Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

632 results about "Dimethylaniline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N,N-Dimethylaniline (DMA) is an organic chemical compound, a substituted derivative of aniline. It consists of a tertiary amine, featuring dimethylamino group attached to a phenyl group. This oily liquid is colourless when pure, but commercial samples are often yellow. It is an important precursor to dyes such as crystal violet.

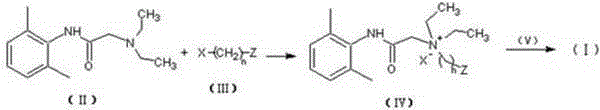

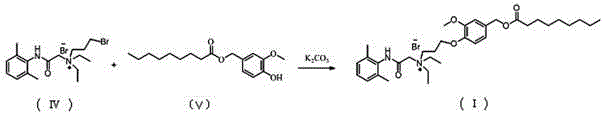

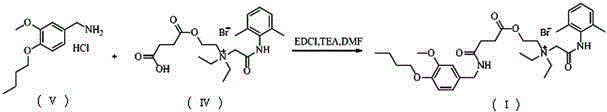

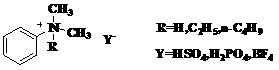

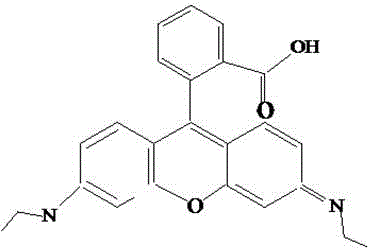

N-diethylaminoacetyl-2,6-dimethylaniline derivatives, preparation method and applications thereof

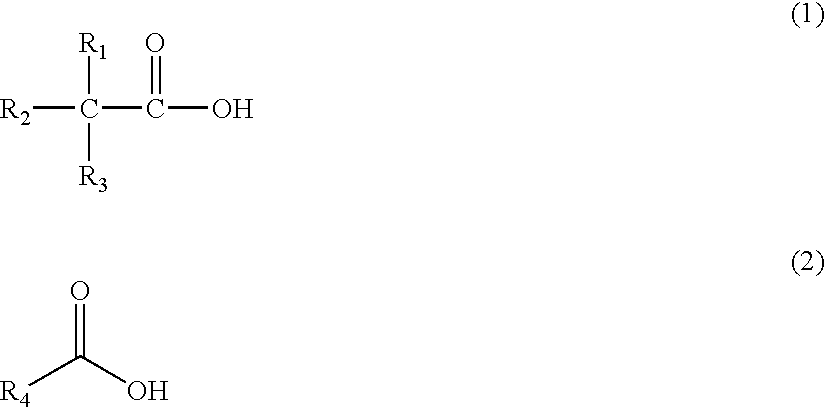

The invention provides N-diethylaminoacetyl-2,6-dimethylaniline derivatives, a preparation method and applications thereof. The structure of the derivatives is represented by the formula (I). The preparation method comprises the following steps: carrying out reactions between N-diethylaminoacetyl-2,6-dimethylaniline and halogenated compounds to obtain a corresponding quaternary ammonium salt intermediate, and then subjecting the quaternary ammonium salt intermediate to react with corresponding 2-methoxyl-4-subsituted phenol derivative raw material so as to obtain the N-diethylaminoacetyl-2,6-dimethylaniline derivatives. The derivatives can be used as a long-acting local anesthetic drug or a pain relieving drug capable of separating the motion and the feeling, can exert a reversible and lasting local anesthetic effect in organism bodies, do not affect motor function in a certain dosage range, and have an ideal retardant effect on separation of motion and feeling.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Cationically polymerizable adhesive composition containing an acidic component and methods and materials employing same

An adhesive composition that includes a mixture of a cationically polymerizable component, an acidic component, and an initiator is provided. Preferably, the initiator comprises an iodonium salt, a visible light sensitizer, and an electron donor compound, wherein the initiator has a photoinduced potential greater than or equal to that of N,N-dimethylaniline in a standard solution of 2.9x10-5 moles / g diphenyl iodonium hexafluoroantimonate and 1.5x10-5 moles / g camphorquinone in 2-butanone. This adhesive composition is cationically polymerizable and is able to bond to hard tissue and cationic restorative materials upon curing.

Owner:3M INNOVATIVE PROPERTIES CO +1

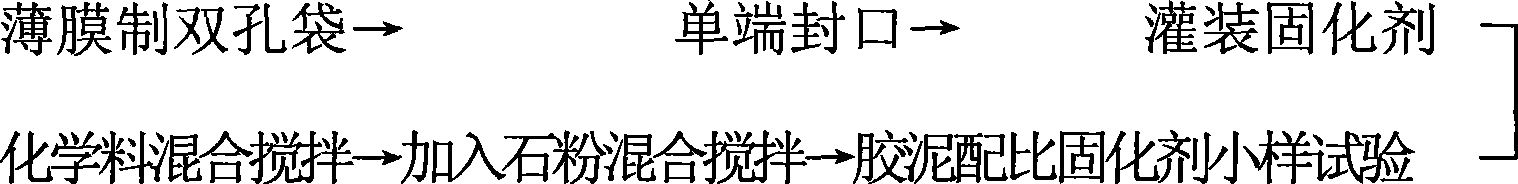

Resin mastic cement for anchorage agent and anchorage agent thereof

InactiveCN101508540AReduce consistencyHigh compressive strengthAnchoring boltsDimethylaniline N-oxideCompressive strength

The invention relates to an anchoring agent, which is resin mortar for an anchoring agent and the anchoring agent, and is used for anchoring large-diameter anchor cables used in the construction of the support of coal mine roadways and the protection of underground engineering. The resin mortar comprises the following compositions in portion by mass: 800 to 1,200 portions of MG unsaturated polyester resin, 4,000 to 6,000 portions of limestone powder, 3 to 10 portions of dimethylaniline, and 6 to 12 portions of white carbon black, wherein the particle size of the limestone powder is between 80 and 120 meshes. The resin mortar and a curing agent form a bi-component anchoring agent. The anchoring agent can effectively reduce the consistency of the resin mortar, and improve the compressive strength after the solidification of the anchoring agent, thereby realizing the effects during the use such as high adhesive force, low stirring resistance and the like; and the anchoring agent meets the requirement of using large-diameter and high-strength anchor cables in the support of the coal mine roadways, reduces anchoring length, construction time and construction personnel, and improves the production efficiency.

Owner:晋城宏圣科威矿用材料有限公司

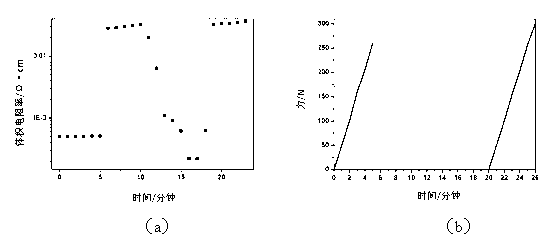

Silver nanowire-filled self-repairing conducting resin and preparation method thereof

InactiveCN102719211ASuitable for welding operationsHigh glass transition temperatureNon-macromolecular adhesive additivesMicroballoon preparationPolymer scienceDimethylaniline N-oxide

The invention relates to a conducting resin and especially relates to a silver nanowire-filled self-repairing conducting resin and a preparation method thereof. Through an emulsion polymerization method, core-shell structure nano-particles comprising shells of polystyrene and cores of a polymercaptan-dimethylaniline mixture with silver nanowires dispersed therein are prepared; the core-shell structure nano-particles are dispersed in an isotropic conducting resin filled with silver nanowires; under the action of an external force, the core-shell structure nano-particles fracture automatically; the polymercaptan-dimethylaniline mixture and an excess amount of epoxy groups in the isotropic conducting resin undergo a rapid reaction so that resin microcracks produced by the external force are repaired automatically; and simultaneously, the silver nanowires of the core-shell structure nano-particles are uniformly dispersed on repaired places so that repairing effects on a conductive network are obtained. Therefore, a service life of a conducting resin is improved and a cost of an electron component is reduced.

Owner:CHANGZHOU UNIV

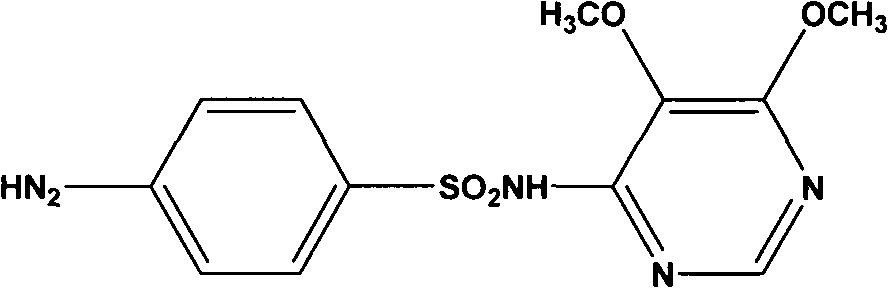

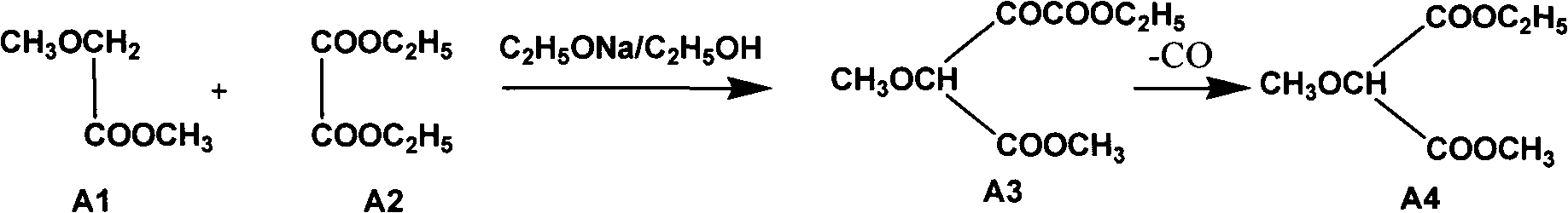

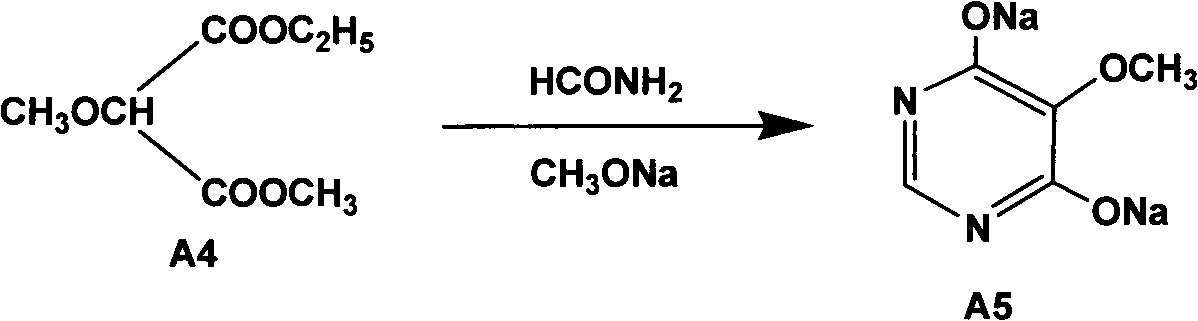

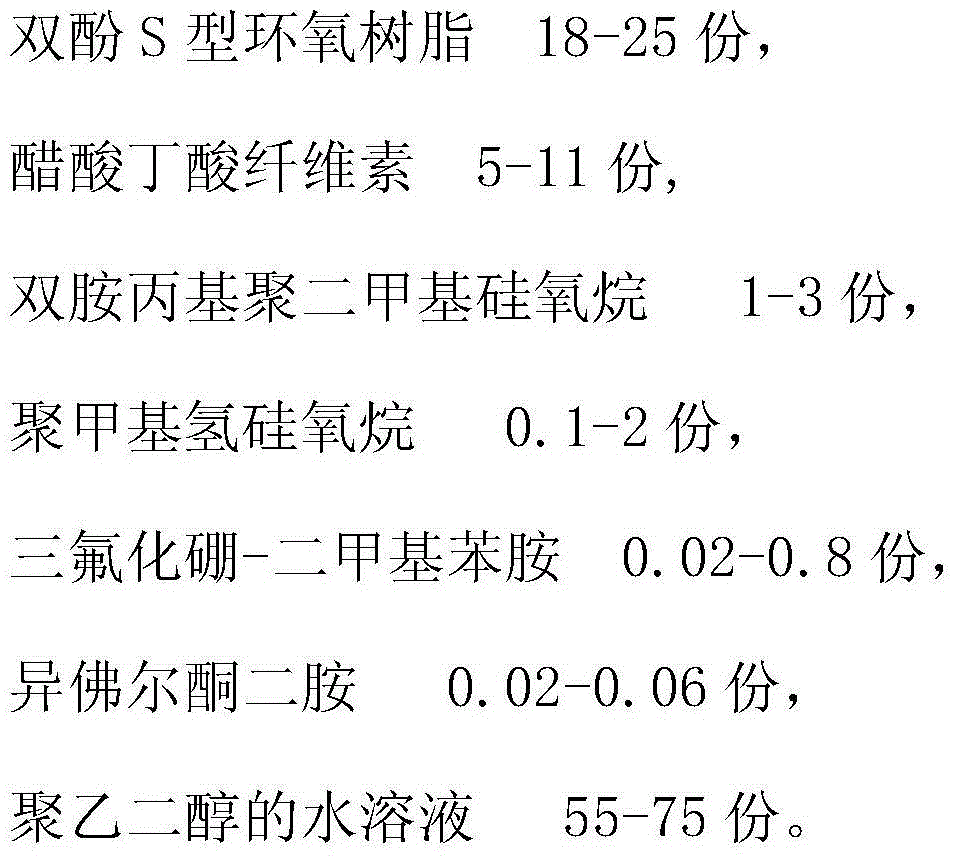

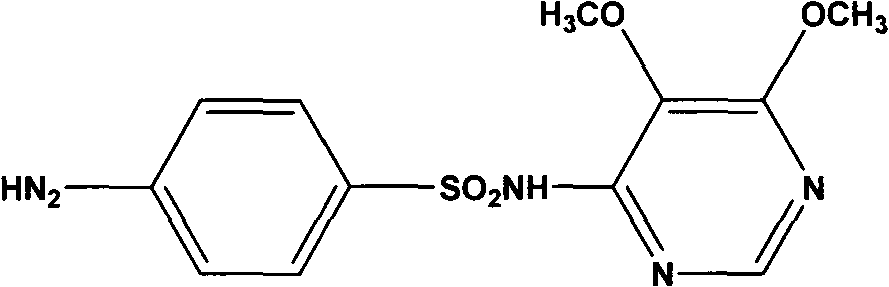

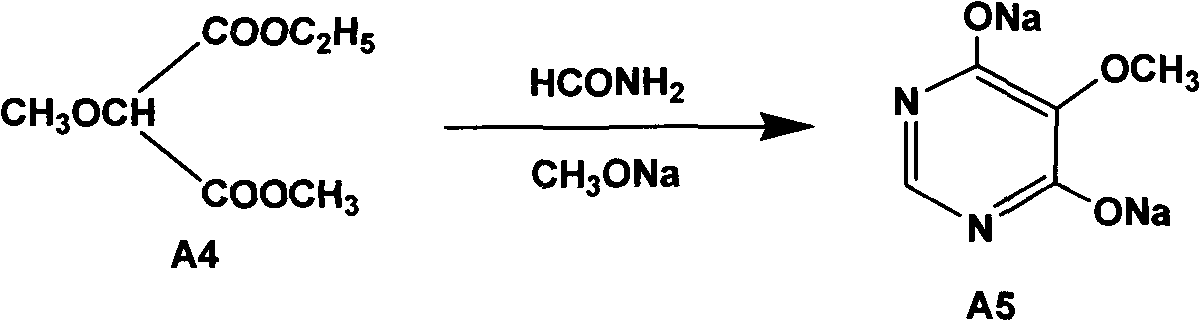

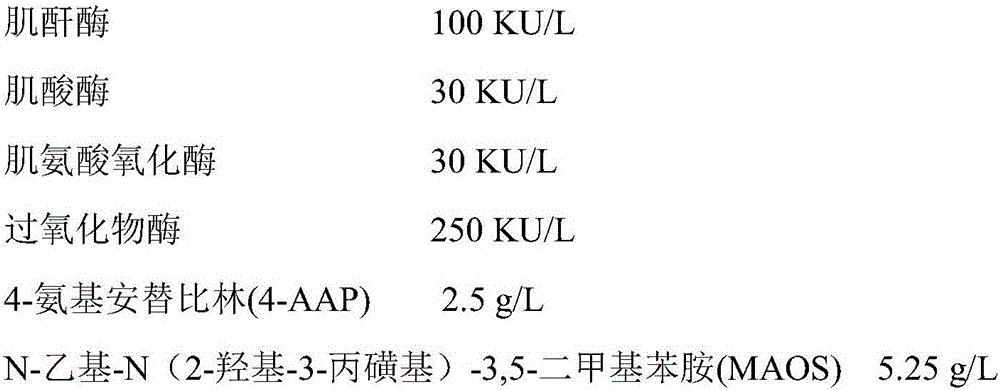

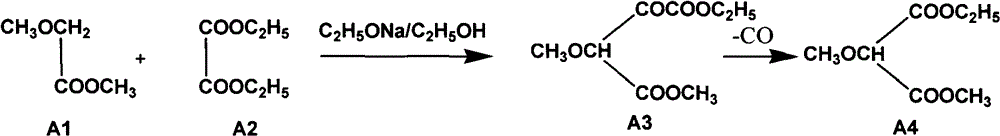

Preparation method of sulfadoxine and intermediate thereof

InactiveCN102304094AReduce manufacturing costHigh purityOrganic chemistryMethyl methoxyacetateMalonate

The invention relates to a preparation method of sulfadoxine and an intermediate thereof. The preparation method of sulfadoxine comprises the following steps: (1) reacting methyl methoxyacetate and excessive diethyl oxalate to generate 3-methoxy-2-oxo-methylethyl succinate, and decarbonylating to obtain 2-methoxy-methylethyl malonate; (2) reacting the 2-methoxy-methylethyl malonate and formamide to generate a cyclocompound; (3) reacting the cyclocompound and phosphorus oxychloride to generate chloride; (4) carrying out condensation reaction; and (5) carrying out methoxylation reaction. The obtained cyclocompound in the step (2) is controlled to exist in the form of anhydrous hydroxy sodium salt, so that N,N-dimethylaniline is not needed as a catalyst in the step (3), thereby lowering the cost, enhancing the quality of chloride and finally enhancing the quality of sulfadoxine.

Owner:CHANGSHU NANHU INDAL CHEM

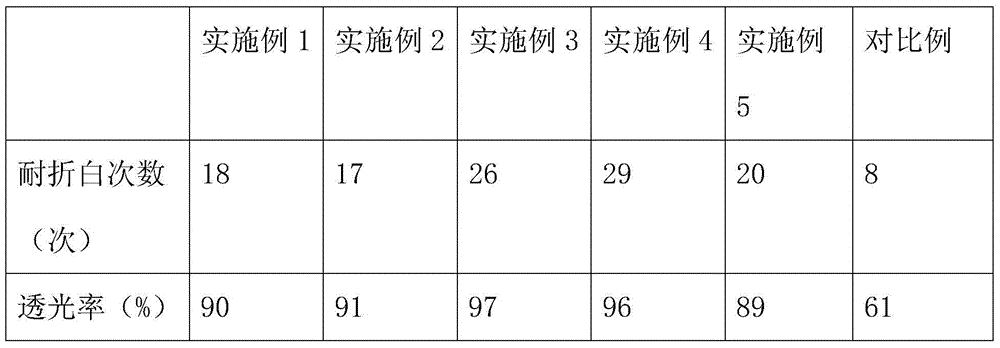

Fold-resistant white plastic film and preparation method thereof

InactiveCN104877310AGood light transmissionImprove high temperature resistanceEpoxyDimethylaniline N-oxide

The invention relates to a fold-resistant white plastic film and a preparation method thereof. The fold-resistant white plastic film is prepared from the following components in parts by weight: 18 to 25 parts of bisphenol S-type epoxy resin, 5 to 11 parts of cellulose acetate butyrate, 1 to 3 parts of diaminopropyl polydimethylsiloxane, 0.1 to 2 parts of polymethyl hydrogen siloxane, 0.02 to 0.8 parts of boron trifluoride-dimethylaniline, 0.02 to 0.06 parts of isophorone diamine and 55 to 75 parts of aqueous solution of polyethylene glycol. The invention also provides the preparation method of the fold-resistant white plastic film.

Owner:苏州靖羽新材料有限公司

Preparation method of sulfadoxine

InactiveCN102304095AReduce usageQuality improvementOrganic chemistrySodium methoxideDimethylaniline N-oxide

The invention relates to a preparation method of sulfadoxine, which comprises the following steps: (1) reacting methyl methoxyacetate and excessive diethyl oxalate to generate 3-methoxy-2-oxo-methylethyl succinate, and decarbonylating to obtain 2-methoxy-methylethyl malonate; (2) reacting the 2-methoxy-methylethyl malonate and formamide to generate a cyclocompound; (3) carrying out chlorination reaction; (4) carrying out condensation reaction; and (5) carrying out methoxylation reaction. The purity of the 2-methoxy-methylethyl malonate obtained in the step (1) is strictly controlled, and the cyclocompound in the step (2) is controlled to exist in the form of anhydrous hydroxy sodium salt; in the step (3), no catalyst, including N,N-dimethylaniline, is used; and in the step (5), solid sodium hydroxide is substituted for sodium methoxide solution. The invention is easy to operate, has the advantage of high product quality, greatly lowers the production cost, and has obvious economic benefit and environmental benefit.

Owner:CHANGSHU NANHU INDAL CHEM

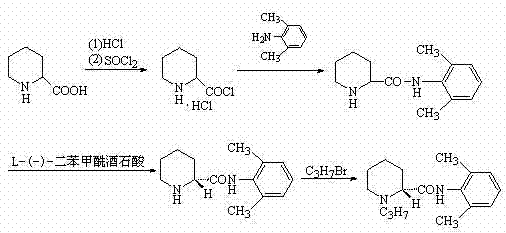

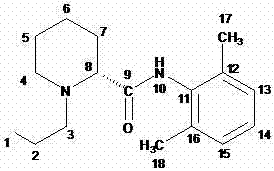

Method for preparing ropivacaine

InactiveCN103086954AAvoid separationSimple processOrganic chemistryDimethylaniline N-oxideCarboxylic acid

The invention relates to a one-pot method for preparing ropivacaine. According to the invention, L-piperidine-2-carbonyl chloride is prepared from L-piperidine-2-carboxylic acid; intermediate separation is not needed, and the material is directly subjected to a reaction with 2,6-dimethylaniline, and (S)-N-(2,6-dimethylphenyl)piperidine-2-carboxamide is prepared; intermediate separation is not needed, and the material is directly subjected to a reaction with bromopropane, such that ropivacaine is prepared. According to the invention, when the intermediate is prepared, no separation is needed, and reactions can be directly carried out. The method is green and environment-friendly. With the method, process operation is simplified, cost is reduced, and yield is improved. The method is more suitable for large-scale industrialized productions.

Owner:SHANDONG INST OF PHARMA IND

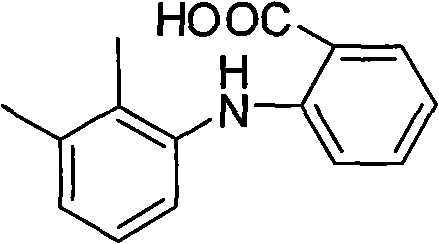

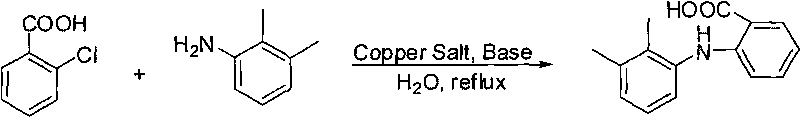

Synthesis method of mefenamic acid

ActiveCN101704761AHigh yieldHigh purityOrganic compound preparationAmino-carboxyl compound preparationDimethylaniline N-oxideOrganic solvent

The invention discloses a synthesis method of mefenamic acid. The method comprises the following steps: firstly adding o-halophenylacetic acid, 2,3-dimethylaniline, acid binding agent, catalyst and water in a reaction container to react; then adding water in the reaction mixture to dilute, then acidifying to ensure that the pH value is 2-3, cooling to the room temperature, filtrating, washing filter residue with warm water to obtain raw mefenamic acid; then adding the raw mefenamic acid in a reaction container, then adding organic solvent to perform recrystallization, filtrating to obtain solid, dissolving the obtained solid in organic solvent to perform second recrystallization, filtrating, and drying to obtain the target product. The synthesis method of mefenamic acid in the invention has the advantage that the production cost is low, the utilization of reaction raw materials is complete, the product purity is high, the environmental pollution is little, the operation safety is high, and the method is environmentally friendly and is applicable to industrial production.

Owner:NINGBO SMART PHARMA

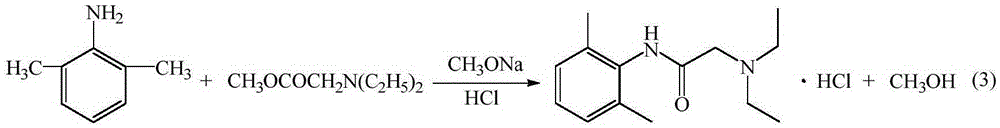

Method for preparing lidocaine

ActiveCN102070483AImprove responseHigh purityOrganic compound preparationCarboxylic acid amides preparationDimethylaniline N-oxideAcetyl chloride

The invention provides a method for preparing lidocaine. The method comprises the following steps: using 2,6-dimethylaniline and chloroacetic chloride as raw materials to prepare an intermediate, namely acetyl chloride-2,6-dimethylaniline, and using the prepared intermediate and diethylamine to react and obtain lidocaine, wherein acetone is used as solvent and carbonate is used as catalyst in thereaction process. The method of the invention has simple synthetic technology and does not require the complicated step that the intermediate is washed with acid firstly and washed with base secondlyin the post-treatment, thus avoiding unnecessary loss. Therefore, the yields of the intermediate and lidocaine prepared by the method are higher; and the prepared lidocaine has high purity which is more than 99%, and good industrial application prospect. In addition, the method of the invention uses acetone as solvent, thus the solvent is non-toxic basically and environmentally friendly, has no stimulation and can be recycled.

Owner:BENGBU BBCA MEDICINE SCI DEV

Cracking process of organosilicon high-boiling components

The invention relates to a cracking process of organosilicon high-boiling components.. The cracking process is characterized in that organosilicon high-boiling components are used as raw materials and are subjected to impurity removal, N,N-dimethylaniline, N,N-diethylformamide or tri-n-butylamine are selected as a catalyst, the catalytic cracking is performed inside a reaction vessel to which hydrogen chloride gas is introduced, and finally, dimethyldichlorosilane, monomethyltrichlorosilane, monomethyldichlorosilane and trimethylchlorosilane are respectively recovered through a layered cooling tower at different temperatures. The cracking process has the advantages that the matching is reasonable, the operation is simple, the recovery ratio is high, and more than 60% of dimethyldichlorosilane product with high added value can be obtained.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

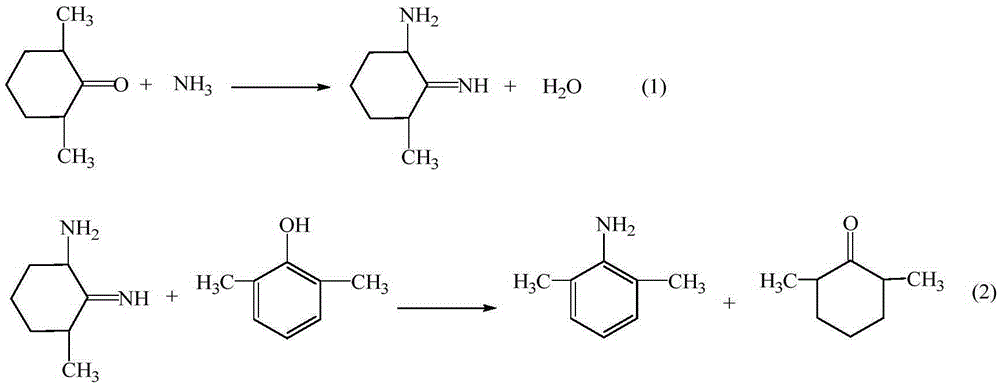

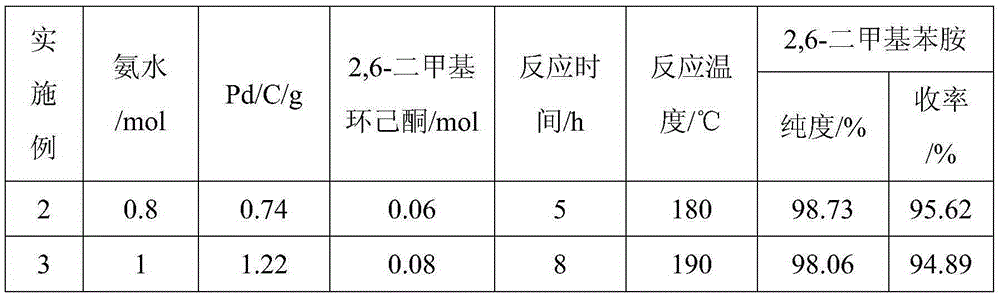

Method for preparing lidocaine hydrochloride

ActiveCN105294477AThe synthesis process is simpleHigh purityOrganic compound preparationCarboxylic acid amides preparationDimethylaniline N-oxideOrganic layer

The invention provides a method for preparing lidocaine hydrochloride, and belongs to the technical field of anesthetic synthesis. The method comprises the following steps: by taking 2,6-xylenol as a raw material, Pd / C as a main catalyst and 2,6-dimethylcyclohexanone as a promoter, performing liquid phase amination with ammonia water at high temperature, thereby obtaining a midbody 2,6-dimethylaniline; enabling sodium methylate, 2,6-dimethylaniline and N,N-lignocaine methyl acetate as raw materials to react at 90-95 DEGC, distilling while reaction is performed to remove methanol till no methanol can be evaporated out, continuously reacting for 30 minutes, cooling to the room temperature, adding dichloroethane, washing with water, and leaving to stand to layer, thereby obtaining an organic layer, namely, a lidocaine based dichloroethane solution; further adding hydrochloric acid into the lidocaine based dichloroethane solution, adjusting the pH value to be 3.5-4 by using hydrogen chloride, adding activated carbon to reflux for 20-40 minutes, filtering, concentrating the filtrate, cooling, crystallizing, and dying, thereby obtaining lidocaine hydrochloride. The lidocaine hydrochloride prepared by using the method is simple in synthesis process and high in product purity, that is, the purity can be greater than 99%, and the total yield is greater than 84%.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD

Waterproof and anticorrosive paint special for marine ships

InactiveCN106318105AAccelerated corrosionImprove water resistanceRubber derivative coatingsAnti-corrosive paintsDimethylaniline N-oxideDefoamer

The invention discloses a waterproof and anticorrosive paint special for marine ships. The paint comprises 60-85wt% of a component A and 15-40wt% of a component B. The component A comprises the following raw materials: epoxy resin, chlorinated rubber, an ethylene chloride-vinyl acetate copolymer, organic fluorine modified acrylic resin, a silane coupling agent, zinc powder, mica powder, iron oxide red, ceramic micro-powder, molybdenum disulfide, propylene glycol butyl ether, propylene glycol methyl ether acetate, a dispersing agent, an organic silicon defoamer, a leveling agent, methyl isobutyl ketone and n-butanol; and the component B includes the following raw materials: poly 2, 3-dimethylaniline modified montmorillonite, a curing agent, ethyl acetate, and butyl acetate. The waterproof and anticorrosive paint special for marine ships provided by the invention has excellent waterproof performance and corrosion resistance, also has excellent impact resistance, abrasion resistance and weather resistance, has good comprehensive performance when used in ship engineering, and has long service life.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

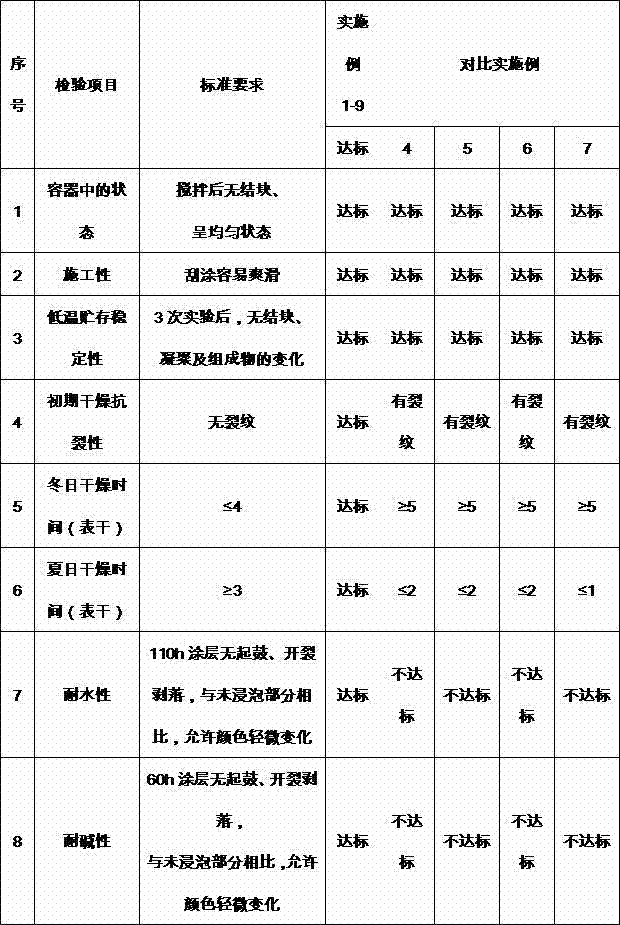

Synthesis method of novel ionic liquid and application of novel ionic liquid to oil product denitrification

The invention relates to a synthesis method of novel ionic liquid and application of the novel ionic liquid to oil product denitrification. The synthesis method is characterized by comprising the following steps: with N,N-dimethylaniline as a raw material, carrying out direct acidification or acidification after alkylation and introducing anions HSO<4->, H2PO<4-> and BF<4->, thus preparing Br.nsted acidic ionic liquid. The ionic liquid is taken as an extraction agent, can efficiently remove such heterocyclic nitrides in simulated oil products as aniline, pyridine, quinoline and indole under mild conditions and has actual oil product 93# gasoline denitrification rate above 85%.

Owner:QINGDAO UNIV OF SCI & TECH

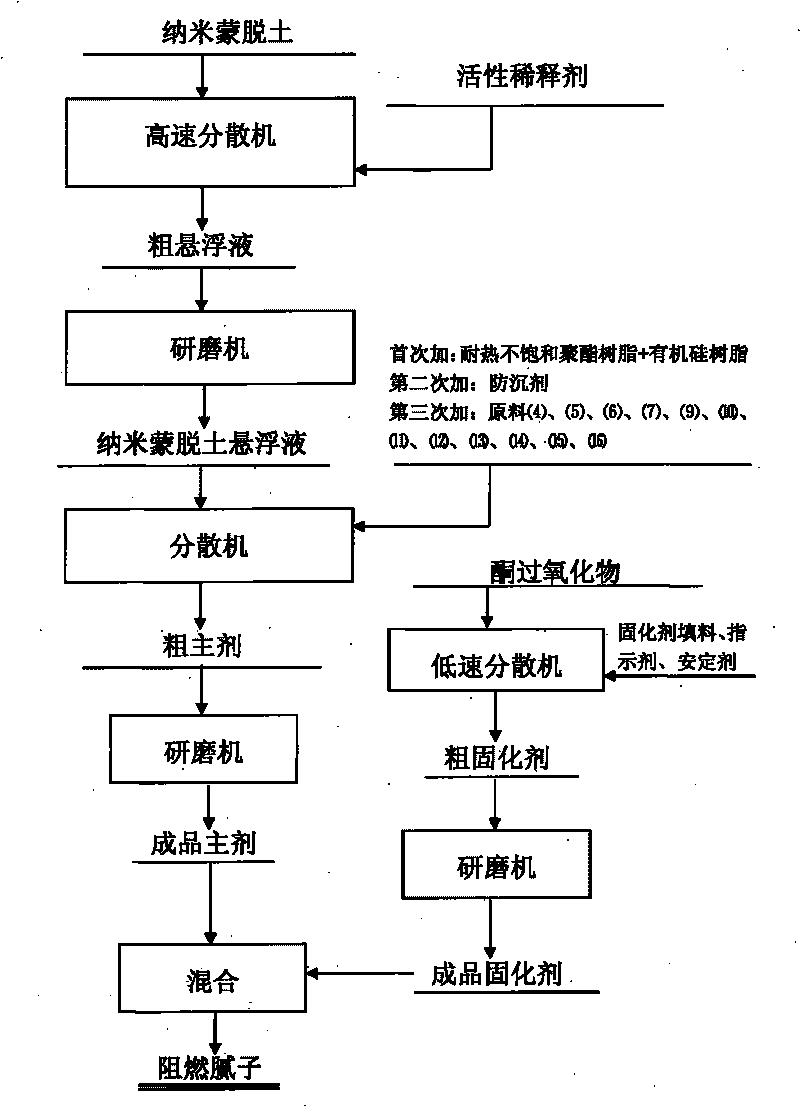

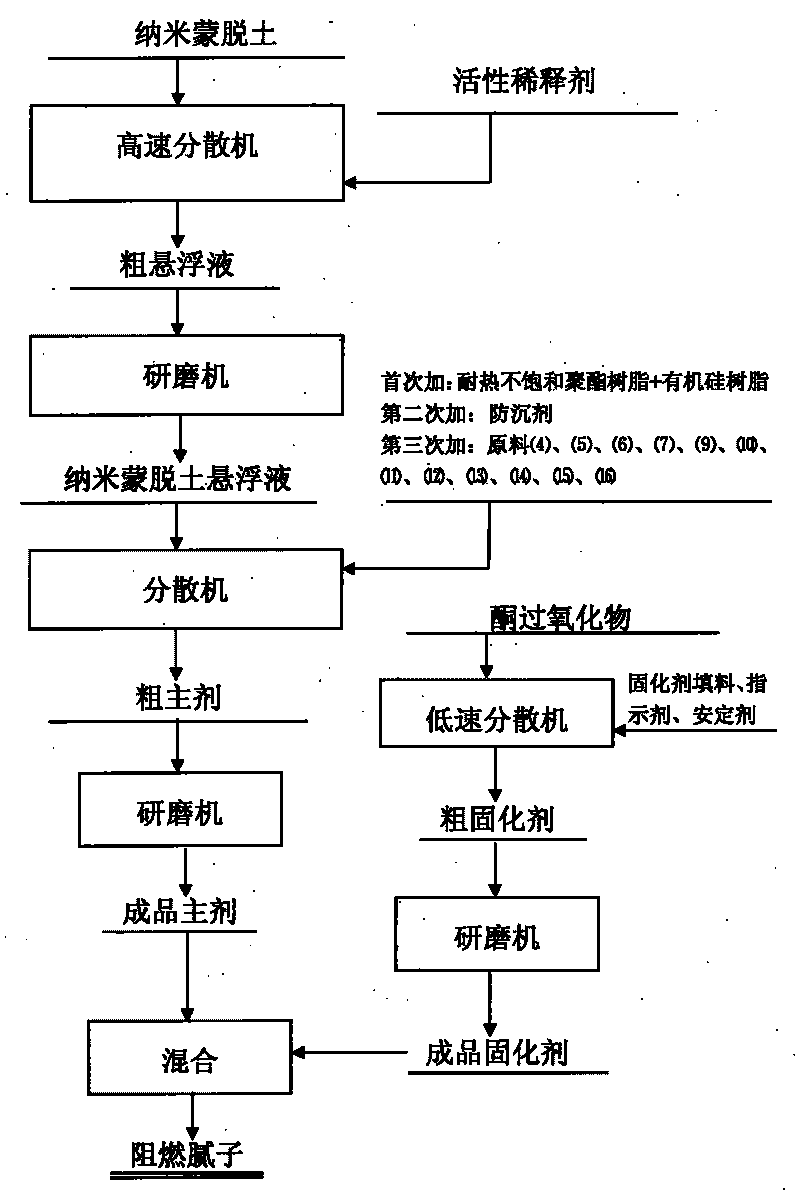

Flame-retarding lacquer putty and preparation method thereof

InactiveCN101696331AImprove heat resistanceImprove air drynessFilling pastesDimethylaniline N-oxideLacquer

Owner:ZHUZHOU HUALIAN HI TECH

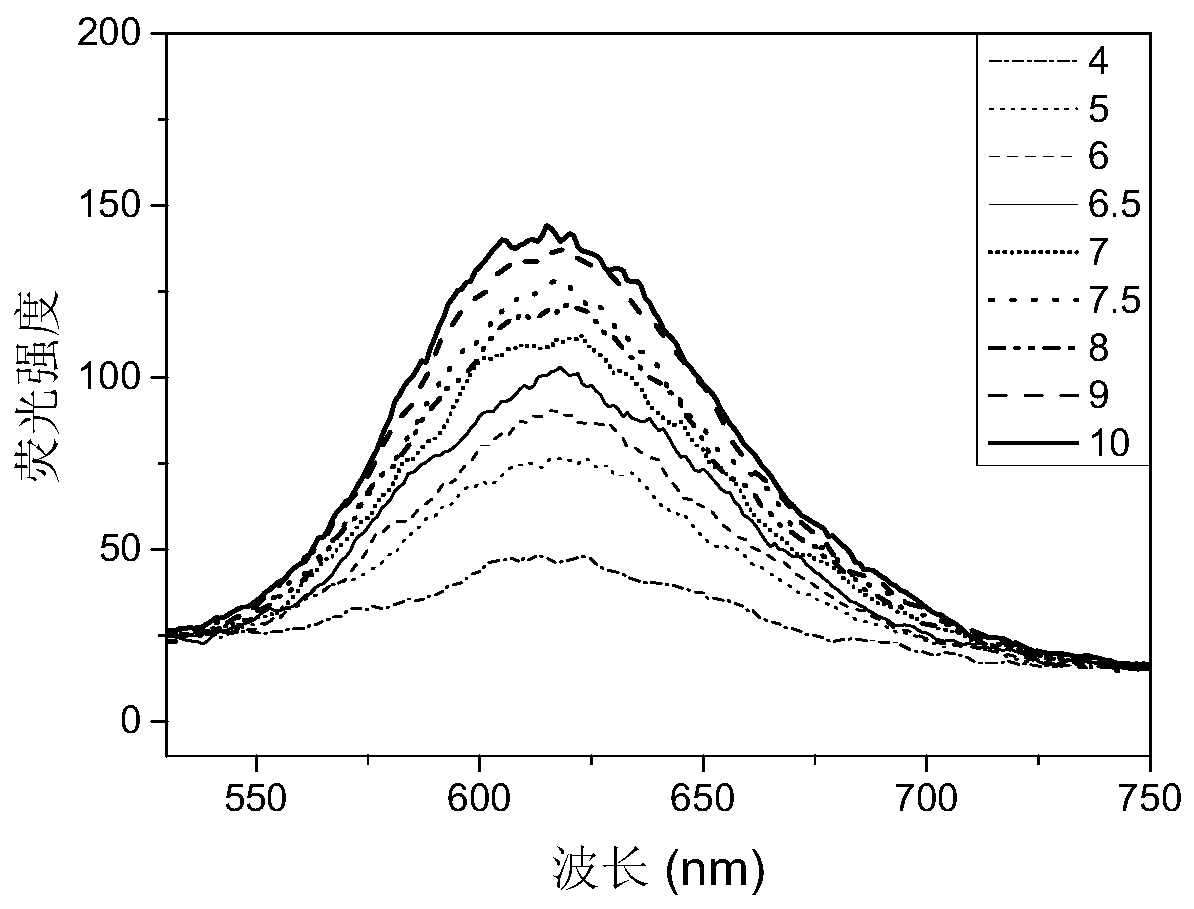

Fluorescent probe based on aggregation-induced emission characteristics, method for determining critical micelle concentration by using fluorescent probe and application of fluorescent probe

ActiveCN110028446AOperational securityEasy to useFluorescence/phosphorescencePhosphorus organic compoundsCritical micelle concentrationAggregation-induced emission

The invention provides a fluorescent probe based on aggregation-induced emission characteristics and a method for determining critical micelle concentration by using the fluorescent probe and application of the fluorescent probe. The aggregation-induced emission dye has a structure as shown in a formula I in the description. According to the invention, the fluorescent probe is innovatively appliedto the critical micelle concentration detection of a surfactant, and the approximate value can be rapidly determined. When the AIE fluorescent probe is used for detecting the critical micelle concentration of the surfactant, the operation steps are simple, the application range is wide, and the critical micelle concentration of an anionic surfactant and a nonionic surfactant can be accurately determined. In the formula I, R1 is independently selected from any one of C1-C8 carboxyl, a sulfonic group, a phosphate group or a phosphite group, and n is equal to 0, 1, 2, 3, 4, 5, 6 or 7; and R2 isindependently selected from any one of methyl, methoxy, N,N-dimethyl, N,N-dimethylaniline, triphenylamine, hydroxyl, amino or sulfydryl.

Owner:EAST CHINA UNIV OF SCI & TECH

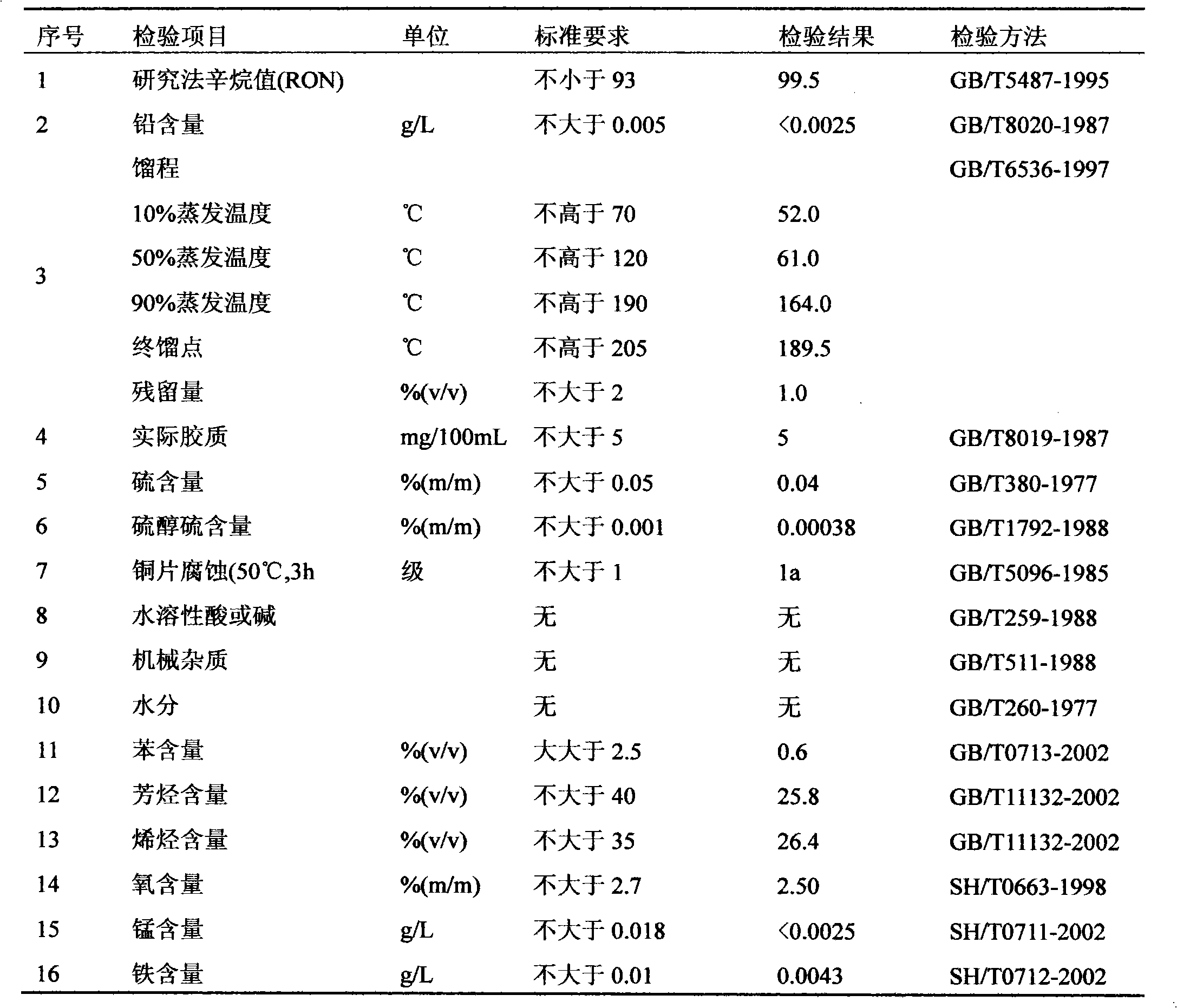

Gasoline additive for environmental protection and energy-saving vehicle

InactiveCN101870891ALow running costImprove powerLiquid carbonaceous fuelsDimethyl acetalButylated hydroxytoluene

The invention discloses a gasoline additive for an environmental protection and energy-saving vehicle. The gasoline additive comprises the following components in parts by weight: 12-18 parts of nitromethane, 5-8 parts of boron, 2-5 parts of pyridine, 6-8 parts of didodecyldimethylammonium, 3-6 parts of carbon fluoride, 1-3 parts of magnesium perchlorate, 2-4 of BHT (butylated hydroxytoluene), 1-3 parts of light calcium carbonate, 4-7 parts of dimethyl acetal, 4-7 parts of 3-methyl-1-butylene, 16-21 parts of methyl tert-butyl ether, 6-9 parts of 2,2,3-triptane, 1-3 parts of cerium oxide, 1-3 parts of beryllium carbide, 5-8 parts of N,N-dimethylaniline and 2-4 parts of amino acid palladium complex. The additive can effectively improve the gasoline quality, increase the gasoline octane number, enhance the fire performance of fuels, can be completely burned together with the fuels without generating precipitation or residues, reduce the tail gas exhaust pollution of motor vehicles, reduce the running cost of the motor vehicles, and has the obvious oil saving effect.

Owner:孙勇

Process for preparing mefenamic acid

ActiveCN101475505AImprove productivityLow yieldOrganic chemistryOrganic compound preparationDimethylaniline N-oxideAnti-inflammatory analgesics

The invention belongs to the technical field of anti-inflammatory drug production, and relates to a method for preparing mefenamic acid. The method comprises: adding o-chlorobenzoic acid and 2,3-dimethylaniline into a system which is formed by a non-protonic polar solvent and a dehydrant, performing condensation reaction in the presence of an acid-binding agent, a catalyst and a phase-transfer catalyst, and obtaining mefenamic sodium; acidifying the mefenamic sodium and obtaining coarse mefenamic acid products; and refining the coarse mefenamic acid products in an organic solvent and water and obtaining finished mefenamic acid products. The method improves the production efficiency of the mefenamic acid and reduces the production cost of the mefenamic acid.

Owner:BAOJI TIANXIN PHARM CO LTD

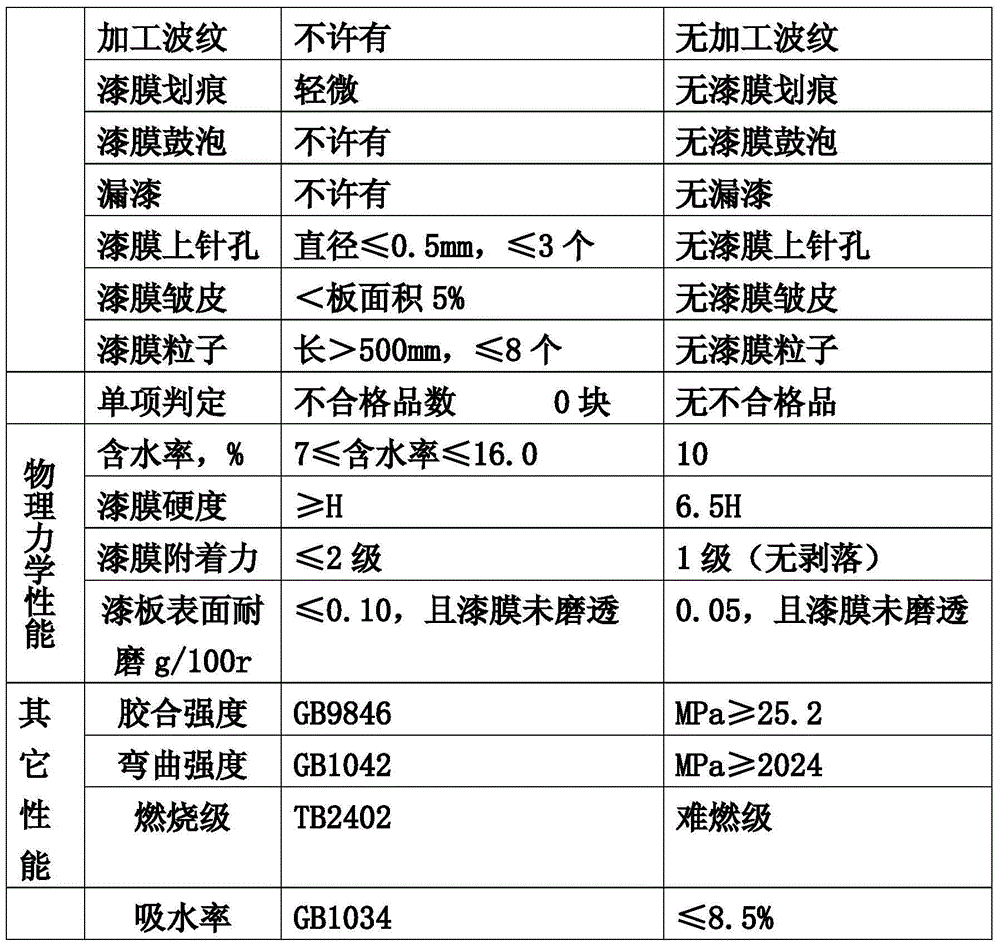

Environment-friendly and anti-cracking paint and preparation method thereof

InactiveCN104559615AAvoid crackingExtended service lifeAnti-corrosive paintsDimethylaniline N-oxideAcrylic resin

The invention discloses an environment-friendly and anti-cracking paint which comprises the following components in parts by weight: 35-55 parts of linear alkyl aryl sulfonate, 25-35 parts of hydroxy acrylic resin, 15-20 parts of soybean plant short oil type alkyd resin, 10-15 parts of glycerin, 10-15 parts of turpentine, 15-25 parts of limonene, 5-10 parts of dimethylaniline, 0.1-1 part of a defoaming agent, 0.1-1 part of a flatting agent, 0.1-1 part of a wetting agent, 10-15 parts of mica powder, 10-15 parts of a filler and 1-3 parts of a pigment. The environment-friendly and anti-cracking paint can effectively prevent the paint surface of a floor from being cracked and prolong the service life of the floor; furthermore, the environment-friendly and anti-cracking paint is environment-friendly and healthy, so that toxic gases such as formaldehyde dispersed by the floor are greatly reduced, and the safety of a user is ensured.

Owner:HUZHOU NANXUN XIANGLONG WOOD FACTORY

Textured coating

InactiveCN104327658AImprove thixotropyPrevent discoloration and sheddingFilling pastesPolyurea/polyurethane coatingsFreeze thawingCellulose

The invention belongs to the field of building materials and relates to a textured coating. The textured coating is formed by combining the following raw materials in parts by weight: 10-15 parts of water, 40-50 parts of composite latex, 15-20 parts of quartz sand, 8-13 parts of silica-based active gel, 6-9 parts of putty, 12-18 parts of cellulose ether, 2-4 parts of a mould-proof preservative, 1-3 parts of an organic zirconium complex, 3-5 parts of dimethylaniline, 4-7 parts of pentaerythritol and 3-6 parts of lignocellulose aerogel liquid, wherein the composite latex contains 10-20 percent of polyurethane resin, 30-50 percent of polyacrylate resin, 10-20 percent of polyvinyl alcohol resin, 15-25 percent of epoxy resin and 5-15 percent of an emulsifying agent. A preparation method of the lignocellulose aerogel liquid comprises steps of crushing, purifying, freeze-thawing, solidifying and regenerating. The coating is long in opening time, high in caking property, good in alkali resistance and excellent in water retaining property.

Owner:湖州三利德装饰材料有限公司

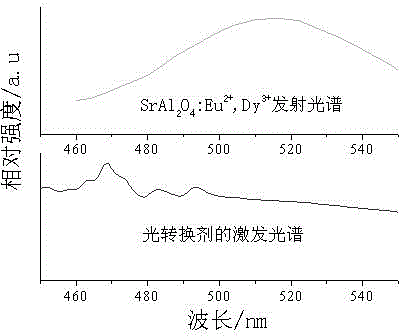

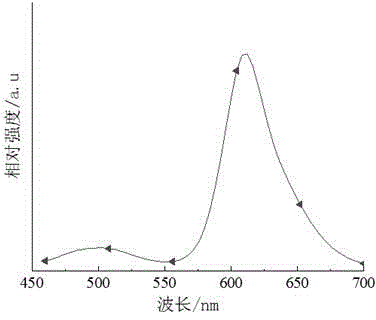

Preparation method of noctilucent fibers capable of emitting red light in darkness

ActiveCN104674361AImprove luminous brightnessMonocomponent polyolefin artificial filamentLuminescent compositionsFiberDimethylaniline N-oxide

The invention discloses a preparation method of noctilucent fibers capable of emitting red light in darkness. The preparation method comprises the following steps: mixing 2-hydroxybenzaldehyde with 3-hydroxyl-N,N-dimethylaniline which can be dissolved in water to obtain a mixture, heating the mixture, mixing the mixture with anhydrous zinc chloride and sulfuric acid to obtain a mixture I, and carrying out the reaction on the mixture I to obtain a light conversion agent; mixing the light conversion agent with SrAl2O4:Eu<2+>, Dy<3+> and a fiber forming polymer base material to obtain a mixture II, smelting the mixture II, and granulating to obtain noctilucent particles for spinning; and drying the noctilucent particles, then smelting the noctilucent particles and spinning to obtain the noctilucent fibers. The red light emitted by the noctilucent fibers prepared by adopting the preparation method can be maintained for more than ten hours, the highest luminance can reach 3.0cd / m<2>, the emitted red light is one of three basic colors, and the noctilucent fibers can be compounded with one or two of blue light noctilucent fibers and green light noctilucent fibers to prepare luminous colorful noctilucent fibers, so that the important significance can be realized.

Owner:扬州江辉纺织科技有限公司

Production method of mefenamic acid

ActiveCN102344384AIncrease profitAvoid pollutionOrganic chemistryOrganic compound preparationSodium bicarbonateDimethylaniline N-oxide

The invention discloses a production method of mefenamic acid, which comprises the following steps of: (1) adding water and o-chlorobenzoic acid into a reaction kettle, evenly mixing, and dropwise adding a sodium hydroxide solution while stirring, thereby obtaining a mixed solution; (2) adding solid sodium bicarbonate into the mixed solution in the step (1), adding chalcanthite, 2,3-dimethylaniline and cetyl trimethyl ammonium chloride, and carrying out reflux reaction; (3) after the reflux reaction in the step (2) is finished, dropwise adding hydrochloric acid, and filtering to obtain the crude product; (4) washing the crude product in the step (3) with water, filtering, and drying under reduced pressure to obtain the crude product; and (5) adding dimethyl formamide and water to dissolvethe crude product in the step (4), adding activated carbon to carry out reflux decolorization, filtering, cooling to room temperature to crystallize, filtering, recrystallizing, washing with water after the filtration for the last recrystallization, and drying under reduced pressure to obtain the fine mefenamic acid product. The invention can lower the production cost, easily implement industrialproduction, and overcome the defects in the prior art.

Owner:DEZHOU BOCHENG PHARMA

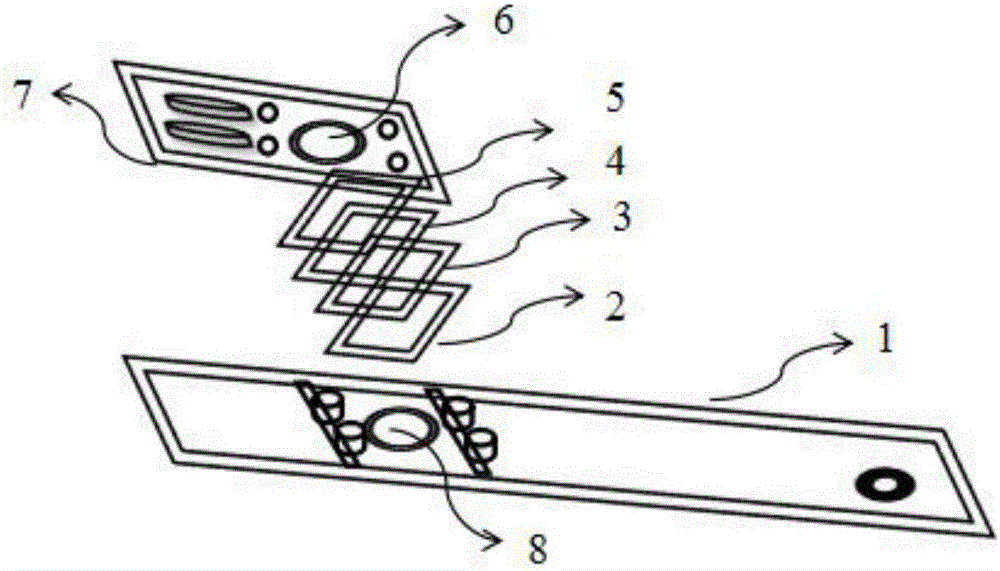

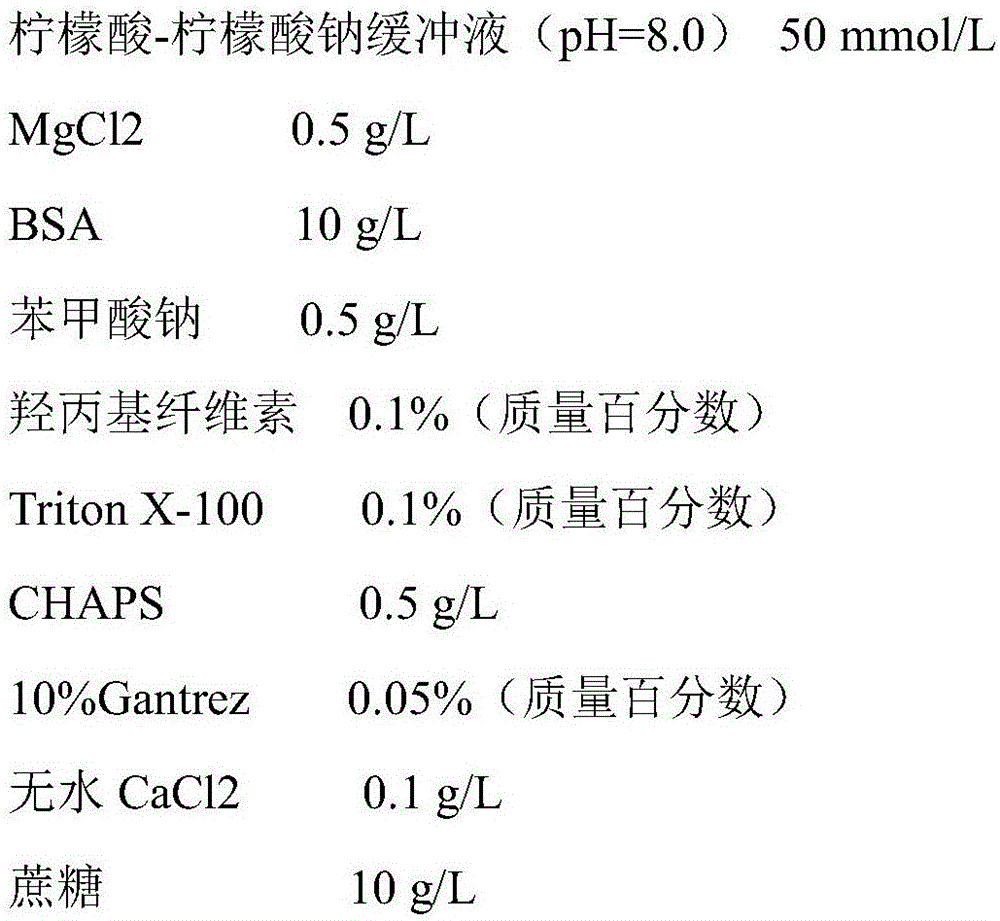

A dry-sheet type serum creatinine detection reagent strip and a preparing method thereof

A dry-sheet type serum creatinine detection reagent strip and a preparing method thereof are disclosed and belong to the field of in-vitro diagnosis. A creatinine reacting membrane, a filtering membrane and a diffusion layer in the reagent strip are fixed to a plastic plate in an appropriately overlapping manner. The reagent strip is characterized in that the reacting membrane includes a diluting liquid and a reacting reagent, the diluting liquid includes a buffer liquid, a surfactant, a stabilizer, an adhesive, a coenzyme factor and an aseptic, and the reacting reagent includes creatinine amidohydrolase, creatinase, sarcosine oxidase, peroxidase, 4-aminoantipyrine and N-ethyl-N-(2-hydroxy-3-sulfopropyl)-3,5-dimethylaniline. The Trinder reagent is utilized as an indicator probe, an analyte finally generates a colored quinone compound through various enzyme functions, and the creatinine content of a sample is indirectly detected through the coloration degree of the quinone compound. According to the reagent strip and the method, a liquid phase reaction is transferred to a solid carrier, objectives of simple operation and rapid and convenient detection of the creatinine content of the sample are achieved, and the reagent strip and the method are high in sensitivity, good in accuracy and convenient in popularization and application.

Owner:GETEIN BIOTECH

Quick healant with low viscosity and high performance for concrete structure

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

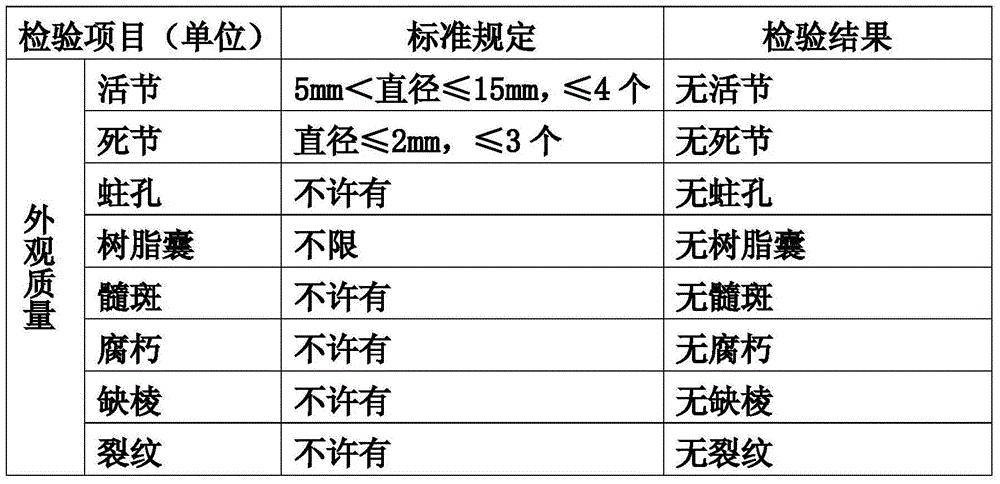

Antibacterial mildew-proof PVC (polyvinyl chloride) wood-plastic composite material

The invention discloses an antibacterial mildew-proof PVC (polyvinyl chloride) wood-plastic composite material, made from, by weight, 30 to 40 parts of wood powder, 10 to 20 parts of butyl acrylate, 0.02 to 0.03 part of benzoyl peroxide, 0.01 to 0.02 part of N, N-dimethylaniline, 3 to 4 parts of polyethylene wax, 1 to 1.2 parts of dilauryl thiodipropionate, 1.5 to 2 parts of calcium stearate, 95 to 100 parts of polyvinyl chloride, 2 to 3 parts of AC foamer, 1 to 2 parts of cell regulator ACR530, 6 to 8 parts of chlorinated polyethylene, 2 to 4 parts of methylisothiazolinone, 3 to 4 parts of nano carbon powder, 3 to 5 parts of chitosan, 3 to 4 parts of ceramic fiber, and 0.3 to 0.4 part of silane coupling agent kh570. A preparation process of the material is simple and highly operable, and the material is good in quality stability, has excellent performances in terms of antibiosis, bacteriostasis, mildew prevention, corrosion resistance and the like, has high cost performance and is worthy of vigorous popularization.

Owner:ANHUI BEIMA TECH CO LTD

Method for preparing high-compactness titanium or titanium alloy by using gel casting formation

InactiveCN105543526ALow costSuitable for large-scale industrial productionBenzoyl peroxide(Hydroxyethyl)methacrylate

The invention belongs to the technical field of powder metallurgy, and in particular, relates to a method for preparing high-compactness titanium or a titanium alloy by using gel casting formation. Firstly, an organic monomer-beta hydroxyethyl methacrylate and solvent-toluene are prepared to premixed liquid; mixed powder of pure titanium hydride or titanium hydride and an alloy element is added for preparing pulp; an initiator-benzoyl peroxide and a catalyst-dimethylaniline are added for curing to obtain a blank; the blank is dried, degreased and sintered in vacuum to obtain a sintered body with a relative density of higher than 95%; and then, the cover-less hot isostatic pressure treatment is performed to obtain a titanium alloy part with high compactness (relative density higher than 99.5%). The method is low in cost, suitable for preparation of titanium or titanium alloy products with large size, complex shape and high compactness and suitable for large-scale industrial production.

Owner:CHINA IRON & STEEL RES INST GRP +1

Thermoplastic fiber-reinforced epoxy composite and applications thereof

ActiveCN102774013AImprove processing and manufacturing speedRealize mass production4-MethoxyphenolEpoxy

The invention discloses a thermoplastic fiber-reinforced epoxy composite and applications thereof. The thermoplastic fiber-reinforced epoxy composite is prepared by taking epoxy resin and crylic acid as raw materials, thermoplastic fiber aramid woven cloths as reinforcing materials, N,N-dimethylaniline as catalyst, 4-methoxyphenol as polymerization inhibitor, trimethylolpropane triacrylate as diluted monomer, isopropylthioxanthone as photoinitiator, silane coupling agent as modifier, and metahanol as solvent, firstly synthesizing epoxy acrylate, diluting with the trimethylolpropane triacrylate, synthesizing photosensitive resin, dipping the thermoplastic fiber aramid woven cloths with the photosensitive resin, and carrying out fast forming of a novel electric car body support frame on photocuring forming equipment. The photocured electric car body support frame prepared by using the method has excellent performances, is environment-friendly, and has no harm influence on human body and ambient environment, and the curing effect meets the national standard.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Preparation process of cefamandole nafate

The invention discloses a preparation process of cefamandole nafate. The preparation process comprises steps of: heating and stirring 7-amino cephalosporanic acid, 5-mercapto-1-methyltetrazole and a catalyst boron trifluoride acetonitrile complex for a reaction; and carrying out a cooling post-treatment to obtain cefditoren nuclear parent; conducting a heating reflux reaction on the cefditoren nuclear parent and a silanizing agent until the solution turns to a clarified state; adding N, N-dimethyl aniline under the protection of inert gas at a low temperature, dropwise adding D-(-)-O-formyl mandeloyl chloride for reaction, and carrying out post-treatment to obtain formyl cefamandole acid; and reacting the formyl cefamandole acid with an organic acid salt, and recrystallizing to obtain the cefamandole nafate. By the above way, the preparation process of cefamandole nafate provided by the invention employs a simple and easily implemented process to obtain high-yield cefditoren nuclear parent with low impurity content; dichloromethane is used as a solvent to obtain the cefamandole acid with greatly enhanced color grade and yield; and dosage of activated carbon in the post-treatment is obviously reduced, so as to reduce the production cost.

Owner:苏州盛达药业有限公司

Preparation method of sulfadoxine

InactiveCN102304095BHigh melting pointReduce usageOrganic chemistrySodium methoxideDimethylaniline N-oxide

Owner:CHANGSHU NANHU INDAL CHEM

Bamboo strip softener and preparation process thereof

InactiveCN104526808AWood treatment detailsReed/straw treatmentPotassium persulfateDimethylaniline N-oxide

The invention provides a bamboo strip softener and a preparation process thereof. The bamboo strip softener is prepared by the following steps: weighing glycerol, alkylethoxyglucoside, polyoxyethylene ether and a surfactant, putting into a stirring tank, stirring for 30 minutes with the stirring temperature to be 80 DEG C, then adding potassium persulfate, formaldehyde and ammonium persulfate, simultaneously adding cobalt naphthenate, dimethylaniline and calcium carbonate, rapidly stirring for 3 minutes with the stirring temperature to be 130 DEG C, finally adding stearyl alcohol, stearic acid, stearic acid, urethane and paraffin, stirring for 1h, and cooling at room temperature. The bamboo strip softener has the beneficial effects that the prepared softener is good in softening effect without corrosion and good in effect, is capable of strengthening the strength and the toughness of the softening part and is convenient in popularization and using.

Owner:界首市祥雨竹编专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com