A kind of welding wire for aluminum-copper alloy and its preparation method and application

An aluminum-copper alloy and welding wire technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of easy crystallization cracks in the weld metal, low weld metal strength, poor plasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031]The present invention provides the preparation method of the aluminum copper alloy wire of the above technical solution, including the following steps:

[0032](1) The chemical composition of the welding wire according to the above-described technical solution is made, and the raw material is mixed and cast, and the ingot is obtained.

[0033](2) The ingot of the step (1) is sequentially handled and heat extrudent, resulting in an extruded material;

[0034](3) Pull the extruded material of the step (2) to obtain a steel wire for aluminum copper alloy.

[0035]The present invention corresponds to the chemical composition of the wire of the above-described technical solution, and the raw material is mixed and refined to obtain a casting liquid. In the present invention, the raw material preferably includes an aluminum copper intermediate alloy, an aluminum manganese intermediate alloy, an aluminum-based intermediate alloy, an aluminum-rare earth alloy, preferably comprising an Al-50Cu allo...

Embodiment 1

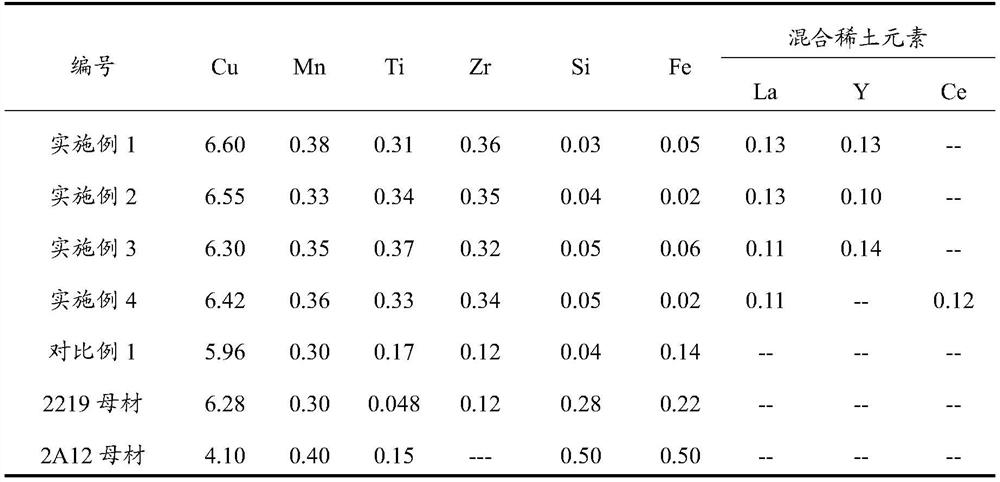

[0065]According to the amount of the components shown in Table 1, the material is prepared, according to the mass percentage, the margin is Al, and is not listed in the table. Among them, each component raw material is an Al-50Cu intermediate alloy, an Al-10 mN intermediate alloy, Al-10Ti intermediate alloy, Al-10RE intermediate alloy, and an aluminum having a purity of 99.99%.

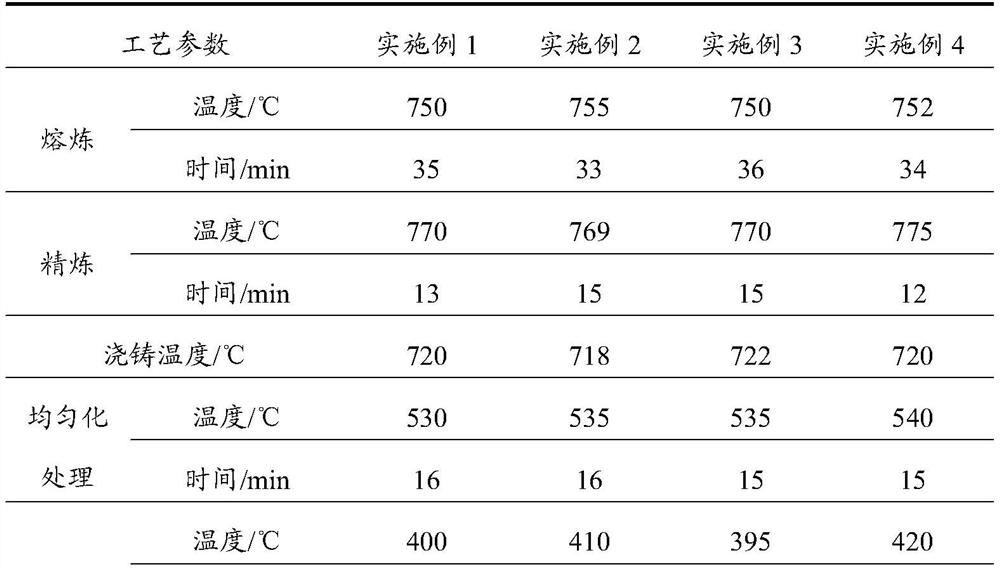

[0066]After mixing the raw material, the smelting in the well furnace with graphite crucibles, the melting temperature is 750 ° C, heat insulation 35min; adding ZS-AJ01C, which is 0.15% of the material, is refined, the refining temperature is 770 ° C, the time is 15 min, and the time is refined after refining Total hexachloroethane in the total mass of the refined liquid is subjected to slagm dehydrogenation; the refined liquid after the slag dehydrogenation is poured into the preheated iron mold to form a ingot, and the preheating temperature of the iron mold is 200. ° C. After the homogenization of the ingot...

Embodiment 2~4

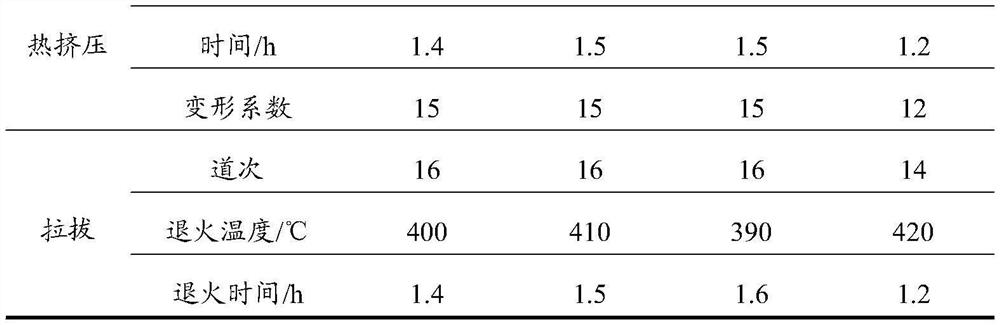

[0070]The preparation method and the welding method are the same as in Example 1, and the different amounts and process parameters of each group are in particular, and in particular, Table 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com