Magnesium alloy weld joint surface nanocrystallization device and method

A technology of welding seam surface and magnesium alloy, applied in auxiliary devices, electrode support devices, welding equipment, etc., can solve problems such as limited ability to solve, coarse grains, reduced mechanical properties of joints, etc., to eliminate discontinuity and stress concentration. , the effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the technical features, technical contents and technical effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are not intended to limit the present invention.

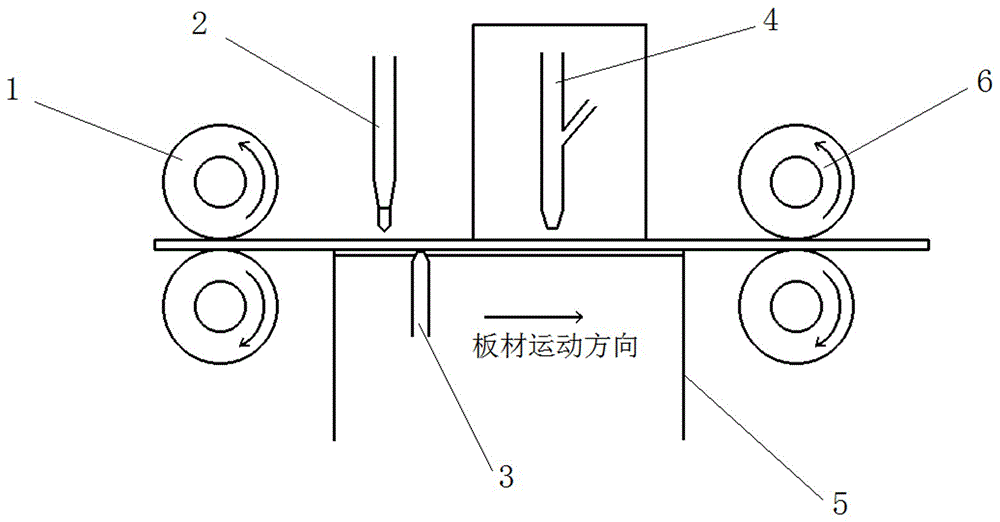

[0029] like figure 1 As shown, a magnesium alloy weld surface nanometerization device includes a plate feeding roller group 1, a welding torch 2, a water quenching device 3, a shot blasting device 4, a welding platform 5, and a shaping roller group 6.

[0030] The upper and lower plate feeding rollers of plate feeding roller group 1 are set facing each other, and the magnesium alloy plate is sent into the welding channel through the plate feeding roller set; Group 1 moves the welded magnesium alloy sheet out of the welding channel. Between the plate feeding roller group 1 and the shaping roller group 6 is a welding area, and a welding platform 5 is arranged in the welding area, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com