Welding wire used for Al-Cu-Li system aluminum lithium alloy and Al-Cu system aluminum alloy

An al-cu-li, aluminum-lithium alloy technology, applied in welding media, welding equipment, welding equipment, etc., can solve the problems of poor weld strength and formability, hot cracking, etc., to achieve good crack resistance, no cracks, The effect of increased elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

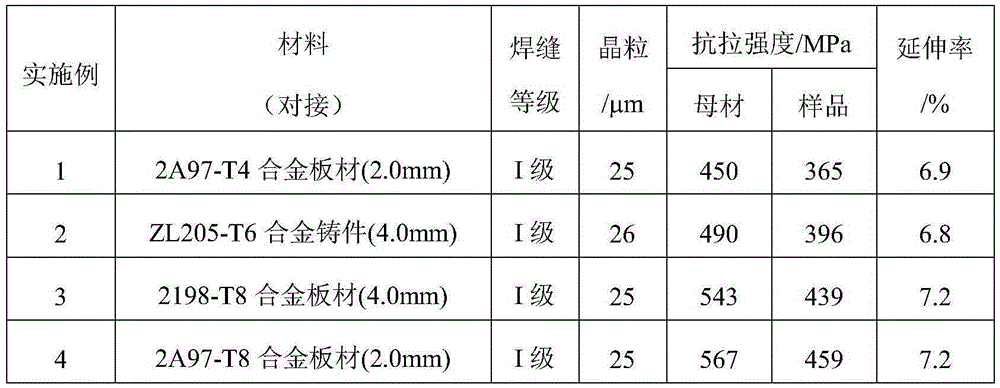

Examples

Embodiment 1

[0019] The chemical composition of the Al-Cu-Sc aluminum alloy welding wire of the present invention is calculated by mass percentage: Cu: 4.60, Sc: 0.35, Mn: 0.30, Zn: 0.06, Mg: 0.02, Fe: 0.12, Si: 0.04, other impurities Single ≤0.05%, total ≤0.15%, the balance is Al.

Embodiment 2

[0021] The chemical composition of the Al-Cu-Sc aluminum alloy welding wire of the present invention is calculated by mass percentage: Cu: 4.60, Sc: 0.35, Mn: 0.40, Zn: 0.06, Mg: 0.02, Fe: 0.12, Si: 0.04, other impurities Single ≤0.05%, total ≤0.15%, the balance is Al.

Embodiment 3

[0023] The chemical composition of the Al-Cu-Sc aluminum alloy welding wire of the present invention is calculated by mass percentage: Cu: 4.60, Sc: 0.35, Mn: 0.50, Zn: 0.06, Mg: 0.02, Fe: 0.12, Si: 0.04, other impurities Single ≤0.05%, total ≤0.15%, the balance is Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com