Liquid-phase hydrogenation feed preheating system and process

A liquid-phase hydrogenation and liquid-phase technology, which is used in the liquid-phase hydrogenation feed preheating system and the liquid-phase hydrogenation feed preheating field, can solve the problem of product coking in the tube, furnace tube scaling, harsh feeding conditions, etc. problems, to achieve the effect of reducing coking and scaling, ensuring recycling, and small temperature differential pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

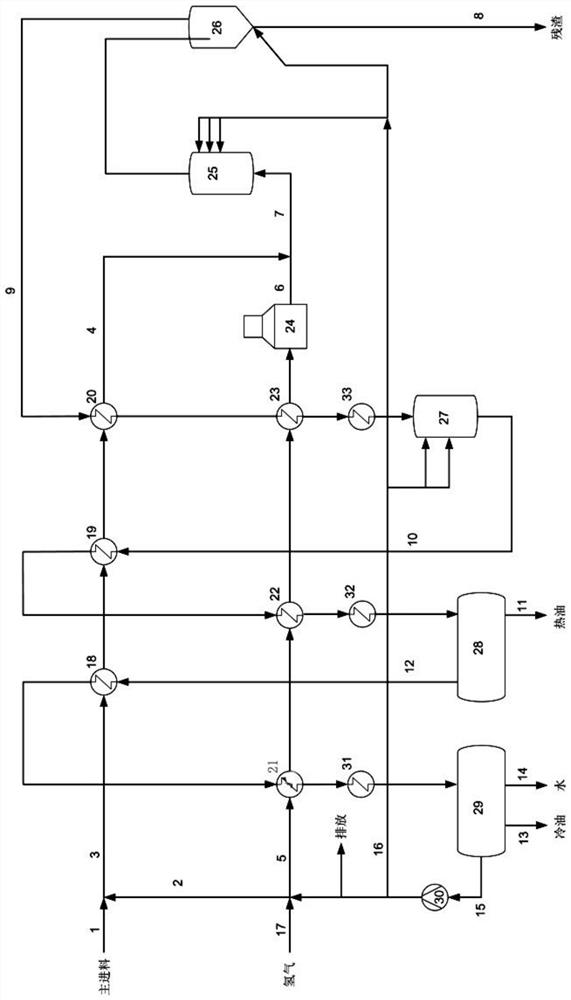

Method used

Image

Examples

Embodiment 1

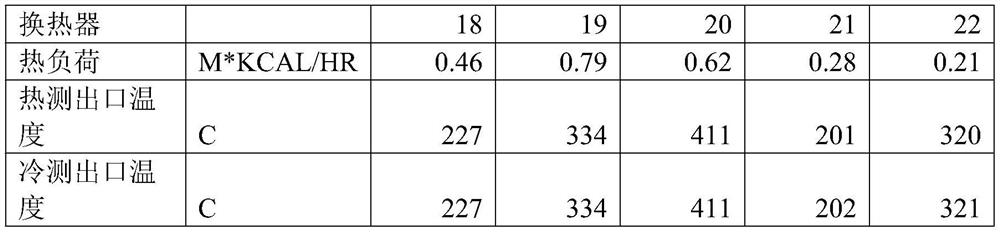

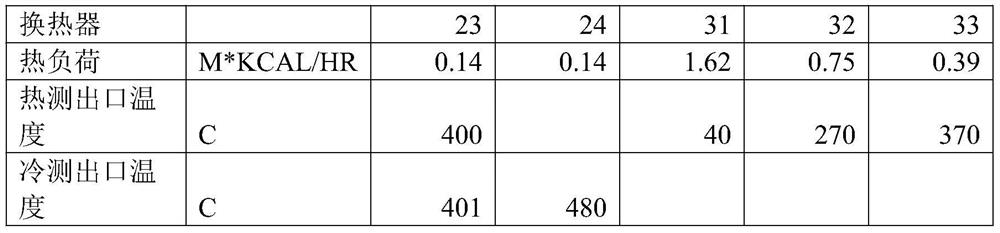

[0035] Choose the vacuum residue of Arabian light crude oil as raw material, mix 1wt% solid additive / catalyst, the hydrogen-oil ratio at the inlet of the liquid phase reactor is 750 Nm / ton of oil, the operating temperature of the liquid phase reactor is 470°C, and the gas phase reactor is operated The temperature is 370-390°C, the operating temperature of the hot high fraction of the liquid phase reactor is 460°C, the operating temperature of the second hot separator is 270°C, and the operating temperature of the cold separator is 40°C. The process parameters are shown in Table 1.

[0036] Table 1 process parameter list

[0037] logistics 1 2 3 4 5 6 temperature C 180 40 157 411 40 480 pressure BARG 210.0 210.0 210.0 208.5 210.0 207.5 flow KG / HR 10100 202 10302 10302 722 722

[0038] logistics 7 8 9 10 11 12 temperature C 423 460 460 390 270 270 pressure BARG 207.5 206.0 206.0 ...

Embodiment 2

[0043] Select the vacuum residue of Arabian light crude oil as raw material, mix 1wt% solid additive / catalyst, the hydrogen-oil ratio at the inlet of the liquid phase reactor is 750 Nm / ton of oil, the operating temperature of the liquid phase reactor is 450°C, and the gas phase reactor is operated The temperature is 360-380°C, the operating temperature of the hot high fraction of the suspended bed is 460°C, the operating temperature of the second hot separator is 270°C, and the operating temperature of the cold separator is 40°C. The process parameters are shown in Table 2.

[0044] Table 2 process parameter list

[0045] logistics 1 2 3 4 5 6 temperature C 180 40 157 396 40 510 pressure BARG 210.0 210.0 210.0 208.5 210.0 207.5 flow KG / HR 10100 202 10302 10302 722 722

[0046] logistics 7 8 9 10 11 12 temperature C 416 440 440 380 270 270 pressure BARG 207.5 206.0 206.0 205.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com