DIC technology-based automobile thin plate FLC curve determination device and method

A measuring device and thin plate technology, which is applied in the direction of testing the ductility of materials, etc., can solve the problems of strain value measurement accuracy, accuracy error, waste of manpower and material resources, and low accuracy of experimental data, so as to improve lubrication conditions and adjust daylighting Convenience and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

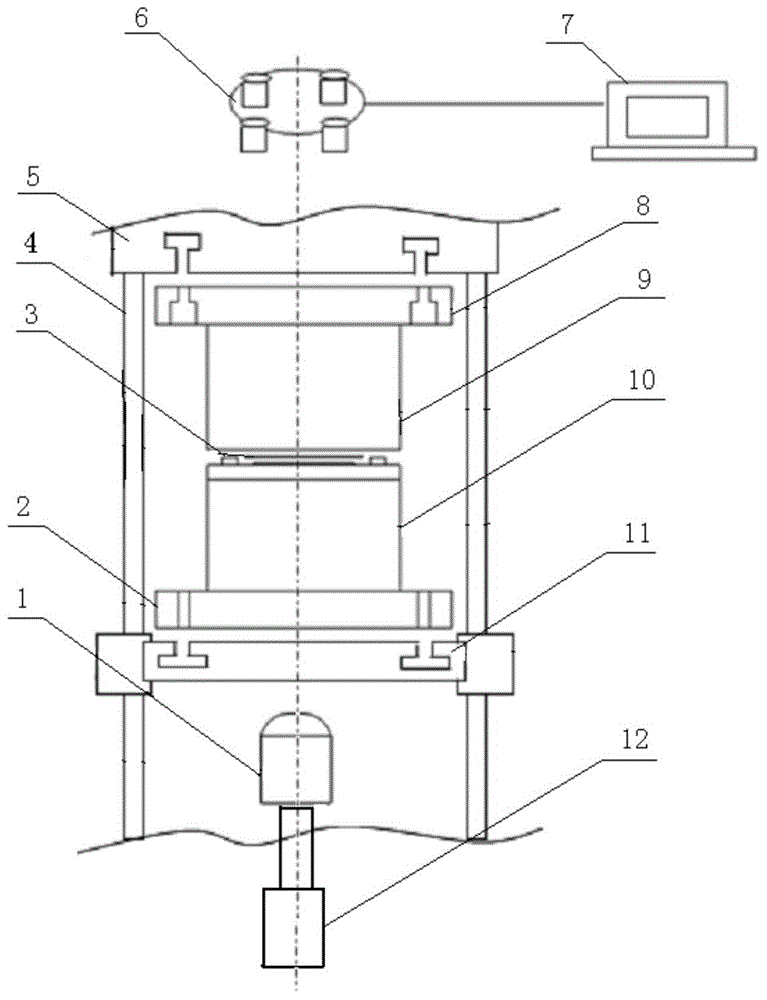

[0025] Depend on figure 1 It can be seen that the automobile thin plate FLC curve measuring device of the present invention is composed of a material testing machine 4, a high-speed camera 6, a computer 7 and a bulging test device. A high-speed camera 6 with 4 cameras is connected with a computer 7 . The material testing machine 4 is supported by 4 guide pillars. The upper end of the guide pillars is provided with an installation platform 5, the lower part is provided with a lifting platform 11, and the bottom is equipped with a hydraulic cylinder 12. The lifting platform 11 can move up and down along the guide pillars.

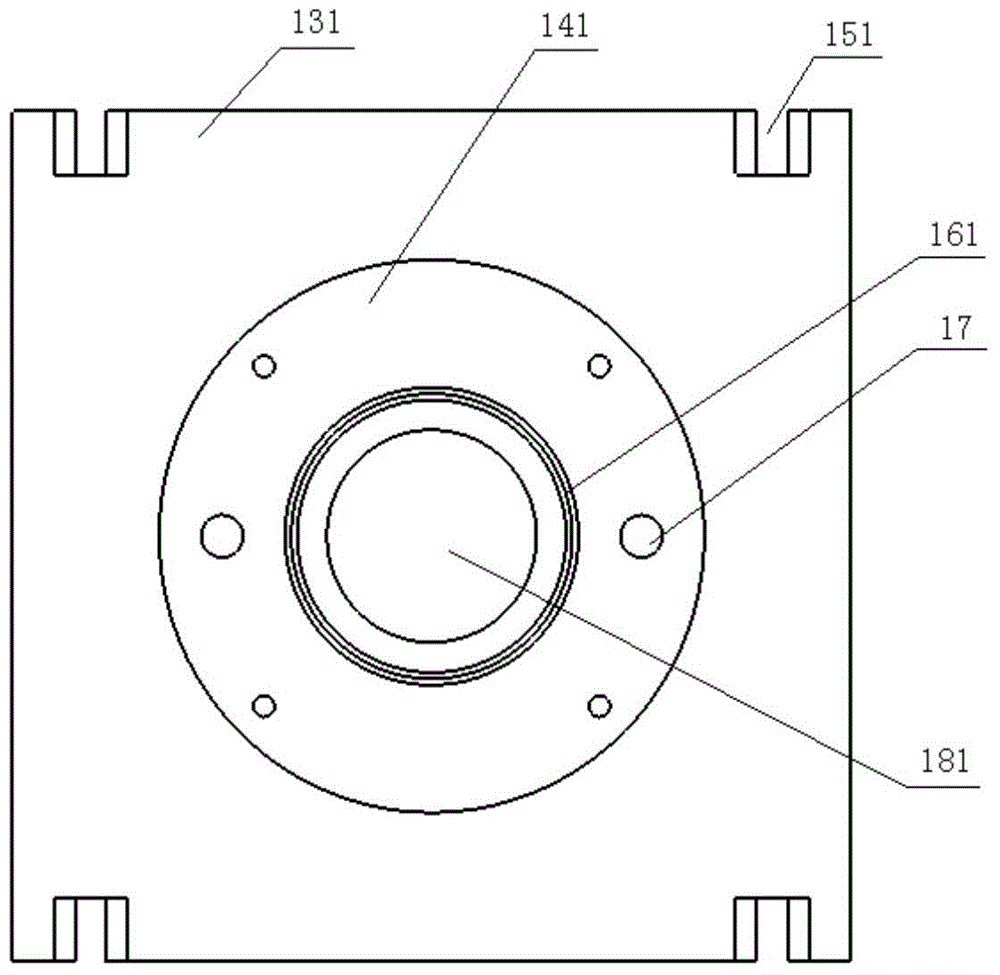

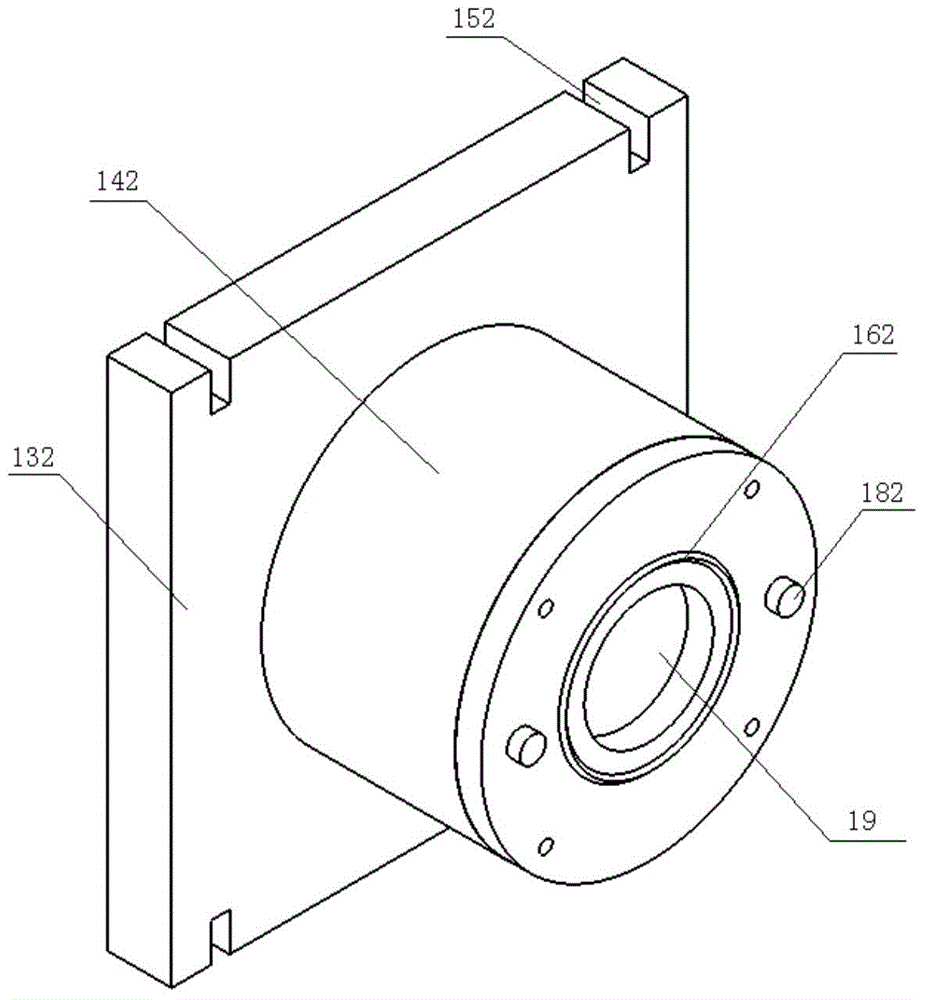

[0026] The bulging test device comprises a punch 1, a lower base 2, an upper base 8, a die 9 and a blank holder 10. The punch 1 is a cylinder as a whole, with a hemispherical pressure head 20 on the upper end of the cylinder (see Figure 4 ). figure 2 It is shown that the die 8 and the blank holder 10 are basically the same in shape, and the overall shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com