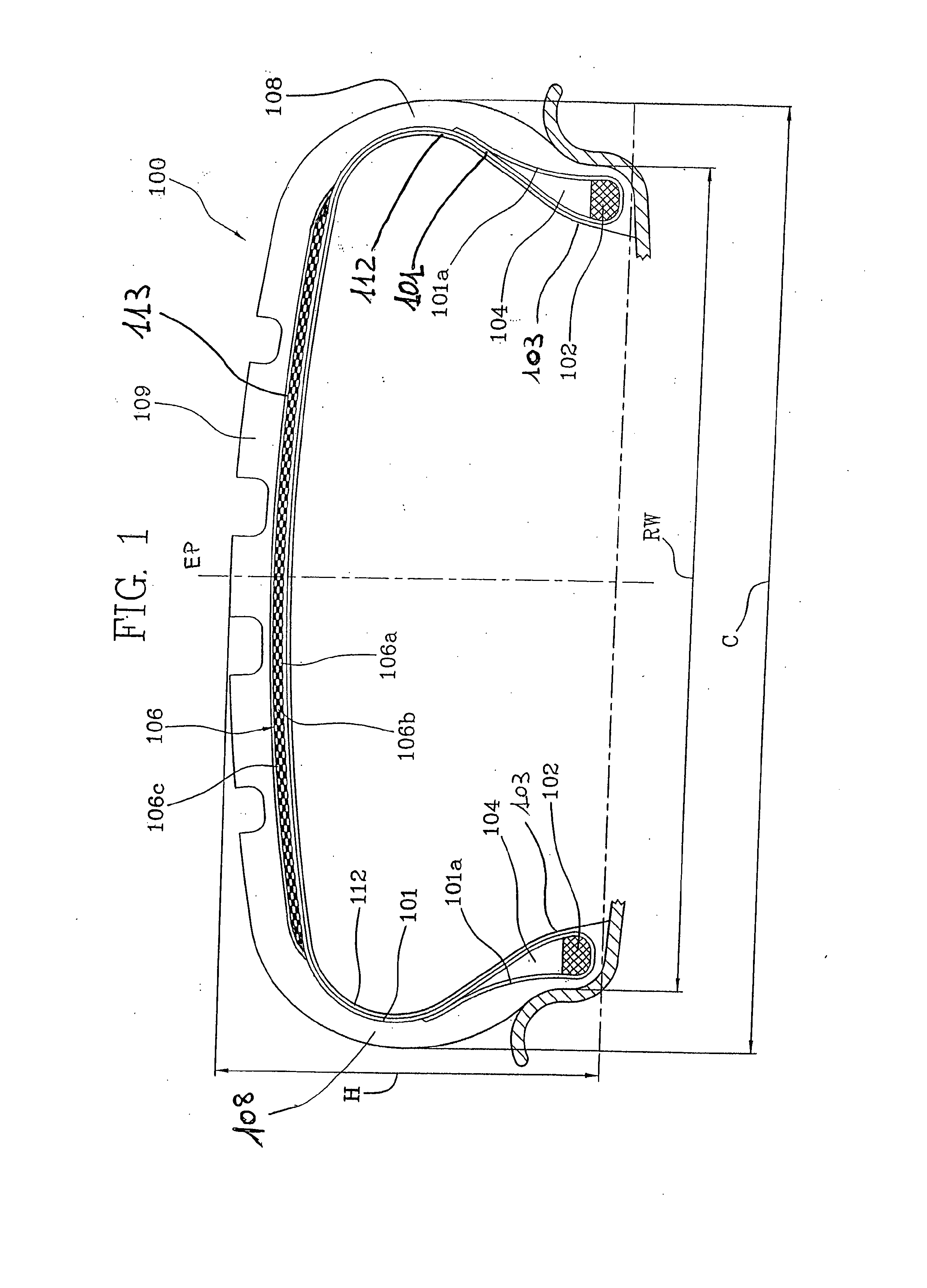

Pneumatic tire and process for its manufacture

A pneumatic tire has a carcass structure having at least one carcass ply and at least one annual reinforcing structure associated with the carcass ply, a tread band made of an elastomeric material at a radially outer position with respect to the carcass structure, a belt structure interposed between the carcass structure and the tread band and a pair of axially opposite side walls on the carcass structure, wherein the tread band has i) at least one first sector, radially extending, substantially of a first elastomeric material; ii) a plurality of second sectors radially extending, positioned at axially opposite sides of the at least one first sector and substantially of a second elastomeric material; iii) at least one longitudinal groove formed in the at least one first sector and extending substantially for the entire circumferential development of the tread band, wherein the first elastomeric material has a modulus of elasticity under compression at 23° C. greater than the modulus of elasticity under compression at 23° C. of the second elastomeric material, and wherein the modulus of elasticity under compression at 23° C. of the first elastomeric material is about 20 to about 80 MPa.

Owner:PIRELLI TYRE SPA

Tires with high strength reinforcement

InactiveUS7082978B2Light weightIncrease resistanceOff-road vehicle tyresTyresHigh intensityUltimate tensile strength

A strip of tire ply stock is reinforced with steel cords wherein the steel cords are constructed of high strength wire filament having at least a tensile strength of −2000×D+4400 MPa where D is the filament diameter in mm. Tires are constructed with the ply stock in the belt and / or carcass.

Owner:THE GOODYEAR TIRE & RUBBER CO

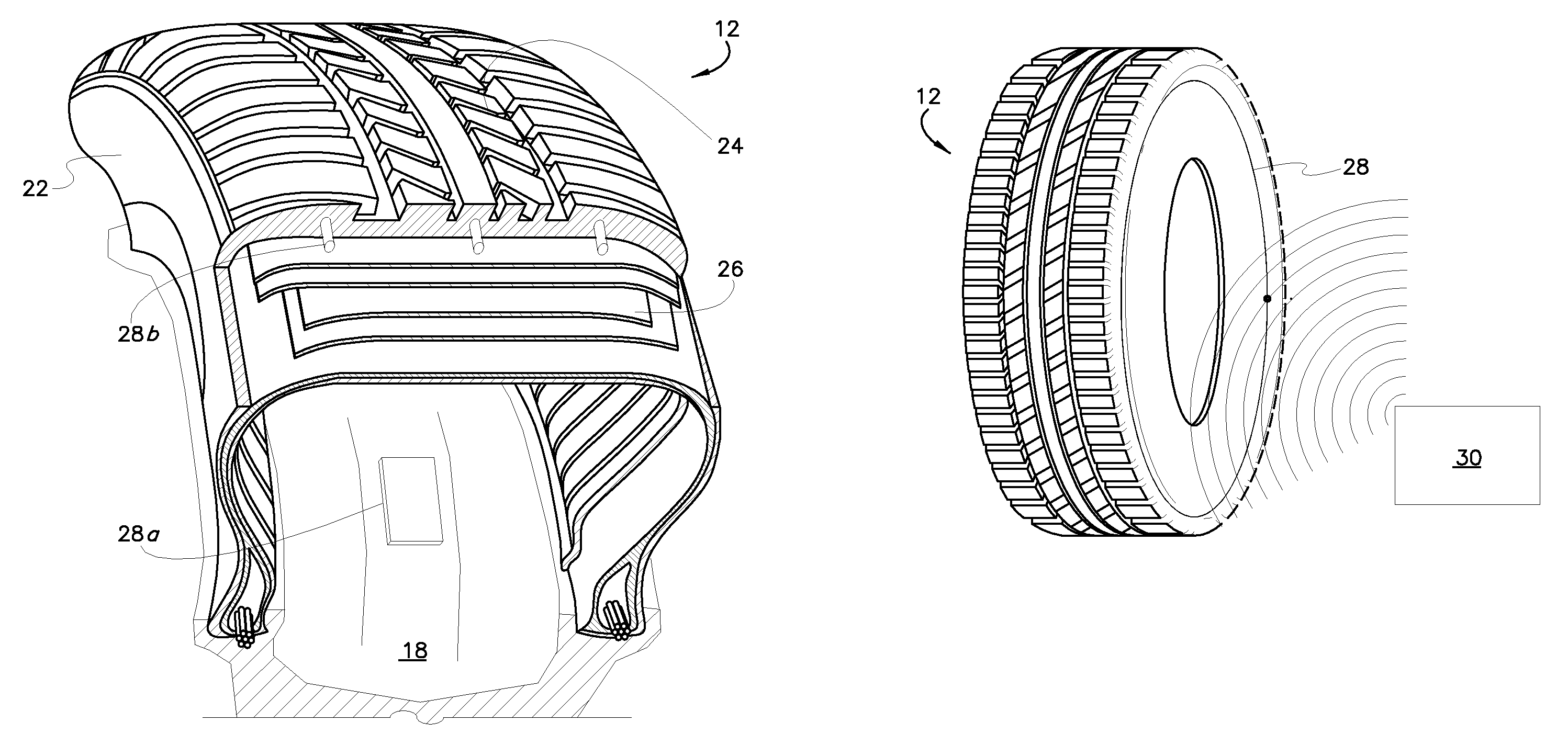

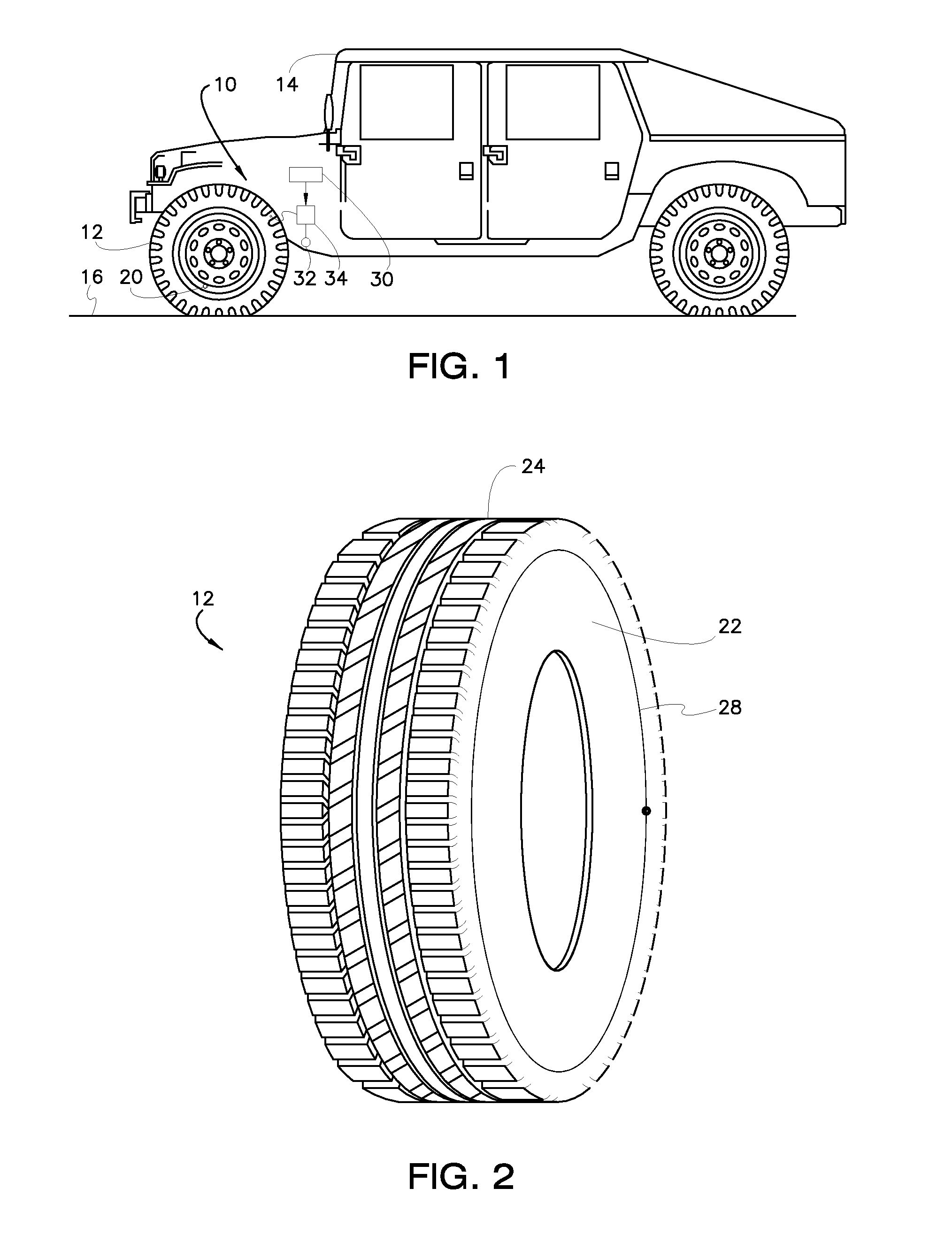

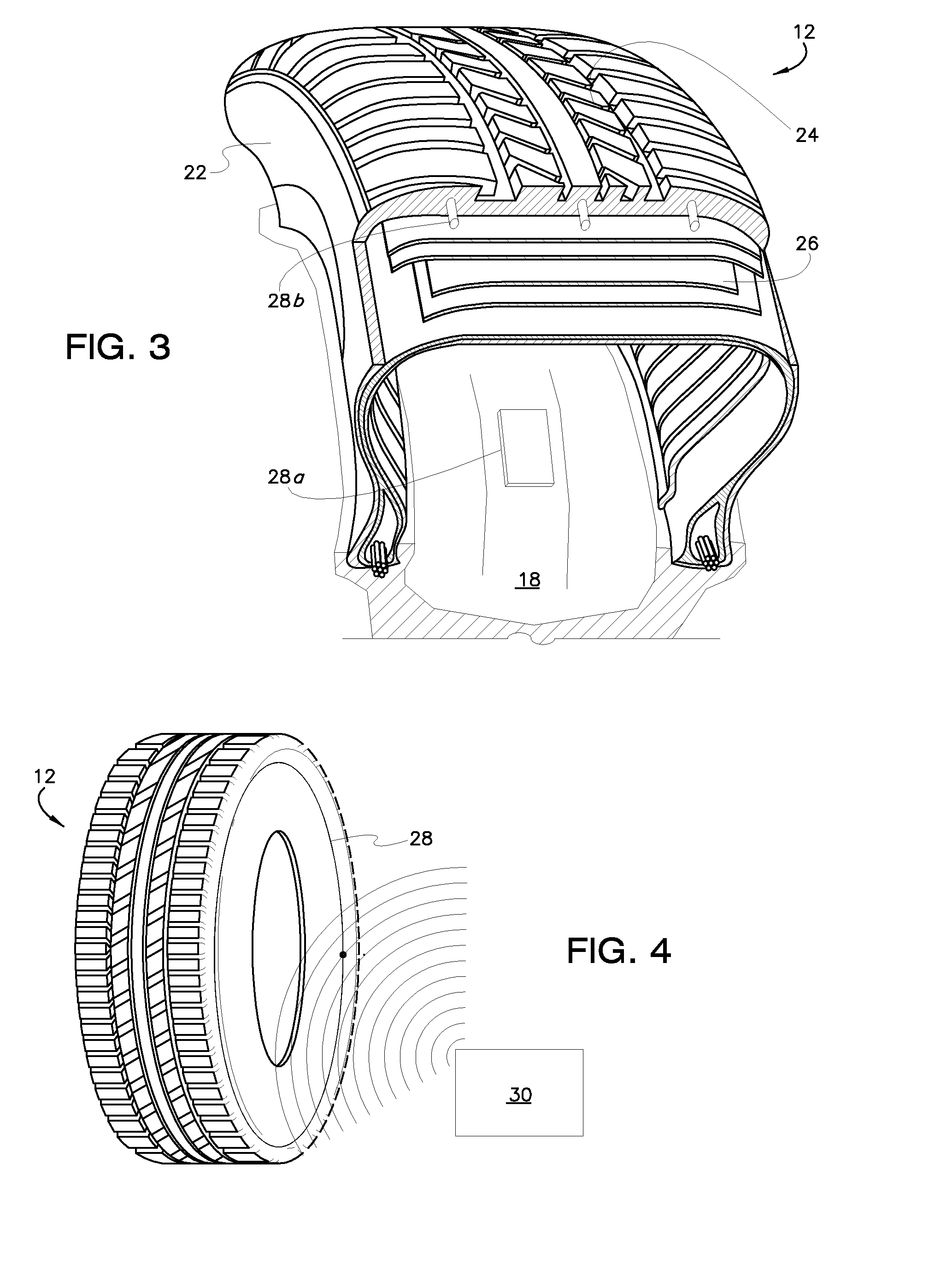

Reducing tire rolling resistance through pre-heating

InactiveUS20090314407A1Reduce rolling resistanceImprove tire performanceTyresPneumatic tyre reinforcementsTweelRolling resistance

A system for and method of reducing the rolling resistance of a tire by pre-heating the tire prior to use.

Owner:GM GLOBAL TECH OPERATIONS LLC

Rubber composition for tread groove reinforcement

ActiveUS8919404B2Reduce distortionStabilize crown structureSpecial tyresPneumatic tyre reinforcementsEngineeringHigh surface area

The present invention relates to a rubber composition comprising at least one rubber component, between about 50 phr and about 120 phr of a filler, wherein at least 20 phr of the filler is a high surface area carbon black. Further, the composition comprises between 10 phr and 30 phr of a phenolic resin. The present invention is further directed to a tire tread or a tire comprising such a composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

Rubber composition for tread and tire comprising thereof

There is provided a rubber composition for a tread having excellent hardness and improving the processability and grip performance of a tire, and a tire comprising thereof. A rubber composition for a tread comprising 30 to 80 parts by weight of silica having a BET specific surface area of less than 150 m2 / g and 10 parts by weight or less of carbon black based on 100 parts by weight of a rubber component comprising an epoxidized natural rubber, and a tire comprising thereof.

Owner:SUMITOMO RUBBER IND LTD

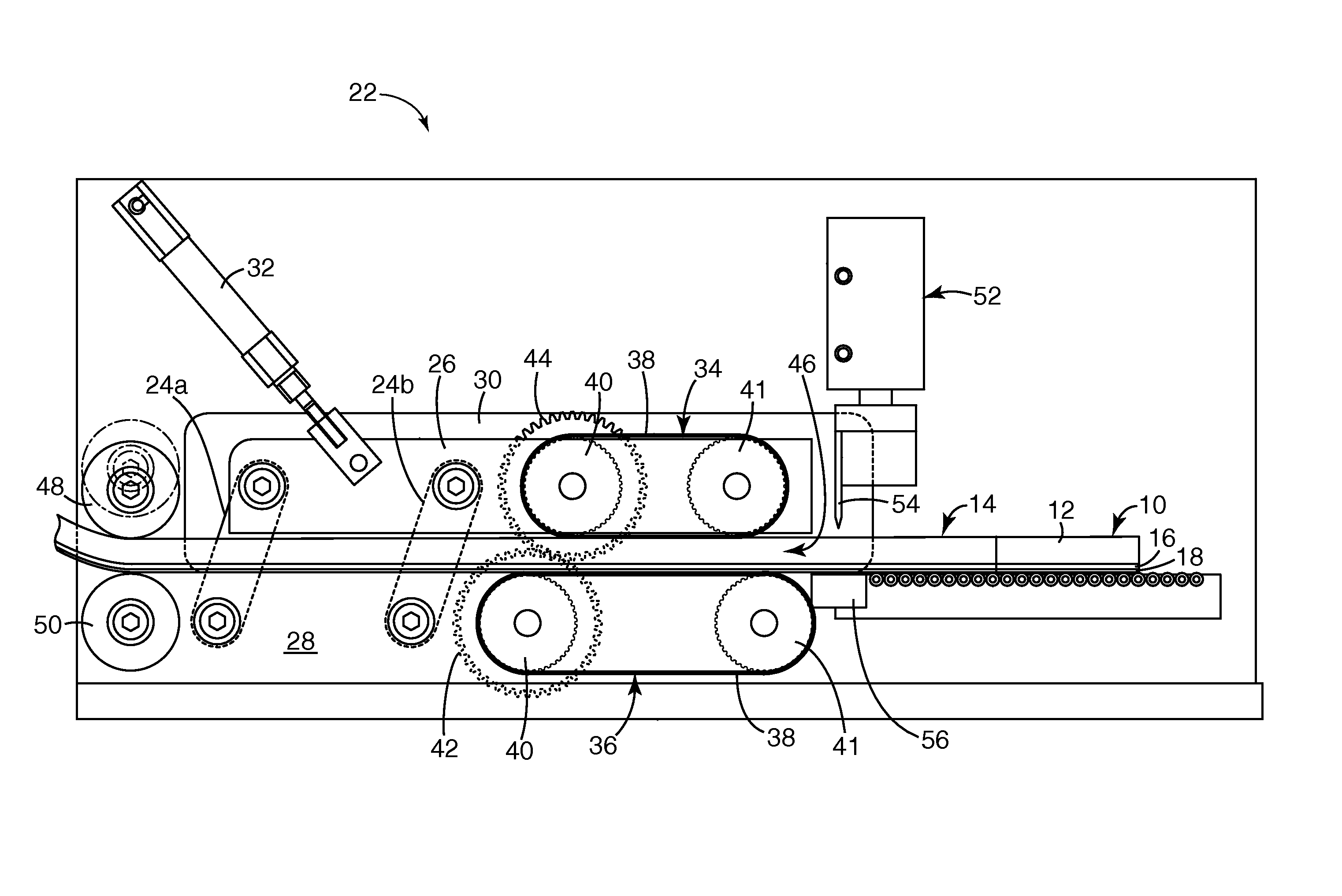

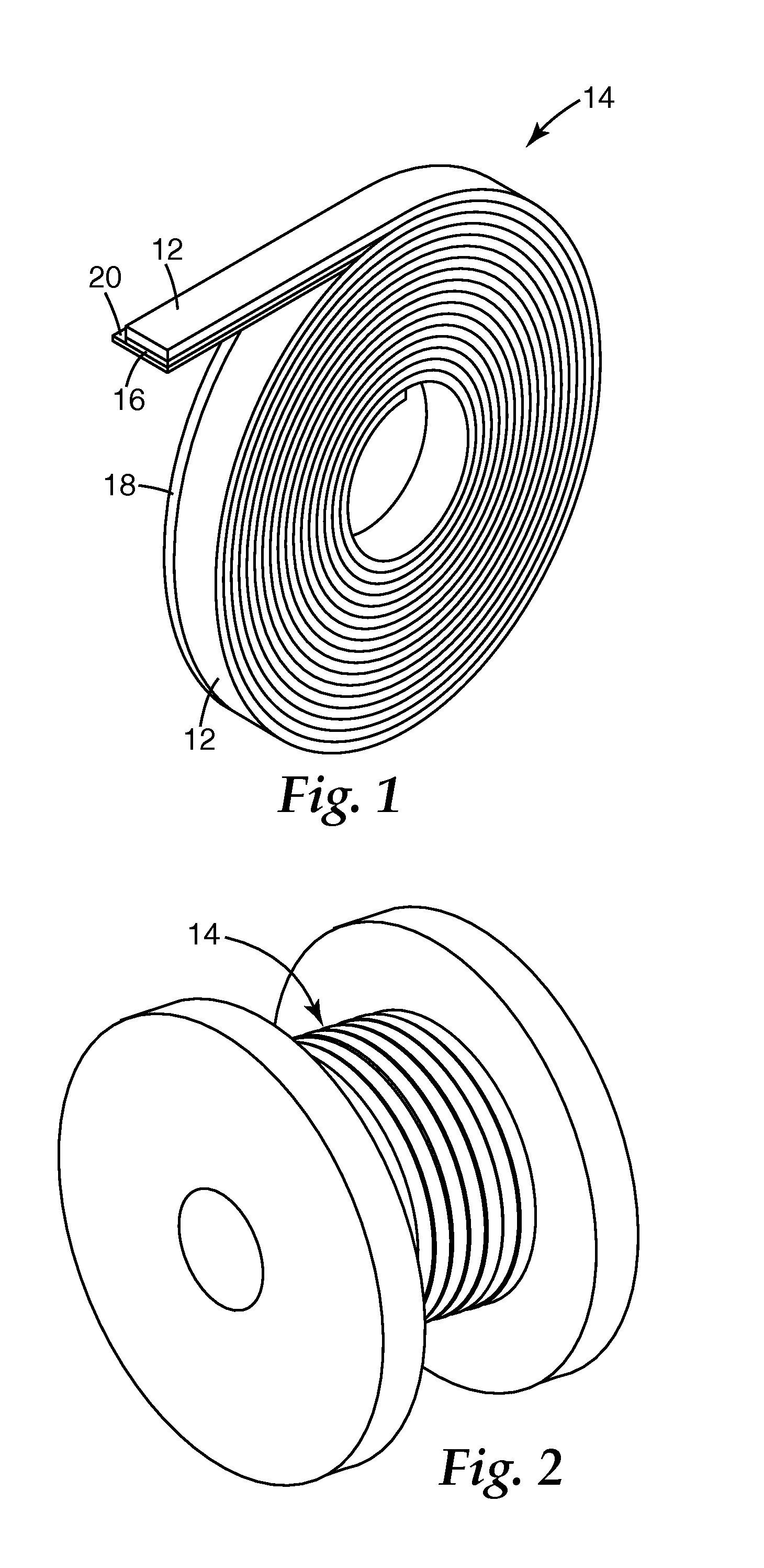

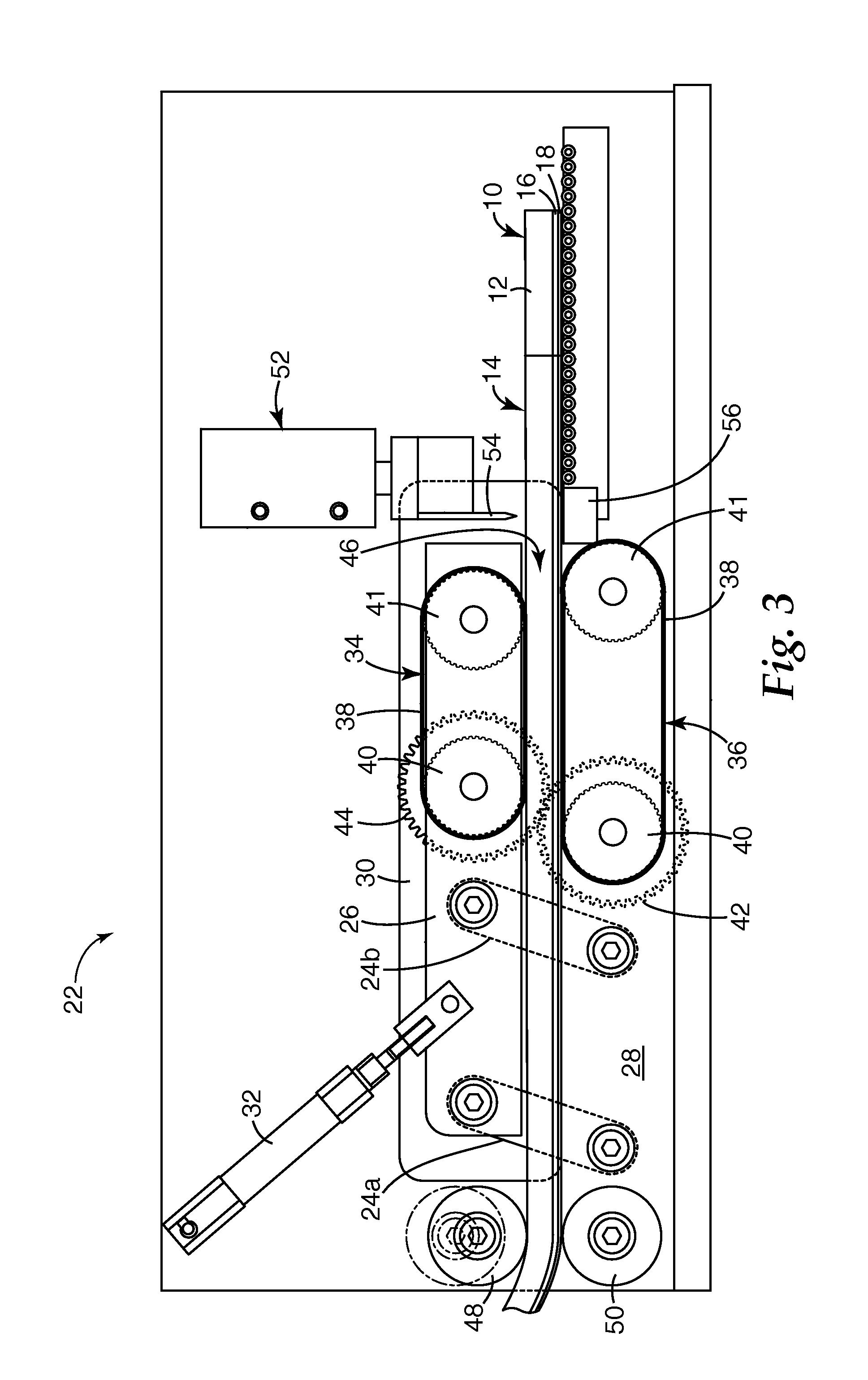

Apparatus and method for dispensing vehicle ballasting weights

InactiveUS20100059154A1Decrease stockImprove tire performanceTyre partsRotating bodies balancingAutomotive engineeringEngineering

An apparatus for and a method of dispensing a vehicle ballasting weight for balancing a portion of a vehicle. The method comprises dispensing a vehicle ballasting weight material comprising a flexible polymeric matrix material filled with a high density particulate material, and severing an incremental length of the vehicle ballasting weight material from an initial length of the weight material, where the incremental length can correspond exactly to a desired mass for the vehicle ballasting weight.

Owner:3M INNOVATIVE PROPERTIES CO

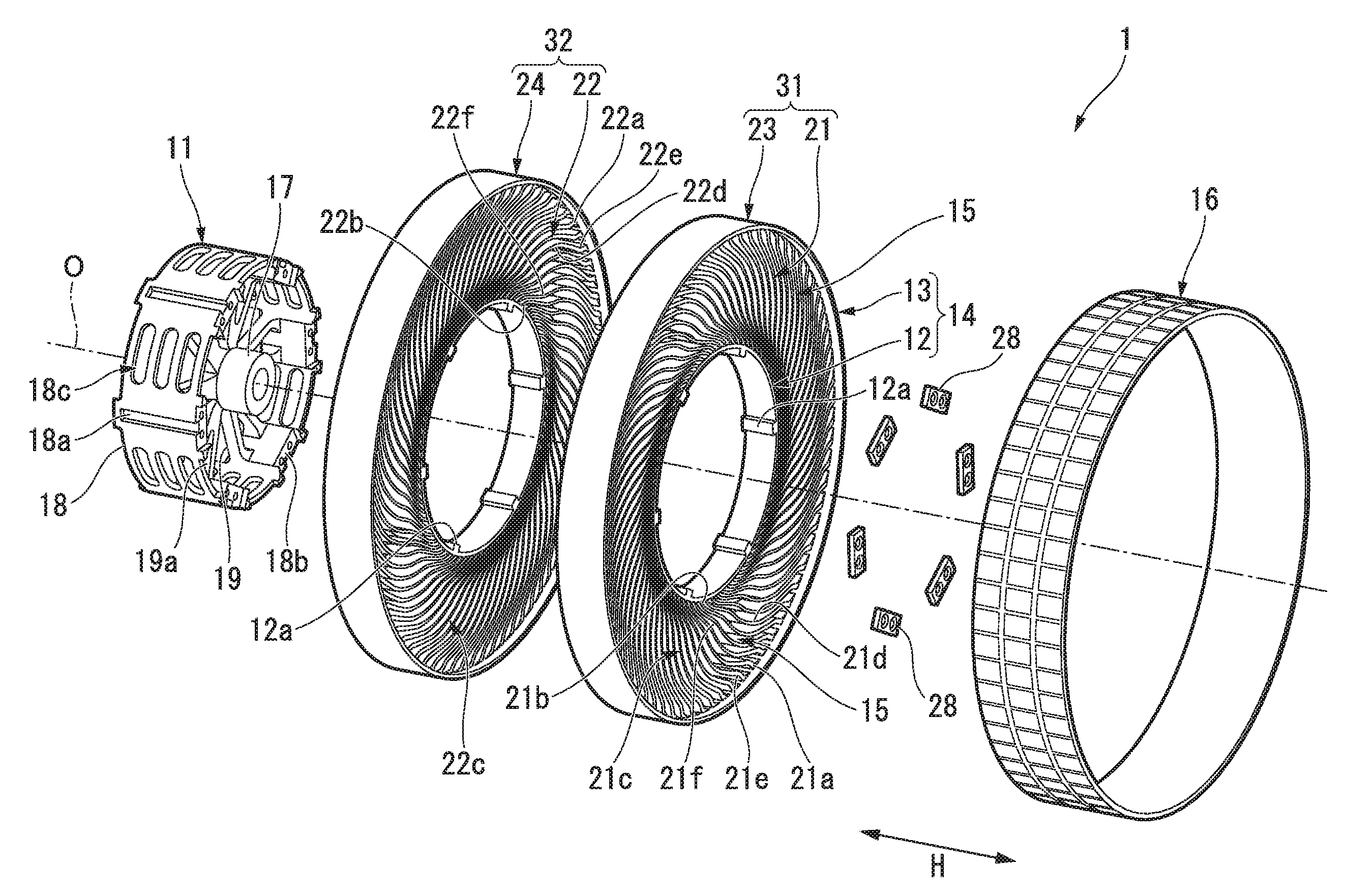

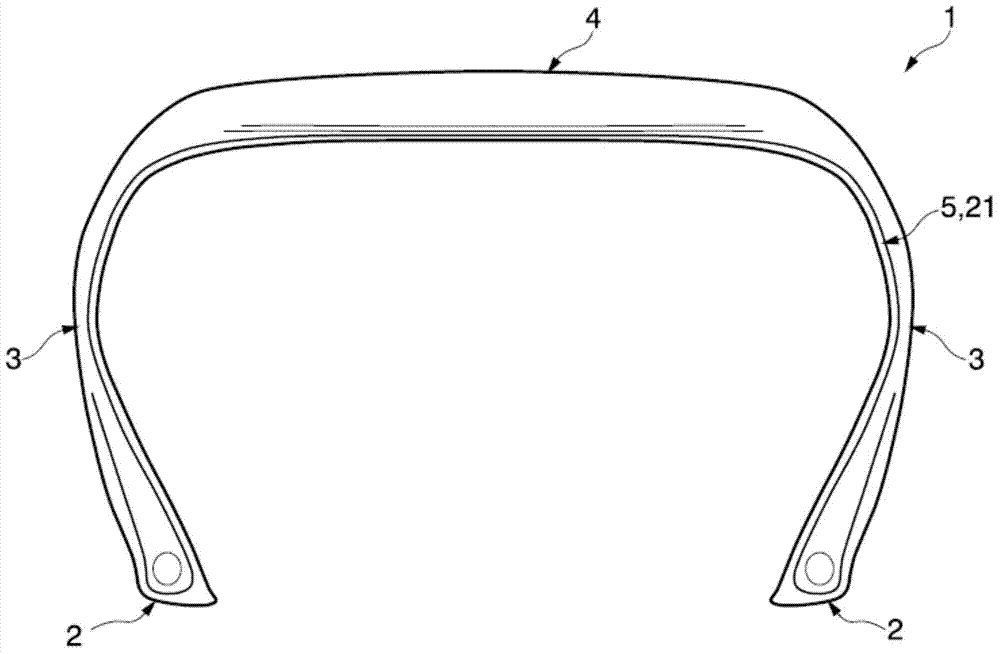

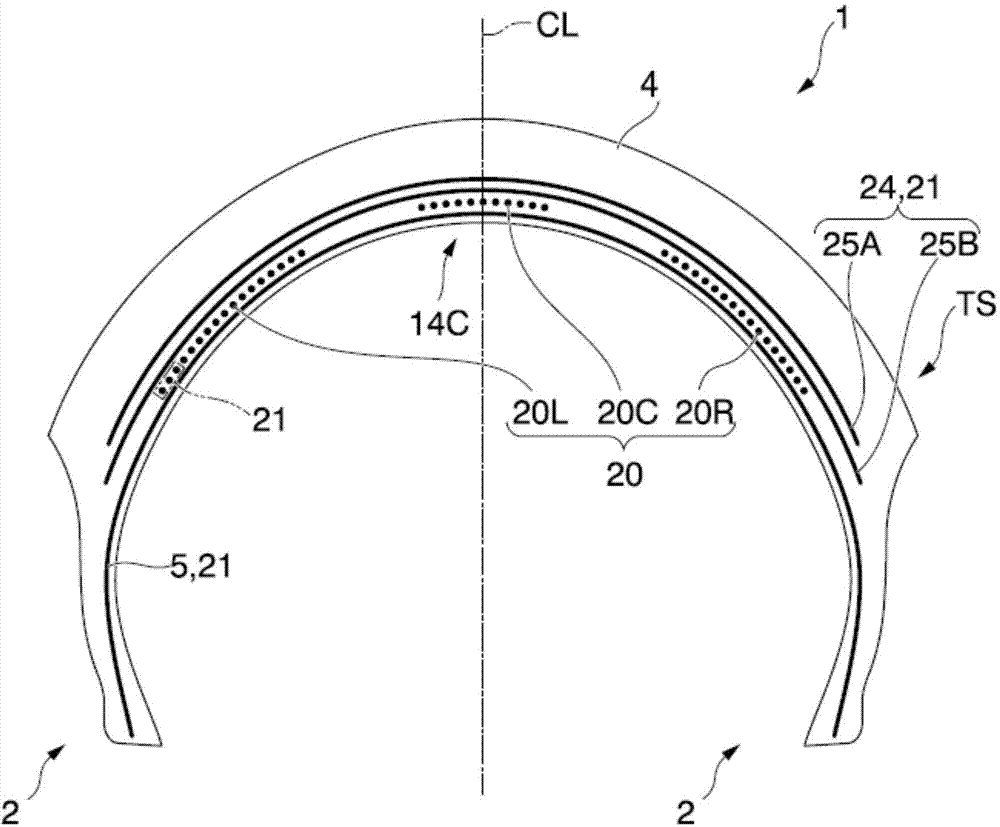

Non-pneumatic tire

ActiveUS20160297244A1Improved tire performanceLateral force on resistNon-inflatable tyresTyresEngineeringMechanical engineering

Owner:BRIDGESTONE CORP

Pneumatic tire

ActiveUS20080093000A1Uneven wearTraction performance and brake performance be improveTyre tread bands/patternsNon-skid devicesEngineering

Owner:TOYO TIRE & RUBBER CO LTD

Anisotropic homogeneous elastomeric closed torus tire design & method of manufacture

InactiveUS20050072507A1Effective installationImprove tire performanceWithout cord reinforcementNon-inflatable tyresMechanical engineeringAnisotropy

Owner:CHROBAK DENNIS S +1

Pneumatic tire

InactiveUS20070125469A1Improve tire performanceIncrease asymmetrySpecial tyresPneumatic tyre reinforcementsFiberCarbon fibers

A pneumatic radial tire has a carcass and a tread. The carcass has at least one carcass reinforcing ply and opposing bead portions. Each bead portion has a bead core and a bead apex radially. The apexes in each bead portion having the same radial height (HA), as measured from a bead base line (B). The tire has a bead reinforcing ply comprising chopped carbon fiber in the amount of 0.5 to 30 parts per hundred rubber located in only one bead portion of the tire, with the bead reinforcing ply being adjacent to the carcass reinforcing ply.

Owner:POLING DAVID CHARLES +11

Tire tread with groove reinforcement

ActiveUS9027615B2Reduce distortionStable structureSpecial tyresTyre tread bands/patternsEngineeringTread

The present invention relates to a tire tread comprising a plurality of circumferential grooves separating circumferential ribs, each groove comprising a bottom and two sidewalls, and a plurality of laterally separated reinforcements, wherein one reinforcement is arranged adjacent each circumferential groove, and wherein each reinforcement extends from the radially inner surface of the tread in a radial direction at least to the bottom of an adjacent circumferential groove to form the bottom of that groove. Further, the invention relates to a tire comprising a tread in accordance with the present invention.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire with tread having crossed configuration sipe

InactiveUS7546861B2Improve tire performanceImprove featuresTyresTyre tread bands/patternsLinear configurationEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

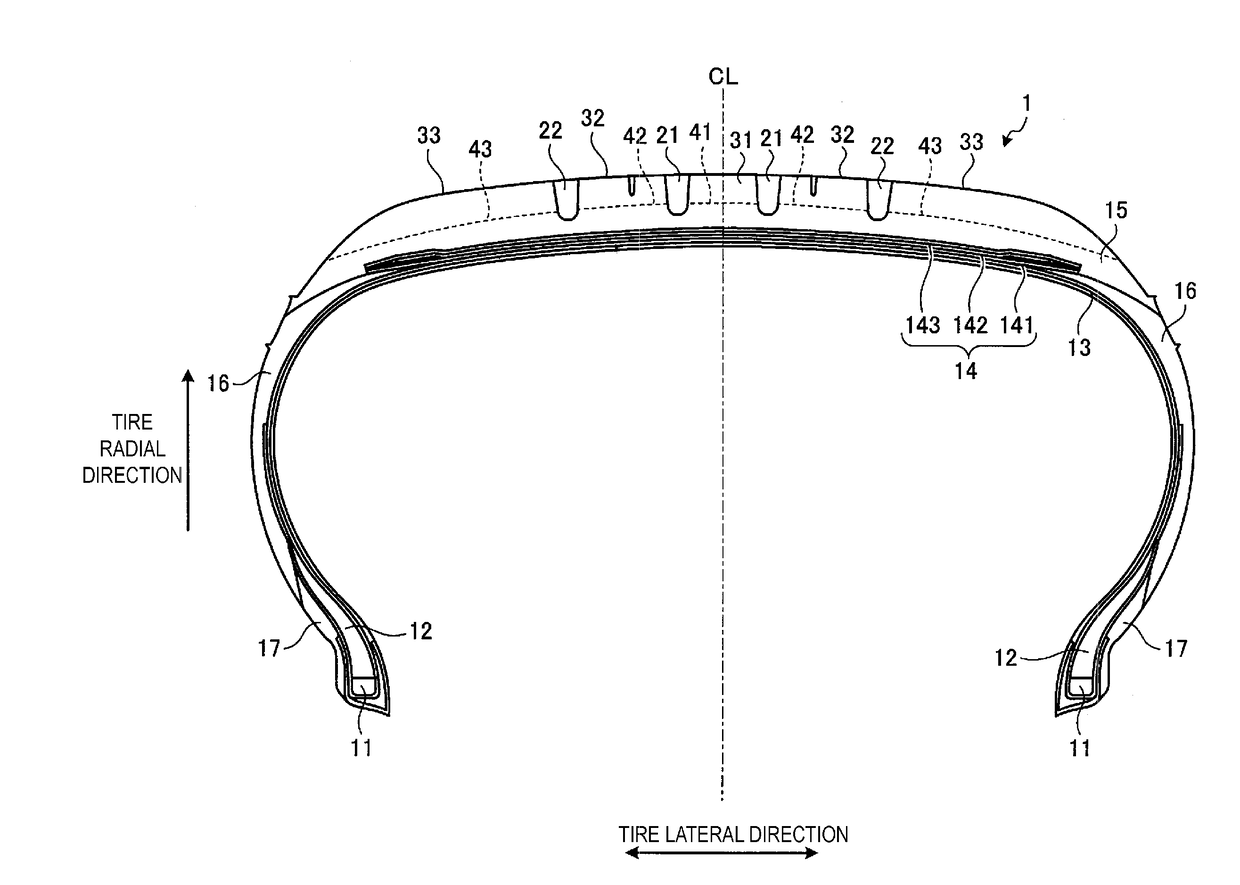

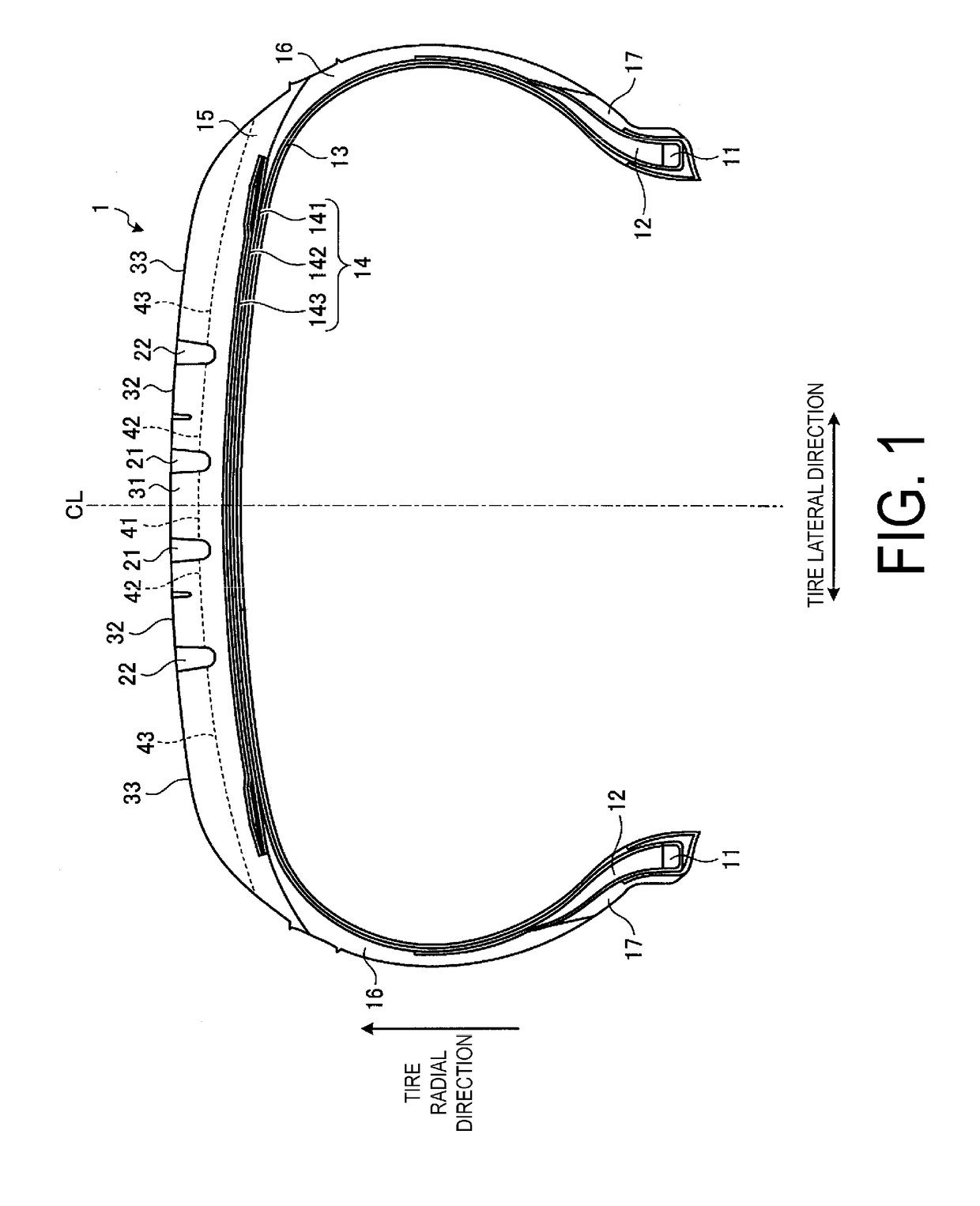

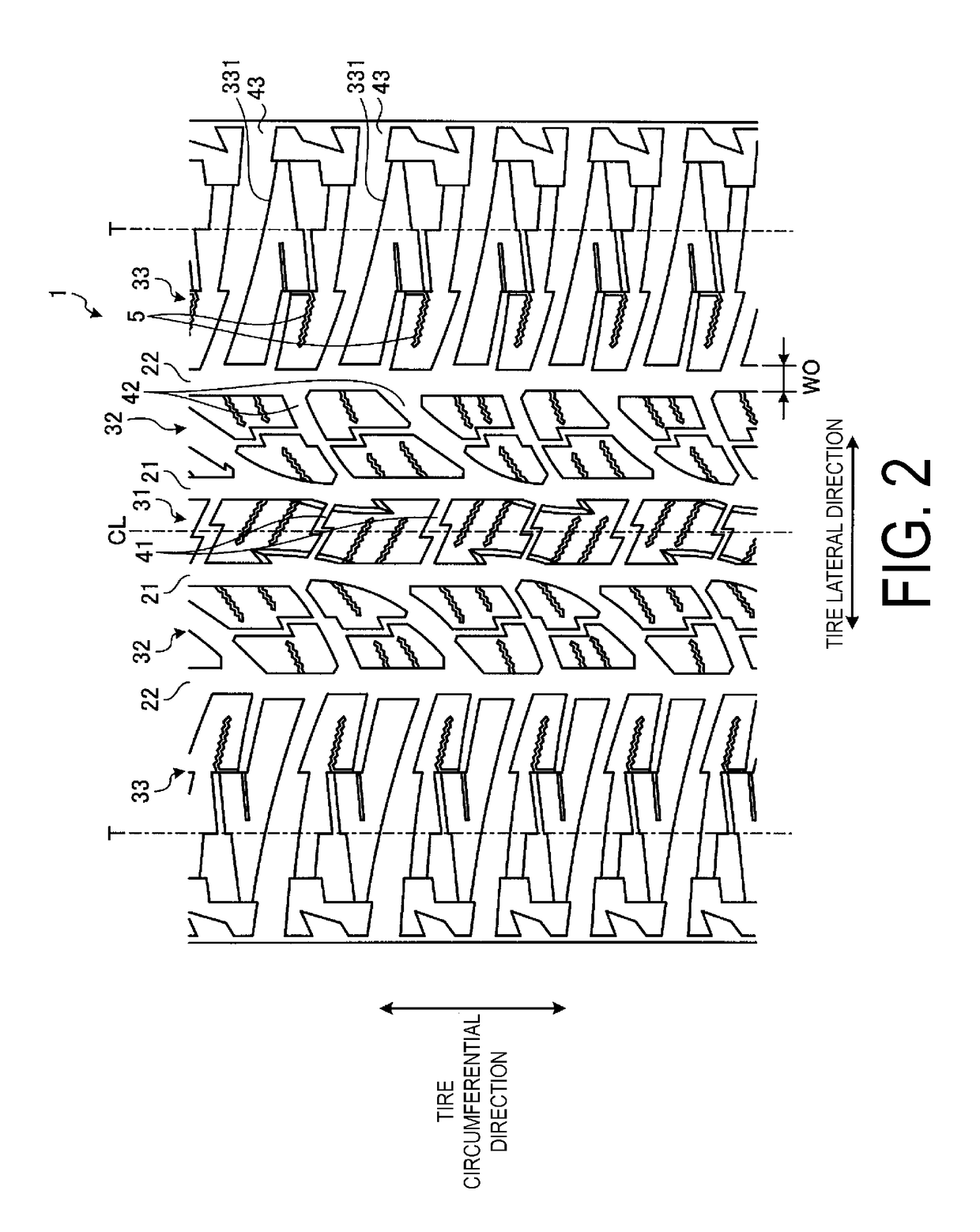

Pneumatic Tire

ActiveUS20170305201A1Improved snow performance and wear resistance performanceImprove tire performanceTyre tread bands/patternsGround contactMechanical engineering

A pneumatic tire comprises a plurality of blocks arranged on a tire ground contact edge. The plurality of blocks each comprise at least one main sipe that comprises: a two-dimensional sipe portion extending in a tire circumferential direction, and a three-dimensional sipe portion extending in a tire lateral direction that connects to the two-dimensional sipe portion.

Owner:THE YOKOHAMA RUBBER CO LTD

Cord, rubber-cord composite structure, and tire

InactiveCN104508194AReduce loadImprove tire performanceArtificial filaments from cellulose solutionsPneumatic tyre reinforcementsYarnFiber

An object of the present invention aims to provide a cord formed by twisting purified polysaccharide fibers which are manufactured by using a raw material with a low environmental impact and do not emit carbon disulfide, in which the cord is able to confer durability and resistance to external damage to a tire when the cord is used in the tire. A cord is provided formed by bringing a polysaccharide solution which is formed by dissolving a polysaccharide raw material in a liquid including an ionic liquid in contact with a solidifying liquid, and by twisting raw yarn which is purified polysaccharide fibers formed by spinning polysaccharides, in which a relationship between tenacity TB (cN / dtex) of the raw yarn at 25°C and elongation at break EB (%) of the raw yarn at 25°C satisfies the following expression (1) and the following expression (2), and a twisted yarn tenacity utilization rate (CT / TB) at the time of setting cord tenacity at 25°C to CT (cN / dtex) when the raw yarn is twisted to be a cord is greater than or equal to 70%.

Owner:BRIDGESTONE CORP

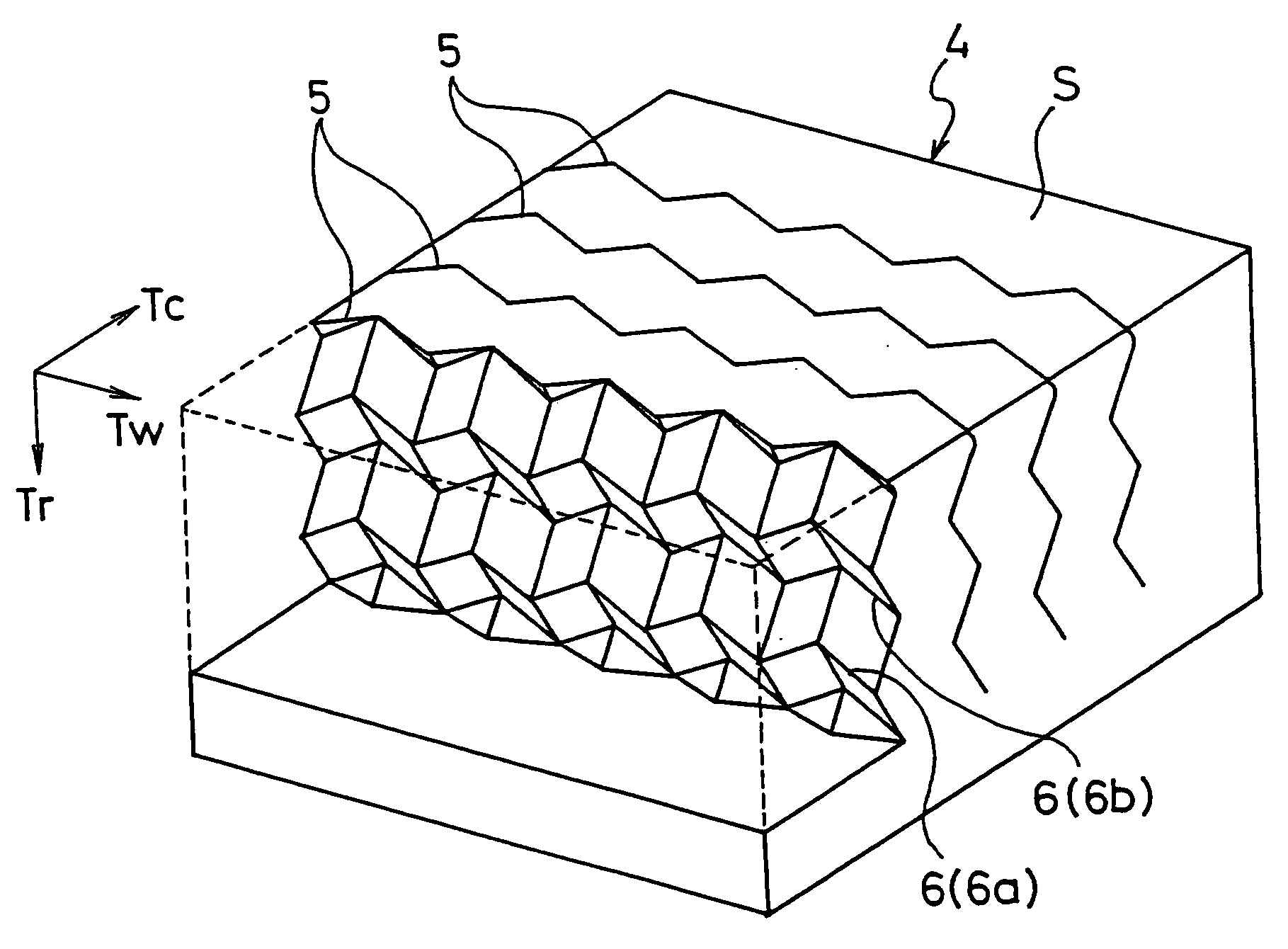

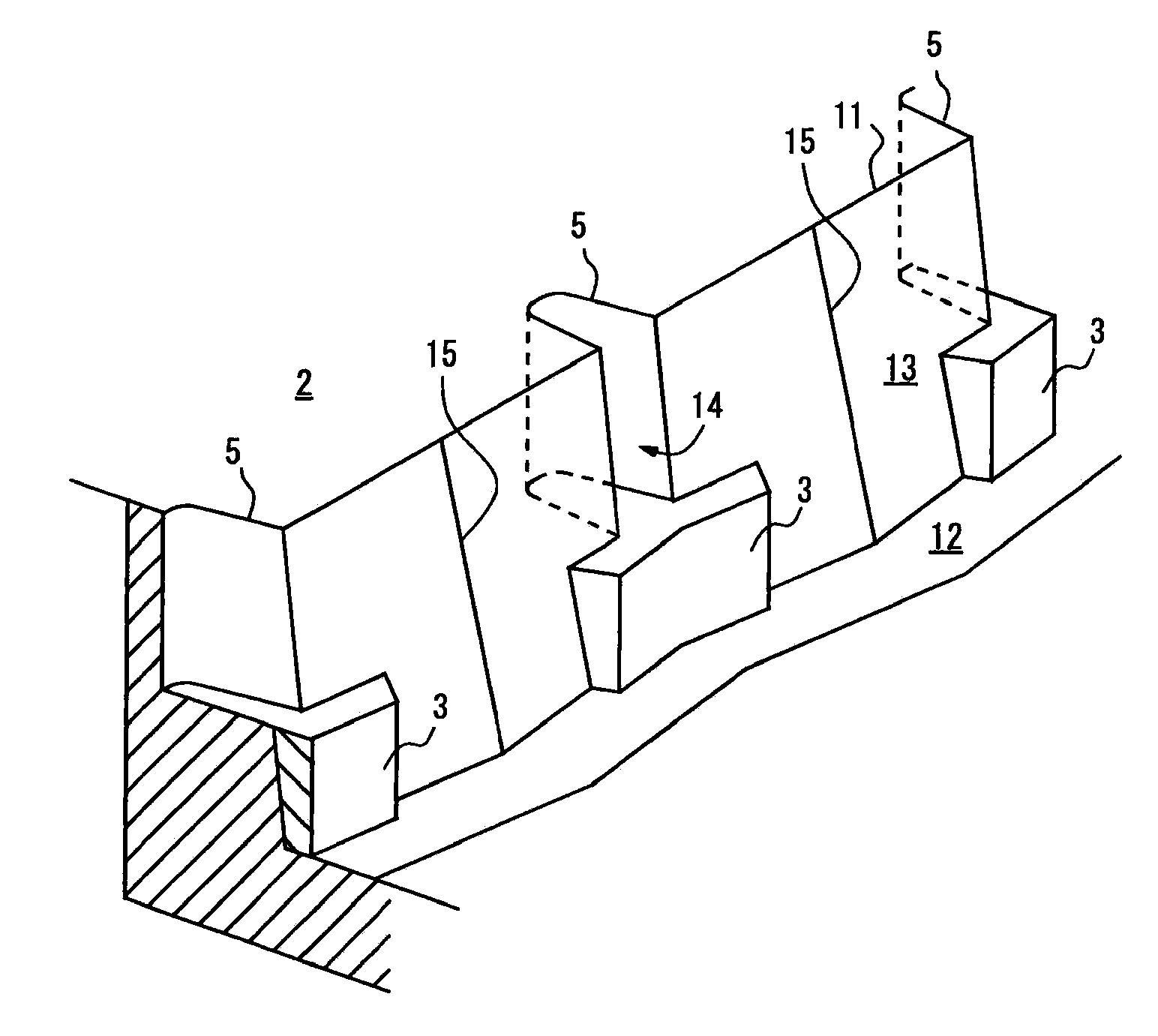

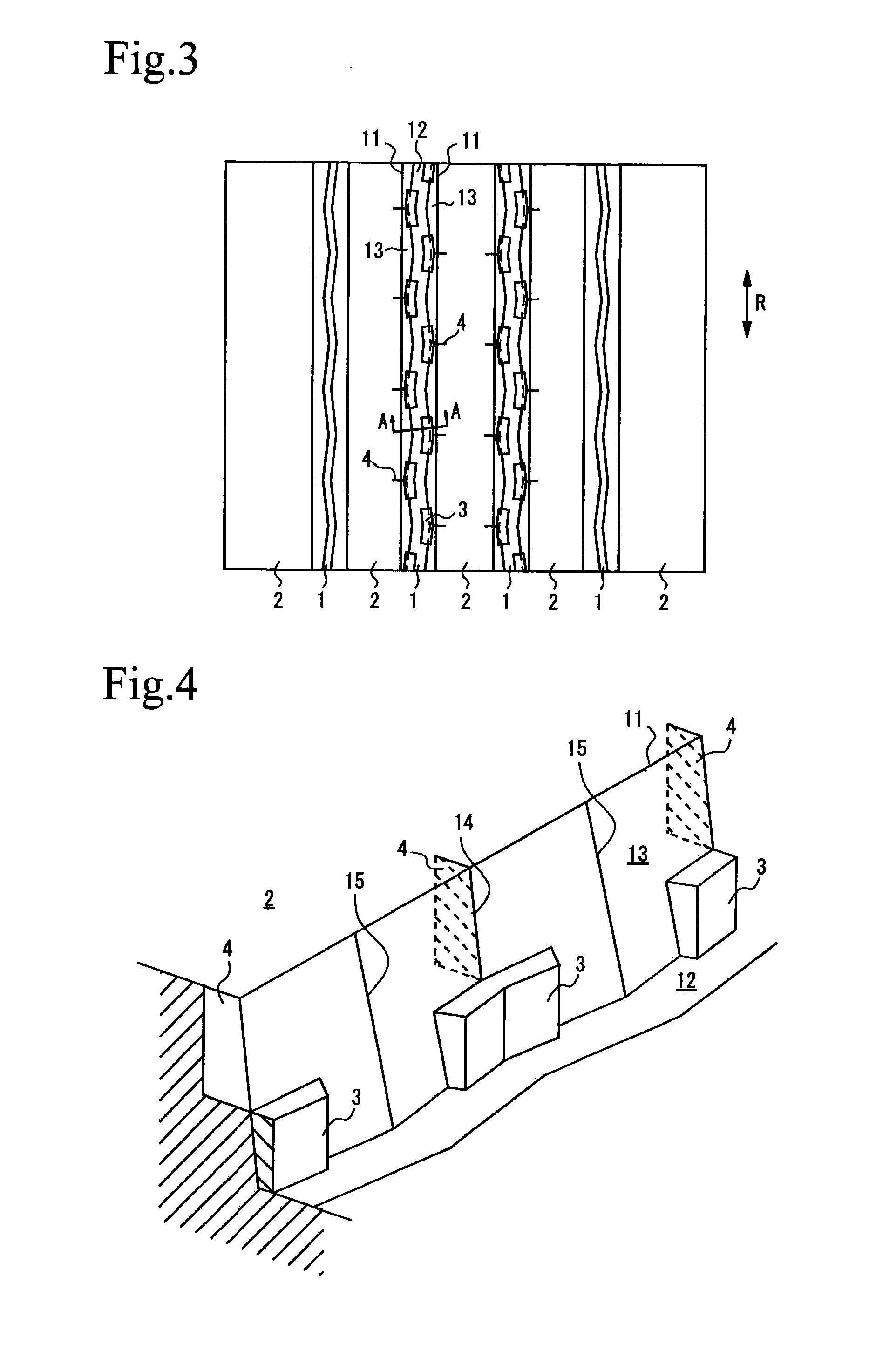

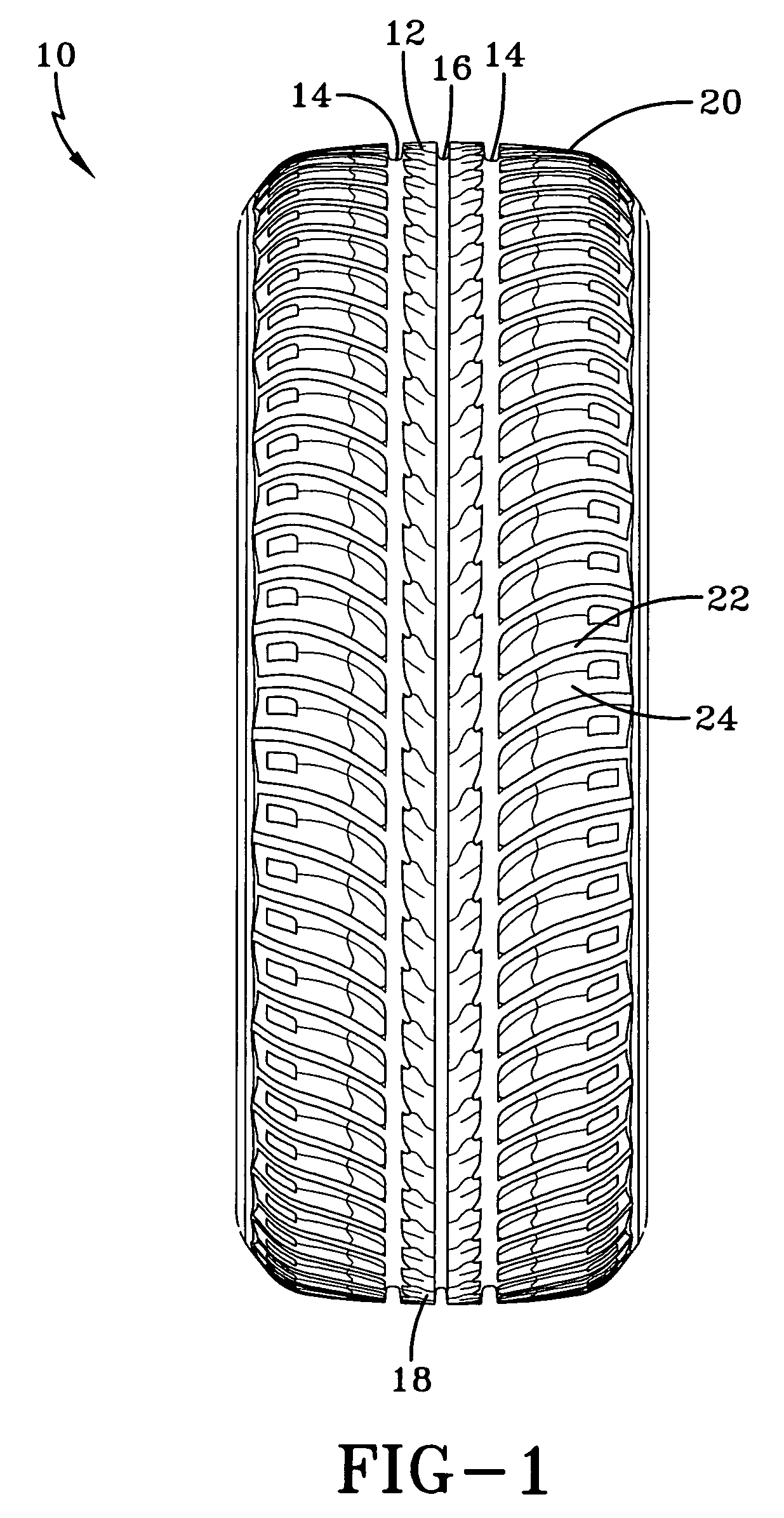

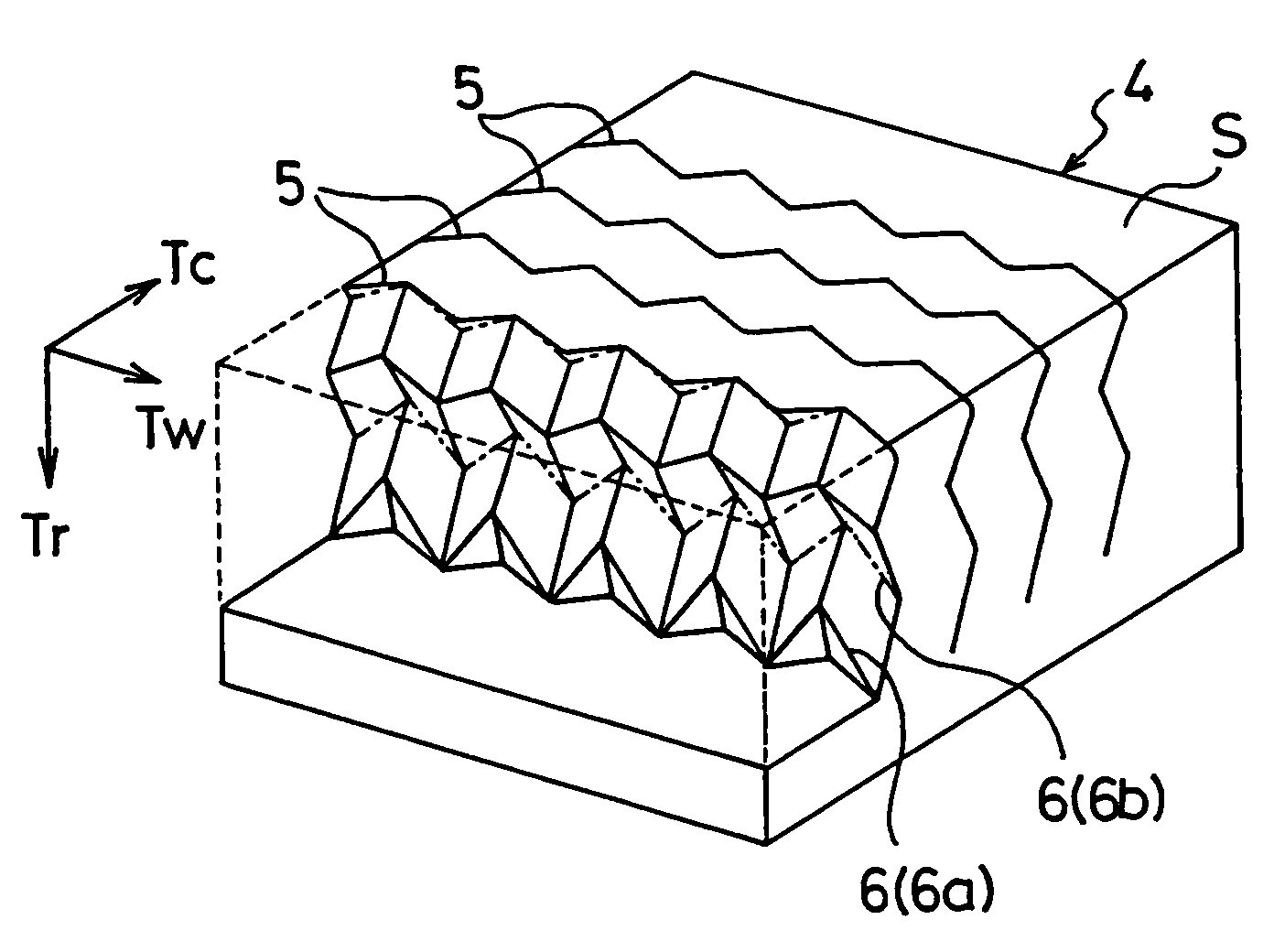

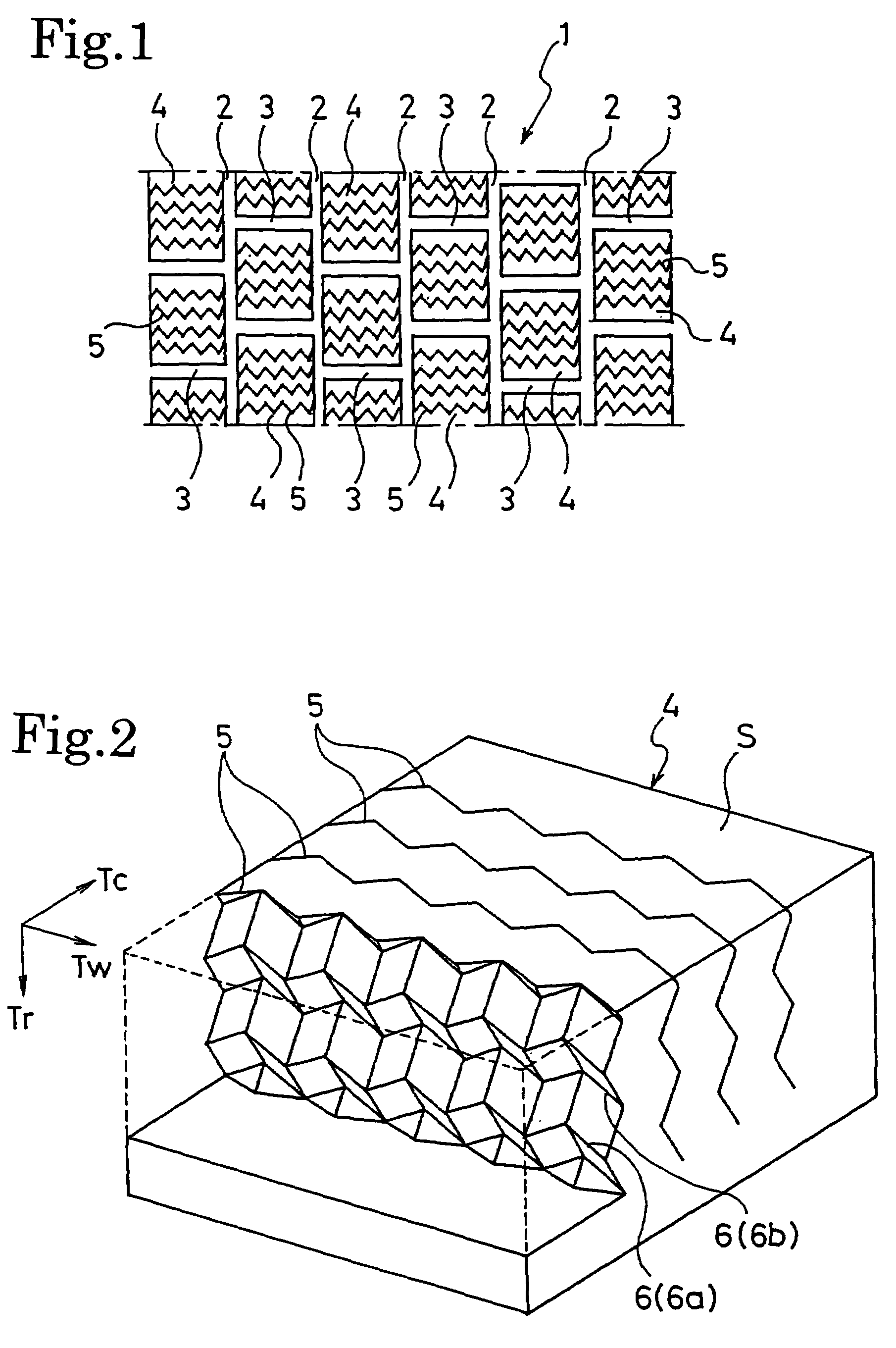

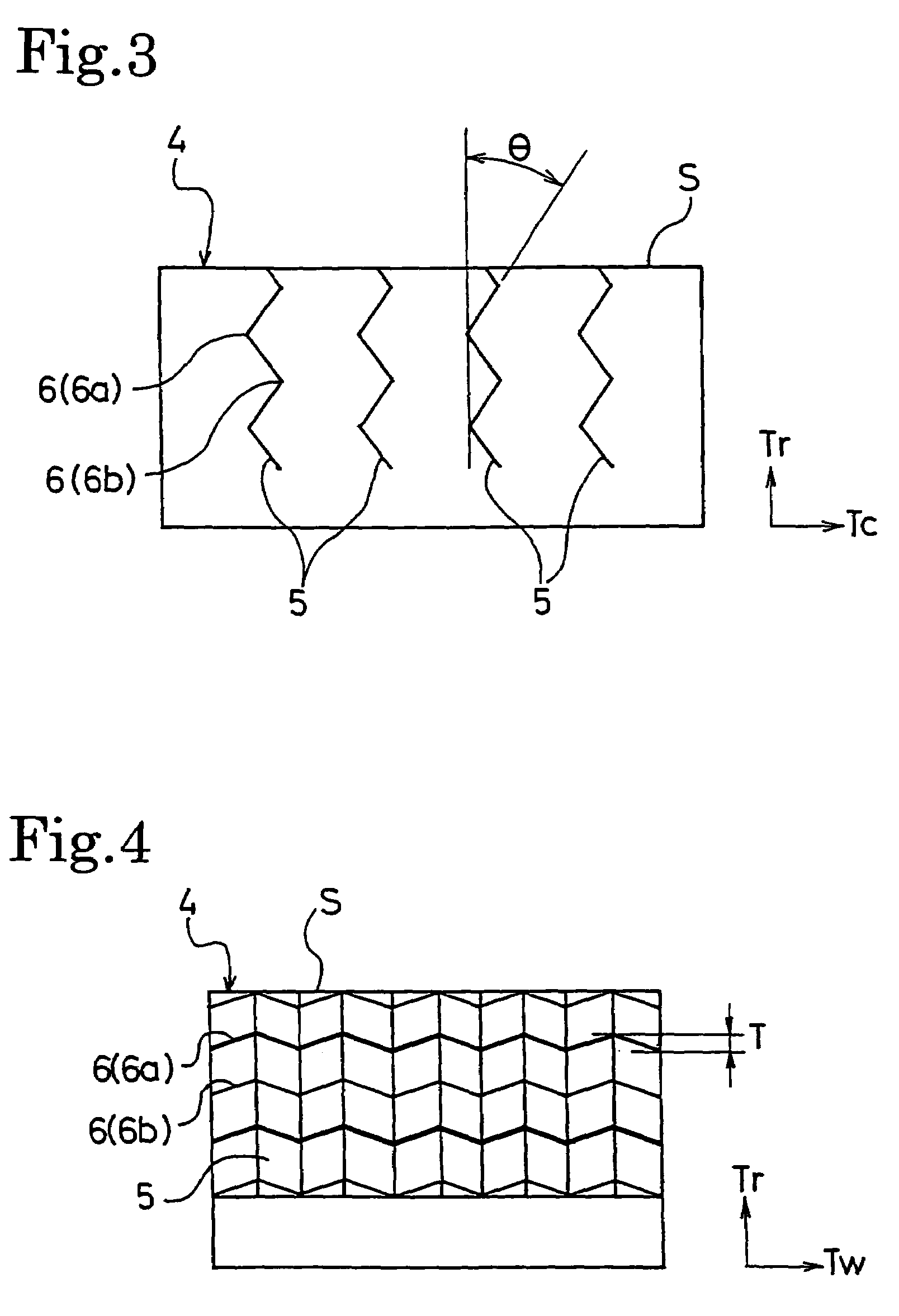

Pneumatic tire with tread including sipes having bent portions formed with zigzag shape with amplitude in radial direction

ActiveUS7637295B2Increase stiffnessImprove tire performanceTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

Disclosed is a pneumatic tire which is allowed to increase block stiffness not only during braking and driving but also during cornering, and is allowed thereby to compatibly enhance tire performances both during braking and driving and during cornering. The pneumatic tire of the present invention is one where a plurality of longitudinal grooves extending in a tire circumferential direction and a plurality of lateral grooves extending in a tire widthwise direction are provided in a tread portion, a plurality of blocks are defined by these longitudinal and lateral grooves, and a plurality of sipes extending in the tire widthwise direction are provided to each of the blocks, wherein, with regard to each of the sipes, a zigzag shape is formed on a tread surface, bent portions ranging in the tire widthwise direction while bent in the tire circumferential direction are formed inside the block at at least two positions in the tire radial direction, and a zigzag shape with an amplitude in the tire radial direction is formed in each of the bent portions.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveUS20070125468A1Improve tire performanceIncrease asymmetrySpecial tyresPneumatic tyre reinforcementsTire beadFiber

A pneumatic radial tire has a carcass and a tread. The carcass has at least one carcass reinforcing ply and opposing bead portions. Each bead portion has a bead core and a bead apex radially. The apexes in each bead portion having the same radial height (HA), as measured from a bead base line (B). The tire has a bead reinforcing ply comprising carbon fiber reinforcing cords located in only one bead portion of the tire, with the bead reinforcing ply being adjacent to the carcass reinforcing ply.

Owner:POLING DAVID CHARLES +9

Pneumatic tire

InactiveUS7779878B2Improve performanceEnhance layeringHeavy duty tyresHeavy duty vehicleEngineeringMechanical engineering

Owner:THE YOKOHAMA RUBBER CO LTD

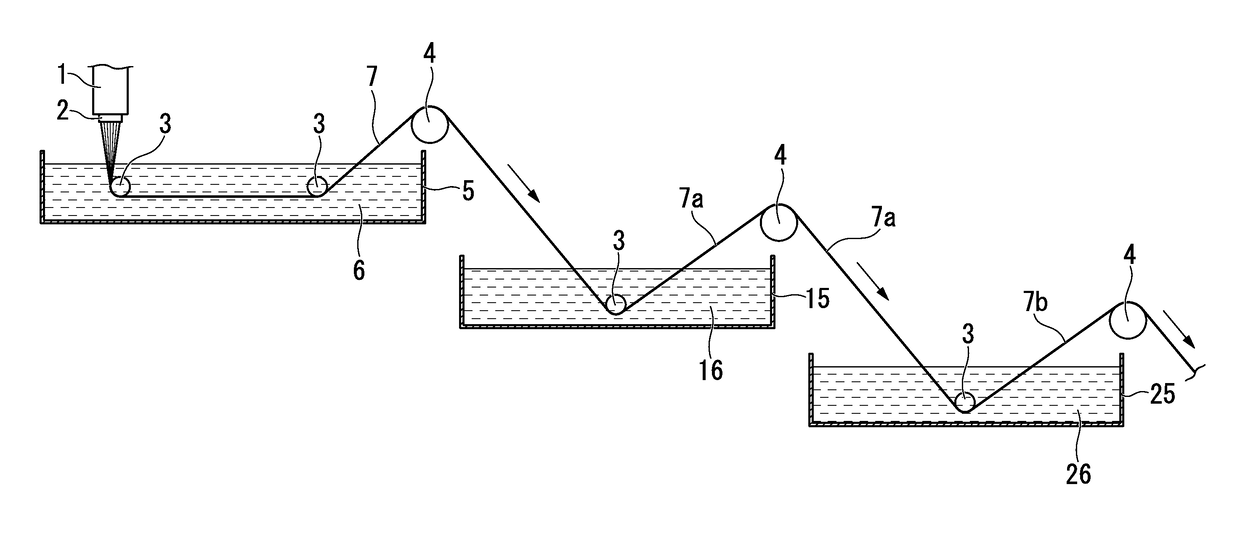

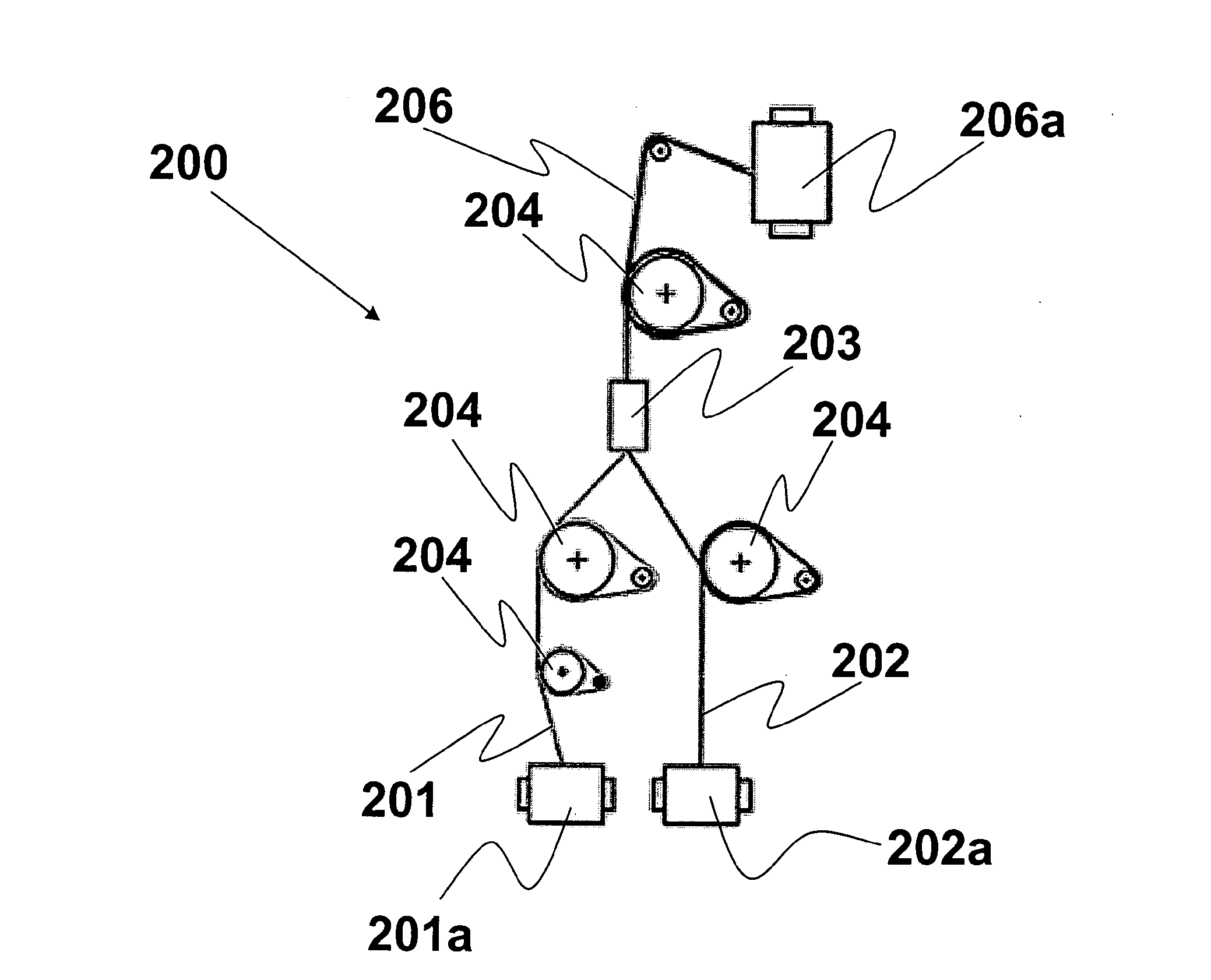

Production method for purified polysaccharide fibers, purified polysaccharide fibers, fiber-rubber complex, and tire

ActiveUS9670596B2Efficient productionHigh strengthArtificial filaments from cellulose solutionsArtificial filament recoveryFiberPhosphate ion

The present invention provides a production method for purified polysaccharide fibers in which carbon disulfide emission is suppressed while efficiently producing purified polysaccharide fibers having excellent strength, purified polysaccharide fibers produced by using the production method, a fiber-rubber complex using the purified polysaccharide fibers, and a tire having excellent tire characteristics using the fiber-rubber complex. The production method for purified polysaccharide fibers of the present invention is a production method for purified polysaccharide fibers of wet-spinning or dry-wet-spinning polysaccharide by bringing a polysaccharide solution obtained by dissolving a polysaccharide raw material in a liquid including an ionic liquid into contact with a solidification liquid including an ionic liquid, in which a concentration of the ionic liquid in the solidification liquid is 0.4% by weight to 50% by weight and the anionic moieties of the ionic liquid in the polysaccharide solution and the ionic liquid in the solidification liquid have one or more types selected from the group consisting of a phosphinate ion, a phosphate ion, and a phosphonate ion.

Owner:BRIDGESTONE CORP

Natural rubber, rubber composition using the same, and tire

InactiveUS20130303686A1Stable mechanical propertiesAvoid changeSpecial tyresPolymer sciencePreservative

The natural rubber of the present invention is natural rubber obtained by leaving standing for a prescribed period of time a hydrous coagulum obtained from a natural rubber latex to which a preservative is added and / or from a coagulum of a natural rubber latex to which a preservative is added and drying it. The natural rubber coagulum is inhibited from being changed in a molecular weight even in a standing step (aging) in a high moisture condition, whereby the natural rubber having stable mechanical properties is obtained. An isothiazoline base compound is used for the preservative. Further, a rubber composition containing the natural rubber is prepared, and a tire is produced by using the rubber composition.

Owner:BRIDGESTONE CORP

Tires with high strength reinforcement

InactiveUS6857458B2Light weightIncrease resistanceOff-road vehicle tyresTyresHigh intensityUltimate tensile strength

A strip of tire ply stock is reinforced with steel cords wherein the steel cords are constructed of high strength wire filament having at least a tensile strength of −2000×D+4400 MPa where D is the filament diameter in mm. Tires are constructed with the ply stock in the belt and / or carcass.

Owner:THE GOODYEAR TIRE & RUBBER CO

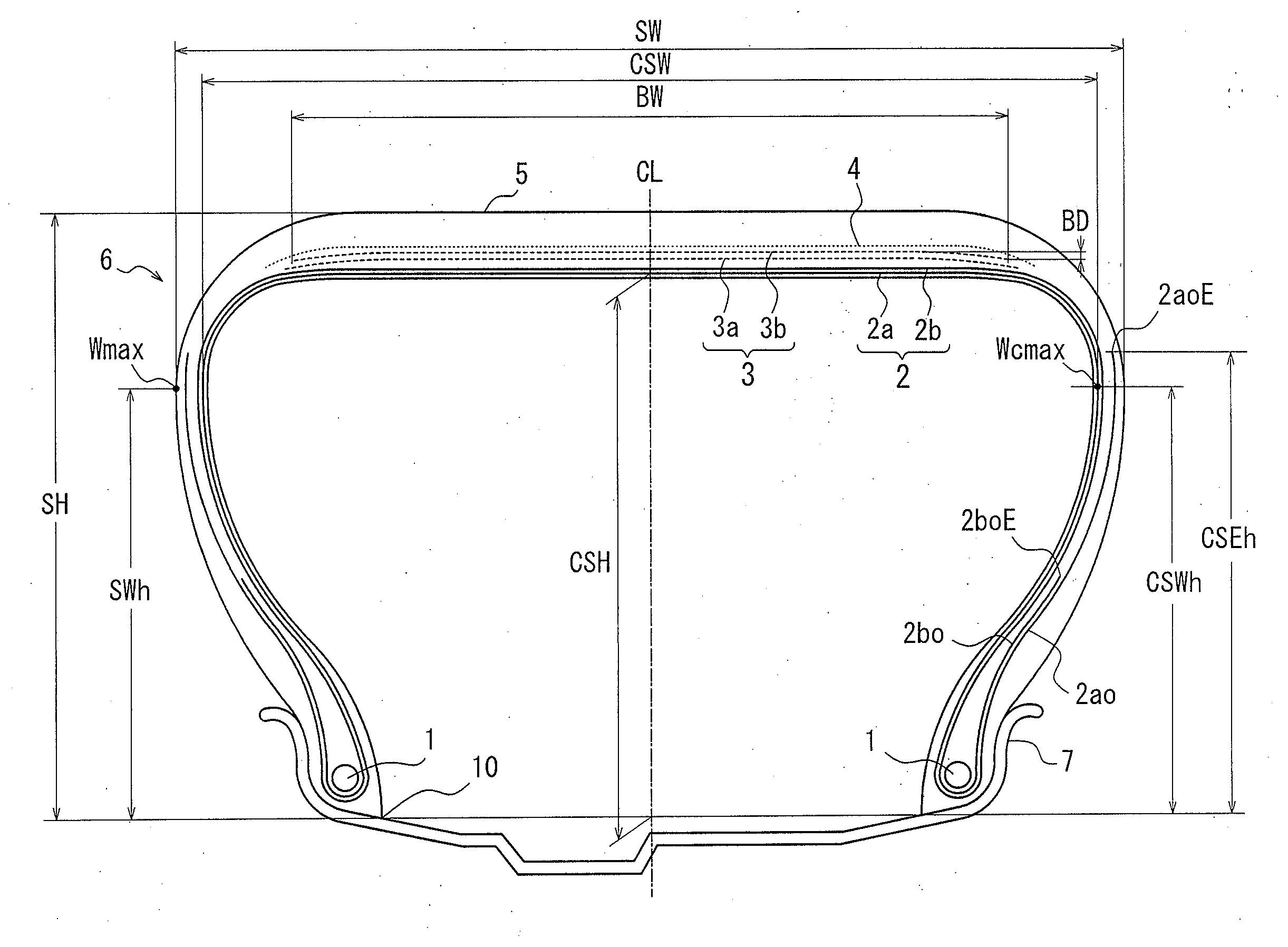

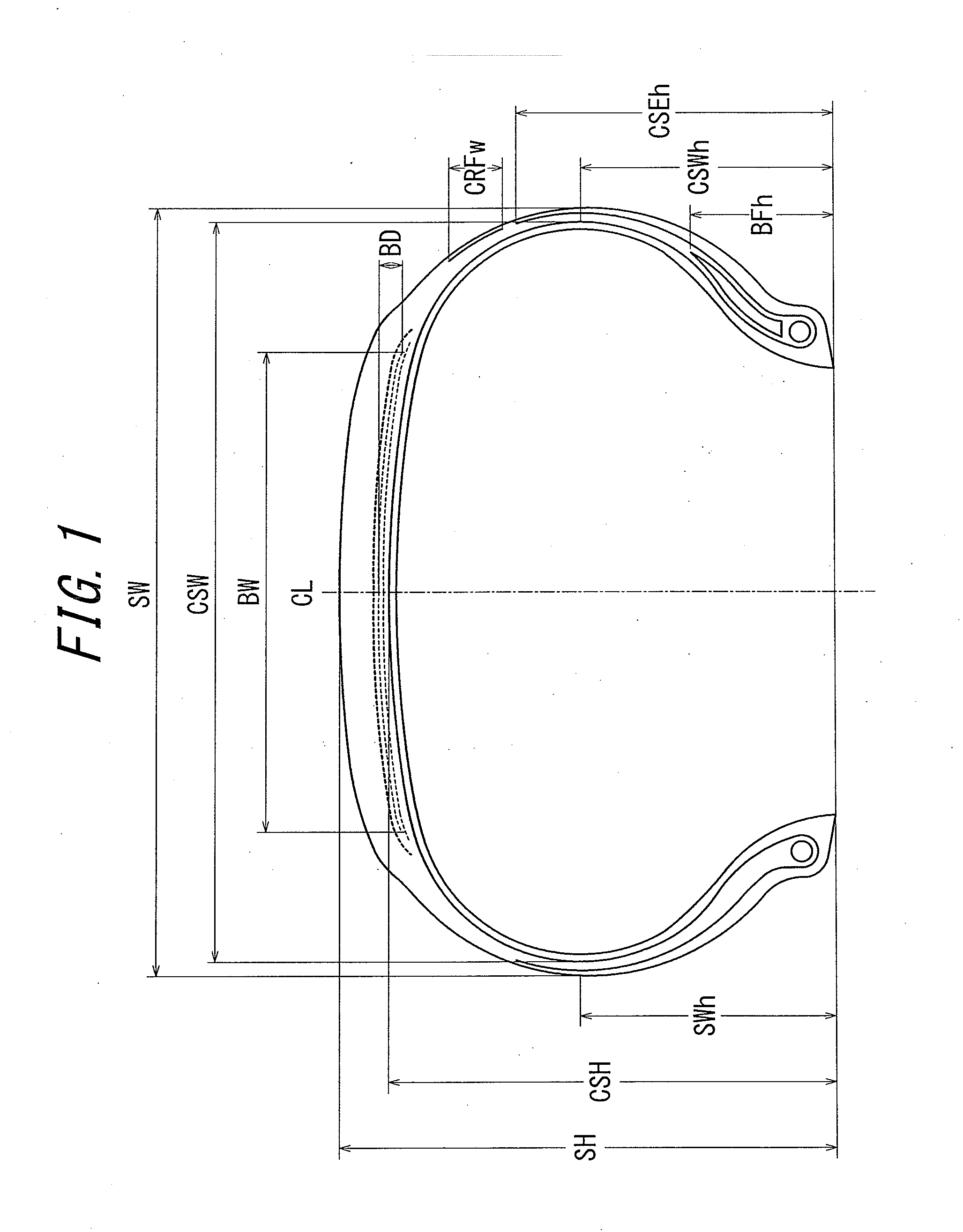

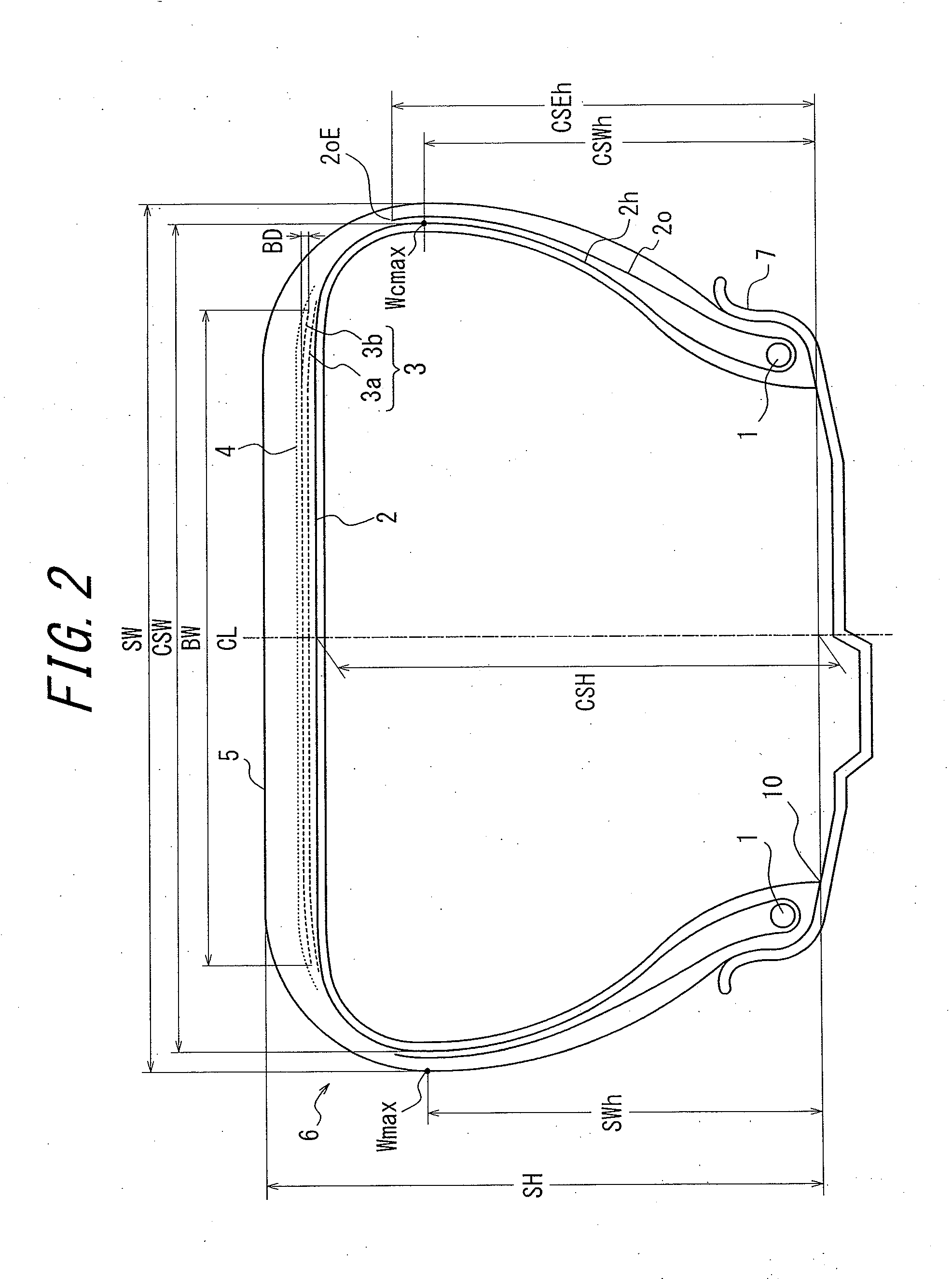

Pneumatic tire

ActiveUS20120193008A1Excellent wear resistance performanceHigh durabilitySpecial tyresPneumatic tyre reinforcementsTire rotationShort distance

There is provided a pneumatic tire having excellent uneven wear resistance performance, low rolling resistance and durability of side portion's appearance. The pneumatic tire comprises a carcass as a framework consisting of at least one carcass ply troidally extending between bead portions embedded with a pair of bead cores and turned around the bead cores from an inner side to an outer side in a tire width direction, a belt comprising at least one inclined belt layer and a tread successively disposed on a radially outer side of a crown portion of the carcass, wherein a ratio BD / BW is in a range between 0.01 and 0.04 in a section of the tire in the width direction in a state where the tire is mounted on an application rim, where BD is radius difference between radius at a central portion and radius at an end portion in the tire width direction of the outermost layer of the inclined belt layer and BW is a width of the outermost layer and CSEh is larger than SWh, where CSEh is a shortest distance from an end of a turn-up portion of the at least one carcass ply to a line drawn in parallel with a tire rotation axis at a bead toe and SWh is a shortest distance between a line drawn in parallel with the tire rotation axis at a maximum width position of the tire and the line drawn in parallel with the tire rotation axis at the bead toe.

Owner:BRIDGESTONE CORP

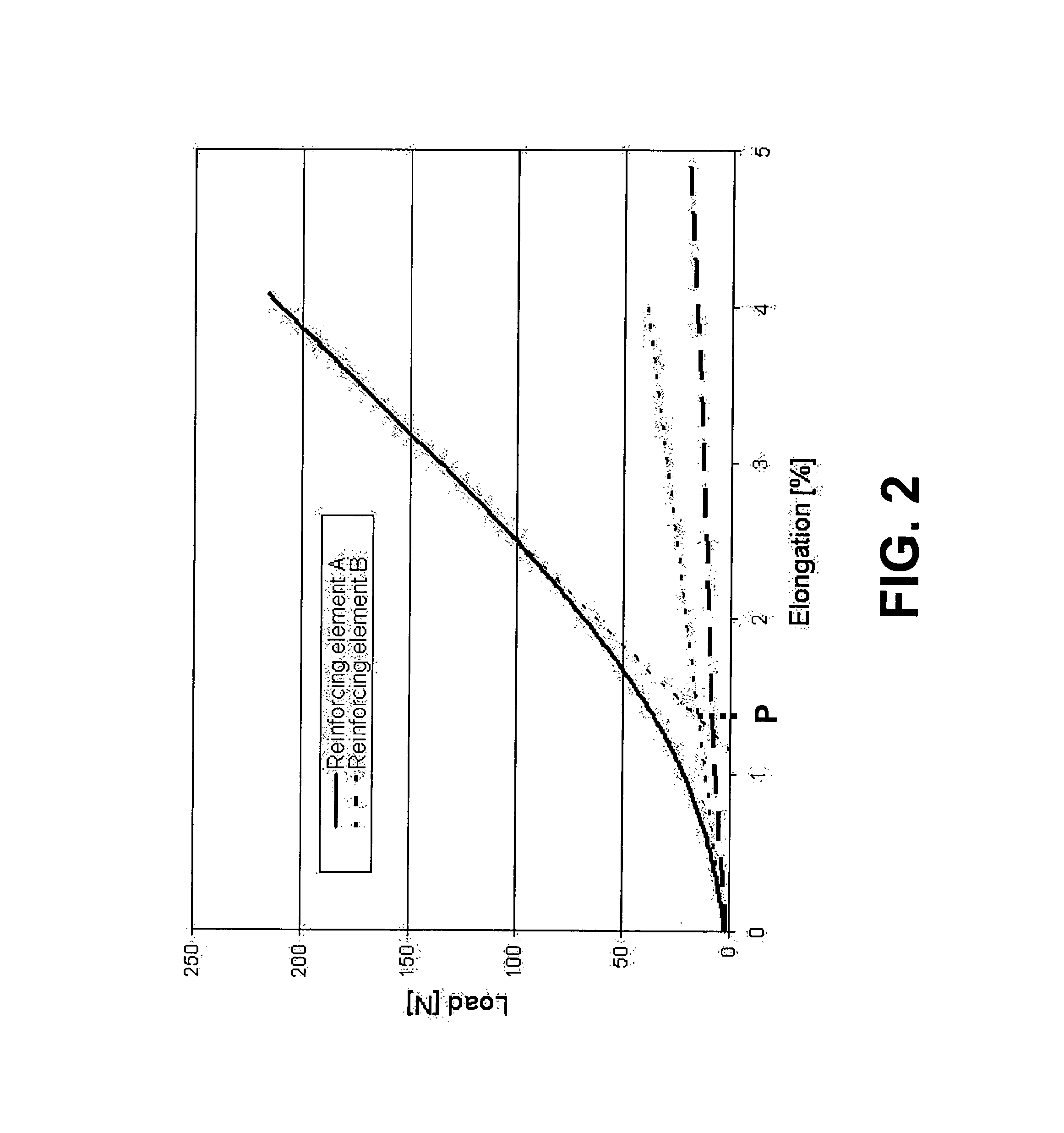

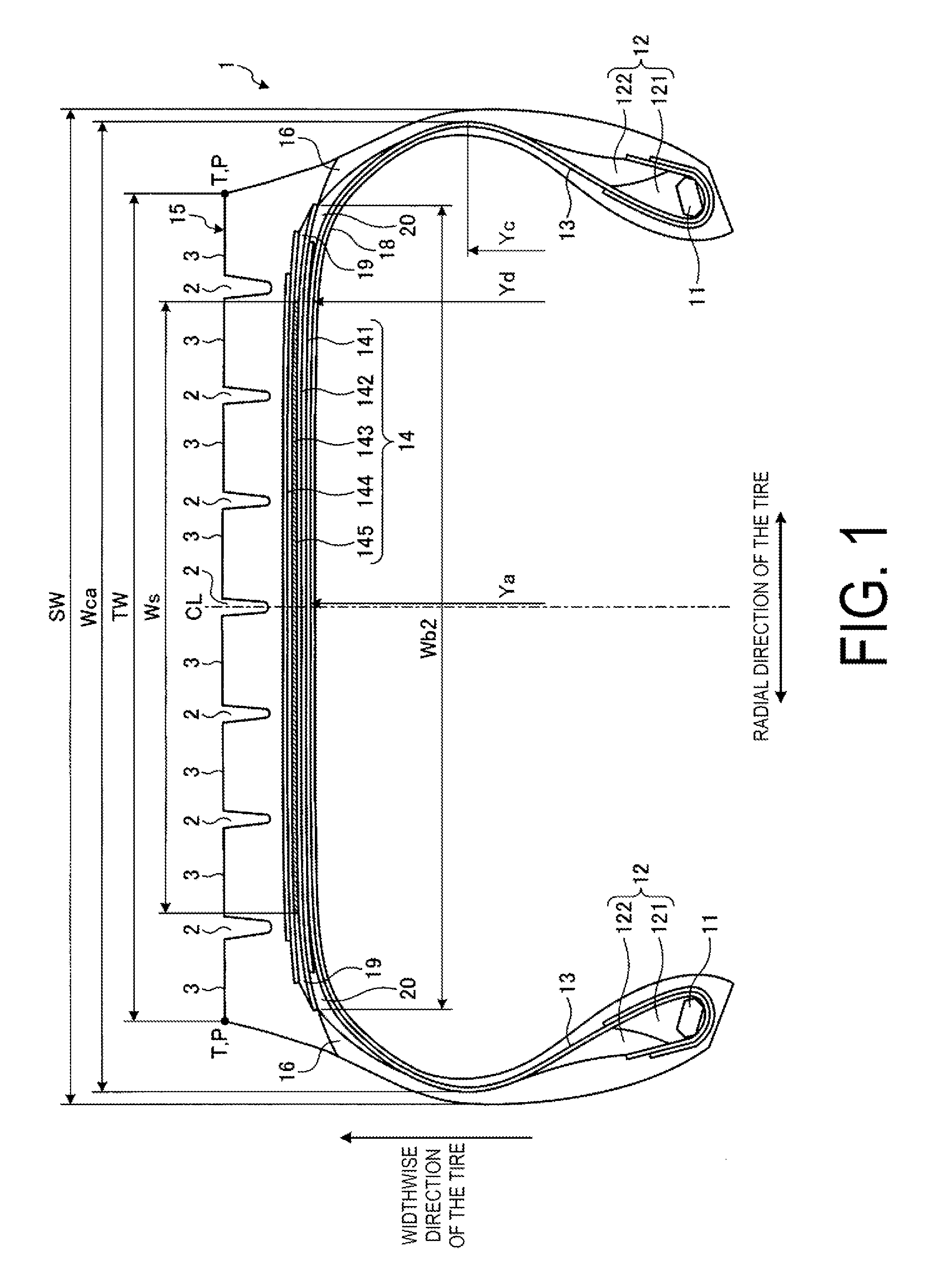

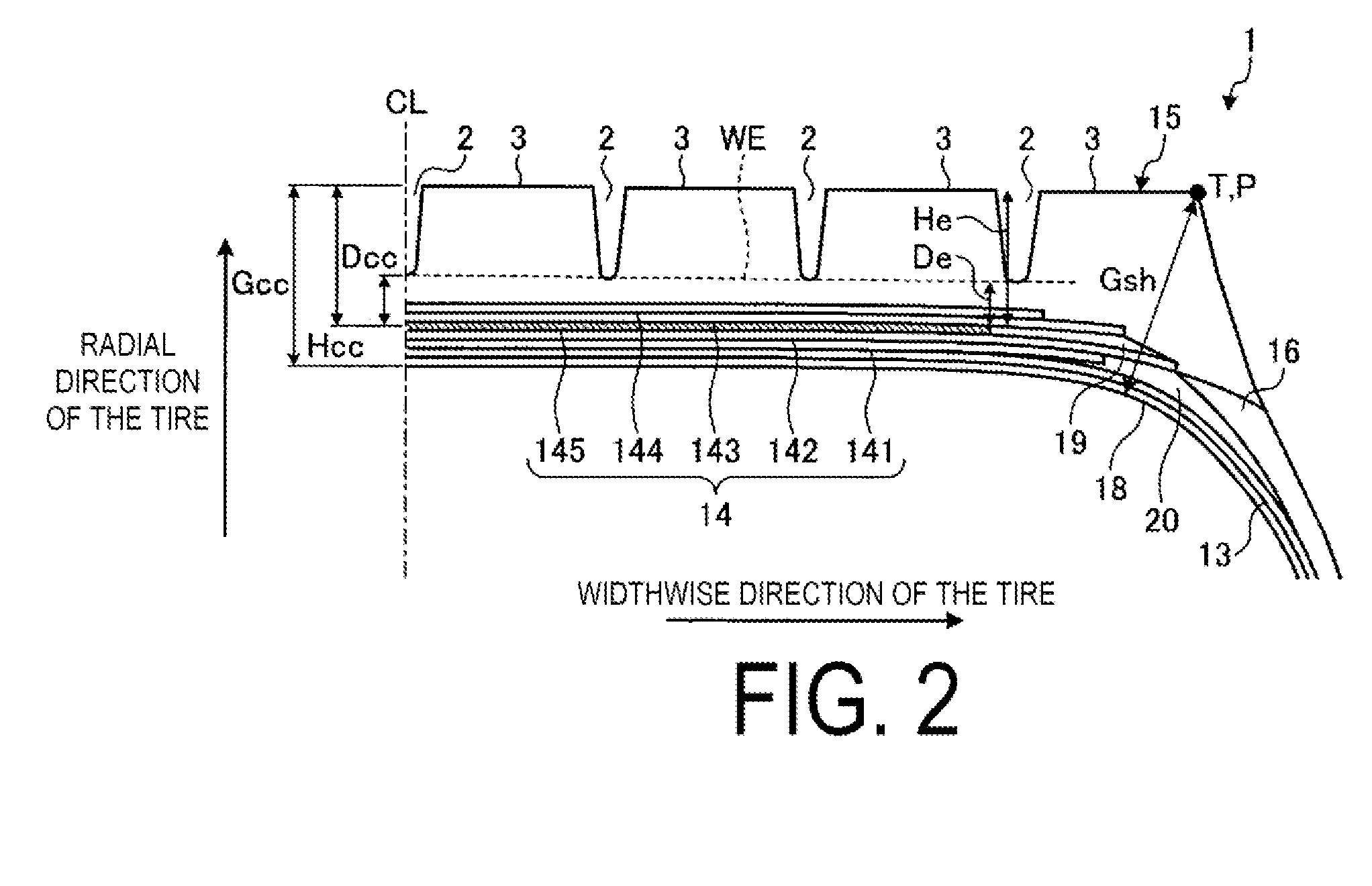

Tire having a structural element reinforced with a hybrid yarn

ActiveUS20130042593A1Improve performanceImprove tire performancePneumatic tyre reinforcementsYarnYarnEngineering

A tire includes at least one structural element which includes at least one reinforcing element which includes at least one hybrid yarn, the at least one hybrid yarn including a plurality of filaments obtained from at least one first multifilament yarn having a first initial tangent modulus and at least one second multifilament yarn having a second initial tangent modulus, the first and the second initial tangent modulus being different from each other, each one of the first and the second multifilament yarn including a plurality of individual filaments, the individual filaments of each one of the first and the second multifilament yarns being at least partially intermixed with each other. The tire may be a high performance or ultra high performance tire, or a tire suitable for being employed in sporting contests such as track motor races, or a tire suitable for sports utility vehicles.

Owner:PIRELLI TYRE SPA

Pneumatic Tire

ActiveUS20150328930A1Increase pressureFine surfaceHeavy duty tyresHeavy duty vehicleGround contactMechanical engineering

A pneumatic tire is provided with at least three circumferential main grooves extending in the circumferential direction of the tire and a plurality of land portions defined by the circumferential main grooves. Additionally, the belt layer is formed by layering a pair of cross belts having a belt angle, as an absolute value, of no less than 10° and no more than 45° and having a belt angles of mutually opposite signs, and a circumferential reinforcing layer having a belt angle within a range of ±5° with respect to a circumferential direction of the tire. A tire ground contact width (Wg) and a carcass cross-sectional width (Wca) of a carcass layer have a relationship such that 0.64≦Wg / Wca≦0.84.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com