Silver nanowire-filled self-repairing conducting resin and preparation method thereof

A silver nanowire and self-repairing technology, which is applied in the field of conductive adhesives, achieves the effects of good controllability, simple and easy preparation method, and expanded application range

Inactive Publication Date: 2012-10-10

CHANGZHOU UNIV

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

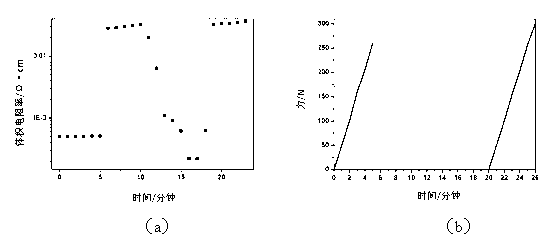

[0003] Microcapsule self-healing technology is a method developed in recent years to repair internal cracks in composite materials. The main mechanism is to embed microcapsules in composite materials during the preparation of composite materials. After the micro-cracks are generated, the cracks expand and tear the pre-embedded capsules, releasing the self-healing agent in the capsule core. The self-healing agent polymerizes with the accelerator on the surface of the crack, and the bonding crack prevents the crack from further expanding to achieve self-healing. Since the embedded microcapsule self-healing technology was reported in the journal Nature in 2001, various related research reports have been carried out on the system and types of capsules in the self-healing technology. At present, the self-healing technology of microcapsules is limited to the composite materials industry. Application, in the patent of this invention, the microcapsule self-healing technology widely used in composite materials is applied to the preparation of conductive adhesives that require high impact resistance. At present, there are no reports about self-healing conductive adhesives at home and abroad. patent

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~10

[0041]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

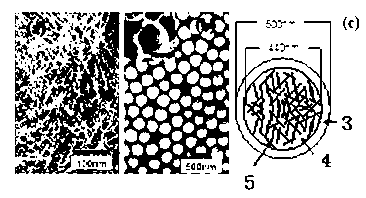

The invention relates to a conducting resin and especially relates to a silver nanowire-filled self-repairing conducting resin and a preparation method thereof. Through an emulsion polymerization method, core-shell structure nano-particles comprising shells of polystyrene and cores of a polymercaptan-dimethylaniline mixture with silver nanowires dispersed therein are prepared; the core-shell structure nano-particles are dispersed in an isotropic conducting resin filled with silver nanowires; under the action of an external force, the core-shell structure nano-particles fracture automatically; the polymercaptan-dimethylaniline mixture and an excess amount of epoxy groups in the isotropic conducting resin undergo a rapid reaction so that resin microcracks produced by the external force are repaired automatically; and simultaneously, the silver nanowires of the core-shell structure nano-particles are uniformly dispersed on repaired places so that repairing effects on a conductive network are obtained. Therefore, a service life of a conducting resin is improved and a cost of an electron component is reduced.

Description

technical field [0001] The invention relates to a conductive adhesive, more specifically to a self-repairing conductive adhesive filled with silver nanowires and a preparation method thereof. Background technique [0002] As the main connecting material of electronic components, Sn-Pb solder has the disadvantages of high soldering temperature, great environmental hazards, and inability to meet the working environment with small pitches, etc., which have gradually emerged in recent years; conductive adhesives are used as Sn-Pb electronic packaging materials The substitutes of conductive adhesives are used more and more widely. With the widespread use of conductive adhesives in the microelectronic packaging industry, their service life, safety, and stability have gradually become the focus of researchers. Microelectronics bonded with conductive adhesives When the device is subjected to external impact, microcracks will be generated inside the conductive adhesive, and the expan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J163/00C09J163/02C09J9/02C09J11/04C09J11/06B01J13/14

Inventor 陶宇吴海平王标兵

Owner CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com