Heavy oil hydrogenation modifying method

A heavy oil upgrading and heavy oil technology, which is applied in the fields of hydrocarbon oil cracking and petroleum industry, can solve the problem of high coking rate, achieve the effects of reducing coking rate, restoring hydrogen supply capacity, and reducing coking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

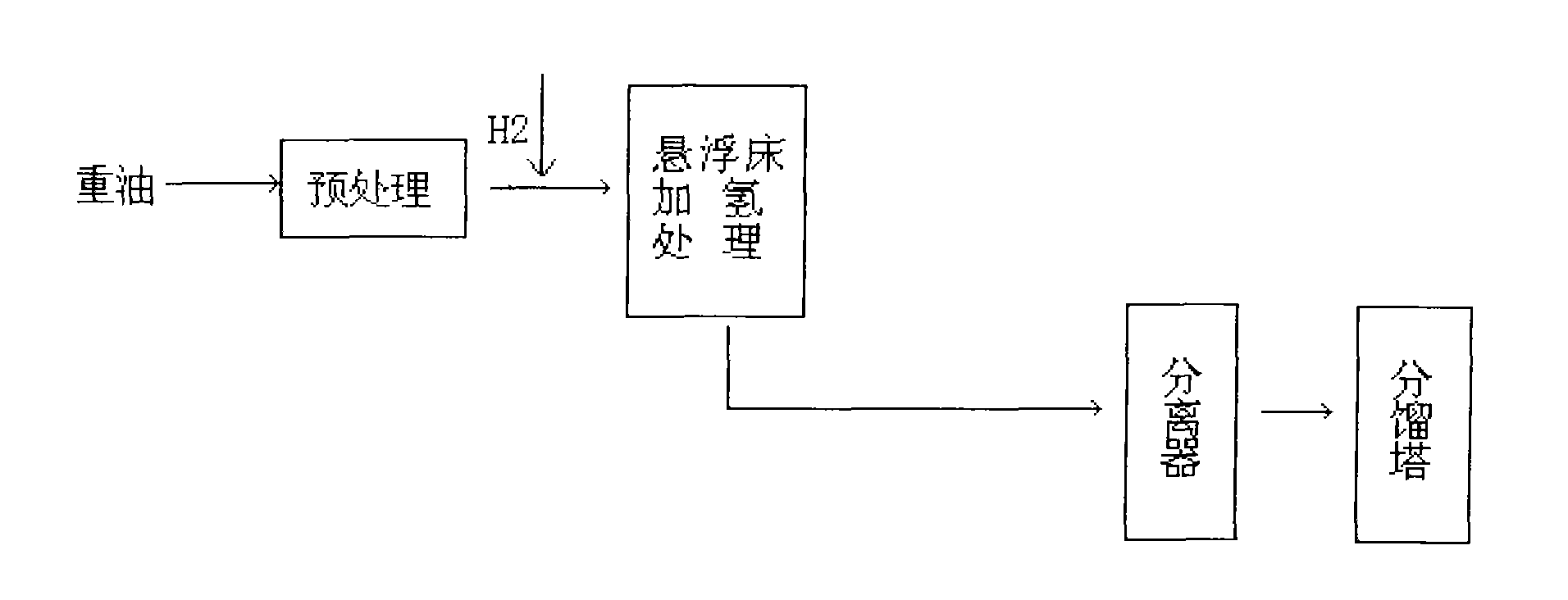

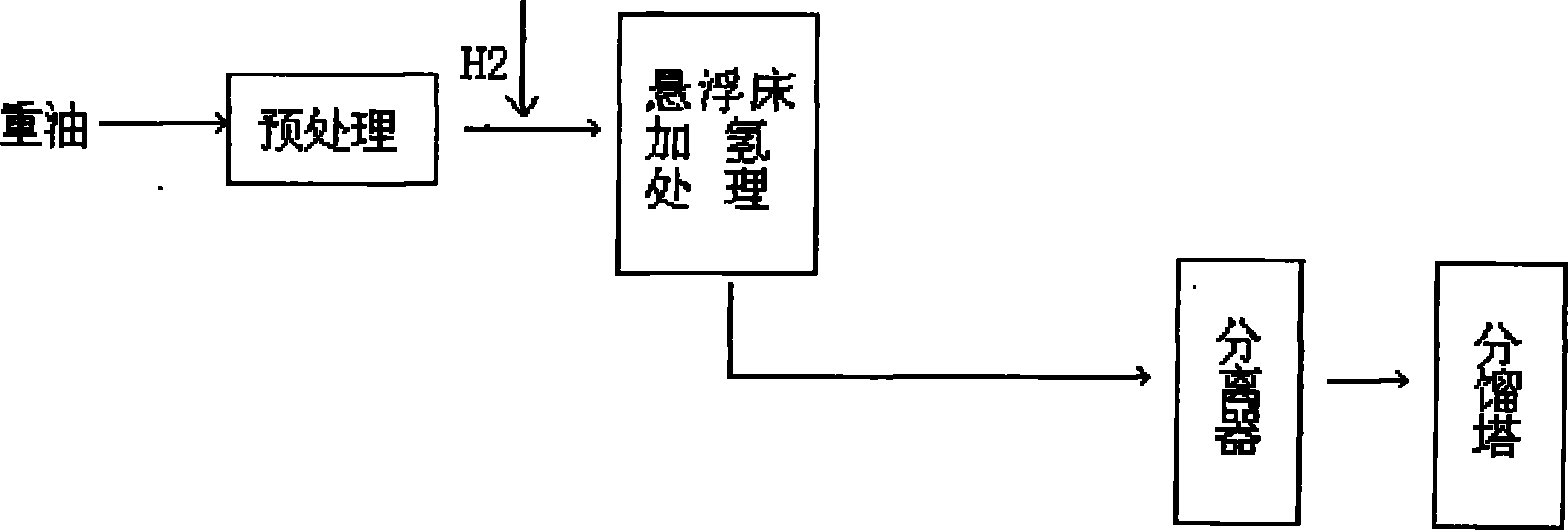

Image

Examples

Embodiment -1

[0028] After the Tahe residual oil is treated with the same filtration as the conventional process, add 200 μg / m water-soluble or oil-soluble multi-metal catalyst (using Ni-containing salt and Mo-containing salt as raw materials, the atomic ratio of the two metals is 1:3) solution , and mixed with the supercritical hydrogen-donating solvent tetrahydronaphthalene (tetralin accounts for 2% of the residual oil raw material) for suspension bed hydrocracking, the conditions are conventional process operating conditions, temperature: 390 ° C, pressure 15 MPa, space velocity 1.0h -1 , the ratio of hydrogen to oil is 600:1, and the conversion rate of the suspension-bed hydrocracking is 62%. The suspension-bed hydrocracking can operate stably for a long period at this low conversion rate.

[0029] The reacted product enters the separator after being filtered to separate the gas phase and the liquid phase, and the liquid phase enters the fractionation tower. A fractionation column sepa...

Embodiment -2

[0031] Using Tahe residual oil as raw material, the suspension bed hydrocracking steps are the same as in Example-1, the reaction temperature is controlled at 405°C, and the conversion rate is 74%. Suspension bed hydrocracking can operate stably for a long period at this conversion rate. However, the supercritical hydrogen-donating solvent is decahydronaphthalene, which accounts for 2% of the heavy oil raw material. After being processed by the method of the present invention, the reaction results are shown in Table 2.

Embodiment -3

[0033] By the same method as in Example 2, water was added while using decahydronaphthalene, and water accounted for 2% of the heavy oil raw material. The reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com