Welding wire for preparation of aluminum-based wear-resistant coating through magnetron deposition formation

A technology of wear-resistant cladding and wire materials, which is applied in the field of Al-Si wire materials, can solve the problems that Al-Si wire materials cannot meet the production requirements, and achieve the effects of excellent mechanical properties, excellent wear resistance, and smooth grain transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The Mg element added separately in the Al-Si alloy welding wire with the grade of 4043, the Mg element content is 0.15%, 0.25%, and 0.35% respectively, and three kinds of welding wires are made into 4143-1, 4143-2, and 4143-3. Using the Fronius full digital TPS-4000 DC pulse MIG welding deposition forming technology with external longitudinal magnetic field in the remanufacturing state key laboratory, using 4043, 4143-1, 4143-2, 4143-3 welding wires to weld aluminum alloys, and get welded connector. Tensile test is carried out on the joint, and the yield strength σ 0.2 Respectively 104MPa, 108MPa, 105MPa, tensile strength σ b 168MPa, 179MPa, and 170 MPa respectively; the flexural strength of the welds is 400 MPa, 426 MPa, and 405 MPa respectively; comparing the tensile test results of 4043 and 4143-1 welding wires, the yield strength ratio of joint welds obtained using 4143-1 welding wires is The 4043 welding wire increased by 5.6%, the tensile strength increased by 8...

Embodiment 2

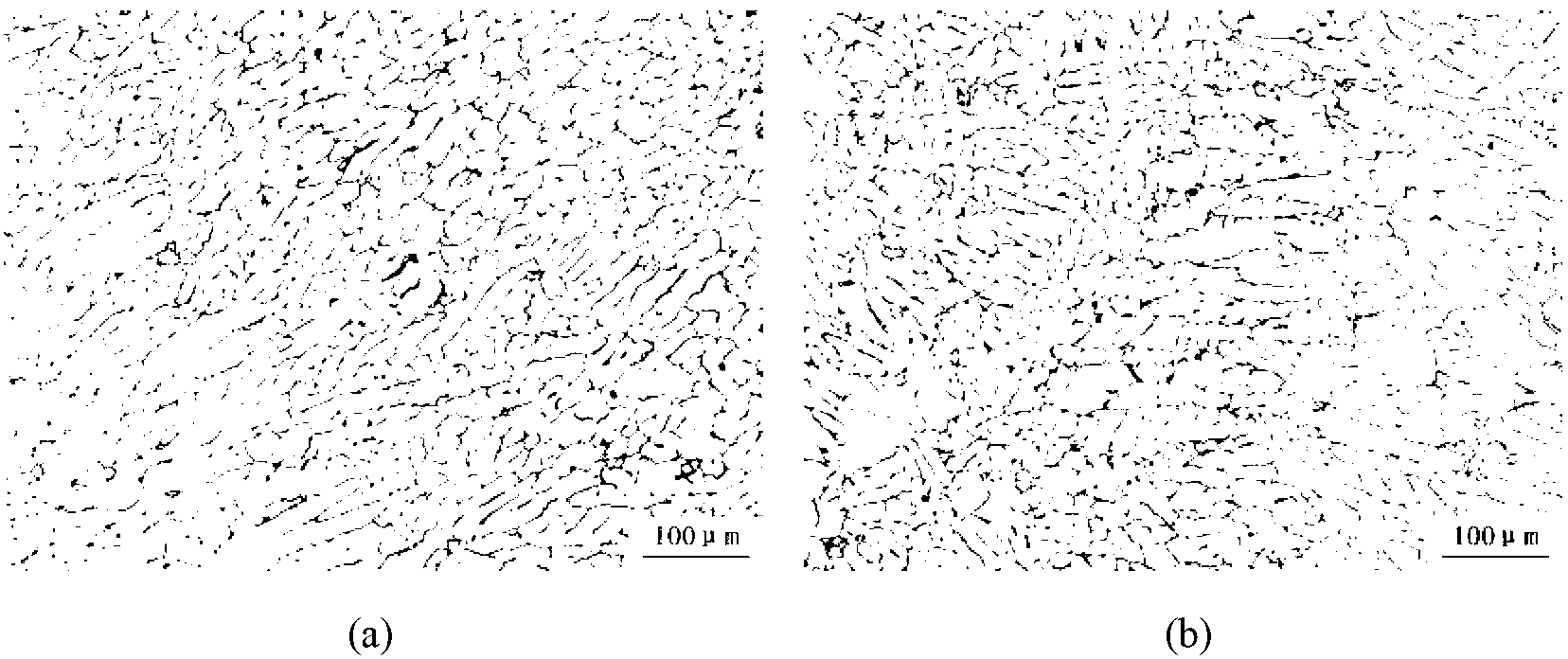

[0019] Welded joints obtained by welding wires 4043 and 4143-2 in Example 1 were used to observe the structure of each welding area, and the fusion zone is the position where the joint is easy to break. figure 1 (a) is the metallographic structure of the fusion zone of the 4043 welding wire welding joint, figure 1 (b) is the metallographic structure of the fusion zone of the 4143-2 welding wire welding joint. The analysis shows that the grains in the fusion area of 4043 welding wire are columnar grains, while the growth area of columnar grains in the fusion area of 4143-2 welding wire becomes narrower, the directionality is weakened, and it grows in the form of equiaxed grains, and the transition of the grain form tends to be gentle, reducing Mutations in the tissue are eliminated, which leads to a more uniform performance of the joint.

Embodiment 3

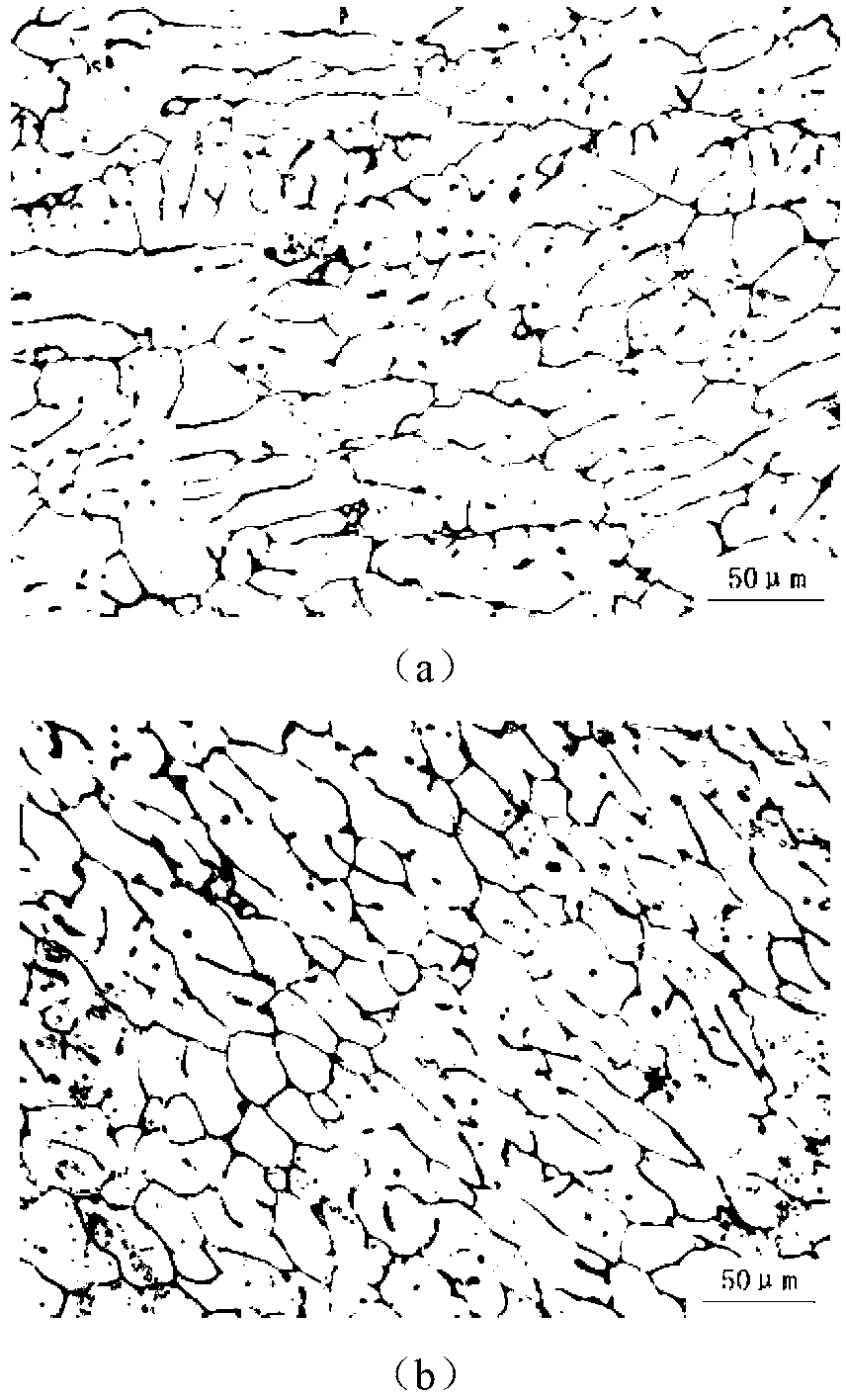

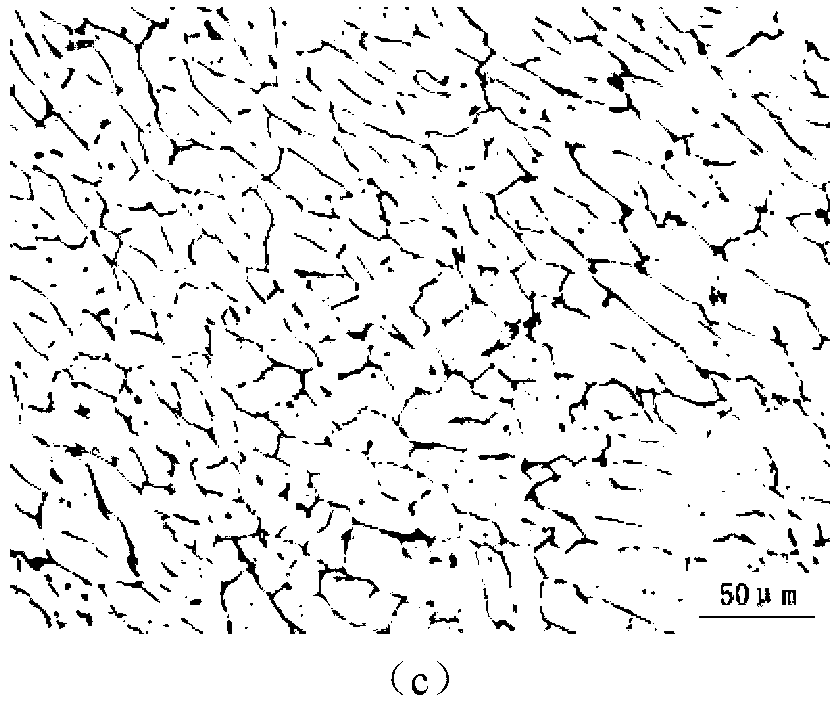

[0021] Welding wires were prepared by adding Mg, Sc, and Zr elements to Al-Si alloy welding wires of grade 4043. When the content of Mg element is 0.25%, the content of Sc is 0.3%, and the content of Zr is 0, the 4143-4 welding wire is made; but the content of Mg element is 0.25%, the content of Sc is 0, and the content of Zr is 0.15%. When the 4143-5 welding wire is made; when the content of Mg element is 0.25%, the content of Sc is 0.3%, and the content of Zr is 0.15%, it is made into 4143-6 welding wire; Fronius full-digital TPS-4000 DC pulse MIG welding deposition forming technology uses 4143-4, 4143-5, 4143-6 welding wires to weld aluminum alloys to obtain welded joints. Observe the metallographic structure of the welding fusion zone, figure 2 (a) is the metallographic structure of the fusion zone of the 4143-4 welding wire welding joint, figure 2 (b) is the metallographic structure of the fusion zone of the 4143-5 welding wire welding joint, figure 2 (c) is the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com