Catalytic cracker with internal tubular settler

A catalytic cracking unit and settler technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problem that it is difficult to quickly separate oil and gas from catalyst and quickly extract oil and gas, affect the long-term operation of the catalytic cracking unit, and unplanned shutdown of the catalytic cracking unit. and other problems, to achieve the effect of eliminating coking coke body retention, avoiding excessive contact time, and eliminating oil and gas retention space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

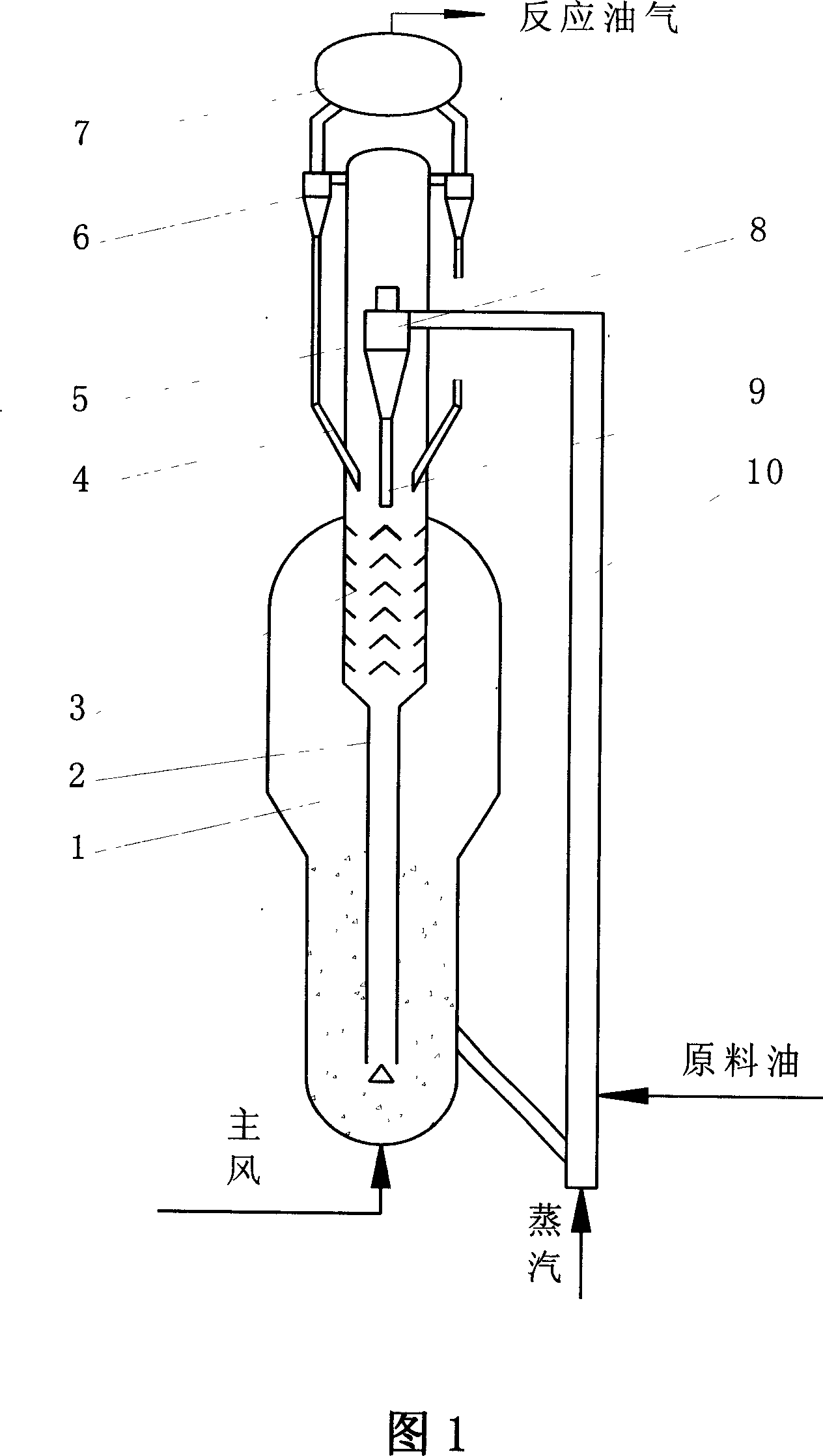

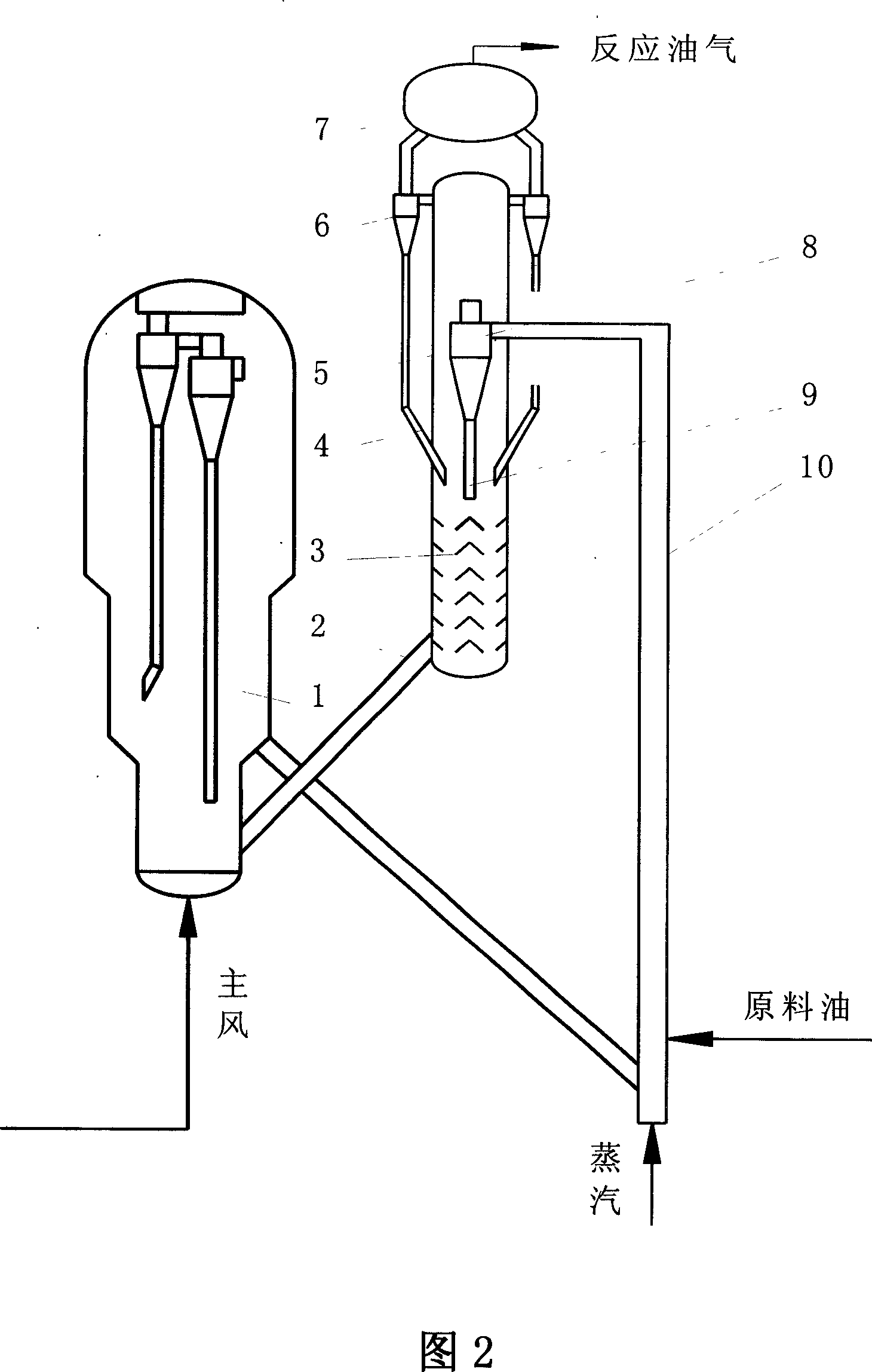

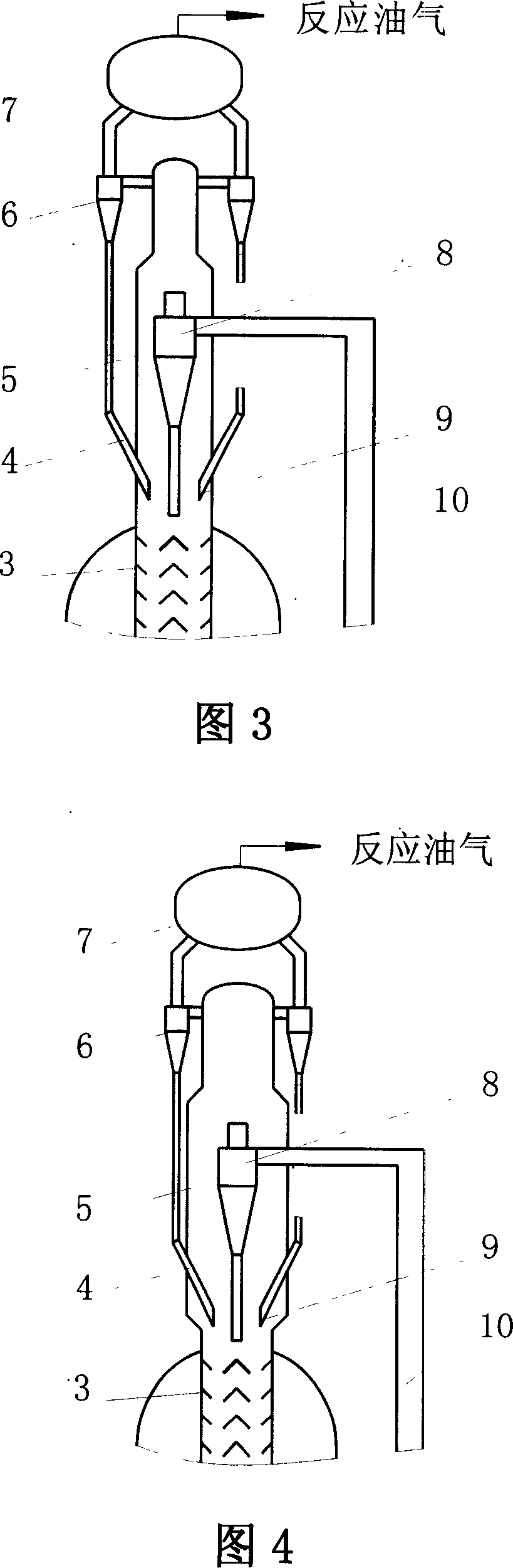

[0042] When using a fluidized catalytic cracking device with a built-in rough cyclone tube-type settler of the present invention, the feedstock oil and recycled oil enter the riser 10, mix with the regenerated catalyst from the regenerator, and have a lifting effect in lifting steam or lifting dry gas Downward and upward mixing flow, while the catalytic cracking reaction occurs. The reaction oil gas and catalyst enter the coarse rotary 8 at the outlet of the riser 10 for a separation. The separated oil gas and the oil gas stripped from the stripper are combined with the steam, and carry a small amount of unseparated fine catalyst particles, and enter the tube settling The upper part of the tank 5 enters the top spin 6 for secondary separation, and the separated oil and gas flow into the gas collection chamber 7 and are quickly drawn out by the oil and gas pipeline to the fractionation tower, where the catalyst separated by the rough spin 8 and the top spin 6 separate The catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com