Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

332 results about "ALUMINUM STEARATES" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum Stearate (C54H105AlO6) exists as white powder and is an aluminum salt of stearic acid. In the pharmaceutical industry, it is used as an anticaking agent; colorant; emulsion stabilizer; and viscosity increasing agent.

Defoaming agent for linerboard paper making

InactiveCN101158131AEffective controlMeet actual needsDefoamers additionALUMINUM STEARATESPapermaking

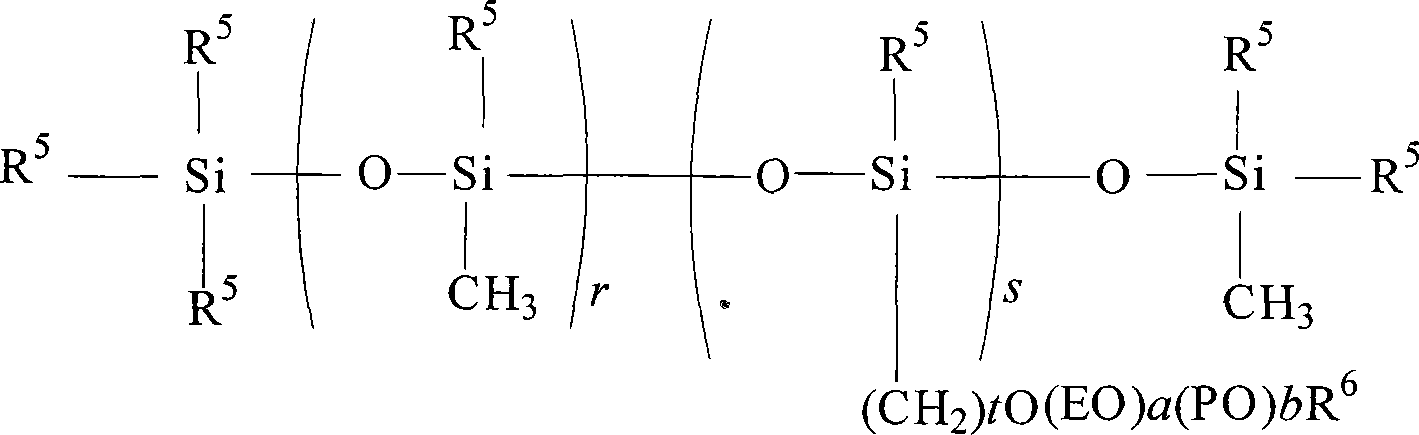

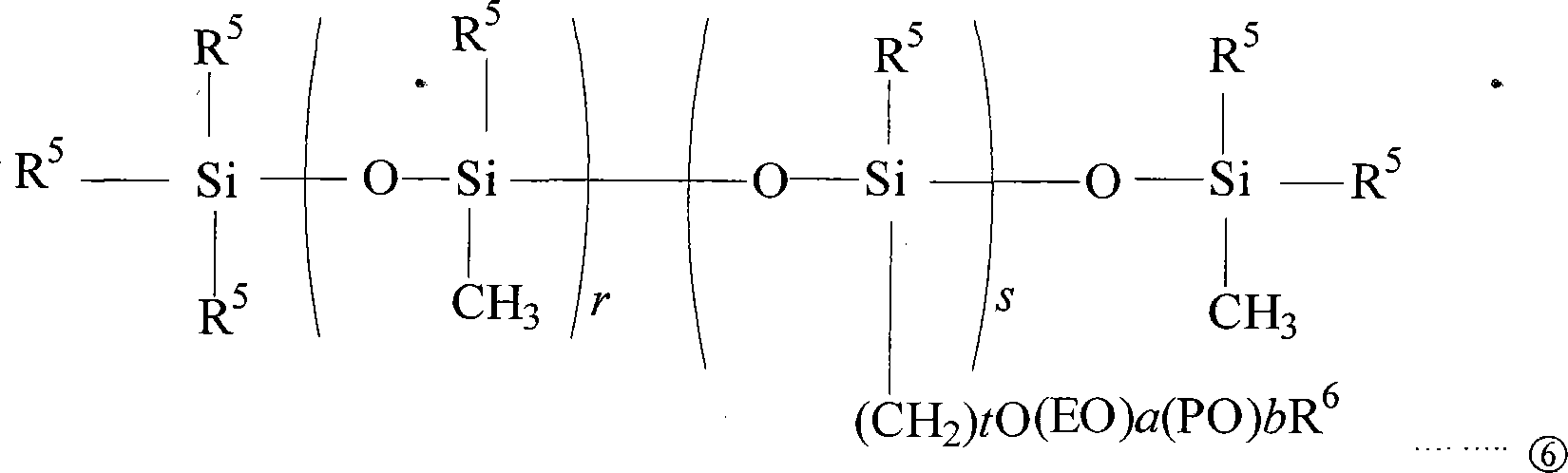

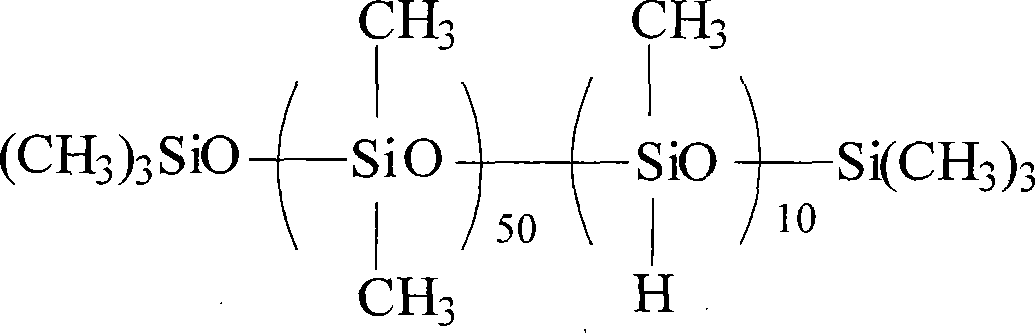

The invention provides a defoaming agent for a boxboard paper making, which belongs to the field of chemical preparation special for papermaking, and is characterized in that the invention consists of the following components. (1) 5 to 40 percent organic hydrocarbon defoaming mixture consists of organic hydrocarbon and superfine particles consisting of hydrophobic inorganic particles, a surface area of which is bigger than 50m2 / g, and organic particles such as ethyl pillared double stearic amide (EBS), aluminum stearate, MQ silicone resin and so on; (2) 1 to 30 percent fatty alcohol; (3) 5 to 70 percent fatty alcohol polyether; (4) 5 to 50 percent fatty alcohol polyether; (5) 5 to 60 percent common group modified polyether; (6) 1 to 10 percent polyether organic silicon modification, also simply called 'silicon polyether'. The invention is a cheap and high-efficiency defoaming agent for a linerboard paper making, improves the performance by complex and increasing effect of the components, and further solves the problem of the foams in the boxboard production system.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Toughened and reinforced polylactic acid nano composite material and preparation method thereof

InactiveCN101037532AGood adhesionIntercalation effect improved significantlyALUMINUM STEARATESFunction group

The invention relates to method of preparing secondary functionalization organic modified montmorillonite (TFC), toughening and reinforcement biodegradable polylactic acid nano composite material using the organic montmorillonite and preparing method thereof. The novel double-function group organic modified montmorillonite (TFC) enhances adhesion force between montmorillonite and polymer molecule and obviously increases property of the composite material. The toughening and reinforcement biodegradable polylactic acid nano composite material is prepared by using polylactic acid as main raw material, and adding certain poly(epsilon-caprolactone) and lactic acid-epsilon-caprolactone copolymer; plasticizer selects acetyl tri-n-butyl citrate, tri-n-butyl citrate, triethyl citrate, dioctyl phthalate, and dibutylphthalate; lubricant selects aluminum stearate and calcium stearate; heat stabilizer selects maleic anhydride and epoxy soybean oil (EOS); and intensifier selects TFC montmorillonite (MMT). The prepared composite material possesses high strength and good toughness, and is hopeful of replacing traditional non-degradable material to be applied in field such as packaging, medical, and engineering for solving environment problems generated by white pollution.

Owner:SHANGHAI UNIV

Method for preparing Al4SiC4 powder

The invention belongs to the technical fields of ceramic and fireproof material, providing a method used for preparing Al4SiC4 powder. The method comprises the specific processes as follows: metal Al powder, Si powder, carbon black or graphite are taken as raw materials; the metal Al powder, Si powder and carbon black or graphite are uniformly mixed according to the molar ratio of 4:1:4.2-4.5; the mixture of the metal Al powder, Si powder and carbon black or graphite is arranged in the ball-grinding tank of a high-energy ball-grinder where aluminum stearate used as a dispersant is added; the ball material ratio is 10-15:1; the ball-grinding is carried out for 20-40 hours under a vacuum argon state, the rotation speed is 800-1000r / min; therefore, the Al4SiC4 powder is gained. The method has simple preparation process, stable process parameter, easy controlling, high ball-grinding efficiency and complete raw material reaction, and can prepare the high-purity powder containing no Al3C4 phase.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Porous ceramic supporting body for high-strength inorganic separation film

InactiveCN101318808AMeet the requirements of filtration and purificationLow costSemi-permeable membranesCeramicwareALUMINUM STEARATESElectrolysis

The invention relates to a high intensity porous ceramic supporting body used for an inorganic separation membrane. The porous ceramic supporting body is characterized by consisting of the following compositions by weight portion: 100 portions of pulverized corundum, 10 to 15 portions of kaolin and / or clay, 8 to 15 portions of potassium feldspar, 1 to 2 portions of carbonate, 3 to 5 portions of aluminum stearate and / or graphite, 2 to 10 portions of methylcellulose and / or dextrine, and 8 to 12 portions of colloidal alumina with a solid content between 8 and 12 percent. The breaking strength of the porous ceramic supporting body of a filter pipe is greatly increased, and the mechanical intensity of a sample is up to 55 to 65MPa; a ceramic inorganic membrane filter pipe made by taking the ceramic supporting body as a matrix can meet the non ferrous metal electrolytic refining technology completely and the use requirements of the filtration and purification of the electrolyte; moreover, the porous ceramic supporting body has simple preparation process, does not have special requirement, has low cost of raw materials, and does not need expensive raw materials; therefore, the cost is not increased greatly. The colloidal alumina plays a special function in the compositions, thereby improving the drying production yield and having marked reinforcing function which is unexampled.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Technique for preparing compound ceftiofur oil suspension injection

InactiveCN101406447AAntibacterial agentsPharmaceutical delivery mechanismGraduated cylinderALUMINUM STEARATES

The invention discloses a preparation process for compound recipe ceftiofur oil suspensoid injection. The preparation process comprises the following steps: (1) taking neutral soybean oil, filtrating, heating and sterilizing and cooling down the soybean oil, adding aluminum stearate into the soybean oil to prepare gel, diluting the gel into factice of 2+-0.2 percent through the filtrated and sterilized soybean oil, and filtrating the factice through a No.3 sintered glass funnel for standby; and (2) taking hydrochloric acid ceftiofur / sulbactam according to a recipe, mixing the hydrochloric acid ceftiofur / sulbactam with the factice, grinding the mixture, adding lecithin into the mixture till the mixture is ground evenly, and then obtaining the compound recipe ceftiofur oil suspensoid injection through shifting the ground hydrochloric acid ceftiofur / sulbactam into a graduated cylinder and so on. As the invention adopts the preparation method, compared with a single recipe ceftiofur preparation, the compound recipe ceftiofur oil suspensoid injection has the advantage that the compound recipe ceftiofur oil suspensoid injection has antibacterial activity against bacteria capable of resisting the single recipe ceftiofur, that is, the compound recipe ceftiofur oil suspensoid injection can effectively treat bacterial infection generating ESBLs.

Owner:HENAN AGRICULTURAL UNIVERSITY

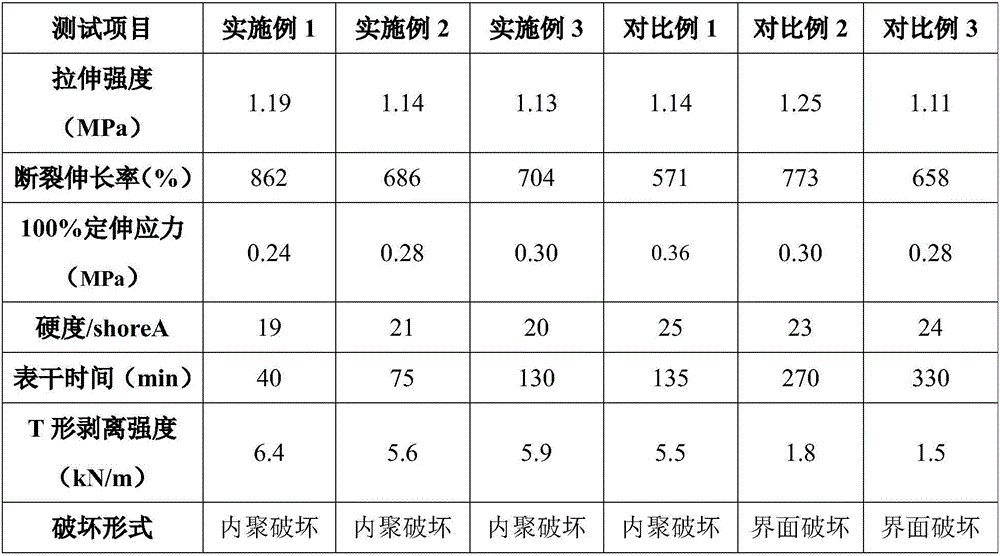

Low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and preparation method thereof

InactiveCN106833503AImprove adhesionImprove mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationALUMINUM STEARATES

The invention discloses a low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and a preparation method thereof. The silicon sealant is prepared from hydroxyl end-blocked dimethylsiloxane, a plasticizer, white mineral oil, gas phase method silica aerogel, a reinforcing filler, aluminum stearate, pigment, a crosslinking agent, a vulcanization accelerator, a silane coupling agent and a catalyst. The preparation method comprises the following steps: 1) uniformly mixing the hydroxyl end-blocked dimethylsiloxane, the plasticizer, the white mineral oil, the gas phase method silica aerogel, the reinforcing filler, the aluminum stearate and the pigment, and drying the mixture fully to obtain a premix compound; 2) performing vacuum full kneading on the premix compound to obtain base; 3) adding the crosslinking agent, the vulcanization accelerator and the silane coupling agent into the base, performing vacuum stirring uniformly;4) adding the catalyst into the base, performing vacuum stirring uniformly, discharging the mixture, and performing filling and sealing. The low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant provided by the invention has the advantages of neutral solidification, strong bonding power, excellent mechanical property, and good heat resistance and oil resistance.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

Self-foaming sun block and preparation method thereof

ActiveCN104688623ADoes not affect the sun protection effectFeel refreshedCosmetic preparationsToilet preparationsALUMINUM STEARATESButanediol

The invention discloses a self-foaming sun block and a preparation method thereof. The self-foaming sun block is prepared from deionized water, glycerinum, butanediol, propylene glycol, methyl parahydroxybenzoats, EDTA-2Na, potassium cetyl phosphate, dicyl polyglycoside, allantoin, xanthan gum, dipotassium glycyrrhizinate, ethylhexyl Methoxycinnamate, C12-15 cholesteryl benzoate, C12-20 alkyl polyglycoside, polydimethylsiloxane, caprylic acid / tricaprin, dicaprylyl carbonate, methylenebis-benzotriazolyl tetramethyl butylphenol, ethylhexyl triazone, diethylaminohydroxybenzoyl hexyl benzoate, a VP / eicosylene copolymer, polyhydroxystearic acid, cyclopentasiloxane, tocopheryl acetate, cyclotetrasiloxane, dimethiconol, propyl p-hydroxybenzoate, aluminum stearate, Novec HFE-7100 and the like. The self-foaming sun block disclosed by the invention is good in sunscreen effect, so that people feel relatively fresh and breathable.

Owner:SHANGHAI ZHONGYI DAILY CHEM CO LTD

Art oil paint containing nano-pigment and method for manufacturing same

InactiveCN101225253ABright and brightSaturated and IntenseWax coatingsArtist's paintsALUMINUM STEARATESCobalt

The invention relates to art oil paint with nano-pigment and the preparation method, which is characterized in that the beeswax is added into refined linseed oil and polly seed salad oil and blended evenly to make bond after heating and melting. The nano-pigment is added into the bond to blend evenly and then the pigment is added in and blended evenly. Then aluminum stearate, 2-ethyl hexanol cobalt (CAS No.13586-82-8), silicon dioxide hydrate, hydrafil, phenoxetol, butyl-p-cresol and lithopone are added in and then blended evenly. The product can be obtained after grinding. The preparation method first disperses the nano-pigment into the bond and drains most air on the surface of the common pigment grain, and then disaggregates the large grain and small gobbet of the sizing agent by the large shearing force, extrusion force and grinding force between the two rollers generated by the turn of the three-roller muller. During the grinding process, the bond with nano-pigment or latex covers the surface of the pigment grain and then permeates through the gaps of the grains. The product made has the advantages of rich color, bright colour and luster, fresh tint, strong tinctorial strength and good chromaticity.

Owner:宋健

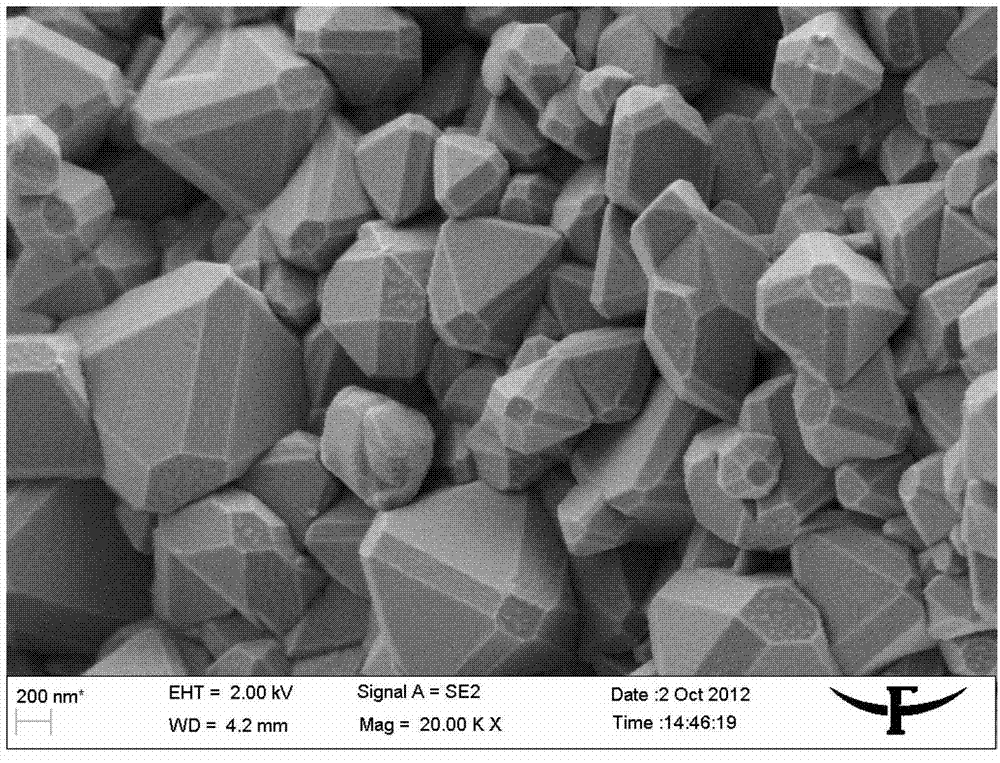

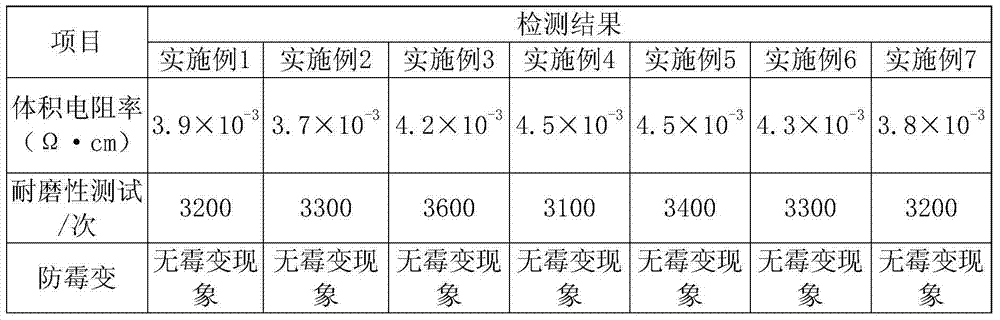

Lithium-ion power battery anode material lithium manganate and preparation method thereof

ActiveCN102931392ALarge ionic radiusIncrease lattice parametersCell electrodesALUMINUM STEARATESManganate

The invention discloses lithium-ion power battery anode material lithium manganate and a preparation method thereof. The molecular formula of the lithium manganate is Li<1+x>Mn<2-y>TayO4 / zAl2O3, wherein 0<x<=0.2, 0<y<=0.2, and 0<z<=1.0. The preparation method includes the steps of proportionally mixing a lithium source compound, a manganese source compound and a tantalum element additive and subjecting the lithium source compound, the manganese source compound and the tantalum element additive to ball milling and high-temperature roasting to obtain the lithium manganate; and dispersing the lithium manganate in a dispersing agent, adding aluminum stearate for reaction to obtain precipitate, and finally subjecting the precipitate to two-section roasting, second annealing, cooling and sieving to obtain the lithium-ion power battery anode material lithium manganate. By means of a composite metal dual-doping mechanism, doping vario-property of two elements of tantalum and lithium is performed to the lithium manganate, a John-Teller effect is inhibited, and normal temperature and high temperature cycle performances of a lithium manganate material are greatly improved; and by means of sectional roasting and multi-time annealing processes, controllability of particle diameters and specific surface areas is achieved, tap density and processing performances of the material are improved, and simultaneously, oxygen defect levels during material sintering are effectively reduced.

Owner:焦作伴侣纳米材料工程有限公司

Polymer cement waterproof coating

The invention discloses a polymer cement waterproof coating. The coating comprises a liquid ingredient and a powder ingredient. The liquid ingredient comprises a polymer emulsion, triethanolamine, a dispersant, an antiseptic, an antifoaming agent and the balance water. The powder ingredient comprises special cement, ultrafine slag, ultrafine steel slag, metakaolin, an antifoaming agent, water-soluble cellulose, acrylamide powder, bisacrylamide powder, instant sodium silicate, aluminum stearate and the balance heavy calcium carbonate of 400 meshes. The coating has excellent anti-sagging and anti-cracking performances, has a self-repair function, can form crystals in concrete and has a certain secondary anti-permeability.

Owner:安徽朗凯奇科技股份有限公司

High-activity and high-permeating-rate powder zinc impregnation agent

InactiveCN107022734AHigh activityFast penetrationSolid state diffusion coatingALUMINUM STEARATESBoron nitride

The invention discloses a high-activity and high-permeating-rate powder zinc impregnation agent. The powder zinc impregnation agent comprises the following raw materials of, by weight, 60-100 parts of zinc powder, 2-6 parts of sea-foam stone powder, 3-5 parts of aluminum powder, 1-2 parts of aluminum oxide powder, 1-3 parts of magnesium powder, 0.6-2 parts of cobalt powder, 0.4-1.5 parts of lead powder, 0.8-1.4 parts of aluminum stearate powder, 0.2-0.5 part of boron nitride powder, 0.5-1 part of silicon dioxide powder, 0.6-1.2 part of graphene powder, 0.1-0.3 part of a reinforcing agent, 0.2-0.4 part of a dispersing agent, 0.3-0.6 part of a conditioning agent, 0.8-1.2 parts of an activating agent, 0.6-0.9 part of accelerant and 0.3-0.6 part of a stabilizer. The zinc impregnation agent is high in activity, high in permeating rate and excellent in reuse performance, the thickness of the zinc impregnation layer is considerable and uniform, strength of combination with workpieces is high, hardness is high, wear-resisting and corrosion resisting properties are high, and appearance is excellent.

Owner:南宁普来得工贸有限公司

Printing ink

The invention provides a sort of ink manufactured by raw materials with the following mass percent: 10-15 percent of butadiene acrylonitrile rubber, 9-15 percent of neoprene, 5-10 percent of acetone, 5-10 percent of toluene, 10-15 percent of glycol butyl et her, 9-15 percent of linseed oil, 5-11 percent of silicon oil, 1-5 percent of titanate coupling agent, 10-25 percent of pigment, 1-4 percent of polyethylene wax, and 0.5-3 percent of aluminum stearate; the ink of the invention is mainly applicable to printing of various plastic material carriers and is provided with high adhesive attraction and good adhesive effect. In the applying facet, superficial treatment is not needed to be carried out to the plastic material carrier when used; printing can be carried out directly, thus guaranteeing good printing effect.

Owner:郜爱民 +1

Super environment-friendly coating for abrasive paper, abrasive cloth and abrasive belt and preparation method of coating

InactiveCN103992681AIncrease grinding timeImprove wear resistanceCoatingsWater basedALUMINUM STEARATES

The invention discloses a super environment-friendly coating for an abrasive paper, an abrasive cloth and an abrasive belt and a preparation method of the coating. The coating is prepared from a component I, a component II and a component III, wherein the mass ratio of the component I to the component II to the component III is 50:(200-300):(150-250); by weight percent, the component I comprises 70%-90% of an adhesive and 10%-30% of water, the component II comprises 70%-80% of a heat absorber and 20%-30% of water, and the component III comprises 65%-80% of fillers and 20%-35% of water; the heat absorber adopts one or a mixture of two or more of water-soluble stearic acid, water-based calcium stearate, water-based zinc stearate, water-based aluminum stearate and water-based lithium stearate. The preparation method comprises the following steps: preparing the component I, the component II and the component III respectively, and uniformly stirring according to the ratio. The coating is safe and environmentally friendly, and has an anti-blockage function; the preparation method is simple in flow process and easy to operate.

Owner:洛阳惠尔纳米科技有限公司

Method for making new, branch and flow H9 sub-type tri-combined inactived vaccine

InactiveCN101112617AImprove the inspection methodUnique characteristicsViral antigen ingredientsAntiviralsInfectious bronchitisDisease

The present invention relates to a preparation method of a triple inactivated vaccine for the prevention of H9 subtype newcastle disease, infectious bronchitis and avian influenza, which is characterized in that: the content of the using NDVLaSota stain virus liquid is 10 to 22 percent, the content of IBVM41 stain virus liquid is also 10 to 22 percent and the content of the AIVHL stain virus liquid is 8 to 15 percent; the present invention uses the concentration and inactivation methods; the white oil adjuvant and the immune auxiliaries of Tween, Span and aluminum stearate are added to prepare the triple inactivated vaccine; the present invention realizes the multiple vaccine prevention and achieves the purpose of prevention a plurality of diseases by one needle, which can be used for greatly developing the husbandry, so as to benefit the mankind and improve the living standard of the people.

Owner:PU LIKE BIO ENG

Method for preparing bigeminy inactivated vaccine of newcastledisease and H9 hypotype bird flu

InactiveCN101607084AIncrease concentrationHigh potencyAntiviralsAntibody medical ingredientsALUMINUM STEARATESBird flu

The invention discloses a method for preparing a bigeminy inactivated vaccine of newcastledisease and H9 hypotype bird flu. The method is characterized by comprising the following steps: (1) preparing virus seed for production; (2) preparing virus liquid for preparing vaccine; (3) evenly mixing virus liquid of the inactivated NDV LaSota strain and AIV HL strain with virus liquid of AIV HL strain, wherein the virus liquid of the inactivated NDV LaSota strain is condensed by 2 times; adding 97 to 99 volume portions of mixed virus liquid into 1 to 3 volume portions of tween-80, and mixing the substances to prepare aqueous phase; mixing 96 volume portions of white oil, 4 volume portions of span-80 and 2 volume portions of aluminum stearate to prepare oil phase; and (4) mixing the aqueous phase and the oil phase in a mixed ratio of 1:1.5-2.5, and emulsifying the mixture to prepare the bigeminy inactivated vaccine of the newcastledisease and the H9 hypotype bird flu. The prepared bigeminy inactivated vaccine of the newcastledisease and the H9 hypotype bird flu has the advantages of capability of effectively preventing the current morbidity caused by the newcastledisease and the H9 hypotype bird flu, good effect and the like.

Owner:PU LIKE BIO ENG

Oil paint pigment

InactiveCN105419435AGood weather resistanceStable consistencyArtist's paintsVegetable oilALUMINUM STEARATES

The invention discloses an oil paint pigment which is composed of following raw materials, by weight: 30-35 parts of a pigment, 20-25 parts of acrylic resin modified by silane, 5-10 parts of dry vegetable oil, 2-6 parts of paraffin, 1-3 parts of a plastic agent, 5-8 parts of a filling material, 0.5-1 part of a drying promoter, 0.5-1 part of a gloss agent, and 0.8-1 part of a dispersing agent. The plastic agent is aluminum stearate. The dry vegetable oil is one or more selected from linseed oil, walnut oil, poppy oil, safflower oil and sunflower seed oil. The drying promoter is one or more selected from cobalt, manganese and lead. The oil paint pigment is good in coloring property, is strong in adhesion force, can form solid film and is good in flatting property. A pigment film is bright after being dried, is good in weather resistance and is easy to store.

Owner:QINGDAO DAFANG WISDOM NETWORK TECH CO LTD

Method of preparing pig replication and respiration syndrome deactivation concentrated vaccine 'SD1 strain'

InactiveCN101234198ANo side effectsImprove immunityViral antigen ingredientsInactivation/attenuationALUMINUM STEARATESPorcine reproductive and respiratory syndrome virus

The invention provides a preparation method of an inactivated and concentrated vaccine 'SD1 strain' for a Porcine reproductive and respiratory syndrome, which is prepared with a water phase and an oil phased according to the following weight percentage content: the water phase is prepared by fully mixing 96 shares of 'SD1 strain' virus culture solution, which is American Porcine reproductive and respiratory syndrome that is inactivated for 20 hours and concentrated 2 times, with 4 shares of Tween minus 80, which occupies 33 percent of the vaccine; the oil phase is prepared by mixing 94 shares of No. 10 white oil with 6 shares of Span minus 80 and then adding a 2 percent aluminum stearate according to the total amount to stir to be transparent, and sterilizing with a high pressure at a temperature of 116 DEG C, which occupies 67 percent of the total amount of the vaccine. The vaccine, with a preservation period of 12 months, is safe and reliable to the Porcine reproductive and respiratory syndrome easily infected animals, and is suitable for pigs of different species and various day old, the immunity protection rate of which reaches 80 percent above, the immunity period of validity of which continues more than 6 months. The safety and immunity efficacy of the vaccine reaches an advanced level among the similar products in the world.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

Modified high-density polyethylene flame-retardant cable sheath

InactiveCN105623043AImprove flame retardant performanceRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneALUMINUM STEARATES

The invention discloses a modified high-density polyethylene flame-retardant cable sheath. The modified high-density polyethylene flame-retardant cable sheath is made of raw materials including modified high-density polyethylene, neoprene, butyl rubber, dicumyl peroxide, high-abrasion-resistance carbon black, antimony trioxide, nano calcium carbonate, magnesium carbonate, talc powder, furnace slag powder, alum powder, chlorinated paraffin, trioctyl trimellitate, aluminum triphosphate, aluminum stearate, anti-aging agents ODA, accelerators TMTM, vulcanizing agents DCBP, antioxidants and benzotriazole. The modified high-density polyethylene flame-retardant cable sheath has the advantages that the modified high-density polyethylene flame-retardant cable sheath is mainly made of the modified high-density polyethylene, fillers and additives are added into the high-density polyethylene to prepare the modified high-density polyethylene flame-retardant cable sheath, and accordingly the modified high-density polyethylene flame-retardant cable sheath is excellent in flame-retardant performance, good in toughness and high in hardness.

Owner:繁昌县菲德通讯材料设计有限公司

High temperature resistant automobile special putty not influencing adhesion and preparation method thereof

ActiveCN102250504AImprove sanding effectImprove storage effectFilling pastesSodium BentoniteALUMINUM STEARATES

The invention discloses a high temperature resistant automobile special putty not influencing adhesion. The putty consists of a main body ash and a curing agent in a weight ratio of 100:(2-3), wherein the main body ash consists of the following components in part by weight: 100 parts of air-dried unsaturated polyester resin, 1 to 5 parts of styrene, 1.5 to 2 parts of cobalt isooctoate, 0.5 to 1 part of white carbon black, 1 to 2 parts of organic bentonite, 3 to 5 parts of aluminum stearate, 1 to 2 parts of hydrogenated castor oil, 5 to 10 parts of kaolin, 90 to 100 parts of heavy calcium carbonate and 20 to 30 parts of light calcium carbonate. The putty for an automobile body has good drying property, polishing property and baking resistance, excellent adhesion and physical properties, and wide application range.

Owner:石家庄市油漆厂

Paint pigment containing graphene and preparation method of paint pigment

ActiveCN104497673AAvoid adsorptionImprove friction resistanceArtist's paintsALUMINUM STEARATESPrinting ink

The invention discloses paint pigment containing graphene. The paint pigment is prepared from the following components in parts by weight: 20-35 parts of refined sunflower seed oil, 2-5 parts of printing ink adjusting oil, 5-20 parts of pigment color powder, 15-35 parts of barium sulfate, 5-10 parts of kaolin, 0.5-5 parts of graphene, 3-10 parts of nano silicon dioxide, 2-8 parts of refined linseed oil, 0.1-1.5 parts of aluminum stearate, 0.2-1.5 parts of bee wax, 0.5-2.0 parts of 422 glyceride maleic anhydride resin and 0.2-2 parts of BCM anti-mold agent. The paint pigment has the beneficial effects that firstly, due to addition of graphene, the paint pigment has good anti-electrostatic property, dust adsorption is avoided, and the friction property, the hardness and the adhesion property of the paint pigment are improved; secondly, due to addition of nano silicon dioxide, the antibacterial effect of the pigment is improved, the ultraviolet resistance is good, the aging resistance of the paint pigment is remarkably improved, and a drawing paint completed by using the paint pigment can be preserved for a relatively long time.

Owner:宁波康大美术画材集团股份有限公司

Formula and preparation method of aluminum type aluminum alloy additive

The invention discloses a formula and a preparation method of an aluminum type aluminum alloy additive. The additive comprises, by weight, 80-85% of metal powder, 14-18% of aluminum powder, 1-1.5% of aluminum stearate and 0.5-1% of aluminum-magnesium powder. The metal powder is any one of iron, manganese, copper, titanium and chromium. The purity of the metal powder is larger than or equal to 98%, the average grain diameter of the powder ranges from 0.01 mm-0.5 mm, the purity of the aluminum powder is larger than or equal to 96%, and the average grain diameter of the power ranges from 0.01 mm-0.5 mm. The metal powder, the aluminum powder, the aluminum stearate and the aluminum-magnesium powder are evenly mixed and pressed into blocks through an oil press, and the blocks are packaged with aluminum foil to form finished products. The addition method is simple, and the additive rapidly fuses at the normal temperature of aluminum alloy melting, no fusing agent exists, and influences on the environment are small. The casting yield is high and stable, and components of melt are easy to control.

Owner:正邦(福建)冶金材料有限公司

Method of preparing newcastle disease, infectiousness bronchitis bigeminy killed vaccine

InactiveCN101108248AReduce usageReduce stepsViral antigen ingredientsRespiratory disorderInfectious bronchitisAdjuvant

The invention relates to a method to prepare a combined inactive vaccine of newcastle disease and infectious bronchitis vaccine for chicks. The invention is characterized in that: firstly, concentrate and inactivate the NDVLaSota virus strains (10 per cent to 22 per cent weight ratio) and IBVM41 virus strains (10 per cent to 22 per cent weight ratio) respectively; and then add white oil and immune additives including tween, span and stearic acid to prepare the combined vaccine.

Owner:PU LIKE BIO ENG

High-strength tear-resistant methyl vinyl silicone rubber material

The invention discloses a high-strength tear-resistant methyl vinyl silicone rubber material. The high-strength tear-resistant methyl vinyl silicone rubber material comprises, by weight, 80-100 parts of raw methyl vinyl rubber, 1.5-2.5 parts of Teflon, 1-3 parts of methyl silicone oil and 0.4-0.8 parts of aluminum stearate, and also comprises, based on the raw methyl vinyl rubber, 0.8-1wt% of gamma-aminopropyltriethoxysilane, 1-1.4wt% of N-(beta-aminoethyl)-gamma-aminopropyltriethoxysilane, 3.5-4wt% of nano-cellulose whisker, 12-15wt% of silica micropowder, 0.5-0.9wt% of hydrosilicone oil and 33-48wt% of modified white carbon black. Compared with the original silicone rubber, the high-strength tear-resistant methyl vinyl silicone rubber material improves density and tensile strength, has good flame retardation, excellent wear resistance and tear resistance, and improves silica gel safety.

Owner:天长市荣盛有机硅科技有限公司

Novel slow-release breast perfusion agent for preventing cow subclinical mastitis in milk shortage stage

ActiveCN103230365AImprove stabilityReduce the number of dosesOrganic active ingredientsAerosol deliveryALUMINUM STEARATESPolyethylene glycol

The invention provides a novel slow-release breast perfusion agent for preventing cow subclinical mastitis in a milk shortage stage. 100g of the novel slow-release breast perfusion agent comprises 7-11g of cefalonium, 0.5 to 8g of polyethylene glycol-400, Tween materials or propylene glycol, 0.5 to 8g of fatty alcohol polyoxyethylene ether, cyclomethylene glyceryl ether, triacetin or poloxamer, 0.5 to 8g of aluminum stearate or silica, 0.02 to 0.05g of vitamin E, 0.05 to 0.1g of benzyl alcohol, and the balance liquid paraffin, soybean oil for injection or median chain triglyceride. The invention also provides a preparation method of the novel slow-release breast perfusion agent. The novel slow-release breast perfusion agent is suspension colloid, can be slowly released, can effectively reduce administration frequency, can effectively prevent and treat cow subclinical mastitis by being used in a milk shortage stage, and does not produce residues. Compared with the like foreign products, the suspension colloid has better stability.

Owner:中国牧工商集团有限公司 +1

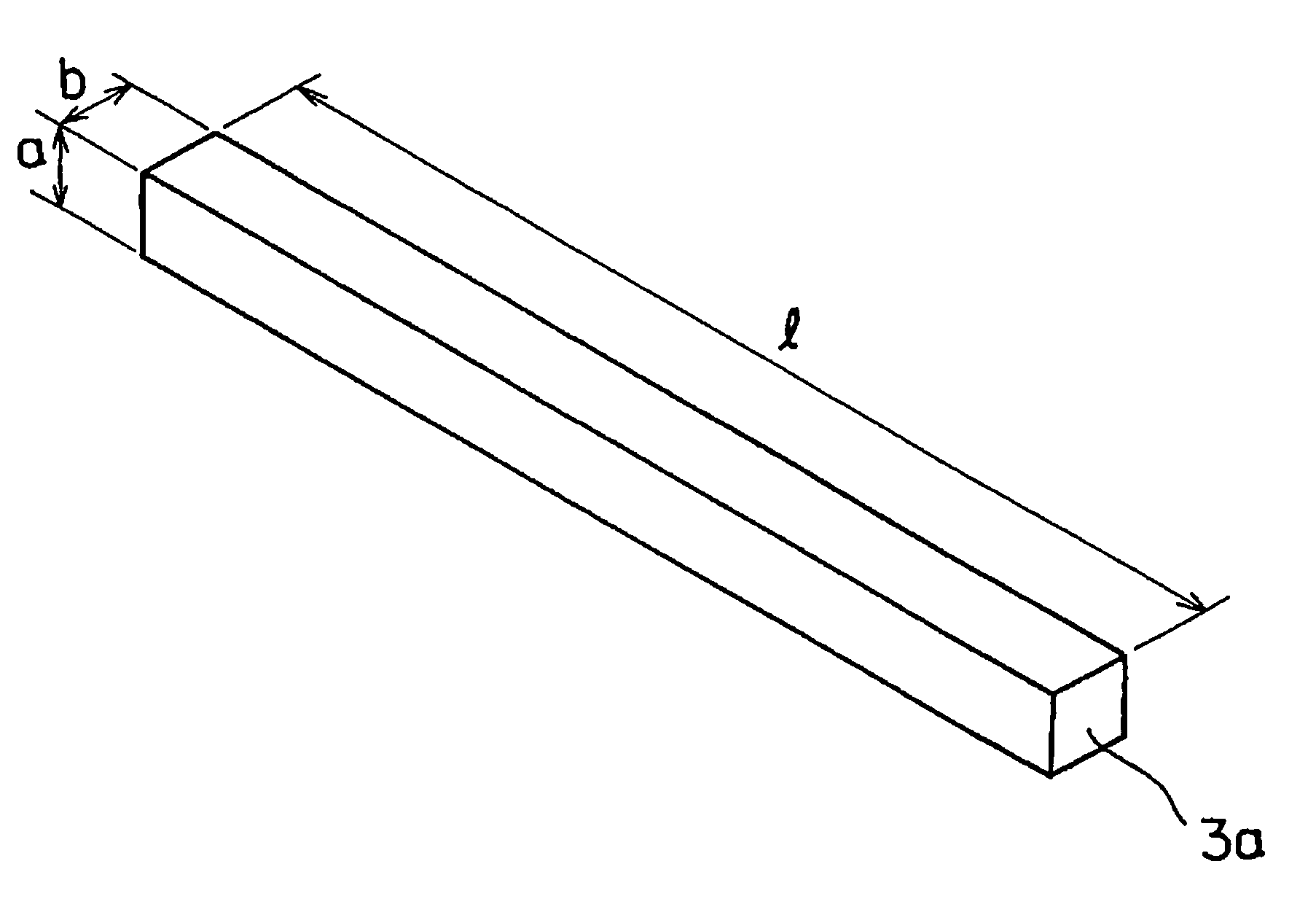

Lubricant molded body, lubricant application apparatus, process cartridge, and image forming apparatus

ActiveUS7691791B2Low costFew cracking and cuttingFibre treatmentSynthetic resin layered productsCarbon numberALUMINUM STEARATES

A lubricant molded body, which is to be applied to a surface of a photosensitive layer for electrophotography in an image forming apparatus, for example, is composed of at least two kinds of higher fatty acid metallic salts having respectively different carbon numbers. As the higher fatty acid metallic salt that forms lubricant molded body, compounds such as zinc stearate, calcium stearate, barium stearate, aluminum stearate, zinc laurate, calcium laurate, etc. may be recited. The higher fatty acid metallic salts may contain at least one kind of fillers selected from the group consisting of silica, alumina, tungsten disulfide, molybdenum disulfide, graphite fluoride, graphite, boron nitride, polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and polyvinylidene fluoride (PVDF).

Owner:RICOH KK

Geopolymer grouting material

ActiveCN106699037AThere is stable and adjustable performanceLow costCement productionAlkaneALUMINUM STEARATES

A geopolymer grouting material is prepared from, by weight, 20-40 parts of stone flour, 30-45 parts of fly ash, 10-25 parts of silicon micro-powder, 25-35 parts of mineral slag powder, 5-10 parts of an alkali exciting agent, 5-10 parts of sodium hydroxide, 0.5-1 part of sugar calcium, 3-5 parts of re-dispersible latex powder, 1-3 parts of a polycarboxylic water reducer, 1-3 parts of sodium alkane sulfonate, 1-3 parts of aluminum stearate, 10-15 parts of phenolic resin, 0.5-1 part of N,N-dimethylaniline, 0.5-1 part of methylethyl ketone peroxide, 0.5-1 part of sodium polyacrylate, 0.5-1 part of triethanolamine and 0.5-1 part of citric acid. The 1d strength of the prepared grouting material is not less than 20.0 MPa, the flowability is not more than 20 s, the initial setting time is not less than 25 min, and the final setting time is not more than 60 min. The grouting material is widely suitable for rapid repairing of roads, underside grouting of cement concrete pavement soft base processing, bridge reinforcing and crack repairing, deep curtain grouting, lower margin bolt anchoring and other engineering positions. Compared with traditional cement-based grouting materials, the grouting material disclosed in the invention has the advantages of low cost, good corrosion resistance, good heatproof stability, good erosion resistance and good durability.

Owner:CHENGDU JIAXIN TECH +3

Highlight high hardness acrylic resin water-based ink

The invention discloses highlight high hardness acrylic resin water-based ink which is prepared from the following raw materials in percentage by weight: 20-40% of acrylic resin, 10-20% of nitrile rubber, 5-10% of a chloroprene rubber adhesive, 5-10% of acetone, 10-15% of methylbenzene, 5-10% of ethylene glycol butyl ether, 1-5% of a titanate coupler, 20-30% of aluminum paste paint, 1-4% of polyethylene wax, 0.5-3% of aluminum stearate and 0.1-5% of a photocuring photoinitiator. The ink disclosed by the invention can be suitable for printing various plastic carriers and has higher adhesive force and a good adhesive effect. The plastic carriers are not treated on the surface, and can be directly printed, so that highlight bright printing effect can be ensured.

Owner:TIANCHANG JULONG TRAVEL PAINT

Protective grease, and its use and preparing method

The invention provides preservative lubricating oil with the good resistance of low temperature and the adhesive of the base material. It includes: 35-82% of PAO with the viscidity 25-55 sq mm / s in 100 degree C, 8-15% aluminum stearate soap and 10-50% polyisobutylene with molecular weight of 2, 000-2,500. The invention also provides the preparing method and the application as the repellent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-rubber compounded sealing gasket material and preparation method thereof

The invention discloses a multi-rubber compounded sealing gasket material. The invention is characterized in that the material is prepared from the following raw materials in parts by weight: 40-45 parts of butyl rubber (CBK139), 14-18 parts of silicon rubber, 32-35 parts of fluororubber, 4-5 parts of turpentine, 1-2 parts of orchid essential oil, 3-4 parts of manganese peroxide, 2-3 parts of aluminum stearate, 2-4 parts of rapeseed oil, 1-2 parts of silane coupling agent KH550, 1-2 parts of accelerator DM, 3-4 parts of zinc oxide, 1-2 parts of magnesium oxide, 1-2 parts of anti-scorching agent CTP, 1-2 parts of accelerator CZ, 12-15 parts of aluminum oxide, 15-20 parts of nano calcium carbonate, 24-28 parts of N220 carbon black and 10-12 parts of modified attapulgite. The modified attapulgite is added to improve the technical properties of the rubber material; and the environment-friendly compounding agent is utilized to reduce the toxic or side effect and environmental pollution. The material has the advantages of favorable processability, high oil resistance, high corrosion resistance and high elasticity.

Owner:WUHU WANRUN MACHINERY

Electrolytic polishing agent

The invention discloses an electrolytic polishing agent which comprises the following aqueous solutions according to massic volume concentration: 890-1280g / L of phosphoric acid, 168-340g / L of sulfuric acid, 20-50g / L of AL<3 plus> and 1-5g / L of a coupling agent. The electrolytic polishing agent is used for regulating the ratio of phosphoric acid to sulfuric acid, and the corrosivity of the polishing agent is also effectively reduced through adding aluminum stearate, so the quality of the electrolyzed workpiece is enabled not to be influenced. The viscosity of the electrolytic polishing agent is increased by adding the coupling agent, the gas flow which is released during the electrolytic process can be changed, and is enabled not to leave gas marks on the workpiece which is electrically polished, so a polished surface can be uniform and complete, and has no defects.

Owner:广州波耳化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com