900MPa high-strength welding wire for mining machine and application method

A high-strength, welding wire technology, applied in welding media, welding equipment, welding equipment, etc., can solve the problem of high price, and achieve the effect of reducing price, reducing manufacturing cost, and reducing ductile-brittle transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

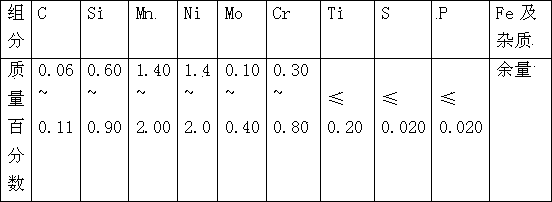

[0021] A kind of 900MPa high-strength welding wire for mining machinery, its composition and mass percentage are as follows:

[0022]

[0023] Below in conjunction with specific examples, the balance is iron and unavoidable impurities.

[0024] 1 2 3 4 5 6 7 8 9 C 0.060 0.110 0.100 0.062 0.070 0.105 0.089 0.090 0.080 Si 0.60 0.90 0.70 0.80 0.65 0.76 0.85 0.78 0.85 mn 1.40 2.00 1.45 1.90 1.85 1.50 1.48 1.78 1.85 Ni 1.40 2.00 1.70 1.00 1.80 1.90 1.56 1.79 1.85 Cr 0.30 0.80 0.70 0.32 0.75 0.45 0.34 0.45 0.50 Mo 0.10 0.40 0.35 0.28 0.24 0.27 0.38 0.15 0.20 Ti 0.16 0.09 0.087 0.086 0.11 0.09 0.15 0.08 0.09 S 0.02 0.010 0.014 0.005 0.007 0.009 0.015 0.012 0.017 P 0.02 0.010 0.020 0.008 0.010 0.013 0.015 0.007 0.004

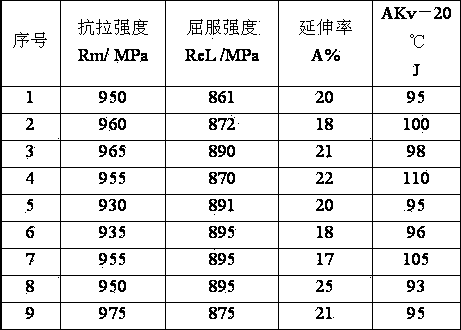

[0025] The welding wire of the above-mentioned embodiment was welded in 80%Ar+20%CO Argon-rich gas protection, and tested....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com