Device for underwater local dry process welding and welding method

A local dry method and welding power supply technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of fast cooling of the weld pool, reducing the mechanical properties of the weld, and difficult transfer of molten droplets to the base metal. Achieve the effects of low manufacturing cost, improved penetration ability, and wide range of engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

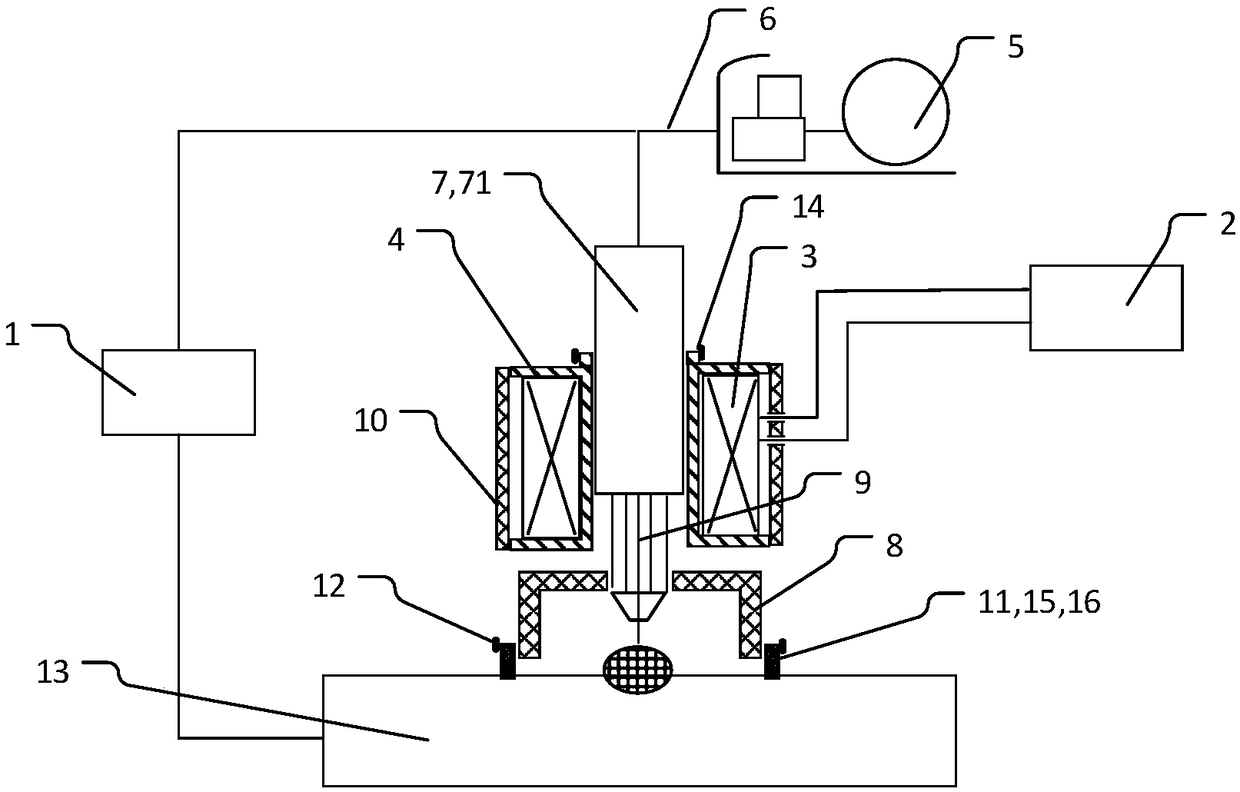

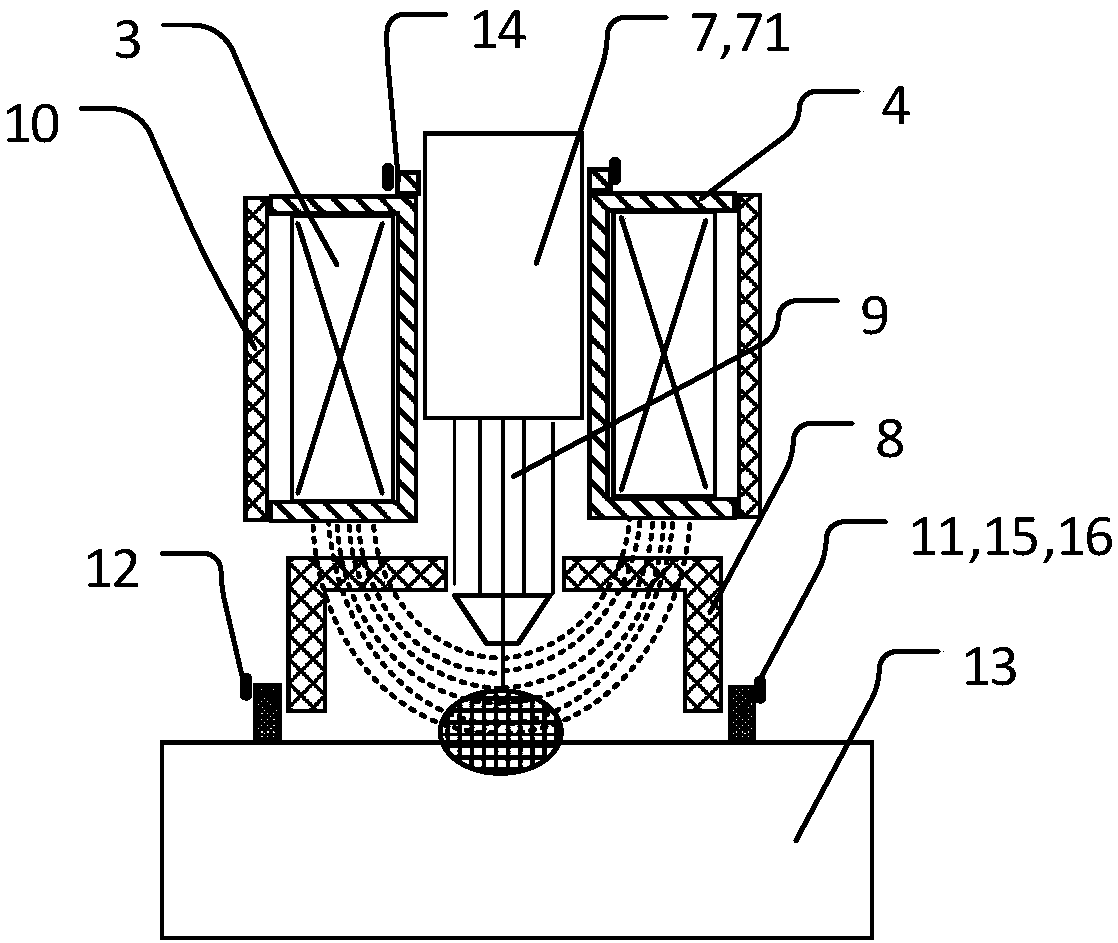

[0032] The present invention is described below based on the embodiments, and those skilled in the art should understand that the drawings provided here are for the purpose of illustration, and the drawings are not necessarily drawn to scale.

[0033] Unless the context clearly requires, throughout the specification and claims, "comprises", "comprises" and similar words should be interpreted in an inclusive sense rather than an exclusive or exhaustive meaning; that is, "including but not limited to" meaning.

[0034] Note: In this application, the up-down direction is defined as: figure 1 In the axial direction of the middle permeable magnetic core 4, the direction close to the workpiece 13 is down, and the direction away from the workpiece 13 is up; and, the figure 1 The radially outer side of the middle magnetically permeable core 4 is defined as outer, and the radially inner side of the magnetically permeable core 4 is defined as inner.

[0035] Such as figure 1 , figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com