Preparation method for micro-fine particle iron ore reverse flotation collector

A collector and iron ore technology, applied in flotation, solid separation, etc., can solve the problems of low silicon content in ore, low recovery rate of concentrate, high silicate and phosphorus content, and achieve strong collection capacity , The preparation process is simple, and the effect of environmental protection performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of collector: react tetradecyl tertiary amine with benzyl chloride at 95°C for 2 hours, then cool to 45°C, add fatty alcohol polyoxyethylene ether nonionic surface active agent accounting for 4% of tertiary amine mass Finally, add diesel oil accounting for 3% of the mass of tertiary amine, and stir evenly at 40°C for 10 minutes to obtain the collector of the present invention.

[0022] The test ore sample is a fine-grained magnetite ore in Australia, the raw ore iron grade is 31.82%, the main gangue mineral is quartz, followed by magnesite and orthoclase. The particle size of the magnetite crystal embedding is extremely fine, and the monomer dissociation can only be achieved by finely grinding to P80 25μm. Firstly, the crude concentrate with an iron grade of about 61% is obtained through stage grinding and stage magnetic separation processes. Further grind the coarse concentrate to -0.038mm particle size content of 85% to 95%, the amount of slurry regulator...

Embodiment 2

[0027] Collector preparation: react cetyl tertiary amine and benzyl chloride at 95°C for 2 hours, then cool to 45°C, add fatty alcohol polyoxyethylene ether nonionic surfactant accounting for 4% of tertiary amine mass, Finally, add diesel oil accounting for 3% of the mass of the tertiary amine, and stir evenly at 40°C for 10 minutes to obtain the collector of the present invention.

[0028] Test ore samples and beneficiation process conditions are the same as in Example 1, and the test results are shown in Table 2.

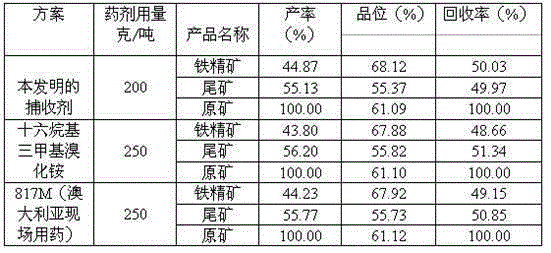

[0029] Table 2 Laboratory test results

[0030]

[0031] The result in table 2 shows, the collector consumption of the present invention is 200 grams / ton, and when other two kinds of comparison agent consumptions are 250 grams / ton, reverse flotation collector developed by the present invention and cetyl trimethyl Compared with ammonium bromide and 817M (applied on site in Australia), the collector of the present invention has significant advantages in terms of...

Embodiment 3

[0033] The collector of the present invention in Example 2 was applied to the extended re-selection test. The expansion continuous selection test does not add how to adjust the agent, only adds the collector of the present invention, through the first rough and second fine open circuit process, obtains relatively excellent flotation index, and the index of the flotation part is shown in Table 3.

[0034] Table 3 Results of extended re-election test

[0035]

[0036] The experimental results in Table 3 also show that the collector of the present invention has excellent selectivity and strong collection capacity for fine-grained iron ore.

[0037] After the above-mentioned reverse flotation foam product is regrinded, the iron ore is further recovered by magnetic separation, and the magnetic separation tailings are used as the final tailings. Under the condition that the iron grade of the original magnetite ore is 31.82%, the beneficiation technical indicators finally obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com