Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Refined weld structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Mg-Sc series solder wire

ActiveCN1954959AImprove crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaChemical compositionManganese

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

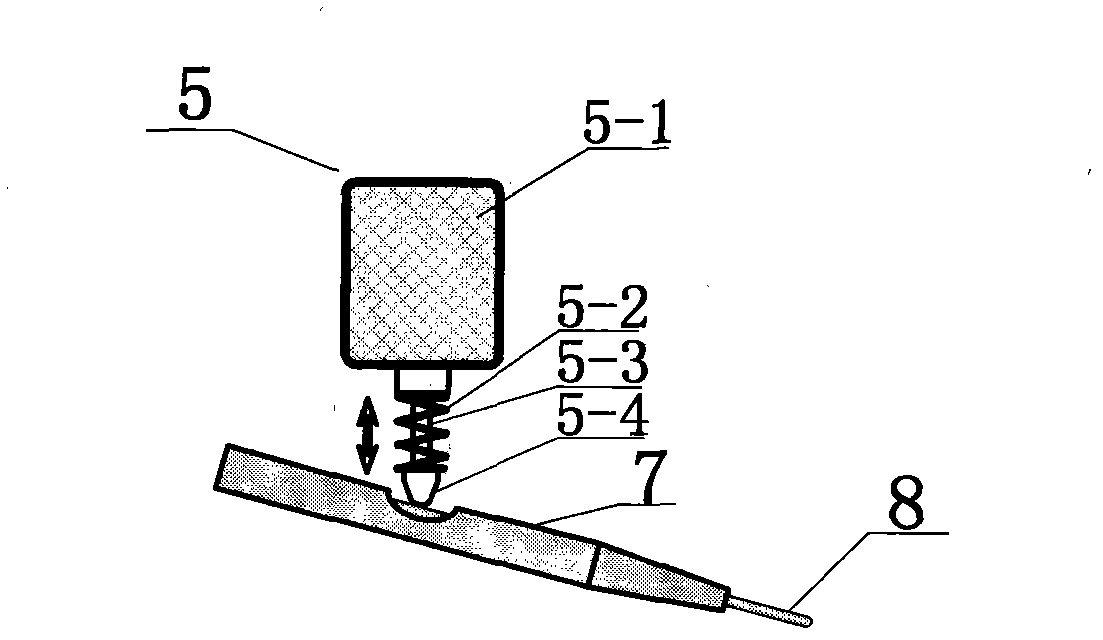

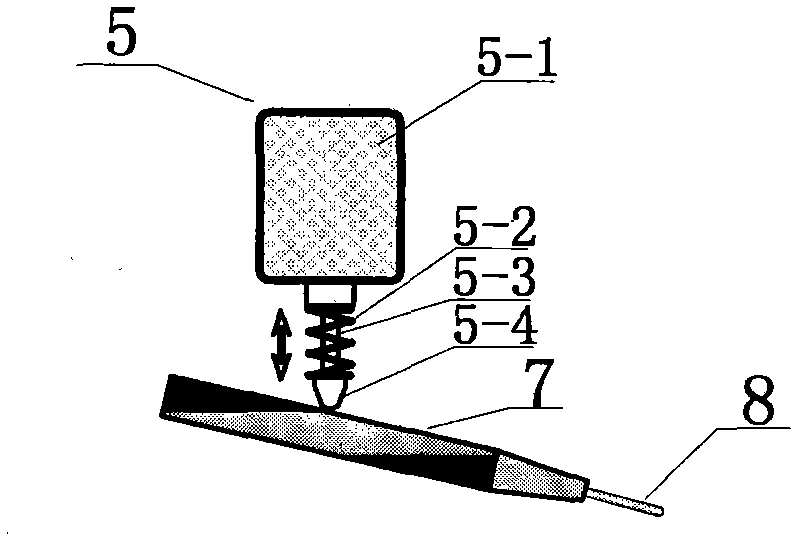

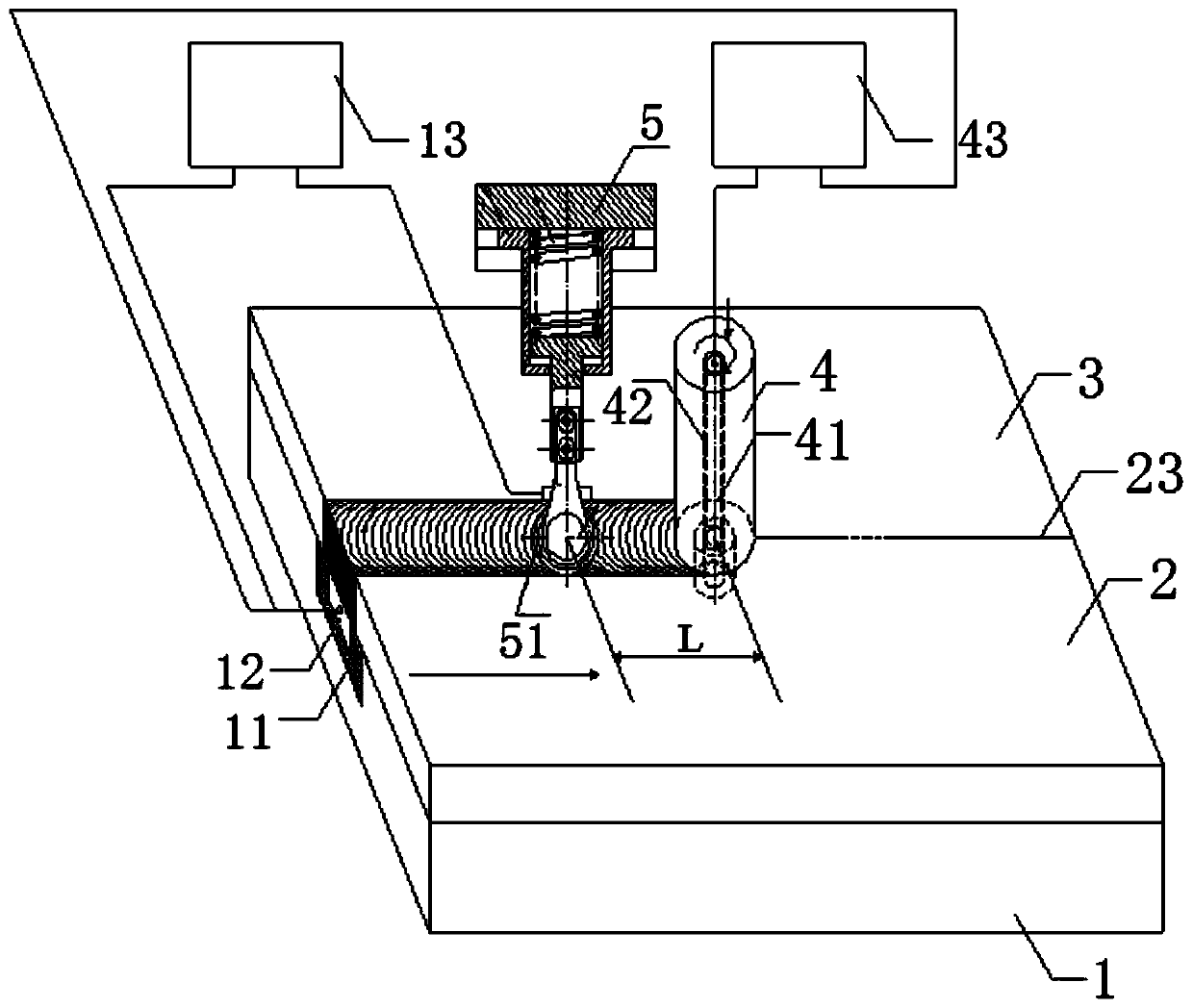

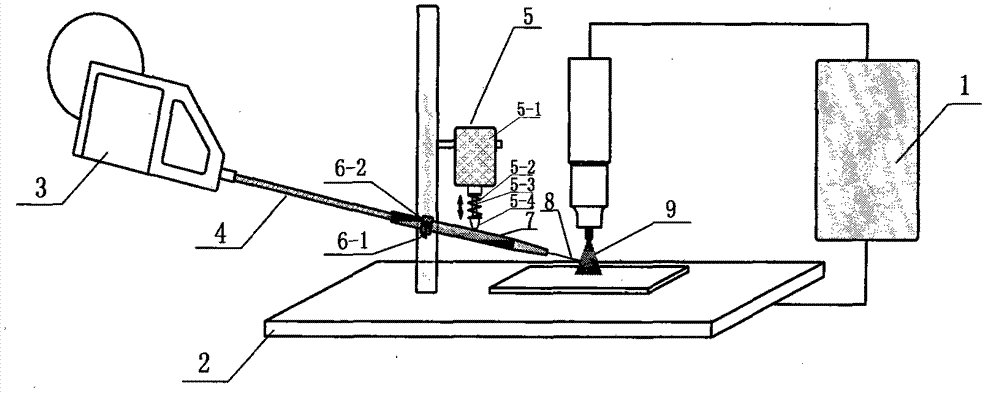

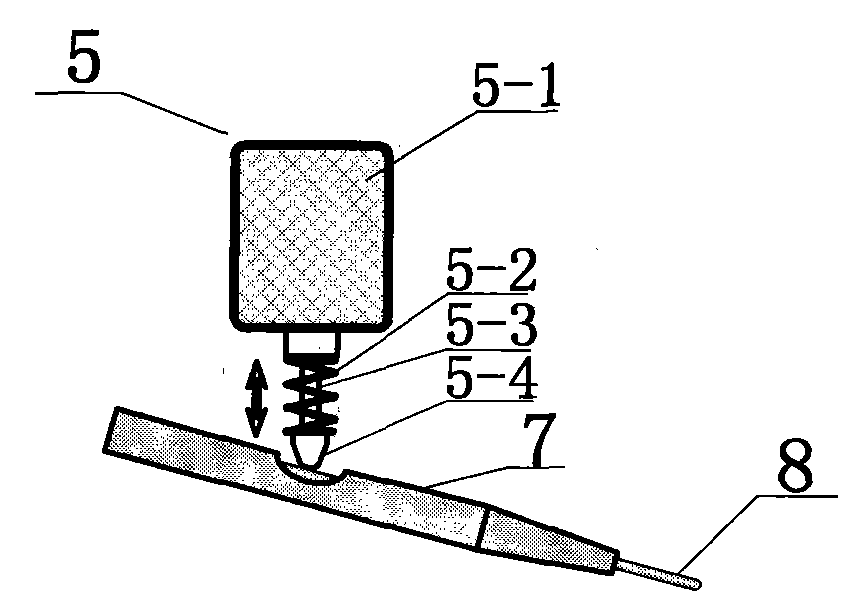

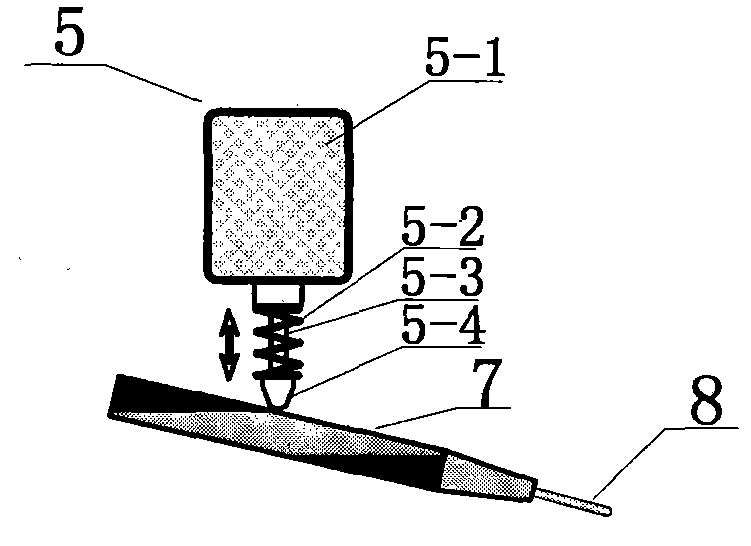

TIG (tungsten inert gas) welding method for auxiliary mechanical vibration droplet transfer and TIG welding device for same

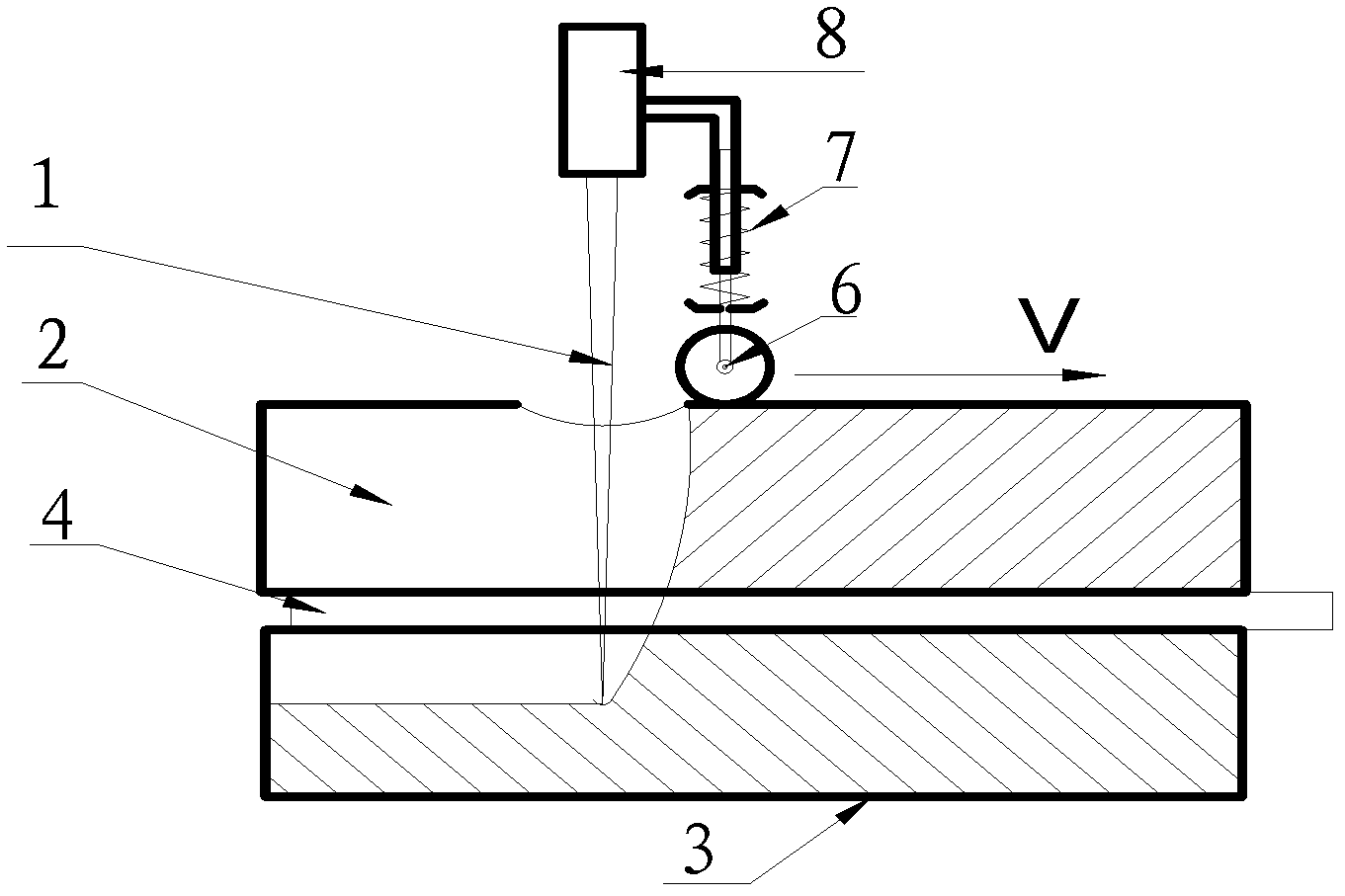

The invention provides a TIG (tungsten inert gas) welding method for auxiliary mechanical vibration droplet transfer and a TIG welding device for the same. The TIG welding device comprises a TIG power supply, a wire feeder, a guide tube, an auxiliary mechanical vibration device, a wire feeding nozzle and a welding wire, wherein the wire feeder is connected with the guide tube, the guide tube is connected with the wire feeding nozzle, and the auxiliary mechanical vibration device is fixed to a frame. A vibration rod is driven to vertically vibrate in a reciprocating manner by an internal body driving motor and a transmission device, and a buffer spring is sleeved between the vibration rod and a contact. The TIG welding method includes the steps: igniting an arc heating workpiece, forming a molten bath after arc is stable, and then starting the wire feeder to automatically feed in the welding wire; and starting the auxiliary mechanical vibration device, leading the vibration rod, the contact and the welding wire to mechanically vibrate, and performing welding under the action of auxiliary mechanical vibration. The TIG welding device is simple, convenient in operation and high in applicability, and compared with digital control equipment, the TIG welding device greatly reduces cost and is convenient for industrial popularization.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

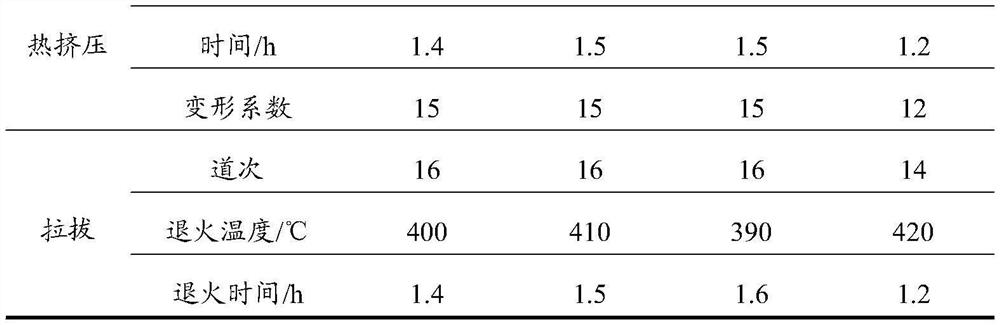

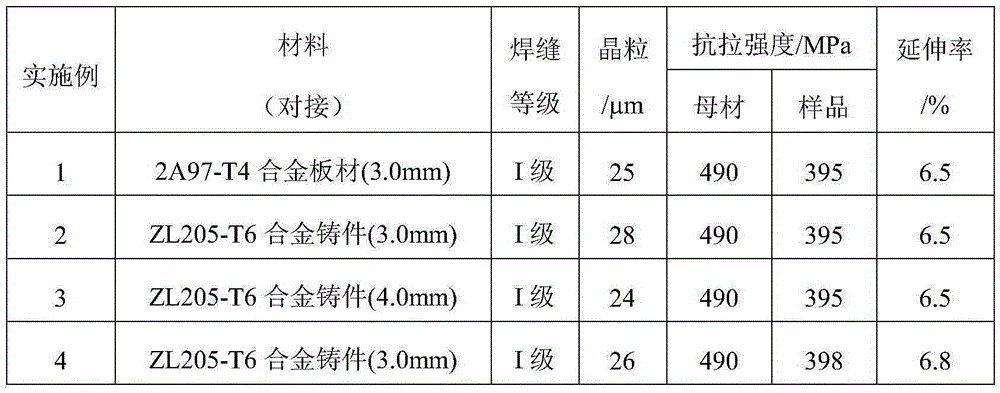

Aluminum alloy welding wire for high speed train and preparation method of aluminum alloy welding wire for high speed train

InactiveCN105772981AHigh tensile strengthImprove plasticityWelding/cutting media/materialsSoldering mediaCrack resistanceAlloy

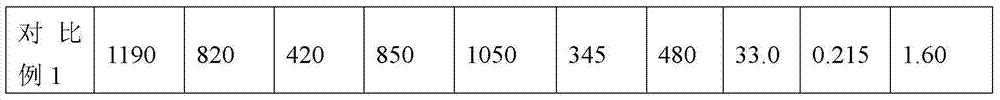

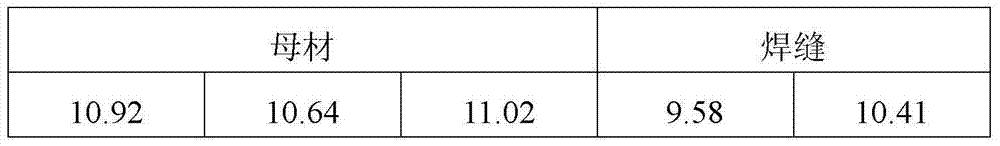

The invention relates to an aluminum alloy welding wire for a high speed train and a preparation method of the aluminum alloy welding wire for the high speed train. The aluminum alloy welding wire for the high speed train is characterized by comprising the following chemical components in percentages by mass: 4.0-6.5% of Mg, 0.06-0.2% of Ti, 0.1-0.3% of Cr, 0.05-0.2% of Mn, 0.05-0.2% of La, 0.05-0.2% of Te, 0.01-0.05% of Bi, less than or equal to 0.25% of Si, less than or equal to 0.2% of Fe, less than or equal to 0.20% of Zn, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. The preparation method of the aluminum alloy welding wire for the high speed train comprises the following steps: smelting, refining, casting, homogenization, extrusion, drawing, and surface treatment. The aluminum alloy welding wire for the high speed train provided by the invention is fine in weld microstructure and good in crack resistance; the tensile strength, the plasticity and the toughness of welded joints are remarkably higher than those of common ER5356 and ER5183 welding wires.

Owner:GUILIN UNIV OF AEROSPACE TECH

Ferritic stainless steel for tubular heat exchangers and manufacturing method thereof

The invention relates to a ferritic stainless steel for tubular heat exchangers and a manufacturing method thereof. The ferritic stainless steel comprises the following chemical components in percentage by weight: at most 0.015% of C, at most 0.020% of N, at most 0.5% of Si, at most 0.5% of Mn, at most 0.035% of P, at most 0.01% of S, 22-24% of Cr, 1.5-3.0% of Mo, 0.0050-0.050% of Al, and the balance of Fe and inevitable impurities, wherein 10(C+N)<=(Nb+Ti)<=0.6%. The manufacturing method comprises the following steps: smelting by an arc furnace+AOD (argon oxygen decarburization)+VOD (vacuum oxygen decarburization) three-step process, carrying out continuous casting to obtain a continuous casting blank, and carrying out hot rolling, acid washing, cold rolling, annealing, acid washing and the like to obtain the high-weldability cold-rolled stainless steel sheet strip. The high-weldability cold-rolled stainless steel sheet strip is suitable for manufacturing welded tubes with higher requirements for corrosion resistance and flaring performance; and the flaring ratio is up to higher than 35%.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Single-surface traceless welding method for stainless steel composite panel of elevator

ActiveCN102248297AHigh strengthGuarantee the appearance qualityLaser beam welding apparatusSheet steelShielding gas

The invention discloses a single-surface traceless welding method for a stainless steel composite panel of an elevator, comprising the following steps of: (1) eliminating oil stains on respective surfaces to be welded of a cold (hot) rolled steel plate and a stainless steel surface plate; (2) placing the stainless steel surface plate on a work table, respectively placing a separation bar at two sides of a position to be welded and 5-10 mm away from the position to be welded, and then placing the cold (hot) rolled steel plate on the separation bar so that a gap of 0.08-0.12mm is reserved between the cold (hot) rolled steel plate and the stainless steel surface plate; (3) carrying out laser welding on the cold (hot) rolled steel plate and the stainless steel surface plate with a mixed gas of oxygen gas and inert gas as a protective gas to ensure that a welding seam penetrates through the cold (hot) rolled steel plate and the depth of the welding seam on the stainless steel surface plate is controlled to be 1 / 3-1 / 2 of the thickness of the stainless steel surface plate; and ensuring that the stainless steel surface plate, the cold (hot) rolled steel plate and the separation bar are clamped tightly in a welding process. The method provided by the invention has the characteristics of no trace on a single stainless steel panel surface, high welding seam quality and high strength of a combination structure.

Owner:ZHEJIANG UNIV OF TECH +1

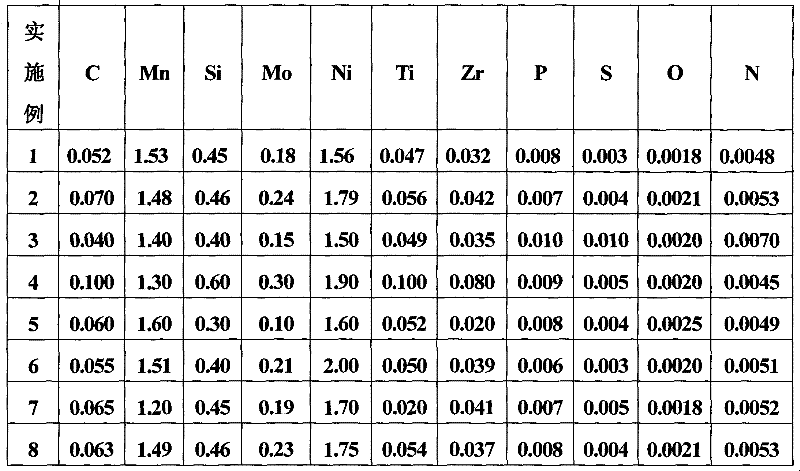

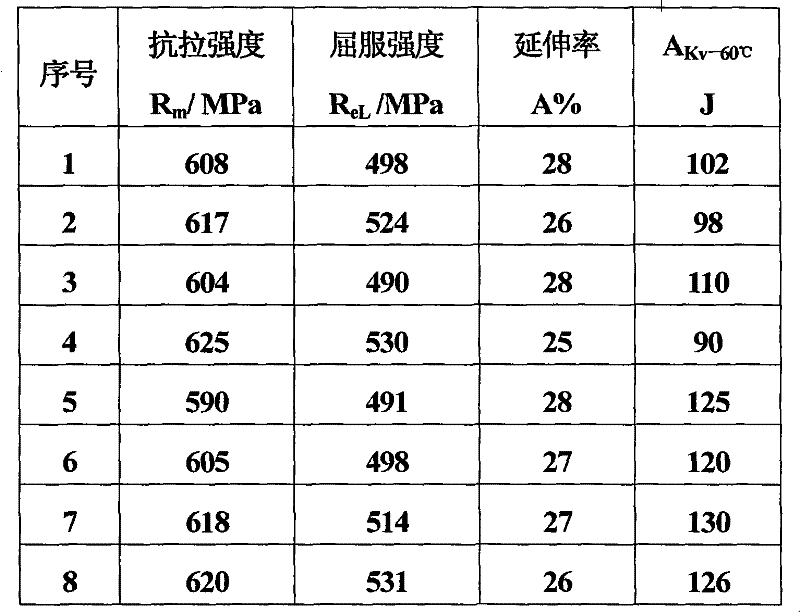

High-tenacity gas shielded welding wire for welding low-temperature steel and using method thereof

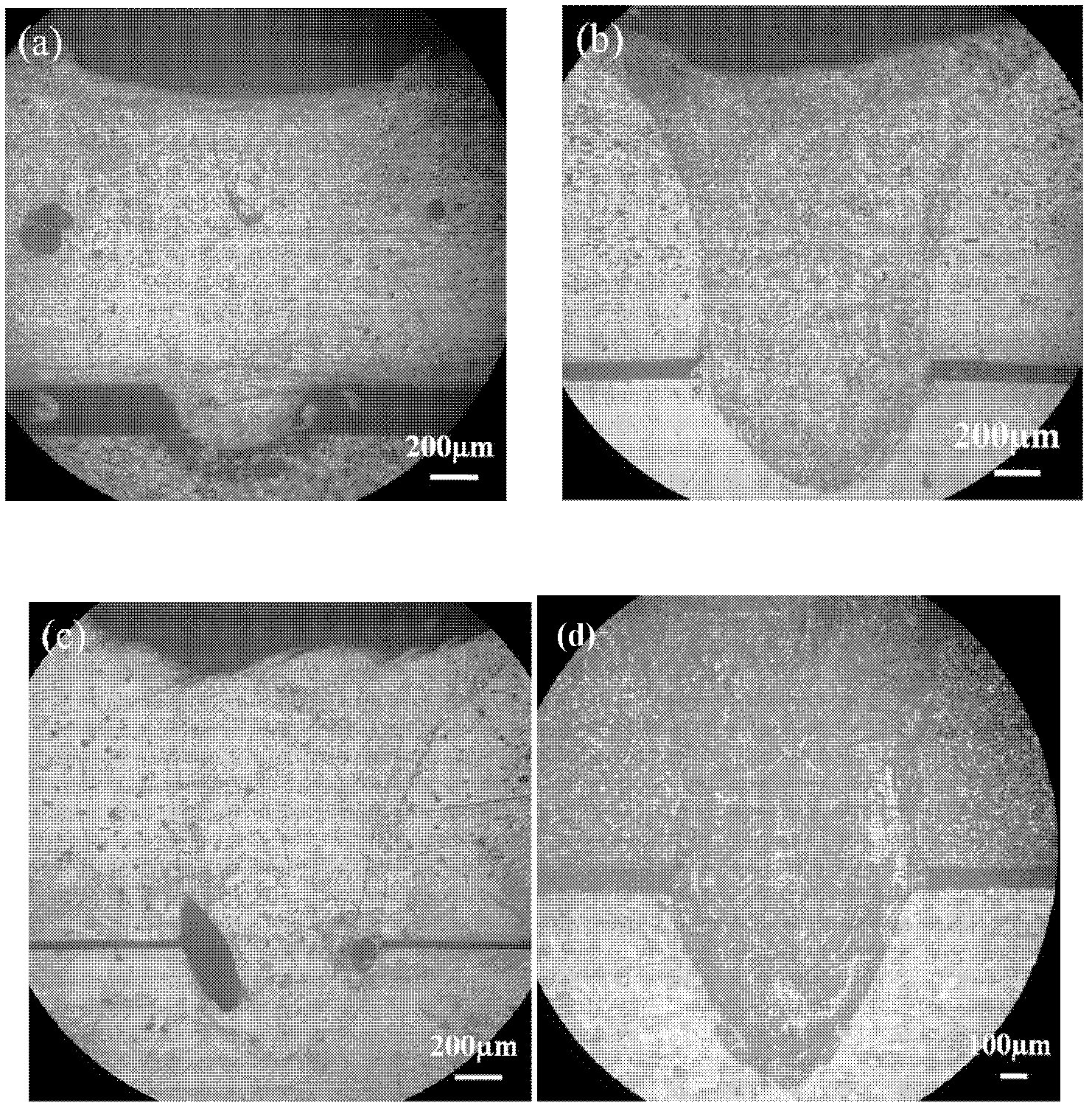

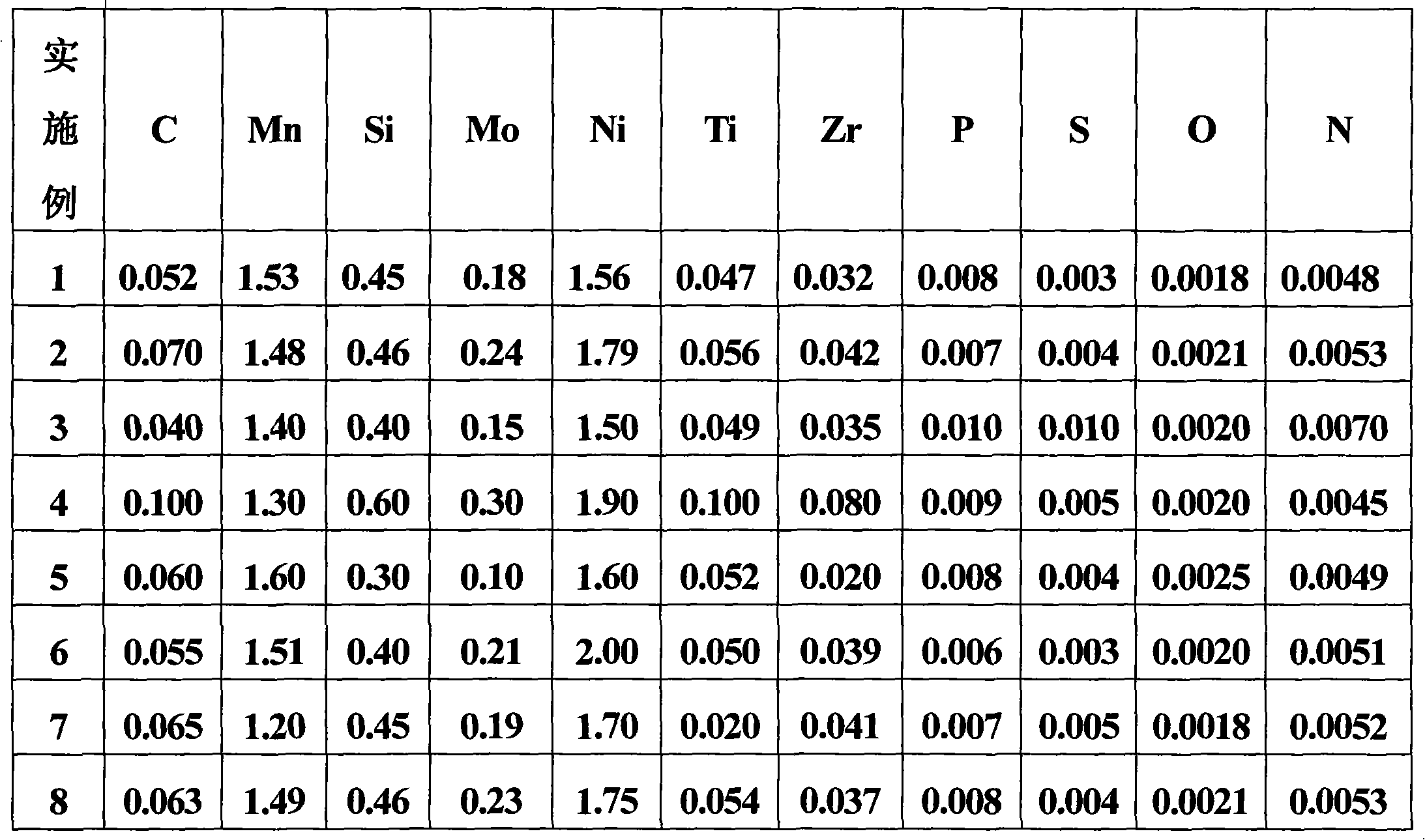

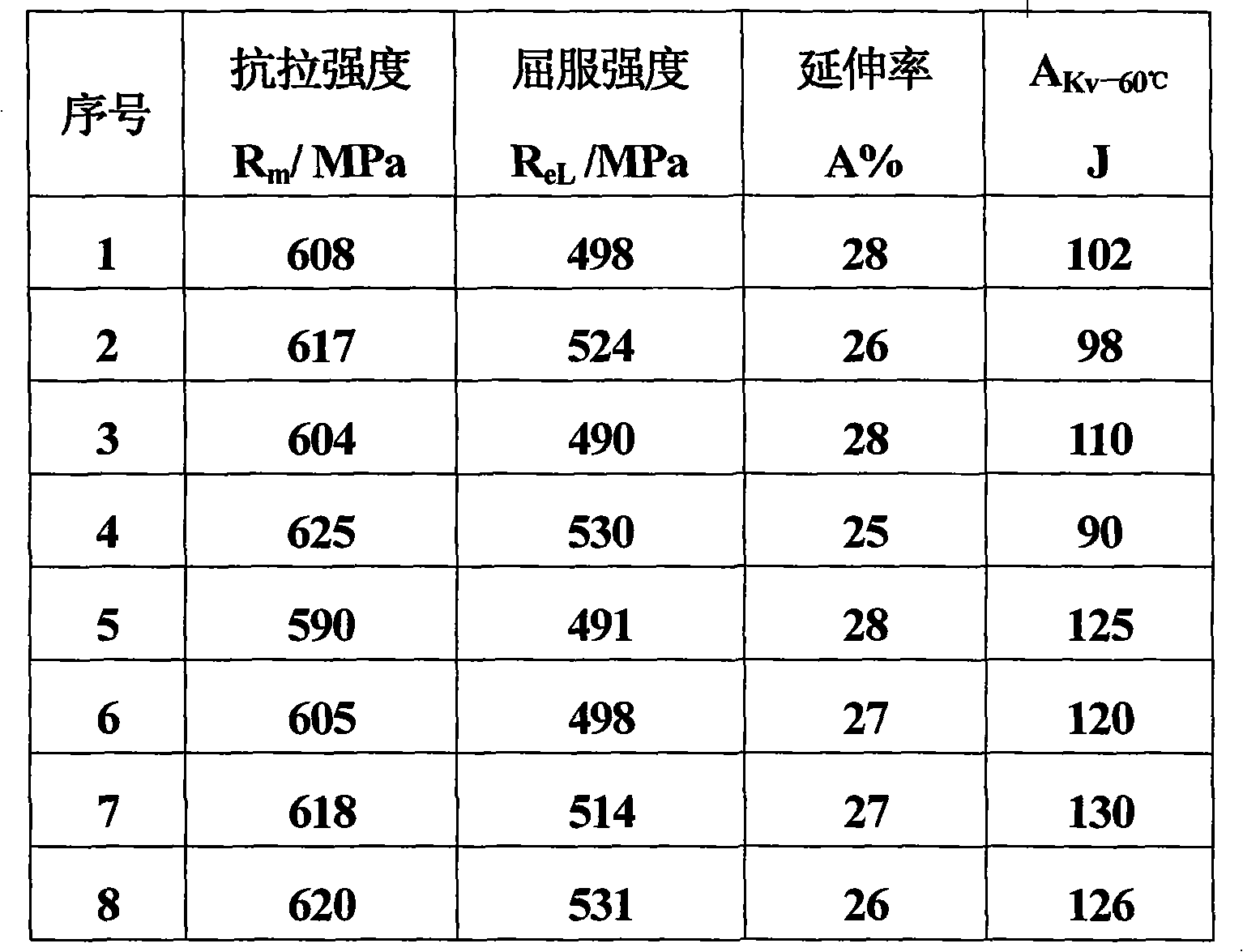

ActiveCN101913035AReduce the ductile-brittle transition temperatureReduce contentArc welding apparatusWelding/cutting media/materialsImpurityArgon gas

The invention provides a high-tenacity gas shielded welding wire for welding low-temperature steel, which is suitable for welding the low-temperature steel subjected to service in the environment of over minus 60 DEG C. The gas shielded welding wire comprises the following chemical components in percentage by mass: 0.04 to 0.10 percent of C, 0.20 to 0.60 percent of Si, 1.20 to 1.60 percent of Mn, 1.5 to 2.0 percent of Ni, 0.10 to 0.30 percent of Mo, 0.02 to 0.10 percent of Ti, 0.02 to 0.08 percent of Zr, less than or equal to 0.010 percent of S, less than or equal to 0.010 percent of P, less than or equal to 0.0025 percent of O, less than or equal to 0.0070 percent of N, and the balance of Fe and inevitable impurities. The welding wire welds by adopting Ar + 20%CO2 full-argon gas shielding so a weld metal has high low-temperature tenacity in a welding state and under a heat treatment condition after welding.

Owner:山东索力得焊材股份有限公司

NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and preparation method thereof

InactiveCN109894770AAvoid oxidation burnAvoid welding requirements for high temperature and corrosion resistanceWelding/cutting media/materialsSoldering mediaAcid washingAlloy

The invention discloses a NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and a preparation method thereof, and belongs to the field of welding materials. The welding wire comprises the following components in percentage by weight: 45-50% of Ni, 35-40% of Cr, 1.00-1.50% of Nb, 0.01-0.10% of Re, 0.30-0.55% of C, 0.50-2.00% of Si,1.00-2.00% of Mn, 0.01-0.10% of Al, 0.05-0.20% of Ti, 0.01-0.10% of Zr, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of alloy smelting-electroslag remelting-blooming by hot forging-hot-rolled annealing-mechanical stripping-diameter reduction by drawing-straightening and cutting or precise layer winding. The preparation method is environmentally friendly, free of acid washing pollution, stable in welding arc, free of splashing, beautiful in welding line molding, excellent in welding process and mechanical performance and dense in welding line structure, and can totally meet high-temperature-resistance and corrosion-resistance welding requirements of the ethylene cracking furnace cast pipes.

Owner:DANYANG XINHANG SPECIAL ALLOY

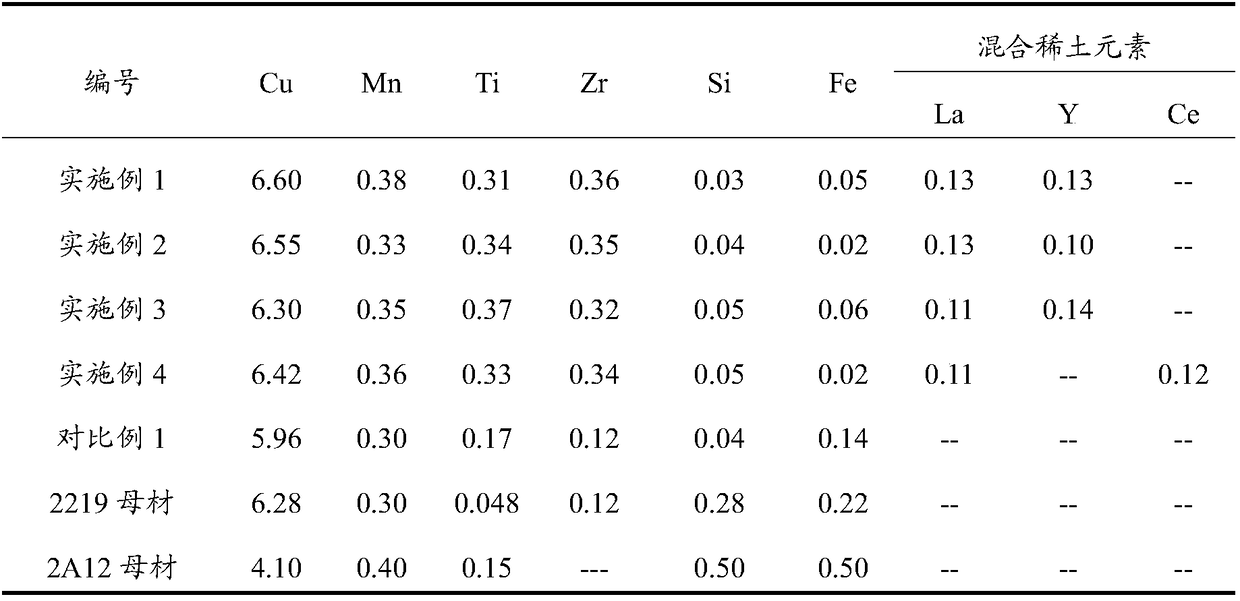

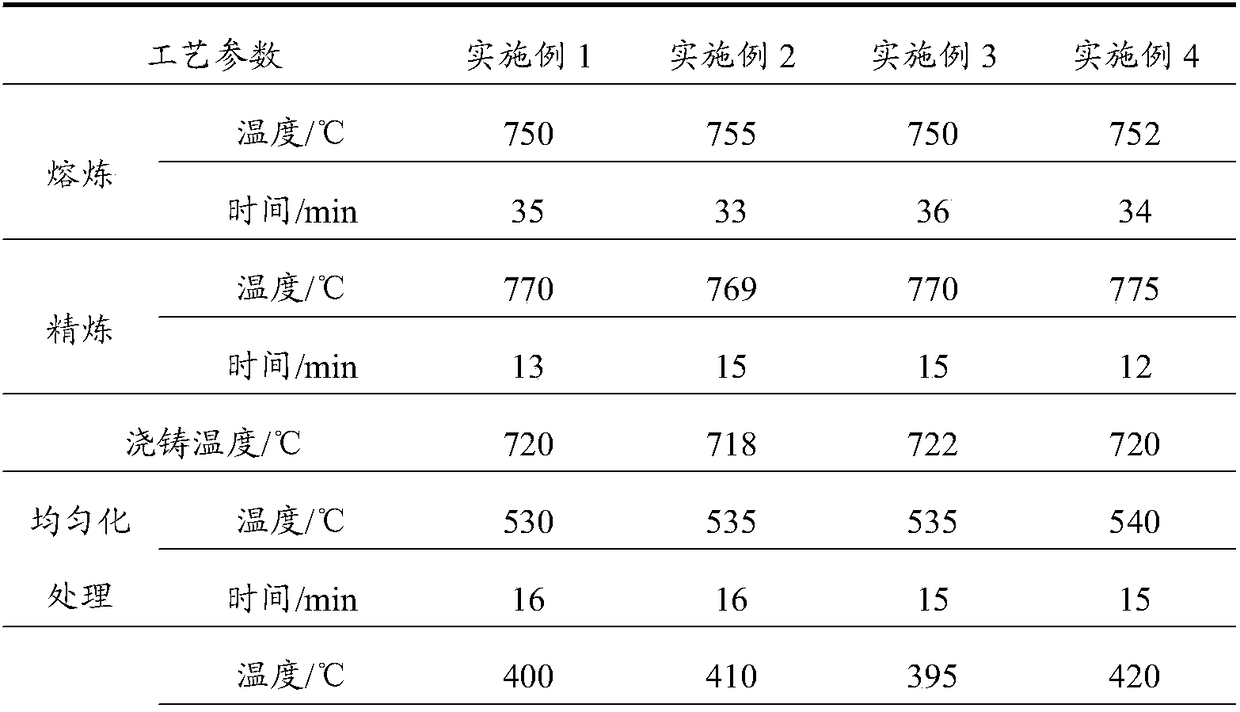

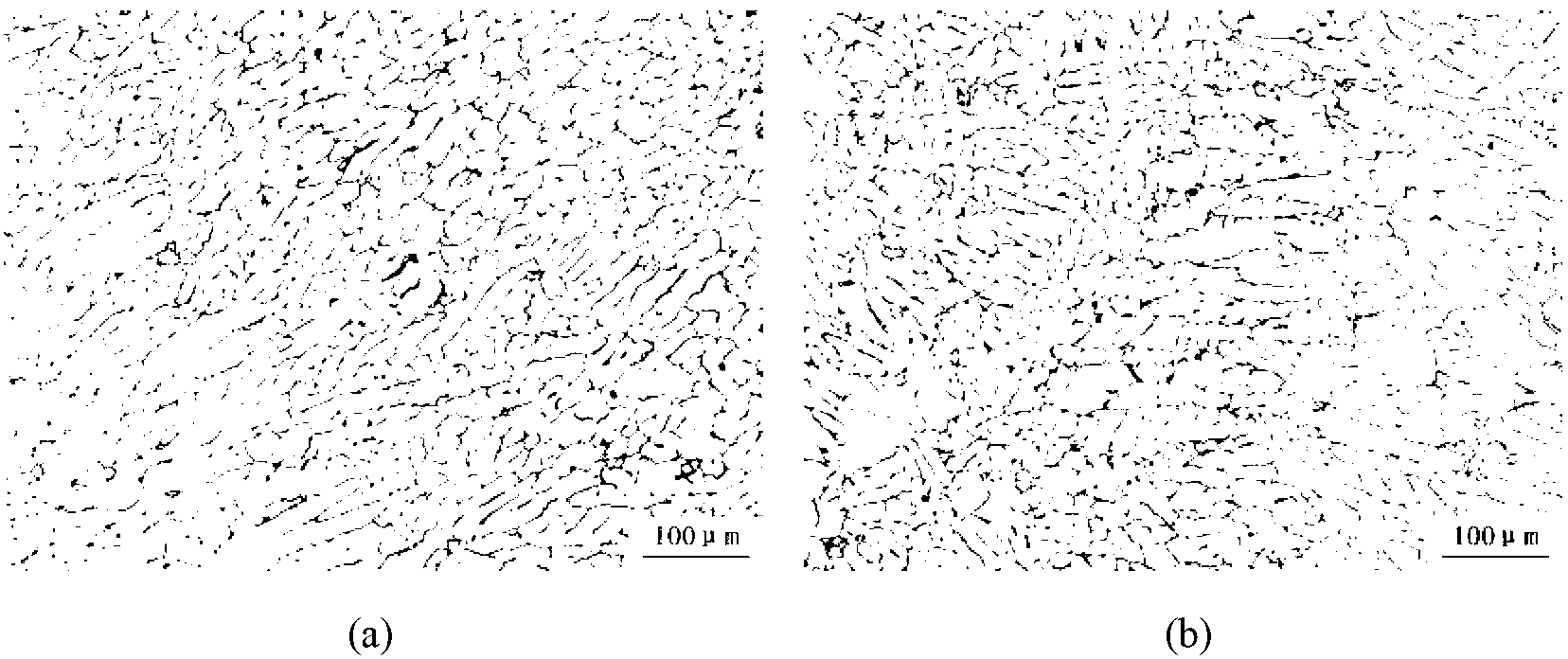

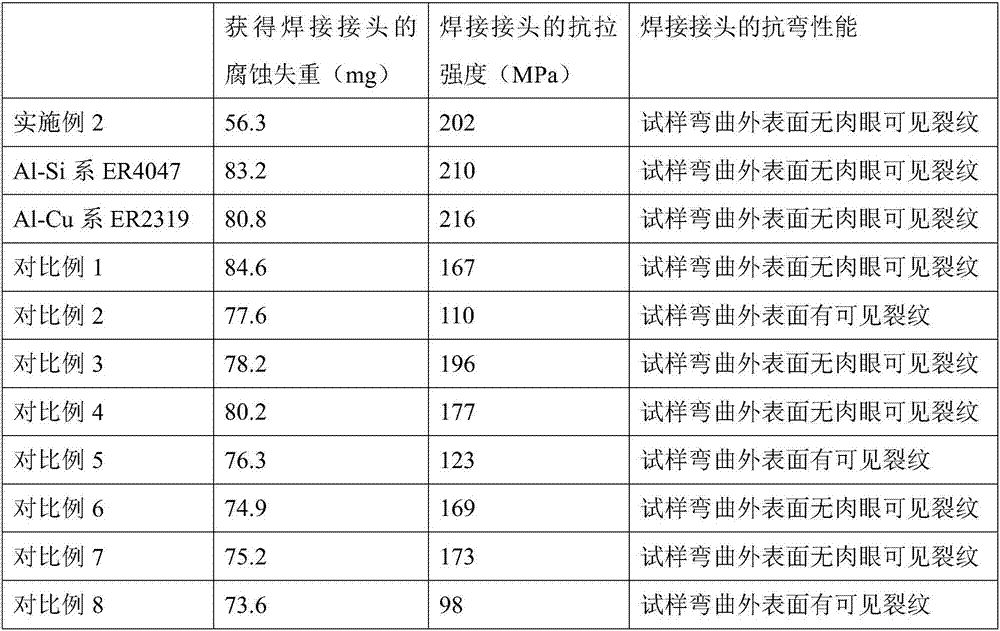

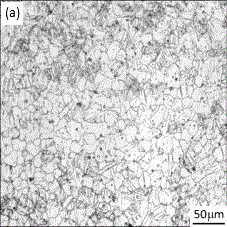

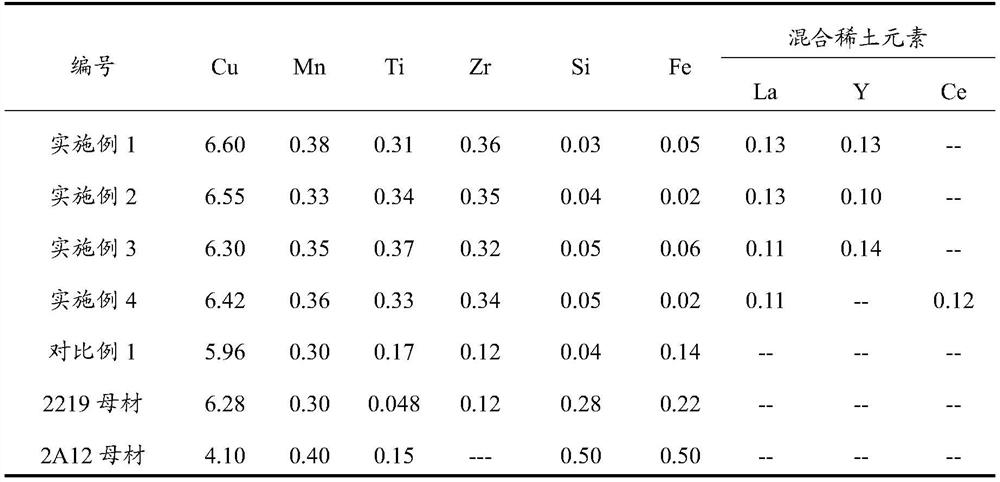

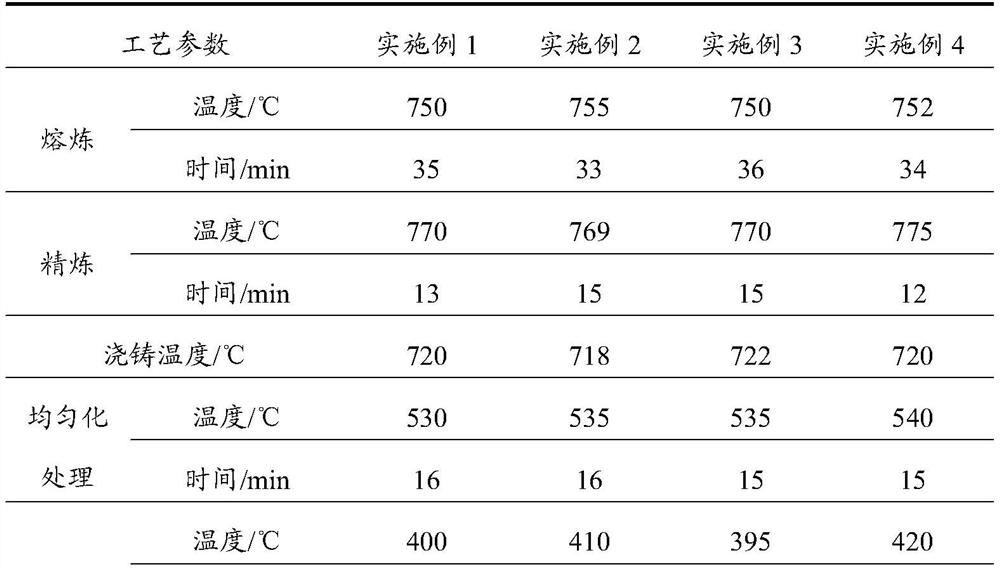

Welding wire for aluminum copper alloy and preparation method and application thereof

InactiveCN109128572APromote formationHigh strengthWelding/cutting media/materialsSoldering mediaRare-earth elementNucleation

The invention belongs to the technical field of aluminum alloy welding materials, and in particular, relates to a welding wire for an aluminum copper alloy and a preparation method and application thereof. Mixed rare earth elements are matched with Ti and Zr for use; the mixed rare earth elements, Ti and Zr can be reacted with Al to correspondingly generate high-melting-point particles; and the mixed rare earth elements can inhibit roughening, agglomeration and precipitation of the high-melting-point particles, so that the high-melting-point particles can serve as cores of basal body nucleation to accelerate formation of isometric crystals, to refine the welding line structures and to improve the strength and the plasticity of welding line joints. When the welding wire for the aluminum copper alloy is used for welding the aluminum copper alloy, the strength of the welding line joints reaches above 308 MPa, and the strength coefficient reaches 66.0-70.4%.

Owner:NANCHANG HANGKONG UNIVERSITY

Surface active agent for alternating TIG welding of aluminium and alumnium alloy and its coating process

InactiveCN1623721AIncrease weld penetrationImprove welding efficiencyWelding/cutting media/materialsSoldering mediaAlloyButanone

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Soldering agent and method for laser welding Al-Mg alloy plates with different thicknesses

InactiveCN1583351AGood lookingImproved laser welding stabilityWelding/cutting media/materialsSoldering mediaAl powderVariable thickness

A welding flux for the laser welding of Al-Mg alloy plate with variable thickness is prepared from Mg powder and Al powder through proportional mixing, grinding, baking at 100-180 deg.c, mixing with aceotne or butaneous and stirring. It is applied through coating it on the surface to be welded, volatilizing solvent and laser welding under protection of inertial gas.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Welding wire for preparation of aluminum-based wear-resistant coating through magnetron deposition formation

ActiveCN103008906AReduce mutationImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaTrace elementWear resistant

The invention relates to a welding wire for preparation of an aluminum-based wear-resistant coating through magnetron deposition formation, belonging to the field of weldments. The wire is prepared by adding Mg, Sc, Zr and other trace elements based on an ordinary Al-Si alloy wire, and comprises the following components by mass percent: 4.5-6 percent of Si, 0-0.2 percent of Fe, 0-0.3 percent of Cu, 0-0.2 percent of Ti, 0-0.45 percent of Zr and Sc, 0.15-0.35 percent of Mg, and Al as a remaining component. When the welding wire is used for preparation of the coating, grain transition is smooth, tissues are not subject to mutation, and excellent mechanical properties can be achieved. The wear resistance of the coating is excellent, the friction coefficient is only 0.32, surface scratches of an aluminum alloy substrate can be effectively reduced by the coating, and the wear resistance of the aluminum alloy substrate in high-temperature as well as hot and humid environments can be improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

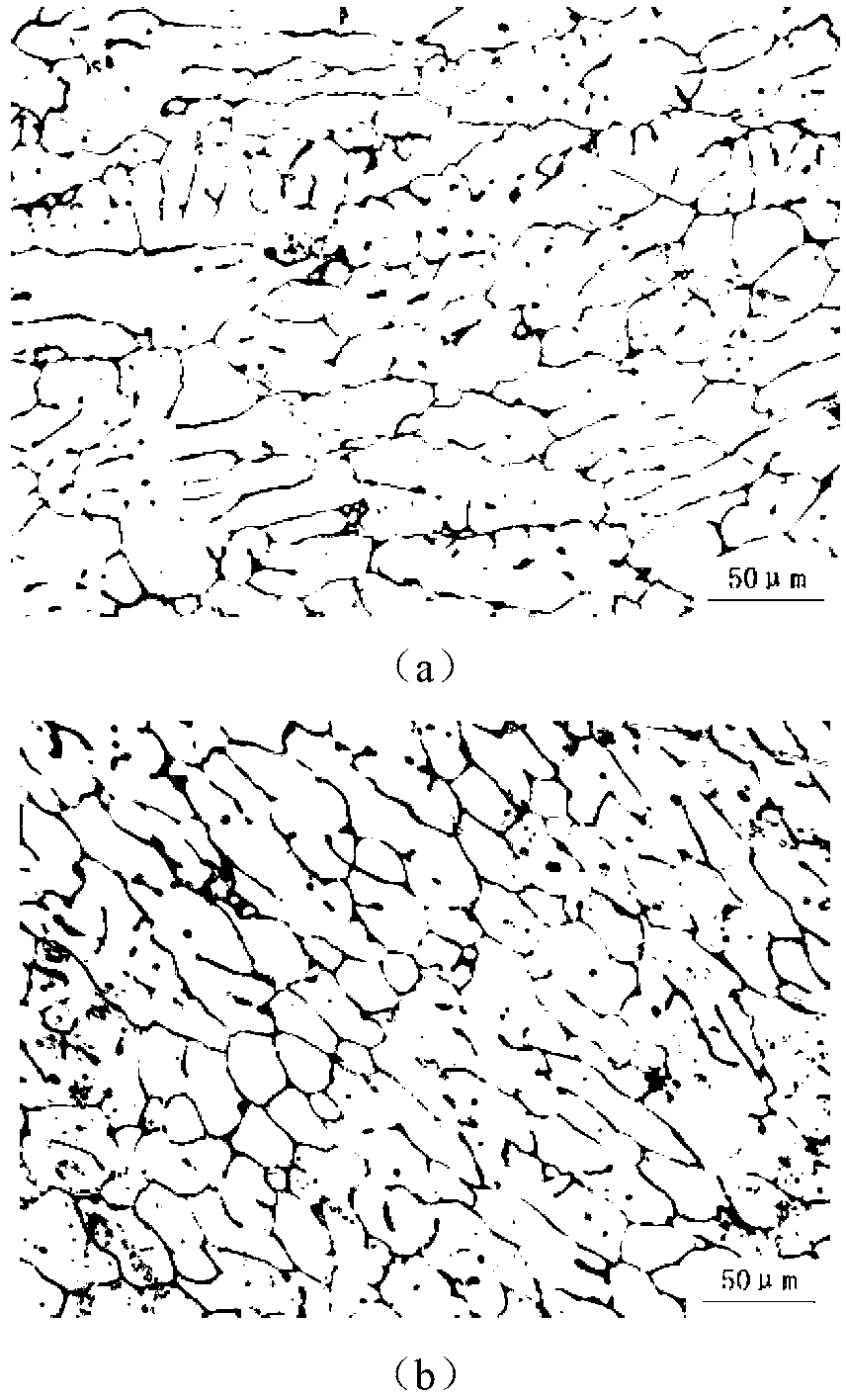

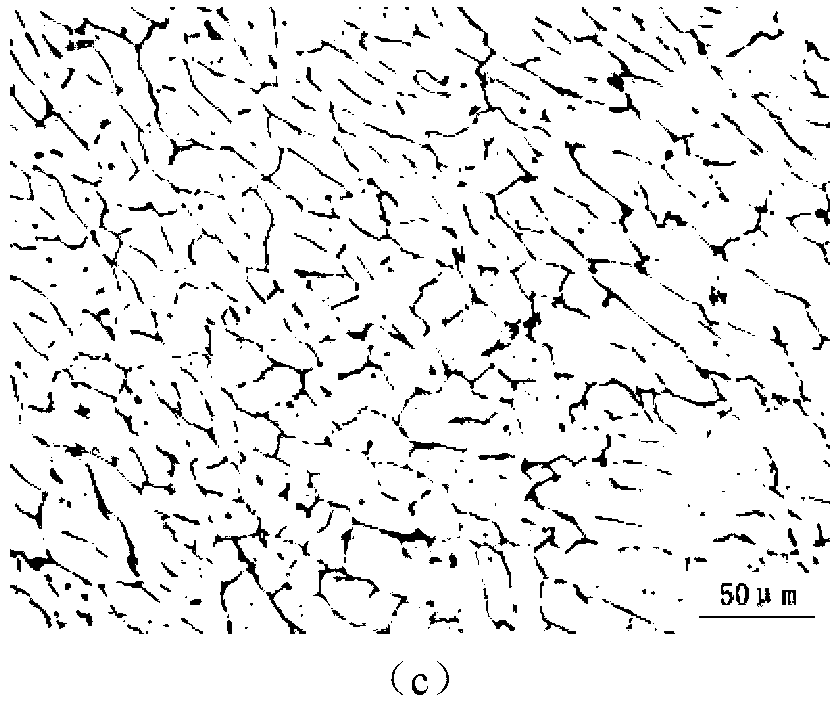

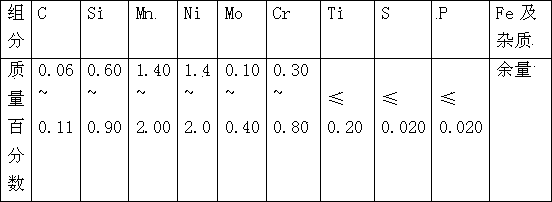

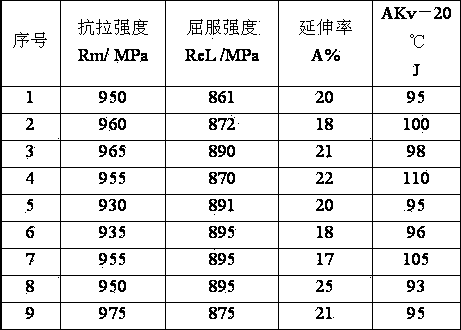

900MPa high-strength welding wire for mining machine and application method

InactiveCN103495812AImprove toughnessImprove low temperature toughnessArc welding apparatusWelding/cutting media/materialsGas protectionChemical composition

The invention provides a 900MPa high-strength welding wire for a mining machine and an application method. The 900MPa high-strength welding wire is suitable for welding Q890 plates, Q900 plates and other high-strength plates. The gas shielded welding wire comprises the following chemical components, by mass, including 0.06-0.11% of C, 0.60-0.90% of Si, 1.40-2.00% of Mn, 1.4-2.0% of Ni, 0.30-0.80% of Cr, 0.10-0.40% of Mo, less than or equal to 0.20% of Ti, less than or equal to 0.020% of S, and less than or equal to 0.020% of P with balance being Fe and inevitable impurities. The 900MPa high-strength welding wire is used for welding under the protection of gas rich in argon, that is Ar + 20% of CO2, thereby having high strength and low-temperature toughness.

Owner:山东索力得焊材股份有限公司

Aluminum-copper alloy grounding material welding wire and preparation method thereof

ActiveCN106862796AReduce compositional differencesGood resistance to soil corrosionWelding/cutting media/materialsSoldering mediaPotential differenceRare earth

The invention discloses an aluminum-copper alloy grounding material welding wire and a preparation method thereof. The aluminum-copper alloy grounding material welding wire comprises, by mass, 1%-3% of silicon, 1%-3% of copper, 0-0.3% of iron, 0.001%-0.05% of zirconium, 0.001%-0.5% of rare earth, and the balance aluminum. The aluminum-copper alloy grounding material welding wire can achieve welding of an aluminum-copper alloy grounding material, the structure of a weld zone is fine, the components are similar to those of parent metal, the potential difference is small, and the soil corrosion resistance is good.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Large-area metal wall surface field patching surfacing welding method and surfacing welding device

InactiveCN104827168ASoft textureGood high temperature resistanceArc welding apparatusInstabilityEngineering

The invention provides a large-area metal wall surface field patching surfacing welding method. A synchronous moving mechanism is installed on a welding gun of a surfacing welding device, in a surfacing welding process, a graphite sliding block on the synchronous moving mechanism is always located at the back of a welding pool and tightly pressed onto a surface welding layer by an elastic pressing mechanism on the synchronous moving mechanism, the graphite sliding block moves together with the welding gun, and welding current enters into a workpiece through electric arcs from a welding wire of the welding gun and returns to the welding machine power source negative pole from the graphite sliding block. The surfacing welding device comprises the welding gun, a welding machine power source and the synchronous moving mechanism. The synchronous moving mechanism comprises an elastic pressing mechanism and an insulation connecting plate. The elastic pressing mechanism comprises a shell, a pushing plate, a spring, an end cap, the graphite sliding block and a concave disk, and in surfacing welding, the spring generates a pressing force on the graphite sliding block. According to the large-area metal wall surface field patching surfacing welding method, the graphite sliding block is used for achieving the moving type connection between welding machine ground wires and the workpiece, the backward current distribution in the welding pool is strengthened, and combined with an externally added transverse magnetic field or a longitudinal magnetic field, the problems of the welding pool instability and organizational regulation and control caused by the gravity of metal wall surface field patching surfacing welding are solved.

Owner:NANHUA UNIV

Seamless flux-cored wire for high-strength steel welding of ocean engineering

ActiveCN111761254AImprove low temperature impact toughnessAvoid growing upWelding/cutting media/materialsSoldering mediaFerrosiliconWeld seam

The invention discloses a seamless flux-cored wire for high-strength steel welding of ocean engineering. The seamless flux-cored wire comprises low-carbon steel strip skin and flux core powder. The mass of the low-carbon steel strip skin accounts for 80% to 90% of the total mass of the seamless flux-cored wire, and the mass of the flux core powder accounts for 10% to 20% of the total mass of the seamless flux-cored wire. The flux core powder comprises the following components of, by mass, 43% to 48% of rutile, 1% to 2% of quartz, 1.2% to 2% of sodium fluoride, 3.5% to 5.5% of potassium titanate, 0.05% to 0.1% of bismuth oxide, 8% to 11% of high-carbon ferromanganese, 5.5% to 8.5% of nickel powder, 3% to 4.8% of rare earth ferrosilicon, 1.5% to 3.5% of magnesium powder, and the balance ironpowder. The seamless flux-cored wire is the seamless flux-cored wire for high-strength steel welding of ocean engineering; and by using the seamless flux-cored wire, a weld joint which is formed after welding with the seamless flux-cored wire is excellent in performance after being subjected to thermal treatment, has the good yield ratio, has higher impact toughness at a low temperature, has thedeposited metal impact energy of no lower than 90 J in the environment of minus 60 DEG C, and can be applied to welding on high-strength thick steel plates of ocean engineering.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Friction stir butt welding device for high-resistivity alloy and processing method

PendingCN111421224AImprove plasticityImprove liquidityNon-electric welding apparatusButt weldingHigh resistivity

The invention relates to a friction stir butt welding device for a high-resistivity alloy and a processing method. The friction stir butt welding device comprises a worktable and a friction stir welding mechanism, the worktable is used for placing and fixing to-be-welded workpieces, the to-be-welded workpieces comprise a first workpiece and a second workpiece which are flatly laid on the surface of the worktable in parallel, a butted interface is formed at the mutual-contact position, the friction stir welding mechanism comprises friction stir welding equipment arranged above the worktable, astirring head of the friction stir welding equipment is located over the butted interface of the to-be-welded workpieces, the bottom of the butted interface is further provided with a copper plate electrode, and the device further comprises a rolling electrode assembly. By arranging a copper core electrode, the copper plate electrode and a second power supply, a large direct current is applied tothe butted interface of the workpieces, the workpieces are softened by joule heat generated by the large direct current, meanwhile plasticity and liquidity of the workpieces are improved, and the purposes of prolonging the life of the stirring head and increasing the welding speed are achieved.

Owner:TONGLING UNIV

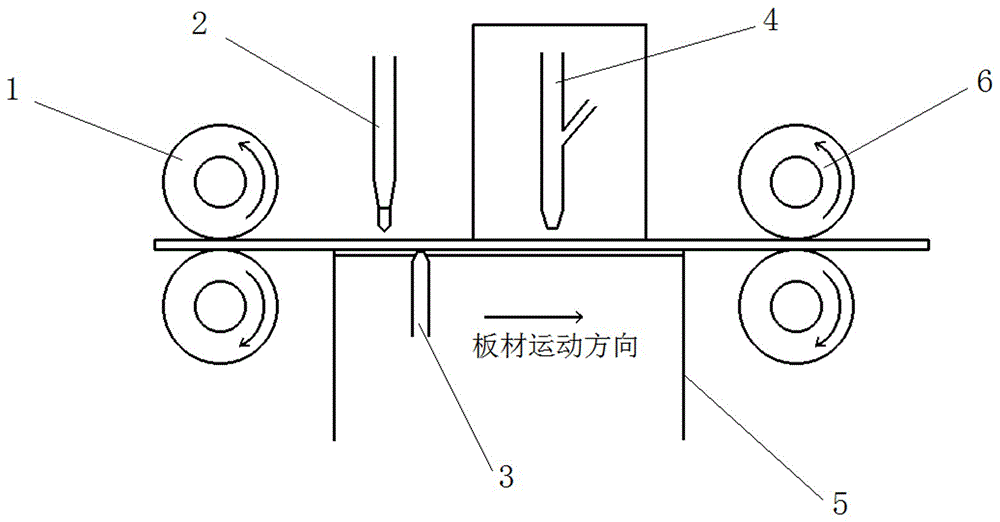

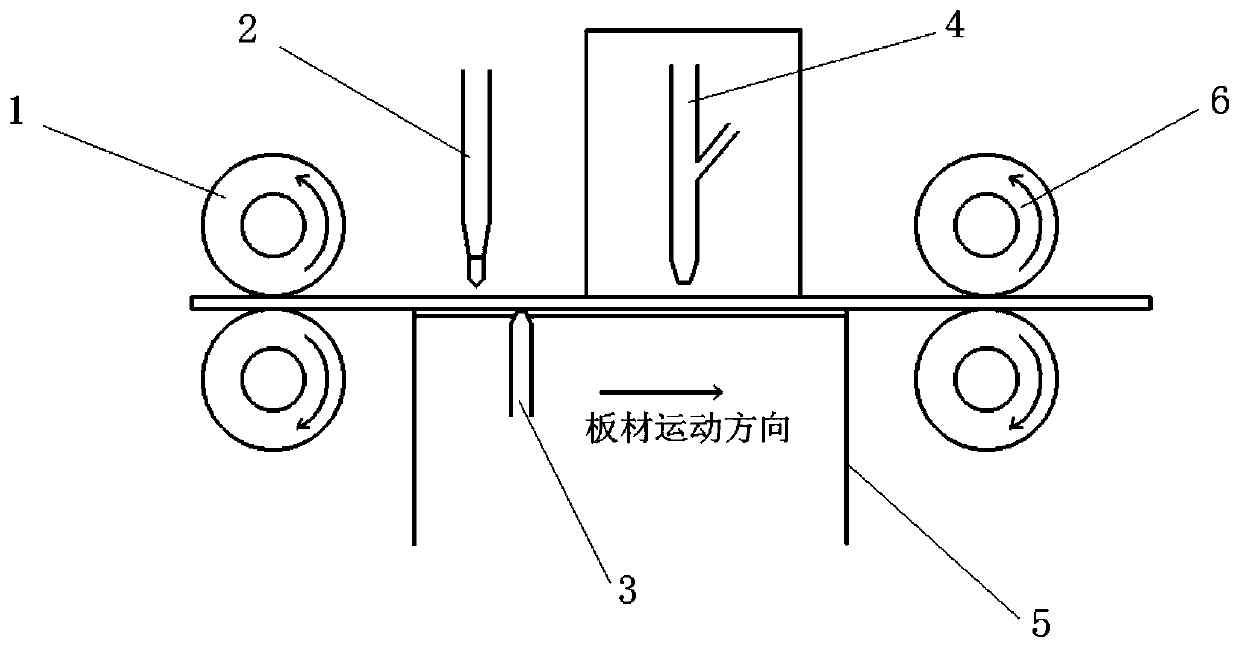

Magnesium alloy weld joint surface nanocrystallization device and method

ActiveCN106513942ASmooth transitionEliminate continuityWelding/cutting auxillary devicesElectrode supporting devicesButt weldingMechanical property

The invention discloses a magnesium alloy weld joint surface nanocrystallization device and method. The device comprises a plate feeding roller wheel set, a welding gun, a water chilling device, a shot blasting device, a welding platform and a shaping rolling wheel set. The welding gun and the shot blasting device are arranged above a magnesium alloy plate. A self-developed magnesium alloy welding wire is arranged in the welding gun. The water chilling device is arranged below the magnesium alloy plate. A base material is fed into a welding channel through the roller wheel set and then is subjected to butt welding through an argon tungsten-arc welding method, and a weld joint obtained after welding is completed is subjected to water chilling and shot blasting treatment. The magnesium alloy welding wire of the device promotes dispersed precipitation of a strengthening phase in a non-equilibrium solidification welding connector structure, the water chilling device has a fast cooling function on a melting pool just formed, grains are refined, and the mechanical property of the magnesium alloy weld joint is improved.

Owner:NANJING INST OF TECH

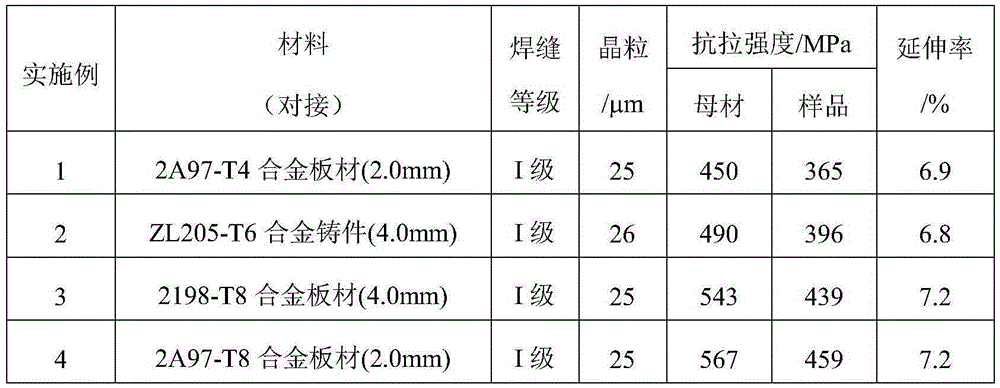

A welding wire for al‑cu‑li aluminum-lithium alloys and al‑cu aluminum alloys

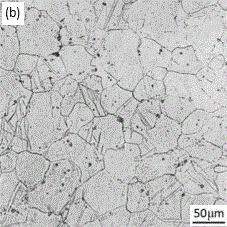

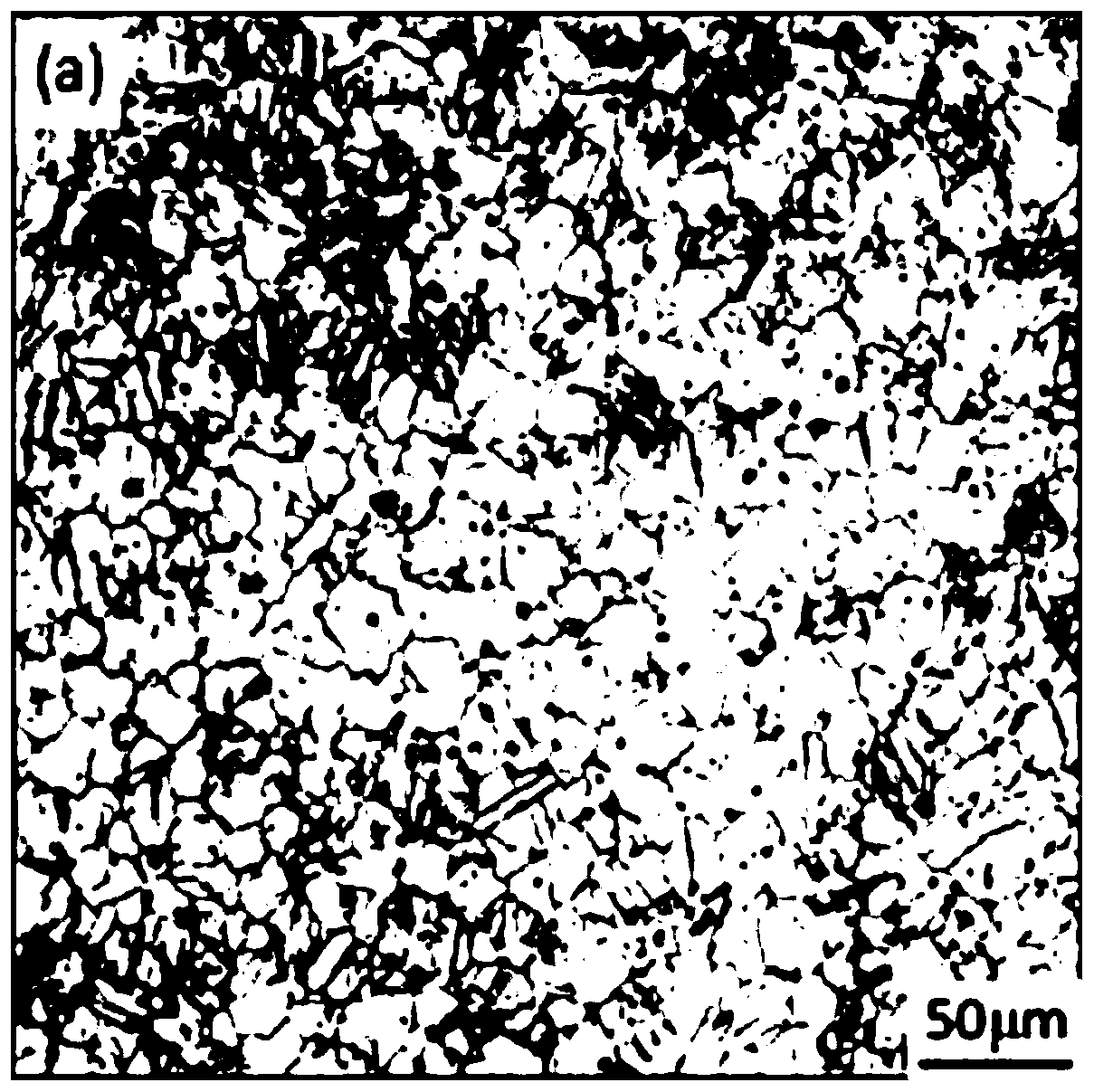

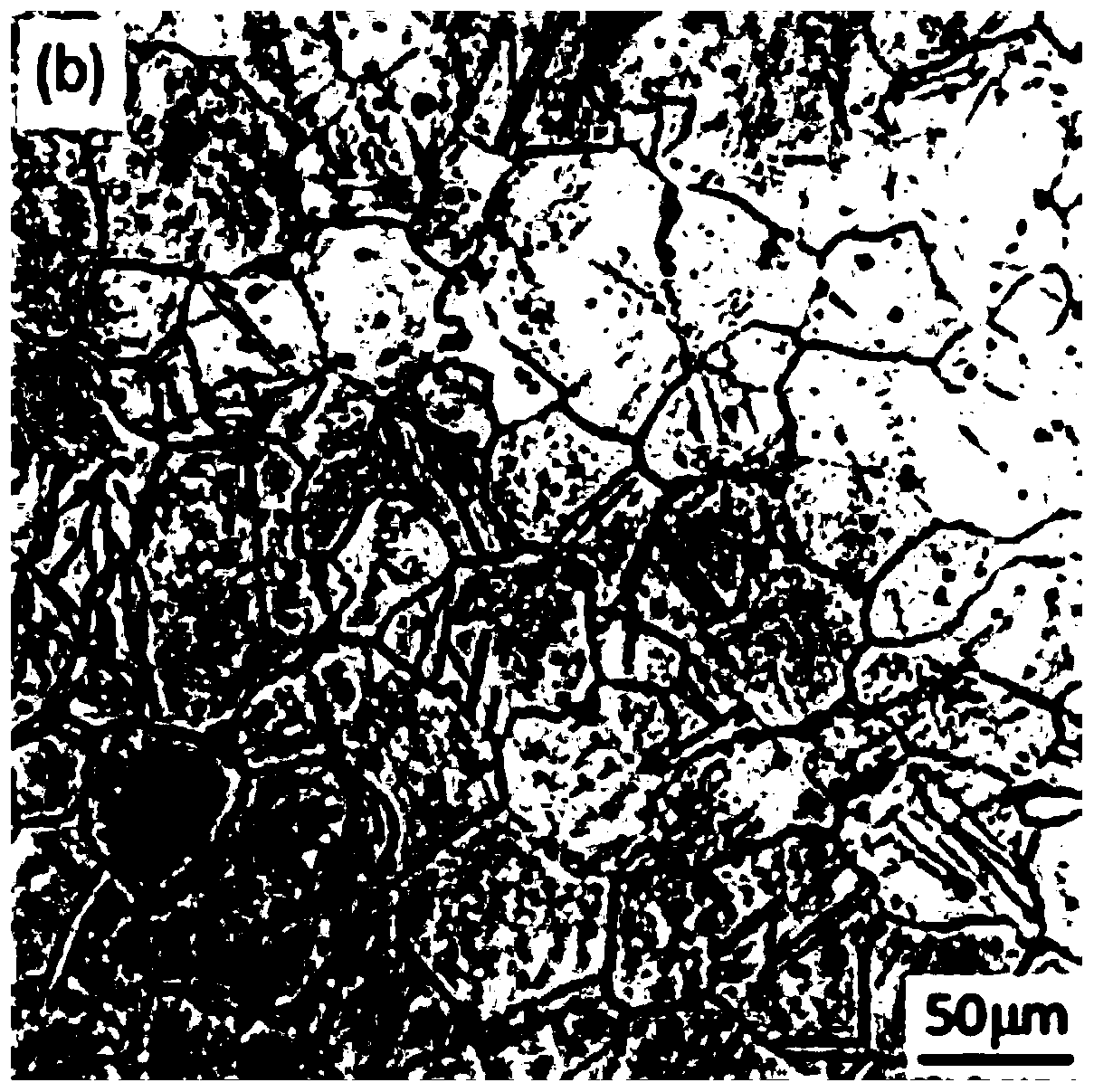

ActiveCN105345309BImprove mechanical propertiesRefined weld structureArc welding apparatusWelding/cutting media/materialsLithiumCrack resistance

The invention discloses a welding wire used for an Al-Cu-Li system aluminum lithium alloy and an Al-Cu system aluminum alloy. The welding wire is prepared from, by mass percentage, 5.00% of Cu, 0.35% to 1.00% of Sc, 0.1% to 0.7% of Ag, smaller than or equal to 0.10% of Zn, smaller than or equal to 0.05% of Mg, smaller than or equal to 0.06% of Si, smaller than or equal to 0.15% of Fe, smaller than or equal to 0.15% of other impurities and the balance Al, wherein the mass percentage of each kind of the impurities is smaller than or equal to 0.05%. When the Al-Cu-Sc system welding wire is used for fusion welding of the Al-Cu-Li system aluminum lithium alloy and the Al-Cu system aluminum alloy, the structure of a welding joint is fine, the crack resistance is good, and the comprehensive mechanical properties of a connector are good.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

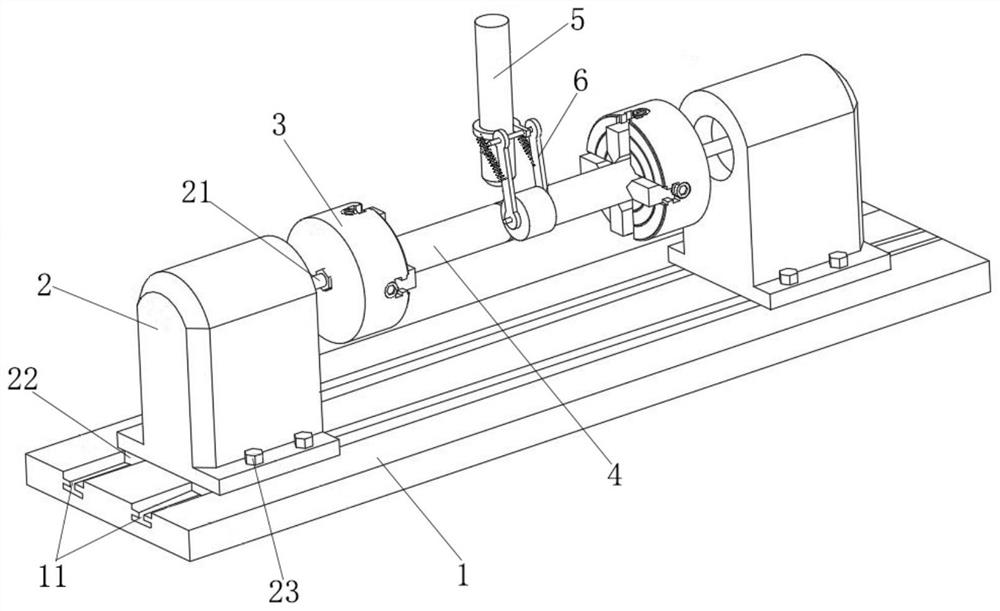

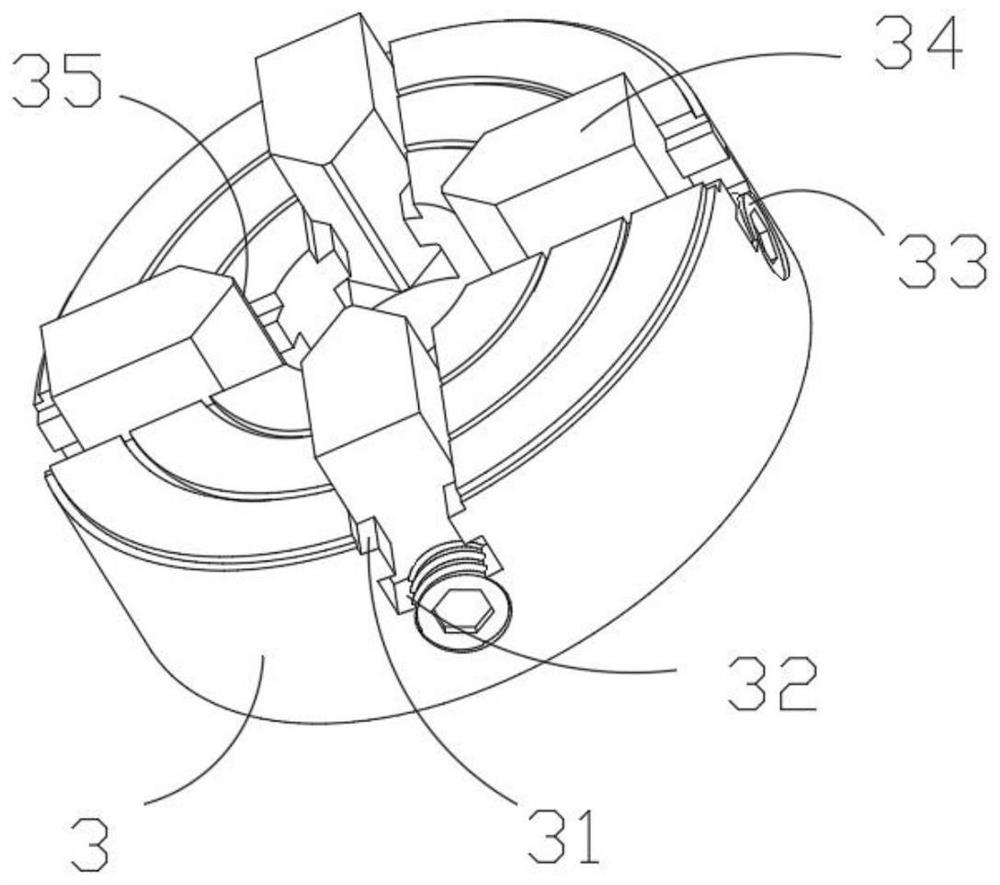

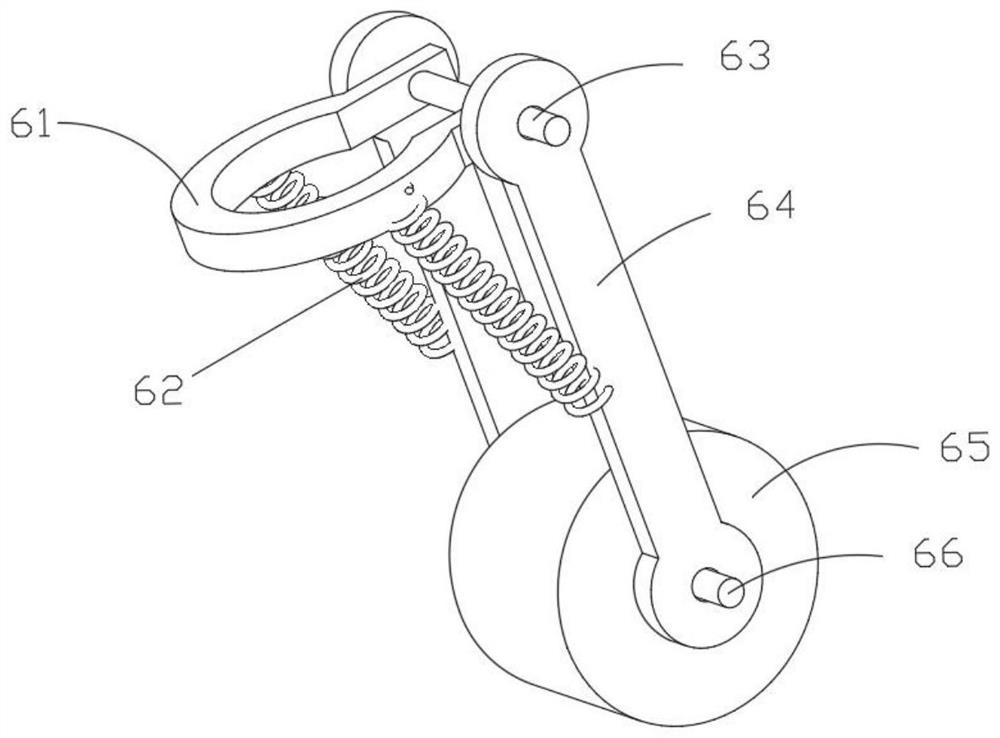

Device for rotary rolling welding of circular tubes

PendingCN111843367AGuaranteed stabilityGuaranteed coaxialityWelding/cutting auxillary devicesFurnace typesPipe fittingElectric machinery

The invention belongs to the technical field of pipe welding, and particularly relates to a device for rotary rolling welding of circular tubes. The device comprises a bottom plate, two reduction motors, two clamping mechanisms, a welding gun and a rolling wheel mechanism. The two reduction motors are symmetrically and slidably installed on the bottom plate, and the distance between the two reduction motors is adjusted by sliding the two reduction motors; the two clamping mechanism are symmetrically installed on the two reduction motors, the reduction motors can drive the clamping mechanisms to rotate, and the two clamping mechanisms are used for clamping the two circular tubes which need to be welded, so that connection of the two circular tubes is achieved. The rolling wheel mechanism comprises a clamping sleeve, two swing rods, a rolling wheel and two elastic pieces, wherein the clamping sleeve is rotationally installed between the ends of the two circular tubes and used for clamping the welding gun, the rolling wheel is rotationally installed between the other ends of the two swing rods, one end of the two elastic pieces is fixedly connected with the clamping sleeve, and the other ends of the two elastic pieces are fixedly connected with the corresponding swing rods. When the circular tubes are welded by using the device, the coaxiality, the same rotating speed and the stability can be ensured, and rolling can be conducted while welding is conducted.

Owner:ZHEJIANG UNIV OF TECH

Method for laser welding Al-Mg alloy plates with different thicknesses

InactiveCN100371125CGood lookingImproved laser welding stabilityPipeline systemsWelding/cutting media/materialsVariable thicknessAl powder

A welding flux for the laser welding of Al-Mg alloy plate with variable thickness is prepared from Mg powder and Al powder through proportional mixing, grinding, baking at 100-180 deg.c, mixing with aceotne or butaneous and stirring. It is applied through coating it on the surface to be welded, volatilizing solvent and laser welding under protection of inertial gas.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Al-Mg-Sc series solder wire

ActiveCN100445019CImprove crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaManganesePotassium

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

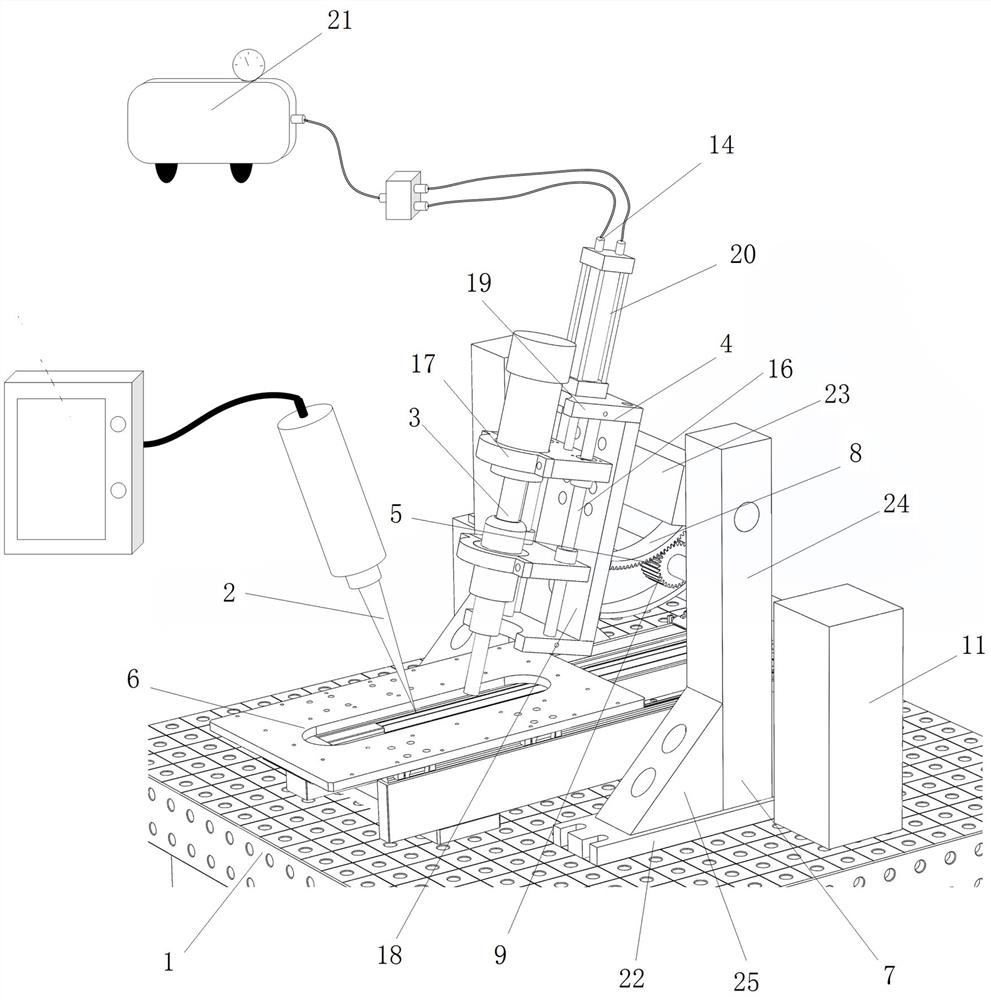

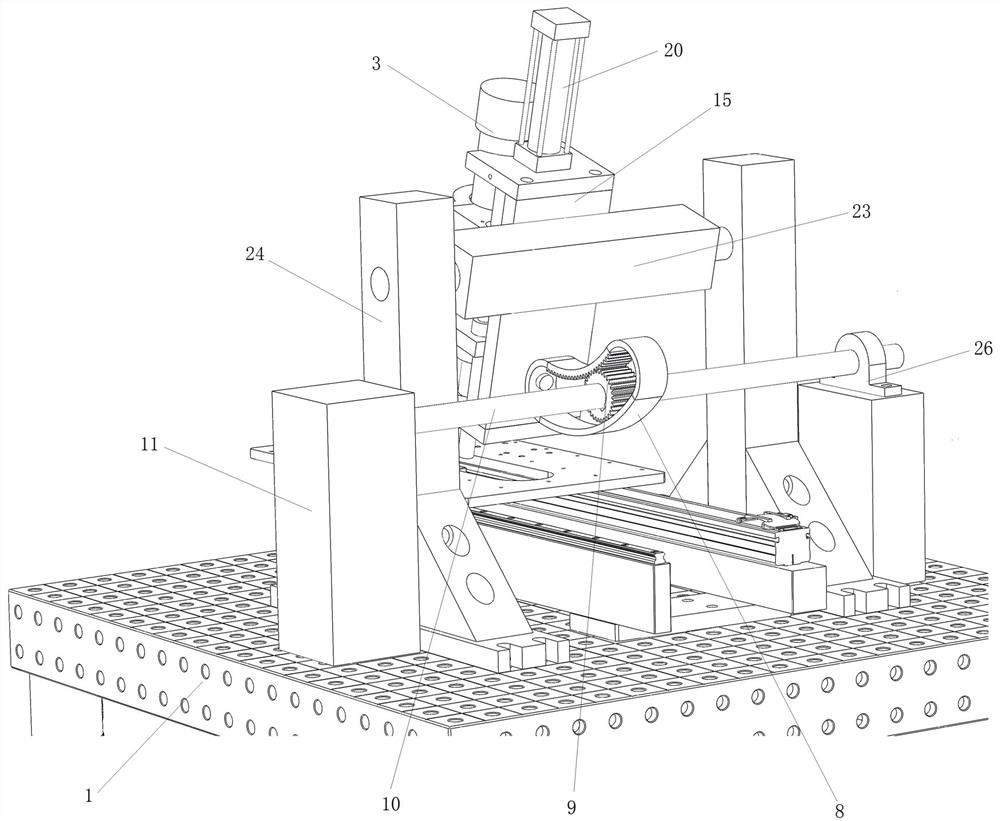

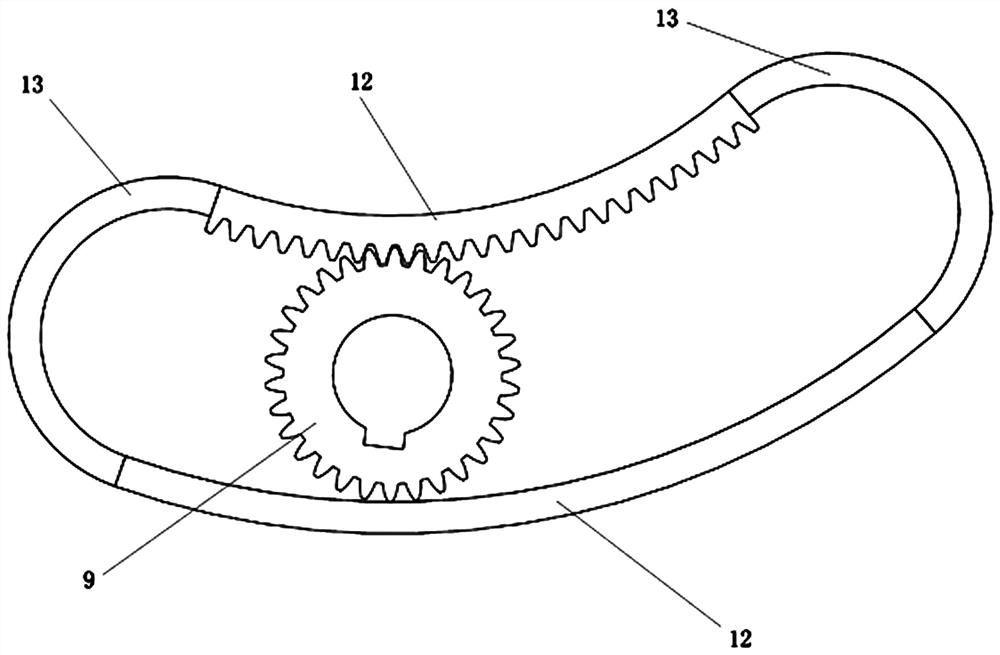

Ultrasonic-assisted laser welding device and method capable of swinging along with welding

ActiveCN114769877AEnhancement and effectAvoid standing wavesLaser beam welding apparatusGear driveGear wheel

The invention discloses an ultrasonic-assisted laser welding device and method capable of swinging along with welding. The ultrasonic-assisted laser welding device capable of swinging along with welding comprises a base, a laser device, an ultrasonic device, an axial moving mechanism and a swinging mechanism. The laser device is installed above a workbench of the base, the axial moving mechanism is installed on the base through a supporting frame, and the ultrasonic device is installed on the axial moving mechanism. The swing mechanism comprises a curve track, a gear, a transmission shaft and a motor, the motor is installed on one side of the base, one end of the transmission shaft is connected with a power output shaft of the motor, the other end of the transmission shaft is installed on the other side of the base through a bearing seat, and the gear is installed in the curve track through the transmission shaft; the gear is meshed with inner teeth of a curve track, and one end of the curve track is connected with an axial moving mechanism. Exhaust of a molten pool can be accelerated, the air hole defect can be eliminated, thick primary dendrites are effectively broken, nucleation particles are increased, the weld joint structure is refined, and the welding quality is improved.

Owner:SUN YAT SEN UNIV

Ferritic stainless steel for tubular heat exchanger and manufacturing method thereof

The invention relates to a ferritic stainless steel for tubular heat exchangers and a manufacturing method thereof. The ferritic stainless steel comprises the following chemical components in percentage by weight: at most 0.015% of C, at most 0.020% of N, at most 0.5% of Si, at most 0.5% of Mn, at most 0.035% of P, at most 0.01% of S, 22-24% of Cr, 1.5-3.0% of Mo, 0.0050-0.050% of Al, and the balance of Fe and inevitable impurities, wherein 10(C+N)<=(Nb+Ti)<=0.6%. The manufacturing method comprises the following steps: smelting by an arc furnace+AOD (argon oxygen decarburization)+VOD (vacuum oxygen decarburization) three-step process, carrying out continuous casting to obtain a continuous casting blank, and carrying out hot rolling, acid washing, cold rolling, annealing, acid washing and the like to obtain the high-weldability cold-rolled stainless steel sheet strip. The high-weldability cold-rolled stainless steel sheet strip is suitable for manufacturing welded tubes with higher requirements for corrosion resistance and flaring performance; and the flaring ratio is up to higher than 35%.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

High-tenacity gas shielded welding wire for welding low-temperature steel and using method thereof

ActiveCN101913035BReduce the ductile-brittle transition temperatureReduce contentArc welding apparatusWelding/cutting media/materialsImpurityArgon gas

The invention provides a high-tenacity gas shielded welding wire for welding low-temperature steel, which is suitable for welding the low-temperature steel subjected to service in the environment of over minus 60 DEG C. The gas shielded welding wire comprises the following chemical components in percentage by mass: 0.04 to 0.10 percent of C, 0.20 to 0.60 percent of Si, 1.20 to 1.60 percent of Mn,1.5 to 2.0 percent of Ni, 0.10 to 0.30 percent of Mo, 0.02 to 0.10 percent of Ti, 0.02 to 0.08 percent of Zr, less than or equal to 0.010 percent of S, less than or equal to 0.010 percent of P, less than or equal to 0.0025 percent of O, less than or equal to 0.0070 percent of N, and the balance of Fe and inevitable impurities. The welding wire welds by adopting Ar + 20%CO2 full-argon gas shielding so a weld metal has high low-temperature tenacity in a welding state and under a heat treatment condition after welding.

Owner:山东索力得焊材股份有限公司

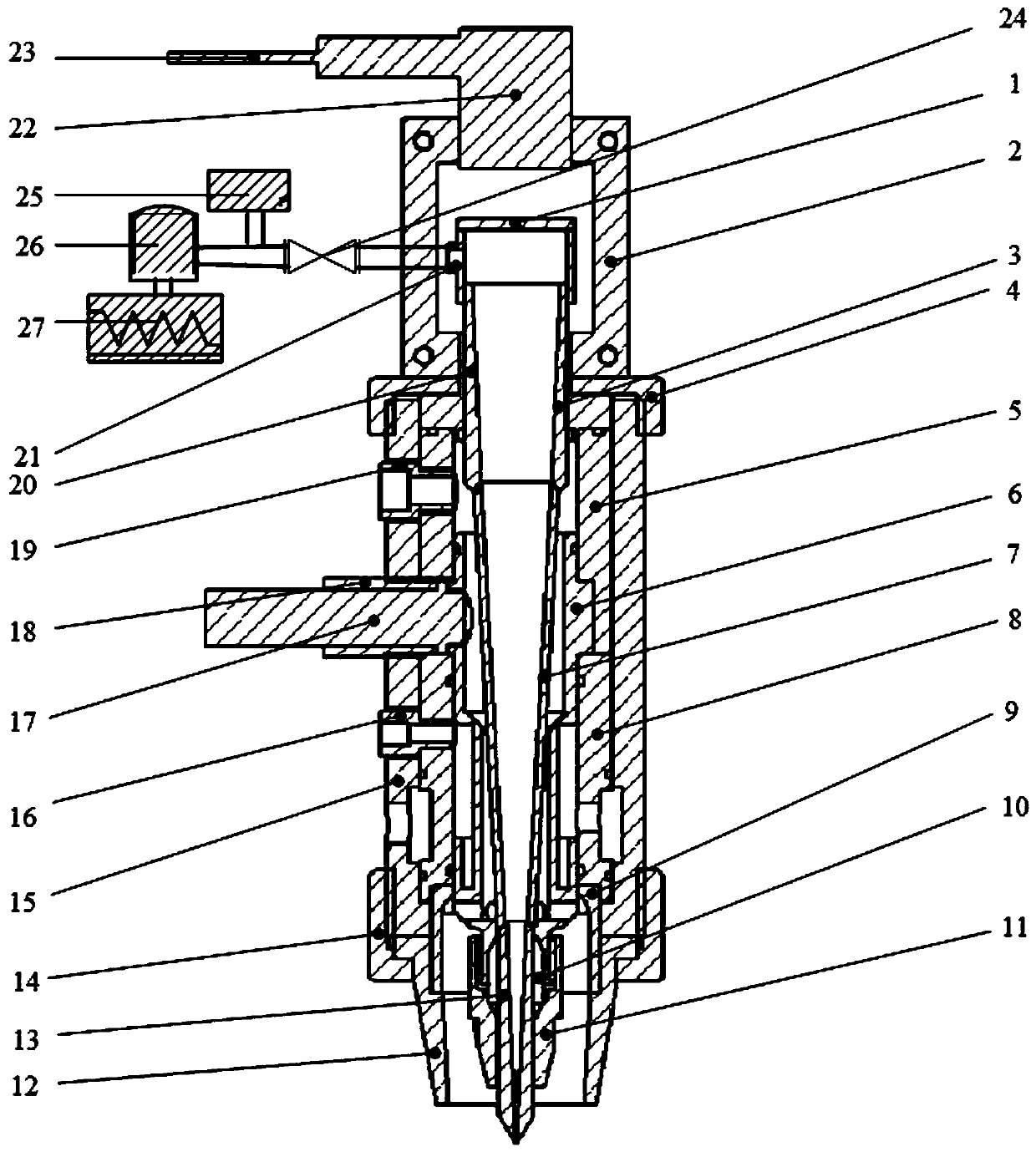

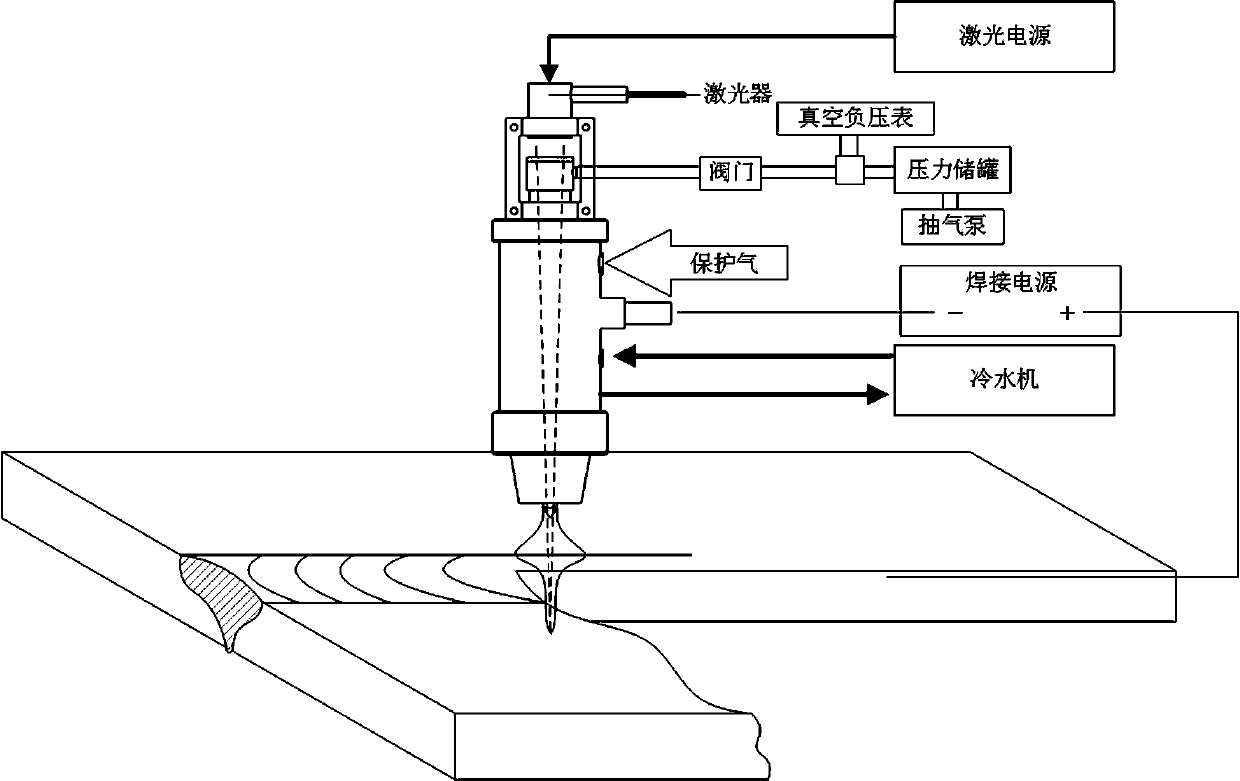

Pulse negative pressure laser enhanced-type lock hole TIG welding device

PendingCN107685193AConstrained arc shapeConstrained formLaser beam welding apparatusHeat-affected zoneTorch

The invention belongs to the technical field of welding devices and discloses a pulse negative pressure laser enhanced-type lock hole TIG welding device. The pulse negative pressure laser enhanced-type lock hole TIG welding device comprises a hollow tungsten electrode, a tungsten electrode clamp, a vacuum negative pressure pipe, an insulation air pipe, a laser, a laser fixing frame, high transmittance glass, a welding gun outer body, an electric conductor, a lantern ring, a transferring rod, a transferring head, an electric conducting rod insulation sleeve, an air transferring head, a vacuum negative pressure connector, an upper insulator, a lower insulator, an air hood, an upper nut, a lower end nut, a locking nut, a pulse solenoid valve, a vacuum negative pressure meter, a pressure storage tank and an air pump. According to the technical scheme, stability of the welding process is ensured, the lock hole TIG welding quality is improved so that the weld joint shape is more reasonable,and the welding process is more stable; meanwhile the electric arc shape is effectively restrained, the weld joint heat-affected zone is reduced, and the electric arc penetrating power is reinforced;an electric arc generates the oscillation effect, the weld joint structure is refined; and the laser reinforcing effect is matched, the weld joint depth-to-width ratio is optimized, weld joint formingis more aesthetic, and promotion and optimization of the weld joint quality and the welding efficiency are achieved.

Owner:HARBIN INST OF TECH AT WEIHAI +1

A kind of magnesium alloy weld surface nanometerization device and method

ActiveCN106513942BRefined weld structureSmooth transitionWelding/cutting auxillary devicesElectrode supporting devicesButt weldingMechanical property

The invention discloses a magnesium alloy weld joint surface nanocrystallization device and method. The device comprises a plate feeding roller wheel set, a welding gun, a water chilling device, a shot blasting device, a welding platform and a shaping rolling wheel set. The welding gun and the shot blasting device are arranged above a magnesium alloy plate. A self-developed magnesium alloy welding wire is arranged in the welding gun. The water chilling device is arranged below the magnesium alloy plate. A base material is fed into a welding channel through the roller wheel set and then is subjected to butt welding through an argon tungsten-arc welding method, and a weld joint obtained after welding is completed is subjected to water chilling and shot blasting treatment. The magnesium alloy welding wire of the device promotes dispersed precipitation of a strengthening phase in a non-equilibrium solidification welding connector structure, the water chilling device has a fast cooling function on a melting pool just formed, grains are refined, and the mechanical property of the magnesium alloy weld joint is improved.

Owner:NANJING INST OF TECH

Welding wire used for Al-Cu-Li system aluminum lithium alloy and Al-Cu system aluminum alloy

InactiveCN105345306AImprove mechanical propertiesRefined weld structureArc welding apparatusWelding/cutting media/materialsLithiumCrack resistance

The invention discloses a welding wire used for an Al-Cu-Li system aluminum lithium alloy and an Al-Cu system aluminum alloy. The welding wire is prepared from, by mass percentage, 4.60% of Cu, 0.35% to 1.00% of Sc, 0.30% to 0.60% of Mn, smaller than or equal to 0.10% of Zn, smaller than or equal to 0.05% of Mg, smaller than or equal to 0.06% of Si, smaller than or equal to 0.15% of Fe, smaller than or equal to 0.15% of other impurities and the balance Al, wherein the mass percentage of each kind of the impurities is smaller than or equal to 0.05%. When the Al-Cu-Sc system welding wire is used for fusion welding of the Al-Cu-Li system aluminum lithium alloy and the Al-Cu system aluminum alloy, the structure of a welding joint is fine, the crack resistance is good, and the comprehensive mechanical properties of a connector are good.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A mechanical vibration-assisted tig welding method and device for droplet transfer

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

A kind of welding wire for aluminum-copper alloy and its preparation method and application

InactiveCN109128572BPromote formationHigh strengthWelding/cutting media/materialsSoldering mediaRare-earth elementUltimate tensile strength

Owner:NANCHANG HANGKONG UNIVERSITY

Welding wire used for Al-Cu-Li system aluminum lithium alloy and Al-Cu system aluminum alloy

InactiveCN105328359AGood effectImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaLithiumFusion welding

The invention discloses a welding wire used for an Al-Cu-Li system aluminum lithium alloy and an Al-Cu system aluminum alloy. The welding wire is prepared from, by mass percentage, 6.80% of Cu, 0.35% to 1.00% of Sc, 0.10% to 0.30% of V, smaller than or equal to 0.10% of Zn, smaller than or equal to 0.05% of Mg, smaller than or equal to 0.06% of Si, smaller than or equal to 0.15% of Fe, smaller than or equal to 0.15% of other impurities and the balance Al, wherein the mass percent of each kind of the impurities is smaller than or equal to 0.05%. When the Al-Cu-Li system aluminum lithium alloy and the Al-Cu system aluminum alloy are subjected to fusion welding through the Al-Cu-Sc system welding wire, the structure of a welding joint is fine and good in crack resistance, and the comprehensive mechanical properties of a connector are good.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com