Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

203results about How to "Stable process parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

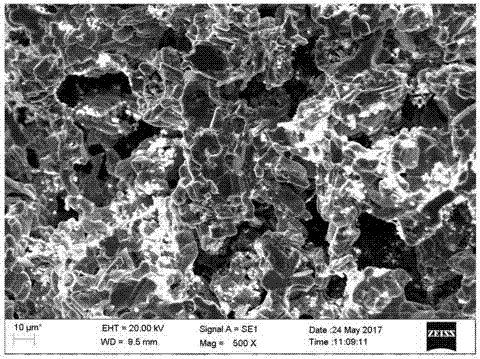

Method for preparing graphene-like two-dimensional laminar titanium carbide nanoplate

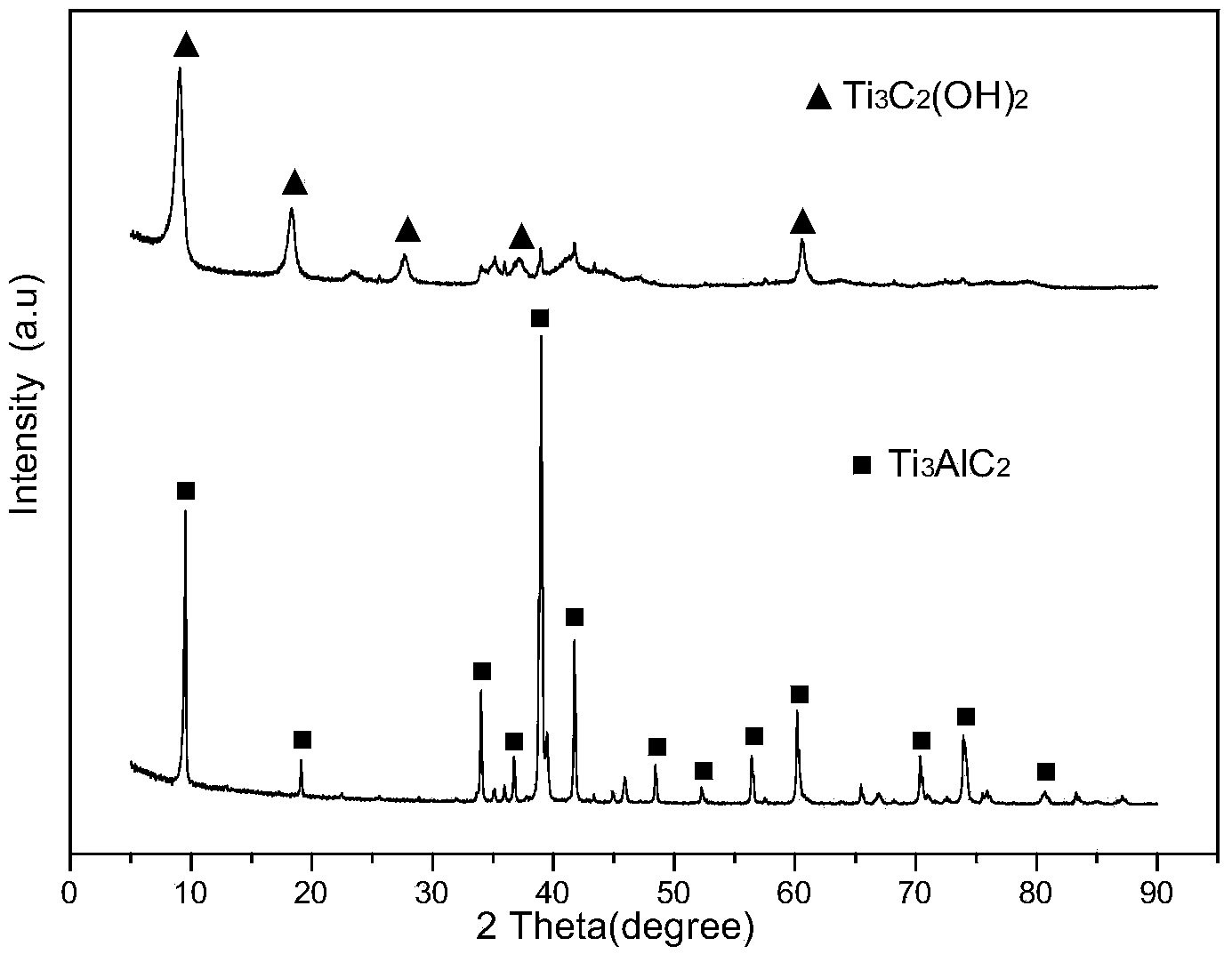

InactiveCN104016345AHigh purityHigh crystallinityMaterial nanotechnologyTitanium carbideSem micrographsCrystallinity

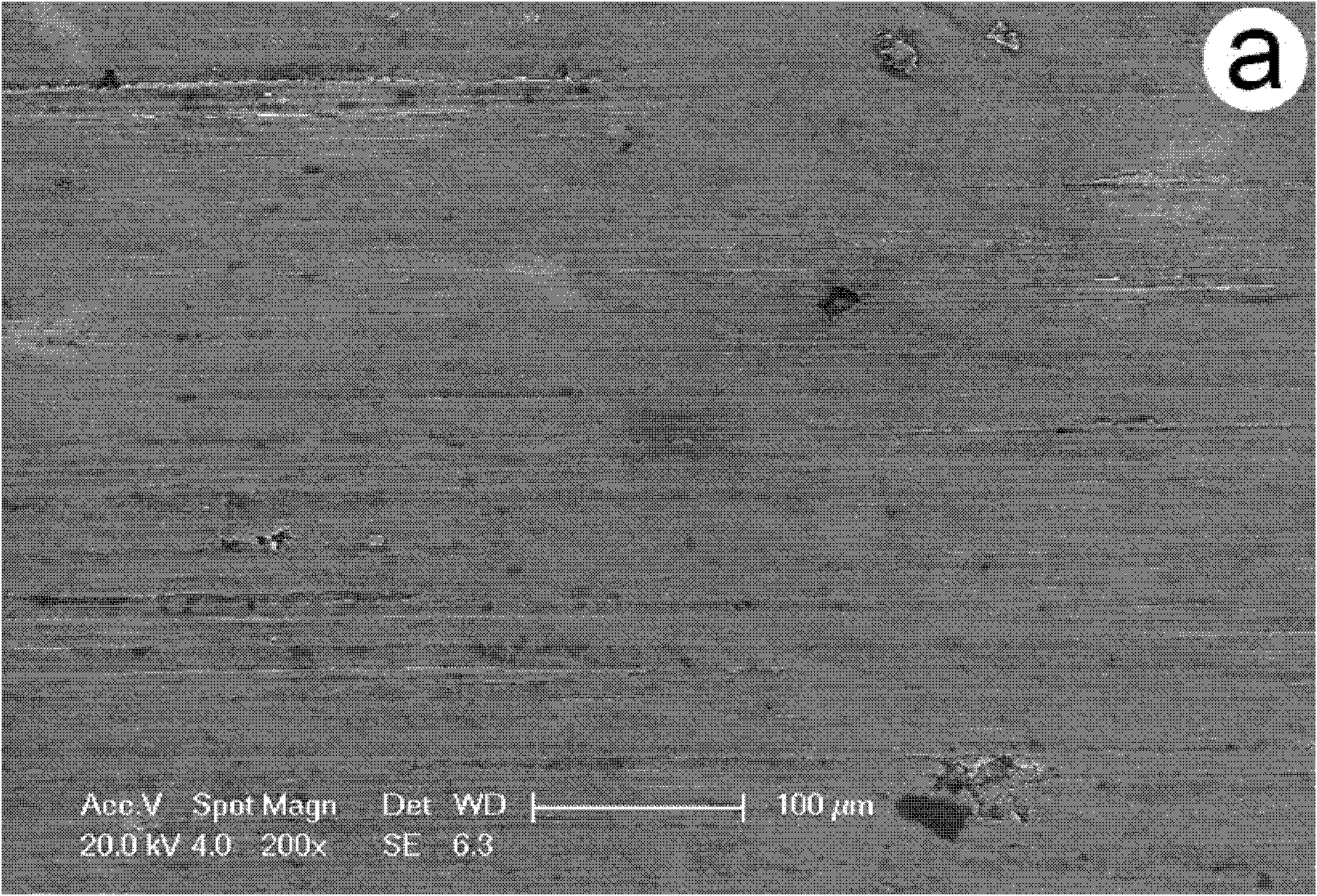

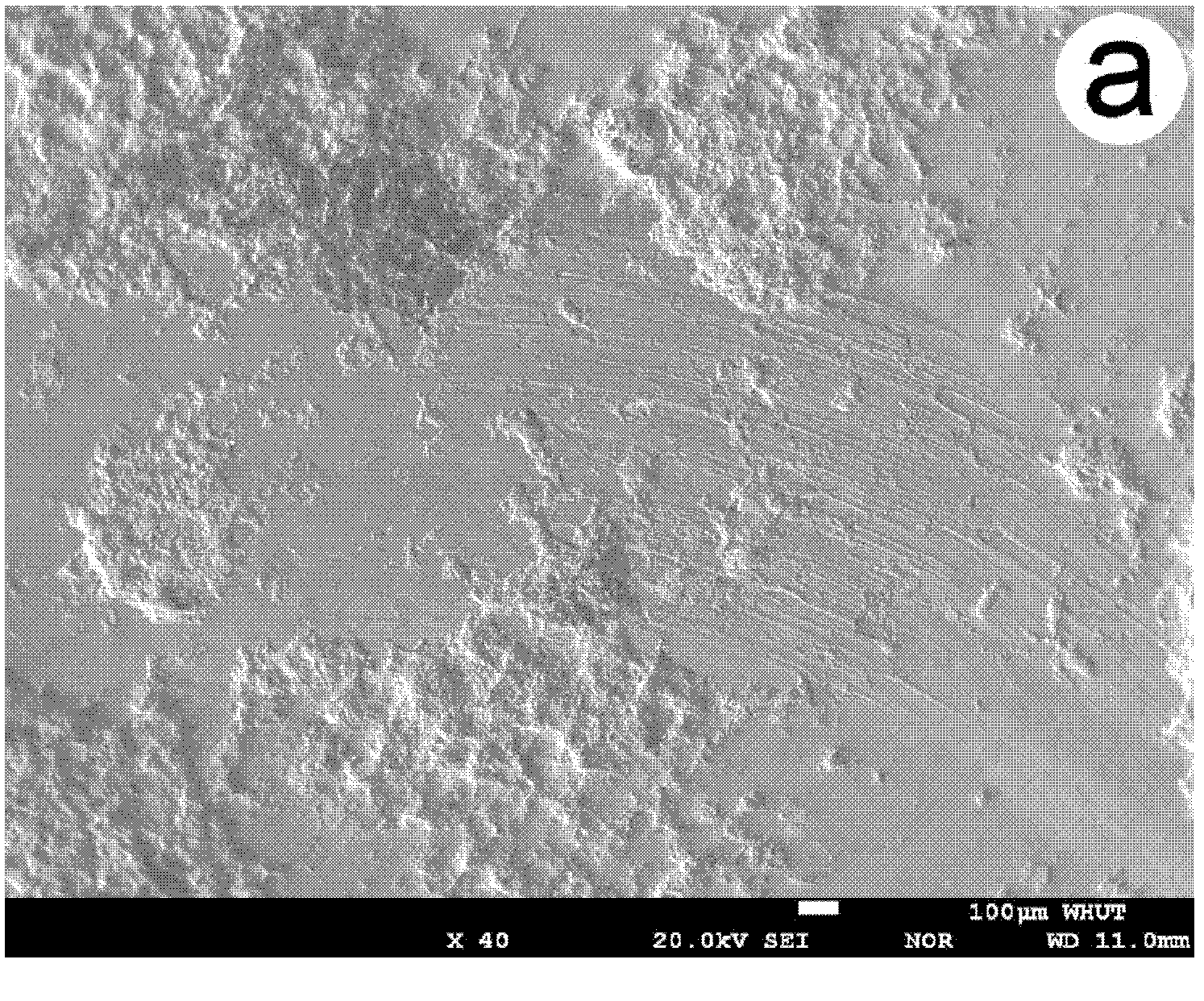

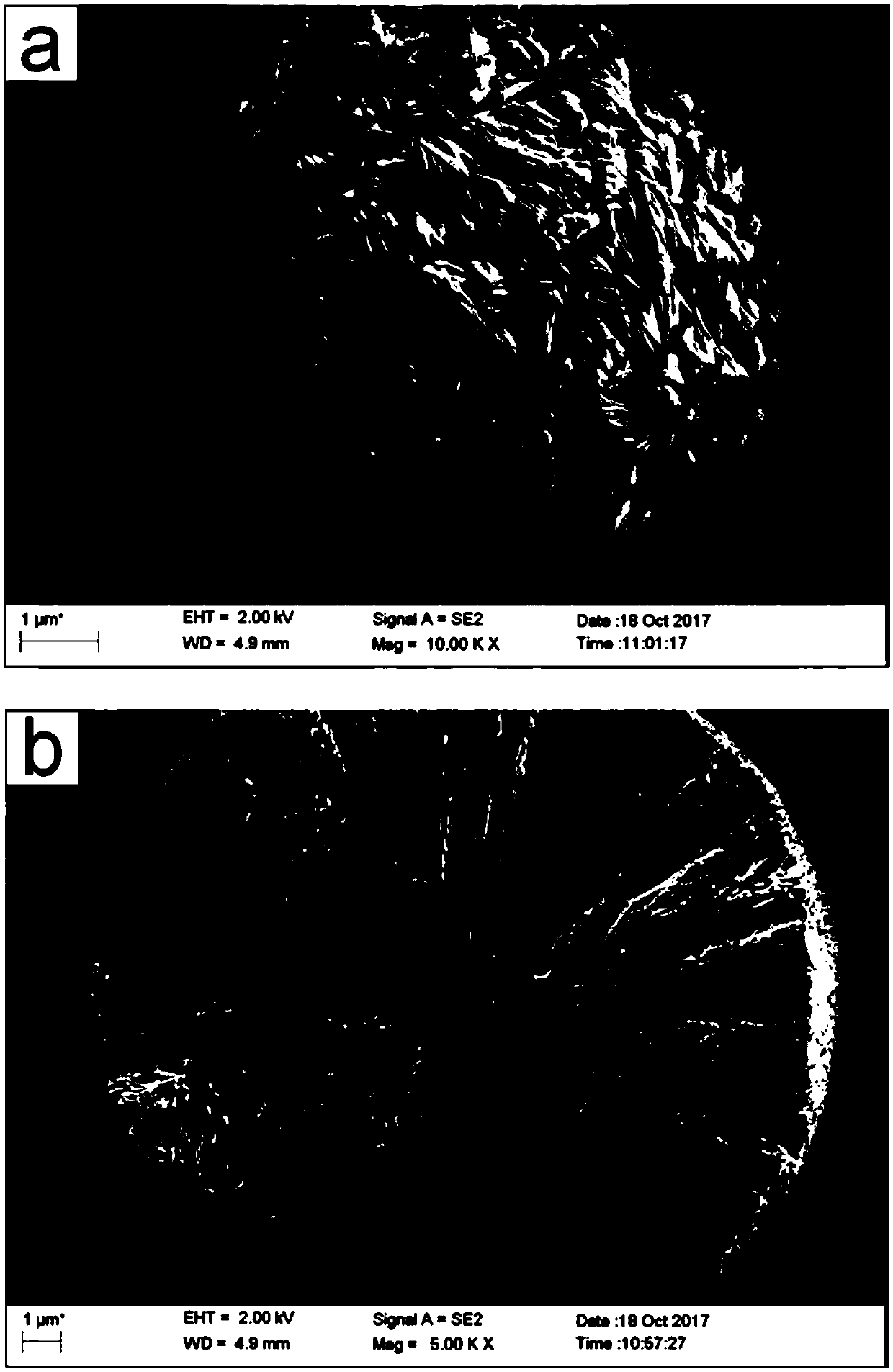

The invention discloses a method for preparing a graphene-like two-dimensional laminar titanium carbide nanoplate. The method comprises the following steps: preparing Ti3AlC2 powder by an in-situ hot-pressing solid-liquid reaction; preparing two-dimensional titanium carbide by a chemical liquid phase reaction; performing vacuum calcination post-treatment, and the like. The method can be used for preparing a Ti3AlC2 precursor with excellent crystallinity and high purity under simple process flow, stable process parameters, controllable process, high efficiency, low cost, short time and low pressure; the information that the transverse size of the two dimensional Ti3AlC2 nanoplate prepared by the method can be 5-10 microns, the average thickness of a single layer is about 10-20 nanometers can be found from an SEM picture, the inter-laminar spacing is remarkably enlarged after calcination treatment, and the laminar surface is regular and smooth.

Owner:HOHAI UNIV

TiAl intermetallic compound-based solid seif-lubricating composite material and preparation method thereof

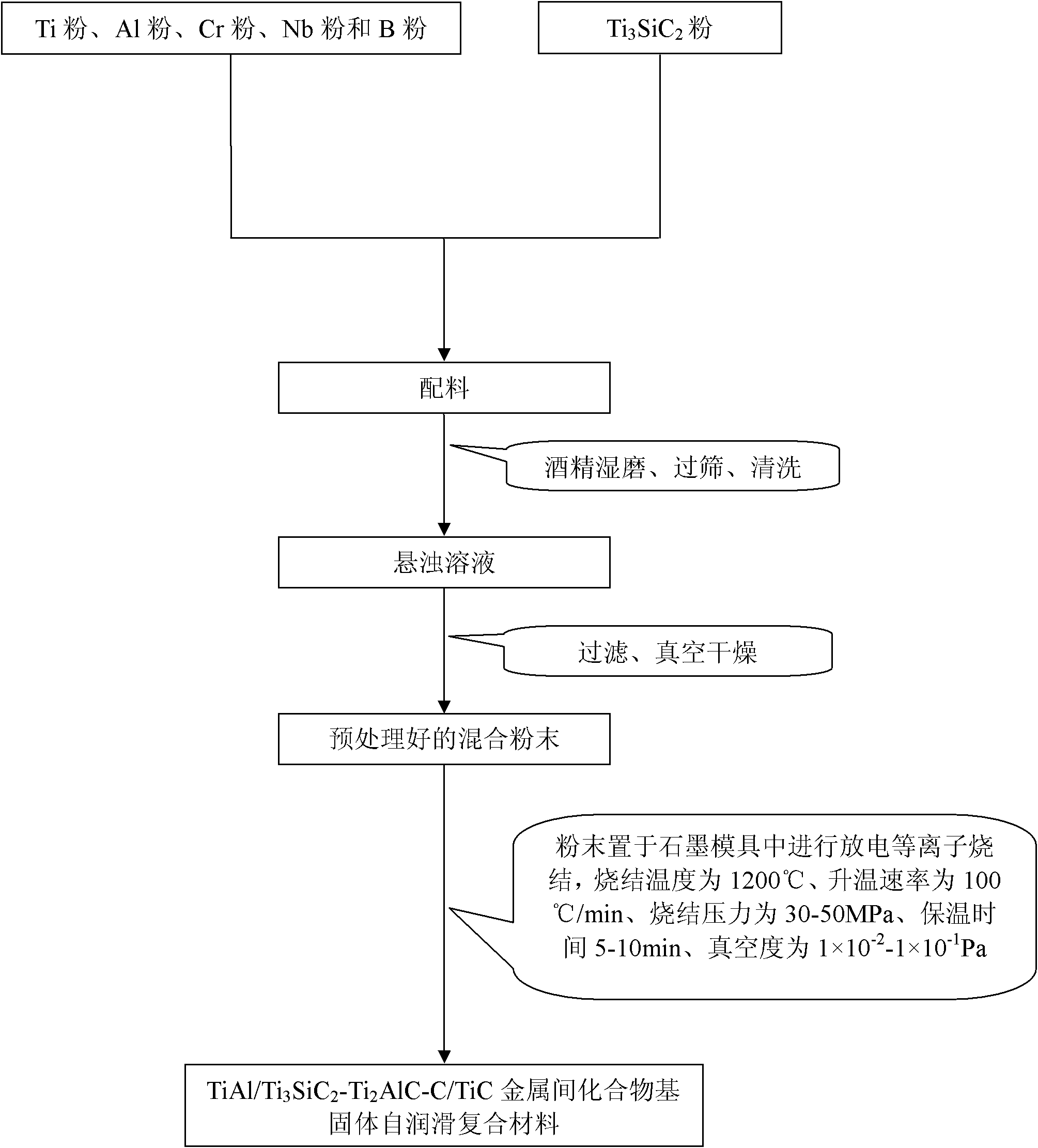

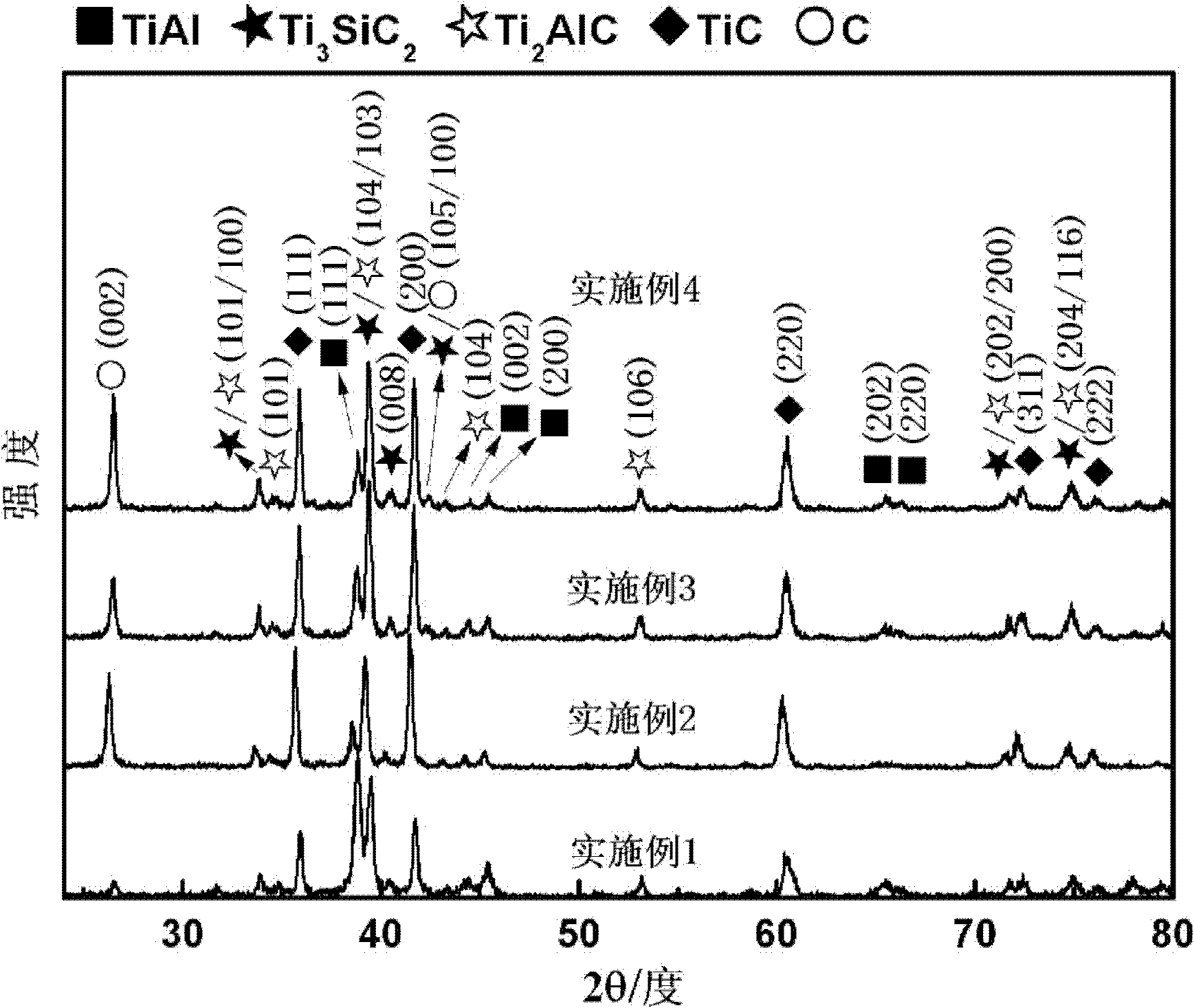

The invention relates to a TiAl intermetallic compound-based solid seif-lubricating composite material which comprises Ti3SiC2, Ti2AlC and C which are used as the ternary composite lubricating phase and TiC which is used as the reinforced phase, and a preparation method thereof. The TiAl intermetallic compound-based solid seif-lubricating composite material is characterized in that the material is prepared from Ti powder, Al powder, Cr powder, Nb powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ti, Al, Cr, Nb and B is 48:47:2:2:1 and the dosage of the Ti3SiC2 powder is 5-20wt.% of the total weight of the Ti powder, Al powder, Cr powder, Nb powder and B powder. The TiAl / Ti3SiC2-Ti2AlC-C / TiC intermetallic compound-based solid seif-lubricating composite material synthesized by the method is novel in component design (the intermetallic compound matrix, the composite lubricating phase and the reinforced phase), high in density, good in tribological properties, stable in technological parameters, fast and simple in preparation process and easy in operation and the method is suitable to be used to prepare the high performance TiAl intermetallic compound-based solid seif-lubricating composite material.

Owner:WUHAN UNIV OF TECH

Preparation method for two-dimensional sheet-shaped titanium dioxide nanosheet material

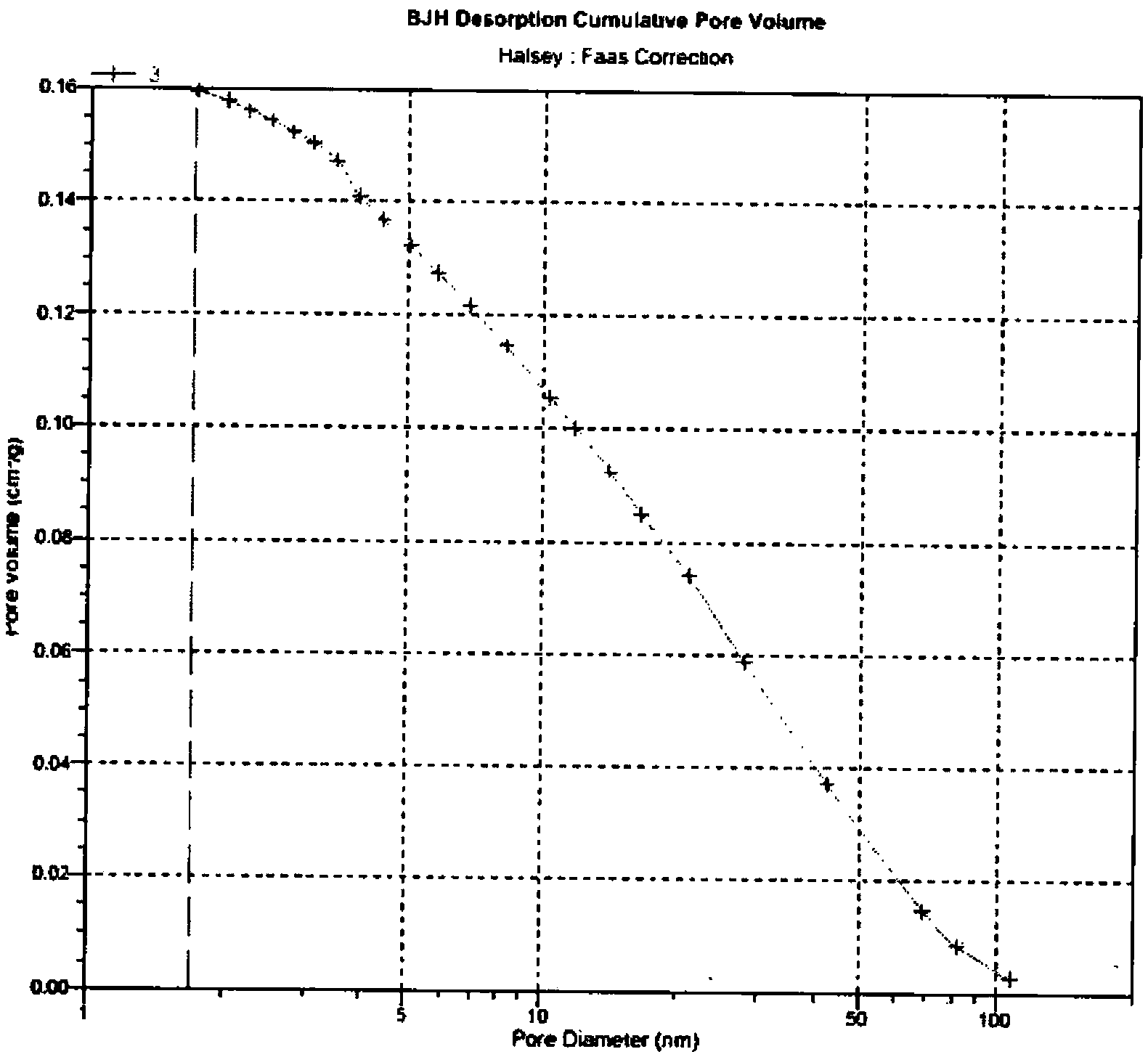

InactiveCN104085920AHigh purityHigh crystallinityMaterial nanotechnologyTitanium dioxideCrystallinityRutile

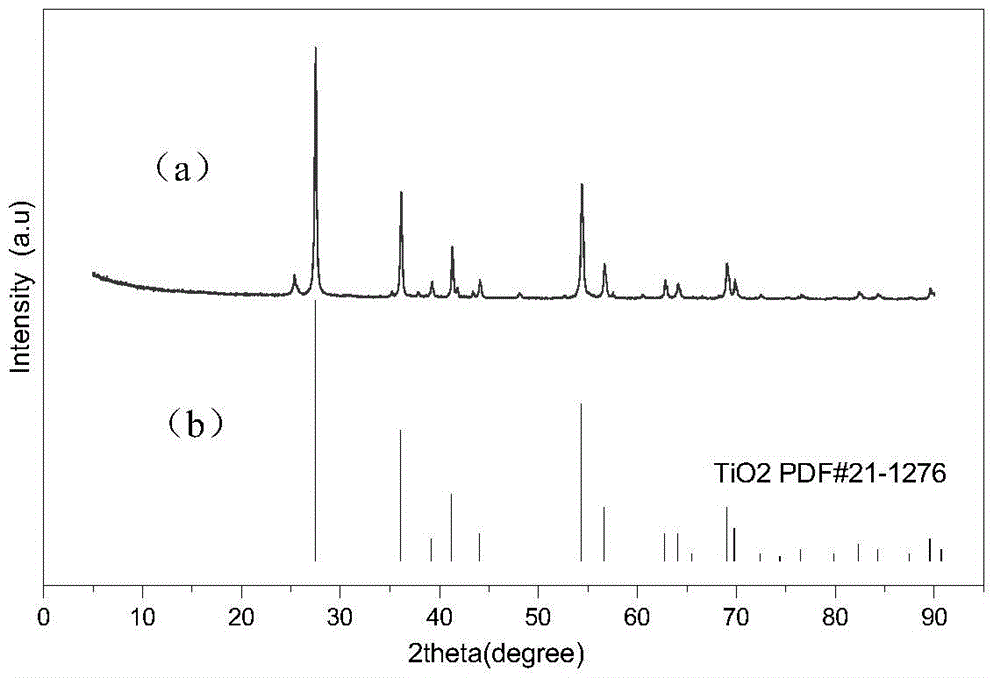

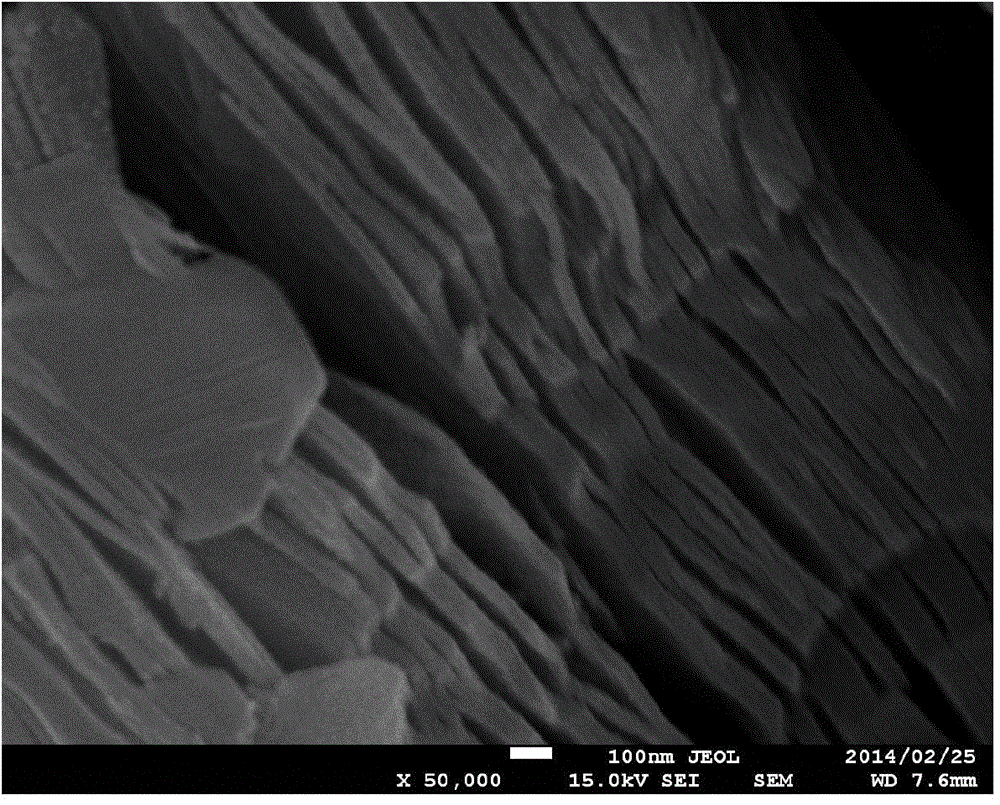

The invention discloses a preparation method for a two-dimensional sheet-shaped titanium dioxide nanosheet material. The preparation method comprises the following steps: soaking three-dimensional laminated Ti3AlC2 powder in an aqueous solution of HF at a room temperature, and removing an Al atom layer by use of a chemical liquid-phase dissection method to prepare a two-dimensional Ti3C2 nanosheet with laminated characteristics still kept; then, placing Ti3C2 in a tubular furnace, ventilating a gas mixture of flowing oxygen gas and argon gas after vacuumizing, realizing in-situ oxidization of the two-dimensional Ti3C2 nanosheet at a high temperature, then cooling, taking out powder, and grinding to obtain the TiO2 nanosheet. According to the preparation method disclosed by the invention, any organic solvent and additive are not needed to be added in the preparation process, process parameters are stable, the procedure is simple, the process is controllable, the efficiency is high and the cost is low; the prepared two-dimensional titanium dioxide nanosheet has transverse dimension of 5-10 microns, and single-layer average thickness of 50 nanometers; the prepared rutile type titanium dioxide nanosheet is high in purity and good in degree of crystallinity, and only contains very little antase phase.

Owner:HOHAI UNIV

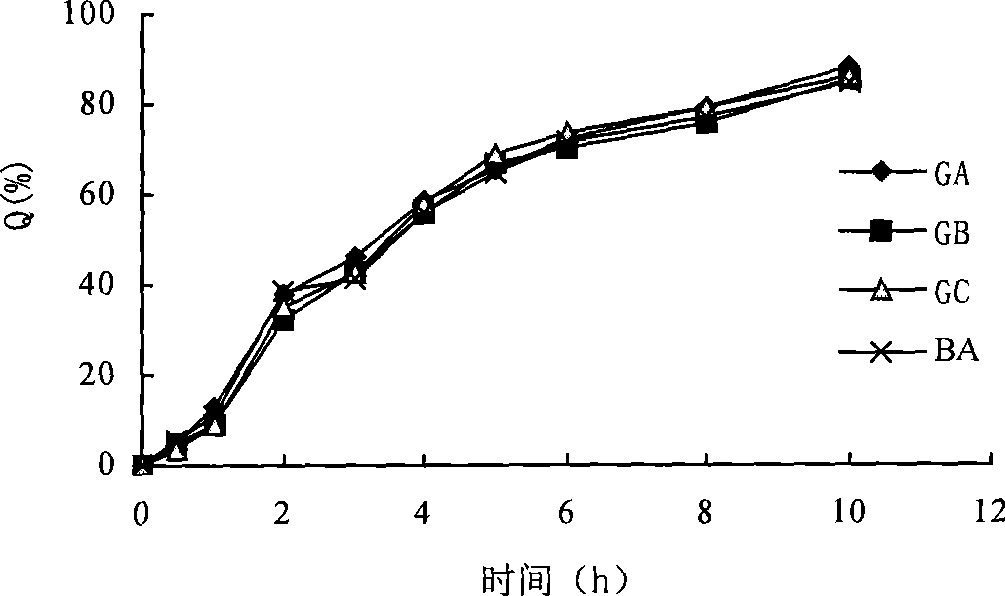

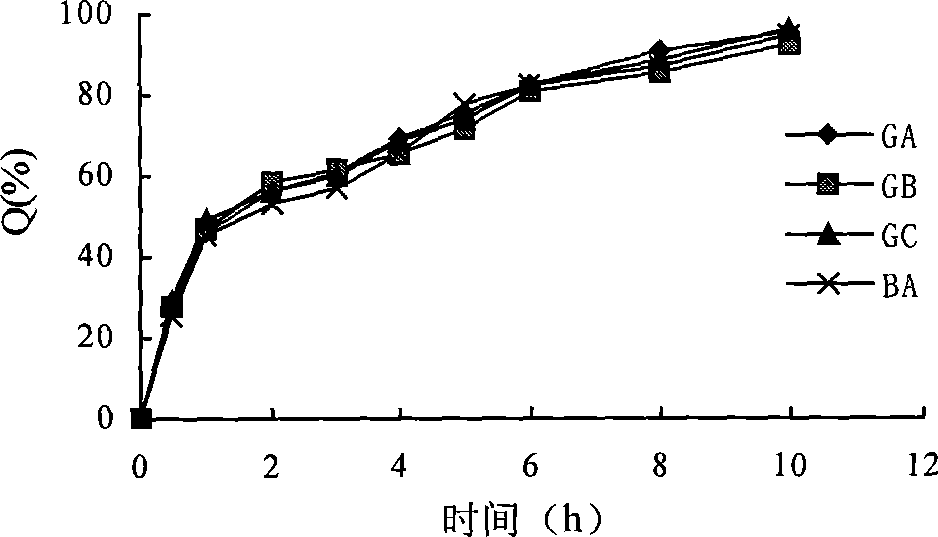

Slow/controlled release pellet composition containing ginkgo leaf extracts and preparation method thereof

InactiveCN101375869ASmall toxicityStable blood concentrationGranular deliveryGinkgophyta medical ingredientsSustained release pelletsHard Capsule

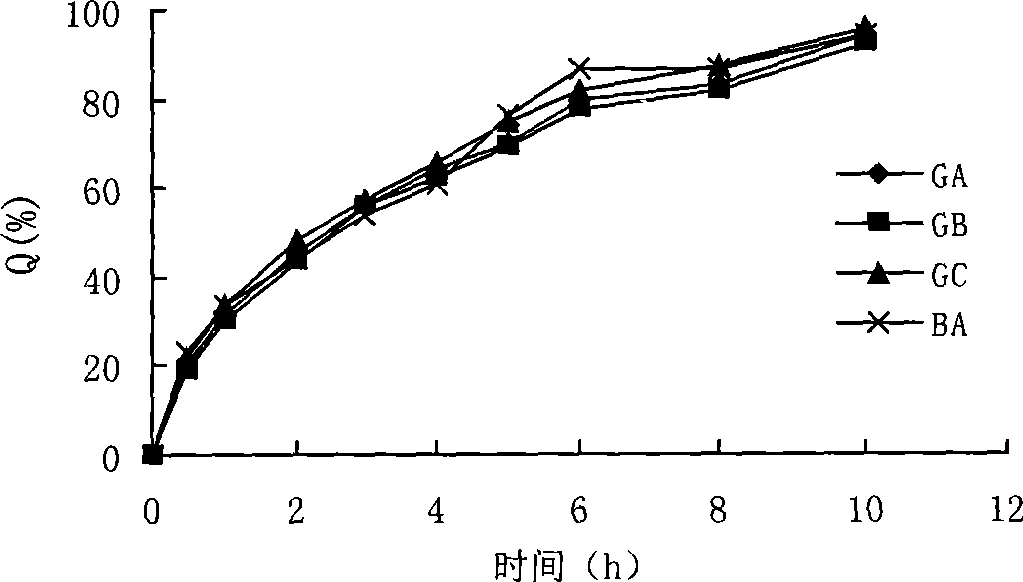

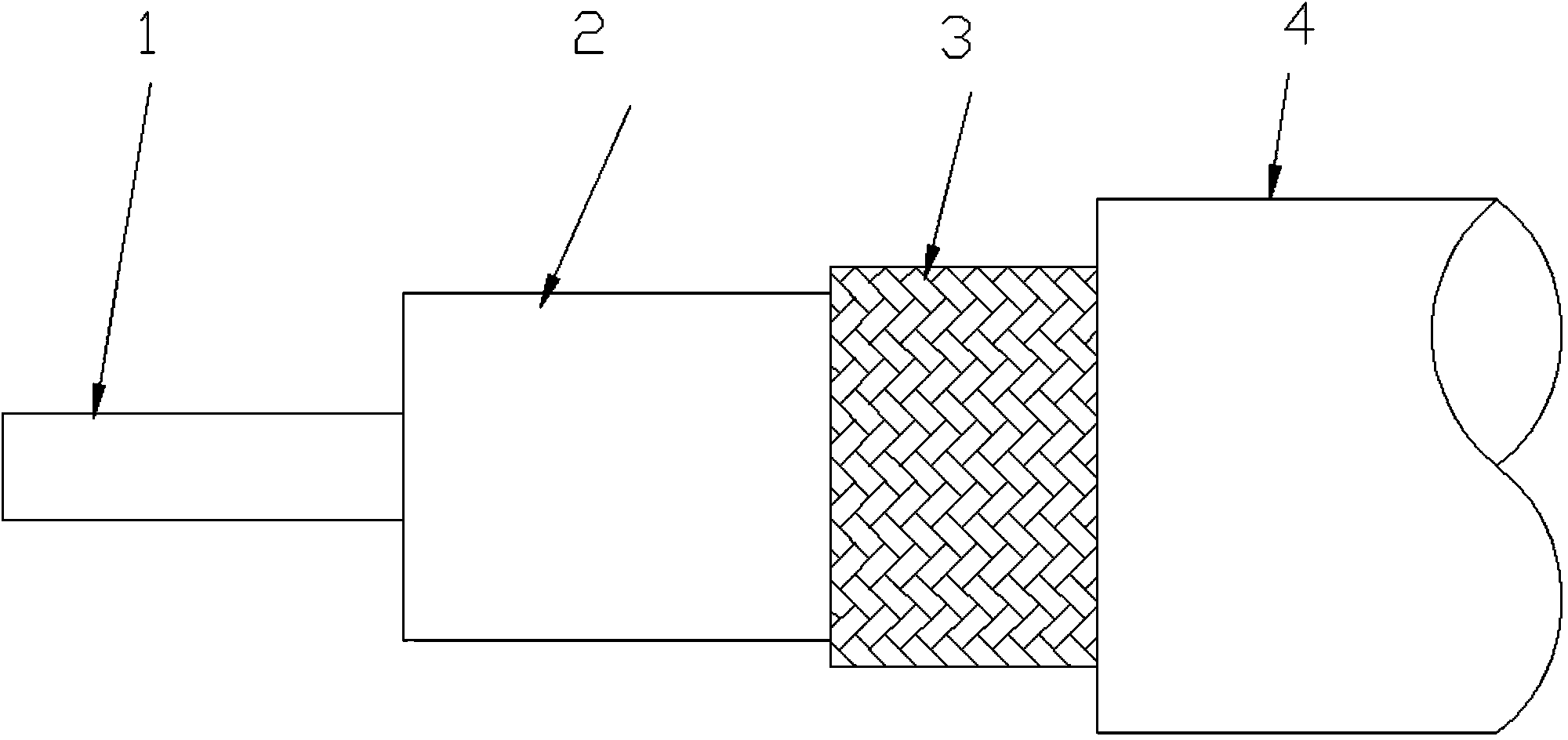

The invention belongs to the field sustained / controlled-release preparations, in particular to an oral sustained / controlled-release pellet combination containing ginkgo biloba extract and a preparation method. The oral sustained / controlled-release pellet combination is composed of (A) a core containing a pill; (B) an insulating coating layer; (C) a sustained-release coating layer; (D) and an enteric-coated coating layer. The invention is the traditional Chinese medicine multi-component sustained-release pellet combination which is taken once by 24 hours and the multi-unit sustained-release pellet combined preparation with the different drug release systems, the core containing the pill is prepared by adopting the extrusion pill rolling method, a novel sustained-release multi-layer coating technology and a fluidized bed are utilized for coating the sustained-release pellet, the rapid-release part and the sustained-release part of the coated pellet are mixedly filled into a hard capsule or pressed into a pellet tablet. The sustained-release pellet has stable coating process and good reproducibility, thereby being applicable to the industrial mass production; and the drug quality of the preparation is stable through the long-term storage. The in vitro release test shows that the multiple components of the traditional Chinese medicine can achieve the sustained-release role, the sustained-release preparation can significantly increase the transmembrane absorption and the stability of various effective active ingredients by oral drug administration, the curve of plasma drug concentration in vivo is smooth, and the design purpose of 24-hour sustained-release is achieved.

Owner:CHINA PHARM UNIV

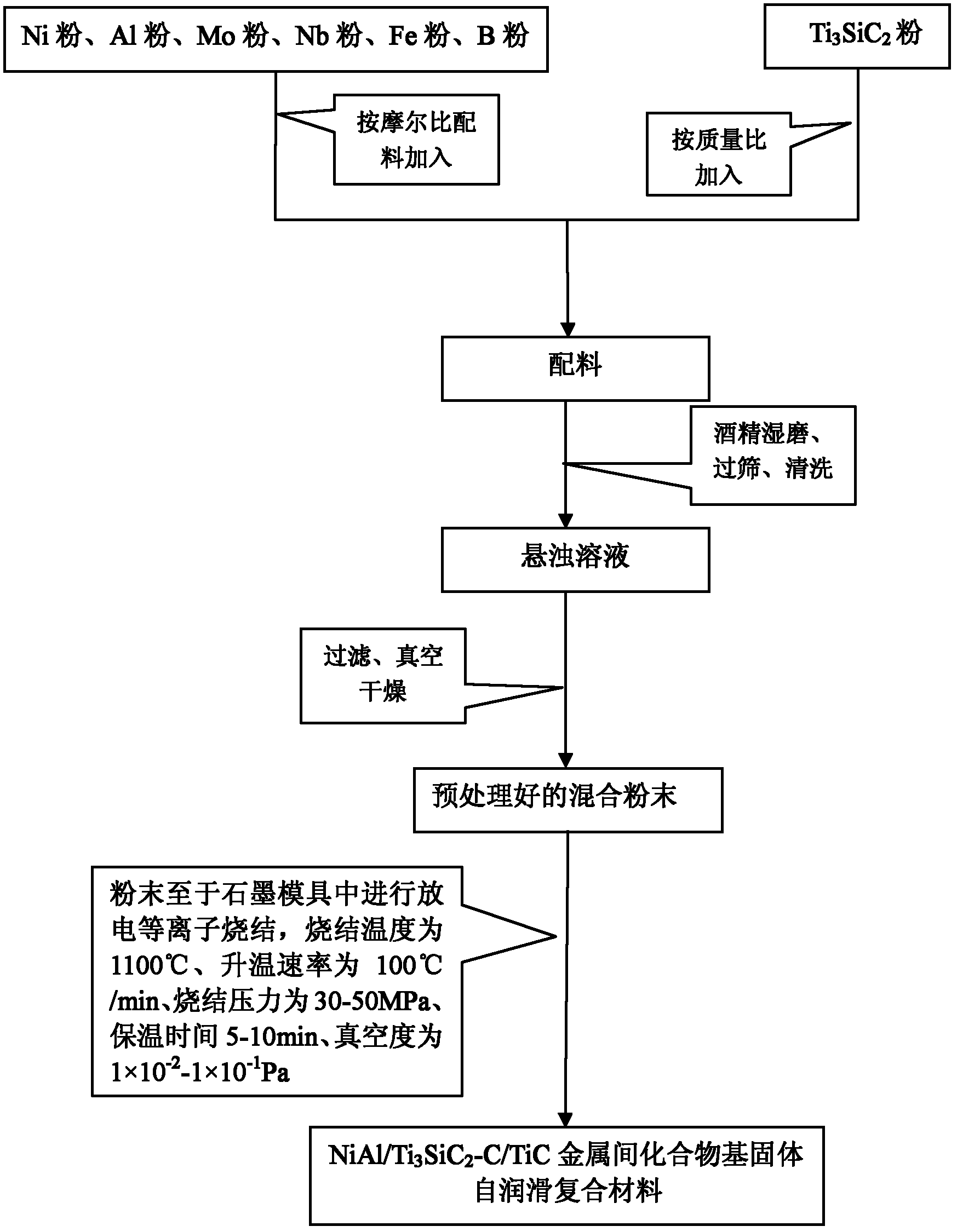

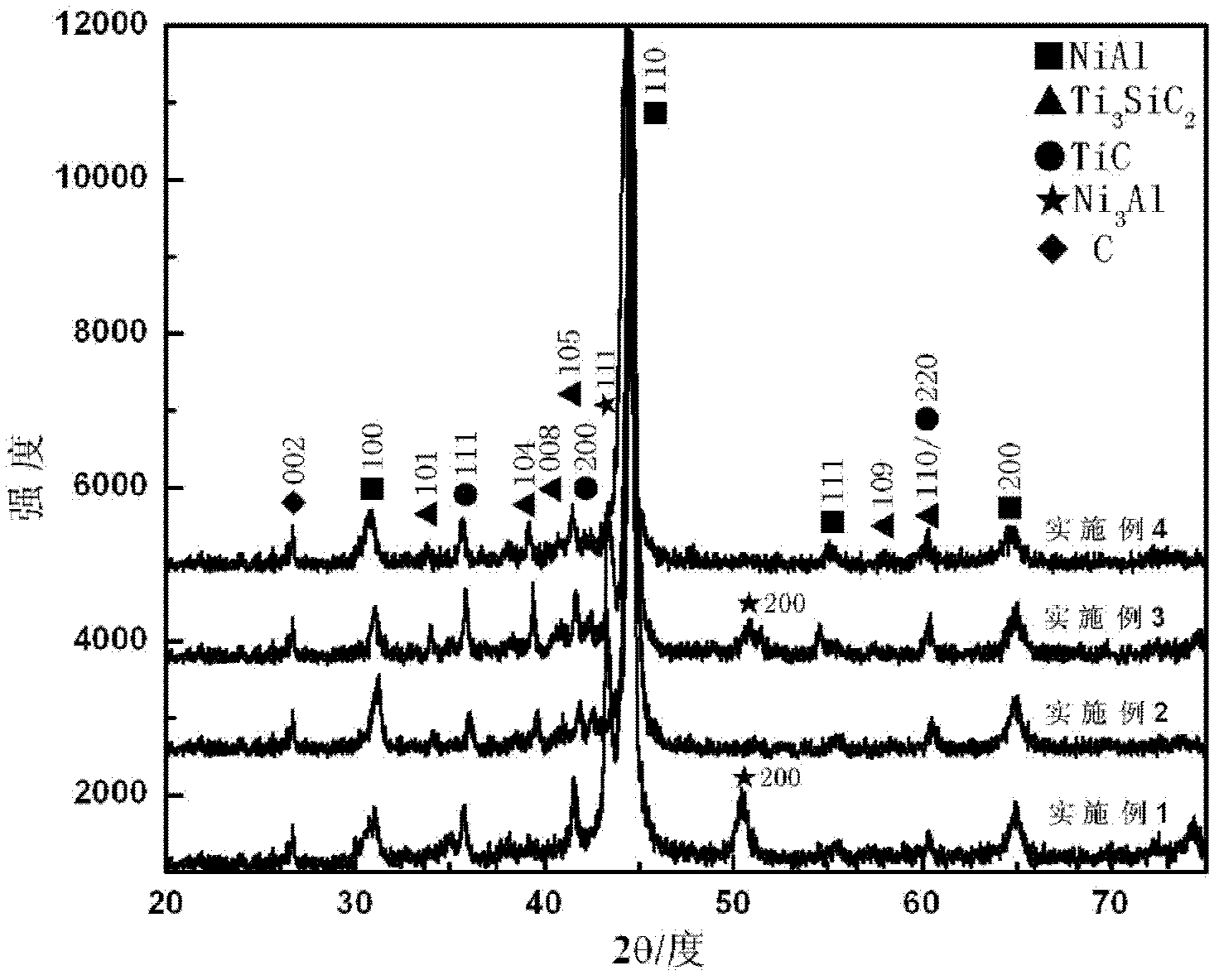

NiAl intermetallic base solid self-lubricating composite material and preparation method thereof

The invention relates to a preparation method of a NiAl intermetallic base solid self-lubricating composite material containing Ti3SiC2 and C binary composite lubrication phase and wild phase TiC. The NiAl intermetallic base solid self-lubricating composite material is prepared from Ni powder, Al powder, Mo powder, Nb powder, Fe powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ni: Al: Mo: Nb: Fe: B=48: 50: 1: 1: 0.5: 0.02, and the addition quantity of the Ti3SiC2 powder is 5-20 weight percent of the total weight of the Ni powder, the Al powder, the Mo powder, the Nb powder, theFe powder and the B powder. The NiAl / Ti3SiC2-C / TiC intermetallic base solid self-lubricating composite material synthesized by the method has novel component design (intermetallic matrix+ composite lubrication phase+ wild phase), high density, good tribological properties and stable technological parameters. The preparation process is fast and simple, and the method is easily operated and is suitable for preparing NiAl intermetallic base solid self-lubricating composite materials with high performance.

Owner:WUHAN UNIV OF TECH

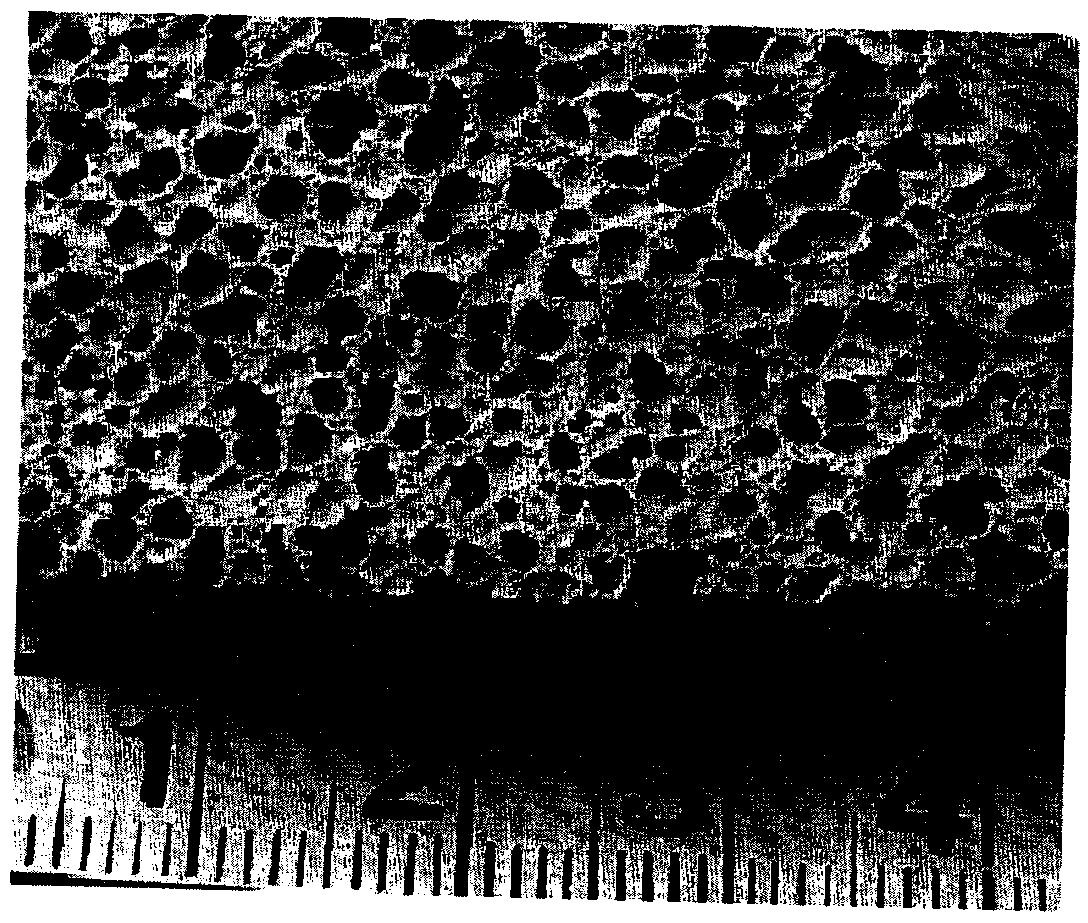

Preparation method of ultralight hierarchical-array-pore foam material

The invention relates to a preparation method of an ultralight hierarchical-array-pore foam material, which comprises the following steps: grinding various industrial solid wastes used as main raw materials with a component regulator, and prefabricating a hierarchical porous structure foam matrix in the required shape by combining a soaking-piling self-assembly technique under the synergetic effects of the special dispersing agent, template, film forming agent, adhesive, accessory pore agent and the like; and sintering to cure the foam matrix under specific sintering schedules to form the ultralight hierarchical-array-pore foam material. The material prepared by the method can be used as an adsorbing and fixing medium for pollutants and gaseous pollutants in various water sources, a catalyst support, a thermal-insulation material and the like, has the characteristics of simple preparation technique and wide raw material sources, and can implement large-scale production.

Owner:HEBEI UNIV OF TECH

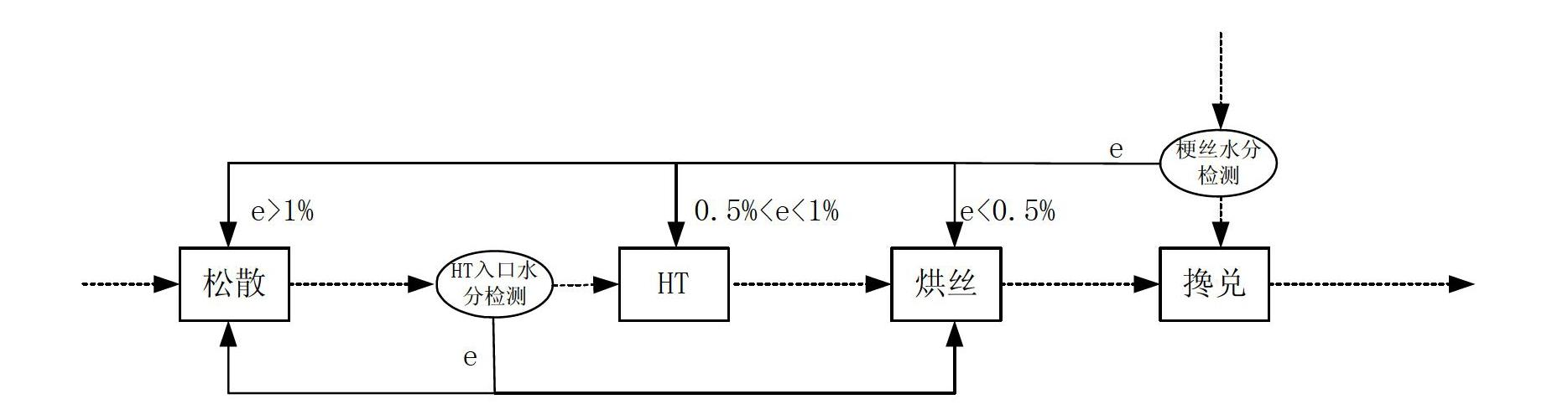

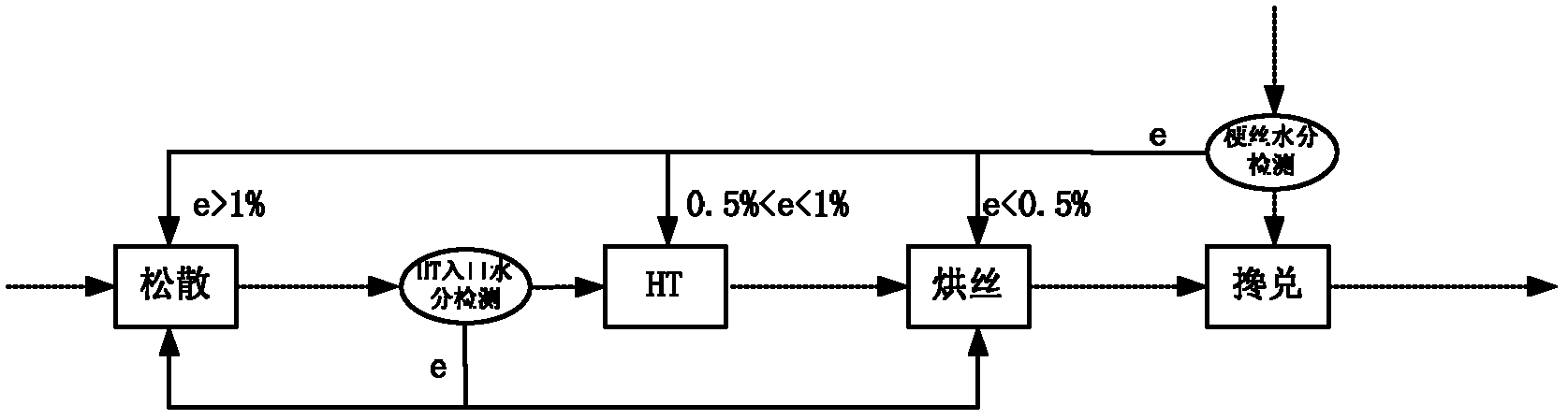

Moisture chain control method for tobacco shred manufacturing process

InactiveCN102613680AGuaranteed process parametersMoisture stableTobacco preparationTobacco treatmentProcess engineeringEngineering

A moisture chain control method for a tobacco shred manufacturing process includes two synchronous steps of adjustment based on moisture fluctuation of blended stems and shreds and adjustment based on moisture fluctuation of tobacco shreds at an HT (humidifying tunnel) inlet. Detection to moisture of stems and shreds before the stems and the shreds are blended is added, moisture of an HT joint and moisture of a stem and shred blending joint are detected, when the HT inlet tobacco shred moisture and stem and shred moisture in the two joints are abnormal, key parameters of other relevant work procedures at joints in front and rear of the two joints on a tobacco shred processing chain are quantitatively adjusted, effective front and rear feedback is realized, stability of shred blending moisture after the stems and the shreds are blended is guaranteed, and stability of technological parameters of a shred drying procedure is ensured.

Owner:CHINA TOBACCO HUNAN INDAL CORP

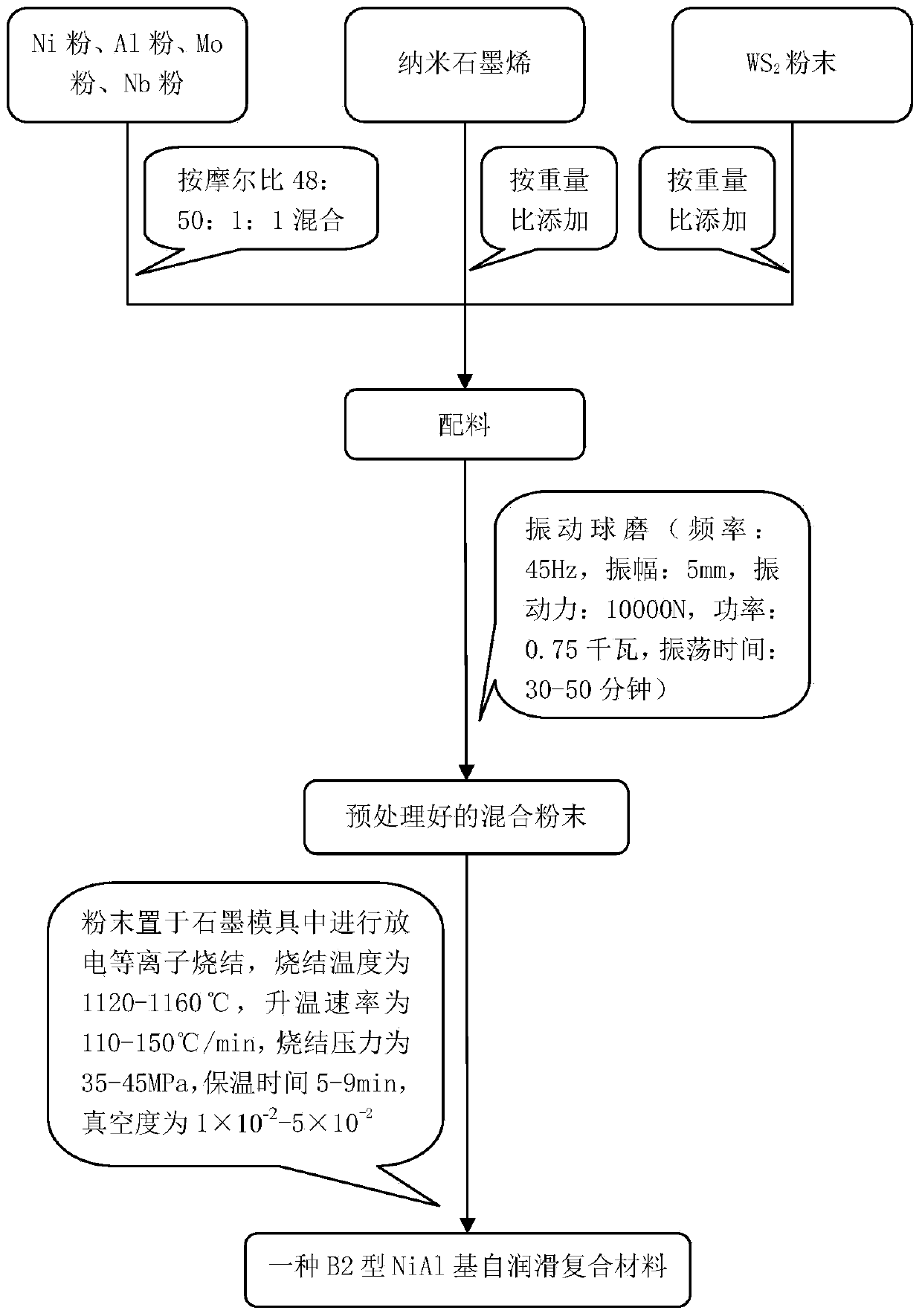

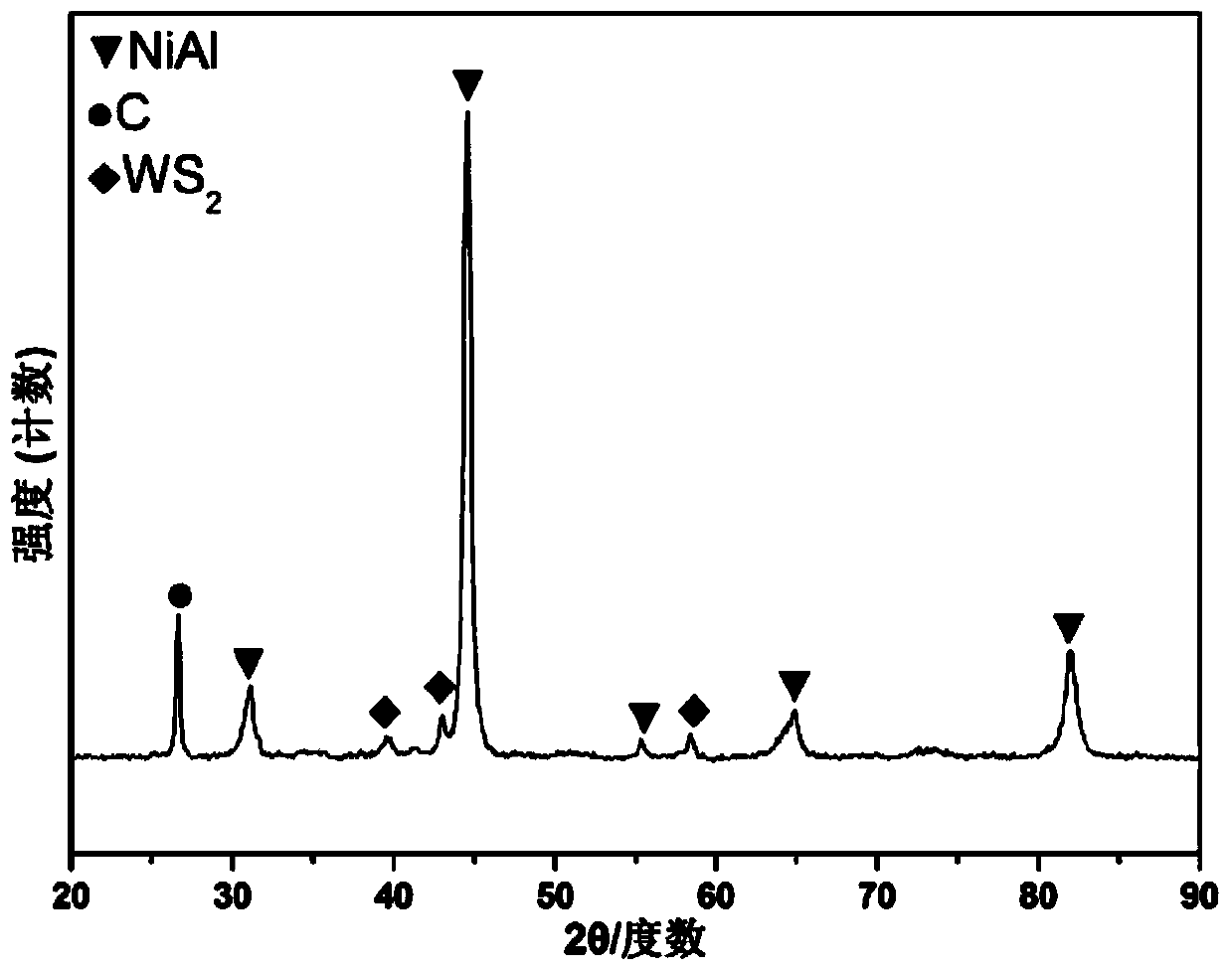

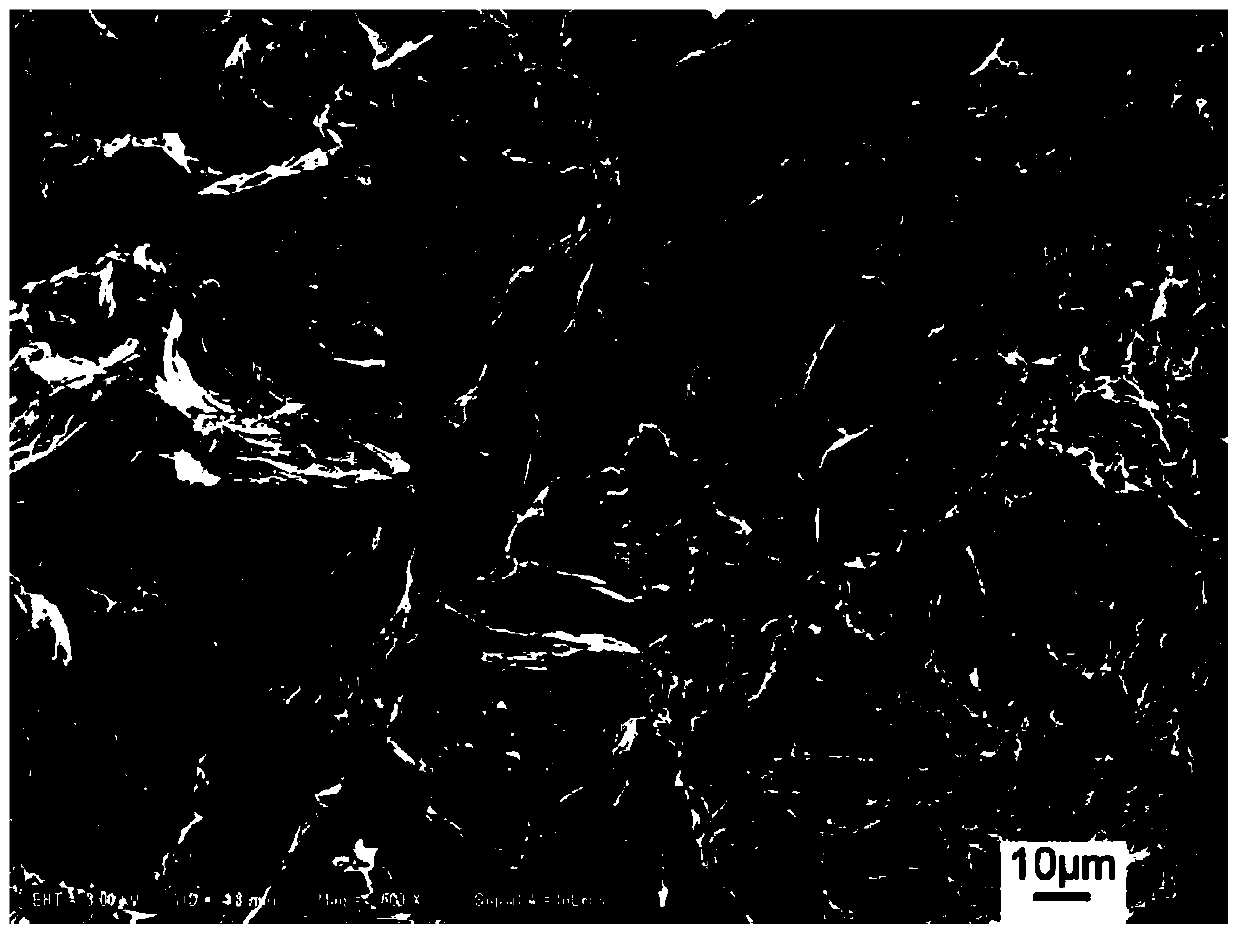

B2 type NiAl-based self-lubricating composite materials and preparing method thereof

The invention provides B2 type NiAl-based self-lubricating composite materials and a preparing method thereof. The method comprises the following steps that (1) Ni powder, Al powder, Mo powder, Nb powder, nano grapheme and WS2 powder are selected according to proportion, and ingredients are obtained; (2) the ingredients are placed in a vibration ball mill for dry grinding, the inner wall of a vibration ball milling tank is made of Teflon, vibration frequency is 45 Hz, amplitude is 5 mm, vibration force is 10000 N, vibration time is 30 minutes-50 minutes, and preprocessed mixed powder is obtained; and (3) the preprocessed mixed powder is placed in a graphite mould with the inner diameter of 20 mm, and then under the vacuum condition, a spark plasma sintering method is used for the B2 type NiAl-based self-lubricating composite materials. The self-lubricating composite materials obtained through the method are high in purity and good in compactness and have good tribology performance. In addition, through the spark plasma sintering method, sintering temperature is lowered, sintering time is shortened, the steps are simple and convenient to achieve, and large-scale batch production can be well achieved.

Owner:重庆三木汽车部件有限公司

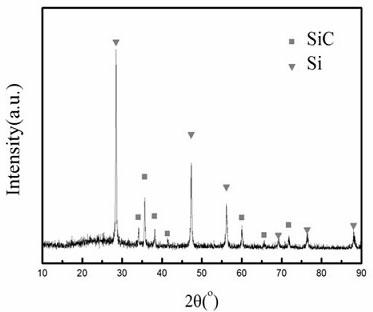

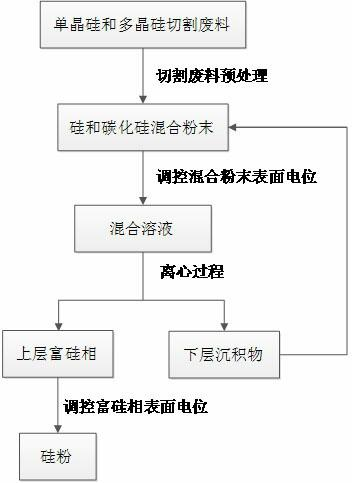

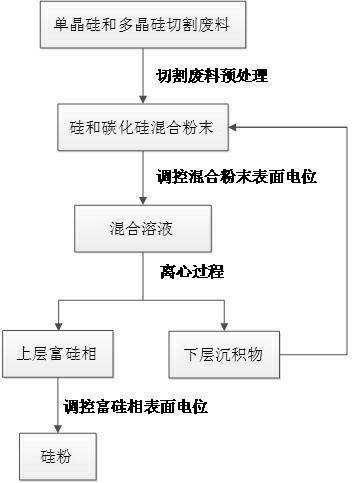

Method for recovering silicon powder from monocrystalline and polycrystalline silicon cutting wastes by utilizing potential adjustment centrifugal process

InactiveCN102659112ASimple processStable process parametersSilicon carbideSilicon compoundsCarbide siliconSilica fume

The invention discloses a method for recovering a silicon powder from monocrystalline and polycrystalline silicon cutting wastes by utilizing a potential adjustment centrifugal process. The method comprises the following steps of: firstly, performing pretreatment on the cutting wastes to remove a polyethylene glycol solution; drying to obtain a mixed powder of silicon and silicon carbide; adding water to the mixed powder and stirring; regulating a pH value to 6-9 by acid and base; performing centrifugal separation for a plurality of times, and then, adding the acid to an isolated upper layer suspension to regulate the pH value to 1-3 so as to enable a silicon powder aggregate to grow up; and performing standing settling for 30min or centrifugal settling for 5min to collect the silicon powder, wherein the purity of the silicon powder can reach more than 80 percent.

Owner:UNIV OF SCI & TECH BEIJING

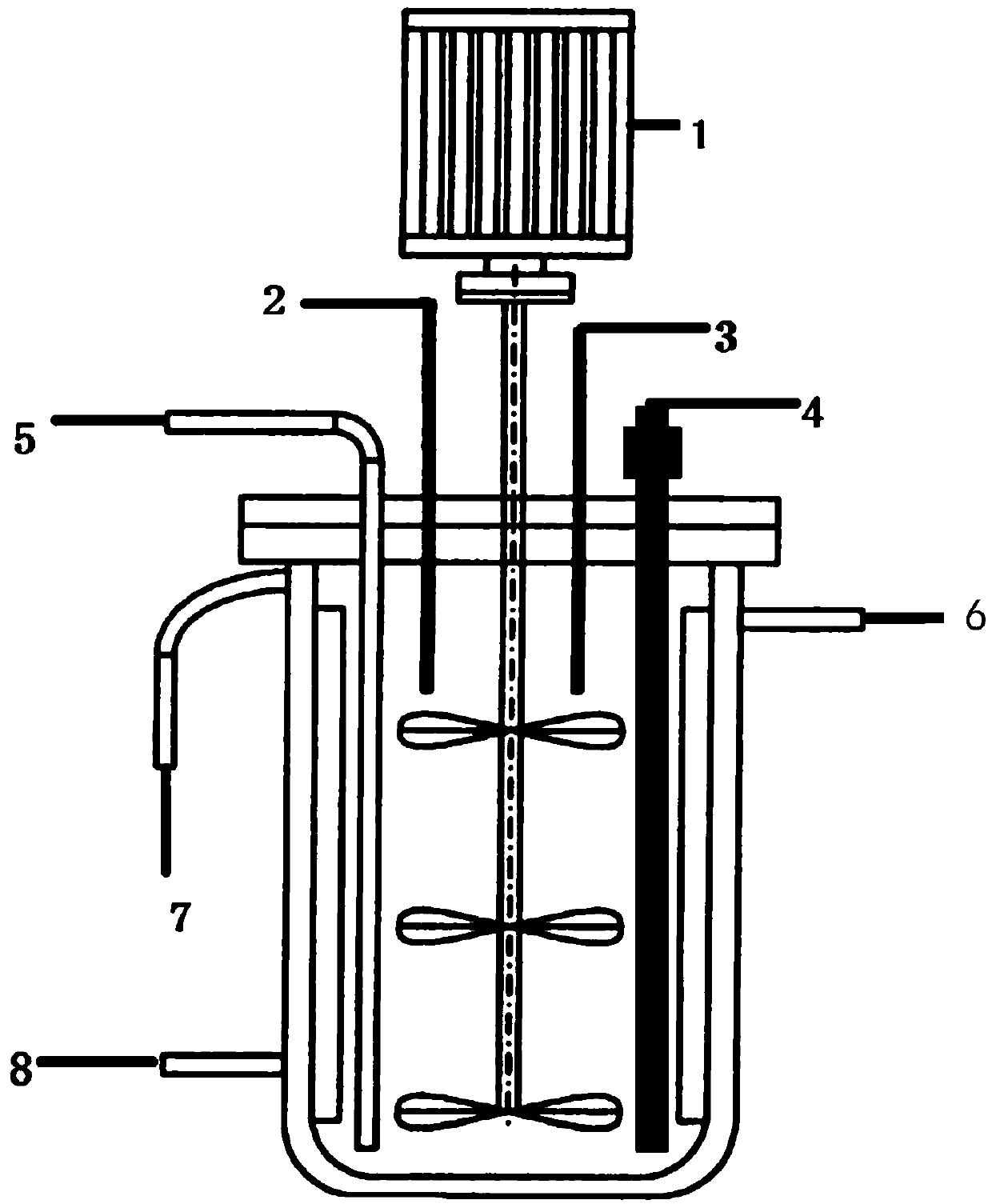

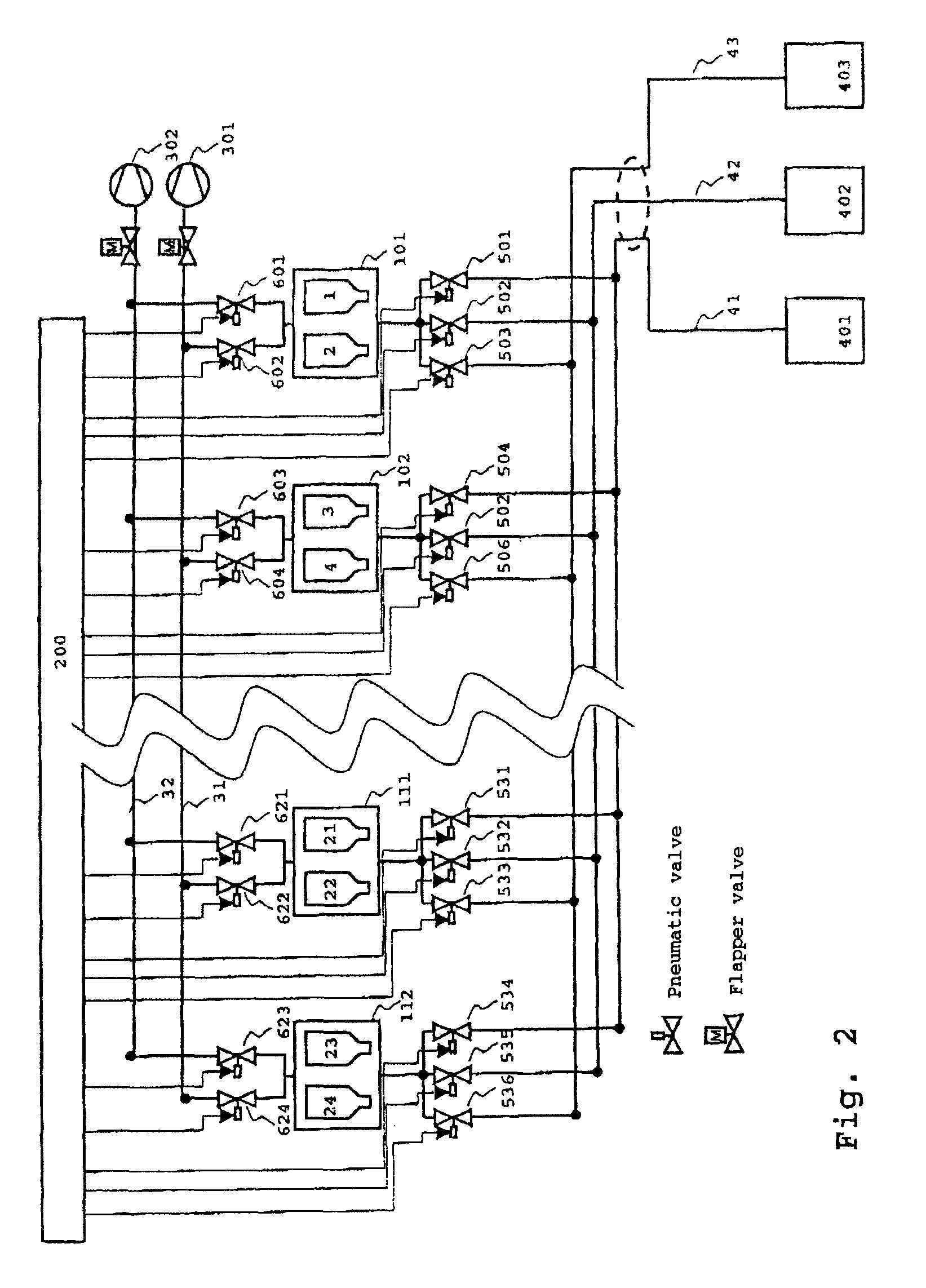

Precursor of lithium ion battery cathode material, preparation method thereof, cathode active material, lithium ion battery, and continuous reactor

ActiveCN108682807AImprove electrochemical performanceUniform particle sizeCell electrodesSecondary cellsAluminium-ion batteryNickel salt

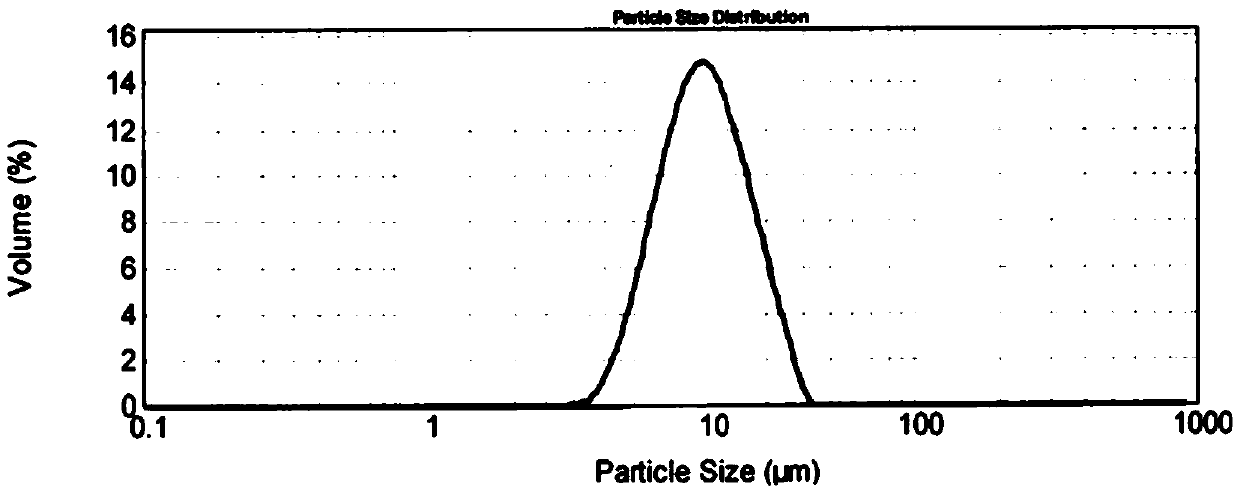

The invention relates to a precursor of a lithium ion battery cathode material, a preparation method thereof, a cathode active material of a lithium ion battery, a lithium ion battery, and a continuous reactor, and belongs to the technical field of new energy materials. The preparation method of the precursor comprises following steps: mixing nickel salt, cobalt salt, manganese salt, doped metal salt (D salt), a precipitating agent, and a complexing agent to obtain a reaction system; carrying out reactions under stirring at a temperature of 30-80 DEG C in an inert gas atmosphere, wherein the pH is 10.0-13.0 during the reaction process, raw materials are fed into the system continuously, and reaction products are discharged continuously through overflowing; and aging the overflowed materials for 1 to 5 hours to obtain the precursor. When the granularity of overflowed materials reaches a set value, the reaction system is subjected to an ultrasonic treatment until the granularity of overflowed materials is lower than the set value. The obtained precursor has the advantages of uniform granularity and morphology, and large tap density, and is benefit for the preparation of a lithium ionbattery cathode material with excellent electrochemical properties.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

High-temperature-resistant low-loss compound insulation coaxial cable

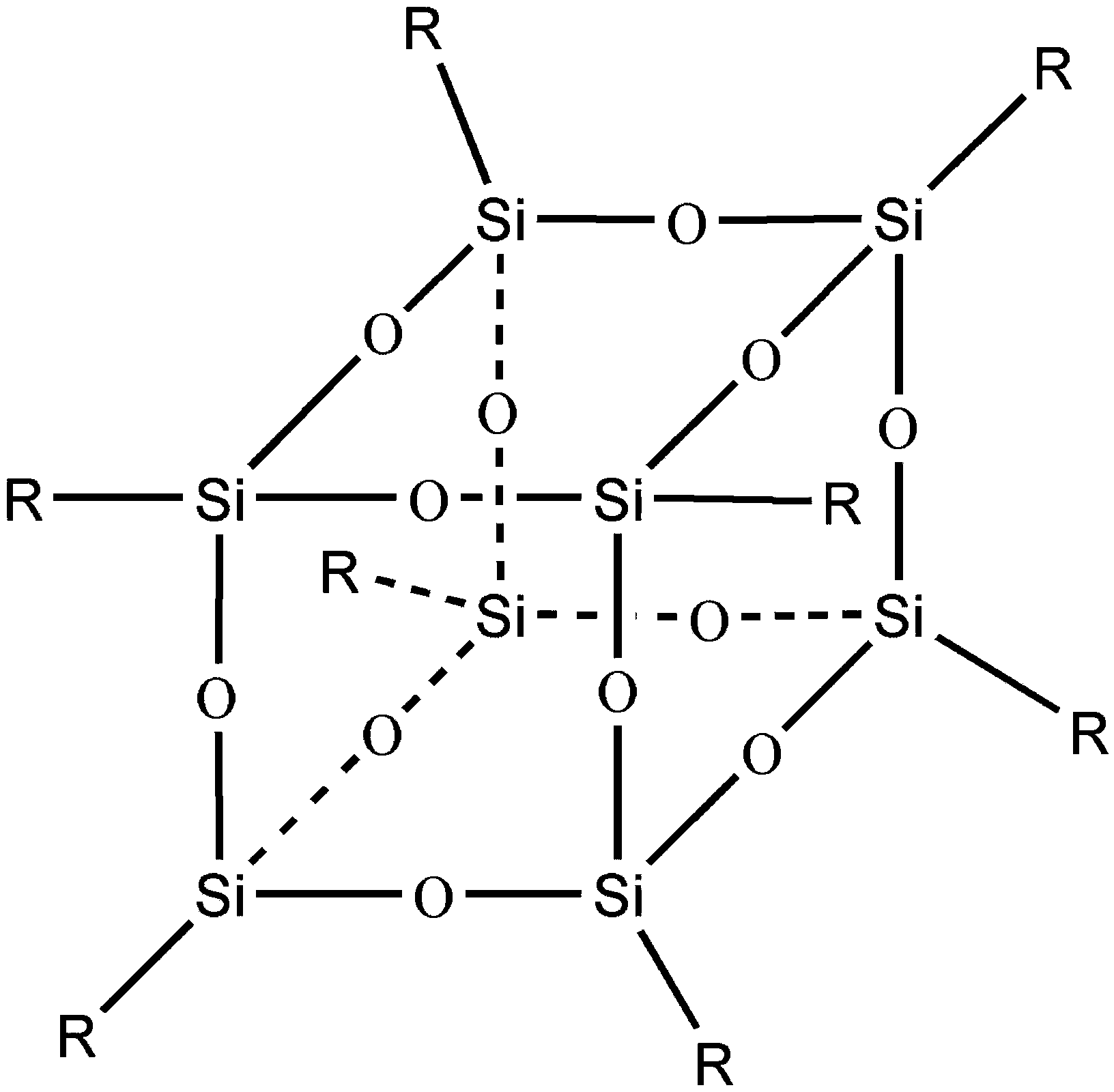

InactiveCN104319008AImprove high-frequency communication performanceLow densityCoaxial cables/analogue cablesInsulated cablesPolytetrafluoroethyleneOrganic inorganic

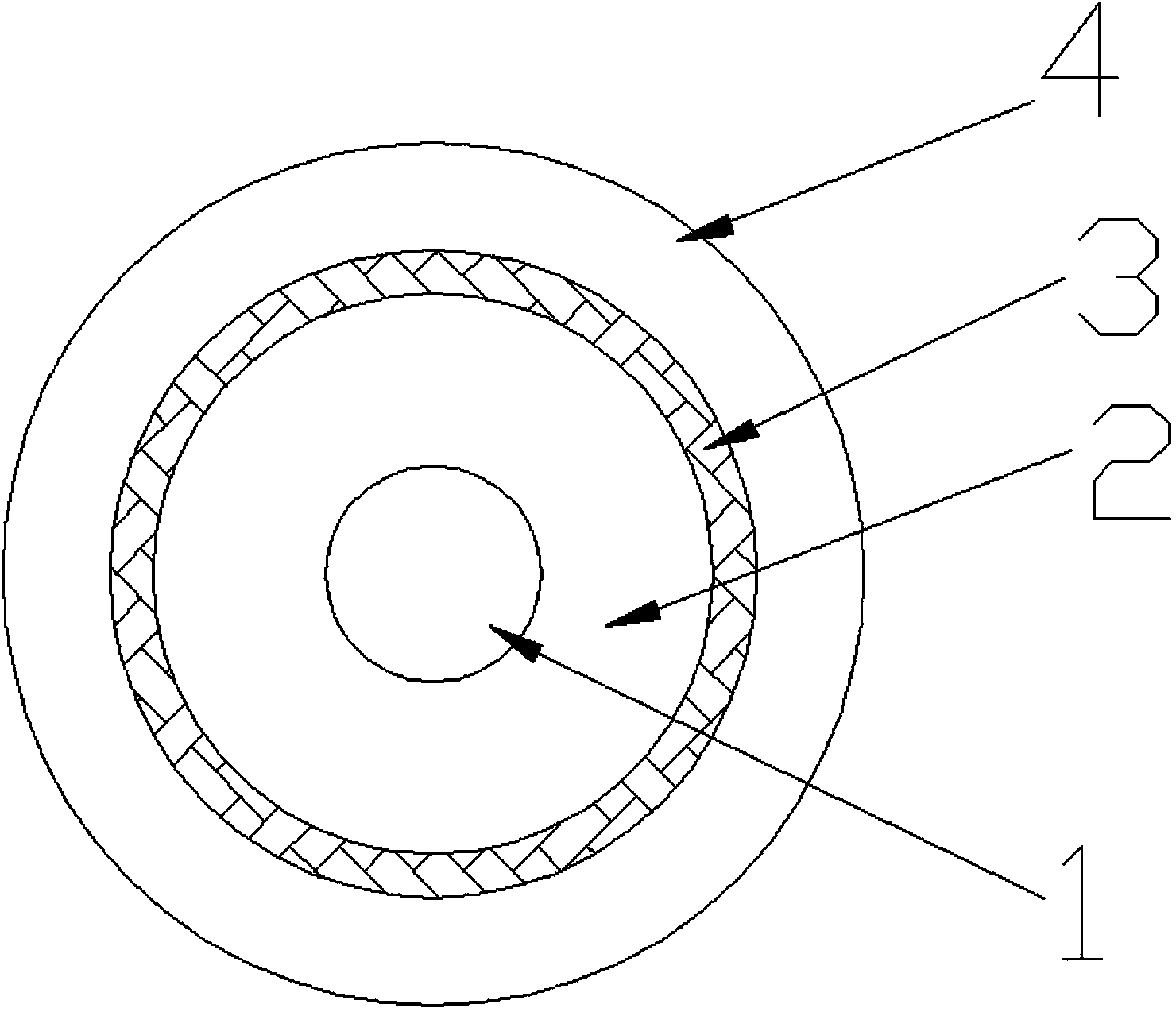

Provided is a high-temperature-resistant low-loss compound insulation coaxial cable. The high-temperature-resistant low-loss compound insulation coaxial cable is characterized in that a solid or stranded inner metal conductor (1), a polytetrafluoroethylene micropore compound insulation layer (2), an outer conductor (3) and a sheath layer (4) are arranged from inside to outside in sequence, the solid or stranded inner metal conductor (1) longitudinally extends along the central axis of the cable, the outer conductor (3) is formed by knitting metal or is additionally provided with an inner shielding layer, the sheath layer (4) is made of FEP copolymer or low-smoke halogen-free flame retardant polyolefin, and the inner metal conductor (1) and the outer conductor (3) are separated by the polytetrafluoroethylene micropore compound insulation layer (2); the polytetrafluoroethylene micropore compound insulation layer (2) is made of modified polytetrafluoroethylene organic-inorganic nanocomposites filled with nano polyhedral oligomeric silsesquioxanes (POSS). According to the coaxial cable, the dielectric constant of the insulation layer of the cable is reduced. A traditional solid polytetrafluoroethylene insulation dielectric constant is reduced to 1.2-1.6 from 2.1 and is reduced by about 24 percent to 43 percent, and the signal attenuation of cable high-frequency communication is reduced.

Owner:JIANGSU TRIGIANT TECH

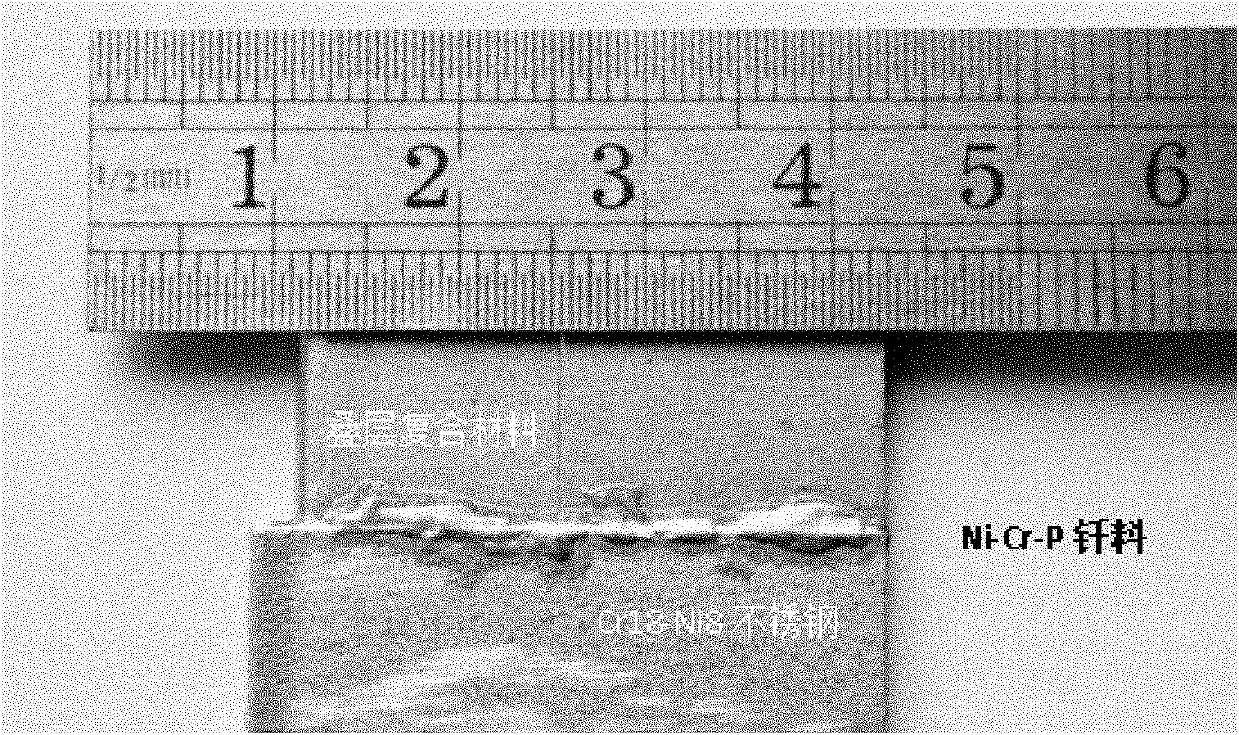

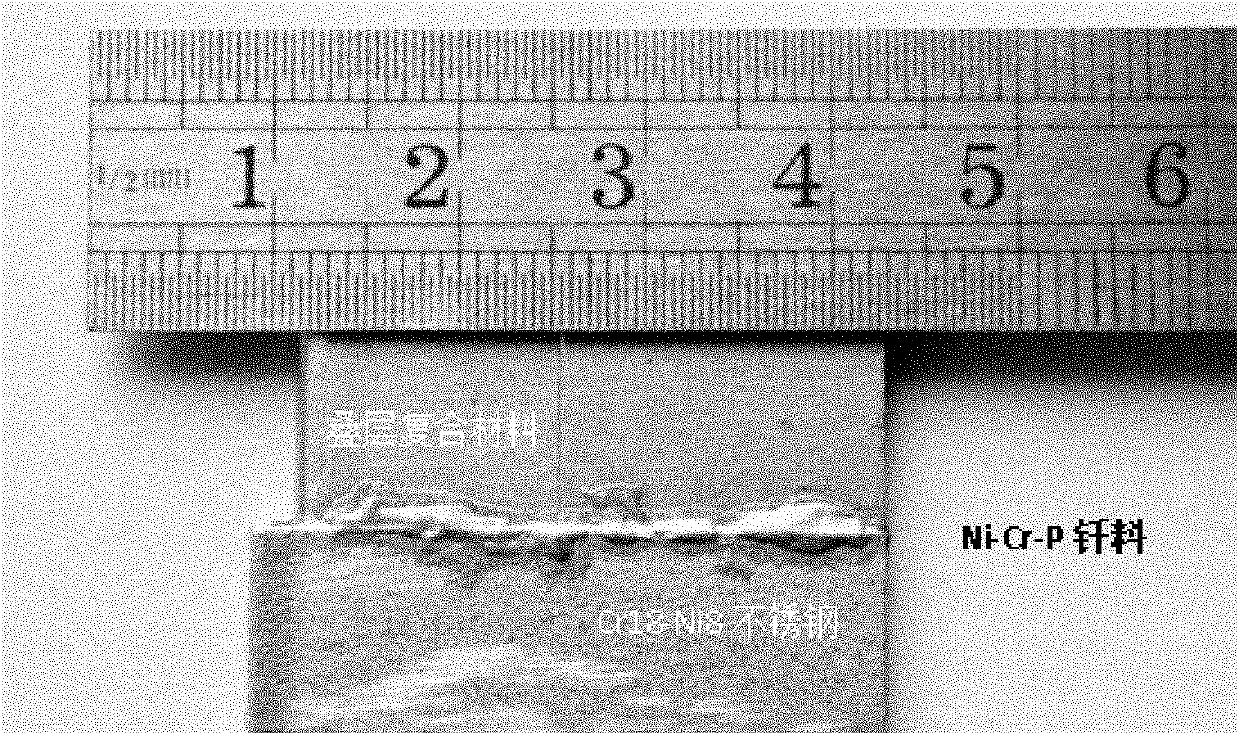

Vacuum brazing process for super-Ni laminated material and Cr18-Ni8 stainless steel

InactiveCN101992331AImprove performanceBeautiful brazing seamWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMetallic Nickel

The invention discloses a vacuum brazing process for a super-Ni laminated material and Cr18-Ni8 stainless steel, which is characterized by comprising the following steps: (1) prior to brazing, cleaning the super-Ni laminated material and the Cr18-Ni8 stainless steel, and removing oil stains on the surfaces of parts and the oxidation film on the surfaces to be brazed; (2) carrying pick-up fitting and fixing on the parts to be brazed in a super-Ni laminated material-brazing filler metal-stainless steel mode, wherein the brazing filler metal is Ni-Cr-P nickel-based brazing filler metal; and (3) carrying out vacuum brazing on the fixed workpiece in a vacuum brazing furnace, wherein the vacuum degree of the vacuum brazing furnace is greater than 1.33*10<-3>Pa, the brazing heat temperature is 920-1100 DEG C, and the holding time is 5-25 min. By using the method, brazed joints having the advantages of no crack, fine interface combination and beautiful surface appearance can be obtained, and the reliable connection of laminated materials can be realized, thereby meeting the requirements of aerospace, power and other fields for high-performance materials.

Owner:SHANDONG UNIV

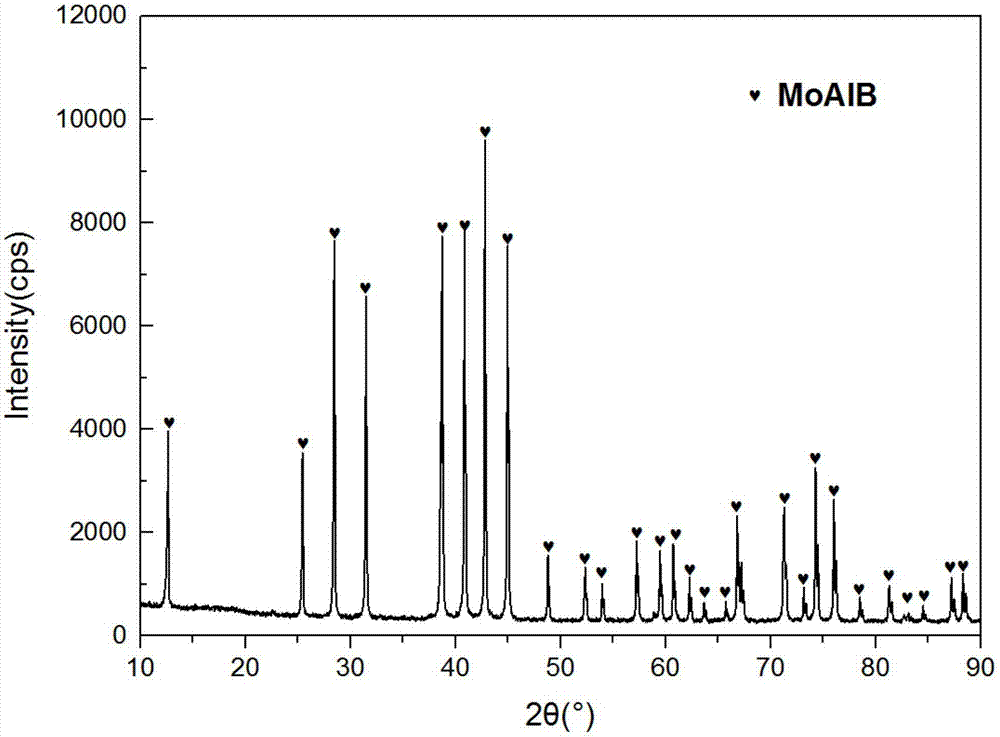

Preparation method of high-purity MoAlB ceramic powder and compact block body

The invention discloses a preparation method of high-purity MoAlB ceramic powder and a compact block body. A method for preparing MoAlB powder is characterized in that Mo powder, Al powder and B powder are used as raw materials; proportioning is performed according to the mole ratio of Mo to Al to B being 1:(1.1 to 1.3):1; dry blending is performed for 5 to 24h in a ball grinding mill; after the mixed materials are subjected to blank pressing on a tableting press; blanks are put into a pressure-free furnace; under the argon gas atmosphere, the furnace temperature is raised to 1000 to 1300 DEG C at the velocity of 10 to 50 DEG C / min; heat insulation is performed for 10 to 120min; then, the temperature is lowered to room temperature; the high-purity MoAlB material is obtained. The obtained MoAlB material is crushed in the ball grinding mill and is sieved by a sieve with different meshes, so that the MoAlB powder with different particle size is obtained. A method for preparing the compact block body is characterized in that Mo powder, Al powder and B powder are used as raw materials; proportioning is performed according to the mole ratio of Mo to Al to B being 1:(1.1 to 1.3):1; dry blending is performed on the material for 5 to 24h in the ball grinding mill; mixed materials are put into a pressure-free furnace; under the argon gas atmosphere, the furnace temperature is raised to 1000 to 1300 DEG C at the velocity of 10 to 50 DEG C / min; pressurization is performed to 10 to 40MPa; heat insulation is performed for 10 to 120min; then, the temperature is lowered to the room temperature; a high-purity compact MoAlB block body material is obtained.

Owner:BEIJING JIAOTONG UNIV

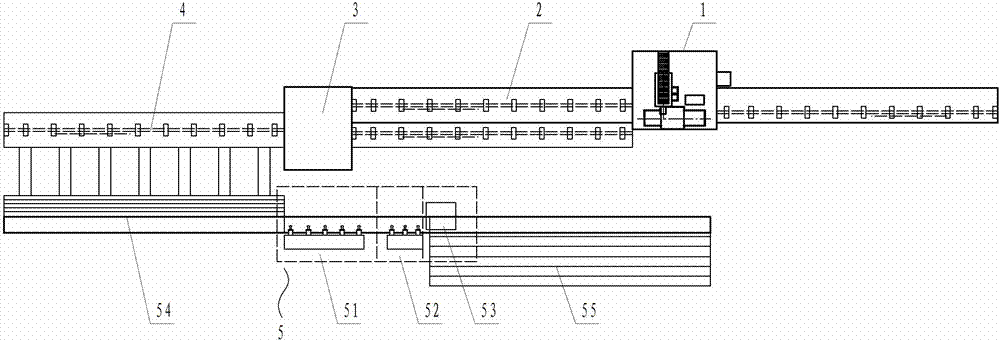

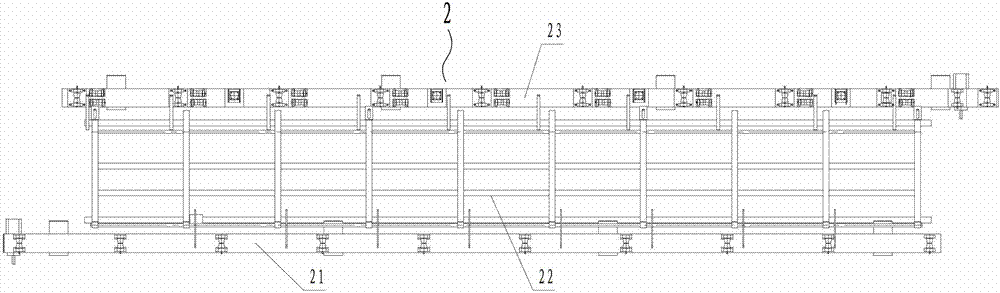

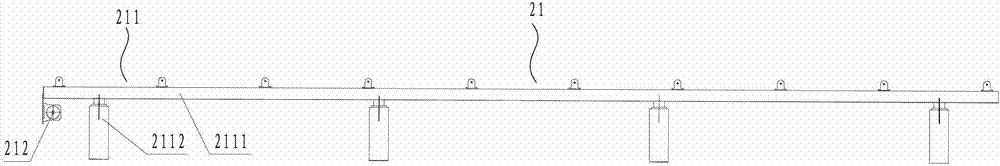

Semiautomatic streamline type production system and method for high-strength threaded steel bar

The invention discloses a semiautomatic streamline type production system and method for a high-strength threaded steel bar and relates to a production system and method for the high-strength threaded steel bar. The production system comprises a centerless lathe, a screw rolling machine and a heat treatment system, wherein the centerless lathe is connected together with the screw rolling machine through an automatic joining device; and the screw rolling machine is connected together with the heat treatment system through an automatic discharging mechanism of the screw rolling machine. The method comprises the steps of feeding S1 blanking, S2 turning, S3 roll threading, S4 heat treatment and S5checking. According to the semiautomatic streamline type production system and method disclosed by the invention, the production efficiency can be increased, the cost of products is reduced and the quality of the products is ensured; and the semiautomatic streamline type production system and method are suitable for producing the high-strength threaded steel bars with the diameter being 50-80mm and the length being 12m.

Owner:LIUZHOU OVM MASCH CO LTD

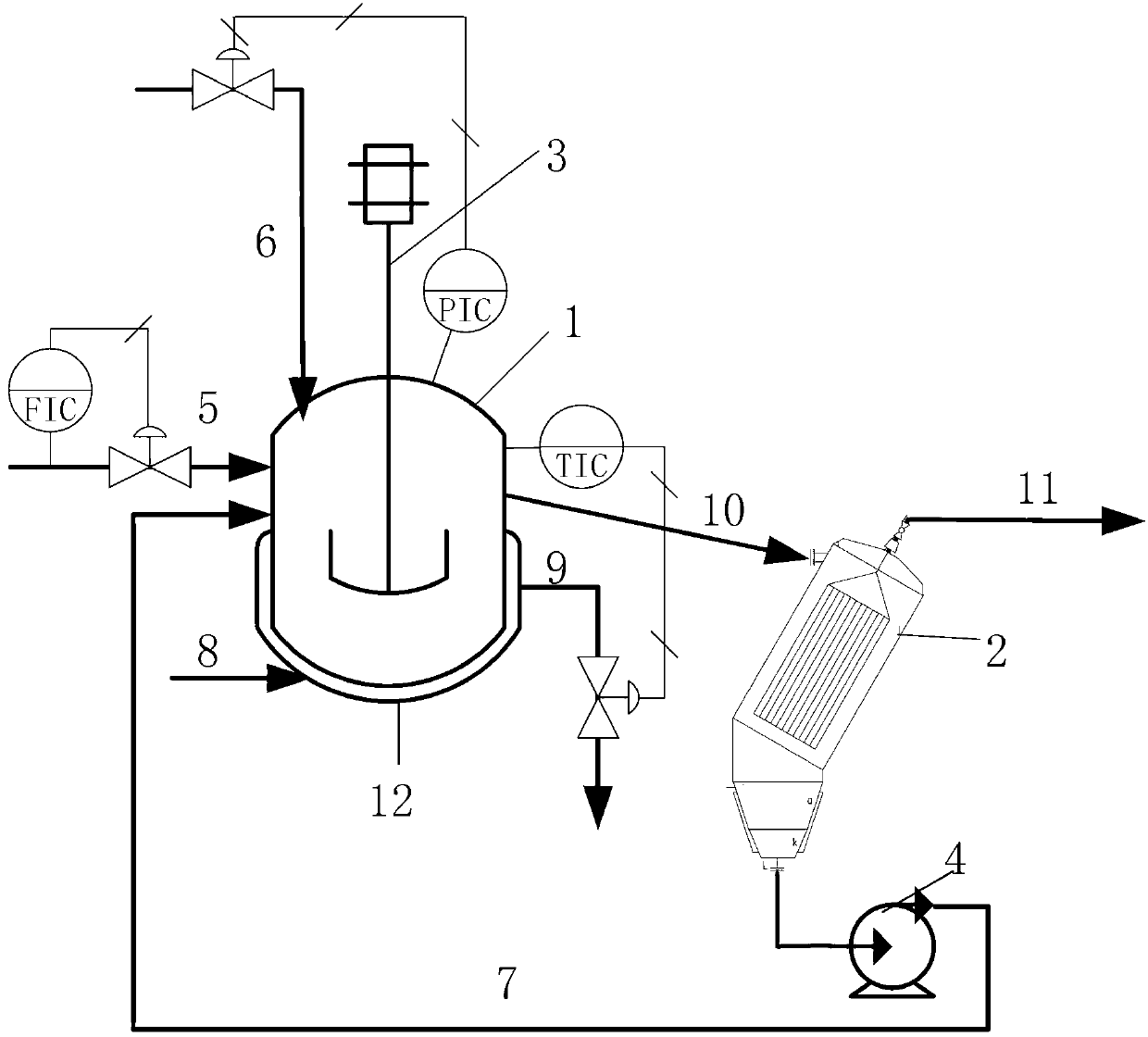

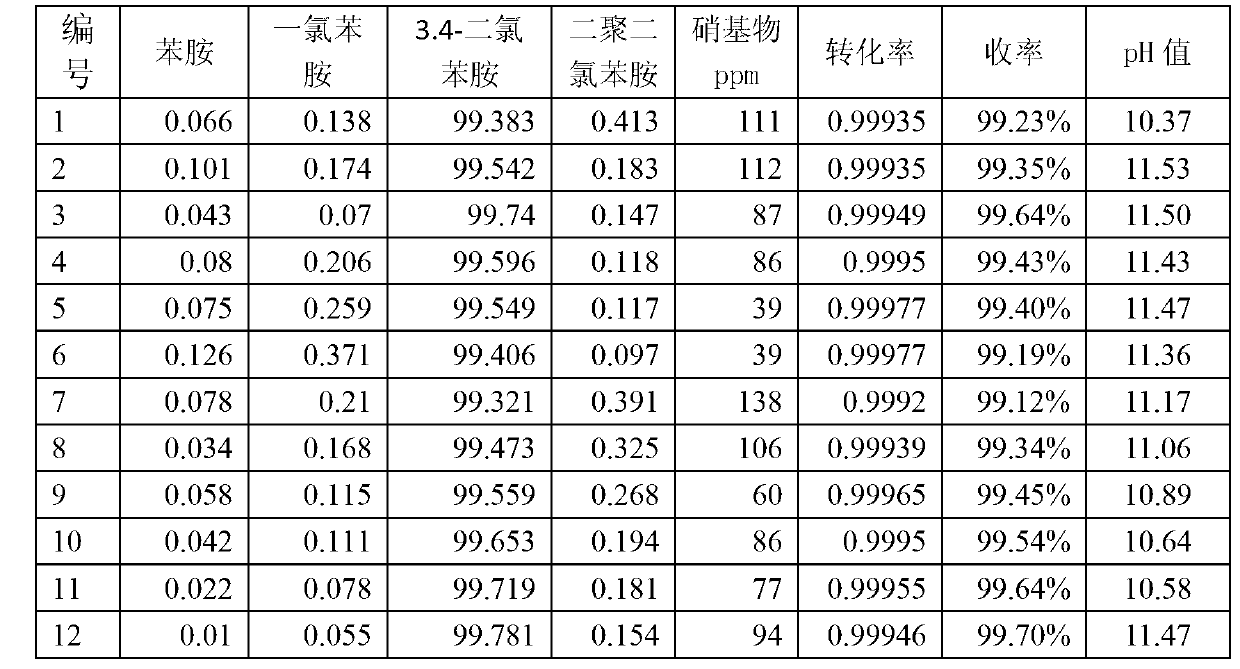

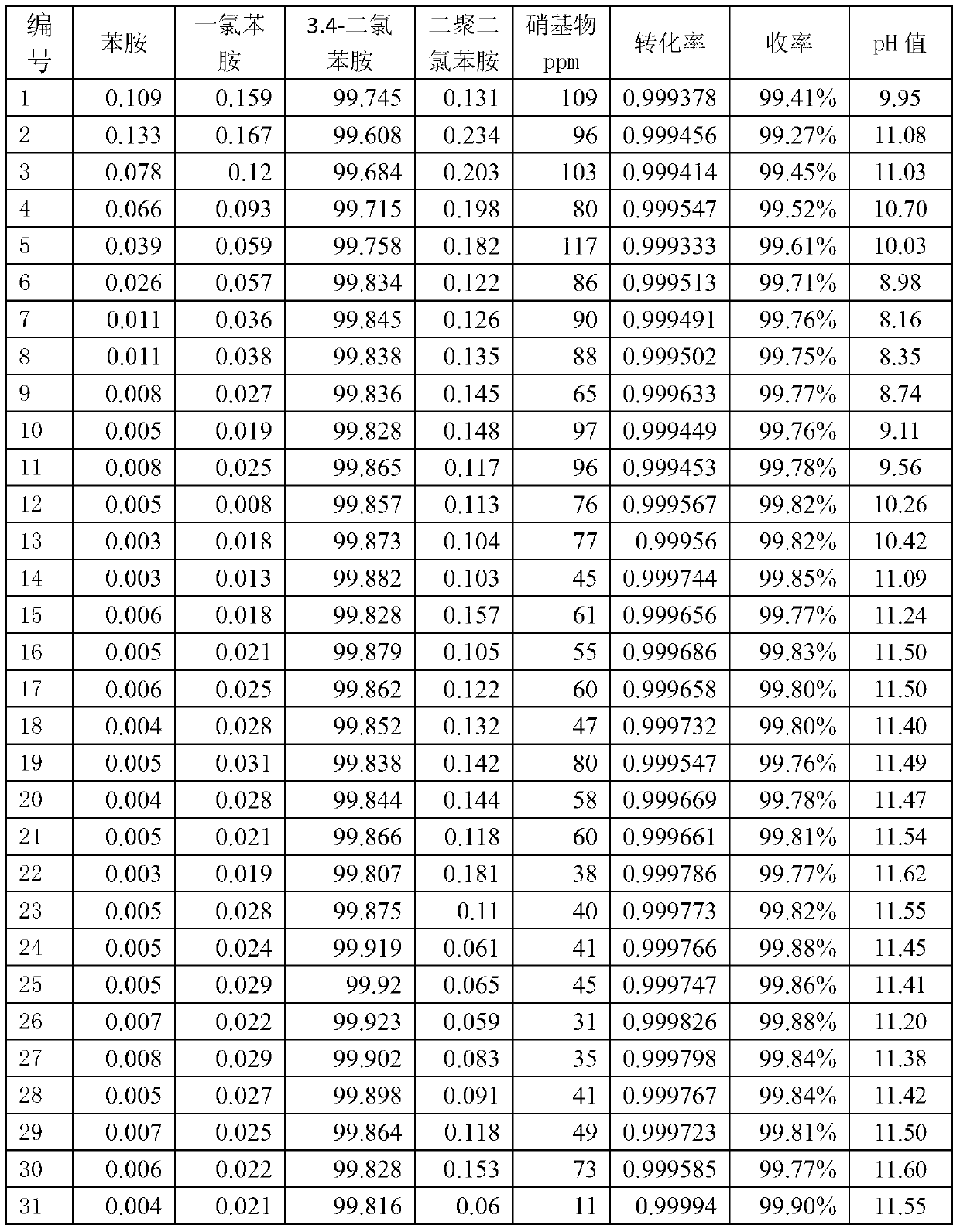

Method for continuously producing 3,4-dichloroaniline

InactiveCN103342650AStable process parametersSimple control methodOrganic compound preparationAmino compound preparationNickel catalystHydrogen

The invention relates to a method for continuously producing 3,4-dichloroaniline. The method comprises the following steps of: continuously putting a 3,4-dichloronitrobenzene solution into a stirred tank reactor, wherein the pressure of the stirred tank reactor is 0.5-2Mpa, the temperature is 60-120 DEG C, and the pH value in a stirred tank is controlled to be between 8 and 12; performing catalytic hydrogenation reaction on the 3,4-dichloronitrobenzene in the stirred tank reactor in the presence of a nickel catalyst, a dechlorination inhibitor, hydrogen and a solvent to generate 3,4-dichloroaniline; overflowing the reaction product into a tilted plate separator, and continuously separating a catalyst concentrated solution and a product clear solution in the tilted plate separator; and continuously returning the catalyst concentrated solution to the stirred tank reactor. According to the method, the yield of the product obtained by the method is more than 99%, the dechlorination mass fraction is less than 0.5%, the loss of the catalyst is low, the consumption of the hydrogen is small, and the operation is stable and easy to control, so that the method is suitable for industrial large-scale production.

Owner:QINGDAO UNIV OF SCI & TECH +1

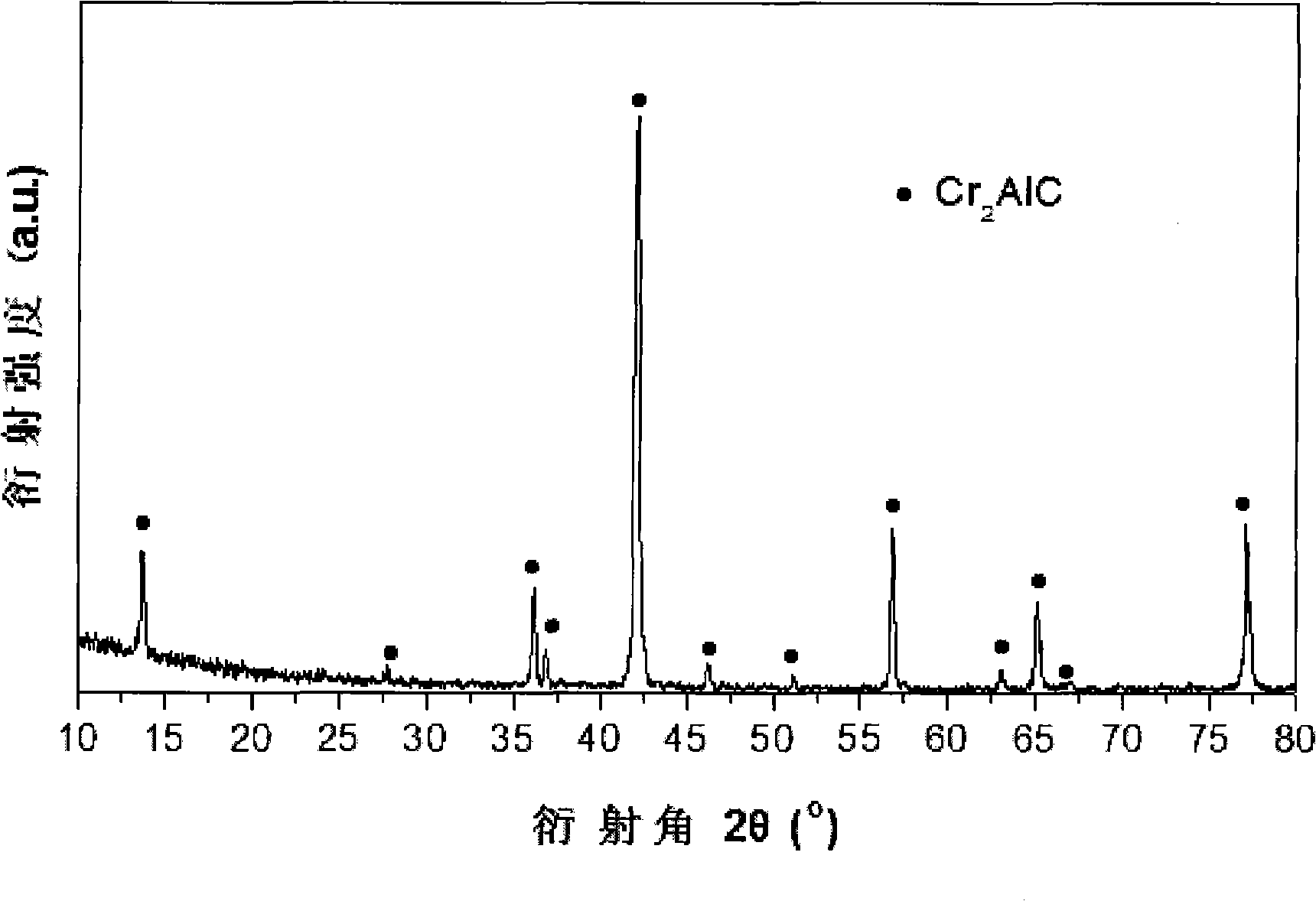

Constant pressure synthesis method for aluminum chromium carbide ceramic powder

The invention relates to a method for synthesizing aluminum chromium carbide powder under normal pressure. The method comprises the following steps: mixing Cr powder, Al powder and C powder as raw materials at the molar ratio of Cr to Al to C of 2:(1-1.3):1, stirring for 10 hours, molding under 30-50 MPa to obtain a blank block, heating the blank block up to 1350-1500 DEG C at a temperature rise rate of 15-50 DEG C / min in the presence of argon gas, and maintaining the temperature for 5-30 min, to obtain high-purity Cr2AlC powder with low cost. The method has the advantages of wide temperature range of Cr2AlC powder synthesis, short synthesis time, high purity, low cost, simple equipment, stable processing parameters, and suitability for bulk production.

Owner:BEIJING JIAOTONG UNIV

110KV intermediate head and production process thereof

ActiveCN102185274AImprove visibilityConvenient inspectionLine/current collector detailsCable junctionsEngineeringSilicon rubber

The invention provides an 110KV intermediate head and a production process thereof. The intermediate head comprises two stress cones (1), a screening tube (2), insulating layers (3) and outer screening layers (4), wherein the screening tube (2) is arranged between the two stress cones (1); the insulating layers (3) are filled between the screening tube (2) and the two stress cones (1); and the outer screening layers (4) are coated outside the insulating layers (3). The process of producing the 110KV intermediate head comprises three formations, that is, the first formation is the formation ofthe conductive stress cones and the screening tube; the second formation is the formation of the insulating layers: the formed stress cones and a formed stress tube are arranged in a mould during glue injection and then integrated after formation; and the third formation is the formation of outer conducting layers: all parts are integrated after formation to form the intermediate head. The formedinsulating layers of the intermediate head are made from transparent insulated rubbers, thus being high in visibility and being convenient to check.

Owner:江苏远航电缆附件有限公司

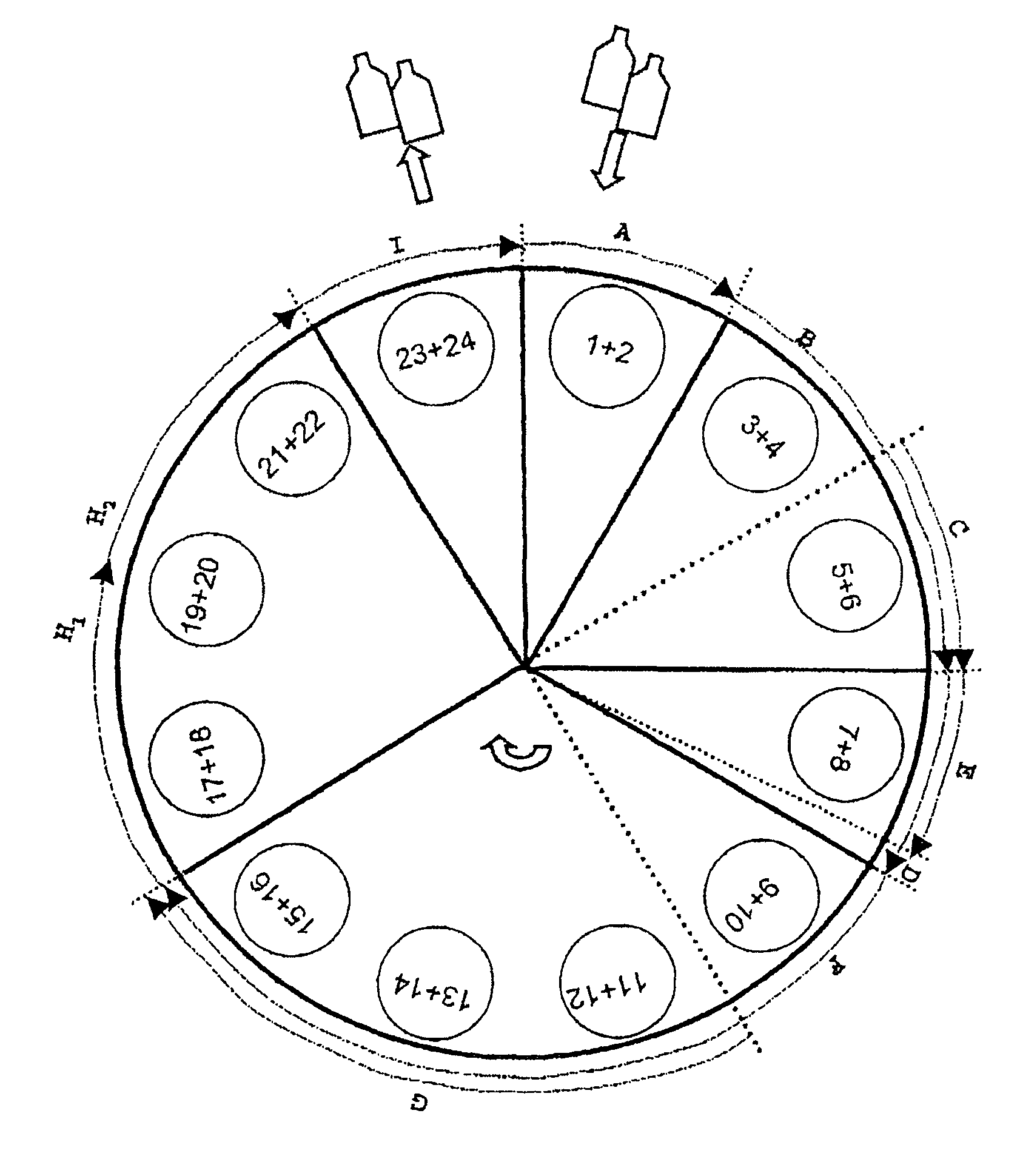

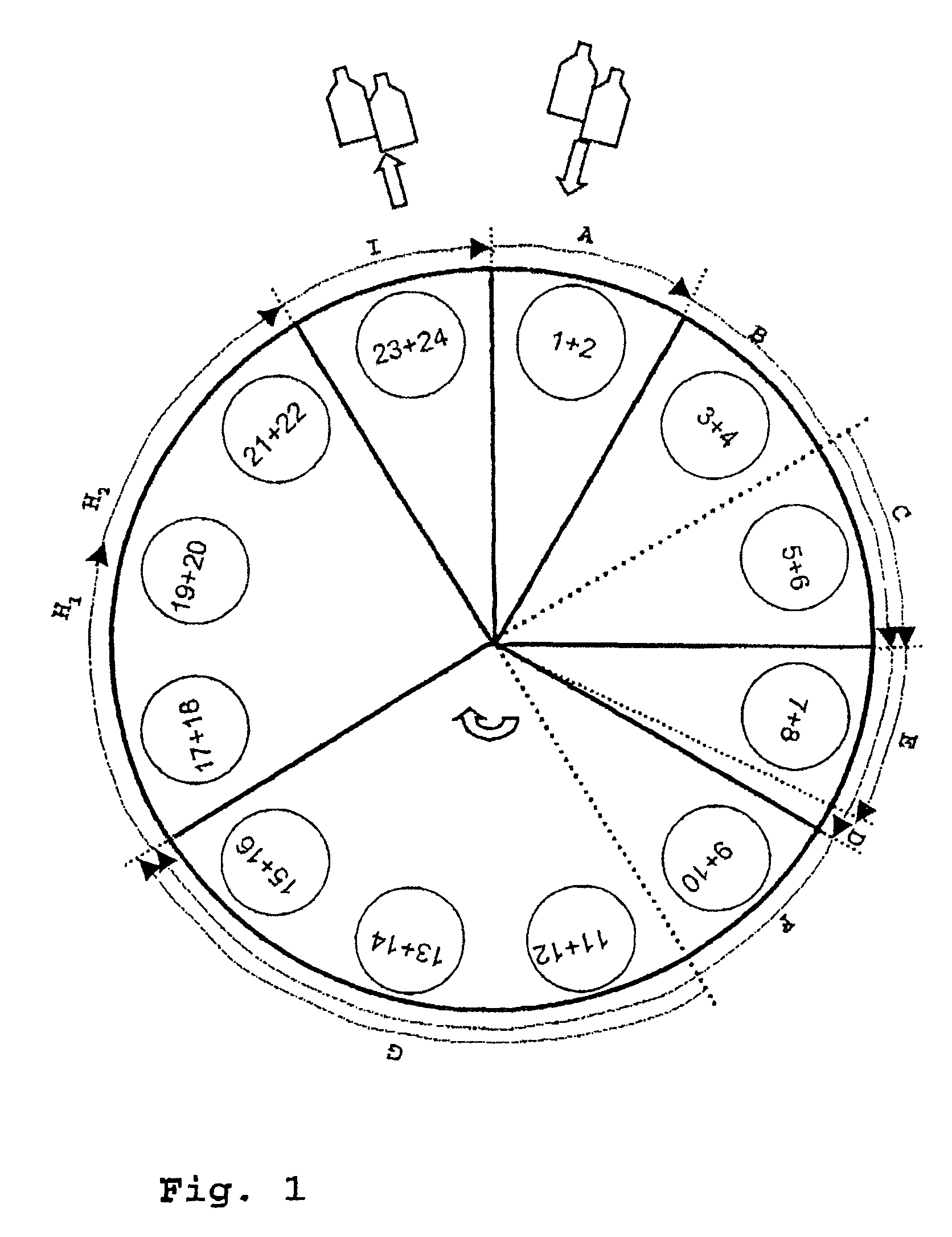

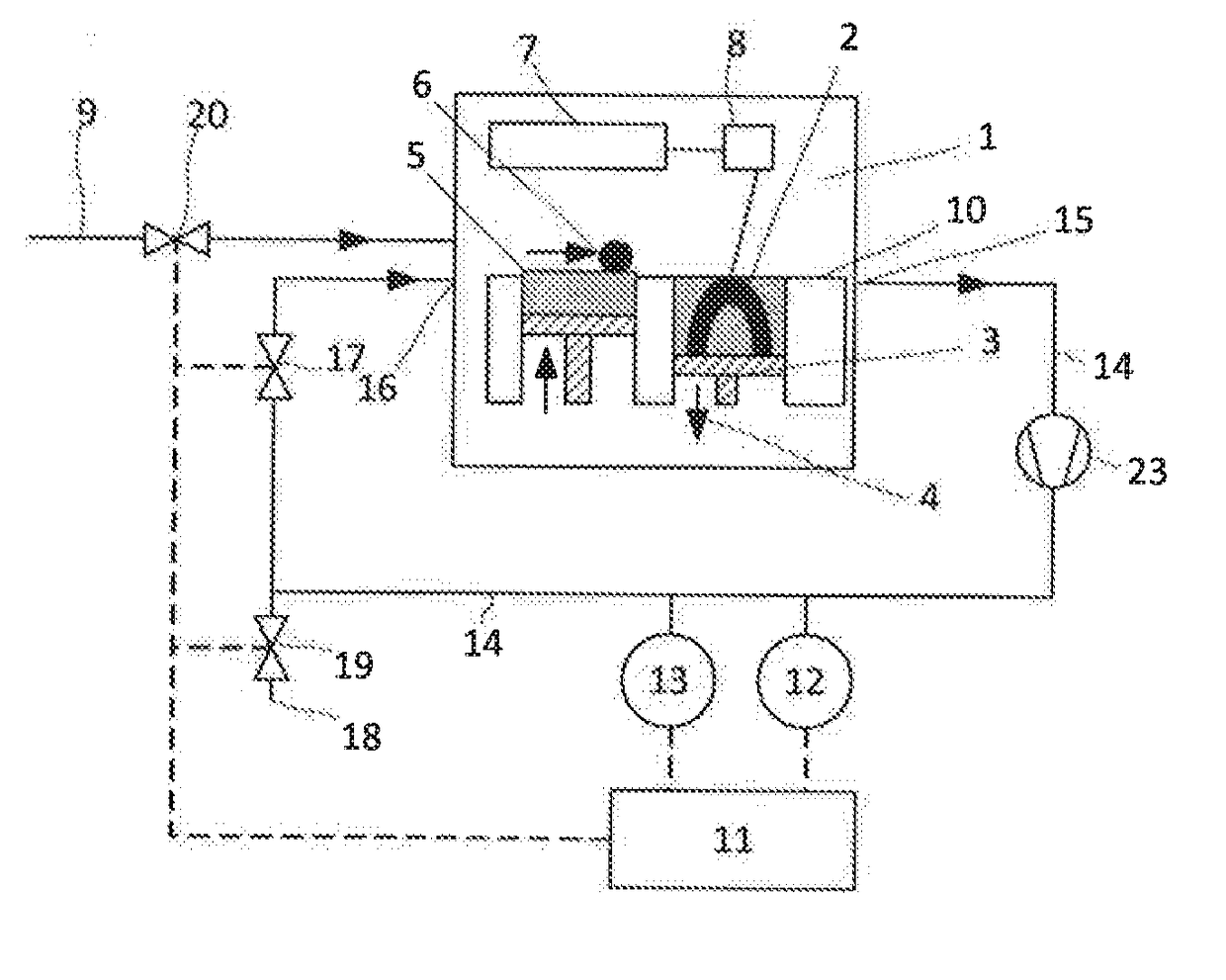

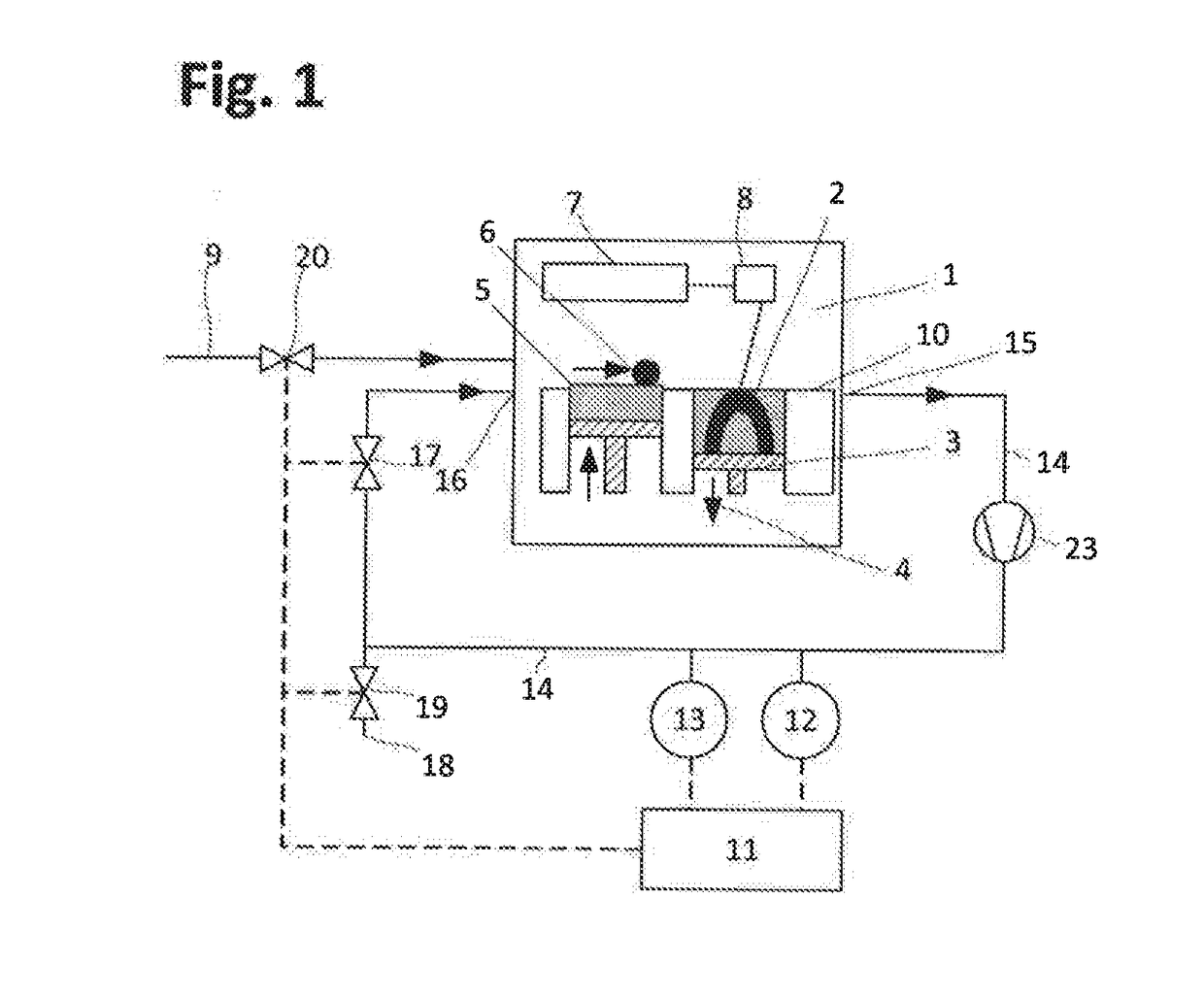

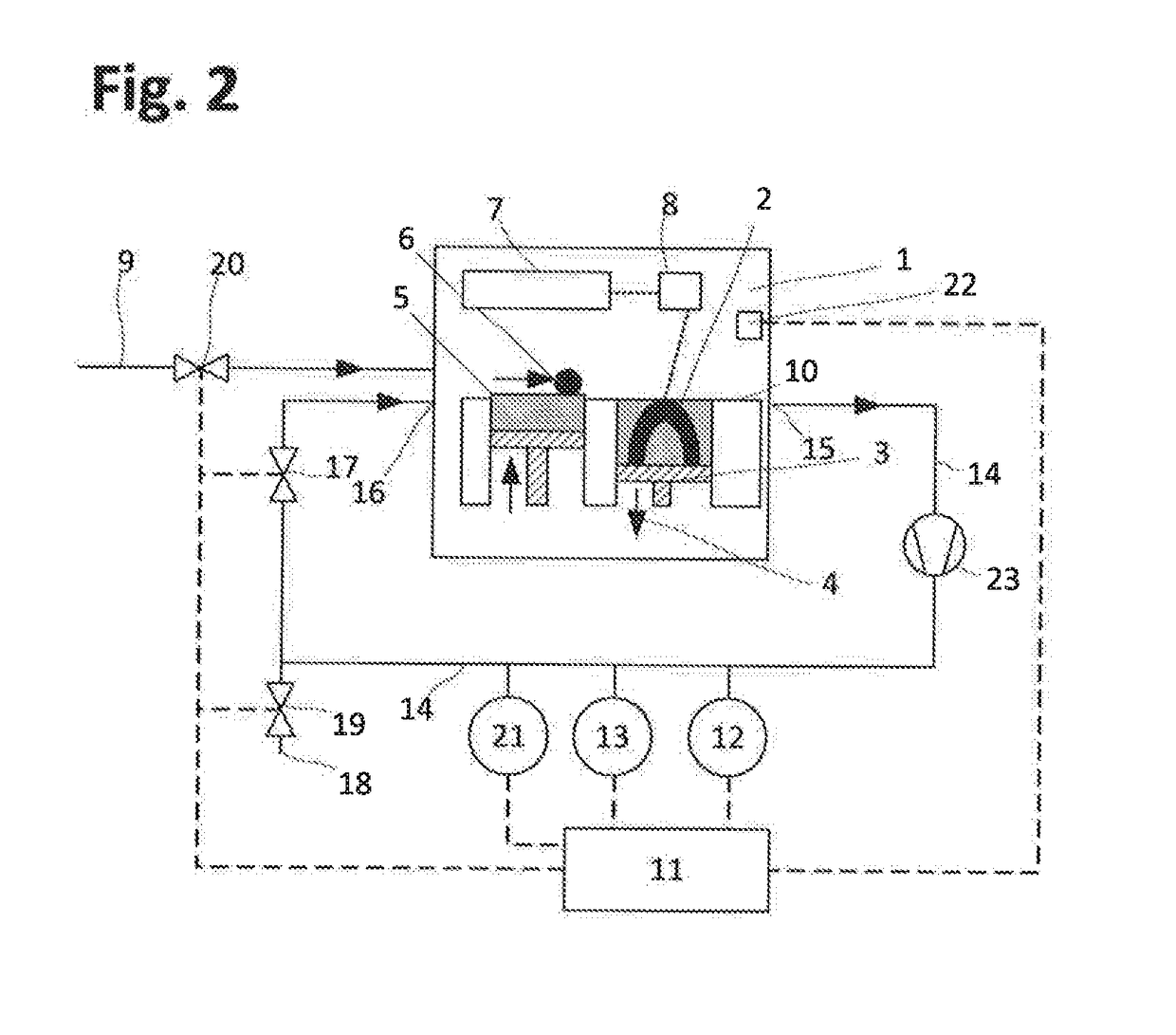

Method and apparatus for treating substrates in a rotary installation

ActiveUS7811384B2Stable process parametersImprove throughputCellsLiquid surface applicatorsEngineeringMechanical engineering

The invention relates to a method and an apparatus for the treatment of substrates, in particular for the coating of plastic containers on a rotary installation. A plurality of treatment devices are arranged on the rotor and pass through a plurality of process phases as a function of their angle position on the rotor. For at least one process phase, the angle position can be set variably as a function of the current rotational speed of the rotor.

Owner:SCHOTT AG

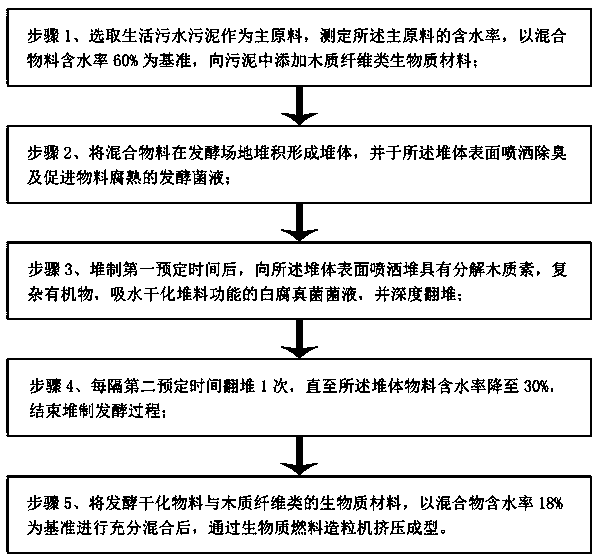

Manufacturing method of sludge biomass compact briquette fuel

InactiveCN103805304AThe pre-processing process is simpleAvoid the pitfalls of large fluctuations in moisture contentBiofuelsSolid fuelsFiberEnvironmental resistance

The invention provides a manufacturing method of a sludge biomass compact briquette fuel. The traditional method has different weaknesses. The manufacturing method comprises the following steps: selecting the domestic sewage sludge as a main raw material; stacking the mixed material on a fermentation field to form a stack body, and spraying a deodorized fermentative bacteria liquid capable of promoting the rotting of the material on the surface of the stack body; spraying white-rot fungi liquid containing decomposed lignin and composite organism and having a function for absorbing the water and drying the stacked material on the surface of the stack body after the stack body is stacked for a first predetermined time, and deeply turning the stack body; turning the stack body one time every a second predetermined time until the moisture content of the stack body material is reduced to 30 percent, and ending the stacking fermentation process; adequately mixing the fermented dry material and the wood fiber biomass material by adopting the water content of the mixture of 18 percent as a benchmark, and extruding and forming the mixture. The method is simpler to operate, the technological parameters are stable and easy to control, the energy consumption is greatly reduced, no non-biomass additive is added, and the product is cleaner and more environment-friendly.

Owner:汪兴华

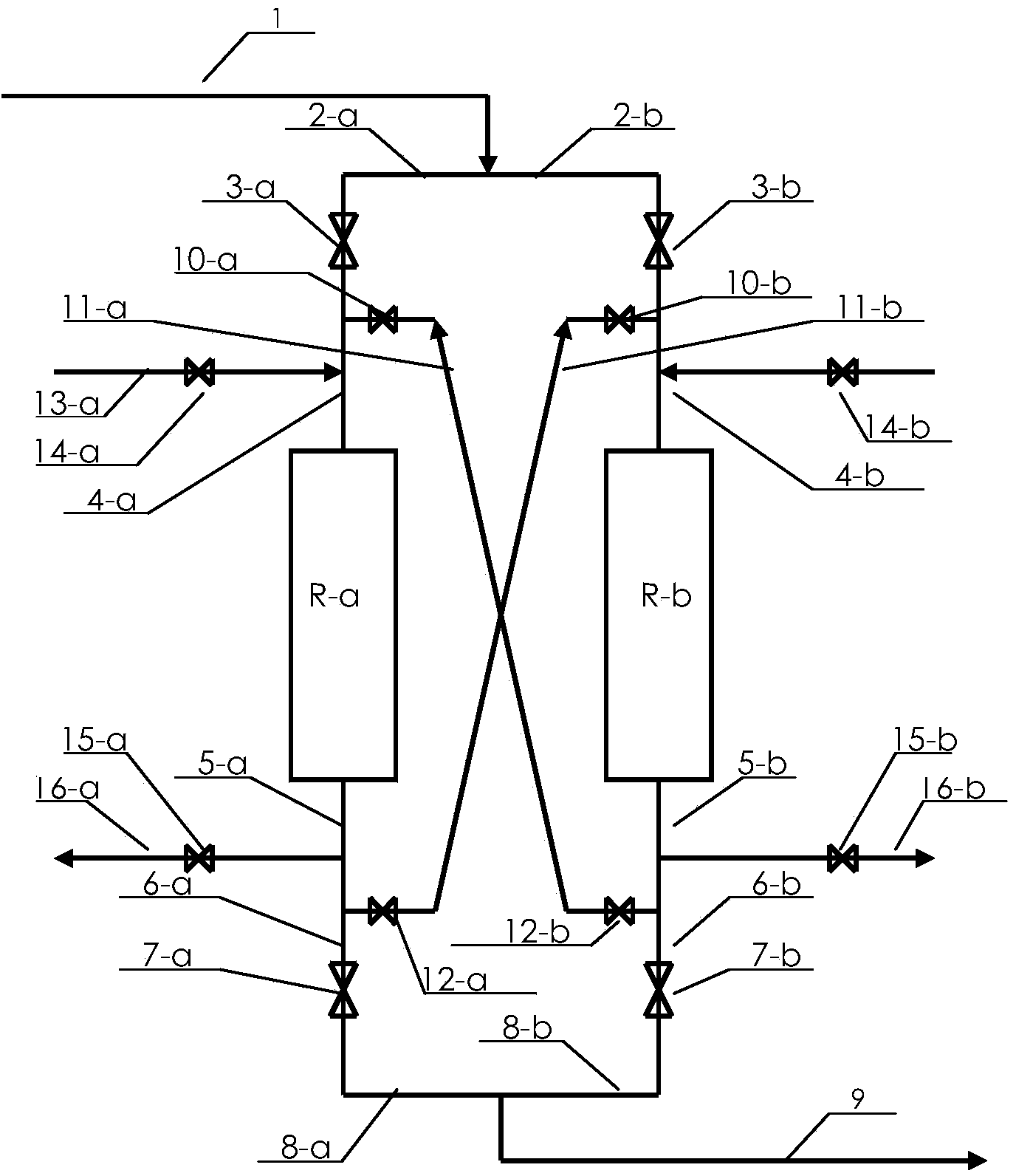

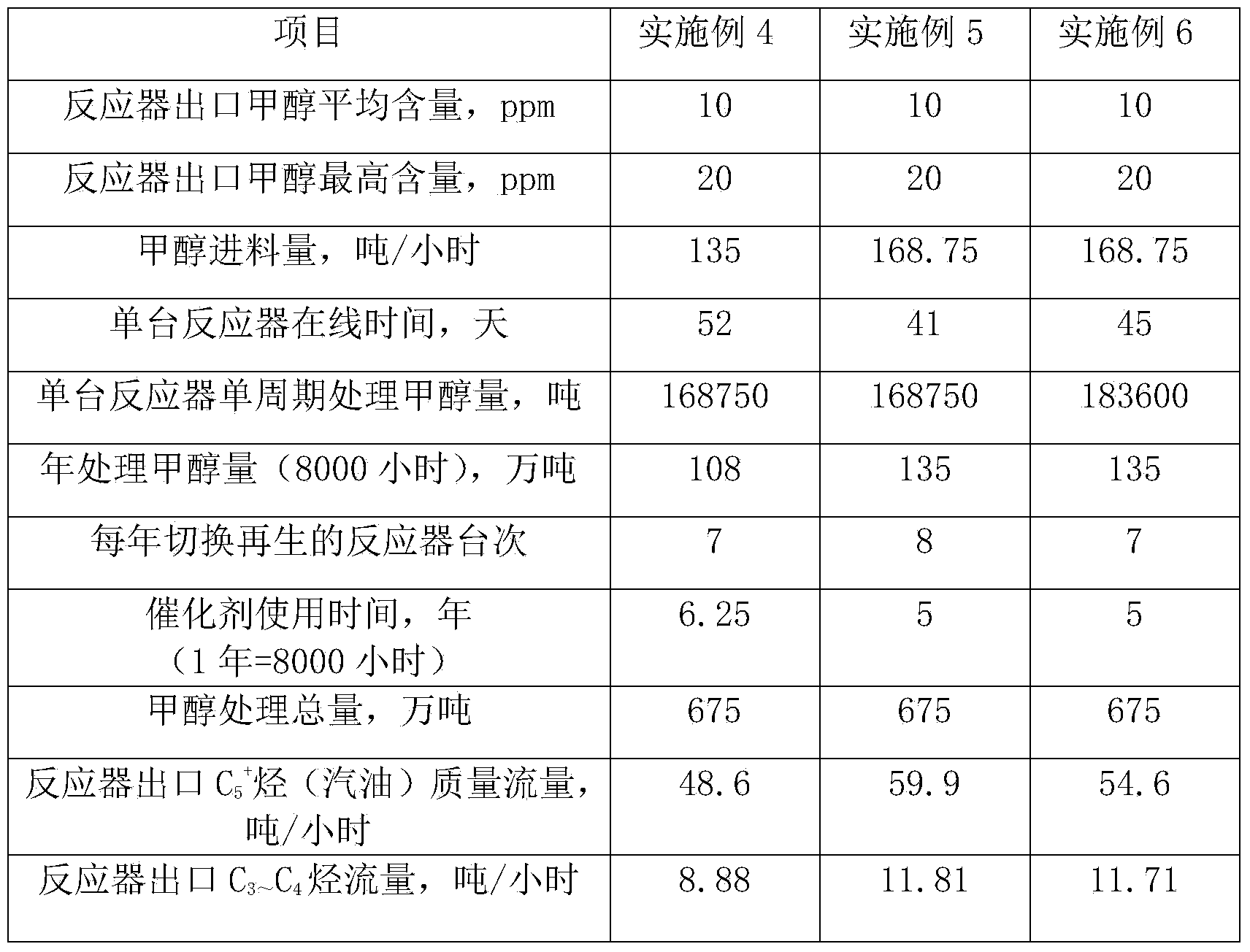

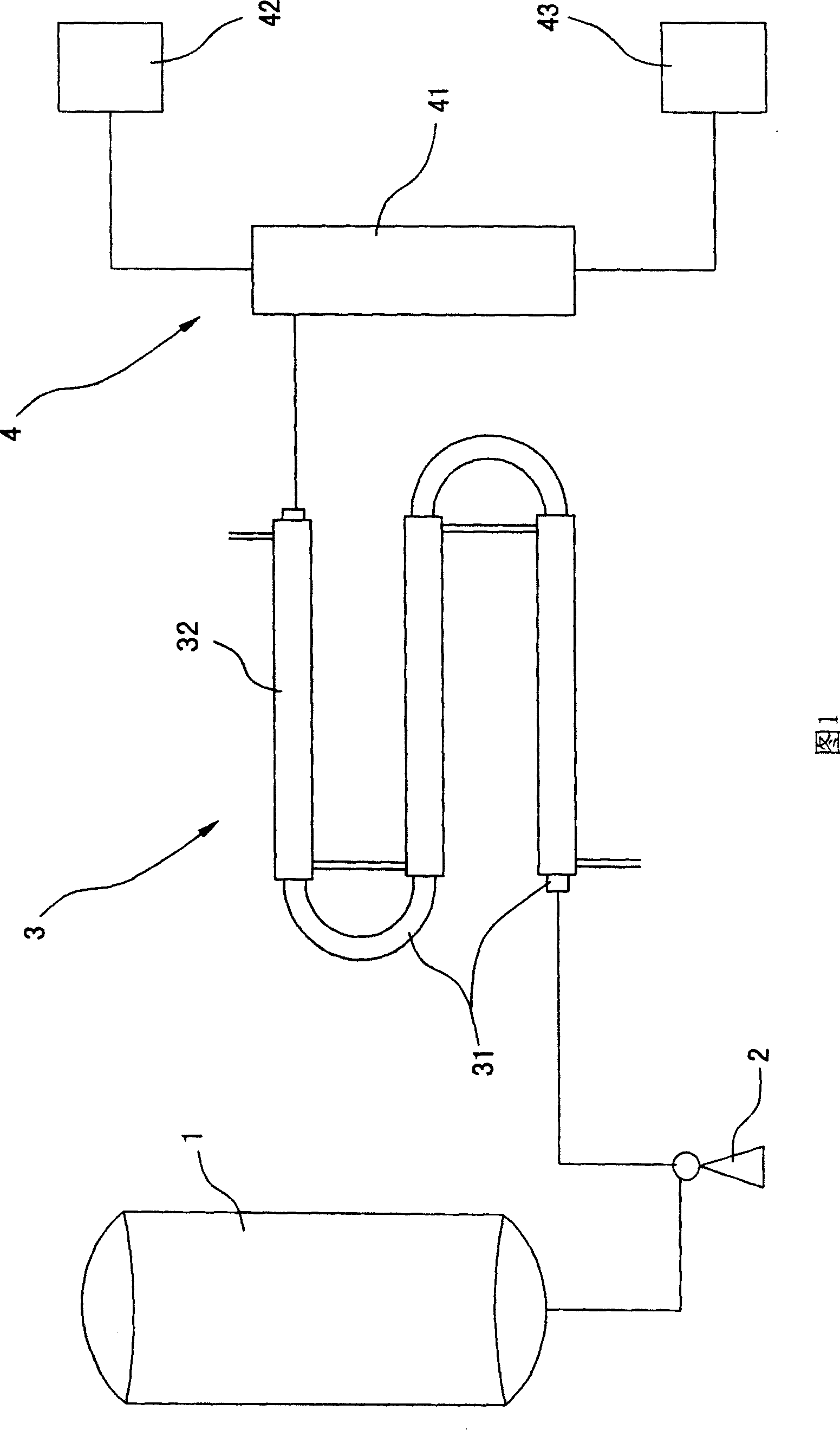

Continuous reaction and regeneration technology used for conversion of methanol to gasoline through stationary bed adiabatic reactors

ActiveCN104140839AImprove effective utilizationIncreased operating lifeLiquid hydrocarbon mixture productionBio-feedstockGasolineResidual activity

Provided is a continuous reaction and regeneration technology used for conversion of methanol to gasoline through stationary bed adiabatic reactors. The two stationary bed adiabatic reactors work independently, the first reactor carries out a reaction for conversion of methanol to gasoline independently, and the second reactor is in a standby state; when catalysts in the first reactor approach to inactivation, the two reactors can work in a series connection mode through valve switchover until residual activity of the catalysts in the first reactor is fully utilized; the two reactors are made to work in a respective independent mode through valve switchover, the second reactor completes the reaction for conversion of methanol to gasoline independently, and the first reactor finishes catalyst regeneration operation independently and gets into the standby state. The technology is repeated in that way. The technology has the advantages that operation is simple, and the utilization rate of reactivity of the catalysts in the reaction process is high.

Owner:SHANXI FEISHI TECH +2

Low-pressure casting method and device thereof

InactiveCN102962430AIncrease productivityRealize continuous productionControl systemDegrees of freedom

The invention relates to the technical field of casting and discloses a low-pressure casting method and a low-pressure casting device. The low-pressure casting method comprises the following steps: feeding, pressurizing, lifting liquid, keeping pressure, solidifying, decompressing and taking a mould. The low-pressure casting device comprises a temperature keeping chamber, a mould, a pressurizing chamber, a liquid lifting chamber, a plug rod, a liquid level pressurizing control system and a liquid level sensor, wherein the plug rod is used for controlling a feeding channel to open and close. The low-pressure casting method and device provided by the invention have the following advantages: the production efficiency is greatly increased; the continuous production is realized; the casting parameter is stable; the metal liquid level at each time of pouring is kept constant, so that the fluctuation of the pressurized pressure is small and athe control system is simplified; the quality of the metal liquid level is stable; and the degree of freedom of the technology is increased.

Owner:GUANGDONG HONGTAI TECH HLDG +1

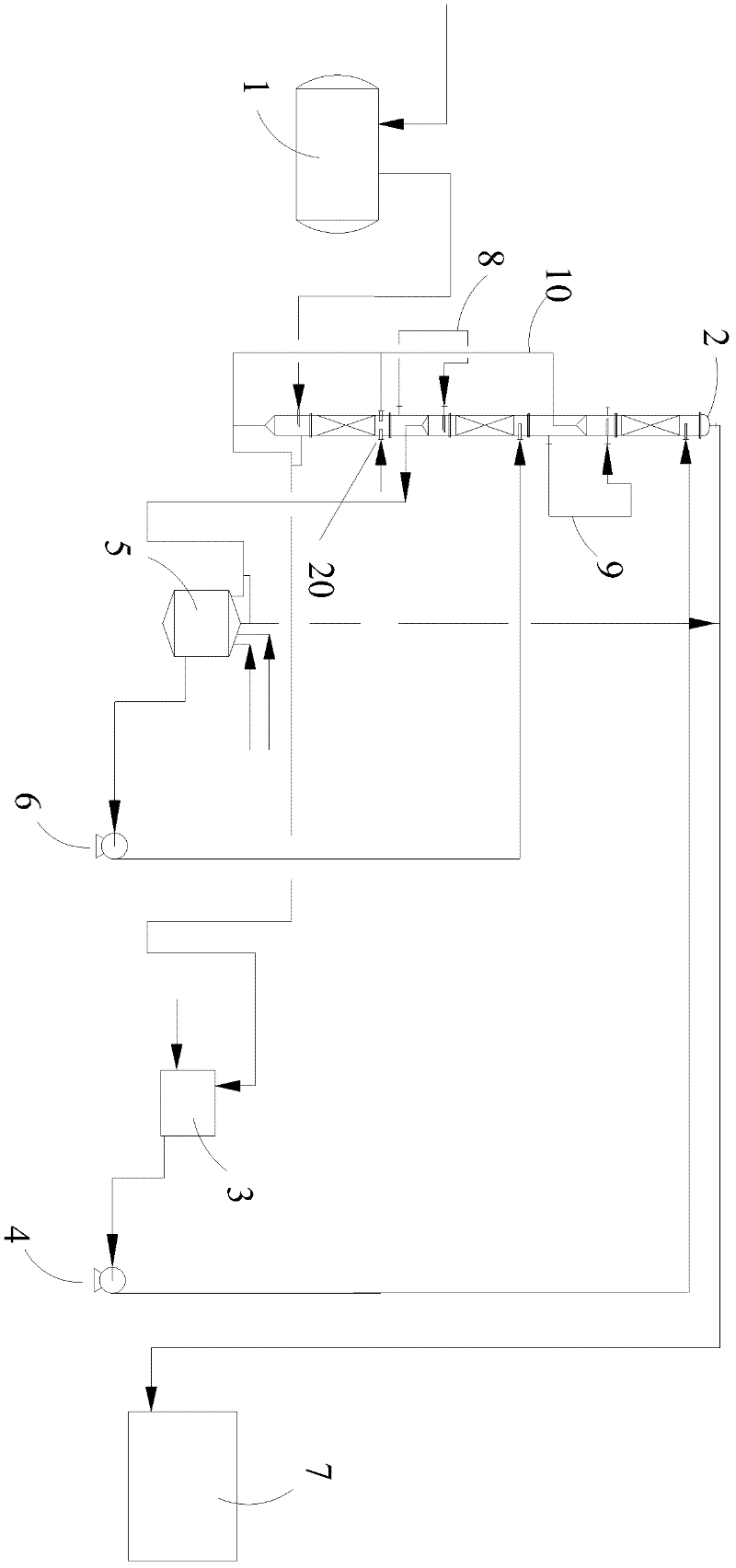

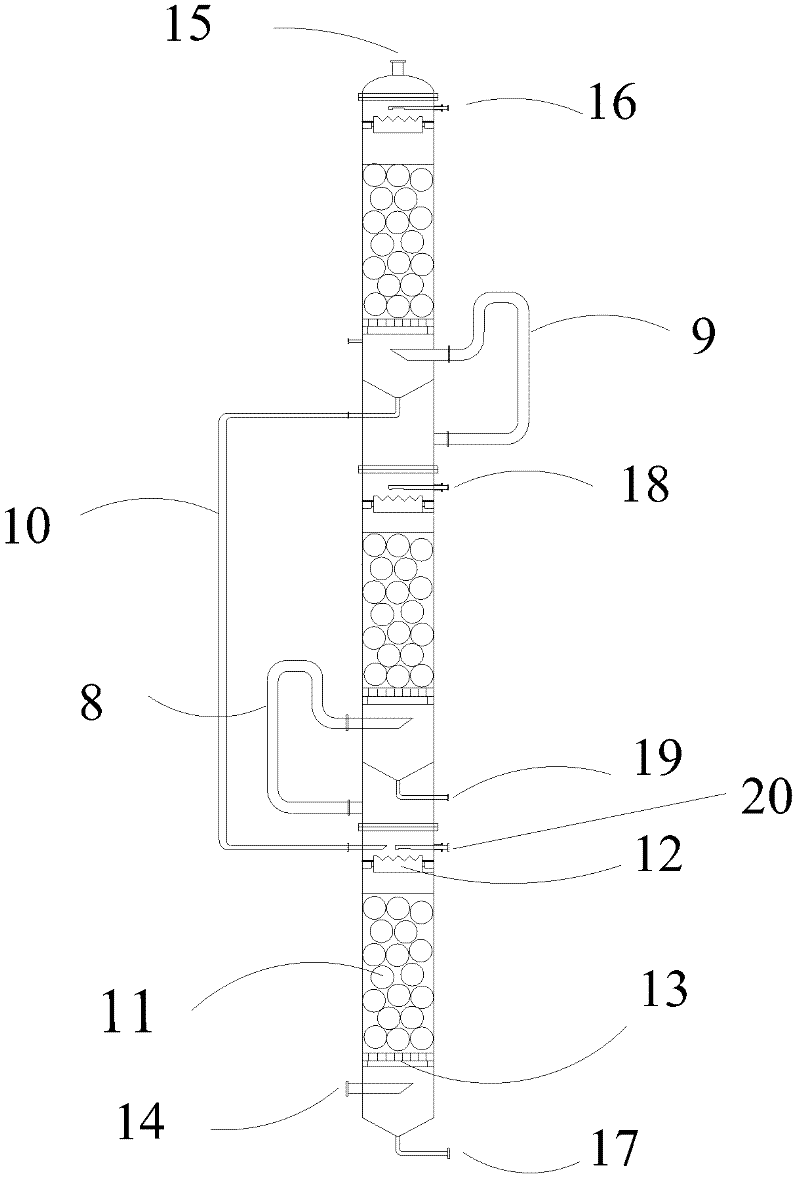

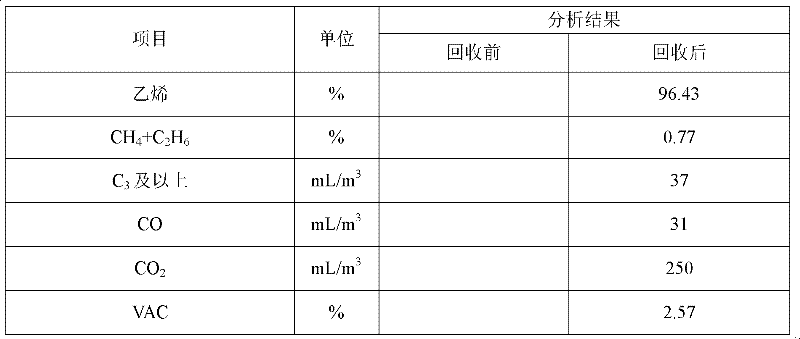

Method for recycling ethylene gas from tail gas and water alkaline washing tower thereof

ActiveCN102527215AEfficient removalIncrease contentOrganic chemistryDispersed particle separationBuffer tankEnvironmental engineering

The invention discloses a method for recycling ethylene gas from tail gas. The tail gas from a buffer tank (1) enters the lower section through a gas inlet (14); after finishing exchange and absorption with water, the tail gas enters the middle section through a bypass gas pipe (8); after finishing exchange and absorption with an alkaline liquid with concentration of 1-3% at the middle section, the tail gas enters the upper section through a bypass gas pipe (9) to perform exchange and absorption with water again; after being purified, the tail gas is delivered to a gas cabinet (7) through a gas outlet (15); the water from a water circulation tank (3) enters the upper section through a water inlet (16); after finishing exchange and absorption, the water enters the lower section through a bypass water pipe (10); after finishing exchange and absorption, the water returns to the water circulation tank (3) through a water outlet (17); the alkaline liquid with concentration of 1-3% from an alkaline liquid circulation tank (5) enters the middle section from an alkaline liquid inlet (18); and after finishing exchange and absorption, the alkaline liquid returns to the alkaline liquid circulation tank (5) through an alkaline liquid outlet (19). Through the method, the content of ethylene gas can be increased from 89.5% to 96.43%, and the content of VAC can be decreased from 9.49% to 2.57%.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD +1

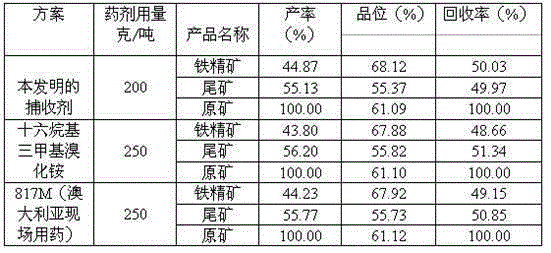

Compound type quaternary ammonium salt cation silicate mineral collecting agent and preparation method thereof

ActiveCN105396698AHigh selectivityPromote environmental protectionFlotationBenzoyl bromideActive agent

The invention discloses a compound type quaternary ammonium salt cation silicate mineral collecting agent and a preparation method thereof. According to the technology, the method comprises the following steps that 1, any one of alkyl tertiary amine containing carbon 14 to carbon 17 reacts with benzyl chloride or benzyl bromide accounting for, by mass, 45%-55% of the alkyl tertiary amine for 90-150 min under the condition of 90 DEG C-100 DEG C, then is cooled to 40 DEG C-50 DEG C and becomes to light yellow paste; 2, fatty alcohol-polyoxyethylene ether nonionic surfactant containing, by mass, 3%-8% of the alkyl tertiary amine is added; and 3, diesel oil accounting for, by mass, 2%-5% of the alkyl tertiary amine is added and uniformly stirred for 5-20 min at the temperature of 35 DEG C-50 DEG C, and the collecting agent is obtained. The compound type quaternary ammonium salt cation silicate mineral collecting agent has high collecting capacity and excellent selectivity on silicate minerals contained in micro-fine particle iron ore, floatation can be conducted normally within the ore pulp temperature of 5 DEG C-40 DEG C, the pH adaptive range of ore pulp is wide, and the floatation can be conducted normally within the pH range of 5-11.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method for producing paper pulp by adopting cotton stalk peel as raw material

InactiveCN101831822APromote degradationEfficient removalPulp beating/refining methodsCellulose material pulpingPectinaseChemical pulp

The invention relates to a method for producing paper pulp by adopting cotton stalk peel as raw material, which adopts an enzyme-ammonium sulfite method. The enzyme-ammonium sulfite method comprises the steps of: firstly, removing pectin of the cotton stalk peel and degrading lignin by using degumming enzyme and then, preparing coarse pulp by an ammonium sulfite boiling step, and finally processing the coarse pulp by a conventional production method to obtain finished product pulp, wherein the degumming enzyme is prepared by compounding pectinase, laccase and lignin enzyme in the weight ratio of 1-3:1:1, and a degumming enzym solution is prepared by compounding the degumming enzyme, urea and water in the weight ratio of 5:5:1000-15:15:1000; the cotton stalk peel is soaked in the sealed degumming enzyme solution for 24-48 hours in the static state at the temperature of 20-30 DEG C. The weight ratio of the ammonium sulfite to the oven dry cotton stalk peel in a boiling solution is 10-13 percent, and the pH value of the boiling solution is 7-9. In the invention, the pectinase is added in the degumming enzyme, which effectively remove pectic substances and solves the problem that subsequent processing is influenced by the existence of the pectin and industrialized production can not be realized. The invention can produce the paper pulp meeting standards. Compared with the traditional chemical pulp producing method, the invention has the advantages of high pulp yield, energy saving, cost reduction and recycled black liquor.

Owner:凌受明

Method for the generative manufacture of a 3-dimensional component

ActiveUS20180117675A1Short reaction timeEliminate disadvantagesAdditive manufacturing apparatusGas treatmentOxygen sensorHydrogen content

A method and apparatus for the generative manufacture of a three-dimensional component in a processing chamber, in which the steps “providing a metallic starting material in the processing chamber” and “melting the starting material by means of energy input” are repeated multiple times, wherein a process gas is provided in the processing chamber are disclosed. The method is characterized by the steps: 1) the hydrogen content of the process gas or a sample of the process gas is determined; 2) the oxygen content of the process gas or a sample of the process gas is determined by means of an oxygen sensor and / or the dew point of the process gas or a sample of the process gas is determined; and 3) the values for the oxygen content and / or the dew point determined in step 2 are corrected by means of the value for the hydrogen content determined in step 1.

Owner:MESSER IND USA INC

Preparation method for micro-fine particle iron ore reverse flotation collector

The invention discloses a preparation method for a micro-fine particle iron ore reverse flotation collector. The adopted process steps include that any one of alkyl tertiary amine containing carbon 14 to carbon 18 reacts with benzyl chloride or benzyl bromide accounting for 45%-55% of the mass of the alkyl tertiary amine for 90-150 min under the condition of 90-100 DEG C, cooling is performed till the temperature is 40-50 DEG C, and the alkyl tertiary amine is made to become light-yellow paste; a fatty alcohol polyoxyethylene ether non-ionic surface active agent accounting for 2%-10% of the mass of the alkyl tertiary amine is added in; and finally, diesel oil accounting for 2%-5% of the mass of the alkyl tertiary amine is added in, uniform stirring is performed under the temperature of 35-50 DEG C, cooling is performed till room temperature is achieved, and the collector is obtained. The collector has high collecting force and excellent selectivity on silicate minerals contained in micro-fine particle iron ore, normal floatation can be performed within the temperature of ore pulp ranging from 5 DEG C to 40 DEG C, the adaptive ore pulp acidity and alkalinity range is wide, and normal flotation can be performed while pH ranges from 5 to 11.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

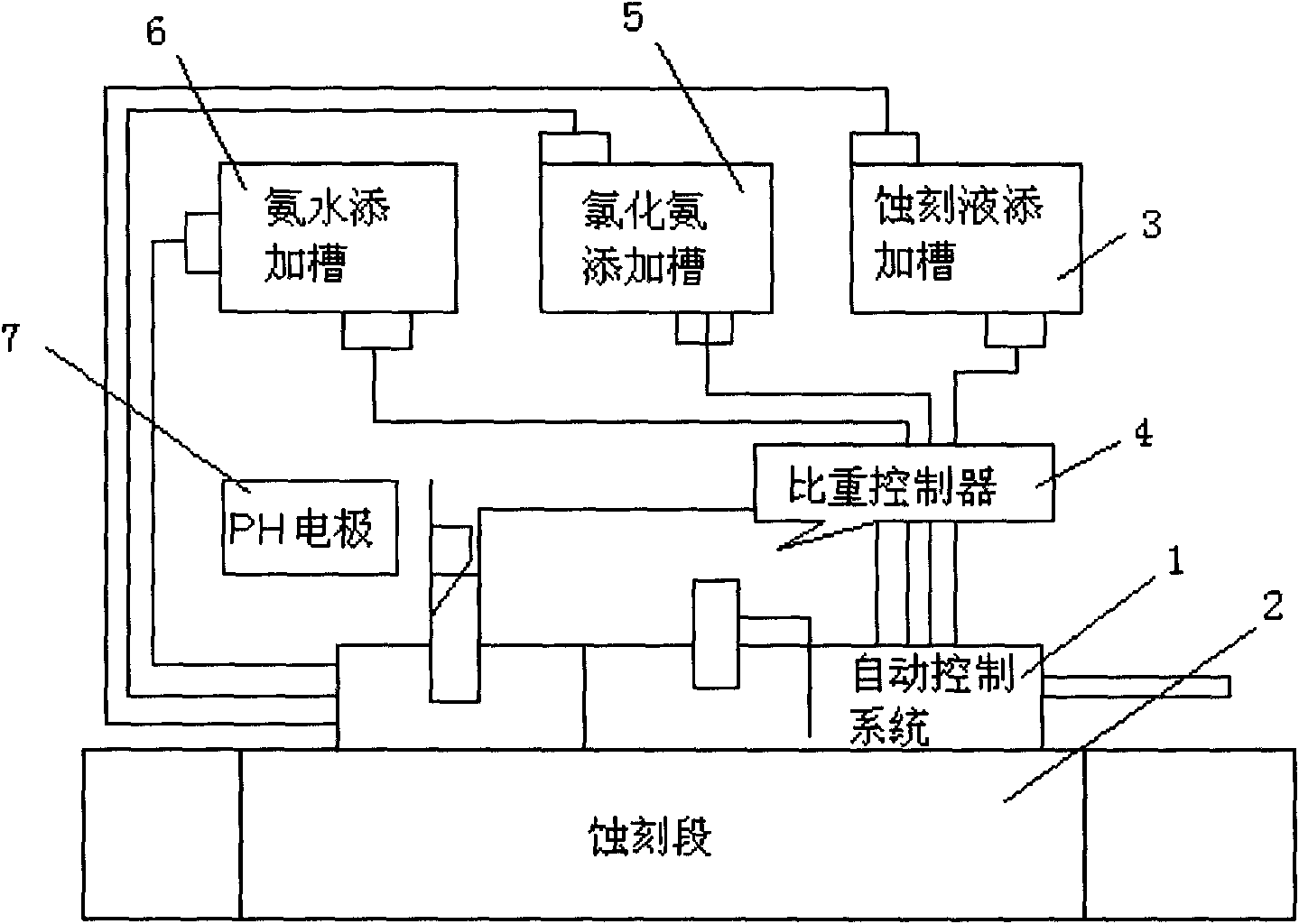

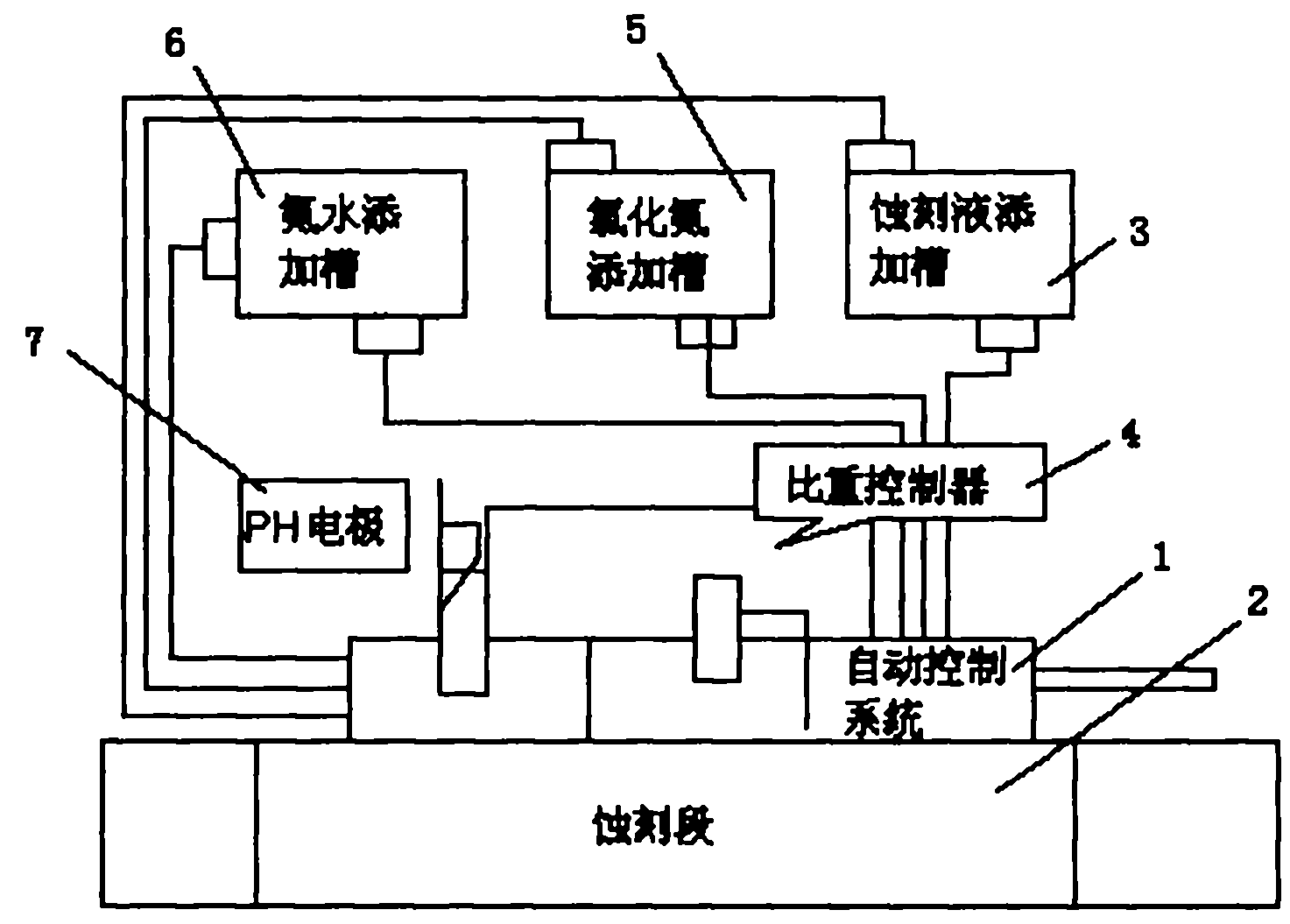

Automatic control system of PH value in alkaline etching and control method thereof

ActiveCN101833341ARealize automatic controlReduce consumptionControlling ratio of multiple fluid flowsChemical variable controlAutomatic controlControl system

The invention discloses a control system of PH value in alkaline etching, relating to a control system of alkaline etching of a printed-circuit board and a control method. The invention aims to solve the problems that the PH value is difficult to control in the alkaline etching and the efficiency is low. The adopted technical scheme is as follows: the automatic control system of PH value in alkaline etching comprises an automatic control system, an etchant addition tank, a specific gravity controller, an ammonia chloride addition tank, and an ammonia water addition tank, wherein the automatic control system is used for controlling the operation of the whole system, the etchant addition tank is used for adding etchant into an etching section, the specific gravity controller is used for detecting and displaying the specific gravity of the solution in the etching section and transmitting the result to the automatic control system, the ammonia chloride addition tank is connected with the etching section and is used for adding the ammonia chloride solution in the etching section, and the ammonia water addition tank is connected with the etching section and is used for adding the ammonia water solution in the etching section. The invention is mainly used for alkaline etching link to adjust the PH value in the producing process of the printed-circuit board.

Owner:CHINA CIRCUIT TECH SICHUAN

Producer and production method for aromatic fluoride compound

InactiveCN100384795CLower requirementEmission reductionHalogenated hydrocarbon preparationFluorideChemistry

Producer and production of aromatic fluorine compound are disclosed. The outlet port on bottom of diazotizing reactive kettle is connected with material transferring pump, outlet of transferring pump is connected to thermal decomposing piping reactor and outlet of piping reactor is communicated with receiver. The production consists of diazotization reaction, thermal decomposition process and separation process. The thermal decomposition process is carried out by transferring material in diazotizing reactive kettle to thermal decomposing reactor and controllable thermal decomposing. It has less consumption and higher production efficiency.

Owner:解卫宇

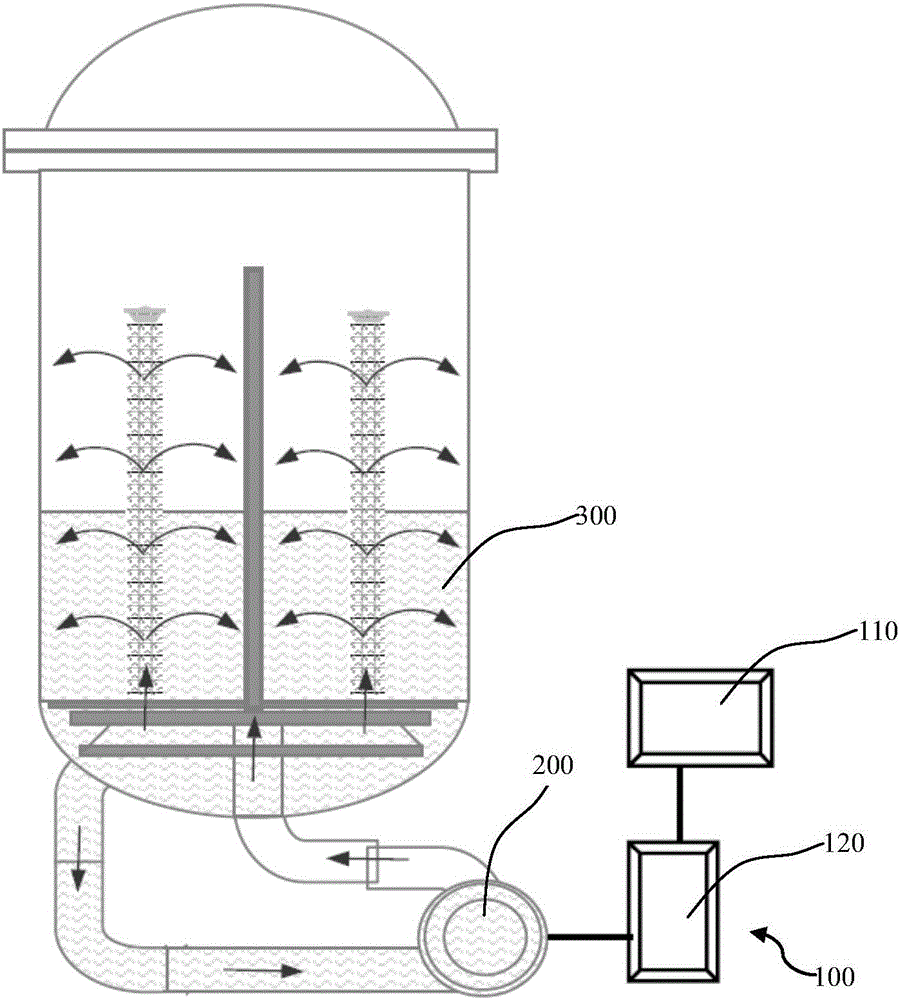

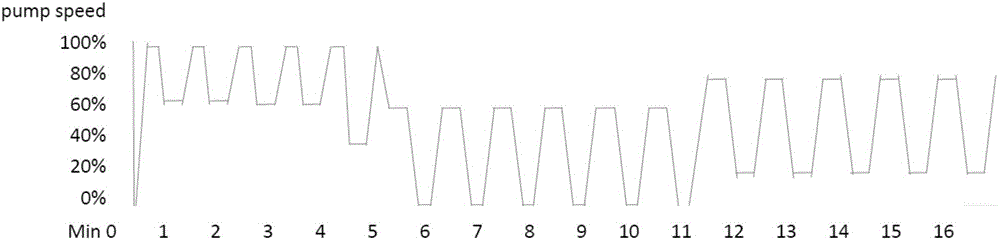

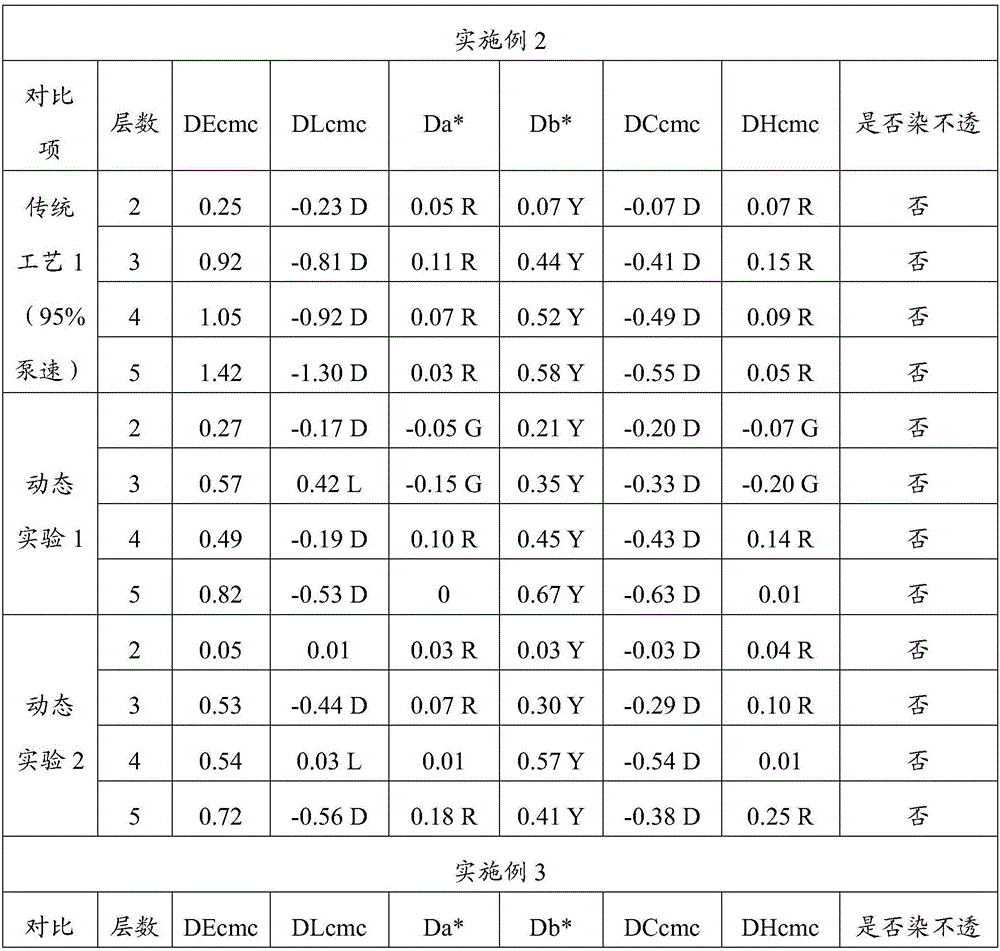

Dynamic dyeing control method of textiles

ActiveCN106757890AFast exchangeAchieve precise adjustmentLiquid/gas/vapor textile treatmentProcess engineeringEnergy source

The invention relates to a dynamic dyeing control method of textiles. The dynamic dyeing control method of the textiles breaks through a concept in a traditional dyeing concept that the effect is better when a pump speed is more rapid; the pump speed of a circulating main pump is pertinently controlled at each process phase or different time periods of each process phase in a dyeing process; the response speed of a dyeing system is adjusted, and the influence degree as great as the influence degree of a chemical preparation is not generated, so that the aim of accurately adjusting is realized. Parameter setting in different phases in a control process of the dyeing process is detailed, and a principle of stable quality, energy saving and consumption reduction is abided; aiming at different order conditions, parameters are formulated pertinently, so that the quality stabilization is facilitated; meanwhile, energy sources are easy to save and the aims of saving energy and reducing consumption are realized.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Multi-band LED UV curing apparatus

InactiveCN104984885ARealize multi-bandExtend your lifePretreated surfacesCoatingsMulti bandUV curing

The invention discloses a multi-band LED UV curing apparatus. The multi-band LED UV curing apparatus includes a three-dimensional copper substrate, a plurality of LED light emitting modules uniformly distributed on the surface of the substrate, a control module for controlling the light emission of the LED light emitting modules, a graphite connecting piece fixed to one side of the substrate, and a heat dissipation unit connected with the substrate through the graphite connecting piece; each LED light emitting module comprises at least two kinds of LED light emitting chips, and the wavelengths of light emitted by different kinds of LED light emitting chips are different; the control module includes a control circuit for controlling the light emission intensity and light emission time of the LED light emitting chips; the heat dissipating unit includes a heat dissipation structure, and a fan assisting the heat dissipation structure to perform heat dissipation; and the surface of the heat dissipation structure is coated with grapheme. The multi-band LED UV curing apparatus of the invention adopted, curing under a single band can be realized independently, and curing under a plurality of bands can be also realized. The multi-band LED UV curing apparatus has the advantages of multiple-purposed performance and high heat dissipation efficiency.

Owner:SUZHOU YULIAN MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com