Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

299results about How to "Improve lubrication conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of high alloy seamless steel tube

InactiveCN101811149AImprove surface qualityImprove lubrication conditionsManufacturing cost reductionPunching

The invention discloses a manufacturing method of high alloy seamless steel tube, comprising the following technical steps: (1) producing a high alloy hollow shell with centrifugal casting technology; (2) heating the hollow shell and plugging the opening of the hollow shell when heating; (3) reaming and wall thinning for the hollow shell after being heated by using a perforating machine so as to form a blank; (4) tube rolling for the bland by using a pipe and tube mill so as to form a pierced billet; (5) sizing and reducing for the pierced billet by using a sizing and reducing machine so as to obtain the high alloy seamless steel tube. The blank with the manufacturing method uses centrifugal casting for the hollow shell and lubricant is added by using the characteristic of hollow shell, thereby avoiding the problems of high alloy material in the technologies of forging, rolling and punching such as low metal yield and high rejection rate due to difficult deformation, thereby greatly reducing the manufacturing cost.

Owner:XINXING DUCTILE IRON PIPES CO LTD

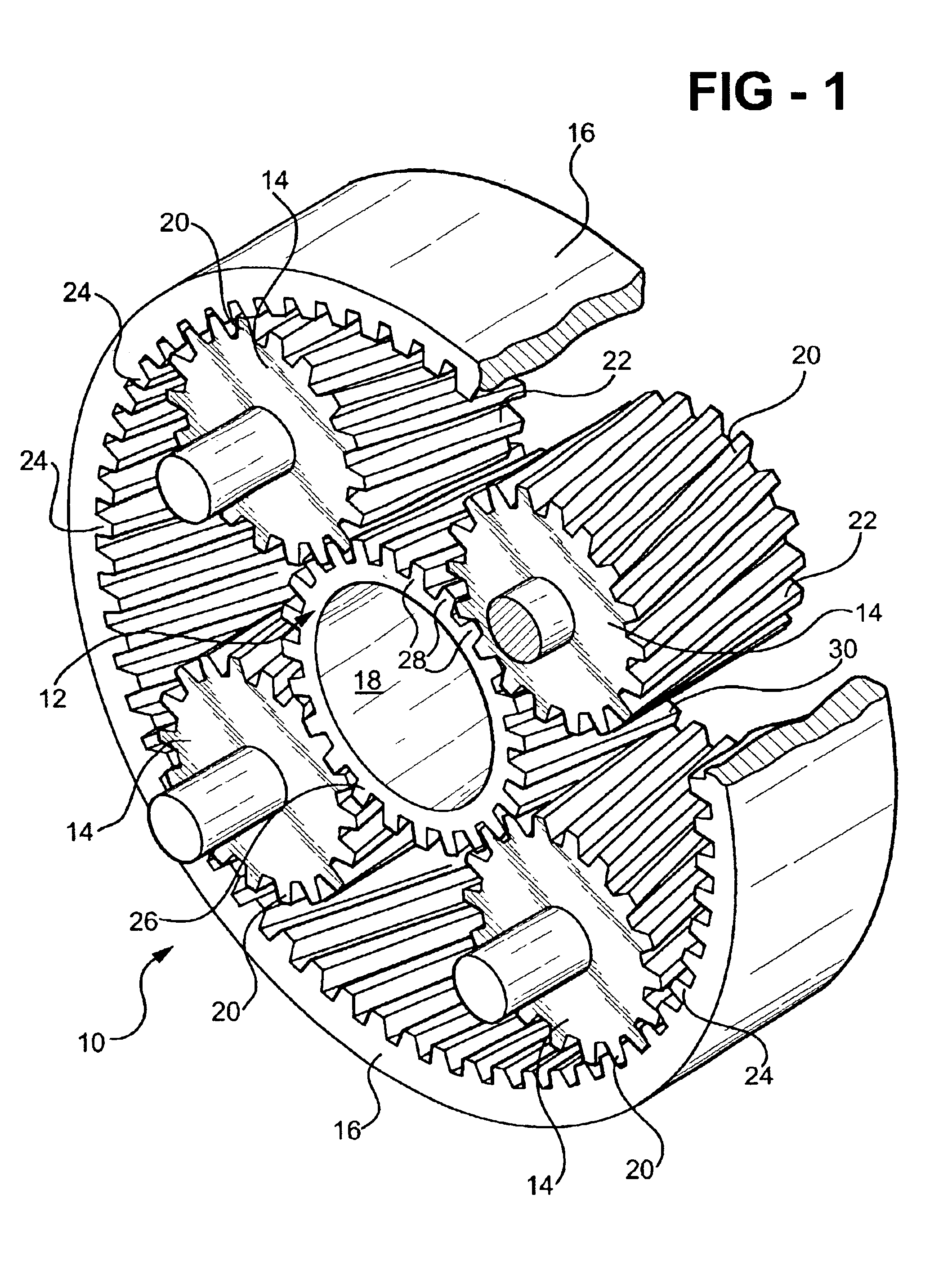

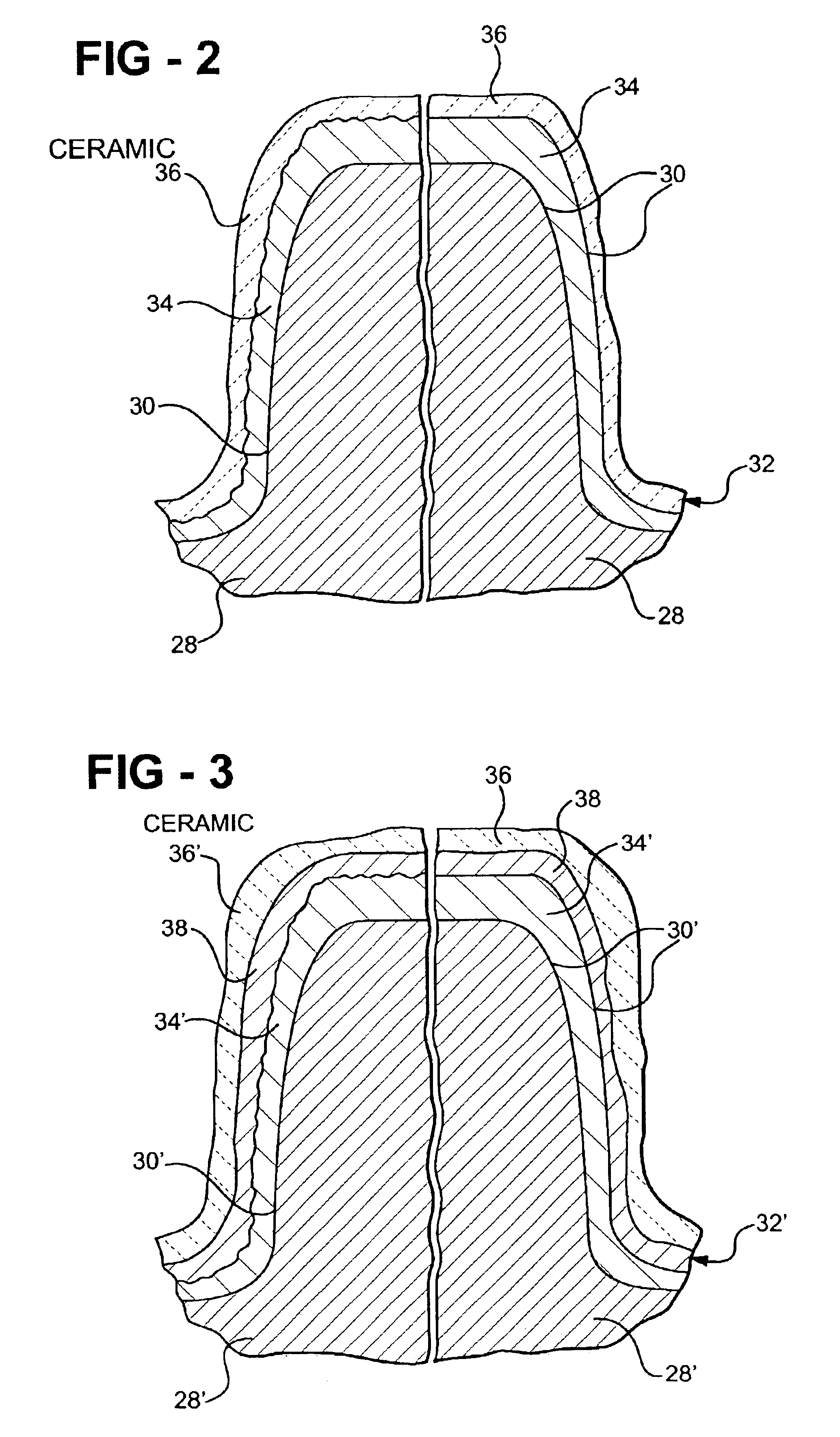

Planetary gearset with multi-layer coated sun gear

InactiveUS6846261B2Improve lubrication conditionsFlat surfaceMetal-working apparatusGear lubrication/coolingGear toothCoating

A planetary gearset includes a sun gear member having a sun gear body made of a steel material and an outer periphery with a plurality of teeth formed thereon. Each of the sun gear teeth has at least one mating surface for engaging mating surfaces on complementary teeth on at least one planet gear. A fatigue-resistant coating is applied to the mating surfaces of the sun gear teeth. The coating is harder and more abrasive than the mating surfaces of the planet gear teeth.

Owner:GENERAL MOTORS COMPANY

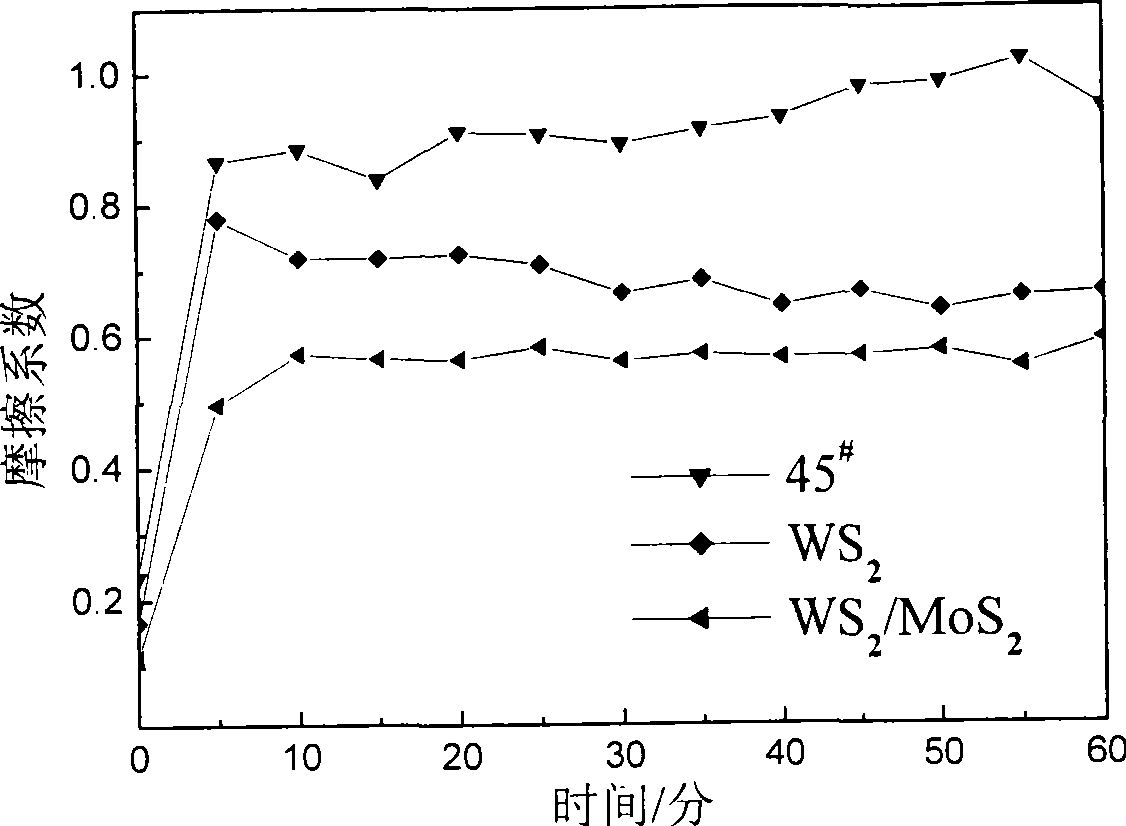

WS2/MoS2 solid lubrication multilayer film and method for making same

ActiveCN101398123AGood effectImprove mechanical propertiesLayered productsVacuum evaporation coatingSputteringSulfur

The invention provides a WS2 / MoS2 solid lubricating multilayer film and a preparation method thereof, which firstly prepares a W / Mo multilayer film through double-target RF sputtering and a W layer and an Mo layer are deposited alternatively on a substrate, and then low temperature ion sulfurizing is carried out to the W / Mo multilayer film and the WS2 / MoS2 solid lubricating multilayer film is prepared. The invention prepares a novel solid lubricating film, namely, the WS2 / MoS2 solid lubricating nano multilayer film through two-step compound treatment. The sublayers of the WS2 / MoS2 solid lubricating nano multilayer film have the same thickness and element sulfur is distributed evenly in the multilayer film, thus leading the multilayer film to have higher rigidity, good nano properties, elasticity modulus and yield strength, better practicability and excellent anti-friction and wear-resistant properties in nano mechanical properties and anti-friction and wear-resistant aspects as being compared with the existing nano multilayer films. The WS2 / MoS2 solid lubricating multilayer film can be used on various friction surfaces of machinery equipment, particularly on precisely matching surfaces to reduce friction and improve lubrication conditions.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

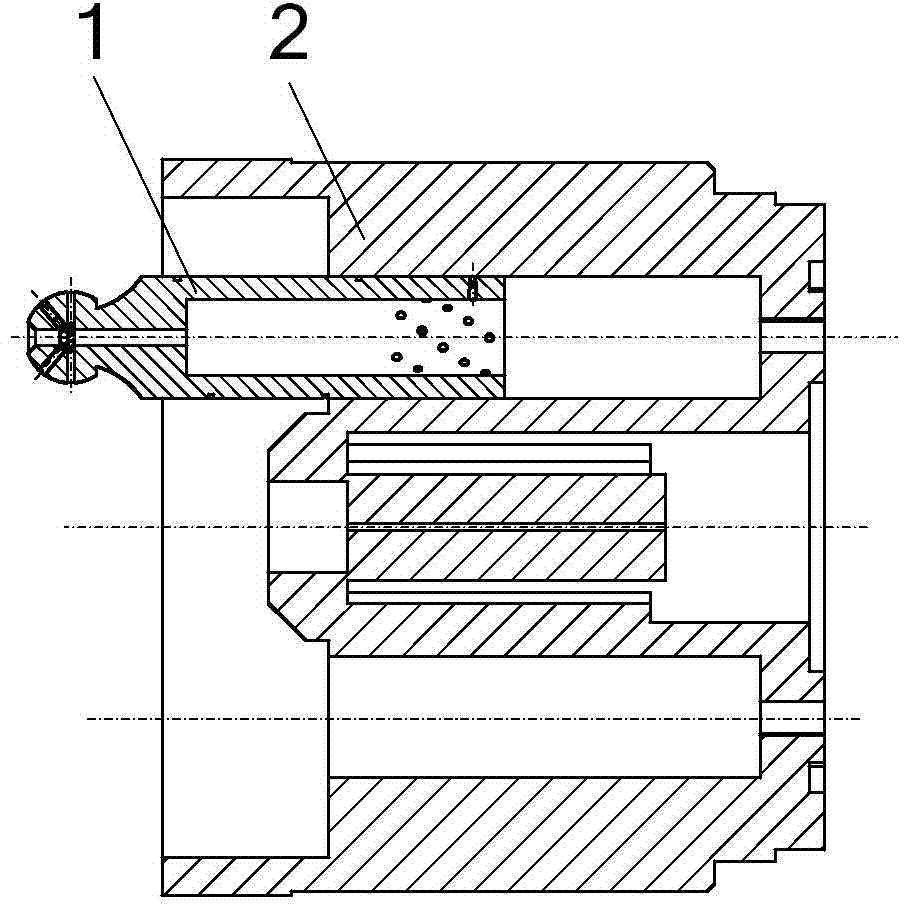

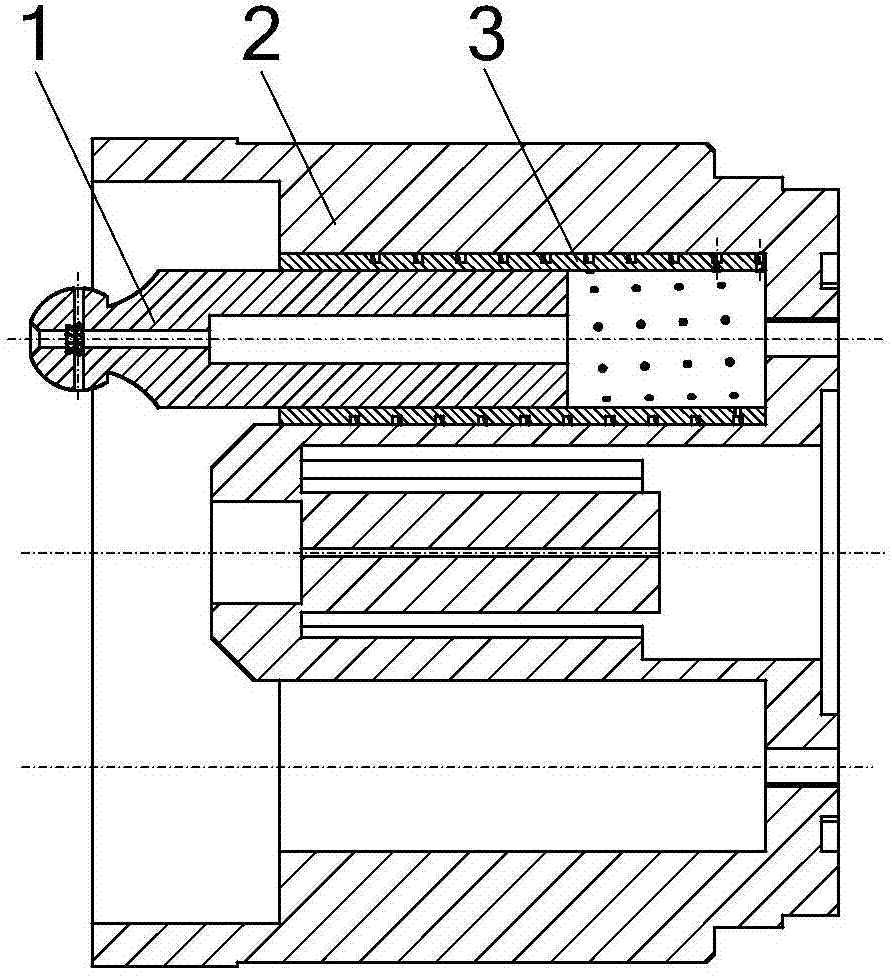

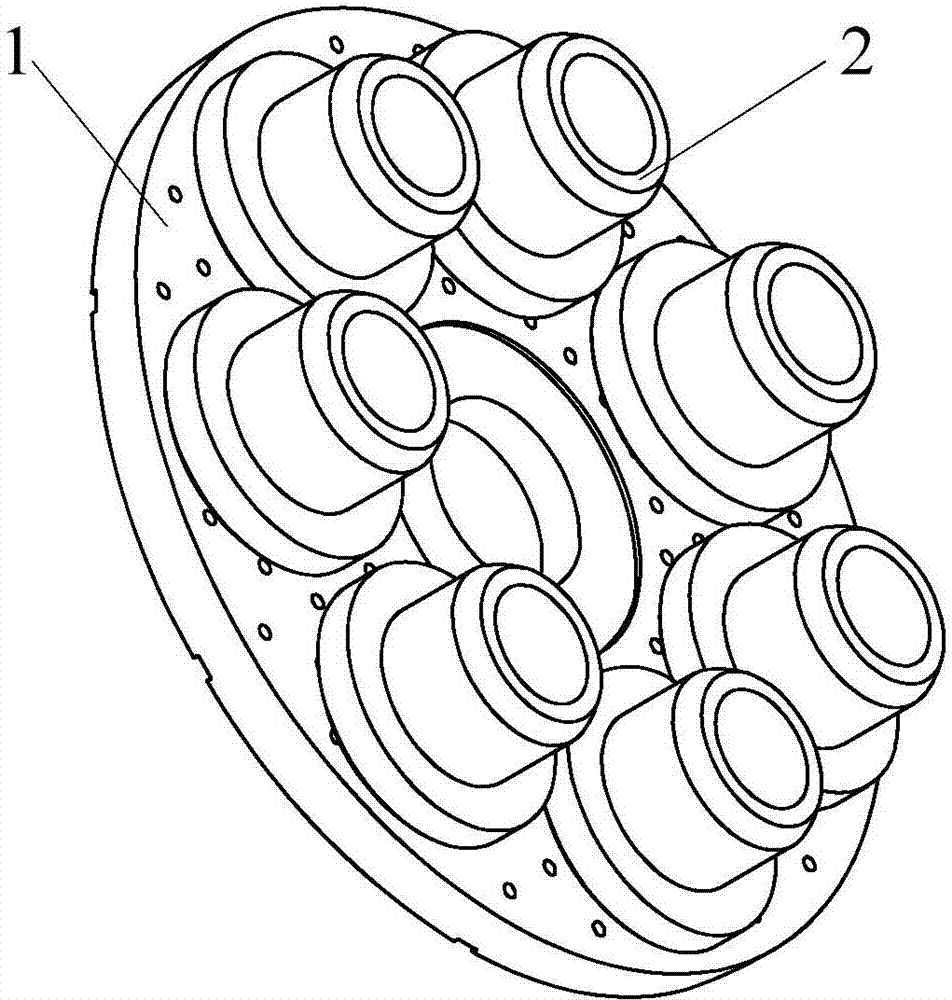

Plunger friction pair of high-pressure seawater axial plunger pump with bionic non-smooth surface

ActiveCN103867432AImprove performanceSimple structurePositive displacement pump componentsLiquid fuel engine componentsHigh pressureCylinder block

The invention discloses a plunger friction pair of a high-pressure seawater axial plunger pump with a bionic non-smooth surface. The plunger friction pair is mainly characterized in that through hole unit bodies communicated with an inner cavity of a plunger are arranged on the friction surface positioned in a cylinder body in the operation process of the outer surface of a plunger of the friction pair; the other friction surfaces of the plunger are provided with pit unit bodies. Preferably, a bush with the bionic non-smooth surface is added between the plunger and the cylinder body, a groove type trench is arranged on the outer wall of the bush, and the through hole unit bodies are regularly arranged at the bottom part of the trench. The plunger friction pair disclosed by the invention has the advantages that the lubricating capability, the bearing characteristic and the friction and wear properties of the plunger friction pair can be reasonably improved by high cost performance.

Owner:赛腾机电科技(常州)有限公司

Medium carbon steel wire rope and production process thereof

InactiveCN103541249AImprove working environmentReduce consumptionRope making machinesCarbon steelEnergy consumption

The invention relates to a medium carbon steel wire rope and a production process thereof. The medium carbon steel wire rope is characterized in that medium carbon steel (SWRH32A-52A steel or 25#-55# steel) is adopted to sever as a production raw material of the steel wire rope, a phosphating film is coated on the surface of a steel wire of the steel wire rope, and the steel wire rope is made by surface processing, pulling and drawing, normalizing heat treatment, galvanizing, phosphating, pulling and drawing, and stranding and rope combining. The medium carbon steel wire rope and the production process thereof are few in production procedures, low in energy consumption, die consumption and wire breakage rate, and high in labor productivity.

Owner:WUXI UNIVERSAL STEEL ROPE

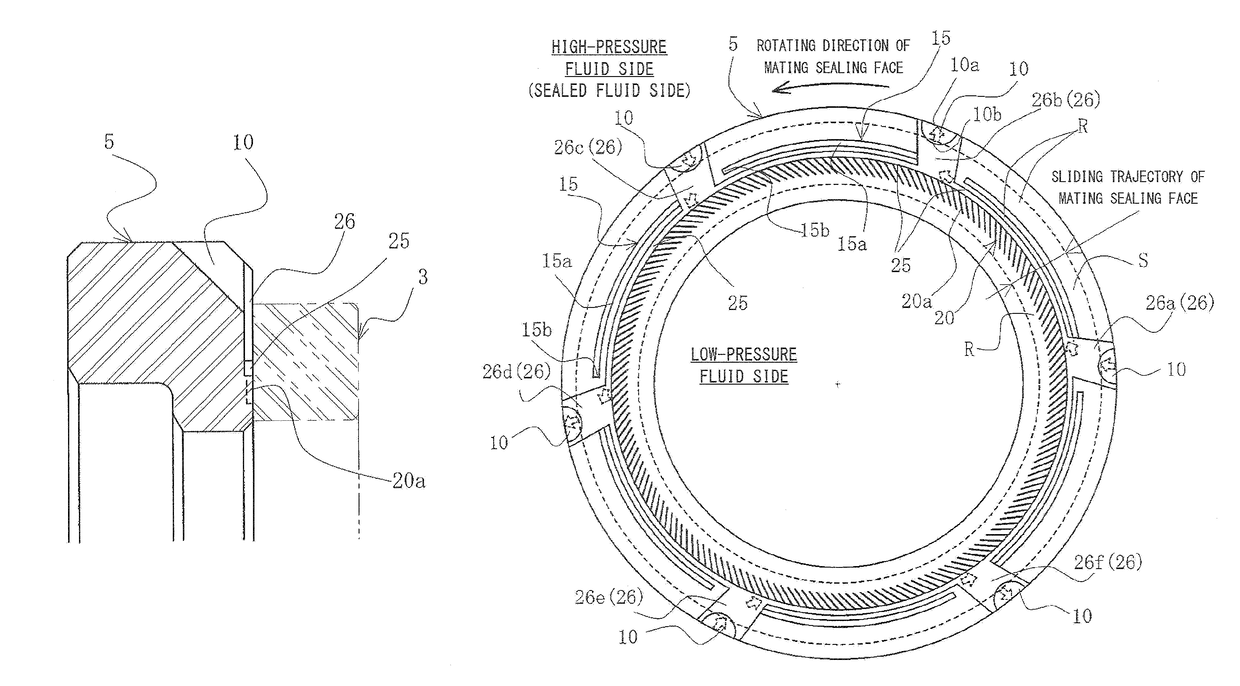

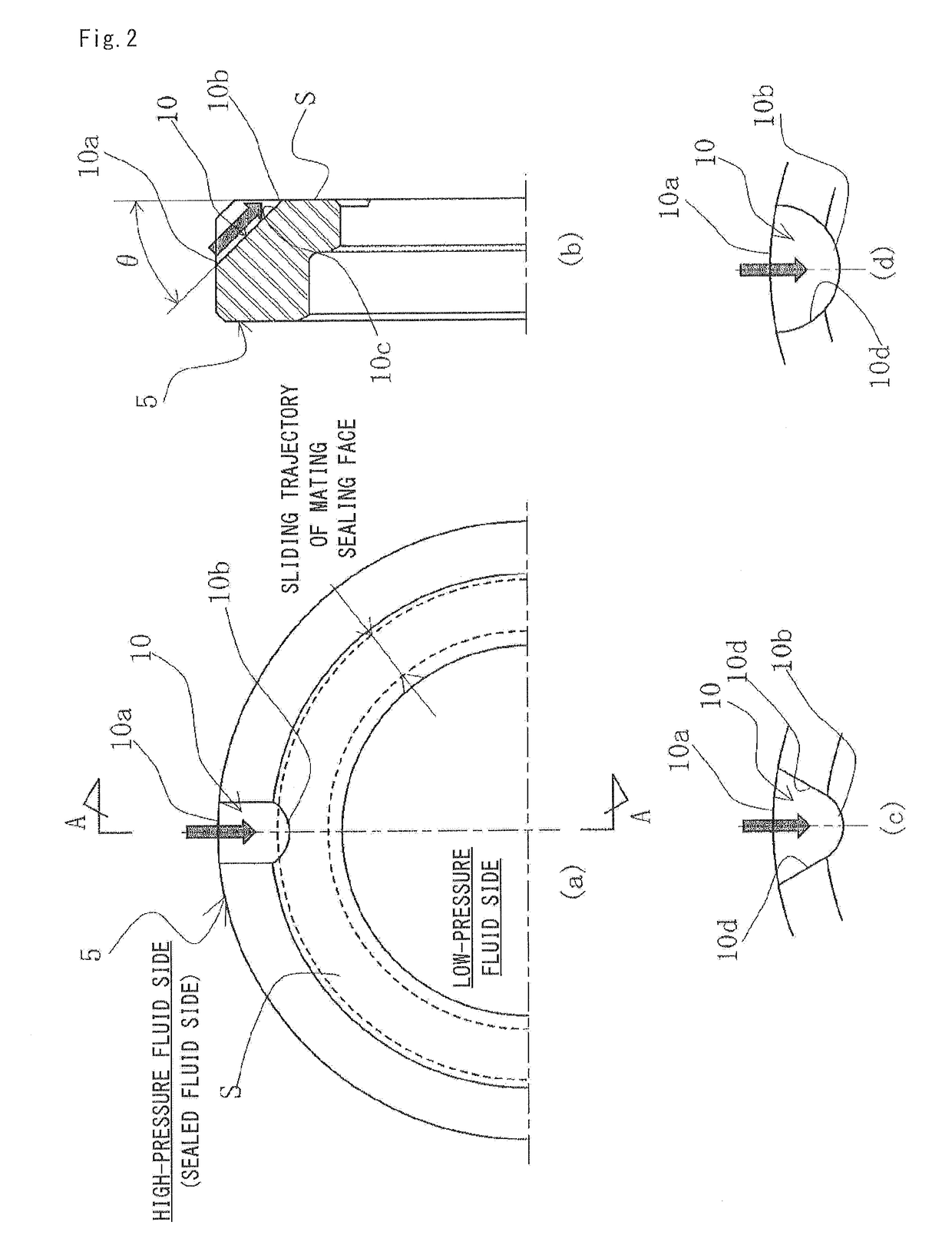

Mechanical seal

Provided is a mechanical seal includes a fluid introduction groove provided in a sealing face of a stationary sealing ring and having an opening portion which is opened to the sealed fluid and an end portion which is provided opposite to the opening portion. The end portion being located between respective sealing faces S, the fluid introduction groove introducing the sealed fluid from the opening portion to a clearance between the respective sealing faces S. The fluid introduction groove is provided to be inclined at an acute angle to the sealing face S of the stationary sealing ring in a direction from the end portion to the opening portion.

Owner:EAGLE INDS

Valve finisher surface modified processing method

InactiveCN1570192AHigh hardnessImprove stress resistanceMetal-working apparatusSolid state diffusion coatingThermal fatiguePlasma technology

The invention relates to a surface modification processing method for the engine critical component, which belongs to the field of the steel surface chemistry thermal treatment processing technology. The processing method comprises: nitriding for the air valve finisher by using the plasma technology, adding carbon-containing gas in the nitrogen-containing gas at the late stage of nitriding and carrying out the nitrocarburizing, and placing the mould in the steam oxidizing furnace for surface oxidizing treatment. The mould treated by said technology has excellent mechanical property, improved surface hardness, improved compression resistance, improved wear resistance and improved thermal fatigue resistance.

Owner:SHANGHAI UNIV

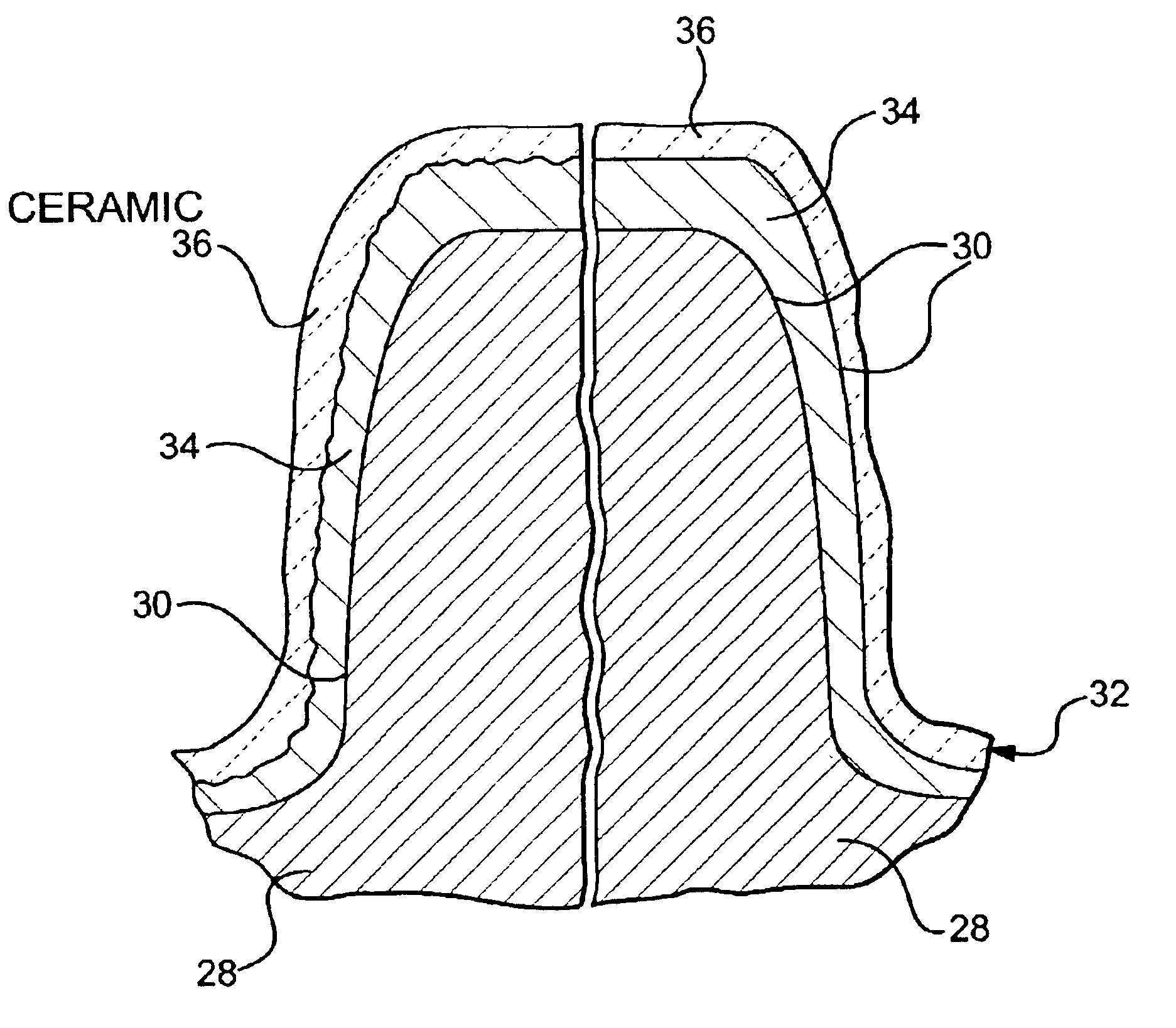

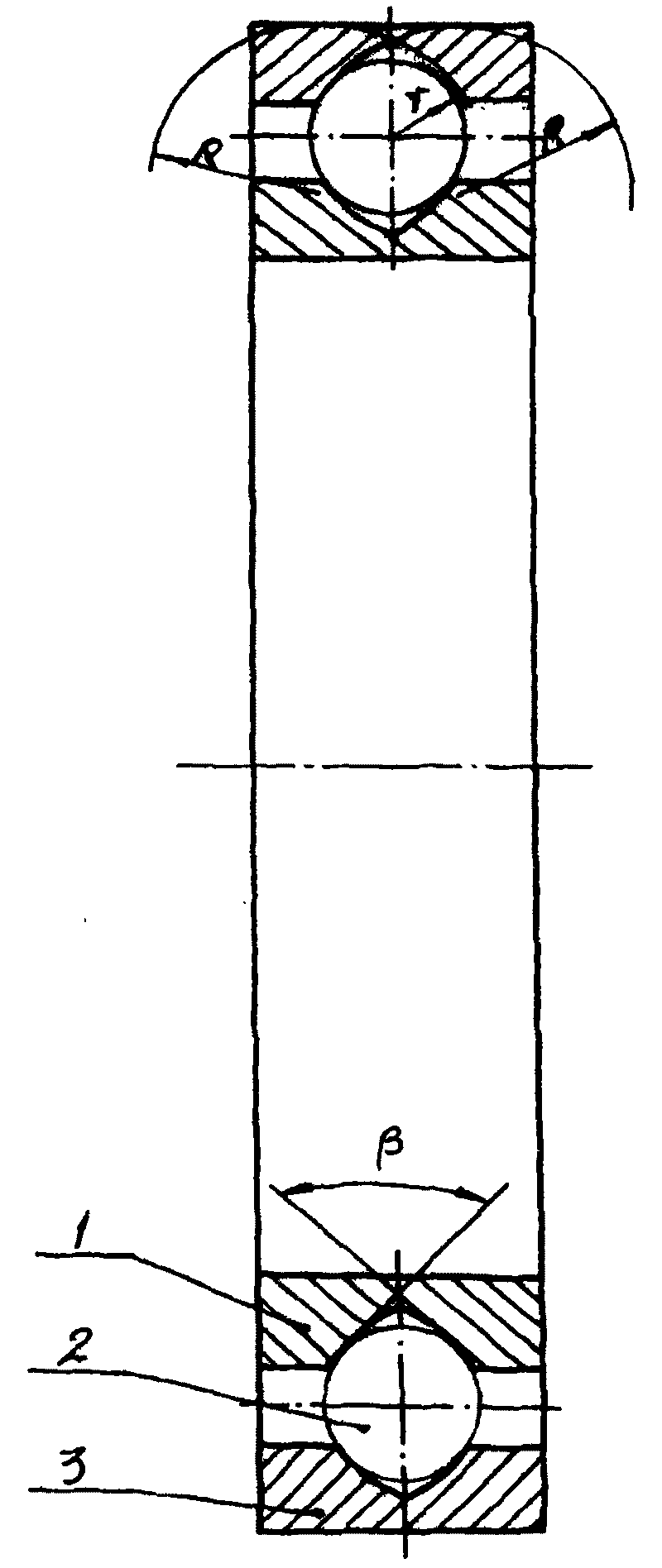

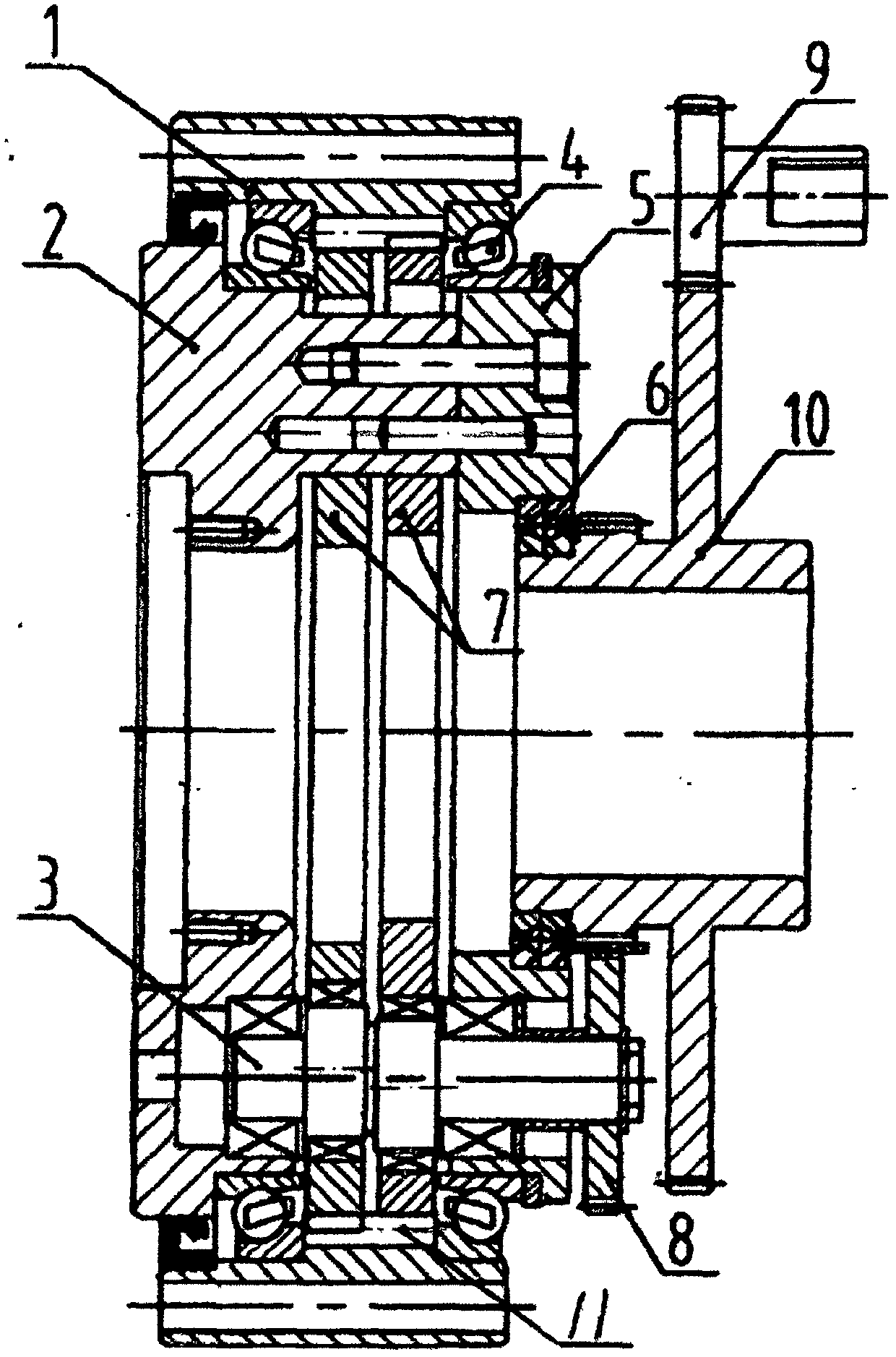

Four-point contact ball bearing

InactiveCN101737423AExtended service lifeImprove lubrication conditionsBall bearingsBearing componentsBall bearingAxial force

The invention discloses a four-point contact ball bearing. The four-point contact ball bearing comprises a bearing inner ring, rolling balls and a bearing outer ring; the rolling balls are arranged between the bearing inner ring and the bearing outer ring; the bearing inner ring and the bearing outer ring are provided with an annular raceway respectively; each annular raceway and each rolling ball are contacted at two points; an included angle B between connecting lines of two contact points and the center of the rolling balls is between 30 and 120 degrees; as two contact points are between each of the annular raceways of the bearing inner ring and the bearing outer ring and each rolling ball, and the included angle B between the two contact points is between 30 and 120 degrees, radial force stressed by each contact point of each rolling ball is smaller than the radial force stressed by a rolling ball of a conventional ball bearing when the bearing is stressed by the equal load; the bearing can also bear the axial force; and as gaps are formed between the rolling balls and the annular raceways, lube or grease lubricant is convenient to store, the lubricating condition of the rolling balls is improved, and the service life of the bearing can be improved.

Owner:陈政

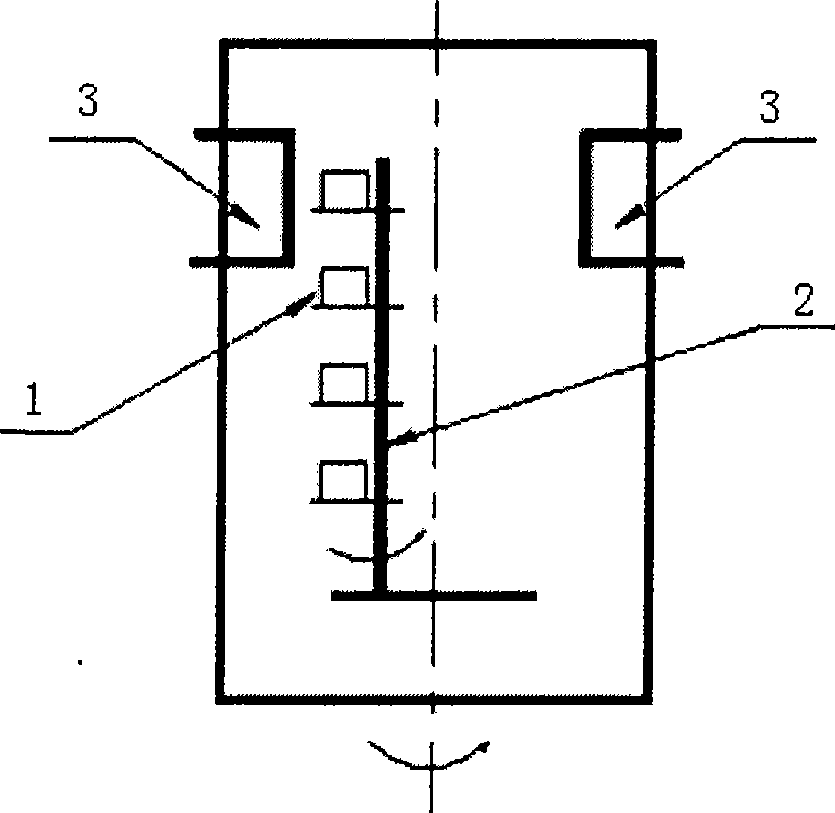

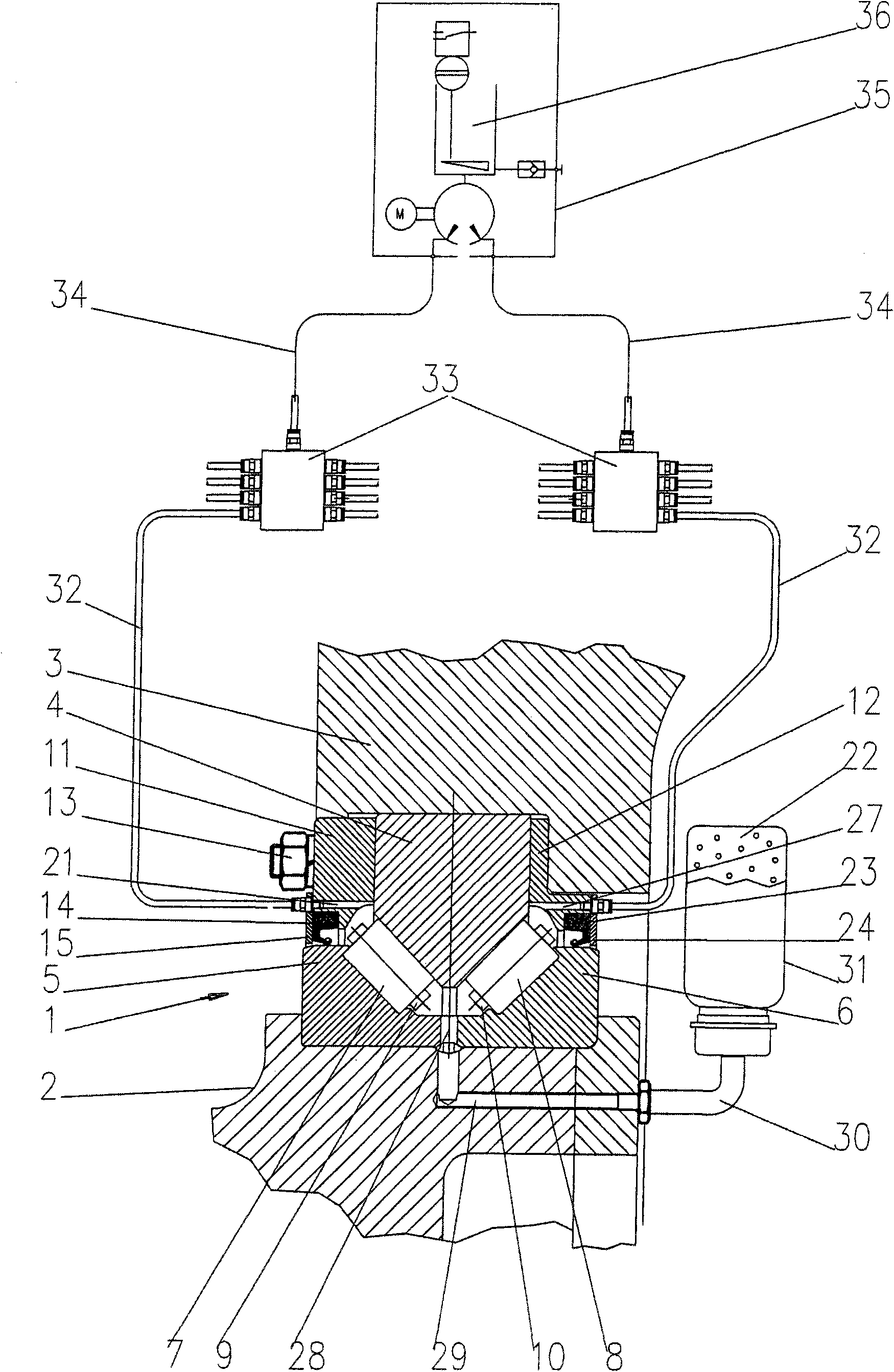

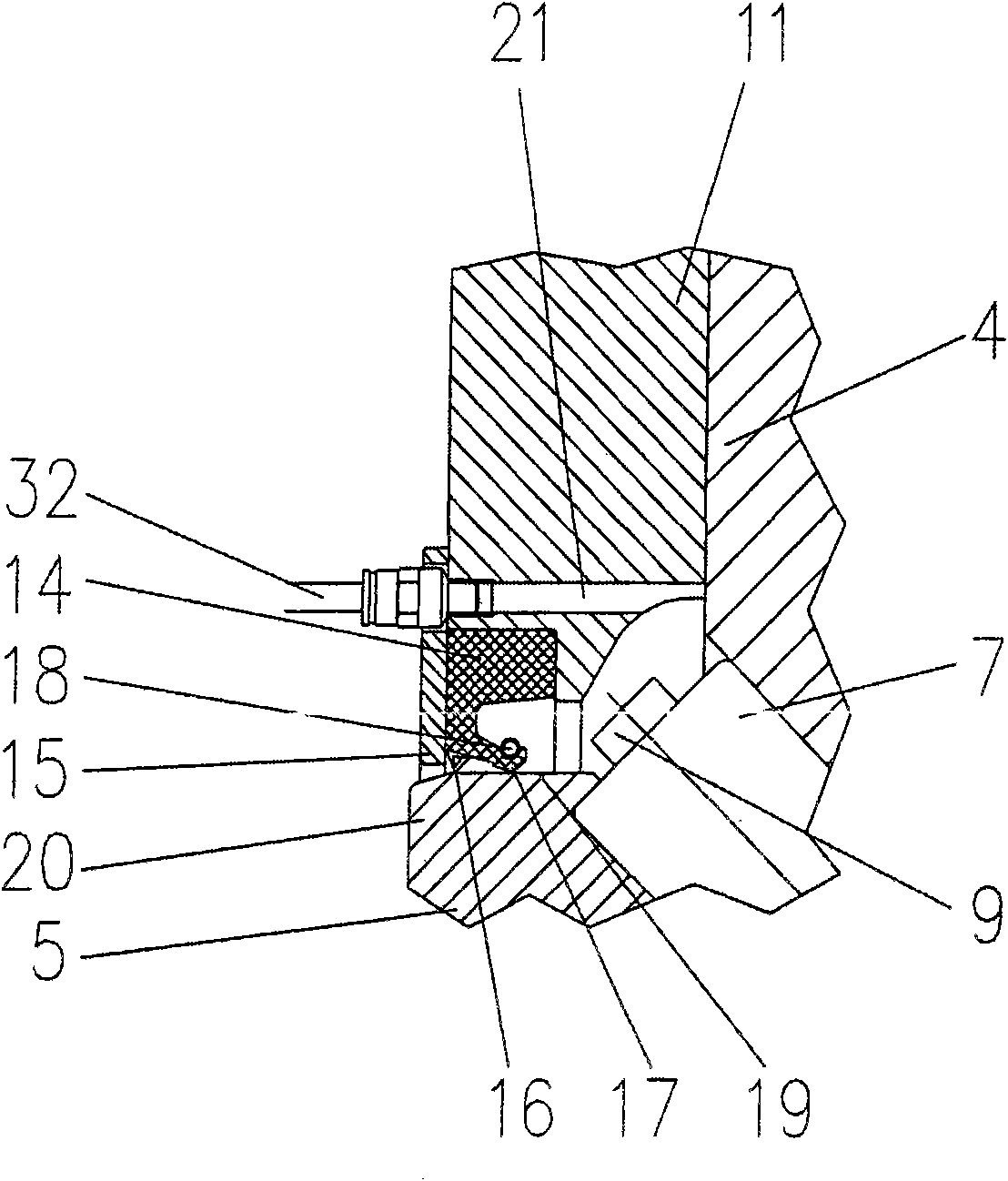

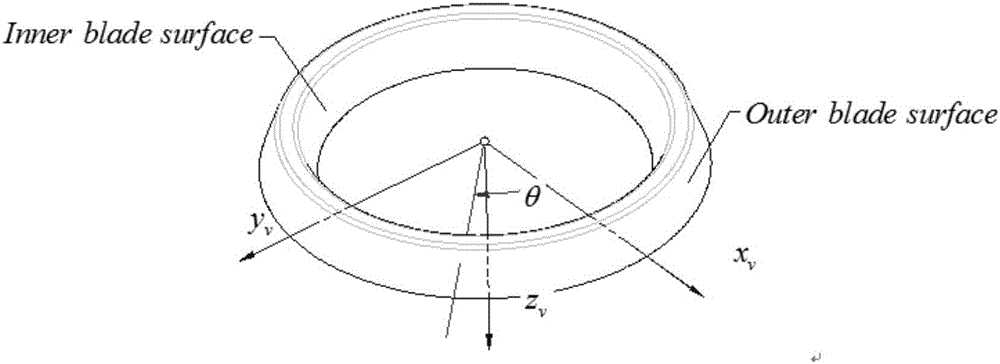

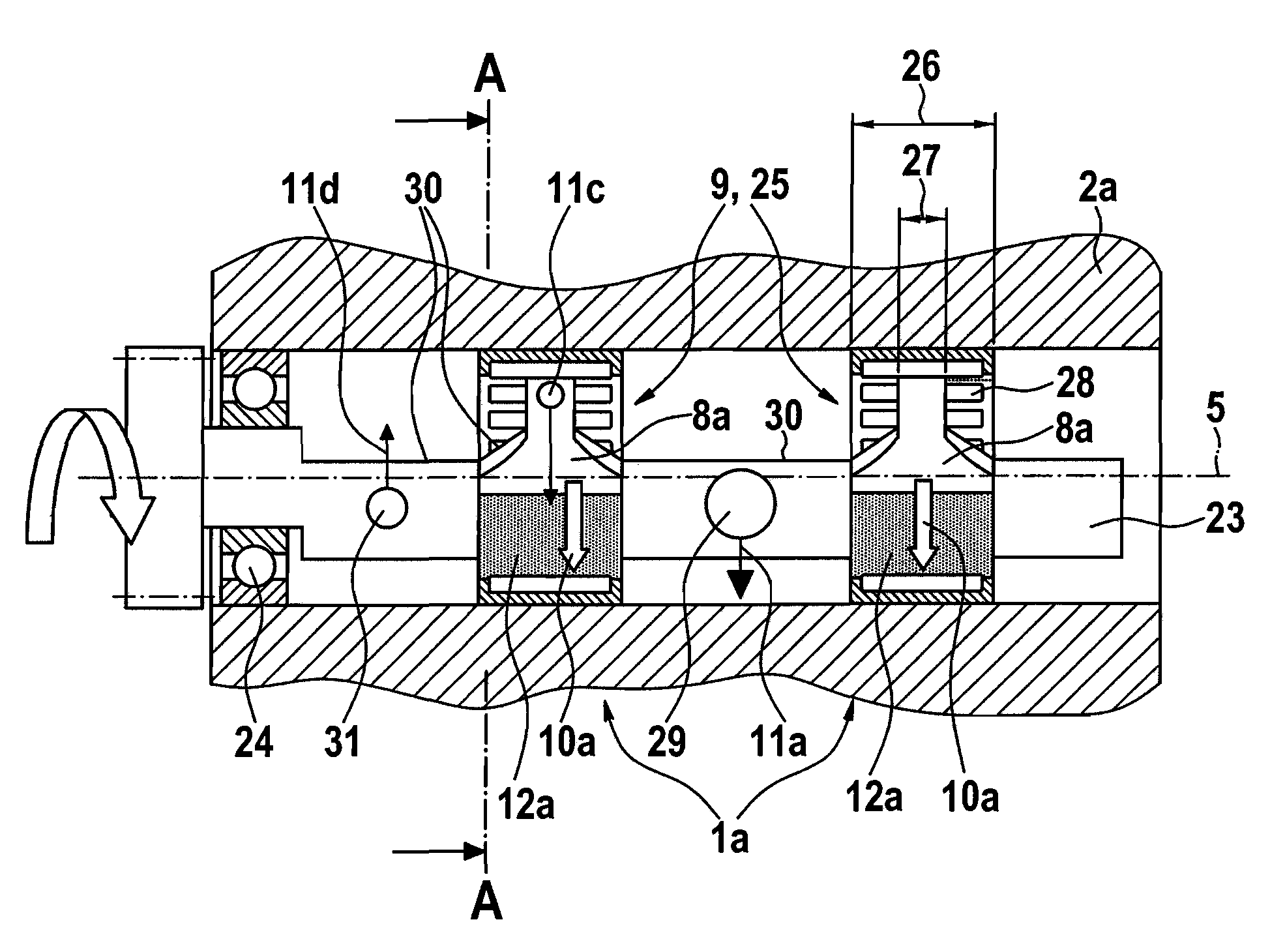

Two-row roller bearing and bearing system with such a roller bearing and a lubricating device

ActiveCN101846129AImprove the lubrication effectFirmly connectedRolling contact bearingsShaftsRolling-element bearingMechanical engineering

The invention relates to a two-row roller bearing (1) for supporting a mechanical part (2) rotatably relatively to a rotation axis. According to the invention, the roller bearing (1) has an outer ring (4) with the outer diameter of at least 1 m, a first inner ring (5), a second inner ring (6) arranged at the side of the first inner ring (5) axially relatively to the rotation axis, a group of first rolling bodies (7) rolling between the outer ring (4) and the first inner ring (5), a group of second rolling bodies (8) arranged at the side of the first rolling bodies (7) along the axial direction relatively to the rotation axis and rolling between the outer ring (4) and the second inner ring (6). The roller bearing (1) is characterized in that a first lubricating grease conveyor (21) is arranged at the first axial side of the outer ring (4) with respect to the rotation axis for supplying the first roller body with lubricating grease (22) and a second lubricating grease conveyor (27) is arranged at the second axial side of the outer ring (4) with respect to the rotation axis for supplying the second roller body with lubricating grease (22).

Owner:AB SKF

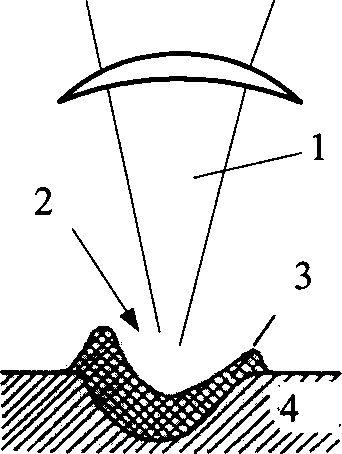

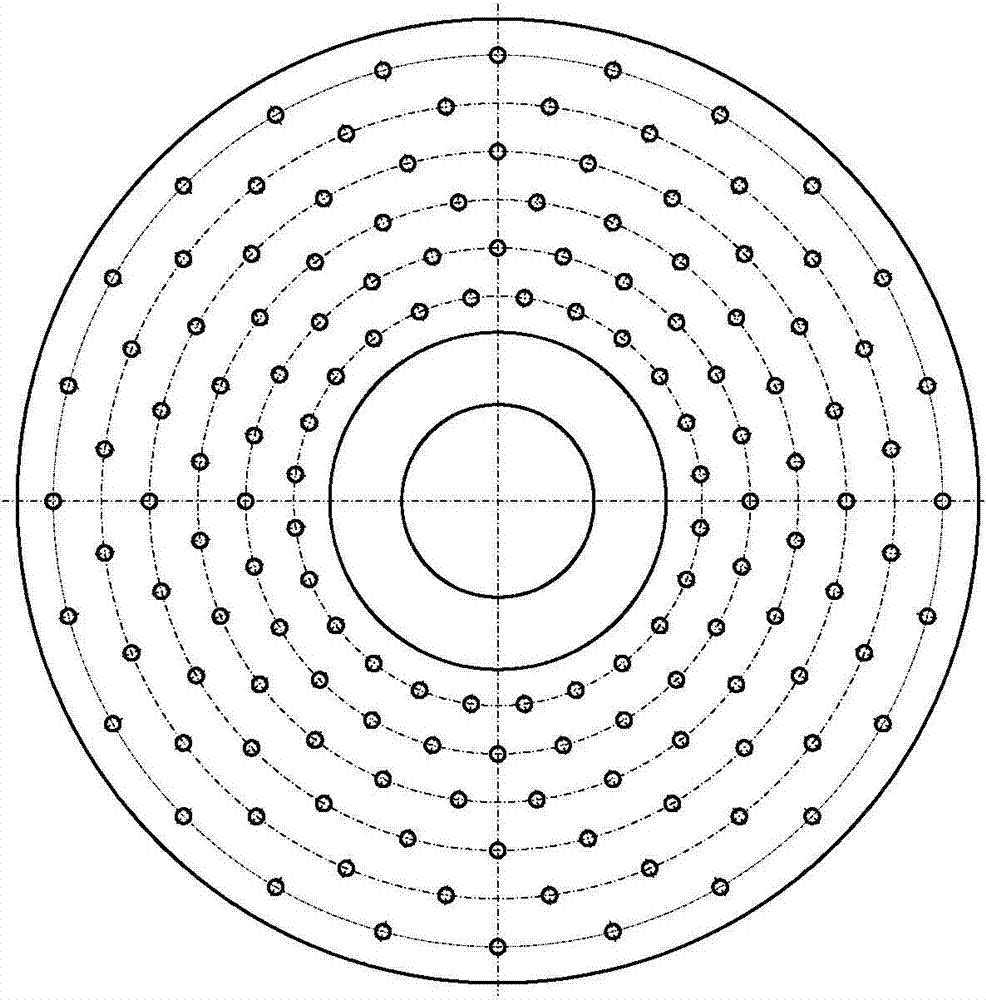

Method for working ball cap convex on roll surface by laser

InactiveCN1358603AImprove wear resistanceExtended service lifeLaser beam welding apparatusLaser technologyStress concentration

The present invention relates to a method using laser technology to process roll surface which can be used for cold-rolling thin sheet steel surface. Said invention uses proper laser single-pulser energy, and pulse width to make laser beam irradiate surface of roll according to a certain quantity out-of-focus in the course of processing roll by using laser, under the condition of proper pulse frequency and laser scanning speed said invention utilizes protective gas and side-blow melting bath according to a certain angle so as to obtain spherical coronal microconvex from on the surface of roll. Said roll surface processed by said invented laser technology can make coll-rolled thin-sheet steel (strip) surface from uniqu microhole lubricating structure so as to effectively reduce friction and wear-and-tear.

Owner:TSINGHUA UNIV

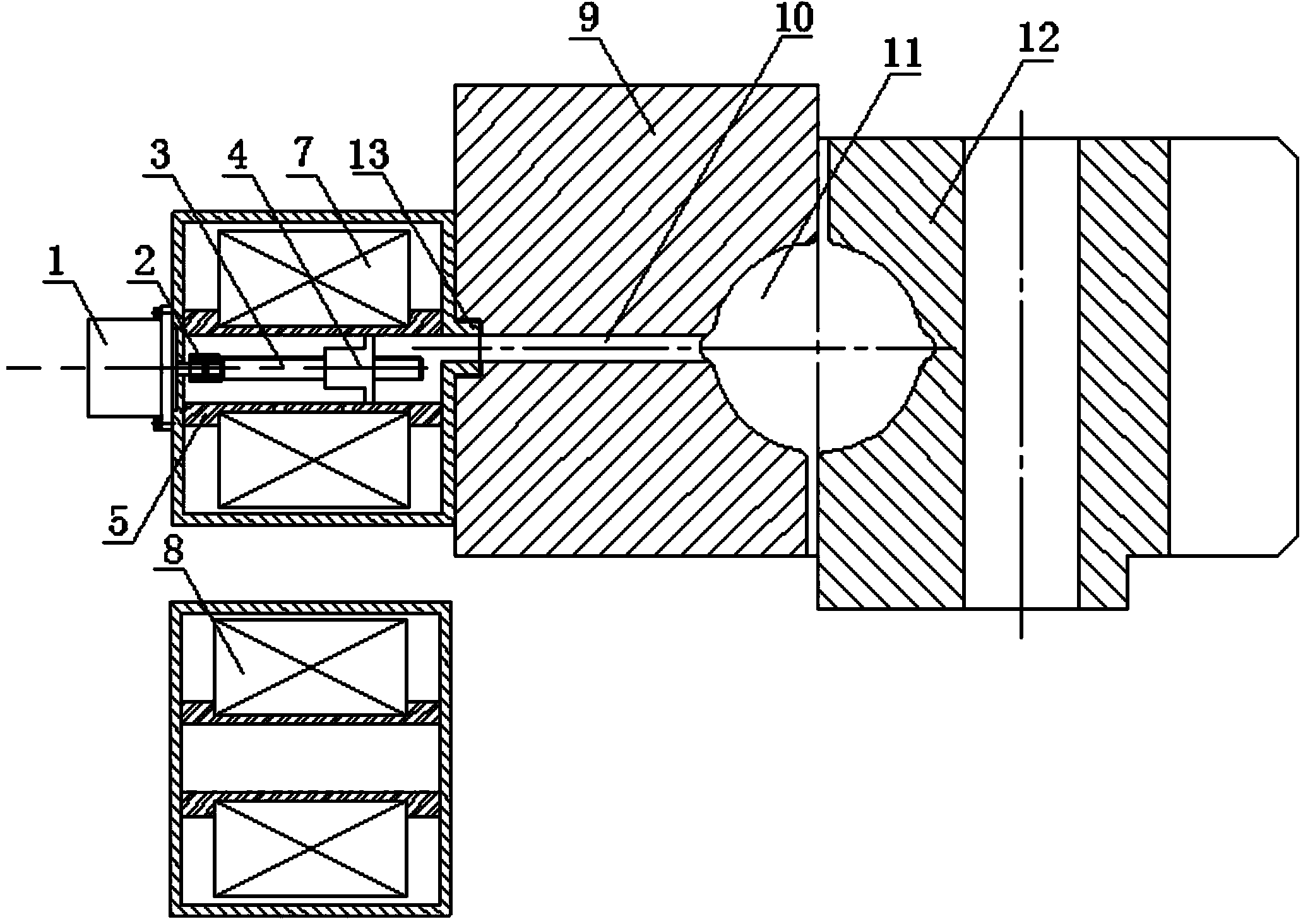

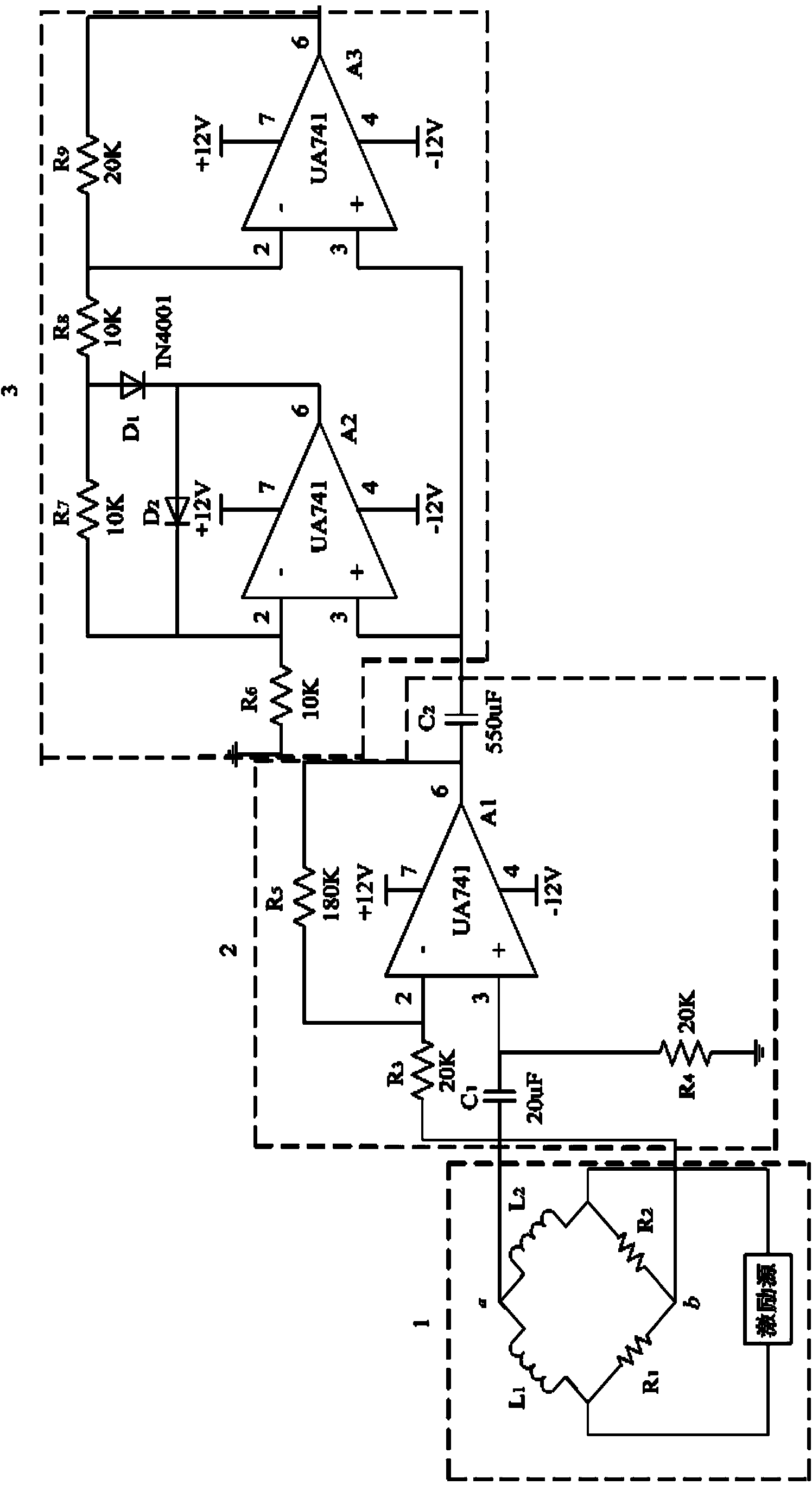

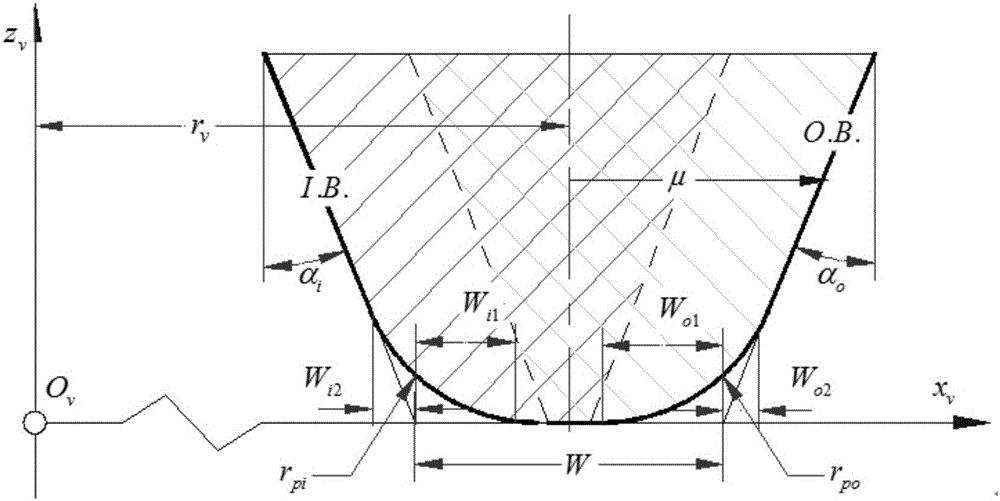

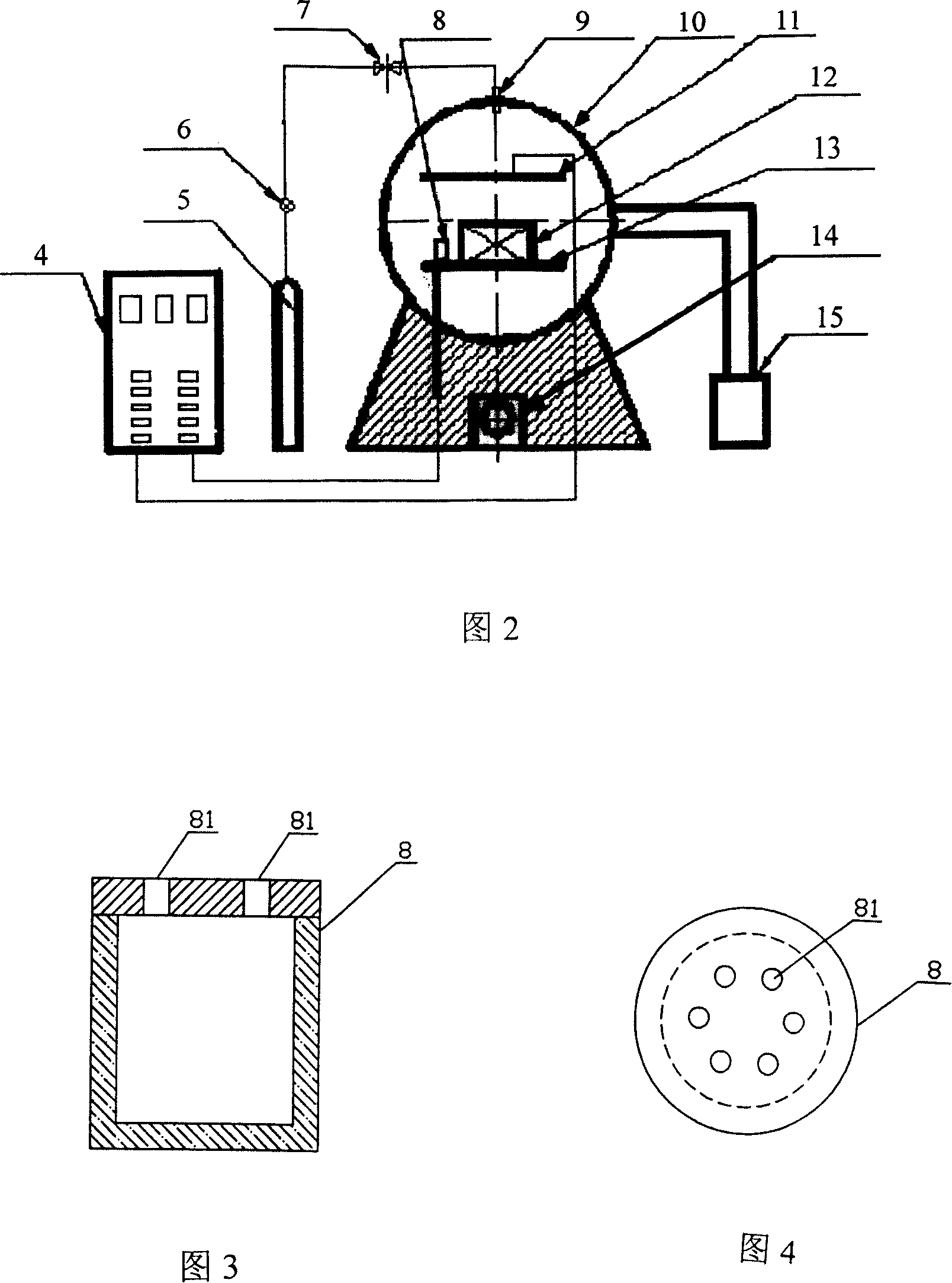

Online detection method for scrap iron content in pivoting support lubricating grease and lubricating grease online detection device

ActiveCN103728343ARealize automatic samplingEffectively judge the degree of wearMaterial impedanceInductanceComputer science

The invention discloses an online detection method for scrap iron content in pivoting support lubricating grease and a lubricating grease online detection device. Automatic sampling of solid lubricating grease is achieved by using a lubricating grease online detection device in the online detection method. The scrap iron content in the lubricating grease is determined by using an inductance value change of a detection coil caused by scrap iron mill grains in the lubricating grease, so as to effectively judge the abrasion degree inside a pivoting support raceway; a real-time detection value is compared with a preset pre-warning value to judge whether the lubricating grease loses efficacy, so as to provide reference for optimization of the lubricating condition of the raceway. By adopting the online detection method, the online sampling difficulty due to the fact that the solid lubricating grease cannot flow is radically solved, online detection is achieved, the problems of long analysis period, complicated detection process and the like in off-line detection are avoided, and the online detection method has important significance on evaluation of the pivoting support operation state, improvement of the lubricating condition, effective prolonging of the service life of the pivoting support, and improvement of the operation reliability. The method is simple, easy to achieve, and high in automatic degree.

Owner:NANJING UNIV OF TECH +1

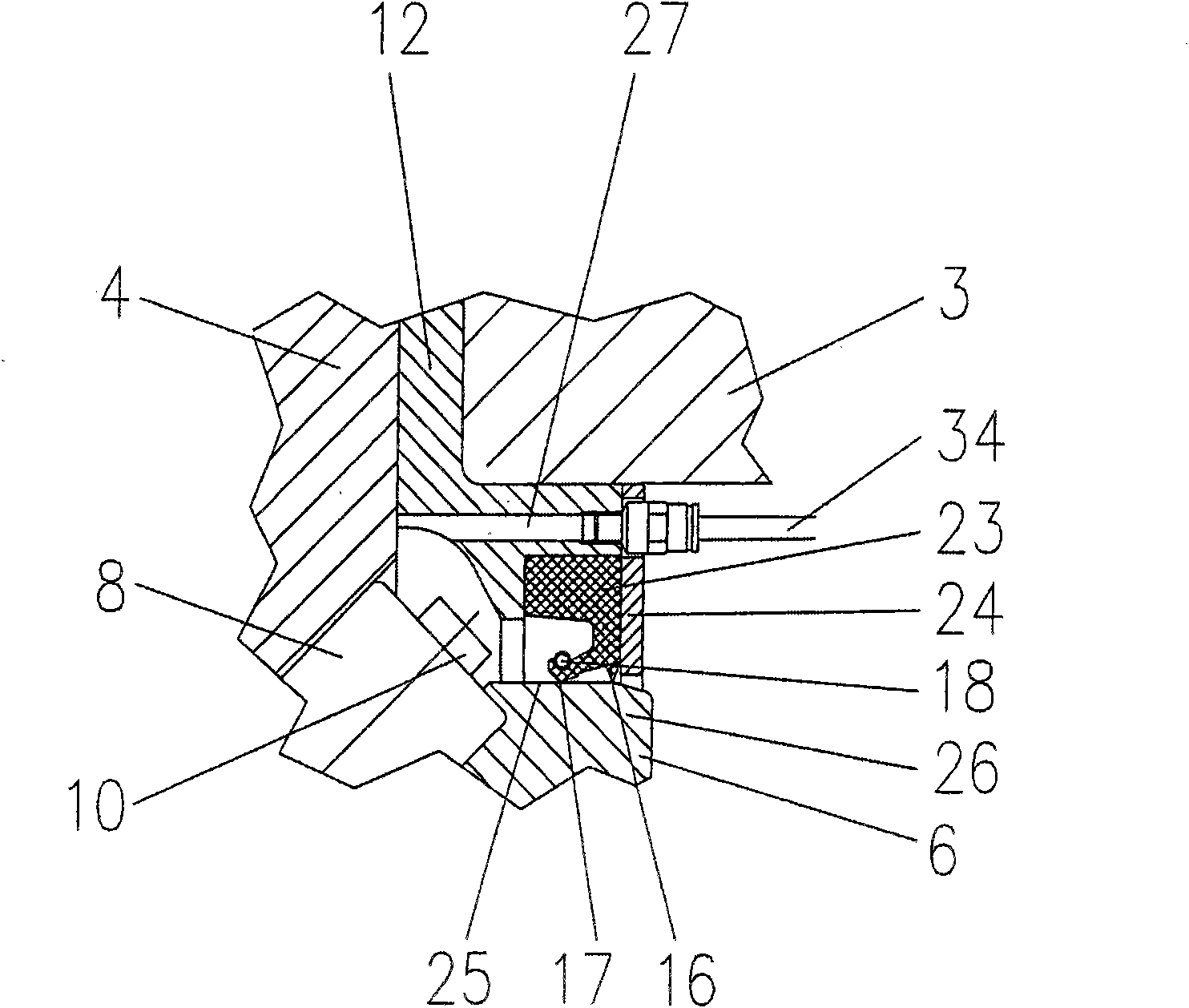

Robot RV-C type speed reducer

InactiveCN108036027AGuaranteed to workIncrease dynamicsToothed gearingsGear lubrication/coolingReduction drivePhase difference

The invention relates to the technical field of robot speed reducers, in particular to a robot RV-C type speed reducer. The robot RV-C type speed reducer comprises four components of an input, a planet, a cycloid and an output and is characterized in that the radial clearance delta is approximately equal to the cycloid wheel expansion quantity, composite modification of positive equidistance and negative shifting distance is adopted for cycloid wheels, the eccentric-shaft eccentric segment phase difference is 179.7-179.95 degrees, semi-buried holes of a needle gear shell are provided with an oil groove, the semi-buried holes are cut with slow wire threads, a left rigidity plate is provided with three cylinder flanges which are evenly distributed, a first bearing is a cross roller bearing,and the cross section of extension ends of the eccentric shafts and an inner hole a planet wheel is extension inner cycloid equidistance curves. The robot RV-C type speed reducer has the beneficial effects that the radial clearance theoretical value delta is approximately equal to the cycloid wheel thermal expansion quantity, the robot RV-C type speed reducer will not get hot in running and is made to have good dynamic performance, the phase difference of two eccentric segments of the eccentric shafts is equal to 180 degrees-delta theta, the fact that the return difference is less than or equal to 1' is realized, the composite modification of positive equidistance and negative shifting distance is adopted, the contact stress is least, the semi-buried holes of the needle gear shell are provided with the oil groove, the cost is 55-70% lower, and the external dimension of the robot RV-C type speed reducer is the same as that of a Japanese robot speed reducer of the RV-C type and can be interchanged with the Japanese robot speed reducer of the RV-C type.

Owner:陈卫

Design method for curved-tooth non-circular gear

ActiveCN105889456AHigh coincidenceImprove carrying capacityGeometric CADPortable liftingDesign methodsAxial force

The invention belongs to the technical field of non-circular gears and discloses a design method for a curved-tooth non-circular gear. The tooth profile of the curved-tooth non-circular gear is designed through a generating gear. The tooth profile equation is solved according to the curved surface of a counterpart rack, the kinematic relation of gear generation and the engagement principle. Compared with a straight gear, the curved-tooth non-circular gear designed through the method is high in contact ratio and bearing capacity. Compared with a bevel gear, the curved-tooth non-circular gear designed through the method does not generate axial force in the transmission process and has low requirements on bearings and installation. Through the arc tooth profile of the curved-tooth non-circular gear, lubricating oil is contained in the tooth surface, and therefore a quite good lubricating condition is achieved.

Owner:WUHAN UNIV OF TECH

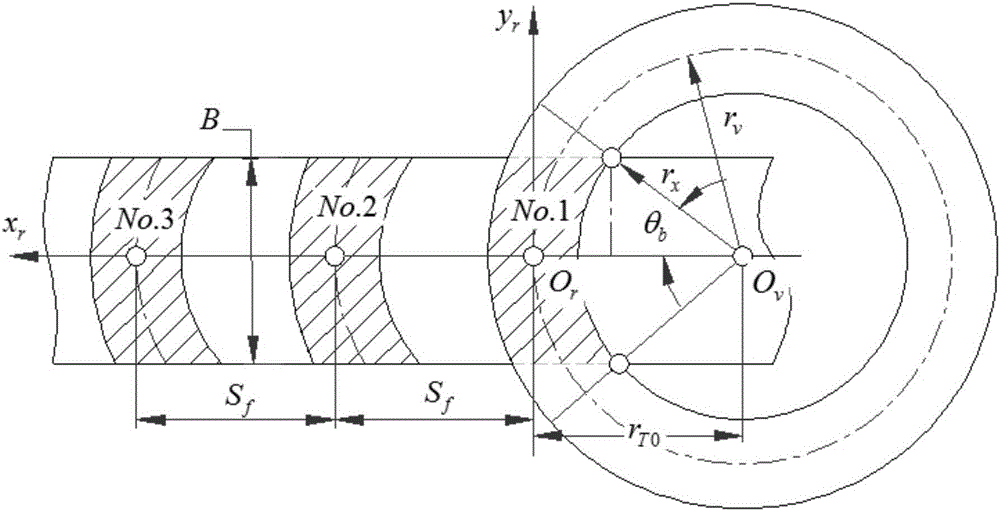

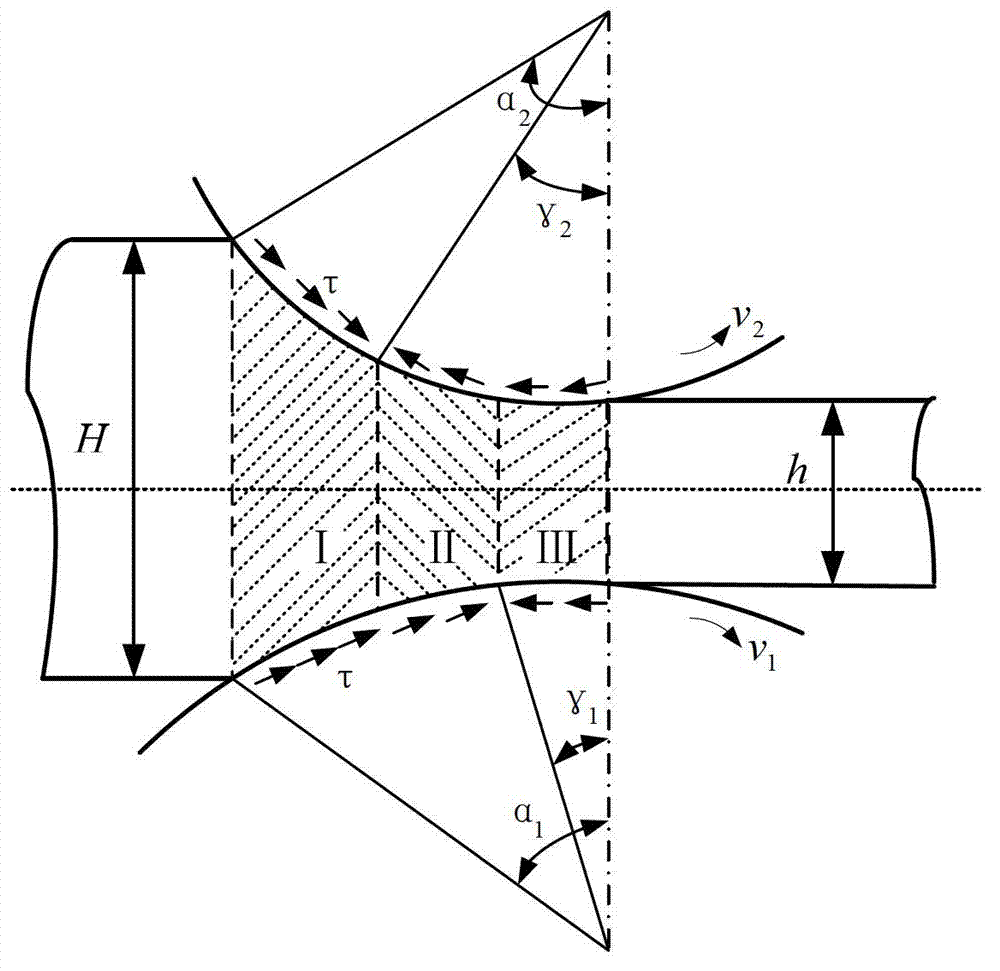

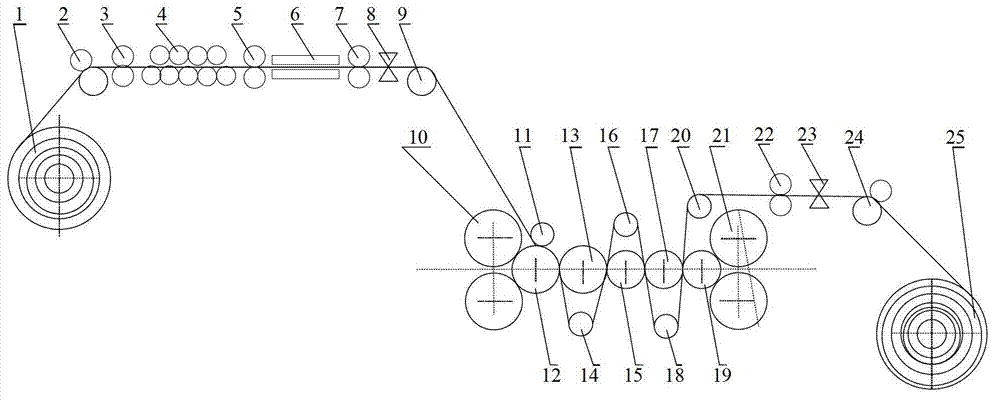

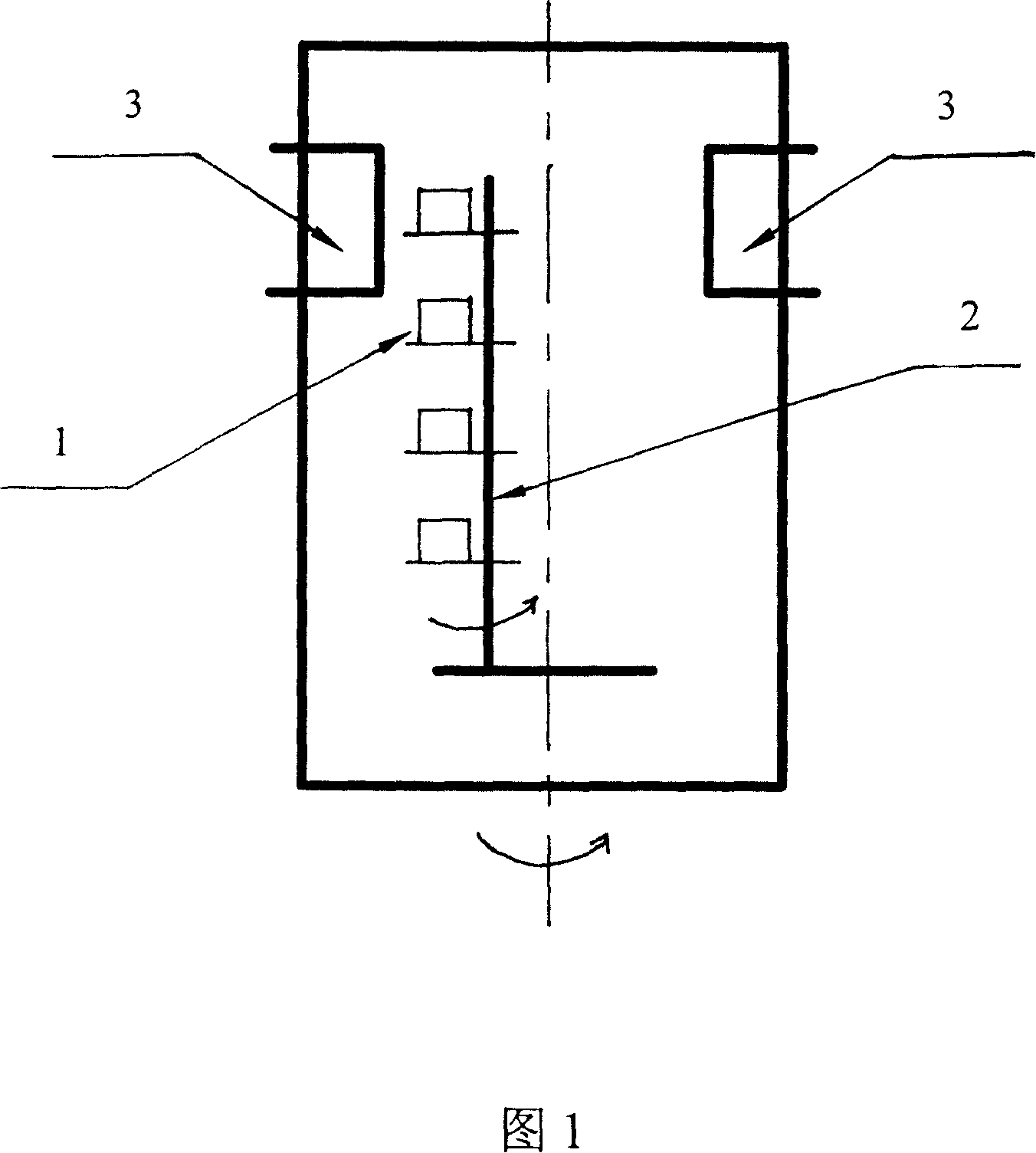

Continuous asynchronous rolling device of magnesium alloy sheet strip coil

InactiveCN102773255AStable rolling tensionRealized strip rollingMetal rolling arrangementsEngineeringEnergy consumption

The invention relates to a continuous asynchronous rolling device of a magnesium alloy sheet strip coil and belongs to the field of magnesium alloy materials. The continuous asynchronous rolling device conducts decoiling on the magnesium alloy strip coil through a decoiling device, the magnesium alloy strip coil enters a flattening machine to be flattened through a tension pinch roller and enters a strip coil preheating device through the tension pinch roller after being corrected to be heated to preset temperature, feeding material thickness is measured through a thickness gauge, then the strip coil enters a continuous asynchronous rolling machine for rolling, the rolled strip coil passes through the thickness gauge to measure thickness of a finished product and enters a rolling machine to be rolled through the tension pinch roller, and the whole coiling rolling is achieved after stable rolling tension is finished. The continuous asynchronous rolling device has the advantages of reducing rolling pressure and rolling torque, reducing energy consumption, increasing gate transformation quantity, improving rolling efficiency and the like, thereby being favorable for rolling production of strip coils of magnesium alloy which is hard to deform.

Owner:UNIV OF SCI & TECH BEIJING

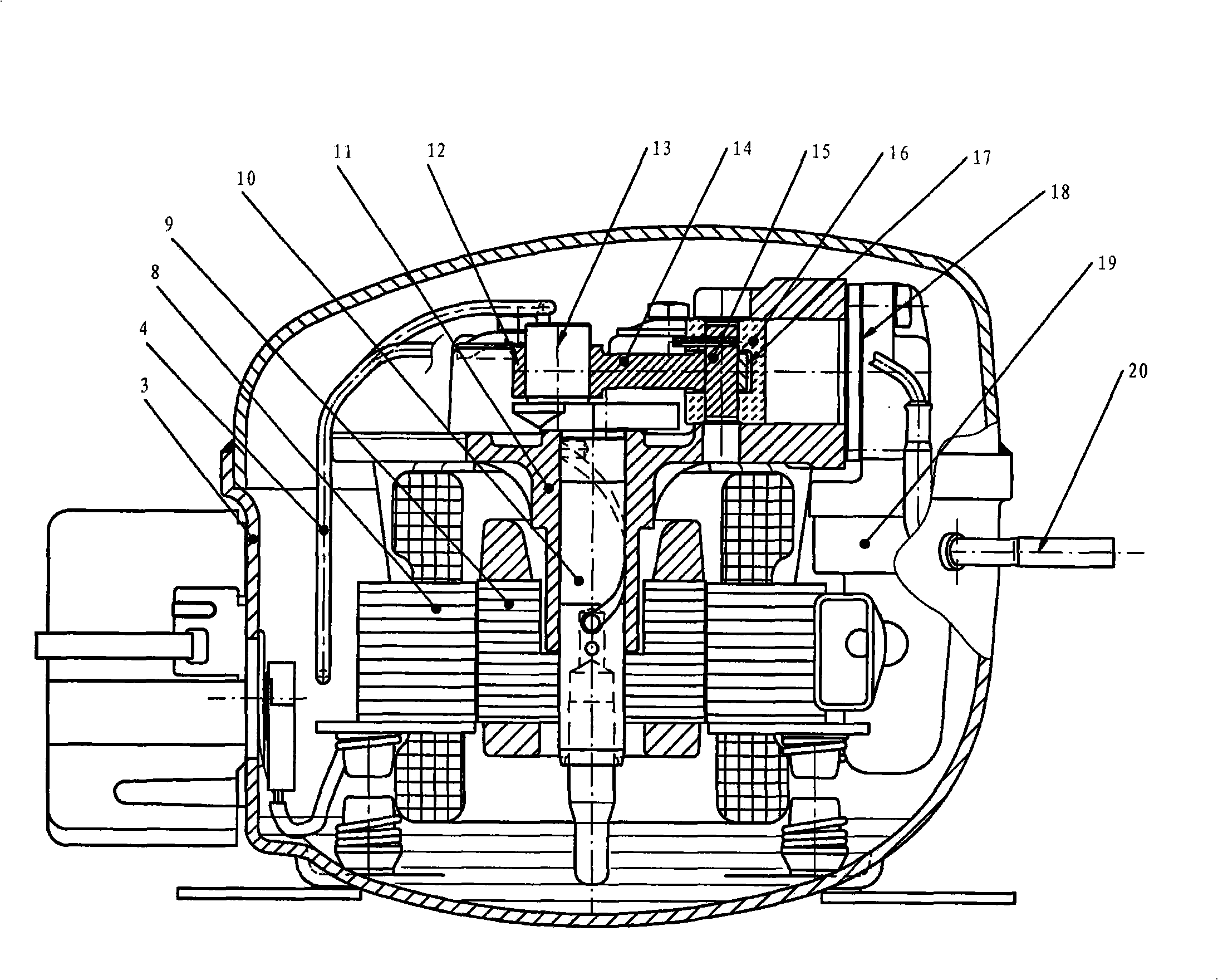

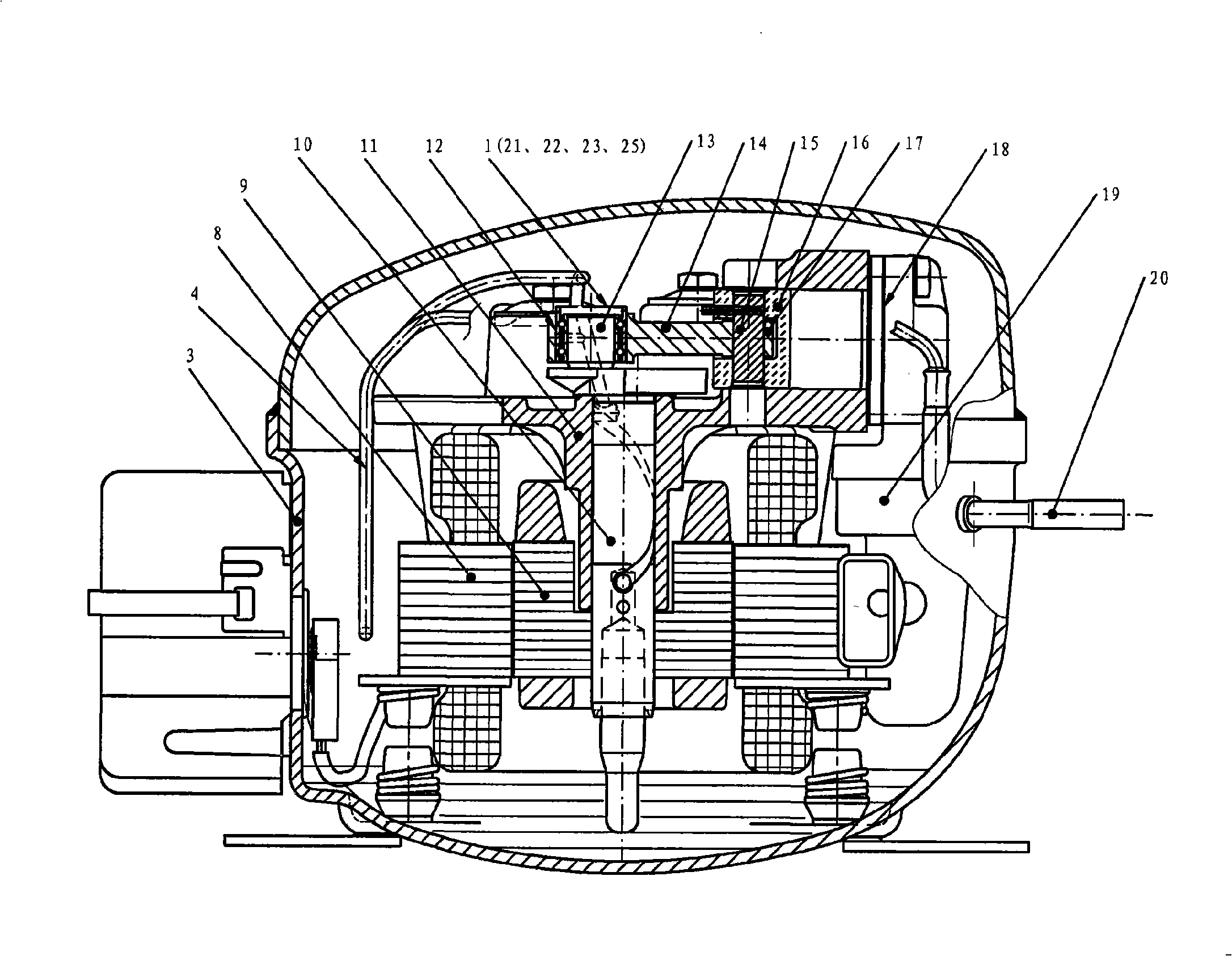

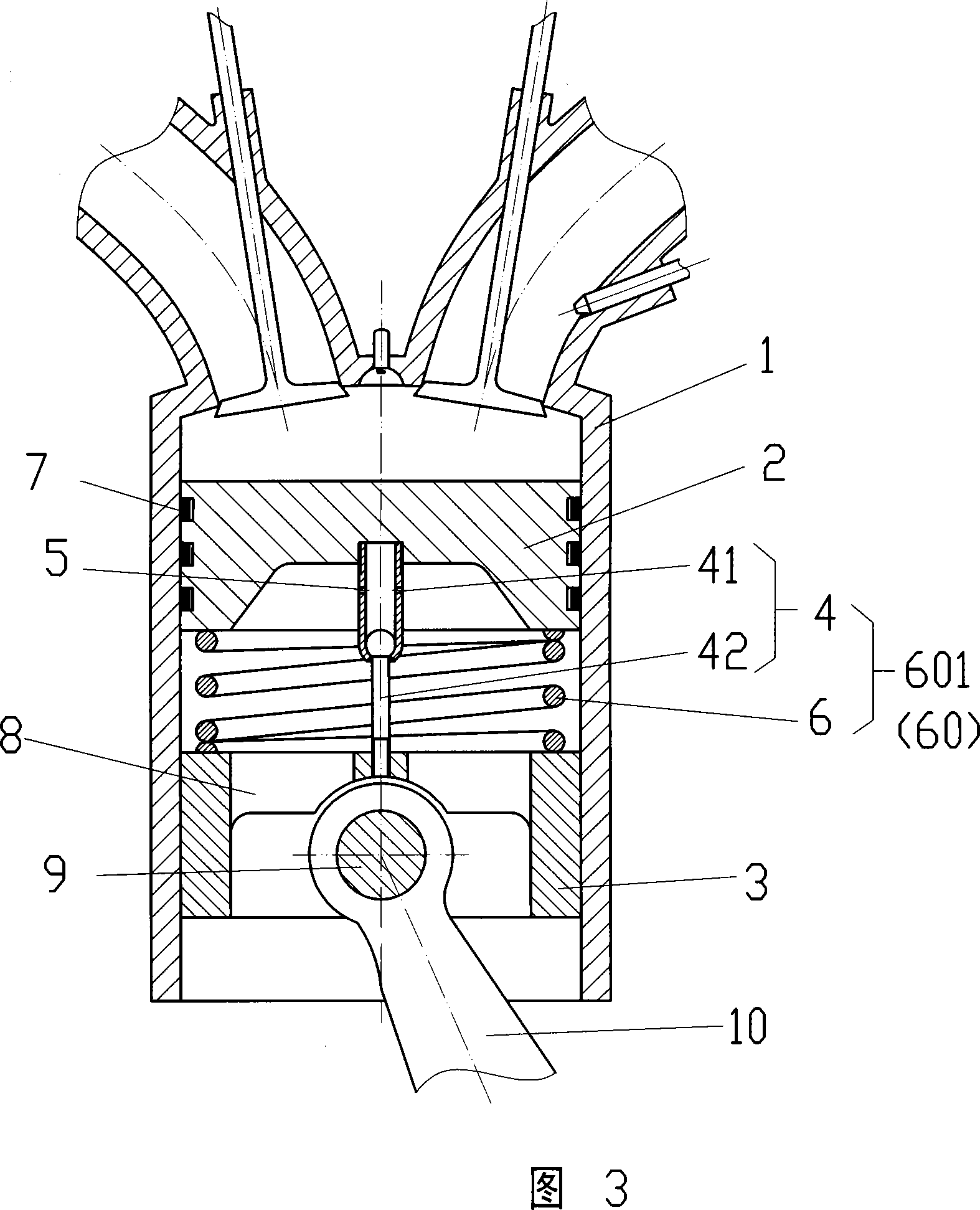

Reciprocating-piston type sealing compressor

ActiveCN101265893AMeet lubrication needsImprove lubrication conditionsPositive displacement pump componentsPositive-displacement liquid enginesBall bearingRolling resistance

The invention discloses a reciprocating piston-type sealing compressor, which comprises housing, a motor, a crank shaft, a crank shaft case, a connecting bar, a piston, a valve bank, an aspiratory muffler and a ball bearing component, wherein, an eccentric shaft on the upper end of the crank shaft is connected with a big-end hole of the connecting bar via the ball bearing component, and the ball bearing component is internally provided with two rows of balls. Therefore, the friction between the eccentric shaft and the connecting bar is converted into rolling friction, thus further deducing the mechanical loss of the position and further enhancing the efficiency of the complete machine of the compressor. Meanwhile, as the design of two-row balls is adopted in the structure, smaller balls can be used and the radial dimension of smaller ball bearing component is used for meeting the needs of integrant loading strength; in addition, a lubricating oil hole is easy to be arranged between the two-row balls, thus ensuring sufficient lubrication of the balls.

Owner:JIAXIPERA COMPRESSOR

High-efficiency engine

InactiveCN101042069AReduce high temperature and high pressure holding timeReduce lossesMachines/enginesCombustion chamberEngineering

A highly efficient engine comprises the cylinder, piston, guide, piston pin and linking lever with active linking device between the piston and the guide, with the linking device setting as prepressure shrinkable spring or nonspring linking device with the guide connecting with the linking lever. With better location of the guide having low temperature and better lubrication, and the piston bearing up and down forces, it can greatly reduce the friction and wearing between the piston and the cylinder. Apart from that, it can quickly reduce the top dead end high temperature and pressure retain time, with greatly reduced shock, improved torque, with higher, more efficient, energy saving and environment protective design.

Owner:靳宇男

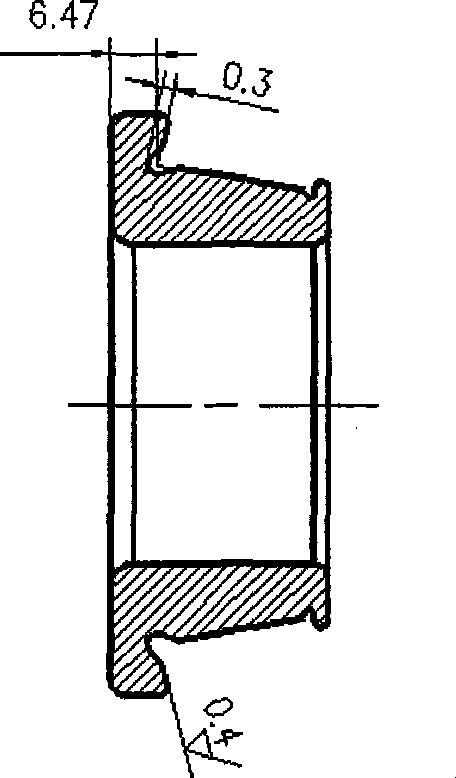

Tapered roller bearing with high strength and low friction torque

The invention relates to a tapered roller bearing with high strength and low friction torque, comprising an outer ring, an inner ring, a plurality of rollers and a cage, wherein the rollers are clamped between the outer ring and the inner ring and used for supporting and realizing relatively rotating; and the cage is used for guiding the rollers to move; a big rib of the inner ring is a convex curved rib; the root part width of the big rib of the inner ring is larger than 6.47 mm, and the axial depth of an oil groove is smaller than 0.5 mm; the raceway buses and the roller buses of the inner ring and the outer ring are in a logarithm curve convexity shape; the number of the rollers is less than 16, the length of the rollers is smaller than 24 mm, and the convex diameter of a raceway is small; the sphere base surface diameter of the rollers is smaller than 136 mm, and the diameter of the rollers is larger than 21.671 mm. The invention has long service life, saves the energy and reduces the energy consumption.

Owner:FUJIAN YONGAN BEARING

Fe/MoS2 nano multilayer film and preparation method thereof

ActiveCN101148761AImprove tribological propertiesPracticalVacuum evaporation coatingSputtering coatingTotal thicknessNanotechnology

The present invention discloses one kind of nanometer multilayer FeS / MoS2 film prepared through one composite treating process including the first alternate deposition of Fe layers and Mo layers and the subsequent ionic sulfinuzing. The nanometer multilayer FeS / MoS2 film has the thickness ratio between the FeS layer and the MoS2 layer of 0.95-1.05, double layer thickness of 5-20 nm, and total thickness of 1-3 microns. The nanometer multilayer FeS / MoS2 film has excellent friction performance, excellent solid lubricating performance or so-called 'super lubricating performance'. It may be applied in various kinds of friction surface, especially precisely fitting surface, to reduce friction and improve lubricating condition.

Owner:王海斗 +2

Grease Composition and Wheel Supporting Rolling Bearing Unit Having Grease Composition Packed Therein

InactiveUS20140193110A1Reduce load sensitivityNecessary performanceRolling contact bearingsCastorsRolling-element bearingMass ratio

There is provided a grease composition decreasing the load sensitivity to a running torque, maintaining necessary performances for a wheel supporting rolling bearing unit, and maintaining a good lubricated condition for a long time, and, a wheel supporting rolling bearing unit having the grease composition packed therein. The grease composition contains base oil, thickeners, rust inhibitors, and anti-wear agents, the base oil contains mineral oil, synthetic oil or blend oil of the mineral oil and the synthetic oil, a mix ratio (mass ratio) of the mineral oil and the synthetic oil is 0:100 to 20:80, a kinematic viscosity of the base oil at a temperature of 40° C. is 70 to 150 mm2 / s, and a pour point of the base oil is equal to or lower than −40° C. The wheel supporting rolling bearing unit is packed with this grease composition.

Owner:NSK LTD

Sliding-shoe friction pair of high-pressure seawater axial plunger pump with bionic non-smooth surface

ActiveCN103867428AImprove wear resistanceExtended service lifePositive displacement pump componentsLiquid fuel engine componentsEngineeringHigh pressure

The invention discloses a sliding-shoe friction pair of a high-pressure seawater axial plunger pump with a bionic non-smooth surface. The sliding-shoe friction pair is mainly characterized in that through hole unit bodies are arranged on an inclined disc regularly; the through hole unit bodies are respectively arranged in inwards-concave water grooves which are regularly arranged; and the water grooves are mutually communicated. Preferably, pit unit bodies are regularly arranged on the sliding-shoe friction surface matched with the inclined disc. The sliding-shoe friction pair disclosed by the invention has the advantages that the lubricating capability, the bearing characteristic and the friction and wear properties of the sliding-shoe friction pair in the lubricating environment of seawater and under the condition of high speed and heavy load can be reasonably improved by high cost performance.

Owner:南通东湖国际商务服务有限公司

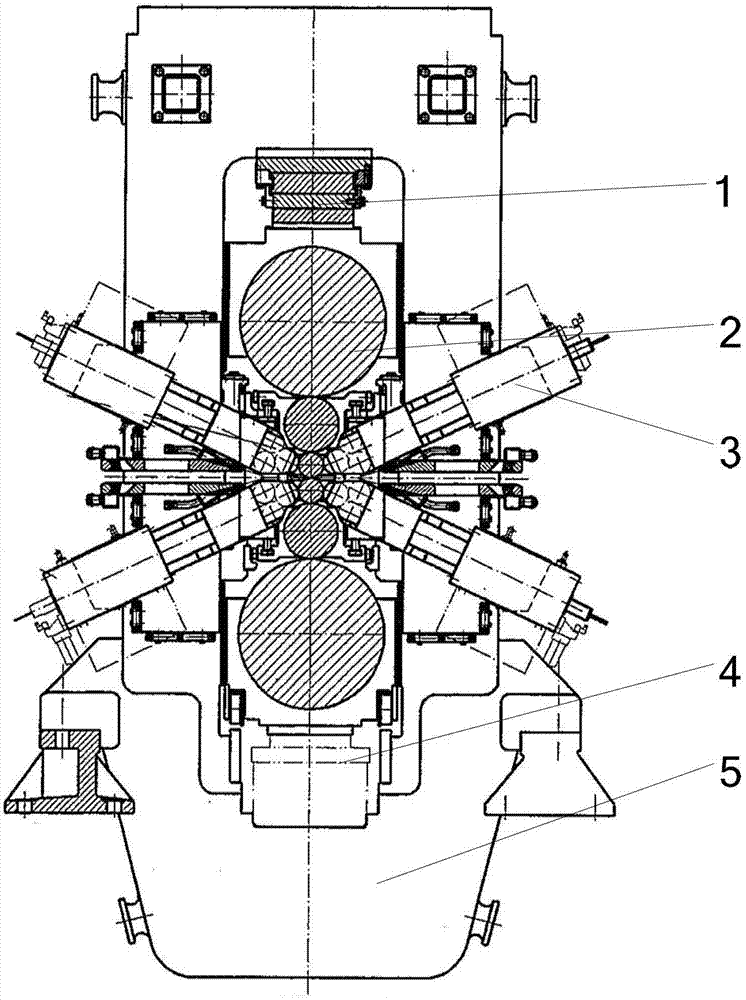

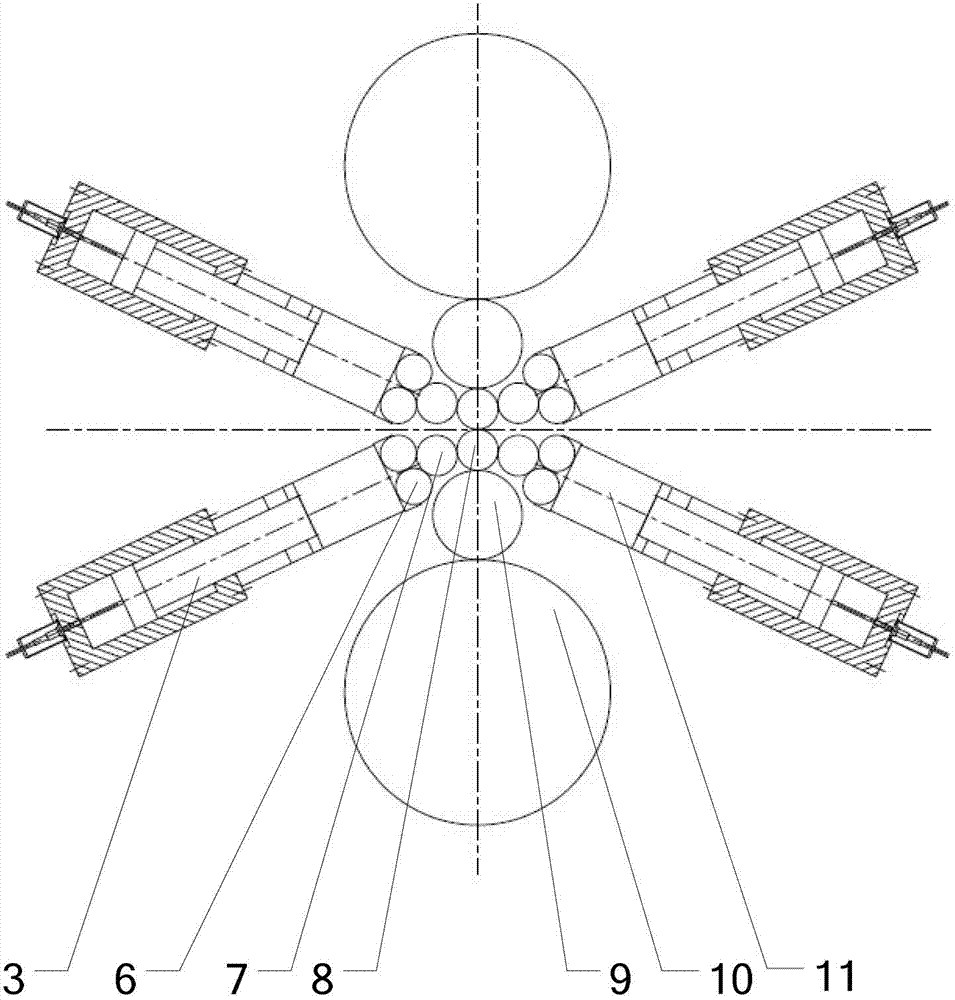

Eighteen-roller rolling mill structure

InactiveCN102886382AStrap for easy observationGuaranteed stiffness requirementsMetal rolling stand detailsCounter-pressure devicesEngineeringLubrication

The invention provides an eighteen-roller rolling mill structure. Side supporting devices of working rollers are respectively arranged in the front and at the back of as well as on and below a rolling mill machine frame assembly; each side supporting device comprises a side supporting bearing pedestal, a side roller and a side supporting roller; the side supporting device comprises a side driving cylinder which is provided with a displacement sensor and a servo valve for controlling the advancing and retreating positions of the side supporting device; when in a rolling work, the side supporting positions are set according to various technical parameters, so that the side deformation caused by the working rollers in a rolling process is counteracted and the rigidities of the working rollers are improved; with the adoption of the small-diameter working rollers and a side driving roller system mode, the demand of roller rigidity in the rolling process is ensured, and meanwhile, the rolling demand of an ultra-thin belt material is satisfied; and the rolling mill structure has the following advantages of high rolling mill opening degree, favorable lubrication for the roller and belt material, high speed, convenience to maintain equipment and low manufacturing cost of the equipment.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Worm wheel and worm with dynamic and static pressure lubricating at engagement zone

InactiveCN101067437AImprove the lubrication effectReduce churning lossToothed gearingsPortable liftingGear driveGear wheel

The invention discloses the worm and gear with the active and static pressure lubricant used in the mechanically-driven meshing zone. The sealing mass is installed in the out of the meshing zone of the worm and the gear, which contacts with the worm and has the sealing strip. The maze tooth is on the relative surface of the sealing mass and the gear, which is directed to the bear without the oil through the oil pipe from the oil hole opened in the sealing zone formed between the sealing mass hollow and the worm or gear. The screw vanes with the same direction are set on the meshed end of the basal leptospira in gear. The ring oil groove in sealing mass hollow is connected to the sealing zone through the oil hole; on the tooth surface of the worm or gear, the unconnected oil slots are opened. The structure of the invention has improved the lubricant of the worm and gear to improve the loading ability. The driven efficiency has improved by 3%, so it can instead the multilevel gear or planet gear and used in the big speed ratio field.

Owner:刘继清

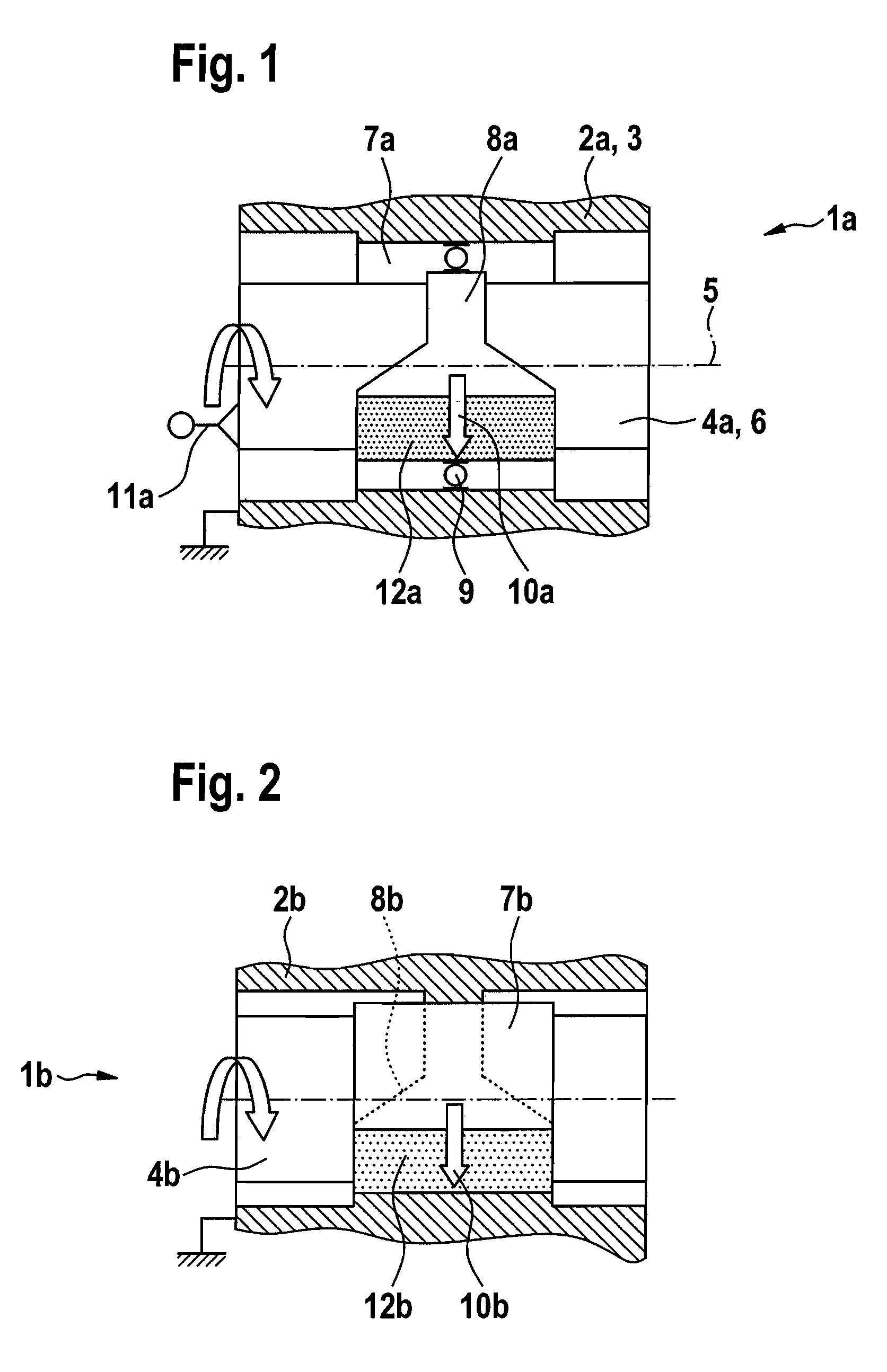

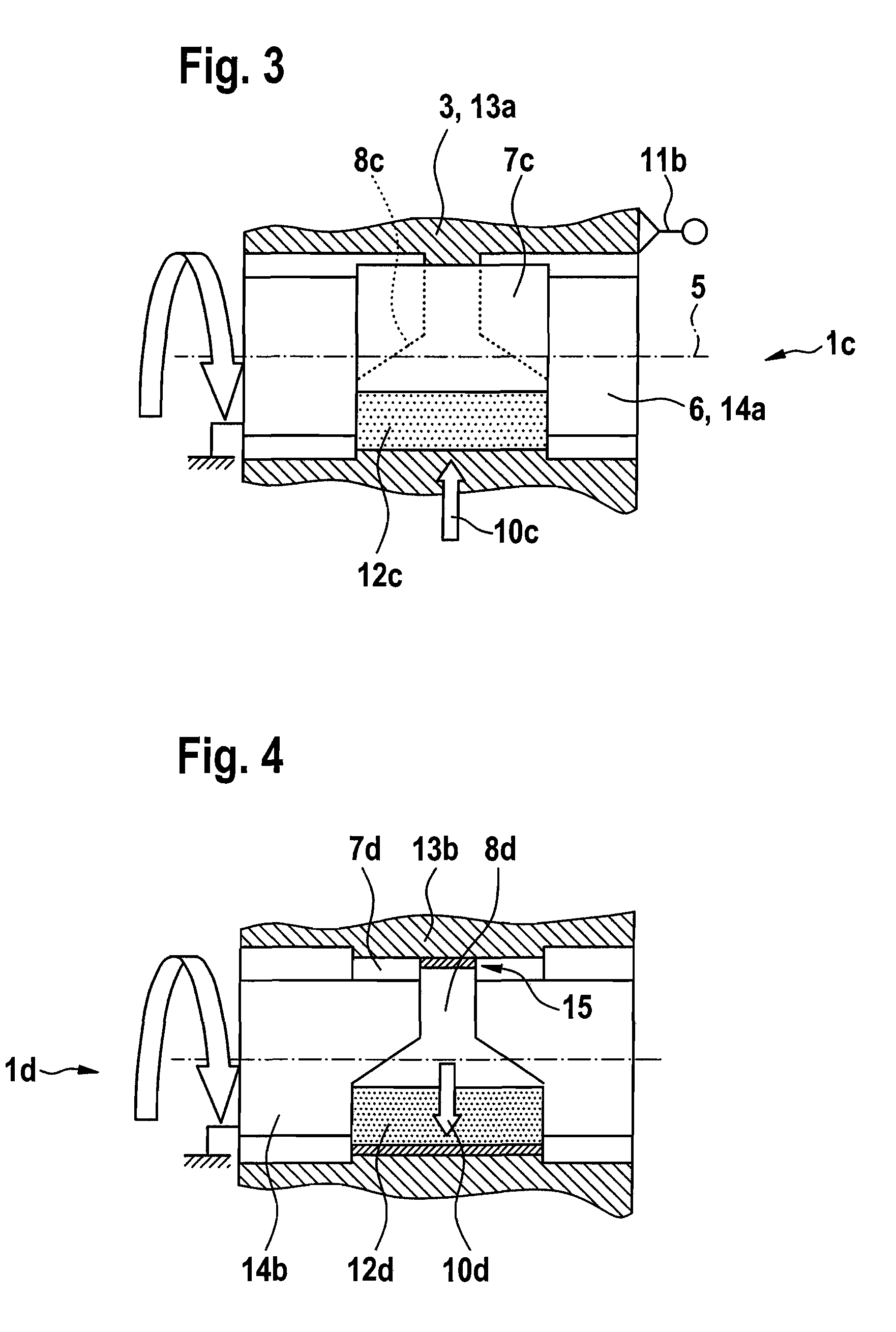

Radial bearing

ActiveUS7628133B2Low costReduce expensesBall bearingsBearing componentsEngineeringMechanical engineering

A radial bearing (1a, 1b, 1c, 1d), especially a roller bearing (9) comprising an outer part (3) opposite an inner part (6), which rotate relative to each other about a common longitudinal axis (5) is provided, wherein the radial bearing (1a, 1b, 1c, 1d) includes a bearing seat (8a, 8b, 8c, 8d), which is formed in the outer part (3) or on the inner part (6) and which is generally stationary relative to a radial load (10a, 10b, 10c, 10d) acting on the bearing seat (8a, 8b, 8c, 8d) in a load zone (12a, 12b, 12c, 12d). The bearing seat (8a, 8b, 8c, 8d) features a variable width over its extent in a direction of the longitudinal axis (5), such that, starting from the load zone (12a, 12b, 12c, 12d), the bearing seat (8a, 8b, 8c, 8d) is significantly narrowed outside of the load zone (12a, 12b, 12c, 12d).

Owner:SCHAEFFLER TECH AG & CO KG

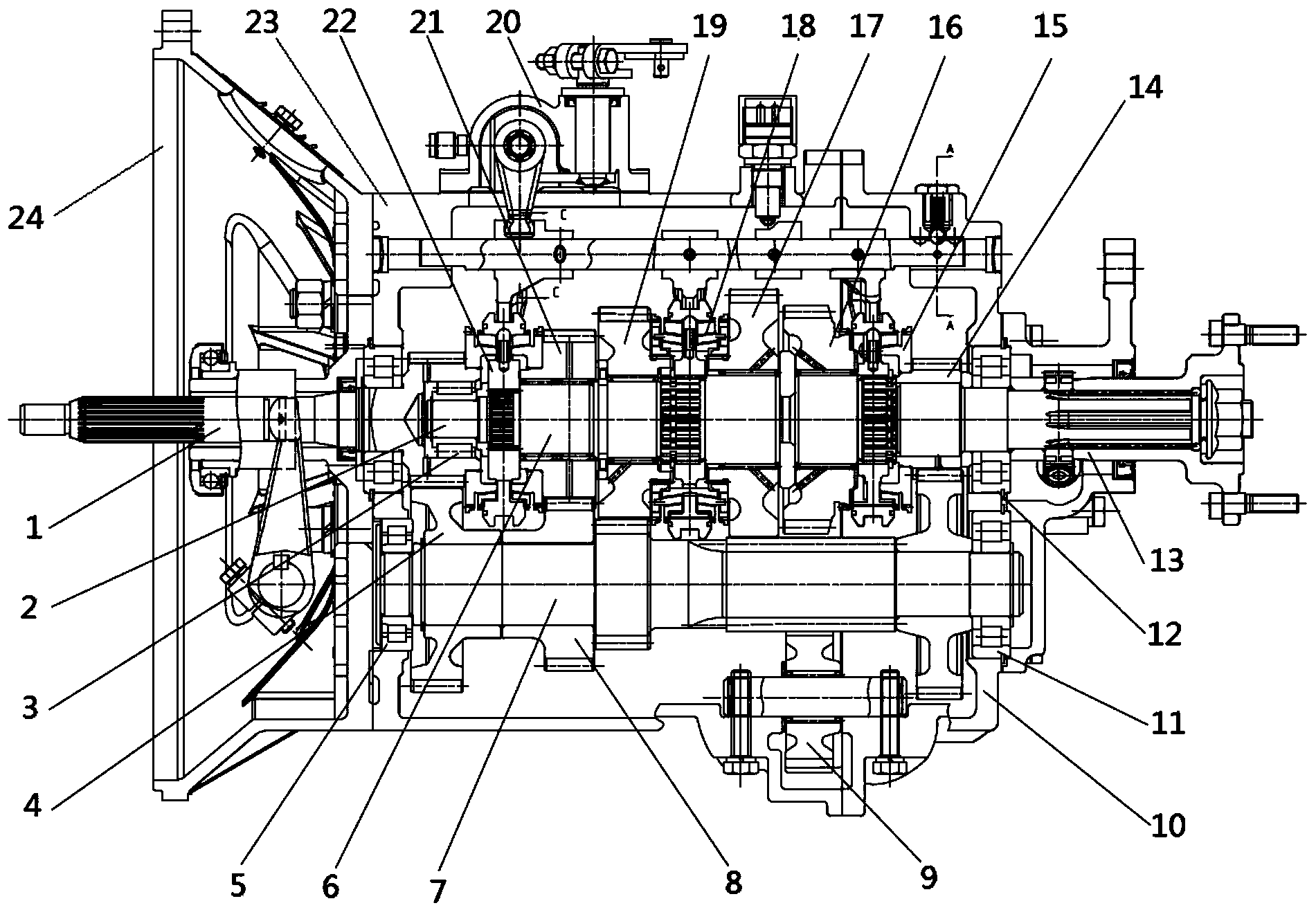

Five-shift car gearbox

InactiveCN103899714AImprove carrying capacityCompact structureToothed gearingsTransmission elementsEngineeringMechanical engineering

The invention discloses a five-shift car gearbox. The five-shift car gearbox comprises a shell, a first shaft assembly, a second shaft assembly and an individual intermediate shaft assembly. The shell comprises a front gearbox shell body, a main gearbox box and a rear gearbox shell body. The first shaft assembly comprises a shaft gear. The second shaft assembly supported in an inner ring of a first shaft and the rear gearbox shell body comprises a third-shift gear, a second-shift gear, a first-shift gear, a backward gear and an overdrive gear of the second shaft, and the third-shift gear, the second-shift gear, the first-shift gear, the backward gear and the overdrive gear of the second shaft sequentially sleeve on the second shaft along the power transmission direction; the intermediate shaft horizontally arranged under the second shaft assembly comprises an intermediate shaft transmission gear constantly meshed with the gear of the first shaft, an intermediate backward gear constantly meshed with the backward gear of the second shaft through the intermediate backward gear and an intermediate gear correspondingly and constantly meshed with the third-shift gear and the second-shift gear of the second shaft; the intermediate backward gear is simultaneously and constantly meshed with the first-shift gear of the second shaft; the intermediate backward gear is axially fixed on the joint of the main gearbox box and the rear gearbox shell body.

Owner:SHAANXI FAST GEAR CO

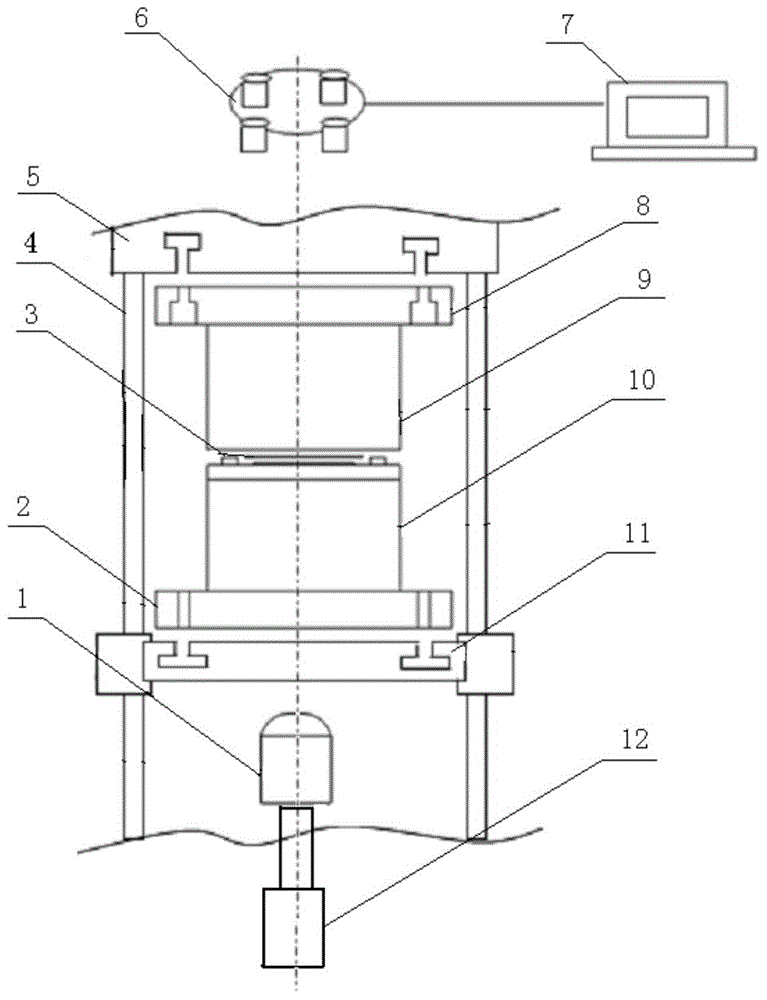

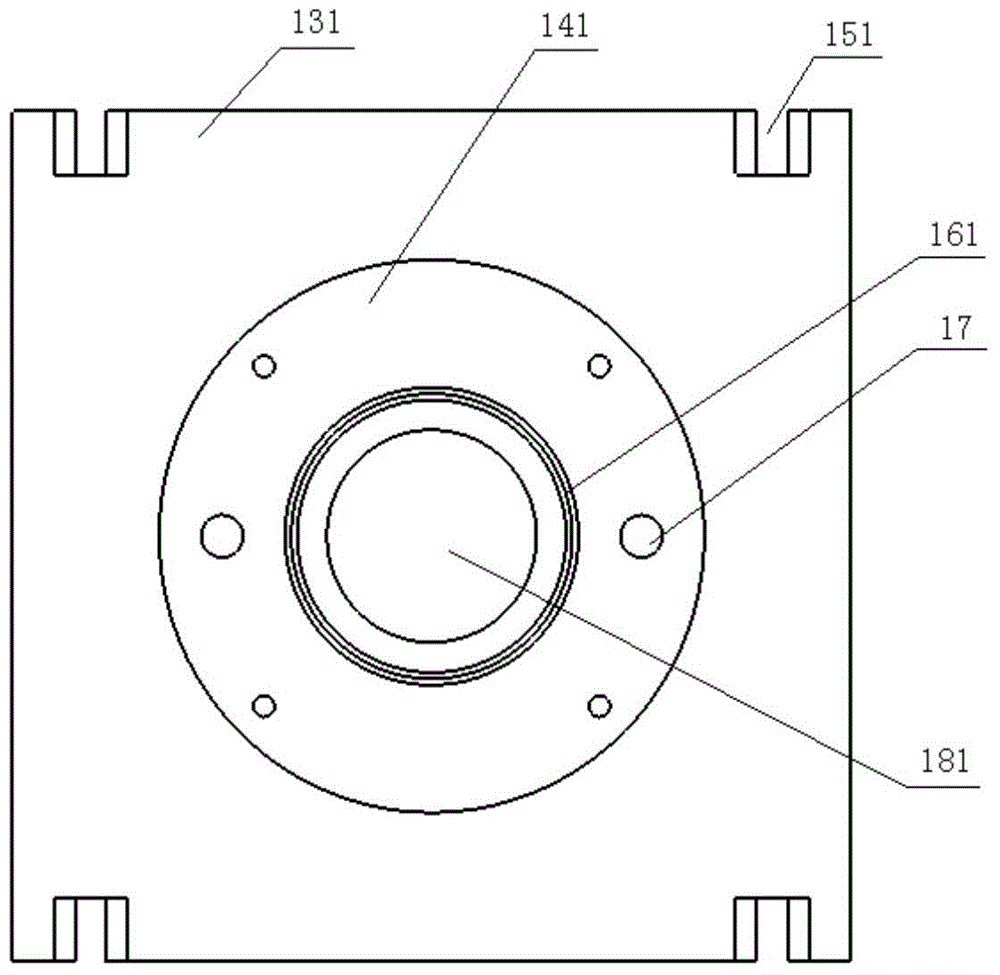

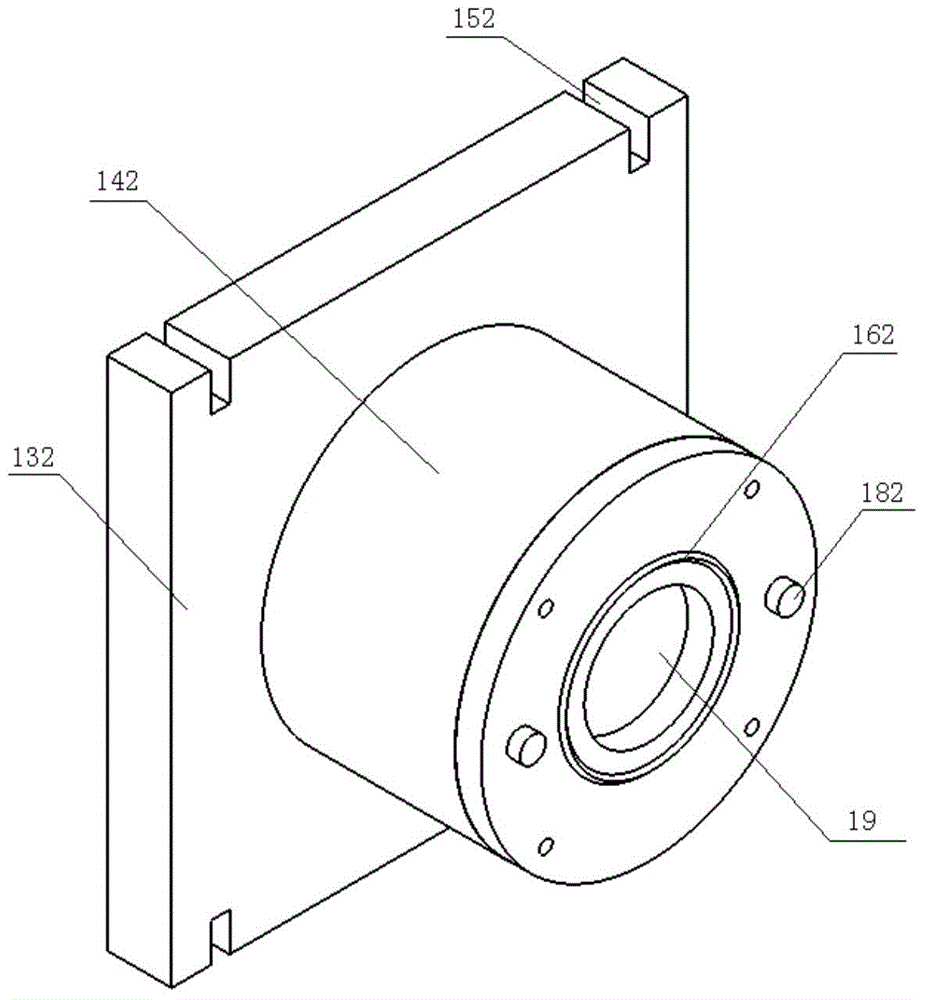

DIC technology-based automobile thin plate FLC curve determination device and method

InactiveCN105223090AReduce usageEasy to observeInvestigating material ductilityHydraulic cylinderTest sample

The invention discloses a DIC technology-based automobile thin plate FLC curve determination device and method. The device comprises a material tester, a video camera, a computer and a bulging tester. The bulging tester comprises an upper base, a female die, a blank holder, a lower base and a puncher pin. The upper base is fixed to an installation platform of the material tester, the female die is connected to the lower surface of the upper base, the blank holder is installed on the upper surface of the lower base, the lower base is fixed to a lifting platform of the material tester and the puncher pin is installed on a hydraulic cylinder. The method comprises tightly clamping a test sample between the female die and the blank holder by the lifting platform, punching the test sample to produce cracks by the puncher pin under the action of the hydraulic cylinder, shooting a test sample mesh deformation process by the video camera, computing a limiting strain value by the computer through DIC software, changing the test sample until all limiting strain values of all the samples are obtained, and drawing a FLC curve of an automobile thin plate by connection of all the limiting strain value points. The device and method are convenient for operation, save time and labor, greatly improve a measurement precision and are convenient for observation and research of necking phenomenon.

Owner:ANGANG STEEL CO LTD

Steering drive device for caterpillar vehicle

The invention relates to a turning driving device of crawler vehicle. Power output shaft connected with small gear is set in box body and the big gear on the shaft is mated with the small gear. The shaft is hollow. Small and big gears are cylinder gear. On the shaft left sun gear mated with left planetary gear connected with the left output shaft, right sun gear mated with right planetary gear connected with the right output shaft are set. Left ring gear connected with left bevel gear is mated with the left planetary gear and right ring gear connected with right bevel gear is mated with the right planetary gear. Left positioner is set on the left output shaft and right positioner is set on the right output shaft. Bearings are set between the left ring gear and the shaft, and between the right ring gear and the shaft. Bearings are set between left shaft sleeve connected with the left ring gear and the body, and between right shaft sleeve connected with the right ring gear and the body. Bearing is set between the left output shaft and the left shaft sleeve and bearing is set between the right output shaft and the right shaft sleeve. Turning control input shaft combined with turning bevel gear together is set on the body. The turning bevel gear is mated with the left bevel gear connected with the left ring gear and the right bevel gear connected with the right ring gear.

Owner:CHANGAN UNIV

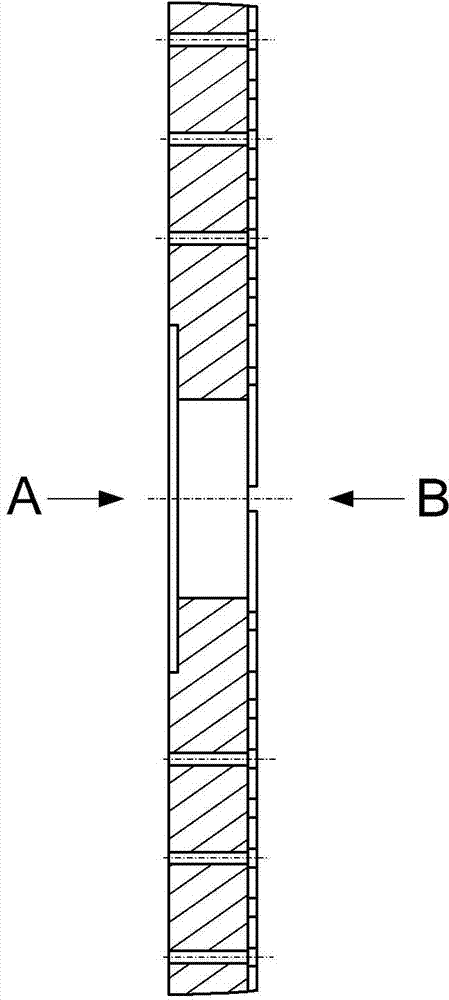

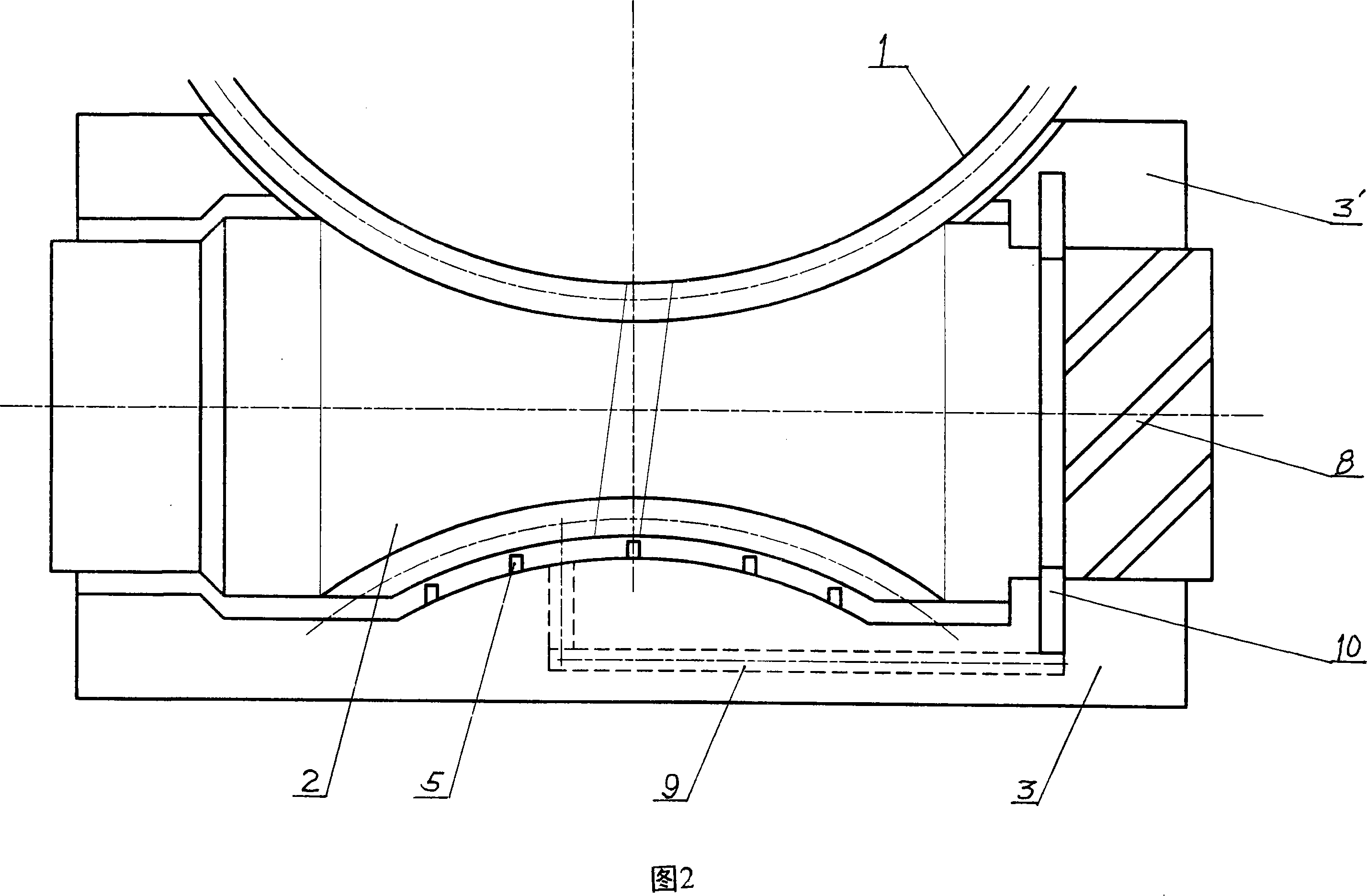

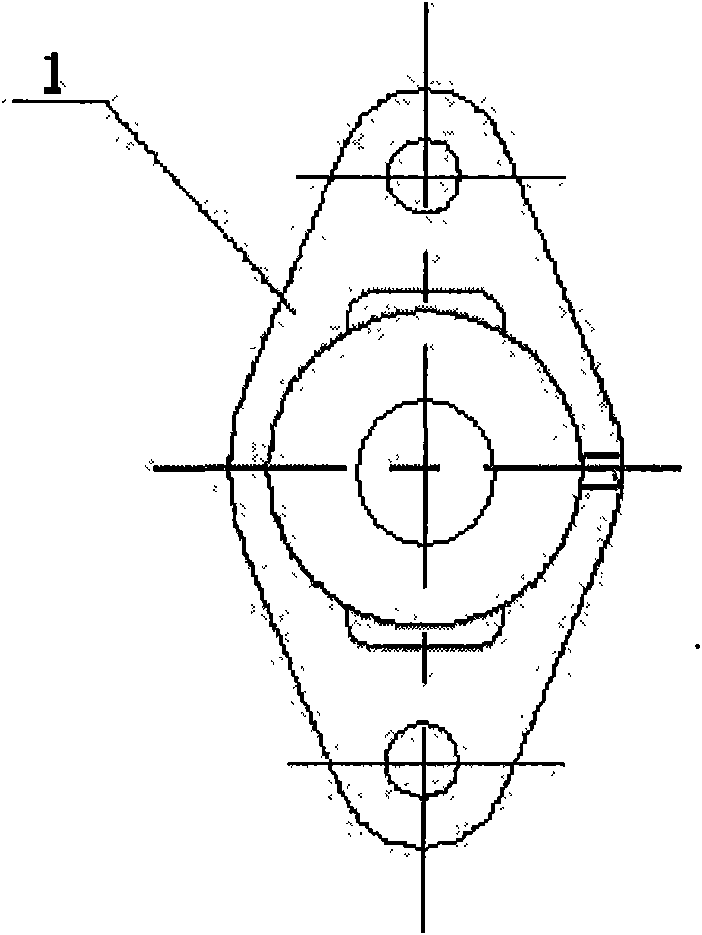

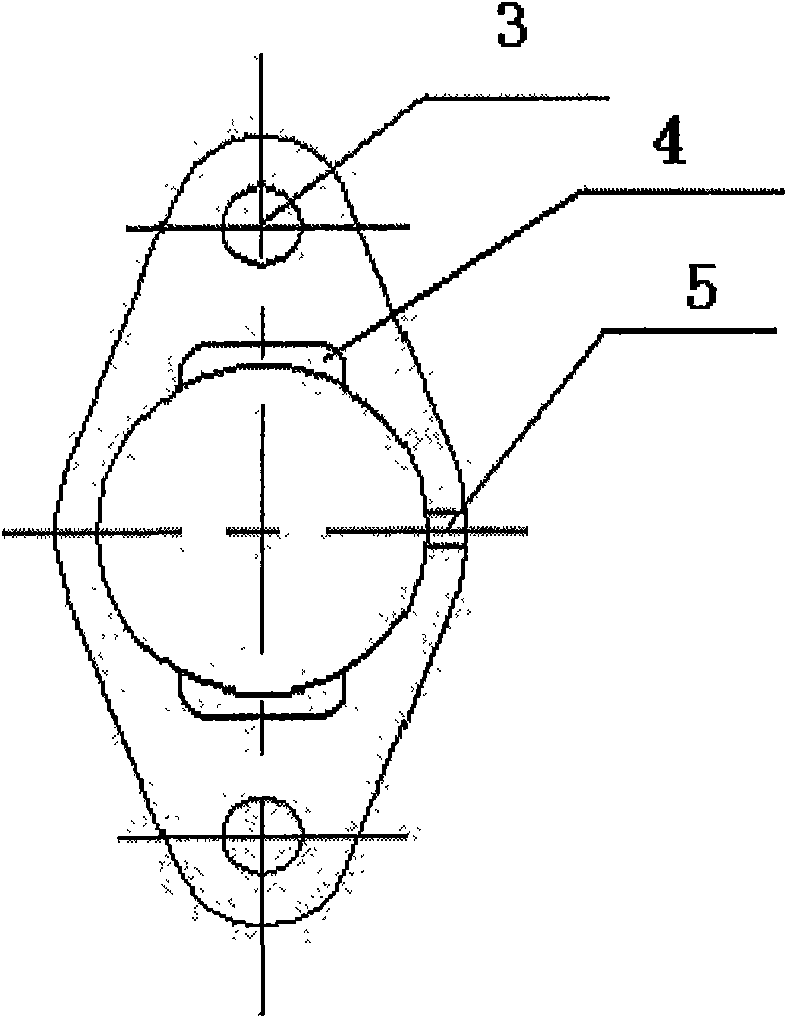

Aligning sliding bearing for efficient air valve of subway

InactiveCN101684842AImprove lubrication conditionsExtended service lifeSliding contact bearingsBearing unit rigid supportAuto regulationMachine parts

The invention belongs to the field of machine parts, and relates to an aligning sliding bearing for an efficient air valve of a subway. The aligning sliding bearing comprises a bearing block body (1),a sliding bearing (2), a bolt hole (3), a demounting hole (4) and an oil hole (5), wherein the bearing block body is fixed with an air valve framework by bolts; the sliding bearing is connected witha blade shaft; the demounting hole is arranged in a square shape along the radial direction of an inner hole of a bearing block; and a position which is in the radial direction of the inner hole of the bearing block and is vertical to the length direction of the bearing block is provided with the oil hole. The spherical contact surface of the sliding bearing is matched with the spherical contact surface on the bearing block, so a sliding ball is difficult to slide off in the bearing block and runs more stably, and the spherical surface assembling mode can automatically adjust the concentricityof two ends of a fan blade shaft so as to effectively solve the problem of unstable running caused by the two non-concentric ends of the fan blade shaft because the fan blade shaft is too long when the air valve is in operation. The design of the oil hole of the sliding bearing block can ensure the spherical surface lubricating condition, reduce the friction, and improve the transmission efficiency and the service life of a material.

Owner:北京凯恩特技术有限公司

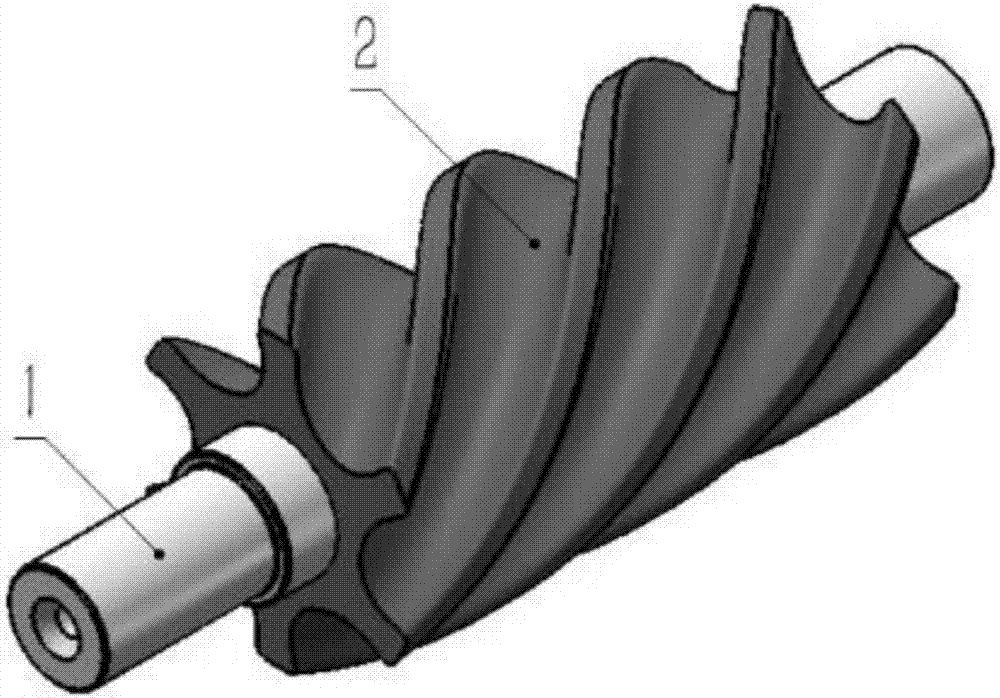

Manufacturing method for double-screw-rod compressor rotor

InactiveCN107448384AGood sealing conditionImprove lubrication conditionsRotary piston pumpsGear wheelsMilling cutterOil free

The invention discloses a manufacturing method for a double-screw-rod compressor rotor. A screw-rod compressor rotor is formed by a stainless steel rotor core and a PEEK engineering plastic tooth-shaped shell through high-temperature mold pressing. In order to make an oil-free screw rod compressor reach the higher exhaust pressure (the gage pressure of 1.3 MPa) and guarantee the long-time operating reliability of the rotor, a screw rod rotor structure is made of the stainless steel rotor core and a special modified PEEK material which is 1-5 mm thick and die-cast to the surface; finally, the die-cast PEEK surface is finished in place by a form milling cutter; and to increase the bonding degree of the PEEK engineering plastic and the stainless steel rotor core, some regular circular pits are machined in the two tooth-shaped end faces of the stainless steel rotor. By the adoption of the manufacturing method, the manufacturing difficulty of the oil-free screw rod compressor rotor can be lowered greatly, the structure manner of an oil-free air screw rod compressor, an oil-free process screw rod compressor and a refrigeration screw rod compressor can be simplified, and finally the service life of the screw rod compressors can be prolonged, and the maintenance cost is lowered.

Owner:SUZHOU ALRBETTER PRECISION MACHINERY

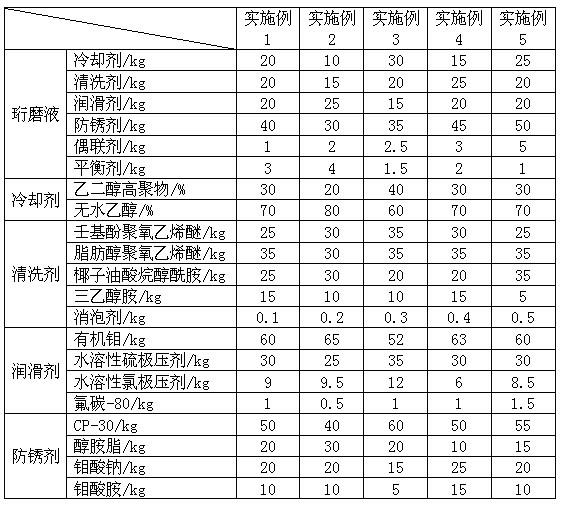

Water-based honing liquid and honing method for using same

The invention discloses a water-based honing liquid and a honing method for using the same. The water-based honing liquid comprises the following components in parts by mass: 10-30 parts of a cooling agent, 15-25 parts of a cleaning agent, 15-25 parts of a lubricating agent, 30-50 parts of an anti-rust agent, 1-5 parts of a coupling agent and 1-5 parts of a balancing agent, wherein the cooling agent consists of the following components in percentage by mass: 20-40 percent of an ethylene glycol high polymer and 60-80 parts of absolute ethanol. The water-based honing liquid has the effects of protecting the environment, cooling, cleaning, lubricating and preventing rust. Due to the adoption of the water-based honing liquid and the honing method disclosed by the invention, the processing efficiency of flat table net grains on an engine cylinder sleeve can be increased, and the quality of the flat table net grains can be enhanced.

Owner:石家庄金刚内燃机零部件集团有限公司

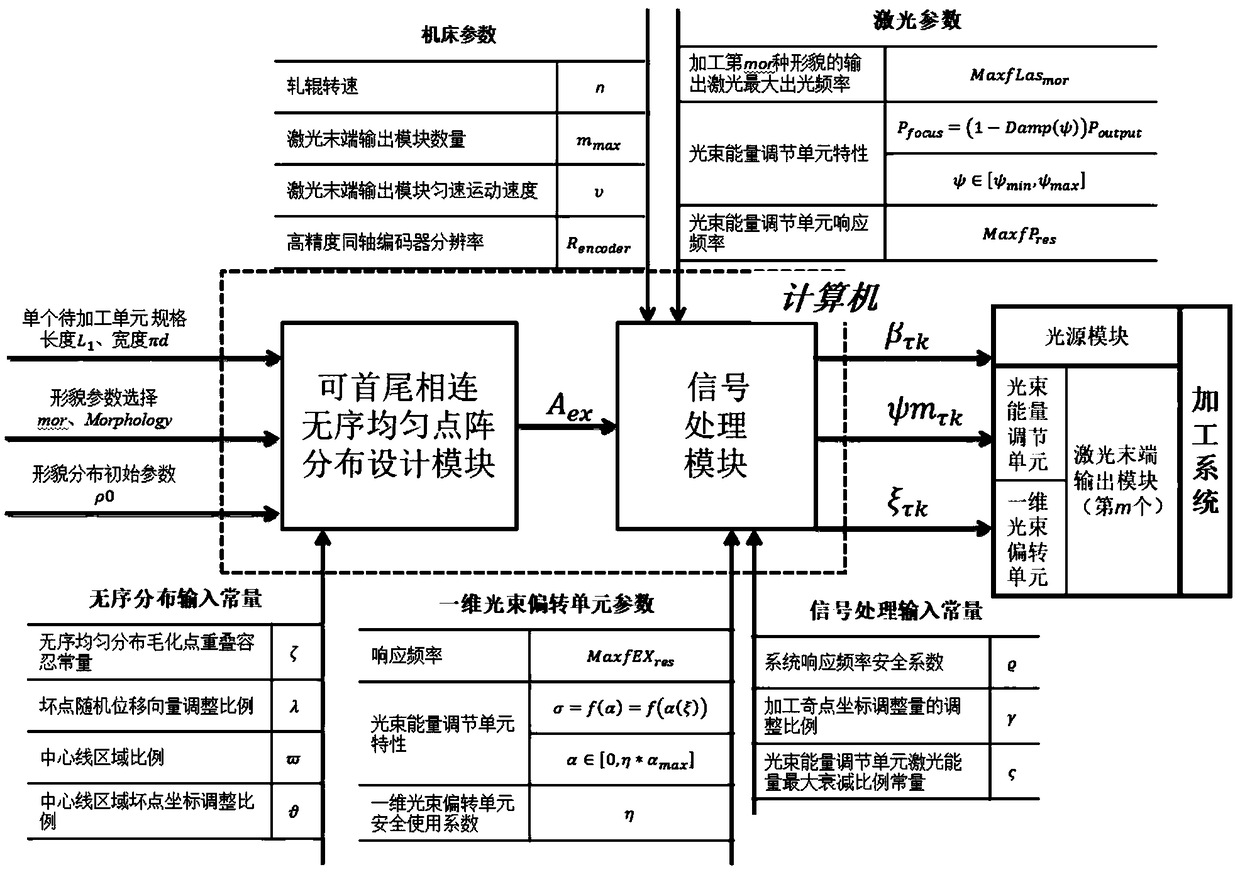

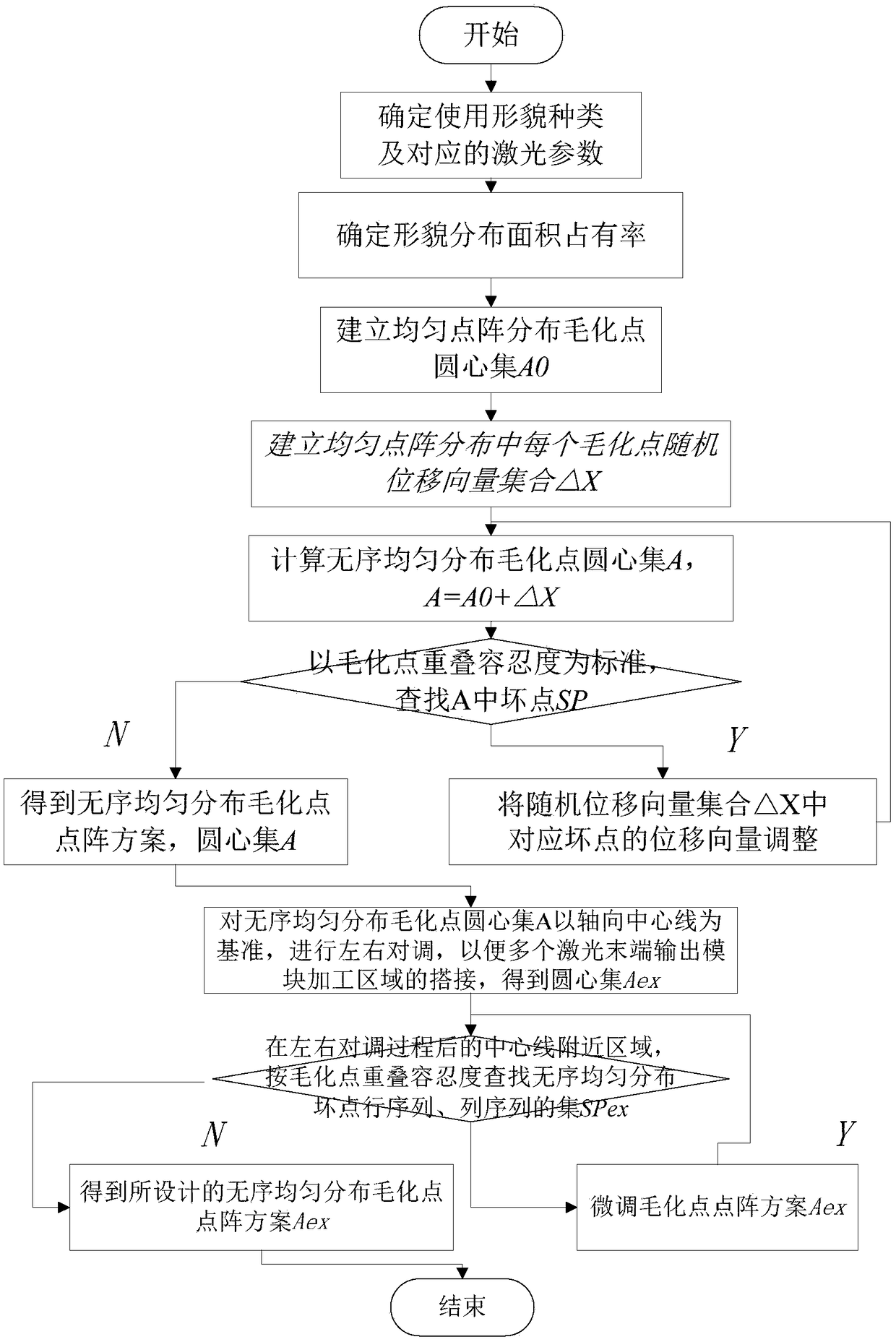

Roller laser roughening machining equipment and machining method thereof

ActiveCN109365993AGuaranteed degree of disorderImprove consistencyWelding/cutting auxillary devicesAuxillary welding devicesOptical beam deflectionLight beam

The invention provides roller laser roughening machining equipment and a machining method thereof. The machining method comprises the following steps that machining area division is conducted; a distribution scheme is determined, and the end-to-end connected disordered uniform distribution roughening lattice distribution scheme can be obtained according to roller machining unit parameters and shape parameters; output signals are determined, and laser light emitting position signals, light beam energy adjusting signals and one-dimension light beam deflection unit deflection signals are obtainedthrough an information processing module; roller laser roughening machining is conducted, and the laser light emitting position signals are used for controlling a light source module to emit lasers;and the light beam energy adjusting signals and the one-dimension light beam deflection unit deflection signals are input into laser tail end output modules for generating disordered laser lattices, and each laser tail end output module is used for machining one roller machining unit. By means of the roller laser roughening machining equipment and the machining method thereof, shape distribution uniformity can be ensured while the roughening point disordered degree is guaranteed, and consistency of the surfaces of produced cold-rolled plates in subsequent coating treatment is better.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com