Moisture chain control method for tobacco shred manufacturing process

A control method and moisture technology, which is applied in the fields of tobacco preparation, tobacco, food science, etc., can solve problems such as unstable flavor absorption quality of shredded leaves, large adjustment range of shredded shredded process parameters, and influence on rolling, so as to improve the stability of moisture control performance, improve quality control capabilities, and ensure the effect of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Let's take this brand as an example, which requires the moisture content of mixed silk to be 12.5±0.5%. The cylinder wall temperature is 155±5°C.

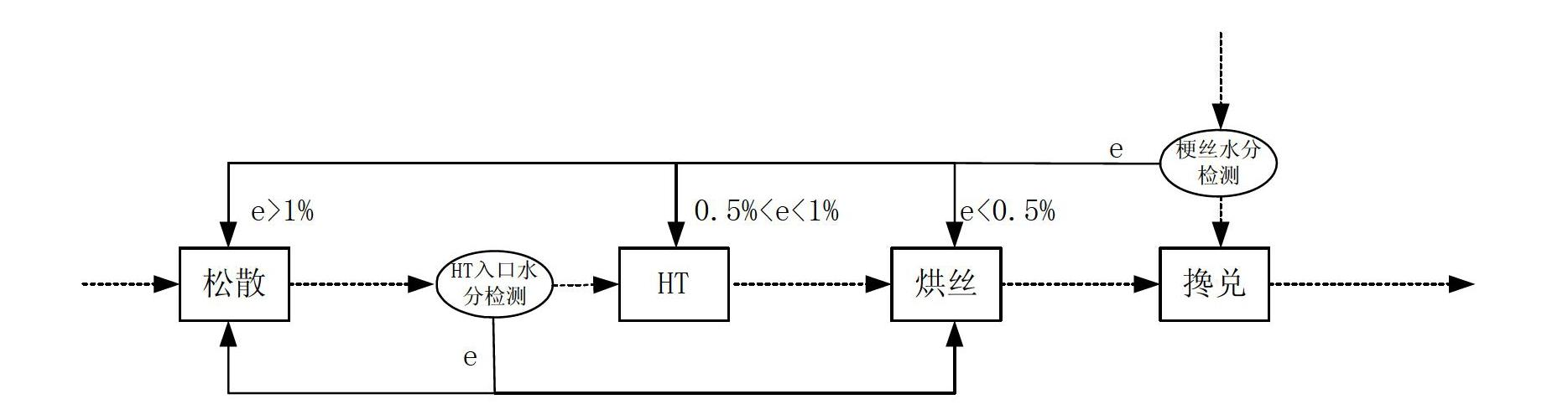

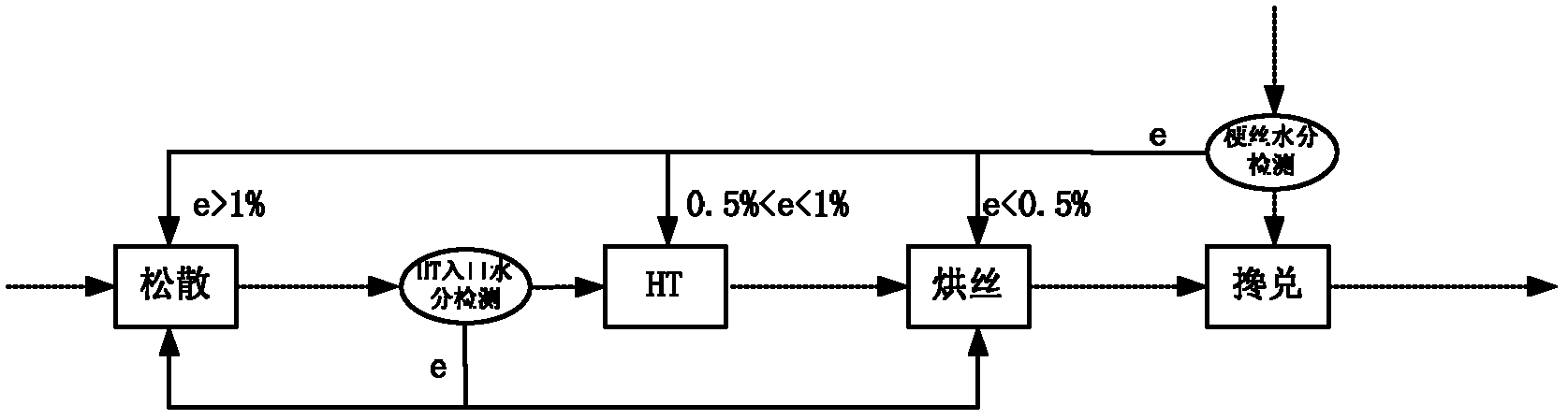

[0025] a. The adjustment method based on the fluctuation of the moisture content of blended shredded stems:

[0026] Adjustment purpose: to eliminate the influence of the moisture fluctuation of cut stems on the moisture of mixed silk, and at the same time reduce the temperature fluctuation of the drying cylinder wall.

[0027] Increase the moisture detection of cut stems before blending, and detect the moisture of cut stems before blending in real time to obtain the deviation Δw2 between the moisture of blended cut stems and the standard center value of cut stem moisture. When the moisture of cut stems deviates, the feedback adjustment is as follows:

[0028] ①When Δw2=0.3, Δw2≤±0.5:

[0029] Calculate the moisture adjustment amount Δw1 at the silk drying outlet, Δw1=-a*Δw2=-0.105 (a==0.35 for a certain brand, the same b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com