B2 type NiAl-based self-lubricating composite materials and preparing method thereof

A technology of composite materials and mixed powders, which is applied in the field of B2-type NiAl-based self-lubricating composite materials and its preparation, achieving the effects of low price, high density and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

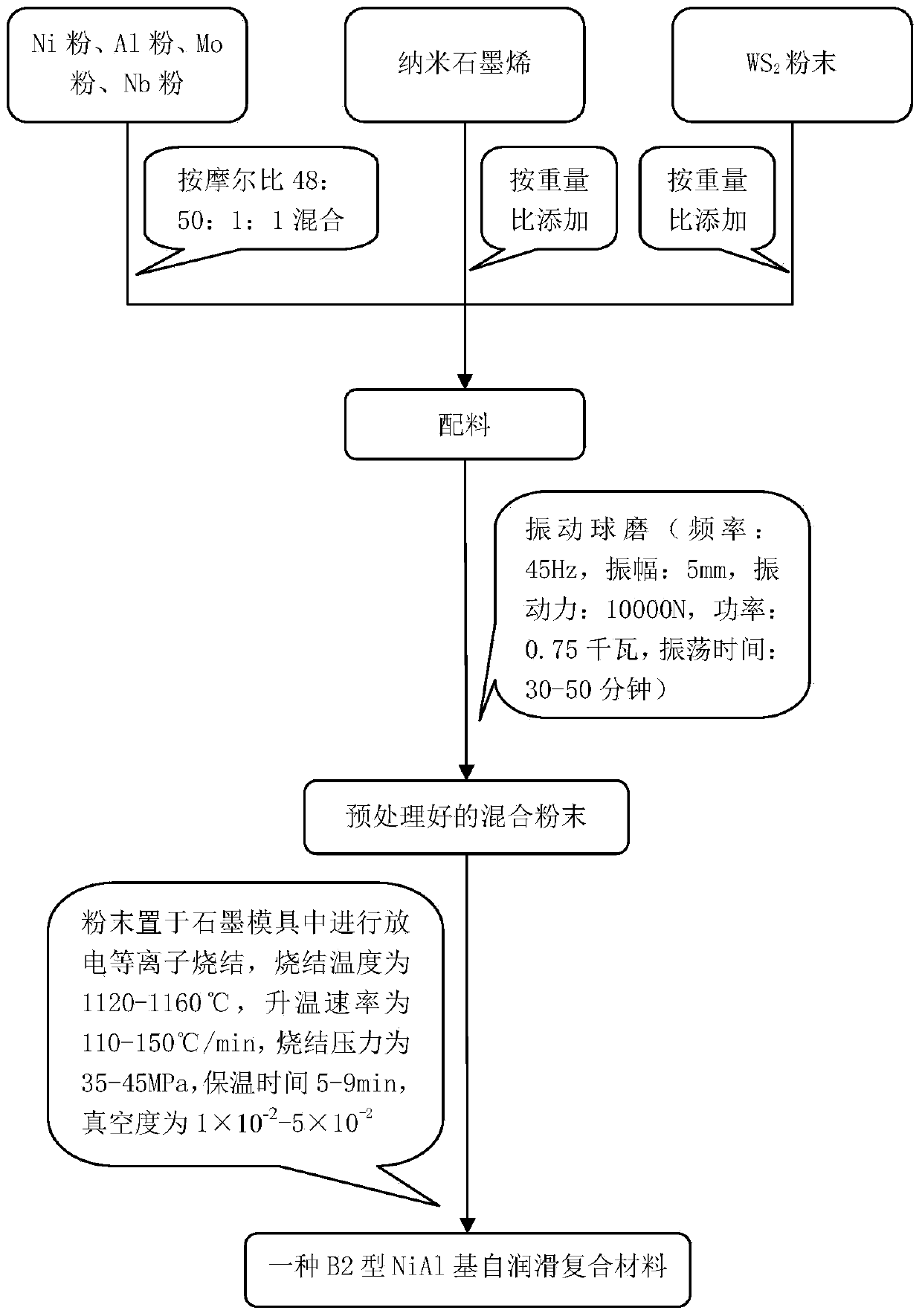

[0027] Such as figure 1 Shown, the preparation method of B2 type NiAl base self-lubricating composite material, it comprises the steps:

[0028] 1) Using Ni powder and Al powder as matrix raw materials, graphene and WS 2 It is a solid lubricant and a reinforcing phase. According to the molar ratio of Ni:Al:Mo:Nb=48:50:1:1, the intermetallic compound NiAl matrix pre-sintered powder is mixed, and 6.469 grams of Ni powder and 3.097 grams of Al powder are weighed. 0.221g Mo powder and 0.213g Nb powder total 10g, then add 0.1g nano-graphene and 0.4g WS 2 into the above-mentioned mixed powder to obtain ingredients;

[0029] 2) Put the above-mentioned ingredients into a vibrating ball mill for dry grinding, the inner wall of the vibrating ball mill tank is made of polytetrafluoroethylene, the vibration frequency is 45 Hz, the amplitude is 5 mm, the vibration force is 10000 N, the power is 0.75 kilowatts, and the oscillation time is 30 minutes, and the desired result is obtained. P...

Embodiment 2

[0033] 1) Using Ni powder and Al powder as matrix raw materials, graphene and WS 2 It is a solid lubricant and a reinforcing phase. According to the molar ratio of Ni:Al:Mo:Nb=48:50:1:1, the intermetallic compound NiAl matrix pre-sintered powder is mixed, and 6.469 grams of Ni powder and 3.097 grams of Al powder are weighed. 0.221g Mo powder and 0.213g Nb powder total 10g, then add 0.2g nano-graphene and 0.6g WS 2 into the above-mentioned mixed powder to obtain ingredients;

[0034] 2) Put the above-mentioned ingredients into a vibratory ball mill for dry grinding, the inner wall of the vibratory ball mill tank is made of polytetrafluoroethylene, the vibration frequency is 45 Hz, the amplitude is 5 mm, the vibration force is 10000 N, the power is 0.75 kilowatts, and the oscillation time is 40 minutes. Processed mixed powder;

[0035] 3) The pretreated mixed powder is placed in a graphite mold with an inner diameter of 20 mm, and then spark plasma sintering is carried out und...

Embodiment 3

[0038] 1) Using Ni powder and Al powder as matrix raw materials, graphene and WS 2 It is a solid lubricant and a reinforcing phase. According to the molar ratio of Ni:Al:Mo:Nb=48:50:1:1, the intermetallic compound NiAl matrix pre-sintered powder is mixed, and 6.469 grams of Ni powder and 3.097 grams of Al powder are weighed. 0.221g Mo powder and 0.213g Nb powder total 10g, then add 0.3g nano-graphene and 0.8g WS 2 into the above-mentioned mixed powder to obtain ingredients;

[0039] 2) Put the above-mentioned ingredients into a vibratory ball mill for dry grinding, the inner wall of the vibratory ball mill tank is made of polytetrafluoroethylene, the vibration frequency is 45 Hz, the amplitude is 5 mm, the vibration force is 10000 N, the power is 0.75 kilowatts, and the oscillation time is 50 minutes. Processed mixed powder;

[0040] 3) Place the pretreated mixed powder in a graphite mold with an inner diameter of 20mm, and then conduct spark plasma sintering (SPS) under vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com