Reciprocating-piston type sealing compressor

A technology of reciprocating piston and compressor, which is applied in the direction of liquid variable volume machinery, mechanical equipment, variable volume pump components, etc., can solve problems such as small lubrication capacity, and achieve the effect of reducing mechanical loss, reducing mechanical loss and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

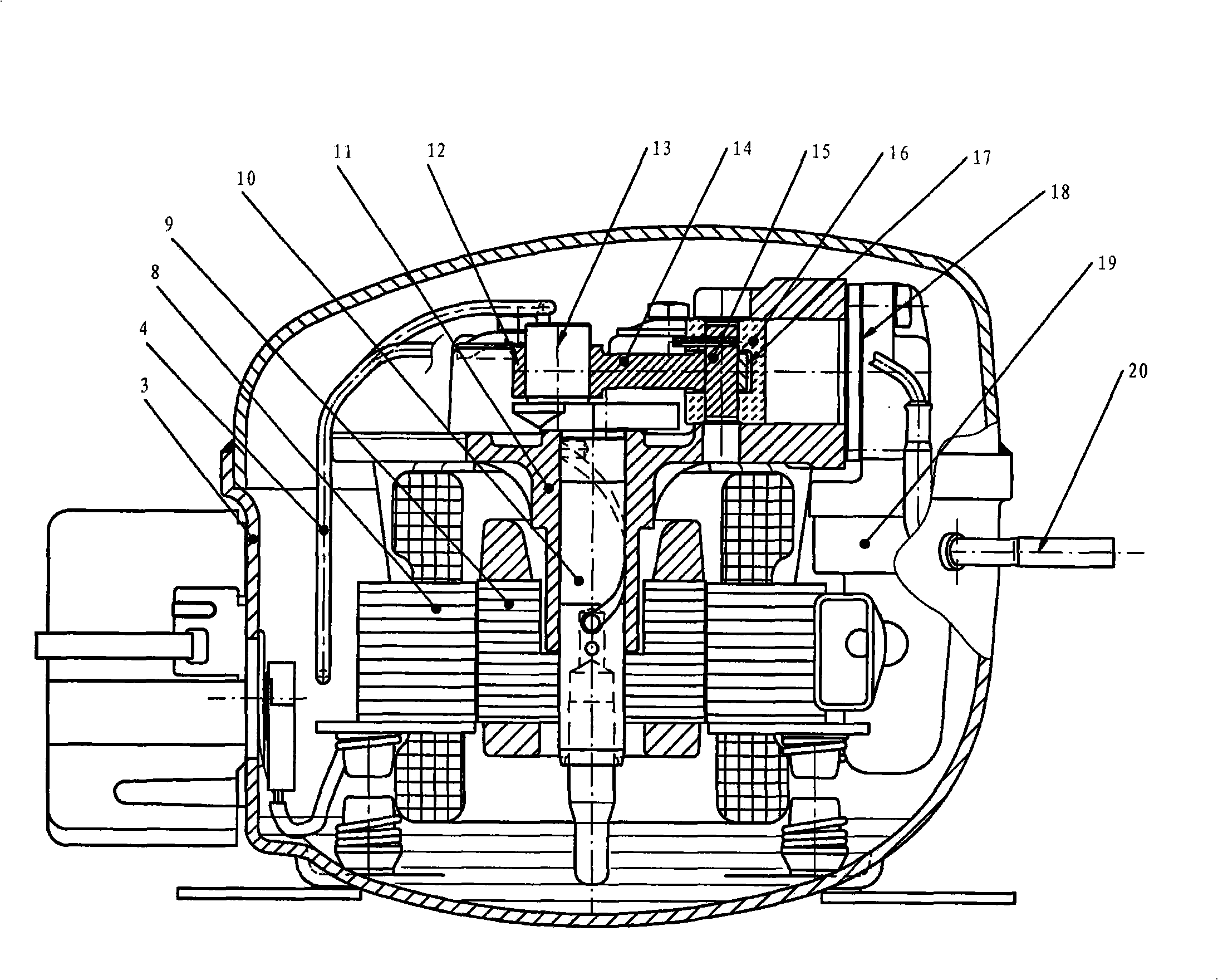

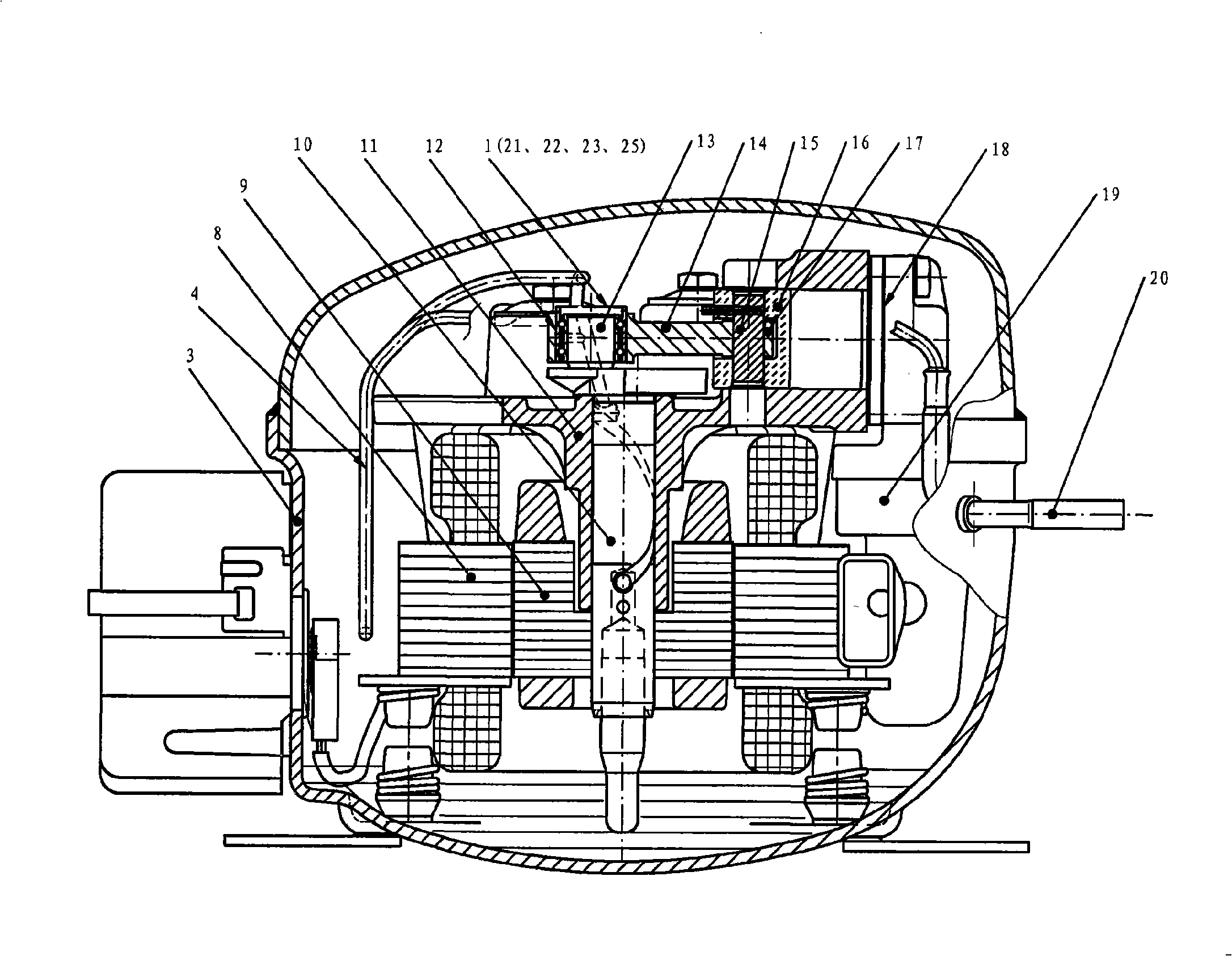

[0022] like figure 2 As shown, the reciprocating piston type hermetic compressor of the present invention includes housing 3, inner exhaust pipe 4, motor stator 8, motor rotor 9, crankcase 11, crankshaft 10, eccentric shaft 13, connecting rod 14, piston pin 15, piston 16. Valve group 18, suction muffler 19, exhaust pipe 20 and ball bearing assembly 1, the connecting rod 14 is an integral connecting rod, and the ball bearing assembly 1 is assembled between the eccentric shaft 13 and the hole of the connecting rod big end 12, The eccentric shaft 13 and the connecting rod 14 are connected. Obviously, when the hermetic compressor adopting the ball bearing structure of the present invention is in operation, the original sliding friction between the eccentric shaft 13 and the big head 12 of the connecting rod 14 is transformed into rolling friction, which further reduces the mechanical loss.

[0023] like image 3 As shown, the ball bearing assembly 1 of the compressor of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com