Worm wheel and worm with dynamic and static pressure lubricating at engagement zone

A worm gear, dynamic and static pressure technology, applied to components with teeth, gear lubrication/cooling, transmission devices, etc., can solve the problems of limited application range, wear of worm gears, low transmission efficiency, etc., and achieve less heat generation and high transmission efficiency Improve and improve the effect of lubrication conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

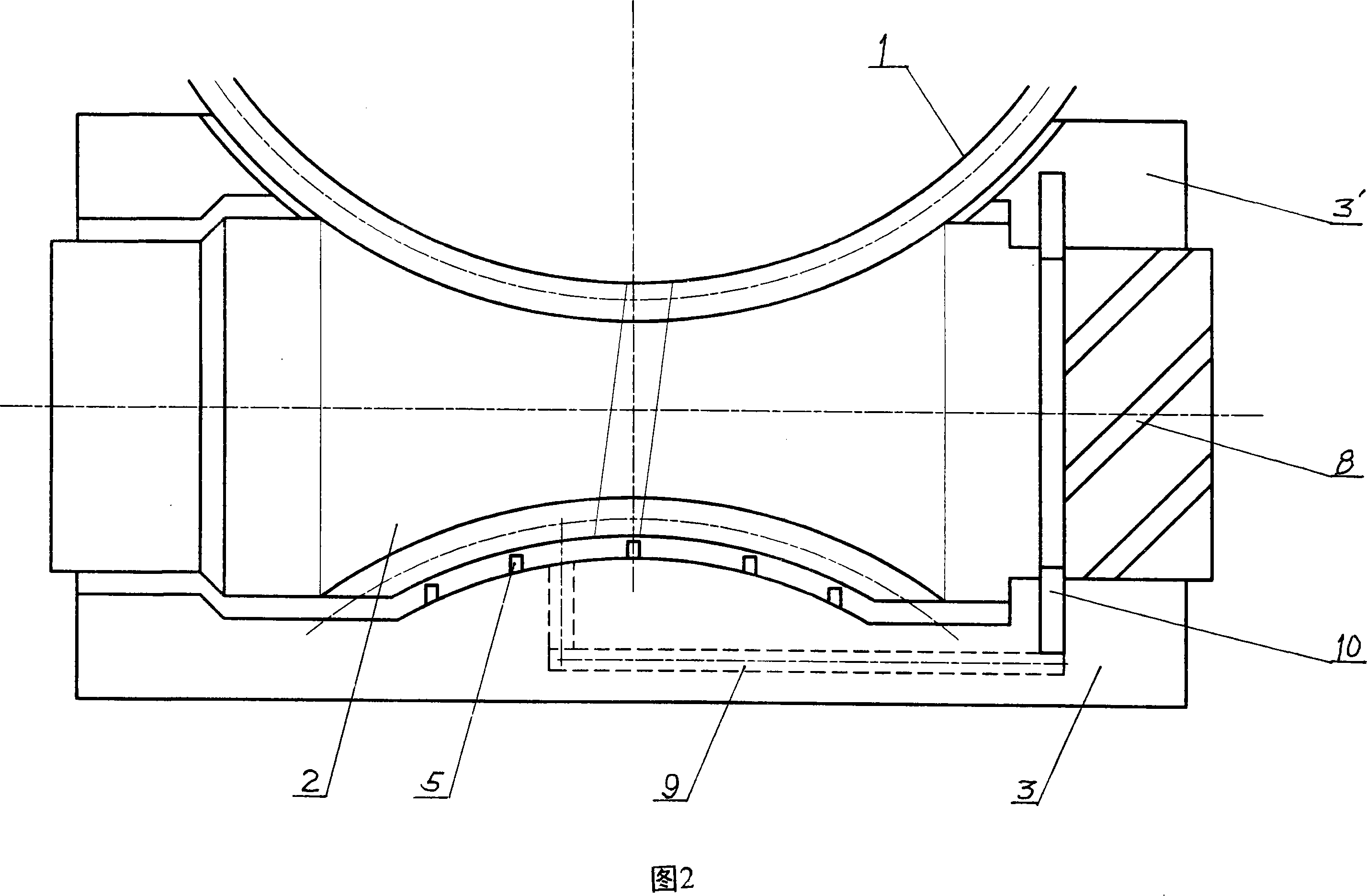

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] The worm gear with dynamic and static pressure lubrication in the meshing area of the present invention is a new type of worm gear formed by improving the known worm gear.

[0016] As shown in Figure 1, a sealing block 3 or 3' is installed on the periphery of the meshing section of the worm wheel 1 and the worm screw 2, and the sealing block 3 or 3' can seal the meshing section of the worm wheel 1 and the worm screw 2. The opposite surfaces between the sealing block 3 and the sealing block 3' can be connected by bonding or bolts. There is a sealing strip 4 or 4' at the contact between the seal block 3 or the seal block 3' and the worm gear 1, and there are labyrinth teeth 5 between the seal block 3 and the worm 2 opposite surfaces or between the seal block 3' and the worm 2 opposite surfaces, and the labyrinth t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com