Low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and preparation method thereof

A vulcanized silicone, one-component technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of difficult control of the reaction process, low crosslinking density, and reduced elongation at break and other problems, to achieve the effect of increasing thermal stability and oxidation resistance, good heat and oil resistance, and improving elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

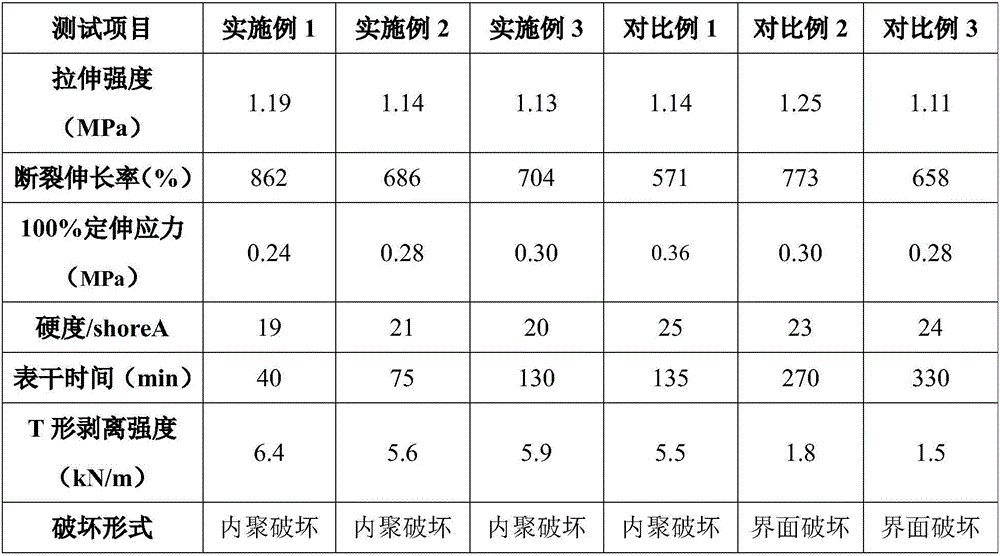

Examples

preparation example Construction

[0057] The preparation method of the above-mentioned low modulus one-component deketoxime type room temperature vulcanized silicone rubber comprises the following steps:

[0058]1) Mix hydroxy-terminated polydimethylsiloxane, plasticizer, white mineral oil, fumed silica, reinforcing filler, aluminum stearate and pigment evenly, and dry at 110-130°C for 2-5 hours, get the premix;

[0059] 2) Knead and stir the premixed material at 110-130°C and a vacuum degree of 0.09MPa-0.1MPa for 2-5 hours, then cool to room temperature to obtain the base rubber;

[0060] 3) Add cross-linking agent, vulcanization accelerator and silane coupling agent to the base rubber, and stir for 20-40 minutes under the condition of vacuum degree of 0.09MPa-0.1MPa;

[0061] 4) Add the catalyst to the rubber base, stir for 20-40min under the condition of vacuum degree of 0.09MPa-0.1MPa, discharge, fill and seal.

Embodiment 1

[0064] A low-modulus one-component deketoxime type room temperature vulcanizing silicone sealant, comprising the following raw materials in parts by mass:

[0065] Hydroxyl-terminated polydimethylsiloxane (viscosity 50000mPa·s): 100 parts;

[0066] Simethicone oil (viscosity 1000mPa s): 20 parts;

[0067] White mineral oil (26#): 2.5 parts;

[0068] Hydrophobic fumed silica surface-modified by dimethyldichlorosilane (specific surface area 130m 2 / g): 5 parts;

[0069] Nano-calcium carbonate modified by fatty acid surface: 90 parts;

[0070] Aluminum stearate: 2.5 parts;

[0071] Aluminum powder: 2.5 parts;

[0072] Methyl tributylketoxime silane: 12 parts;

[0073] Alkoxybutanone oximinosilane: 3 parts;

[0074] N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane: 2 parts;

[0075] Stannous octoate: 0.5 parts.

[0076] The preparation method of the above-mentioned low-modulus single-component deketoxime type room temperature vulcanizing silicone sealant is as follows:

[...

Embodiment 2

[0082] A low-modulus one-component deketoxime type room temperature vulcanizing silicone sealant, comprising the following raw materials in parts by mass:

[0083] Hydroxyl-terminated polydimethylsiloxane (viscosity 10000mPa·s): 100 parts;

[0084] Dimethicone oil (viscosity 1000mPa s): 30 parts;

[0085] White mineral oil (26#): 2 parts;

[0086] Hydrophobic fumed silica surface-modified by dimethyldichlorosilane (specific surface area 130m 2 / g): 7 parts;

[0087] Nano-calcium carbonate modified by fatty acid surface: 105 parts;

[0088] Aluminum stearate: 3 parts;

[0089] Aluminum powder: 3 parts;

[0090] Methyl tributylketoxime silane: 8 parts;

[0091] Alkoxybutanone oximinosilane: 2 parts;

[0092] γ-Aminopropyltriethoxysilane: 1 part;

[0093] Dibutyltin dilaurate: 0.3 parts.

[0094] The preparation method of the above-mentioned low-modulus single-component deketoxime type room temperature vulcanizing silicone sealant is as follows:

[0095] 1) The hydroxyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com