Ultrasonic-assisted laser welding device and method capable of swinging along with welding

An ultrasonic-assisted, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of weak crushing degree of primary columnar crystals, unfavorable rapid overflow of bubbles, and difficulty in obtaining fine weld seam structure, etc. To avoid the formation of stomatal defects, increase the nucleation particles, and enhance the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

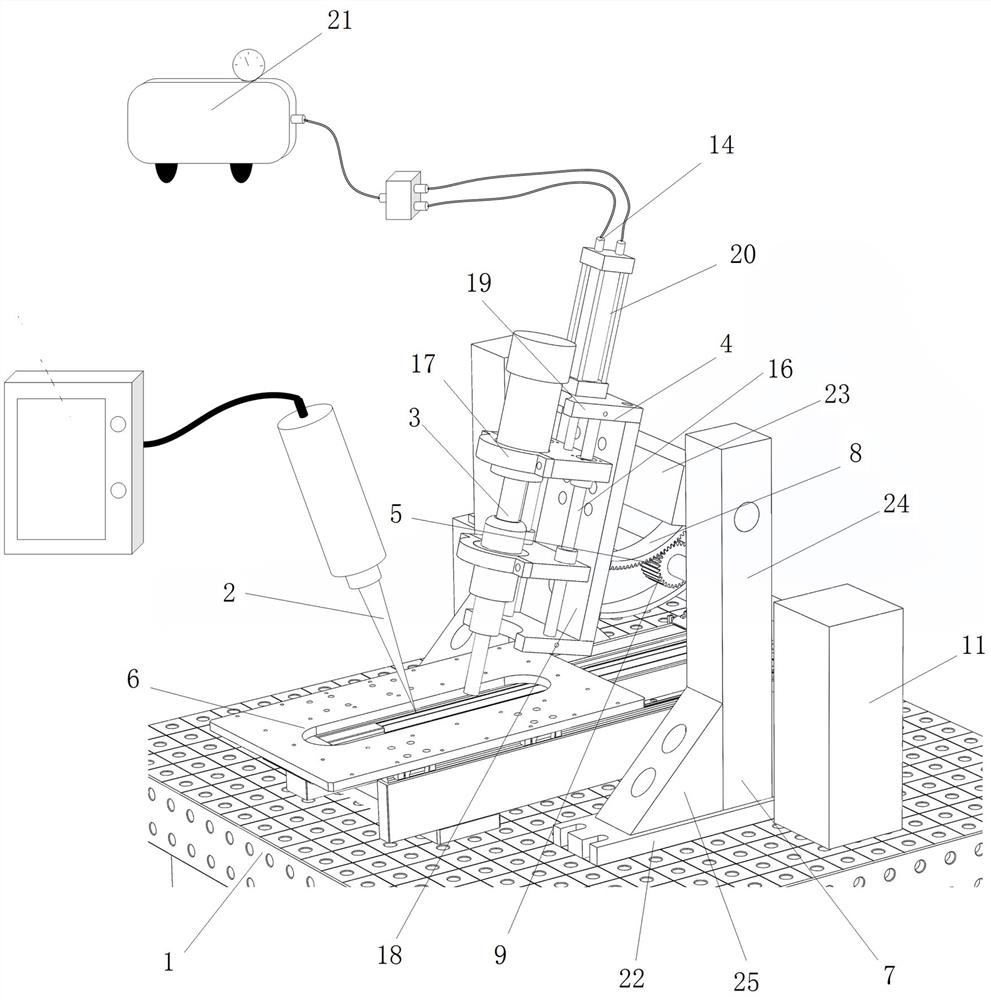

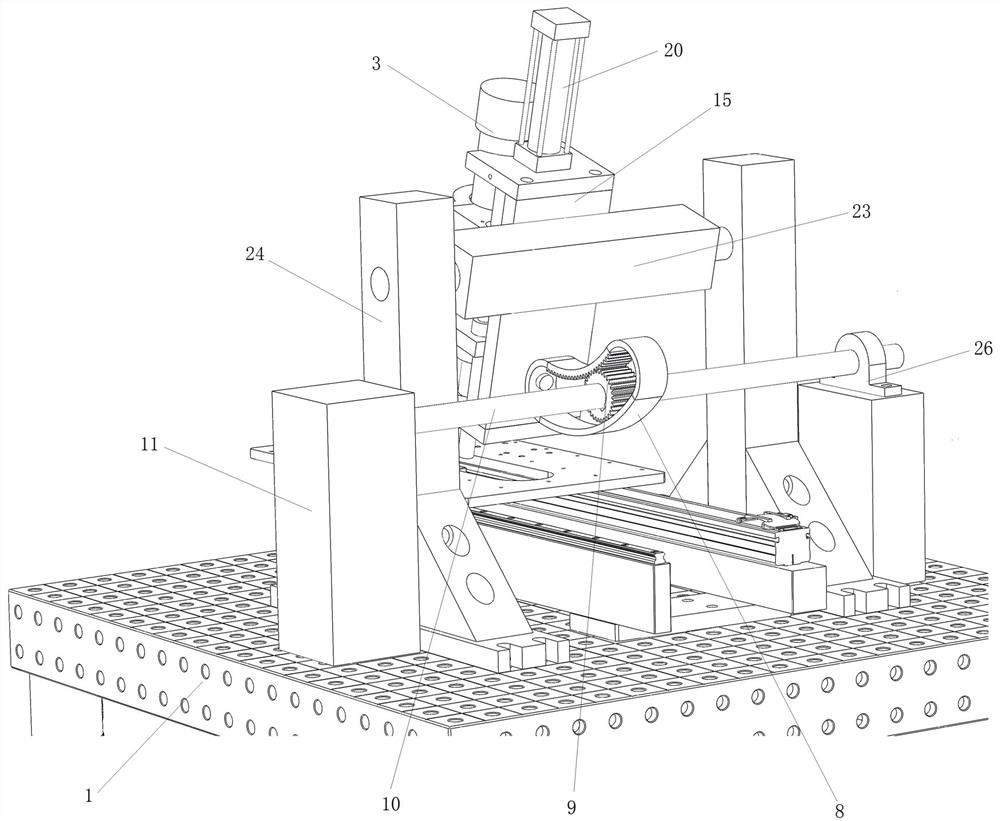

[0026] like figure 1 and figure 2 The shown ultrasonic-assisted laser welding device with swinging welding includes a base, a laser, an ultrasonic device, an axial moving mechanism and a swinging mechanism; the laser is installed above the worktable of the base, and the axial moving mechanism is installed on the support frame through the support frame. On the base, the ultrasonic device is installed on the axial moving mechanism; the swing mechanism includes a curved track, a gear, a transmission shaft and a motor, the motor is installed on one side of the base, and one end of the transmission shaft is connected to the motor. The power output shaft is connected, the other end of the transmission shaft is installed on the other side of the base through the bearing seat, the gear is installed in the curved track through the transmission shaft, and the gear meshes with the internal teeth of the curved track, the One end of the curved track is connected with the axial moving mec...

Embodiment 2

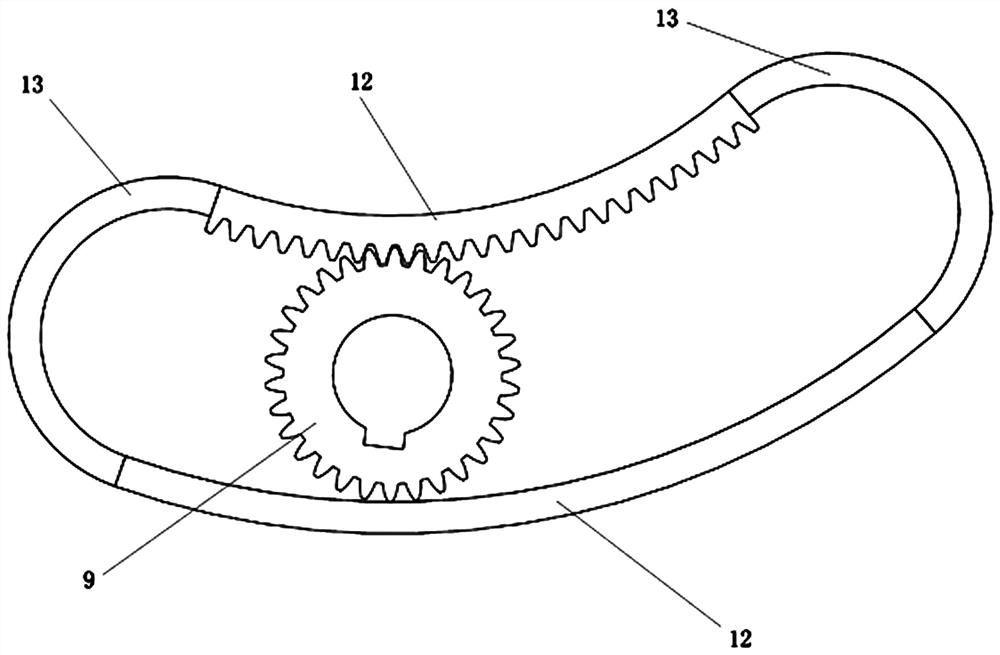

[0039] The ultrasonic-assisted laser welding device of the present embodiment is the same as the embodiment 1 except for the following technical features: Figure 4 As shown, the curved track includes 2 circular arc segments and 2 semicircular segments, and the two ends of the two circular arc segments are respectively connected with the two ends of the two semicircular segments; the inner side of the circular arc segment located below is provided with a The internal teeth of the gear mesh. In order to ensure the stability of the curved track, the curved track of this embodiment is formed together. The set curved track has a simple structure, is convenient to manufacture, and has high stability. This structure can also achieve the effect of driving the ultrasonic device to oscillate repeatedly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com